Patents

Literature

85results about How to "Large amount of feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

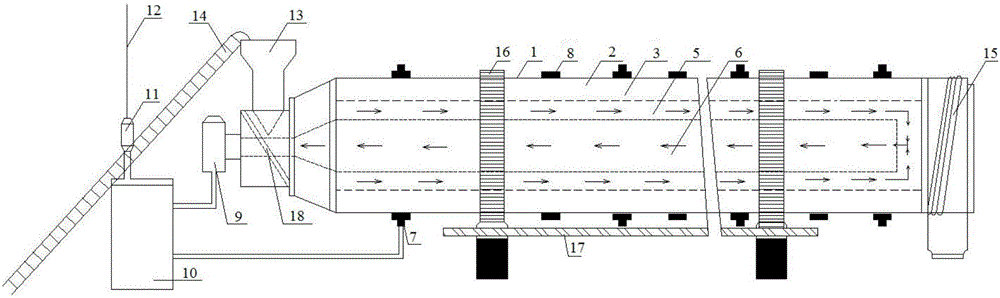

Active carbon activation furnace and active carbon production method

The invention discloses an active carbon activation furnace and an active carbon production method and relates to the field of active carbon production equipment and active carbon production technologies. The safety of an active carbon production process can be improved to a certain extent; the activation furnace works stably for a long term; and the quality and the productive capacity of produced active carbon are greatly improved. The active carbon activation furnace comprises a furnace body, a material entry device and a discharge mechanism, wherein the furnace body is internally provided with a burning passage communicated with the interior of the furnace body; air is admitted to the burning passage; the interior of the furnace body is in a negative pressure state; and air pressure in the burning passage is lower than that in the furnace body. The active carbon production method comprises the following steps: A: arranging the burning passage and material passages, B: admitting steam into the material passages, C: leading liberated gas in the material passages into the burning passage, D: heating materials in the material passages, and E: admitting flue gas generated by burning into a steam generator for heat exchange. The active carbon activation furnace and the active carbon production method are mainly used for active carbon production.

Owner:张西进

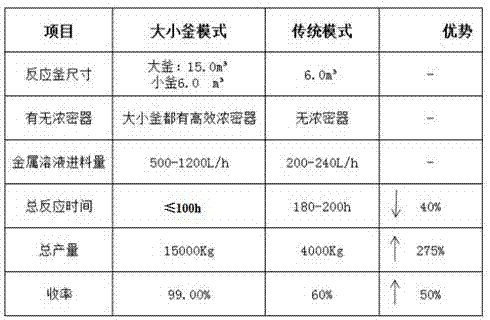

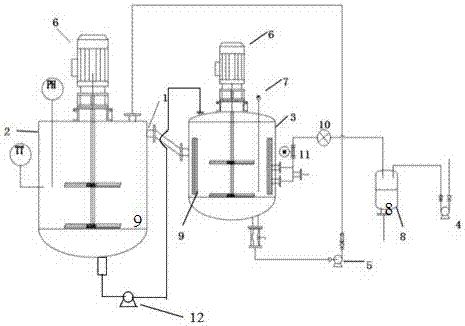

Method of quickly synthesizing ternary lithium battery cathode material precursor with double kettles

The invention belongs to the field of manufacturing battery materials and particularly relates to a method of quickly synthesizing a ternary lithium battery cathode material precursor with double kettles. Materials are fed into a reaction kettle, and when the liquid level in the reaction kettle is raised to an overflow port, the slurry overflows into a thickener. The bottom of the thickener is connected to a circulating pump. An outlet of the circulating pump is led to interior of the reaction kettle so as to pump the slurry in the thickener back to the reaction kettle. In a filter portion in the thickener, filter bars are regularly arranged and are gathered and connected to a vacuum buffer tank; a part of the slurry is filtered through the filter bars so that granules in the slurry is blocked in the thickener; the condensed slurry is pumped back to the reaction kettle through the circulating pump and is continuously subjected to the reaction, while a mother liquid passing through the filter bars is discharged into the vacuum buffer tank. In the method, due to the structure of large kettle and small kettle, crystal seeds are produced in the small kettle and crystal is grown in the large kettle, so that synthesis time is reduced from more than 180 h to lower than 100 h. In addition, due to large feeding quantity to the reaction system, the method has no loss of solid granules and is high in yield; therefore, synthesis efficiency is increased by 275% and yield is increased to 99.0%.

