Gas treatment method of rock protection layer working face under near-distance hard roof

A technology of hard roof and working face, applied in gas discharge, earth-moving drilling, safety devices, etc., can solve the problems of low efficiency, long extraction time, low coal seam permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

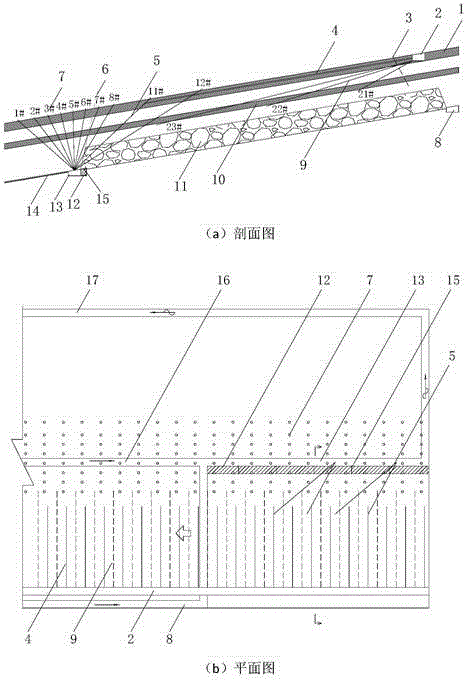

[0013] like figure 1 As shown, a gas control method for the working face of the rock protective layer under the close-distance hard roof is to use the soft mudstone in the suitable layer of the protruding coal seam floor as the protective layer under the condition of no protective layer mining, and the mudstone working face adopts Y-shaped downward ventilation The gas and gas in the protected layer are extracted by means of coal roadway in the protected layer, drilling along the bedding, downward drilling, upward drilling in the roadway of the mudstone working face, lagging drilling, and buried pipes in the goaf. Gob gas.

[0014] The mudstone working face adopts the gob-side retaining method, and the filling wall is built at the position of the lower air entry roadway, and the Y-shaped ventilation is constructed. Considering that the mudstone roof is a hard rock formation, after the filling wall construction is completed, the blasting method is used to cut the mudstone roof. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com