Patents

Literature

198results about How to "Reduce replacement rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

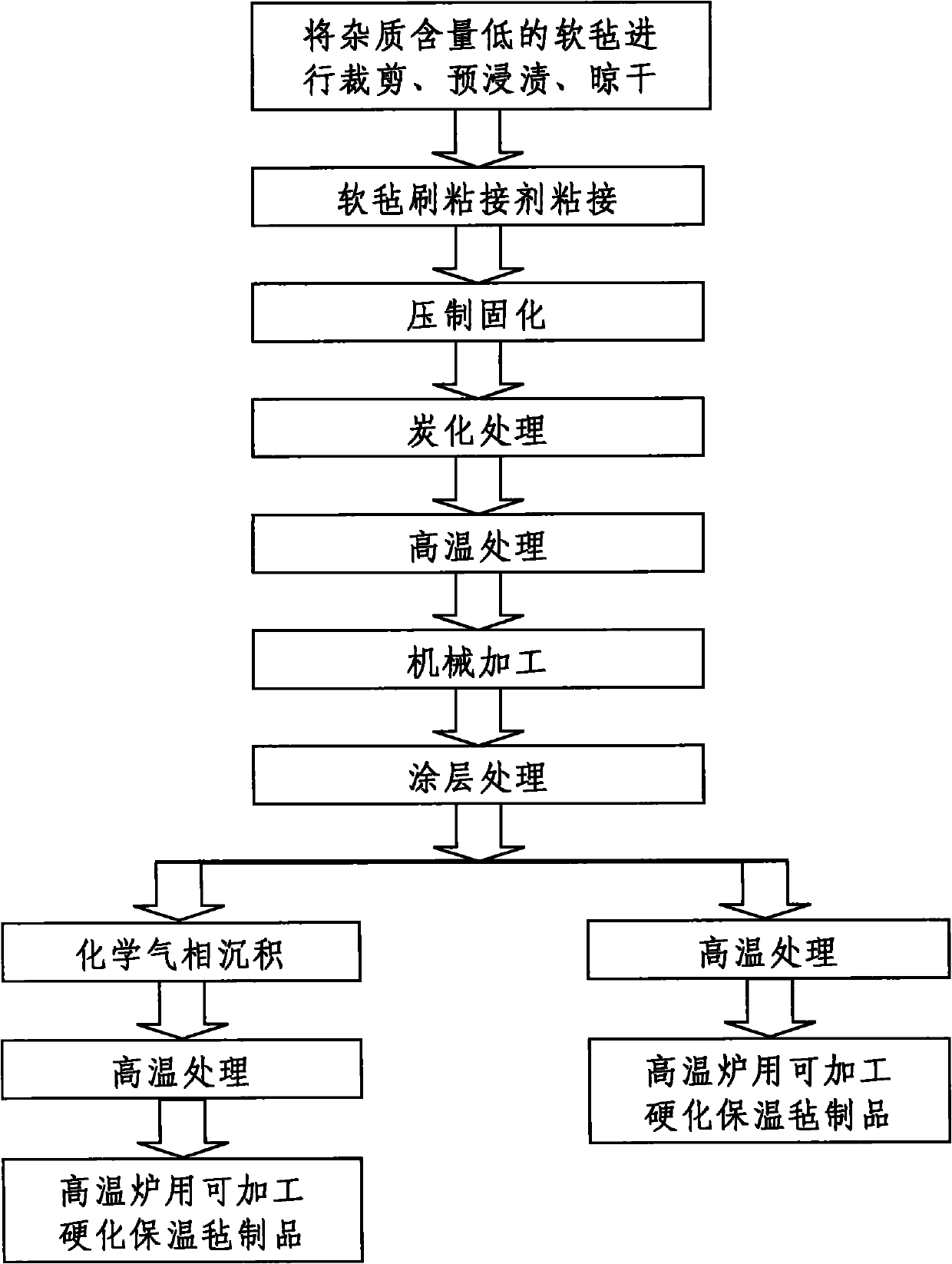

Method for preparing work hardening insulation quilt for high temperature furnace

The invention relates to a method for preparing a work hardening insulation quilt for a high temperature furnace, which comprises the following steps of: 1, cutting, pre-impregnating and airing a soft quilt; 2, adhering the soft quilt by using an adhesive; 3, pressing and curing for forming; 4, performing carbonization treatment; 5, performing high temperature treatment; 6, machining; 7, performing coating treatment; and 8, performing chemical vapor deposition treatment and high temperature treatment, or directly performing high temperature treatment to obtain the work hardening insulation quilt for the high temperature furnace. The method has the advantages of simple technological process and suitability for mass production; and the prepared work hardening insulation quilt has the heat conductivity of less than or equal to 0.5W / m.K, the ash content of less than or equal to 2,000ppm, high mechanical properties and high-temperature dimensional stability and excellent processability, does not generate volatile matters when used in the high temperature furnace, cannot pollute the product, and has important significance for prolonging the service life of the insulation quilt in the high temperature furnace.

Owner:XIAN CHAOMA SCI TECH

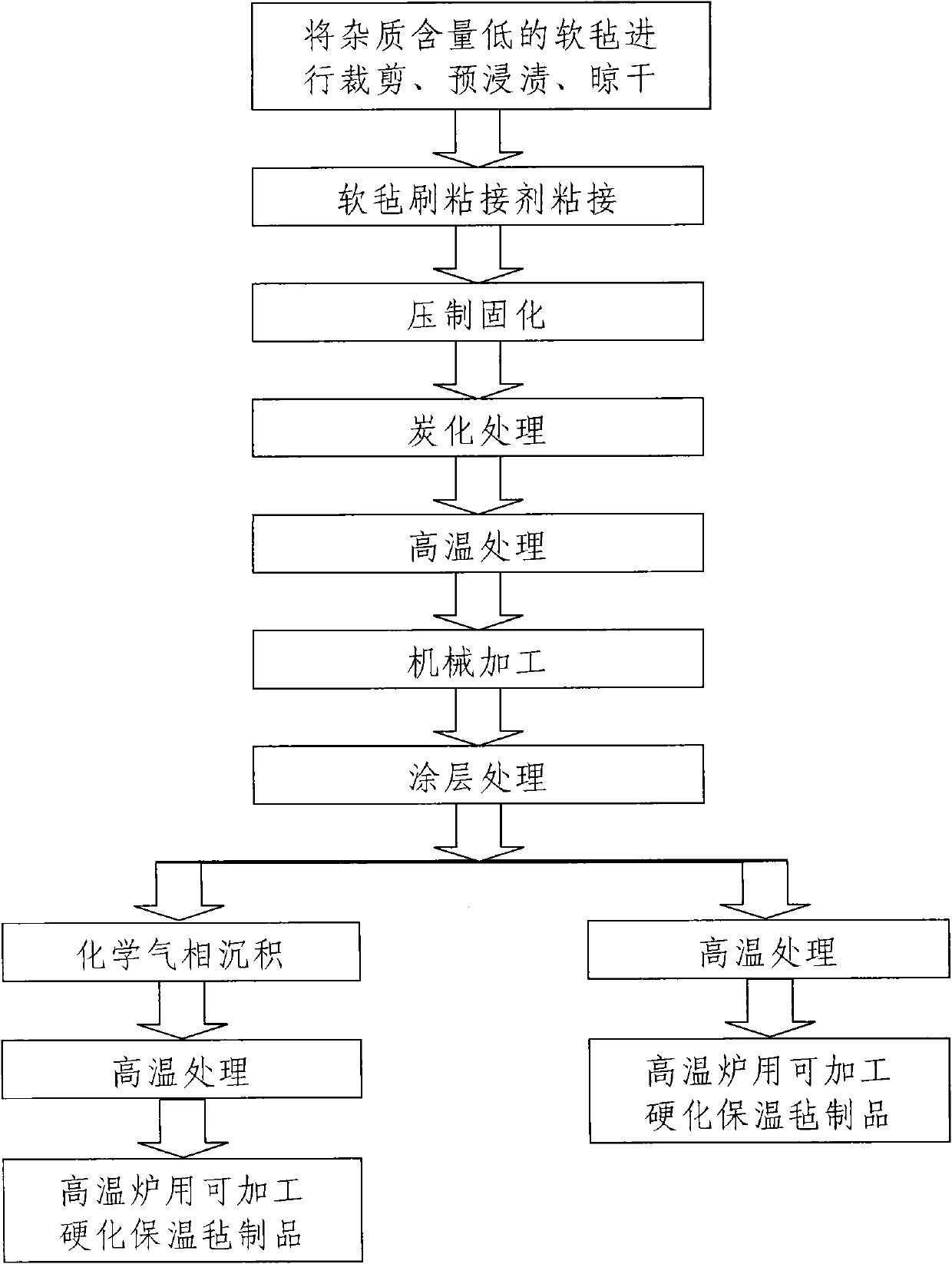

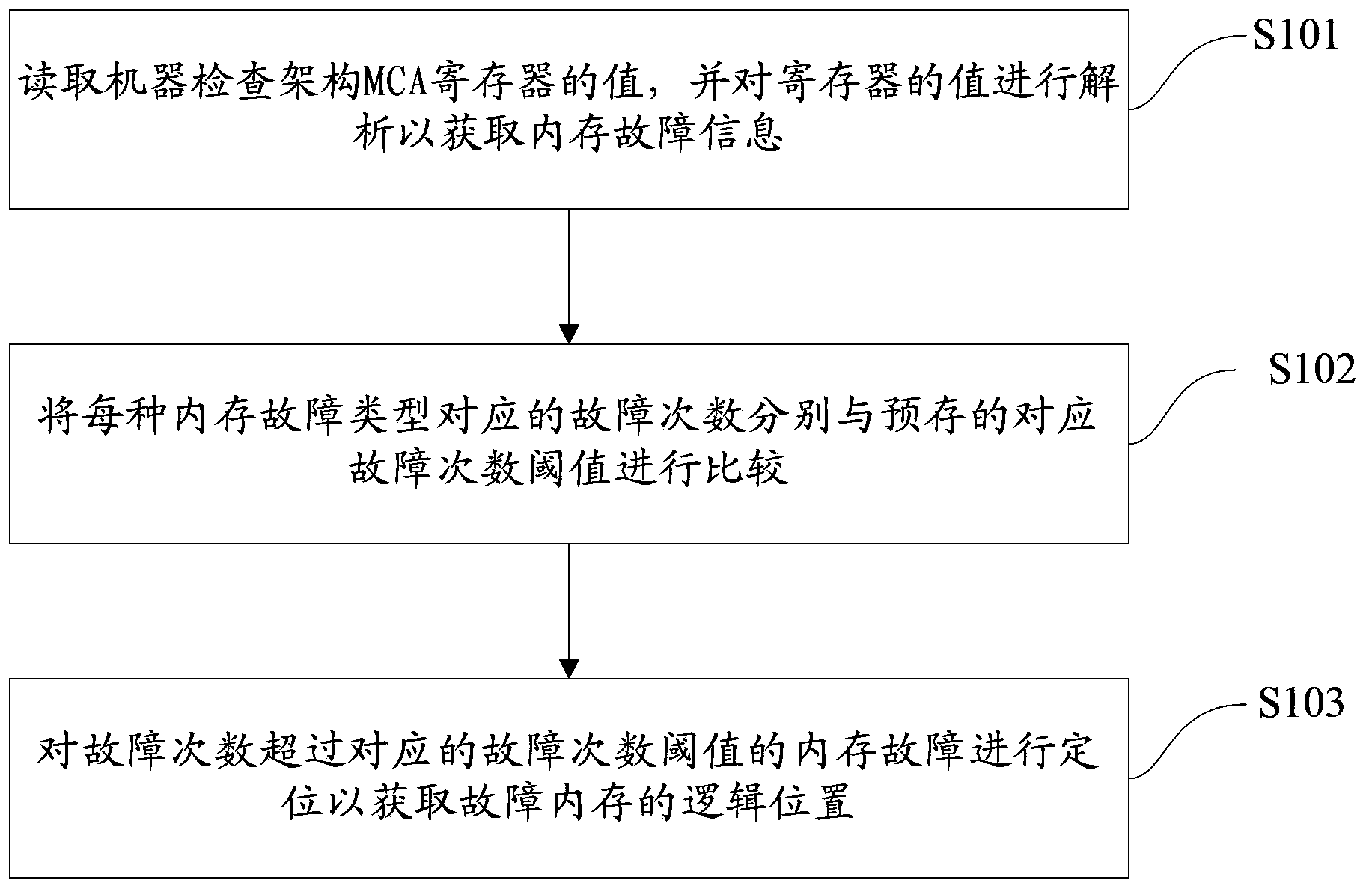

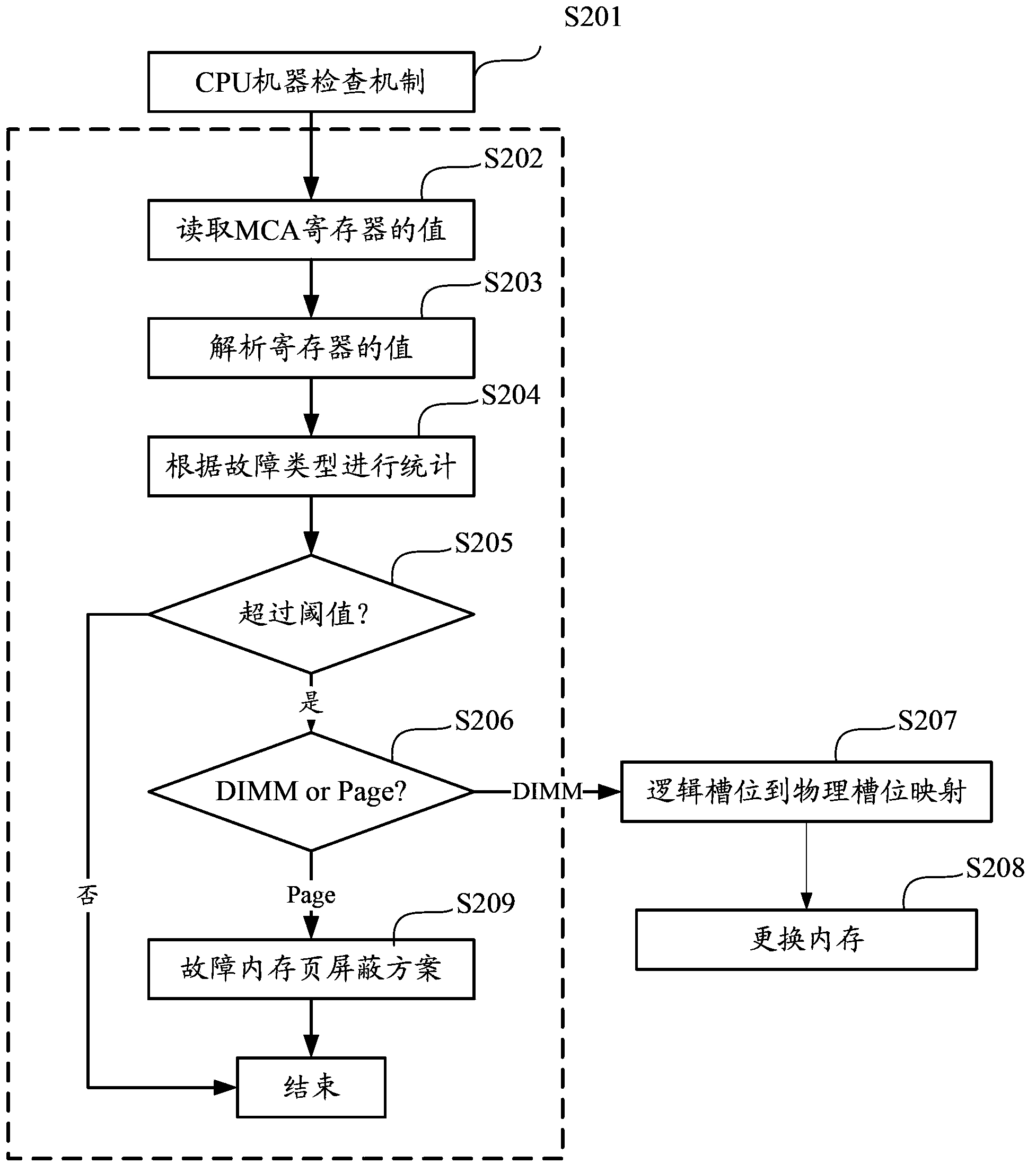

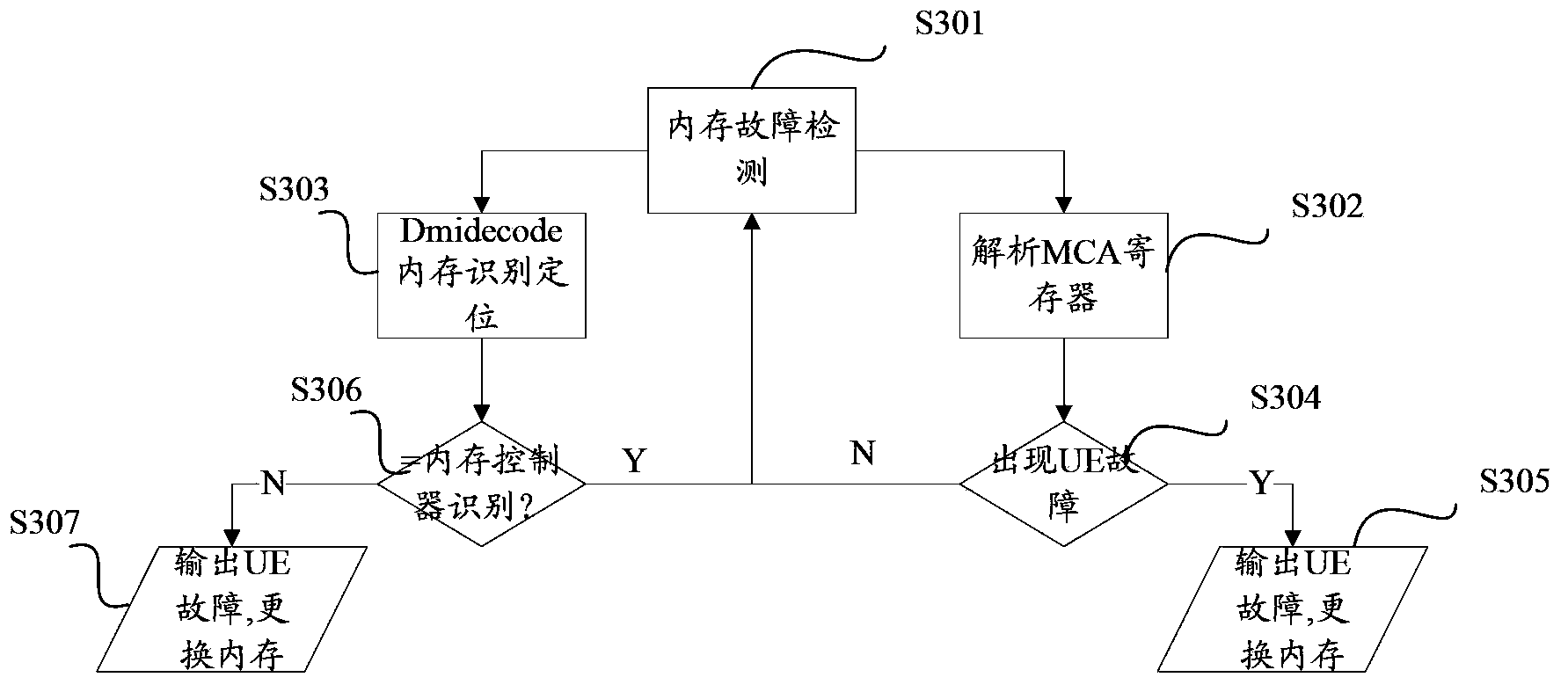

Method for automatically locating internal storage faults

InactiveCN103514068AReduce replacement rateReduce operating costsDetecting faulty computer hardwareProcessor registerMemory failure

The invention provides a method for automatically locating internal storage faults. The method comprises the following steps: reading a value of a register of an MCA, and analyzing the value of the register so as to obtain internal storage fault information, wherein the internal storage fault information comprises internal storage fault types and the number of fault times corresponding to the internal storage fault types; comparing the number of fault times corresponding to each internal storage fault type with a preset threshold value of the number of corresponding fault times; locating the internal storage fault of which the number of fault times exceeds the threshold value of the number of corresponding fault times so as to obtain the logical position of a fault internal storage. By means of the method, the internal storage faults of a server can be located, and the internal storage is repaired according to the internal storage fault types.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

