Patents

Literature

69results about How to "Extend continuous running time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

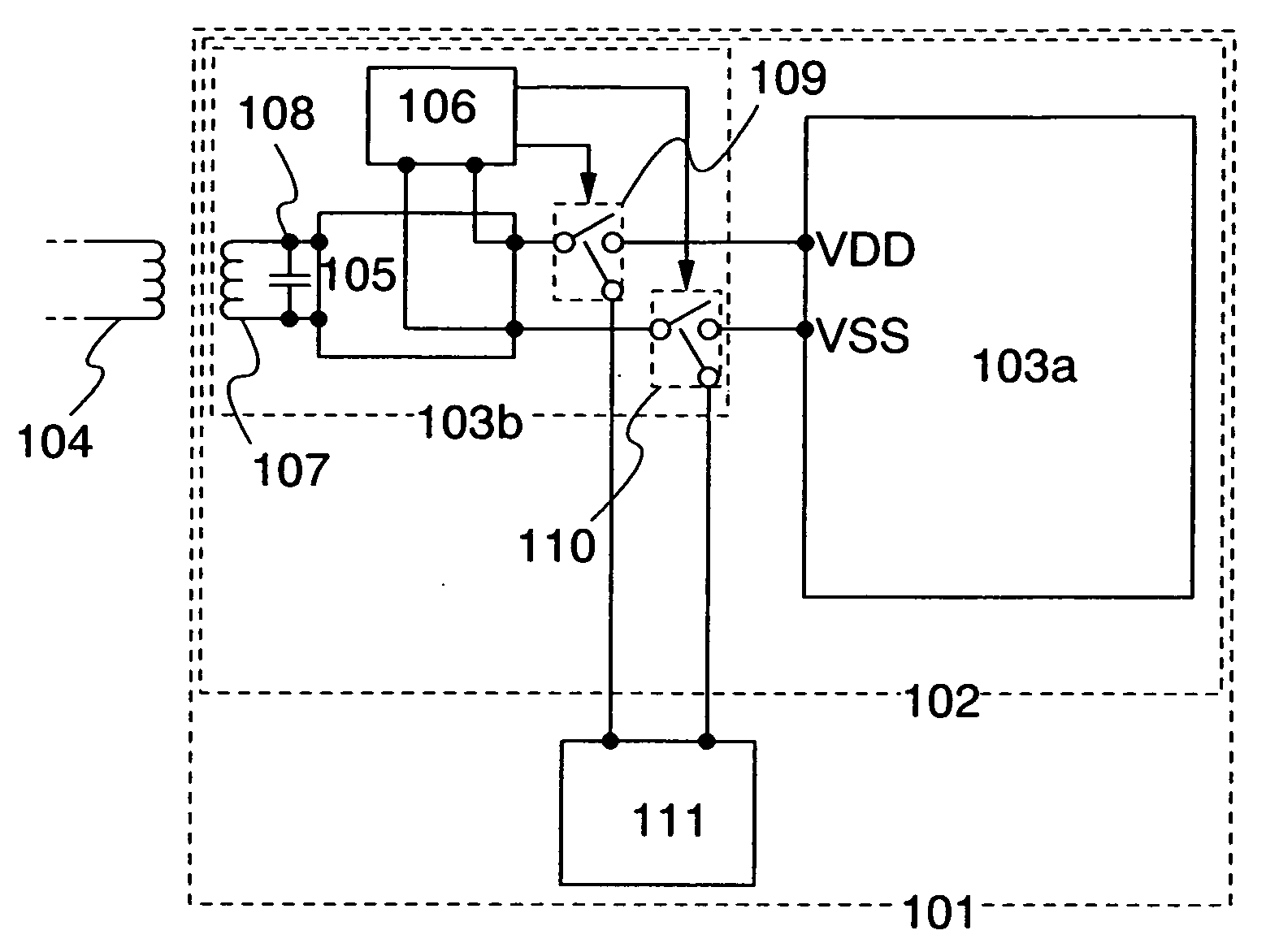

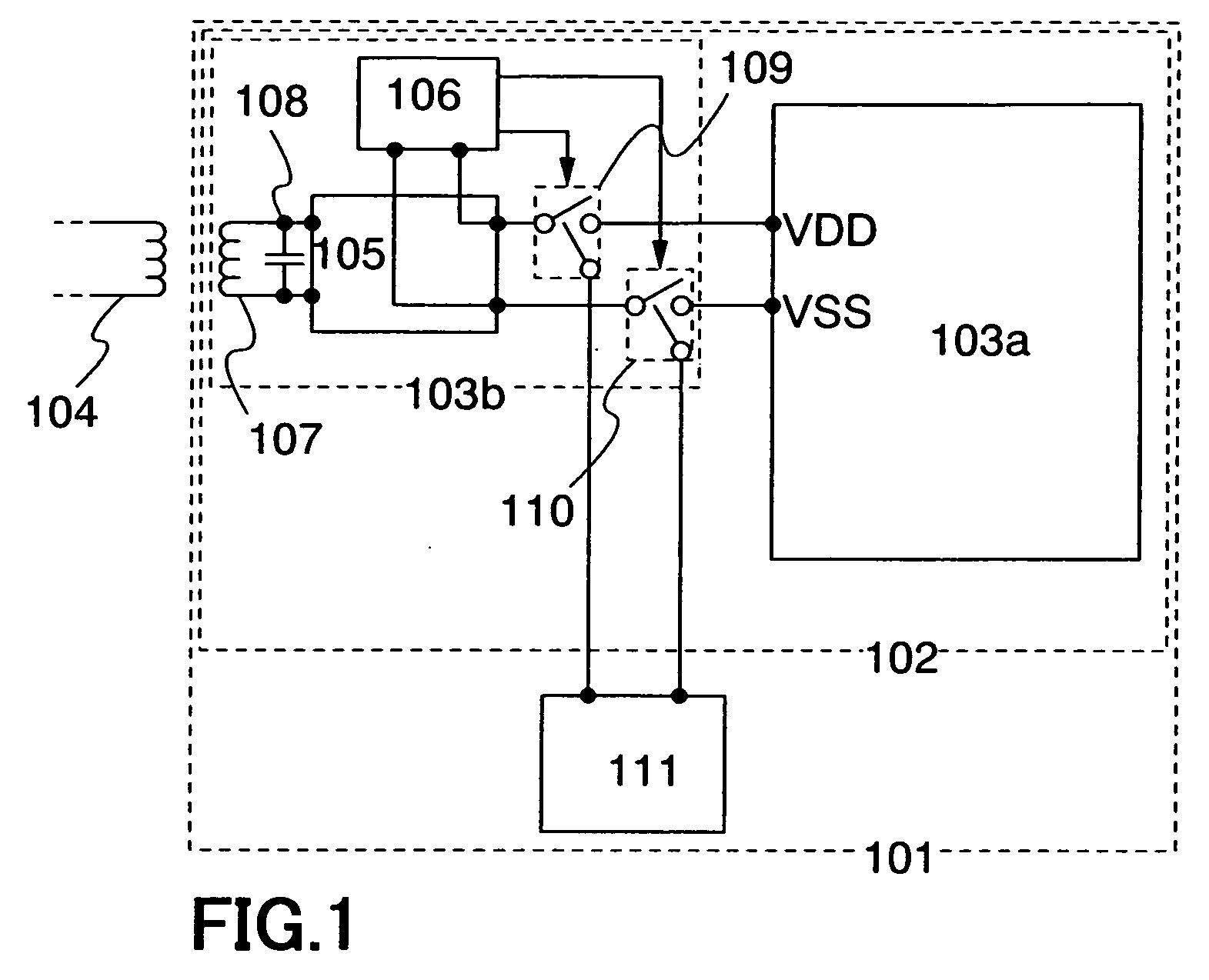

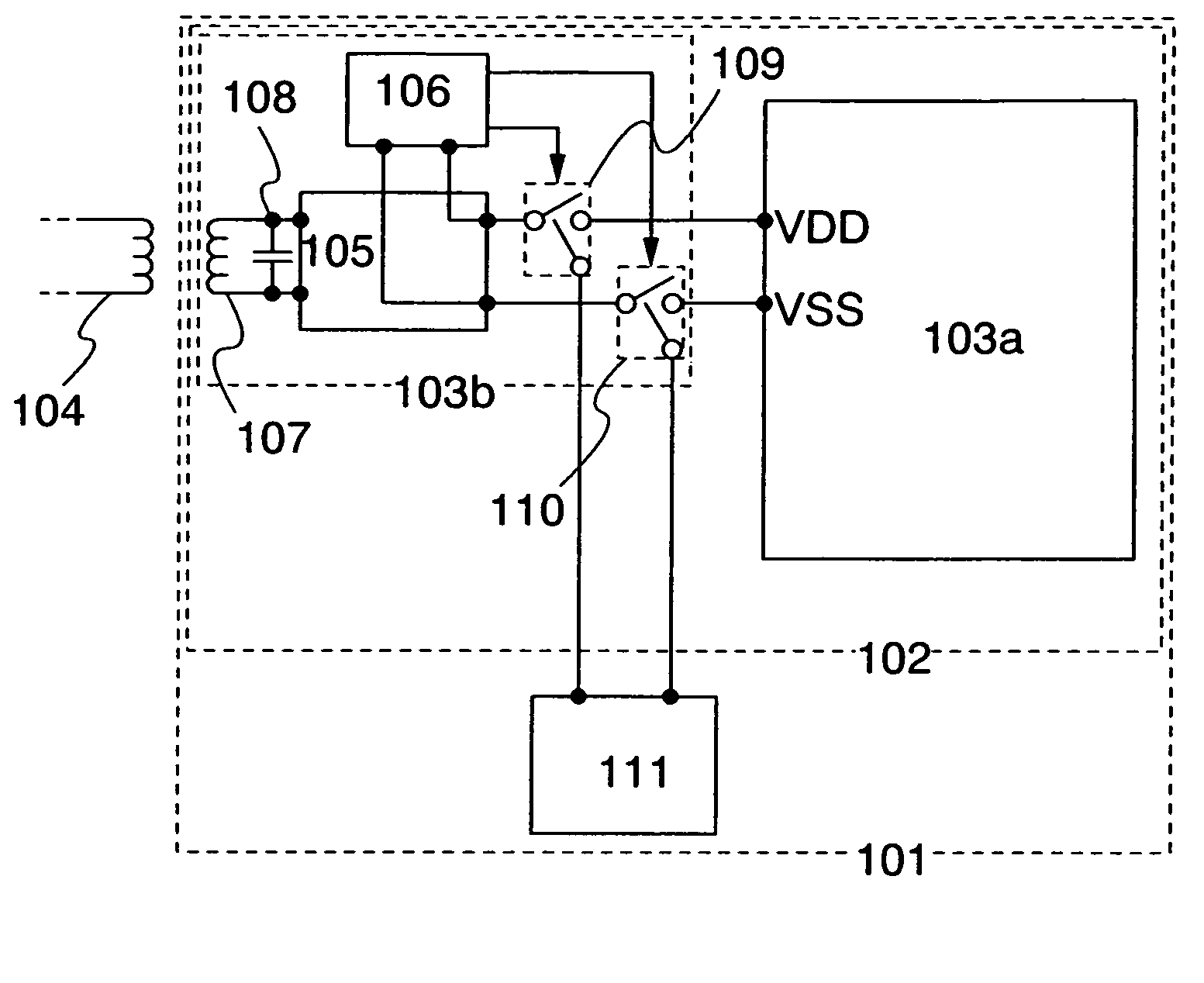

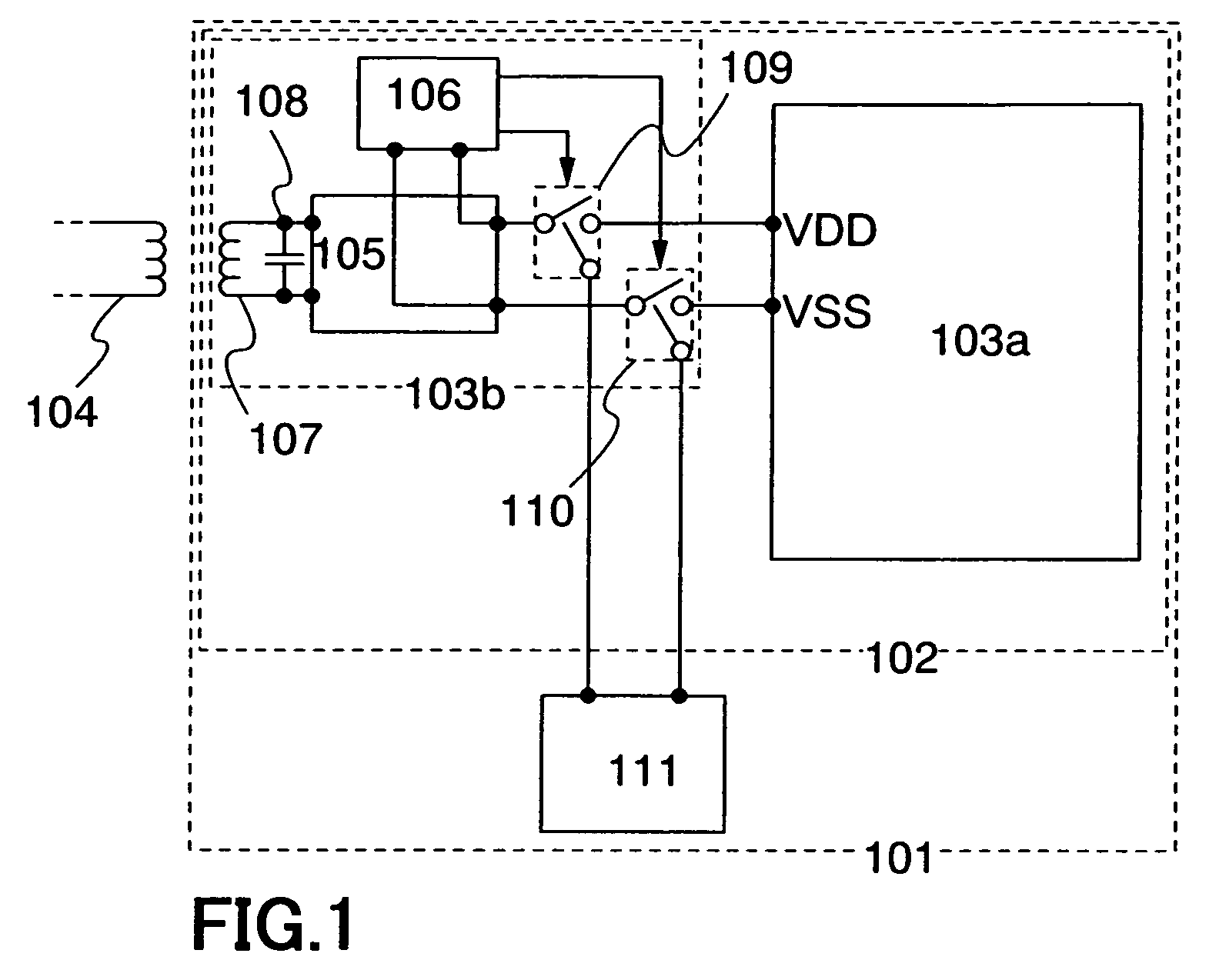

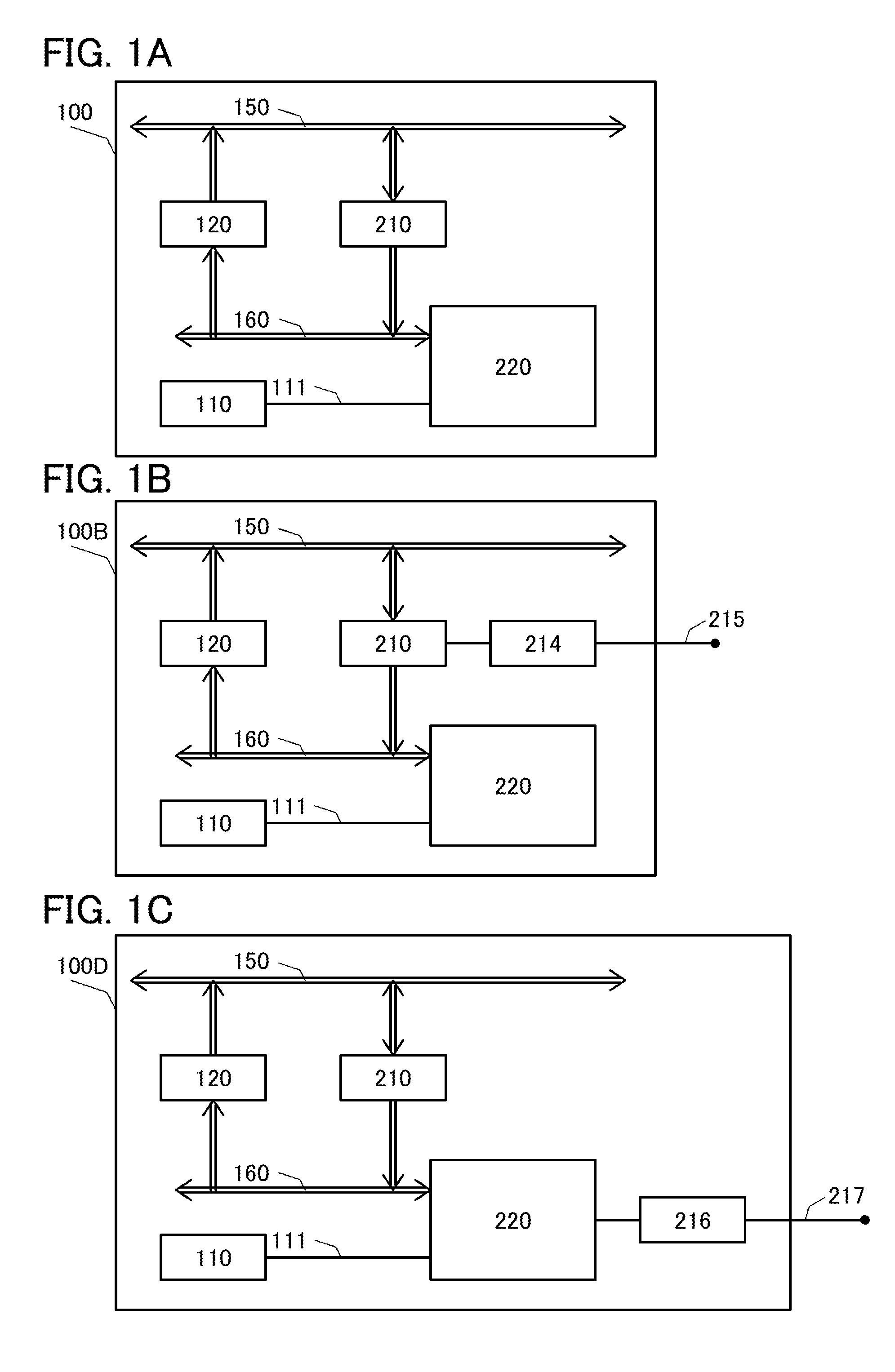

Display device and portable terminal

InactiveUS20060209060A1Reduce component countPortable terminalBatteries circuit arrangementsCathode-ray tube indicatorsElectrical batteryDisplay device

In order to increase the continuous operating time of a display device driven by a battery or the like, and a portable information terminal using the same, the volume and weight of the battery are increased. Thus, there arises a trade-off between the increased capacity of the battery and the portability of the device / terminal. Therefore, the invention provides a display device with portability ensured, which is capable of operating continuously for long periods and a portable information terminal using the same. In the display device, TFTs and an RFID tag are formed over the same insulating substrate. The RFID tag detects signals from a reader / writer, and generates DC power based on the signals. While the RFID tag is detecting signals, the display device is driven by the DC power generated in the RFID tag.