Owner:JINGMEN GEM NEW MATERIAL

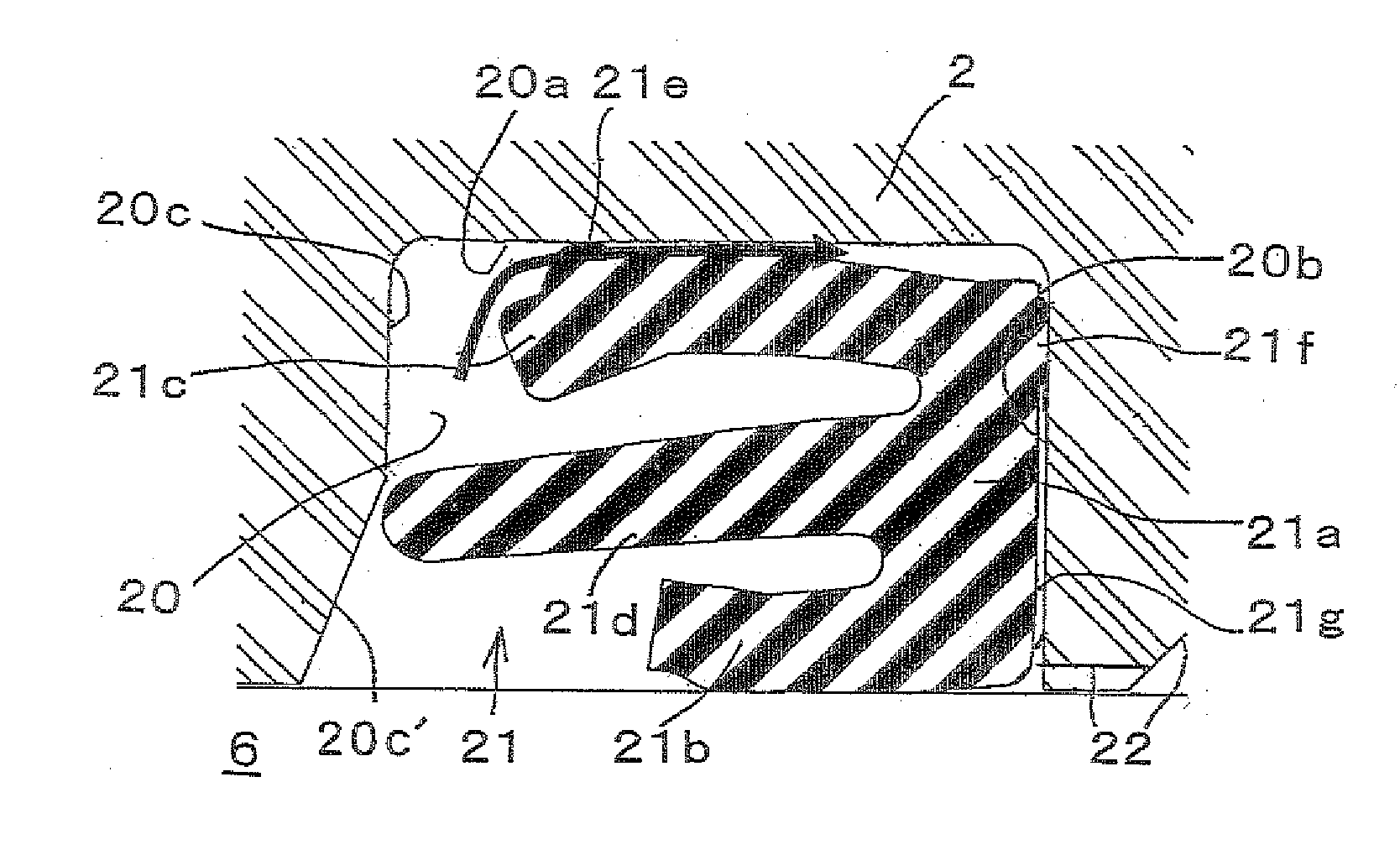

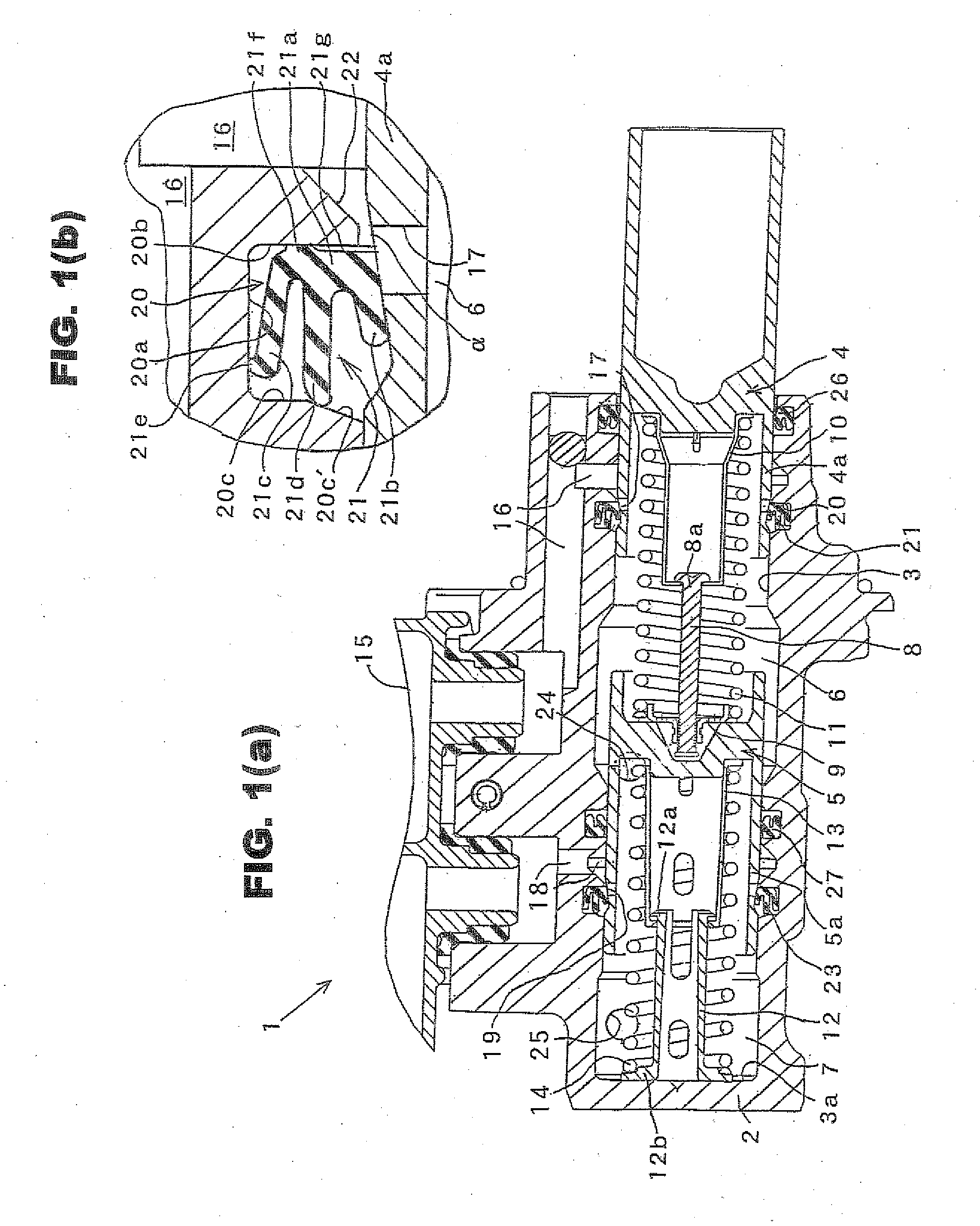

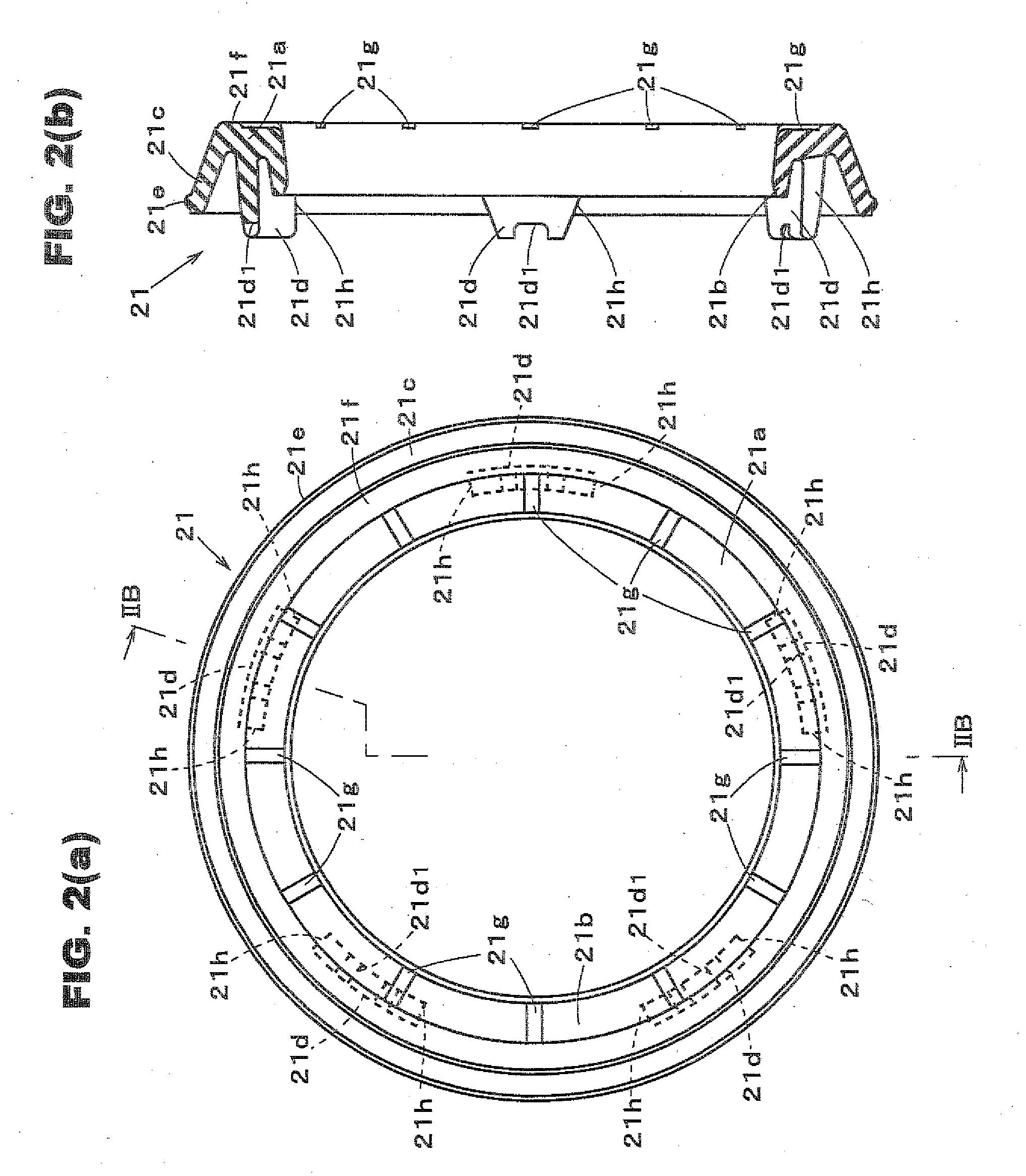

Cup seal and master cylinder using the same

InactiveUS20100066028A1Improve sealingIncrease hydraulic pressureEngine sealsPiston ringsMaster cylinderBrake fluid

In a cup seal, the hydraulic pressure in a first hydraulic chamber (6) causes a first seal portion (21e) of an outer lip portion (21c) to closely contact to a bottom wall (20a) of a recessed portion (20) and causes a second seal portion (21f) of a base portion (21a) to closely contact to a rear surface (20b) of the recessed portion (20). A double seal due to the first and second seal portions (21e) and (21f) reliably prevents the leakage of a brake fluid from the first hydraulic chamber (6). If the pressure becomes negative in the first hydraulic chamber (6), the tip portion of the outer lip portion (21c) deflects inward and the outer peripheral end of the base portion (21a) deflects forward. Therefore, the brake fluid in the reservoir flows into the first hydraulic chamber (6) through the gaps among the second and first seal portions (21f), (21e) and the wall surface of the recessed portion (20) to maintain fluid-feeding performance.

Owner:BOSCH CORP

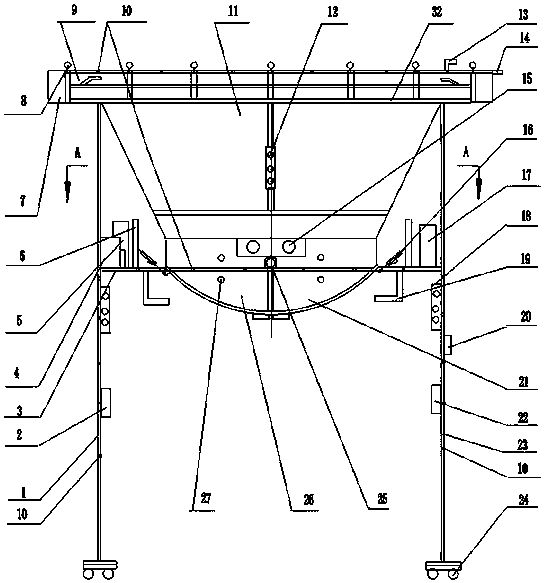

Bulk material discharging, storage and transportation equipment and transportation method

PendingCN108328360ARealize human-computer interactionReduce misuseConveyorsLarge containersControl systemHouse building

The invention discloses bulk material discharging, storage and transportation equipment which comprises a transportation hopper installed on the upper portion of a frame. The lower end of the transportation hopper is provided with a discharge outlet, and the discharge outlet is provided with a bin door capable of being opened and closed. The equipment further comprises a bin door opening-closing and detection system, a vehicle positioning indication human-machine interaction system, a transportation hopper material level detection and indication system, an upper spraying device and a lower spraying device which are connected with a control system, wherein the upper spraying device is installed on the upper portion of the transportation hopper, and the lower spraying device is installed onthe lower portion of the transportation hopper. Transportation vehicle automatic monitoring and reminding are achieved, a boat discharging door machine can work without interruption, the storage capacity of the transportation hopper can be displayed in real time, the bin door is automatically opened and closed for discharging, the lower portion of the transportation hopper is provided with a material weighing system, an empty vehicle weight house, a heavy vehicle weight house and a discharging, storage and transportation device are integrated into a whole, loading and weighing are completed ina one-stop mode, the automobile weight house building cost is reduced, processes are reduced, and production efficiency is improved. The invention further provides a transportation method for transporting bulk materials through the bulk material discharging, storage and transportation equipment.