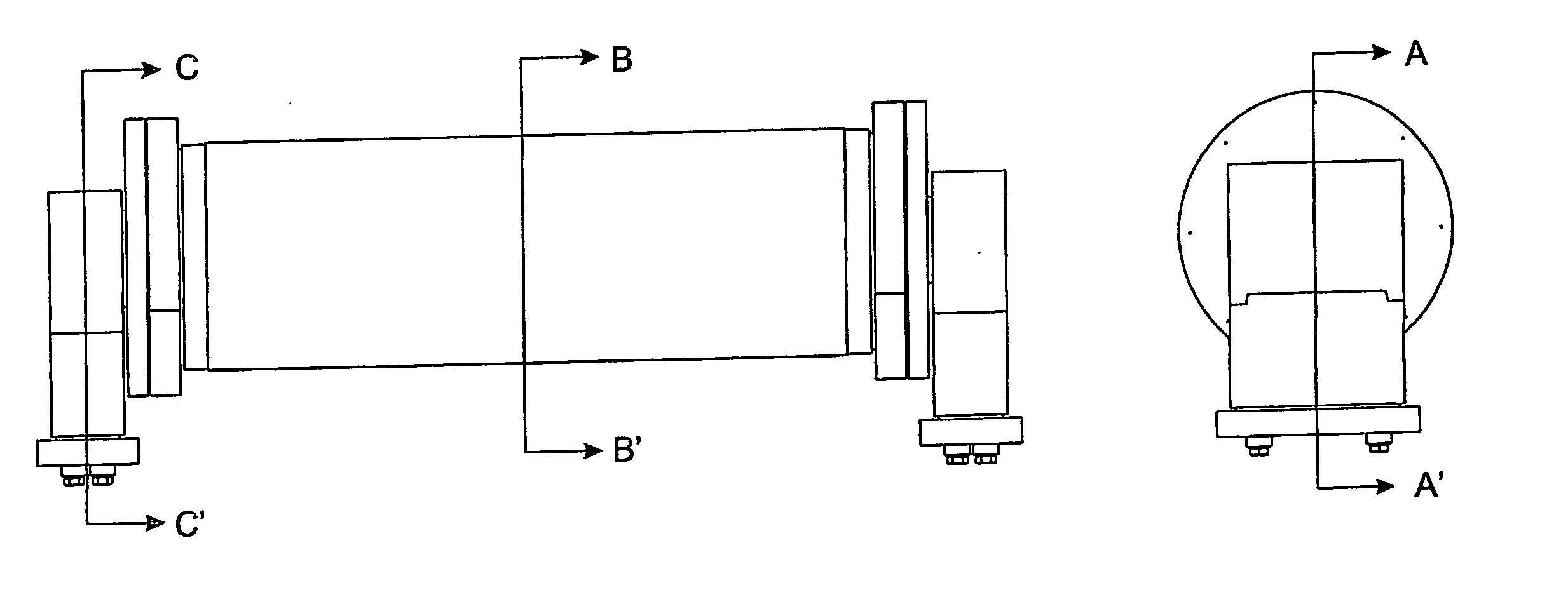

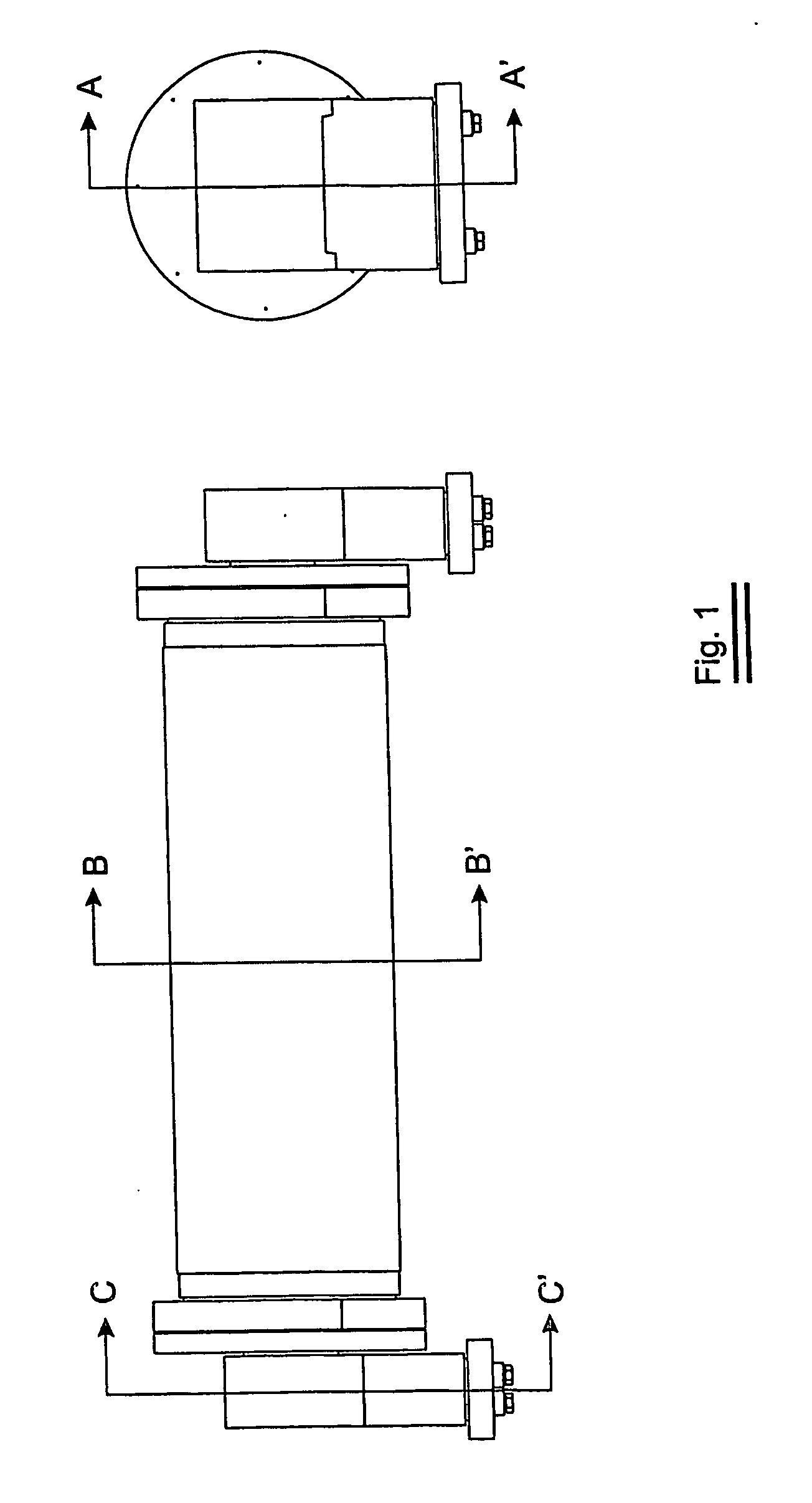

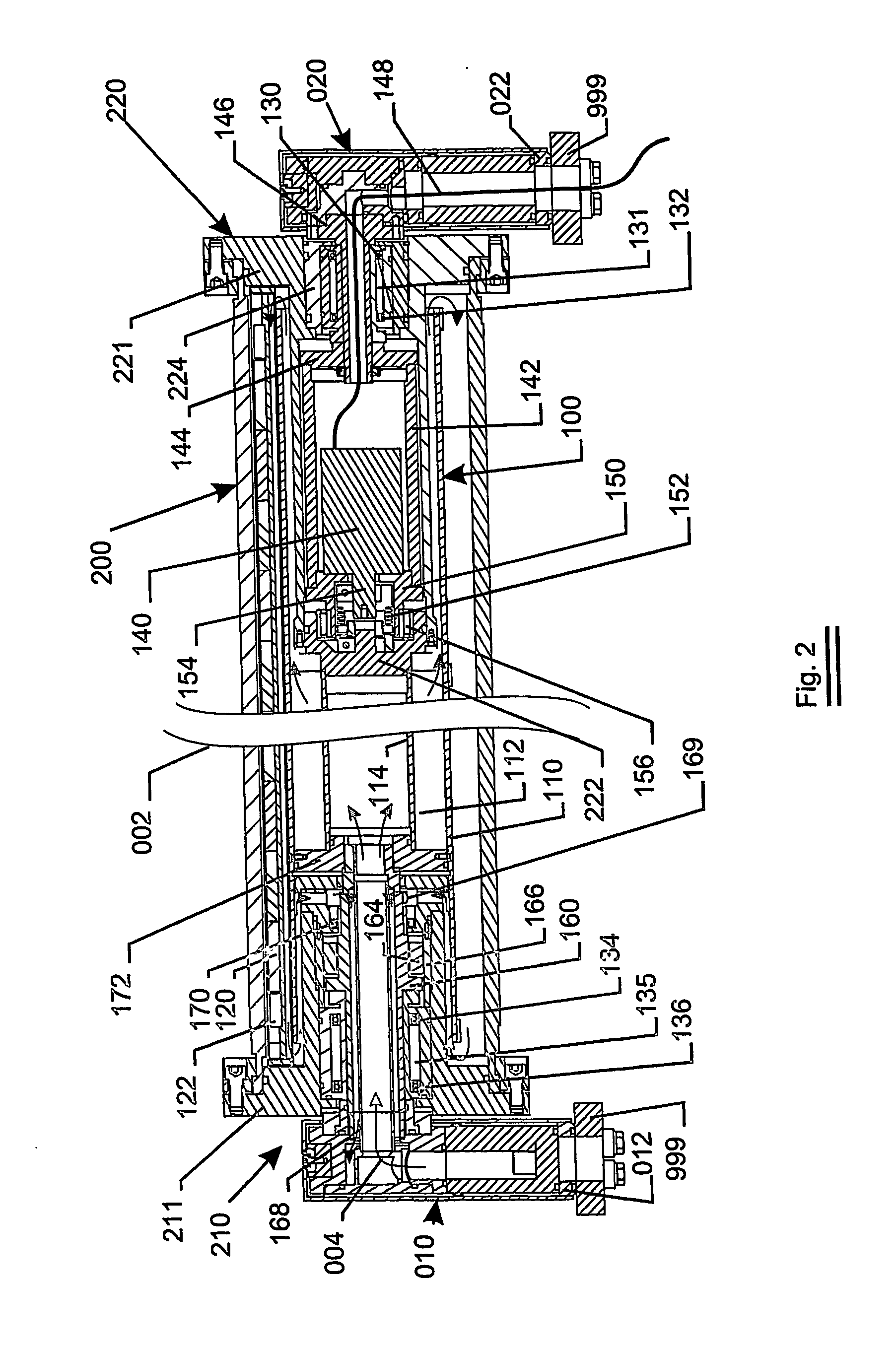

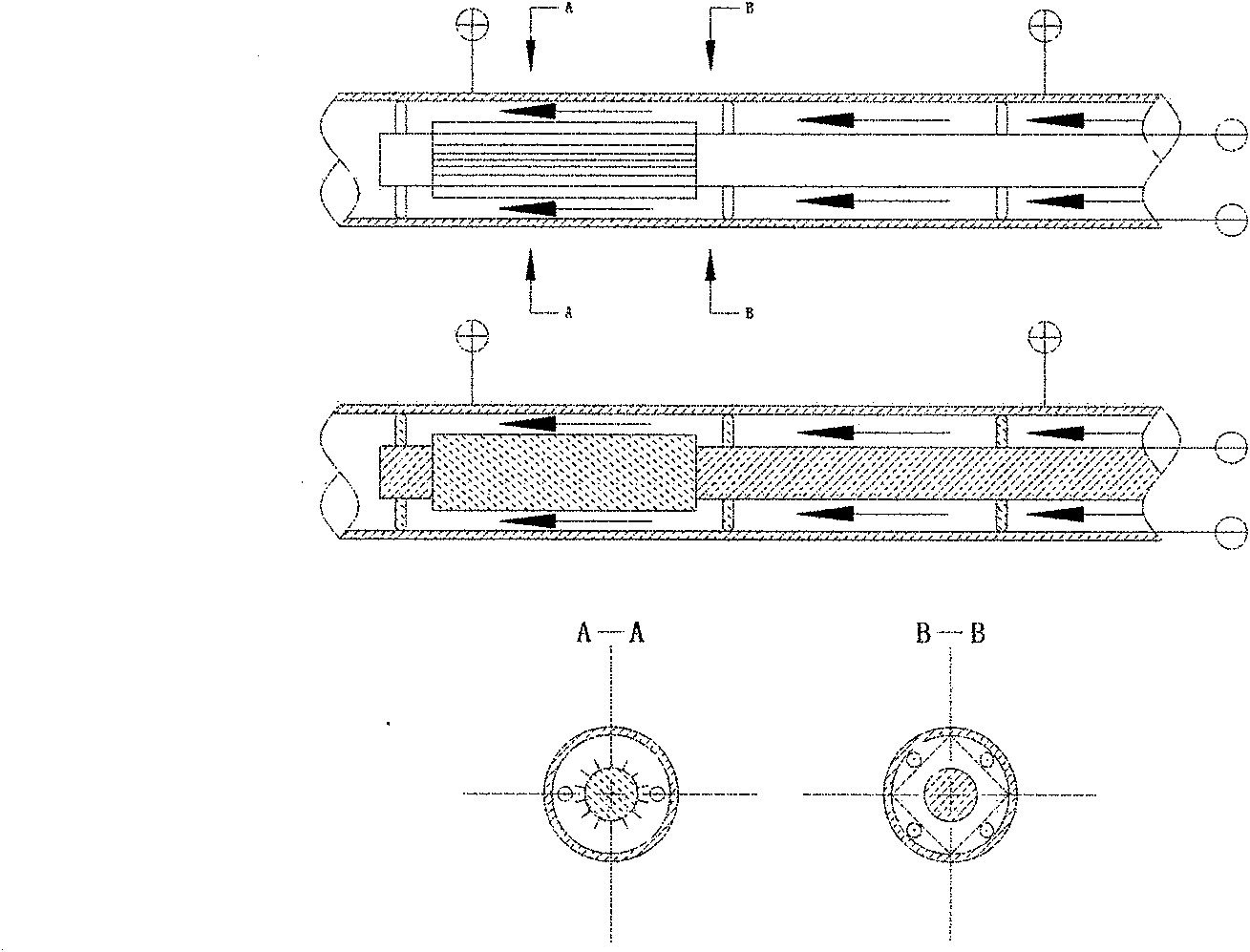

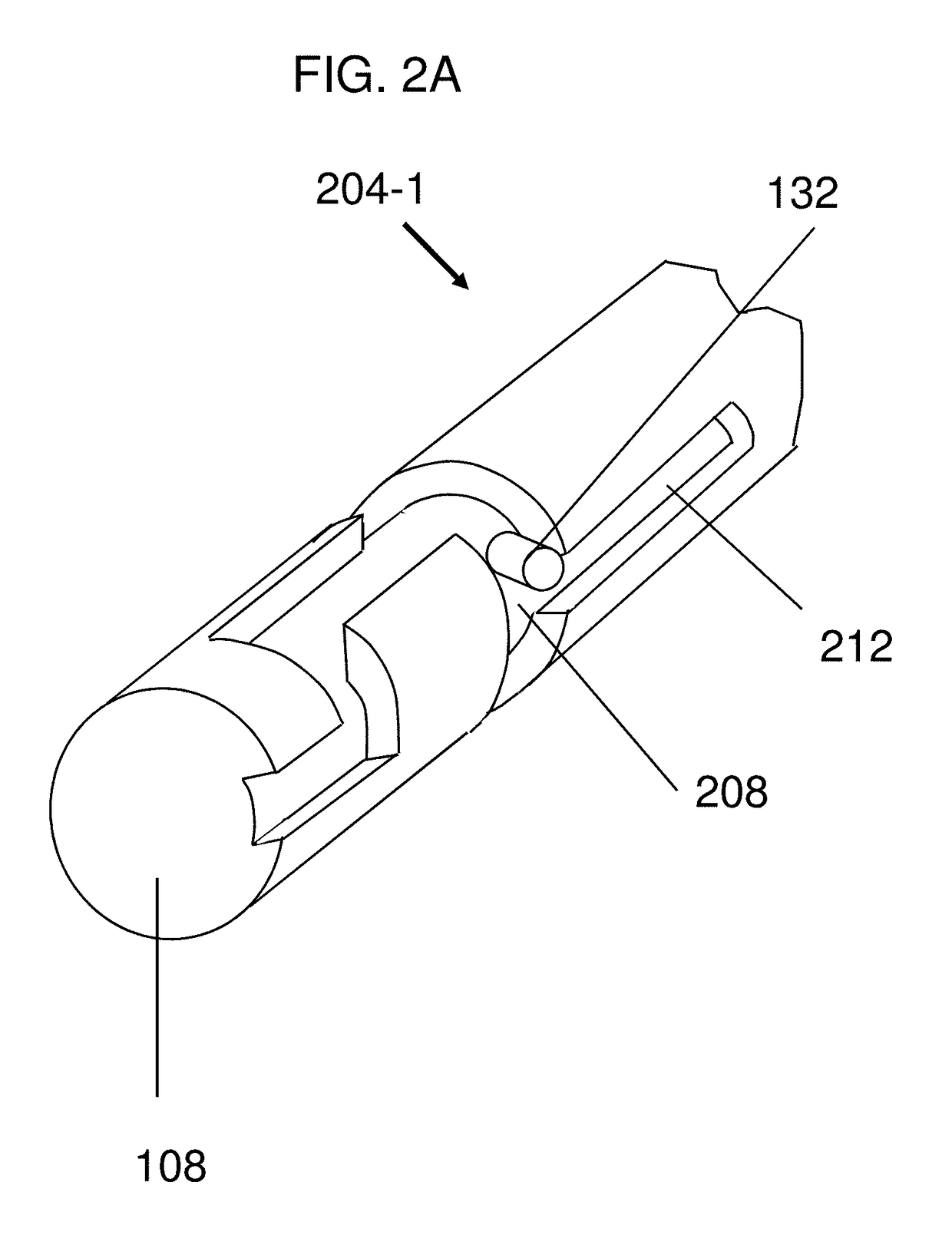

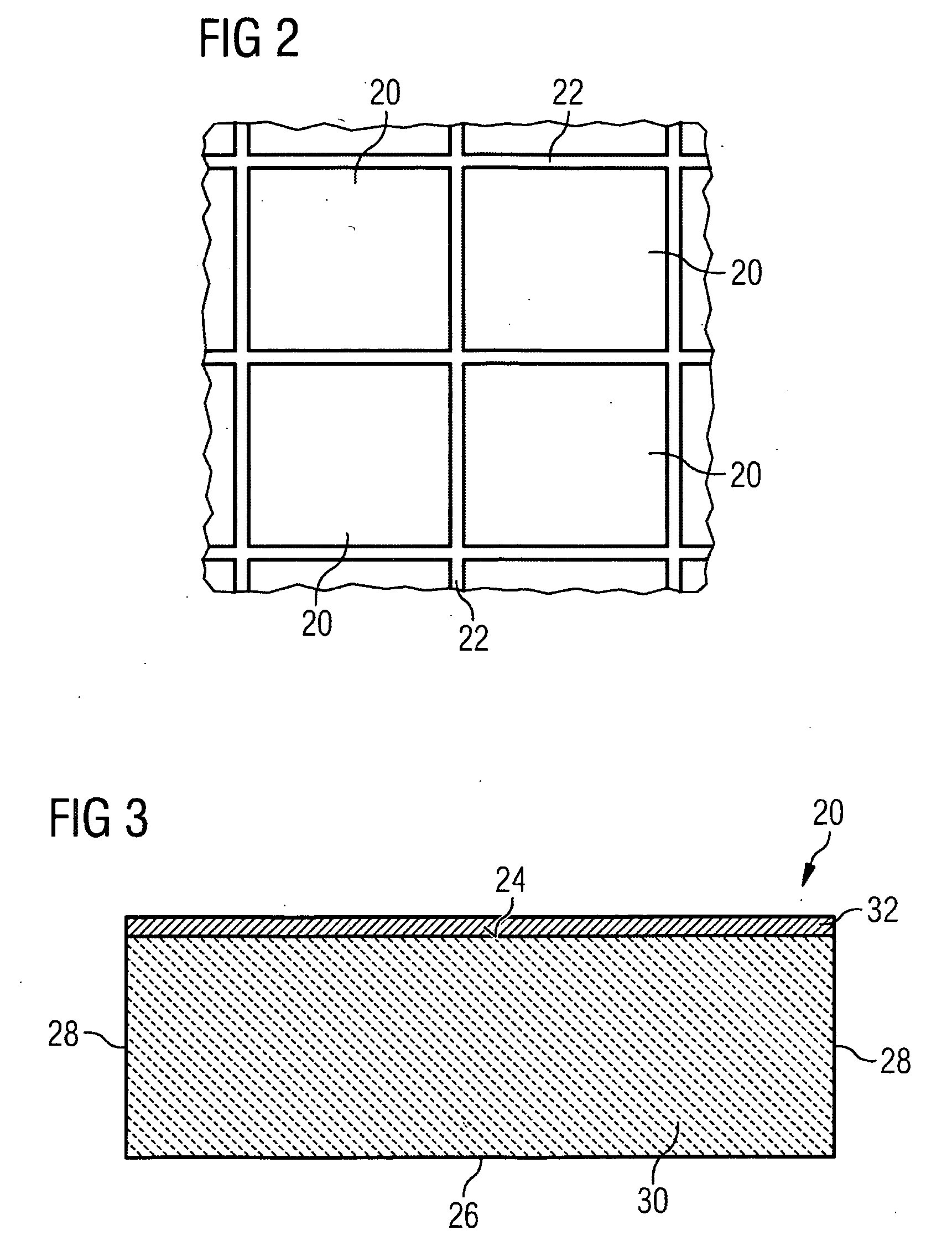

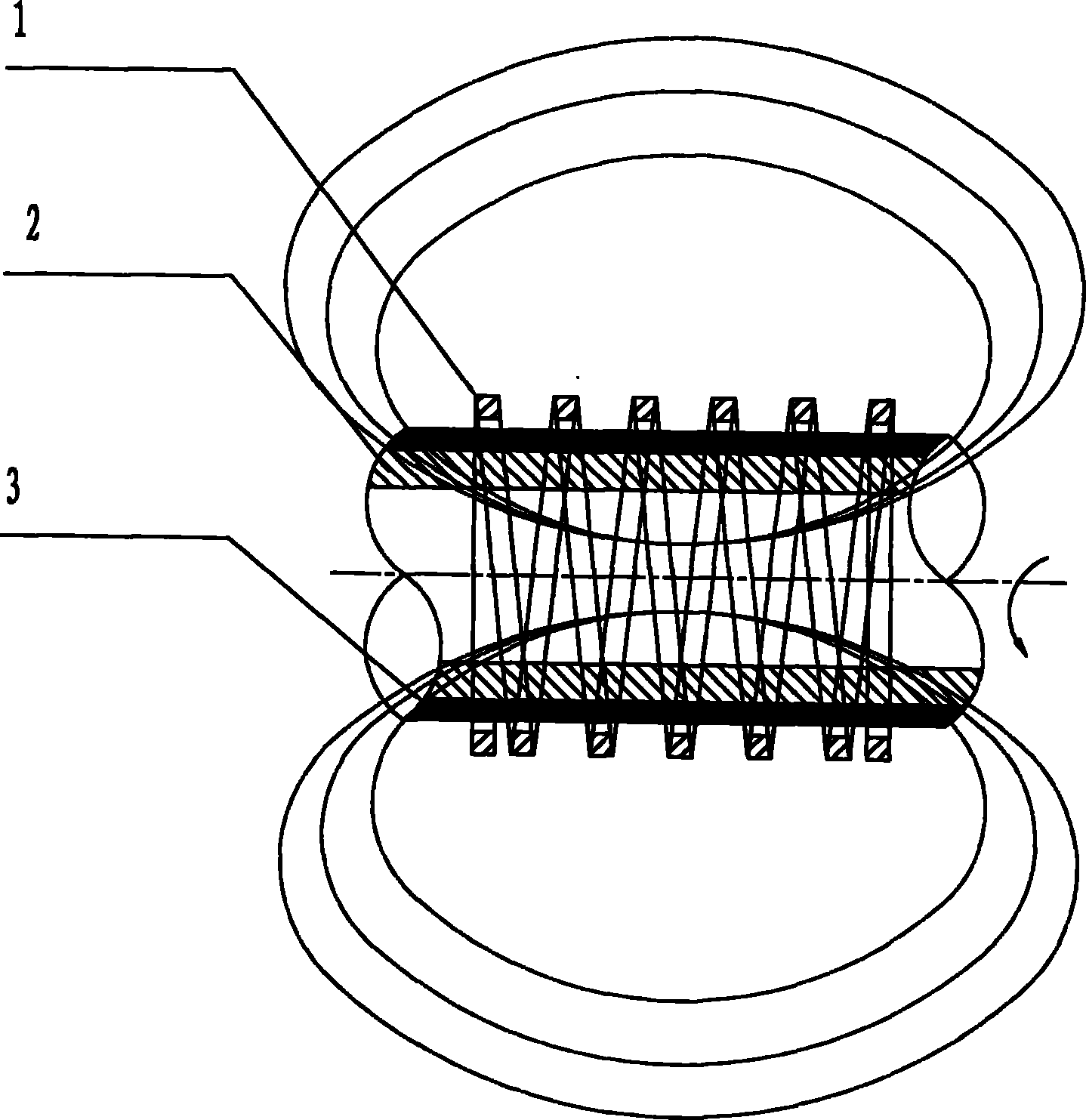

Rotating tubular sputter target assembly

InactiveUS20060157346A1Easy to installSimple conceptCellsElectric discharge tubesElectricityEngineering

A target assembly is claimed for use in e.g. a magnetron deposition apparatus. The target assembly is characterised in that at least one of the functions—bearing of the tube, rotation of the tube, electrical contact, coolant sealing and vacuum sealing—is integrated into the tube itself. Such an assembly has the advantage that it better uses the vacuum space by reducing the volume incorporated by the end blocks. Due to the compactness of the assembly it can also be used in smaller scale installations where now only planar target assemblies can be used.

Owner:CNOCKAERT DIRK +1

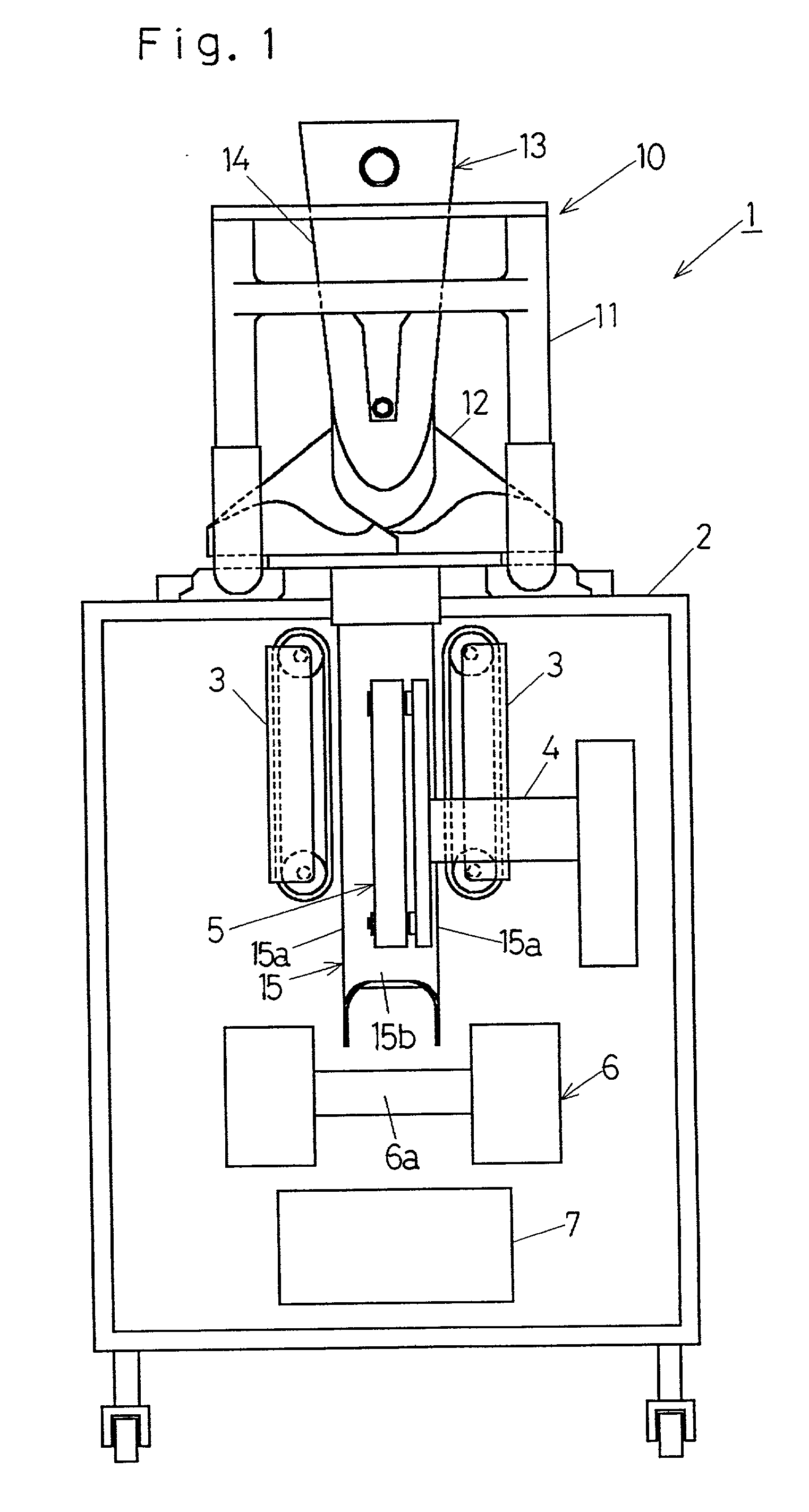

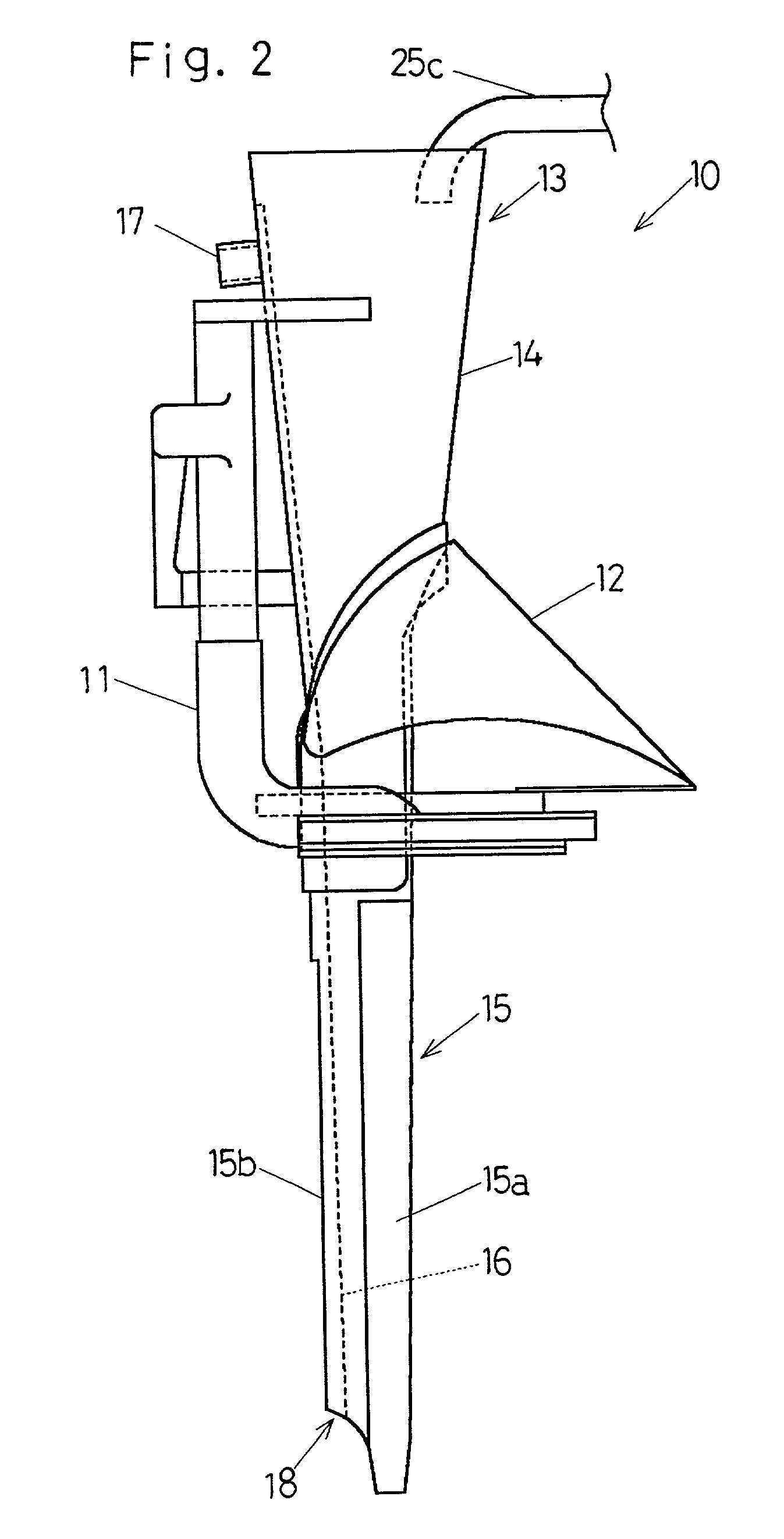

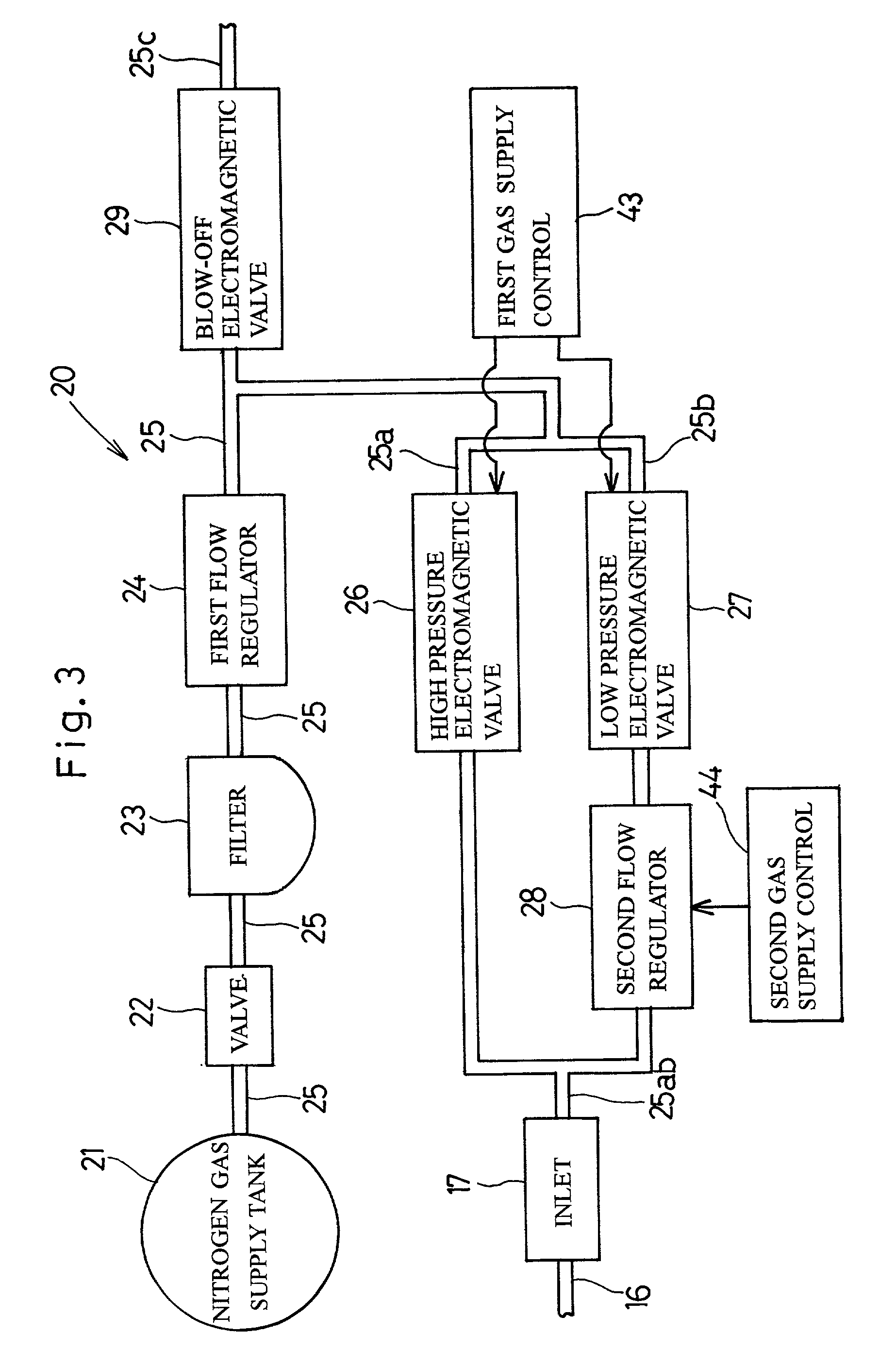

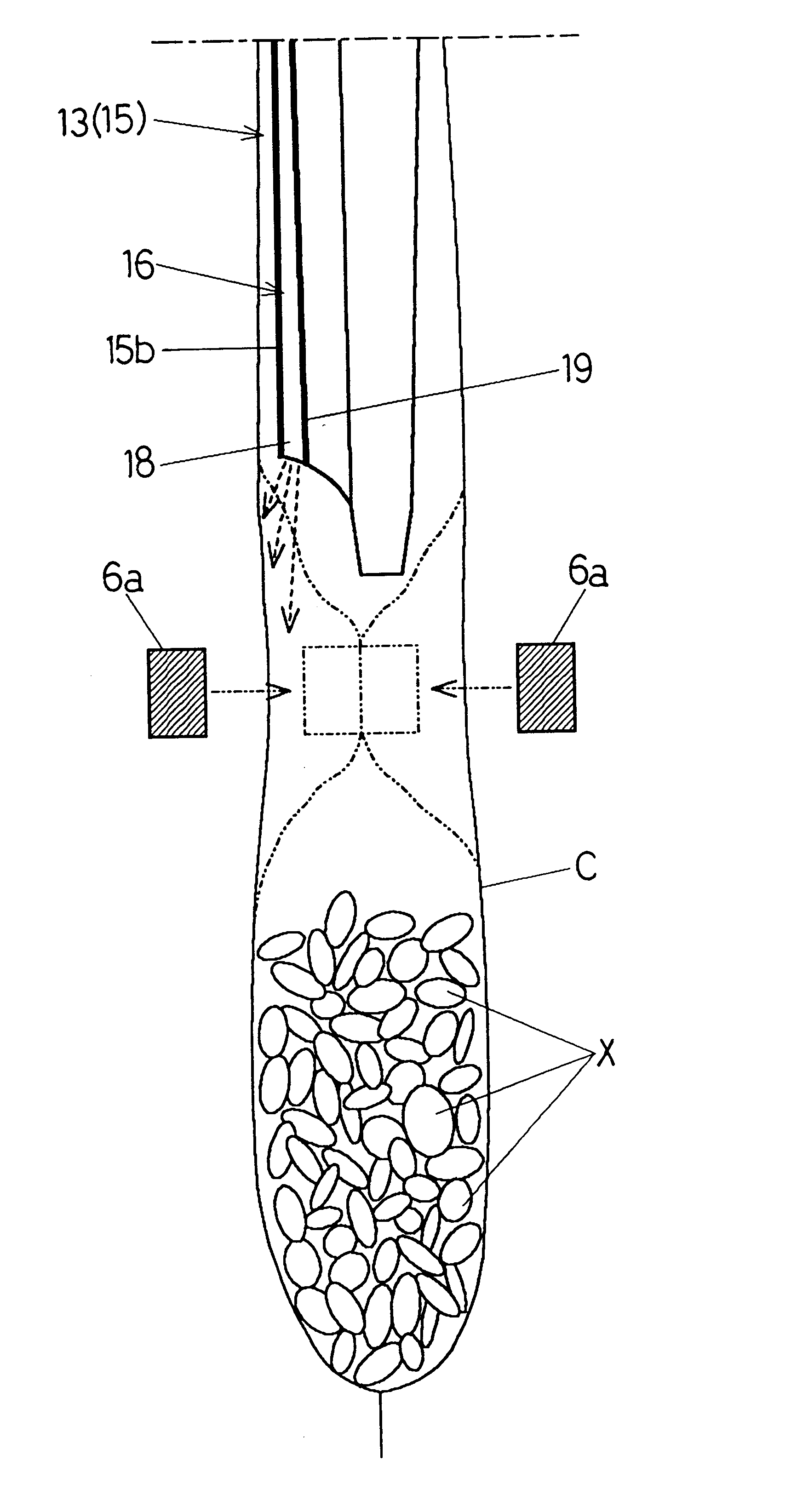

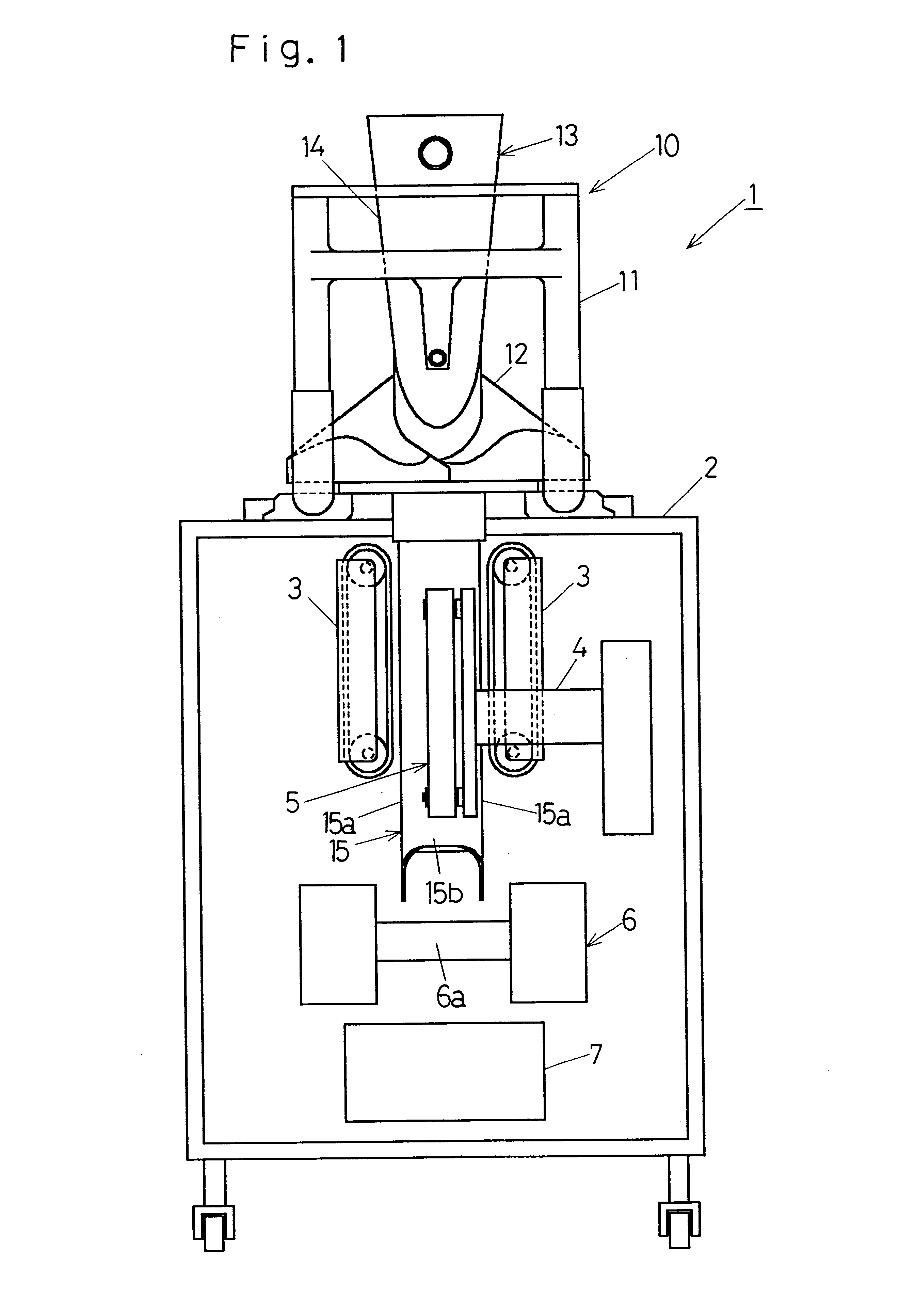

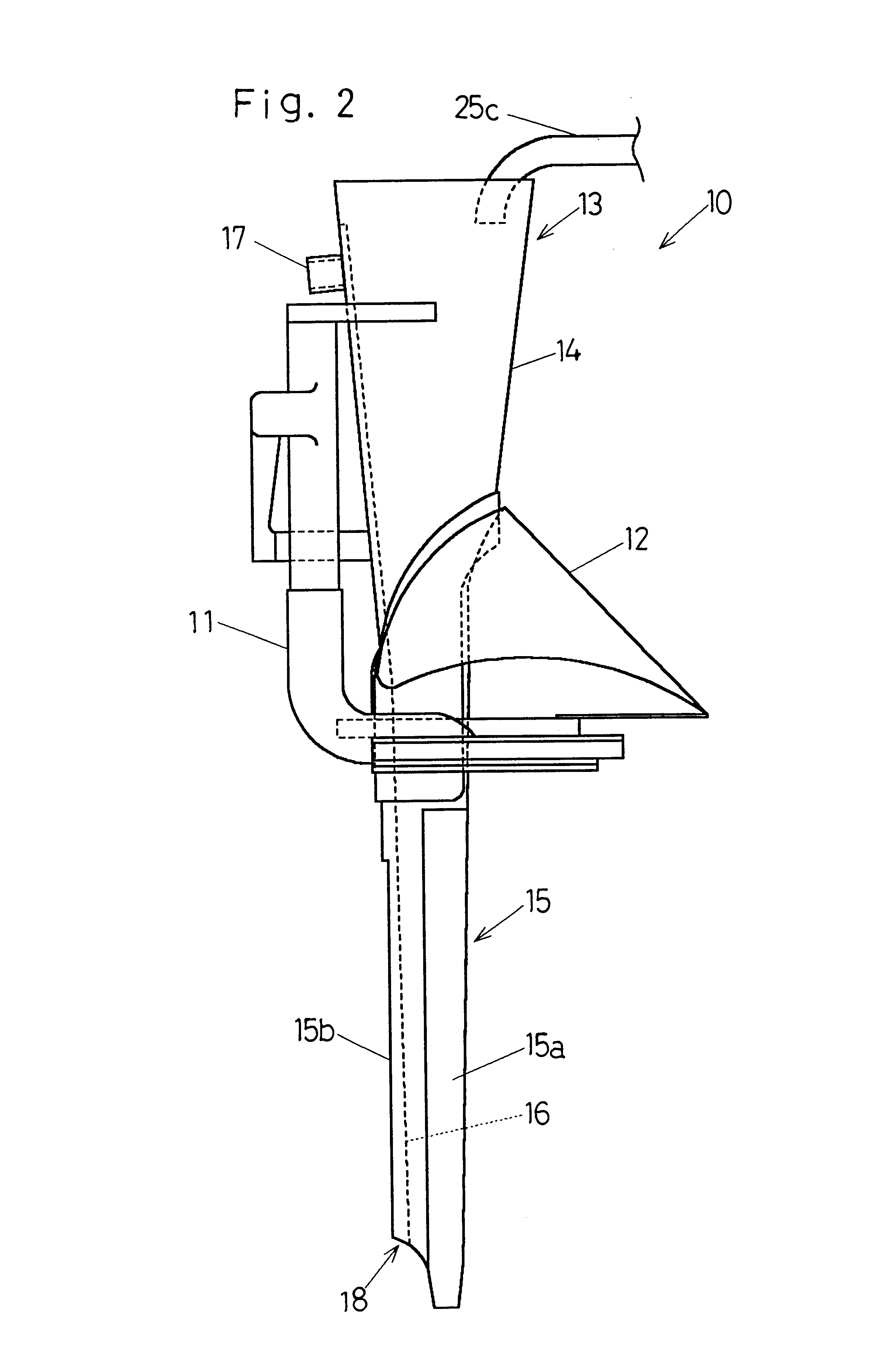

Bagging and packaging machine capable of filling a proper quantity of inert gas into bags

InactiveUS20010005974A1Lightweight productionReduce replacement rateCapsCapping machinery safety/controlProduct gasProcess engineering

A bagging and packaging machine for forming a bag from a strip of bag material and introducing an article into the bag includes a gas supply unit for supplying an inert gas into the bag to substitute for air contained in the bag and a gas supply control means for controlling supply of the inert gas by the gas supply means into the bag. The bagging and packaging machine is designed to allow the inert gas to be supplied under high pressure at a flow rate sufficient to increase the gas replacement rate in the bag when the machine is started, to be supplied under low pressure at a flow rate lower than the high pressure flow rate during a bagging and packaging operation subsequent to the start of the machine. Should the machine is temporarily brought to a halt, the length of time T passing from the timing at which the machine is temporarily brought to a halt is counted by a timer without the supply of the inert gas being interrupted, so that the supply of the inert gas can be interrupted at a timing the counted length of time exceeds a low pressure gas supply time T2. In this way, without the bag being bitten during bagging and / or the bagging and packaging speed being lowered, not only can the inert gas be sufficiently filled in the bag to achieve a high gas replacement rate, but the amount of the inert gas supplied can also be suppressed.