Owner:SEMICON ENERGY LAB CO LTD

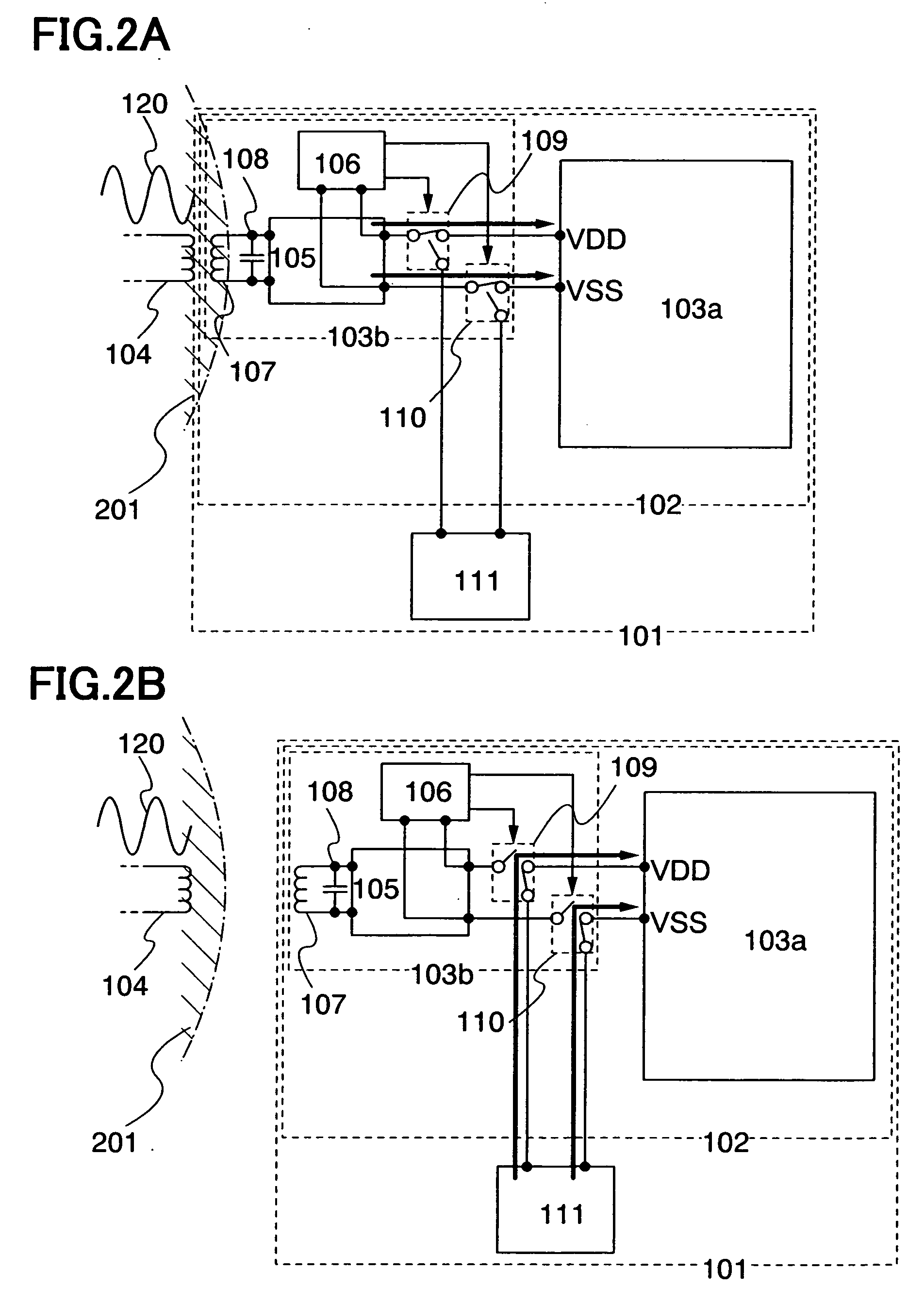

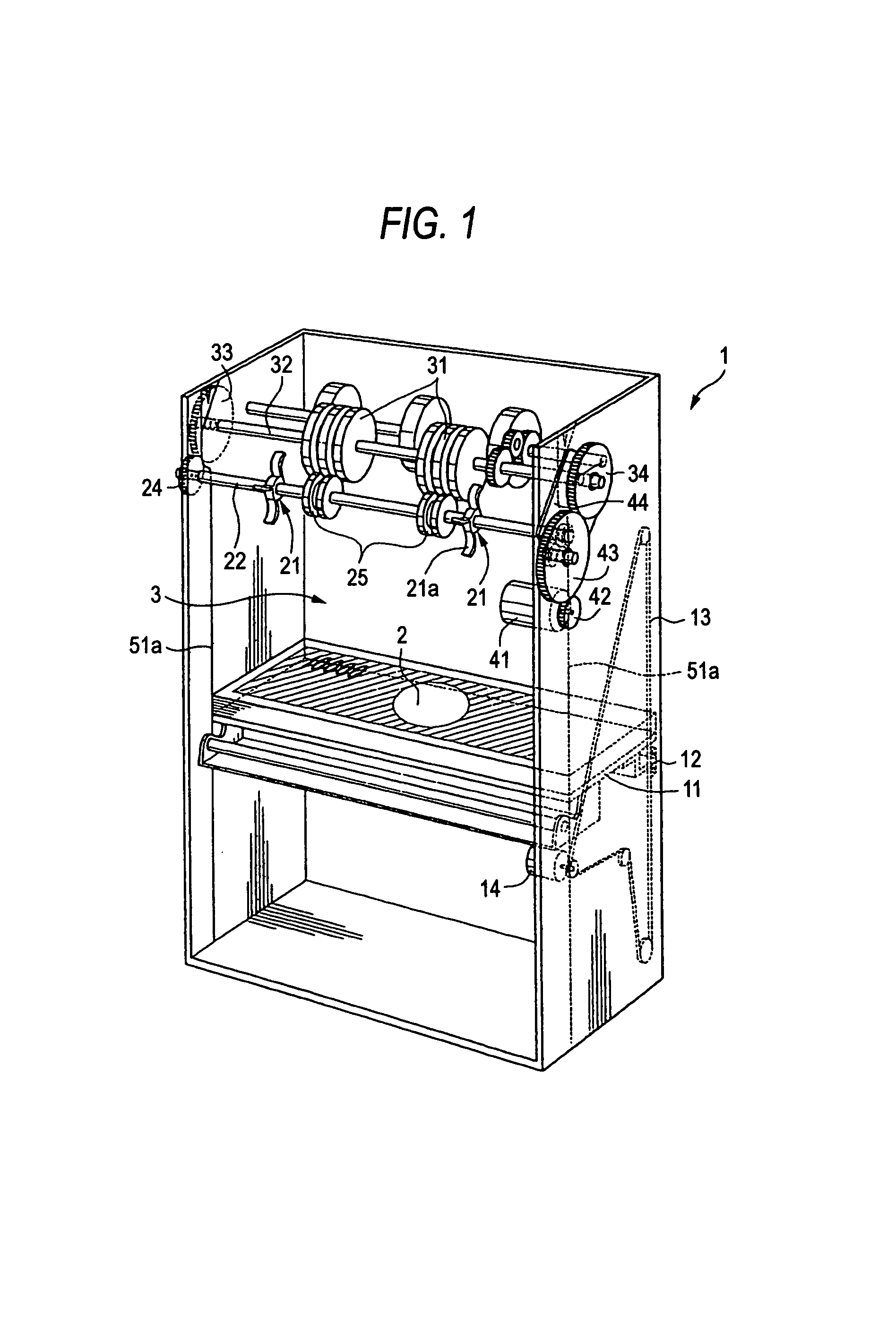

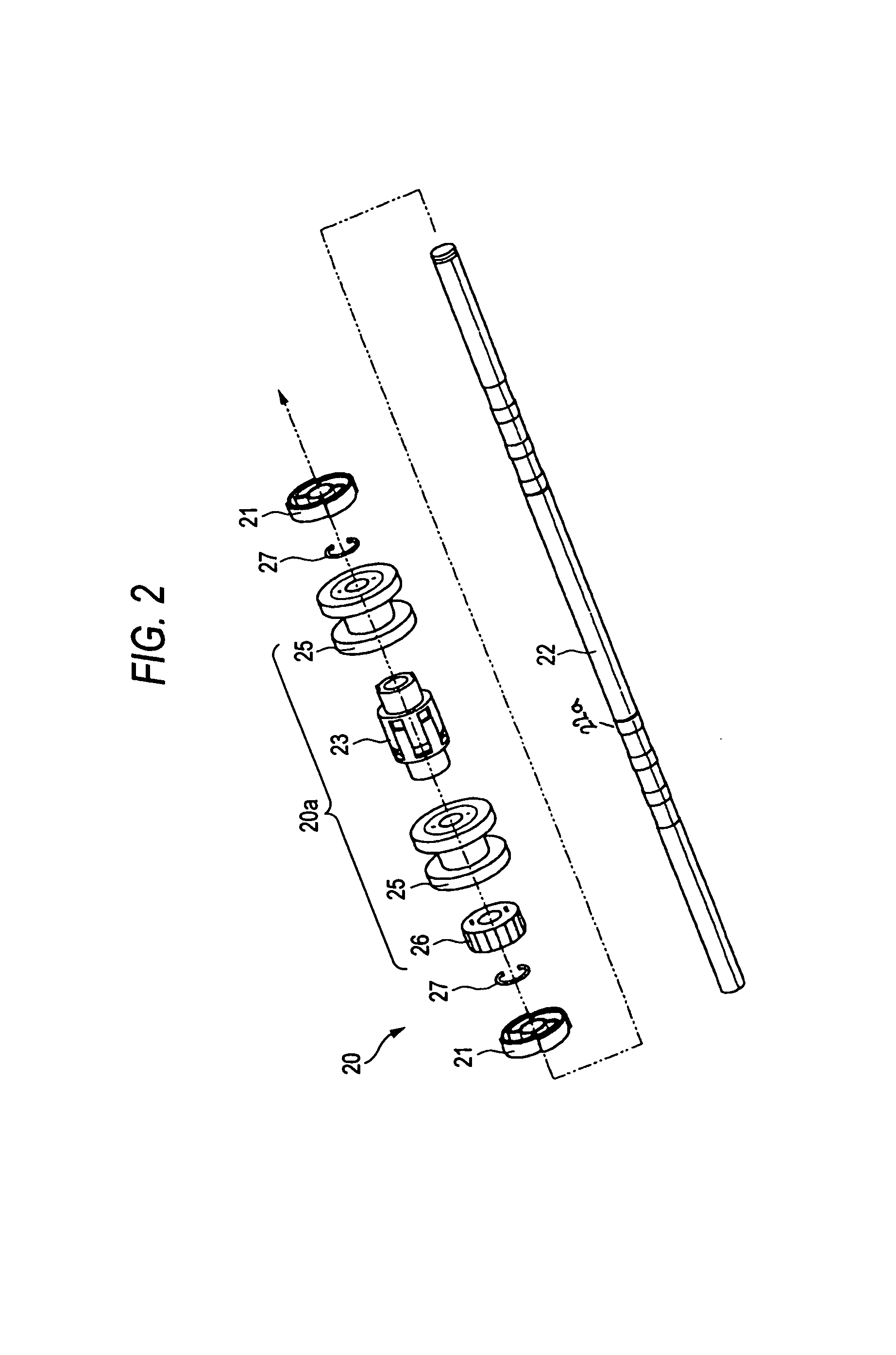

Paper gathering and feeding method and device therefor, and rotation member

Owner:HITACHI CHANNEL SOLUTIONS CORP

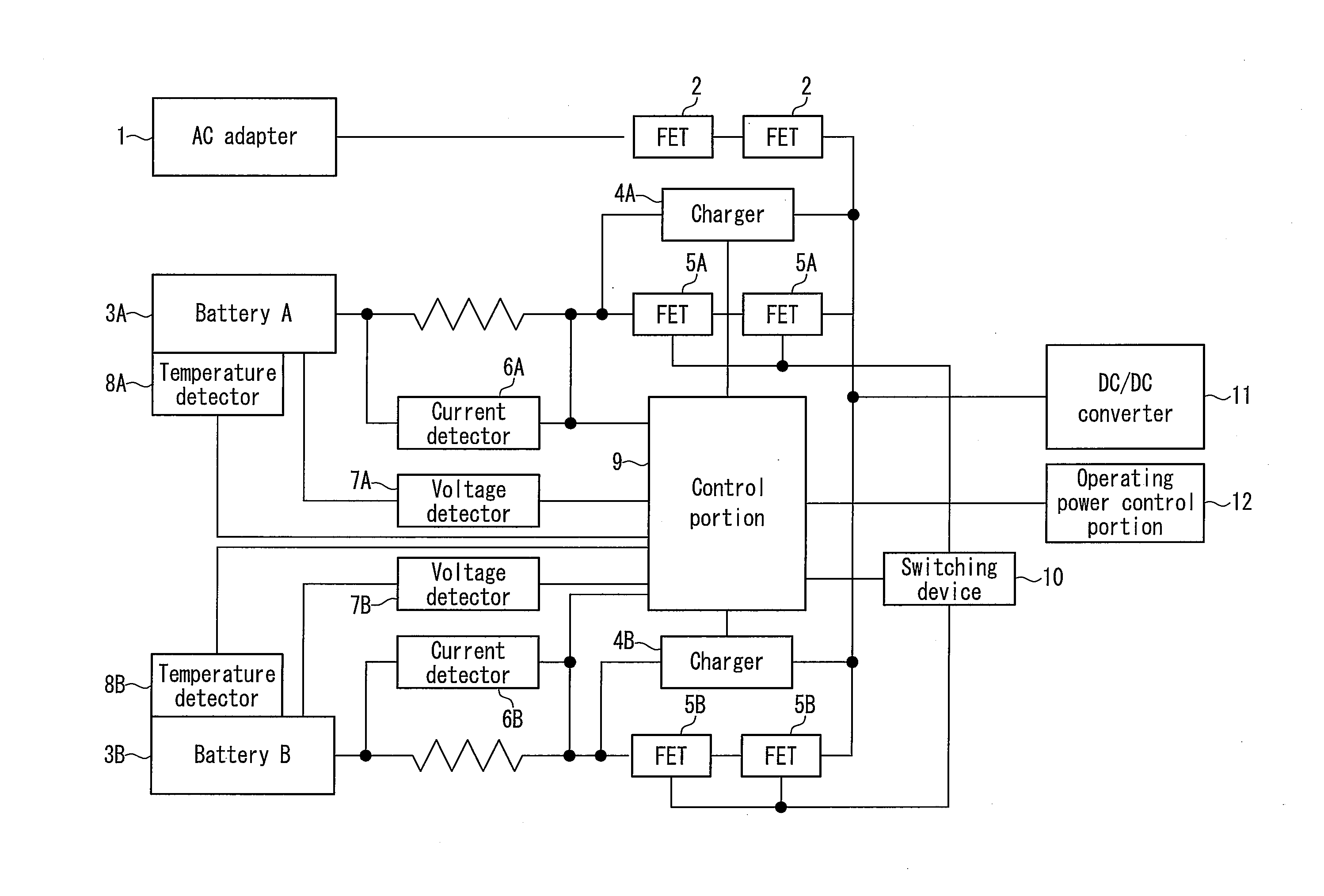

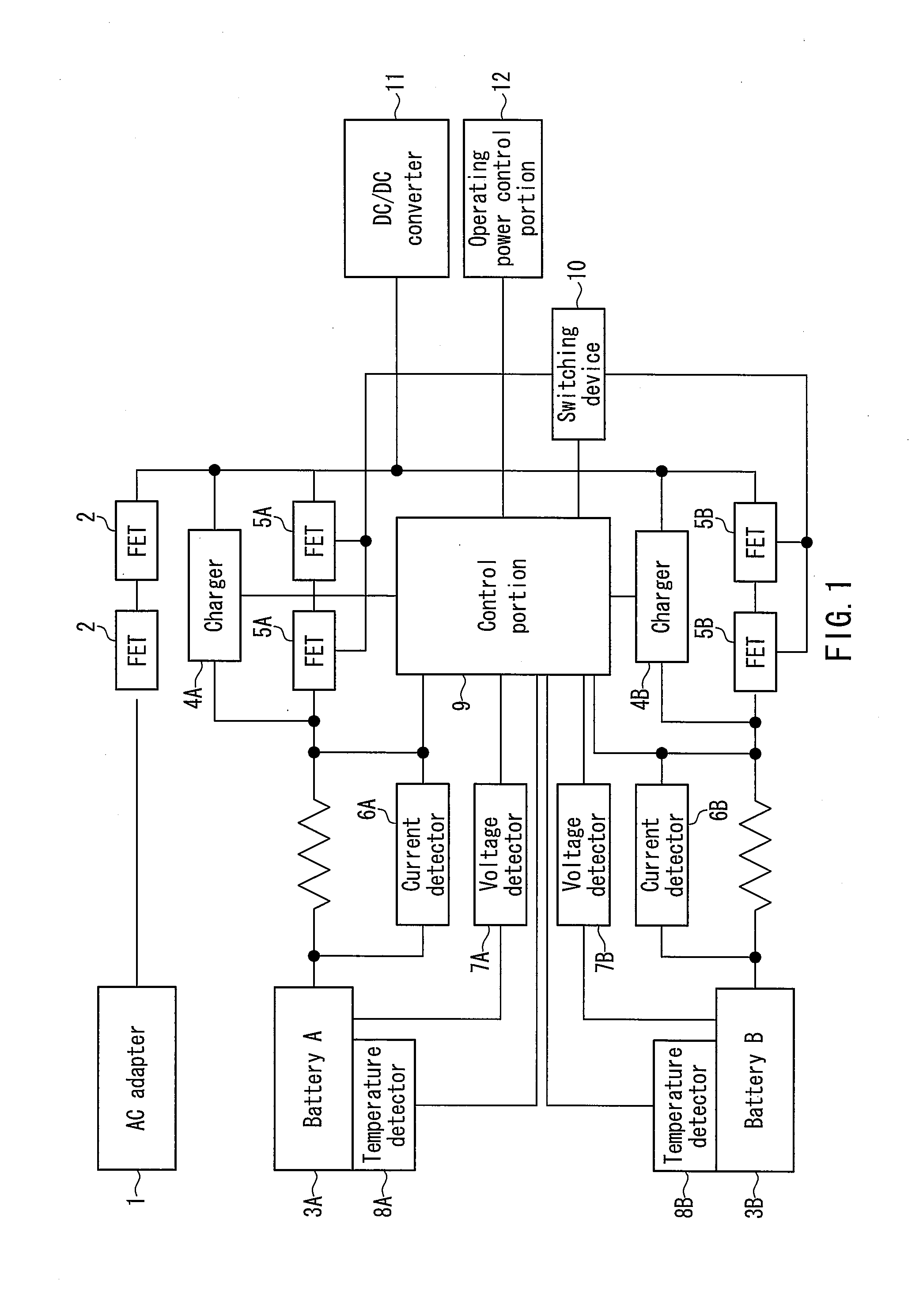

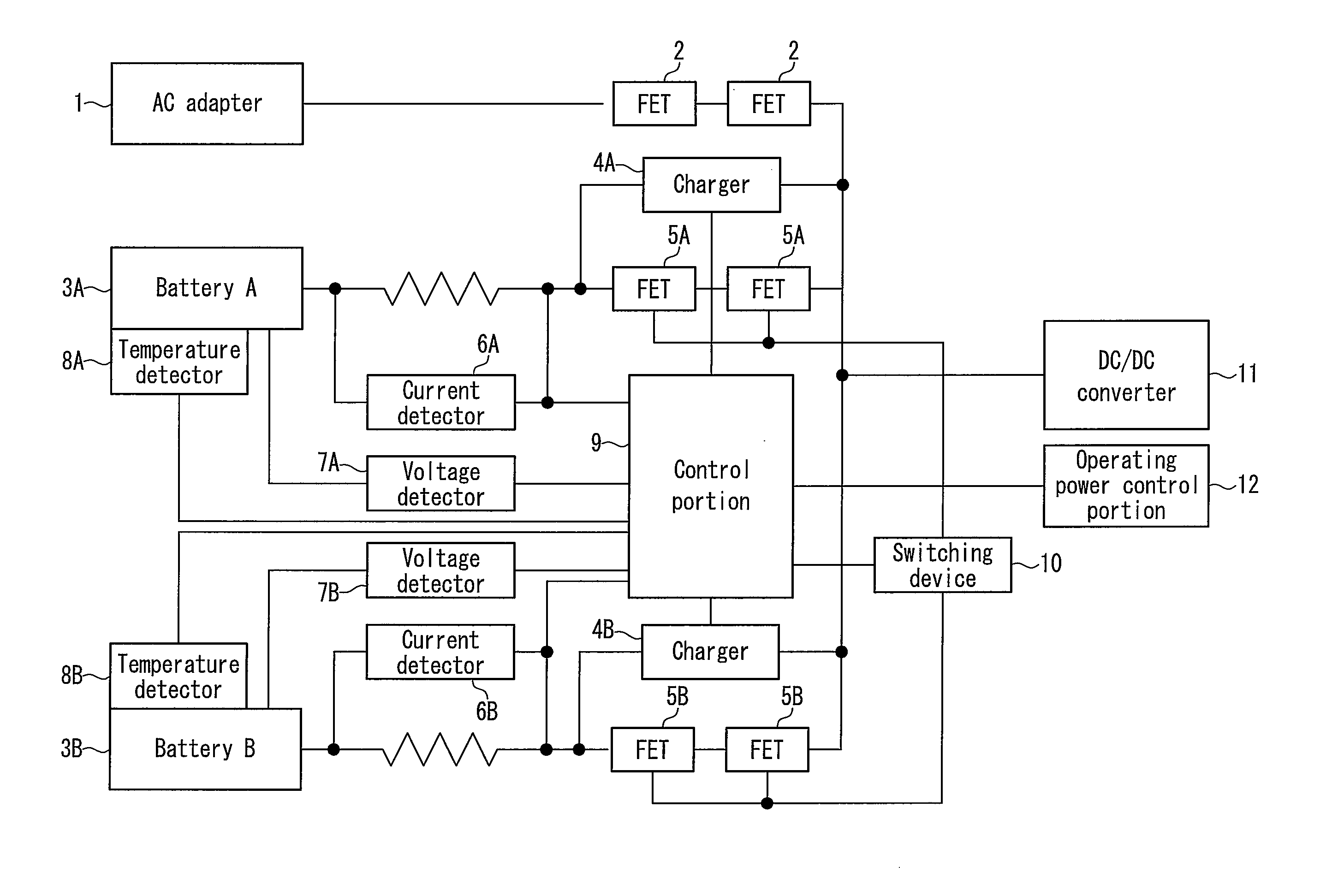

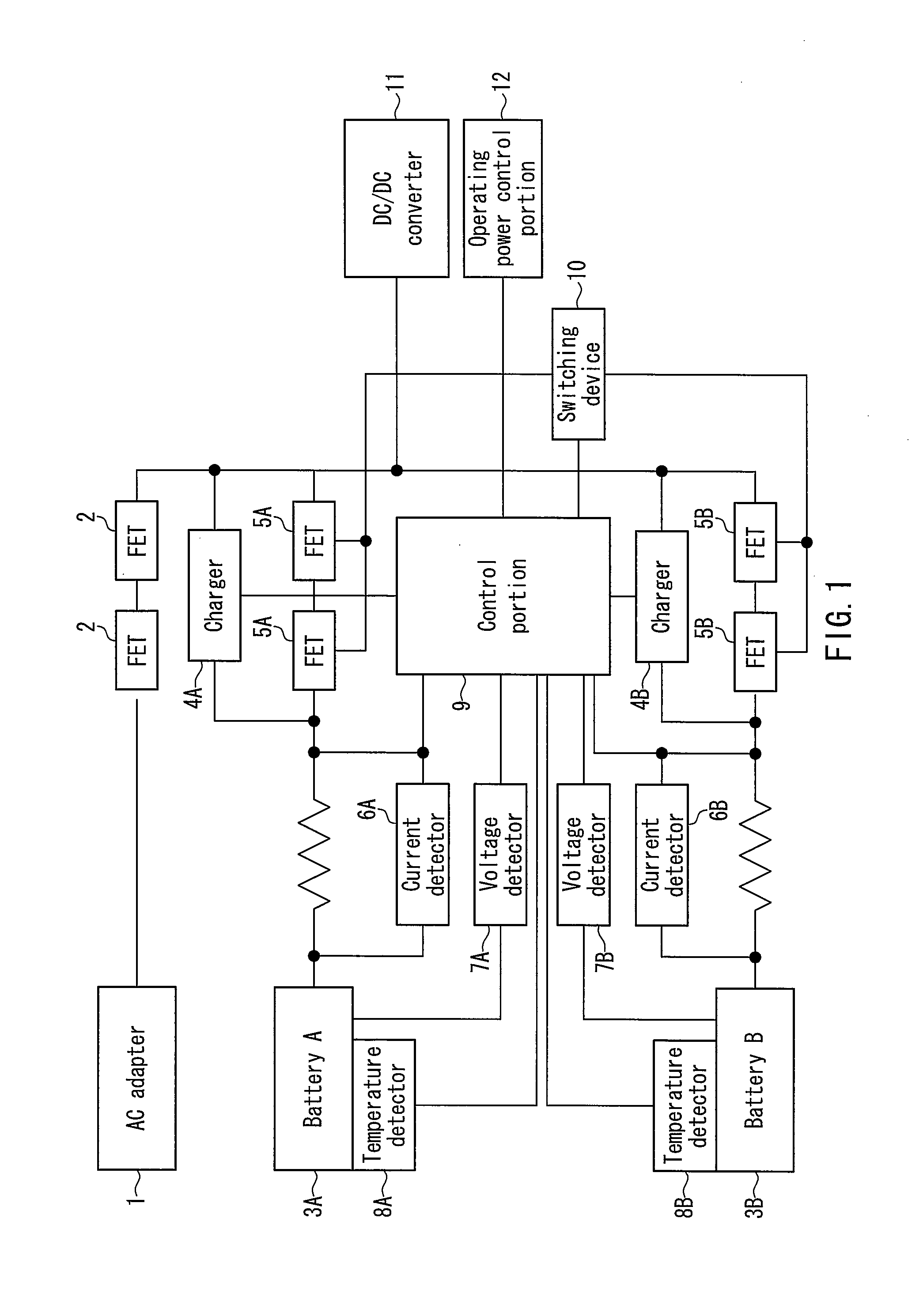

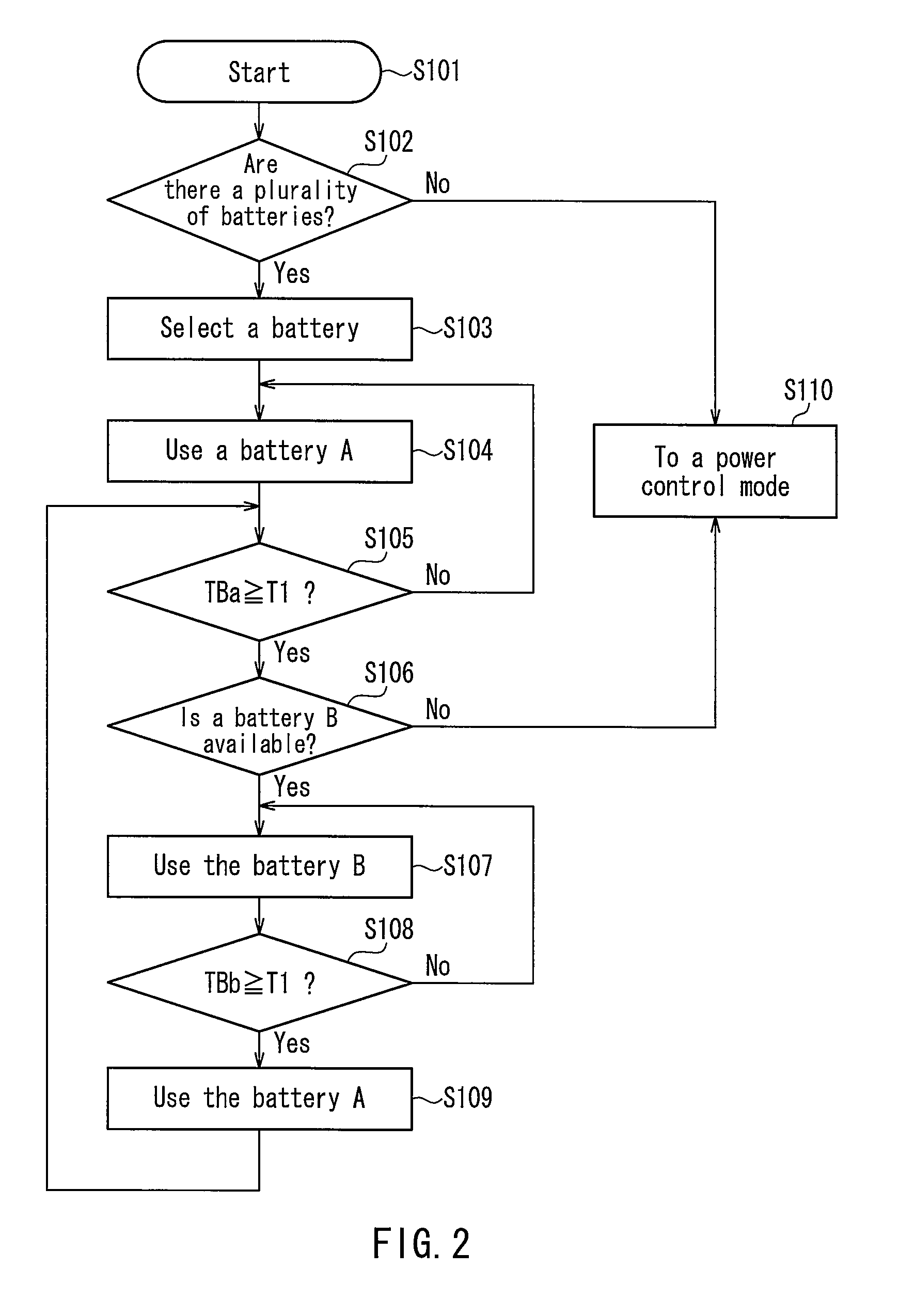

Secondary battery controller and method for controlling secondary battery, and electronic apparatus

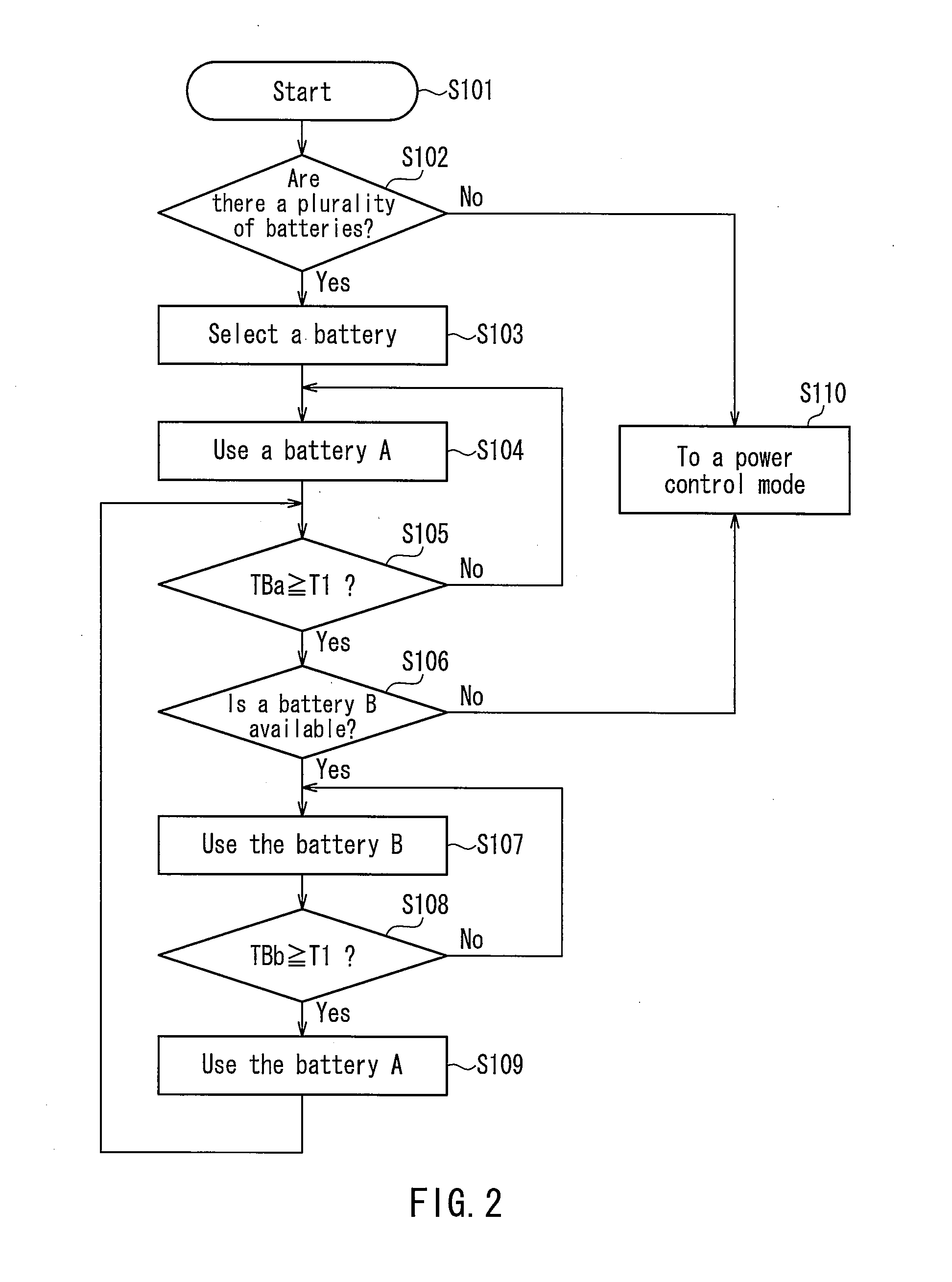

ActiveUS20110309681A1Stable operationExtend continuous running timeSequential battery dischargeElectric powerElectrical and Electronics engineeringThreshold temperature

The present invention provides a secondary battery controller and a method for controlling a secondary battery that can increase the continuous operating time of an apparatus in which a plurality of secondary batteries are switched and used, and an electronic apparatus. The secondary battery controller includes the following; a plurality of temperature detectors that detect temperatures of a plurality of secondary batteries having the same rating, respectively; a switching device that connects an output of any one of the plurality of secondary batteries to a load; and a control portion that selects which secondary battery to use from the plurality of secondary batteries and controls the switching device to switch between the secondary batteries based on temperature information of each of the plurality of secondary batteries obtained by the temperature detectors. The control portion connects the selected secondary battery to the load, and then switches the secondary battery connected to the load to another non-selected secondary battery in sequence when the first selected secondary battery reaches a predetermined threshold temperature, and further reconnects the first selected secondary battery to the load when the last selected secondary battery reaches the threshold temperature after all the secondary batteries have been selected.

