Acid-resistant high-temperature-resistant elastic adhesive

An elastic adhesive and high temperature resistant technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of acid resistance, adhesive layer hardness that cannot meet the requirements of actual use, and high temperature resistance and other problems, to achieve the effect of good extensibility, convenient molding and high cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

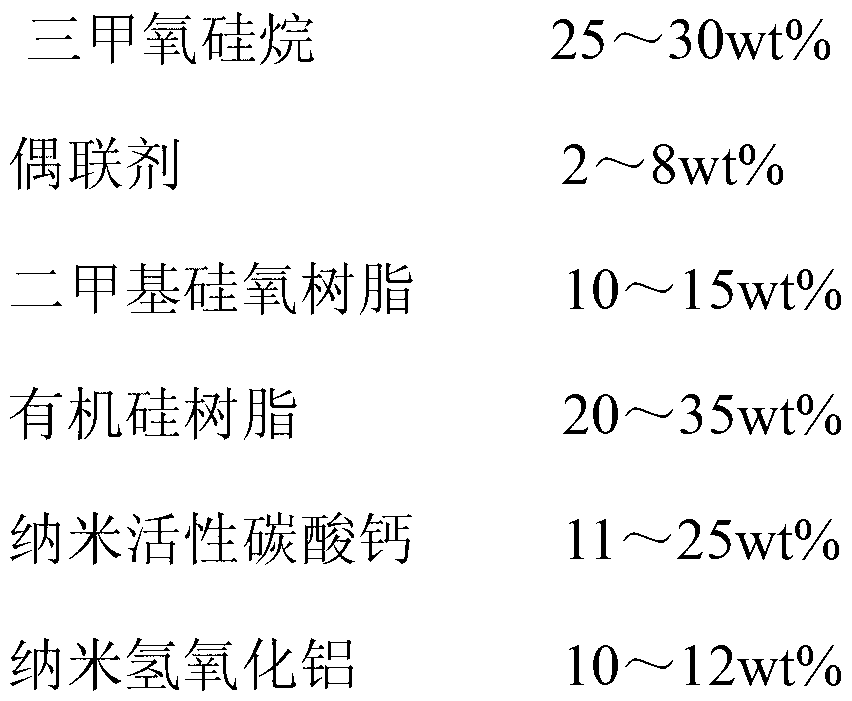

[0020] An acid-resistant and high-temperature-resistant elastic adhesive has a resin mixture and a curing agent, wherein the components of the resin mixture are:

[0021] Trimethoxysilane 30wt%

[0022] Coupling agent 2wt%

[0023] Dimethicone resin 10wt%

[0024] Silicone resin 30wt%

[0025] Nano active calcium carbonate 18wt%

[0026] Nano Aluminum Hydroxide 10wt%

[0027] Mix and stir the above materials in proportion to make a resin mixture;

[0028] When in use, the mass ratio of the resin mixture to the curing agent is 10:1.

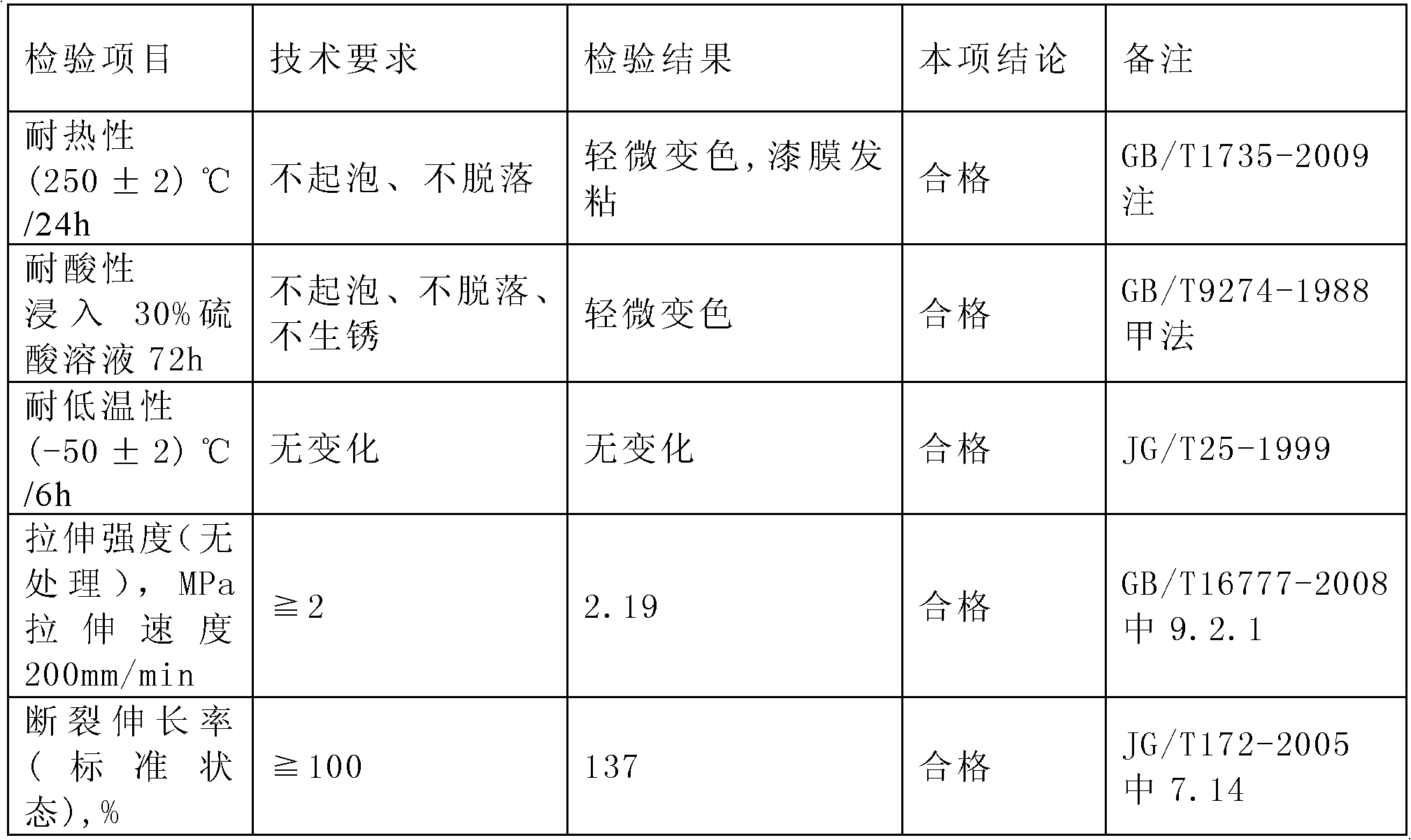

[0029] The test data of the present invention are as follows:

[0030]

[0031] Adhesive performance data are as follows:

[0032] Detection parameters

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com