Low-level multi-step crossing hole gas extraction method for coal interbedding coal seams

A technology of through-layer drilling and gas drainage, which is applied in the directions of gas discharge, earth-moving drilling, mining equipment, etc., can solve the problems of difficult drilling of gas drainage, difficult to return impurities, and difficult to control gas, so as to eliminate outstanding dangers. performance, ensure safe production, and ensure that the extraction meets the standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution, implementation steps and advantages of the present invention clearer, the implementation and steps of the present invention will be further described in detail below in conjunction with the accompanying drawings.

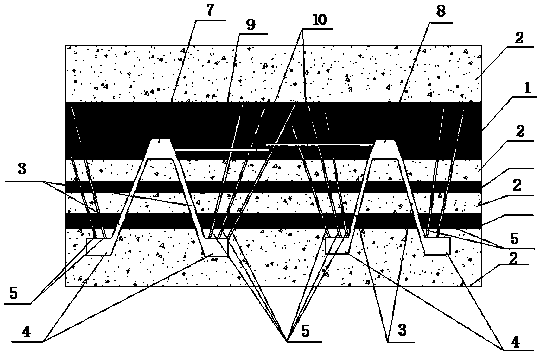

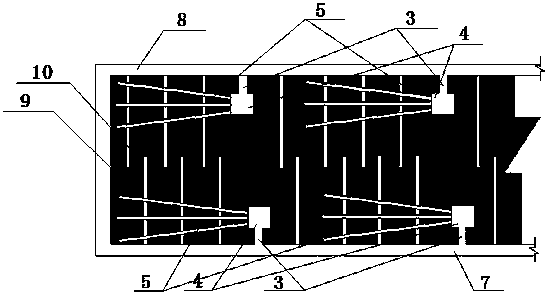

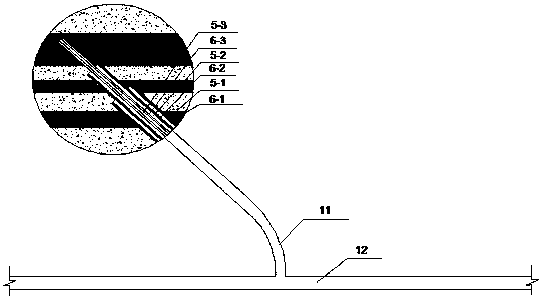

[0028] Figure 1-3 What is shown is a preferred embodiment of the gas extraction method for low-level multi-stage interbedded drilling holes in coal-rock interbedded coal seams of the present invention.

[0029] The described method for gas drainage of low-level multi-stage interbedded drilling holes in coal-rock interbed coal seams comprises the following steps: 1.1 Excavating a transportation channel (7) in the uppermost mining layer (1) of coal-rock interbed coal seams (or return wind trough (8)), along the left (right) side of the roadway, construct a sloped downhill roadway (3) that passes through all coal and rock layers and enters the floor 0.3~1m, and expands a length × width × height = 3.0 m×2.5m×2m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com