Owner:PANASONIC CORP

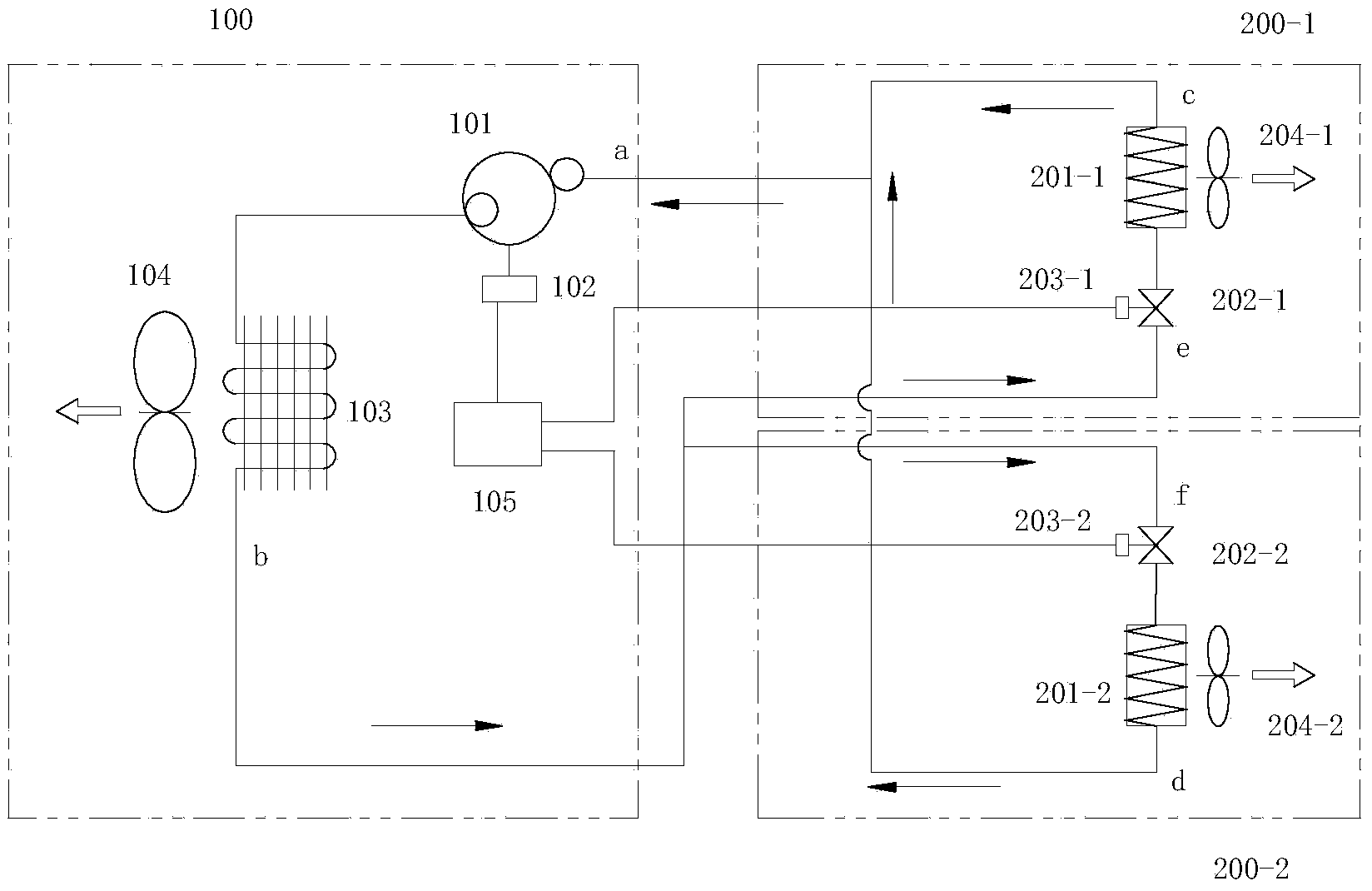

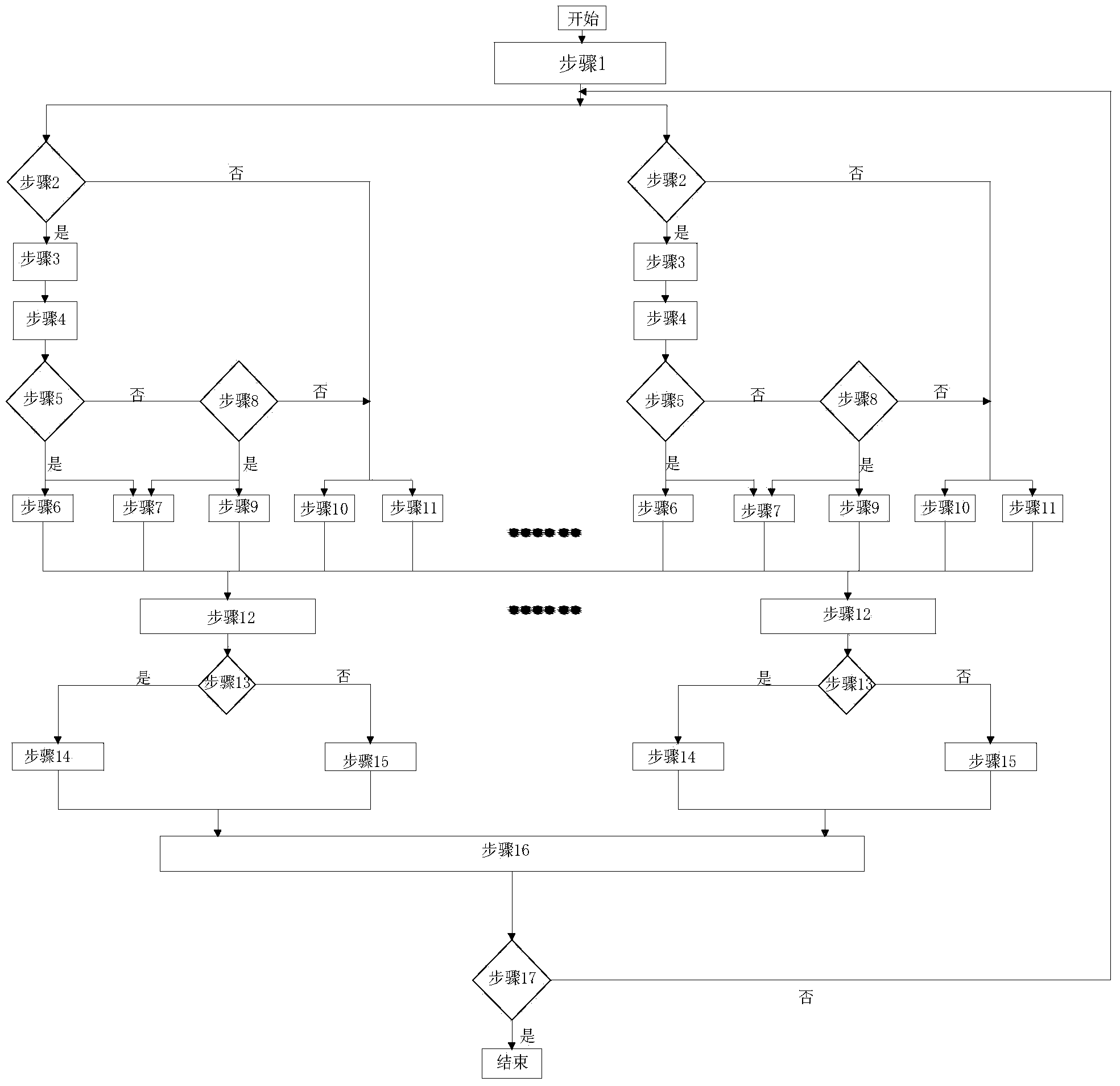

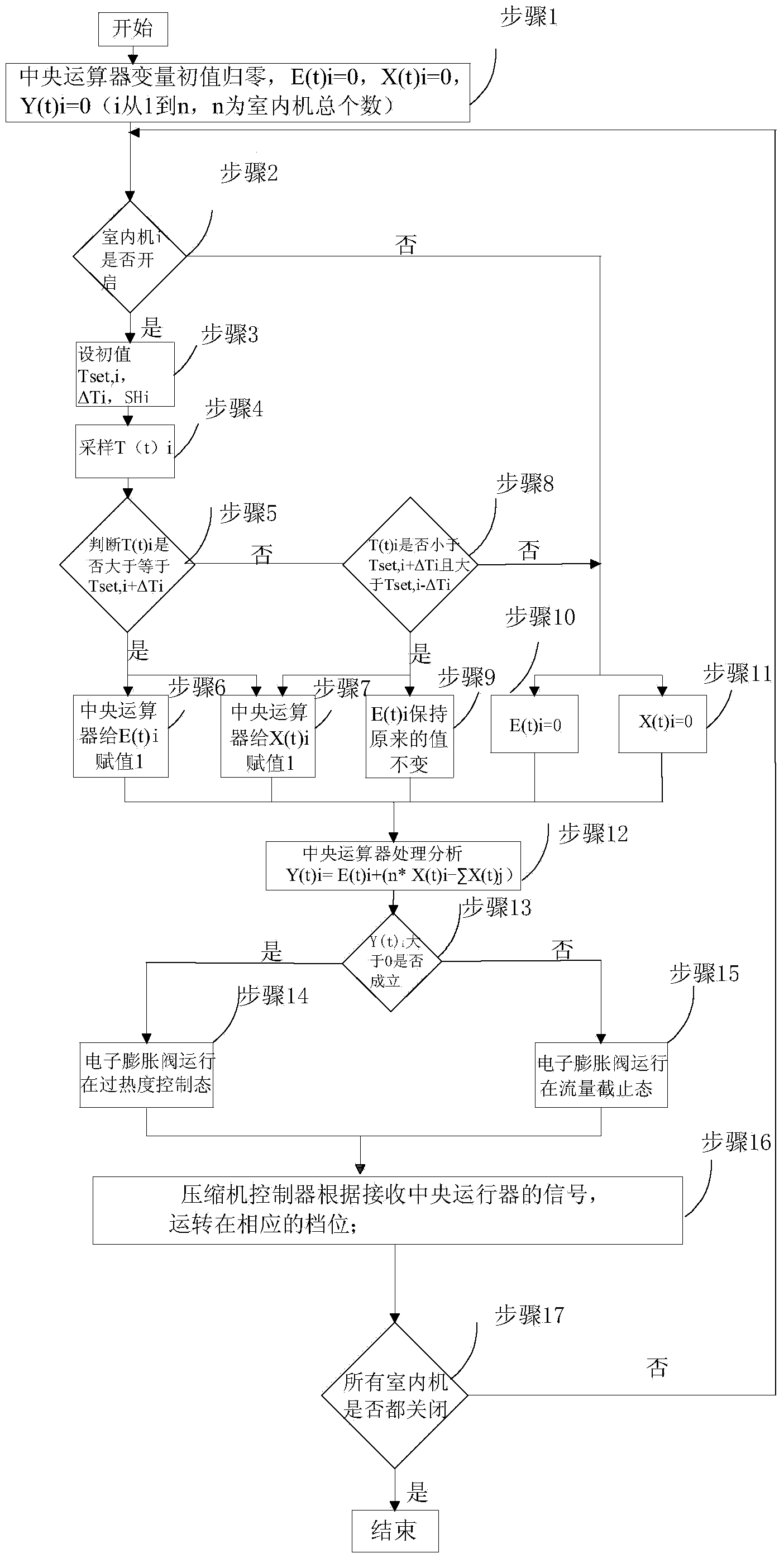

Central arithmetic type multi-split air conditioner system and state switching control method thereof

InactiveCN103644621ASimple structureLow costSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringState switching

The invention discloses a central arithmetic type multi-split air conditioner system and a state switching control method of the central arithmetic type multi-split air conditioner system. The operating states of electronic expansion valves and the operating states of compressors are controlled through a central arithmetic unit, the operating frequency and the corresponding gear of each compressor are determined so that the total refrigerating capacity output by the central arithmetic type multi-split air conditioner system can be controlled easily and efficiently, the refrigerating capacity can be reasonably distributed to rooms, and the refrigerating capacity obtained by each room is matched with the heat load of the room. The central arithmetic unit receives temperature signals of all the rooms, carries out centralized arithmetic processing, sends instructions to the electronic expansion valves and the compressors of indoor units, and has control over execution behaviors of the electronic expansion valves and execution behaviors of the compressors. According to the central arithmetic type multi-split air conditioner system and the state switching control method of the central arithmetic type multi-split air conditioner system, mutual influence among the indoor units is taken into overall consideration, the fluctuation range of the indoor temperature is reduced, the probability that the compressors are in the shutdown state in the operating process of the central arithmetic type multi-split air conditioner system is greatly reduced, loss caused by frequent starting and frequent shutdown of the compressors is reduced, and the fluctuation, caused by starting and shutdown of the compressors, of the indoor temperature can be further reduced.

Owner:ZHEJIANG UNIV

Display device and portable terminal

InactiveUS7659892B2Extend continuous running timeSmall sizeElectric signal transmission systemsBatteries circuit arrangementsElectrical batteryDisplay device

Owner:SEMICON ENERGY LAB CO LTD

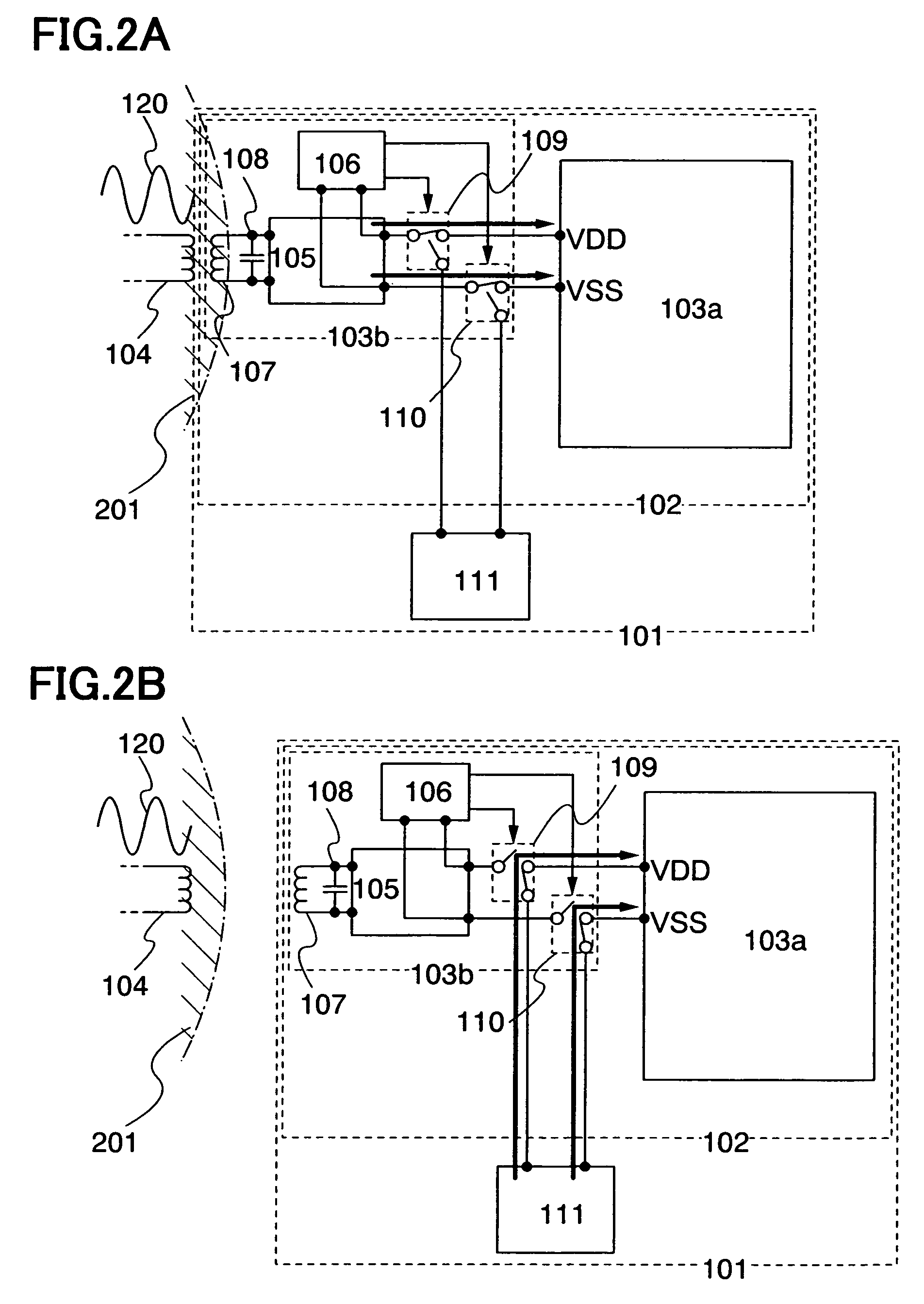

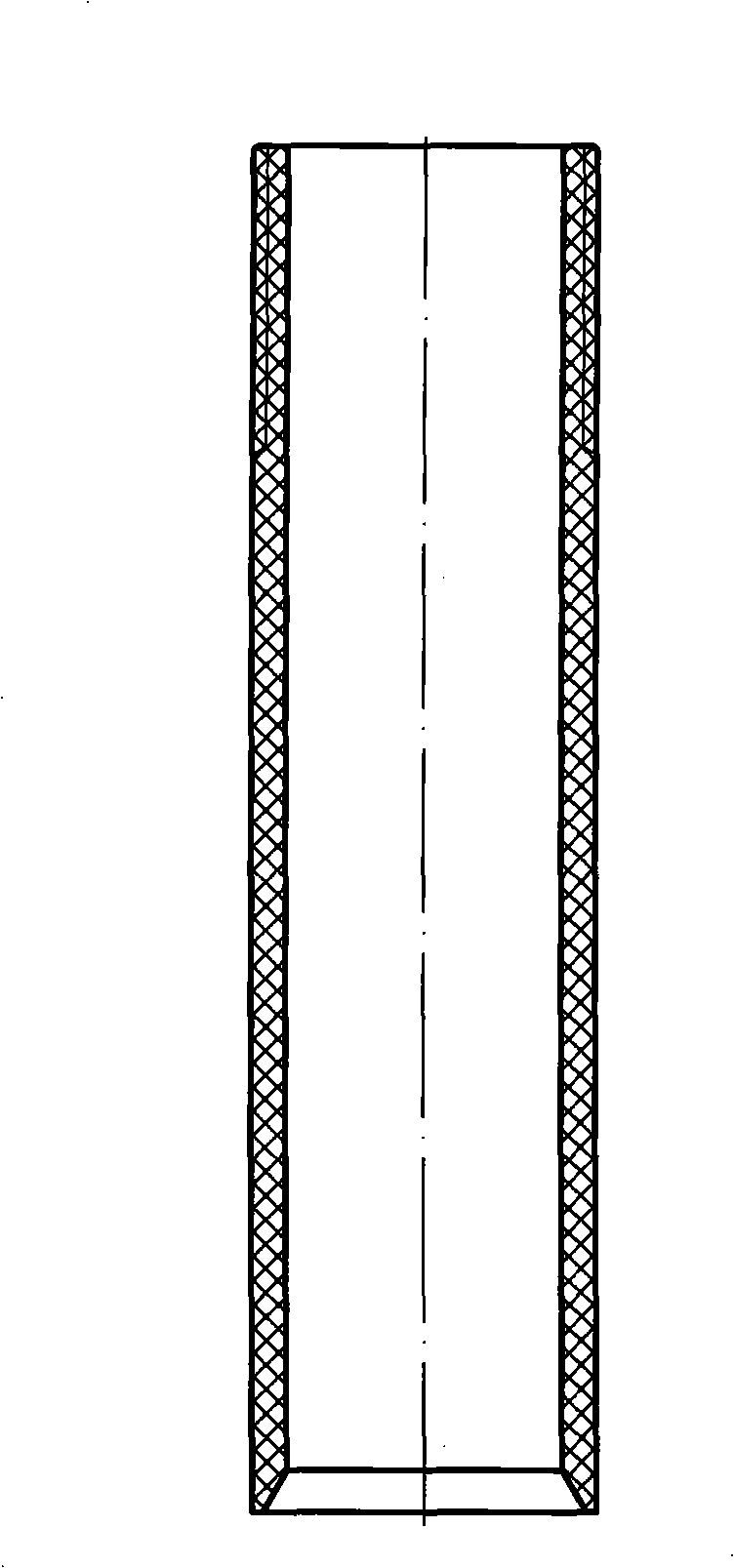

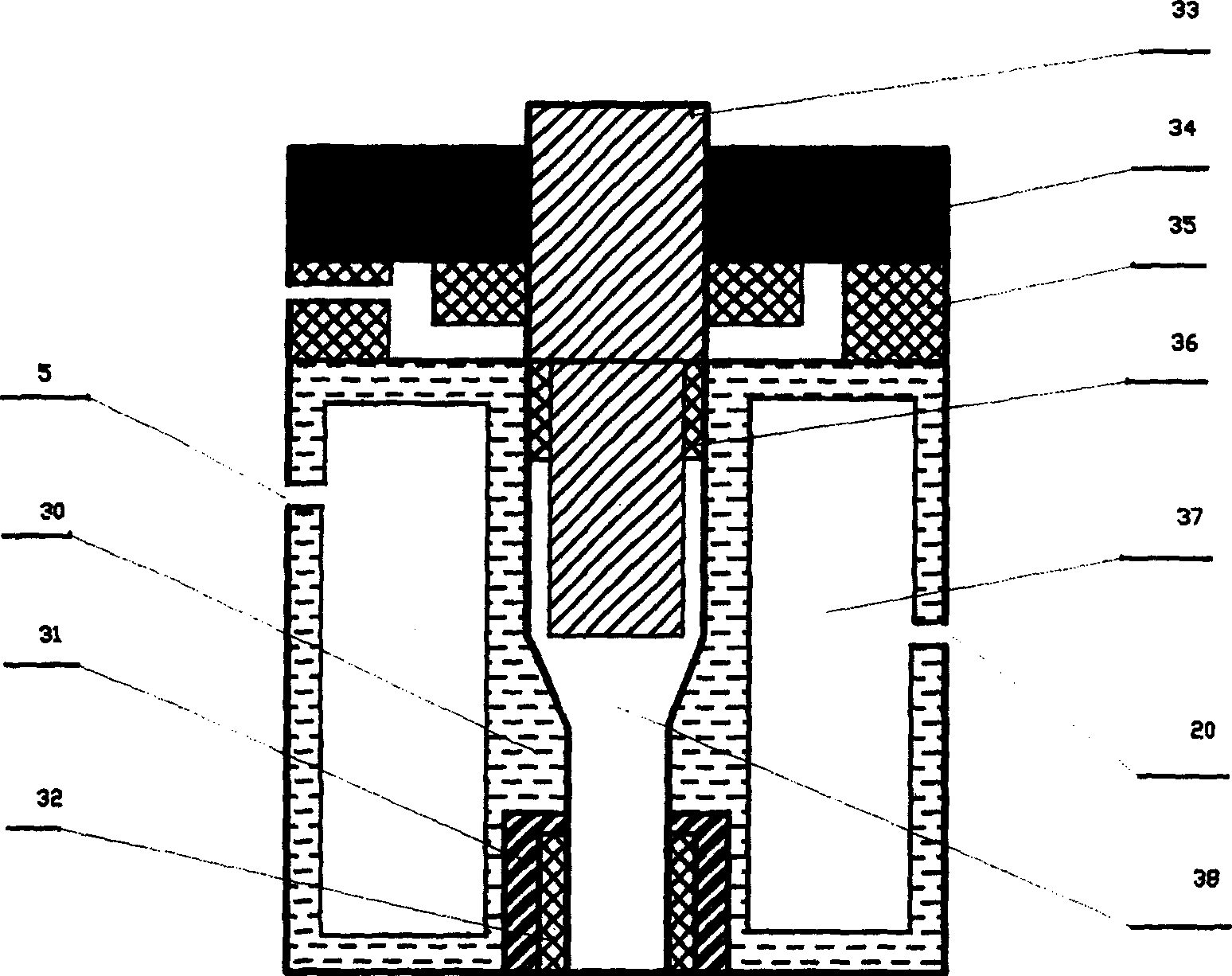

Method for preparing charcoal/charcoal air supply nozzle of high temperature furnace

ActiveCN101311143AHigh strengthThe strength is above 60Mpa, and the compressive strength is highPolycrystalline material growthSiliconGas phaseVolumetric Mass Density

The invention relates to a preparation method for carbon / a carbon nozzle of air supple used in a high temperature furnace, which adopts a needling plain carbon cloth prefabricated body with a pseudo-three-dimensional structure; the prefabricated body is densified by chemical gas-phase permeation and resin impregnation-charing for a plurality of times; the densified blank carries out high-temperature treatment at a certain temperature to increase opening percentage on the surface, and then densification treatment is further carried out; the resin impregnation-charing densification technique is adopted until the density is equal to or more than 1.75g / cm<3>, finally mechanical workout is carried out after high-temperature purification treatment, and the surface is treated with CVD coating to produce the carbon / the carbon nozzle of air supple. The method of the invention adopts the technique of the combination of chemical gas-phase permeation and resin impregnation-charing for densification to produce the material of the carbon / the carbon nozzle; when being applied to the nozzle of air supple in a polysilicon hydrogenation furnace, the material of the carbon / the carbon nozzle can effectively enhance the strength of the nozzle of air supple and scour resistance and corrosion resistance of the nozzle, prolong the service life of the nozzle and lower the replacing rate of the nozzle.

