Patents

Literature

95results about How to "Safe recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Block chain key trusteeship and recovery method and device based on secrecy sharing technology

InactiveCN107623569ASafekeepingSafe recoveryKey distribution for secure communicationRecovery methodRestoration method

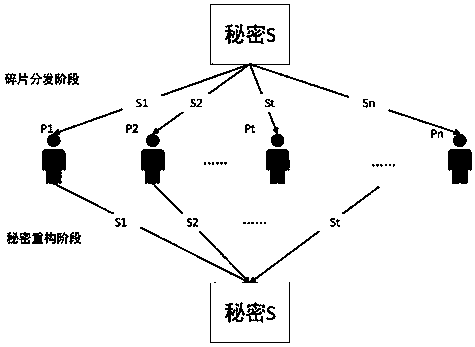

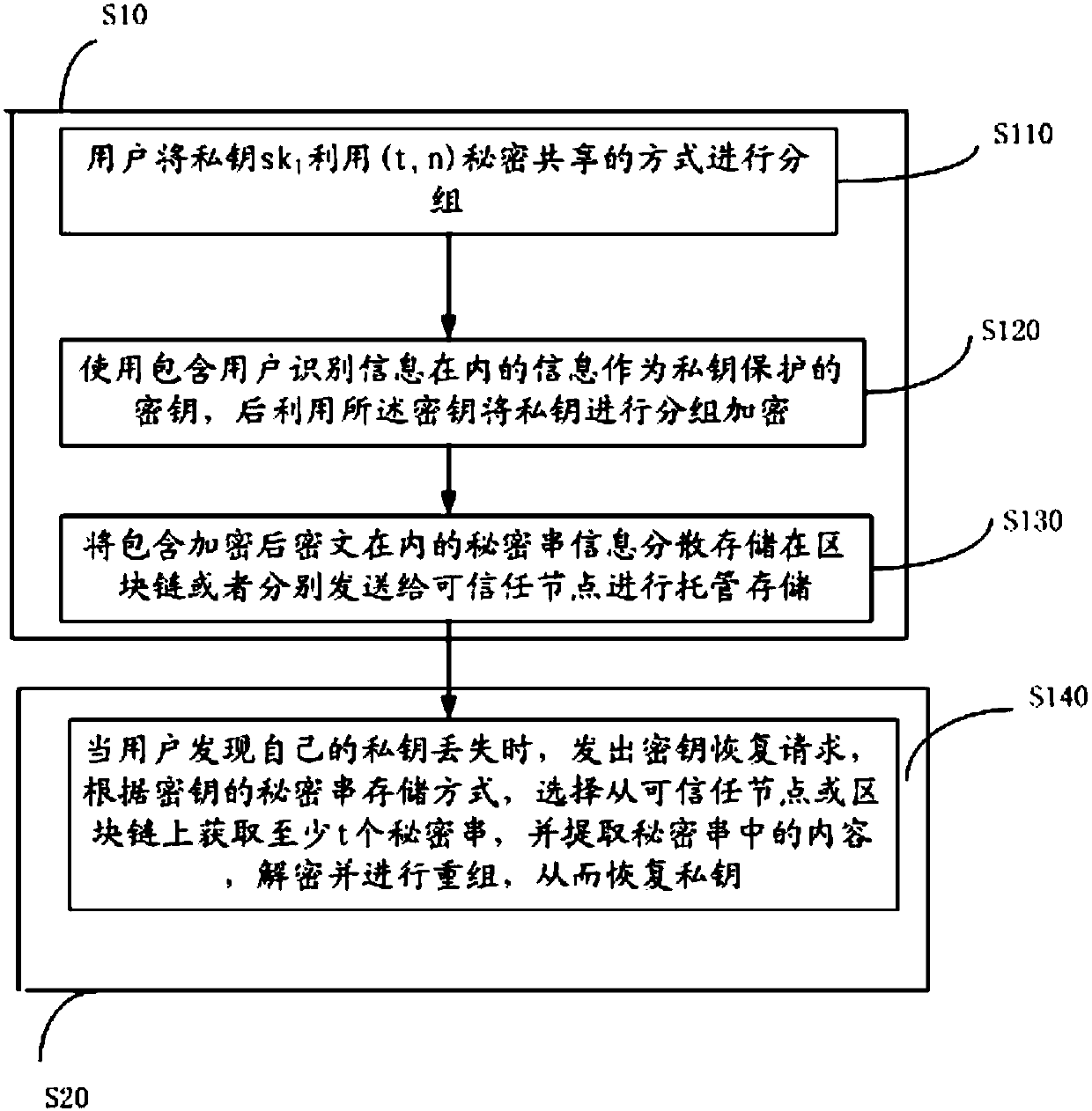

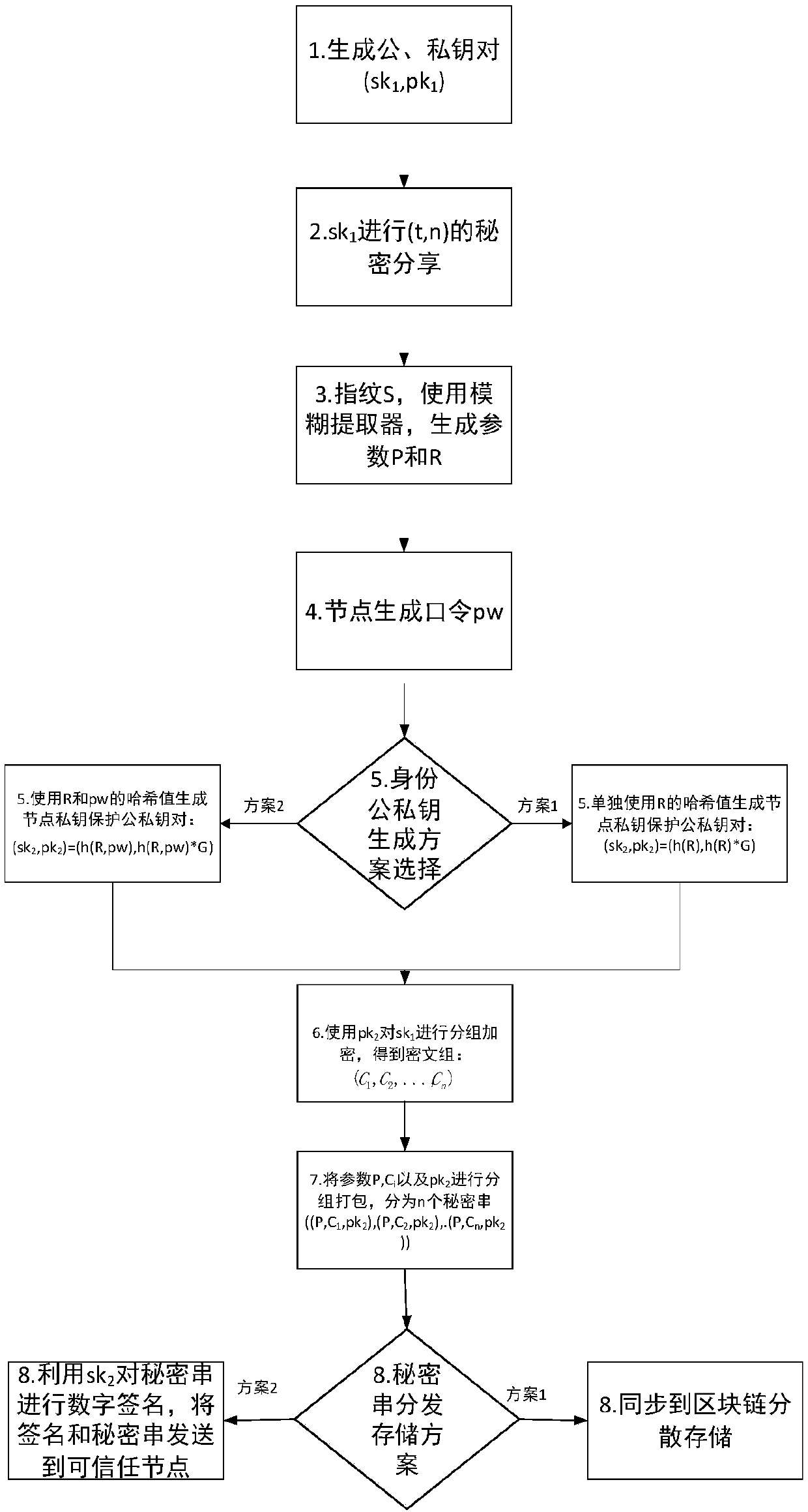

The invention discloses a block chain key trusteeship and recovery method and device based on a secrecy sharing technology. The method comprises the steps that A1, a user groups a private key sk1 in a(t, n) secrecy sharing mode, wherein the n is the number of fragments of shared secrecies obtained by splitting the private key, the t is the minimum number of the fragments for recovery of the private key, and the t is greater than or equal to 2 and is smaller than or equal to the n; A2, information containing user identification information is taken as a private key protection key, and then grouping encryption is carried out on the private key through utilization of the key; and A3, secrecy string information containing encrypted ciphertexts is dispersely stored to a block chain or is sentto trusted nodes for trusteeship and storage, when the user discovers that own private key is lost, a key recovery request is generated, at least t secrecy strings are obtained from the trusted nodesor the block chain in a secrecy string storage mode of the key, and the content in the secrecy strings is extracted, decrypted and recombined, so the private key is recovered. According to the methodand the device, the secrecy sharing technology is applied to a block chain scene for the first time, thereby solving the private key trusteeship and recovery security problem.

Owner:JUZIX TECH SHENZHEN CO LTD

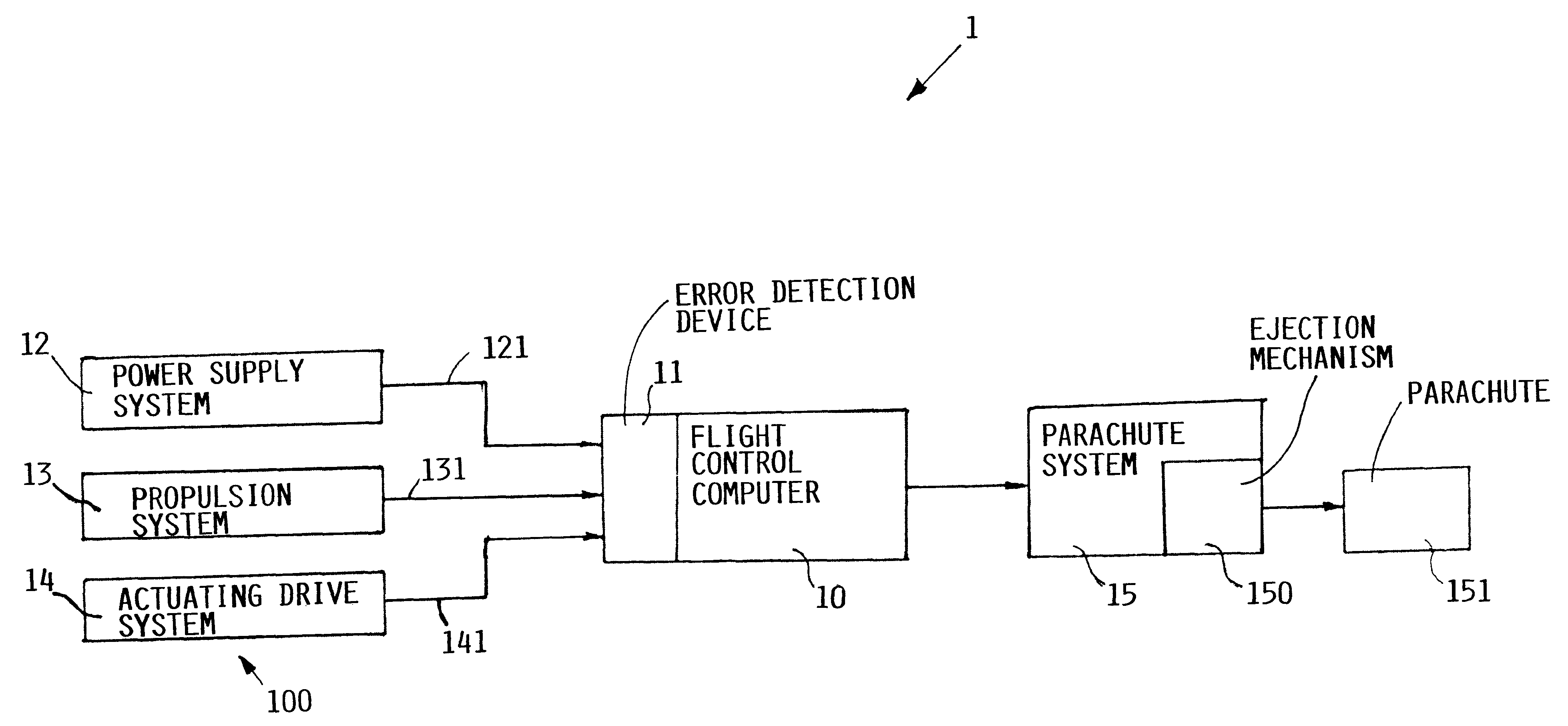

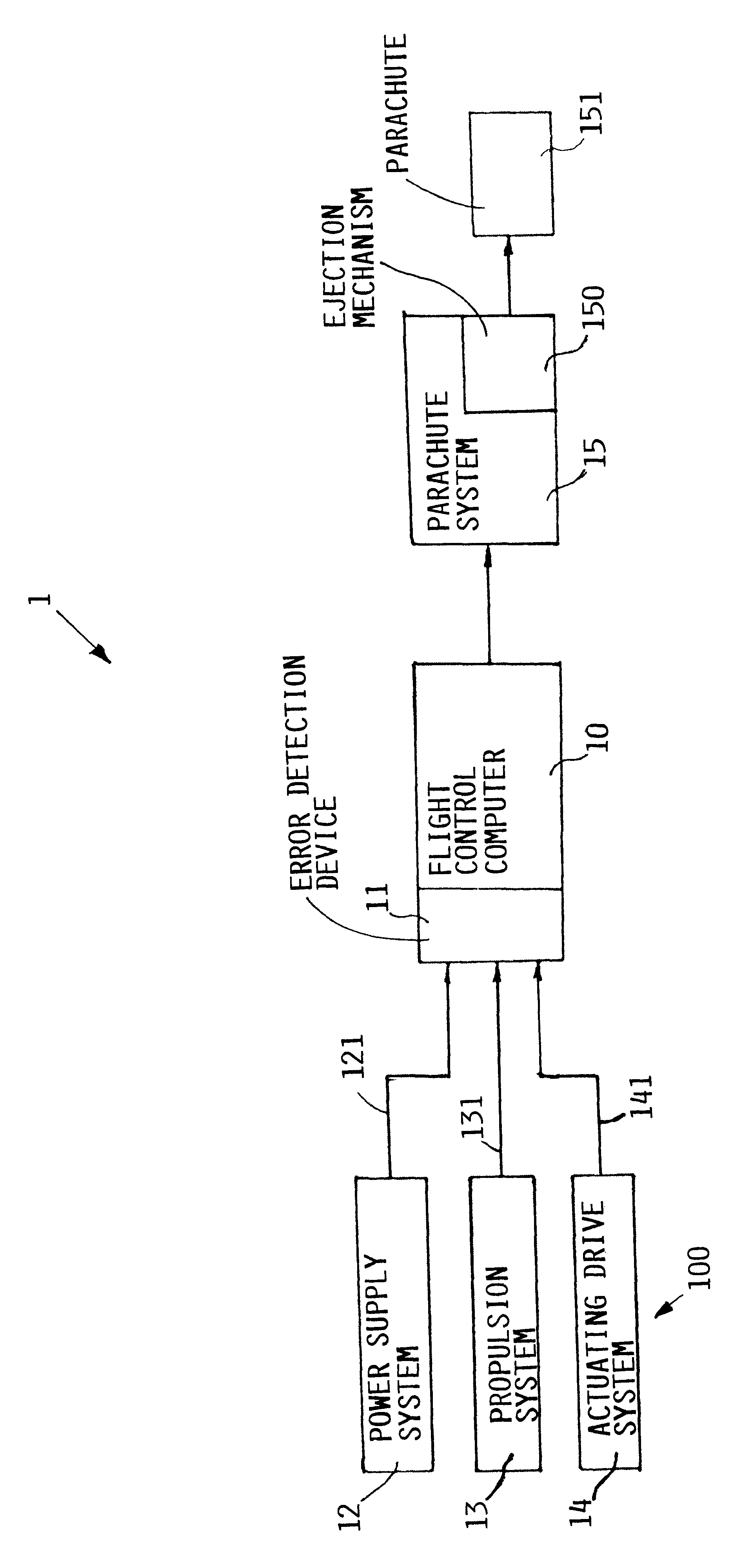

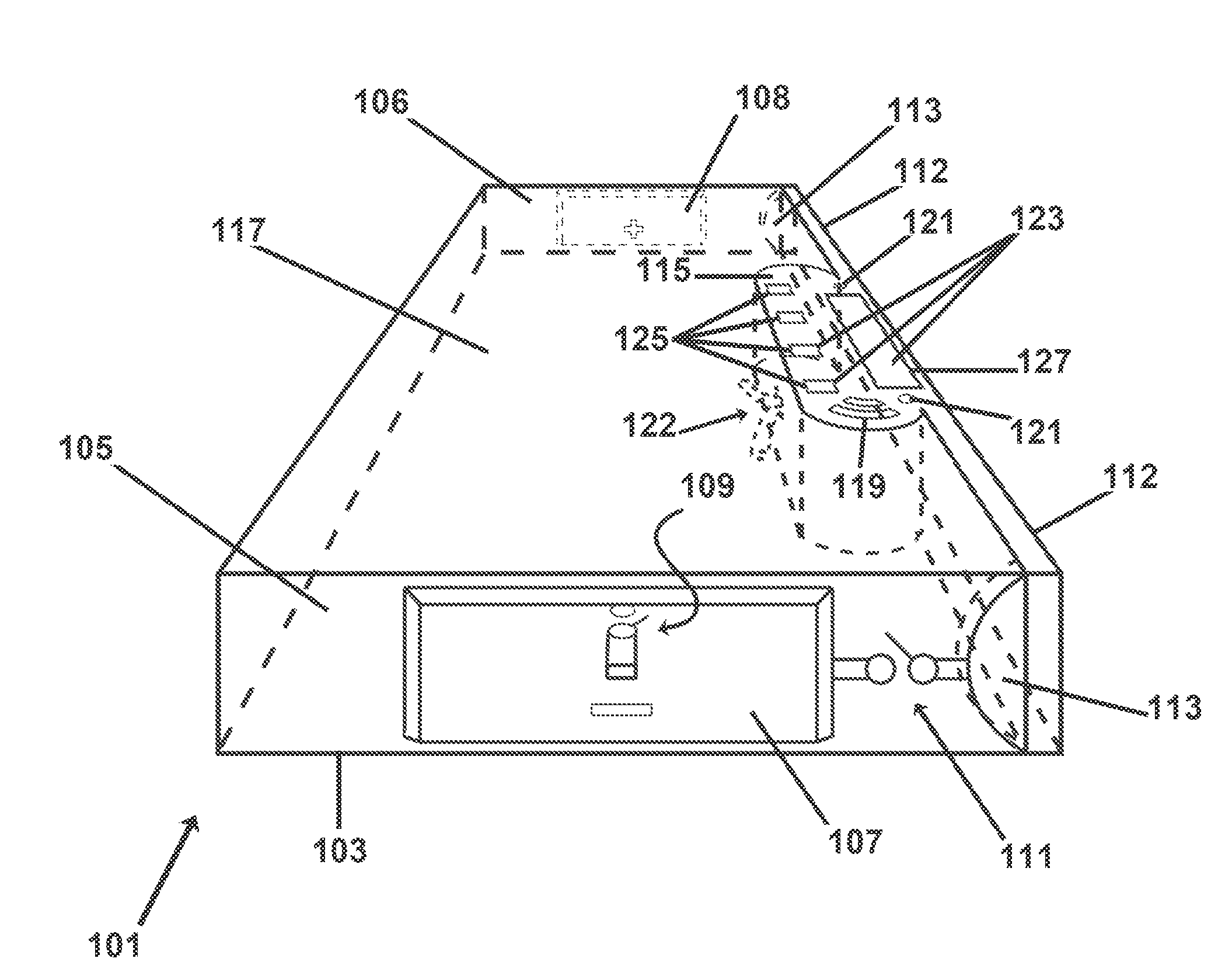

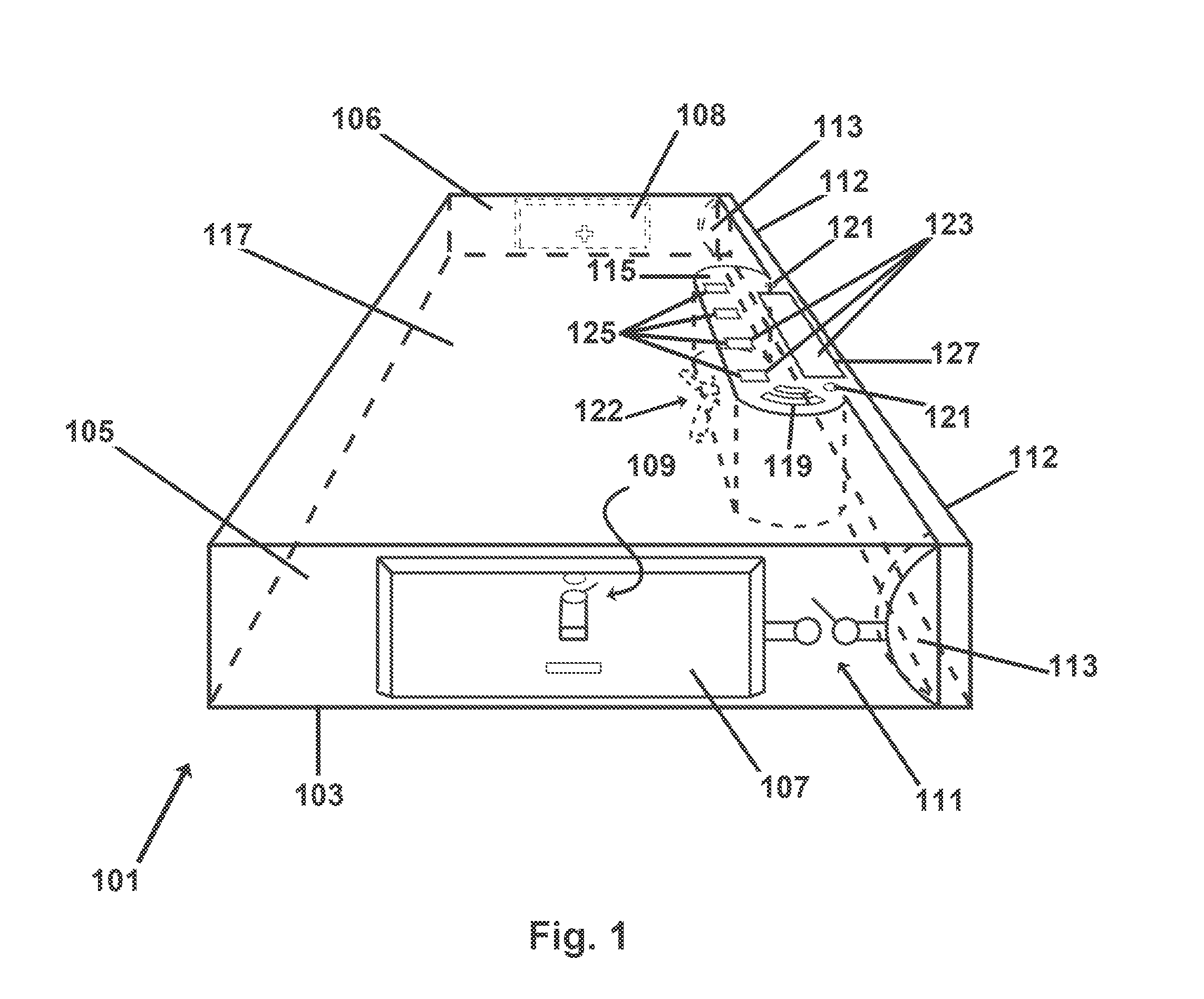

Method for deploying a parachute on a drone

InactiveUS20010048050A1Safe recoveryReduce riskUnmanned aerial vehiclesNon-canopied parachutesControl signalUncrewed vehicle

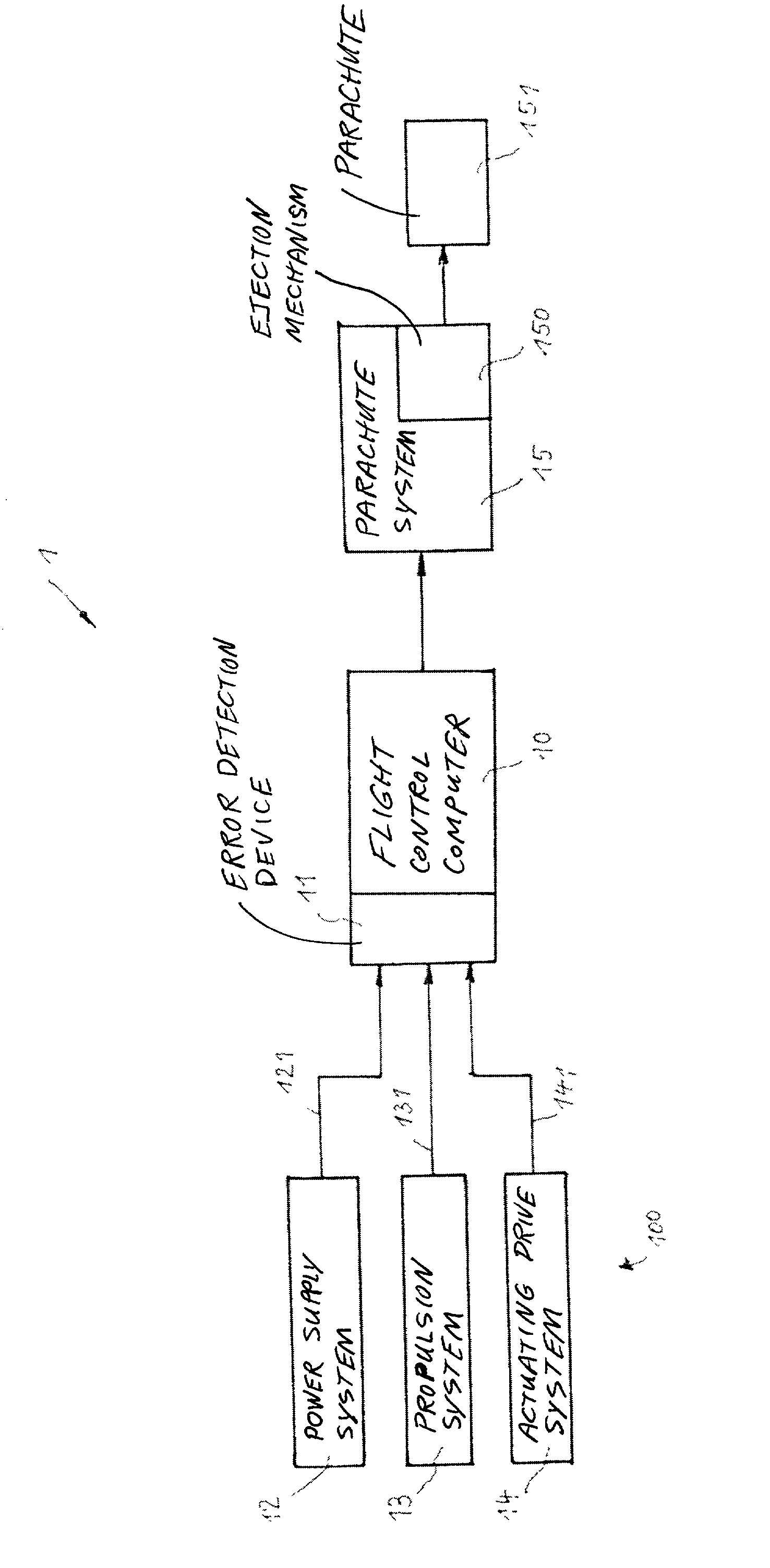

A flying drone includes a flight control computer, a parachute system with a parachute, a power supply system, a propulsion system, and an actuating drive system, without any of these systems being redundantly duplicated. To prevent uncontrolled crashing of the drone due to a critical error of any subsystem, signals or data are supplied from the power supply system, the propulsion system, and the actuating drive system, to an error detection or recognition device, which detects defined errors or error combinations in the provided signals or data and then supplies a deployment signal to the parachute system, which responsively generates a control signal that triggers an ejection mechanism to eject the parachute.

Owner:EUROCOPTER DEUT GMBH

Method for deploying a parachute on a drone

InactiveUS6471160B2Safe recoveryReduce riskFloatsUnmanned aerial vehiclesControl signalUncrewed vehicle

