Heterogeneous phase separation device with tubular type fractal structure

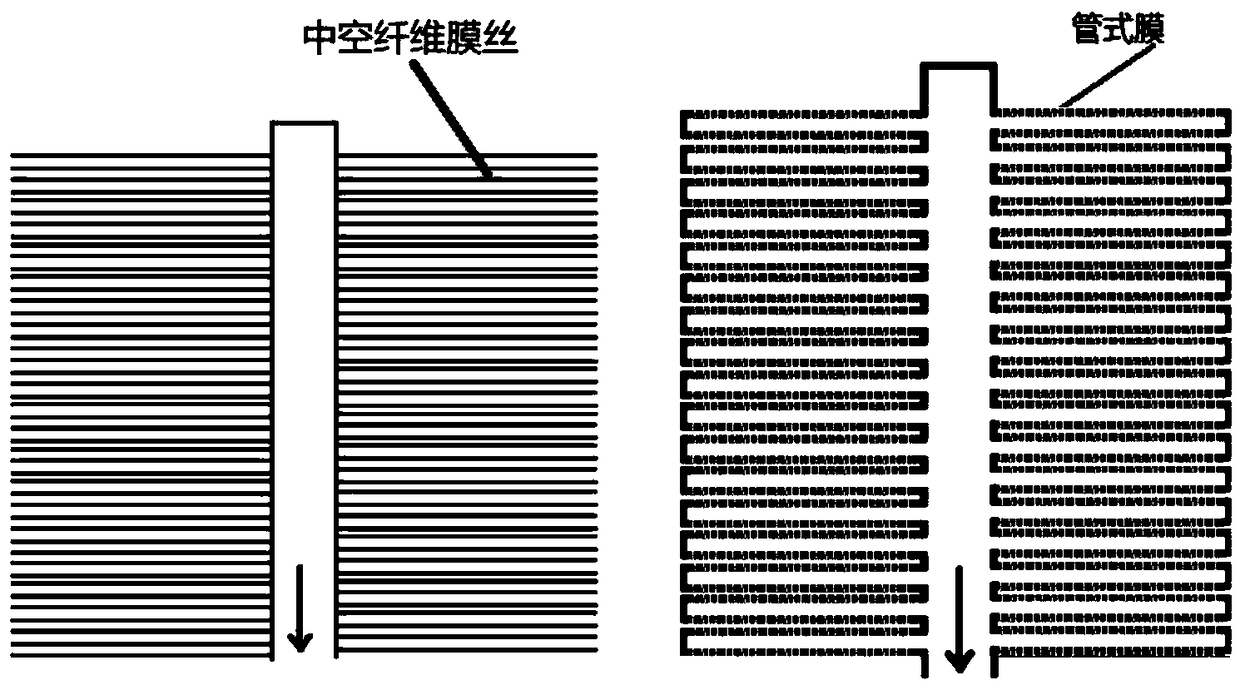

A fractal structure and heterogeneous phase technology, applied in the field of heterogeneous phase separation, can solve the problems of high investment and maintenance costs, resistance, etc., and achieve the effect of increasing continuous operation time, improving separation efficiency and reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