Owner:XIAN CHAOMA SCI TECH

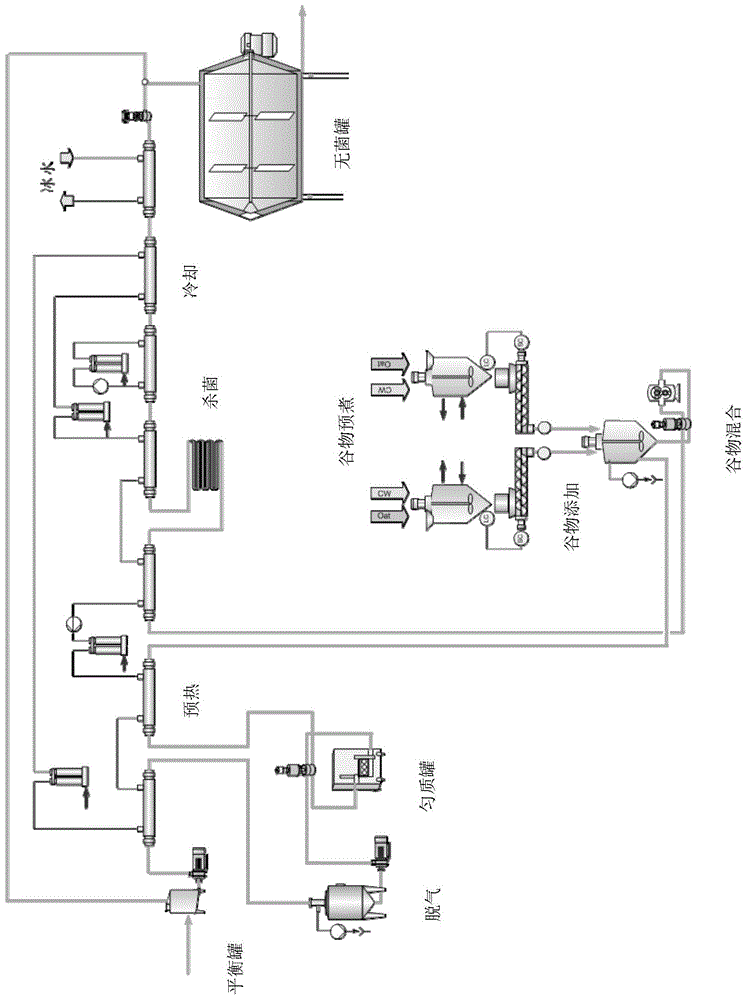

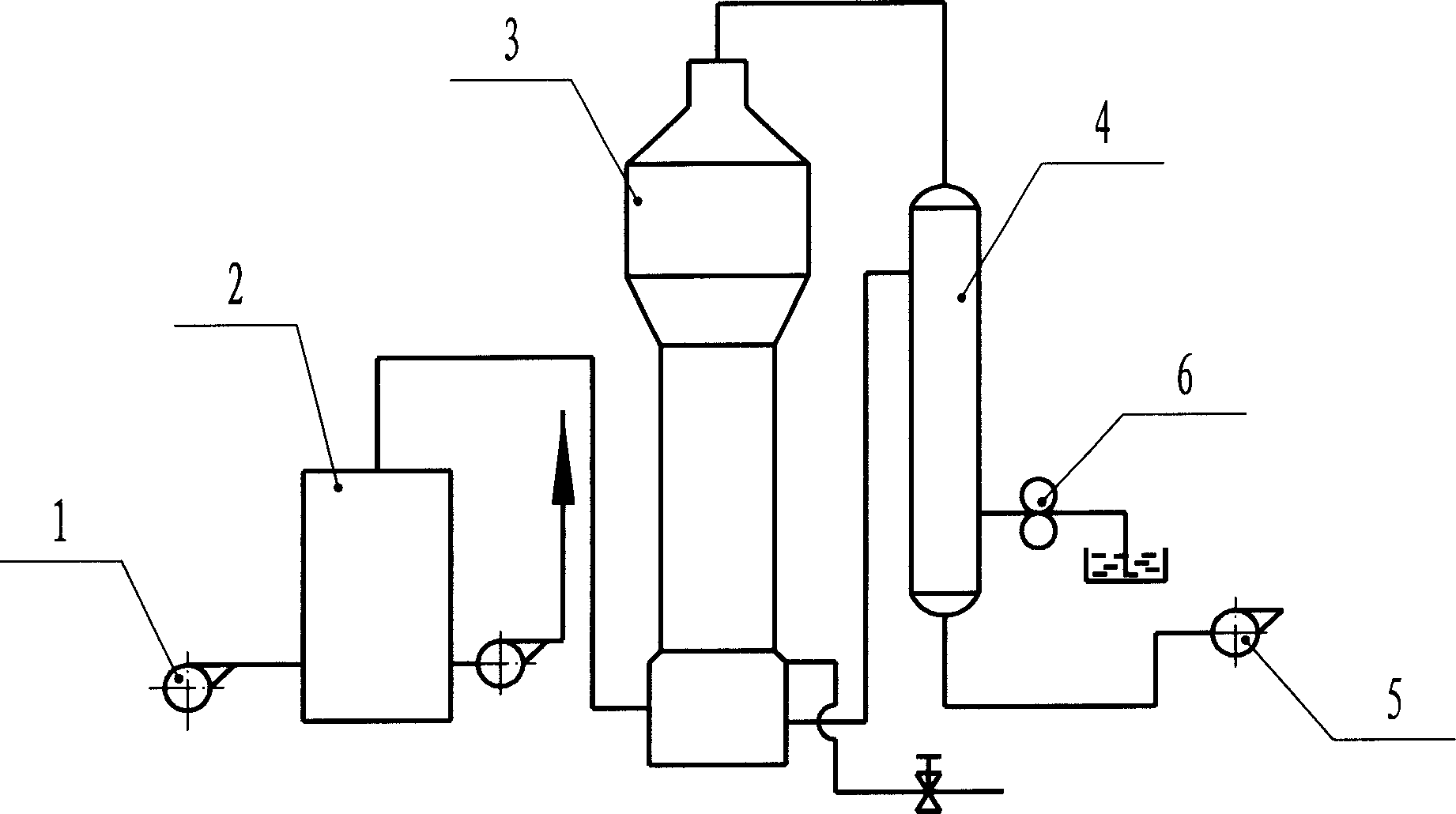

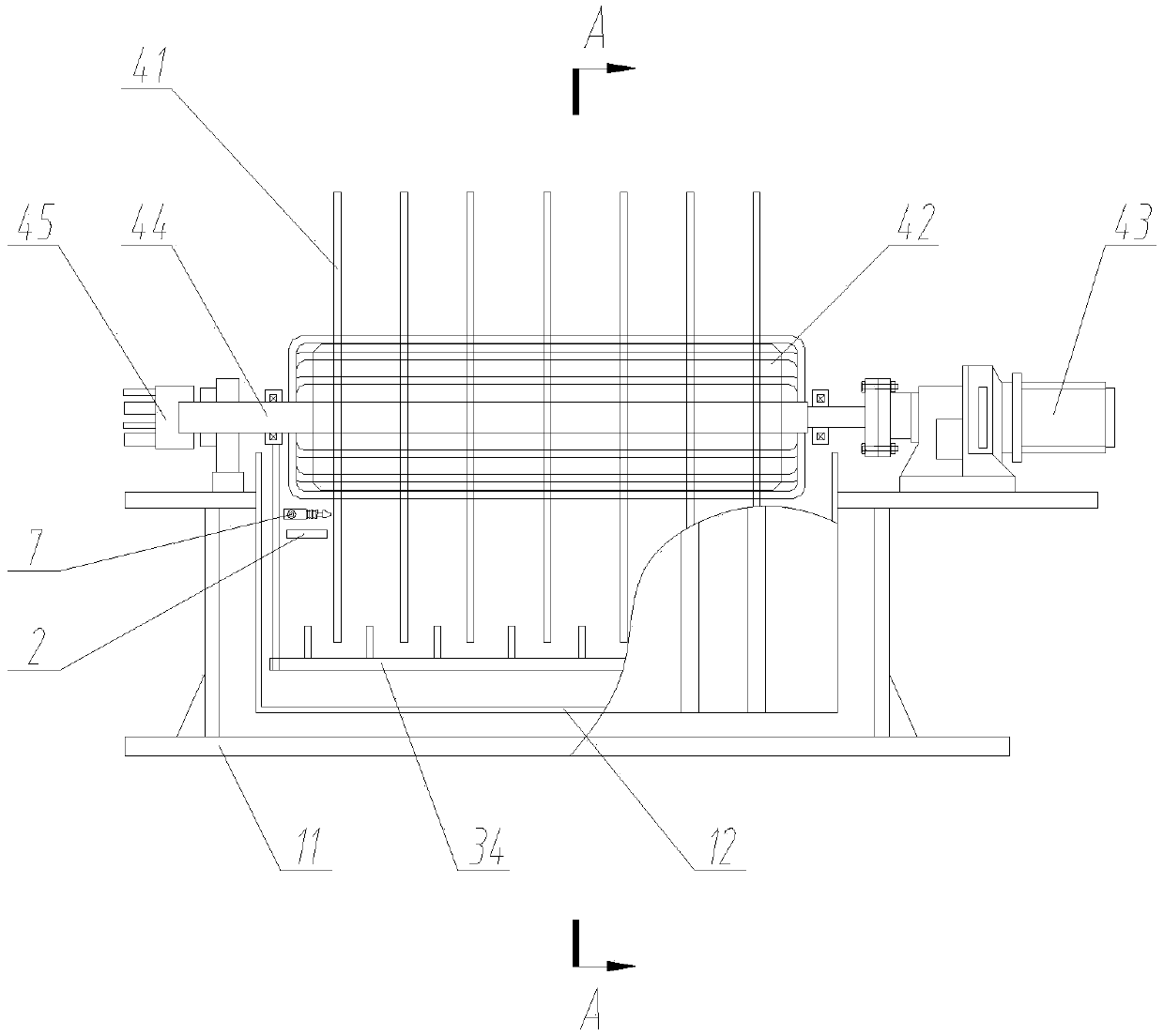

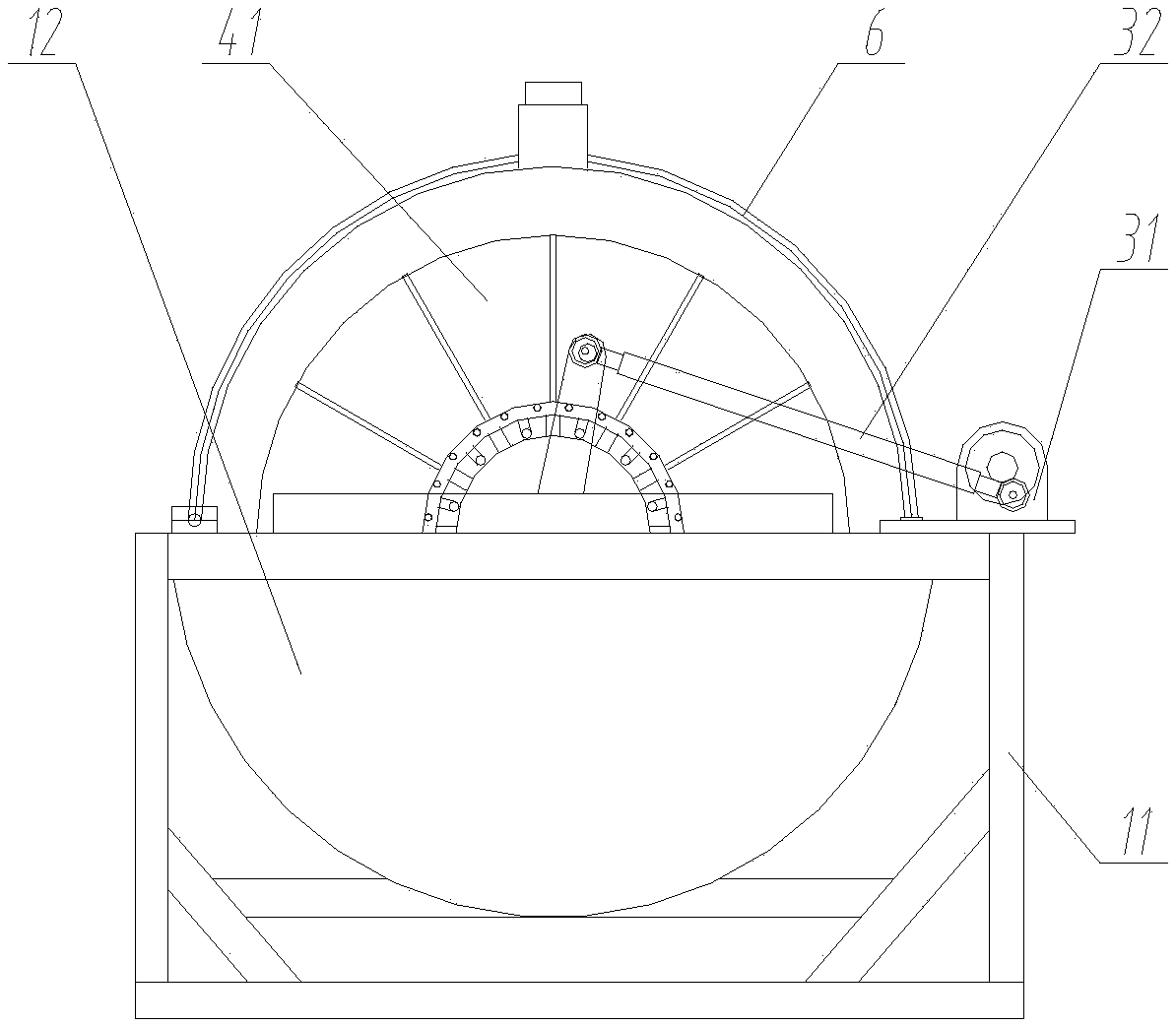

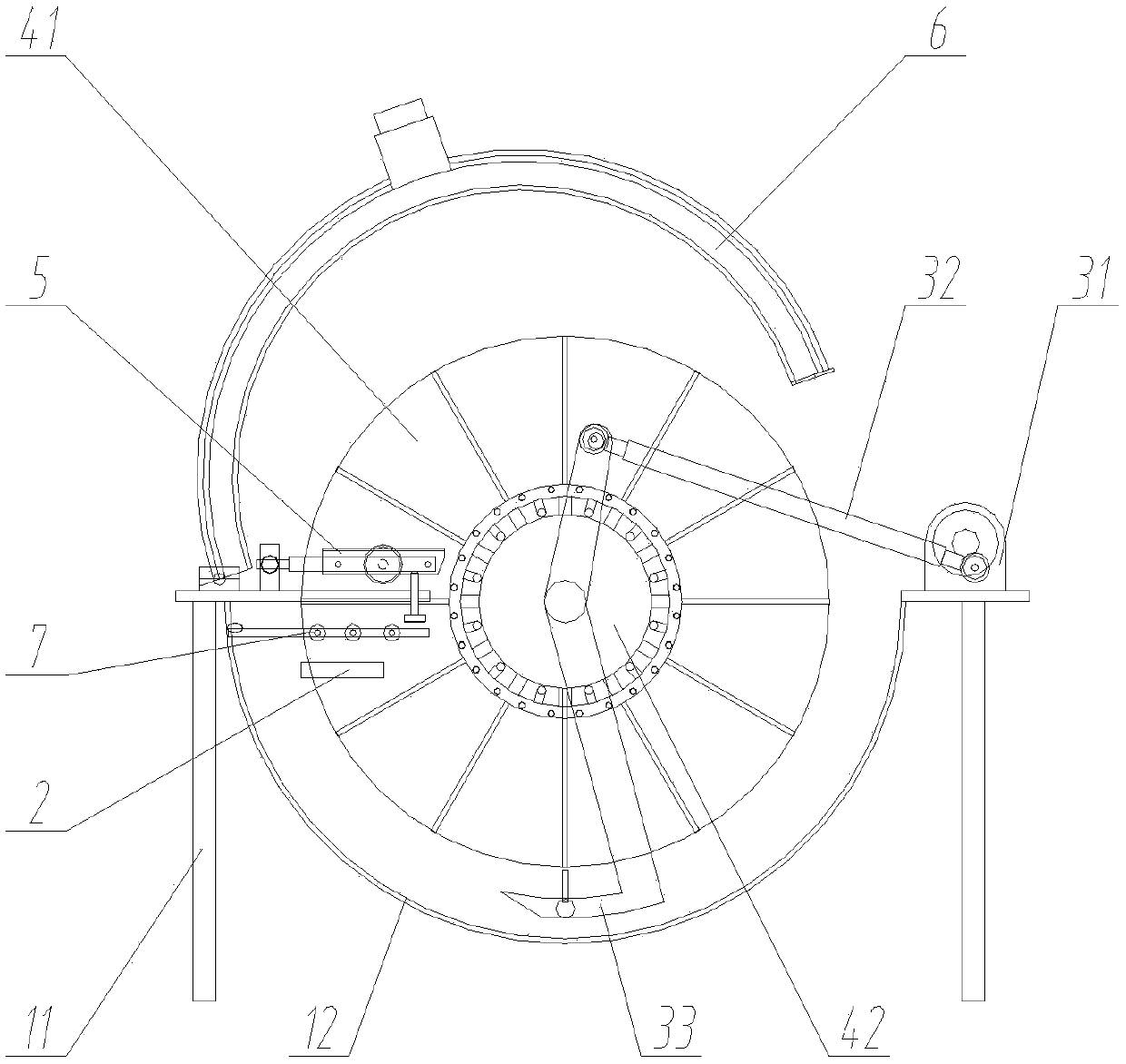

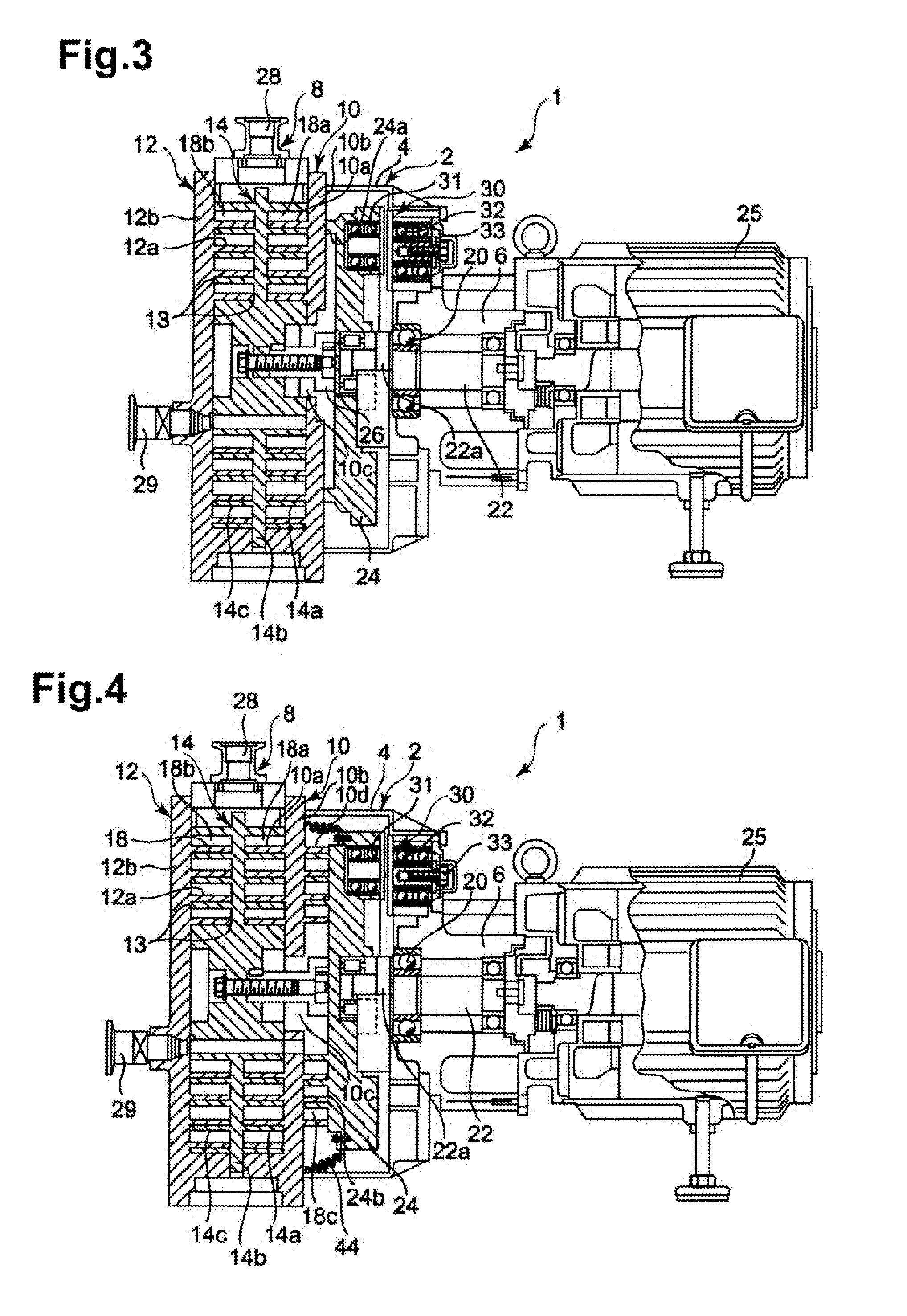

Continuous production process and devices of milk drink containing cereal grains

The present invention discloses a continuous production process and devices of milk drink containing cereal grains. The devices include an aseptic tank, a heat exchange sterilization conveying pipeline, and a grain adding device. The devices are characterized in that: the grain adding device includes a plurality of precooking tanks, mixing tanks and quantitative putting mechanisms. Cereals are put into the precooking tanks, water washing, draining, precooking, and cooling are carried out, the precooked cereal grains are continuously and quantitatively added into the mixing tanks through the quantitative putting mechanisms from the precooking tanks, at the same time, milk or drink is injected into the mixing tanks to be stirred and mixed together, then the mixture is subjected to heat sterilization, the sterilized mixture is cooled, the cooled mixture is injected into the aseptic tank to be stored and stirred, and finally the finished products are obtained by filling. The existing sterilization machine and aseptic tank structures are utilized, which achieves the production of the drink containing cereal grains or milk, online adding and continuous automatic filling, avoids pipeline blockage, improves productivity and reduces production costs.

Owner:GEA PROCESS ENG ASIA LTD

Hot-air mediated evaporation and concentration method

InactiveCN1522779AExtend continuous running timeVisible energy-saving effectEvaporationAgricultural engineeringEvaporation

The present invention relates to the field of concentration by evaporation technology. Said equipment is mainly composed of hot-air indirectly-heating hot-blast furnace, evaporator, condenser and hot-air transferring equipment. The hot-air outlet of indirectly heat-exchanged hot-blast furnace is connected with evaporator by pipeline, the outlet of evaporator is connected with condensation heat-exchanger, and the air outlet of condenser is connected with blower fan by pipeline, so that they are formed into the connected evaporation and condensation system.

Owner:辽宁东大粉体工程技术有限公司

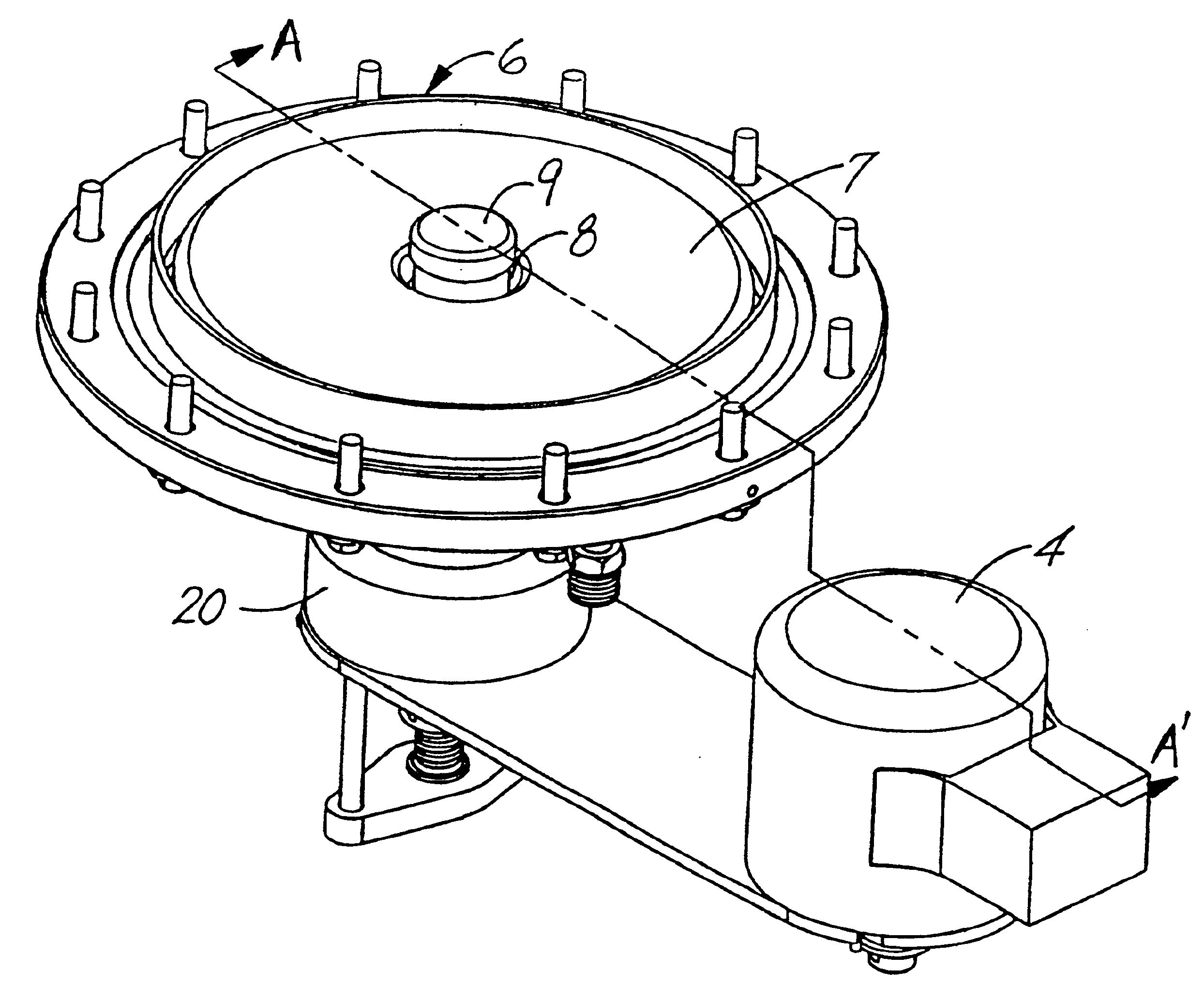

Spinning disk evaporator

InactiveUS6887346B2Increase rangeImprove productivityDrying using combination processesLiquid surface applicatorsOrganic liquidsEvaporation

Liquid organic material is controllably delivered to a receptacle located in the center of a heated surface capable of horizontally rotating about its central axis. As the heated surface rotates, material deposited within the central receptacle is forced outwardly and across the rotating surface. As the material moves radially, it evaporates into a vapor which is then transported to one or more nozzles. From the nozzles, the vapor is applied to a substrate and condensed. Relative to existing devices and methods, the present invention enables the evaporation of a wider variety of organic liquids, greater reliability in continuous operation, a decrease in maintenance, and a larger and more constant material flow rate.

Owner:3M INNOVATIVE PROPERTIES CO

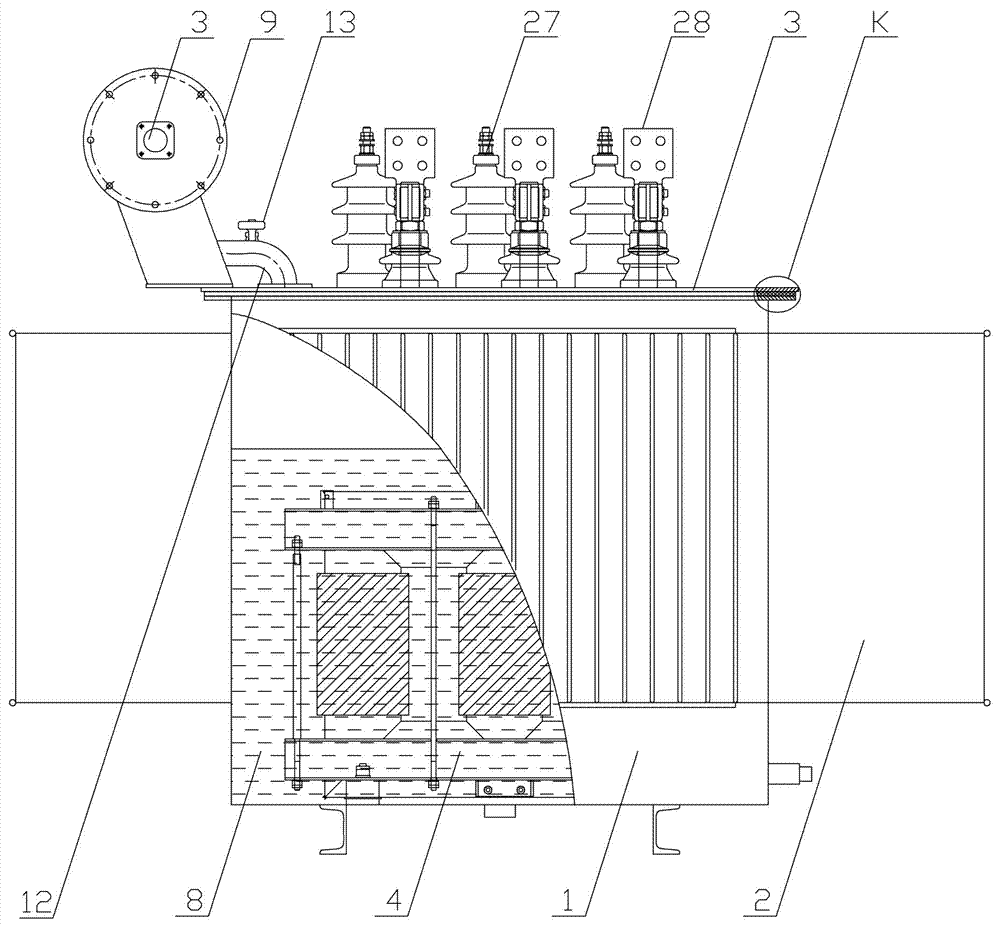

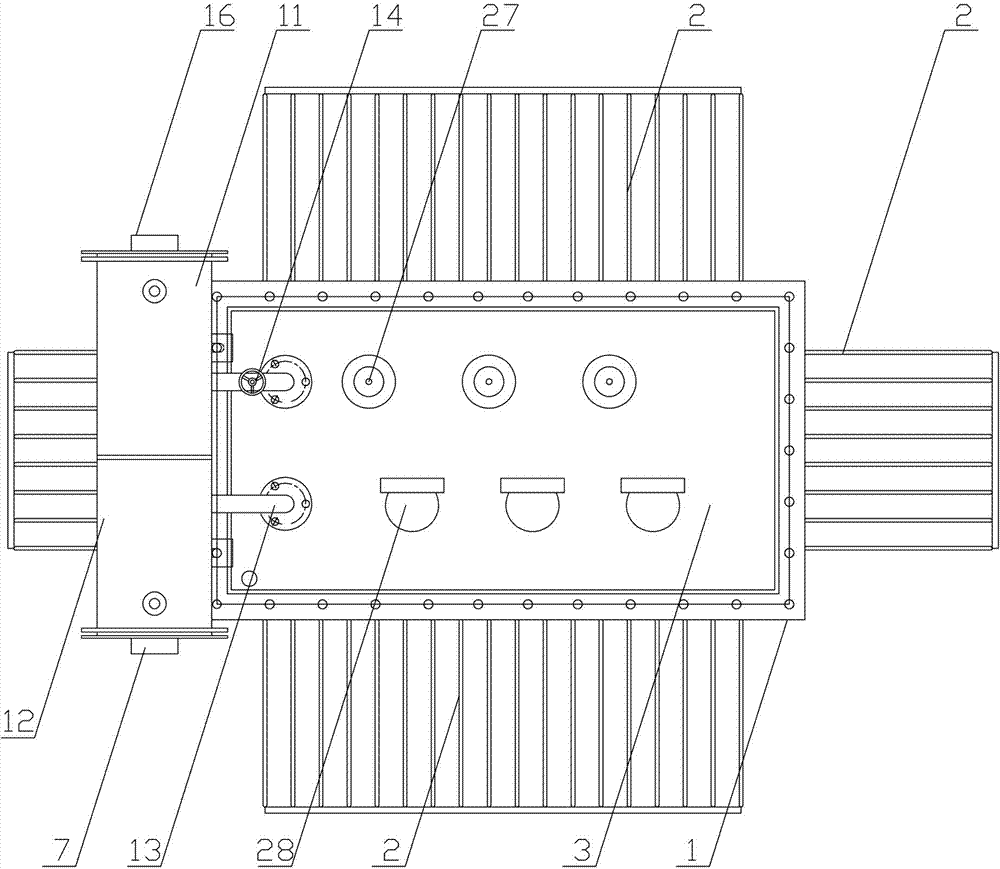

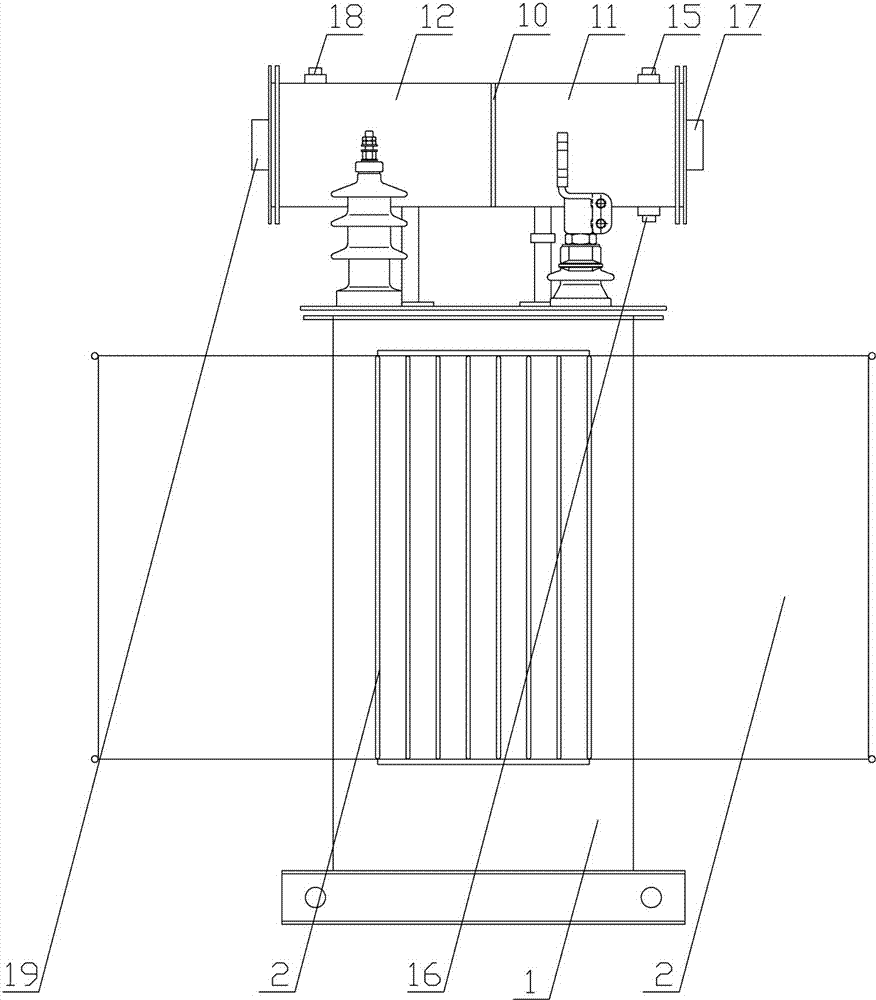

Oil-immersed type high-overload power transformer

ActiveCN104124039AExcellent arc corona resistanceBig room for expansionTransformers/inductances coolingTransformers/inductances casingsTemperature resistancePersonnel safety

An oil-immersed type high-overload power transformer is provided with an open transformer box body. A sealed cover plate is arranged above the box body. A transformer core is arranged in the box body. The oil-immersed type high-overload power transformer is characterized in that organic high-temperature-resisting paint is sprayed on the inner surface and the outer surface of the box body, a sealing cushion made of fluororubber is embedded between an opening edge on the upper portion of the box body and the sealing cover plate, dimethyl silicone oil is arranged in the box body to be used as transformer oil, a cylindrical box body is fixedly arranged on the sealing cover plate of the transformer, a partitioning plate is arranged in the middle of the cylindrical box body, and the partitioning plate divides the whole cylindrical box body into an oil storage box and an expanding box in a partitioning mode. According to the structure, performance is stable, materials has high temperature resistance and corrosion resistance, continuous working time of an oil-immersed transformer under an overload situation is greatly prolonged, meanwhile, the expanding box is added, the problem that inner temperature of the transformer is too high, pressure is increased, and accordingly explosion happens can be avoided, and normal working operation of the transformer and the personnel safety of a using person are guaranteed.

Owner:HUBEI WANGAN TECH

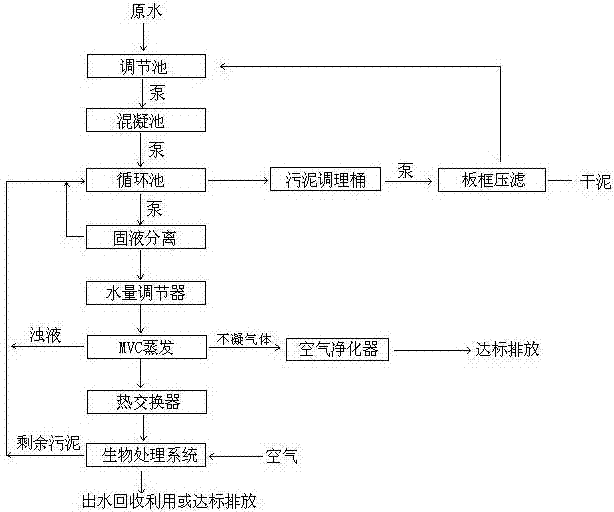

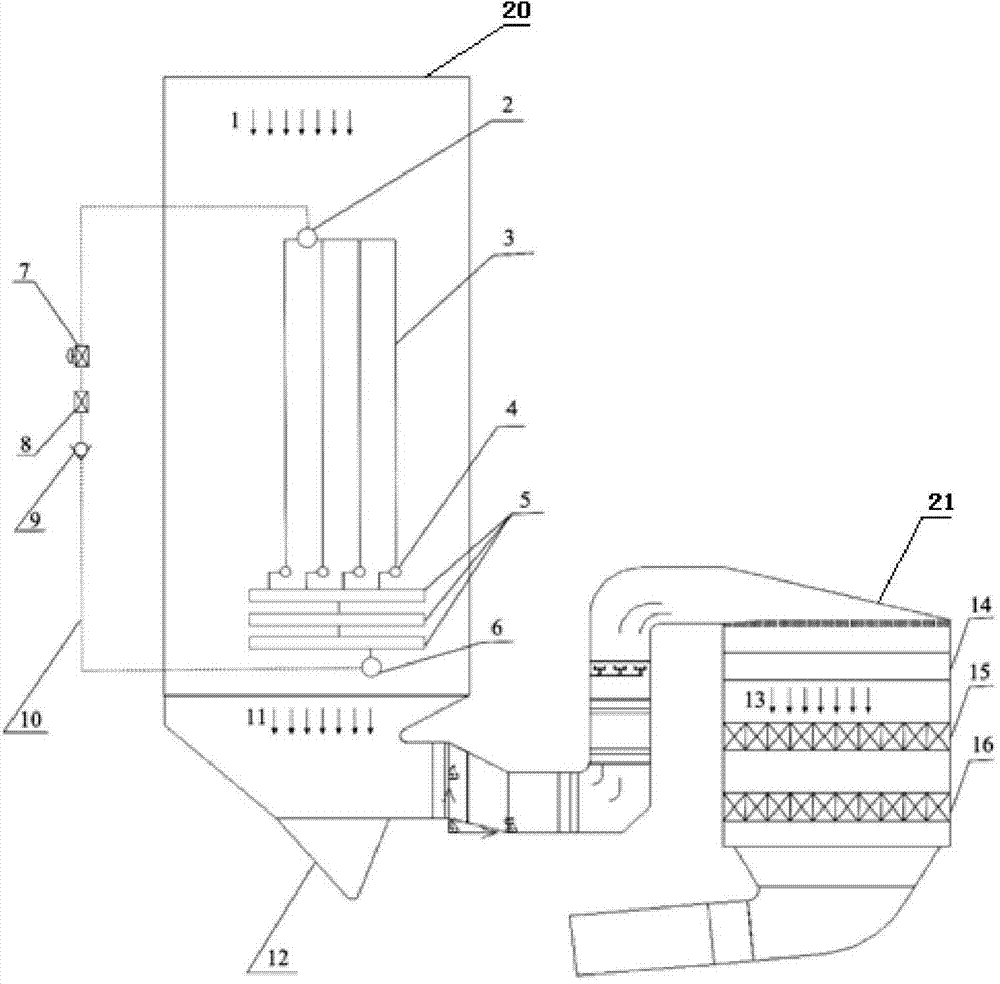

Combination system for treating landfill leachate and method for treating landfill leachate by using combination system

InactiveCN103588356AImprove evaporation efficiencySimple biological treatmentMultistage water/sewage treatmentChemical oxygen demandEnvironmental engineering

The invention discloses a combination system for treating landfill leachate and a method for treating landfill leachate by using the combination system. The combination system for treating the landfill leachate is formed by combining a solid-liquid separation system, an MVC (Mechanical Vapor Compression) evaporation system and a biological treatment system. When being treated, the landfill leachate firstly passes through the solid-liquid separation system to ensure that the contents of COD (Chemical Oxygen Demand), SS (Suspended Substances), colloids, grease and the like in a supernatant liquid are greatly reduced, so that the evaporation efficiency of the supernatant liquid entering the MVC evaporation system is greatly increased, the MVC blockage is avoided, the scaling is delayed to the maximum extent, and the scaling problem is easier to solve; meanwhile, the concentration of the COD in water evaporated by MVC is greatly reduced so that the subsequent biological treatment becomes simpler and easier. Therefore, the combined treatment process for the landfill leachate is very remarkable in synergistic effect and suitable for large-scale popularization.