Owner:AIRBUS HELICOPTERS DEUT GMBH

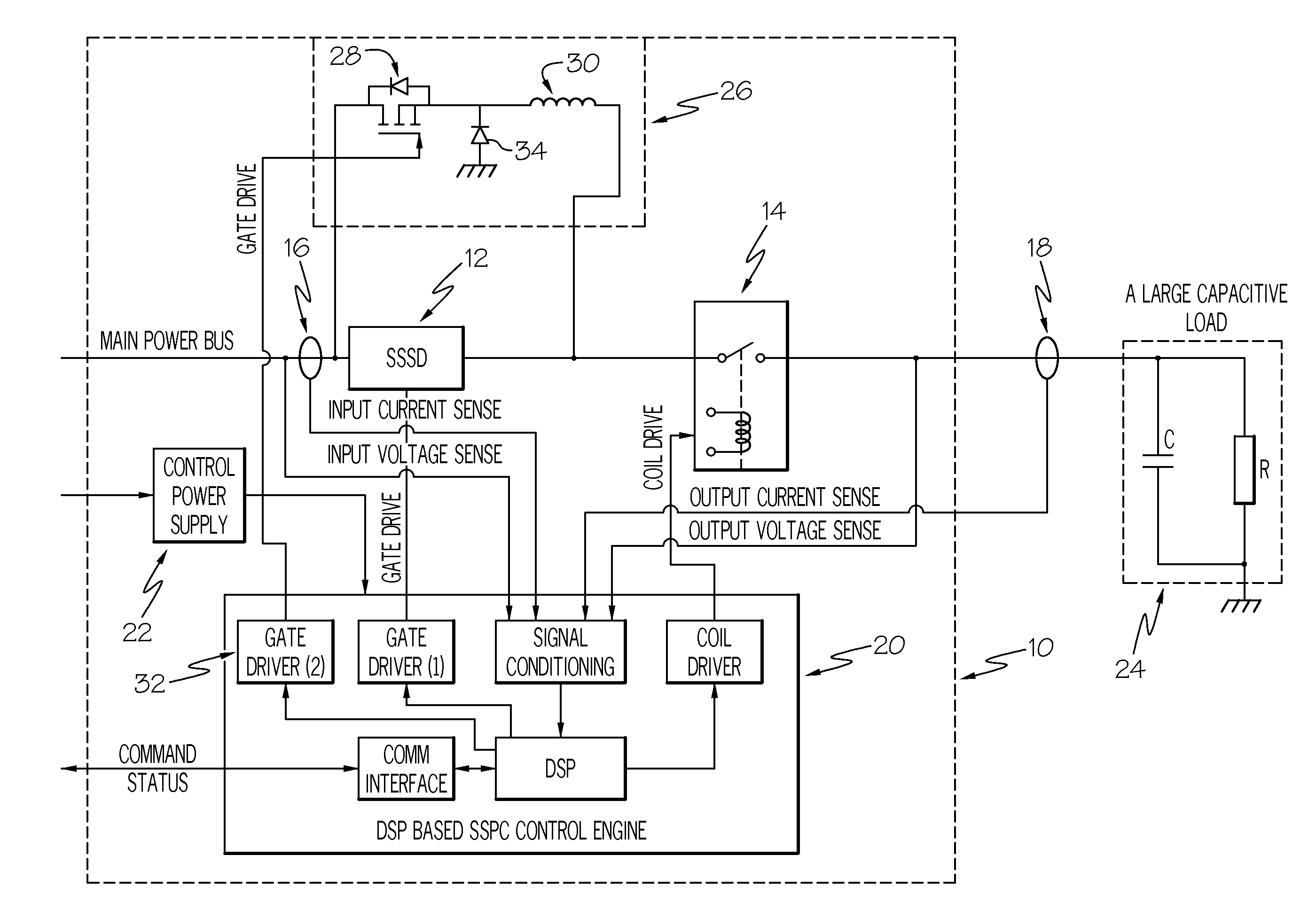

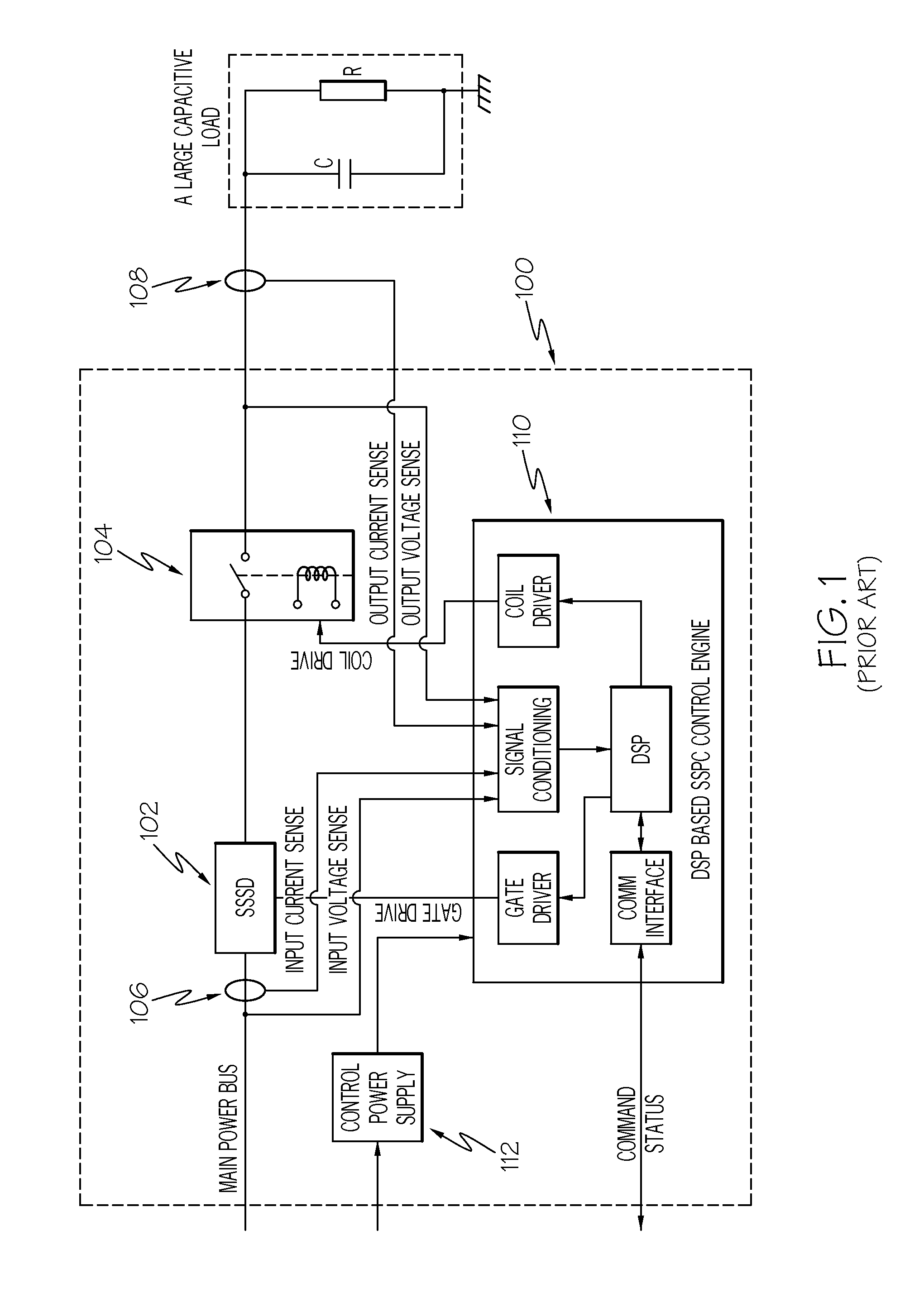

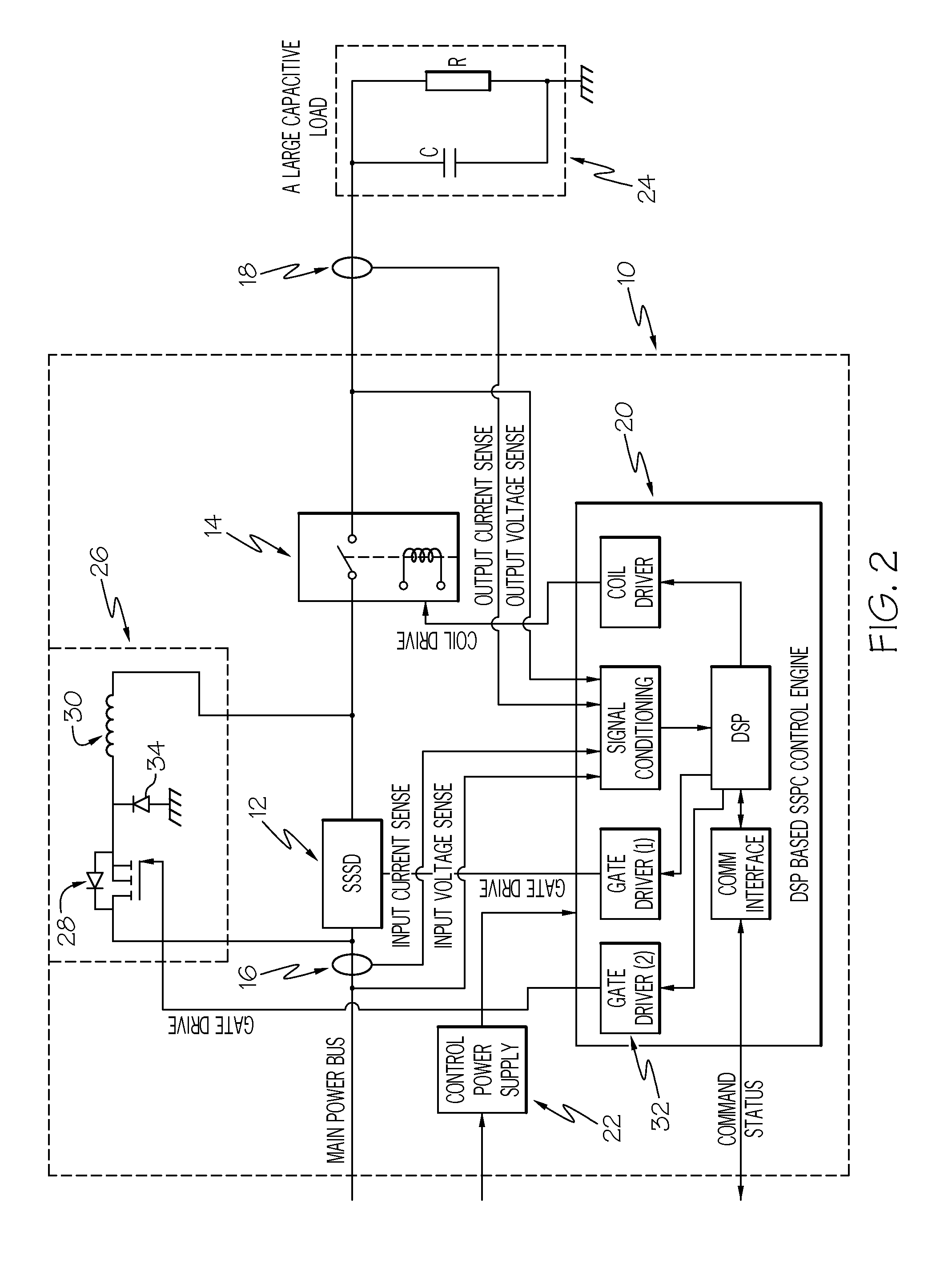

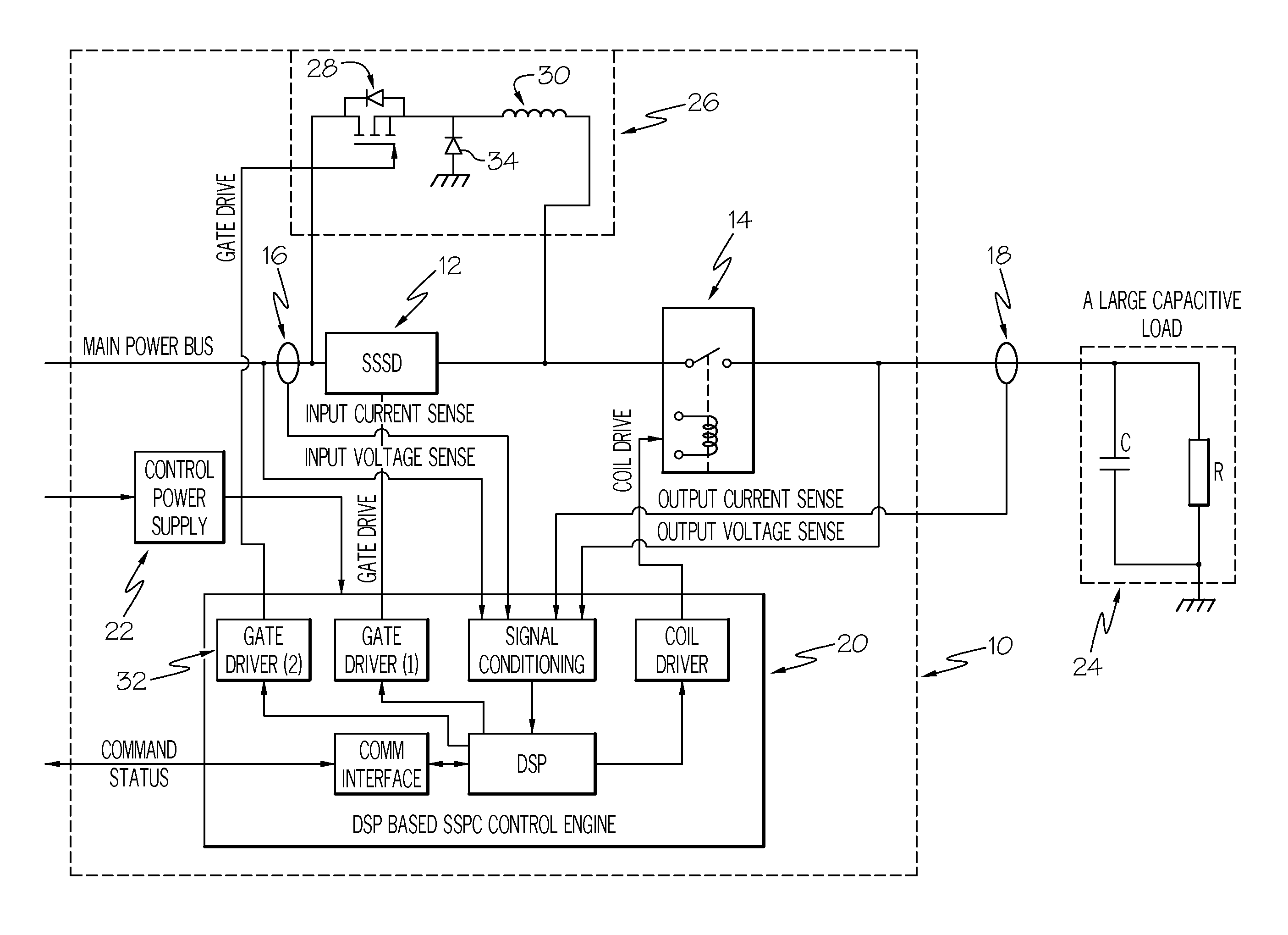

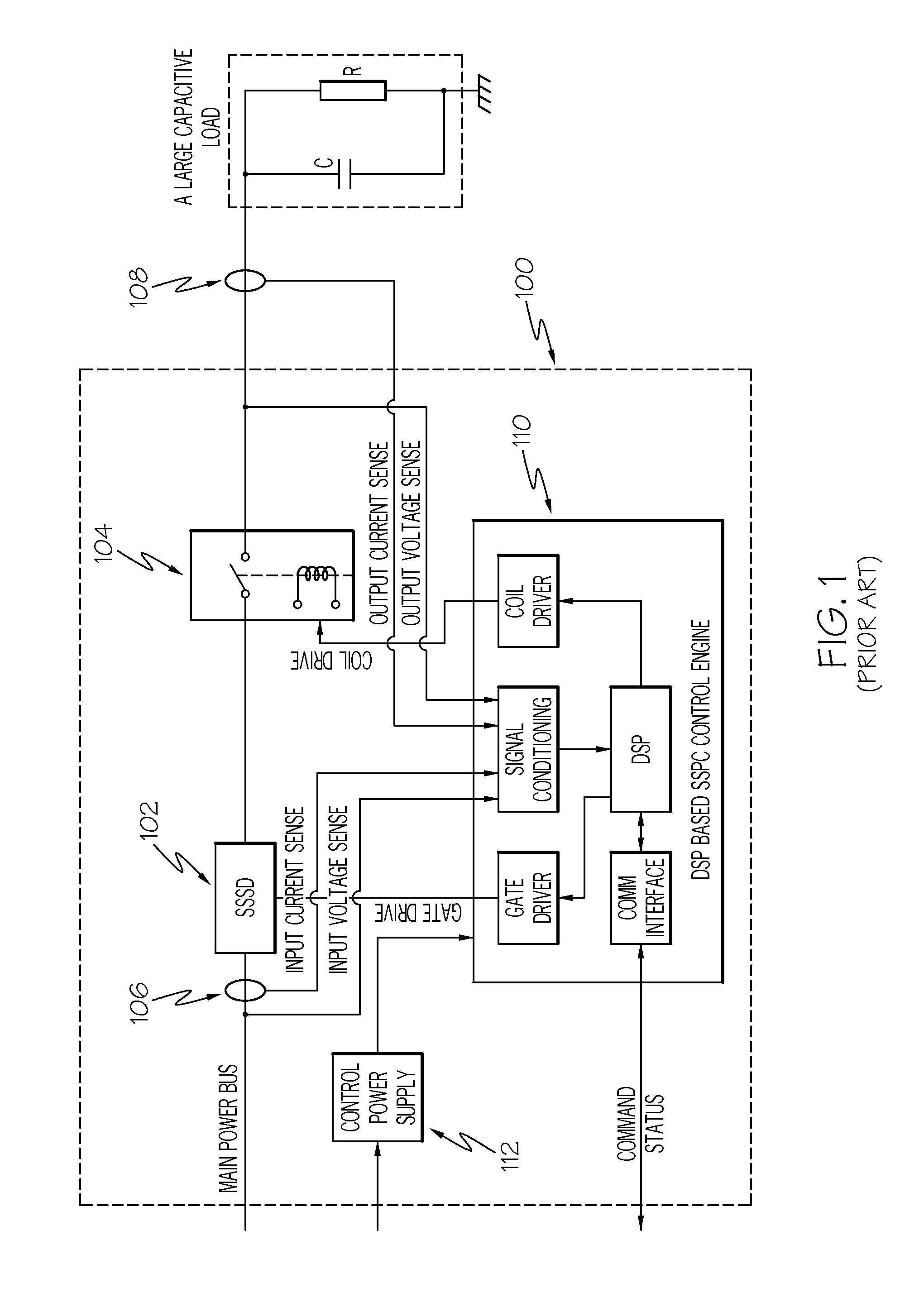

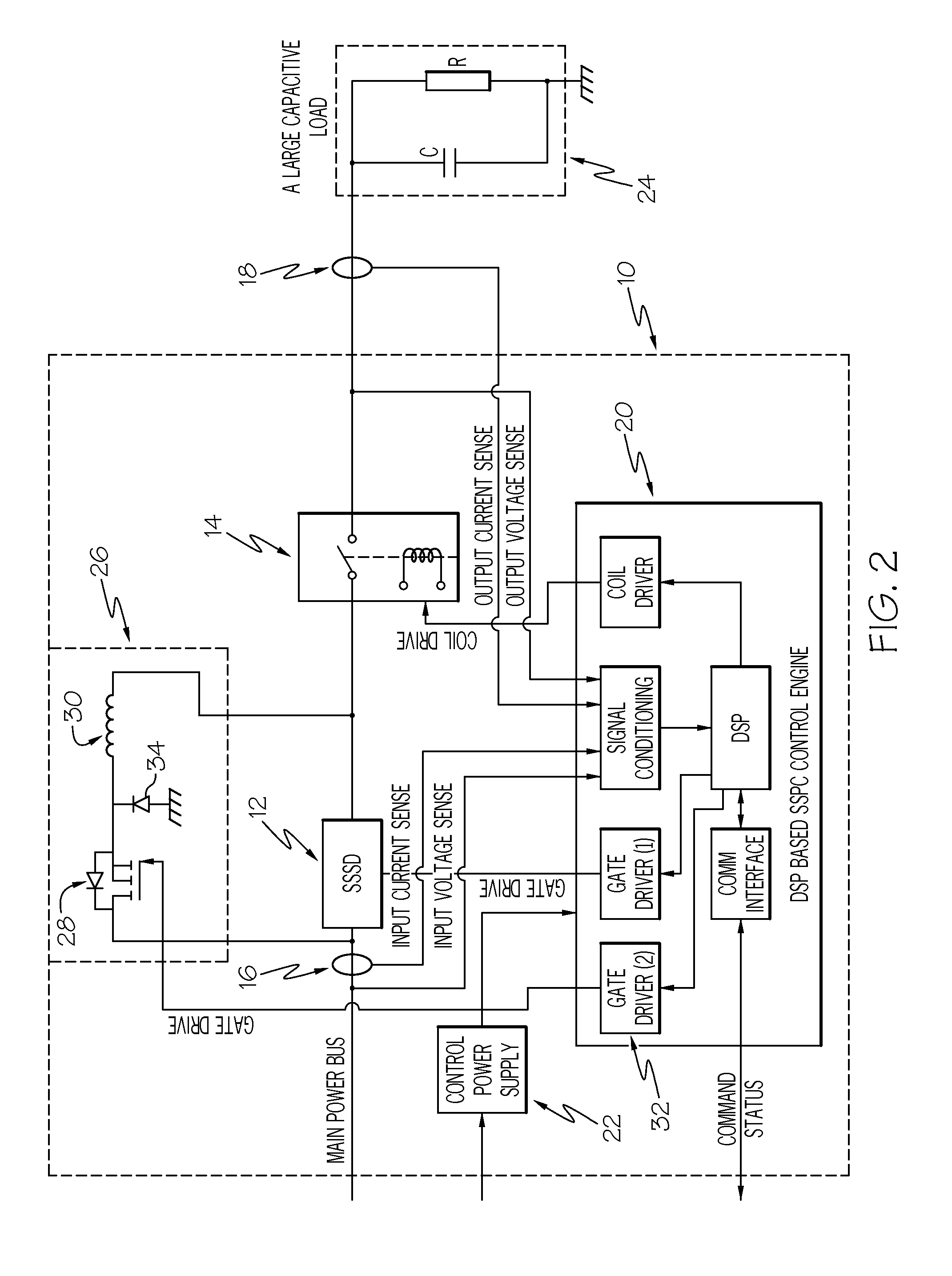

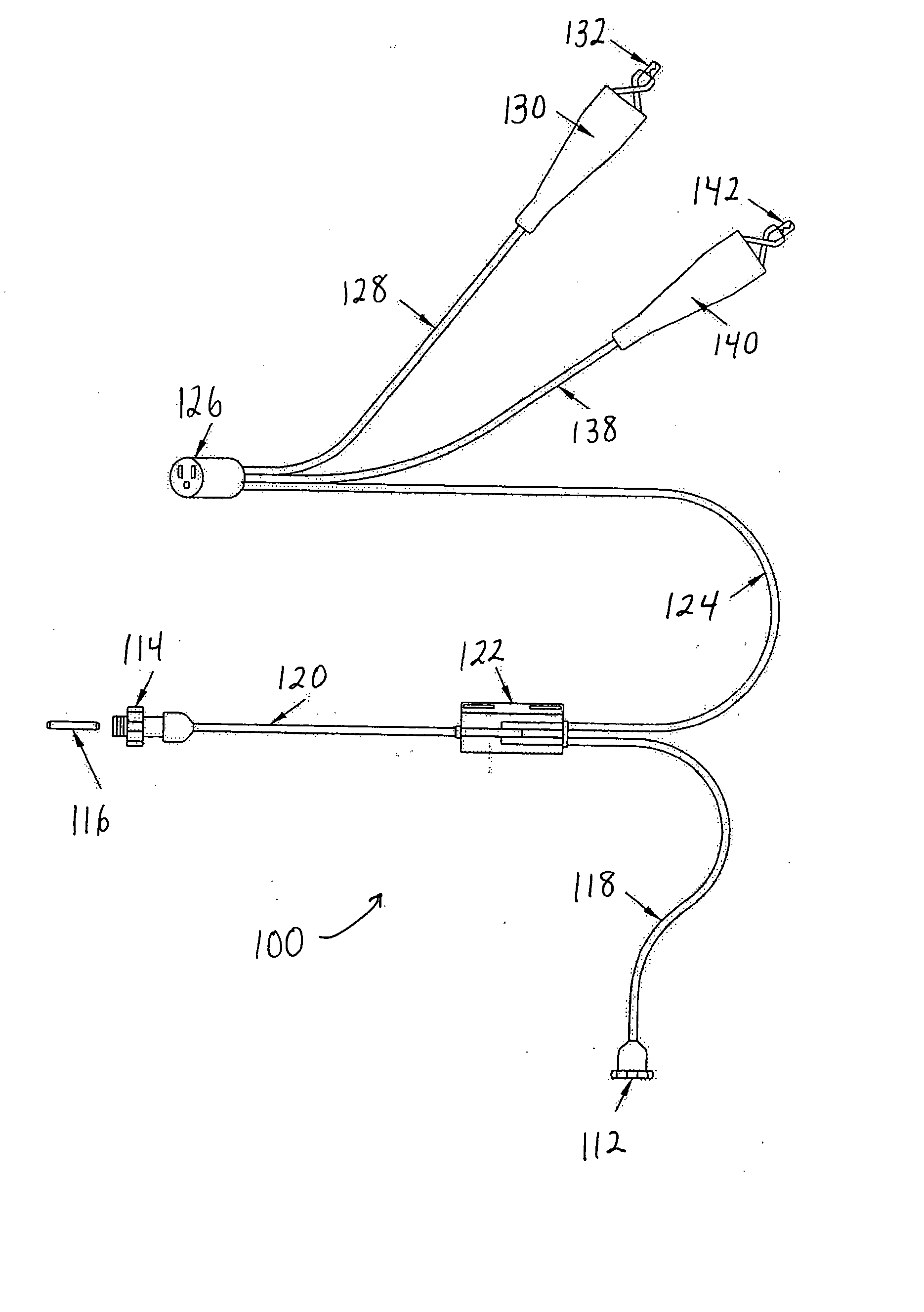

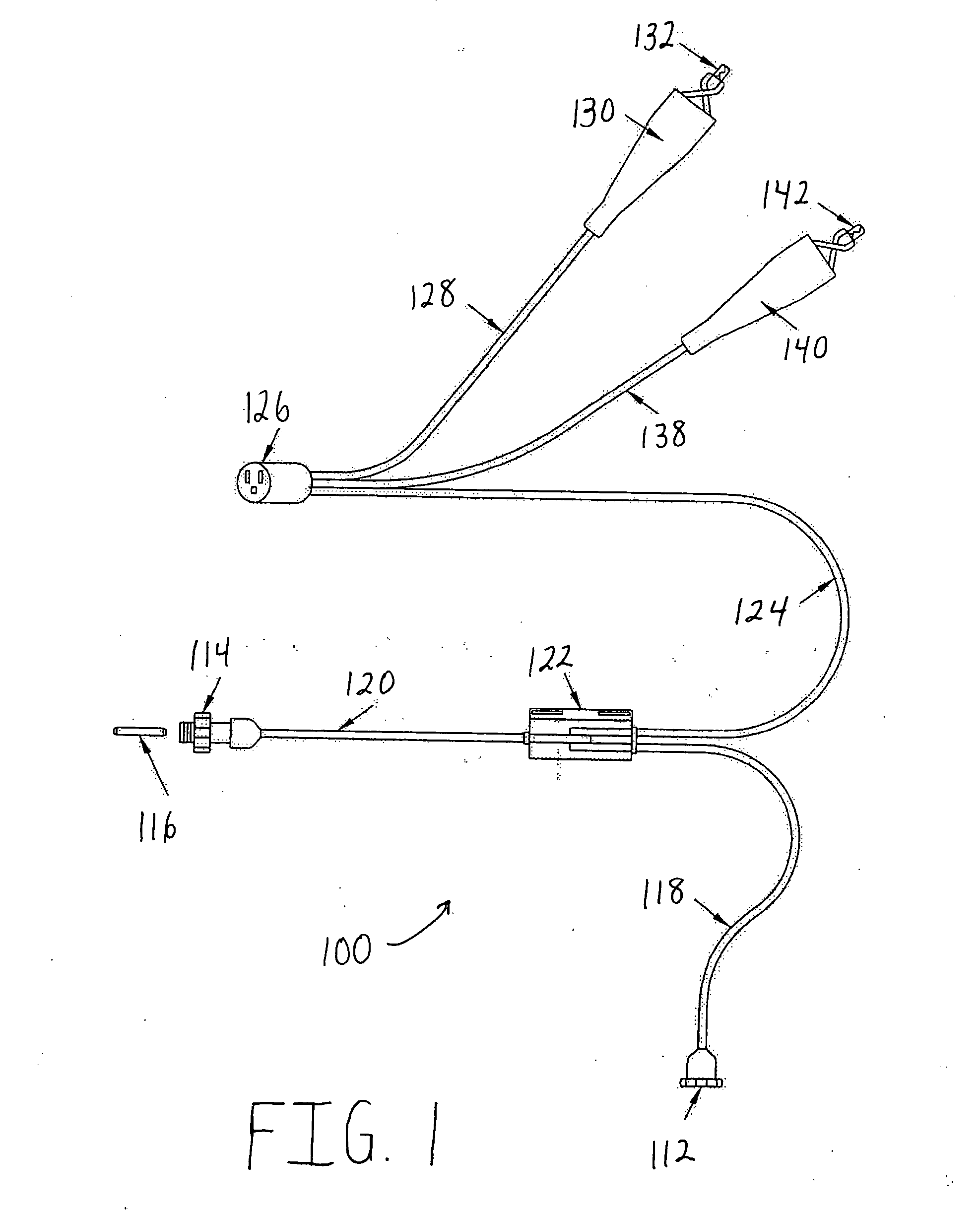

High power DC sspc with capability of soft turn-on to large capacitive loads

ActiveUS20110309809A1Safe recoveryElectronic switchingEmergency protective arrangements for limiting excess voltage/currentMOSFETPower controller

Pre-charge circuitry allows capacitive loads connected to a solid state power controller to be gradually charged up by a PWM, generated with a cycle by cycle current limit, switching a single MOSFET in series with an inductor, before the SSPC is turned on. The pre-charge circuitry may require only three additional components, e.g., a MOSFET, an inductor and a diode, along with a designated MOSFET gate driver.

