Labyrinth type oil-gas separating structure in cover of engine spiracular atrium

An engine valve, oil-vapor separation technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as damage to the crankcase seal, reduced oil performance, increased deterioration, etc., to achieve reliable work performance and easy process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

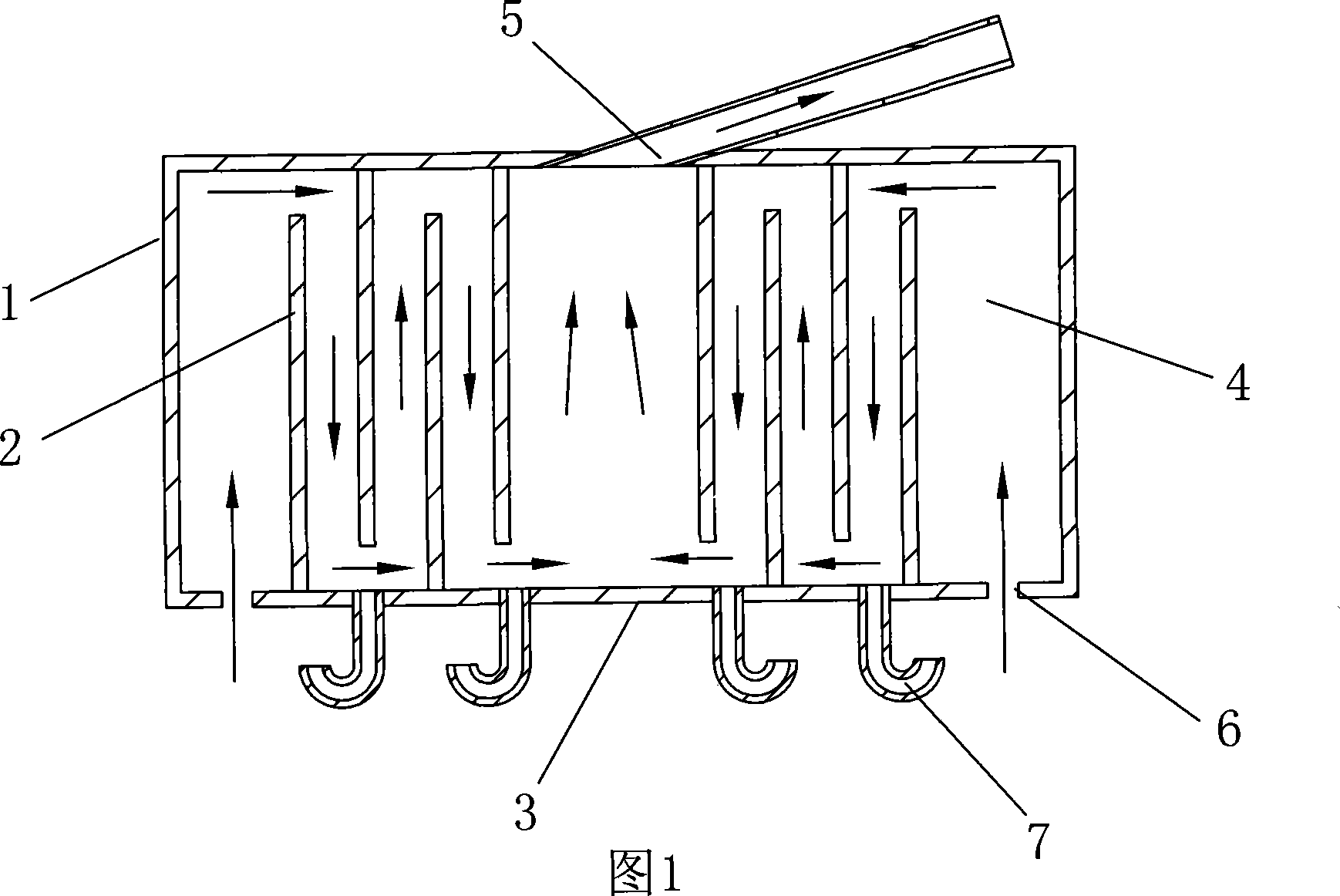

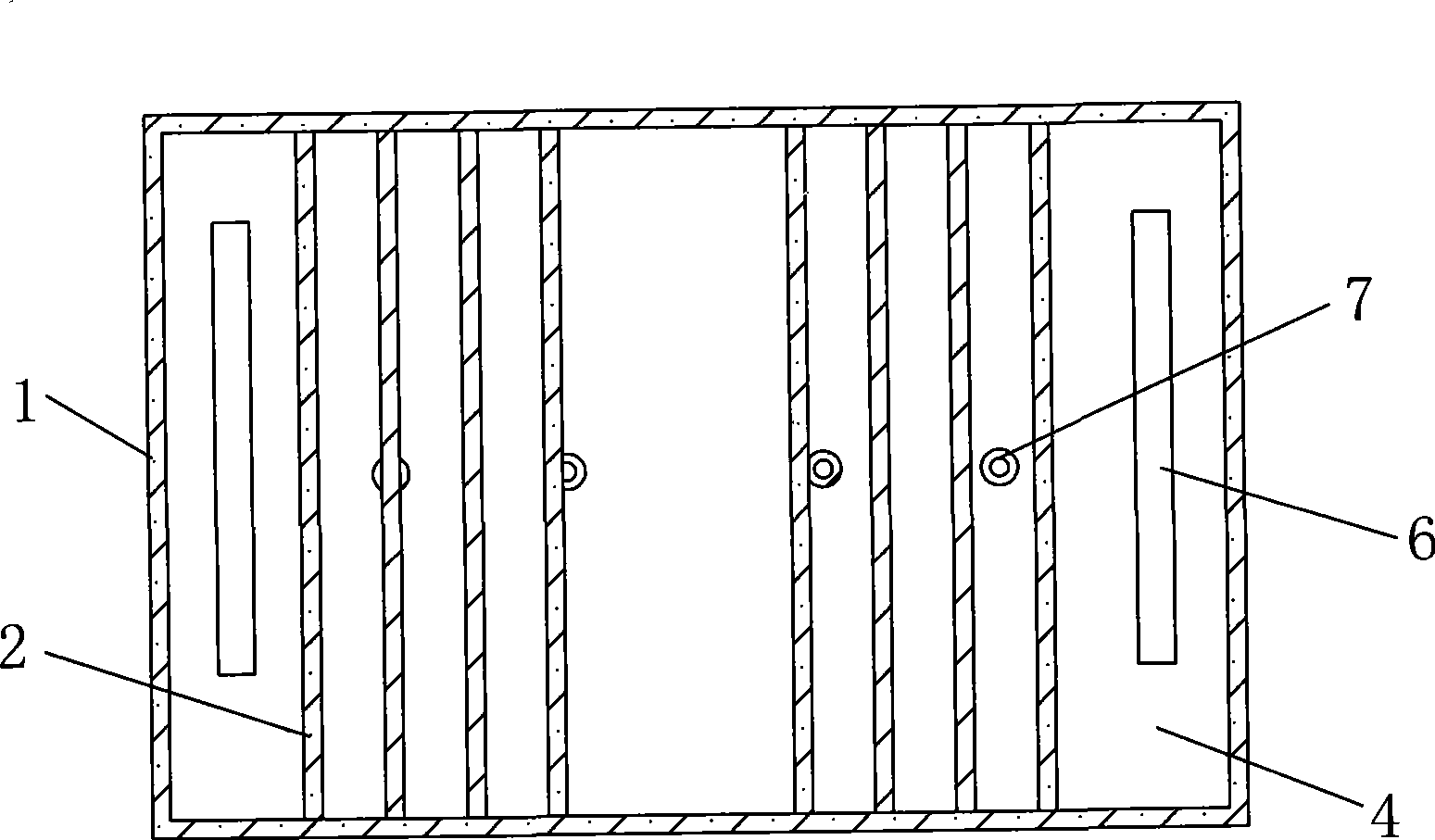

[0021] Referring to Fig. 1, in the oil-air separation chamber 4 with the mixed gas inlet 6 and the ventilation pipe outlet 5, which is composed of the oil retaining bottom plate 3 and the valve chamber cover 1, the residence time of the mixed gas in the oil-gas separation chamber 4 can be prolonged, A labyrinth structure that increases the contact area between the mixed gas and the inner wall of the oil-gas separation chamber 4.

[0022] The corresponding structural setup in a concrete implementation could be:

[0023] In the labyrinth structure, a plurality of blocking baffles 2 are arranged in the oil-gas separation chamber 4 , and the positions of the gas flow channels formed between adjacent blocking baffles 2 and the inner walls of the oil-gas separation chamber 4 are staggered.

[0024] In the labyrinth structure formed in the oil-gas separation chamber 4 by the multi-channel baffle plate 2, the flow direction of the mixed gas is zigzag.

[0025] The gas mixture inlet 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com