Centralized gas control method for coal measures in closed distance seam group

A coal seam gas and coal seam group technology, which is applied in the field of centralized gas control in coal seam groups in short-distance coal seam groups, can solve problems such as large interlayer spacing, high gas content in coal seams, and unsuitable mining conditions, and achieve high gas pressure and outburst hazards , the effect of high gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

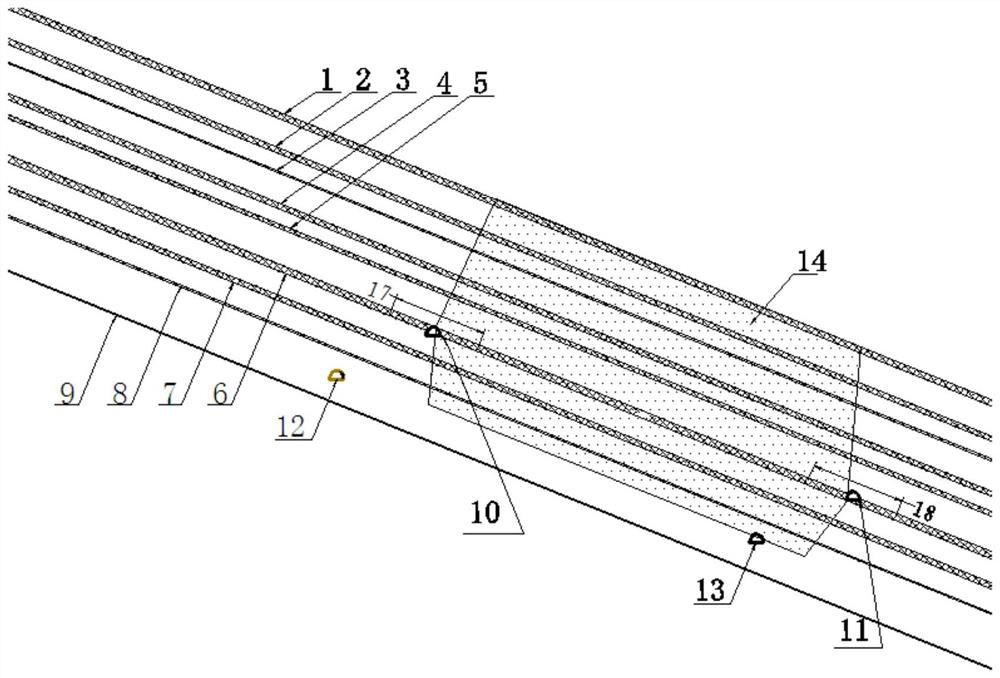

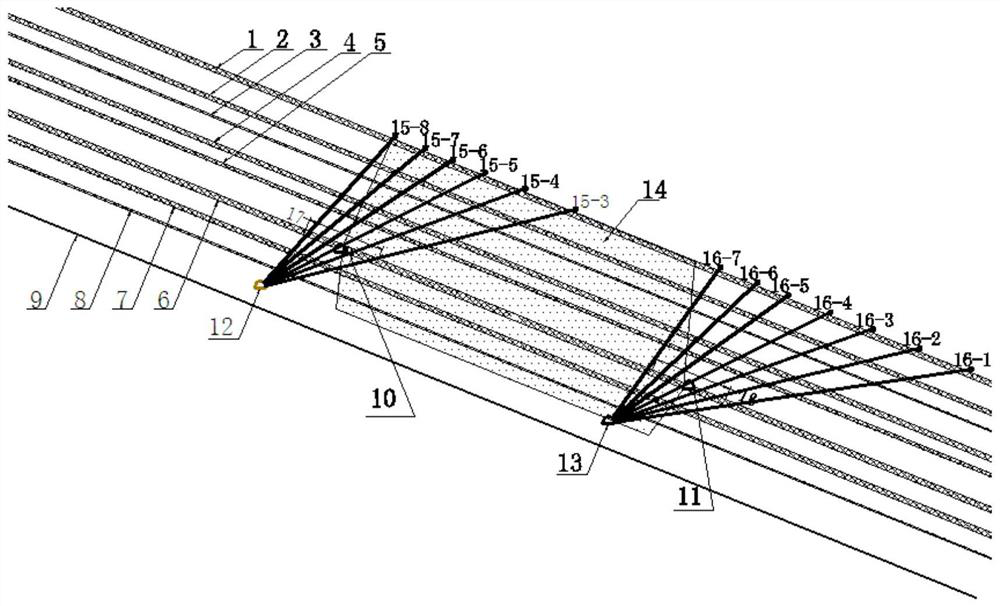

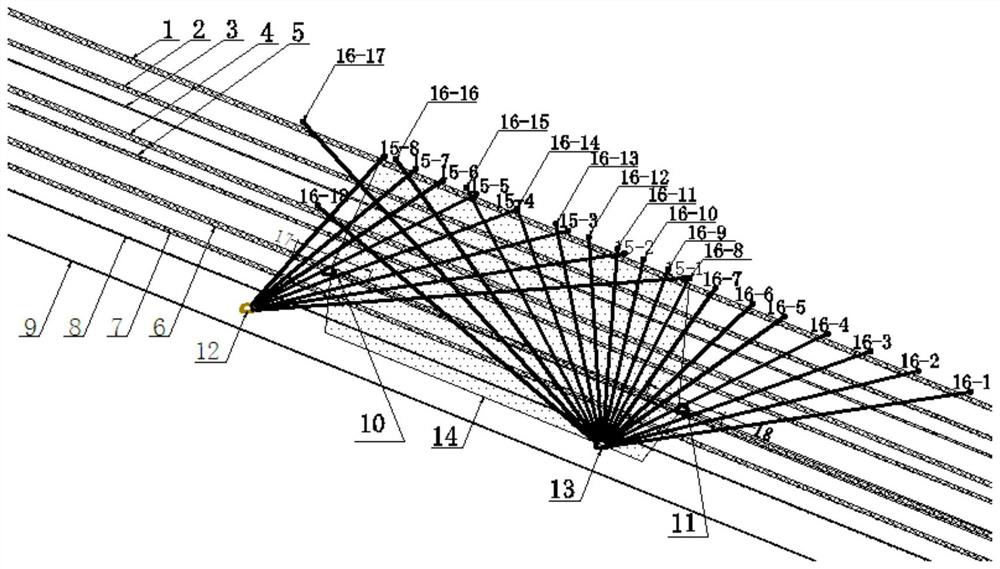

[0022] Embodiment 1: A method for controlling coal group concentrated gas in a short-distance coal seam group, the method includes the following steps:

[0023] 1. The middle coal formations of the short-distance coal seam groups have not been mined, and the coal seams mined by the upper and lower coal formations cannot provide pressure relief protection for the top and bottom coal seams of the middle coal formations. Affected by the mining of the first mining layer, the movement, deformation and rupture of the top and bottom rock layers of each coal seam form the development range of the gas gushing channel, so as to ensure that the protection range of pressure relief after the mining of the first mining layer covers other mineable coal seams;

[0024] 2. Arrange the first mining face in the first mining layer, determine its recovery roadway, and arrange the centralized gas control roadway according to the thickness of each coal seam, interlayer spacing, drilling construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com