Owner:HONEYWELL INT INC

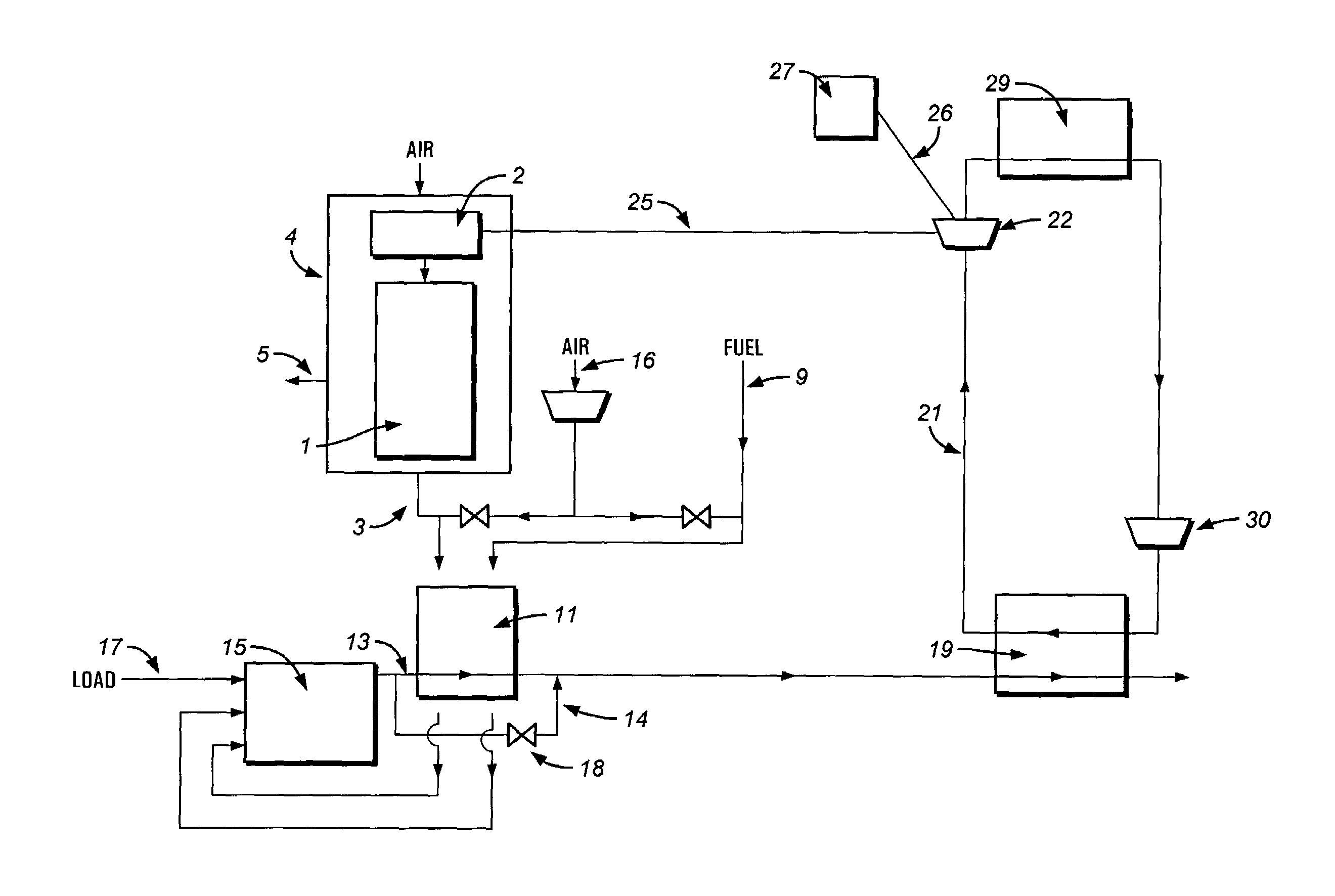

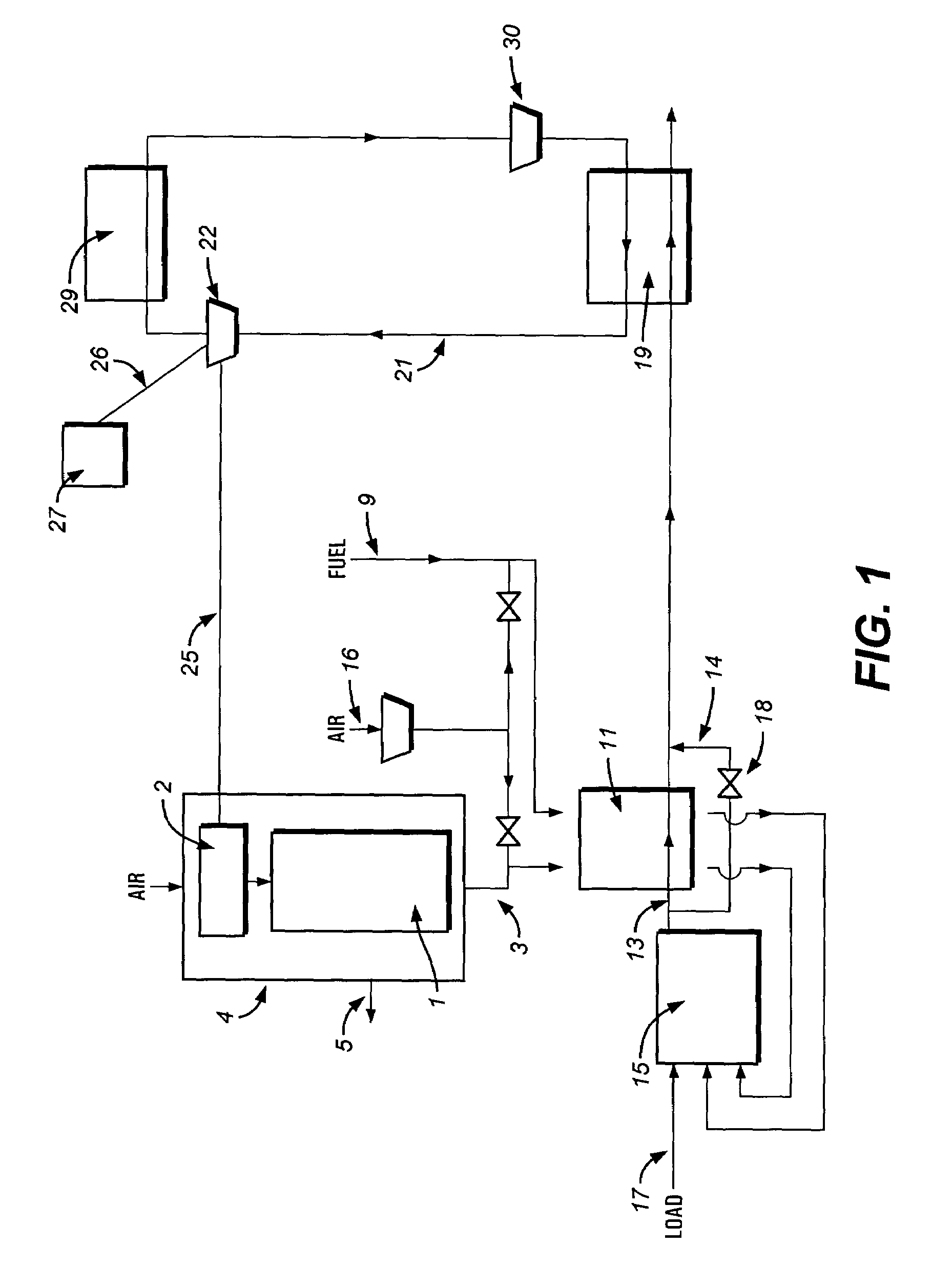

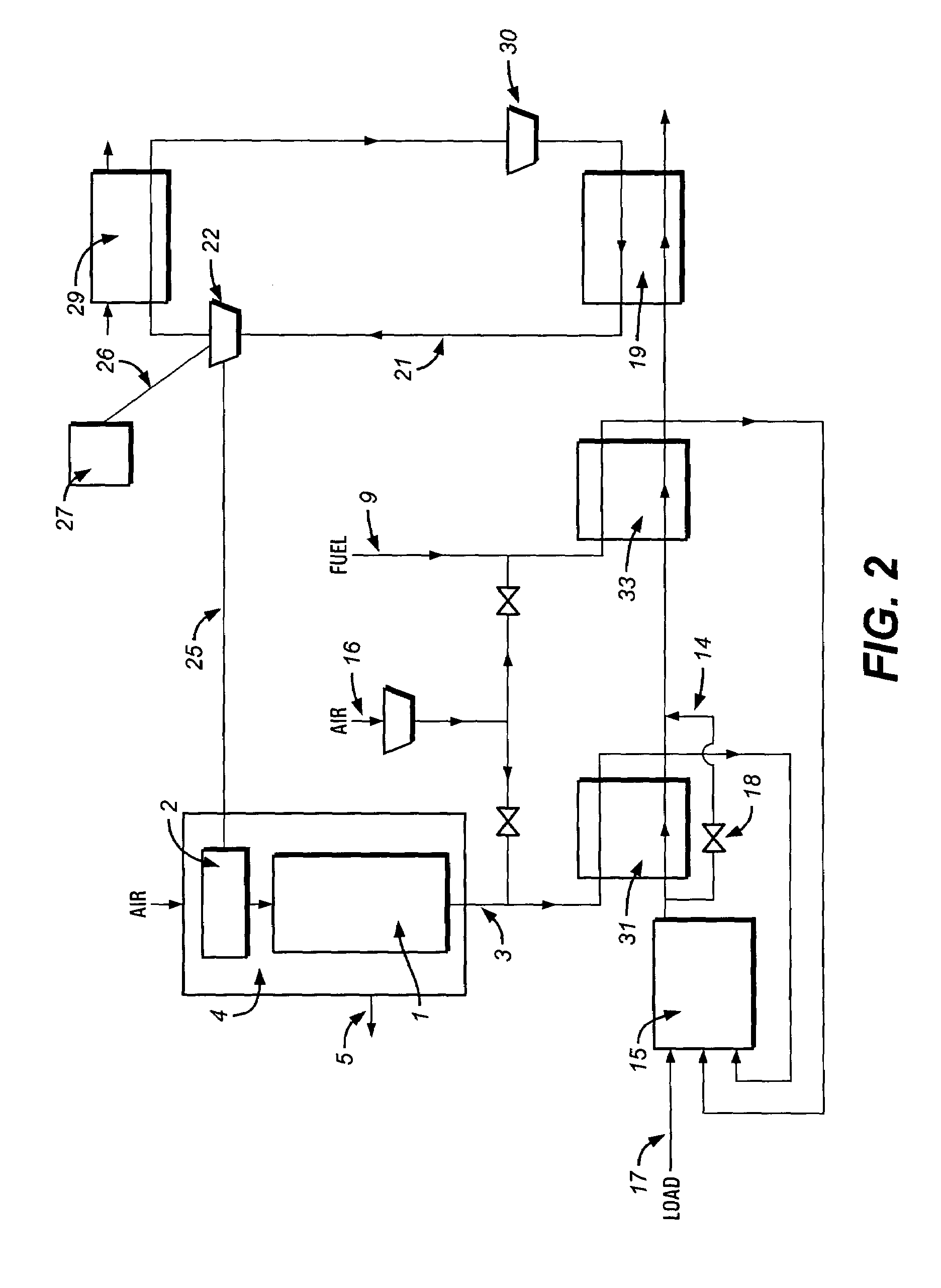

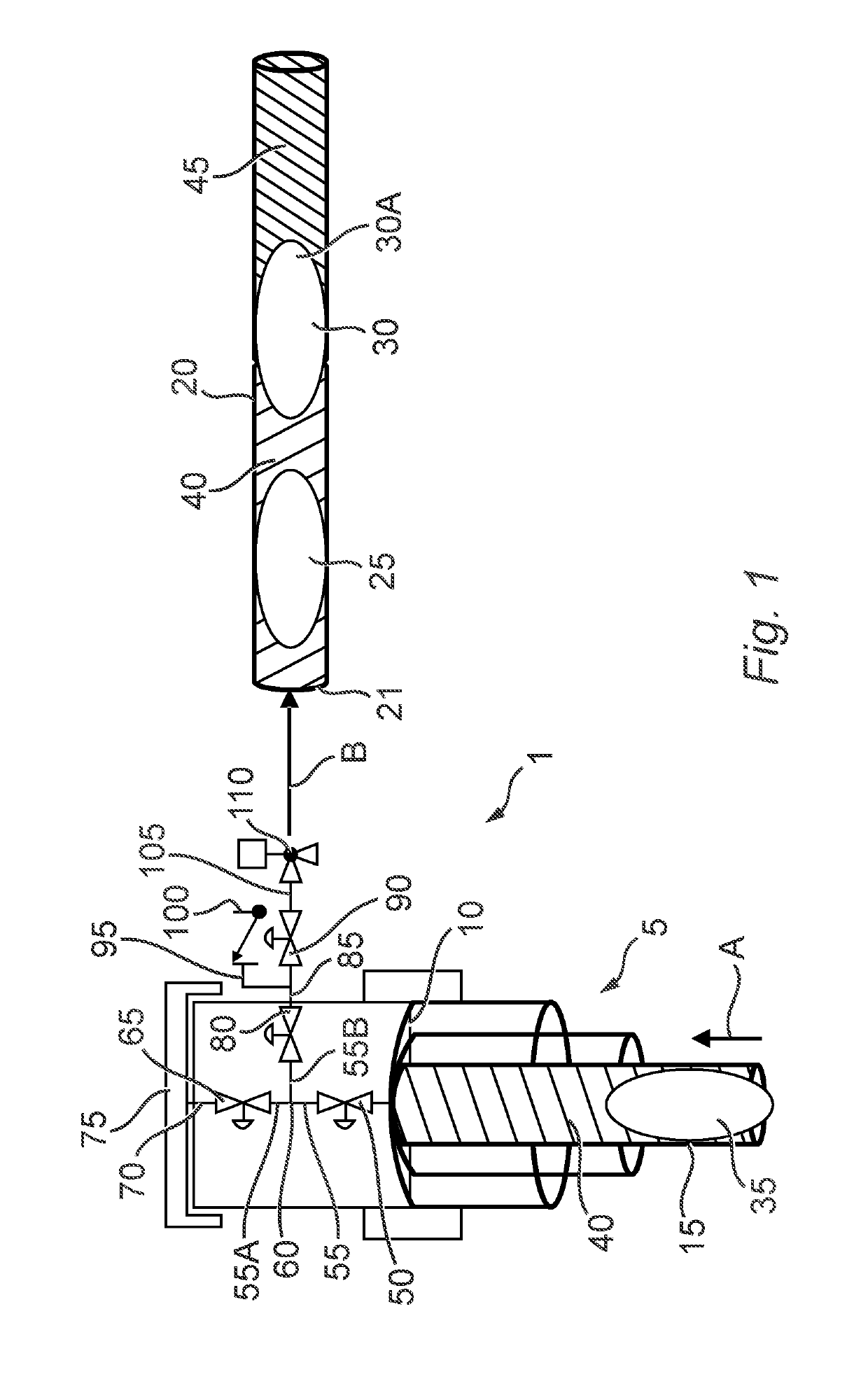

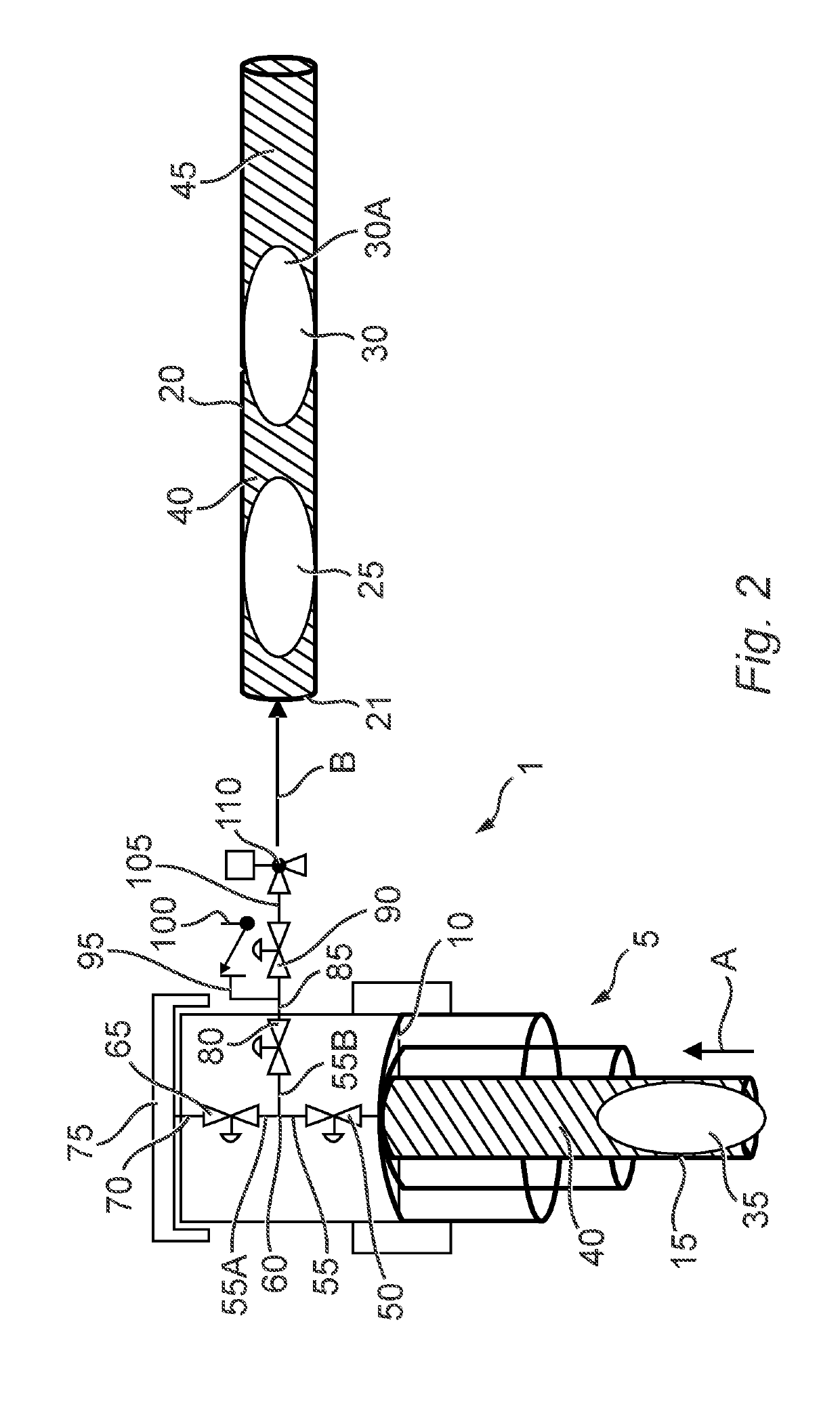

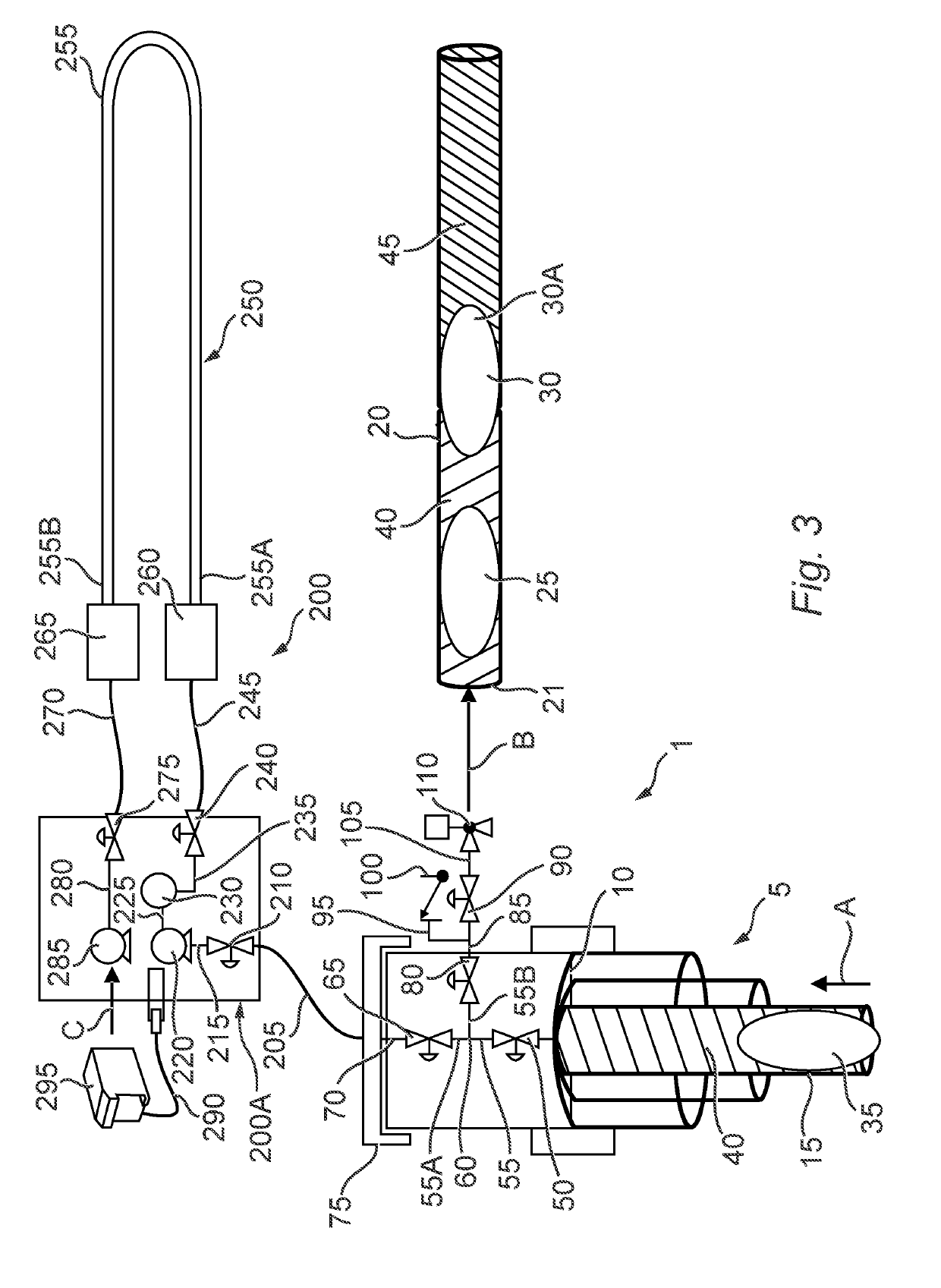

Integrated heat recovery systems and methods for increasing the efficiency of an oxygen-fired furnace

InactiveUS7062912B2Improve energy efficiencyHigh oxygen contentSolidificationLiquefactionFlue gasAbsorbed energy

An air separation unit separates air into an oxygen-rich and oxygen-deficient gas. Fuel gas and the oxygen-rich gas are preheated at heat exchangers through which hot flue gas flows. Combustion of the preheated fuel and oxygen-rich gases result in the hot flue gas. The hot flue gas is cooled at the heat exchangers and flows through a waste heat boiler. Water and / or steam flowing through the waste heat boiler absorbs energy from the cooled flue gas thereby producing heated steam. The heated steam flows through a turbine to produce power. The power is transferred to the air separation unit, thus reducing a power requirement of the air separation unit needed to separate the air.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

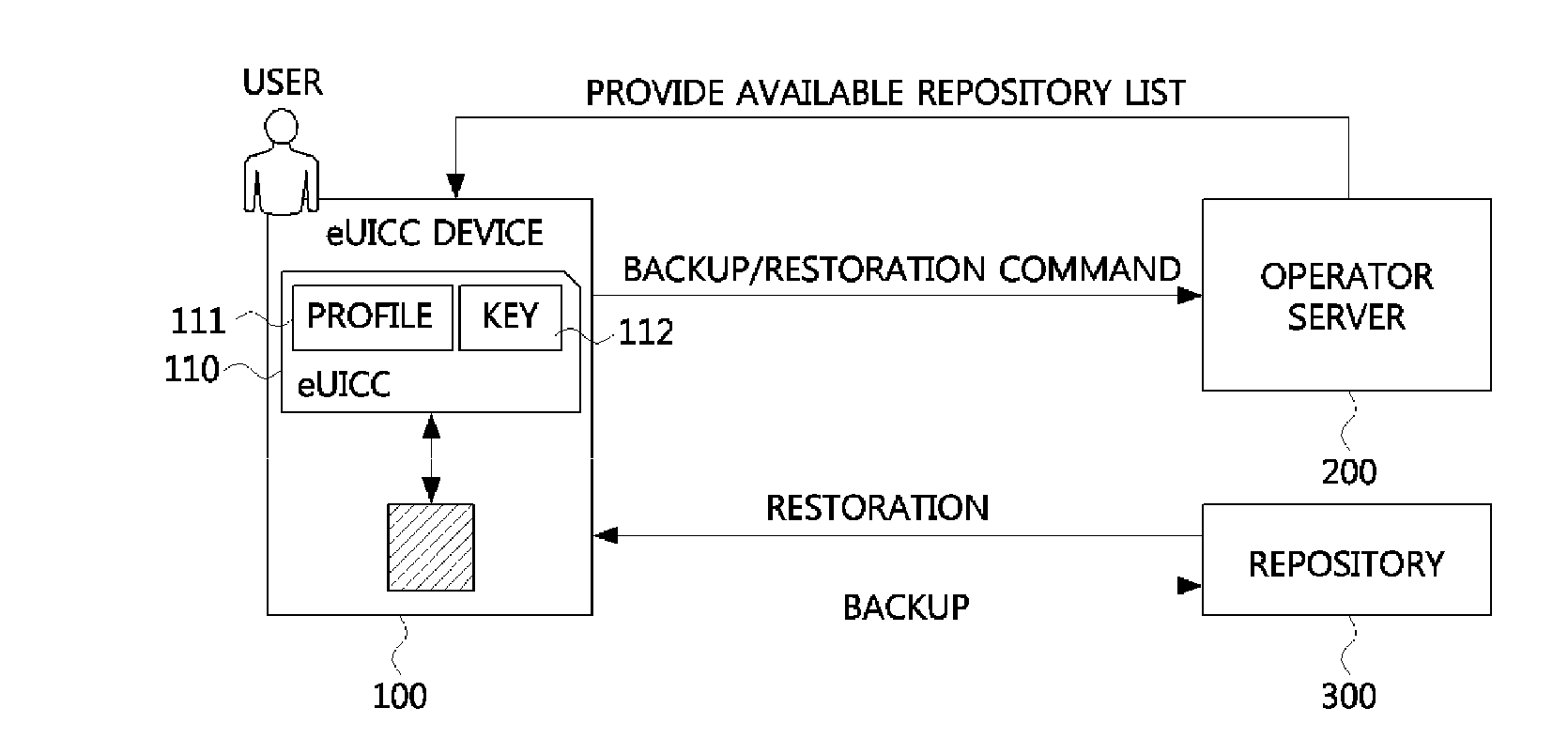

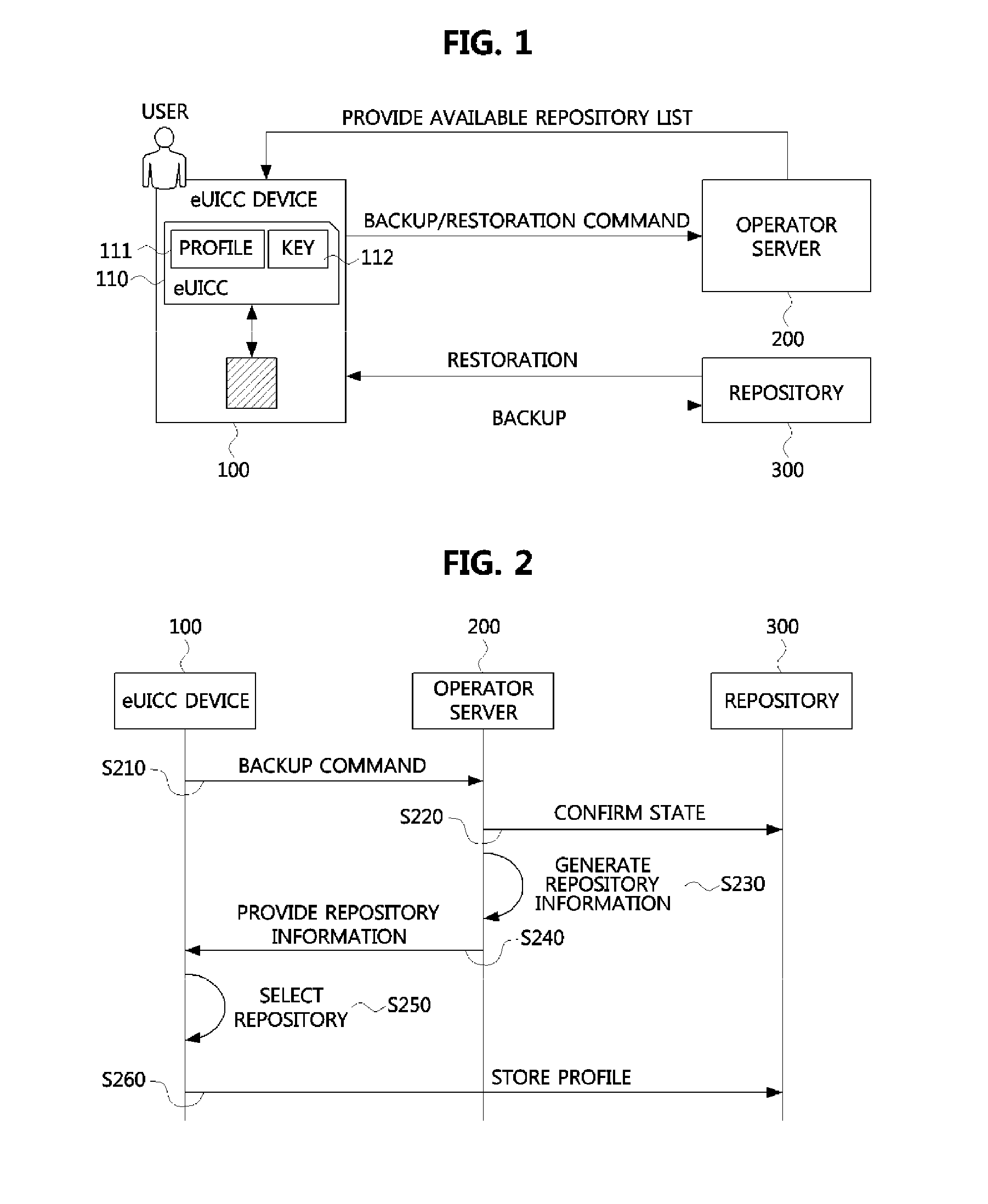

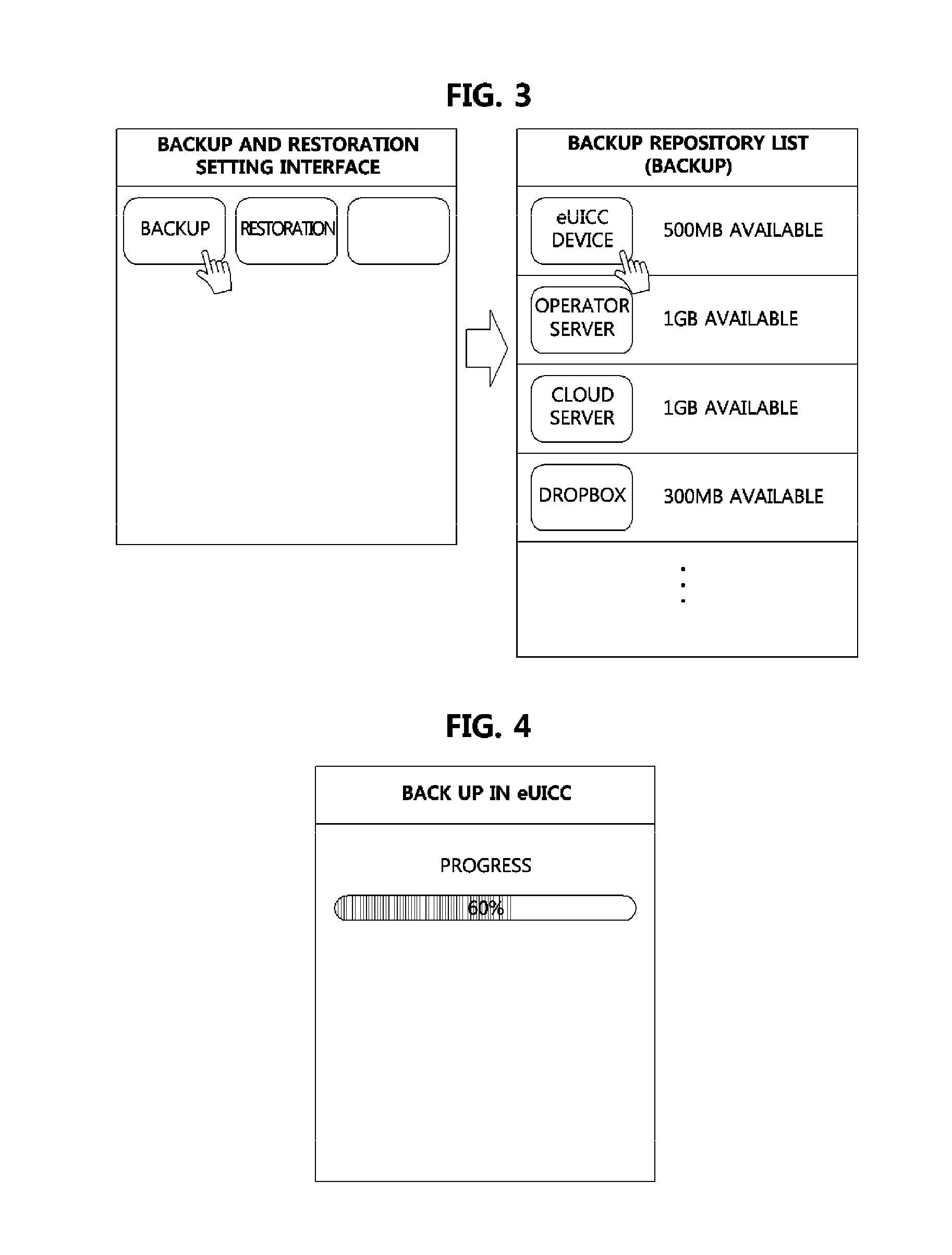

Methods of backing up and restoring profile, and devices therefor

InactiveUS20130339305A1Safe storageSafe recoveryDigital data processing detailsDatabase distribution/replicationInternet privacyAuthentication

Methods of backing up and restoring a profile and devices therefor are disclosed. The method of backing up a profile includes transmitting, by an authentication module, a profile backup command to an operator server, transmitting, by the operator server, information to the authentication module, the information being generated by confirming a state of at least one repository capable of storing the profile, and storing the profile in a selected repository. The method of restoring a profile includes transmitting, by an authentication module, a profile restoration command to an operator server, transmitting, by the operator server, information to the authentication module, the information being generated by confirming a state of at least one repository having a profile stored therein, and restoring, in an authentication module, a profile stored in a selected repository.

Owner:KIM KWAN LAE +3

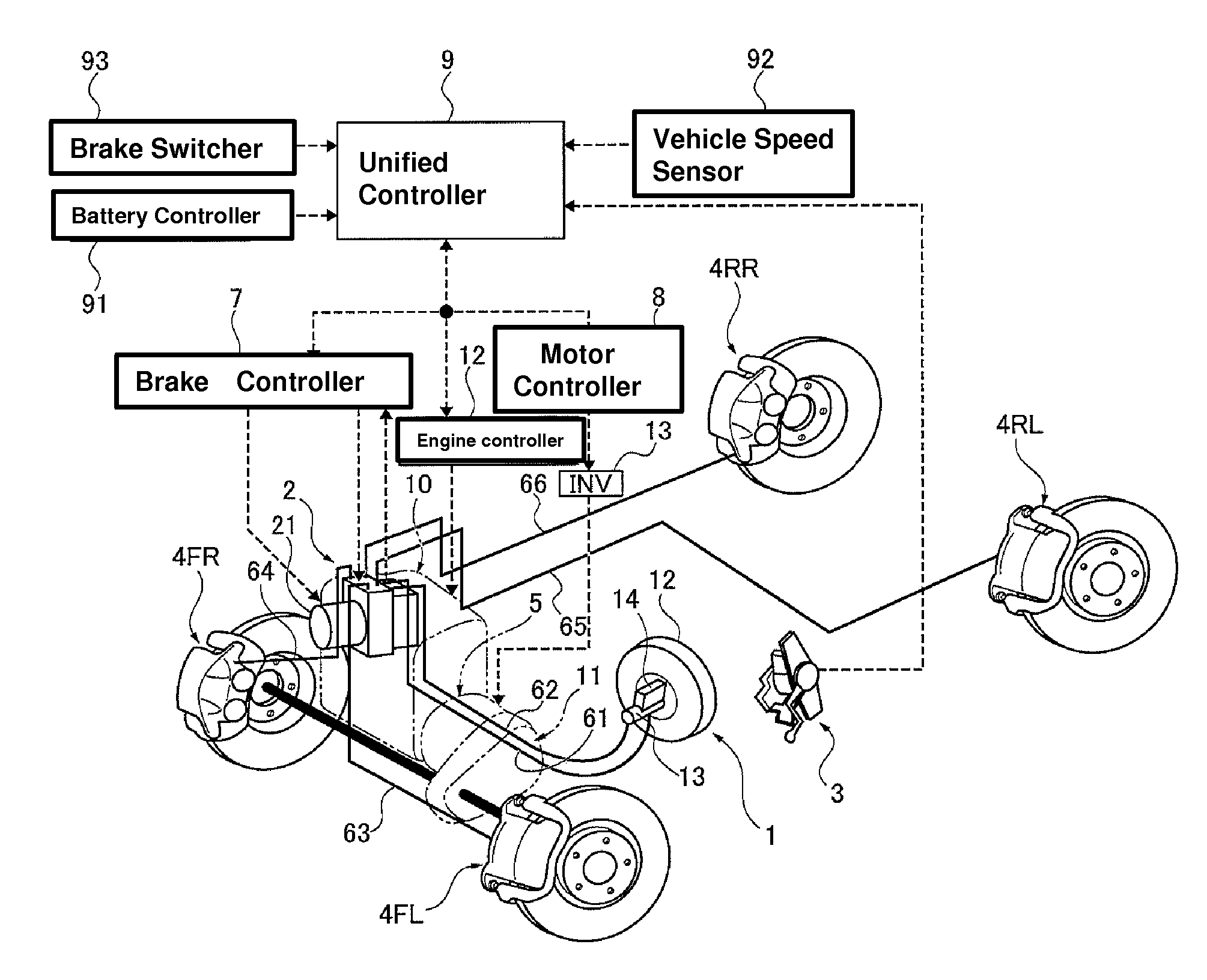

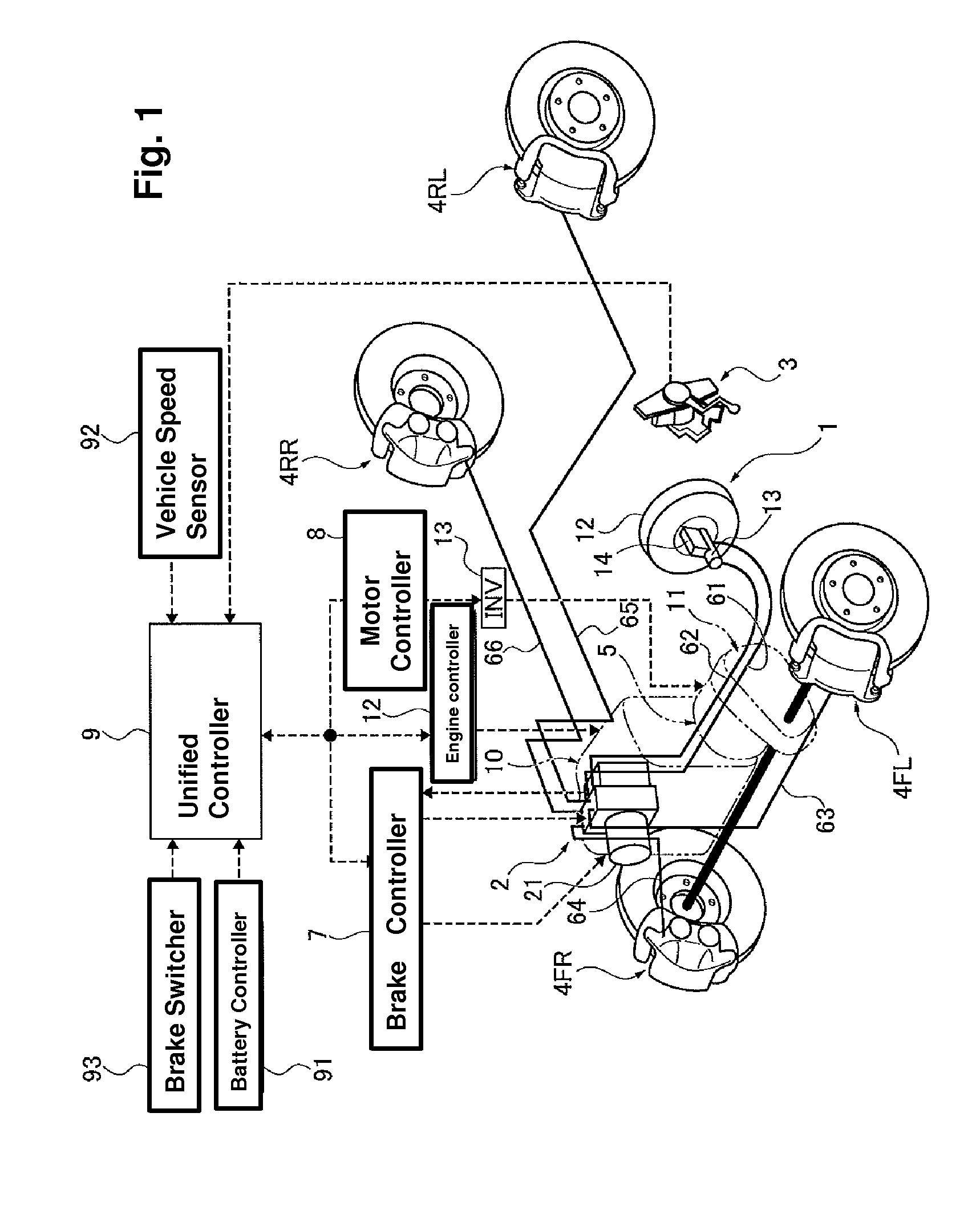

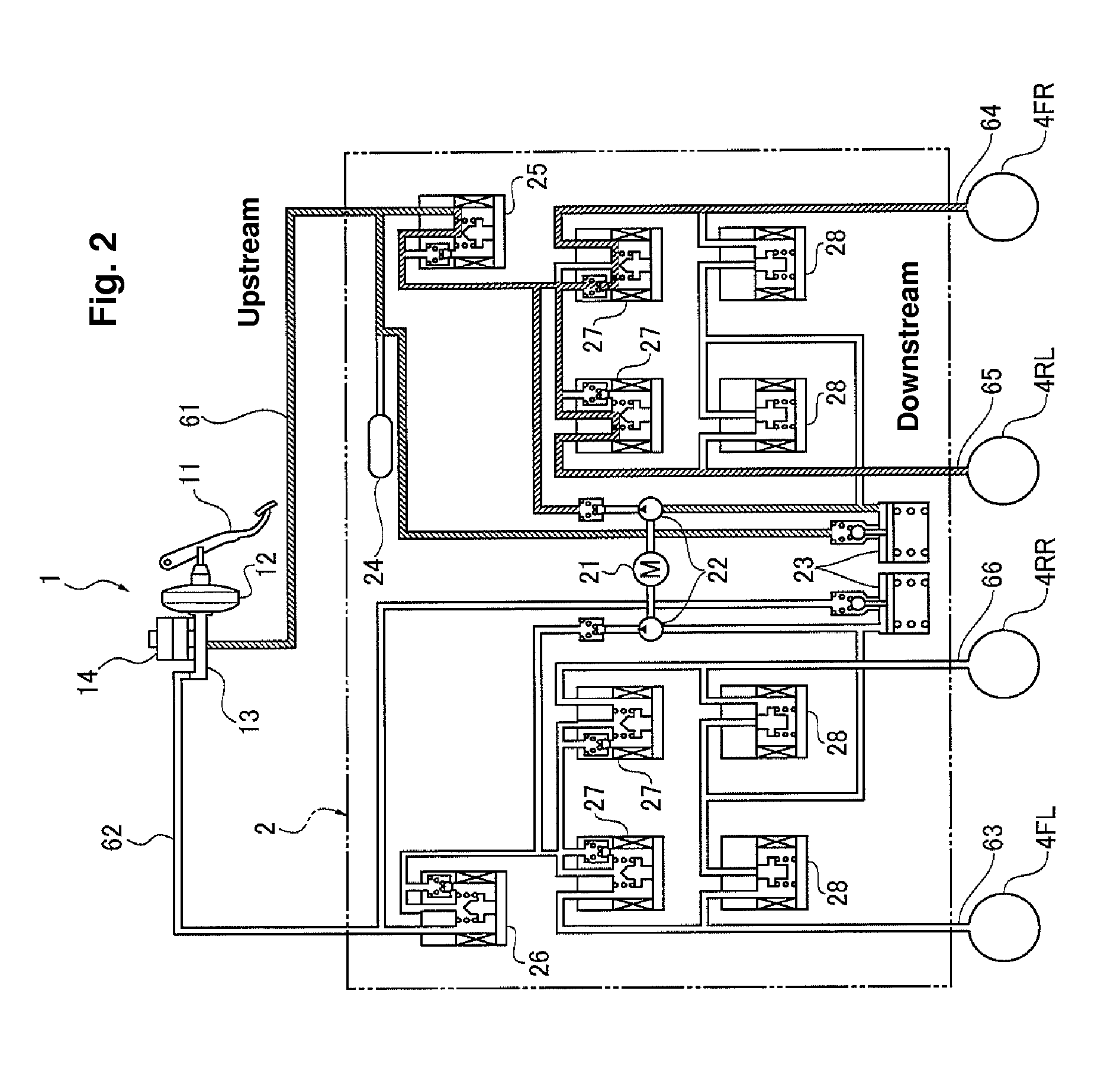

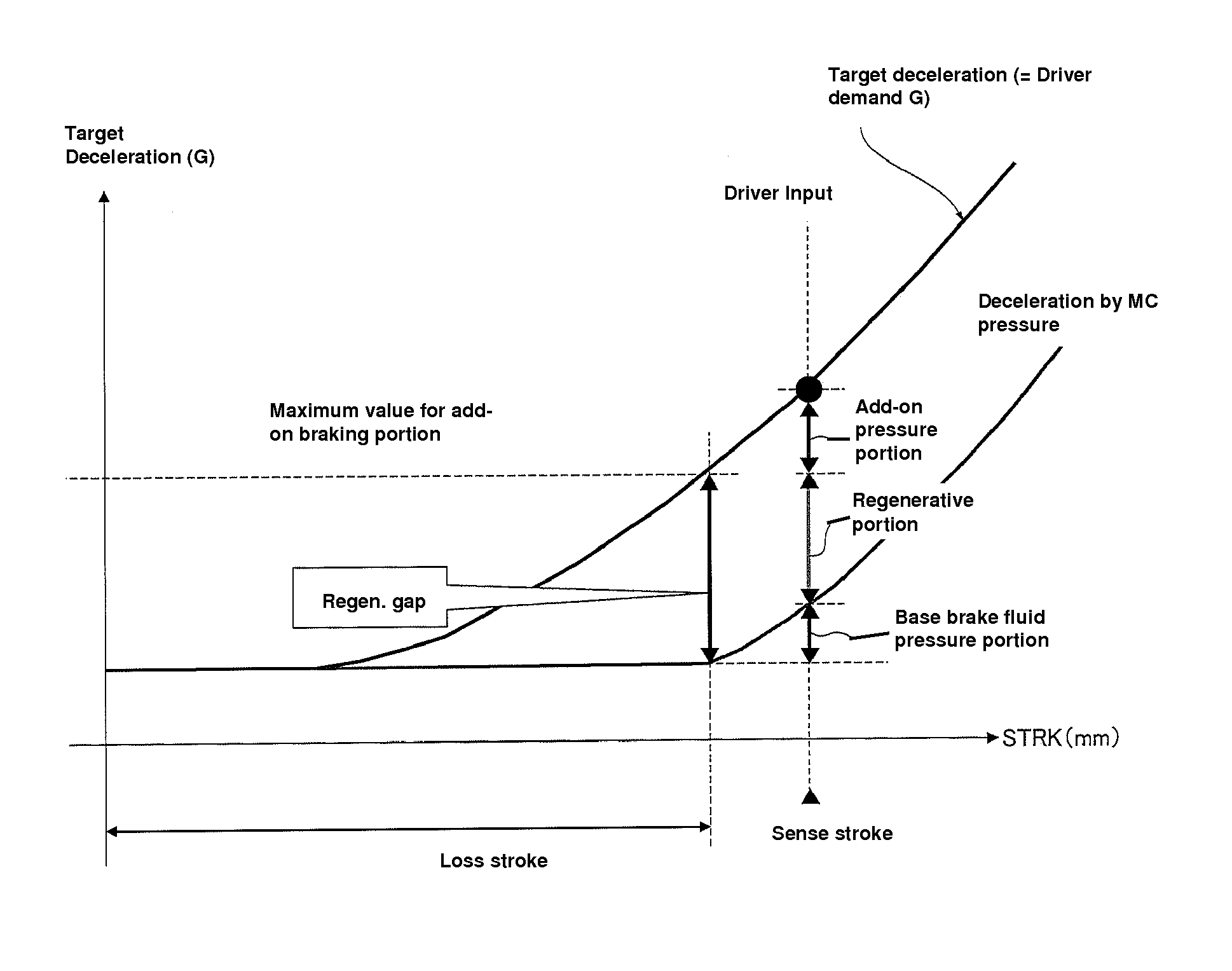

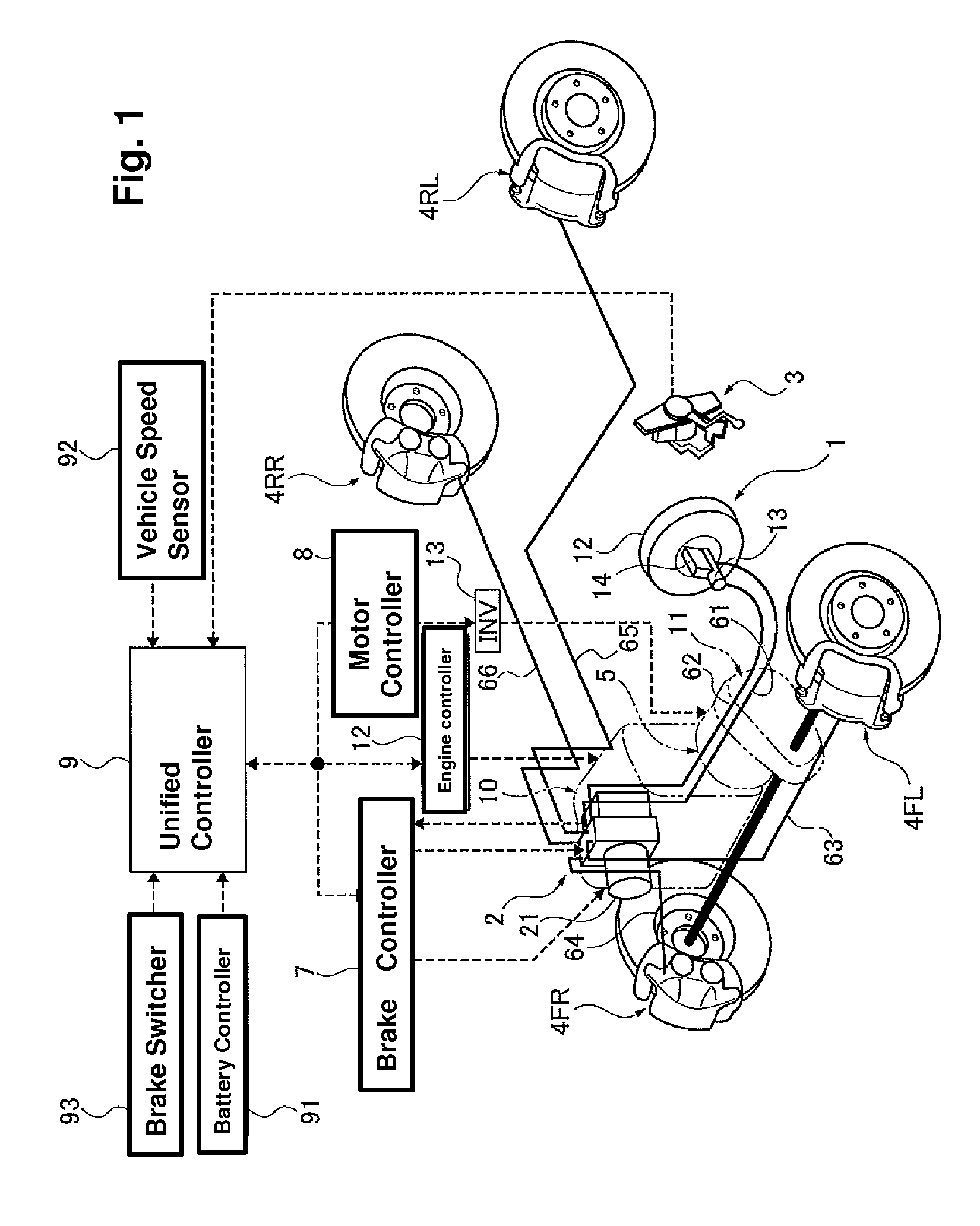

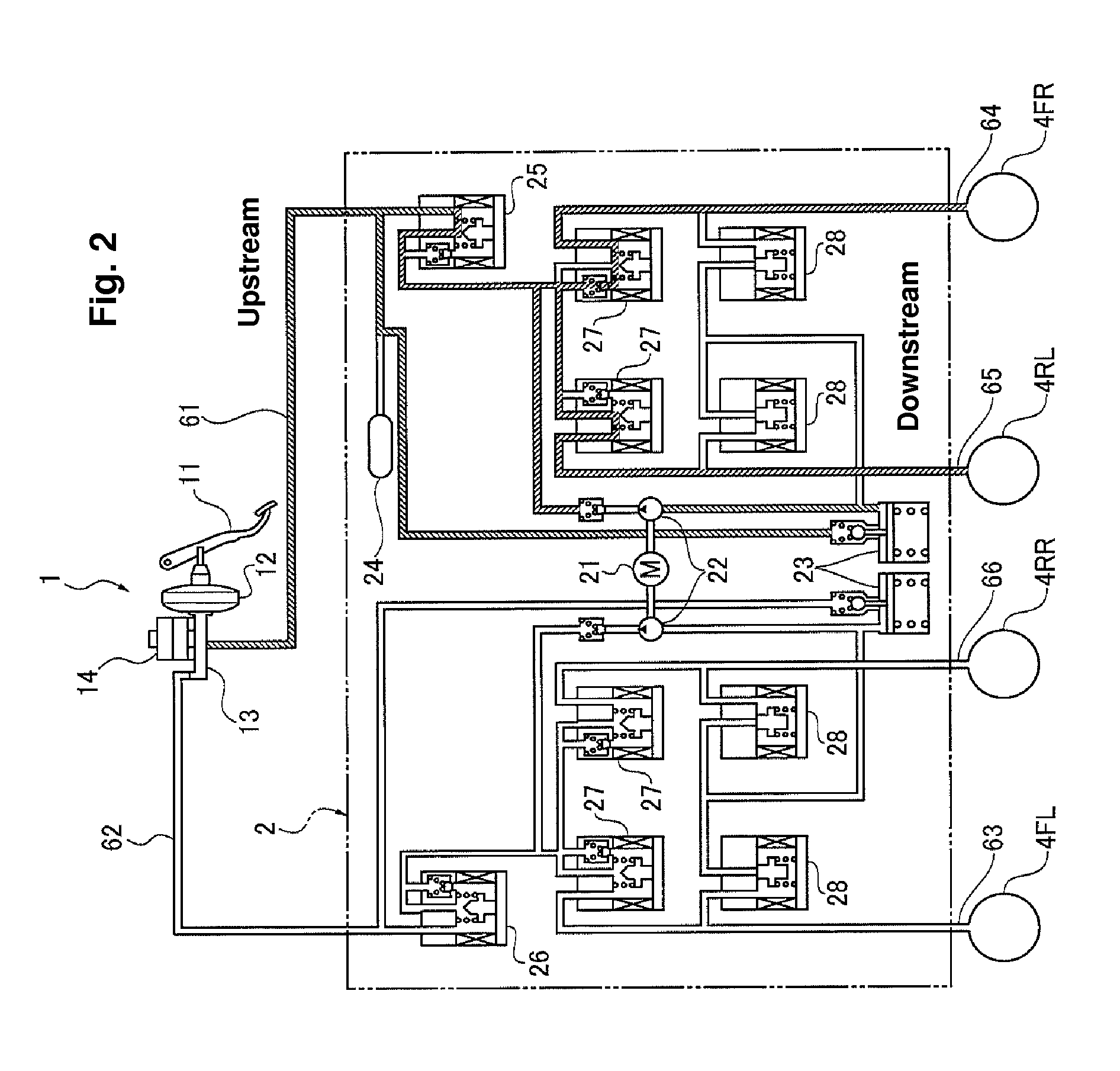

Brake control system for an electrically driven vehicle

ActiveUS20120139330A1Comfortable brake feelSafe recoveryBraking element arrangementsAnalogue computers for trafficRegenerative brakeControl system

During regenerative coordinate braking control, a target brake force is defined by eliminating influences of brake system component tolerances to achieve a comfortable brake feel and secure regenerative energy. A brake control system includes a master cylinder, wheel cylinders, a VDC brake fluid pressure unit and a motor controller. In response to a brake pedal operation by a driver, a brake pedal stroke position is detected at which a pressure in a master cylinder actually begins to be generated. A target deceleration characteristic is adjusted from a theoretical characteristic so that the target deceleration equals a maximum value of an add-on brake force (i.e., the regenerative brake gap) at the detected brake pedal stroke position.