Owner:ISHIDA CO LTD

Bagging and packaging machine capable of filling a proper quantity of inert gas into bags

InactiveUS6735928B2Lightweight productionReduce replacement rateCapsCapping machinery safety/controlProcess engineeringProduct gas

A bagging and packaging machine for forming a bag from a strip of bag material and introducing an article into the bag includes a gas supply unit for supplying an inert gas into the bag to substitute for air contained in the bag and a gas supply control means for controlling supply of the inert gas by the gas supply means into the bag. The bagging and packaging machine is designed to allow the inert gas to be supplied under high pressure at a flow rate sufficient to increase the gas replacement rate in the bag when the machine is started, to be supplied under low pressure at a flow rate lower than the high pressure flow rate during a bagging and packaging operation subsequent to the start of the machine. Should the machine is temporarily brought to a halt, the length of time T passing from the timing at which the machine is temporarily brought to a halt is counted by a timer without the supply of the inert gas being interrupted, so that the supply of the inert gas can be interrupted at a timing the counted length of time exceeds a low pressure gas supply time T2. In this way, without the bag being bitten during bagging and / or the bagging and packaging speed being lowered, not only can the inert gas be sufficiently filled in the bag to achieve a high gas replacement rate, but the amount of the inert gas supplied can also be suppressed.

Owner:ISHIDA CO LTD

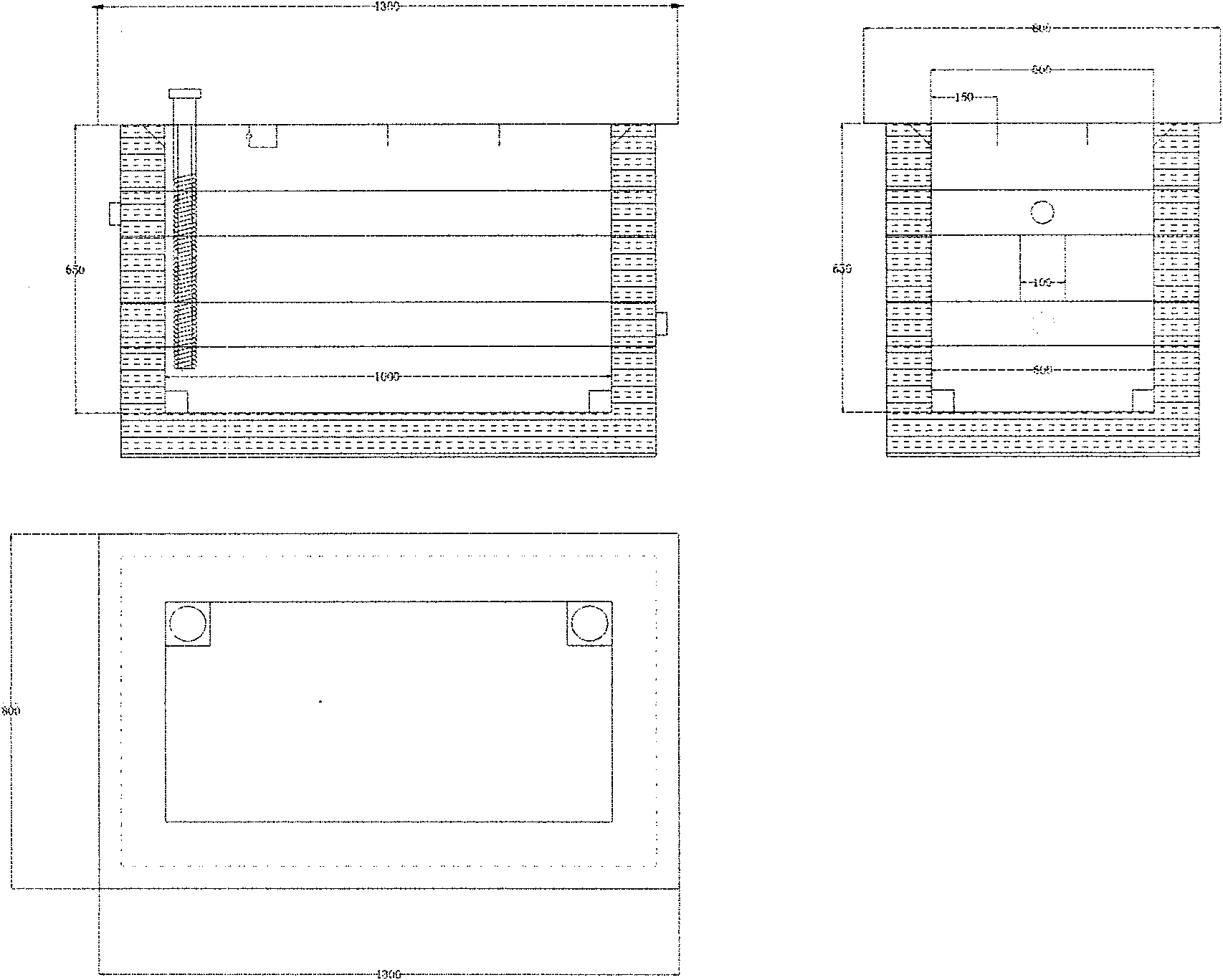

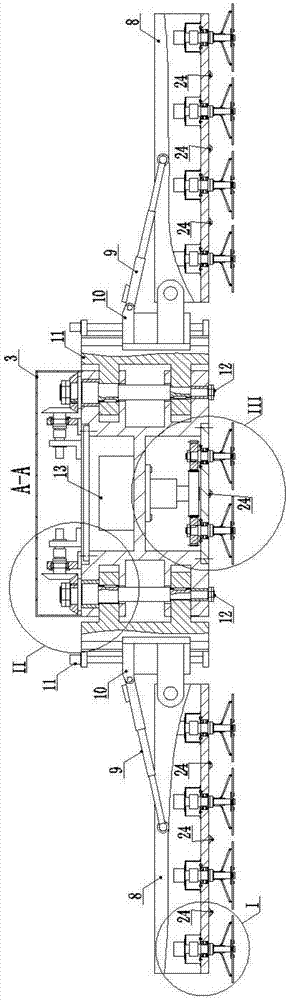

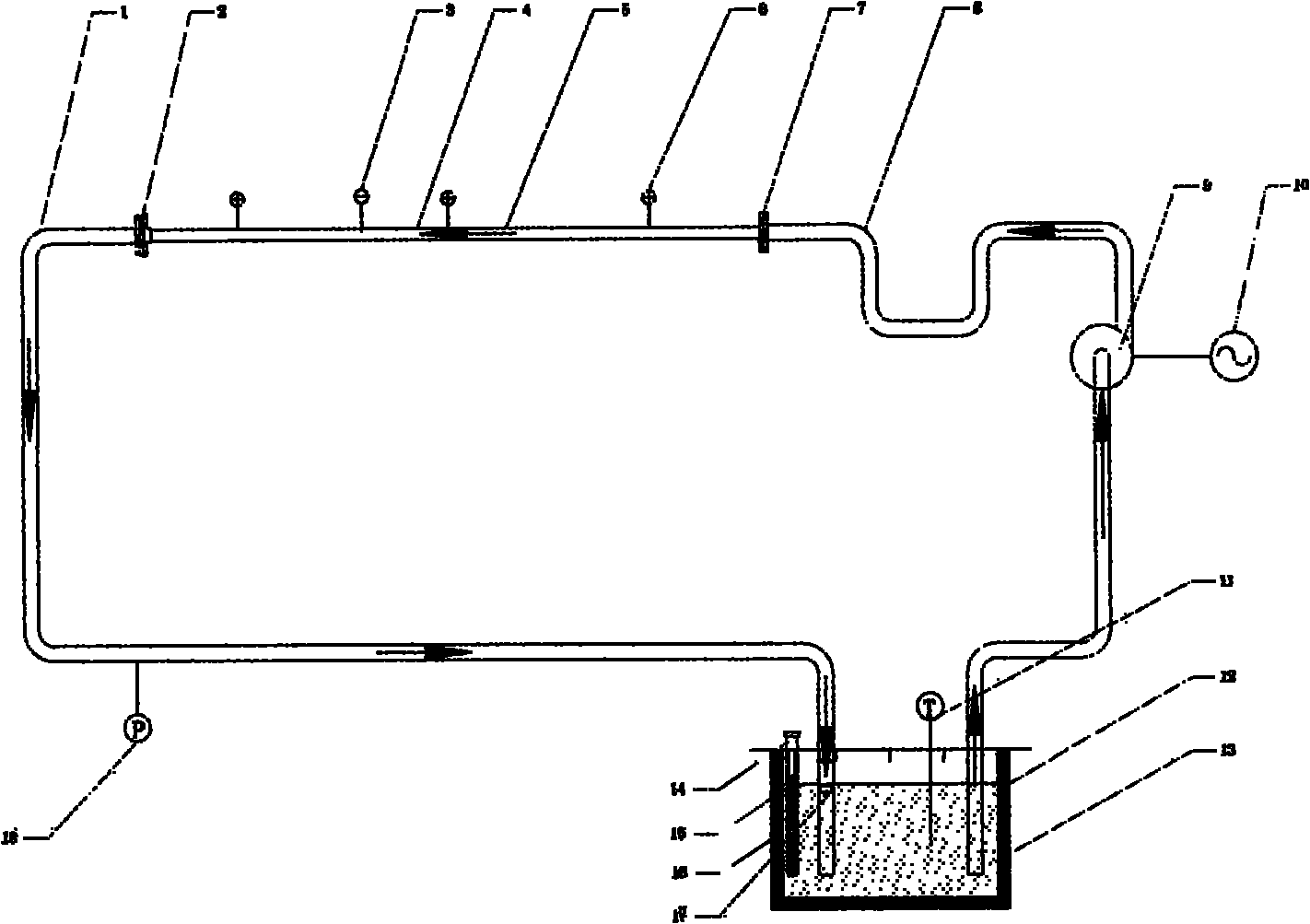

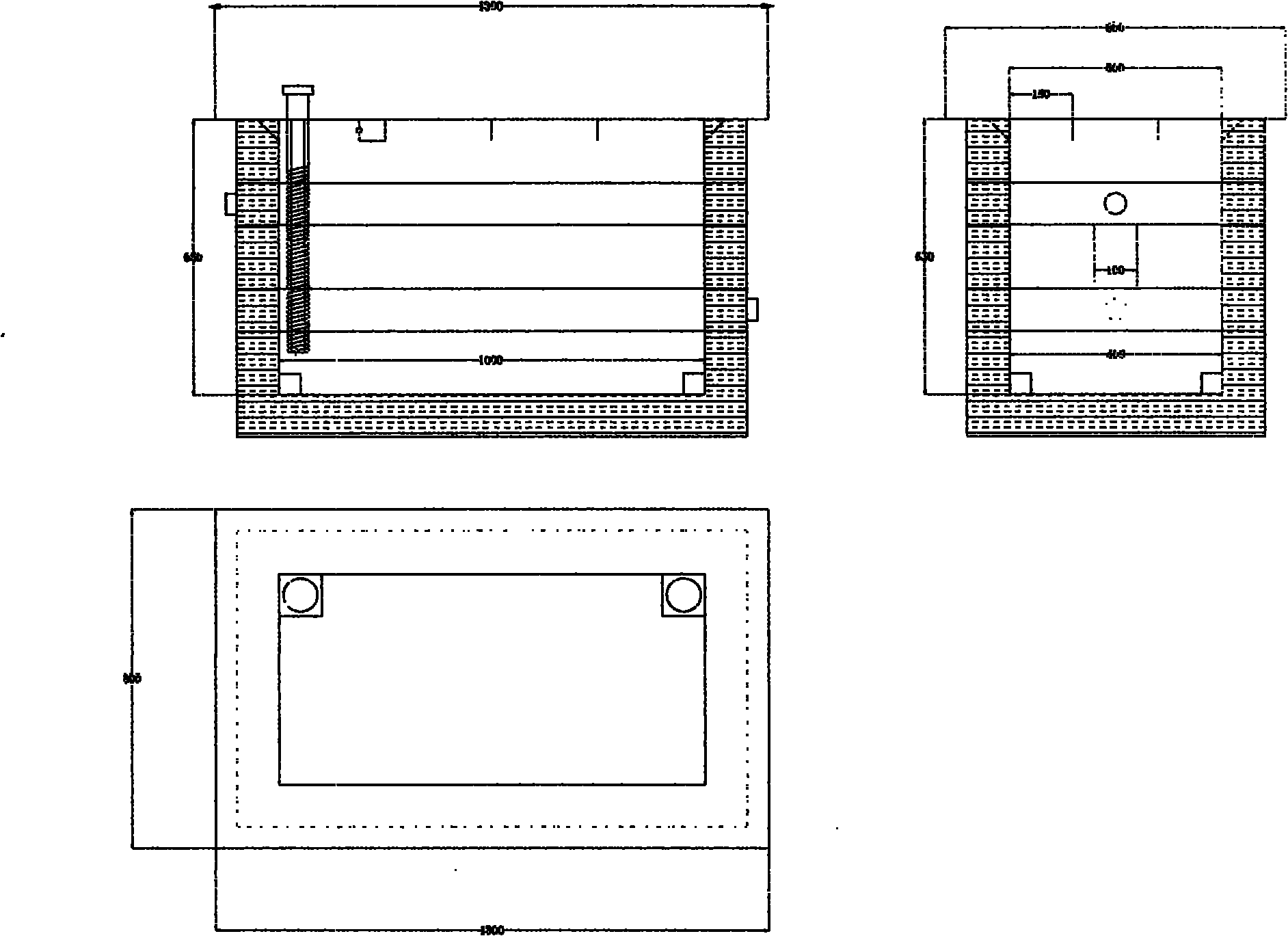

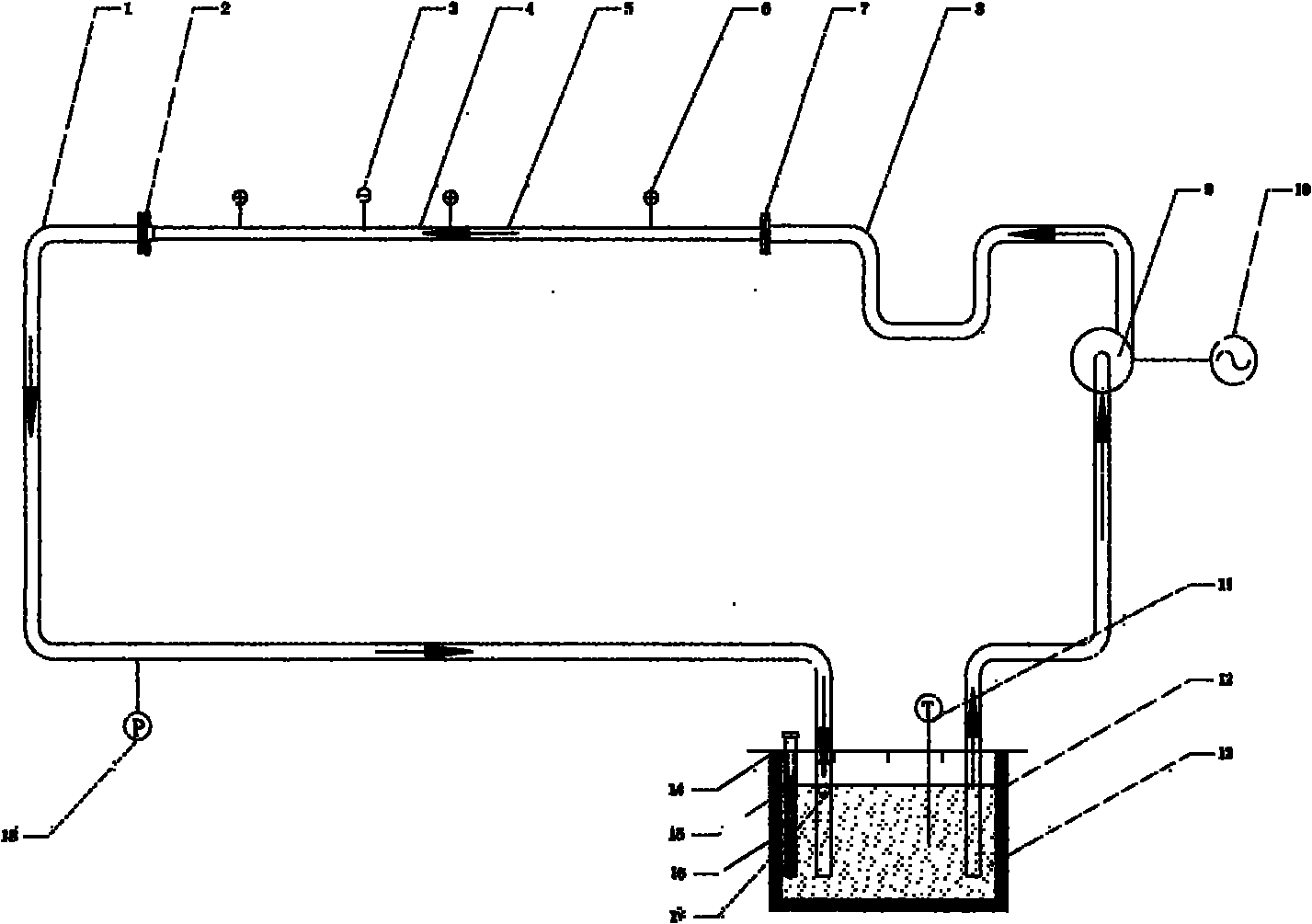

Automatic controlled stainless steel inner tube electrolytic polishing device

The invention relates to the stainless steel inner pipe electrolytic polishing treatment, an automatic operation is employed, the processing parameter is automatically adjusted, thereby the processing quality stabilization can be guaranteed. An electrolytic polishing solution is introduced in the stainless steel pipe, on one hand, the bubbles generated in the electrolytic polishing treatment process can be timely discharged, and on the other hand, the residues generated during the electrolytic polishing treatment can be timely discharged. In addition, during the process of stainless steel inner tube electrolytic polishing, the stainless steel pipe is capable of rolling, the bubbles can be prevented from rising to top of the pipe to influence the electrolytic polishing effect on the top of the inner pipe. The rolling speed is adjustable, the electrolytic polishing solution is environment-friendly type liquid medicine, the current passed through the unit area is small, compared with a traditional electrolytic polishing solution, the power consumption is smaller, and the energy saving performance is provided. The electrolytic polishing device is a stainless steel pipe inner electrolytic polishing special machine, and can be used for electrolytically polishing the stainless steel pipes with various calibers. The device of the invention has the advantages of high automation degree, environmental protection, energy saving, high production efficiency and good polishing effect.

Owner:SHANGHAI MIRROR METAL SURFACE TREATMENT

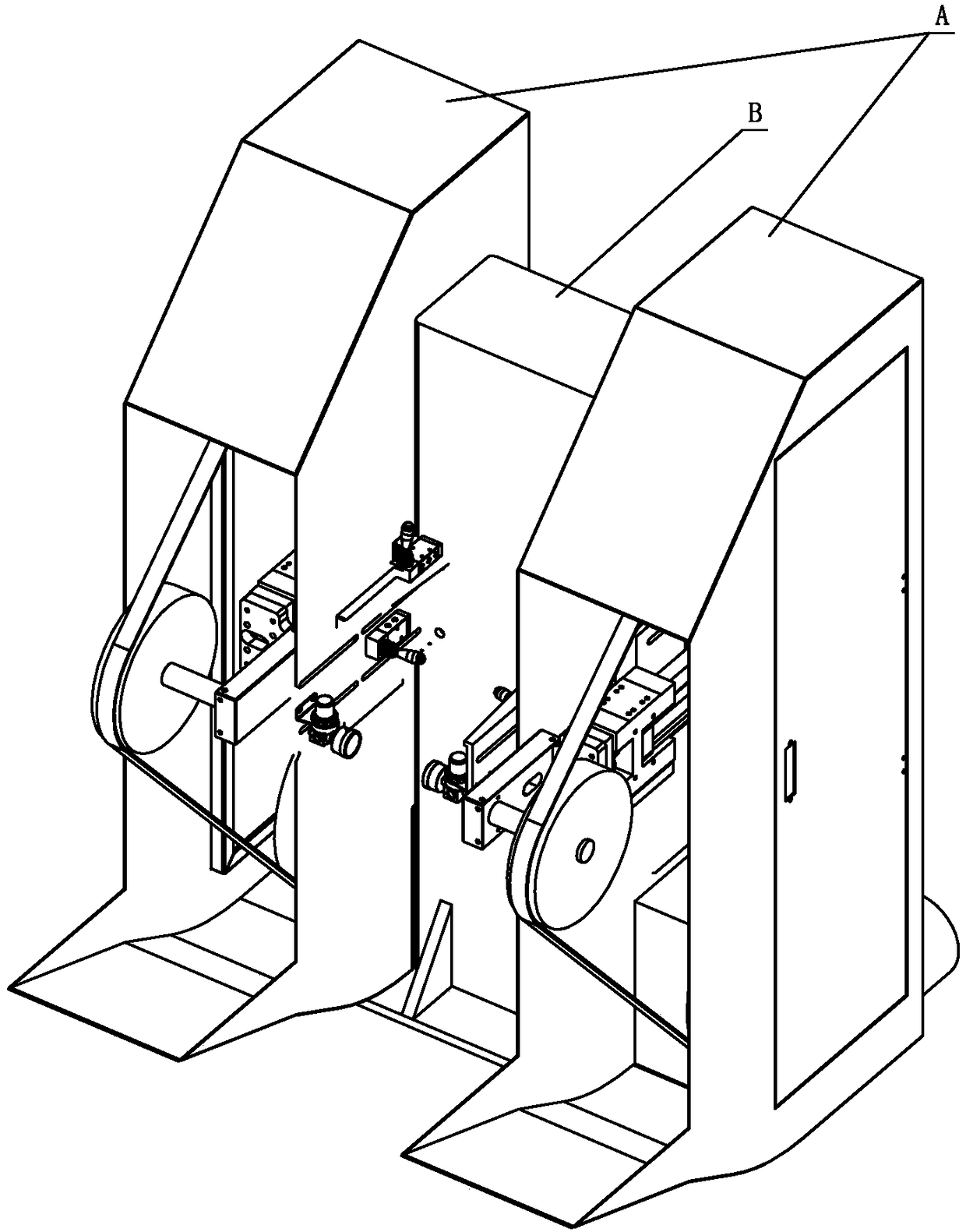

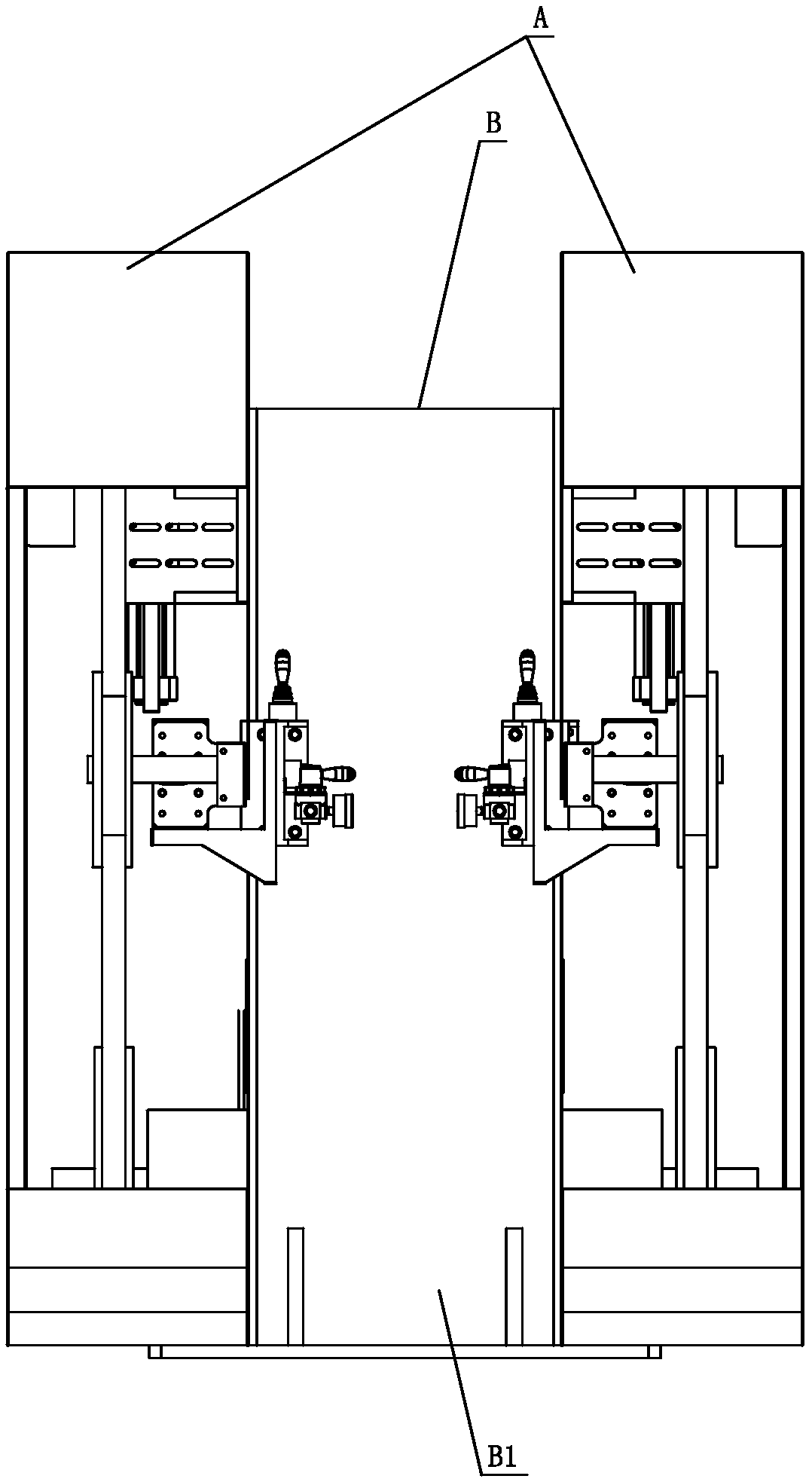

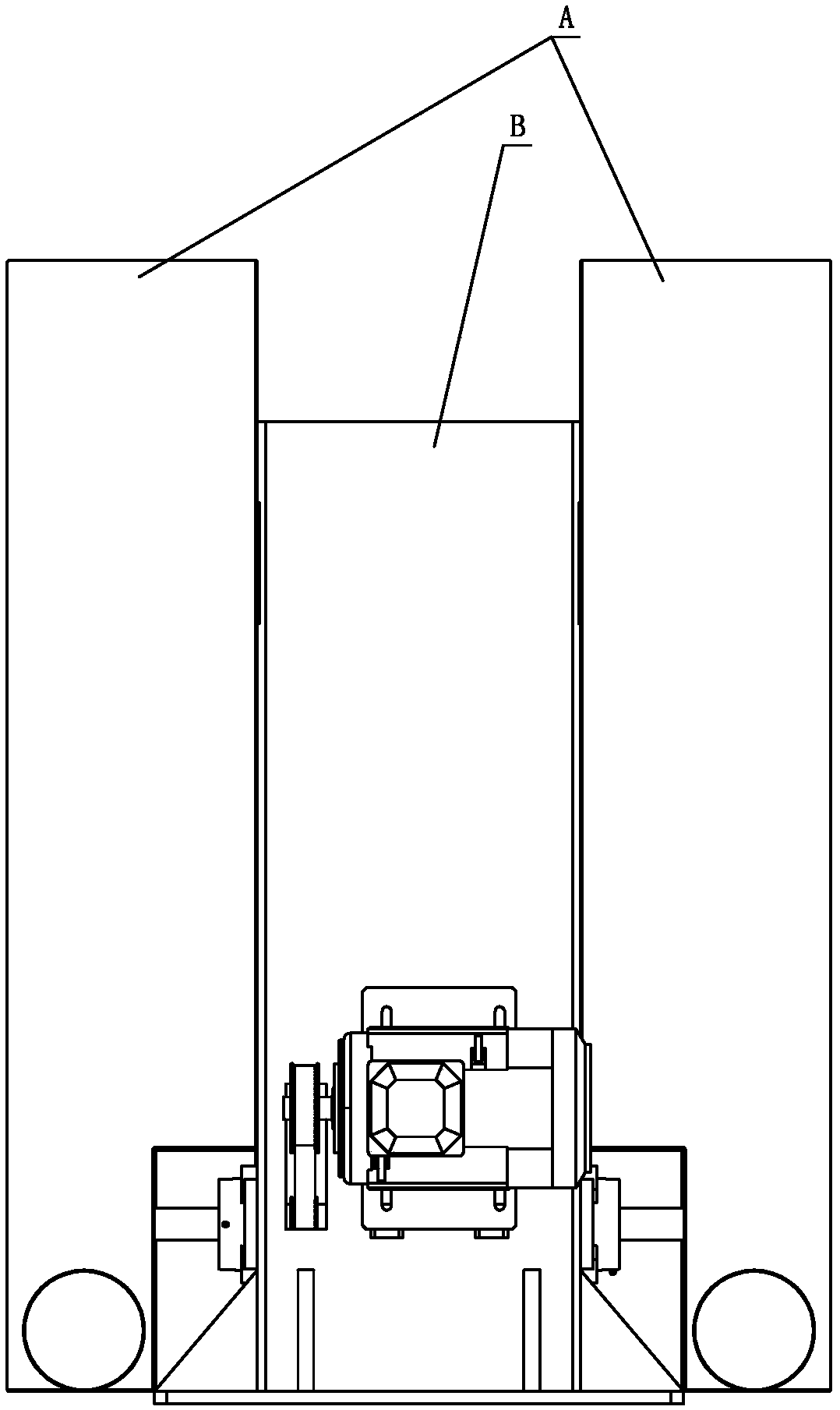

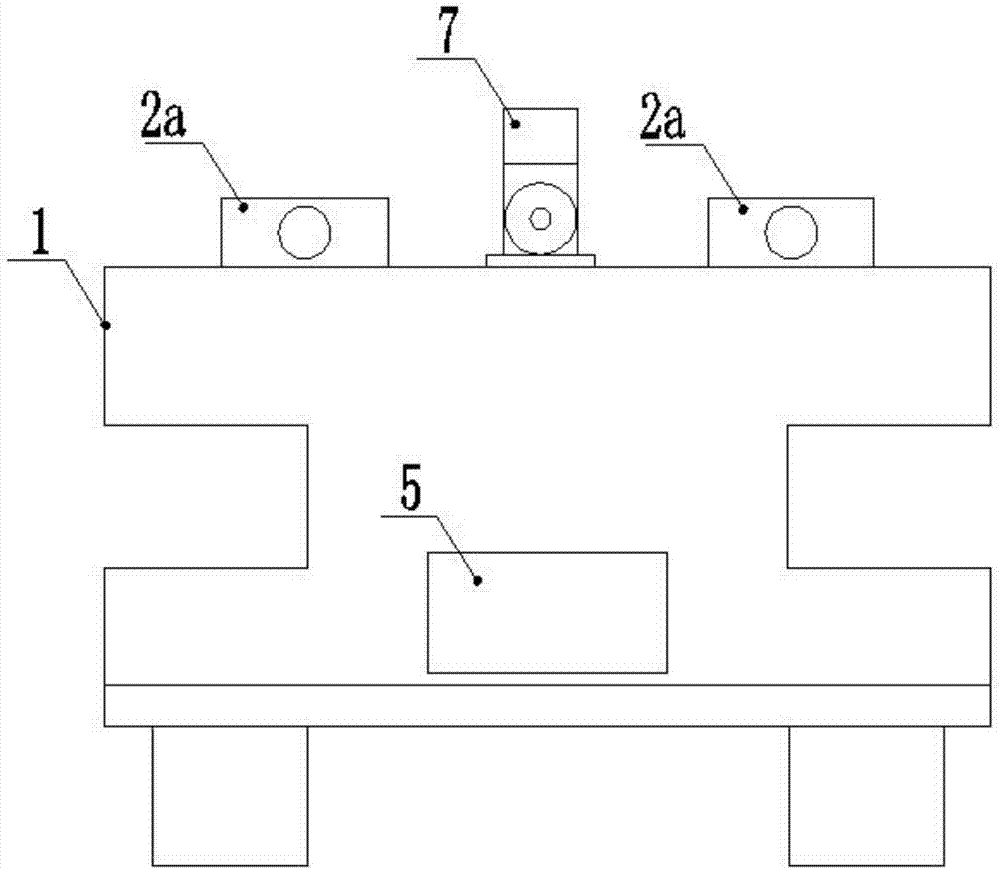

Double-side double-station force control belt sander and polishing work station thereof

ActiveCN108789060AReduce labor intensityReduce job hazardsBelt grinding machinesAutomatic grinding controlSanderDrive wheel

The invention provides a double-side double-station force control belt sander and a polishing work station thereof. The double-side double-station force control belt sander comprises single-station polishing cabinets and a power output cabinet. The two single-station polishing cabinets are arranged. The power output cabinet is arranged between the two single-station polishing cabinets. Each single-station polishing cabinet comprises a polishing system composed of a polishing driving wheel, a polishing abrasion wheel, a polishing driven wheel and a polishing abrasion belt, wherein the polishingabrasion belt is arranged on the polishing driving wheel, the polishing abrasion wheel and the polishing driven wheel in a winding manner. Each single-station polishing cabinet further comprises a force control mechanism and a deviation rectifying mechanism, wherein the force control mechanism drives the polishing abrasion wheel to move linearly, and the deviation rectifying mechanism drives thepolishing driven wheel to swing around one side. The power output cabinet comprises a polishing motor and a transmission shaft. The polishing motor drives the transmission shaft to rotate. The two ends of the transmission shaft are connected with the corresponding polishing driving wheels. The polishing quality and efficiency of the belt sander are improved, sensitivity of force control is high, the polishing applicability is high, the polishing performance is reliable, the abrasion belts are convenient and fast to replace, and the manufacturing cost is low.

