Freezing-thawing cycle anti-reflection promoting extraction safe and efficient rock cross-cut coal uncovering method

A technology of Shimen coal excavation, freeze-thaw cycle, applied in safety devices, earthwork drilling, mining fluids and other directions, can solve the problems of increasing coal strength, reducing resistance, increasing outburst resistance, etc., to reduce the amount of drilling engineering, The effect of accelerating the coal removal process and increasing the permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

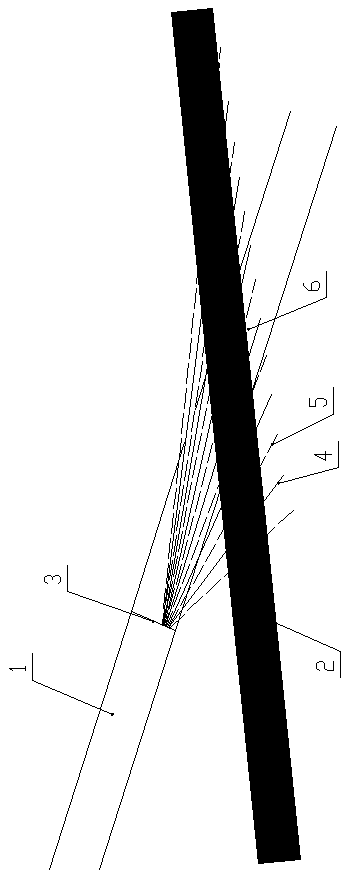

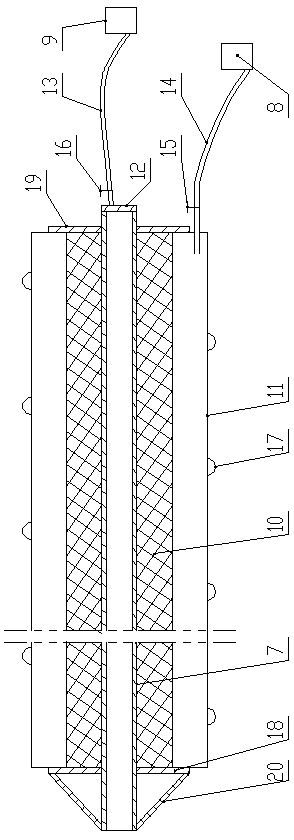

[0035] Such as figure 1 and figure 2 As shown, the freeze-thaw cycle anti-reflection method of the present invention promotes safe and high-efficiency Shimen unearthing coal, comprising the following steps,

[0036] (1) Measure the influence radius φ of high-pressure water injection in coal seam 2 near the coal mining site in Shimen, roadway 1;

[0037] (2) Set up a drilling site 3 at the minimum normal distance of 5-7m from the coal seam 2 in the Shimen coal mining face, and drill holes in the drilling site 3 to the top or bottom of the coal seam 2;

[0038] (3) During the drilling construction process, the water injection hole 4 is constructed first, and then the freezing hole 5 is constructed within the range smaller than φ on both sides of the water injection hole 4, so that the water injection hole 4 and the freezing hole 5 are arranged alternately, and the constructed water injection hole 4 and the freezing hole 5 completely cover the area of the coal mining face in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com