Owner:广东云水谣环保科技有限公司

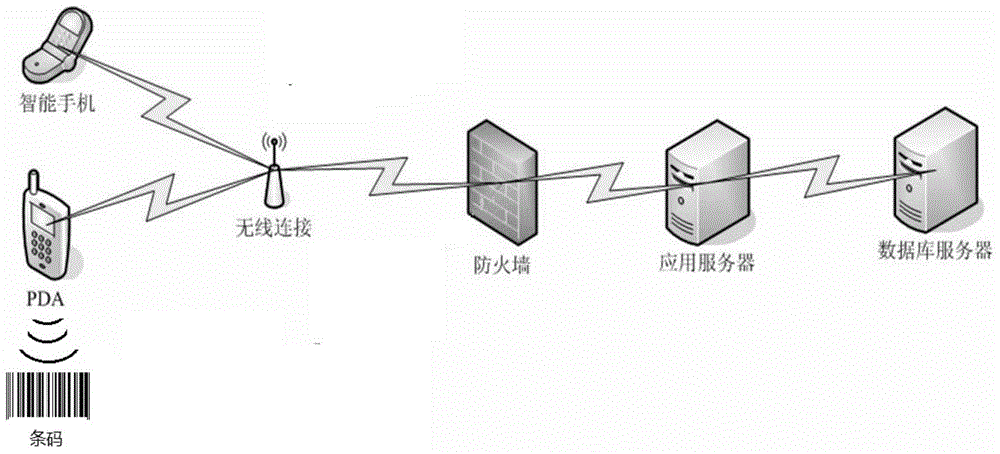

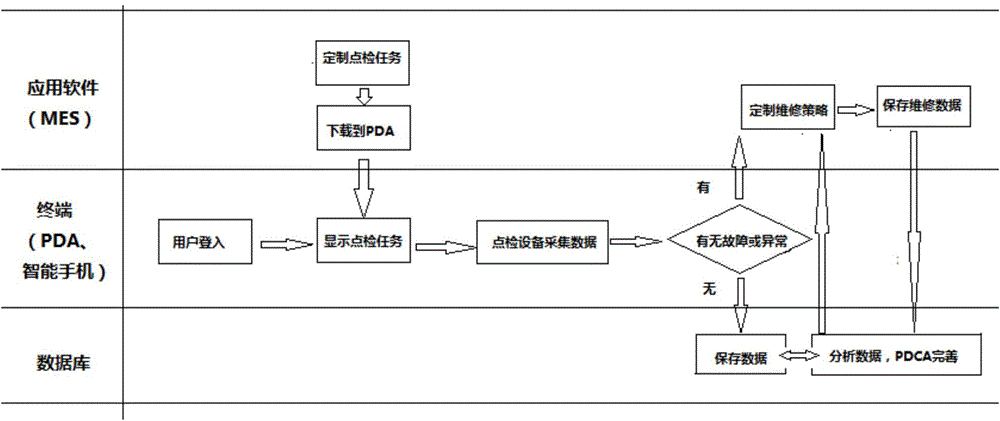

Tobacco production line equipment inspection method based on wireless technology

InactiveCN104680615AQuickly query maintenance strategiesMake fastRegistering/indicating working of machinesProduction lineRelevant information

The invention relates to a tobacco production line equipment inspection method based on a wireless technology. The method specifically comprises the following steps: by utilizing a wireless WIFI technology, inspecting the real-time operating conditions of tobacco production line equipment according to the preset inspection route and requirements by virtue of a portable PDA device, bar codes and an equipment management system, and feeding back the equipment operation related information data in real time; and mastering the operating conditions and potential failure and abnormality condition of the production line equipment by an equipment manager according to the data analysis result, and making a maintenance policy. According to the method disclosed by the invention, the functions of equipment inspection route arrangement, operating state and data recording, maintenance record perfection and data summarization analysis can be realized according to the actual requirements of inspection operations of the tobacco production line equipment, the method can be combined with an existing equipment management system in the factory, the inspection operation condition is effectively known, the potential failure of the equipment is timely discovered, the equipment operating safety is improved, the equipment maintenance cost is reduced, and the equipment management efficiency is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

Secondary battery controller and method for controlling secondary battery, and electronic apparatus

ActiveUS8816646B2Extend continuous running timeElectric signal transmission systemsSequential battery dischargeElectrical batteryOperating time

A secondary battery controller and a method for controlling a secondary battery that can increase the continuous operating time of an apparatus. The secondary battery controller includes a plurality of temperature detectors that detect temperatures of a plurality of secondary batteries; a switching device that connects an output of any one of the plurality of secondary batteries to a load; and a control portion that selects which secondary battery to use from the plurality of secondary batteries and controls the switching device to switch between the secondary batteries based on temperature information of each of the plurality of secondary batteries.

Owner:PANASONIC CORP

In-situ activating agent and method of biological aerated filter filling biological membrane

ActiveCN105753142APrevent severe inhibitionSystem disturbance is smallTreatment using aerobic processesSustainable biological treatmentBiological membraneSewage treatment

The invention discloses an in-situ activating agent and method of a biological aerated filter filling biological membrane and belongs to the technical field of biological membrane process sewage treatment.The method comprises the steps: first, preparing a biological membrane in-situ activating agent; second, adding the biological membrane activating agent while the biological aerated filter is kept running, and treating continuously for 7-12 days; third, stopping the biological aerated filter, stopping adding the in-situ activating agent, and starting a backwash water pump for backwashing; fourth, after in-situ activation, restating the biological aerated filter.The biological membrane in-situ activating agent is made by composting proteinase, amylase and metal ions and can composite and form EPS of biological membrane structure, breakage and dispersion of the aged biological membrane are facilitated, backwash efficiency is improved, the problem in in-situ renewal and activation of the aged biological membrane of the biological aerated filter is solved effectively, and the in-situ activating agent and method are simple to perform and environment-friendly.

Owner:NANJING UNIV

Gasified fly ash dehydration treatment technique

ActiveCN109529440AAvoid wastingReduce moisture contentMoving filtering element filtersThermal energyWater quality

The invention discloses a gasified fly ash dehydration treatment technique. The collaborative dehydration processes of multiple energy fields of chemical energy, ultrasonic waves, heat energy, mechanical energy, electric energy and the like are integrated, the diameters of capillary micropores of dehydration medium ceramic filter discs are small, capillary tubes are distributed densely, the speedof filtrate passing through a filter plate is high, almost all gasified fly ash cannot be subjected to penetration filtering, and the dehydration and filter effects are good; through unique scraping and spray-cleaning operation, sediments can be cleared in time, frequent replacement caused by damage or blockage is avoided, and equipment can operate continuously for a long term and is high in efficiency; and the ceramic filter discs are provided with the micropores generating a capillary effect, the micropores can be always kept in the state of being full of liquid, no air penetrates through the ceramic filter discs, thus the high vacuum degree can be kept for a long time, and thus dehydration energy consumption is low. According to the gasified fly ash dehydration treatment technique, compared with gasified fly ash dehydrated by a filter-cloth-type vacuum filter commonly used at present, the water content of the dehydrated gasified fly ash is decreased by 15-20%, the water quality of the filtrate is improved significantly, the content of suspended matter is 6-16 mg / L, the maximum turbidity is 2.95 NTU, and PH is 5.0 to 9.0.

Owner:王华 +2

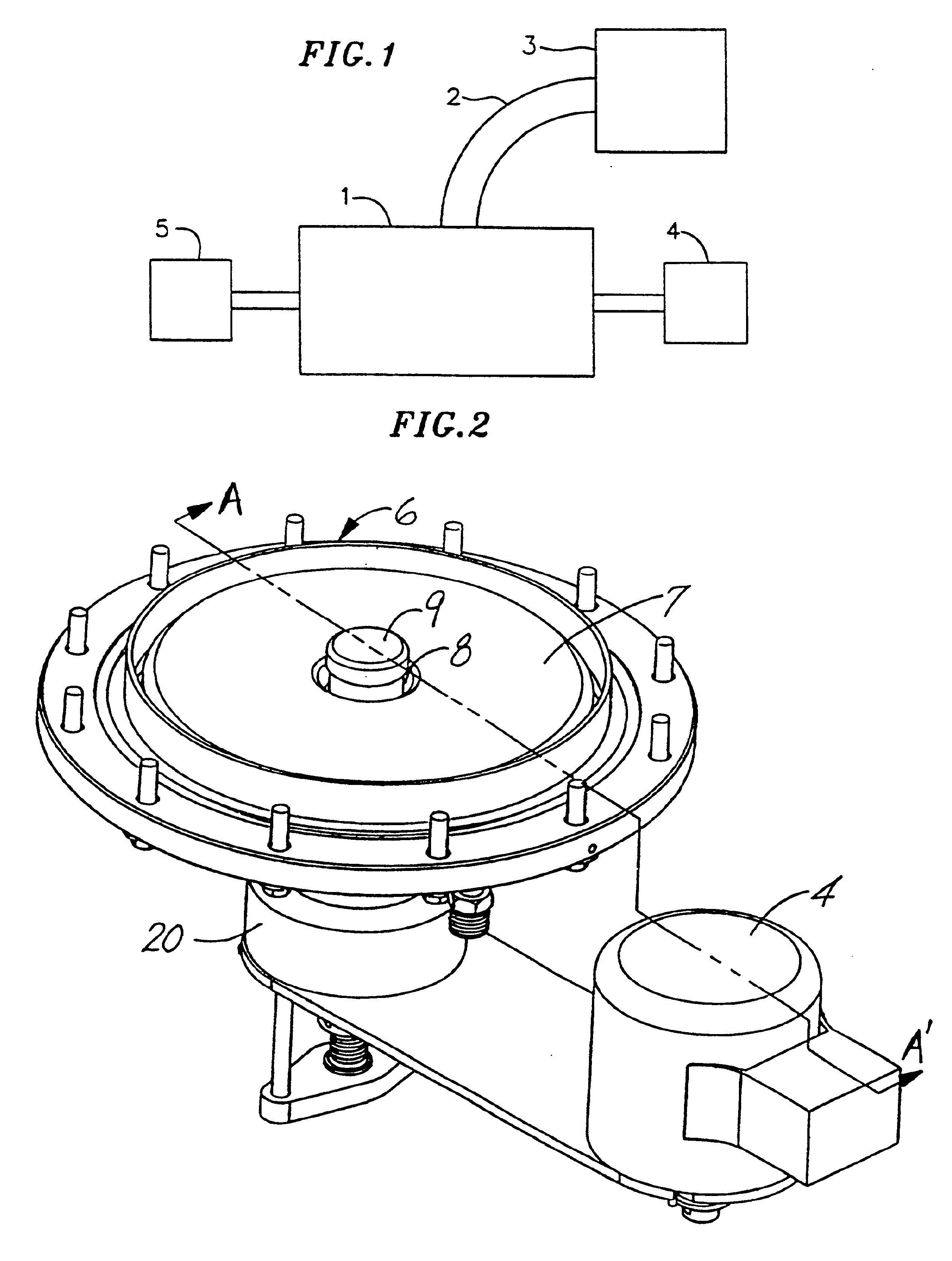

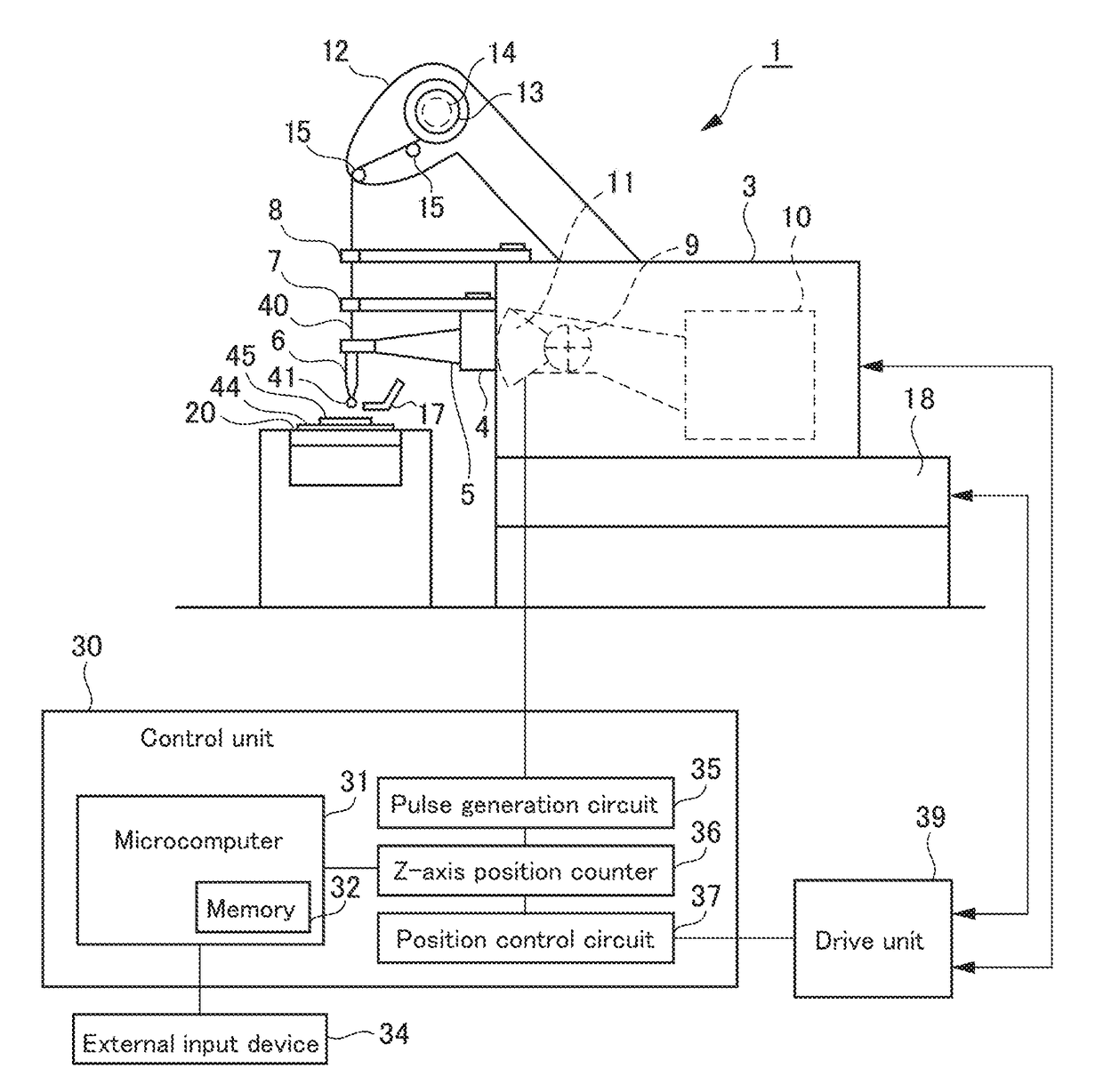

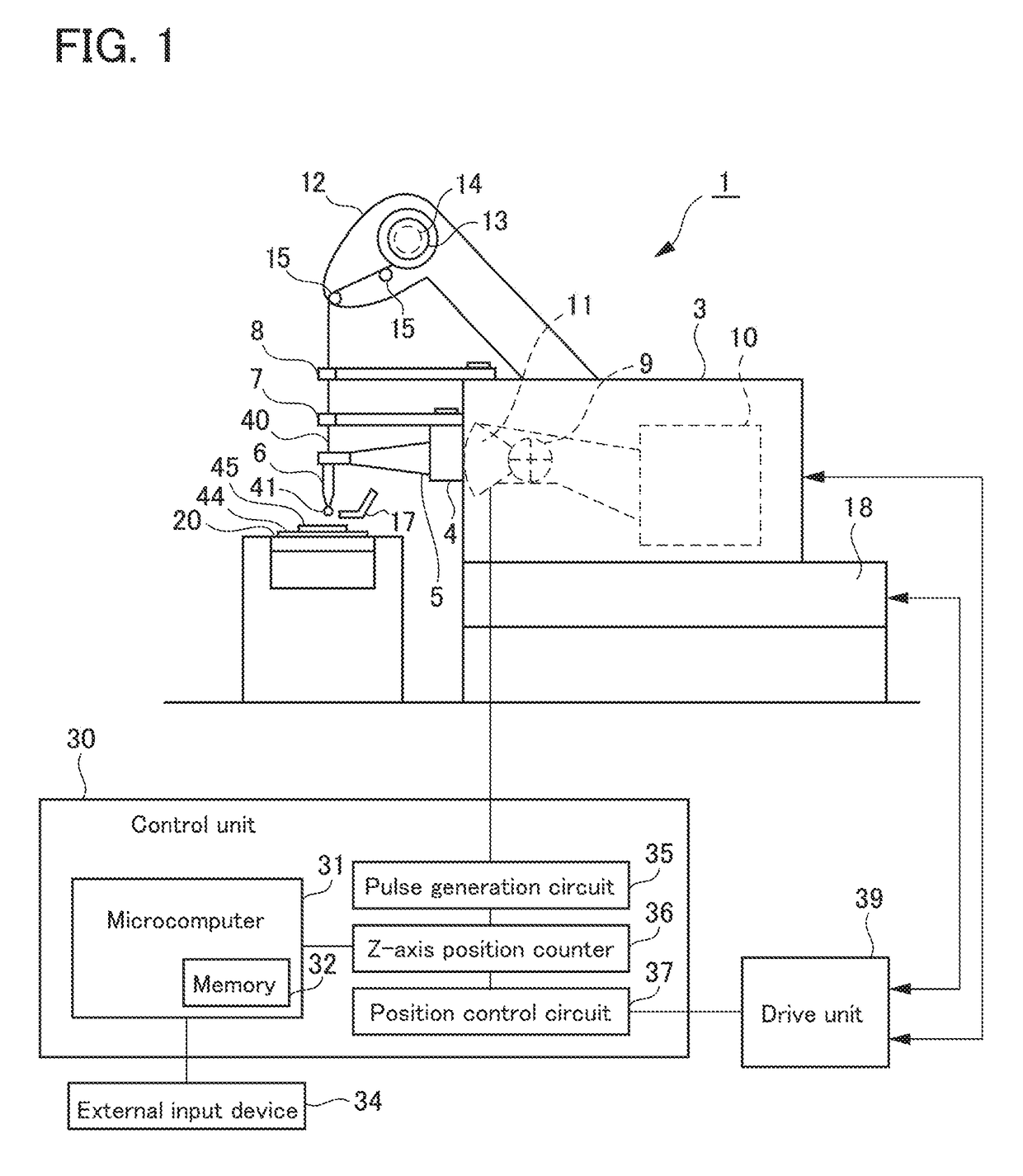

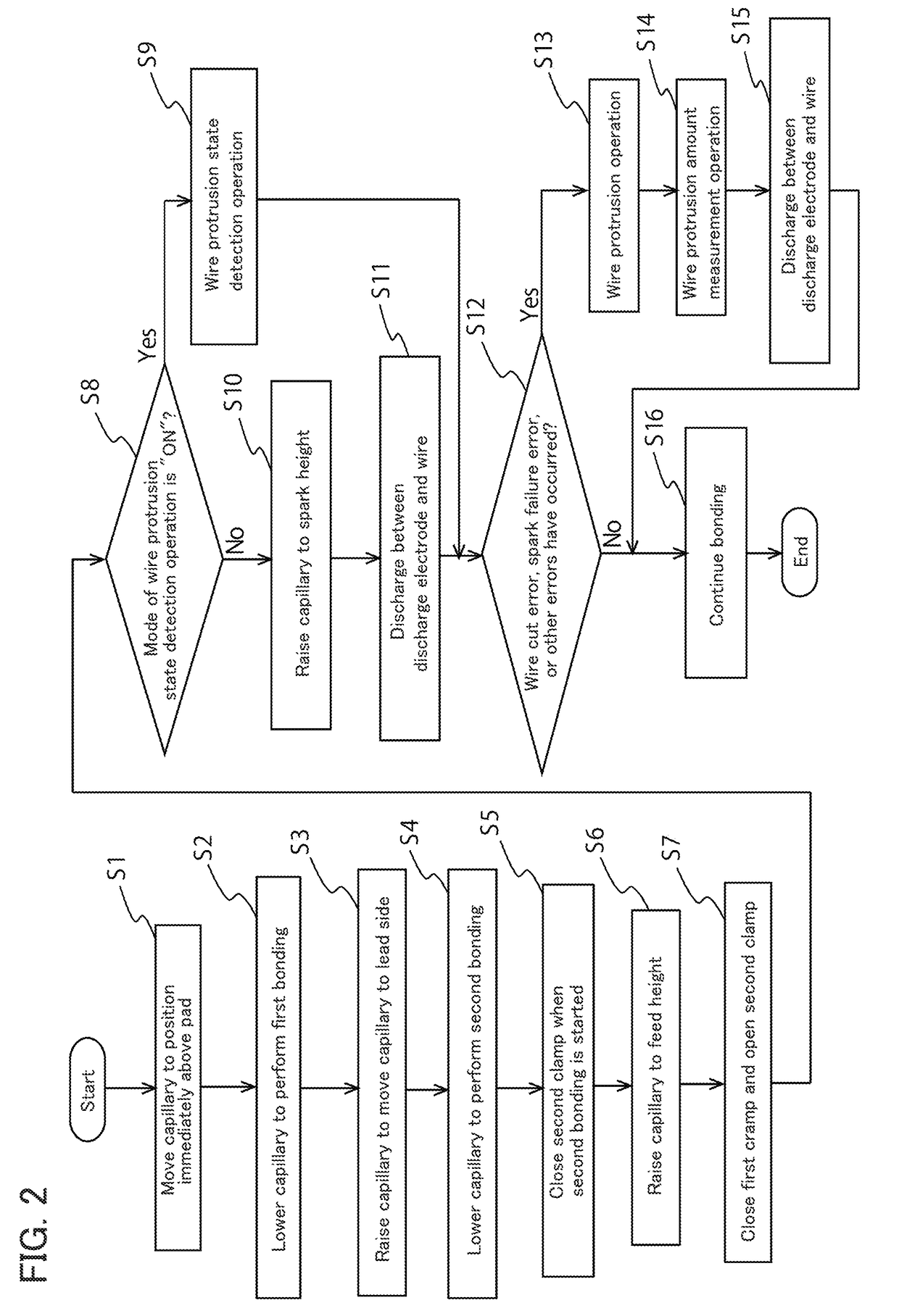

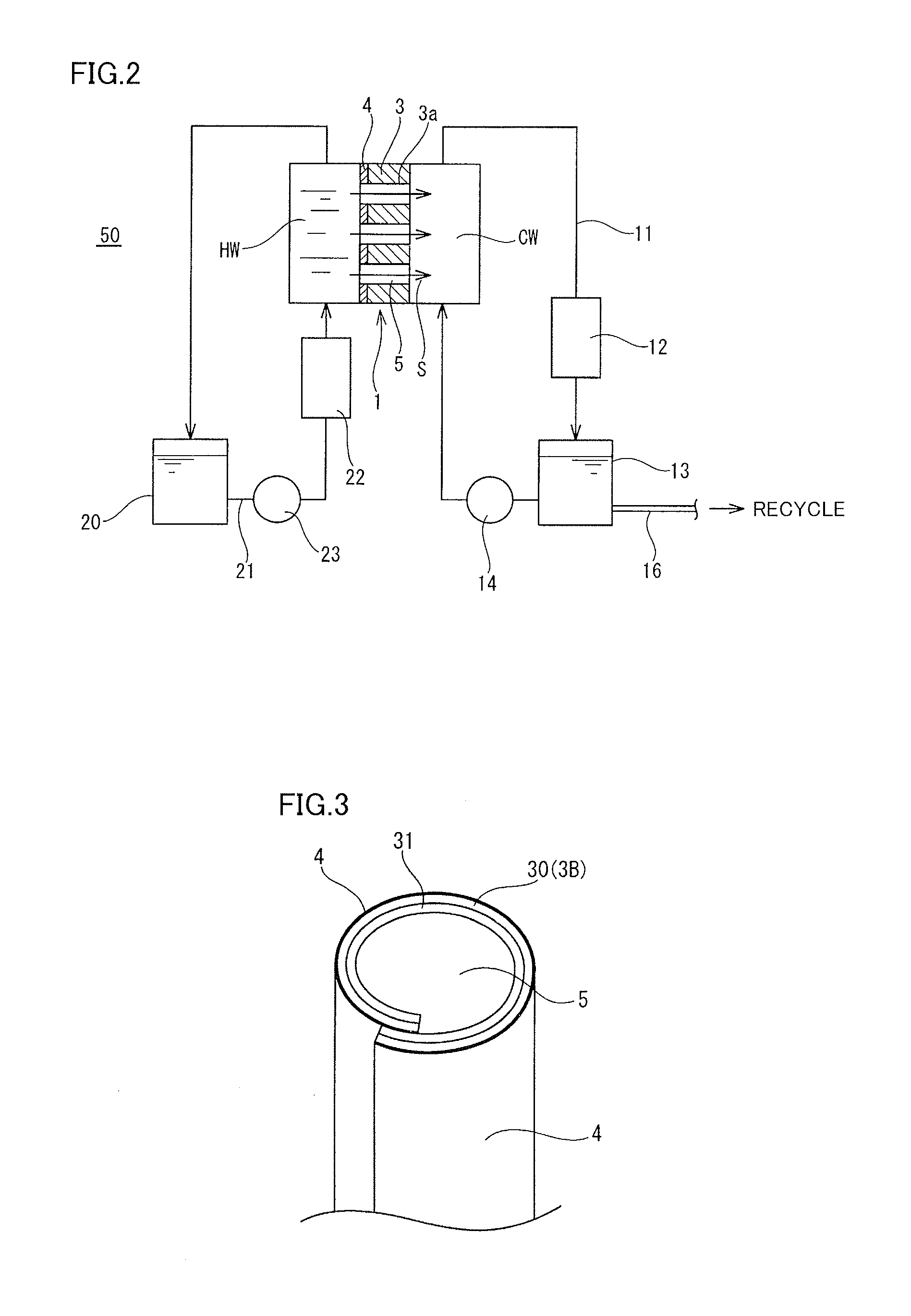

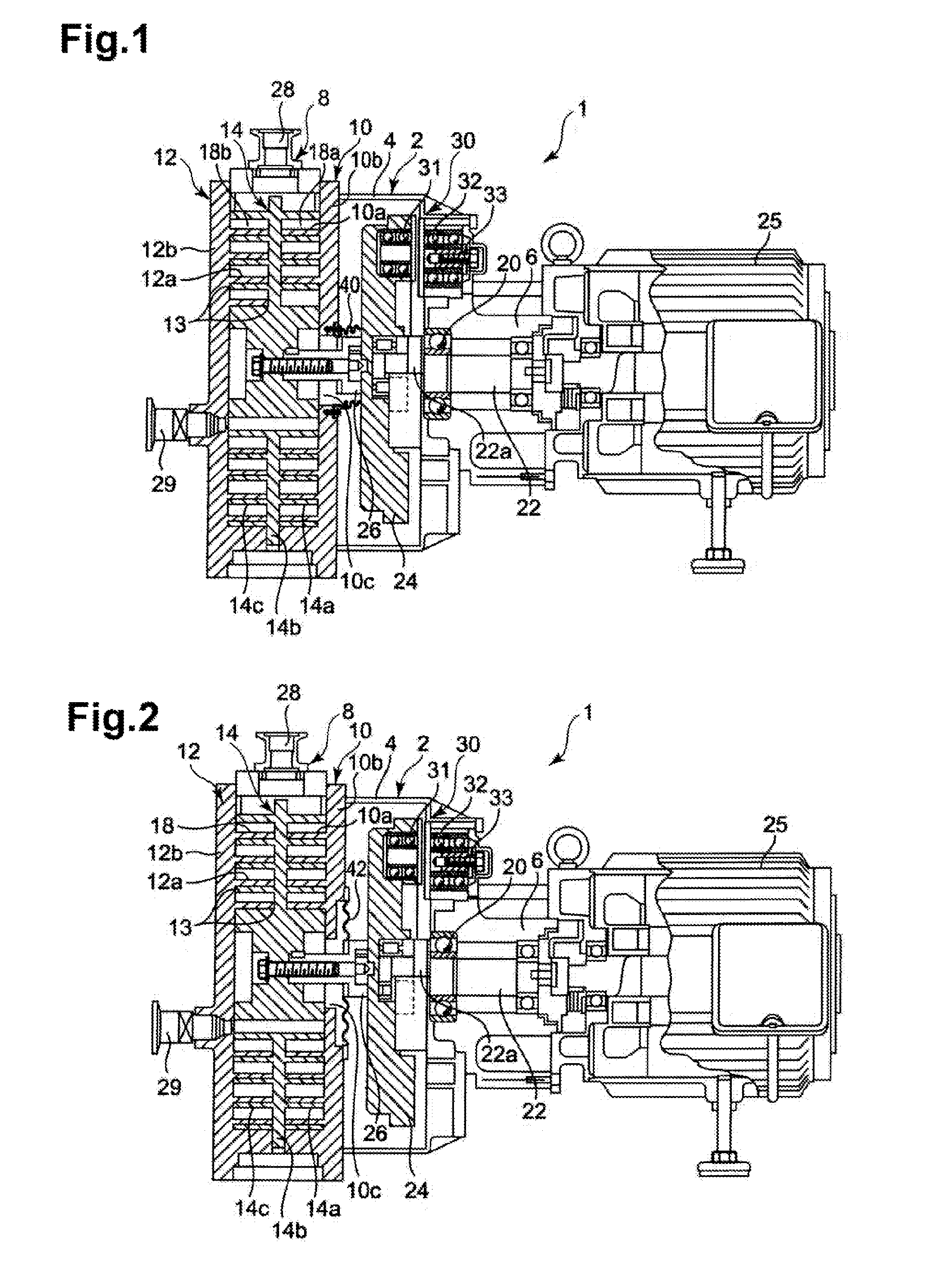

Wire bonding apparatus

InactiveUS20180151532A1Easily protrudedSmoothly protrudedSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectric wire

To provide a wire bonding apparatus, which is insusceptible to a bonding state at a second bonding point due to a wire cut error or the like, or to members such as a capillary and a wire, and is capable of automatically protruding the wire from a leading end of the capillary, provided is a wire bonding apparatus including: a capillary (6) having a through hole through which a wire (40) is to be inserted; a holding unit, which is provided above the capillary (6), and is configured to hold the wire (40) inserted through the capillary (6); and a vibrating unit configured to vertically vibrate the capillary (6). Under a state in which the holding unit holds the wire (40), the vibrating unit vertically vibrates the capillary (6) so that the wire (40) is protruded from the leading end of the capillary.