Owner:GUANGDONG LXD ROBOTICS CO LTD

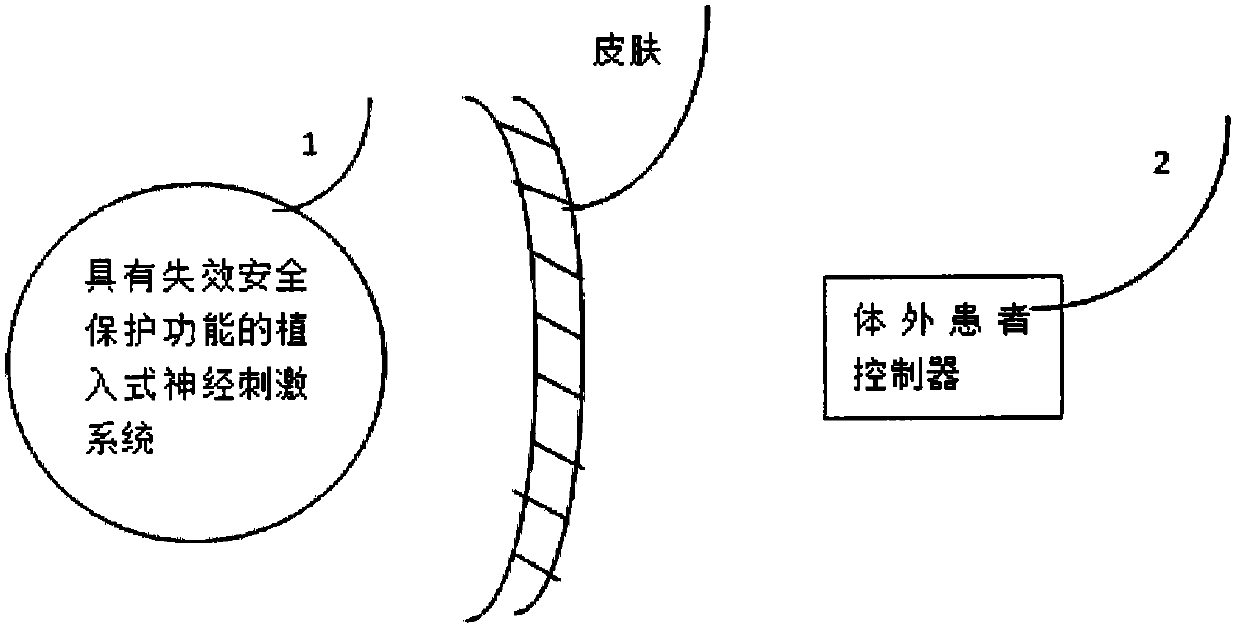

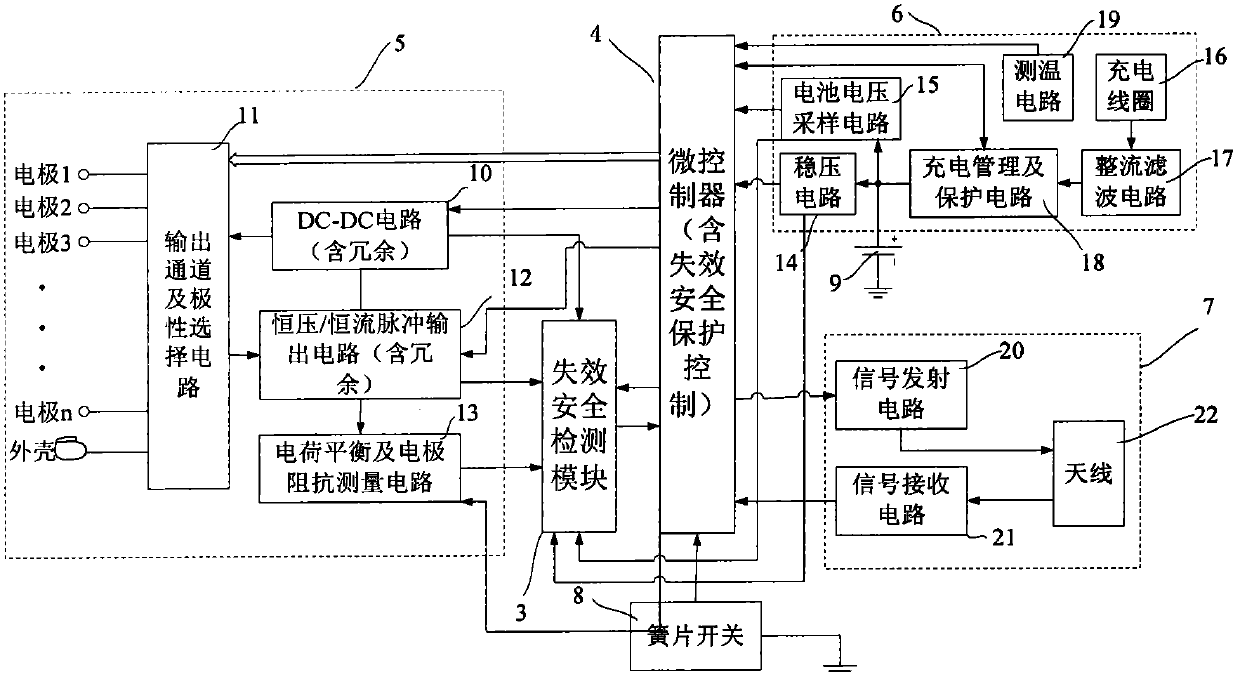

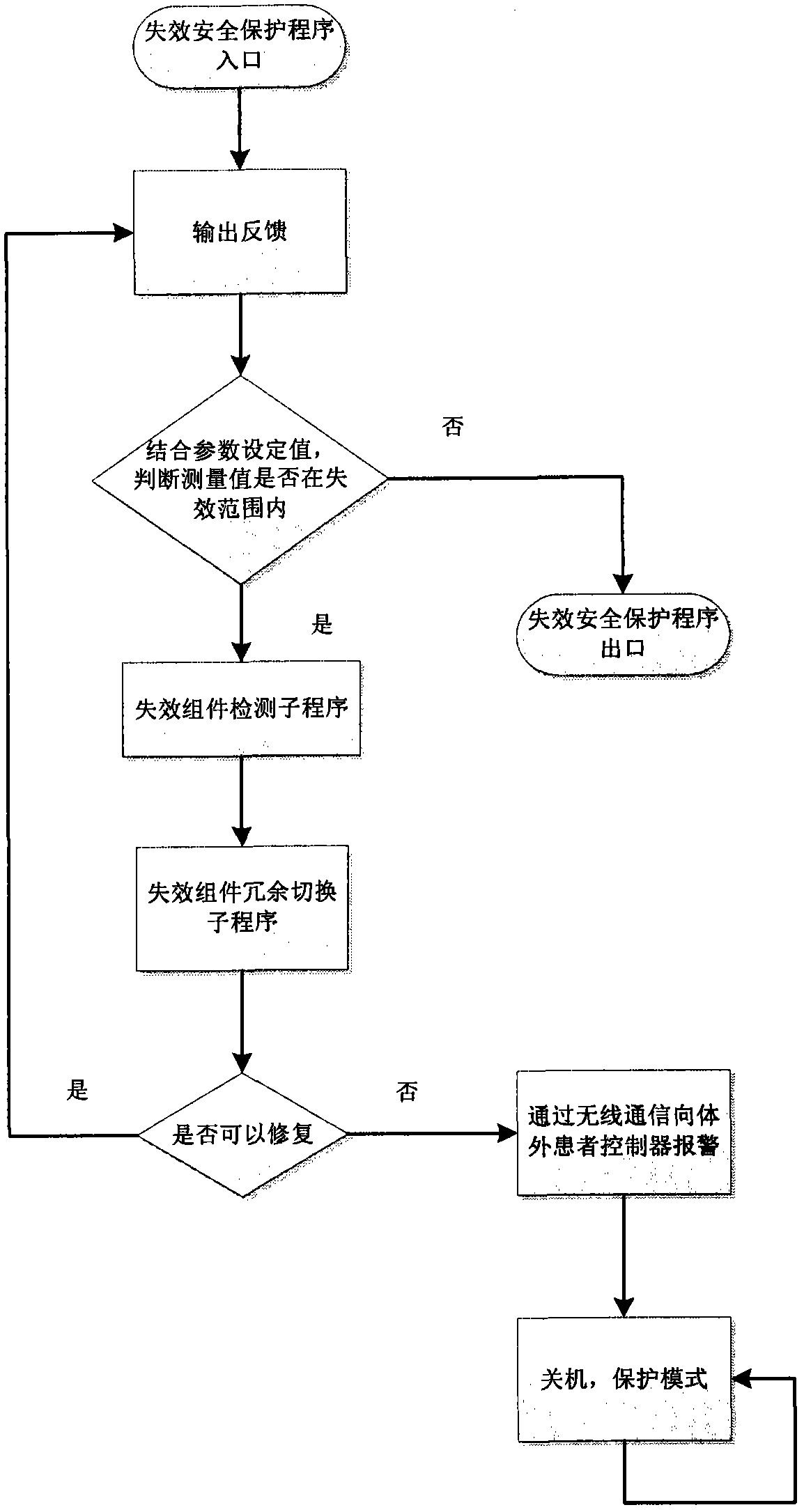

Implanted medical device with invalidation safety protection function

ActiveCN103736206ANot harmful to healthAvoid discomfortArtificial respirationEngineeringElectrode impedance

The invention discloses an implanted medical device with an invalidation safety protection function and belongs to the technical field of implanted medical instruments. The implanted medical device comprises two following functions: invalidation safety detection and invalidation safety protection. The device comprises the following components and features of the real-time detection of the safety performance of the implanted medical device, wherein the monitoring range comprises a DC (Direct Current)-DC circuit, a constant voltage / constant current pulse output circuit, an electric charge balance and electrode impedance measuring circuit, a voltage stabilizing circuit, temperature measurement and the like; fault diagnosis; the continued application of the implanted medical device after fault removal; wireless fault alarm; an automatic off function when a fault cannot be removed. The implanted medical device has the characteristics of outstanding reliability, simple implementation method, high intellectualization degree, low power dissipation, strong instantaneity and the like, the safety, the effectiveness and the reliability of the implanted medical device are greatly improved, and the invention can be widely applied to various implanted medical devices.

Owner:BEIJING PINS MEDICAL +1

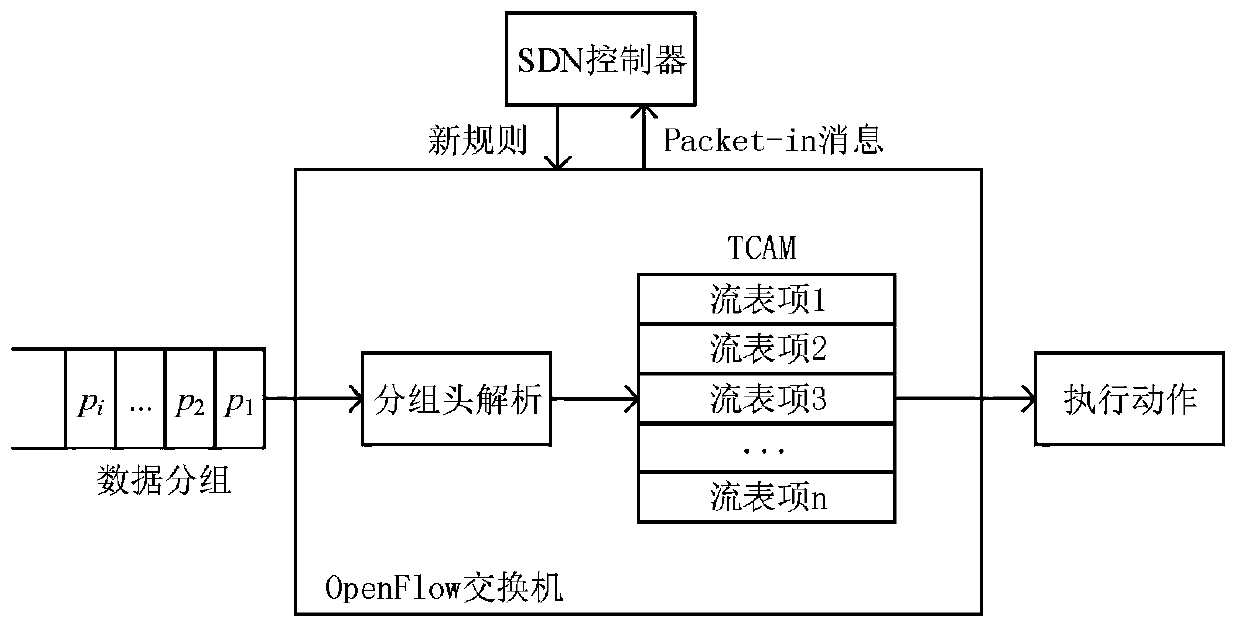

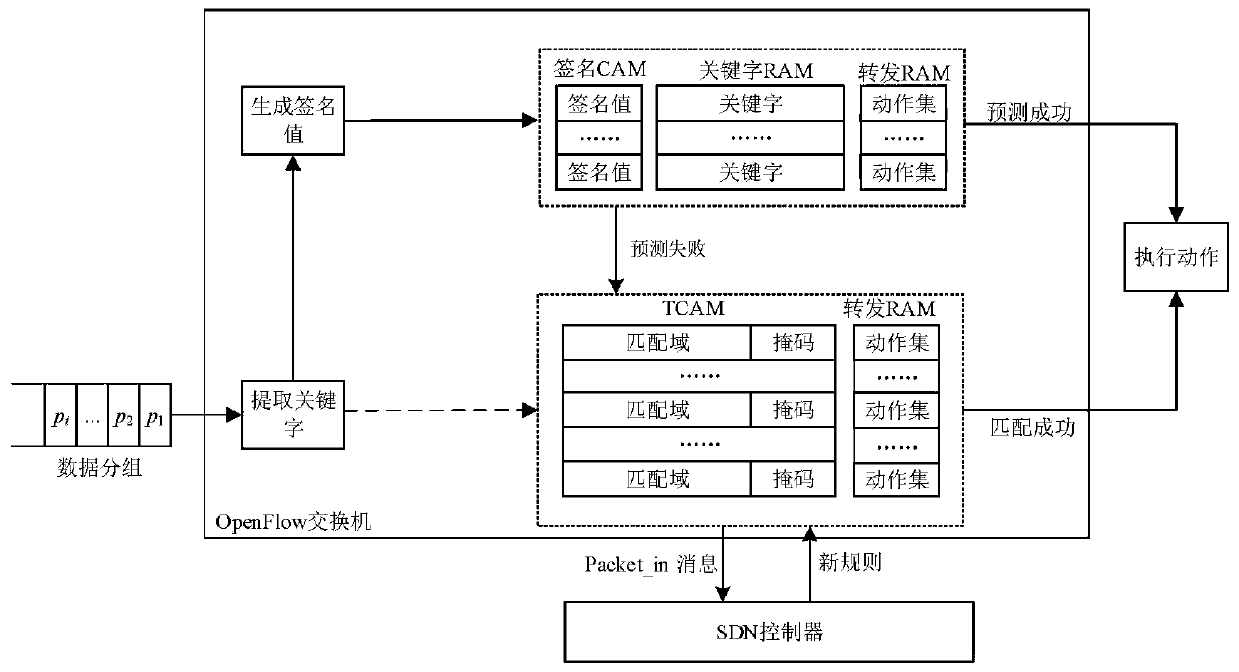

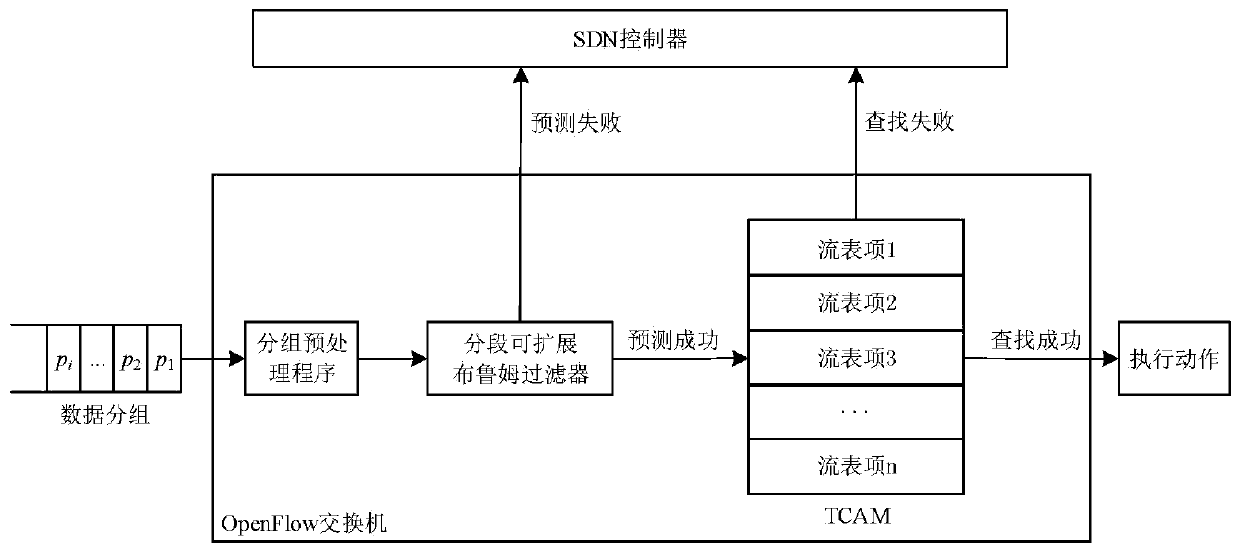

OpenFlow flow table energy-saving storage architecture supporting QoS (Quality of Service) and application thereof

ActiveCN110808910AGuaranteed service qualityGuaranteed flow table lookup performanceData switching networksQos quality of serviceEngineering

The invention provides an OpenFlow flow table energy-saving storage architecture supporting QoS (Quality of Service) and application of the OpenFlow flow table energy-saving storage architecture. Thearchitecture comprises three layers, namely a priority flow / elephant flow layer, a mouse flow layer and an active connection cache layer, wherein the priority flow / elephant flow layer adopts a TCAM and a DRAM as storage media, the mouse flow layer adopts an SRAM and a DRAM as storage media, the active connection cache layer adopts an SRAM as a storage medium, and a Cuckoo hash structure is adoptedto cache a mapping relationship between active connection and flow table entries in the TCAM. According to the architecture, the TCAM is adopted to preferentially store the identification fields of the priority flow table entries, and quick flow table lookup of priority data packets is realized, so that the network service quality is guaranteed. Meanwhile, a Cuckoo cache is designed to dynamically store the current active connection and the corresponding TCAM flow entry index value in the elephant flow; the cache is hit by most of the data packets, and the corresponding flow table item is found according to the address of the hit cache item, so that a TCAM flow table lookup process is bypassed, and the flow table lookup energy consumption overhead is greatly reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

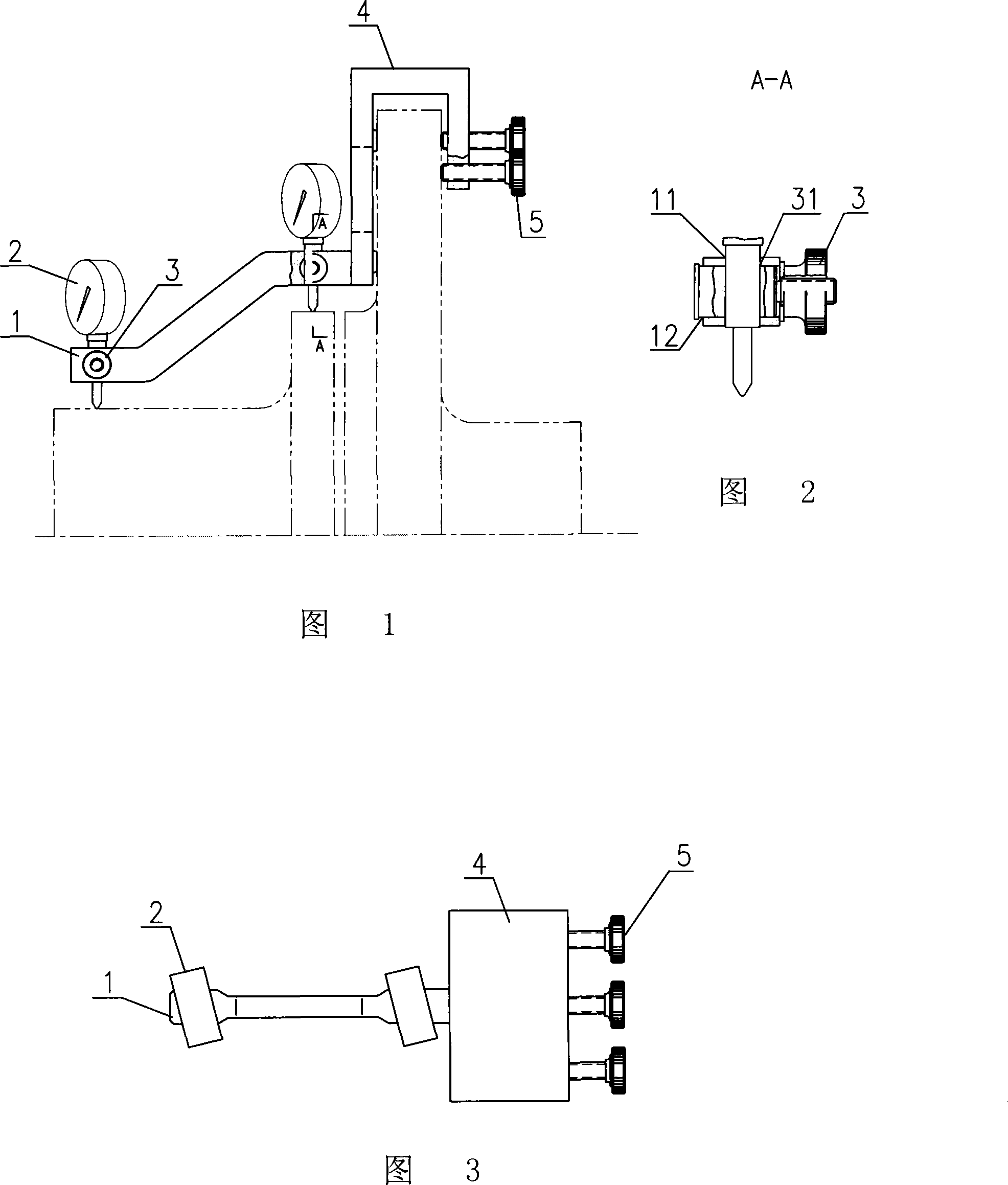

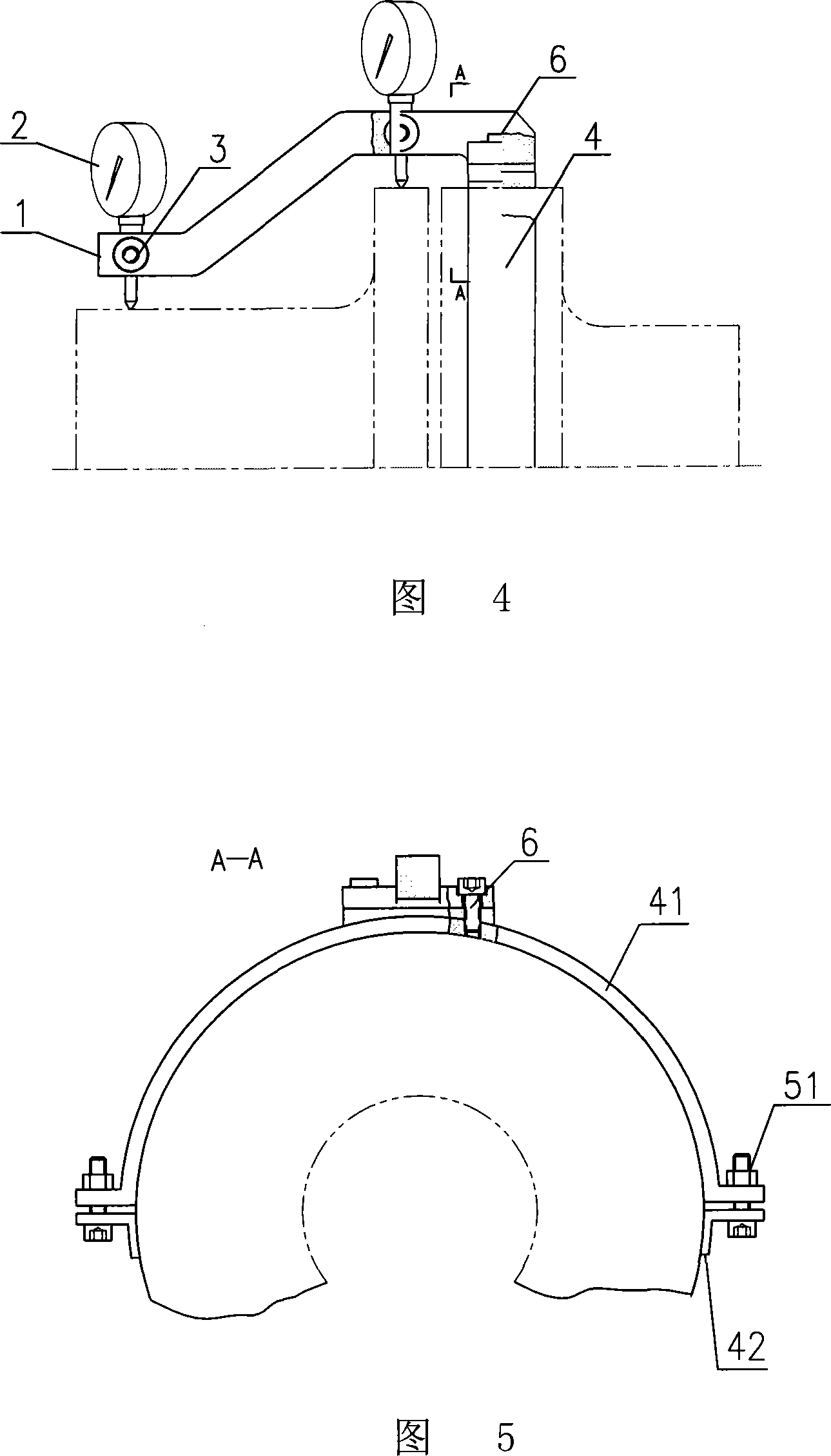

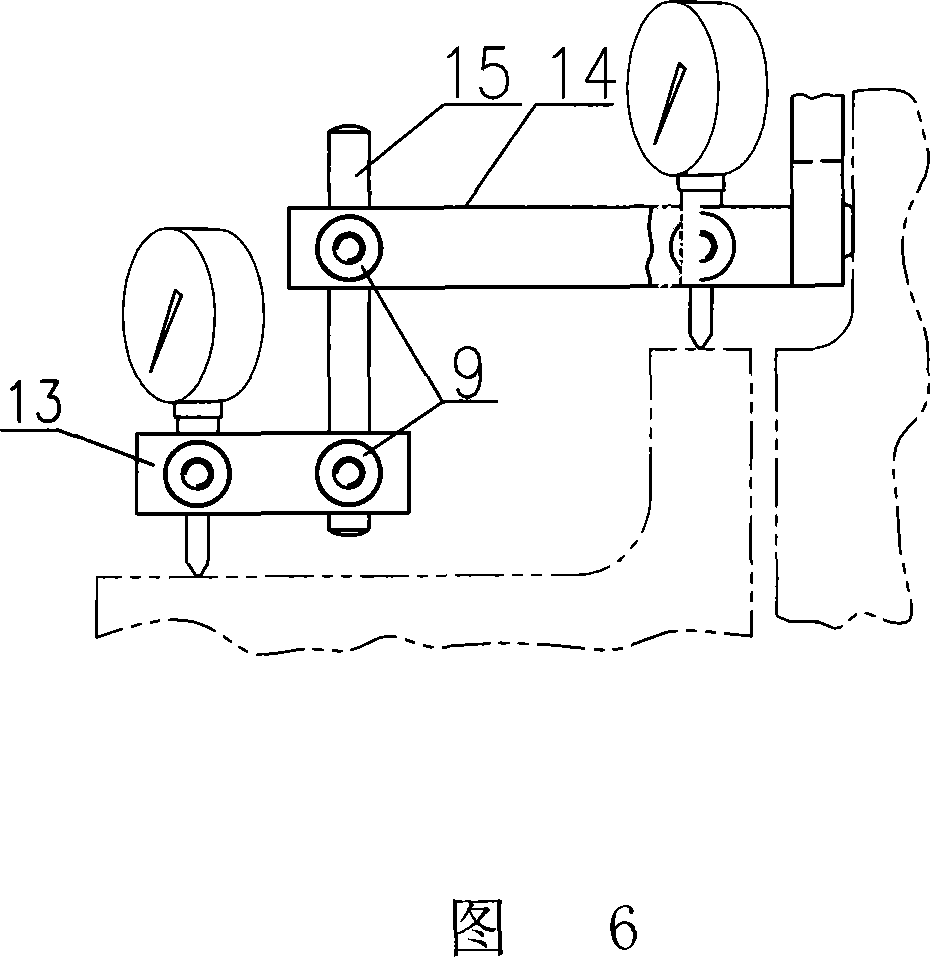

Axle coupler dedicated tester and method of use thereof

The invention relates to a special test instrument for a coupling and an application method thereof. The test instrument comprises a micrometer gauge, a micrometer gauge bracing frame, an adjusting knob, a fixed knob and a fixing bracket, wherein the micrometer gauge bracing frame is fixedly connected with the fixing bracket; the micrometer gauge bracing frame is in a stepped shape, a mounting hole is respectively provided on the two steps, and a lateral hole for containing the adjusting knob is provided in a direction perpendicular to the mounting holes; a pinhole corresponding to the mounting hole and having the same diameter with the mounting hole is disposed on the adjusting knob, and the micrometer gauge is fixedly disposed in the mounting hole and the pinhole of the adjusting knob corresponding to the mounting hole; and the fixing bracket is provided with a fixed knob. The test instrument can conveniently measure the eccentricity and inclination of two half-couplings; and has the advantages of simple structure, easy operation, low cost, low abrasion, good durability and good testing effect.

Owner:CHINA CAMC ENG

Preparation of a quartz glass body in a melting crucible of refractory metal

ActiveUS20190071344A1Reduce contentIncrease pointsPot furnacesMaterial analysis by optical meansSilica particleLight guide

The invention relates to a process for preparing a quartz glass body comprising the process steps i.) Providing a silicon dioxide granulate, ii.) Making a glass melt from the silicon dioxide granulate in a melting crucible, and iii.) Making a quartz glass body from at least a part of the glass melt, wherein the melting crucible is comprised in an oven and is made of at least one material comprising tungsten or molybdenum or a combination thereof. The invention further relates to a quartz glass body which can be obtained by this process. Further, the invention relates to a light guide, an illuminant and a formed body, each of which can be obtained by processing the quartz glass body further.

