Mining method of top coal caving with oblique cutting in steeply inclined seam

A coal mining method and a technology of oblique cutting and subsection, which are used in surface mining, earthwork drilling, underground mining, etc., to achieve the effects of simple ventilation system, improved mechanization degree and safety, and improved mine output and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

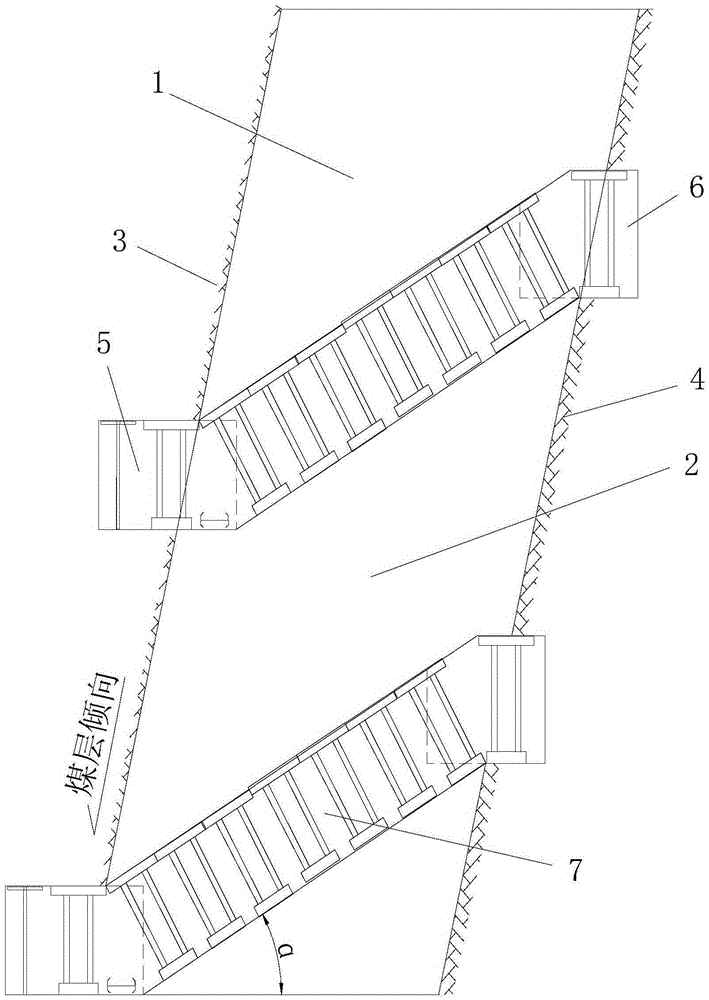

[0026] As shown in the figure, the steeply inclined coal seam obliquely cutting and segmented top-coal caving mining method includes steps:

[0027] (1), divide the coal seam into several sections along the direction of coal seam dip, such as image 3 In the first section coal seam 1 and the second section coal seam 2, in this embodiment, the interval between adjacent coal seam sections along the direction of coal seam inclination is 10m. Of course, the interval between adjacent coal seam sections along the direction of coal seam inclination The distance can also be adjusted according to the actual situation;