Owner:RIZHAO PORT +1

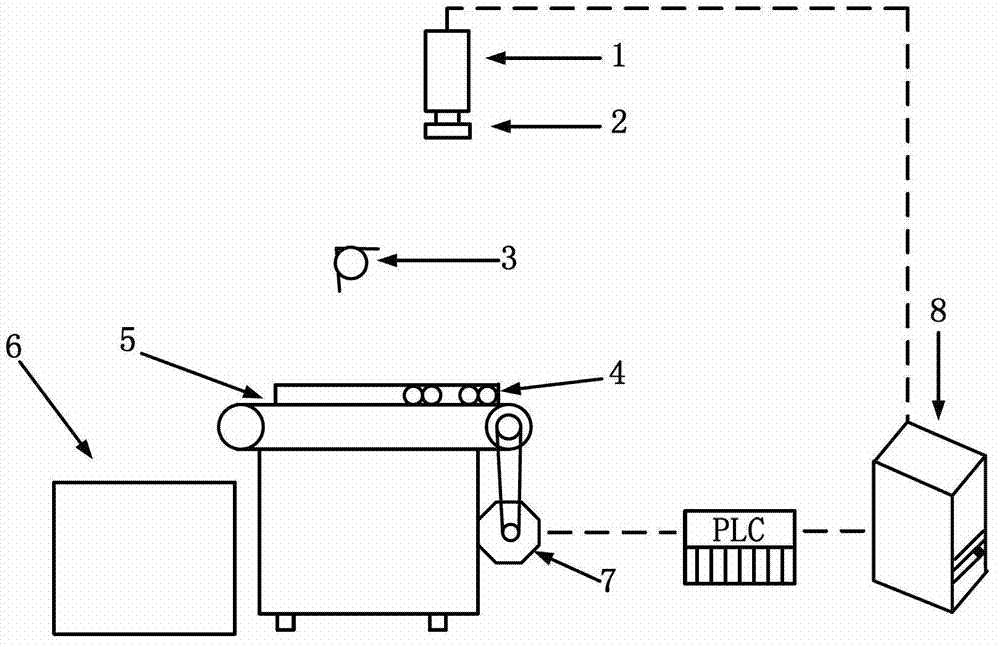

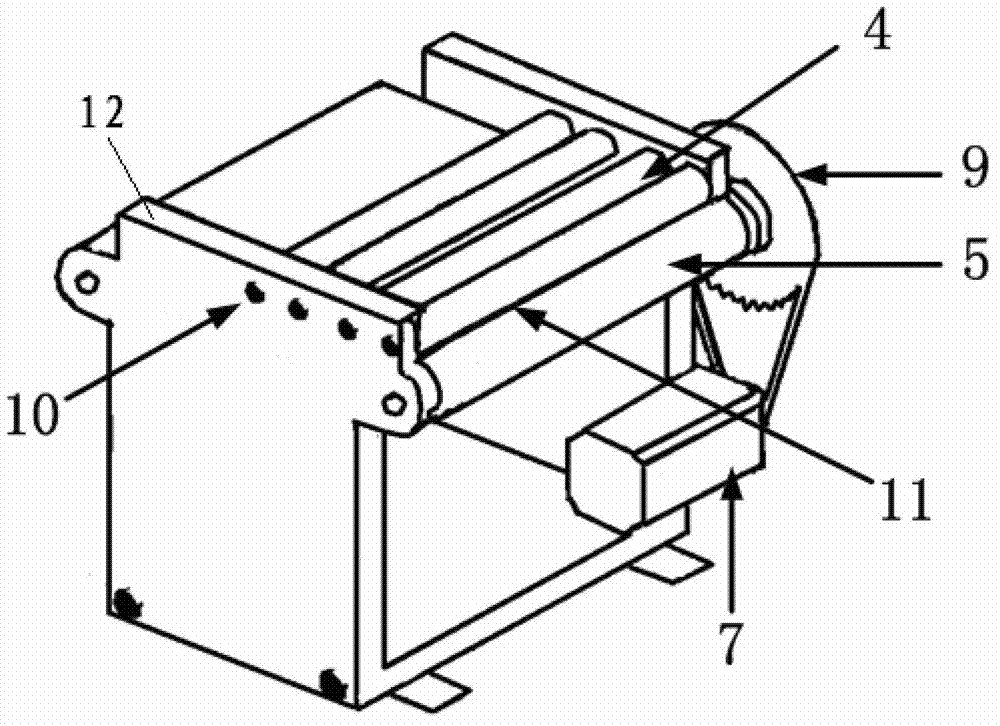

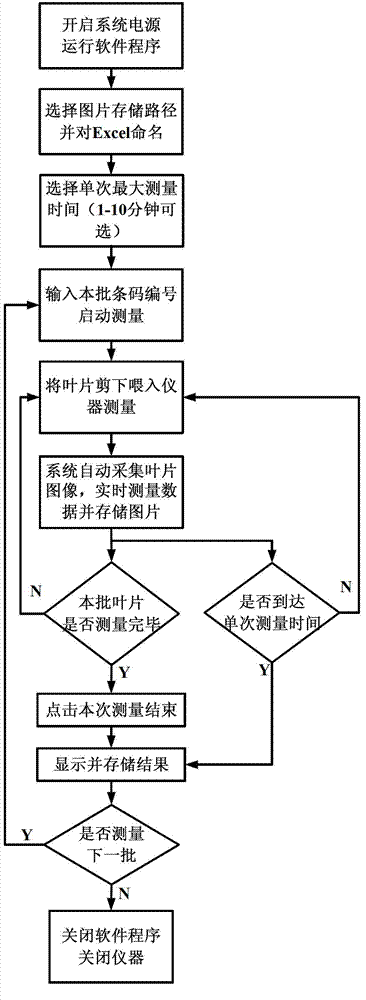

Automatic measuring and analyzing instrument for crop leaf area information

The invention discloses equipment for measuring and analyzing the total leaf area, green leaf area, yellow leaf area and the green leaf index of a crop in a high-precision and high-speed manner. The instrument comprises a leaf transmission device, an image acquisition device, a PLC (Programmable Logic Controller) and a computer system. According to the invention, a machine vision technology is adopted to dynamically acquire the leaf color information of the crop, and the leaves of the crop can be quickly measured at the same time; the defect that a current measuring method can not quickly and efficiently measure the total leaf area, green leaf area and yellow leaf area of the crop is overcome; the measuring process adopts a feeding type flow operation mode, and the operation is convenient; the software compatibility is good; and the foreign part can be automatically removed, and the green leaf part and the yellow leaf part can be recognized. Therefore, the leaf color information can be obtained as long as the leaf is sheared down and directly put into the instrument for measuring and analyzing, without pretreatment for the yellow and green parts of the leaf such as trimming.

Owner:HUAZHONG AGRI UNIV

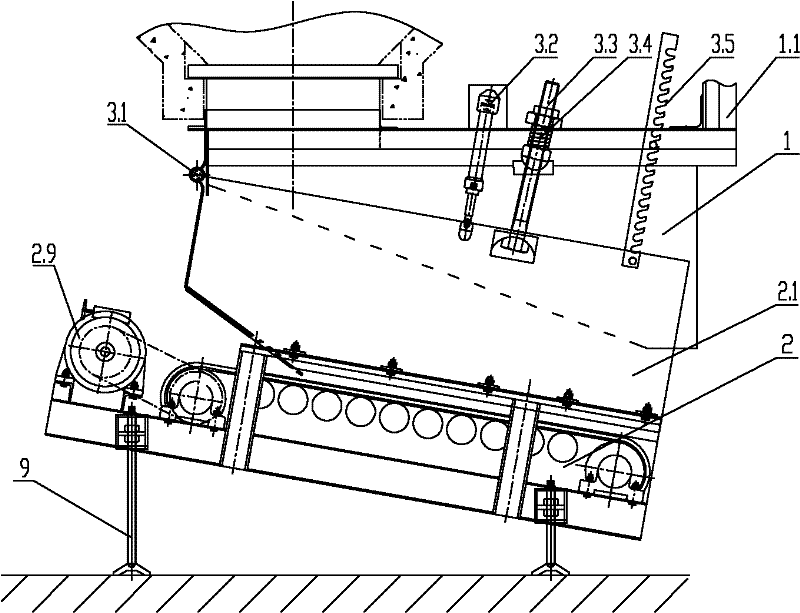

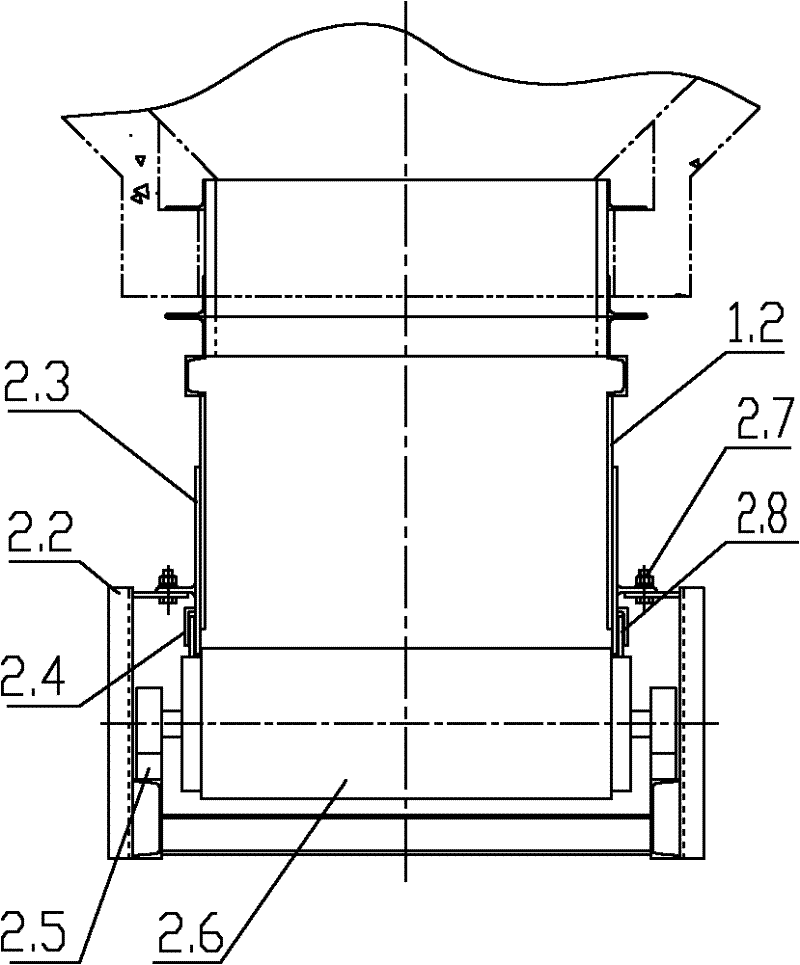

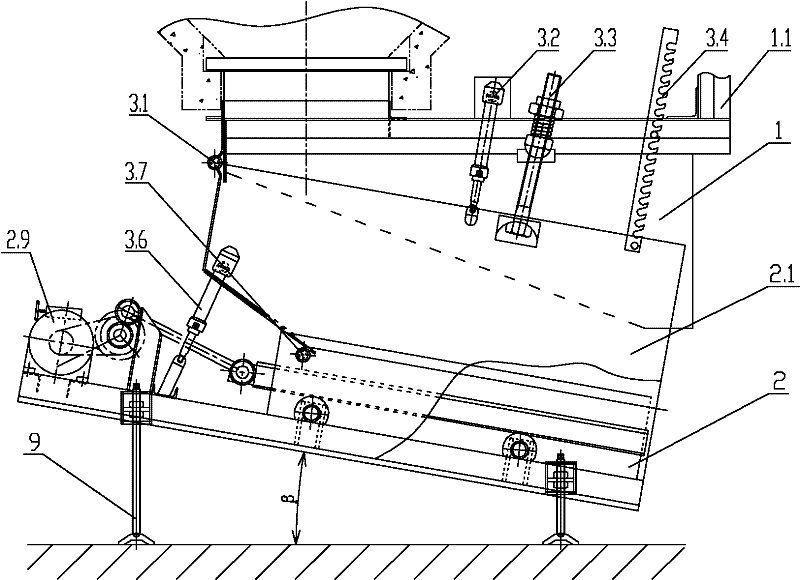

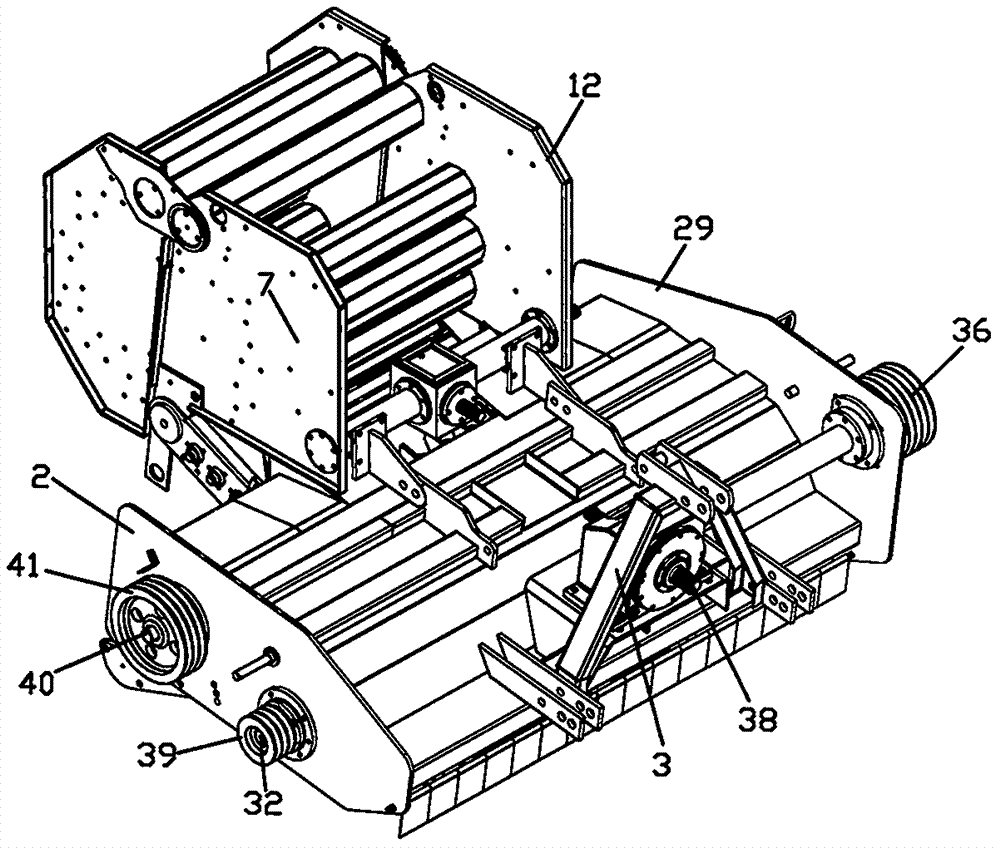

Variable inclination angle energy-saving feeder easy to assemble and change

ActiveCN102452547AExtended service lifeFor quick replacementConveyorsConveyor partsEngineeringPower consumption