Owner:KAIJOO KK

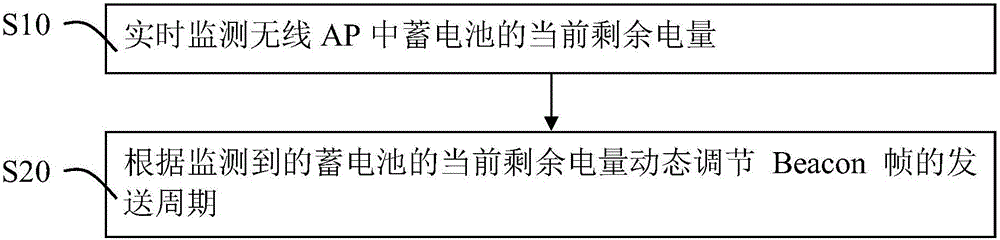

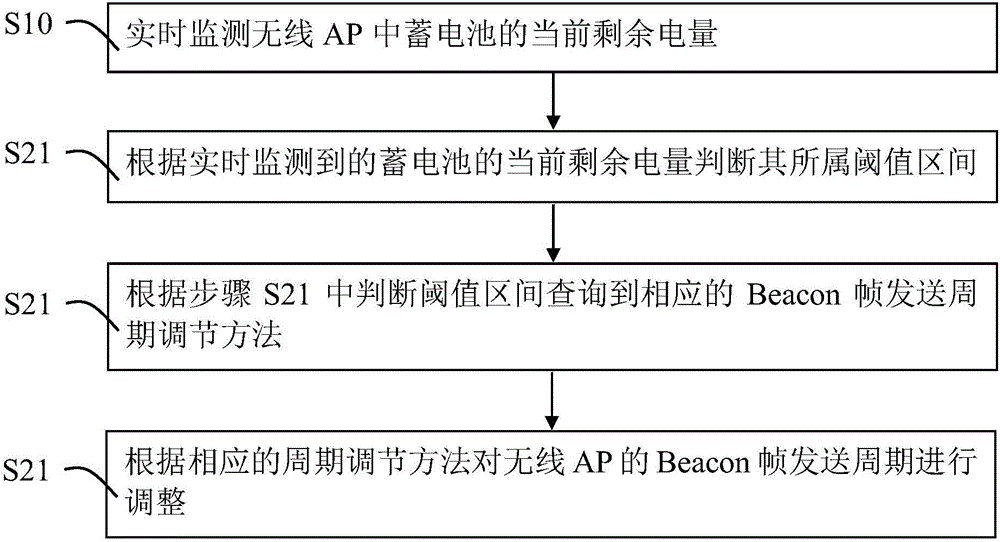

Wireless AP energy saving method and device thereof

InactiveCN106572524AExtend continuous running timeLess power consumptionPower managementHigh level techniquesBeacon framePower consumption

The invention provides a wireless AP energy saving method and a device thereof. The method comprises the steps that S10 the current remaining electric power of a battery in a wireless AP is monitored in real time, and S20 the sending cycle of a Beacon frame is dynamically adjusted according to the monitored current remaining electric power of the battery. The sending cycle of the Beacon frame of the wireless AP is adjusted according to the monitored current remaining electric power / current voltage of the battery in the wireless AP in real time. Specifically, the sending cycle of the Beacon frame is gradually increased as the electric power of the battery is reduced. The power consumption of the battery is reduced. The service life of the battery is extended. Electric power is saved. The sustainable operation time of the wireless AP is improved.

Owner:PHICOMM (SHANGHAI) CO LTD

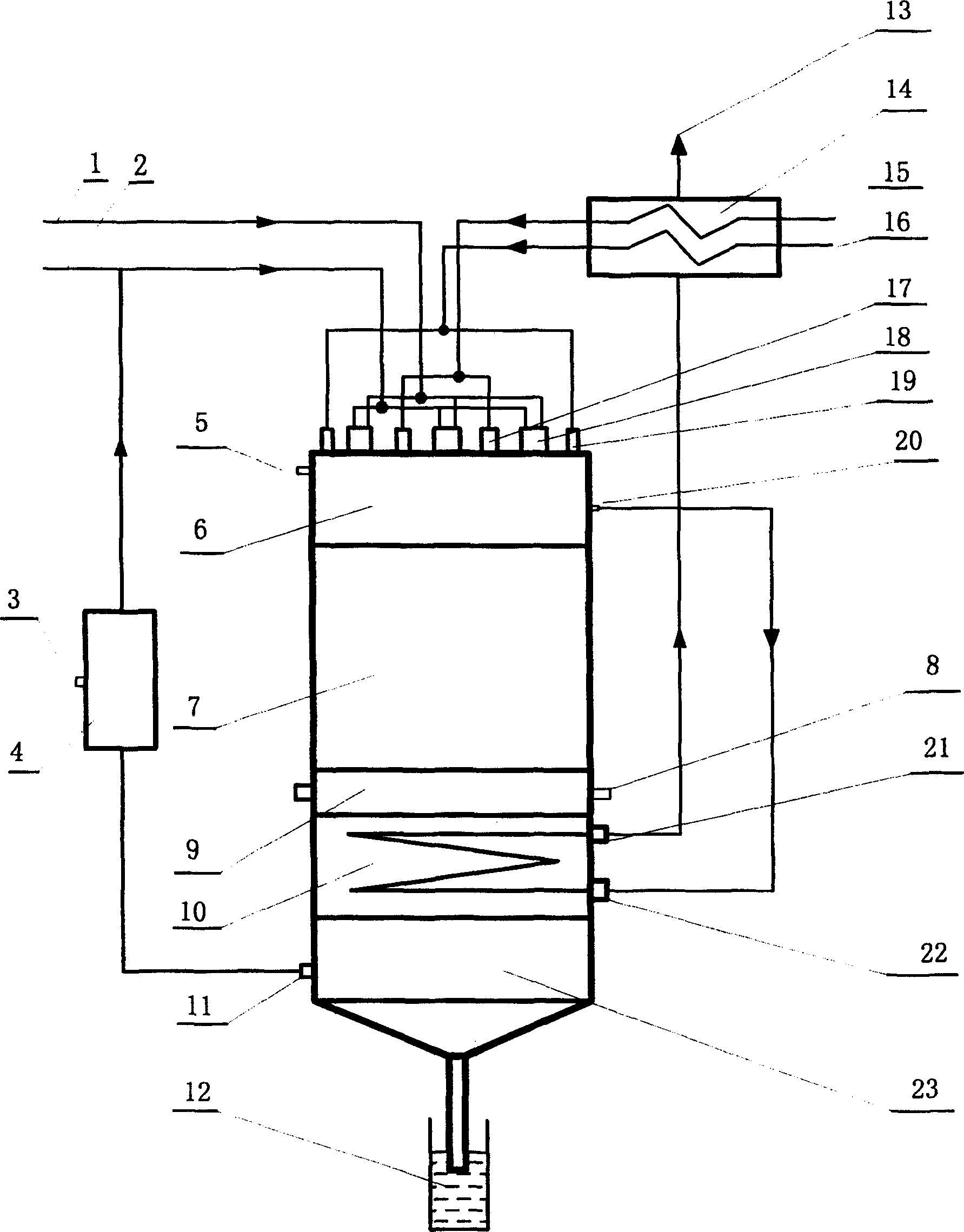

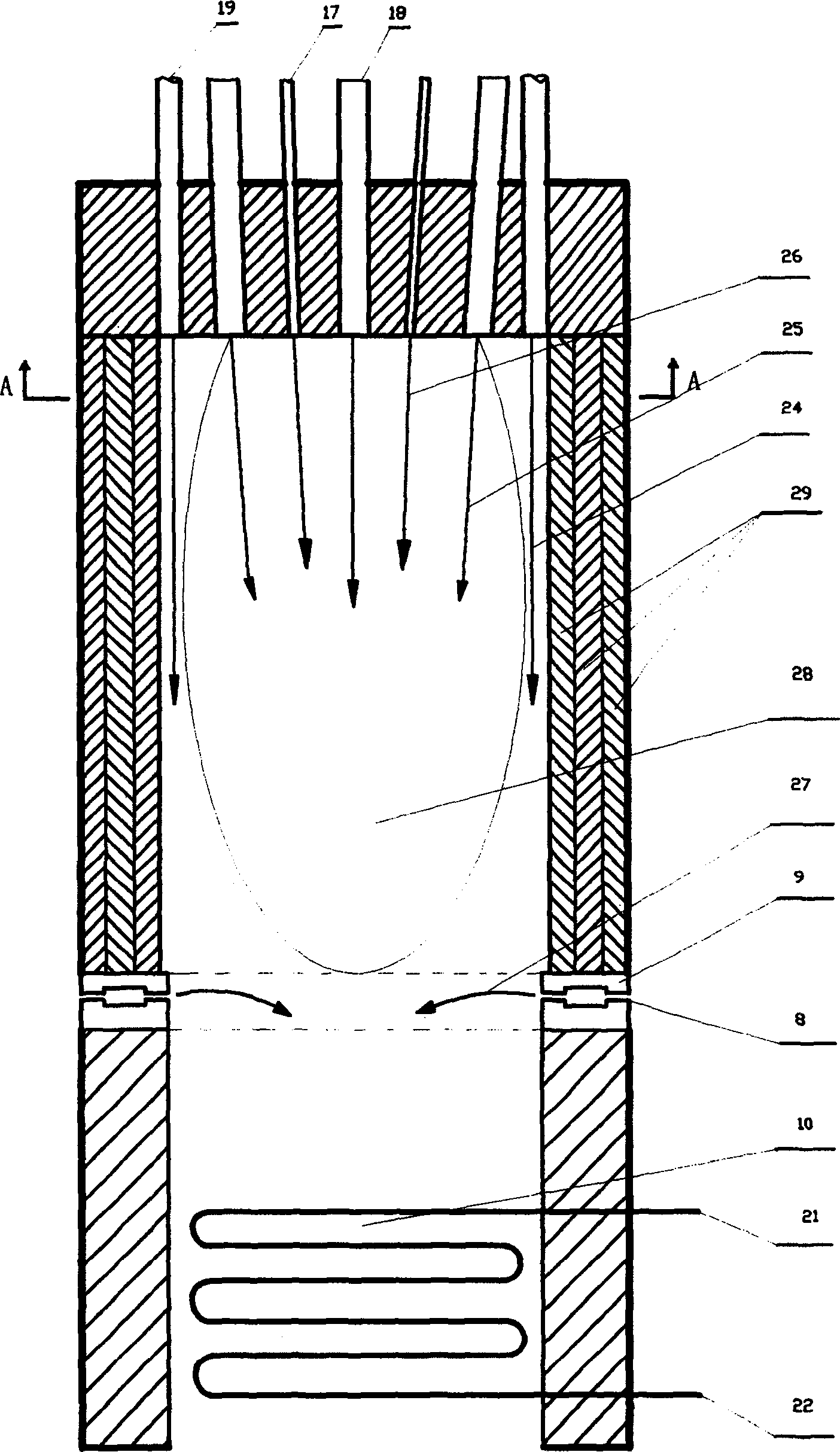

Apparatus and process for producing acetylene by plasma pyrolysis of coal and natural gas

Production of ethyne by coal and natural gas plasma pyrolyzation and its apparatus are disclosed. It is produced by spraying plasma, buggy steam current and natural gas protective gas in plasma reactor, reacting and generating mixed ethyne gas, cooling, separating, storing ethyne, passing gas into plasma generator and reutilizing, sprayed natural gas forming gas protective layer on plasma reactor wall to prevent carbon fragment from coking, and pyrolytic reacting to obtain mixed ethyne gas. It achieves high converting efficient and reacting efficient.

Owner:TAIYUAN UNIV OF TECH

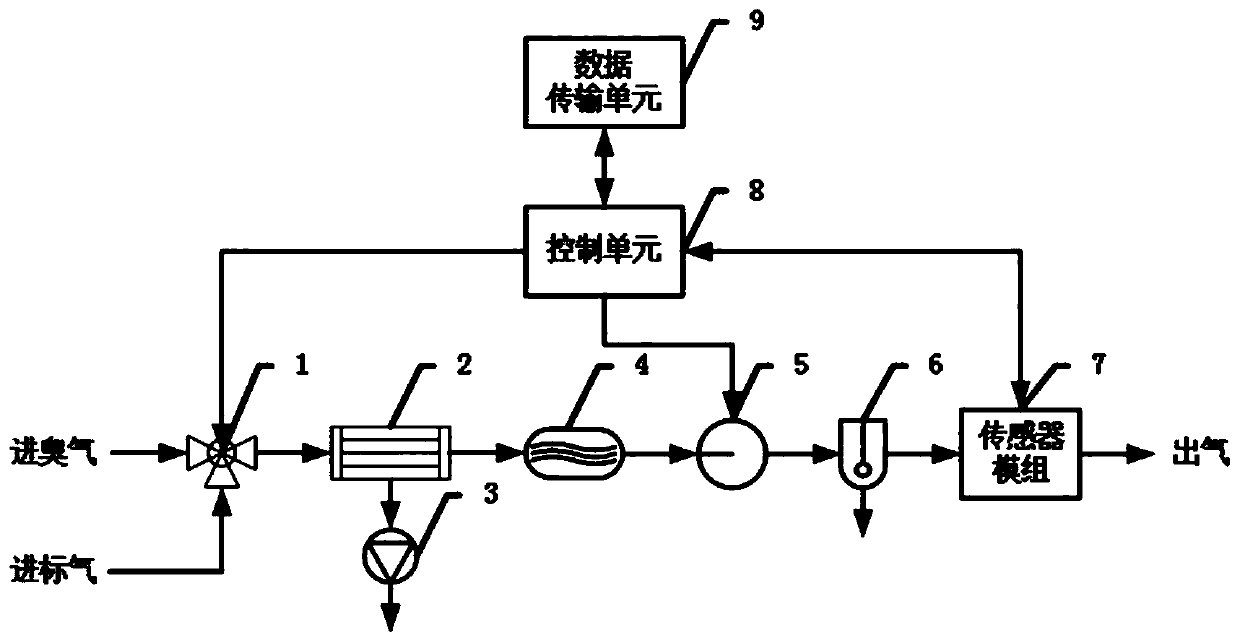

Malodorous gas online monitoring device

InactiveCN110133181AEffective filteringImprove monitoring accuracyGas analyser calibrationGas analyser construction detailsThree levelAir pump

The invention discloses a malodorous gas online monitoring device. The device is mainly formed by a gas channel reversing unit, a first filtering unit, a second filtering unit, an air pump unit, a third filtering unit, a sensor module, a control unit and a data transmission unit. According to the main effect of the device, the control unit realizes regular zero calibration of the sensor module through a reversing valve unit, the first filtering unit, the second filtering unit and the third filtering unit filter moisture and impurities in malodorous gas to guarantee the accuracy and the stability of online monitoring of sensors, the control unit acquires the concentration of the malodorous gas monitored by the sensor module, and the concentration of the malodorous gas is uploaded to a monitoring center or a monitoring station through the data transmission unit to realize the function of online monitoring of the malodorous gas. According to the device, zero calibration of the sensors isregularly and automatically performed, the moisture and the impurities in the malodorous gas are filtered in three levels, the concentration of the malodorous gas is monitored in an online manner, monitoring data is uploaded in real time, the accuracy and the stability of online monitoring of the sensors can be effectively guaranteed, the continuous operation time of the system is increased, and the false alarm rate is reduced.

Owner:上海复纯环保科技有限公司 +1

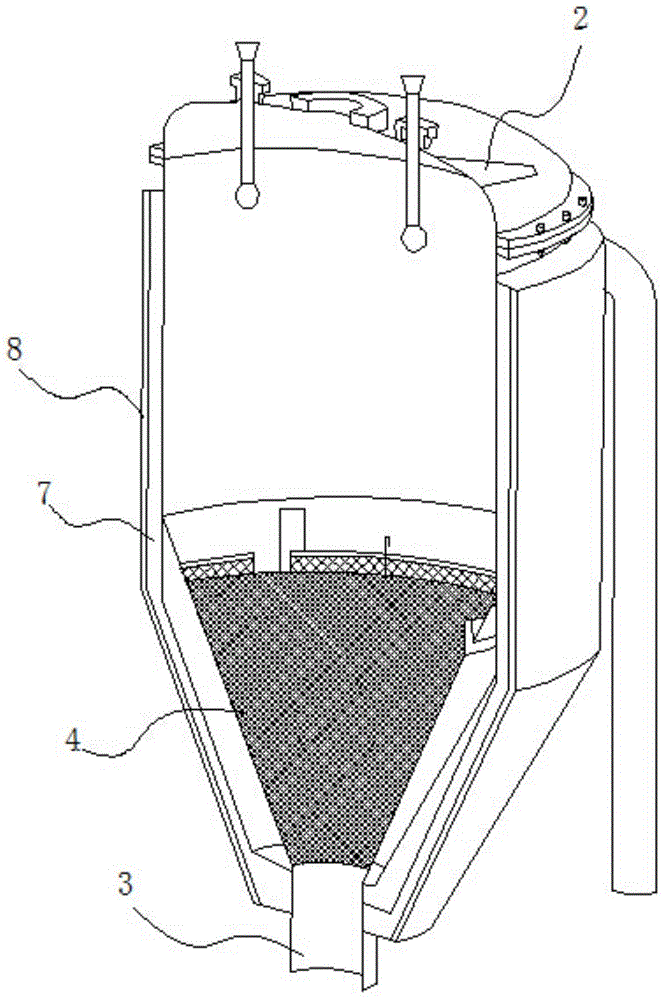

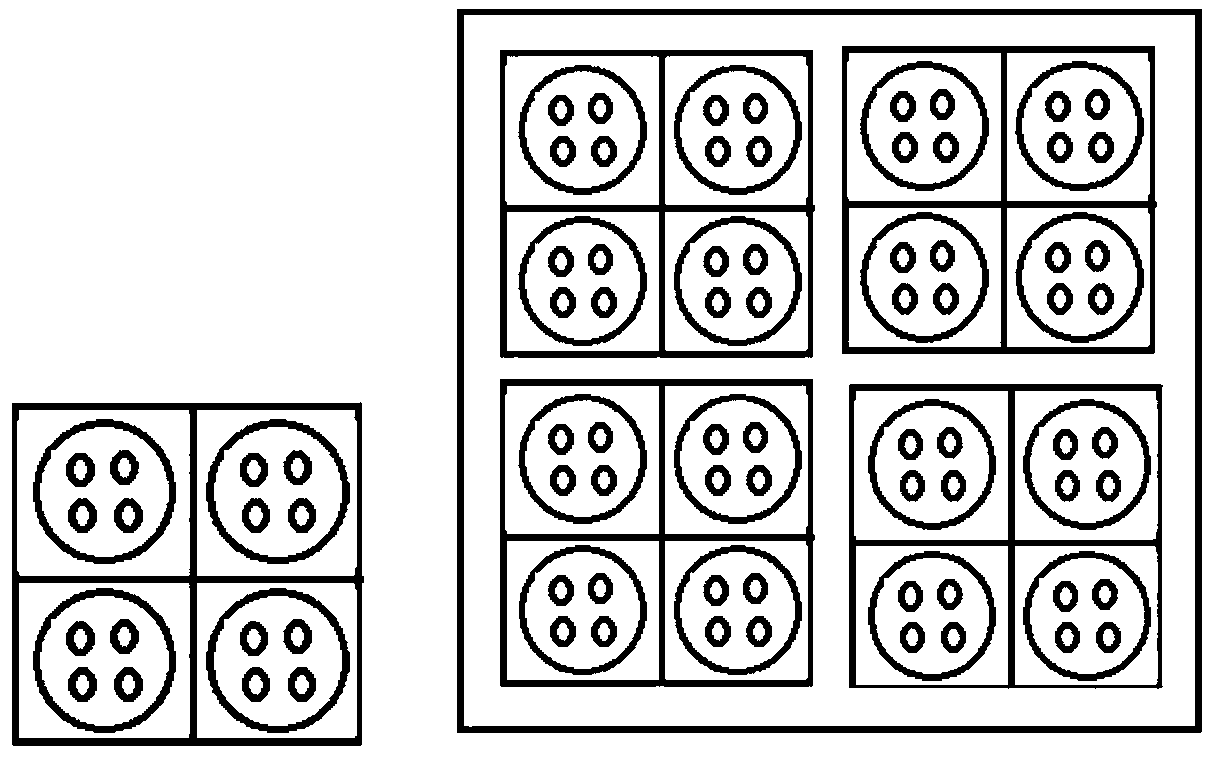

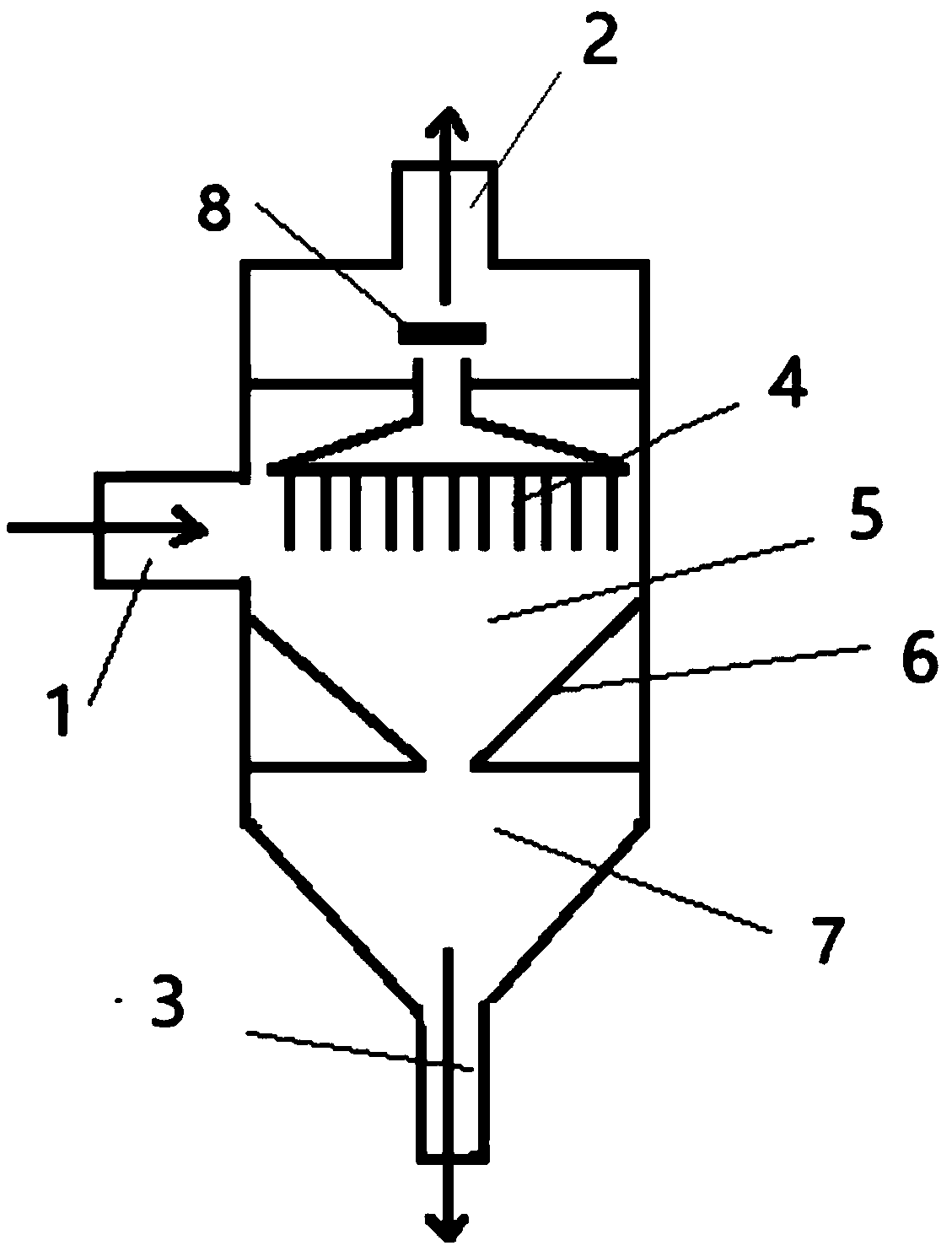

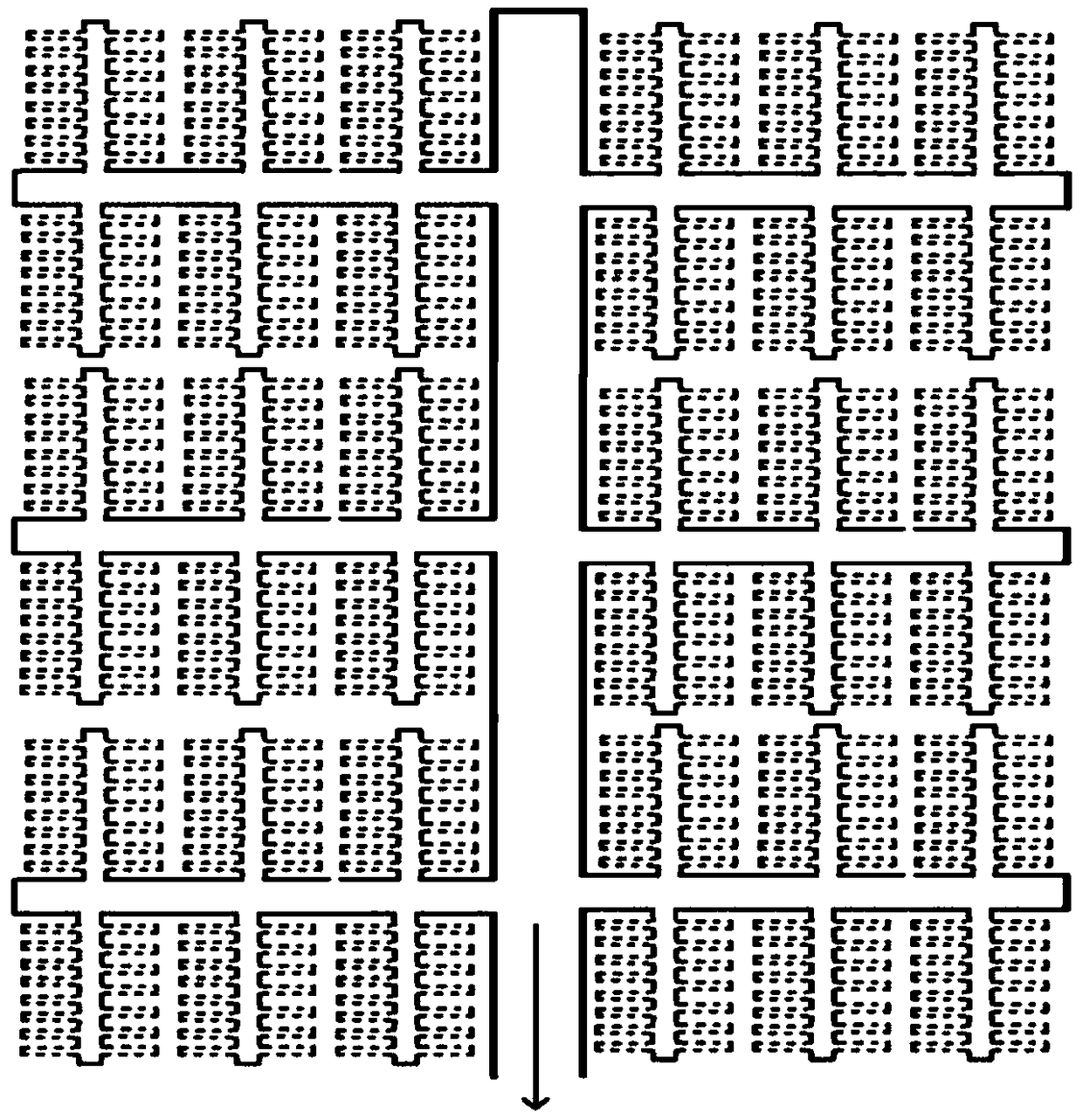

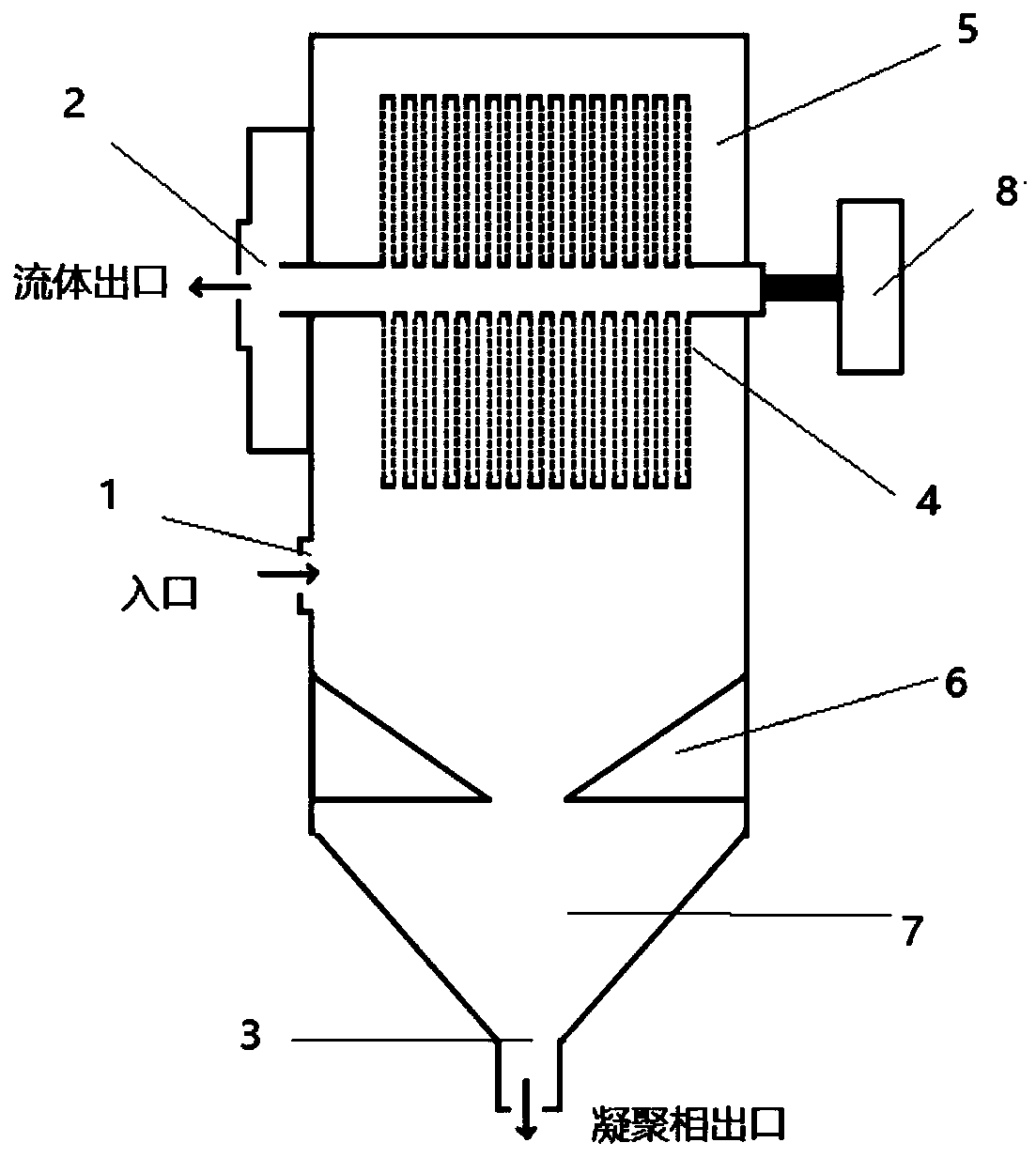

Heterogeneous phase separation device provided with sieve plate type fractal structure