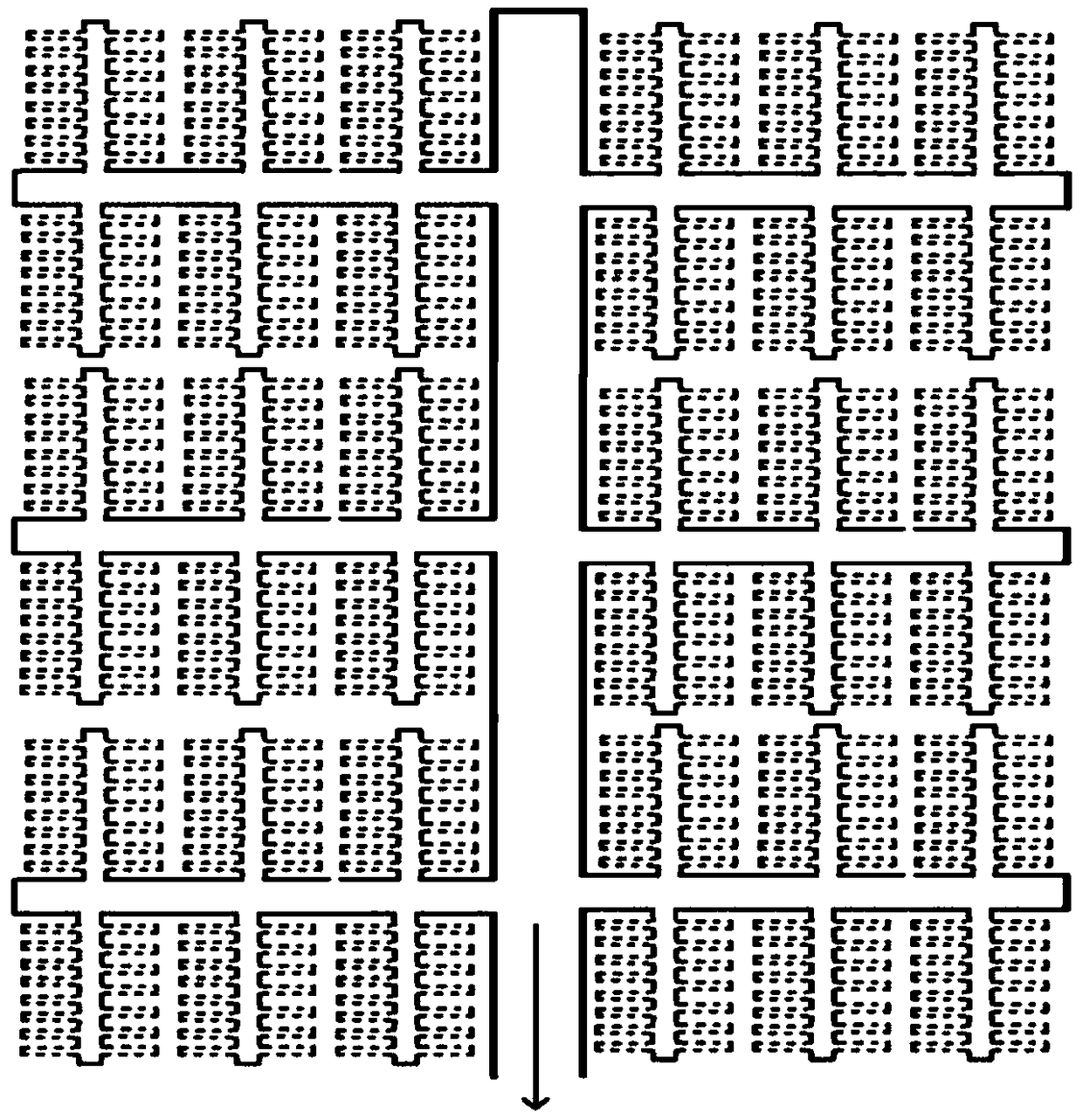

Method used

Image

Examples

Embodiment Construction

[0029] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

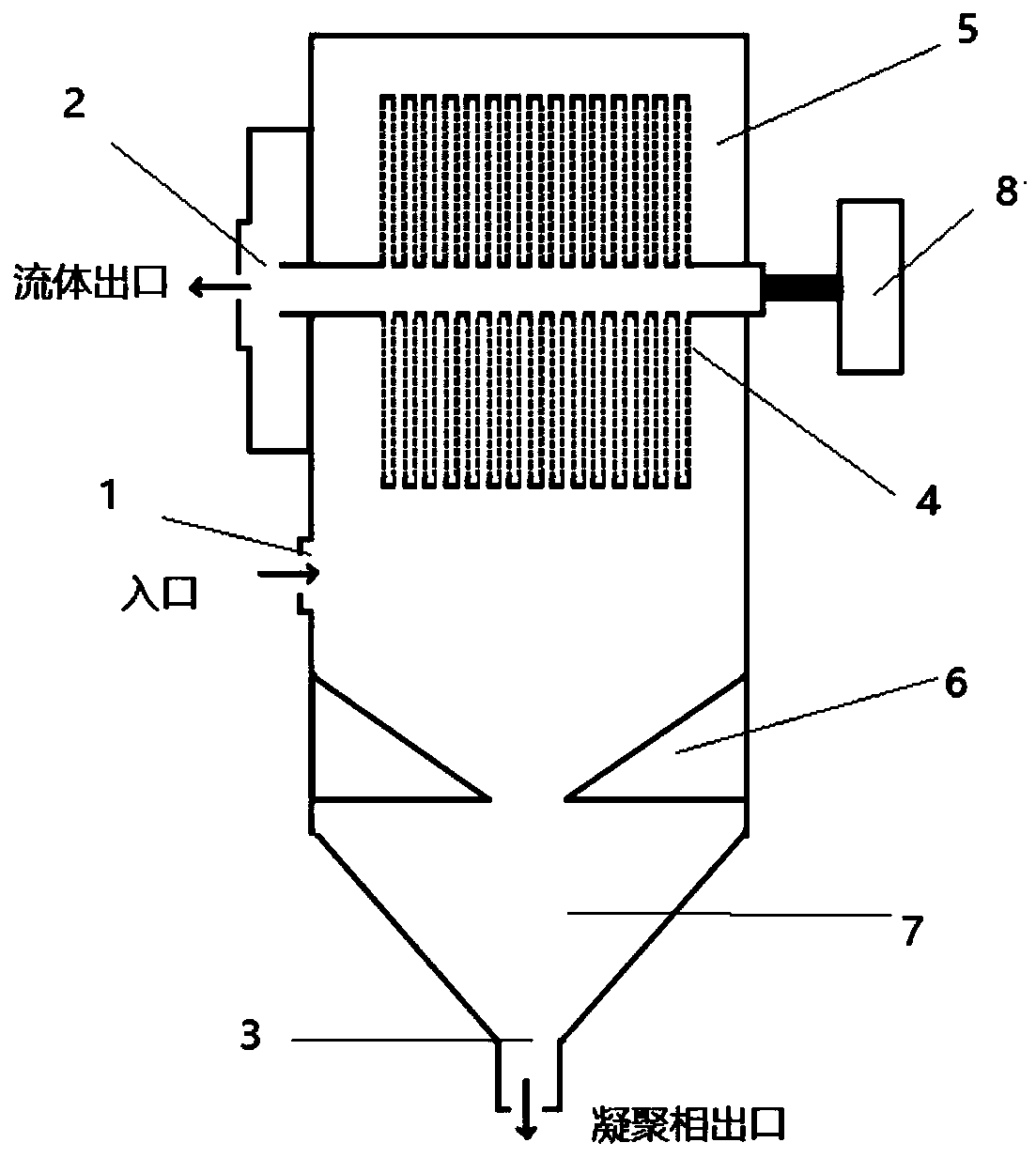

[0030] The heterogeneous fluid separation device with fractal structure of the present invention such as image 3 As shown, it includes a separation chamber 5, a motor 8 and a fractal assembly 4;

[0031] The separation chamber 5 is a cylinder, the upper end of the cylinder is sealed, the side is provided with a heterogeneous fluid inlet 1, the lower end is provided with a conical settling chamber 7, and the bottom end of the settling chamber is a condensed phase outlet 3; the conical settling chamber 7 and the separation chamber 5 A baffle 6 is arranged between them to reduce the communication area between the two.

[0032] The fractal component 4 is arranged on the upper part of the separation chamber, and is center-symmetrically inserted on the wall of the fluid channel and communicated with it; on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com