The invention relates to feeding equipment for mines, metallurgy and ports and in particular relates to a feeder. The variable inclination angle energy-saving feeder easy to assemble and change comprises a guide chute and a delivery chassis, wherein the delivery chassis is arranged below the guide chute. The feeder also comprises an angular adjustment mechanism which is arranged on the guide chute and / or delivery chassis. The feeder has the following beneficial effects: materials can be ensured to flow automatically or stop; feeding quantity increase is realized; the power consumption and wear are reduced; more energy is saved; the service life of the feeder is prolonged; and the integral machine is separately assembled so that the machine is easy to maintain rapidly and components are easy to change rapidly, thus improving the operation efficiency of an integral production system.

Owner:刘素华

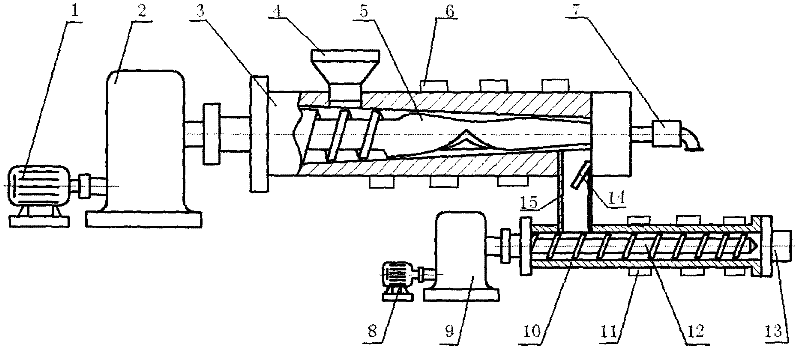

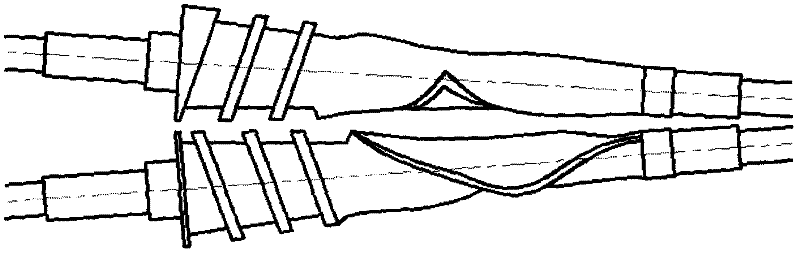

Double-conical-rotor continuous mixing unit

The invention provides a double-conical-rotor continuous mixing unit. The mixing unit mainly comprises a mixing part and a discharging part and can adopt a single-band or dual-band mode; wherein the mixing part mainly comprises a charging device, a cylinder, conical rotors, heating and cooling devices and a transmission device; the two mixing rotors are conical and the center lines of the two rotors form a certain angle when the two rotors are installed; the outer diameter outline of each mixing rotor is gradually reduced and is conical; the mixing rotors are provided with charging segments and mixing segments; the rotors on the charging segments adopt screw conveying structure; seen from the angle vertical to the conical surfaces of the outer outlines of the rotors, the structures of the mixing segments have the typical rotor characteristics such as cam shape, S shape or four-wing shape; when the mixing unit adopts the single-band mode, the tail ends of the rotors adopt the screw structure and pressure is created to convey the materials to the head; and when the mixing unit adopts the dual-band mode, the mixed materials enter into next band of screw extruder via a valve and pressure is created to convey the materials to the head; the mixing unit in any one of the two modes adopts the head fit for the cavity for pelleting or forming; a melt pump can be connected in front of the head; and two rotors can rotate at the same speed or different speed and form a plurality of shearing, drawing and kneading zones during rotation, and exchange of materials among the rotors is more frequent, thus effectively improving the plasticating, melting and dispersing properties of equipment, shortening the processing time and improving the yield. The mixing unit can be used in such processes as mixing, pelleting and the like during processing rubbers, coatings, propellants, explosives, paper pulp, plastics, food, medicaments, feeds and the like.

