Method for preparing charcoal/charcoal air supply nozzle of high temperature furnace

A technology of air inlet nozzles and high-temperature furnaces, which is applied in chemical instruments and methods, crystal growth, silicon halide compounds, etc. It can solve the problems of nozzles affecting the continuous operation time of hydrogenation furnaces, pollution of high-purity polysilicon products, and reducing the service life of nozzles. Achieve the effects of increasing continuous running time, improving thermal shock resistance and structural stability, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

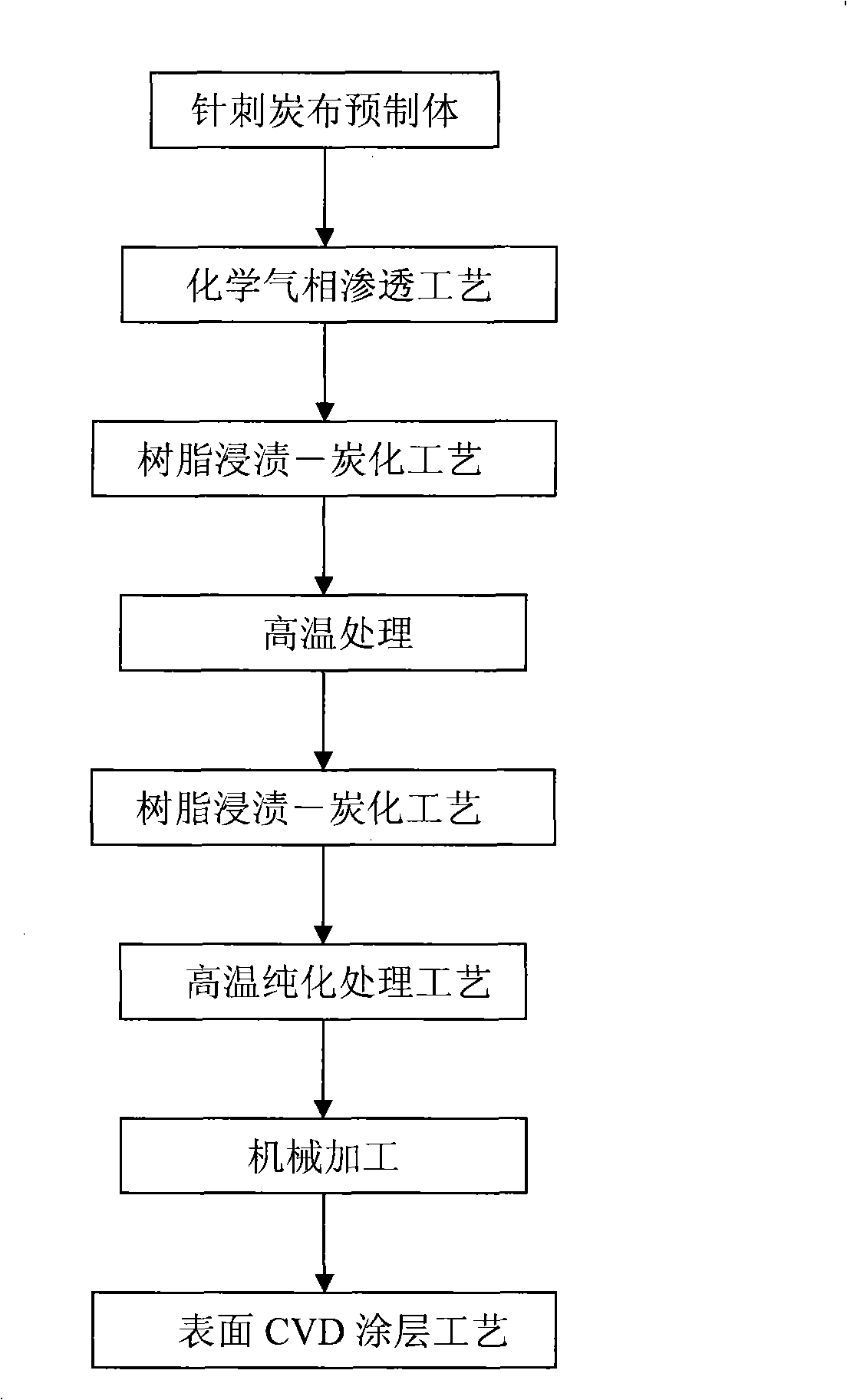

Method used

Image

Examples

Embodiment 1

[0030] (1) Use 12K plain weave carbon cloth and short carbon fiber mesh tires to be laminated alternately, and introduce vertical reinforcement fibers in the thickness direction by acupuncture technology to make a full carbon fiber quasi-three-way structure prefabricated body. The density of the prefabricated body is 0.45g / cm 3 ;

[0031] (2) Chemical vapor infiltration densification treatment: using propylene as a raw material to crack at high temperature, and performing chemical vapor infiltration densification treatment on the preform in step (1); the high temperature temperature is 940°C;

[0032] (3) Furfurone resin impregnation-carbonization: Under the pressure of 2.0MPa, the prefabricated body after the chemical vapor infiltration densification treatment in step (2) was impregnated for 3.5 hours in the impregnation tank, and then transferred to the curing furnace after leaving the tank. Curing treatment, the curing temperature is 190°C, and then transferred to the car...

Embodiment 2

[0040] (1) 6K plain carbon cloth and short carbon fiber mesh tires are alternately laminated, and vertical reinforcing fibers are introduced in the thickness direction by acupuncture to make a quasi-three-dimensional structure prefabricated body of carbon fiber. The density of the prefabricated body is 0.55g / cm 3 ;

[0041] (2) Chemical vapor infiltration densification treatment: using propylene as a raw material to crack at high temperature, and performing chemical vapor infiltration densification treatment on the preform in step (1); the high temperature temperature is 980°C;

[0042] (3) Phenolic resin impregnation-carbonization: Under the pressure of 1.5MPa, impregnate the preform after the chemical vapor infiltration densification treatment in step (2) for 4.5 hours in the impregnation tank, and transfer it to the curing furnace for curing after leaving the tank Treatment, the curing temperature is 190°C, and then transferred to the carbonization furnace for carbonizati...

Embodiment 3

[0050] (1) Use 3K plain weave carbon cloth and short carbon fiber mesh tires to be alternately laminated, and introduce vertical reinforcement fibers in the thickness direction using acupuncture technology to make a full carbon fiber quasi-three-way structure prefabricated body. The density of the prefabricated body is 0.40g / cm 3 ;

[0051] (2) Chemical vapor infiltration densification treatment: using natural gas as raw material to crack at high temperature, and performing chemical vapor infiltration densification treatment on the preform in step (1); the high temperature temperature is 1060°C;

[0052] (3) Furfurone resin impregnation-carbonization: Under the pressure of 2.0MPa, the prefabricated body after the chemical vapor infiltration densification treatment in step (2) was impregnated for 4 hours in the impregnation tank, and then transferred to the curing furnace after leaving the tank. Curing treatment, the curing temperature is 190°C, and then transferred to the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com