Gas and dust collecting device

A dust and gas technology, applied in the field of coal mining, can solve the problems of gas and gas exceeding the limit and dust hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

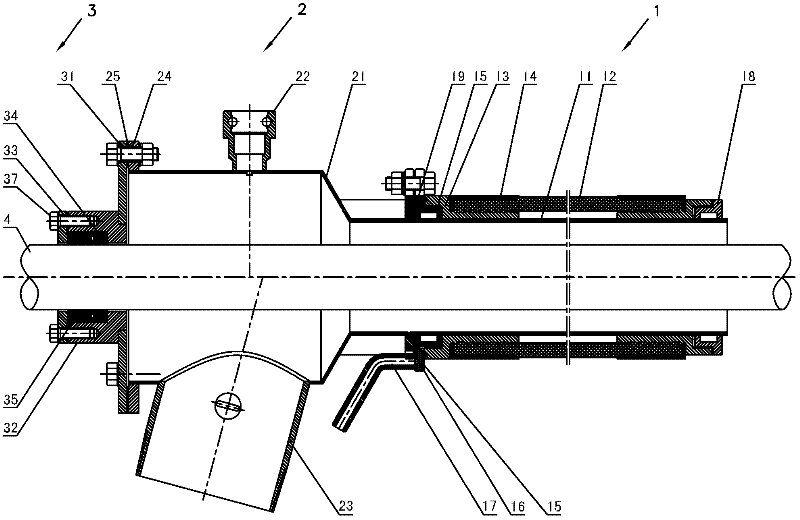

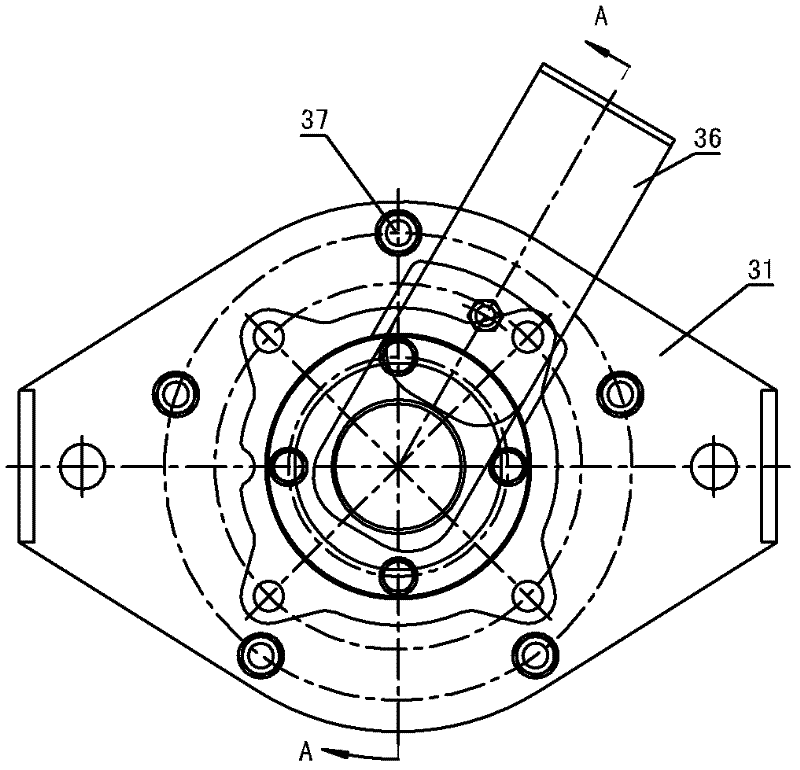

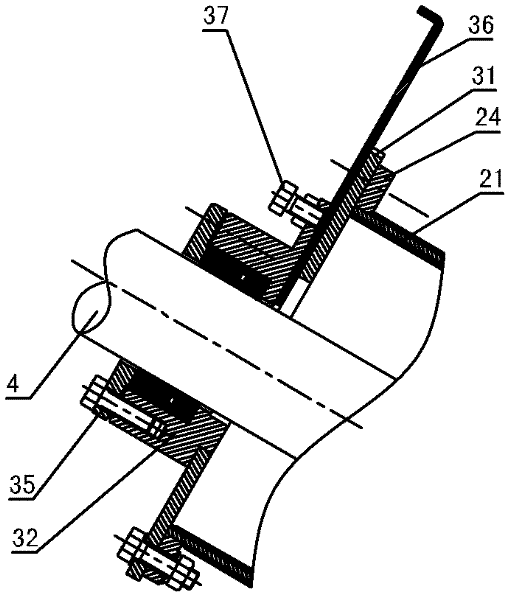

[0019] Such as figure 1 As shown, the gas dust collector includes a sealing assembly 1 , a collecting assembly 2 and a base assembly 3 connected in sequence. The sealing assembly 1 and the collecting assembly 2 are hollow structures for accommodating a drill pipe 4 .

[0020] The hole sealing assembly 1 includes a hole sealing cylinder 11, a hole sealing capsule 12, a capsule inner fixing member 13, a capsule outer fixing member 14, a sealing flange 15, an inner pipeline 16, an outer connecting pipeline 17 and a sealing end cover 18, the The sealing capsule 12 is fixed on the outer circumference of the sealing cylinder 11 by being embedded in the capsule inner fixing member 13 and the outer capsule fixing member 14 at both ends, and one end of the outer circumference of the sealing cylinder 11 is fitted with a capsule with one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com