Oil-immersed type high-overload power transformer

A power transformer, high overload technology, applied in the direction of transformer/inductor shell, transformer/inductor cooling, transformer/inductor core, etc., can solve the problem of short sustainable running time of transformers, poor anti-aging ability of materials, and explosion of transformers and other issues, to achieve the effect of extending the sustainable running time, ensuring safety and stability, and large expansion space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

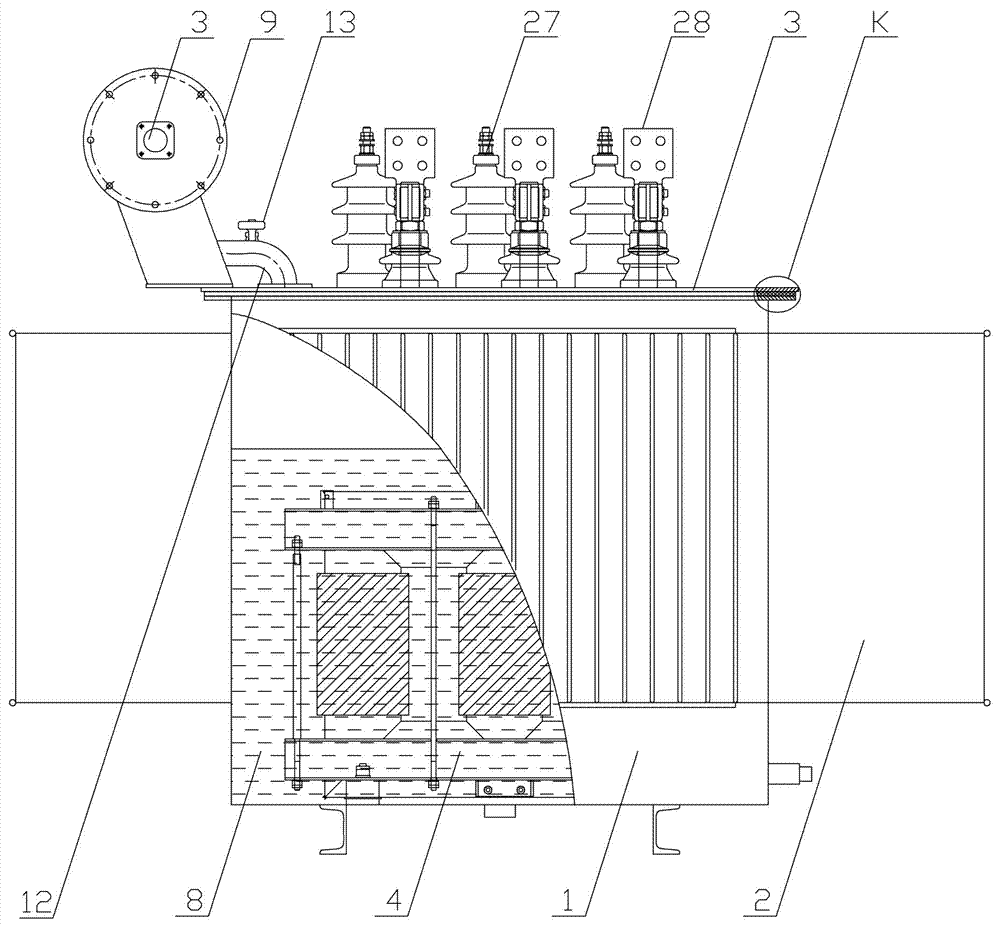

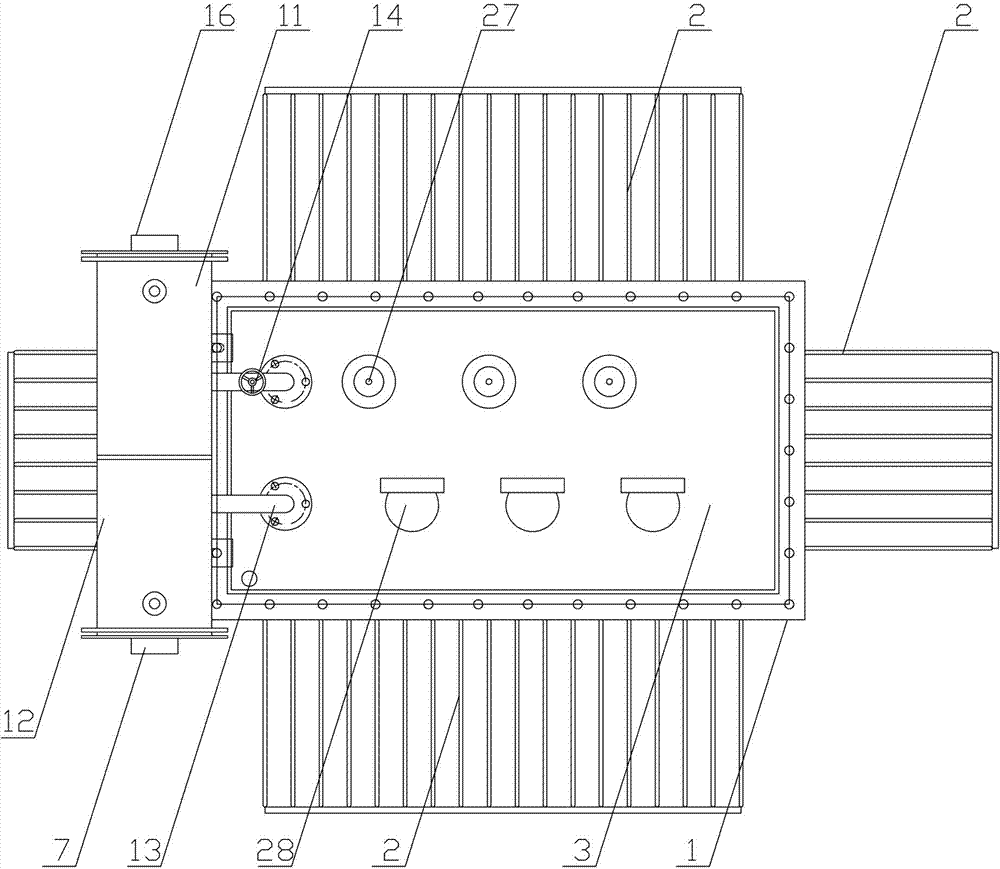

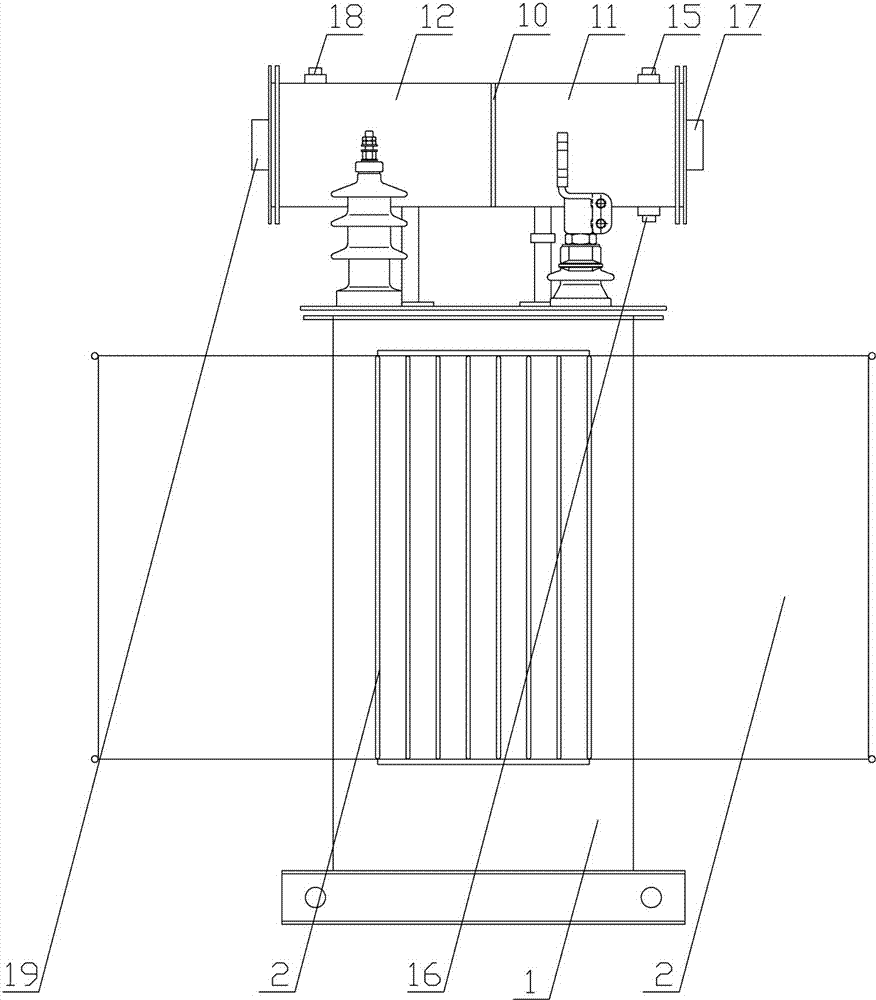

[0024] see Figure 1-3 , the present invention has an open transformer box 1, the outer surface of the side wall of the box 1 is provided with a corrugated sheet 2, a sealing cover plate 3 is installed above the box 1, a transformer core 4 is installed inside the box 1, and the transformer core 4 is composed of an iron core 5 and a winding coil 6; the inner and outer surfaces of the box 1 are sprayed with organic high-temperature-resistant paint, and a sealing gasket 7 made of fluorine rubber is embedded between the upper opening edge of the box 1 and the sealing cover 3 Simethicone oil is installed inside the box body 1 as the transformer oil 8, and the transformer core body 4 is soaked in the transformer oil 8; a cylindrical box body 9 is fixedly installed on the sealing cover plate 3 of the transformer, and the cylindrical box body 9 The cylindrical box 9 is placed horizontally and sealed with a new type of stainless steel corrugated seal. A partition 10 is arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com