PendingCN108722026AIncreased separation contact areaImprove separation efficiencyDispersed particle separationCentrifugal force sediment separationElectric machineEngineering

The invention discloses a heterogeneous phase separation device provided with a sieve plate type fractal structure. The heterogeneous phase separation device comprises a separation chamber, a settlingchamber, a motor, and a sieve plate type fractal assembly; the separation chamber is a column, the side surface of the separation chamber is provided with a heterogeneous phase fluid inlet, and the lower end is communicated with the conical settling chamber; the bottom tip terminal of the conical settling chamber is provided with a condensed phase outlet; a blocking plate is arranged between thesettling chamber and the separation chamber, and communication area is reduced; the sieve plate type fractural assembly is composed of one or a plurality of sieve plate type fractural units; each sieve plate type fractural unit comprises a sieve plate and a plurality of branches pipes through connection; one end of each branches pipe is sealed, and the other end opening is designed to passing through a sieve plate hole, and is fixedly connected with a sieve plate, and the pipe wall of the branched pipe is provided with a micropore structure; the sieve plate type fractural assembly is arrangedat the upper part of the separation chamber, and a plurality of sieve plates are combined, and are used for diving the separation chamber into an upper part and a lower part; and the sieve plate typeassembly is driven by the motor to rotate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

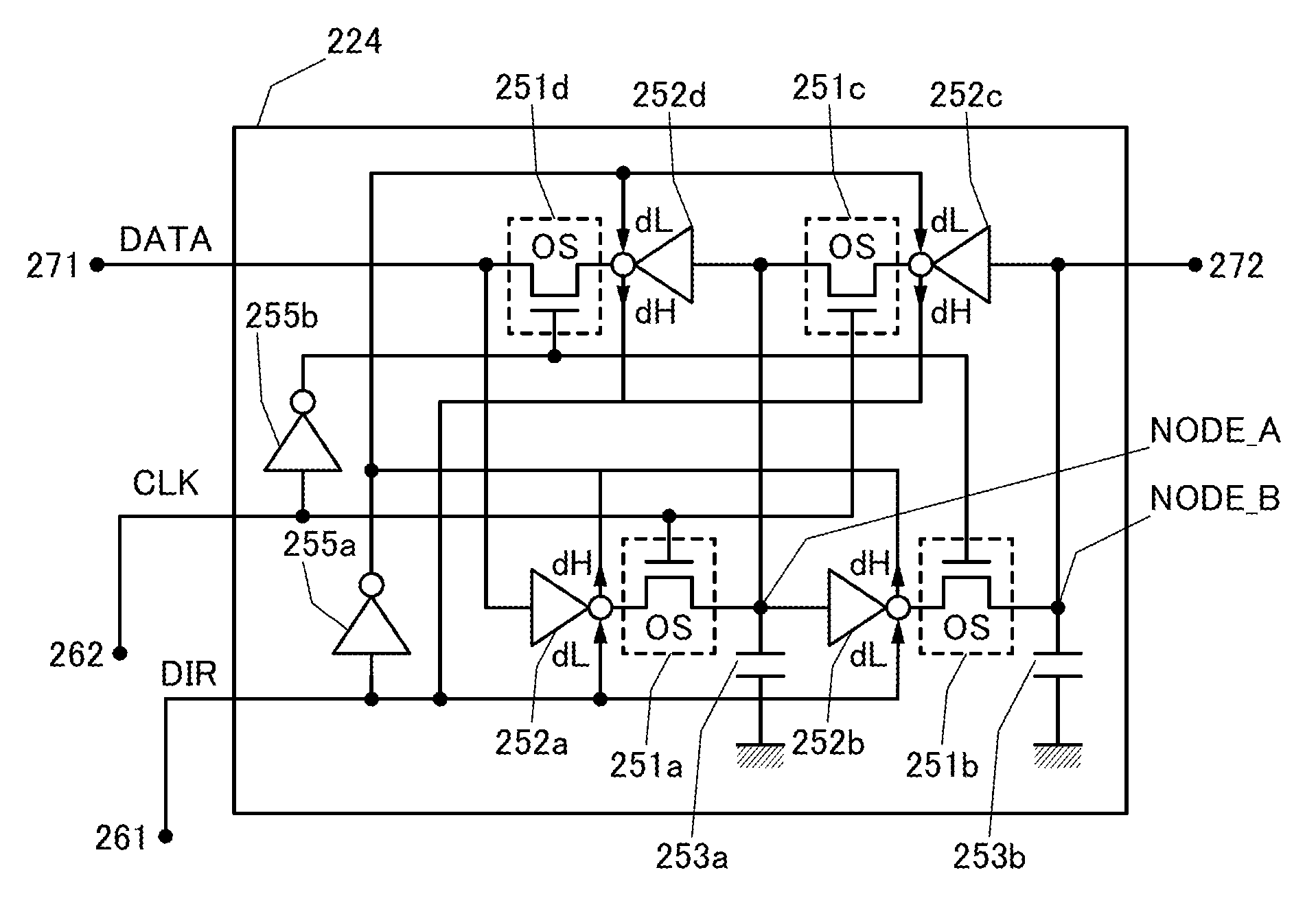

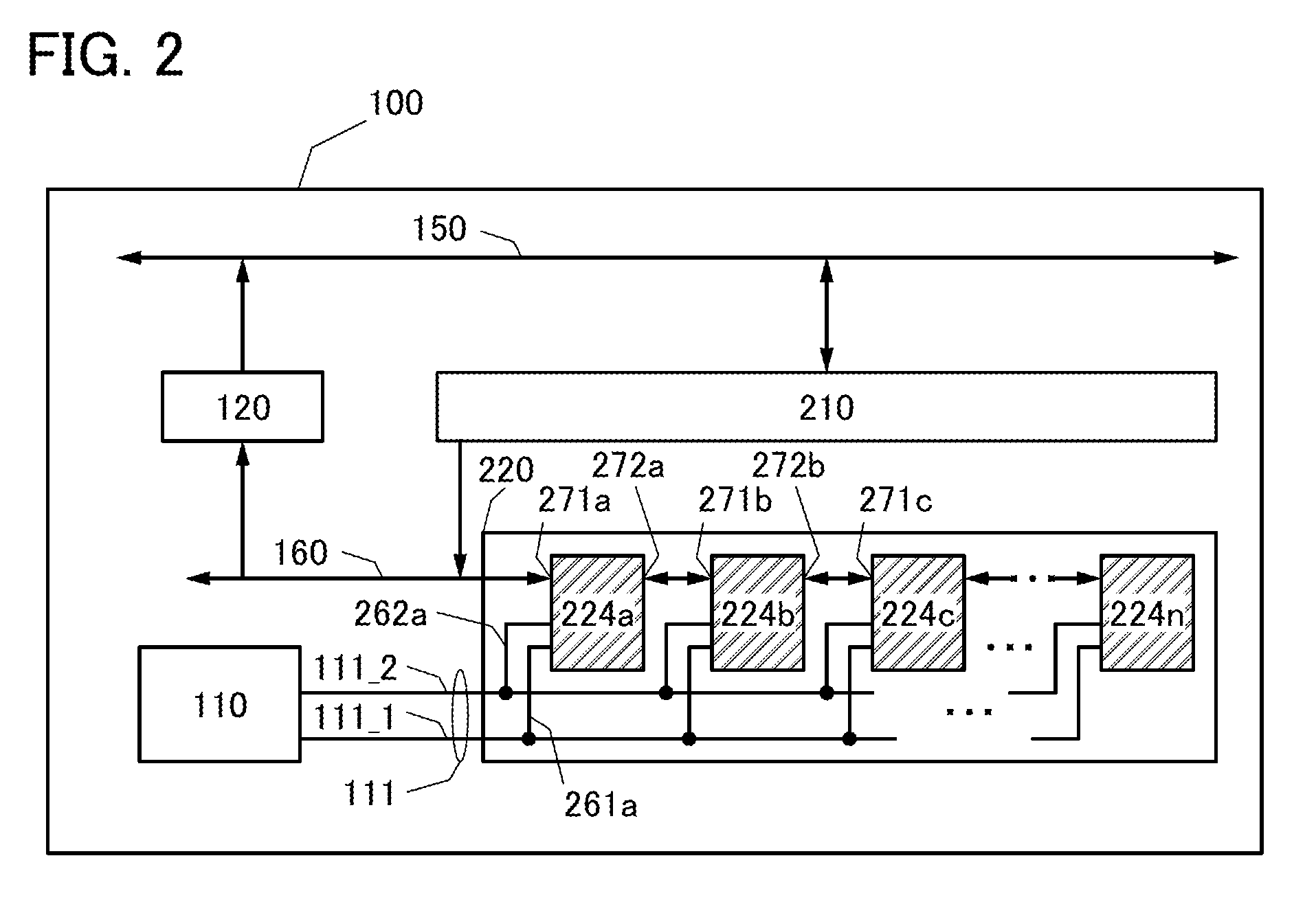

High speed processing unit with non-volatile register

ActiveUS9343120B2Extend continuous running timeReduce power consumptionDigital storageProcessor registerComputer science

A semiconductor device in which the power consumption of a register is low is provided. Further, a processing unit whose operation speed is high and whose power consumption is low is provided. In the semiconductor device, a register operating at high speed and a nonvolatile FILO (first-in-last-out) register capable of reading and writing data from / to the register are provided.

Owner:SEMICON ENERGY LAB CO LTD

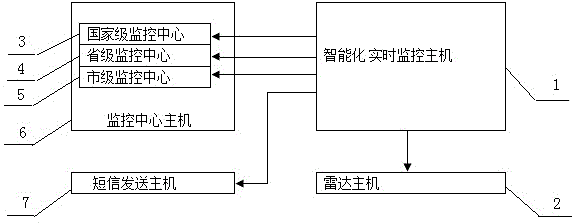

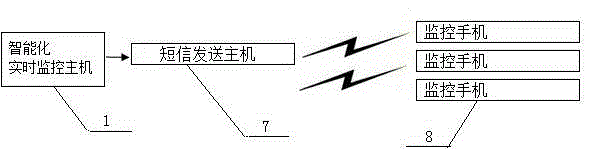

Weather radar real-time alarm method

InactiveCN104064000AExtend continuous running timeReduce downtimeAlarmsICT adaptationWeather radarEnvironmental geology

The invention relates to a method for monitoring the weather radar operation state in real time and giving an alarm in time. Alarm information is classified through an intelligent real-time monitoring host and can be sent to monitoring centers of each level and related personnel in time.

Owner:祁欣

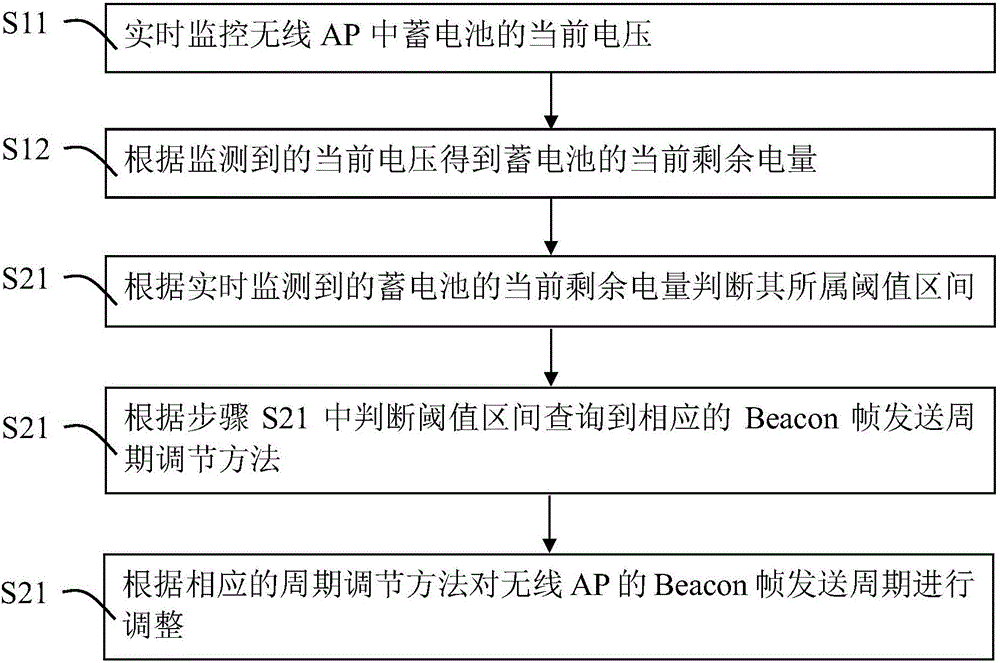

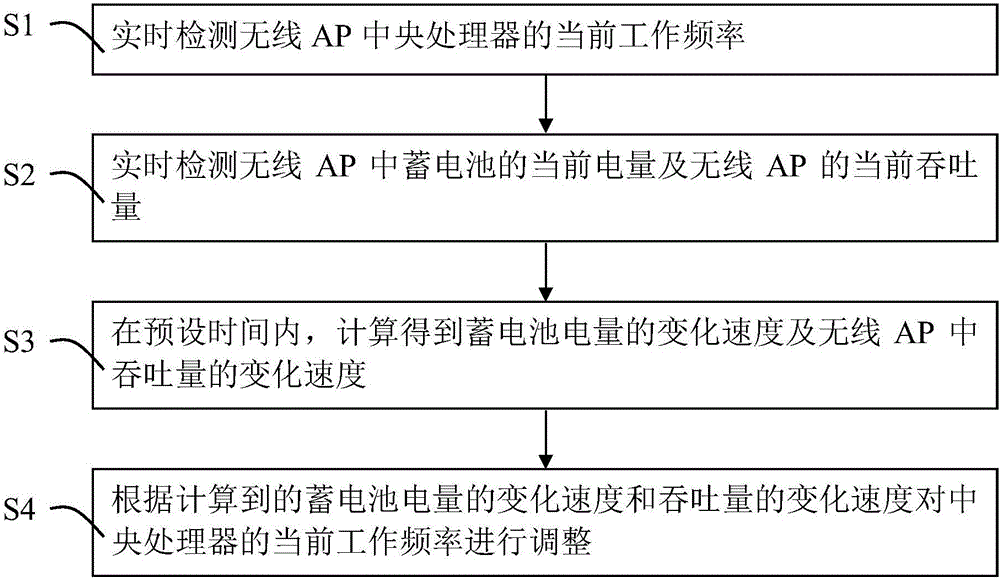

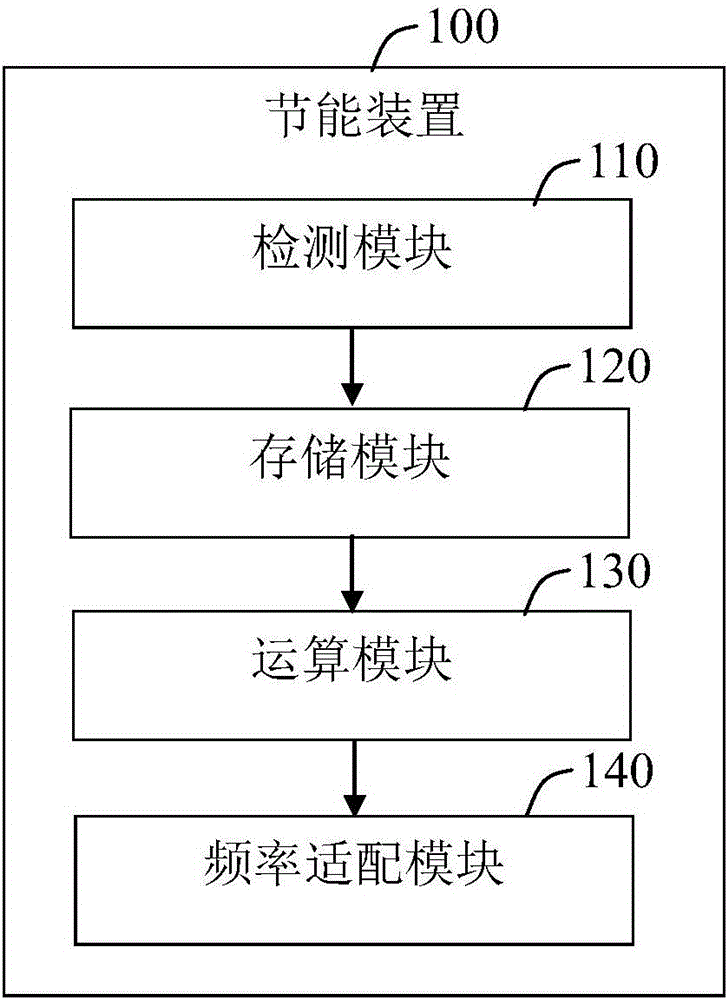

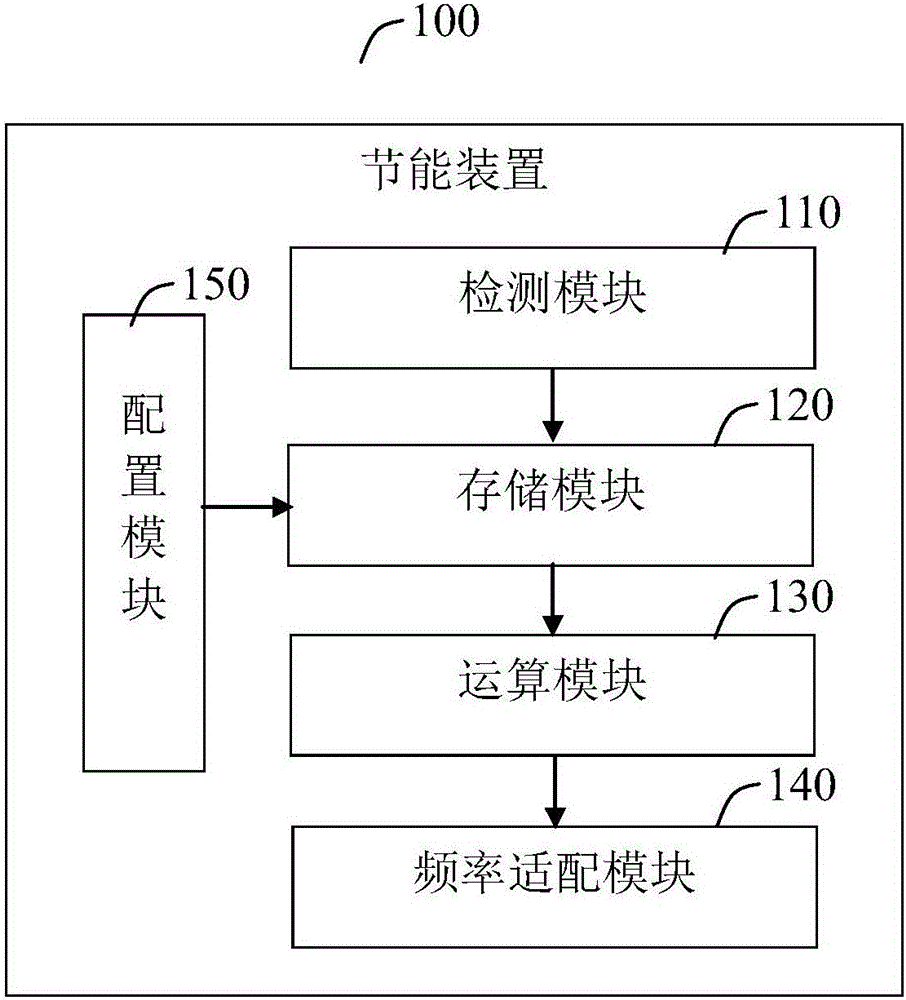

Energy saving method and device based on wireless AP

ActiveCN106507450AExtend continuous running timeReduce energy consumptionPower managementHigh level techniquesEnergy consumptionWireless

The invention provides an energy saving method and an energy saving device based on a wireless AP. The energy saving method comprises the steps of S1, detecting current operating efficiency of a central processor of the wireless AP in real time; S2, detecting current electric quantity of an accumulator in the wireless AP in real time and a current handling capacity of the wireless AP; S3, computing a change rate of the electric quantity of the accumulator and a change rate of the handling capacity of the wireless AP; and S4 adjusting the current operating efficiency of the center processor according to the computed change rate of the electric quantity of the accumulator and the change rate of the handling capacity. Therefore, the operating frequency of the central processor is dynamically adjusted, and thus energy consumption of the accumulator is reduced, service life of the accumulator is prolonged, the purpose of saving power is achieved, and sustainable run time of the wireless AP is prolonged.

Owner:湖州丰源农业装备制造有限公司

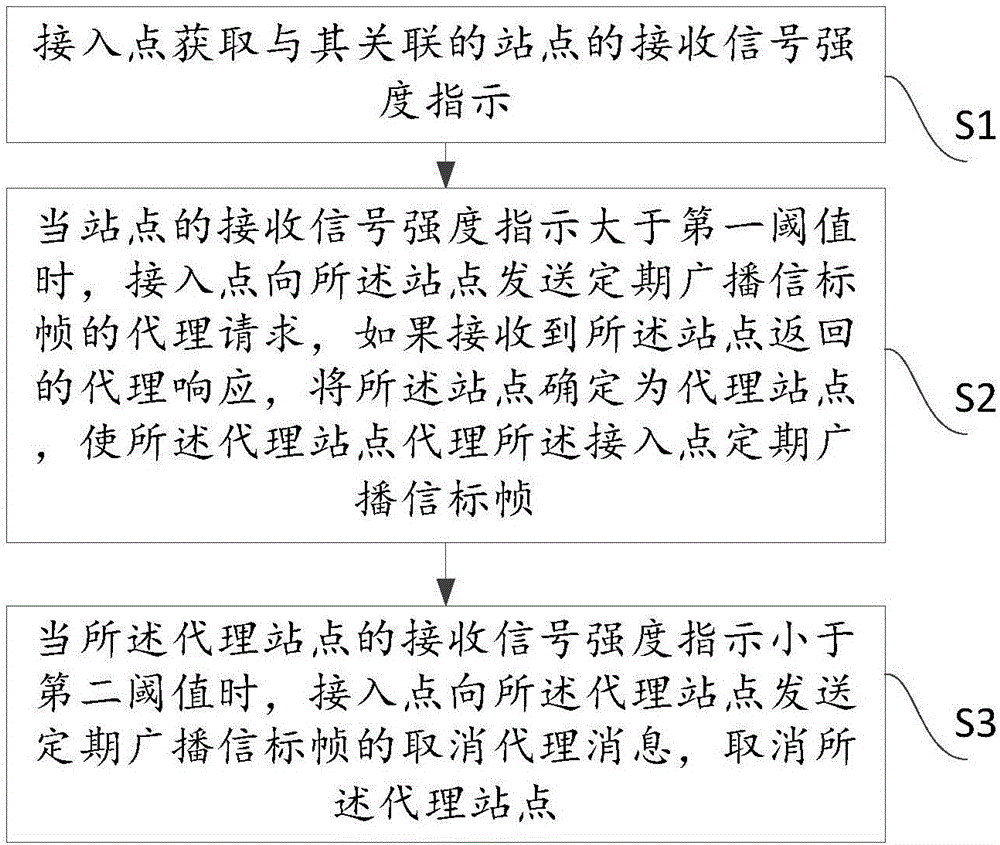

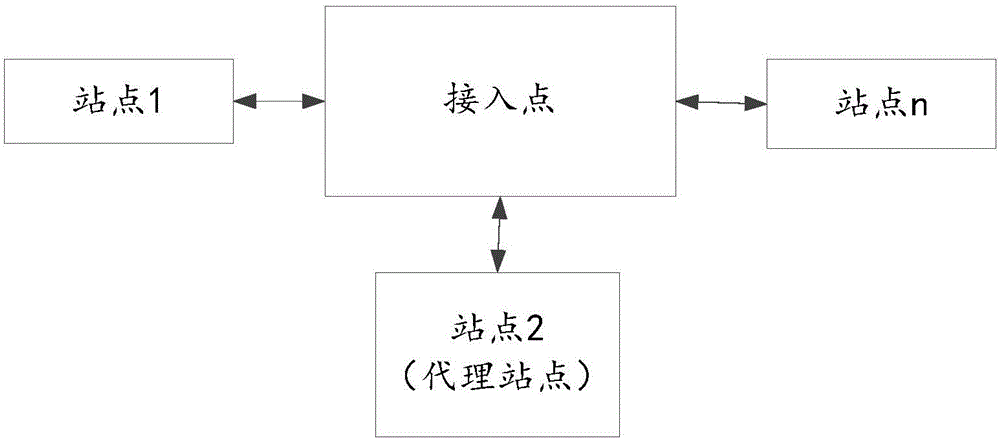

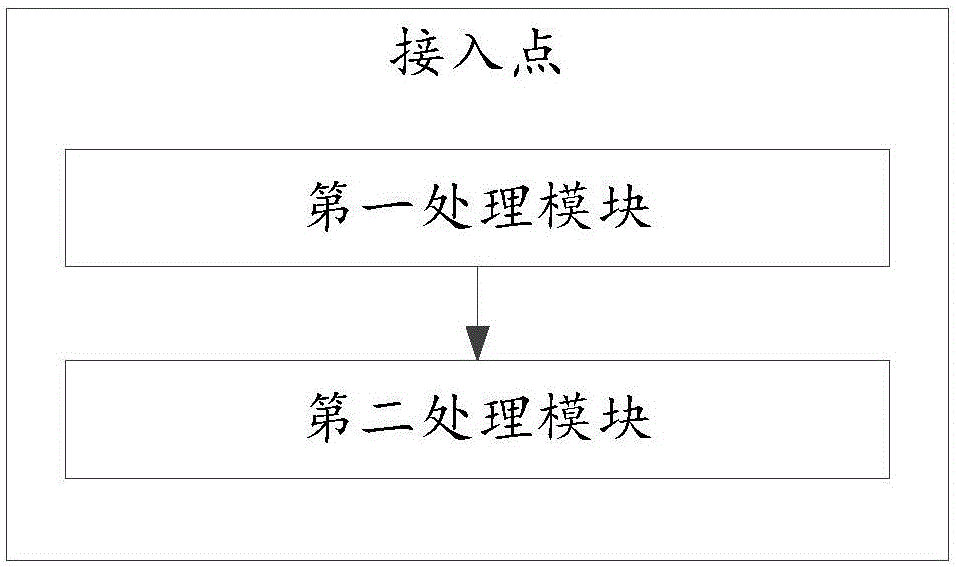

Method, system and access point for sending beacon frame

ActiveCN106535292AExtend continuous running timeAvoid electricityPower managementAssess restrictionSite agentReceived signal strength indication

The invention provides a method, a system and an access point for sending a beacon frame. The method comprises the following steps: the access point obtains a received signal intensity indication of a site associated with the access point; when the received signal intensity indication of the site is greater than a first threshold value, the access point sends an agent request of periodically broadcasting the beacon frame to the site, and if an agent response returned by the site is received, determines the site as an agent site, so that the agent site agents the access point to periodically broadcast the beacon frame; and when the received signal intensity indication of the agent site is smaller than a second threshold value, the access point sends an agent cancellation message of periodically broadcasting the beacon frame to the agent site, and cancels the agent site. According to the method, the system and the access point for sending the beacon frame provided by the invention, the energy and the electricity can be saved by enabling the site to agent the access point to send the beacon frame.