Owner:HERAEUS QUARZGLAS

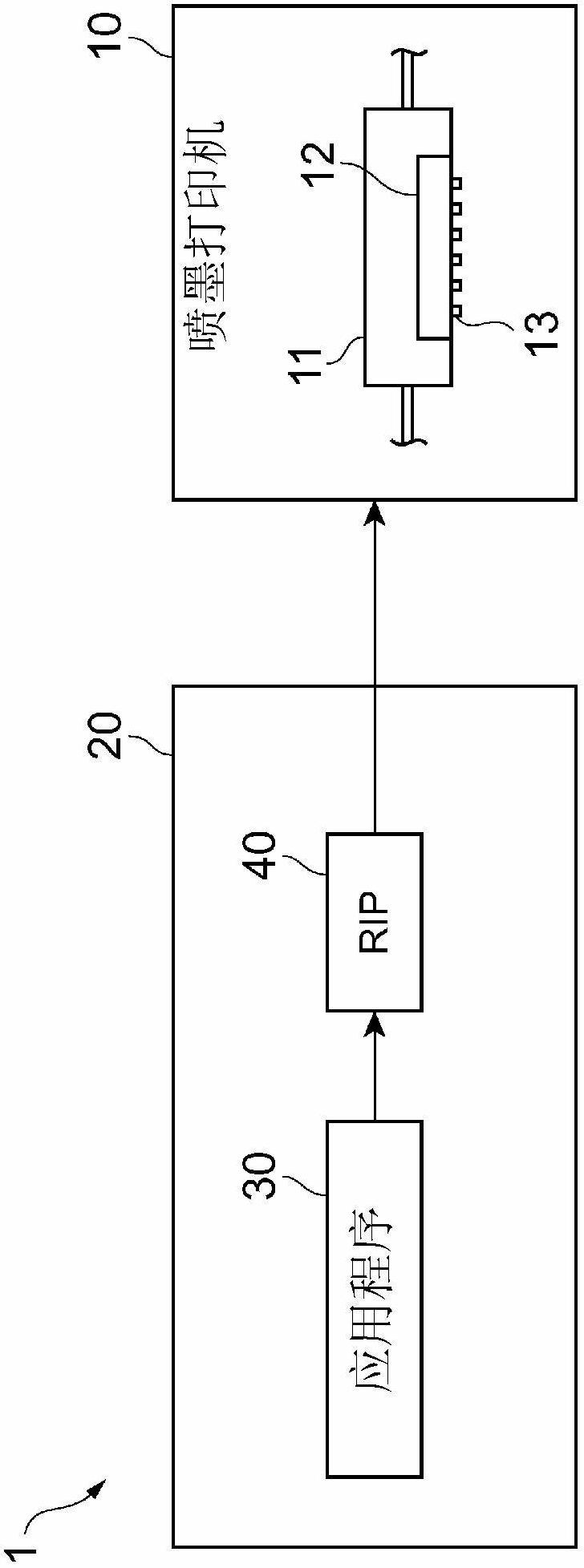

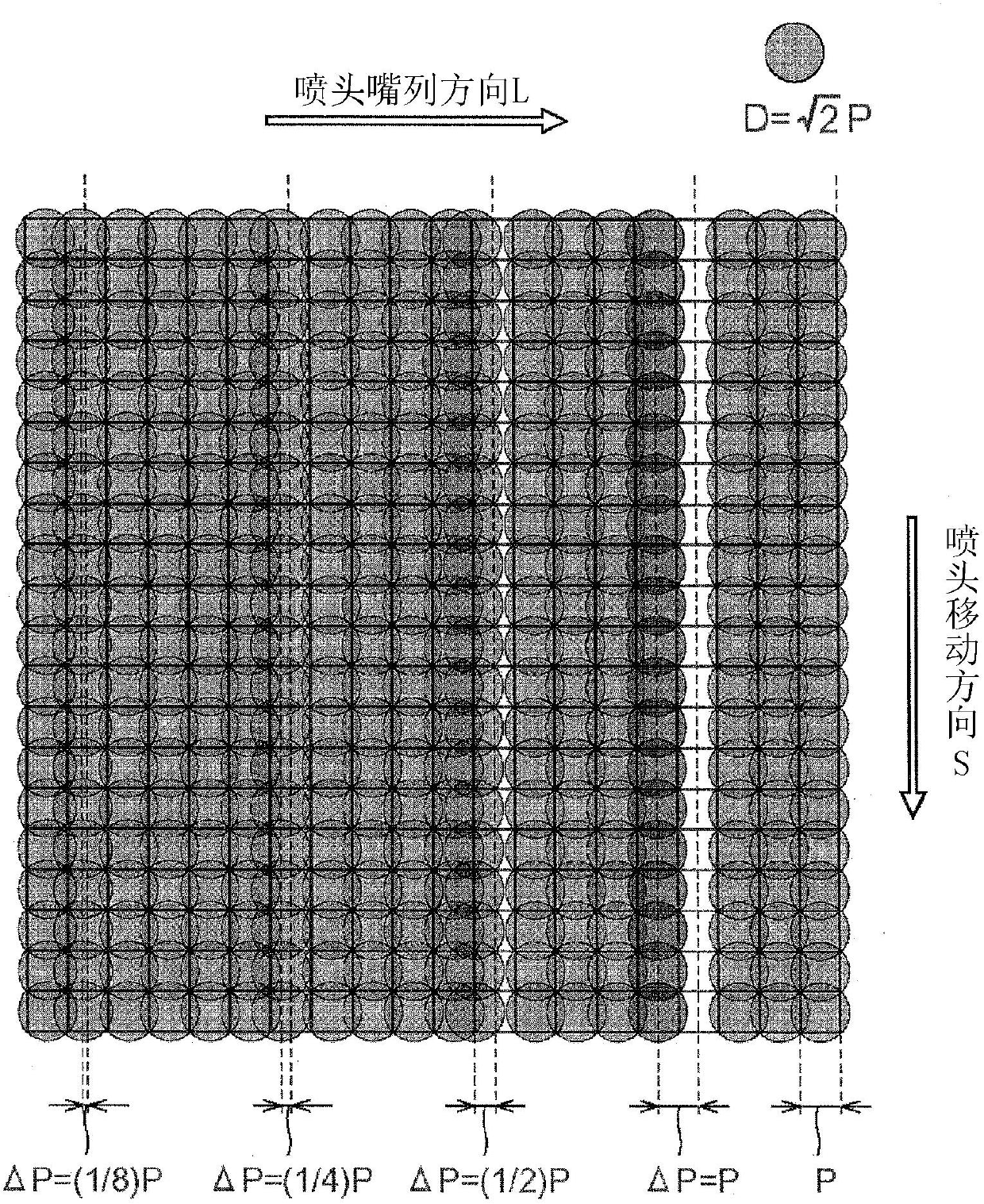

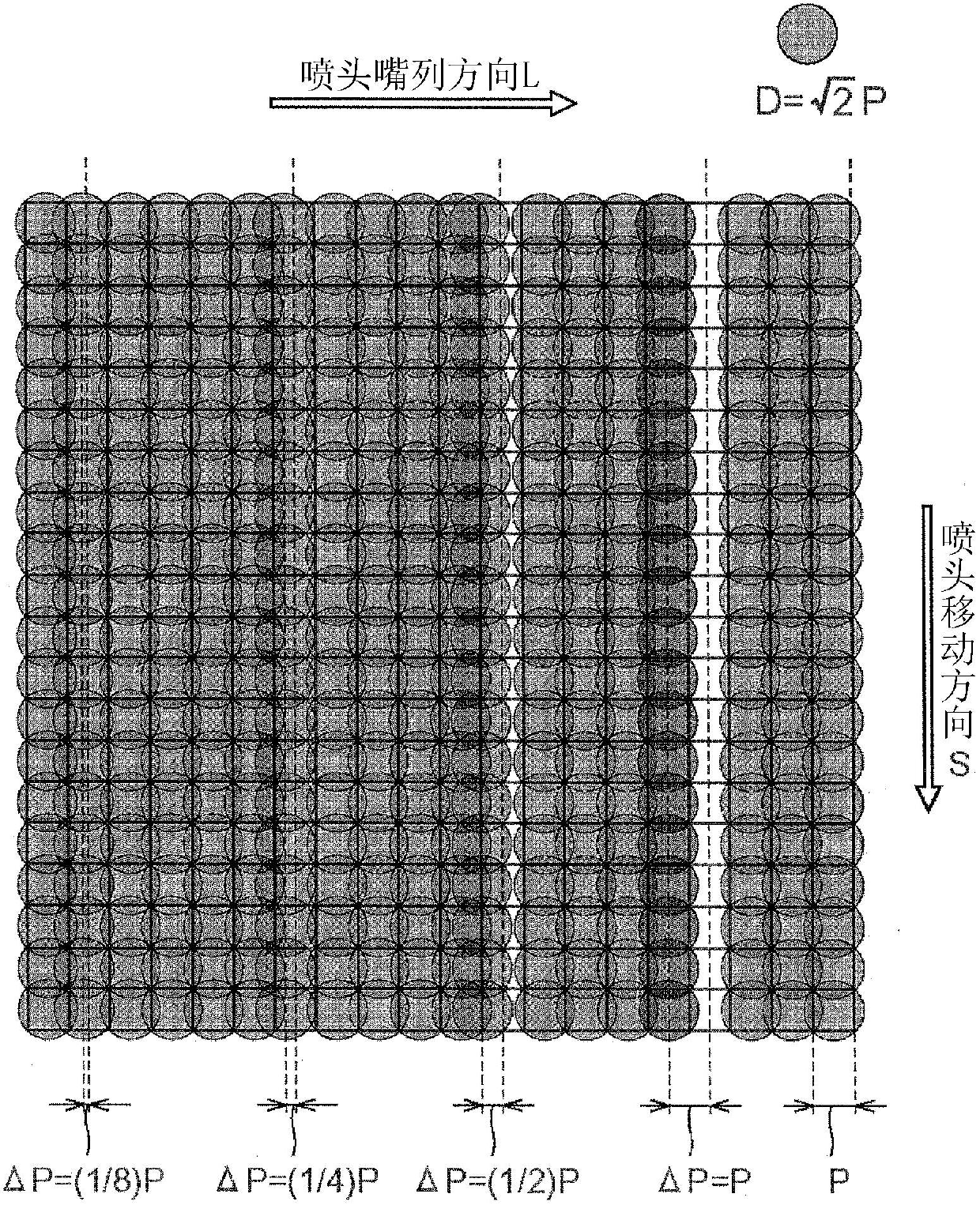

Print data generating device, print data generating method, and print data generating program

InactiveCN102666105AIncrease the number of spraysIncrease the amount of ejectionSpacing mechanismsOther printing apparatusImage resolutionVolumetric Mass Density

A print data generating device, a print data generating method, and a print data generating program suppress occurrence of streaks in an image printed by an inkjet printer. An RIP (40) is provided with: a dot displacement amount detection unit (41) which detects a displacement amount of the landing position of an ink; a contour detection unit (42) which detects one pixel corresponding to a contour; a dot size setting unit (43) which on the basis of the displacement amount detected by the dot displacement amount detection unit (41) and the pixel corresponding to the contour and detected by the contour detection unit (42), sets the dot size of each pixel to be larger than a resolution pitch; a density setting unit (44) which sets the ink density of the dot to be low; and a print data generation unit (45) on the basis of the dot size of the pixel set by the dot size setting unit (43) and the ink density set by the density setting unit (44), calculates the number of times of ejecting ink droplets and the amount of the ink droplets for each pixel and generates print data to form on a recording medium the dot in the dot size set by the dot size setting unit (43).

Owner:MIMAKI ENG

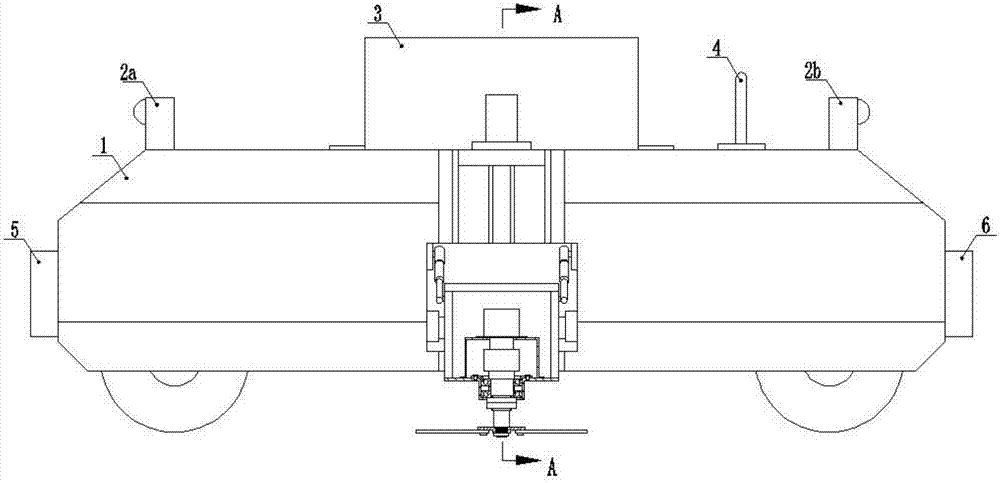

Unmanned efficient mowing vehicle

InactiveCN107333516AReal-time acquisitionRealize intelligent unmanned operationMowersRotational axisGear wheel

The invention discloses an unmanned high-efficiency lawn mowing vehicle, which comprises a vehicle body, an upper stepped rectangular groove in the middle of the vehicle body, a first cabin, a first cover plate, a second cabin, a lower stepped rectangular groove and a second cover plate, and There are upper and lower turning slots on the left and right sides of the car body. There are left turning holes and right turning holes on the top and a rotating shaft. There is a protective cover on the top of the car body. There are gear brackets, motor brackets, and rotating motors inside. There are rotating seats, lifting seats, electric push rods, working frame components on the left and right rotating shafts of the car body, control boxes, second rotating shafts, second cutter head assemblies, monitoring devices, first and second obstacle avoidance on the car body Sensors, front and rear cameras, alarms and booster antennas. The invention does not require manual operation, can be remotely monitored and controlled, can complete undulating and angled lawn weeding, has a large mowing area at one time, can freely choose the mowing method, and improves maintainability and replaceability.

Owner:薛迪宋

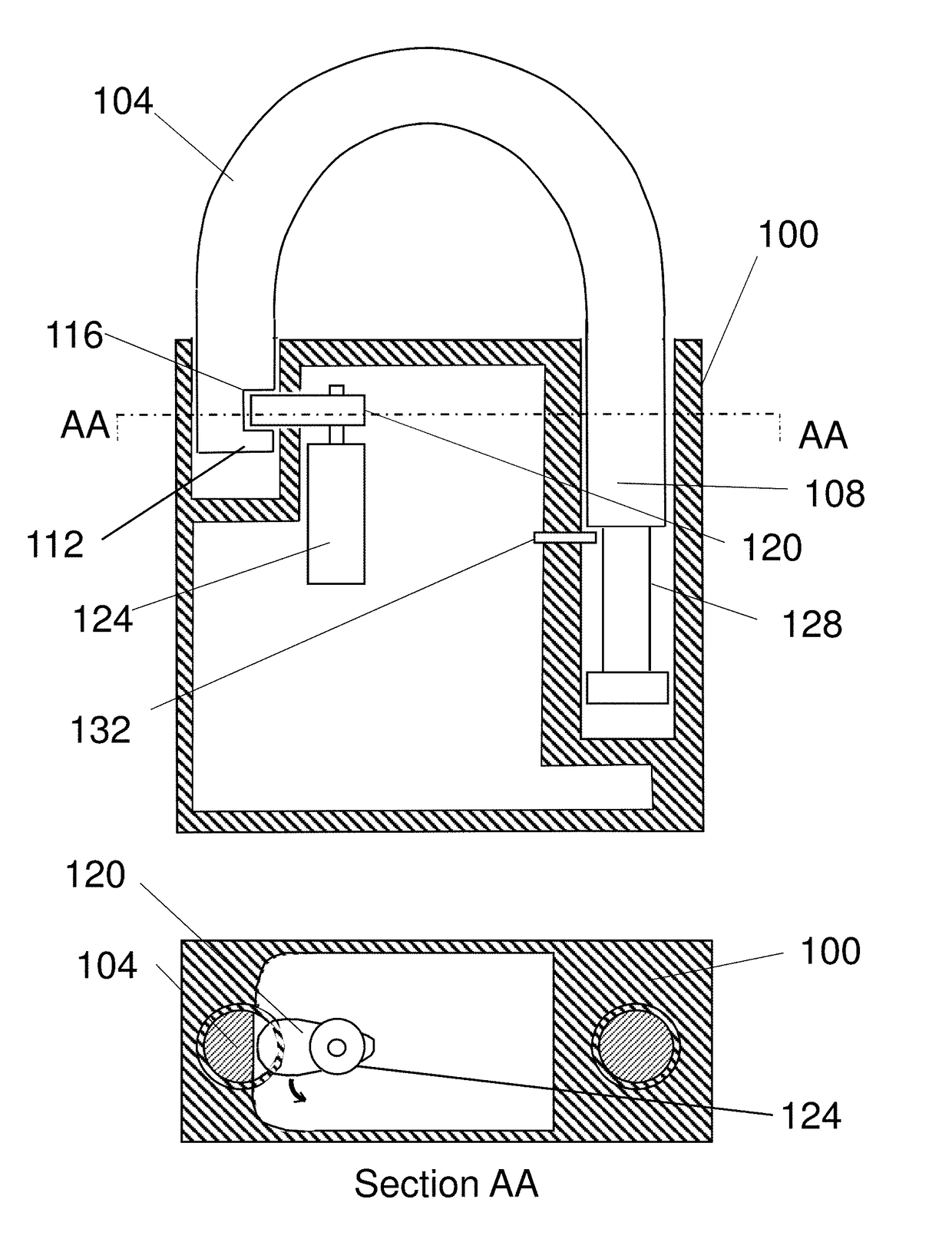

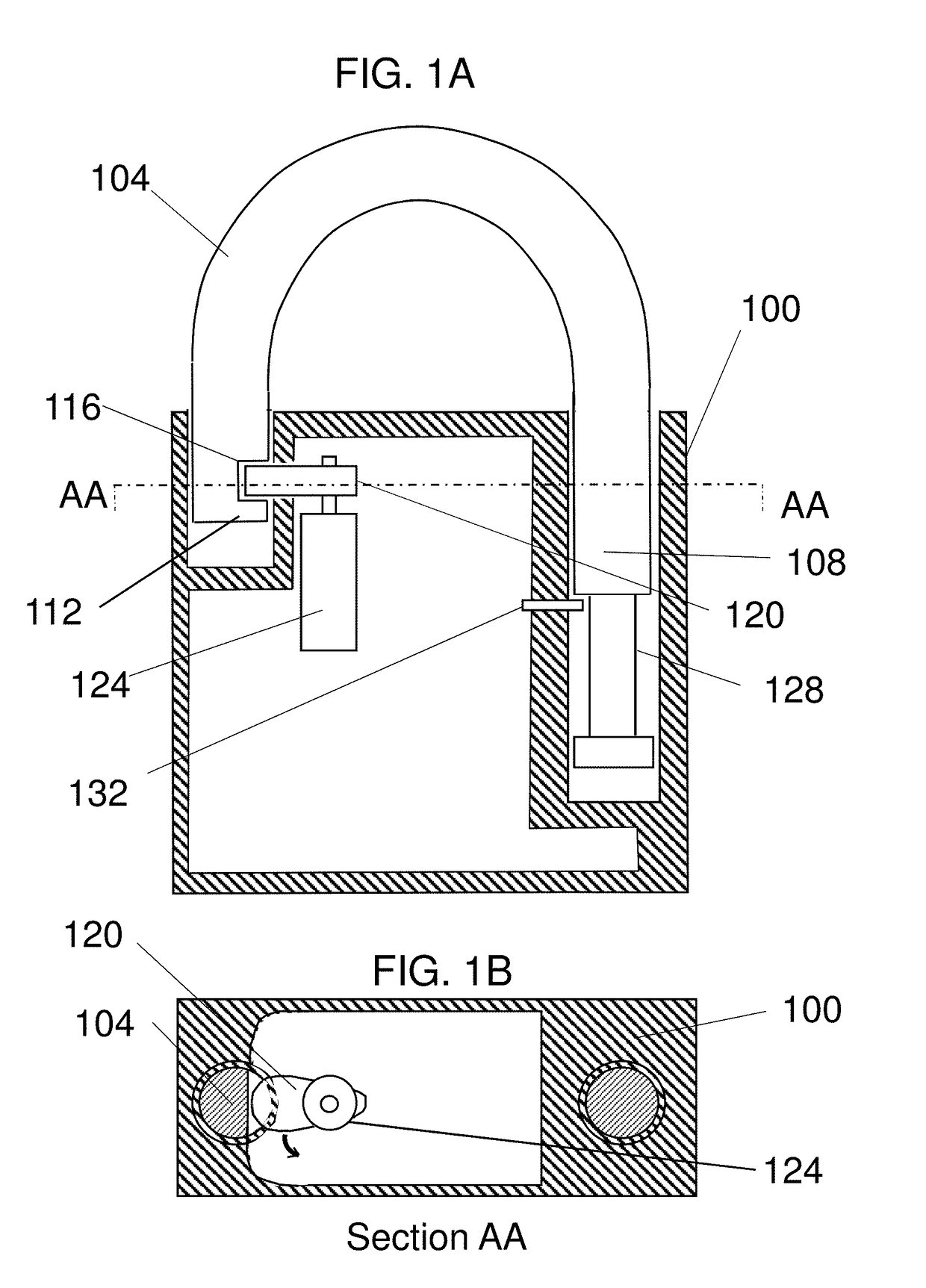

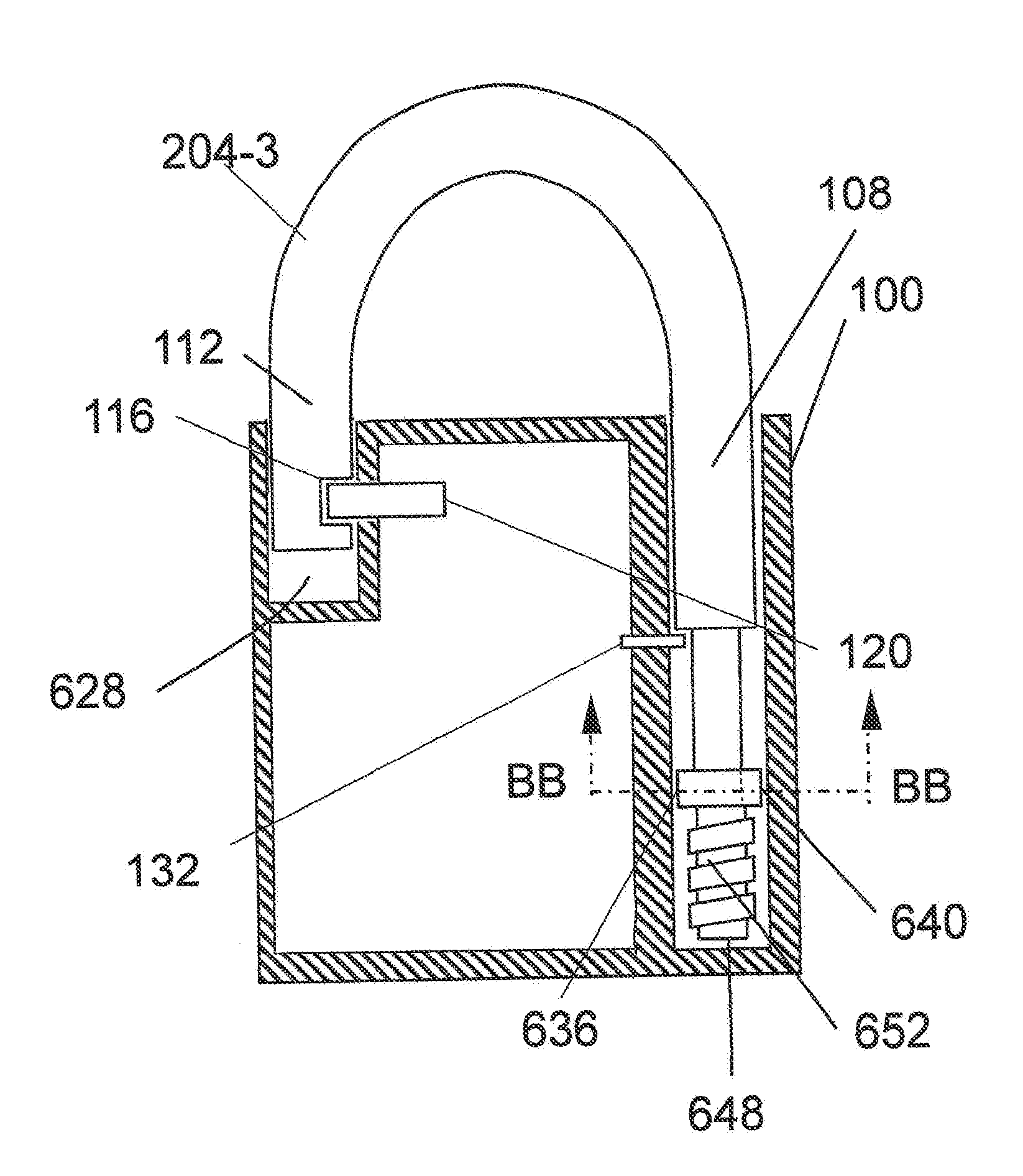

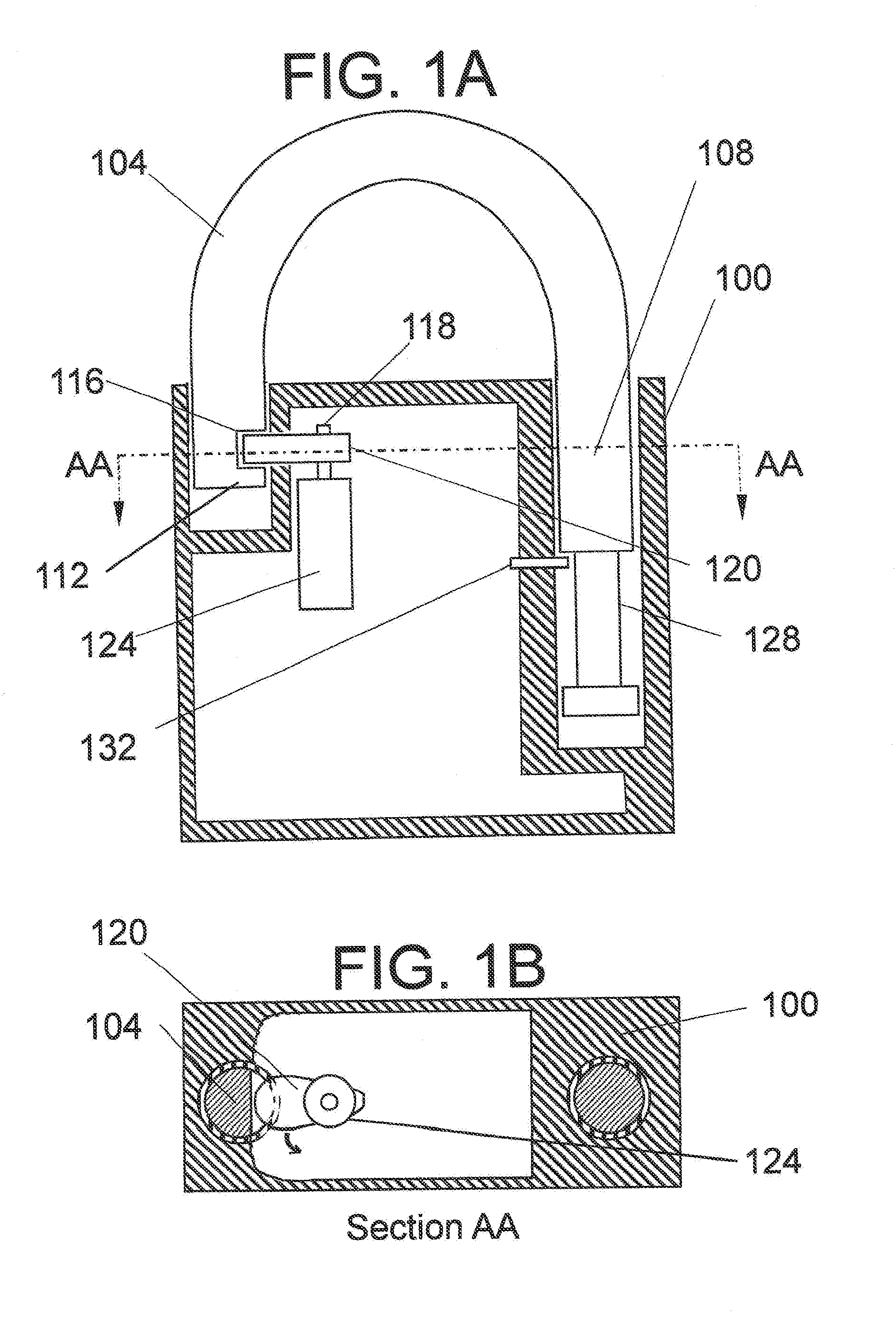

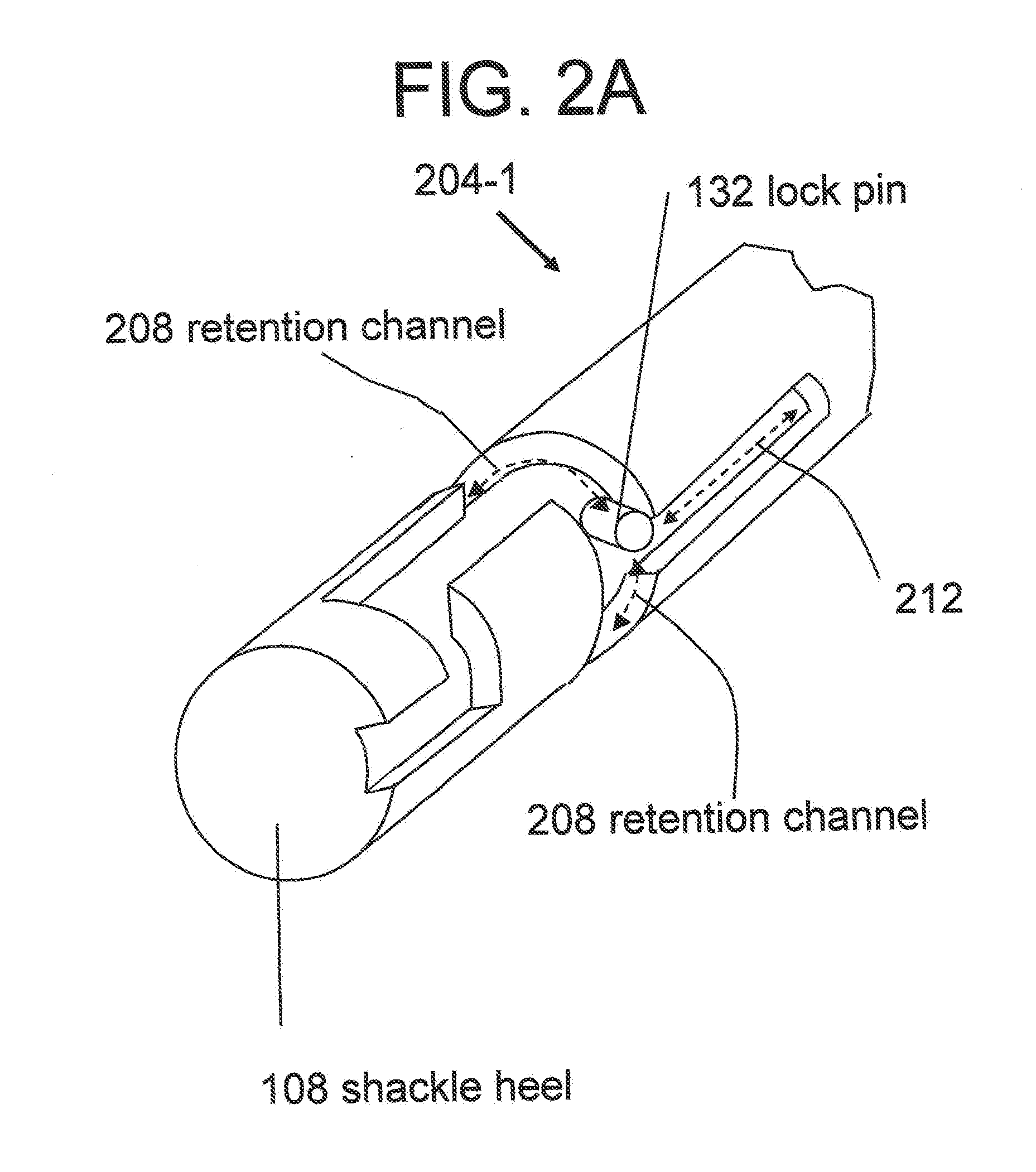

Replacement Shackle for Portable Lock

A group of embodiments for enabling the replacement of damaged shackles for multiple types of portable locks is disclosed. The embodiments have the ability to alter the shackle size and configuration for multiple types of portable locks by substituting one type of shackle with a different shackle, with no tools or special skills required.

Owner:MY TOUCH ID LLC

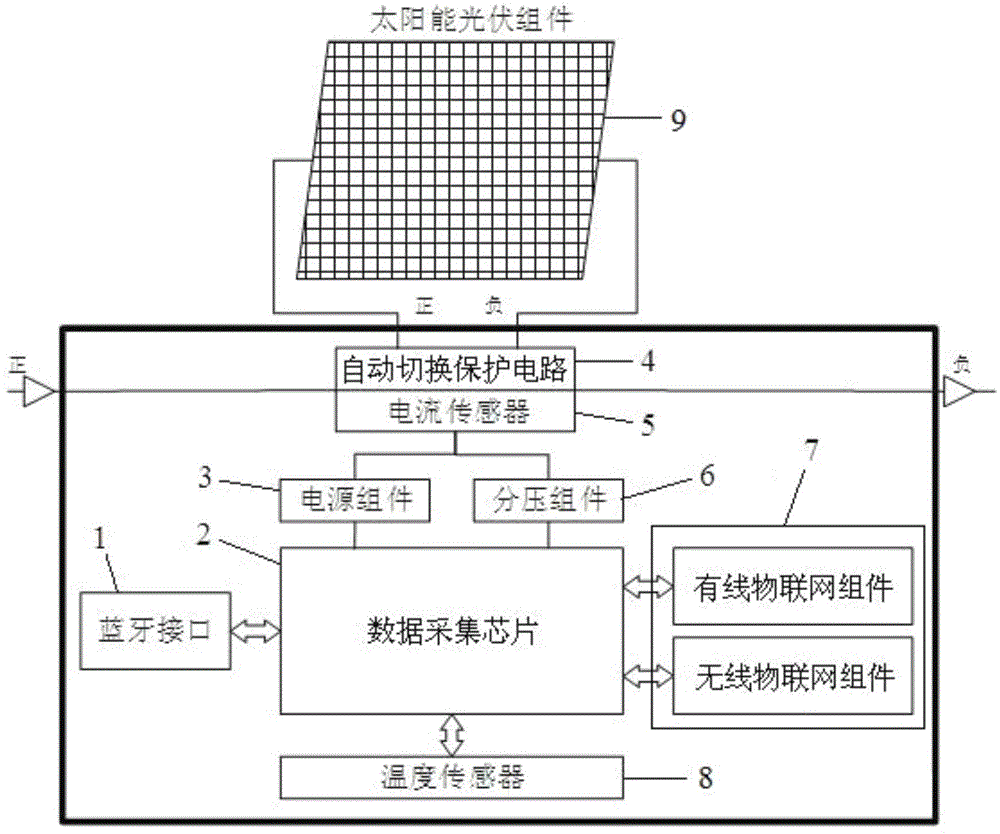

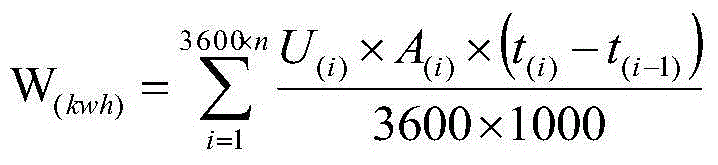

Device and method for monitoring data of embedded solar photovoltaic module data

ActiveCN104868845AReal-time detection of working statusImplement troubleshootingPhotovoltaic monitoringPhotovoltaic energy generationPower flowData acquisition

The invention belongs to the technical field of solar photovoltaic module detection, and specifically relates to a device and a method for monitoring data of embedded solar photovoltaic module data. The device comprises a data acquisition chip, a current sensor, a communication assembly, a temperature sensor, and a bluetooth interface. The data acquisition chip receives operational data of a solar photovoltaic module through the current sensor and the temperature sensor, and performs integral generating capacity calculation and hidden danger judgment according to the operational data. The operational data, the integral generating capacity, and hidden danger judgment results of the solar photovoltaic module are output through the communication assembly. The device uses an embedded microprocessor as the core, and combining with an internet of things technology, detects operating states of the photovoltaic module in real time, so as to realize intelligentized data acquisition and analysis, fault diagnosis, fault location, fault removing and alarm. The device and the method provide a simple solution for intelligentized and remote monitoring of a solar power station system.