Owner:NISSAN MOTOR CO LTD

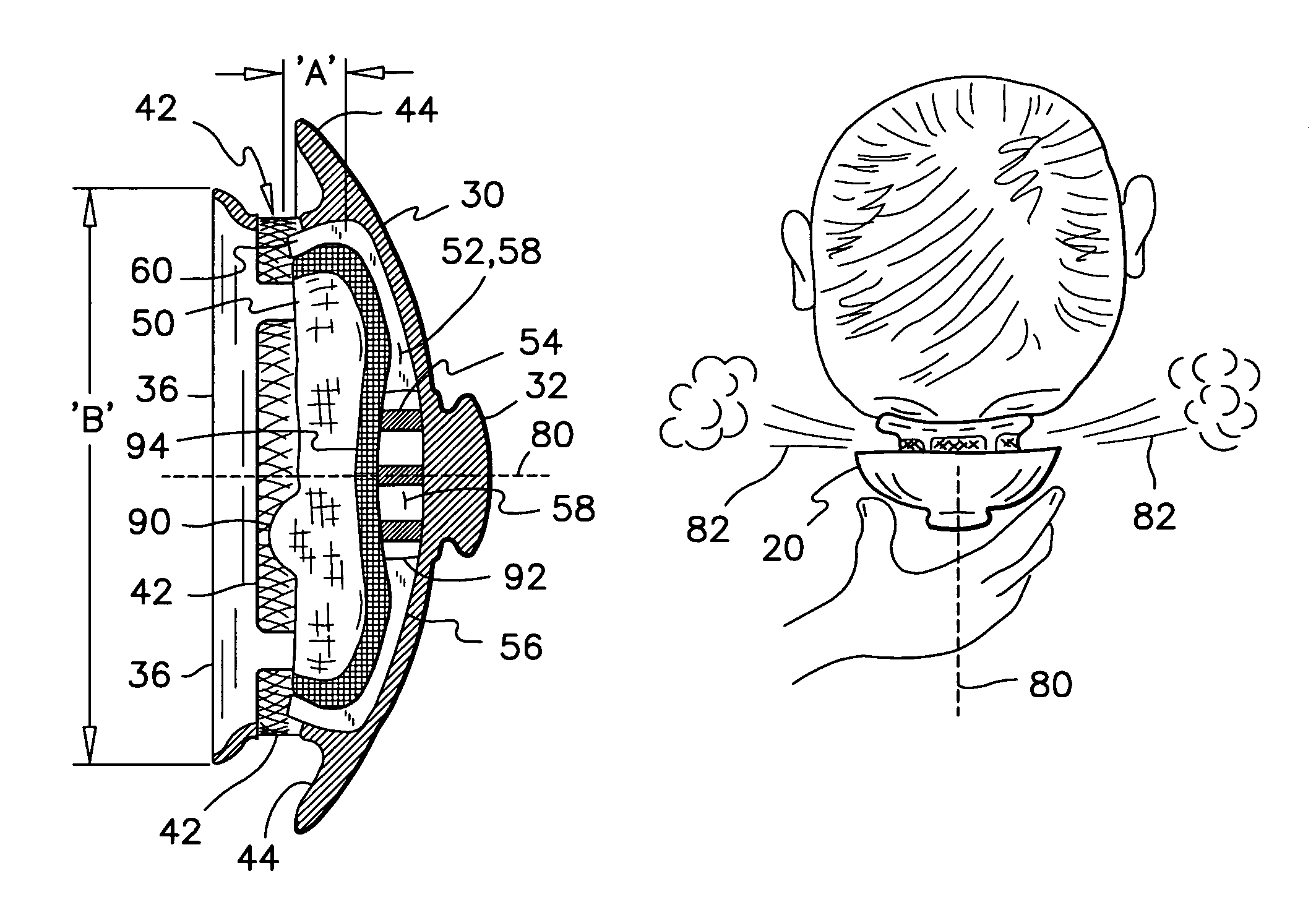

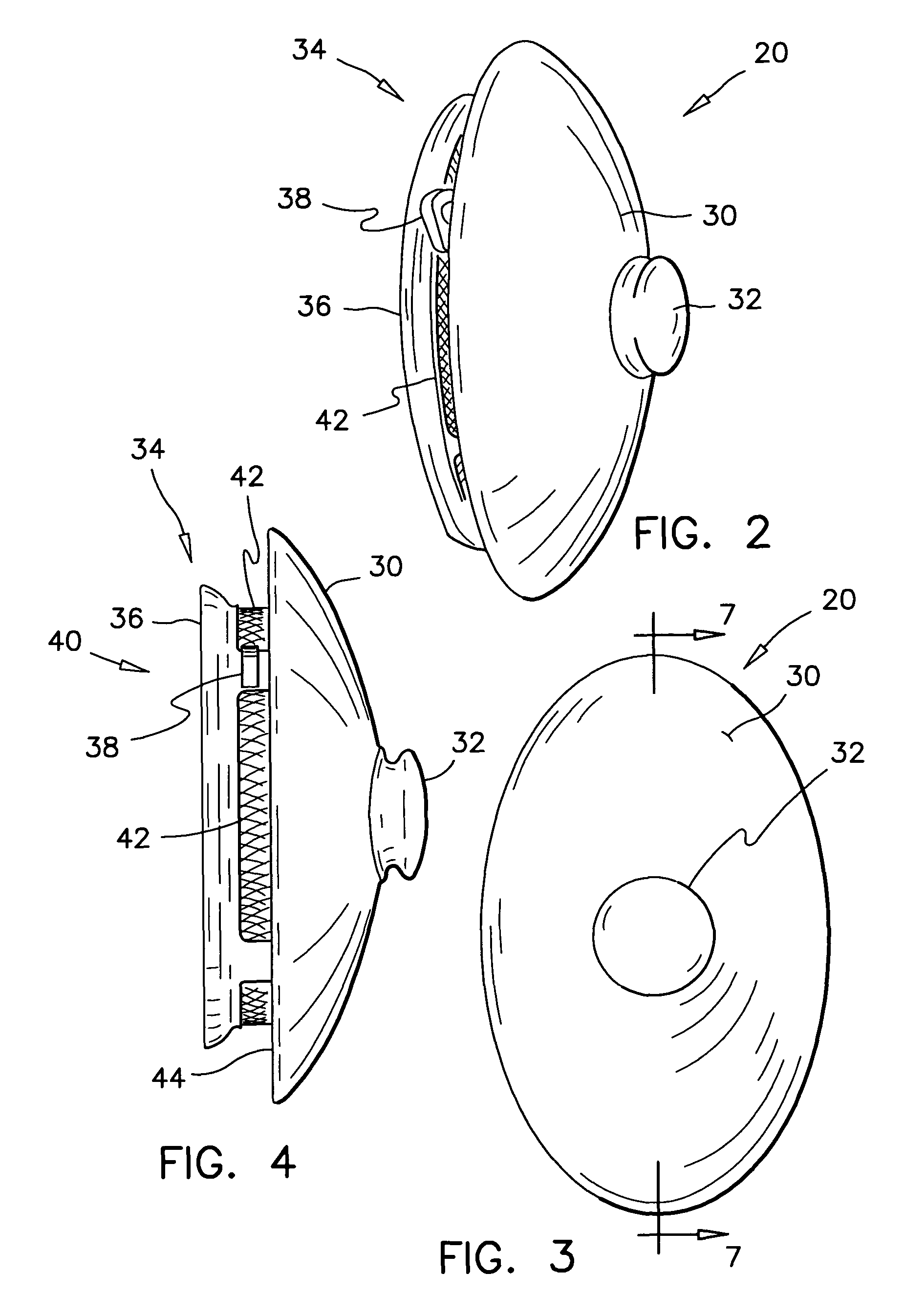

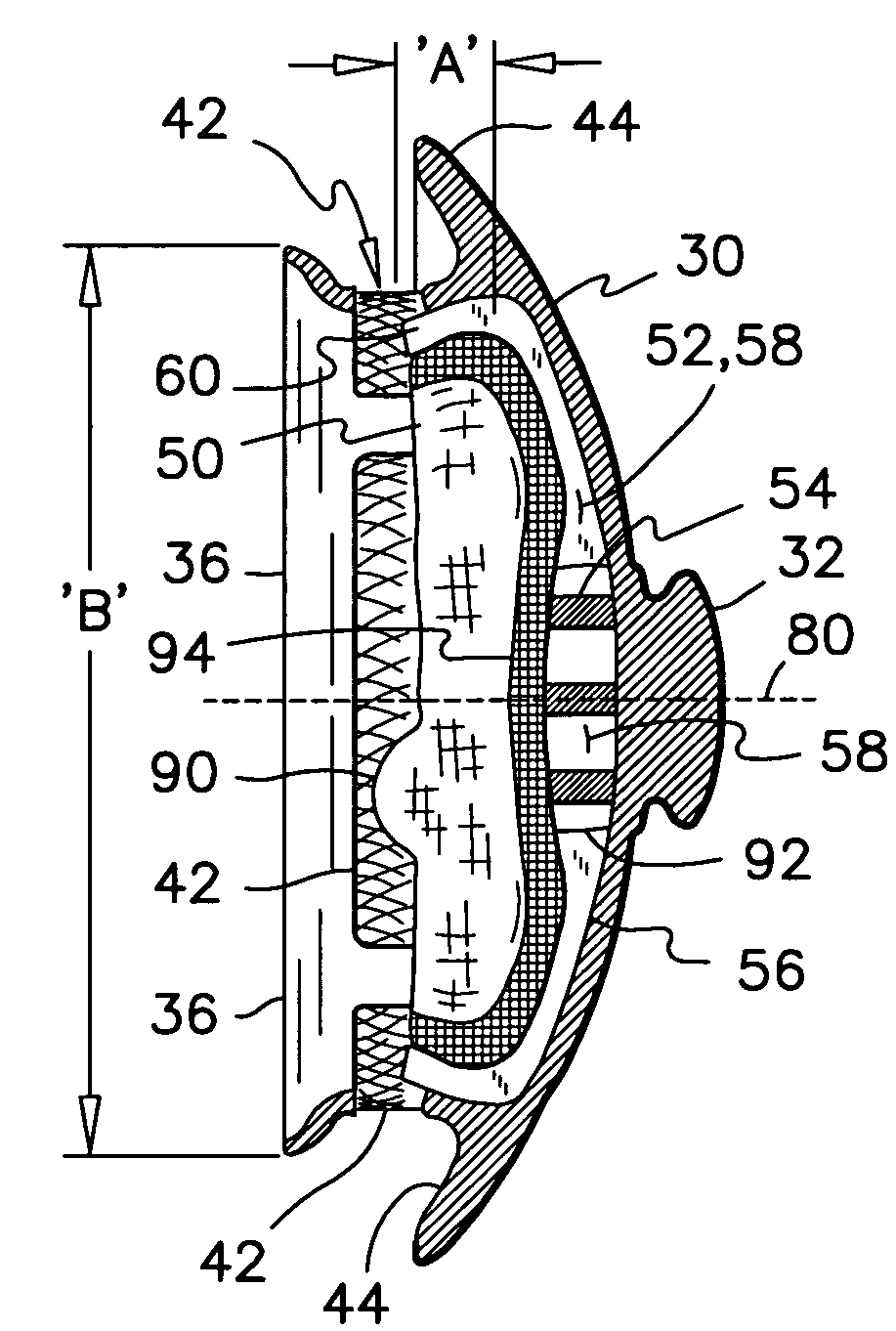

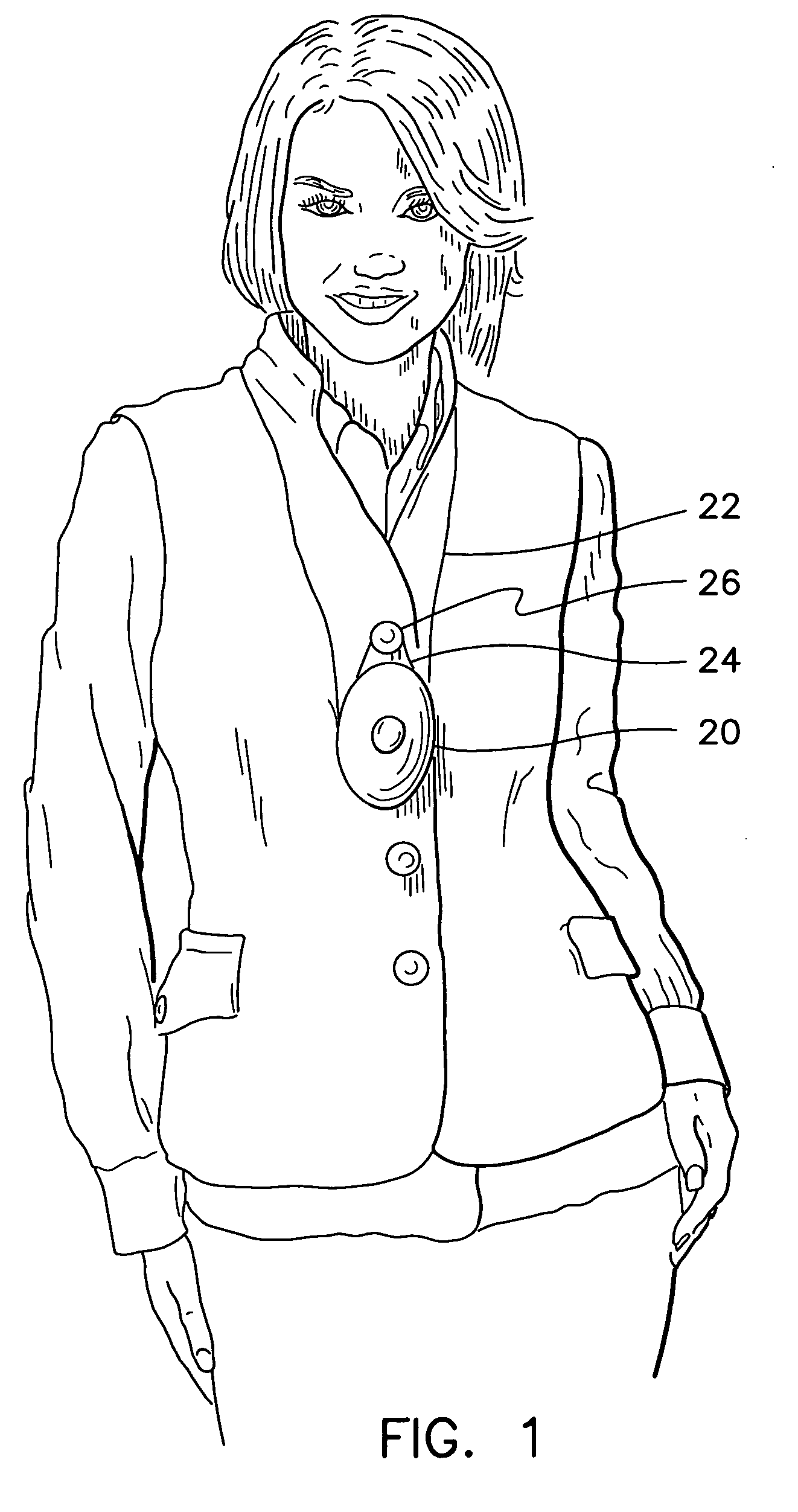

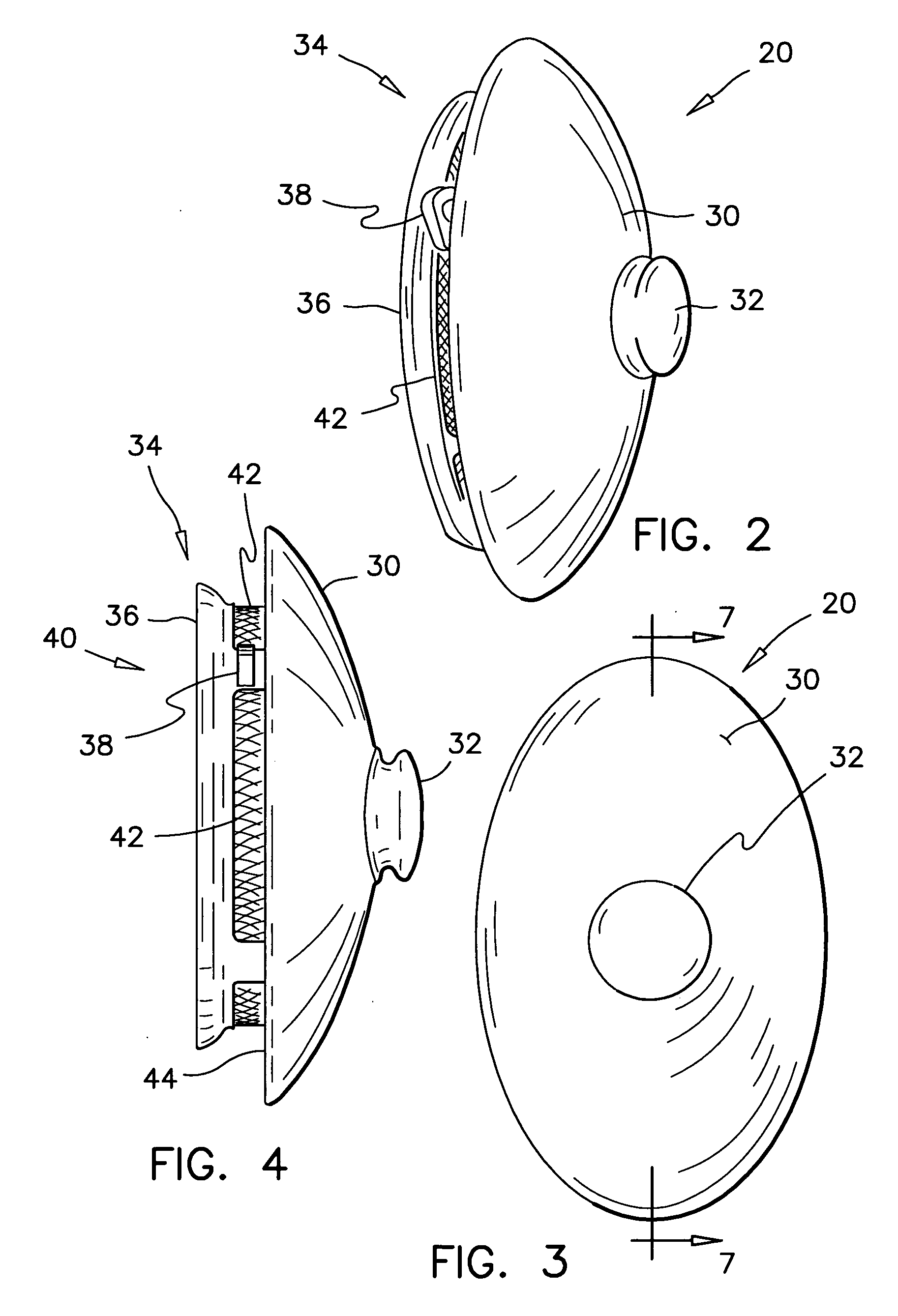

Cough catcher with protection against germ transmission by hand contact

In order to prevent tainting of a cougher's hand with germs, the product from a cough is carried in contact with a germicide inside a hollow article, and is vented out of the hollow article, in directions away from the user's face and hand holding the article. More specifically, the cough catcher has a hollow region for accepting the product from a cough therein. This hollow region has a filter element containing a germicide mounted therein, and a series of channels formed between the filter element and a bottom surface of the hollow region. The channels communicate with vent ports around a rim portion of the cough catcher. The vent ports are oriented away from both the mouth opening and the outside surface of the cough catcher for conveying the product from a cough away from both the face and the hand of a user.

Owner:COVER YOUR COUGH PROD

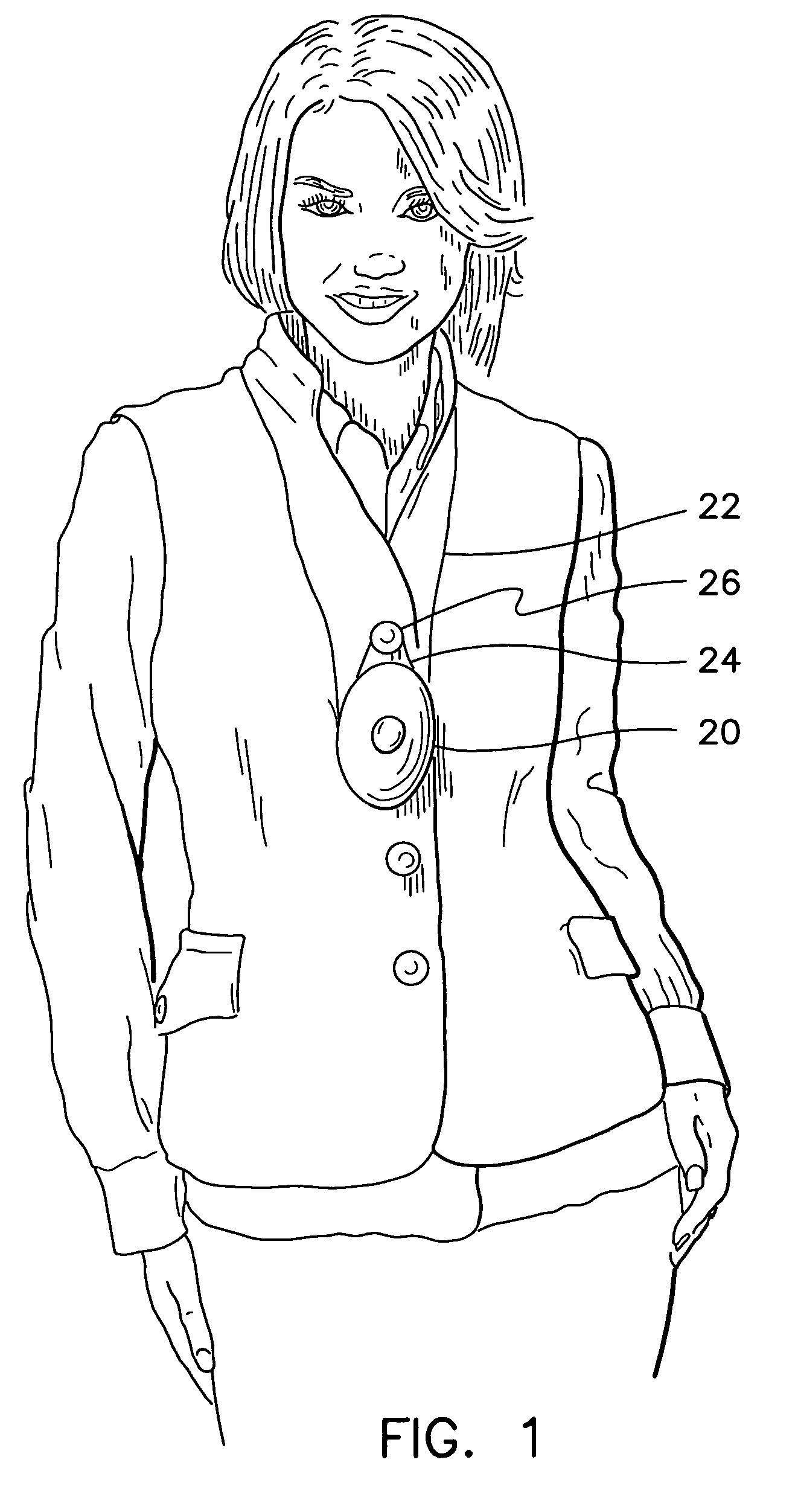

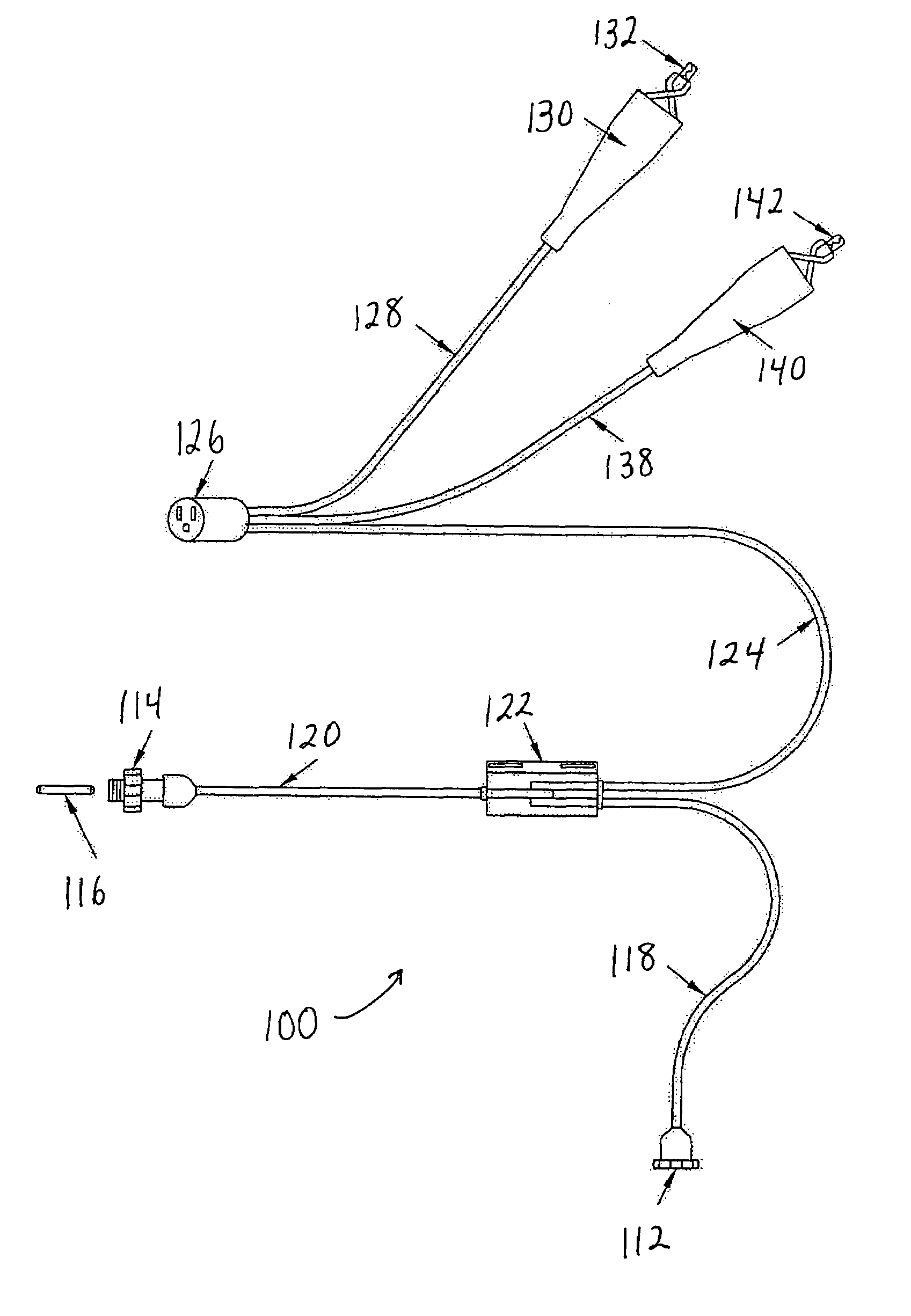

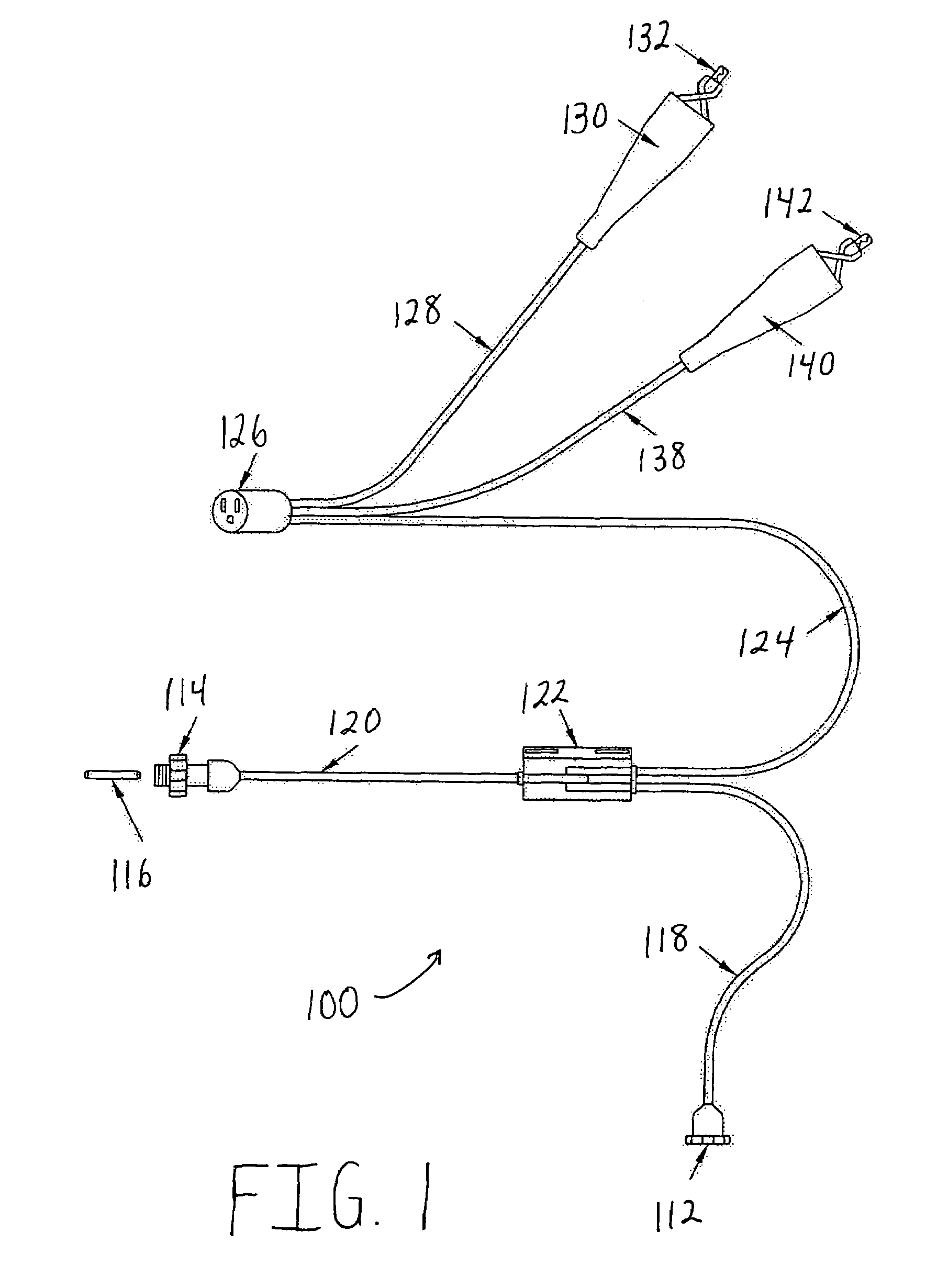

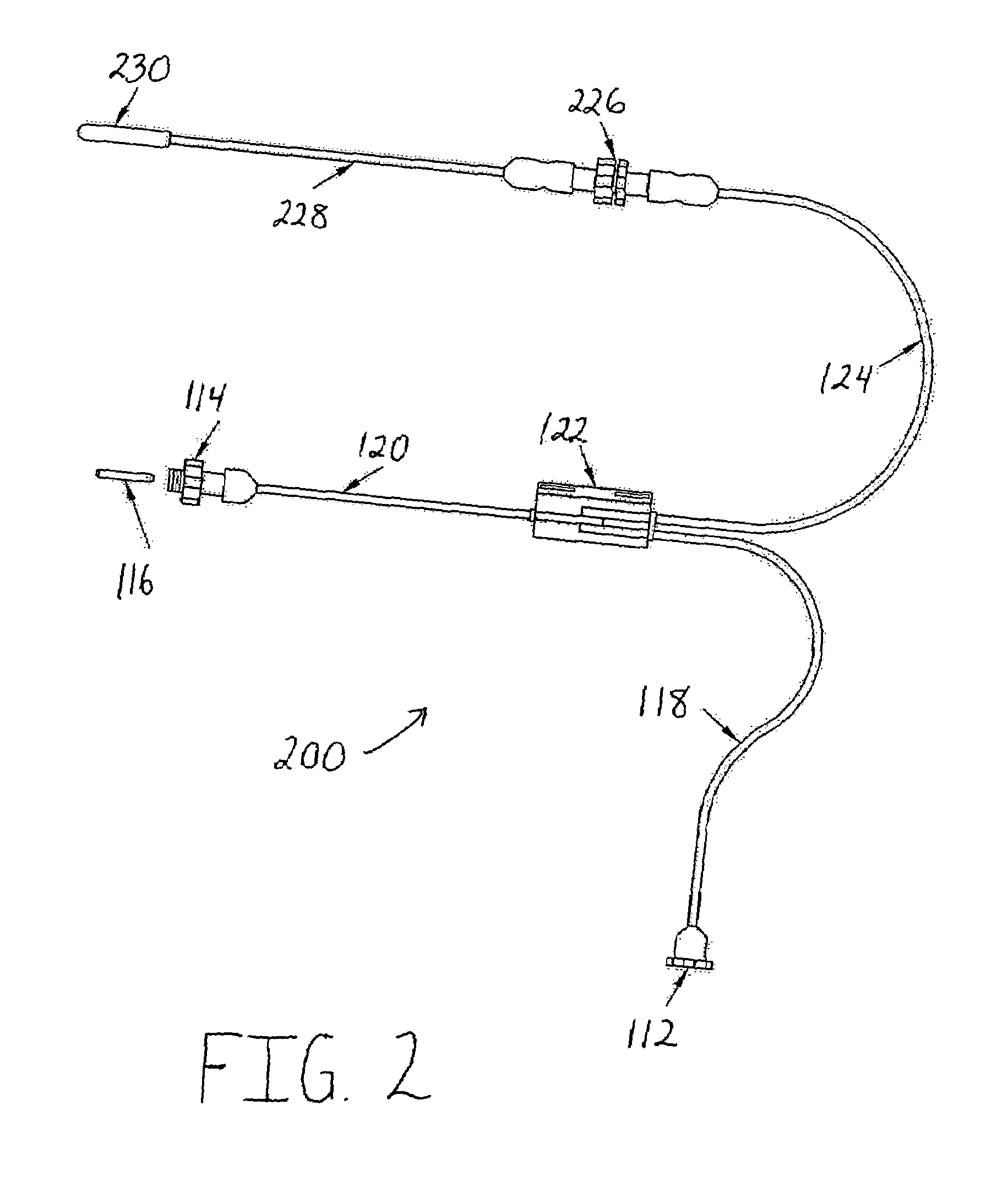

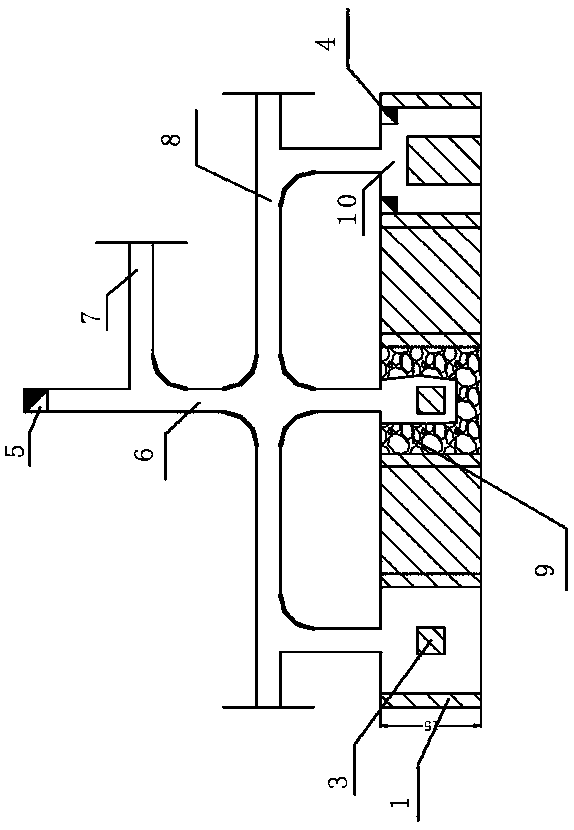

Modular electrical adapter

InactiveUS7416440B2Quickly and easily accessSafe recoveryElectric discharge tubesCoupling device detailsModularityEngineering