Owner:BEIJING UNIV OF CHEM TECH

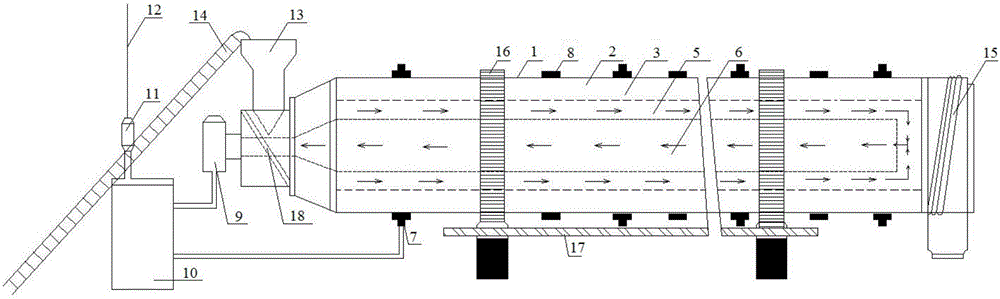

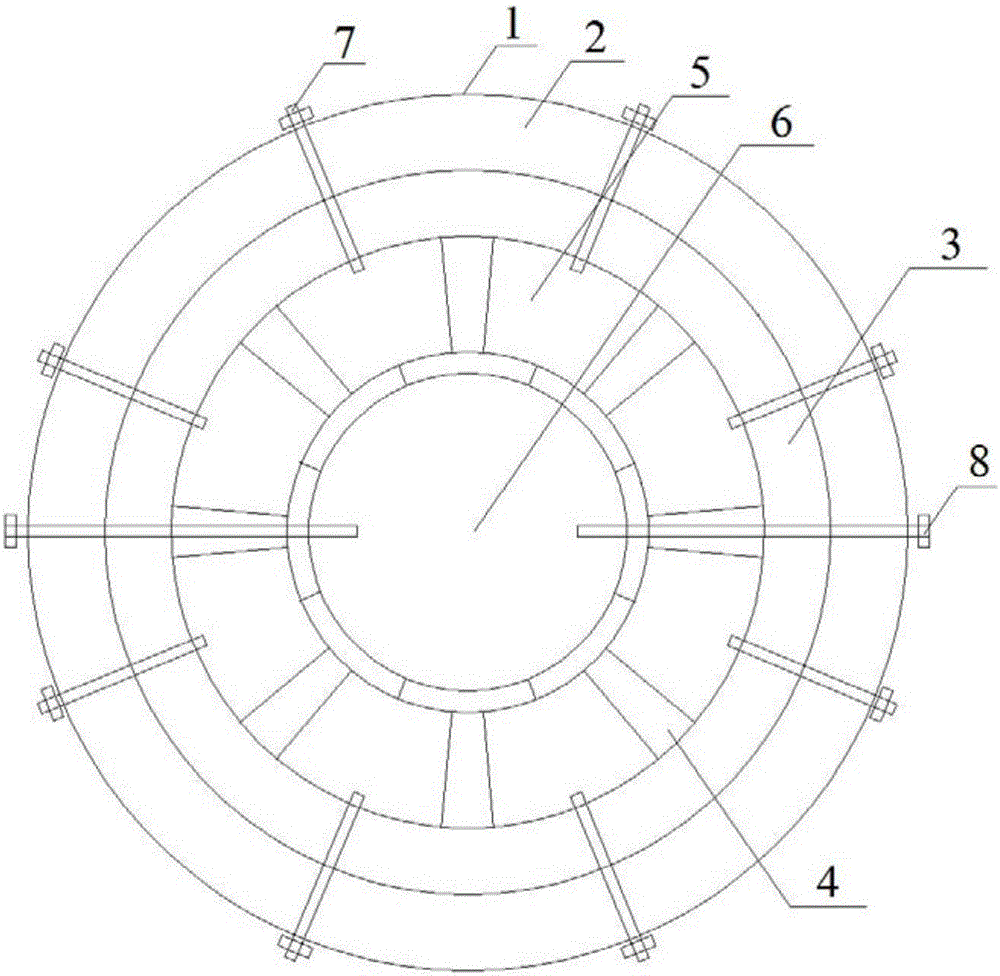

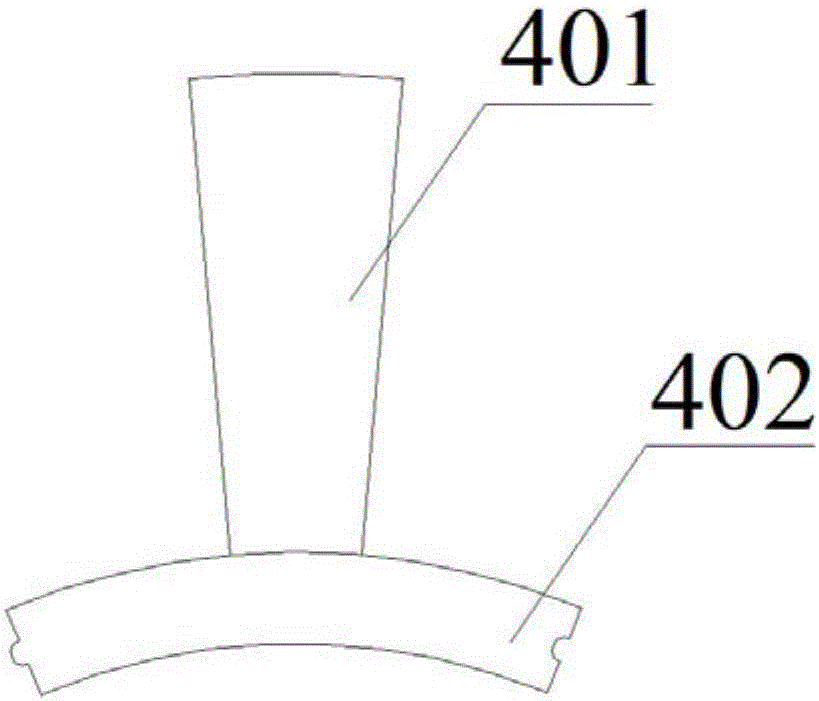

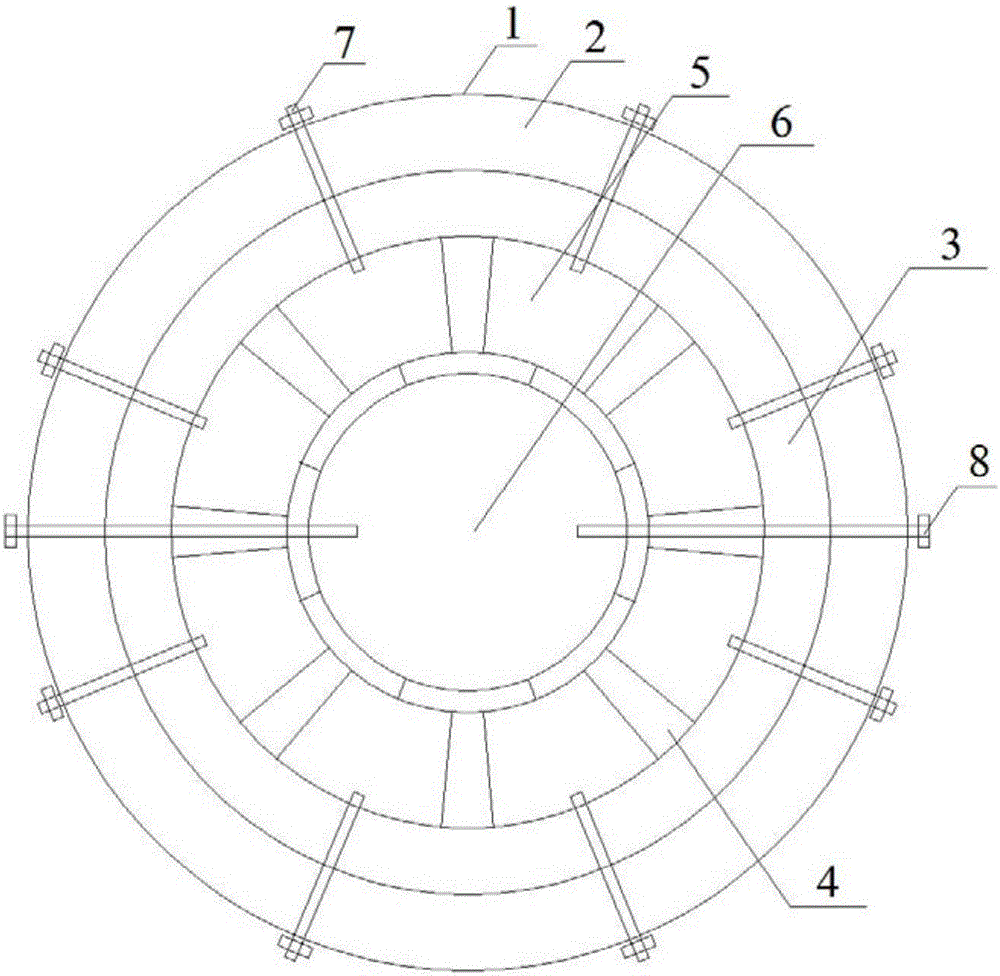

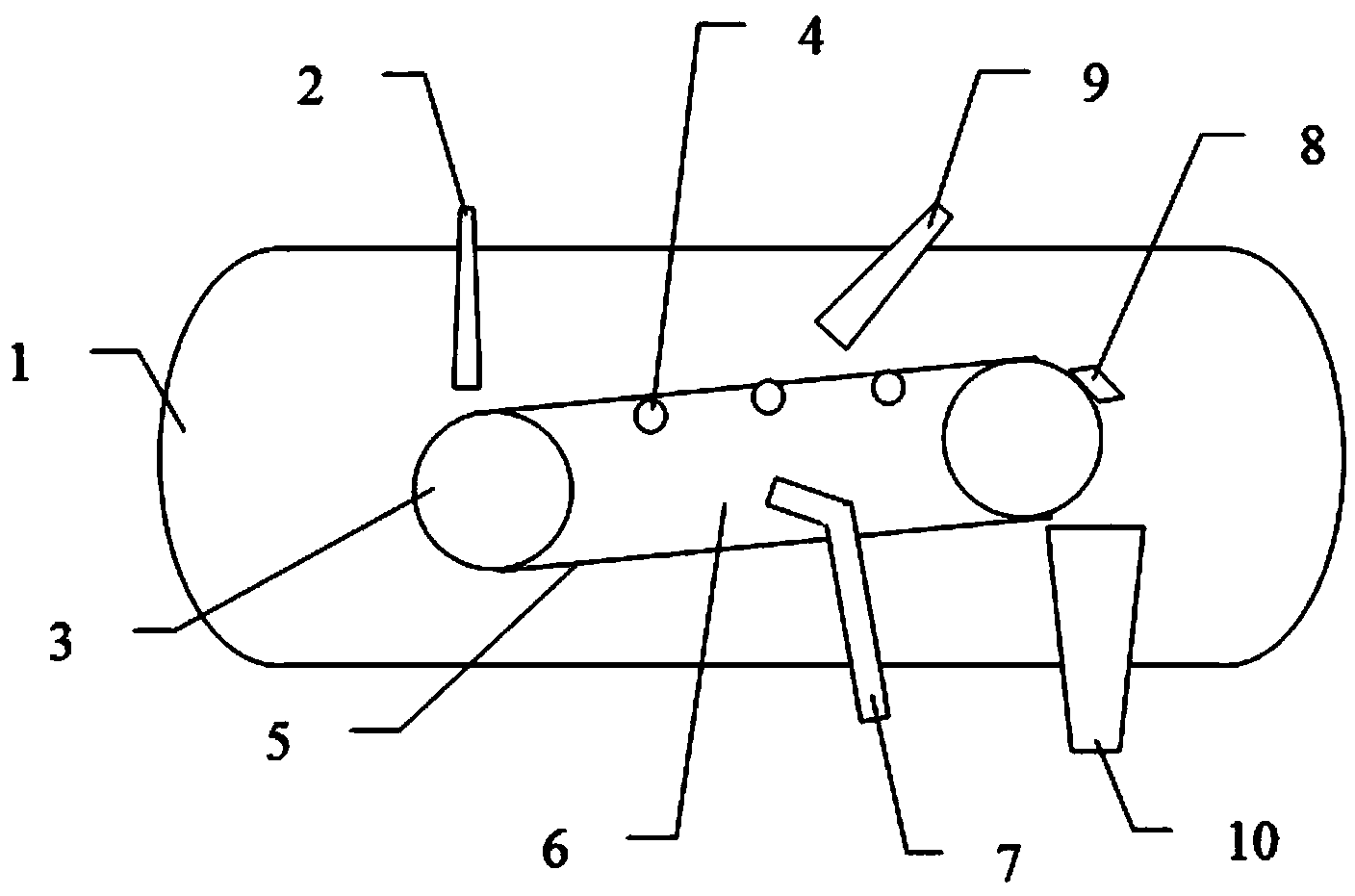

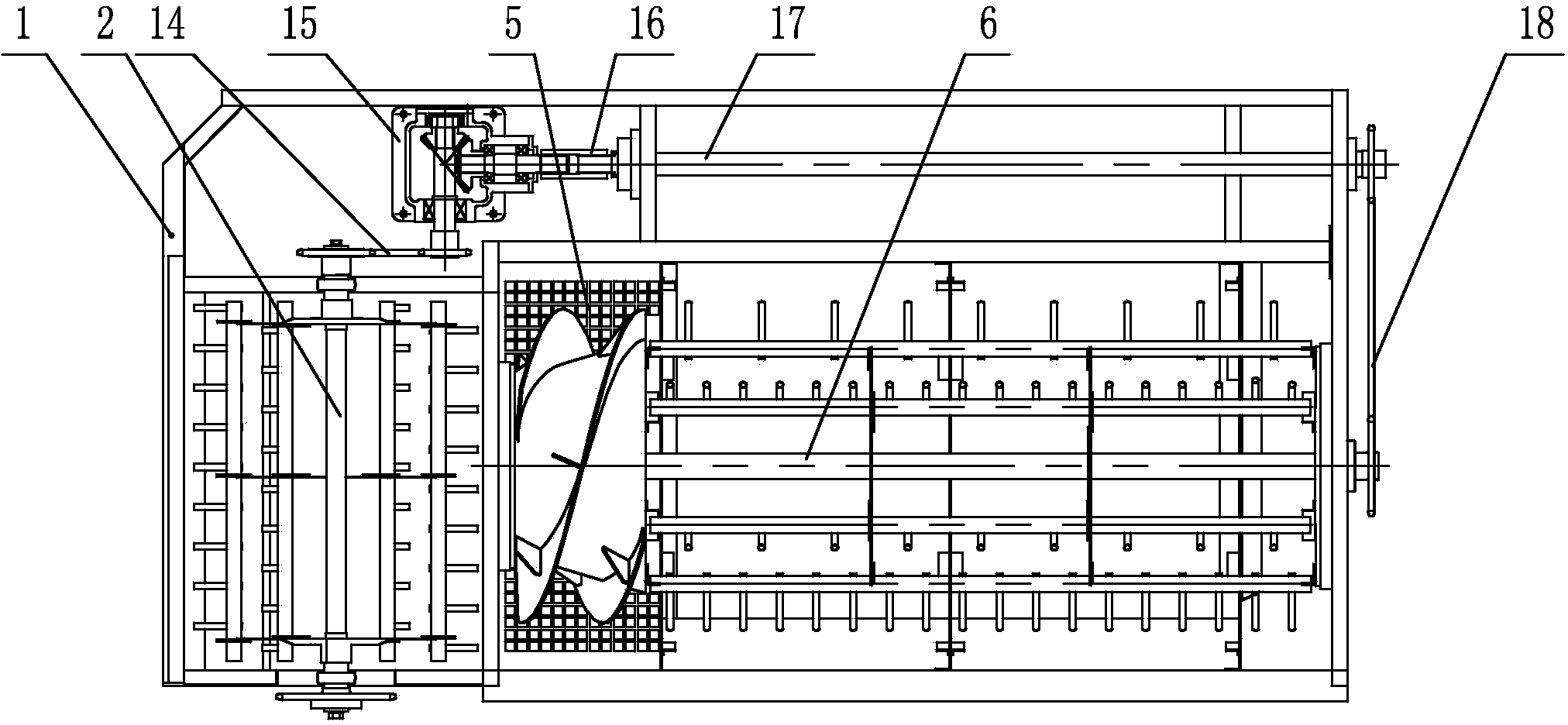

Furnace body of activated carbon activation furnace

ActiveCN106276889AIncrease the number of flipsFlip fullRotary drum furnacesActivated carbonCombustion chamber

The invention discloses a furnace body of an activated carbon activation furnace, and relates to the field of activated carbon production devices. The furnace body can improve the safety of the activated carbon production process to a certain degree, can stably run for a long time, and can greatly improve the quality and yield of produced activated carbon. The furnace body is internally provided with a combustion channel communicated with the interior of the furnace body. Air is introduced in the combustion chamber. The interior of the furnace body is divided into at least two material channels. The material channels are arranged in the length direction of the furnace body. Vapor is introduced in each material channel. The furnace body comprises an outer cylinder. At least two branch warehouse supporting pieces are arranged in the circumferential direction of the inner wall of the outer cylinder and form the combustion chamber. One material channel is formed among two adjacent branch warehouse supporting pieces, the inner wall of the outer cylinder and the outer wall of the combustion chamber. The furnace body is mainly used for producing activated carbon.