Owner:WUHAN SINO HT NEW ENERGY TECH

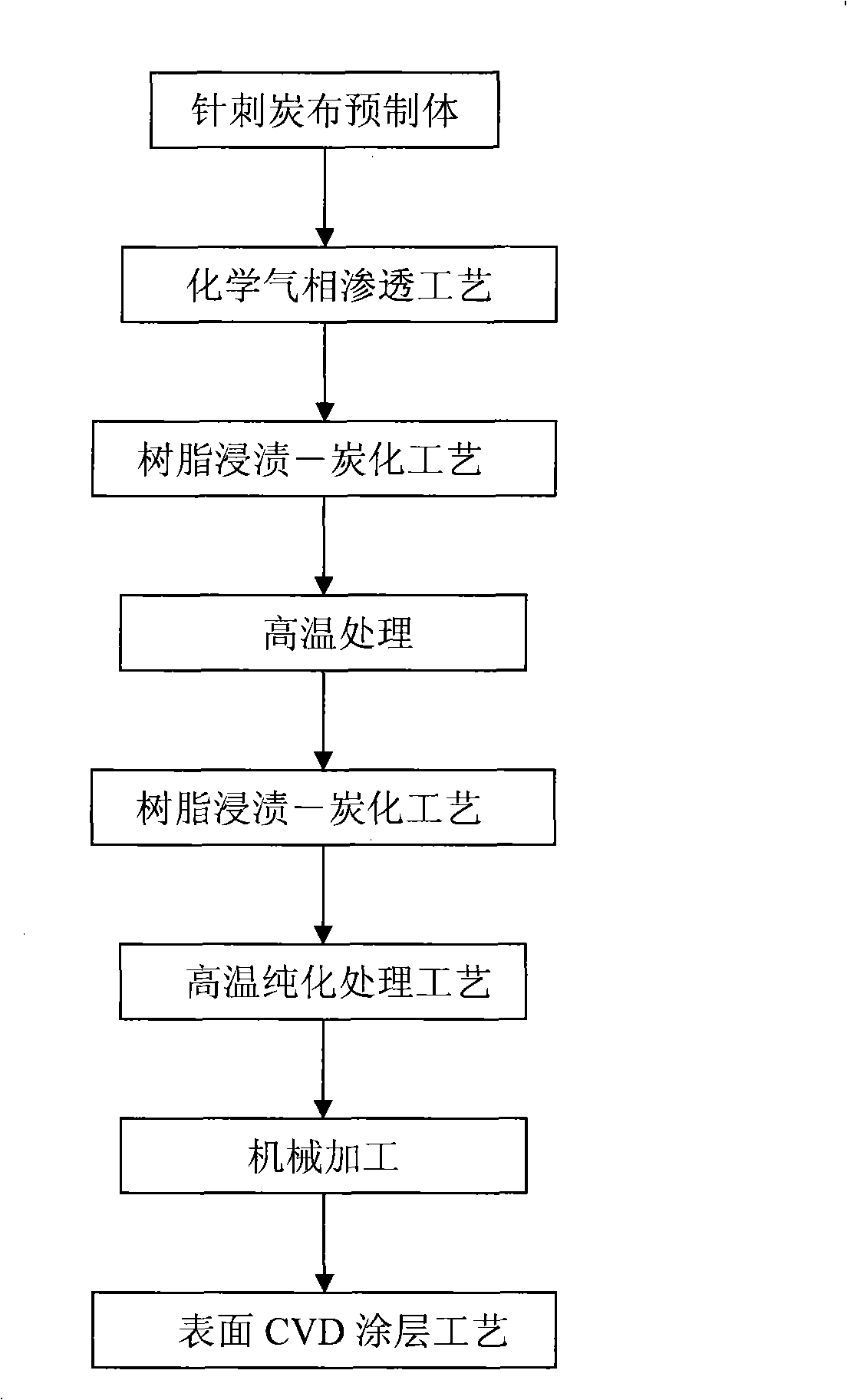

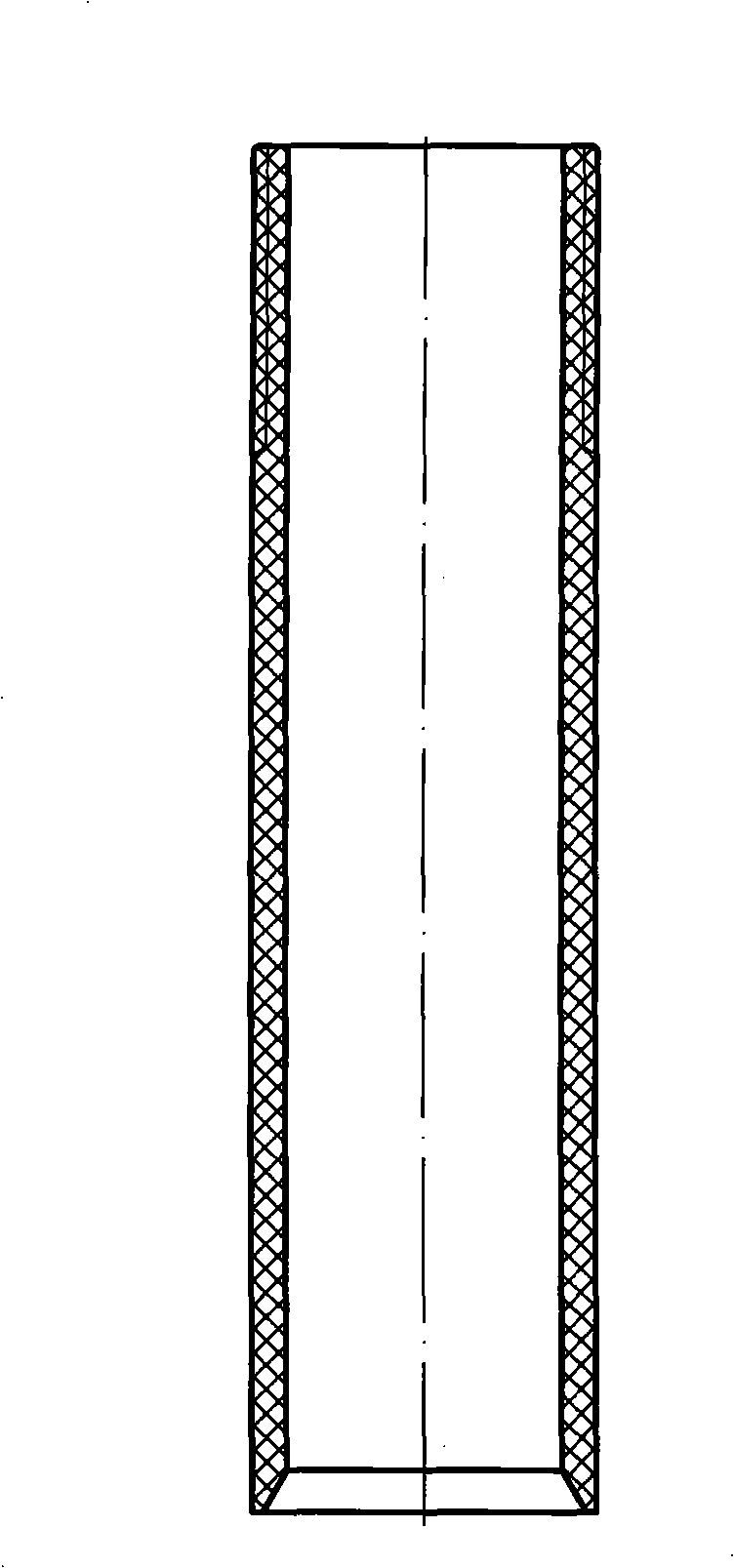

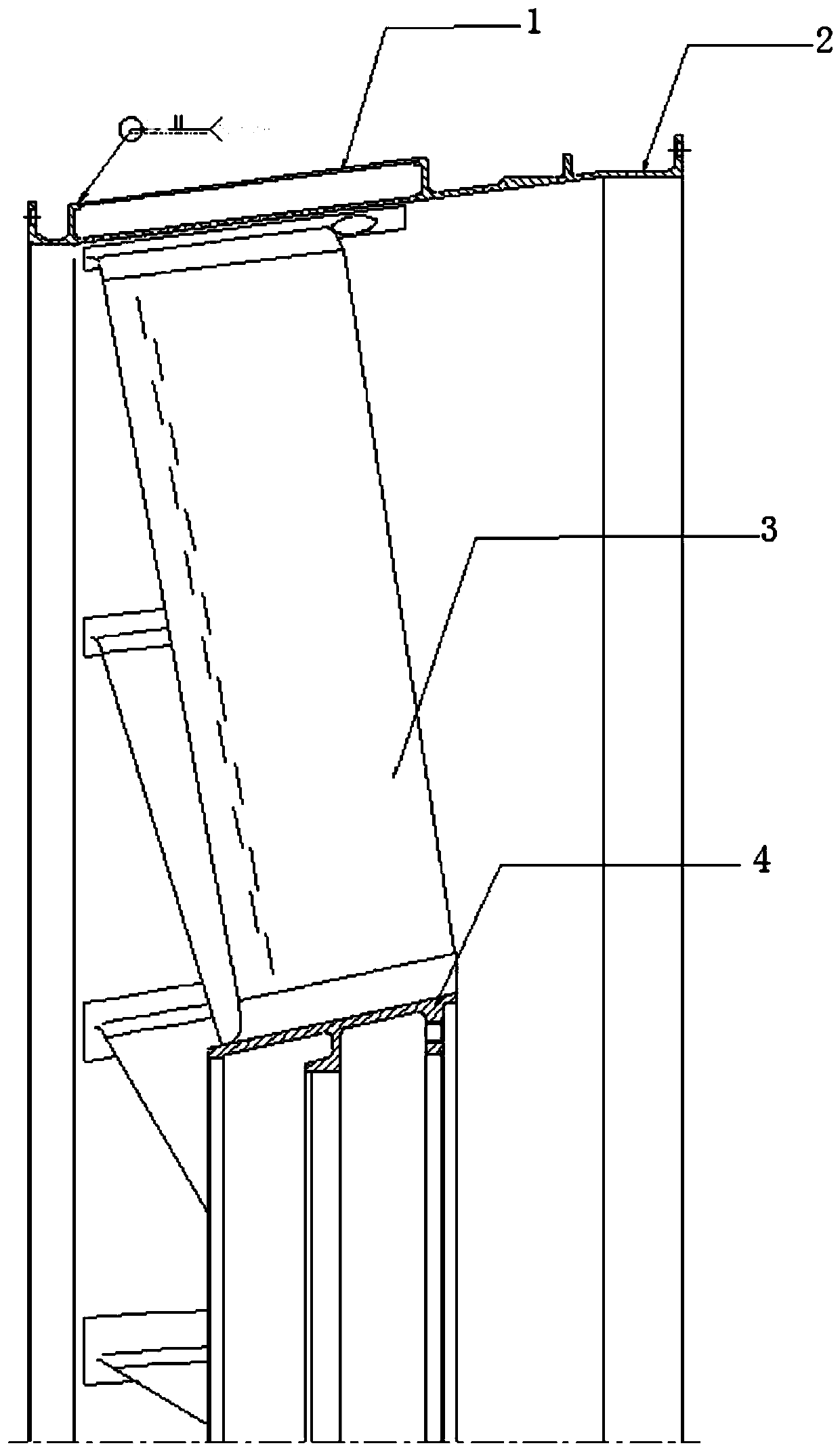

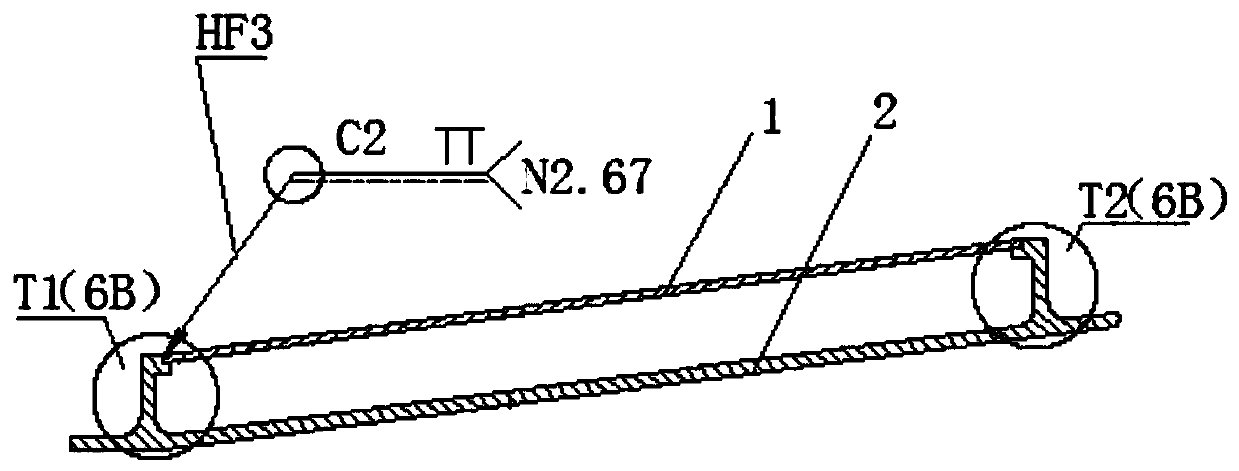

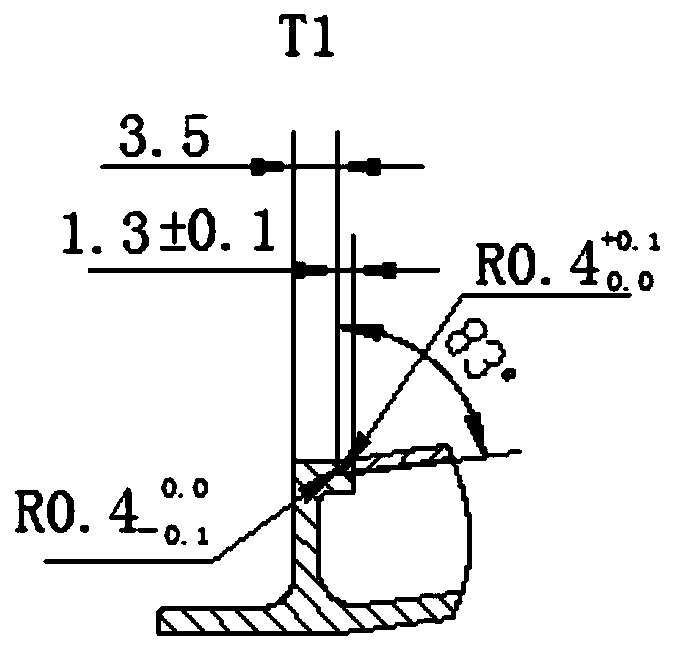

Method for preparing charcoal/charcoal air supply nozzle of high temperature furnace

ActiveCN101311143AHigh strengthThe strength is above 60Mpa, and the compressive strength is highPolycrystalline material growthSiliconGas phaseVolumetric Mass Density

The invention relates to a preparation method for carbon / a carbon nozzle of air supple used in a high temperature furnace, which adopts a needling plain carbon cloth prefabricated body with a pseudo-three-dimensional structure; the prefabricated body is densified by chemical gas-phase permeation and resin impregnation-charing for a plurality of times; the densified blank carries out high-temperature treatment at a certain temperature to increase opening percentage on the surface, and then densification treatment is further carried out; the resin impregnation-charing densification technique is adopted until the density is equal to or more than 1.75g / cm<3>, finally mechanical workout is carried out after high-temperature purification treatment, and the surface is treated with CVD coating to produce the carbon / the carbon nozzle of air supple. The method of the invention adopts the technique of the combination of chemical gas-phase permeation and resin impregnation-charing for densification to produce the material of the carbon / the carbon nozzle; when being applied to the nozzle of air supple in a polysilicon hydrogenation furnace, the material of the carbon / the carbon nozzle can effectively enhance the strength of the nozzle of air supple and scour resistance and corrosion resistance of the nozzle, prolong the service life of the nozzle and lower the replacing rate of the nozzle.

Owner:XIAN CHAOMA SCI TECH

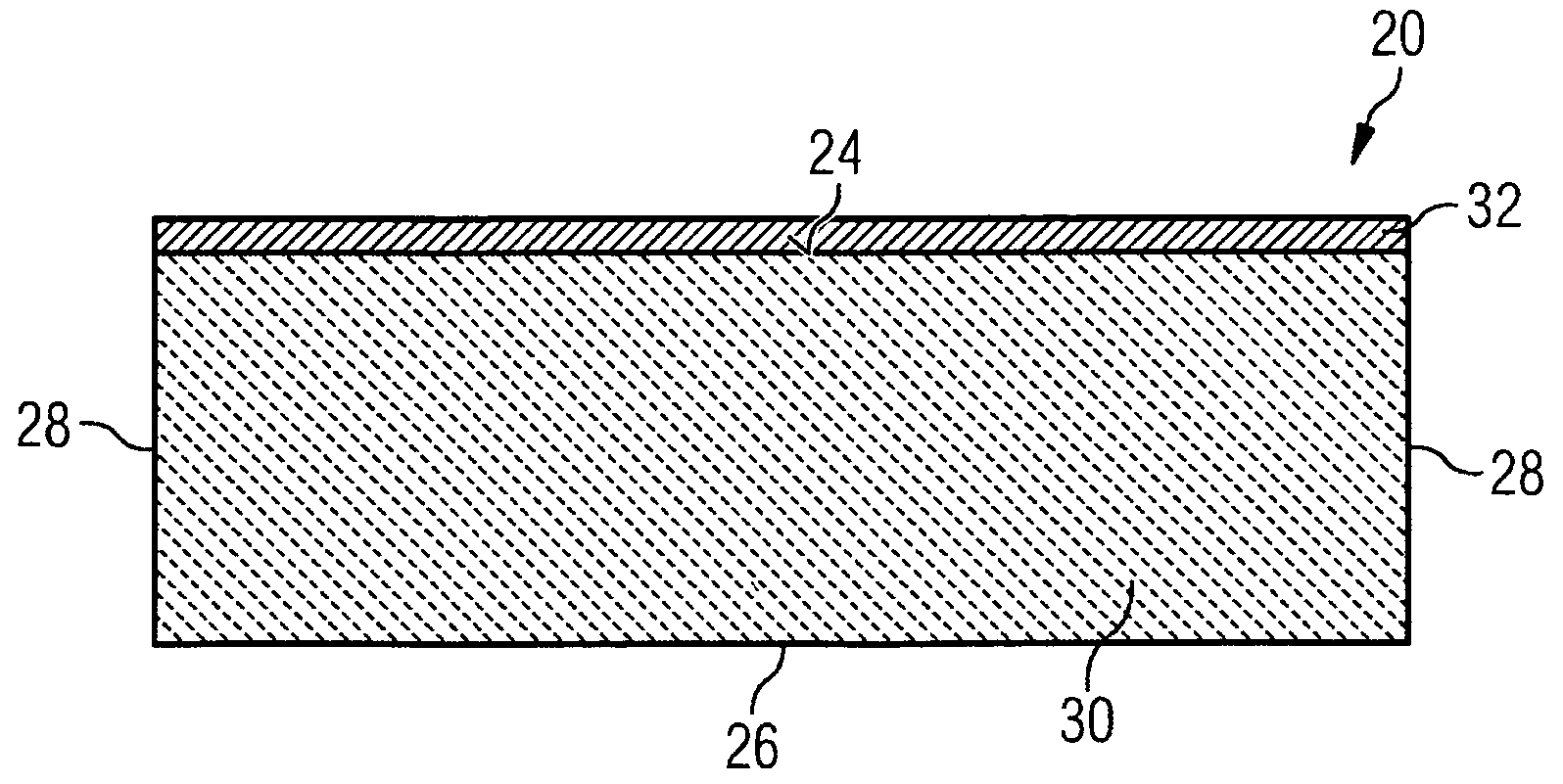

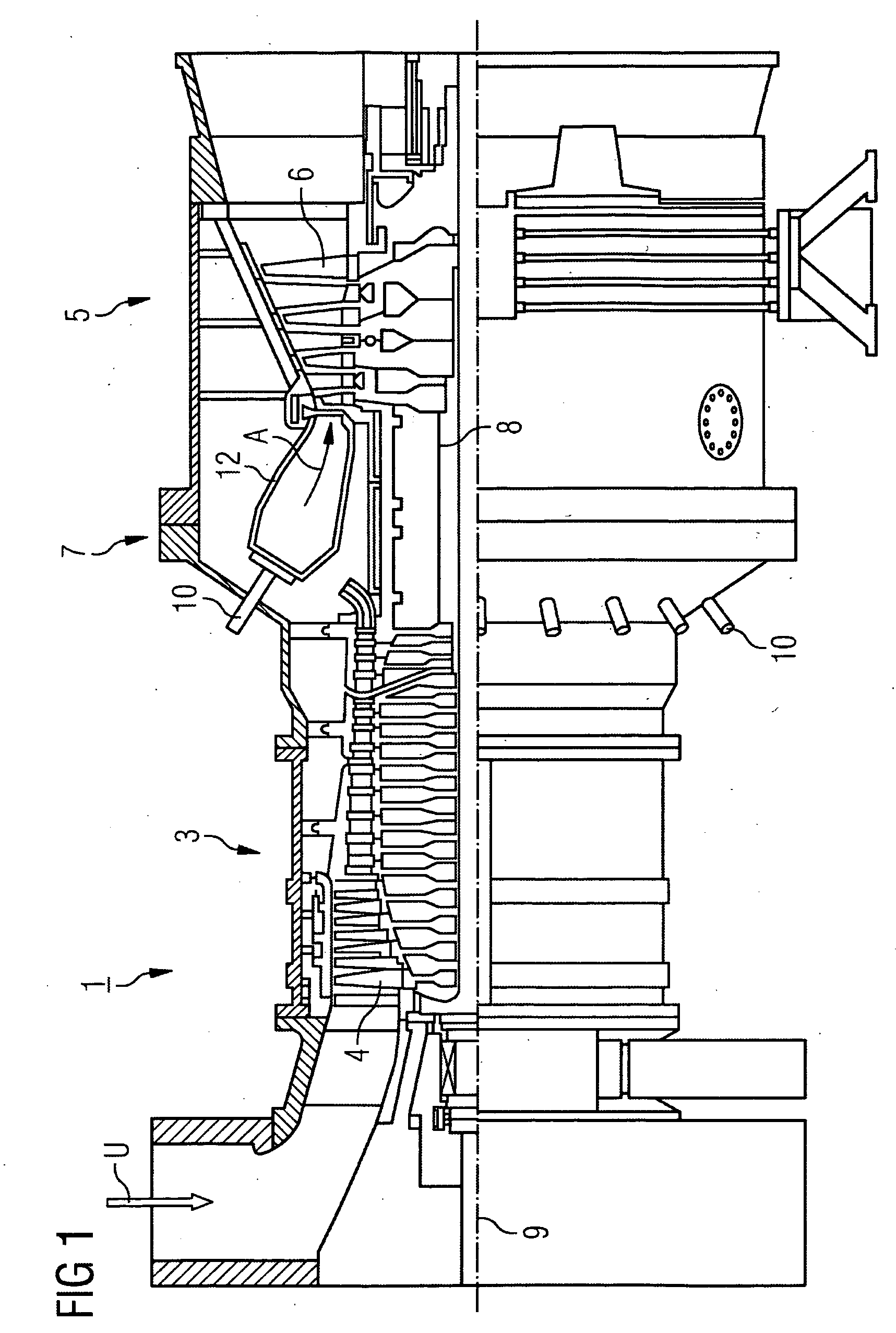

Ceramic Component With Surface Resistant To Hot Gas and Method for the Production Thereof

InactiveUS20090181257A1Improve resistance performanceExtended service lifeContinuous combustion chamberPretreated surfacesMetallurgyProduct gas

The invention relates to a ceramic component comprising a surface which is resistant to hot gas, and a method for the production thereof. Said ceramic component comprises a ceramic body and a surface which is resistant to hot gas. According to the invention, the surface which is resistant to hot gas is provided with a poorly reactive mineral coating.

Owner:SIEMENS AG

Preparation of quartz glass bodies with dew point monitoring in the melting oven

ActiveUS20190092675A1Reduce contentIncrease pointsPot furnacesGlass forming apparatusSilica particleLight guide

The invention relates to a process for the preparation of a quartz glass body comprising the process steps i.) Providing silicon dioxide particles, ii.) Making a glass melt out of the silicon dioxide particles in an oven and iii.) Making a quartz glass body out of at least part of the glass melt, wherein the oven has a gas outlet through which gas is removed from the oven, wherein the dew point of the gas on exiting the oven through the gas outlet is less than 0° C. The invention further relates to a quartz glass body which is obtainable by this process. The invention further relates to a light guide, an illuminant and a formed body, which are each obtainable by further processing of the quartz glass body.

Owner:HERAEUS QUARZGLAS

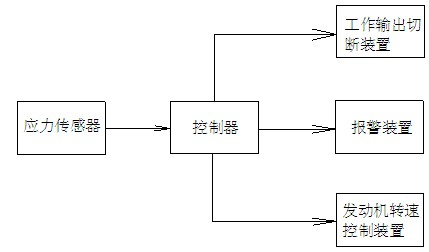

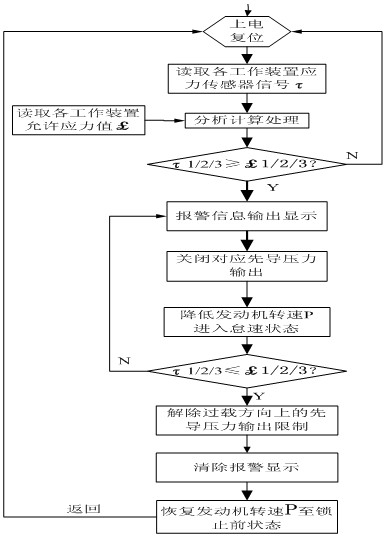

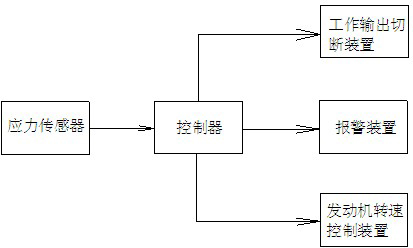

Overload protective system and method of excavator working devices and excavator

InactiveCN102677736AReduce excessive wearReduce replacement rateMechanical machines/dredgersIdle speedEngineering

The invention discloses an overload protective system and method of excavator working devices and an excavator, relating to the technical field of interference prevention of large machines. The system comprises a controller, a plurality of stress sensors, an engine rotating speed control device and an alarm device, wherein the controller is sequentially connected with the stress sensors; the controller is respectively connected with the engine rotating speed control device and the alarm device; and the aim of automatic adjustment for overload protection of the excavator working devices is achieved through comparing stresses allowed by all working devices with the actual stress values tau of all the working devices in working to judge whether the working devices overload, and then, cutting off pilot pressure, outputting alarm information, reducing engine rotating speed P to an idle speed state and the like on each working direction based on the judgment result. By using the overload protective system and method of the excavator working devices, the service life of each working device is prolonged, and therefore, the service life of the excavator is prolonged, the work efficiency of the excavator is increased, and the requirement for operating skills is lowered to a certain extent.

Owner:SHANGHAI SANY HEAVY IND

Replacement Shackle for Portable Lock

A group of embodiments for enabling the replacement of damaged shackles for multiple types of portable locks is disclosed. The embodiments have the ability to alter the shackle size and configuration for multiple types of portable locks by substituting one type of shackle with a different shackle, with no tools or special skills required.

Owner:MY TOUCH ID LLC

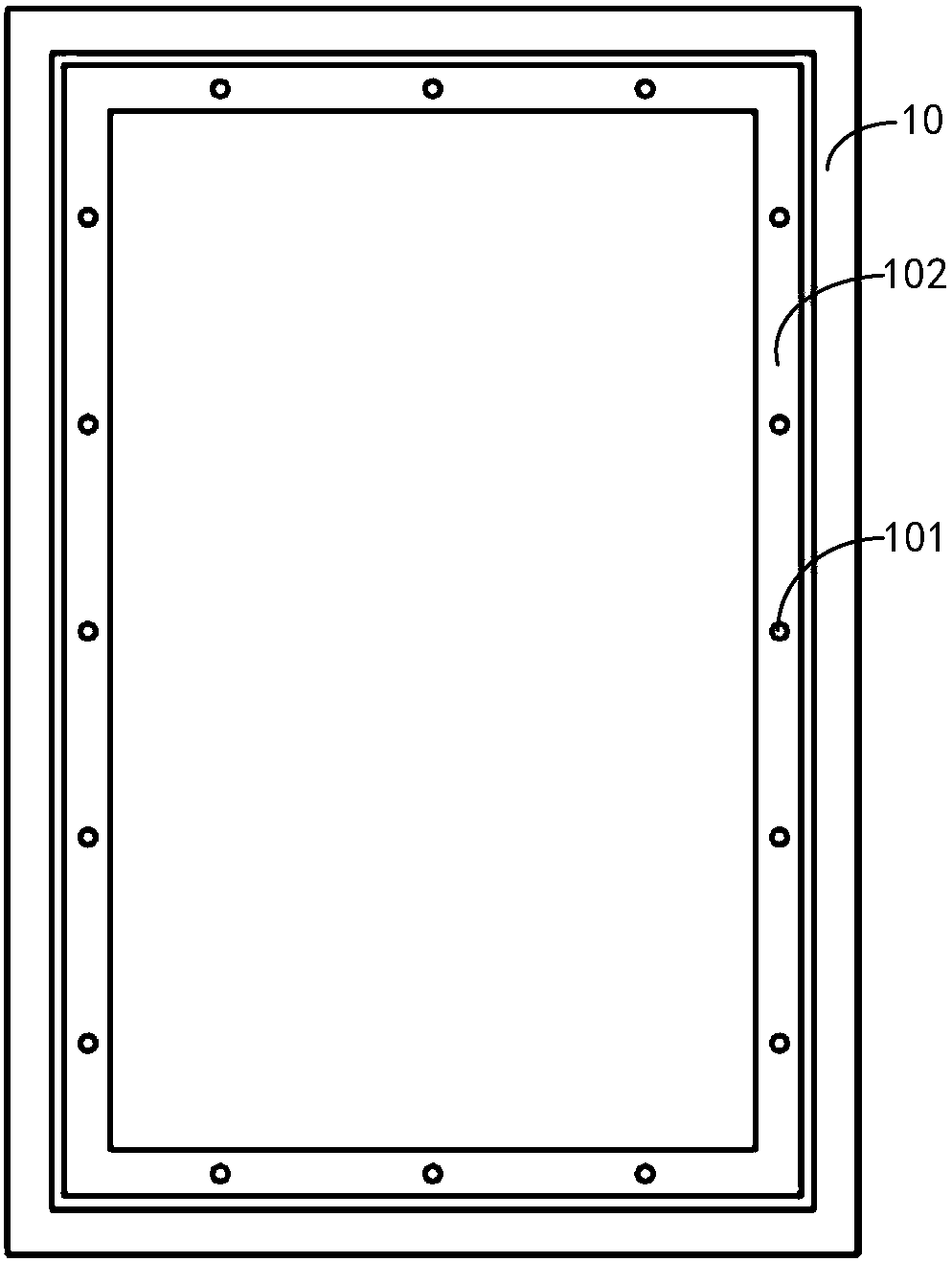

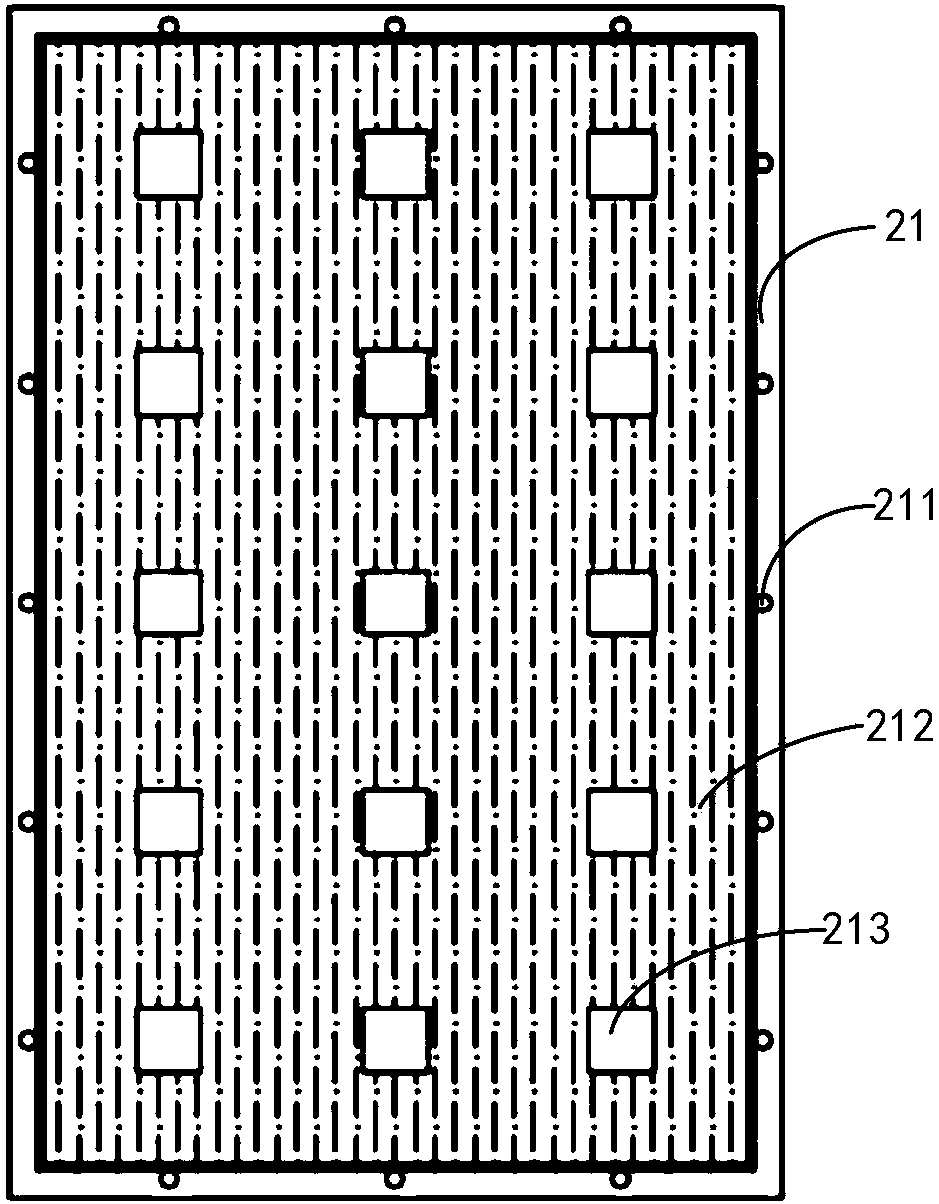

Mask assembly, mask frame and mask supporting frame

ActiveCN108034923ARealize multiple recyclingReduce replacement rateVacuum evaporation coatingSputtering coatingComputer science