Owner:CONSOL EDISON OF NEW YORK

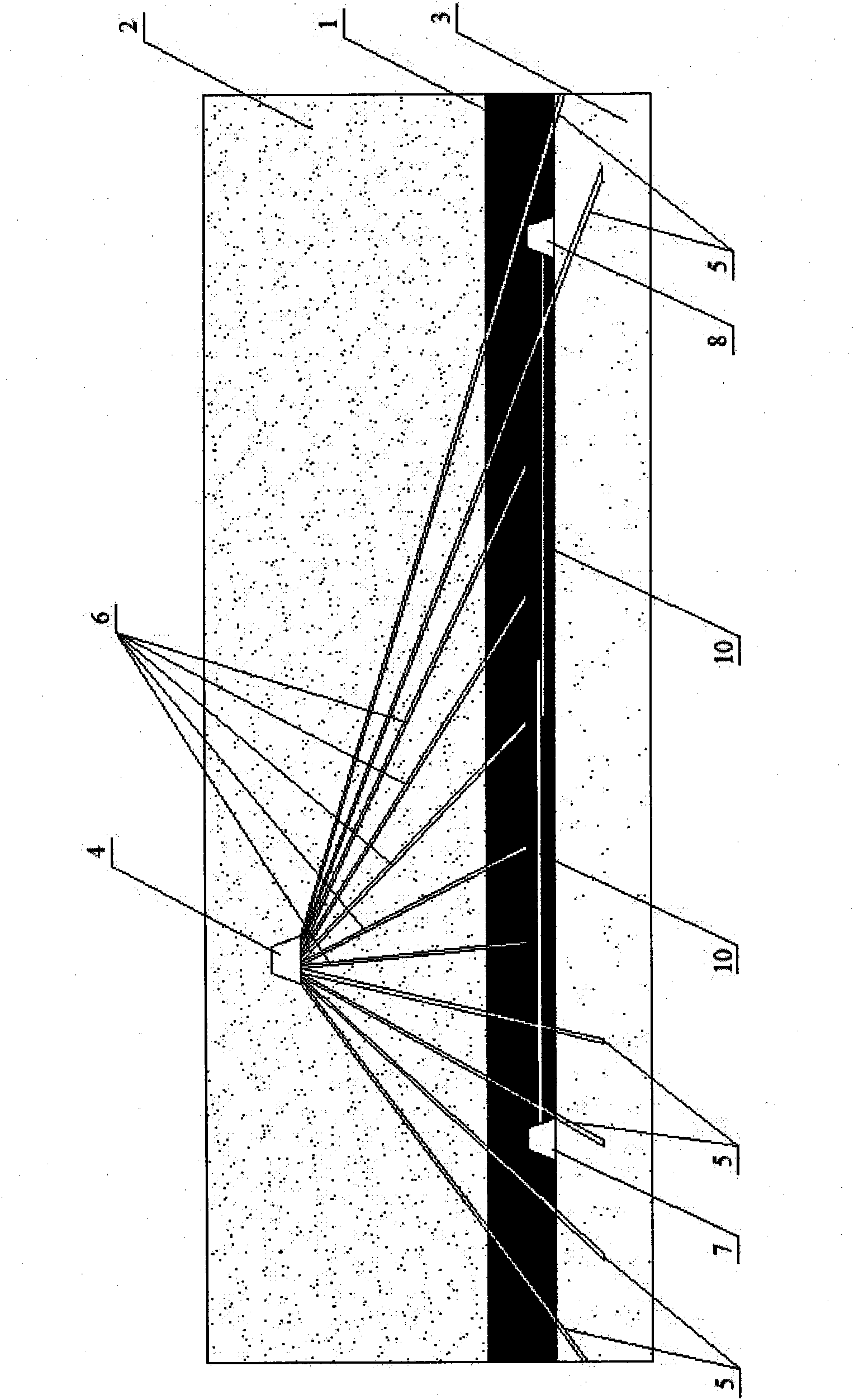

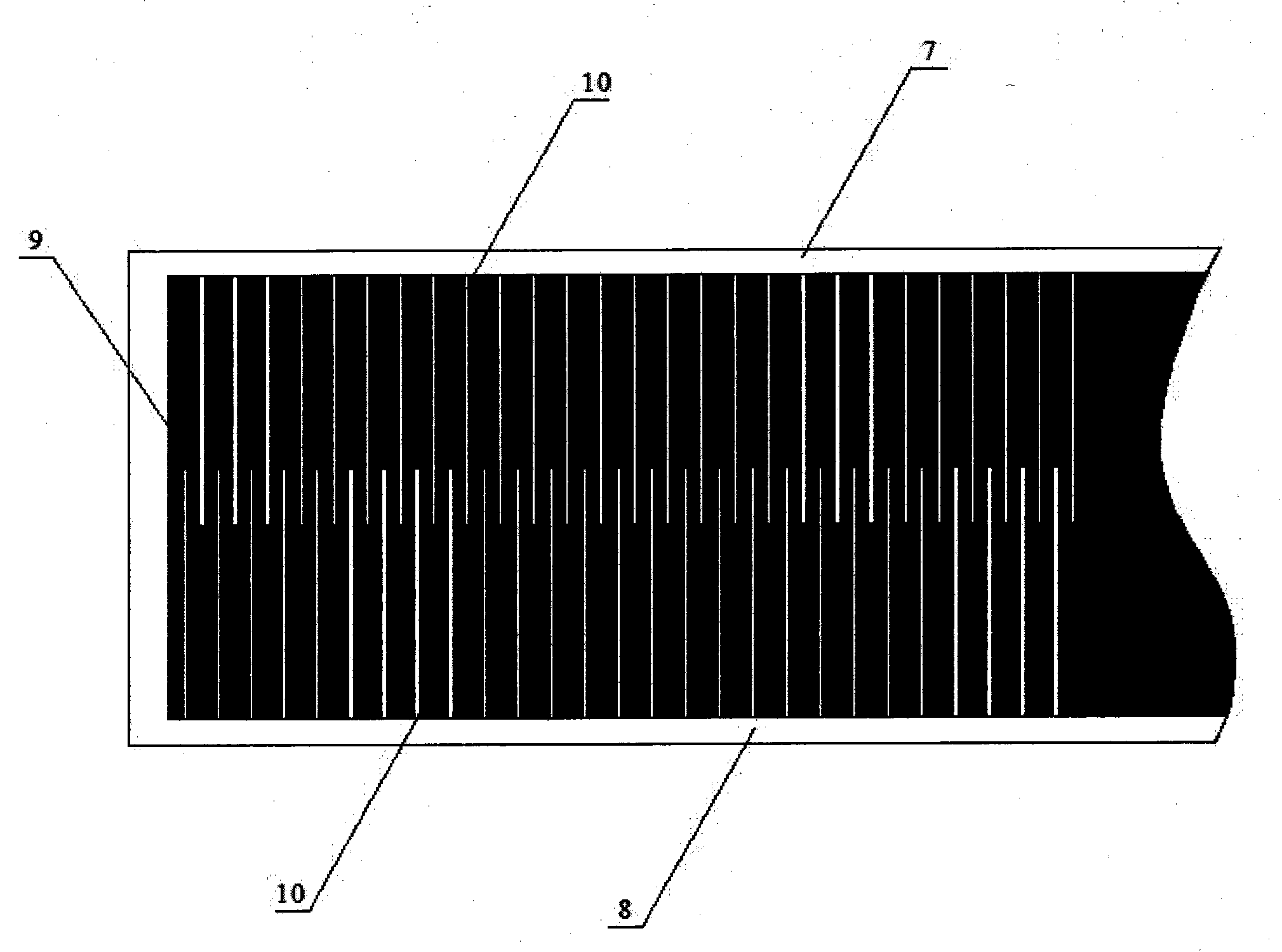

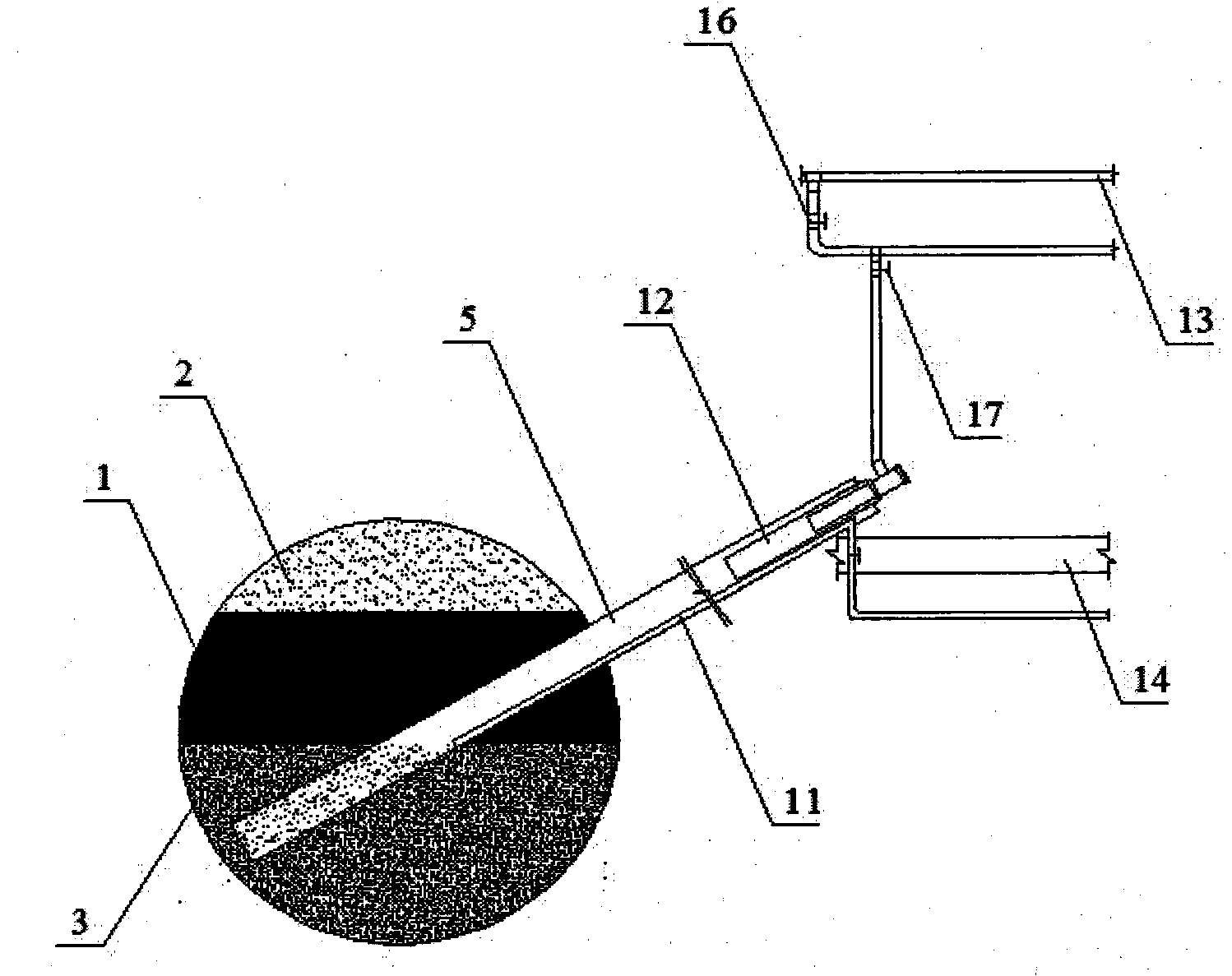

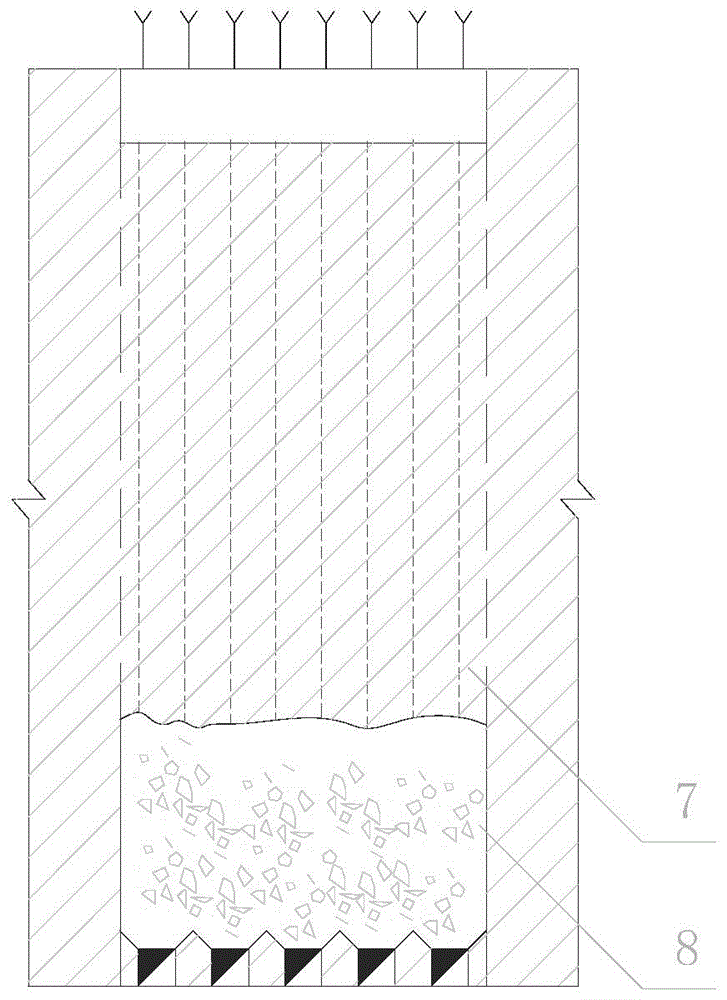

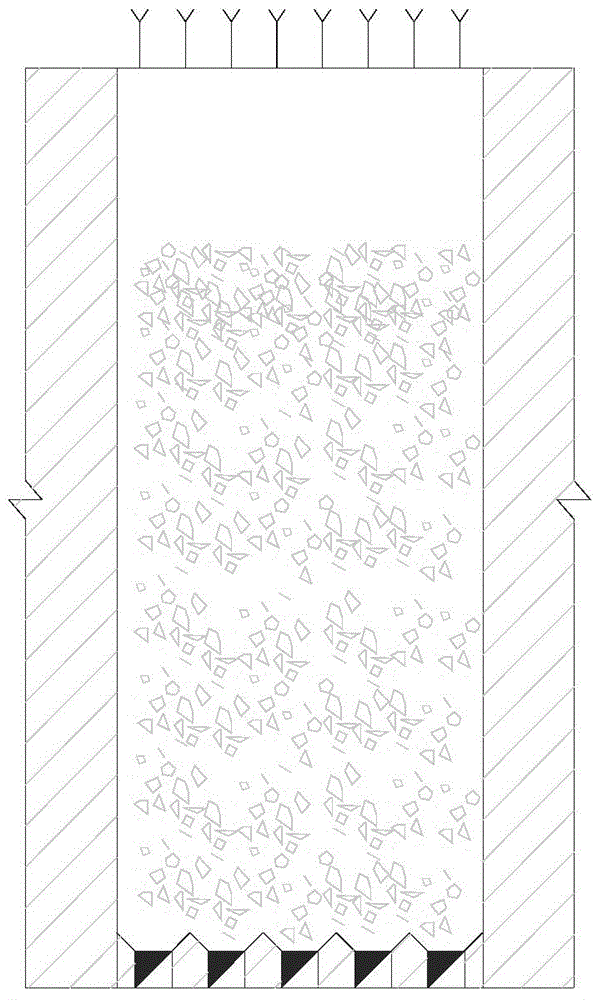

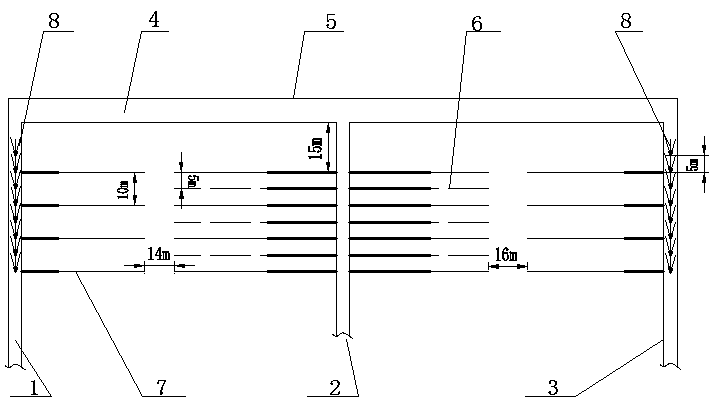

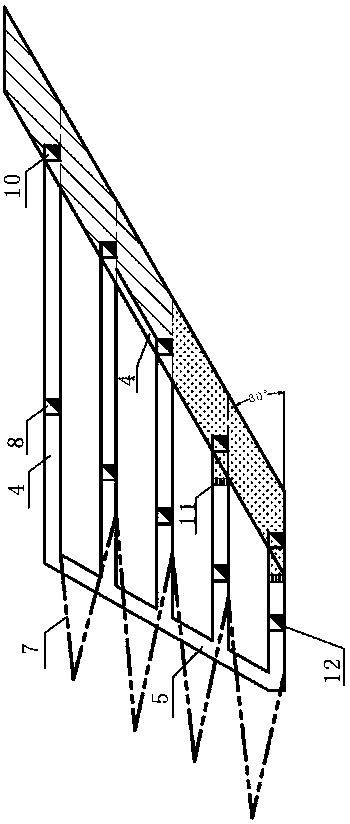

Regional forced gas extraction method for single low-permeability outburst thick coal seam

ActiveCN104100292AEliminate the problem of blank bands in extractionImprove extraction efficiencyGas removalHigh pressure waterHigh pressure

The invention provides a regional forced gas extraction method for a single low-permeability outburst thick coal seam. The regional forced gas extraction method comprises the steps of (a) excavating a rock gangway in a rock fissure zone and drilling a lower-position seam through hole downwards, (b) drilling a high-position seam through hole downwards in the rock gangway, (c) starting a high-pressure water-injection pump station, performing hole expanding operation on the coal seam through sections of the drilled holes under the conditions of the water pressure of 10-20MPa, the flow rate of 8m<3> / h and the single-hole coal output greater than 5t, (d) sealing the drilled holes and carrying out drainage strip networking extraction operation after the hole expanding operation is finished, (e) after the extraction is up to the standard, carrying out tunneling operation of an air return way and a transportation roadway, and meanwhile, drilling a bedding pre-extraction hole in the working face and carrying out the hole sealing and networking extraction operations, and (f) continuously extracting the gas of the goaf in the rock gangway during the recovery of the working face. The regional forced gas extraction method is capable of converting a high-gas outburst coal seam into a low-gas outburst risk-free coal seam, comprehensively guaranteeing safe production of the working face, and meanwhile, obviously increasing the coal roadway tunneling speed.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

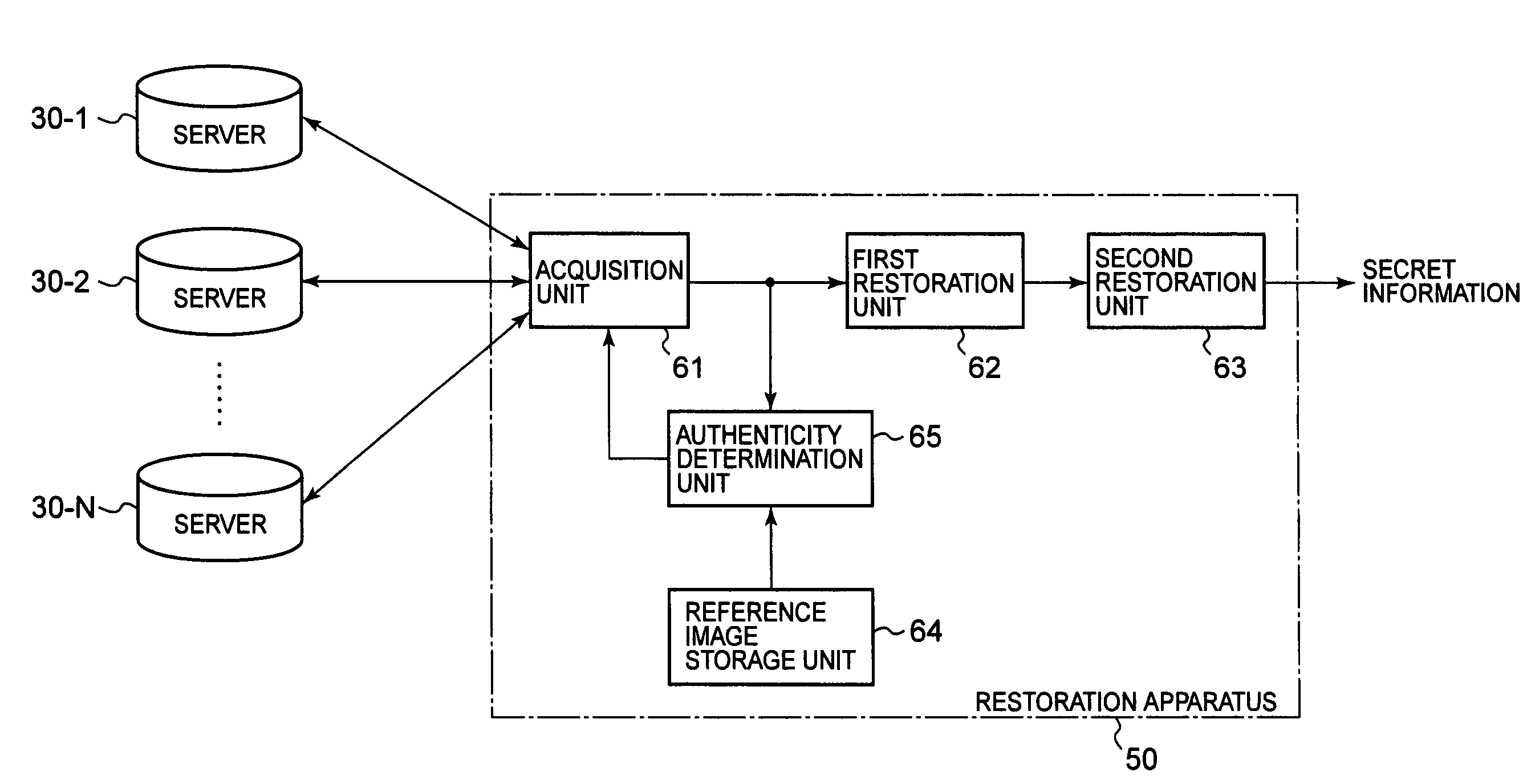

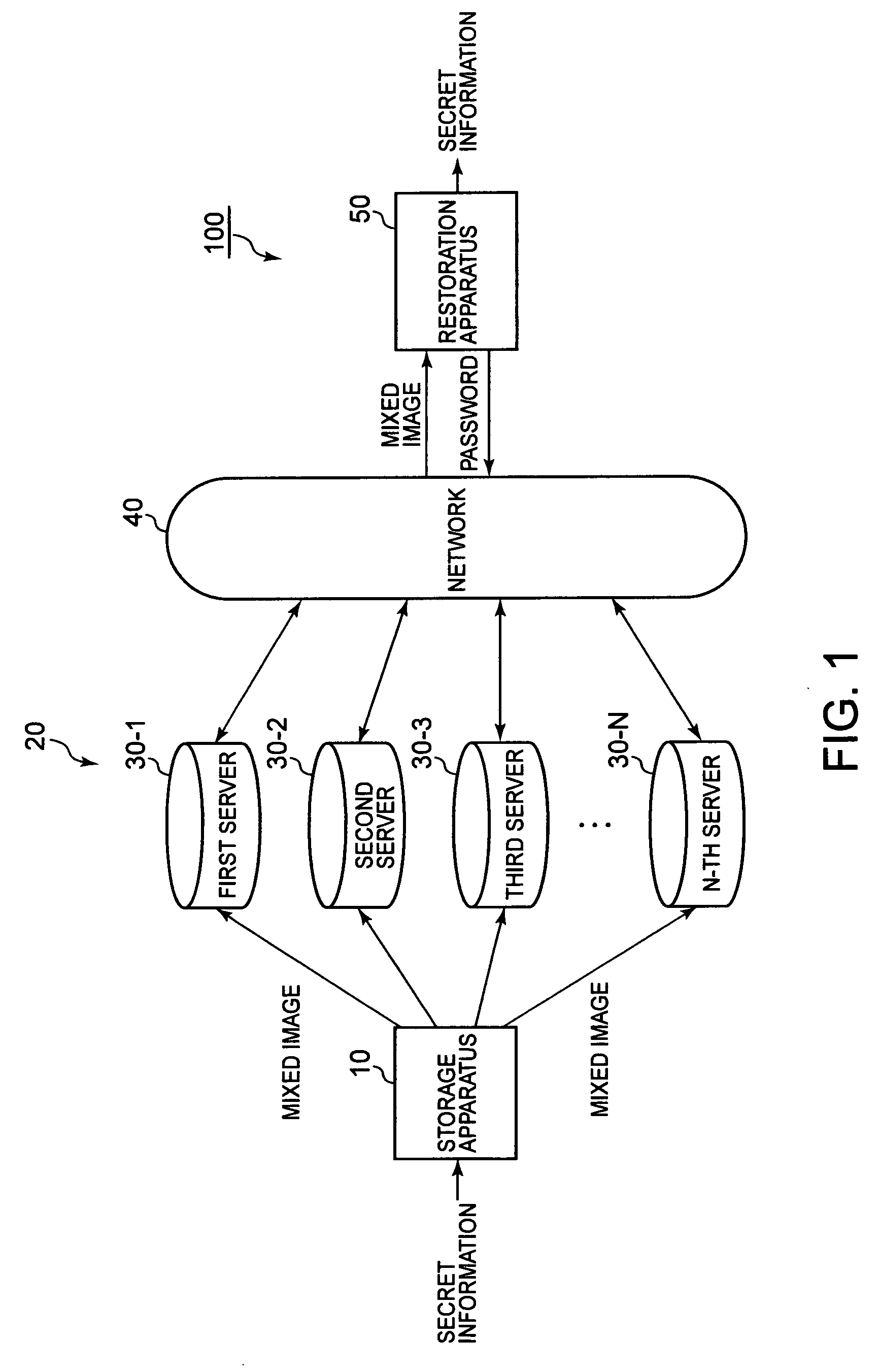

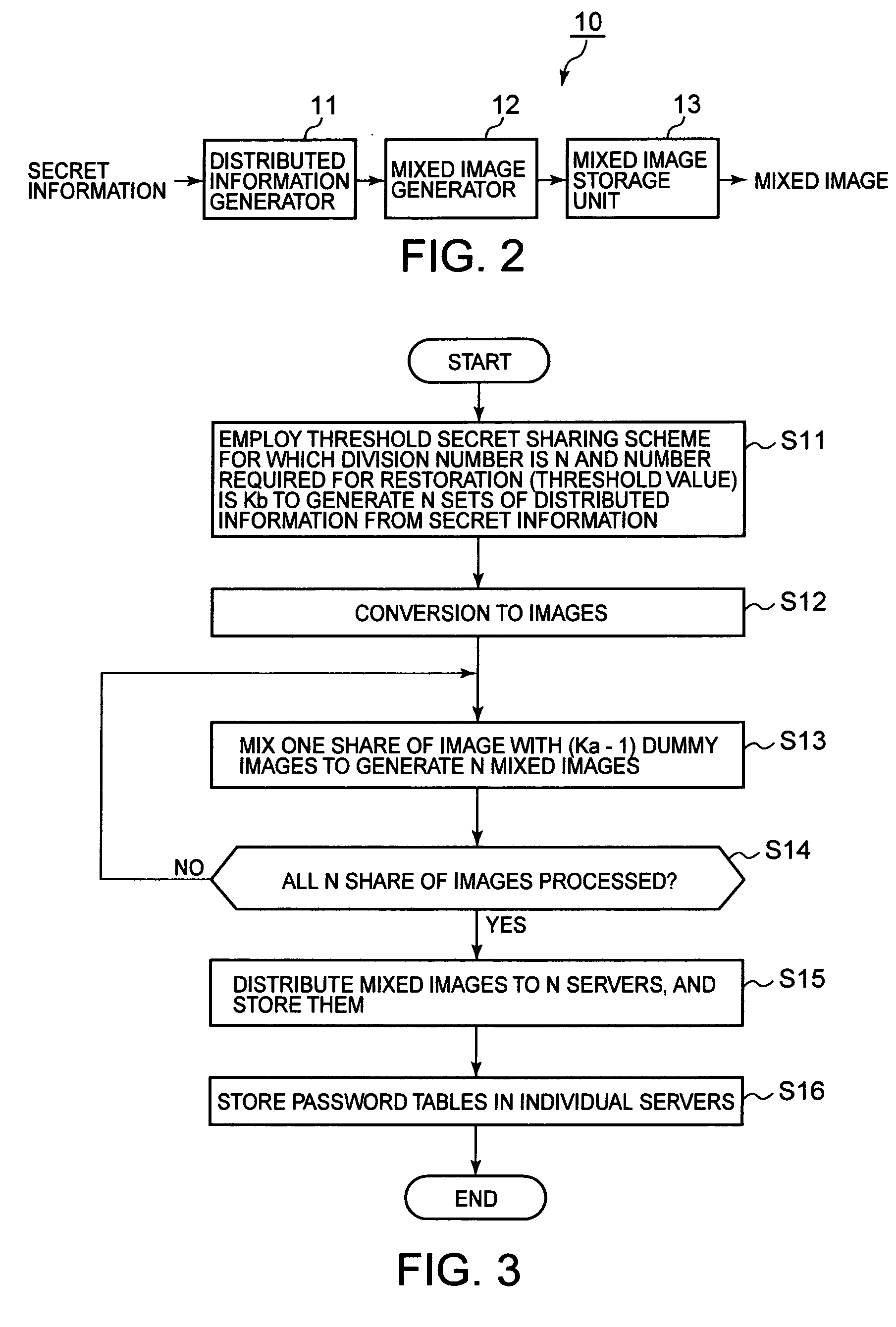

Method and apparatus for distributed management of files

InactiveUS20070118737A1Safe storageSafe recoveryDigital data protectionSecuring communicationPasswordUser input

Apparatus and methods for computer file management including components and steps for distributing to servers a plurality of mixed images that are generated for each of N, where N>=3, sets of distributed information generated by distributing secret information using a threshold secret sharing scheme, the plurality of mixed images being generated by mixing at different mixing ratios an image based on the distributed information with (Ka-1) images, where Ka satisfies 1<Ka<N; transmitting Kb passwords, where Kb satisfies 1<Kb<N, entered by a user, and obtaining from the plurality of servers at least Ka mixed images for each of Kb sets; first restoring the Kb sets of distributed information based on the Ka mixed images that are obtained; and second restoring the secret information using the Kb sets of distributed information that have been restored.

Owner:IBM CORP

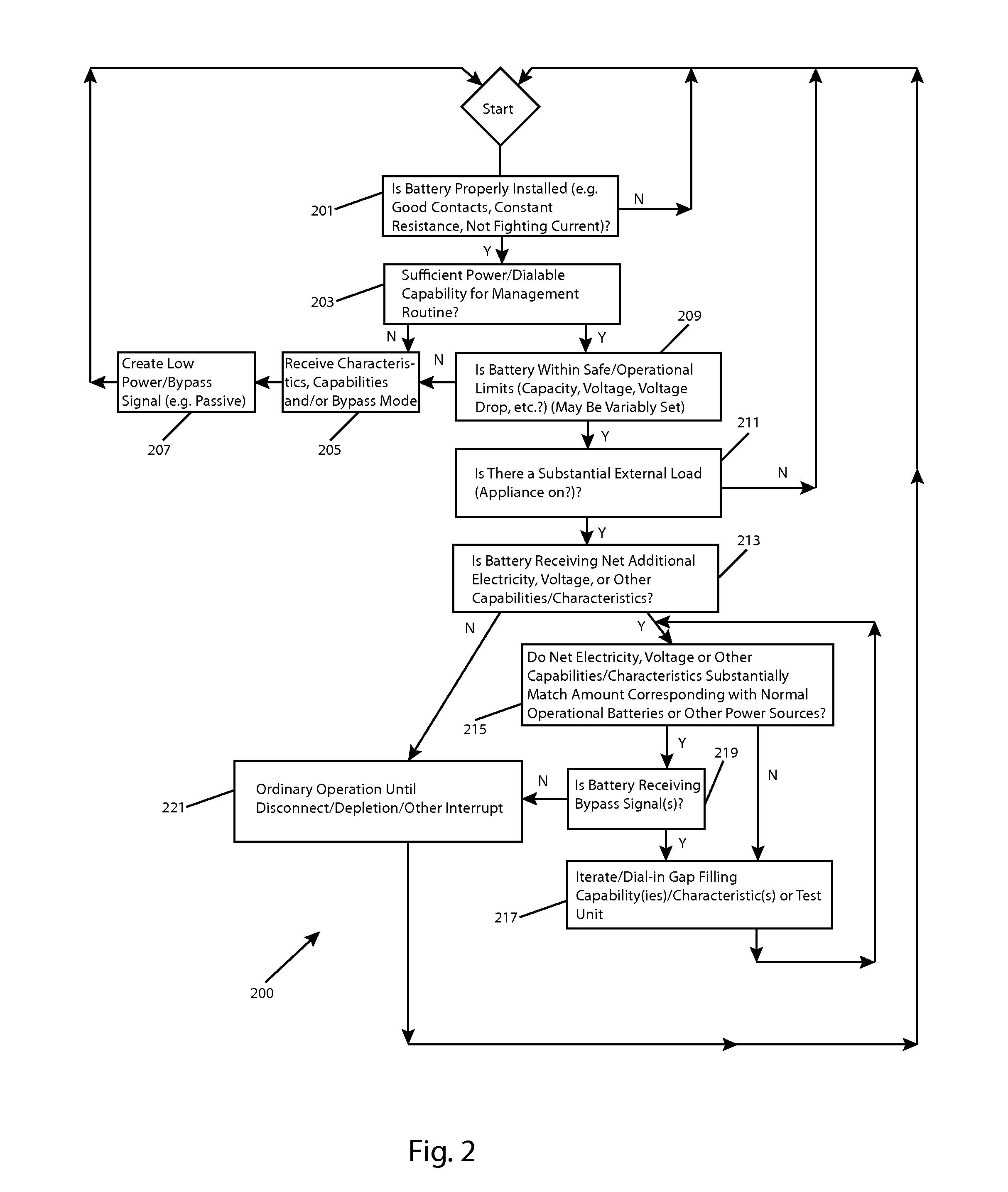

Techniques for Optimizing Power Supply Output

ActiveUS20140368168A1Reduced wiring requirementsReduce manufacturing costCharge equalisation circuitPhotometryPower flowControl system

New power output control systems are provided that maintain optimal voltage, current, and other electrical characteristics. In some aspects of the invention, a lagging or deteriorated power supply aspect is at least partially replaced to avoid limitations while the output of a specialized, stronger aspect is altered and addressed to supply the resulting power, voltage, current charge or other gap.