Owner:张西进

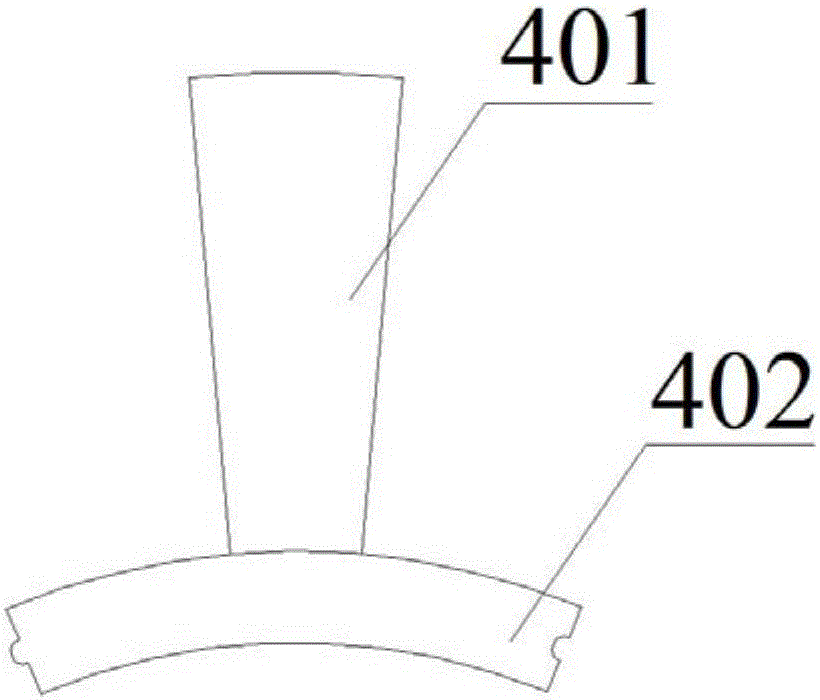

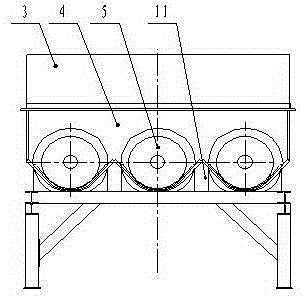

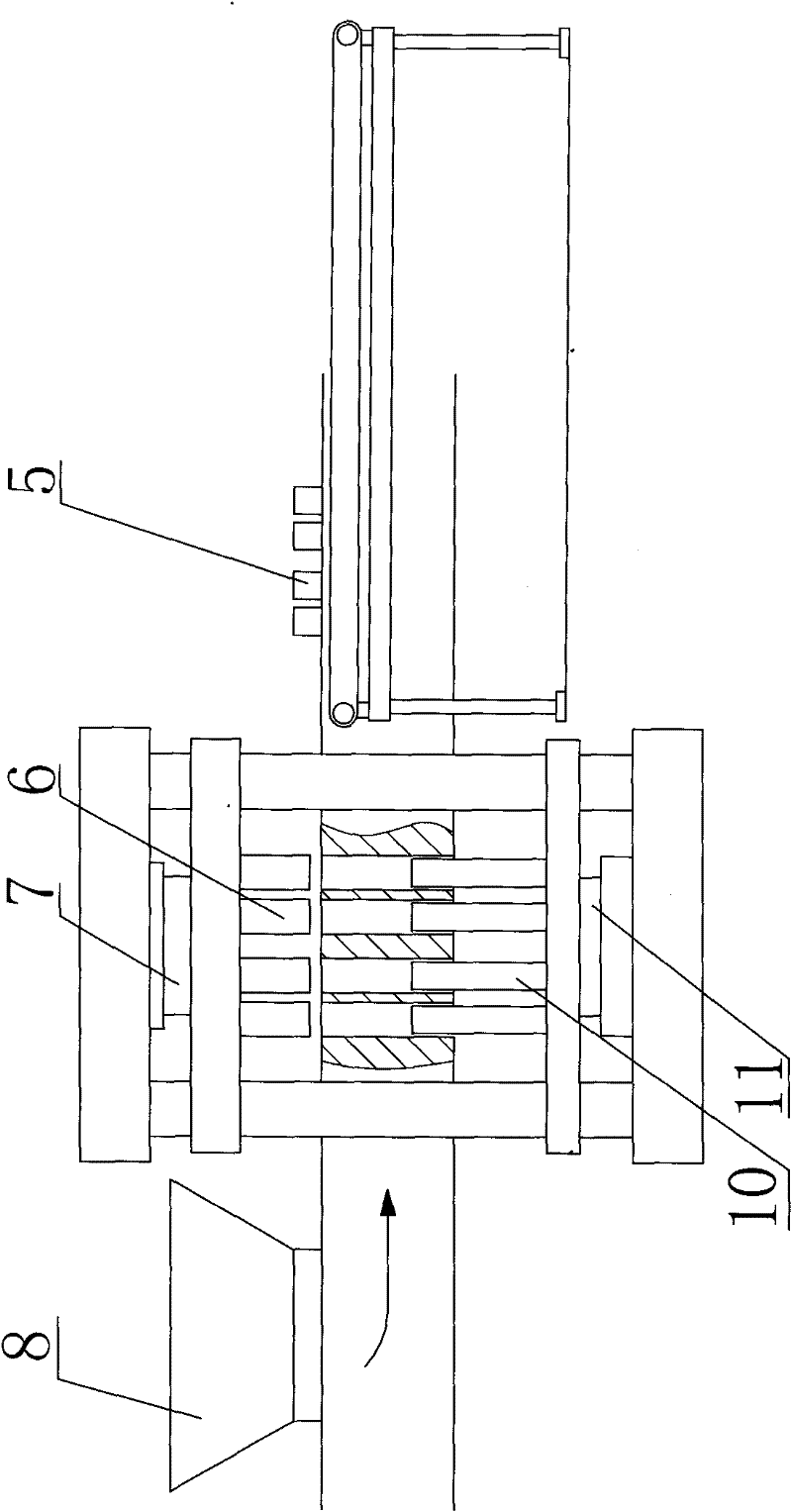

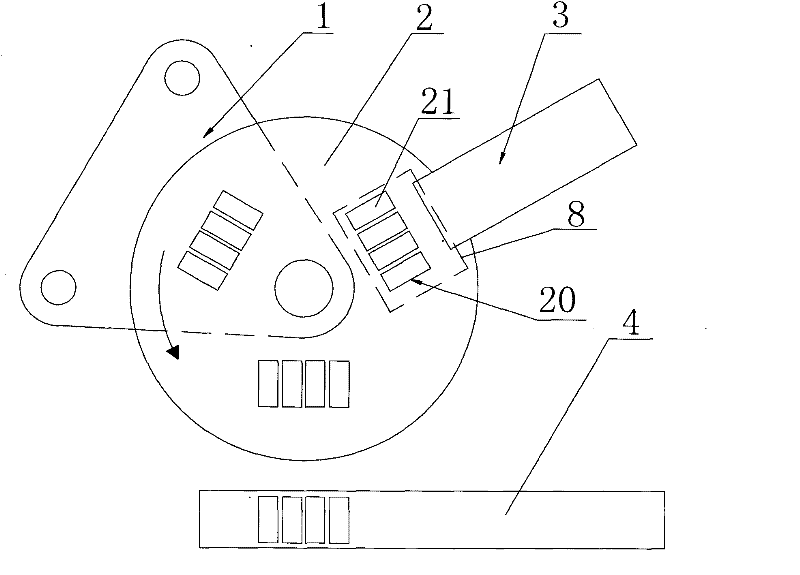

Coal slime spiral buffer feeding method and coal slime spiral buffer feeding machine

The invention relates to a coal slime spiral buffer feeding method and a coal slime spiral buffer feeding machine, and belongs to the technical field of coal slime transportation. A shaftless variable-pitch spiral conveying system (5) is arranged in a shell of the feeding machine; a wear resistant lining plate is arranged at the bottom; a discharge port (1) is formed in the front part of the shell of the feeding machine; an unloading port of a bin (3) is matched with the shaftless variable-pitch spiral conveying system; the tail part of the shaftless variable-pitch spiral conveying system is connected with a driving system, and the head part extends to the discharge port; the shaftless variable-pitch spiral conveying system consists of spiral blades, and is not provided with a central rotating shaft; the spiral blades are arranged on one axle; the pitches of the spiral blades are unequal; the pitch of the tail part is the smallest; and the pitch of the head part is the biggest. The coal slime spiral buffer feeding method and the coal slime spiral buffer feeding machine have the advantages and active effects of possession of a spiral uniform conveying function, capability of achieving a material buffer effect, increment of conveying capacity, effective prevention of material blockage, reduction of maintenance ratio, prolonging of bearing service life and improvement of production efficiency.

Owner:TANGSHAN TIANHE TECH DEV

Hedge trimmer head

PendingCN110178571AEnhanced refinement rateIncrease the number of contacts and contact timeHedge trimming apparatusCuttersEngineeringMechanical engineering

The invention discloses a hedge trimmer head, and relates to the technical field of hedge trimmer tools. The hedge trimmer head comprises a casing, one end of the casing is provided with an opening, at least two rotating cutters are installed in the casing, the rotation directions of the two rotating cutters are opposite to each other in the feeding direction, the end face, opposite to the opening, of the casing is provided with a discharging port, and the discharging port is located between the two cutters. The hedge trimmer head solves the problems that in traditional technologies, since multiple cutters are in single contact with hedges for cutting, combined cutting cannot be formed, so that the throwing direction of branches is not fixed, and partial power is wasted; the branches are thrown on a highway pavement under the rotary cutting function of the cutters, and vehicles driven at high speed are influenced; broken branches obtained after trimming need to be manually broken off and cut off for the second time to facilitate bagging.

