Method for preventing and controlling rock burst and gas emission of high-length short-distance drilling linkage

A technology of rock burst and gas gushing, applied in drilling equipment and methods, gas discharge, earthwork drilling and mining, etc., can solve problems such as coal fragmentation, large gas gushing, coal oxidation and temperature rise, and achieve prevention and control Effects of mine rock burst disasters, reduction of gas gushing intensity, and simple ventilation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

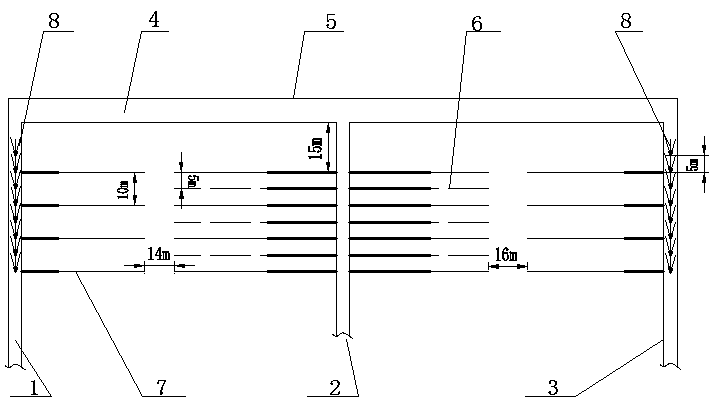

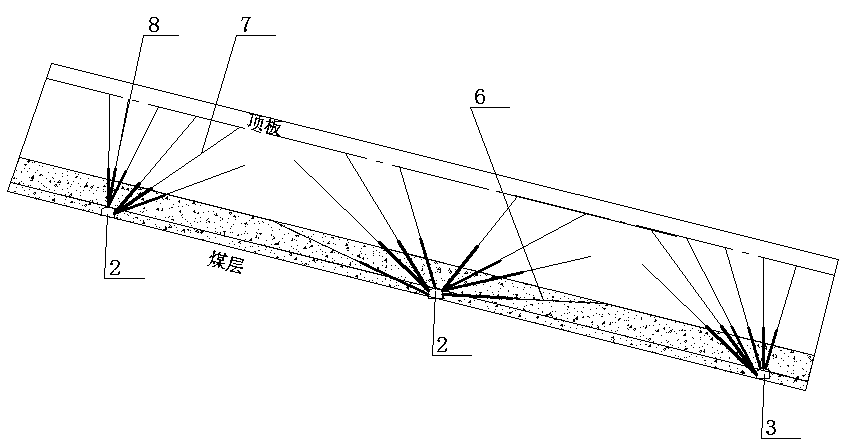

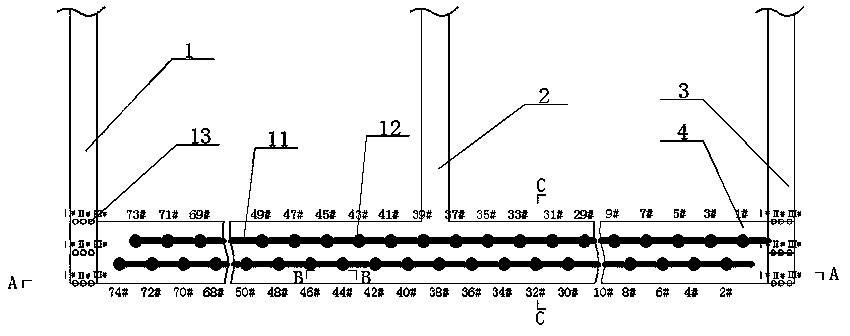

[0034] Such as figure 1 As shown, the method for joint prevention and control of rock burst and gas gushing by high-position long-distance and short-distance drilling includes the following steps:

[0035] Step a) Construct the process lane 2 in the middle of the working face 5, so that it forms a "U+L"-shaped ventilation system with the upper trough 1, the lower trough 3 and the cutting lane 4 of the working face 5, so as to avoid air short circuit (such as figure 1 shown);

[0036] Step b) Before the mining of the working face, construct the top plate advance deep hole pre-splitting blast hole 7 on the upper side of the upper channel 1, the lower side of the lower channel 3, and the process roadway 2, and start the cutting hole 15m ahead of the process roadway 2 Construction of the first group of pre-split blasting holes 7 in the roof ahead of deep holes, with a row spacing of 10m, using φ60 powder rolls for charge, and blast holes arranged perpendicular to the centerline o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com