Owner:BECKMAN CHRIS

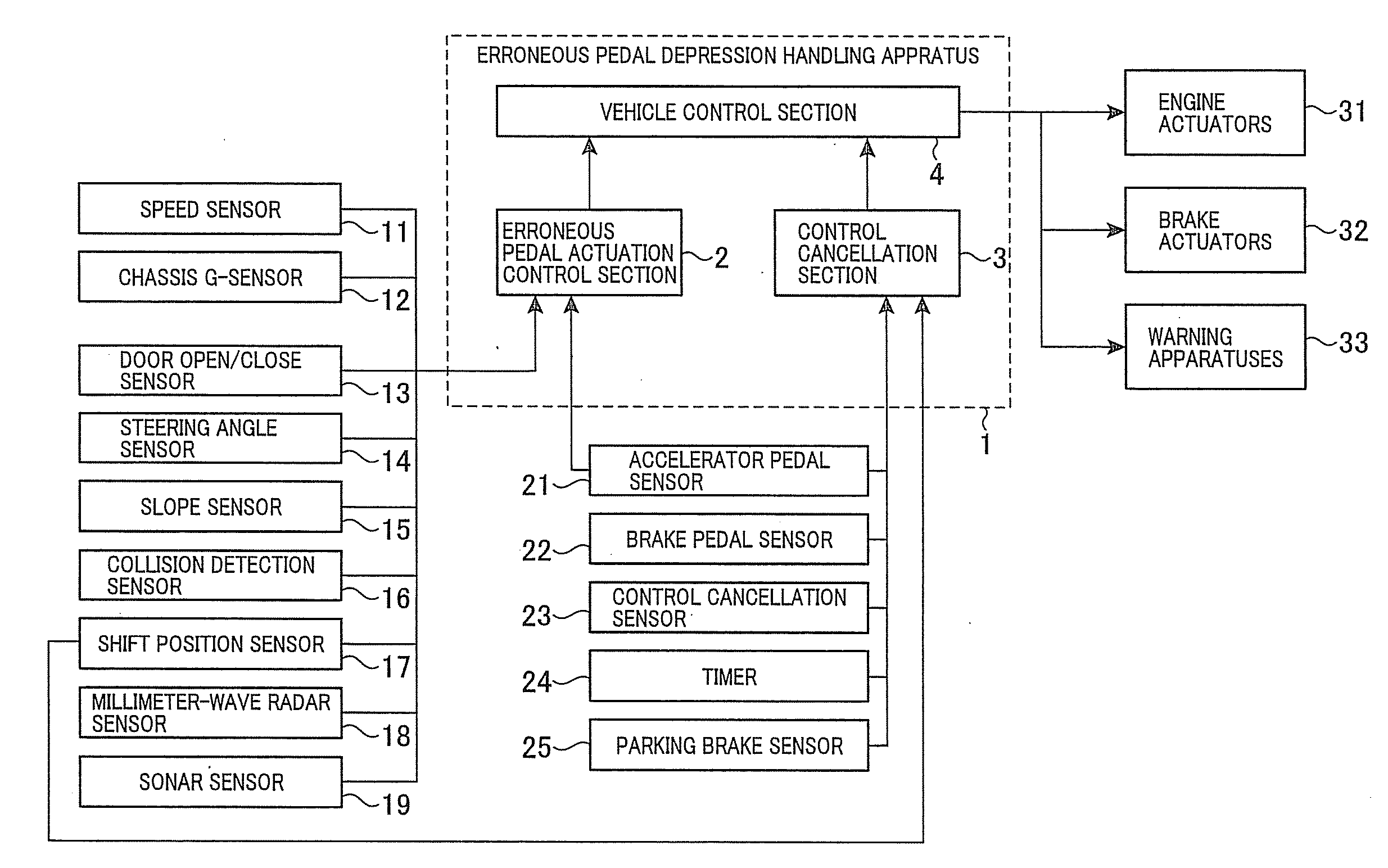

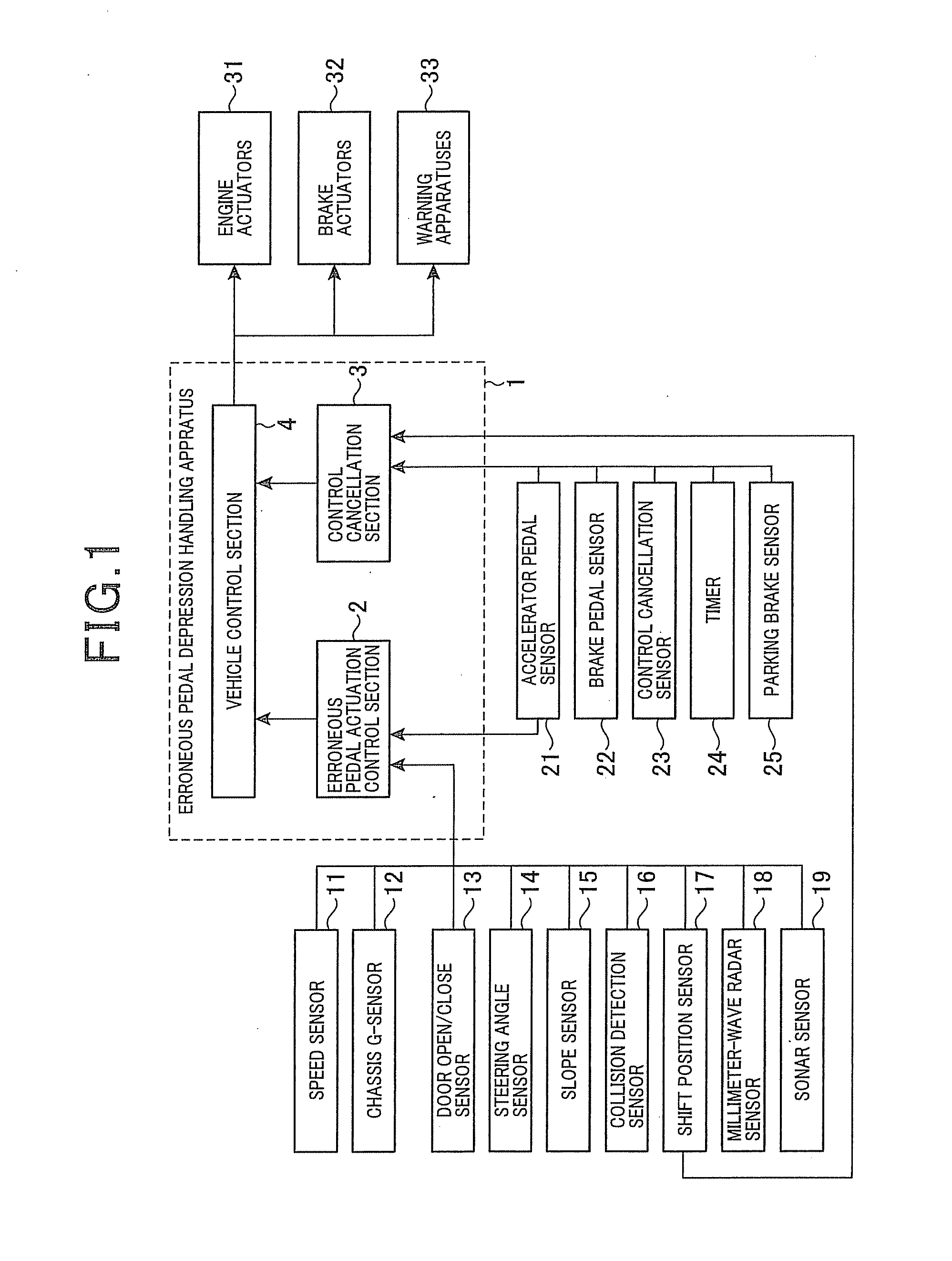

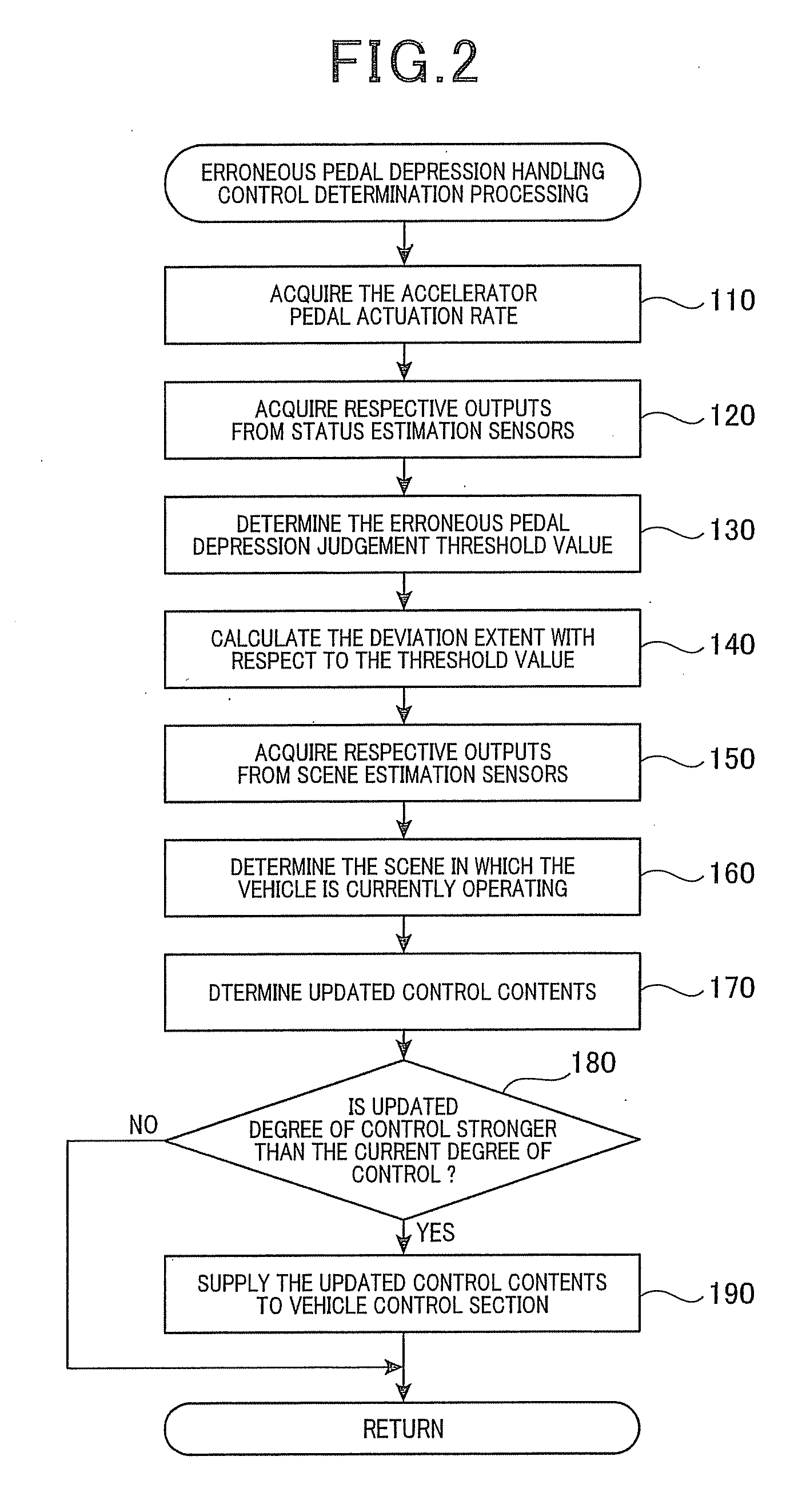

Erroneous pedal depression handling apparatus for motor vehicle and computer program for implementing functions of the vehicle

InactiveUS20120209488A1Threshold value can be loweredRaise the thresholdAnalogue computers for trafficComputations using stochastic pulse trainsMobile vehicleDriver/operator

In an apparatus for handling erroneous depression of the accelerator pedal of a vehicle, after control has been applied for partially or completely preventing the vehicle from being accelerated in response to actuation of the accelerator pedal, normal acceleration control is restored thereafter by a number of steps of successive decrease of the degree of acceleration restriction. Each step may be executed in response to some specific action performed by the vehicle driver, or each time a specific time interval elapses after commencement of the acceleration restriction.

Owner:DENSO CORP

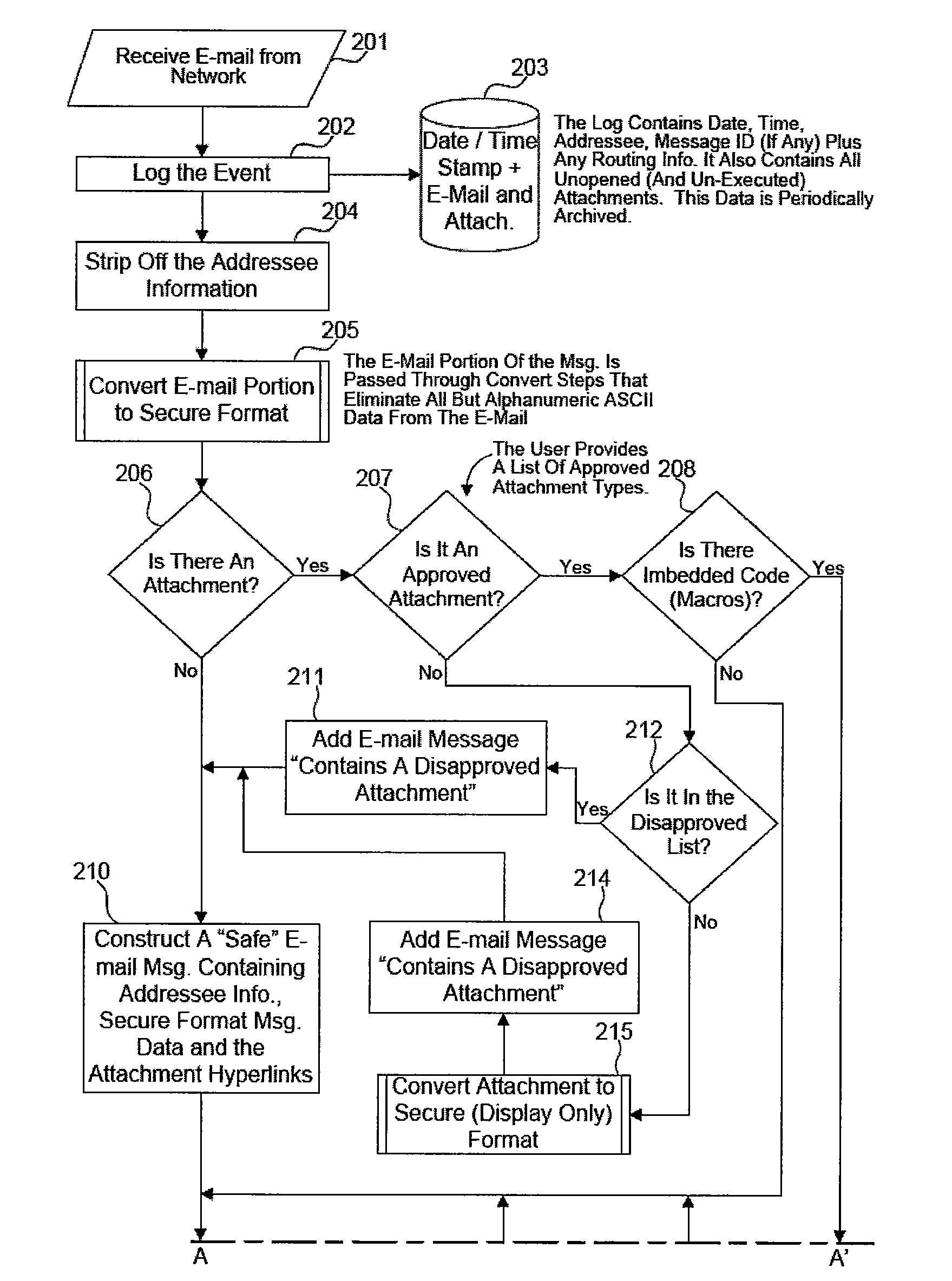

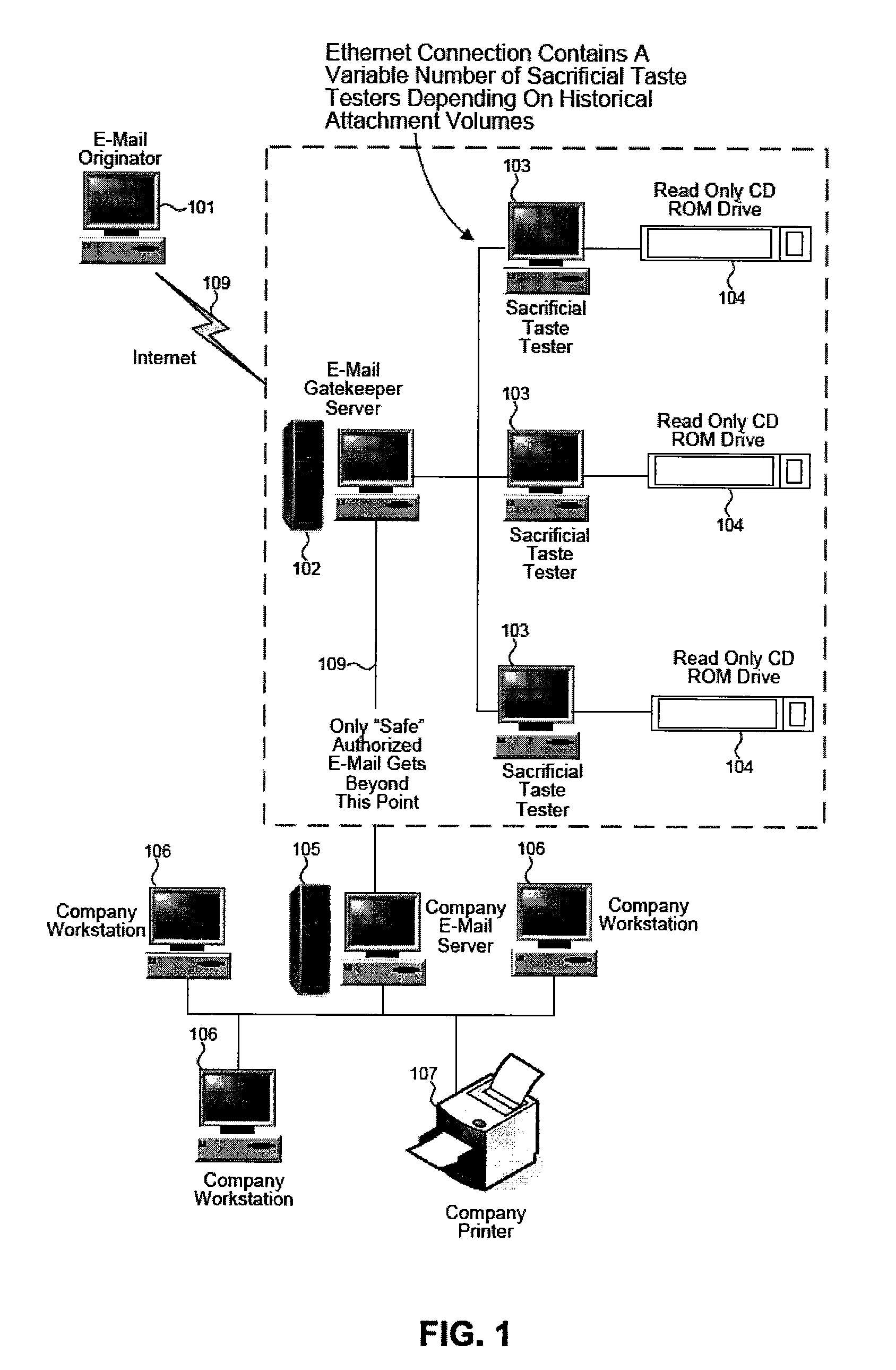

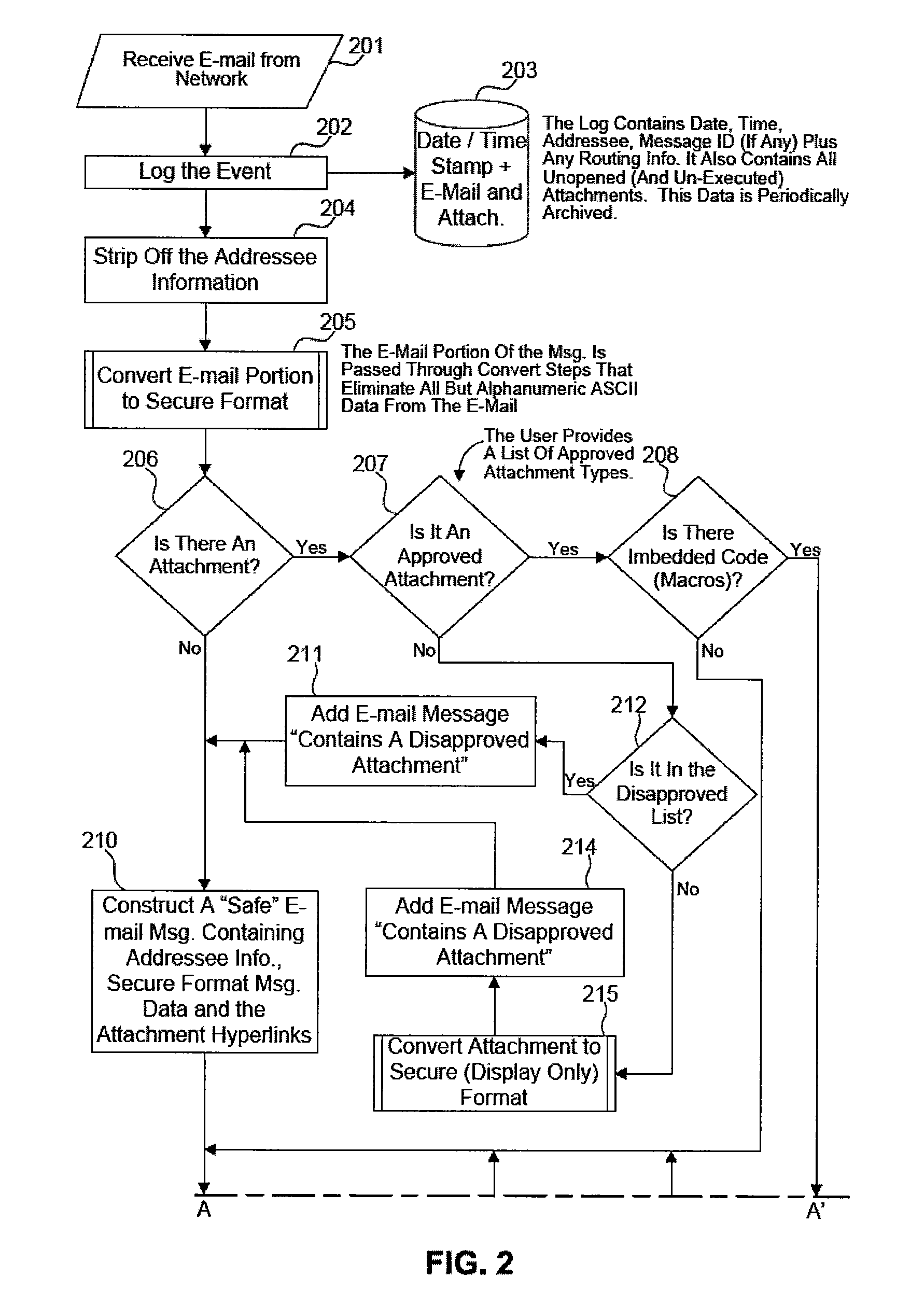

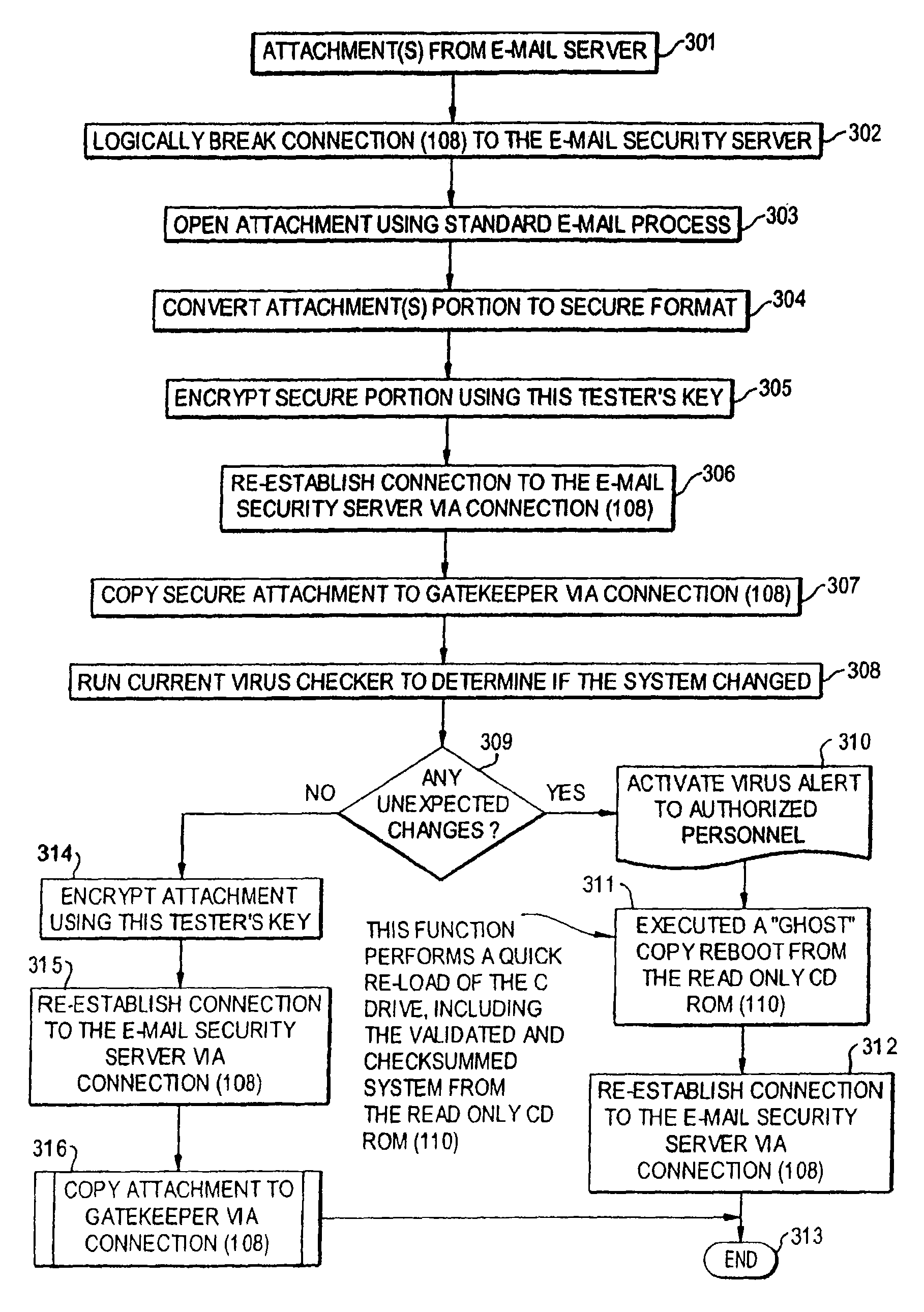

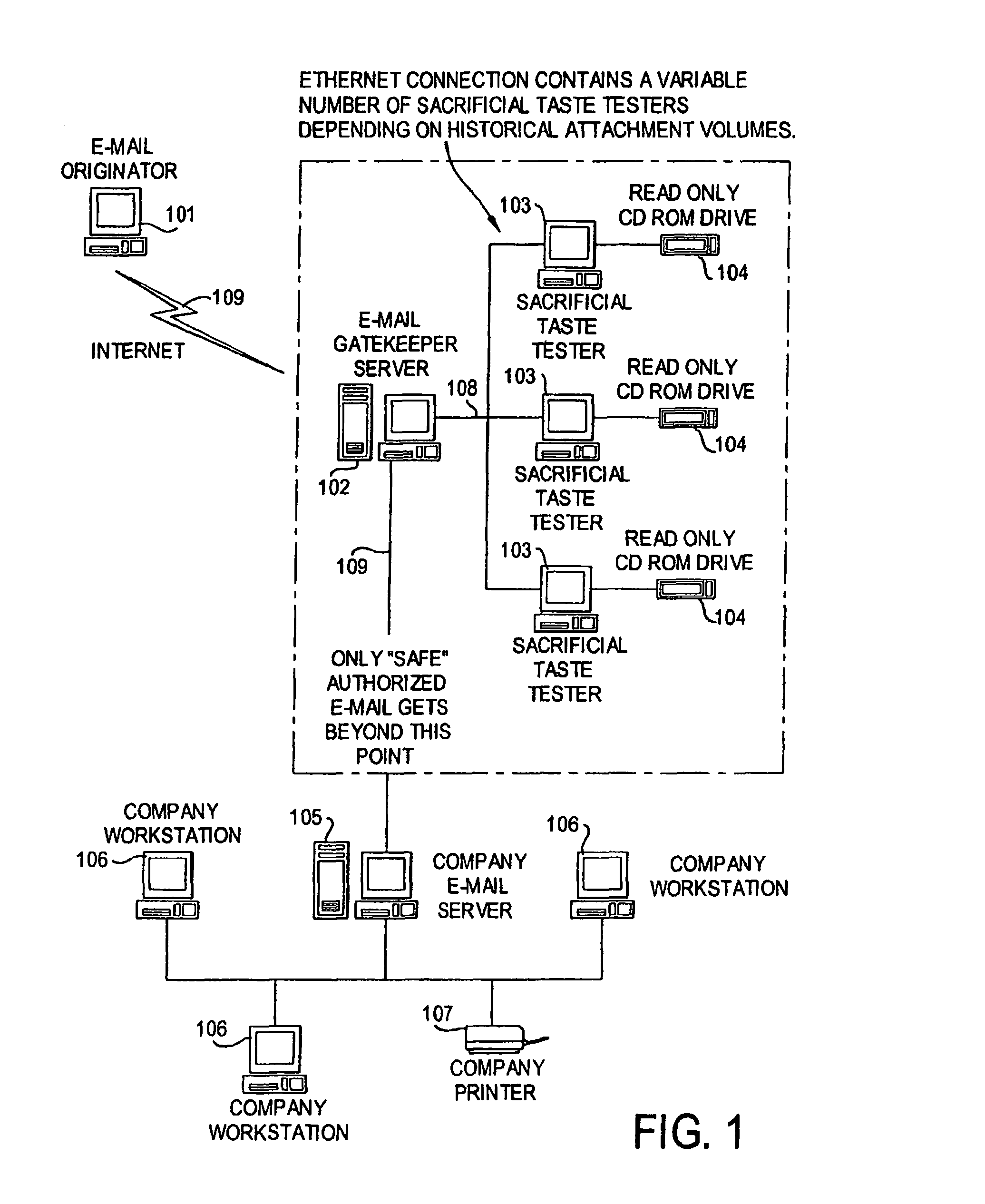

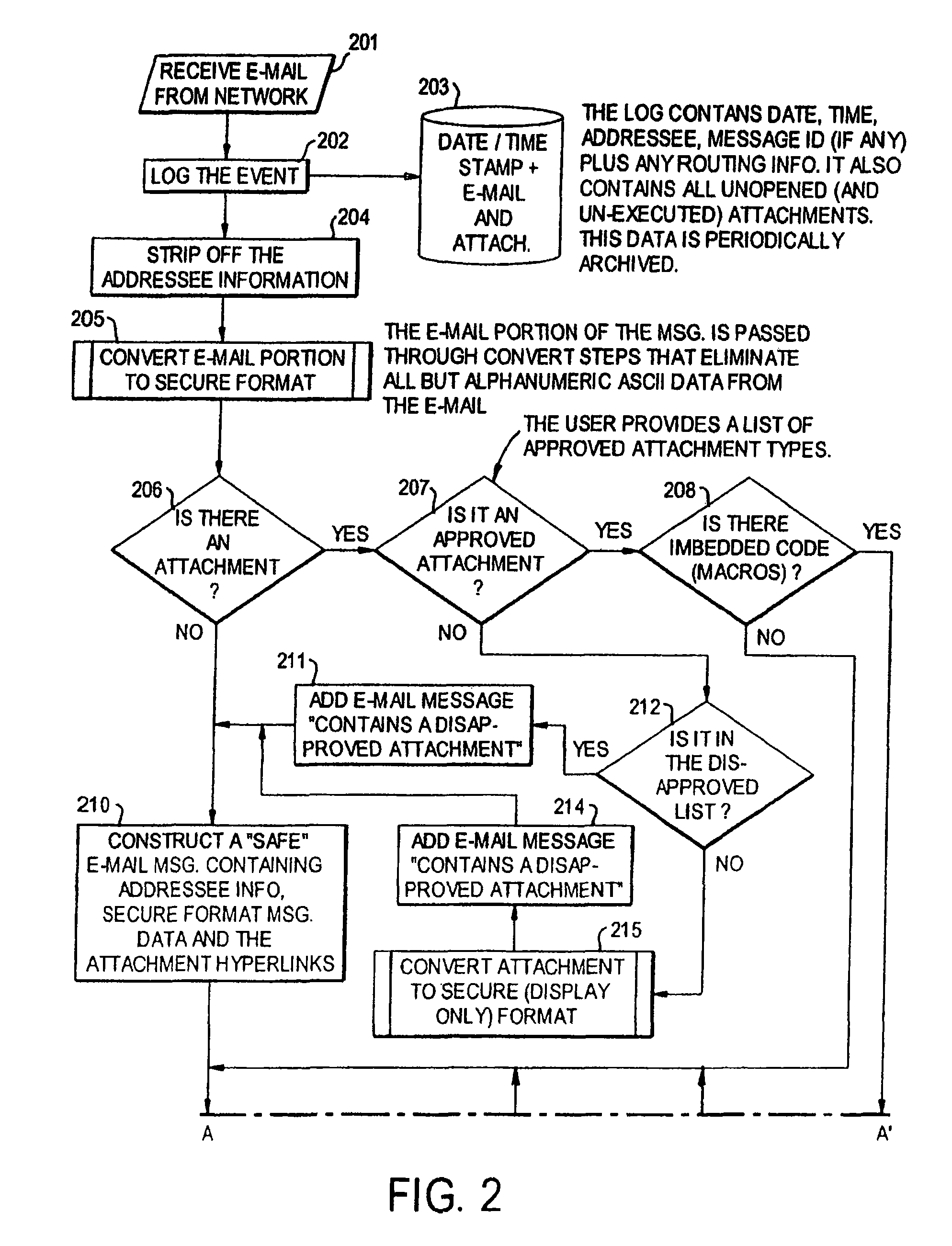

Computer Network Virus Protection System and Method

InactiveUS20080229416A1Detection securityEnsuring Safe ExecutionMemory loss protectionError detection/correctionProtection systemVirus

A network is protected from viruses through the use of a sacrificial server, which may be physical or virtual. Any executable programs or other suspicious parts of incoming e-mail messages are forwarded to a sacrificial server, where they are converted to non-executable format such as Adobe Acrobat PDF and sent to the recipient. The sacrificial server is then checked for virus activity. After the execution is completed, the sacrificial server is rebooted.