Owner:广州交投绿化建设有限公司 +2

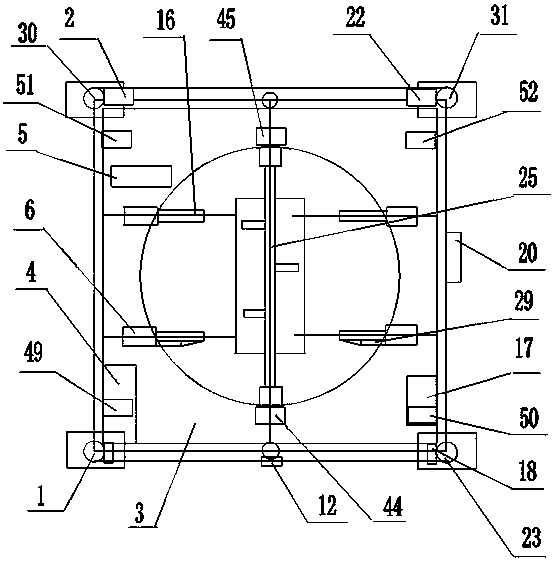

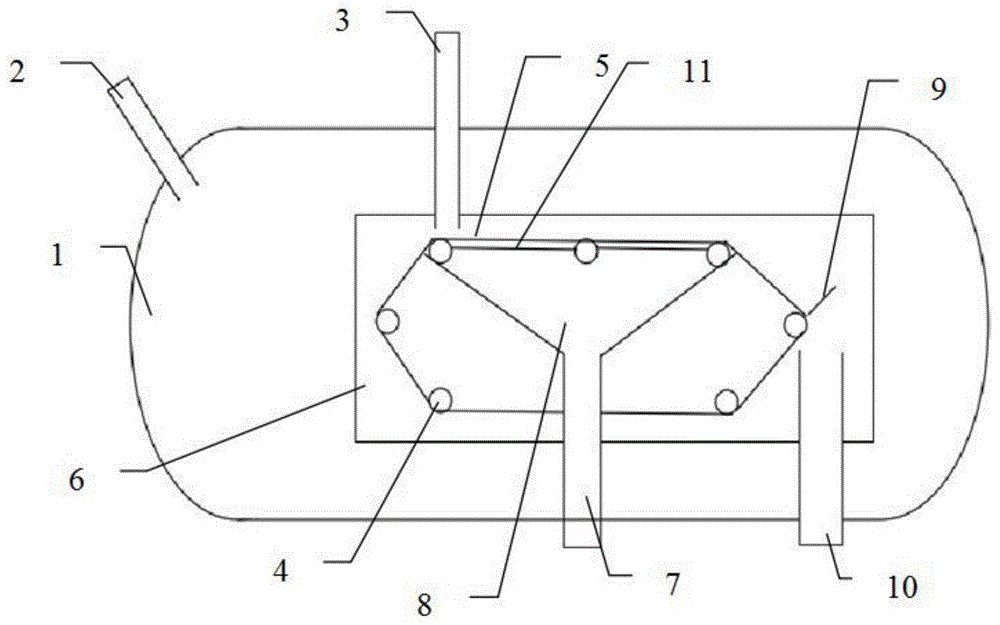

High-pressure filtering device used for steel rolling sludge treatment

InactiveCN104096403AReduce lossExtend the life cycleMoving filtering element filtersDrive wheelSludge

The invention discloses a high-pressure filtering device used for steel rolling sludge treatment. The high-pressure filtering device comprises a sealed pressurizing chamber and a filtering compartment, the sealed pressurizing chamber is an enclosed hollow tank, a gas inlet pipe and a feeding pipe are arranged on the outer wall of the sealed pressurizing chamber, the filtering compartment is arranged inside the sealed pressurizing chamber and comprises driving wheels, transmission rollers and a filtering strip, the driving wheels are arranged at two ends of the filtering compartment, the transmission rollers are arranged between the driving wheels, the filtering strip winds the peripheries of the driving wheels and the transmission rollers to form a filtering transmission mechanism, the filtering compartment and the sealed pressurizing chamber are divided into two independent enclosed spaces by the filtering strip, a filtrate outlet pipe is arranged on the side face of the filtering compartment, and the filtering compartment comprises a scraping plate which is a V-shaped plate and is used for scraping intercepting objects on the filtering strip.

Owner:梁均全

Biomass fuel block production method and equipment

ActiveCN105597862AImprove textureUniform textureBiofuelsSolid fuelsMolding machineProcess engineering

The invention discloses a biomass fuel block production method and equipment. Straw is cut into blocks, rubbed in a straw rubbing machine, extruded in a biomass fuel movable mold forming machine at certain temperature to fill up a movable mold, placed in a heat insulation bin for 2-5 min at the temperature of 190 DEG C or above for shaping and then subjected to demolding. According to the straw rubbing machine, an auger and a rubbing head are matched to carry out rubbing, the fiber structure of the straw is compressed, the size is reduced, density is increased, and therefore the material feeding quantity in the forming machine is increased. According to the biomass fuel movable mold forming machine, the movable mold is adopted, a movable mold track and the heat insulation bin are additionally arranged, a choke pipe in an extruding machine is omitted, a shaping pipeline in a shape keeping area is shortened, frictional force between materials and the mold and loss of the mold are reduced, cost is lowered, and energy consumption is saved; the mold is automatically transferred into a heat insulation device after being filled, the extruding machine continues to operate, production time for a single fuel block is shortened, shape keeping time is prolonged, and the produced biomass fuel blocks are good in shape, high in density, uniform in texture and consistent in specification.

