360-degree axial flow threshing separation system

A technology of threshing separation and axial flow, which is applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of separation capacity limitation, achieve the effects of size reduction, low cost, and reduced entrainment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

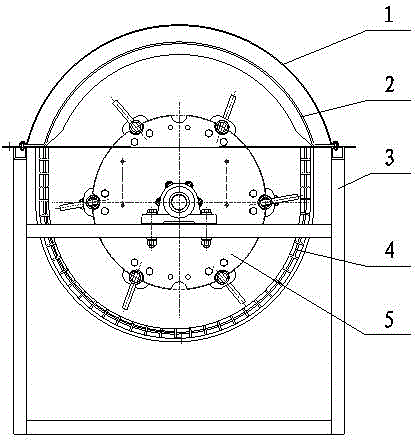

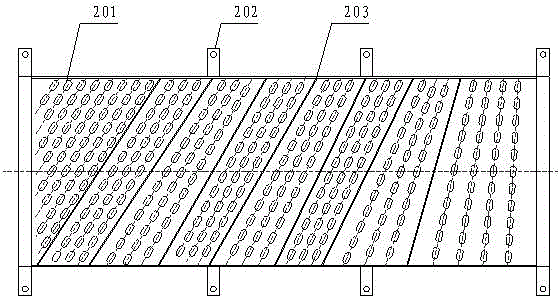

[0016] A 360° axial flow threshing separation system, including an axial flow threshing drum 5, a concave screen 4, a top cover and a frame 3, such as figure 1 shown. The top cover has a double-layer structure, including a closed upper cover 1 located on the outside and a porous air guide cover 2 located on the inside. A plurality of separation holes 201 are opened on the arc-shaped cylindrical surface of the porous hood 2; the porous hood 2 is located above the axial-flow threshing drum 5, and the concave screen 4 is located below the axial-flow threshing drum 5 and connected to the axial-flow threshing drum 5. Coaxial, the porous diversion cover 2 and the concave screen 4 form a closed circle, and the material can fly out from the mesh of the concave screen 4 and the porous diversion cover 2 to achieve 360° separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com