Owner:G K WEBB SERVICES

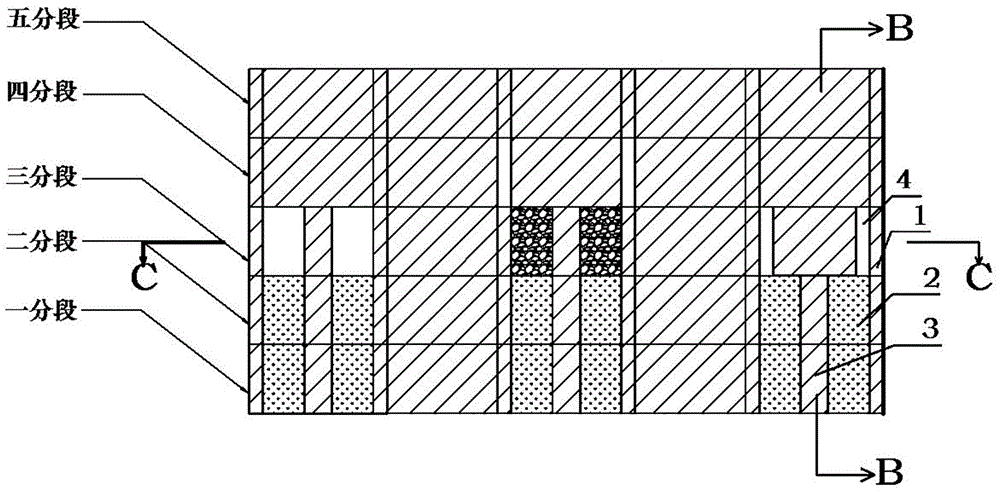

Medium-thickness gentle-dip broken ore body and chamber column type upward horizontal layering filling mining method

The invention belongs to the technical field of metallic mineral deposit underground mining methods, and particularly relates to a medium-thickness gentle-dip broken ore body upward horizontal layering filling mining method. The method includes the steps that firstly, an ore block is divided into multiple mining panels, each panel is further internally divided into multiple stopes, and stoping of each whole panel is conducted in two steps; in the first step, the stoping stopes are arranged at intervals, and studs are reserved on the two sides of each stope; in each stope, a segment is divided every 10 m, after being completely stoped, the next segment is bonded and filled with cement tailings, and the previous segment is stoped; accurate mining engineering in each panel is conducted on an ore body hanging side, and in order to protect the safety of chamber stoping, a pointed column supporting goaf is reserved in the middle of each stope; shallow hole ore falling is adopted, and ores are discharged through a carry-scraper; and after chamber stoping and filling in the first step are finished, the stopes used in the second step are stoped, and the method for stoping the stopes used in the second step is the same as the method for stoping the stopes used in the first step. The method is suitable for mining a medium-thickness gentle-dip broken ore body and has the beneficial effects of being safe in stoping, low in ore dilution and the like.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Large-scale re-mining method for filling small-kiln destruction area

The invention belongs to the technical field of coal mining, which relates to a large-scale re-mining method for filling a small-kiln destruction area and is mainly suitable for recovering coal resource in the area damaged by a small-kiln goaf. The large-scale re-mining method comprises the following technical processes of: probing the small-kiln goaf by the means of geophysical prospecting, drilling, tunnel prospecting and the like; mastering the distribution, the size and the existing hidden danger of the small-kiln goaf; determining the thickness and the strength of a cut layer; determining the thickness and the strength of a bearing key layer; constructing, grouting and drilling; constructing, venting and drilling; grouting and filling; and re-mining the small-kiln destruction area. The large-scale re-mining method has the beneficial effect that the coal resource left in the small-kiln destruction area can be recovered furthest, and the service year limit of a mine is prolonged.

Owner:CHINACOAL PINGSHUO GRP

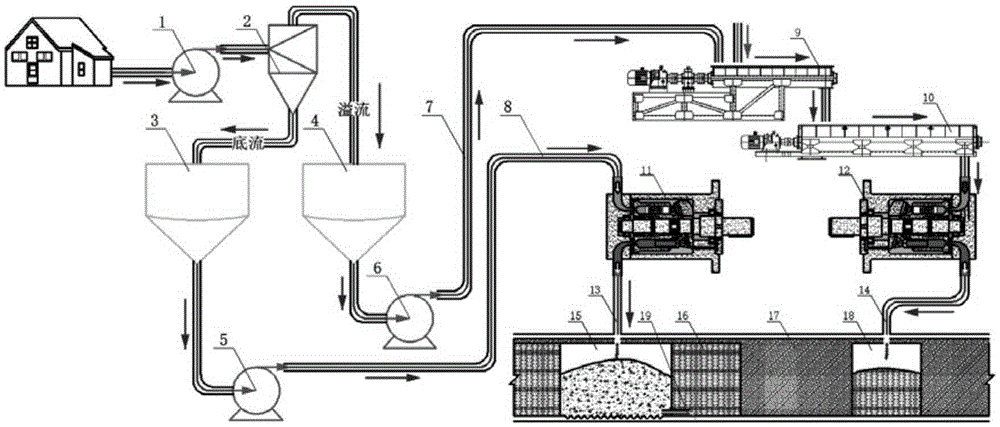

Grading zonal paste backfilling system and method for total tailings of metal minerals

The invention belongs to the field of total tailings paste backfilling and relates to a grading zonal paste backfilling system and method for total tailings of metal minerals. Total tailings of concentrating mills enter a hydrocyclone for grading through a slurry pump, and underflow and overflow of the total tailings are thickened into high-concentration tailings slurry through a thickener. Fine-grained high-concentration tailings slurry is delivered to a backfilling station by a pumping through a pipeline and is backfilled to a step 1 stope after being added with suitable cementing material, while thick-grained high-concentration tailings slurry self-flows or is pumped to a step 2 stope for backfilling, and thus non-cementing backfilling in the step 2 stope is achieved. The high-concentration graded coarse tailings have good water filtration, and a small amount of exudation is discharged out of a backfill through a water filtration facility erected at the stope during non-cementing backfilling. The grading zonal high-concentration backfilling of total tailings can be achieved, and the defect that superfine tailings are poor in dewatering performance can be well overcome.

Owner:UNIV OF SCI & TECH BEIJING

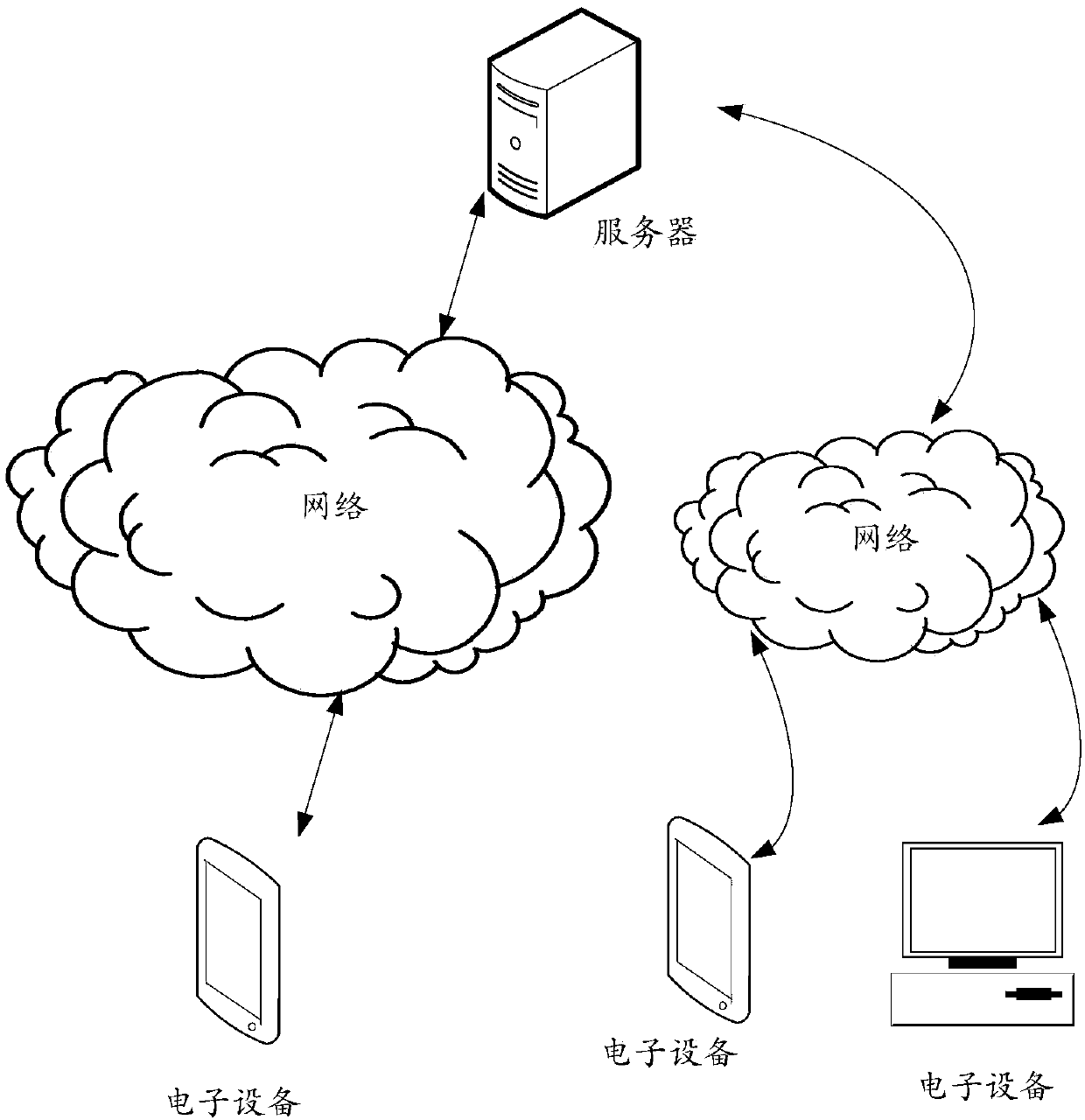

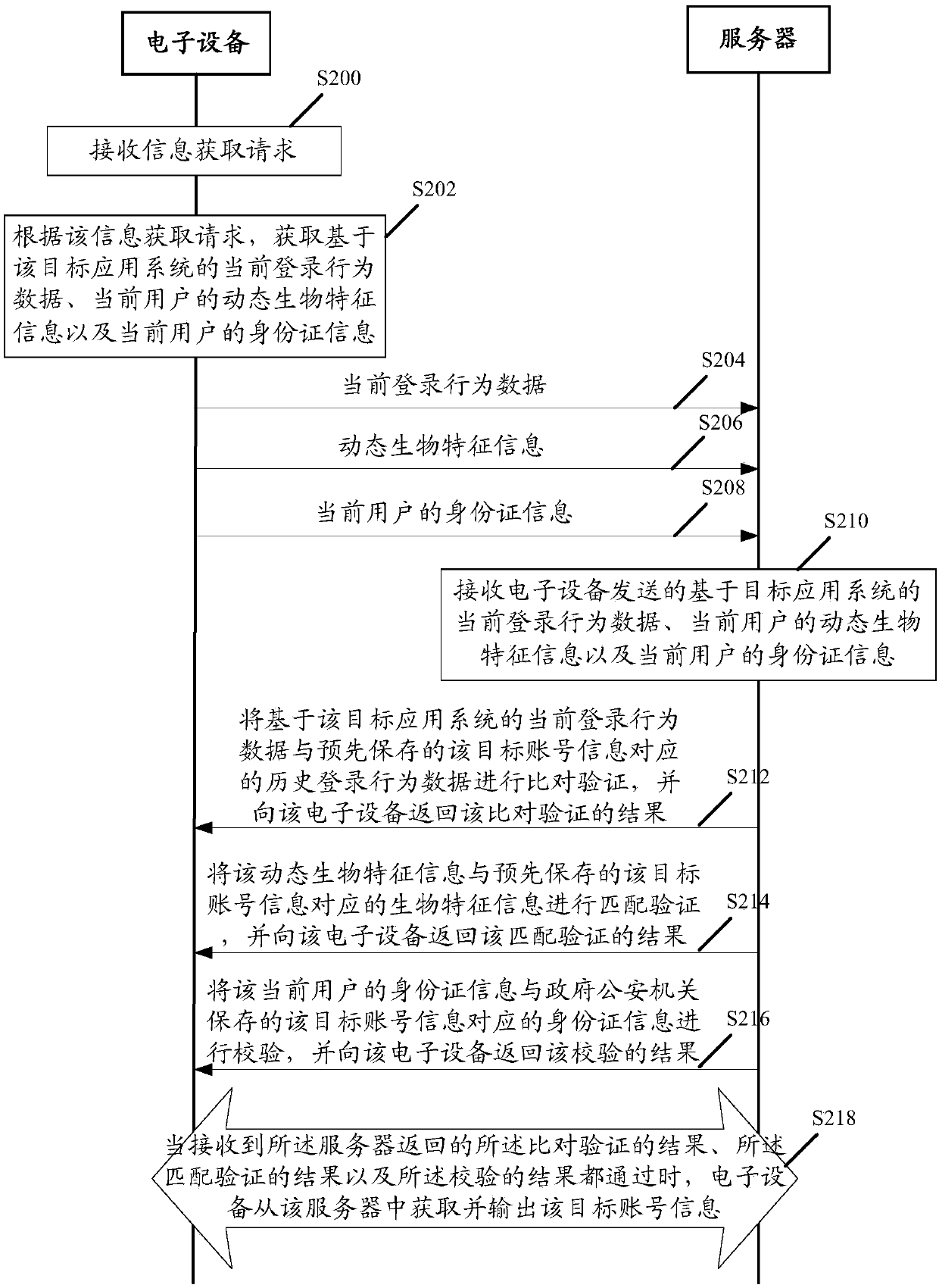

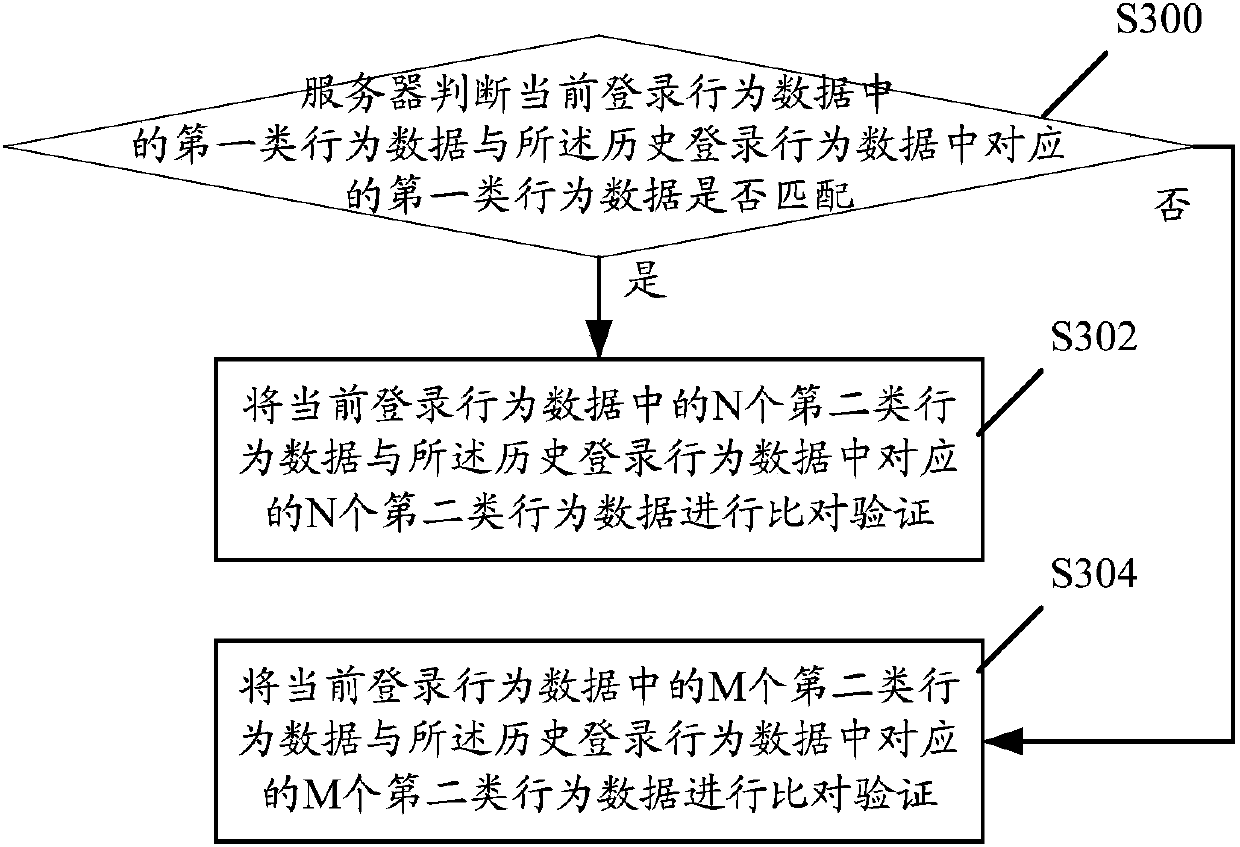

Information verification method, electronic equipment, server and information verification system

ActiveCN107800672AGet back effective securitySafe recoveryTransmissionMessage processingHandling system

The embodiment of the invention discloses an information verification method, including the following steps: receiving an information acquisition request, wherein the information acquisition request instructs to acquire target account information based on a target application system; performing comparison verification on current login behavior data based on the target application system and prestored historical login behavior data corresponding to the target account information according to the information acquisition request; acquiring dynamic biological characteristic information of a current user according to the information acquisition request, and performing matching verification on the dynamic biological characteristic information and prestored biological characteristic information corresponding to the target account information; acquiring identity card information of the current user according to the information acquisition request, and performing verification on the identity card information of the current user and identity card information that is saved by the public security agencies of the government and corresponds to the target account information; and when a comparison verification result, a matching verification result and a verification result are all successfully verified, outputting the target account information. The invention also discloses a message processing system, electronic equipment and a server.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Depressurisation method and apparatus for subsea equipment

ActiveUS20190136671A1Avoiding high hydrostatic pressureReduce pressureCleaning apparatusFluid removalBiomedical engineering

A method for reducing the pressure of fluid within subsea equipment. The method includes the steps of: (a) providing a pipe, (b) laying the pipe on the sea floor, (c) providing a connector, (d) connecting the pipe to the subsea equipment via the connector, and (e) extracting fluid from the subsea equipment through the connector and into the pipe. Apparatus for reducing the pressure of fluid within subsea equipment by extracting fluid from the subsea equipment.

Owner:TECHNIP UK

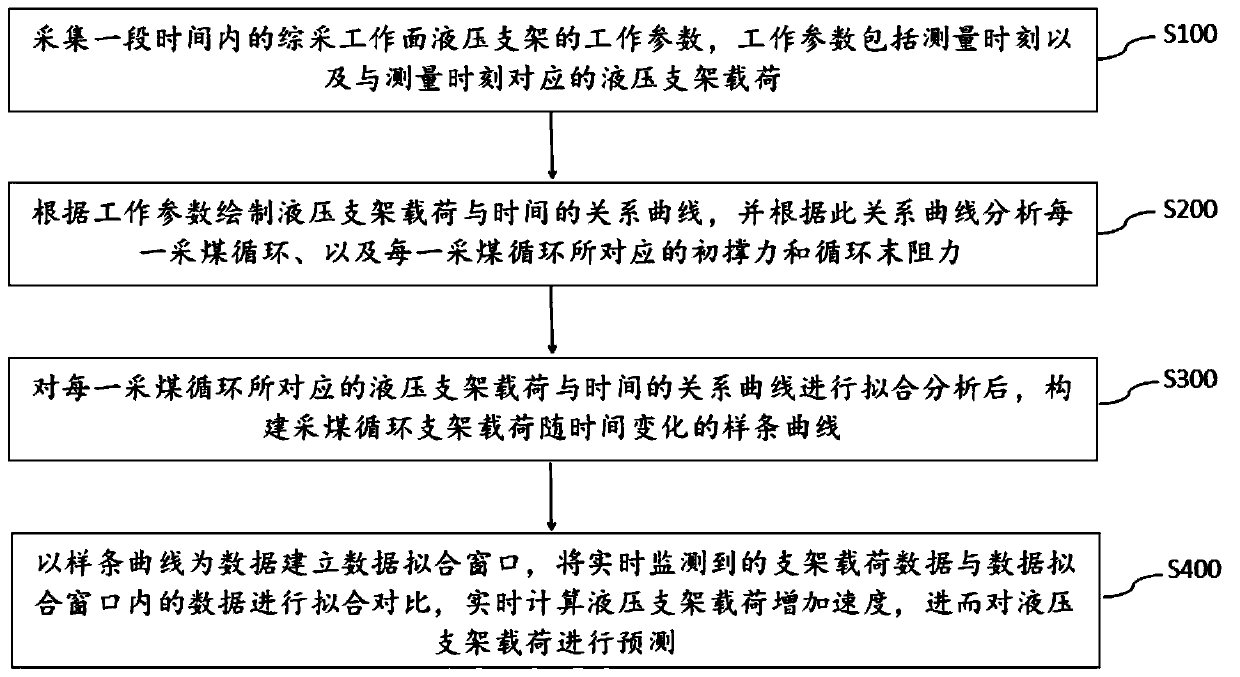

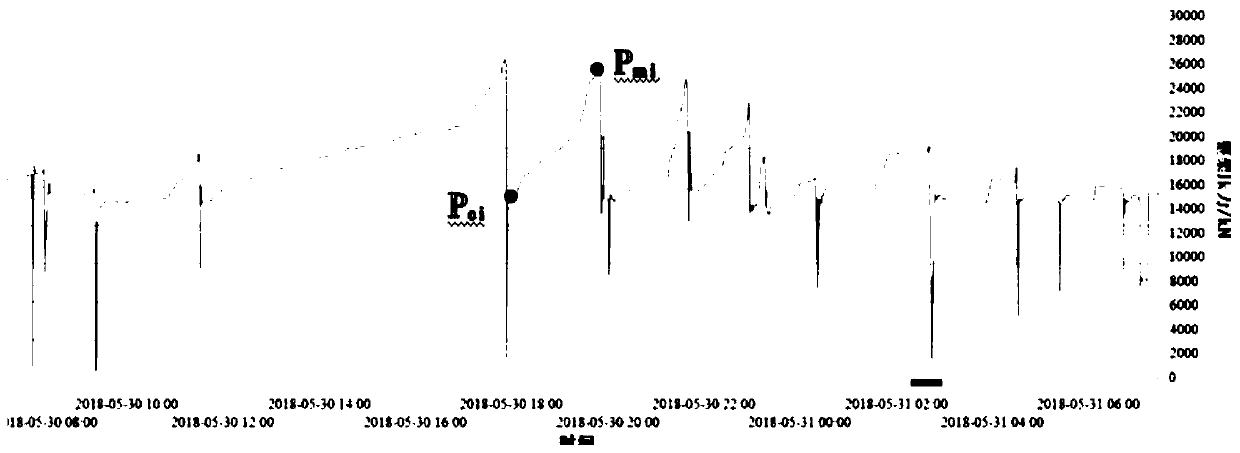

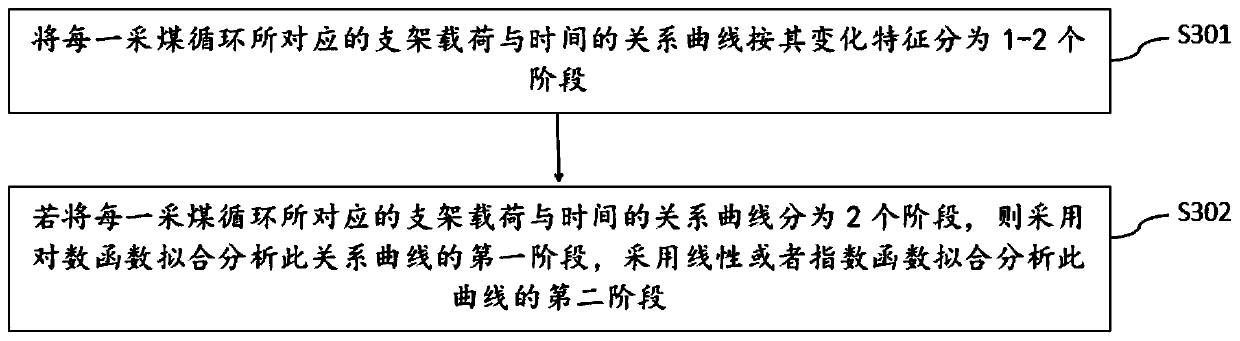

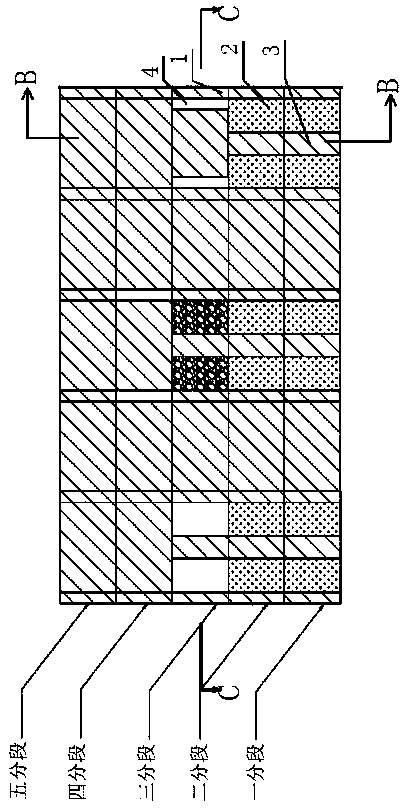

A subsection prediction method for a fully mechanized mining hydraulic support load

ActiveCN109815565ASafe recoveryEffective recoverySpecial data processing applicationsEngineeringShort terms

The invention discloses a segmented prediction method for a fully mechanized mining hydraulic support load. The method comprises the steps of collecting working parameters of a fully mechanized miningworking face hydraulic support within a period of time; drawing a relation curve of the hydraulic support load and the time according to the working parameters, and analyzing each coal mining cycle and the initial supporting force and the cycle end resistance corresponding to each coal mining cycle according to the relation curve; after the relation curve of the hydraulic support load and time corresponding to each coal mining cycle is subjected to fitting analysis, a spline curve of the coal mining cycle support load changing along with time is constructed; and establishing a data fitting window by taking the spline curve as data, fitting and comparing the bracket load data monitored in real time with the data in the data fitting window, calculating the load increase speed of the hydraulic bracket in real time, and further predicting the load of the hydraulic bracket. The method is not only an accurate and reliable hydraulic support load prediction method, but also can realize short-term prediction of the mine pressure.

Owner:TIANDI SCI & TECH CO LTD

Computer network virus protection system and method

InactiveUS7913078B1Detection securityEnsuring Safe ExecutionMemory loss protectionError detection/correctionProtection systemElectronic mail

A network is protected from viruses through the use of a sacrificial server, which may be physical or virtual. Any executable programs or other suspicious parts of incoming e-mail messages are forwarded to a sacrificial server, where they are converted to non-executable format such as Adobe Acrobat PDF and sent to the recipient. The sacrificial server is then checked for virus activity. After the execution is completed, the sacrificial server is rebooted.

Owner:INTELLECTUAL VENTURES I LLC

Brake control system for an electrically driven vehicle

ActiveUS8523297B2Safe recoveryIncrease forceBraking element arrangementsAnalogue computers for trafficRegenerative brakeControl system

During regenerative coordinate braking control, a target brake force is defined by eliminating influences of brake system component tolerances to achieve a comfortable brake feel and secure regenerative energy. A brake control system includes a master cylinder, wheel cylinders, a VDC brake fluid pressure unit and a motor controller. In response to a brake pedal operation by a driver, a brake pedal stroke position is detected at which a pressure in a master cylinder actually begins to be generated. A target deceleration characteristic is adjusted from a theoretical characteristic so that the target deceleration equals a maximum value of an add-on brake force (i.e., the regenerative brake gap) at the detected brake pedal stroke position.

Owner:NISSAN MOTOR CO LTD

High power DC SSPC with capability of soft turn-on large capacitive loads

ActiveUS8716997B2Safe recoveryElectronic switchingEmergency protective arrangements for limiting excess voltage/currentPower controllerMOSFET

Pre-charge circuitry allows capacitive loads connected to a solid state power controller to be gradually charged up by a PWM, generated with a cycle by cycle current limit, switching a single MOSFET in series with an inductor, before the SSPC is turned on. The pre-charge circuitry may require only three additional components, e.g., a MOSFET, an inductor and a diode, along with a designated MOSFET gate driver.