Owner:湖州帷幄知识产权运营有限公司

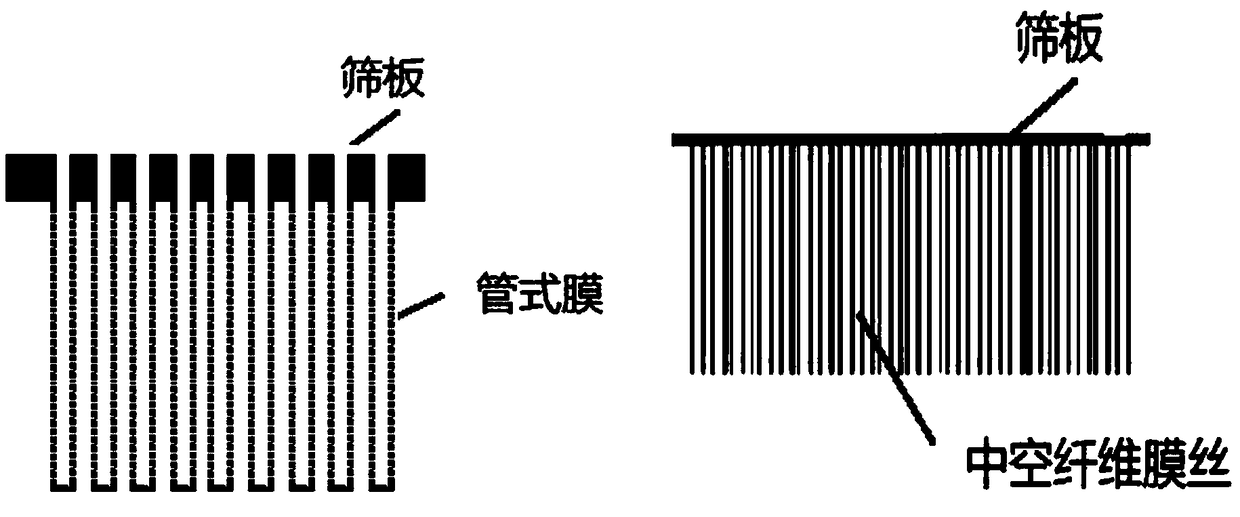

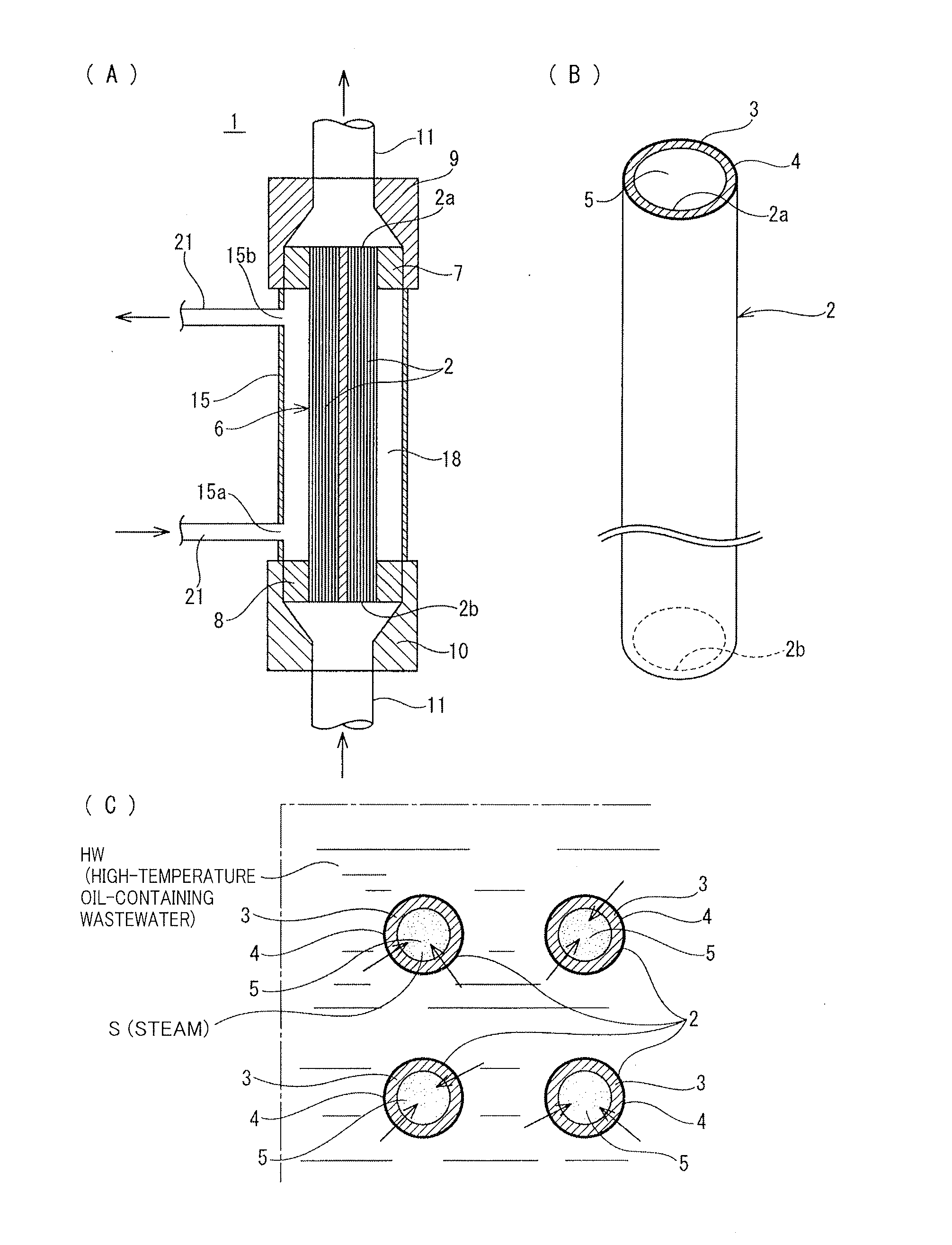

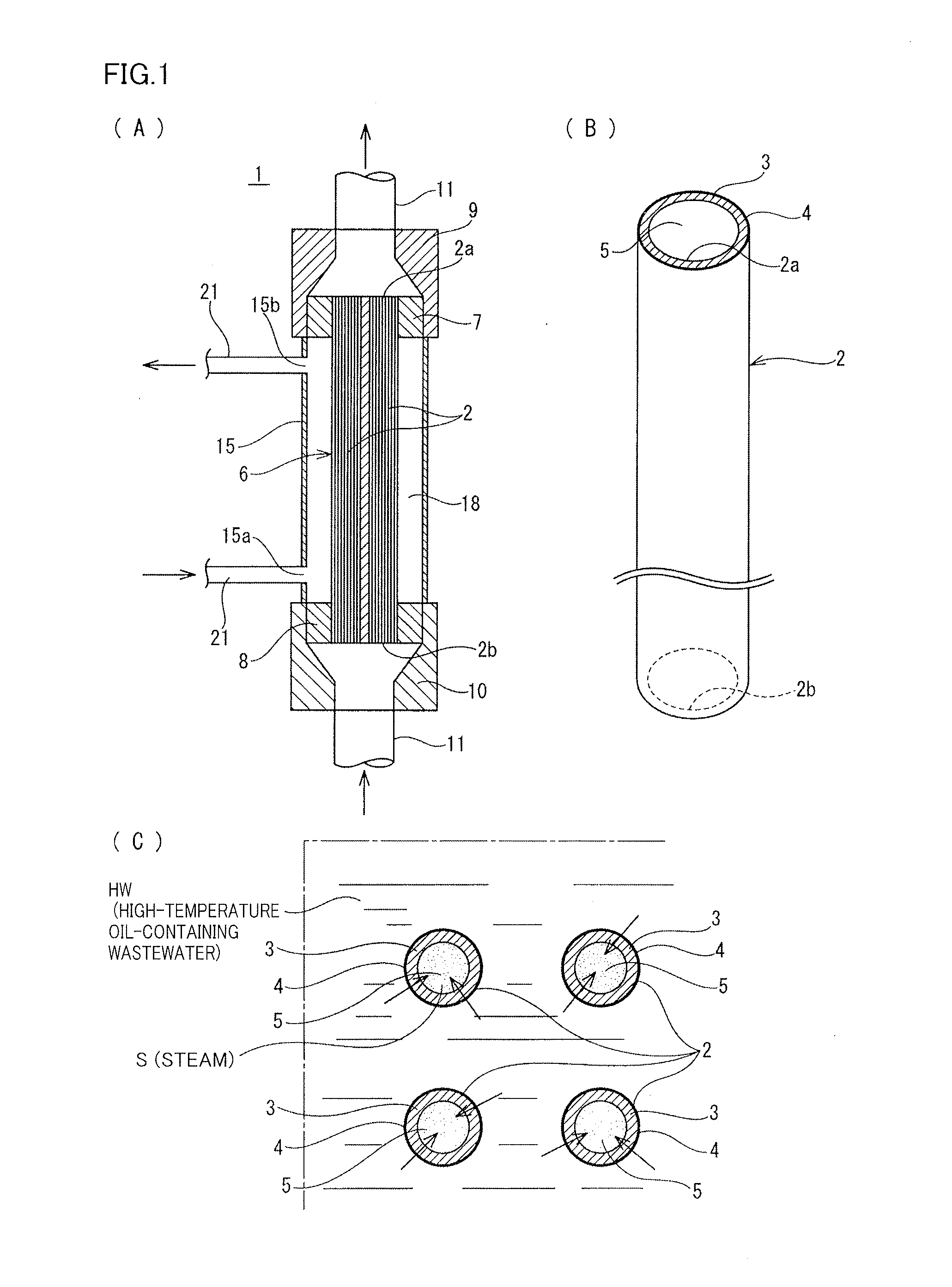

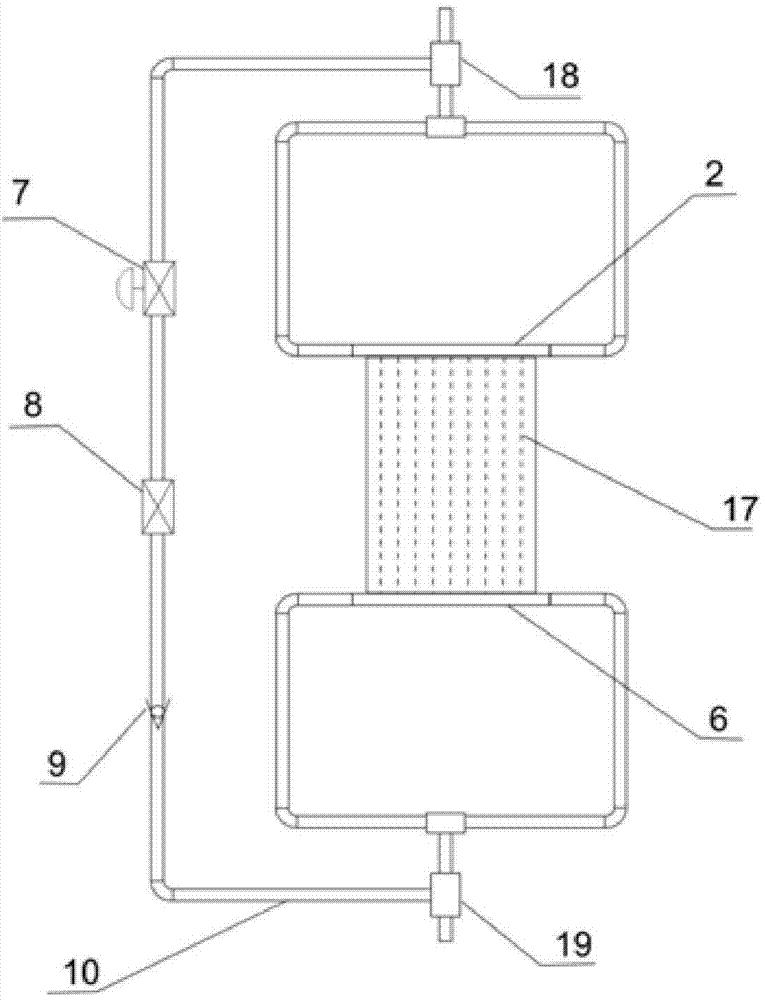

Wastewater treatment method, membrane distillation module and wastewater treatment apparatus

InactiveUS20160039686A1Extend continuous running timeImprove productivityWaste water treatment from quariesMembranesMembrane distillationPetroleum

Provided is a method for purifying wastewater containing an oil component, a salt component, and an organic matter produced when extracting petroleum from a stratum or a bedrock layer, including performing membrane distillation using a fluorine-based resin hydrophobic porous membrane made of PTFE (polytetrafluoroethylene), PVDF (polyvinylidene difluoride) or PCTFE (polychlorotrifluoroethylene) and having a practical maximum operating temperature exceeding 100° C., and simultaneously removing the oil component, the salt component and the organic matter contained in the wastewater.

Owner:SUMITOMO ELECTRIC IND LTD

Scroll fluid machine with axial sealing unit

InactiveUS9353747B2Shorten the timeShorten operation timeRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaft

A scroll fluid machine includes a revolving scroll in which a revolving wrap stands upright on an end plate supported revolvably on a drive shaft, and a fixed scroll which is provided opposite the revolving scroll and in which a fixed wrap stands upright on an end plate. The revolving and fixed wraps overlap to form a compression chamber for compressing a fluid by causing the revolving scroll to revolve. The scroll fluid machine further includes a rod-shaped member attached to the end plate of the revolving scroll and extending to a rear surface side of the fixed scroll, which is a side not opposing the revolving scroll. A revolving plate is attached to the rod-shaped member, provided with a pin crank mechanism, and supported revolvably on the drive shaft. The revolving plate is provided with a sealing unit that seals the compression chamber in an axial direction.

Owner:ANEST IWATA CORP

Steel belt type vacuum air-drying filtering machine

ActiveCN108159768AExtended service lifeReduce frictionMoving filtering element filtersHydraulic cylinderMotor drive

The invention discloses a steel belt type vacuum air-drying filtering machine. The steel belt type vacuum air-drying filtering machine comprises a machine frame, and a driving roller and a driven roller pivotally arranged at two ends of the machine frame, a decelerating motor drives the driving roller to rotate, an endless metal braided mesh conveyor belt is wound around the driving roller and thedriven roller, the metal wire of the metal braided mesh conveyor belt is braided to form uniform arched protrusions at the outside and is flat at the inside, and the two side edges of the metal braided mesh conveyor belt are wrapped and sealed by elastic steel sheet strips; the horizontal section of a filter cloth is attached to the metal braided mesh conveyor belt and runs along with the progress of the metal braided mesh conveyor belt, a vacuum chamber is arranged on the machine frame and corresponding to the lower surface of the upper layer metal braided mesh conveyor belt, and the vacuumchamber is supported by two or more first hydraulic cylinders fixedly arranged on the machine frame, the vacuum chamber and the vacuum balance automatic liquid drainage tank communicate through a pipeline; and an air-drying device is arranged above the filter cloth and at the position corresponding to the back section of the vacuum chamber. According to the steel belt type vacuum air-drying filtering machine, the structure is simplified, lifespan is increased, noise is reduced, water content of a filter cake is reduced, and filtering effect is improved.

Owner:NUCLEAR IND YANTAI TONCIN IND GRP CO LTD

Economizer for improving temperature of smoke in inlet of SCR system

InactiveCN103900072ARaise the reaction temperatureExtend continuous running timeDispersed particle separationFeed-water heatersTime rangeLow load

The invention discloses an economizer for improving the temperature of smoke in an inlet of an SCR system. A branch pipeline is arranged on a water supply pipeline connected with an inlet header of the economizer and connected with a lead-out pipe of an outlet header of the economizer. A one-way valve, a stop valve and a regulating valve are arranged on the branch pipeline. The temperature of smoke in an outlet of the economizer is increased by regulating the opening degree of the valves in the branch pipeline and reducing the amount of heat exchanged between the economizer and smoke under the low-load working condition, and rise of the temperature of the outlet of the economizer means that the reaction temperature of the SCR denitrification system is increased; on one hand, loads meet the requirement for conditions of SCR operation within a wider range, and continuous running time of the SCR denitrification system in a power plant is prolonged; on the other hand, the activity of SCR catalysts is improved under the low-load working condition, the denitrification capacity of the SCR system is enhanced, and the economizer assists the power plant in better reaching the environmental index within the wider time range.

Owner:SOUTHEAST UNIV +1

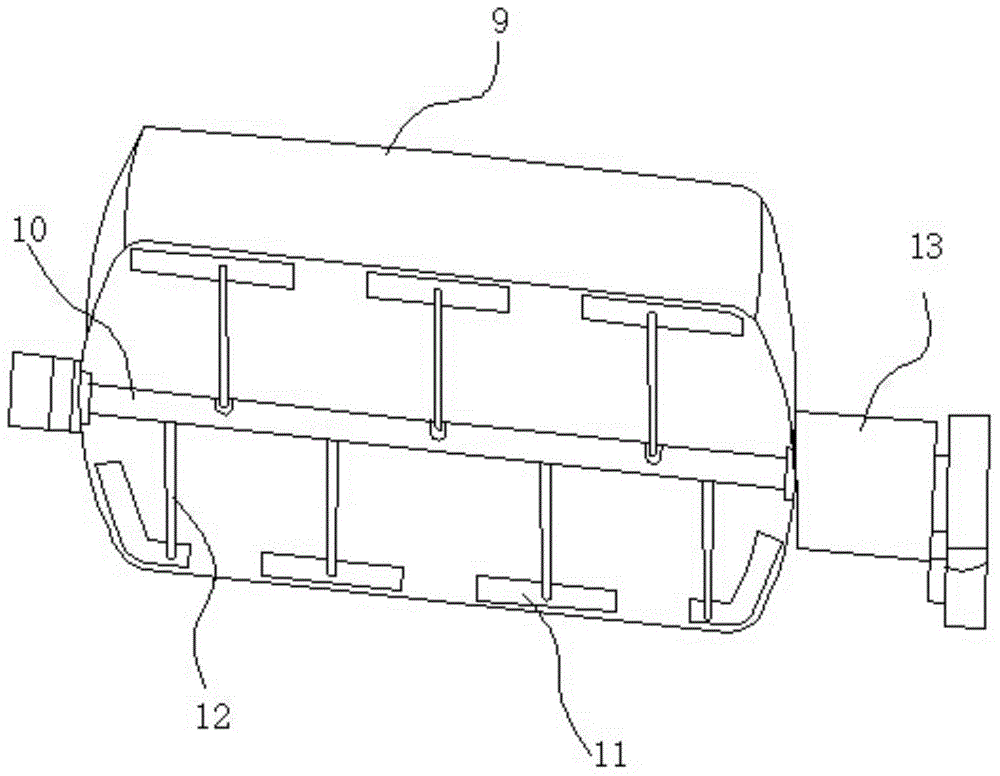

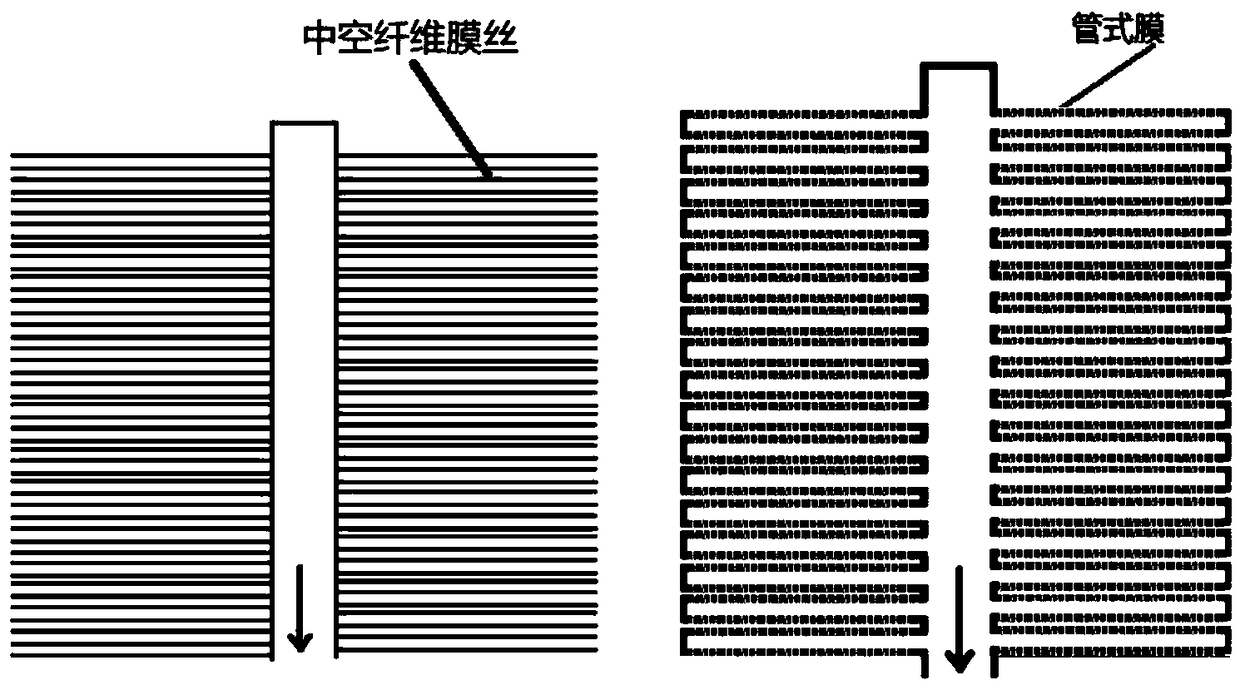

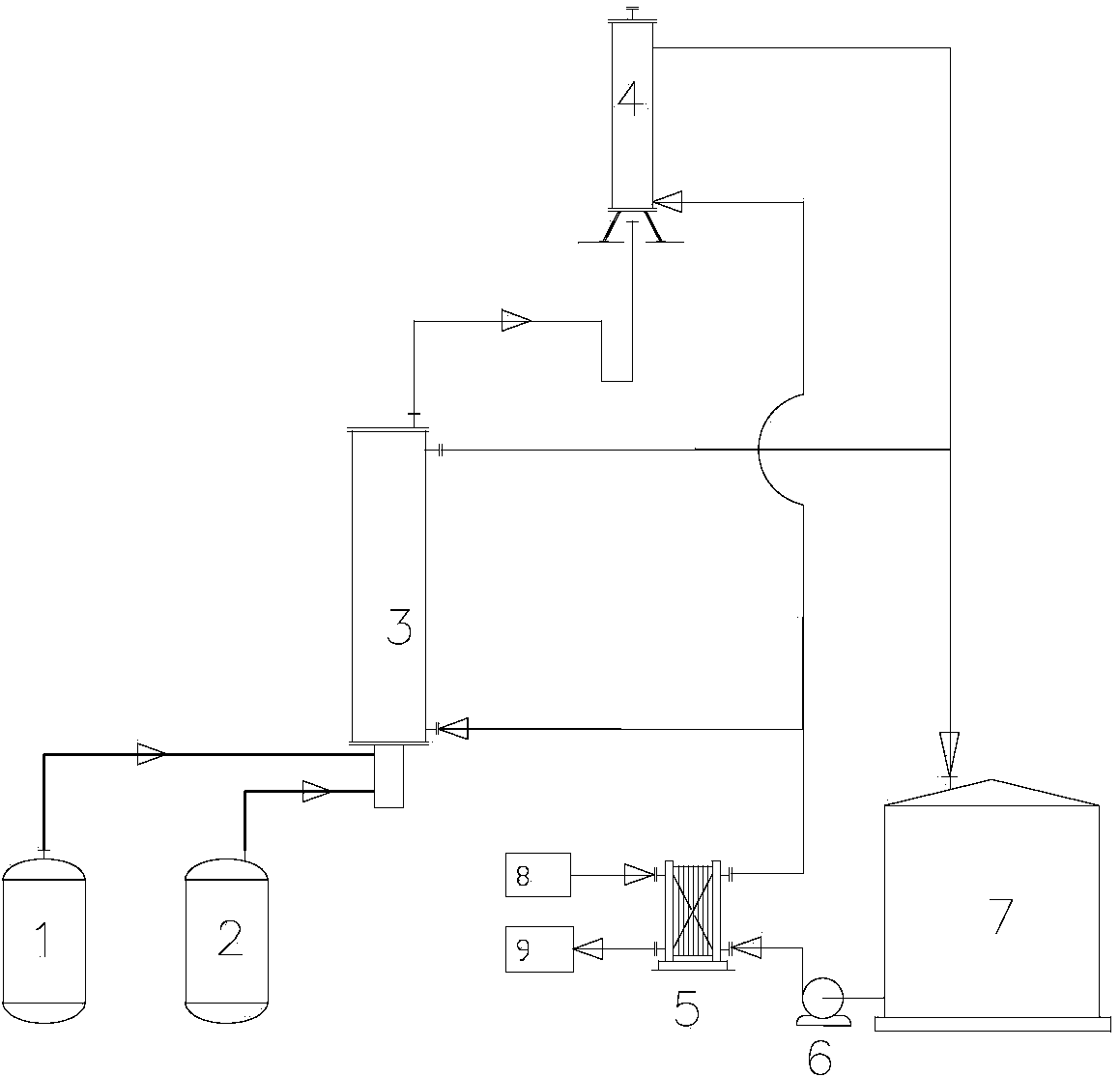

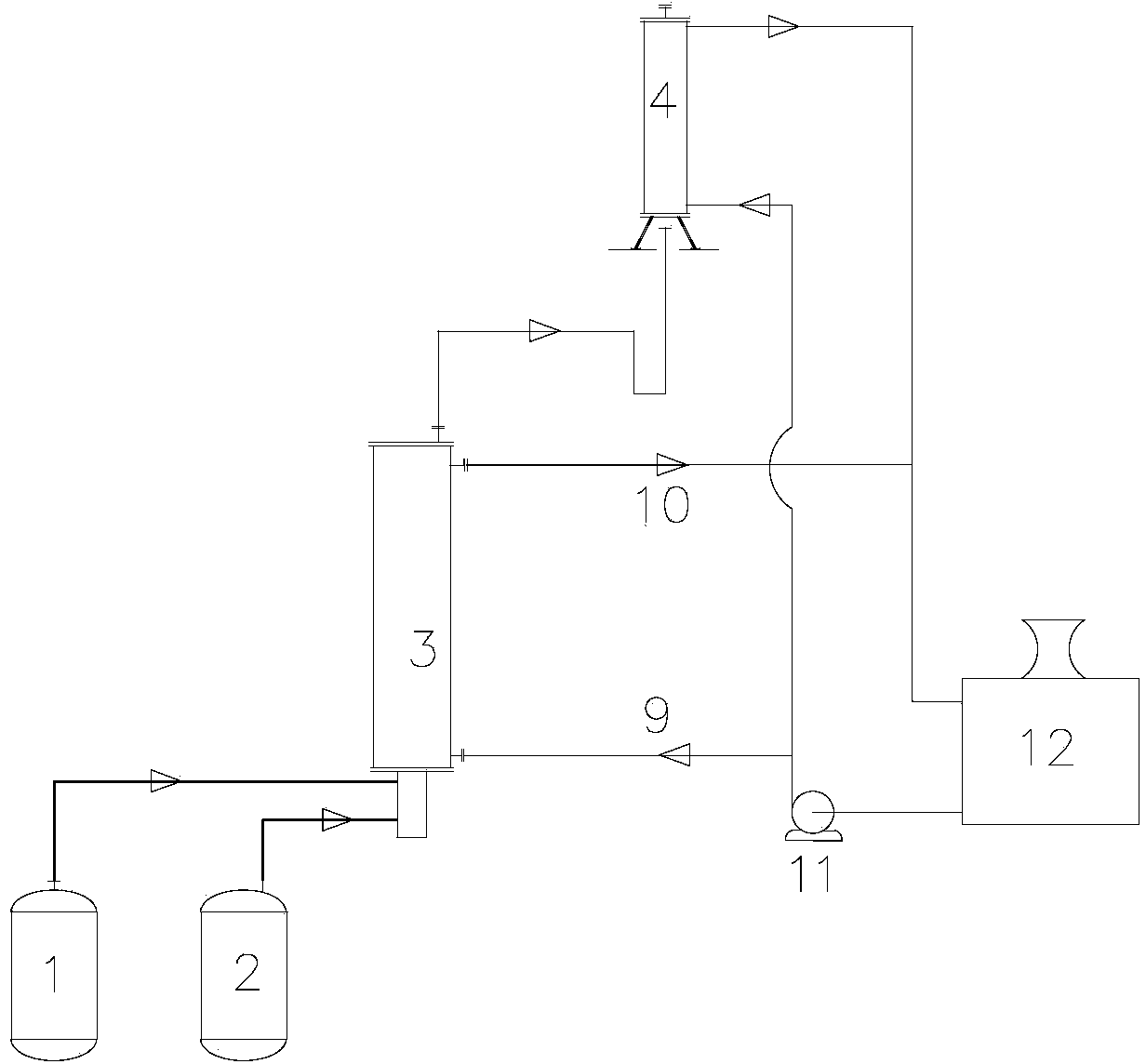

Heterogeneous phase separation device with tubular type fractal structure

PendingCN108722095AIncrease separation areaImprove separation efficiencyCombination devicesFiltration circuitsCENBOLContinuous operation

The invention discloses a heterogeneous phase separation device with a tubular type fractal structure. The heterogeneous phase separation device comprises a separation chamber, a motor, and fractal assemblies; the separation chamber is a column body; the upper end of the column body is sealed, the side surface is provided with a heterogeneous phase fluid inlet, the lower end is provided with a settling chamber; the bottom end of the settling chamber is provided with a condensed phase outlet; the fractal assemblies are arranged at the upper part of the separation chamber, are inserted into thetubular wall of a fluid channel in a centrosymmetrical manner; one end of the fluid channel is connected with the motor, and is taken as a rotating shaft, and is driven by the motor arranged on the external side surface of the separation chamber to rotate, and the other end of the fluid channel is designed to stretch out from the separation chamber to form a continuous phase fluid outlet. The heterogeneous phase separation device is capable of avoiding separation device blocking, prolonging separation device continuous operation time obviously; the motor is adopted to drive the tubular type fractal structure to rotate, or the tubular type fractal structure is pushed by fluid to rotate, so that gas flow turbulence is enhanced, the amount of accumulated solid on branch pipe walls is reducedby more than 90%, and the separation device continuous operation time is prolonged by 2 to 5 times.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Continuous operation production process for synthesizing hydrogen chloride to prepare hydrochloric acid

InactiveCN104003355AStable cooling temperatureReduce production and operation costsChlorine/hydrogen-chlorideHydrogenSalt water

The invention relates to a continuous operation production process for synthesizing hydrogen chloride to prepare hydrochloric acid. The process mainly comprises the steps: burning hydrogen and chlorine in a synthesis furnace after carrying out pressure and flow regulation and proportioning on the hydrogen and chlorine, wherein the obtained hydrogen chloride gas is absorbed into hydrochloric acid; removing the heat generated in the synthesis or absorption process by using a special process, namely, cooling the desalted water in a heat exchanger by using circulating cooling water and then importing the cooled desalted water into the synthesis furnace and / or an absorber for heat exchange; and conveying the desalted water after the heat exchange to a desalted water tank and then pumping the desalted water back to the heat exchanger via a desalted water pump for cooling. According to the continuous operation production process for synthesizing hydrogen chloride to prepare hydrochloric acid, the synthesis effect is ensured, the fault or damage risk of the equipment is effectively reduced and benefit is brought to the safety production and continuous operation.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com