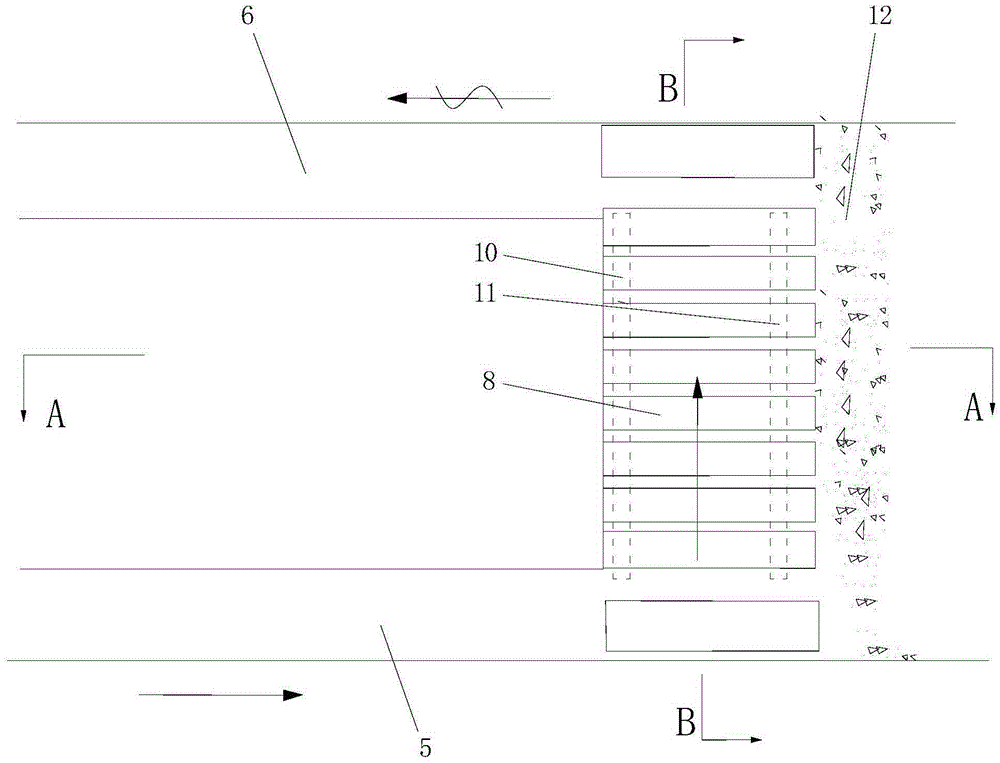

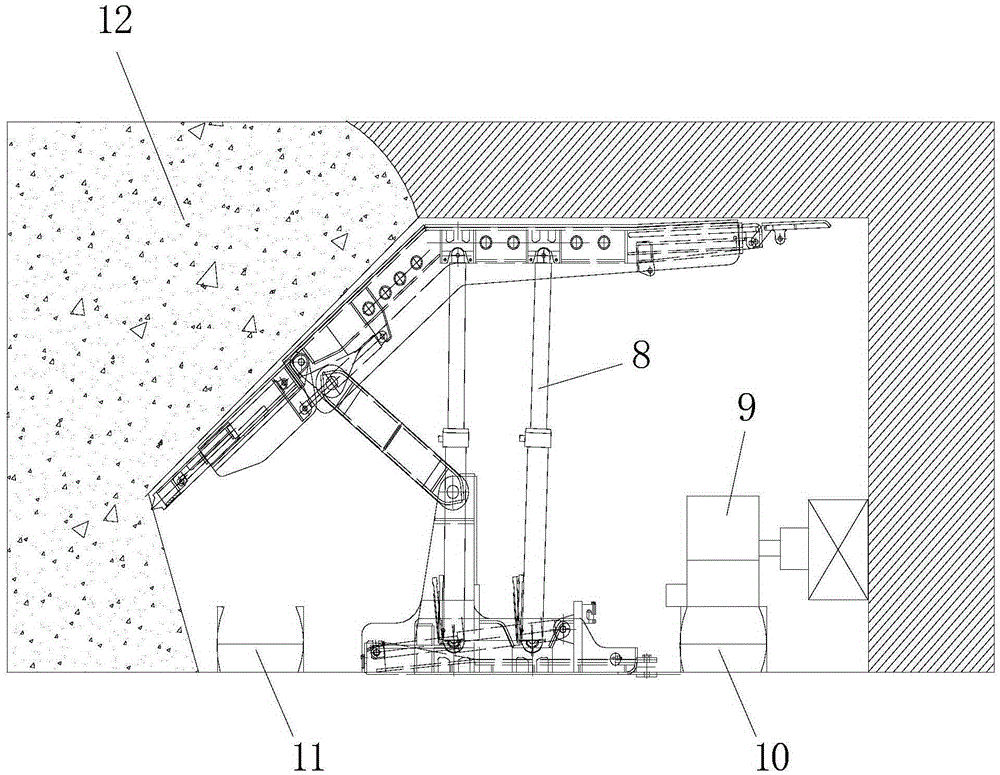

[0028] (2) Excavate transport lane 5 and return air lane 6 on the roof 3 and bottom plate 4 in each section of the coal seam, and connect the transport lane 5 and return air lane 6 to form a "U"-shaped ventilation system. The mining face 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com