Owner:HONEYWELL INT INC

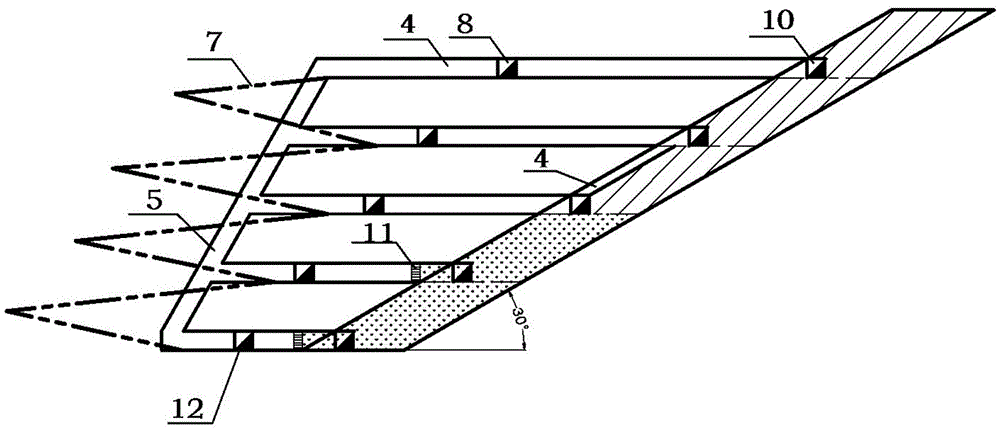

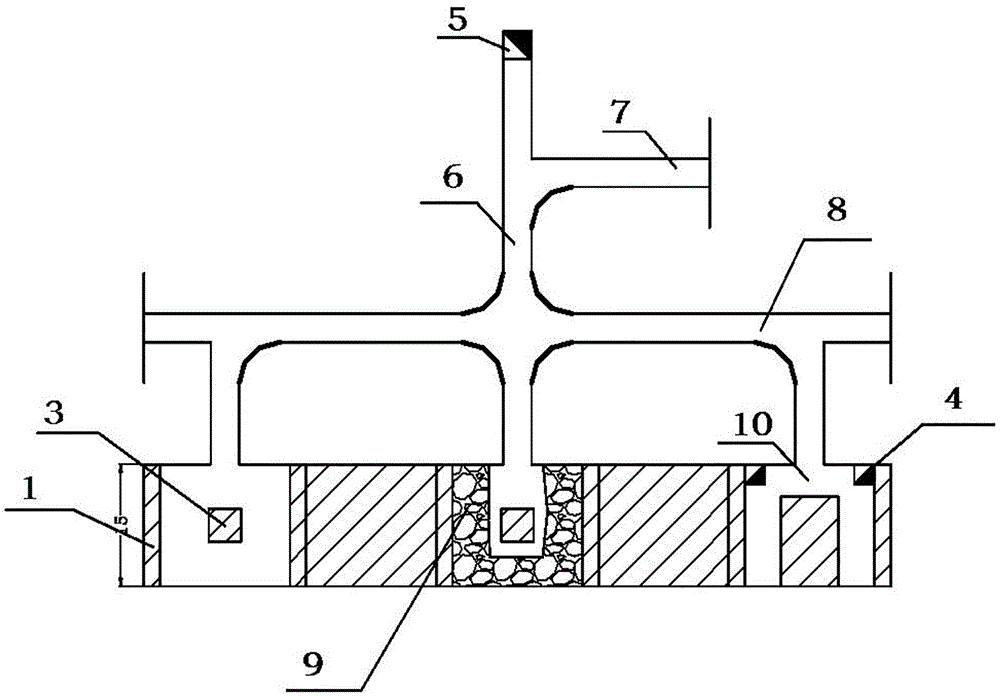

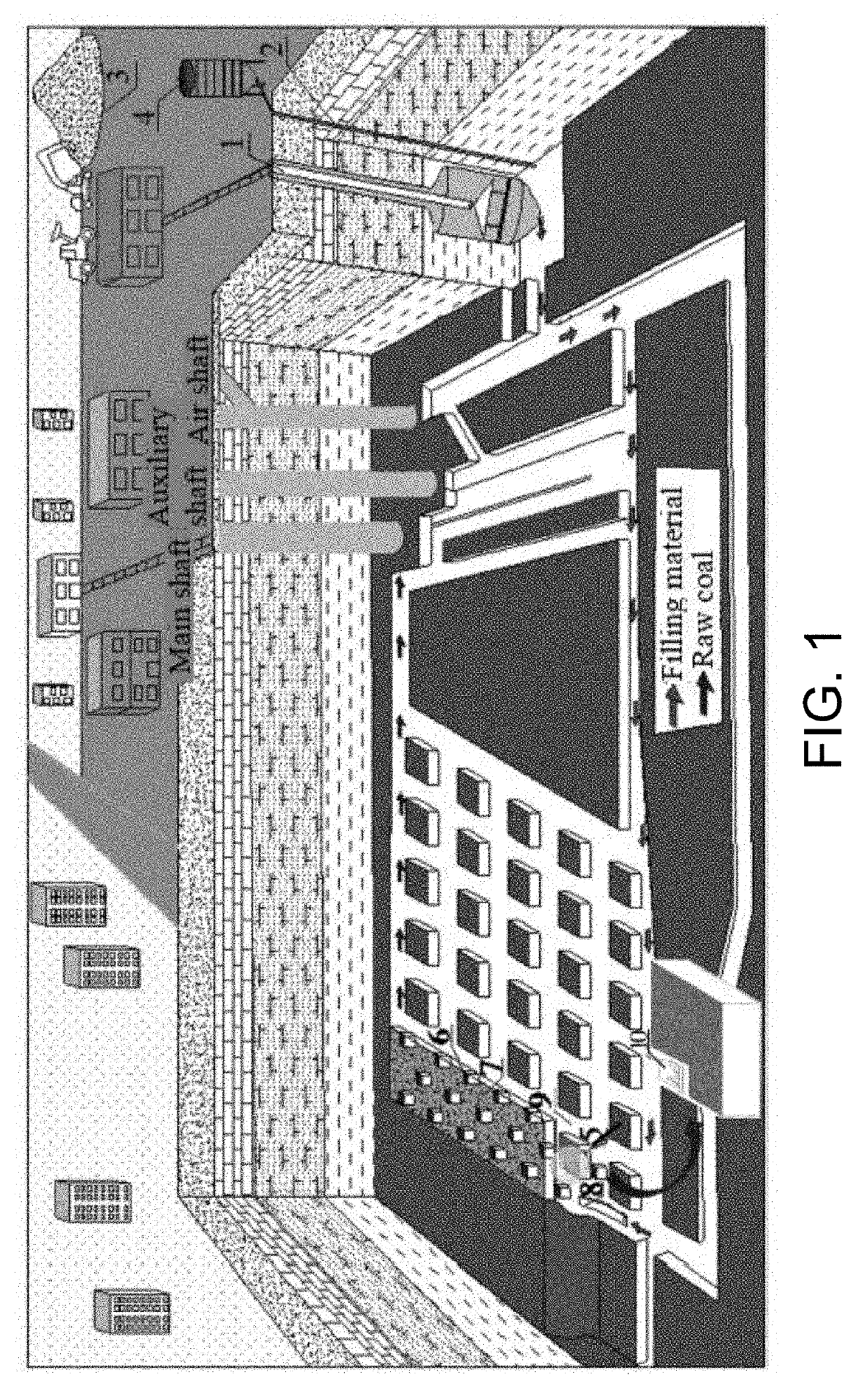

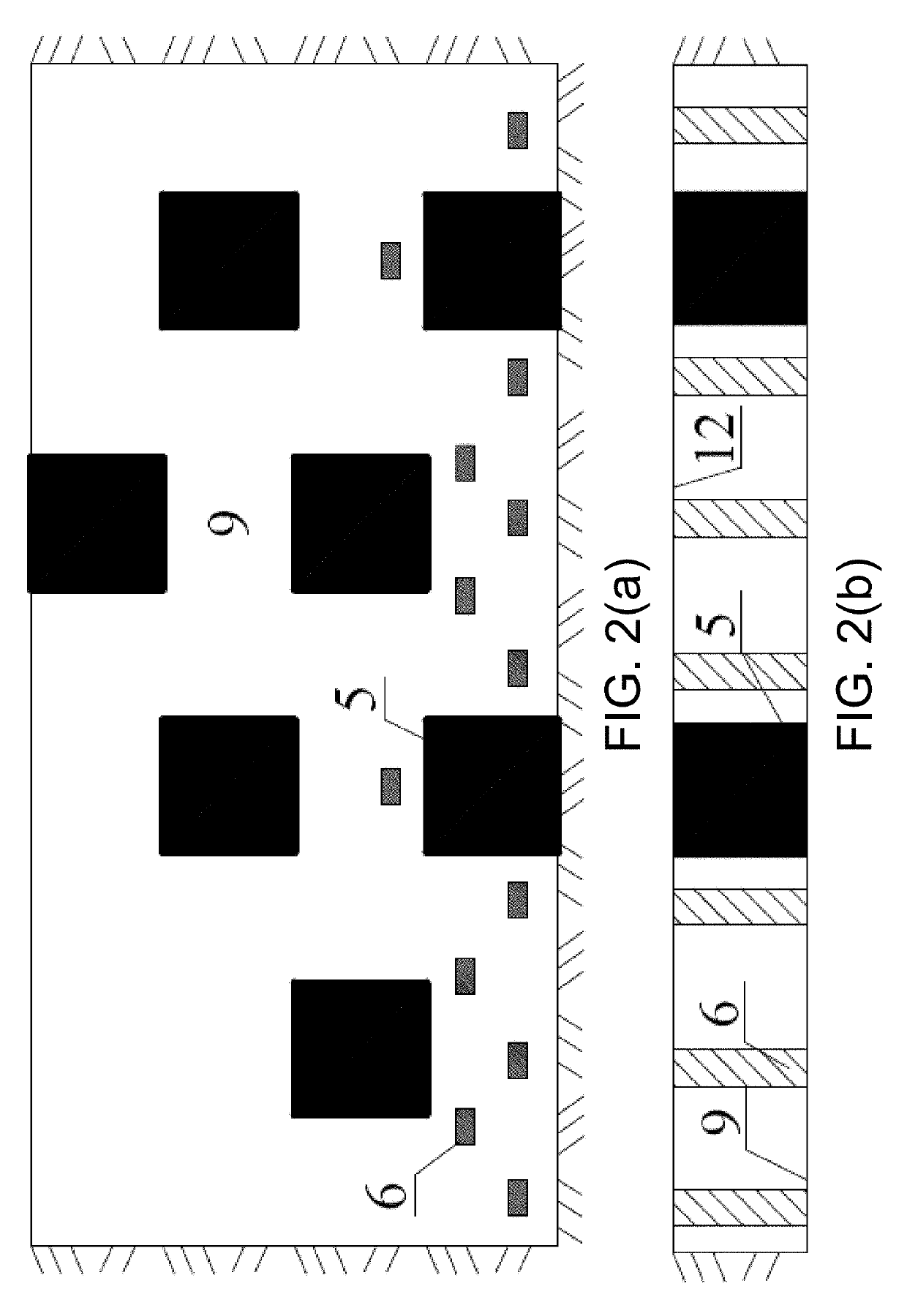

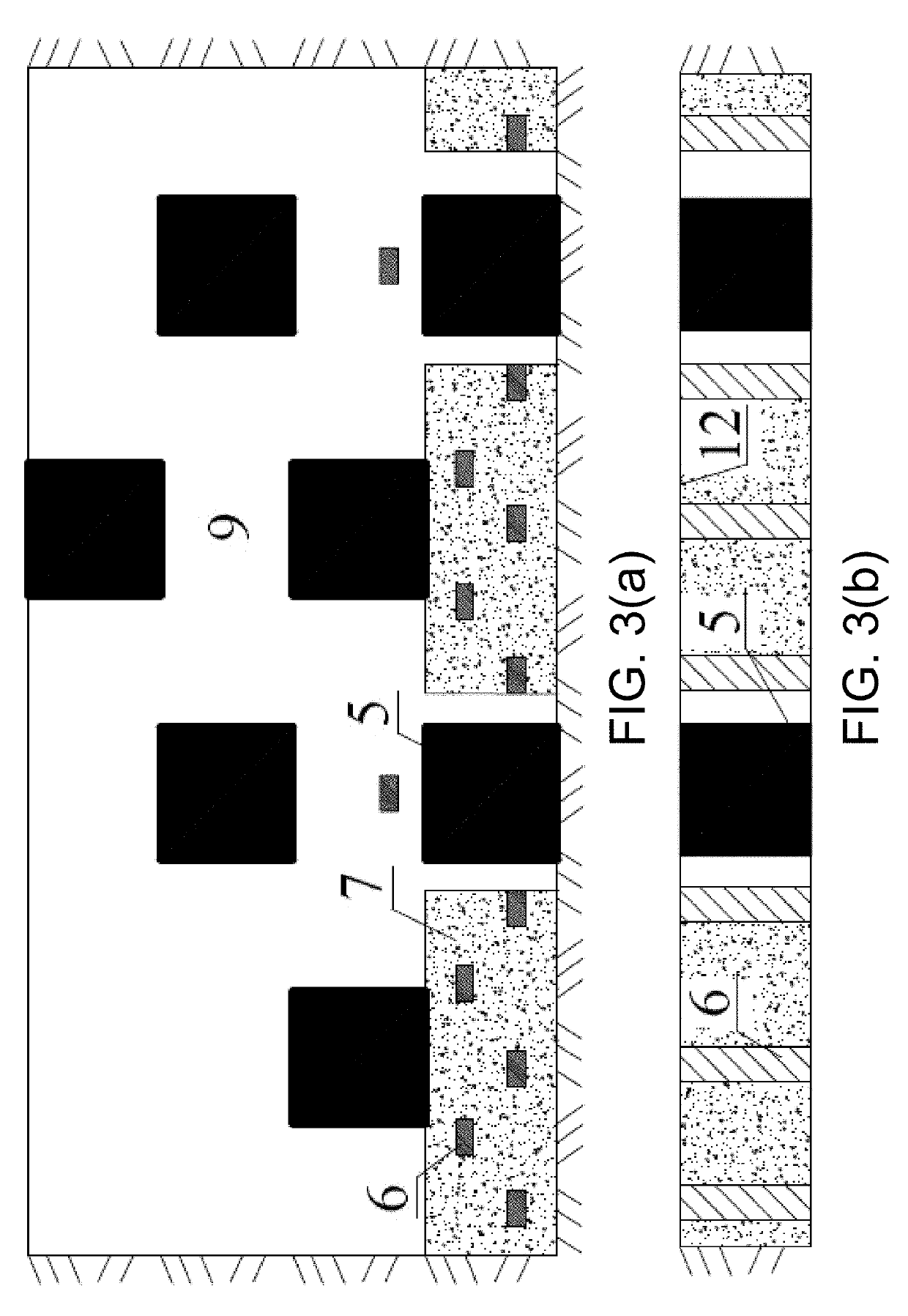

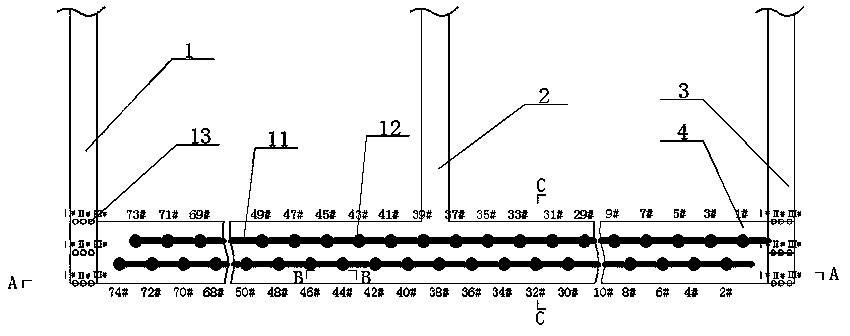

Method for recovering room-mining coal pillars by solid filling in synergy with artificial pillars

ActiveUS20190301283A1Ensure safe and efficient recoveryReduce investmentUnderground miningSurface miningRoom and pillar miningSupporting system

A method for recovering room-mining coal pillars by solid filling in synergy with artificial pillars. Solid materials and cementing materials on the ground are conveyed through a feeding well and a pipeline to a room-and-pillar goaf, a plurality of artificial pillars is cast at an interval in a coal room area, and gangue is cast to fill other regions of the coal room using a gangue casting machine. Under joint support by the artificial pillars and the coal room filler, coal pillars are recovered using a continuous coal mining machine, artificial pillars are cast in the original coal pillar area after recovery, and gangue is cast to fill the original coal pillar area using the gangue casting machine. A system for recovering room-mining coal pillars by solid filling in synergy with artificial pillars mainly includes a material conveying system, a joint support system, and a coal pillar recovery system. By constructing pillar grooves, casting artificial pillars, casting gangue to fill a goaf, and recovering coal pillars, the recovery rate of coal resources can be increased, and room-mining coal pillar recovery theories and technologies in China can be enriched while harmonious development of environmental protection and resource exploitation is promoted.

Owner:CHINA UNIV OF MINING & TECH

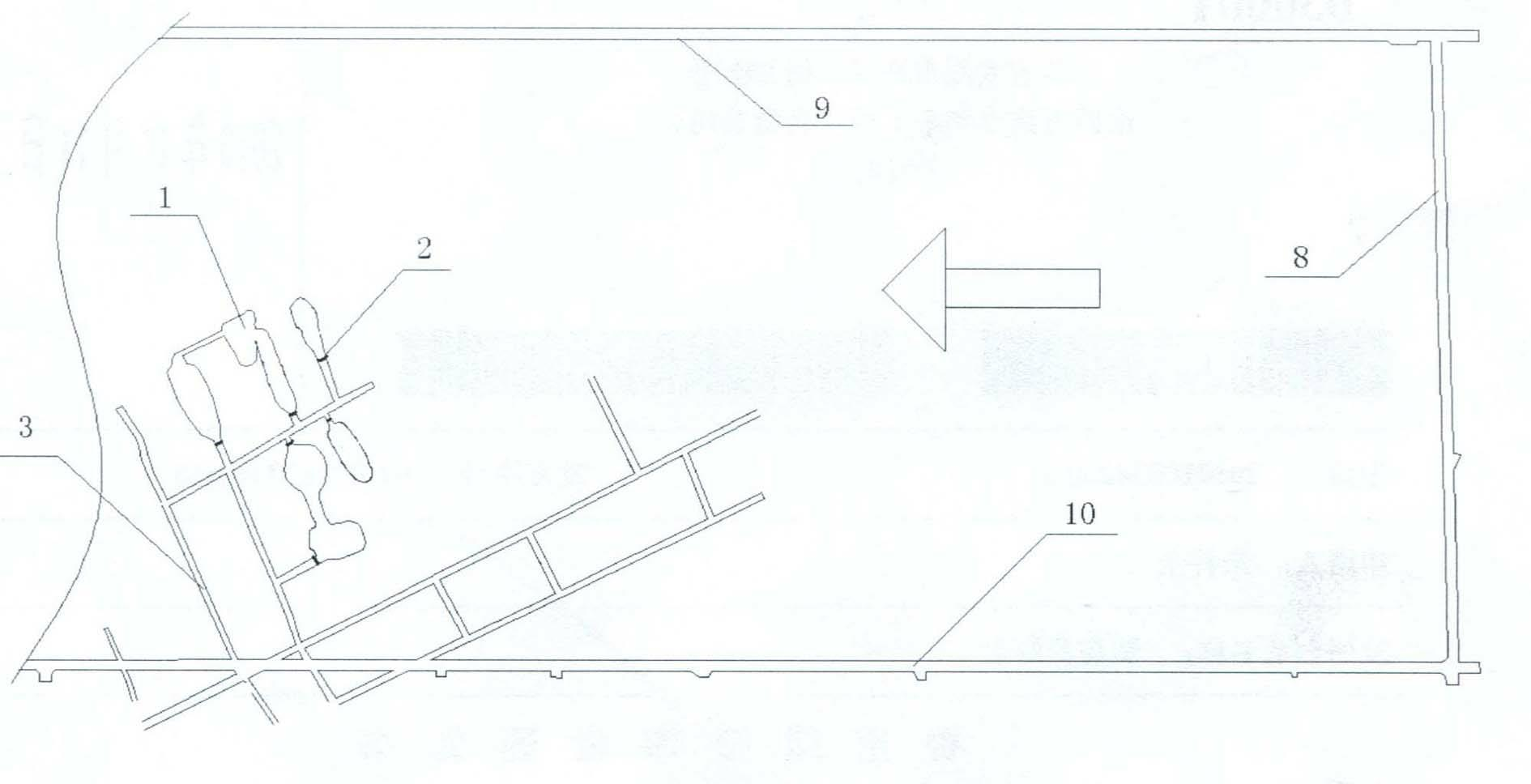

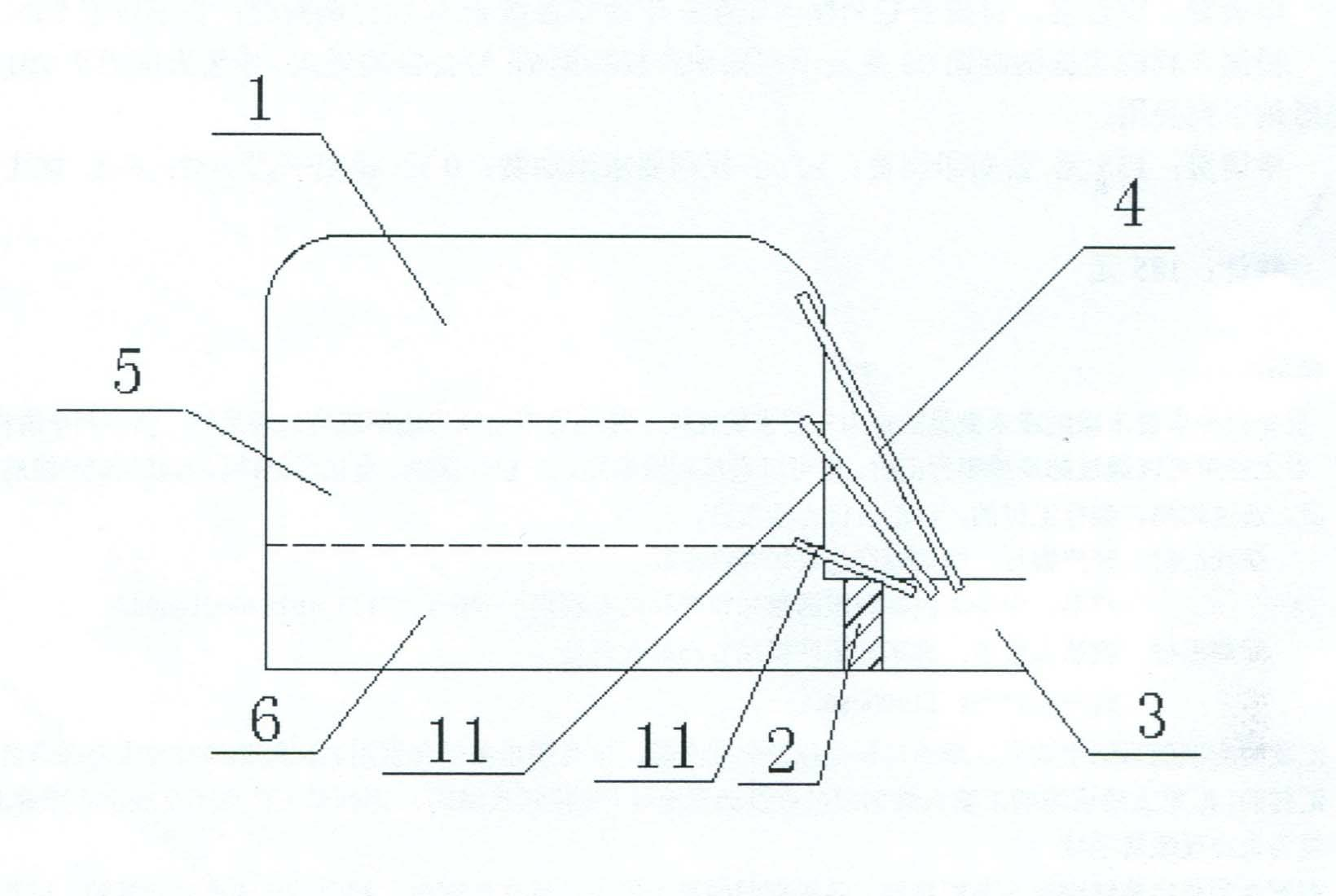

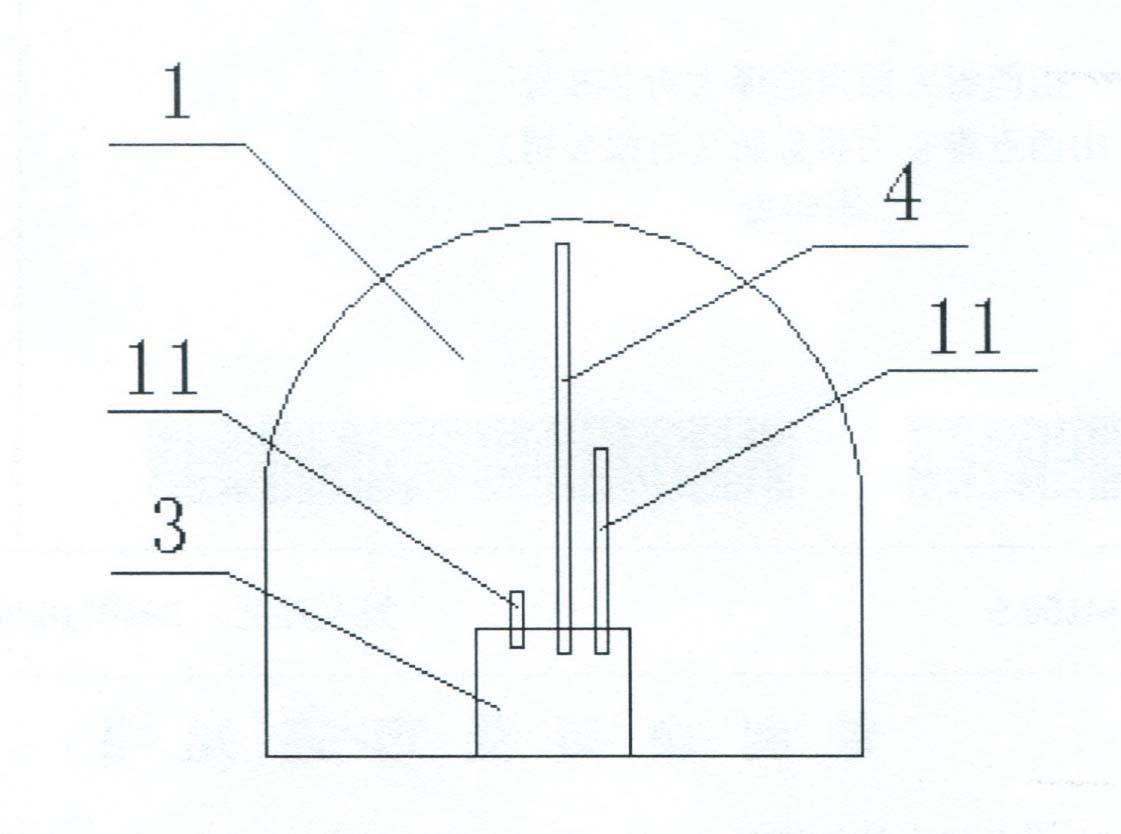

High-segmentation upward deep hole ore extraction zero-dead-zone following filling mining method

The invention discloses a high-segmentation upward deep hole ore extraction zero-dead-zone following filling mining method. Firstly, a drilling chamber is constructed at the top end of a stage stope room, an operating space is formed through supporting, a mine collecting structure is established at the bottom end, upward chambering is carried out, a compensation space is formed, and the mining and cutting work is finished; secondly, a vertical deep hole is drilled in the drilling chamber, and the configuration of a boundary presplitting smooth blasting bomb hole is matched; thirdly, the upward segmentation blasting is carried out, ore reserving and ore removing are carried out, the zero dead zone in the ore removing process is ensured, and meanwhile the compensation space is guaranteed; fourthly, after appropriate ore drawing in the final blasting, an interlayer is arranged on the top of an ore heap, and the interlayer is covered with dead rock to fill the top dead zone along with the ore drawing; fifthly, after ore drawing is finished, stope room dead rock cemented filling is achieved through the potting material at the top end. The mining method is suitable for the environment where mine fragmentation is not stable, the large dead zone is not allowed, but high-segmentation, large-scale and large-yield thick and large ore body mining is urgent. The mining method has the advantages that the structure is simple, and high efficiency and economic efficiency are achieved.

Owner:CENT SOUTH UNIV

Cough catcher with protection against germ transmission by hand contact

In order to prevent tainting of a cougher's hand with germs, the product from a cough is carried in contact with a germicide inside a hollow article, and is vented out of the hollow article, in directions away from the user's face and hand holding the article. More specifically, the cough catcher has a hollow region for accepting the product from a cough therein. This hollow region has a filter element containing a germicide mounted therein, and a series of channels formed between the filter element and a bottom surface of the hollow region. The channels communicate with vent ports around a rim portion of the cough catcher. The vent ports are oriented away from both the mouth opening and the outside surface of the cough catcher for conveying the product from a cough away from both the face and the hand of a user.

Owner:COVER YOUR COUGH PROD

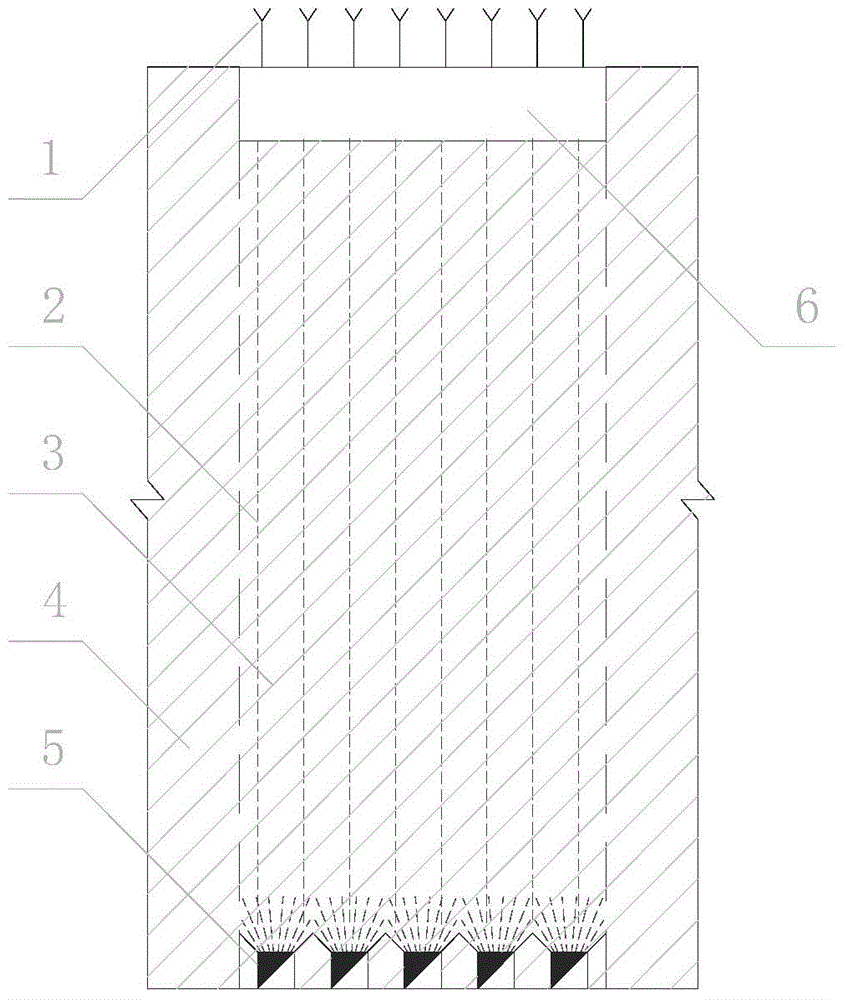

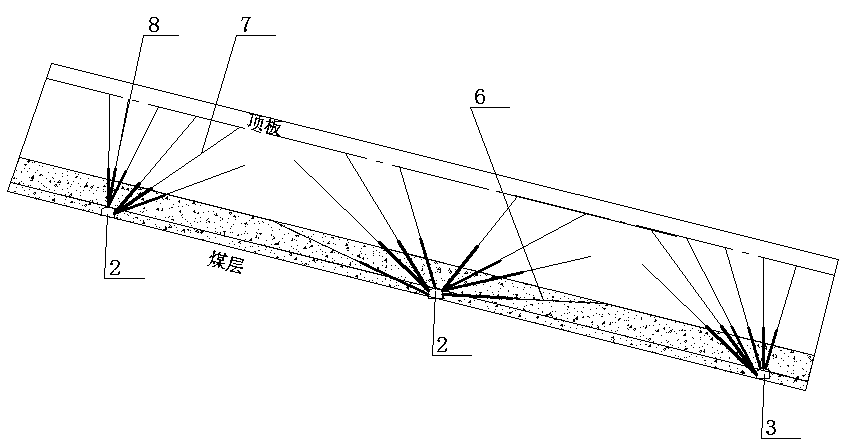

Method for preventing and controlling rock burst and gas emission of high-length short-distance drilling linkage

InactiveCN111237006ASimple ventilation systemReliable ventilation systemTunnel/mines ventillationGas removalMining engineeringStructural engineering

The invention relates to a method for preventing and controlling rock burst and gas emission of high-length short-distance drilling linkage. The method comprises the steps that in the tunneling process of a roadway of a recovery work surface of an underground coal mine, a process roadway is formed in the middle of the work surface, so that the process roadway and upper and lower through grooves ofthe work surface form a ventilation system in U and L shapes, and the ventilation system is easier and more stable and reliable. Top plate super-front deep hole presplitting blast holes are constructed in the process roadway, super-front presplitting holes of upper and lower ends of the construction work surface, close to the upper edge of the upper through groove and close to the lower edge of the lower through groove are used for performing presplitting blasting on a coal bed and a top plate of the coal bed, and the disaster of rock burst of the work surface is prevented and controlled. Through presplitting blast, the top plate of the coal bed generates a large quantity of secondary interstices, so that a good channel is provided for long-distance and short-distance high-position boringexploitation of pressure relief gas when construction is performed in the process roadway and the upper through groove in the recovery period of the work surface, the gas emission intensity of air return corners of the work surface in the recovery period can be greatly lowered, and the safe and efficient exploitation of the work surface are practically guaranteed.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

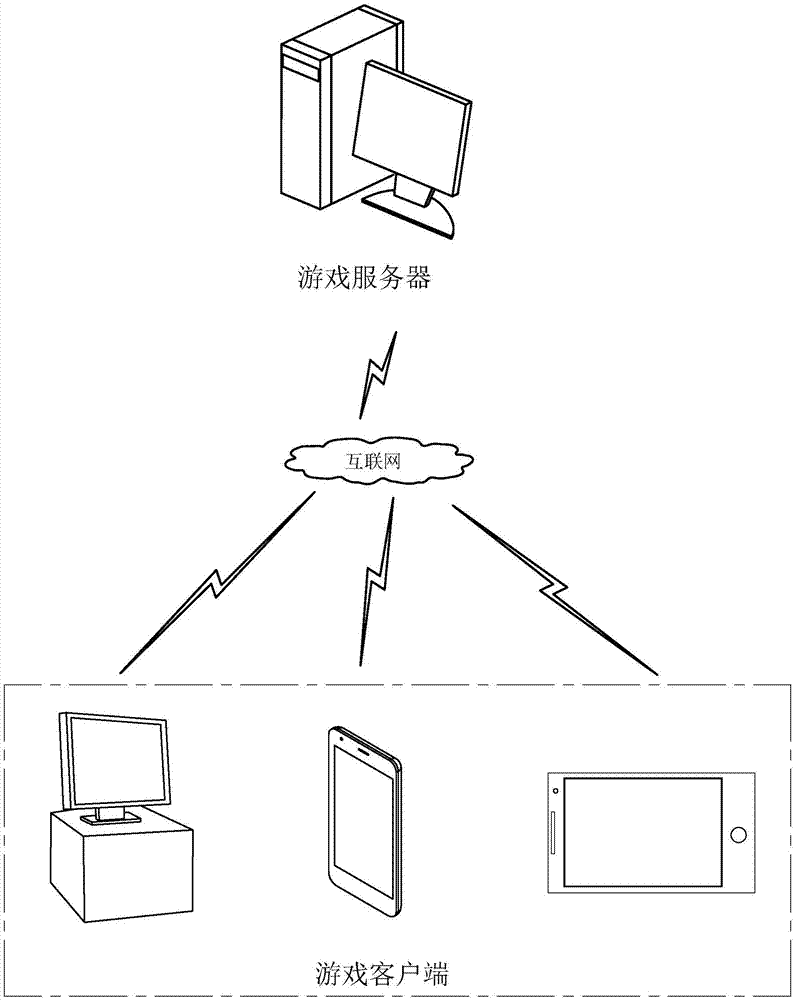

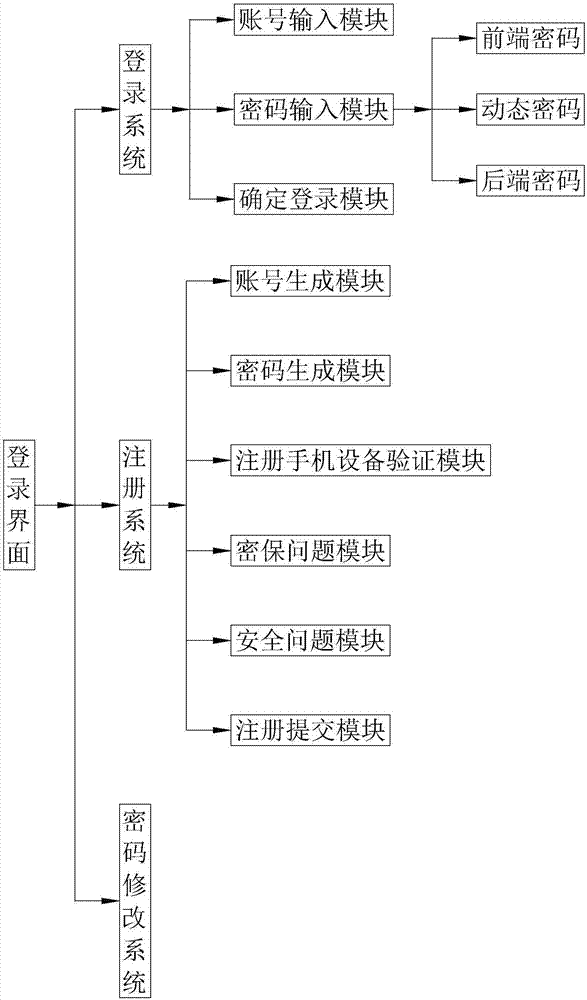

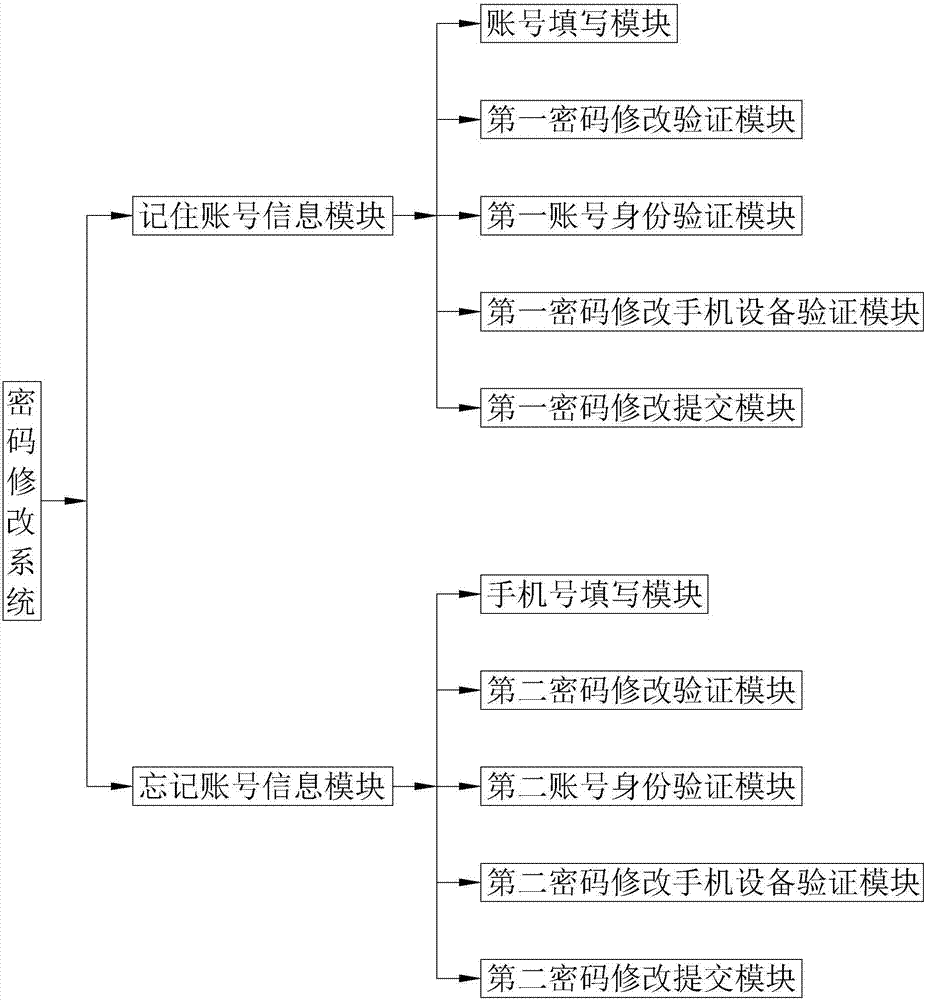

Webgame security system

The invention discloses a webgame security system, which solves the problems that people worry that the accounts will be stolen by others when enjoying the fun of games, and once the accounts are stolen, the waste of time spent on the games can be caused, net friends made in the games can be very difficultly recovered, and the cost of money is wasted. The main points of the technical scheme are that the webgame security system also comprises a login interface, wherein the login interface includes a login system, a registration system and a password modification system; the login system includes an account input module, a password input module and a login confirmation module; the password input module includes a front-end password, a back-end password and a dynamic password, and only when the correct front-end password, back-end password and dynamic password are simultaneously input, normal login can be achieved. According to the webgame security system disclosed by the invention, the security performance of the accounts can be increased through the matching of the front-end password, the back-end password and the dynamic password and the matching of an account freezing system.

Owner:杭州禹乐网络科技有限公司

Upward horizontal stratification filling mining method for medium thickness gently inclined broken ore body

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

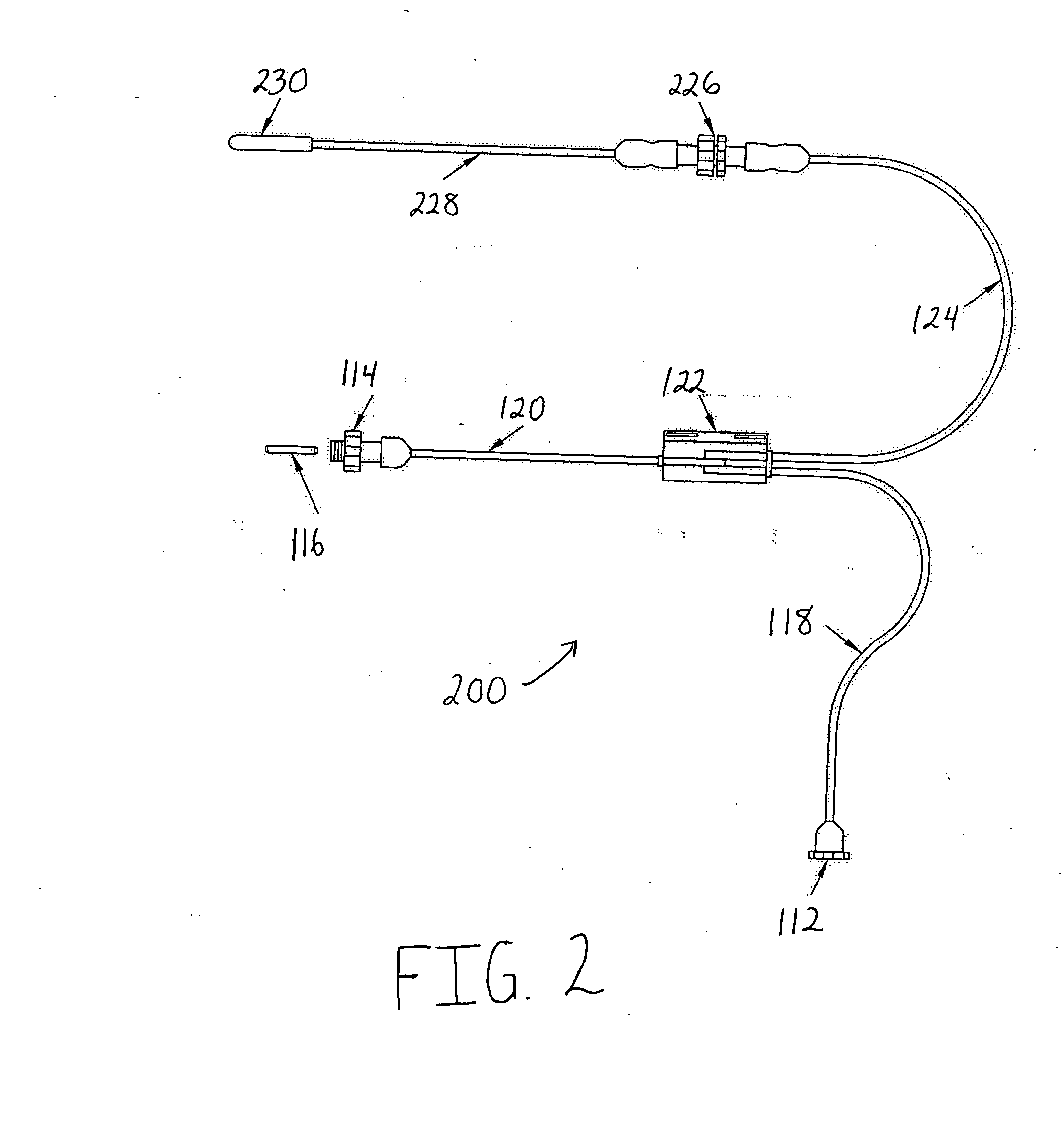

Modular electrical adapter

InactiveUS20080014800A1Quickly and easily accessSafe recoveryElectric discharge tubesCoupling device detailsModularityEngineering

Owner:CONSOL EDISON OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com