Mold for manufacturing obstructing and explosion suppression ball

A technology of explosion suppression balls and molds, which is applied to home appliances, other household appliances, applications, etc., can solve the problems of complex structure, difficult manufacturing, and high replacement rate of explosion suppression fillings, and achieve simple manufacturing process, simple manufacturing materials, and easy replacement. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

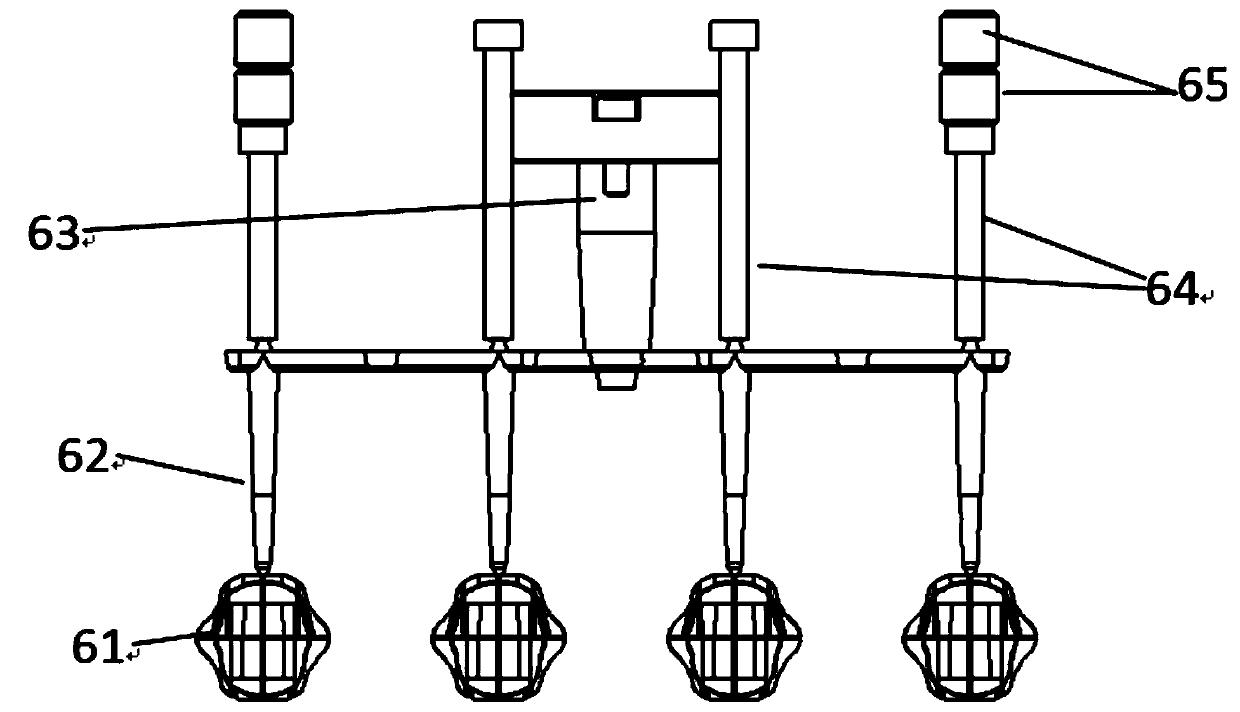

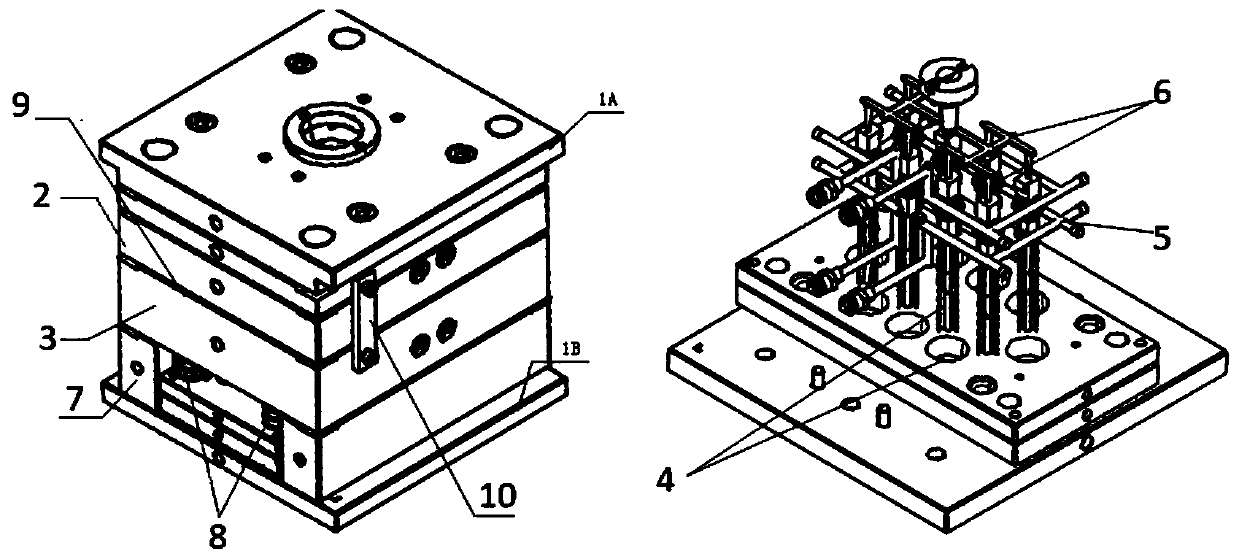

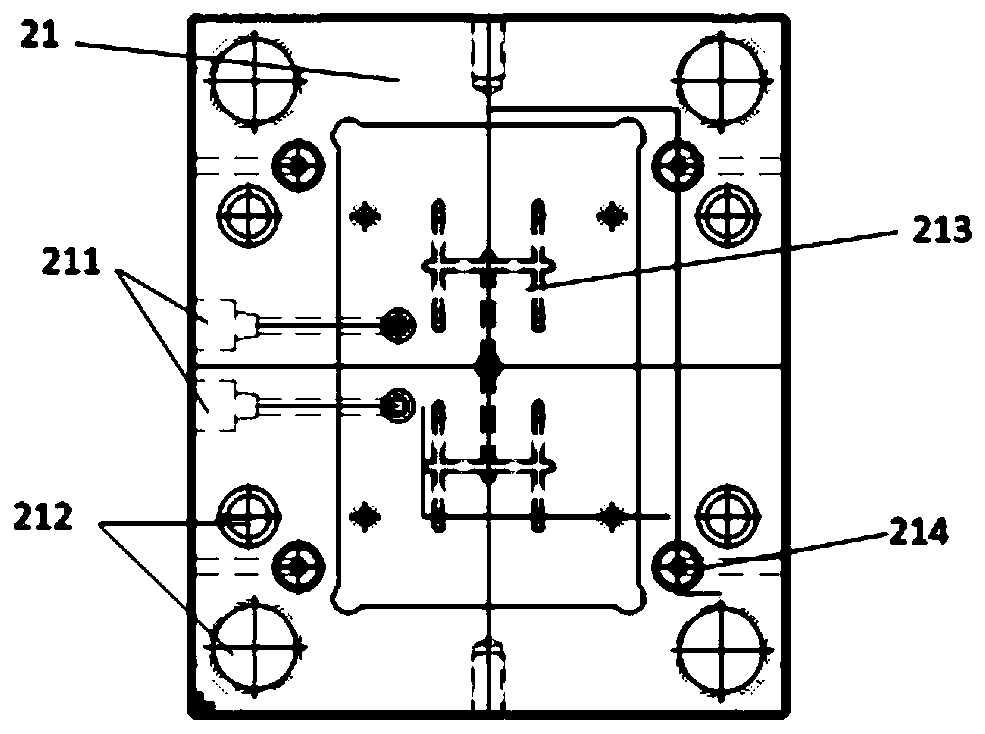

[0030] Such as figure 1 As shown, the present invention provides a kind of injection mold that is used to manufacture barrier explosion suppression ball, and this injection mold comprises first seat plate 1A, second seat plate 1B, fixed mold mechanism 2, movable mold mechanism 3, ejector mechanism 4, cooling Mechanism 5, filling mechanism 6, limit mechanism 7, reset mechanism 8, exhaust mechanism 9 and fixing mechanism 10. Among them: the fixed template 21 and the movable template 31 are fixed on the injection molding machine, the fixed mold mechanism 2 has the upper half of the space for manufacturing the explosion-suppressing ball, and the non-metallic molten material flows through the space of the explosion-suppressing ball for cooling and injection molding; the movable mold mechanism 3 has the function of manufacturing the explosion-suppressing ball In the lower half of the explosion suppression ball space, non-metallic molten material flows through the explosion suppressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com