The invention discloses a mask assembly, a mask frame and a mask supporting frame. The mask assembly comprises the mask frame and the mask supporting frame; the mask frame comprises at least one firstconnecting part; the mask supporting frame comprises at least one second connecting part; and the mask frame is detachably connected with the mask supporting frame through the at least one first connecting part and the at least one second connecting part. The mask assembly comprises the mask frame and the mask supporting frame which are detachably connected, when the mask assembly is replaced, the size of the mask frame is not changed, so that the mask frame can be directly recycled simply by replacing the mask supporting frame. Repeated recycling of the mask frame can be realized, the replacement rate of the mask frame is lowered and the production cost is lowered.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

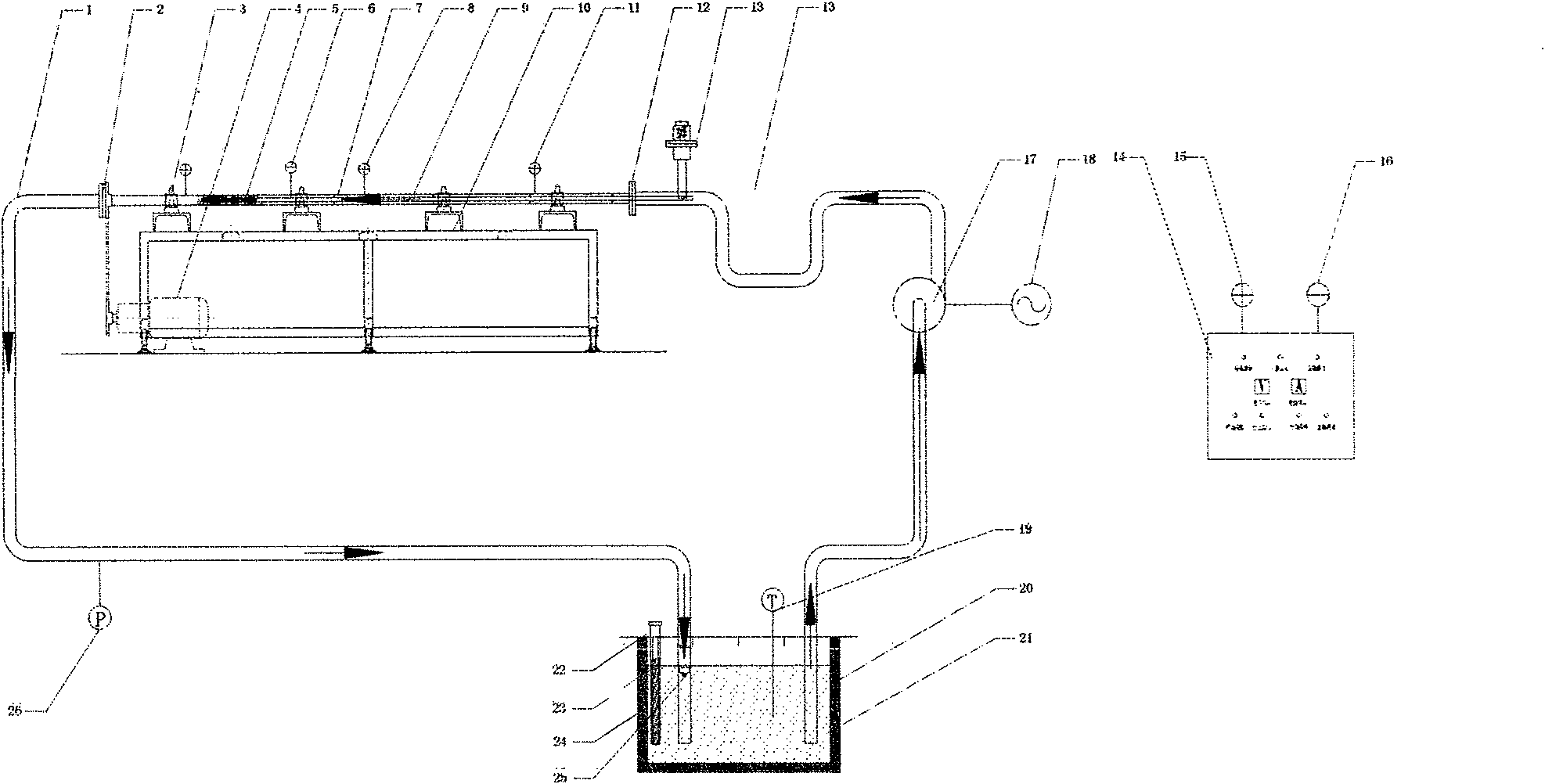

Electrolytic polishing solution circulating device used for electrolytic polishing of stainless steel inner tube

InactiveCN102864489AFlow timelyConsistent processing parametersElectrolysis componentsEnergy preservationElectrolysis

The invention relates to the electrolytic polishing treatment of a stainless steel inner tube, a circulating mode is used for forcing the gas out through the stainless steel tube, so that the influence of the gas on the electrolytic polishing of the inner wall can be completely avoided, the garbage generated by the electrolytic polishing can be removed through the high pressure flow circulating, and the influence on the electrolytic polishing can be avoided. The flow amount of the electrolytic polishing solution can be adjusted for the stainless steel tubes with different calibers and lengths; by the stepless speed regulation of a frequency converter, the revolution of a circulating pump can be regulated, thereby the stepless output of the flow of the electrolytic polishing solution can be carried out. A heating device, a cooling device and an insulation device are provided with a turnover box of the electrolytic polishing solution, the electrolytic polishing solution temperature can be timely adjusted to a reasonable treatment scope; a filtering device is provided in the turnover box, and the quality of the electrolytic polishing solution can be guaranteed; an inhalation device is provided at the upper part of the turnover box, and the gas generated during the processing is absorbed and conveyed into an exhaust-gas treatment apparatus. The electrolytic polishing solution is the environment-friendly type medicinal liquid, compared with a traditional electrolytic polishing solution, the electrolytic polishing solution provided by the invention has the advantages of less power consumption and energy preservation.

Owner:SHANGHAI MINOW SMOOTH IND TRADE

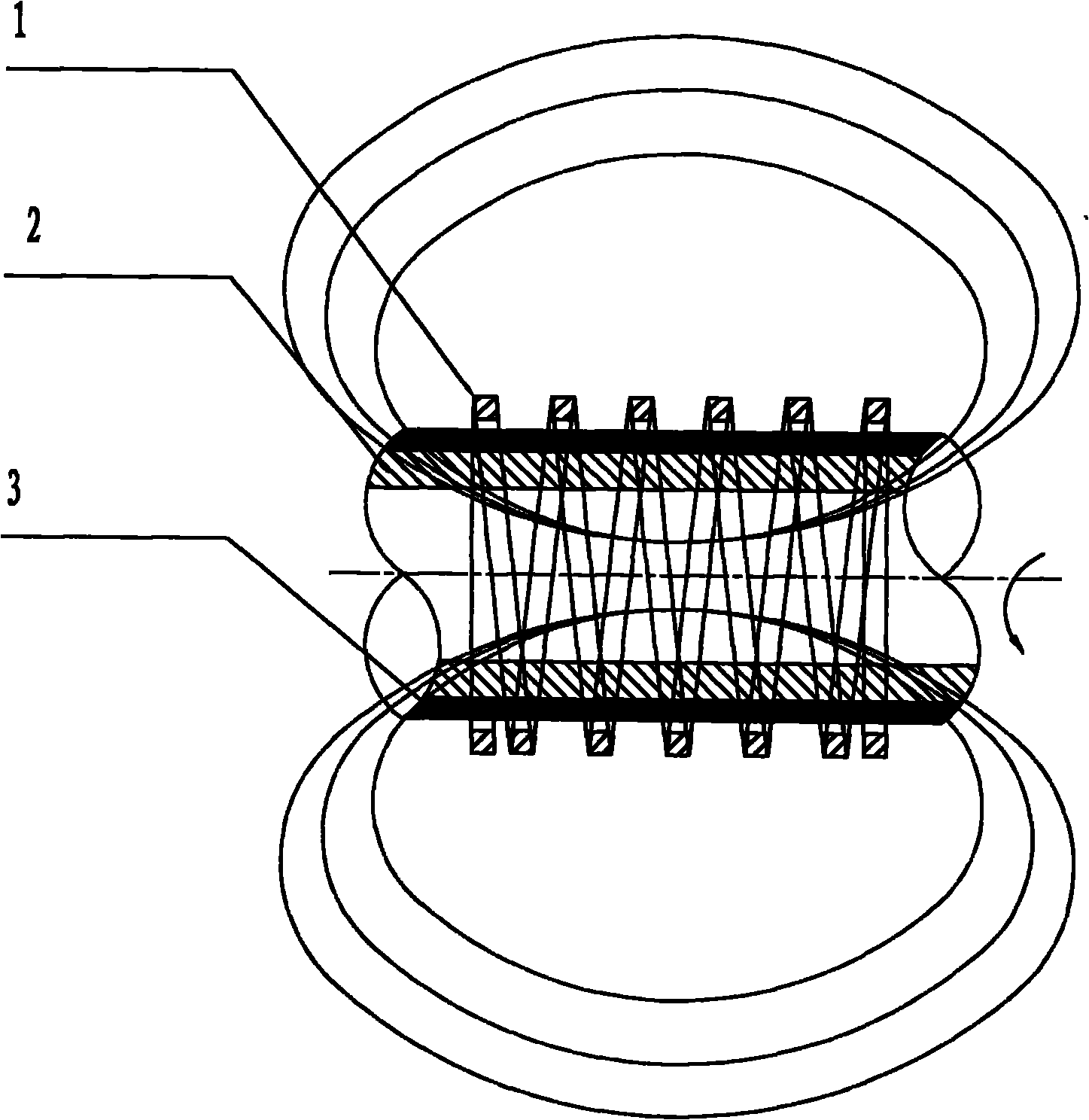

Process for manufacturing hard alloy coating

InactiveCN101864551AHigh hardnessReduce replacement rateMolten spray coatingCarbide coatingInduction heater

The invention discloses a process for manufacturing a hard alloy coating, which comprises the following steps of: 1) coarsening the surface of a workpiece basal body; 2) preheating the workpiece basal body, namely heating the workpiece basal body through electromagnetic induction, wherein the power of a power supply is 60 to 100 kw, the frequency is 2,000 to 10,000 Hz, an induction heater has 1 to 10 turns of coils, the temperature is between 150 and 360 DEG C after heating for 10 to 30 minutes; 3) spraying the hard alloy coating, namely spraying the hard alloy coating on the workpiece basal body, wherein the oxygen pressure is 0.1 to 0.5 MPa, the acetylene pressure is 0.01 to 0.05 MPa, the spraying distance is 150 to 230 mm, and the spraying temperature is between 250 and 300 DEG C; and 4) performing remelting, namely heating up a workpiece through the electromagnetic induction, wherein the power of the power supply is 60 to 100 kw, the frequency of the power supply is 2,000 to 10,000 Hz, the induction heater has 1 to 10 turns of the oils, and the workpiece is heated to the temperature of between 900 and 1,150 DEG C. By the process for manufacturing the hard alloy coating, a compact, high-hardness, high-abrasion and corrosion resistant hard alloy coating can be formed.

Owner:ANHUI TIANYI HEAVY IND

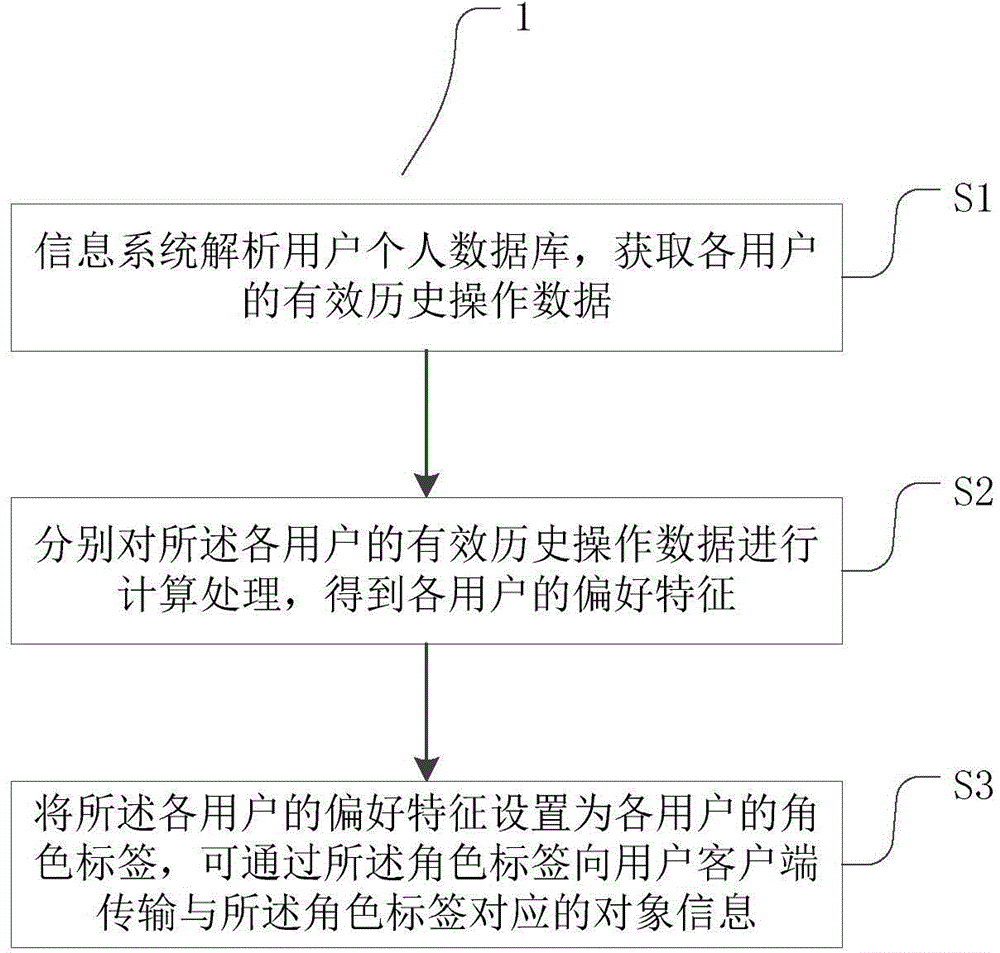

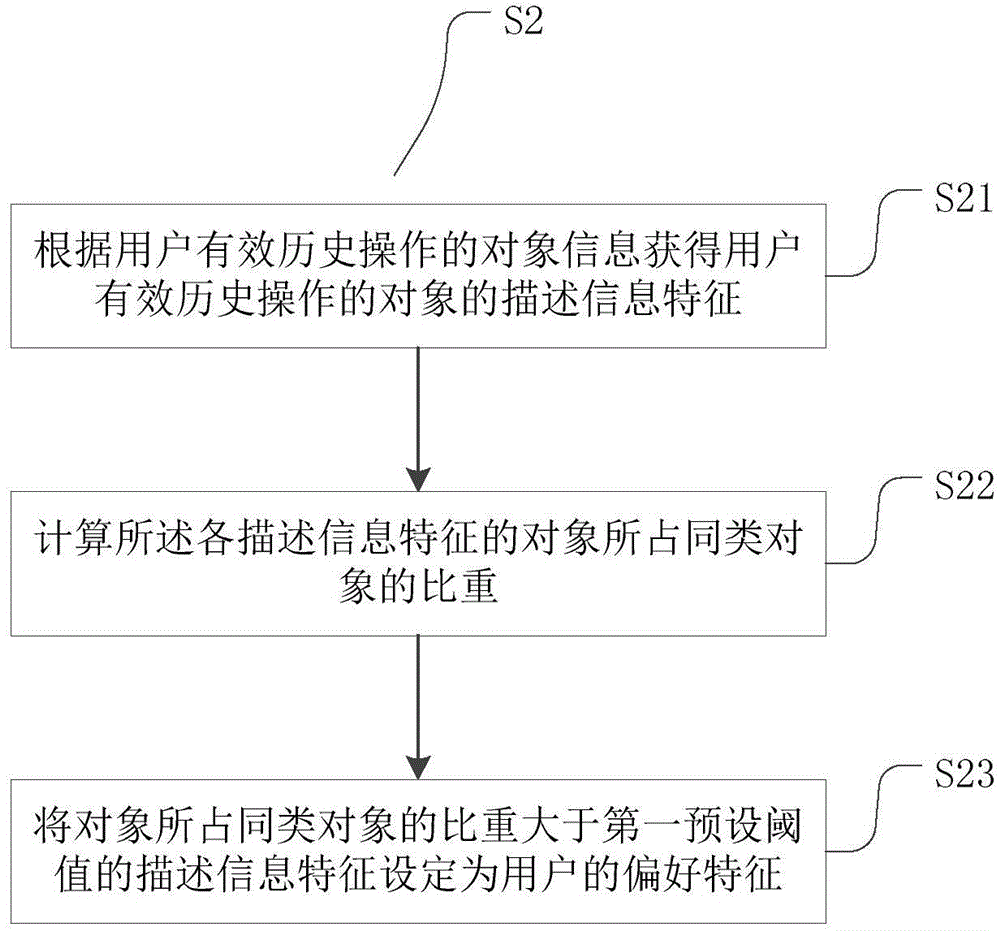

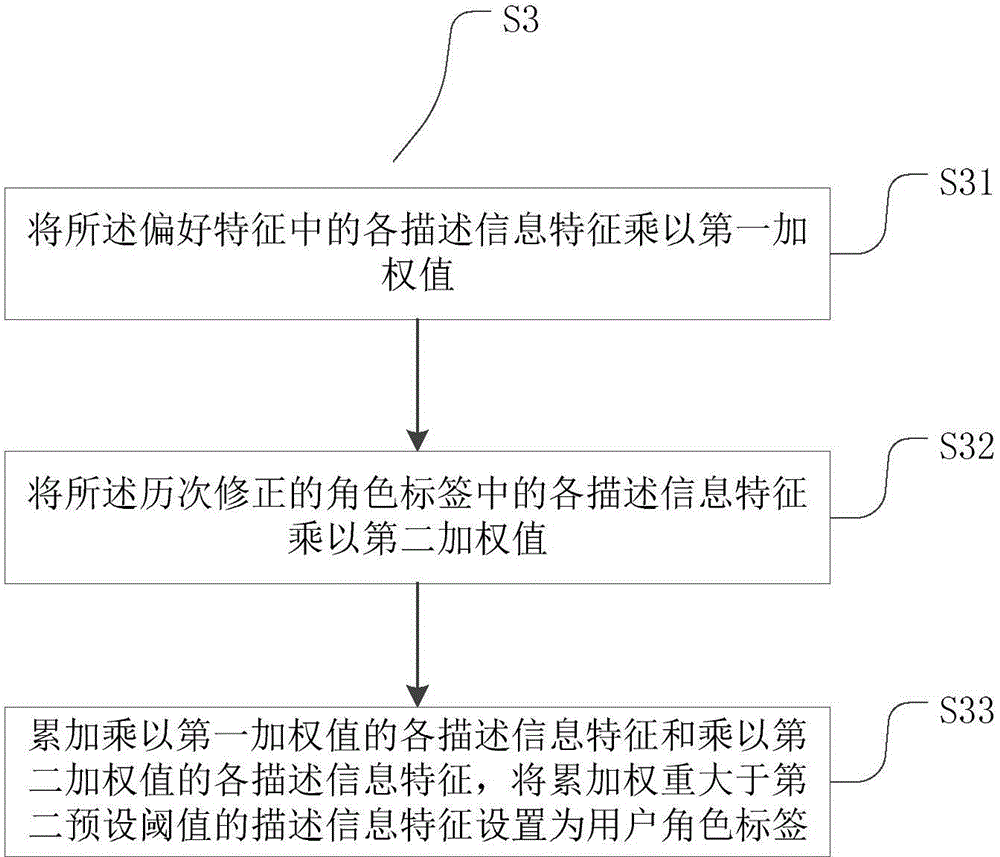

Method and device for setting user label in information system

InactiveCN105653543AReduce search timeShorten the timeSpecial data processing applicationsClient-sideData mining

The invention provides a method and device for setting a user label in an information system. The method includes: analyzing personal databases of users to acquire valid historical operating data of all the users; respectively performing calculation and treatment on the valid historical operating data of all the users to obtain preference characteristics of all the users; and setting the preference characteristics of all the users as role labels of all the users, and transmitting object information corresponding to the role labels through a client. The method can perform role label setting on the users, the object information can be transmitted to the user client according to the role labels of the users, and the time that the users search the objects can be saved.

Owner:ADVANCED NEW TECH CO LTD

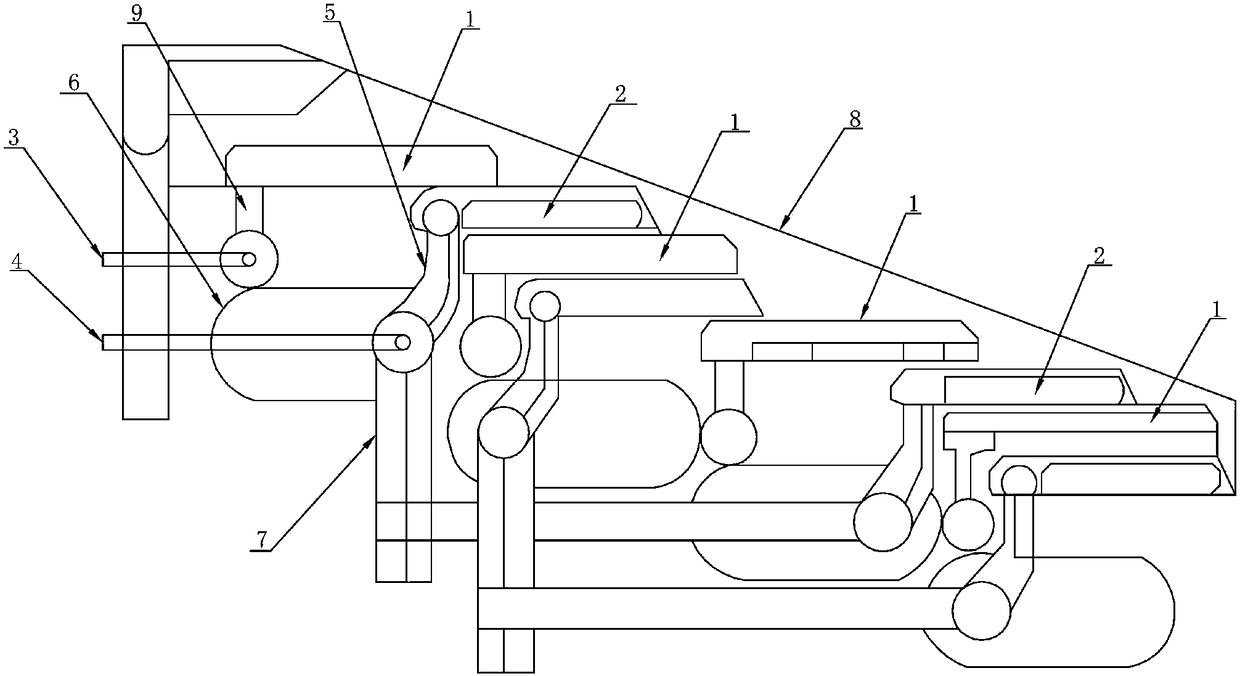

Electron beam welding method of thin-walled casing gas-collecting hood structure

ActiveCN110977170AHigh welding power densityImprove power densityLaser beam welding apparatusWelding residual stressEngineering

The invention provides an electron beam welding method of a thin-walled casing gas-collecting hood structure, and belongs to the technical field of gas-collecting hood welding. The electron beam welding method comprises the following steps of: step 1, designing a welding structure; step 2, performing the single-piece processing of a gas-collecting hood 1; and step 3, welding the gas-collecting hood 1. A gas-collecting hood heat shaping fixture in step 2. 6 comprises a tire 5, a pressure ring 6, pins 7, wedge blocks 8, and a hanger 9, wherein the hanger 9 is welded on the inner surface of the tire 5; the pressure ring 6 is arranged on the top of the tire 5; the wedge blocks 8 are uniformly arranged on the top of the pressure ring 6 in the circumferential direction and are in one-to-one correspondence with through holes of the pressure ring 6; and the pins 7 sequentially pass through the wedge blocks 8 and the pressure ring 6 to fix the pressure ring 6 and the tire 5. The electron beam welding method reduces the welding residual stress and the welding deformation, and improves the quality of parts through the design of the welding structure, the design and process improvement of thegas-collecting hood heat shaping fixture, and the improvement of the welding process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

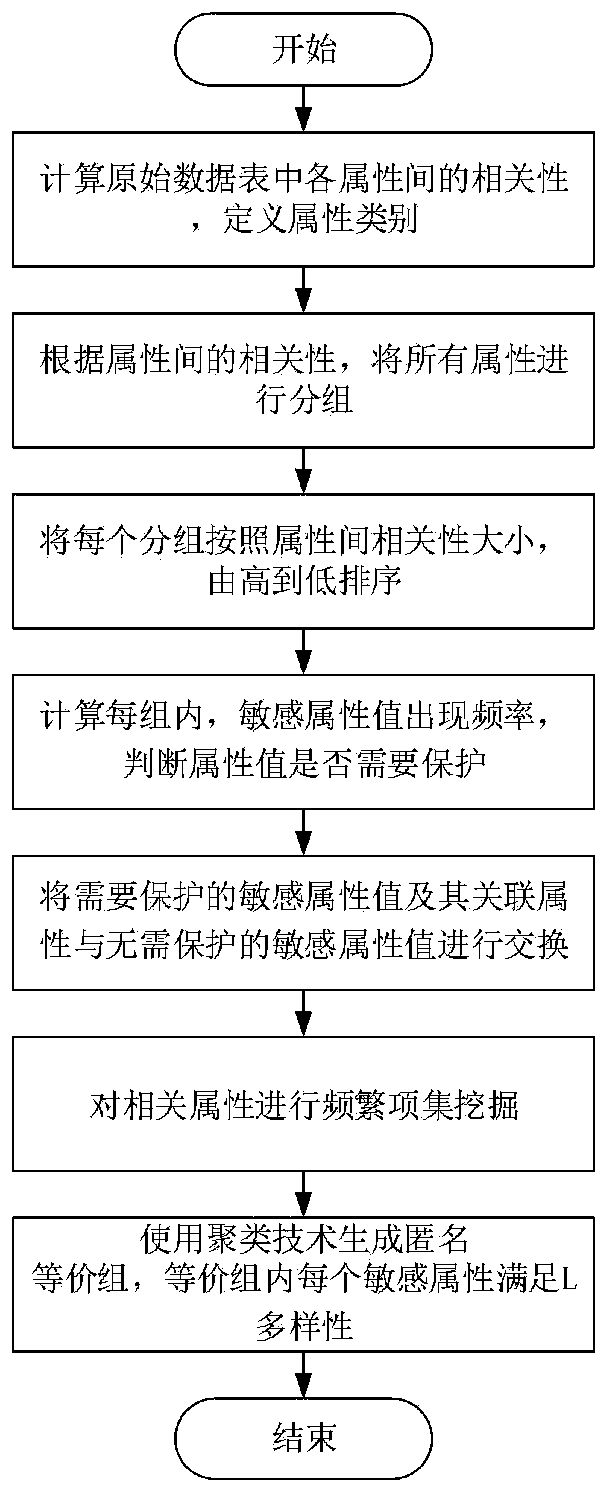

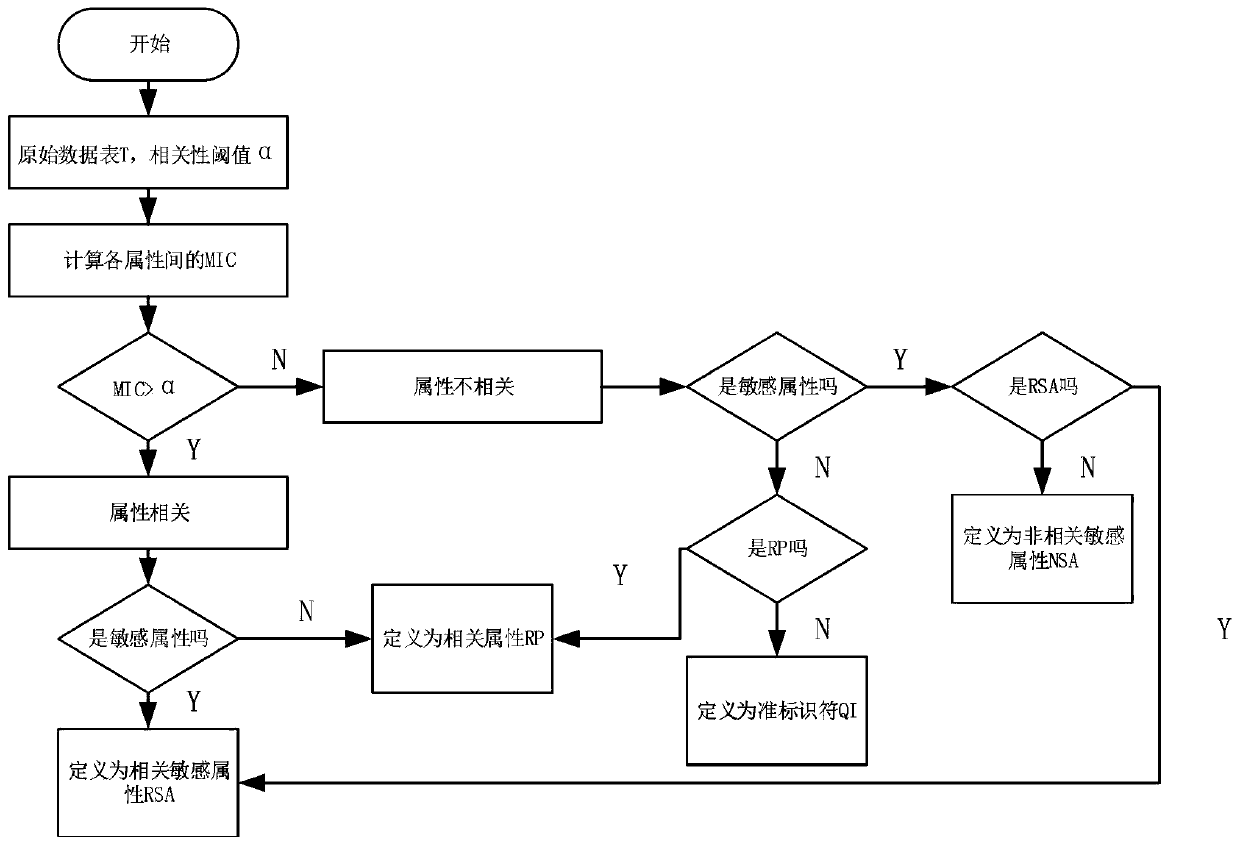

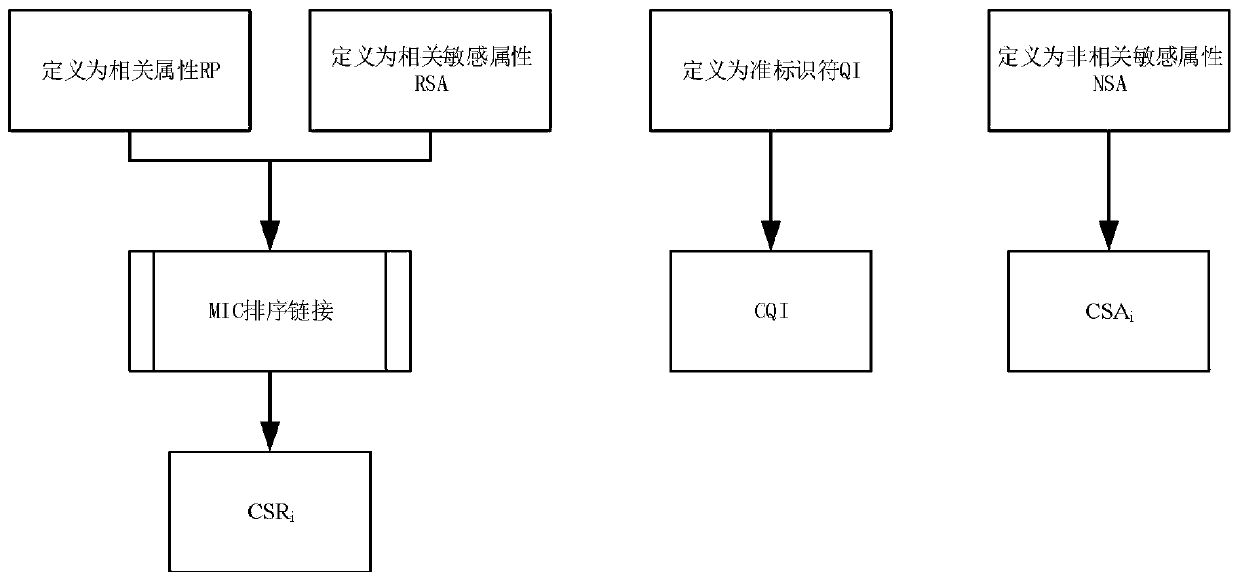

Anonymous privacy protection method for multi-sensitive attribute data release

ActiveCN110659513AAvoid destructionGuaranteed stabilityDigital data protectionOriginal dataPrivacy protection

The invention discloses an anonymous privacy protection method for multi-sensitive attribute data release. The method comprises the steps of 1, calculating correlation among attributes in an originaldata table, and defining attribute categories; 2, grouping all the attributes according to the correlation among the attributes; 3, sorting the groups from high to low according to the correlation among the attributes; 4, calculating the occurrence frequency of the sensitive attribute values in each group, and judging whether the attribute values need to be protected or not; 5, exchanging the sensitive attribute value needing to be protected and the associated attribute thereof with the sensitive attribute value needing not to be protected; 6, performing frequent item set mining on the relatedattributes; and step 7, generating an anonymous equivalent group by using a clustering technology, wherein each sensitive attribute in the anonymous equivalent group satisfies L diversity. By reducing the anonymity rate and jointly replacing the associated attributes, the availability of the data is improved while the privacy protection strength is ensured.

Owner:HARBIN ENG UNIV

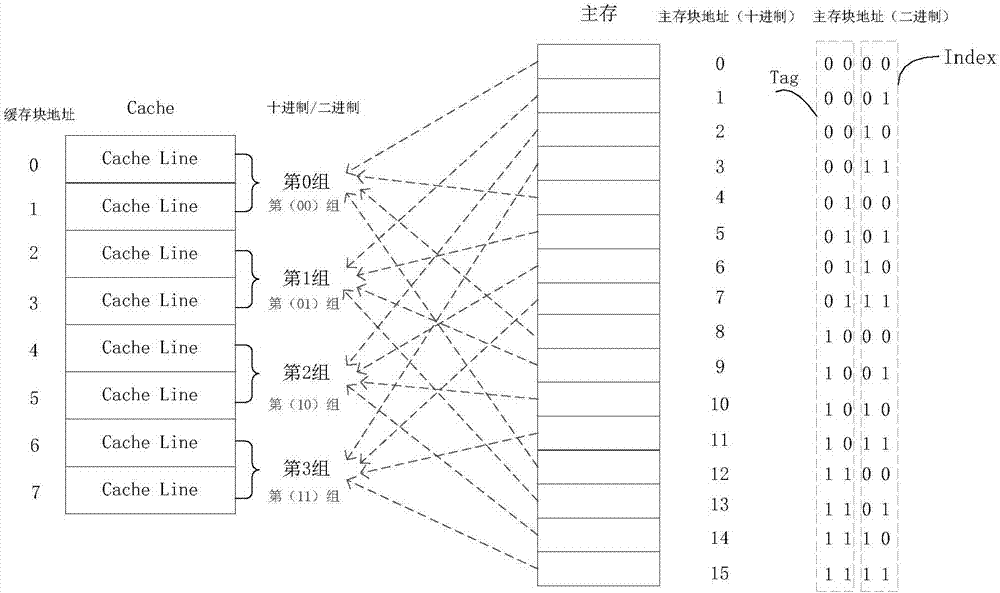

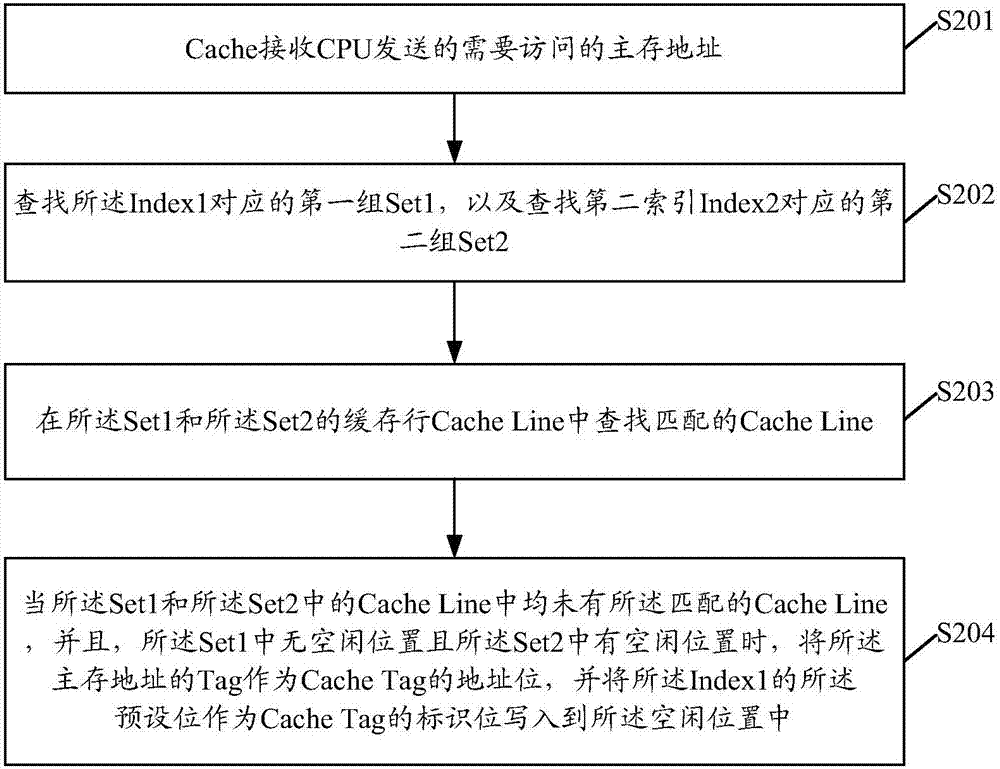

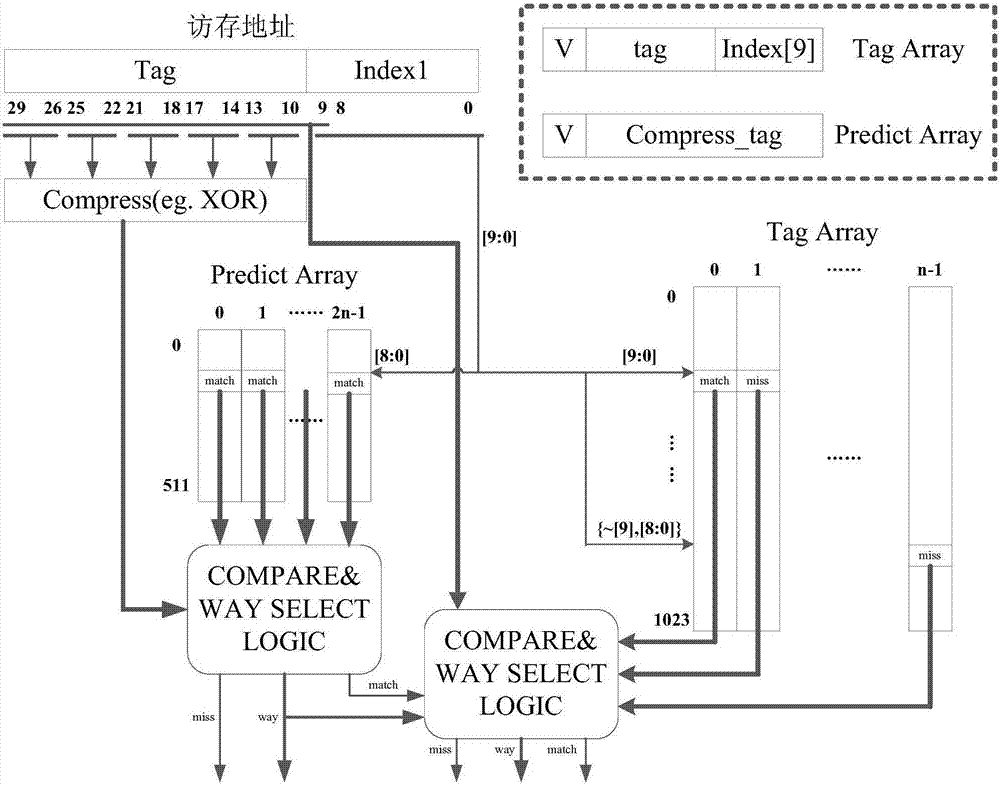

Cache processing method and device

ActiveCN107291630ASpeed up readingSpeed up writingEnergy efficient computingMemory systemsMemory addressParallel computing

The embodiment of the invention discloses a cache processing method and device. The method can comprise the following steps that: Cache receives a main memory address sent from a CPU (Central Processing Unit), wherein the main memory address comprises a Tag and an Index 1; and a Set1 corresponding to the Index1 is searched, and a Set2 corresponding to an Index2 is searched; and a matched Cache Line is searched in the Cache Line of the Set1 and the Set2. When the method is adopted, power consumption expenditures during Cache deficiency can be lowered, and Cache performance is improved.

Owner:HUAWEI TECH CO LTD

Integrated water-cooled grate

InactiveCN108443892AReduce replacement rateSolve the problem that the connection cannot be sealed wellHollow bar grateIncinerator apparatusHydraulic cylinderEngineering

The invention discloses an integrated water-cooled grate. Fixed water-cooled grate bodies and movable air-cooled grate bodies are arranged on a machine body. Each movable air-cooled grate body is arranged between every two fixed water-cooled grate bodies, the movable air-cooled grate bodies are positioned above or below the fixed water-cooled grate bodies, the fixed water-cooled grate bodies and the movable air-cooled grate bodies are alternately arranged, a water-cooled grate support frame is arranged below each fixed water-cooled grate body, an air-cooled grate support mechanism is arrangedon the lower part of each movable air-cooled grate body, a hydraulic actuating mechanism is arranged on the side face of each movable air-cooled grate body, and a hydraulic cylinder is arranged at thelower end of each hydraulic actuating mechanism. According to the integrated water-cooled grate, the problem that the connection between a movable water pipe which is connected with a current water-cooled grate and moves along with the current water-cooled grate and a fixed water cannot be well sealed due to the motion / movement of the current water-cooled grate is solved, and the problems of leakage of cooling water and high cost caused by the high breakage and replacement rate of water-cooled grate segments are solved. Due to the adoption of the grate segments of the integrated water-cooledgrate, the replacement rate of the grate segments can be reduced by 2 / 3.

Owner:西格斯先进技术有限公司

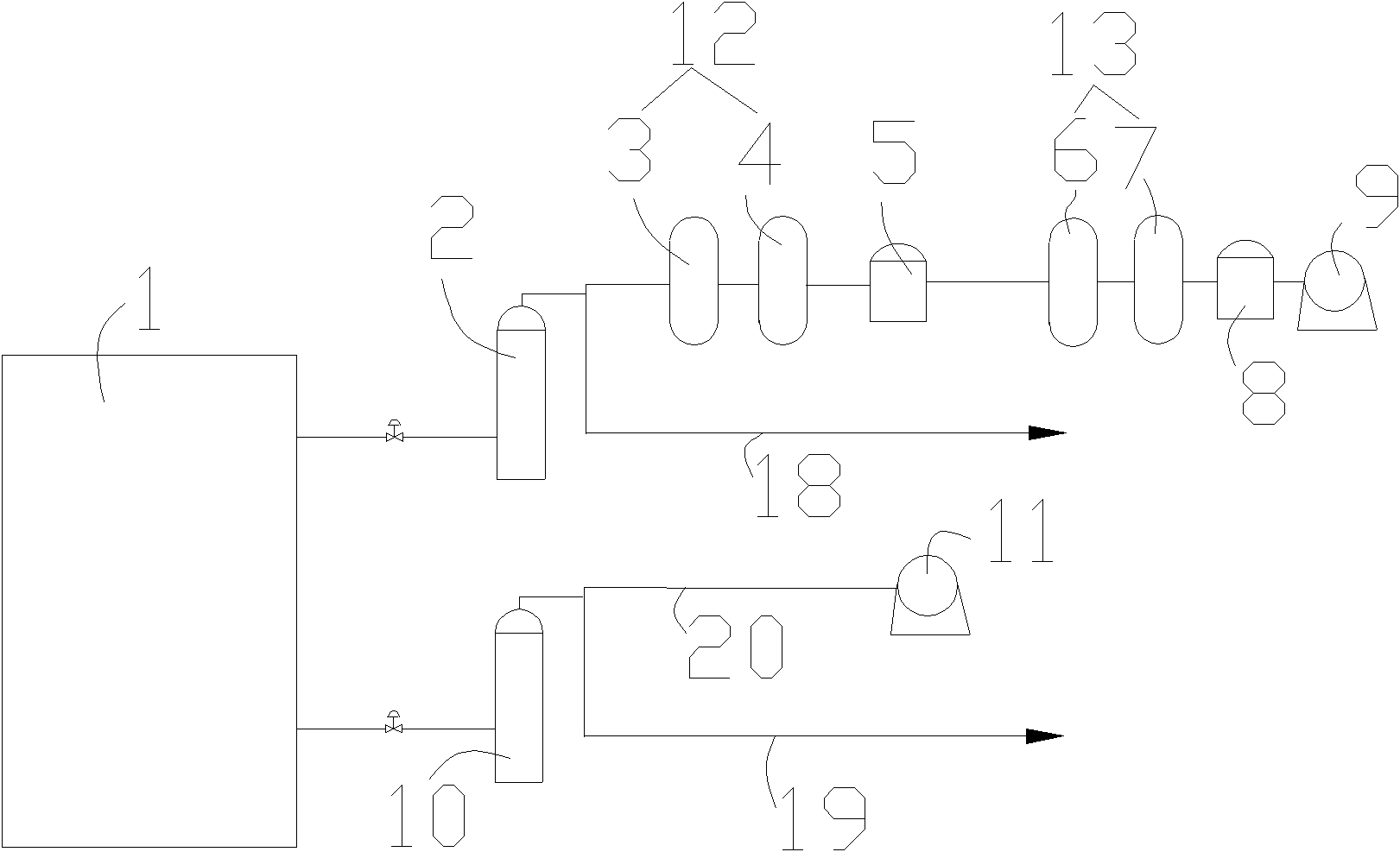

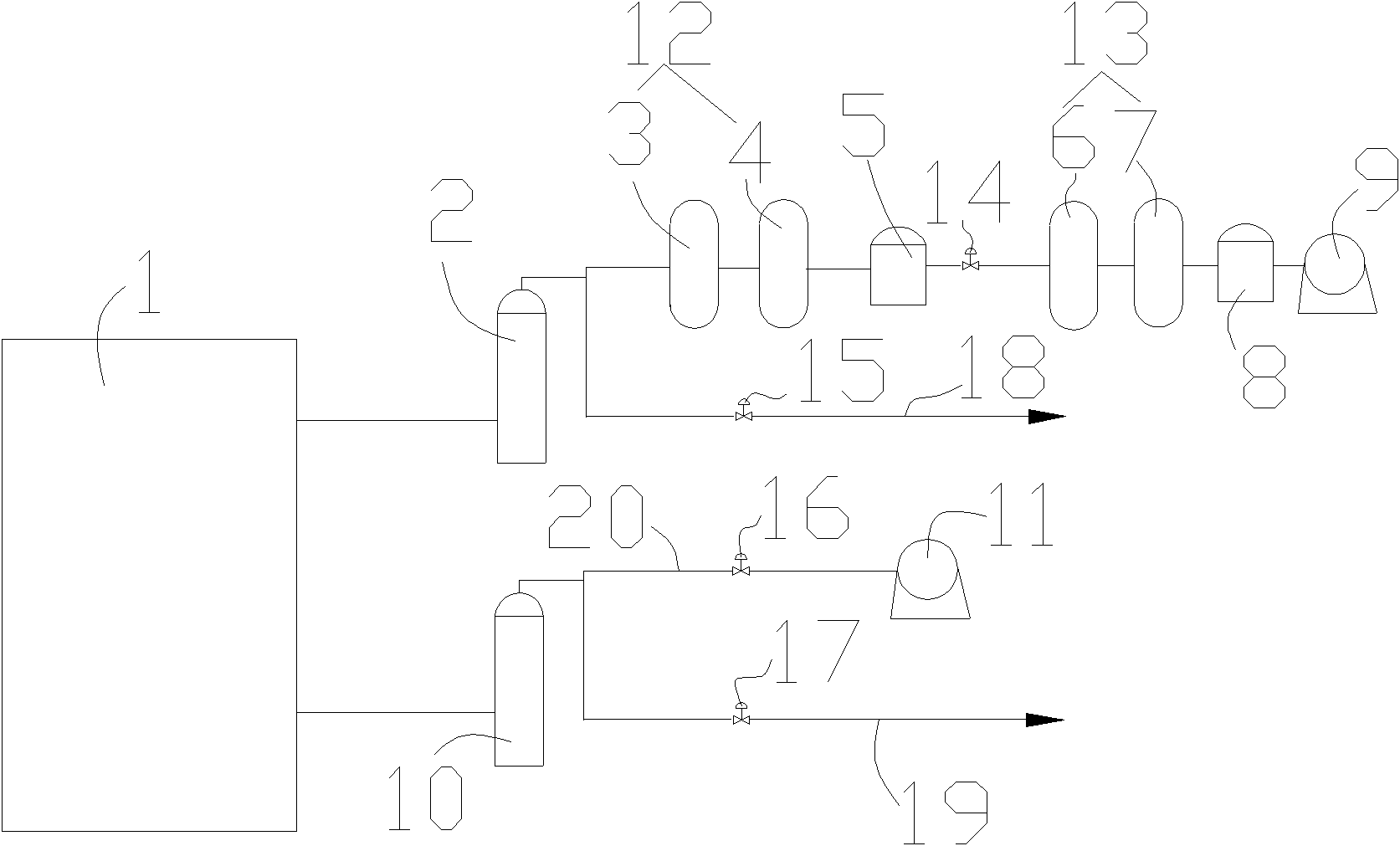

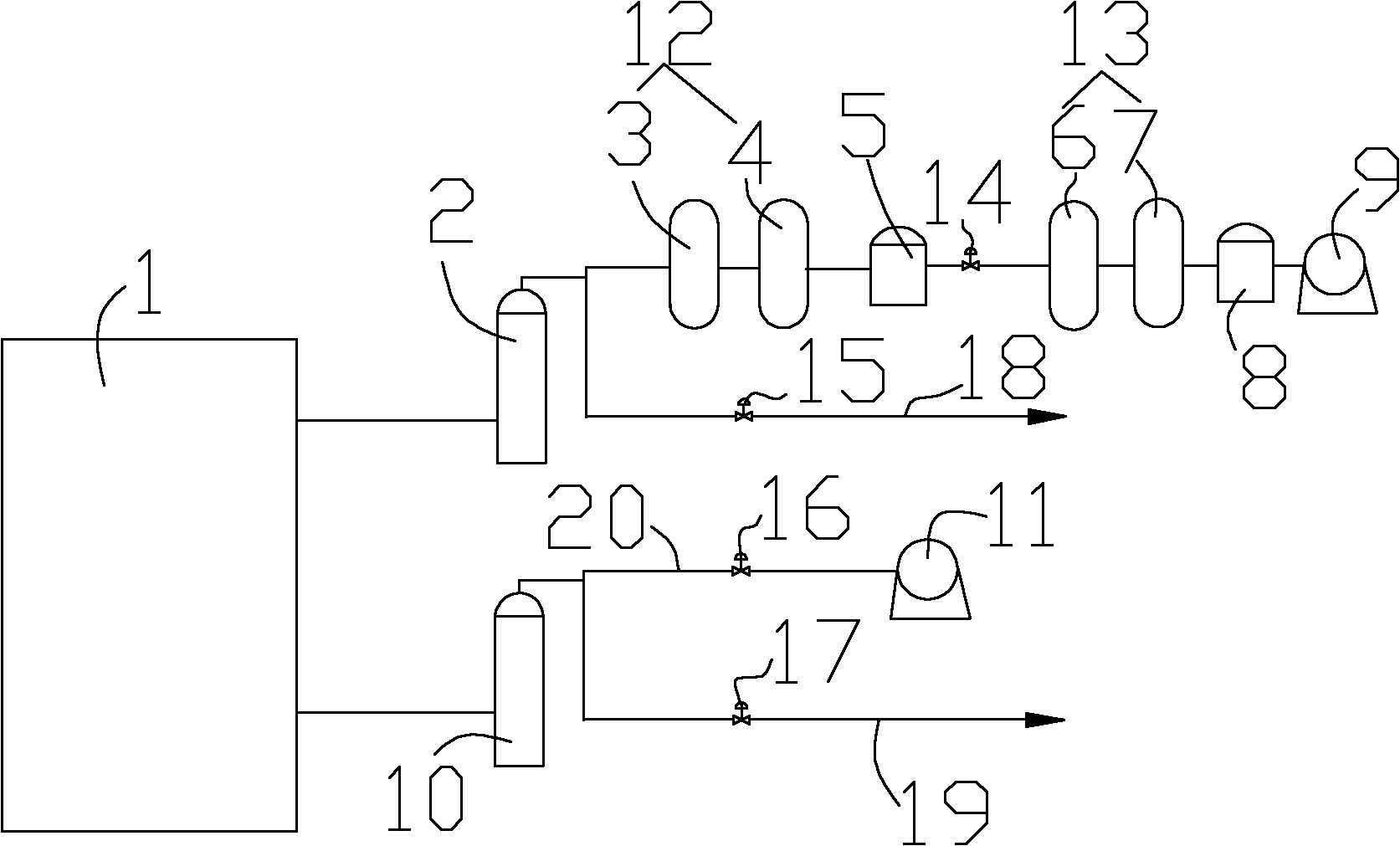

Electrolysis system with ion membrane electrolyzer and pressure regulating method thereof

ActiveCN102424980AReduce air pressure fluctuationsSo as not to damageCellsElectrolysisHydrogen pressure

The invention discloses an electrolysis system with an ion membrane electrolyzer and a pressure regulating method thereof. The gas pressure fluctuation in the ion membrane electrolyzer is small when the chlorine pressure and hydrogen pressure in the ion membrane electrolyzer are regulated. The electrolysis system mainly adopts a chlorine pressure regulating device and a hydrogen pressure regulating device for adjustment, the chlorine pressure regulating device comprises a first chlorine regulating valve on a pipeline between a water trap and a drying device and a second chlorine regulating valve on a waste gas recycling branch pipe; and the hydrogen pressure regulating device comprises a first hydrogen regulating valve arranged between a hydrogen washing tower and a hydrogen compressor on a hydrogen recycling branch pipe and a second hydrogen regulating valve arranged on a hydrogen emptying branch pipe.

Owner:LUZHOU NORTH CHEM IND

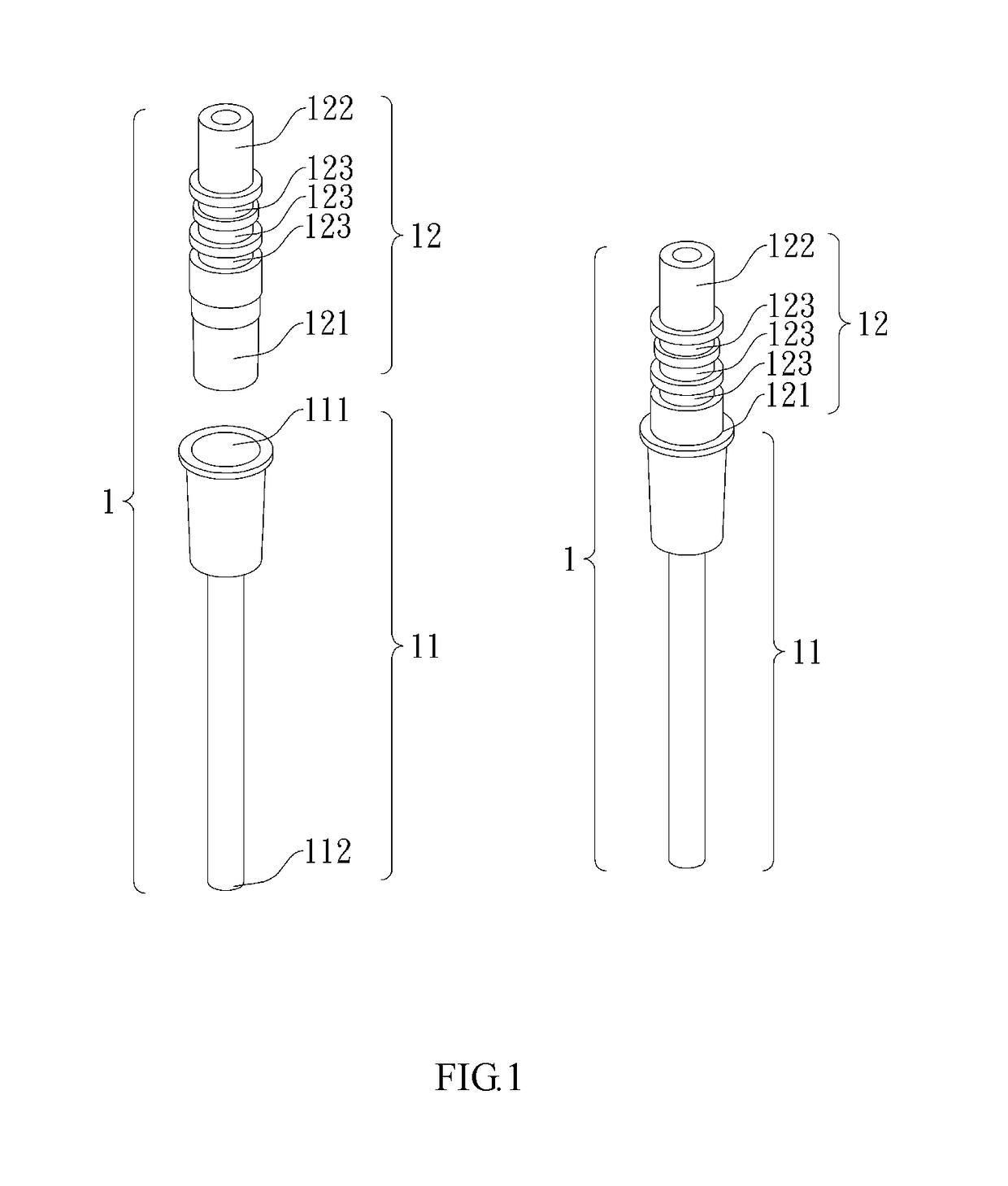

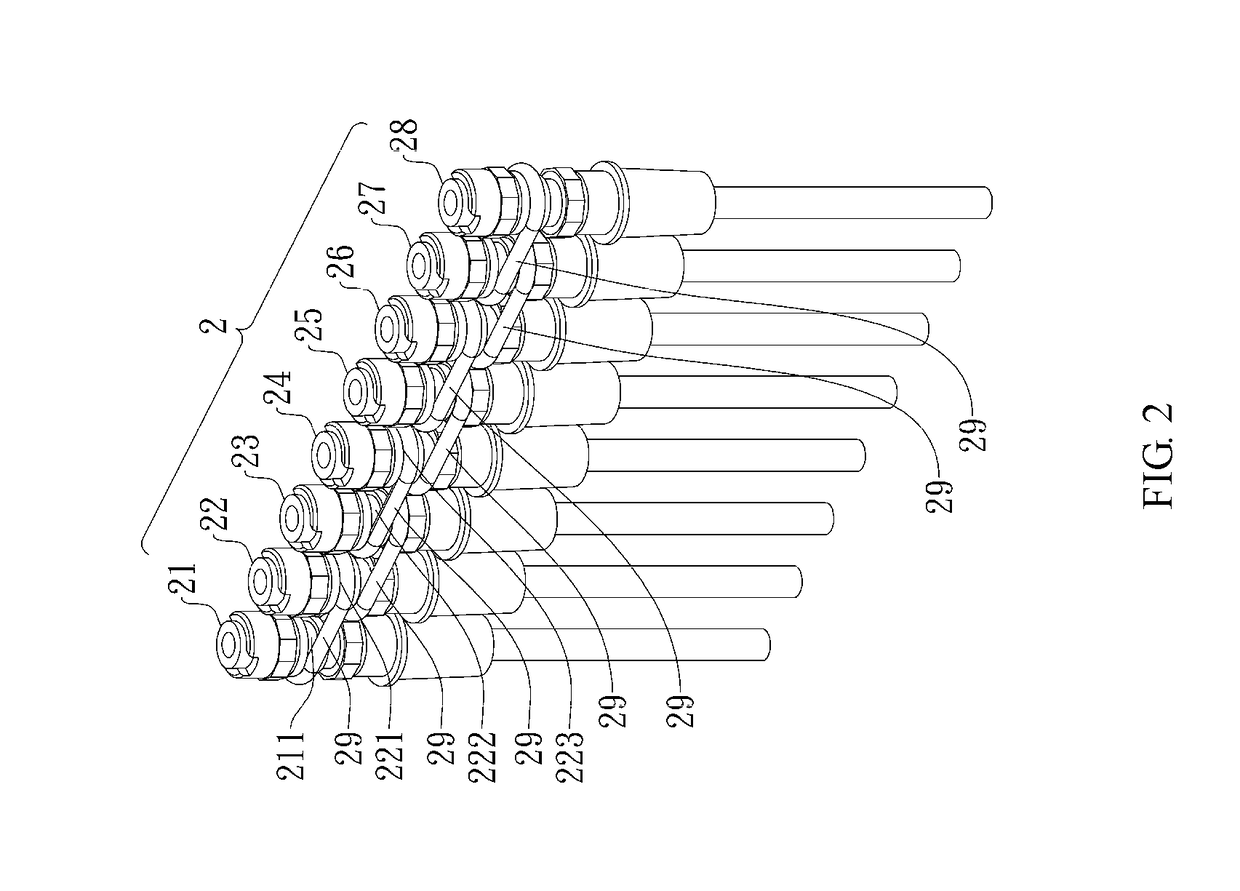

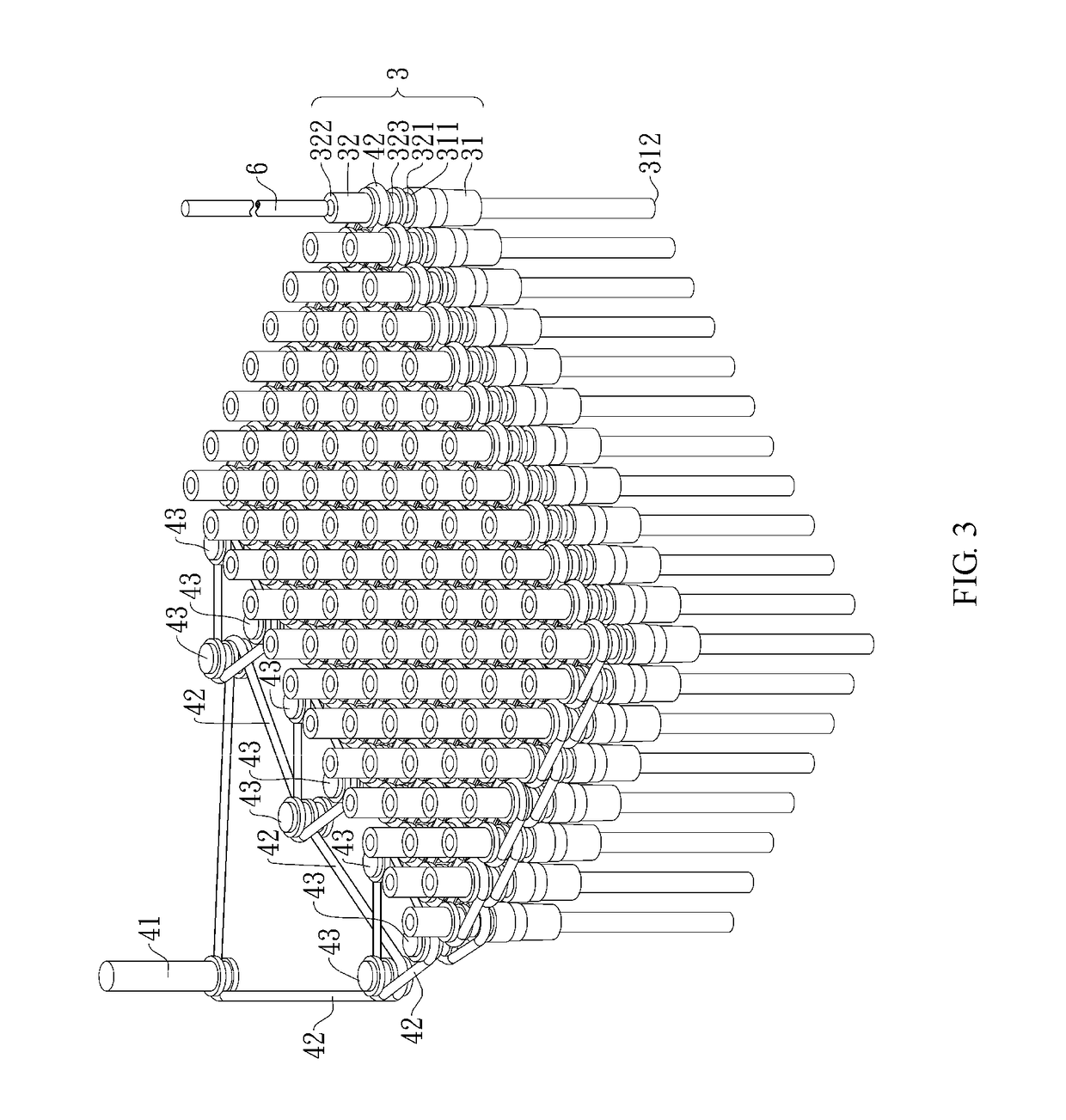

Stirrer set and stirring device

InactiveUS20180345237A1Reduce manufacturing costSimple structureRotary stirring mixersTransportation and packagingRotational axisHigh flux

The present invention provides a stirrer set, comprising: a fitting tube having an opening portion and a hollow rotating shaft fitted into the opening portion, the hollow rotating shaft having an external wall which is annularly recessed to form at least one annular groove. The present invention also provides a stirring device, wherein a drive element comprising a power transmission element, such as a belt, may be rotatably driven to cause, via the power transmission element, the stirrer set to rotate for performing a stirring function. As such, the stirring device provides higher design flexibility when dealing with high-flux samples, and the element replacement rates can be significantly reduced. Thus, the costs related to manufacturing, repair, maintenance and other processes can be reduced in an effective manner.

Owner:TAIWAN ADVANCED NANOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com