Owner:丁启航

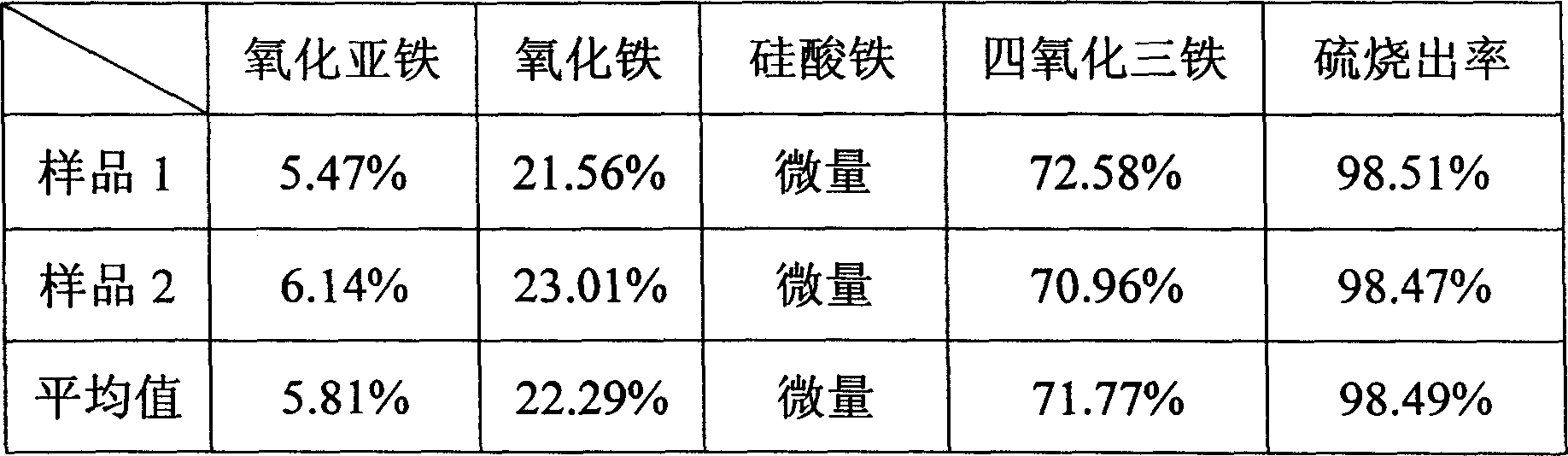

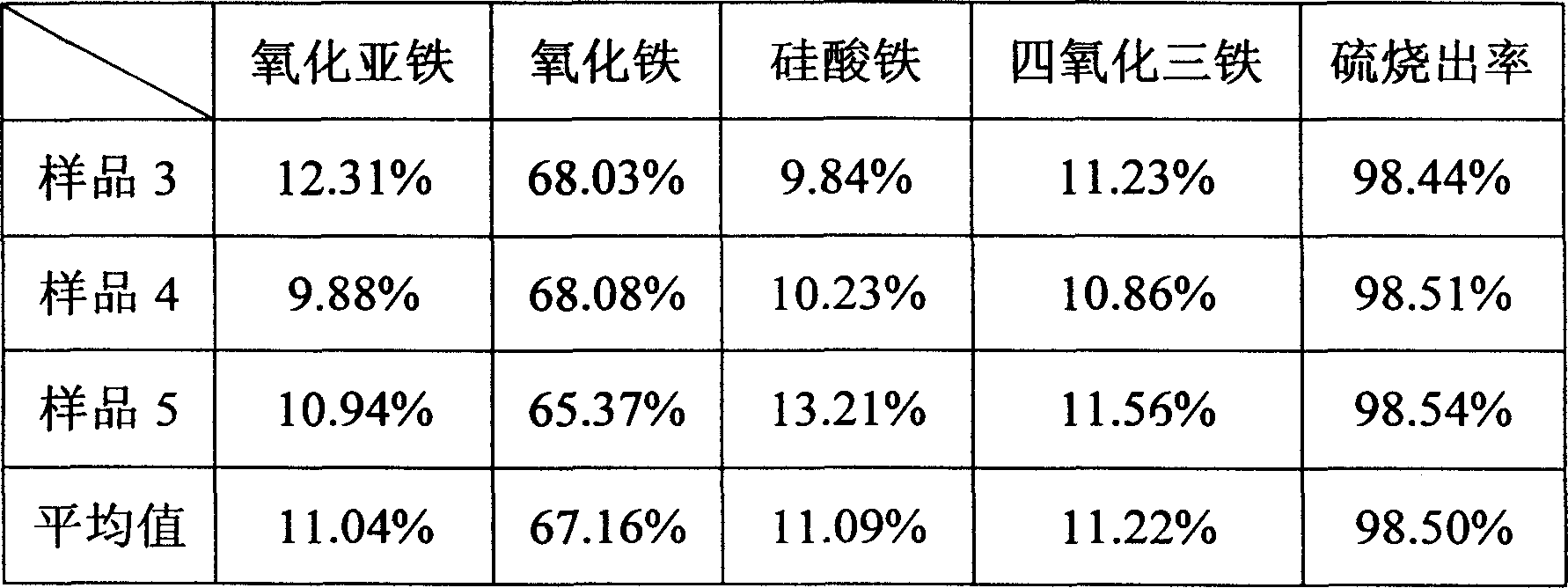

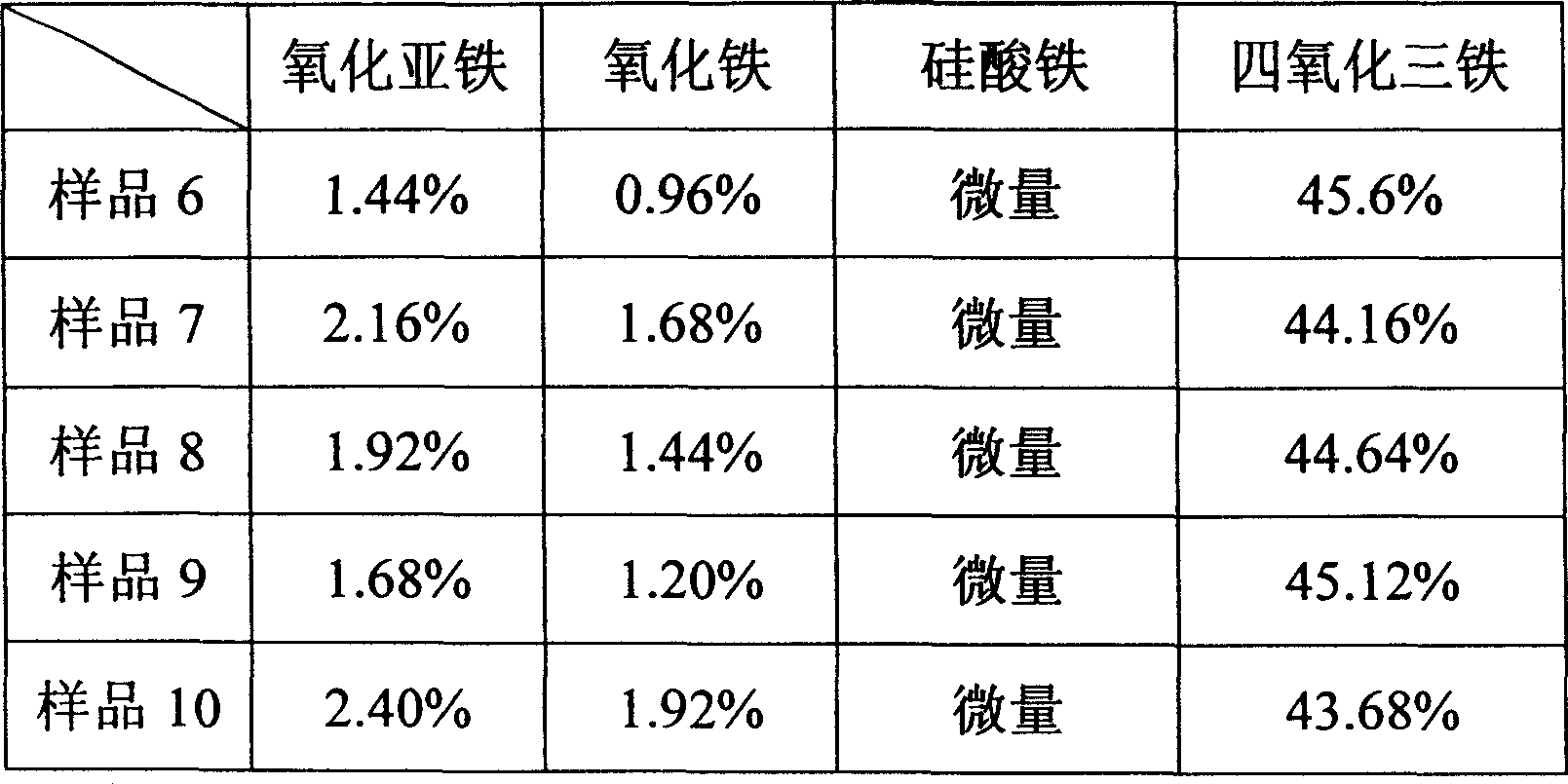

New acid preparing process with pyrite ore

InactiveCN1772598AGuaranteed Separation OxidationChange the form of existenceSulfur-trioxide/sulfuric-acidResource utilizationSulfur

The new acid preparing process with pyrite ore belongs to the technology field of roasting pyrite ore to prepare acid and sorting slag to obtain iron ore. The acid preparing process includes the steps of treating material and roasting at 750-800 deg.c, and features the reduction of the desulfurized and roasted slag with reductant at 550-570 deg.c. The process can convert the iron in the slag into ferric-ferrous oxide capable of being magnetically separated. The present invention results in raised resource utilization rate.

Owner:赵位

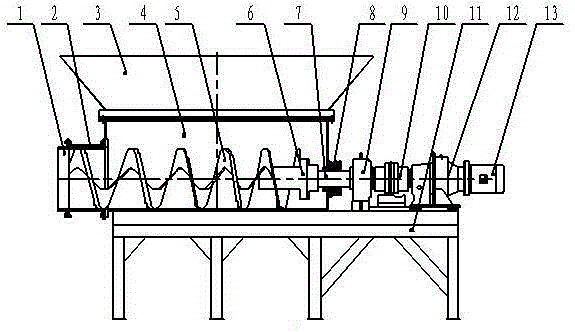

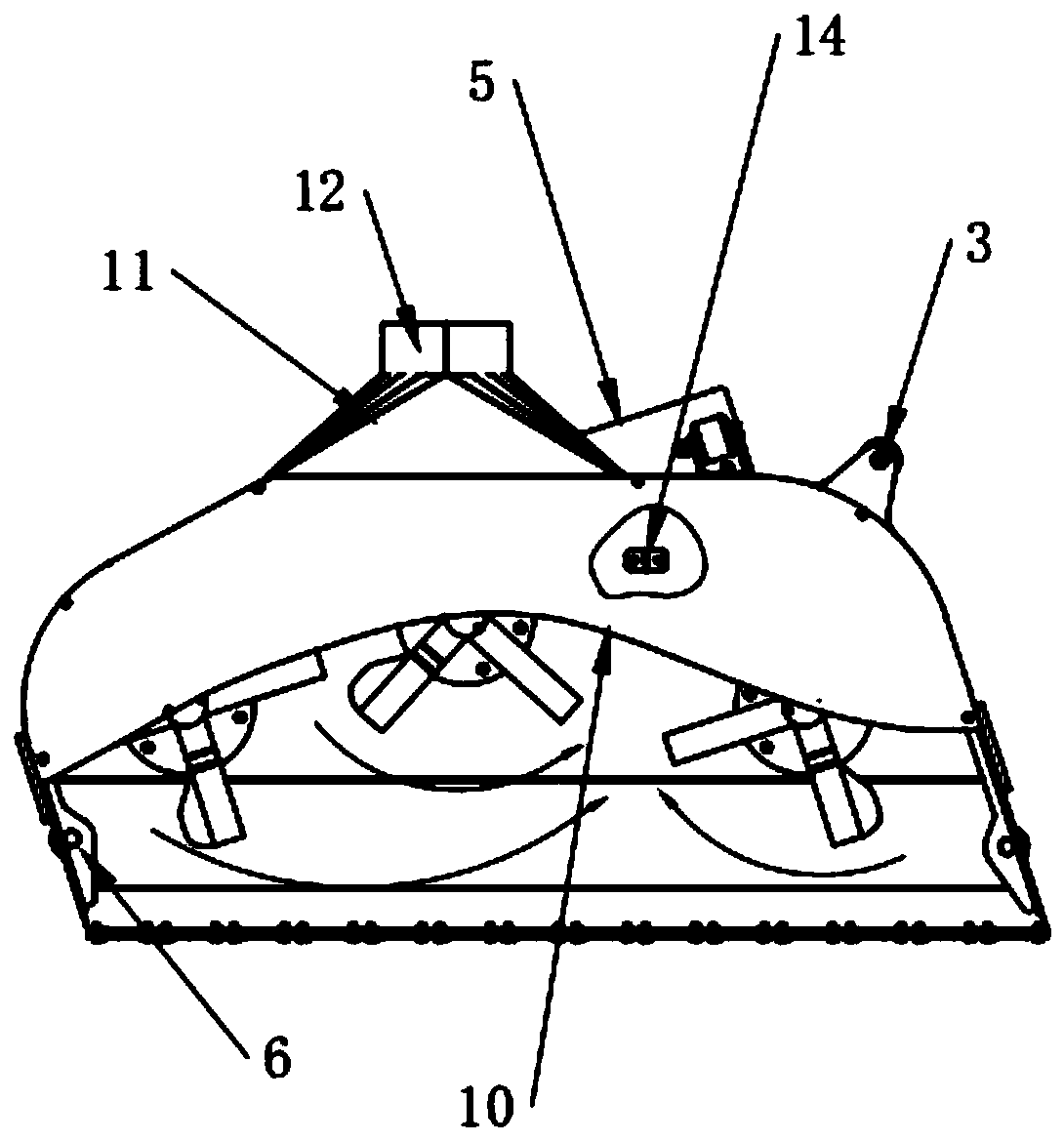

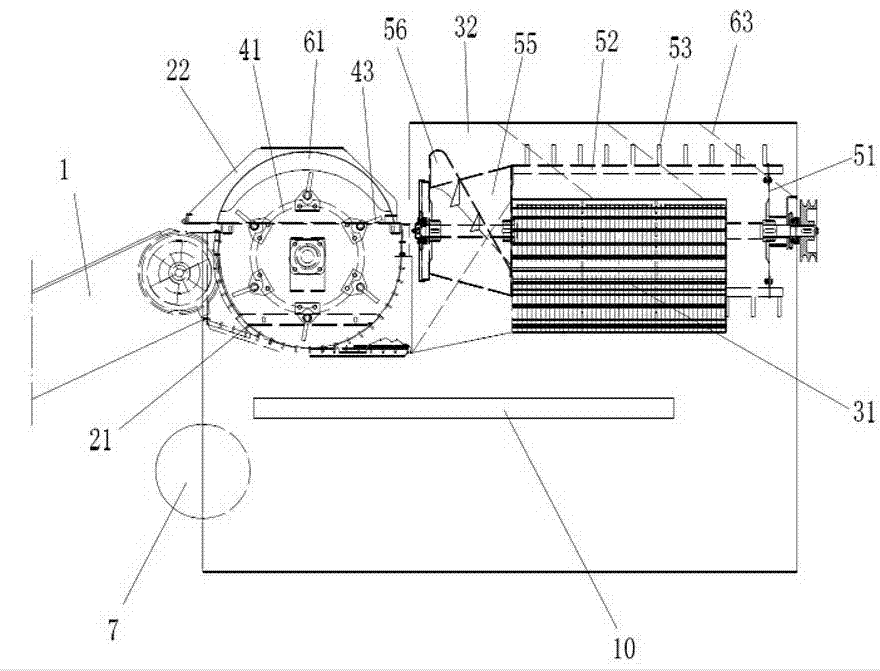

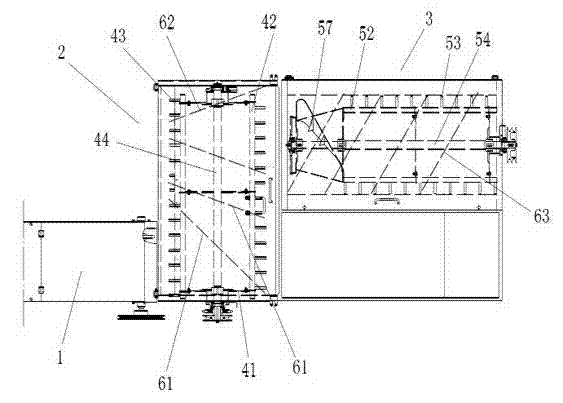

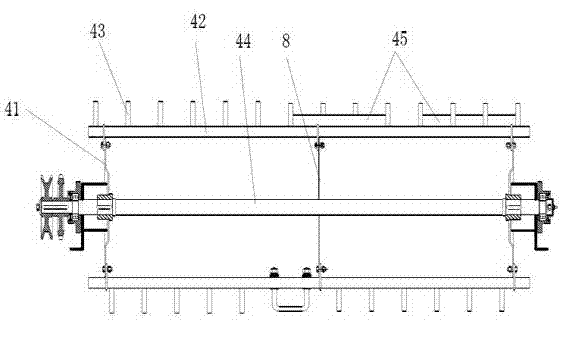

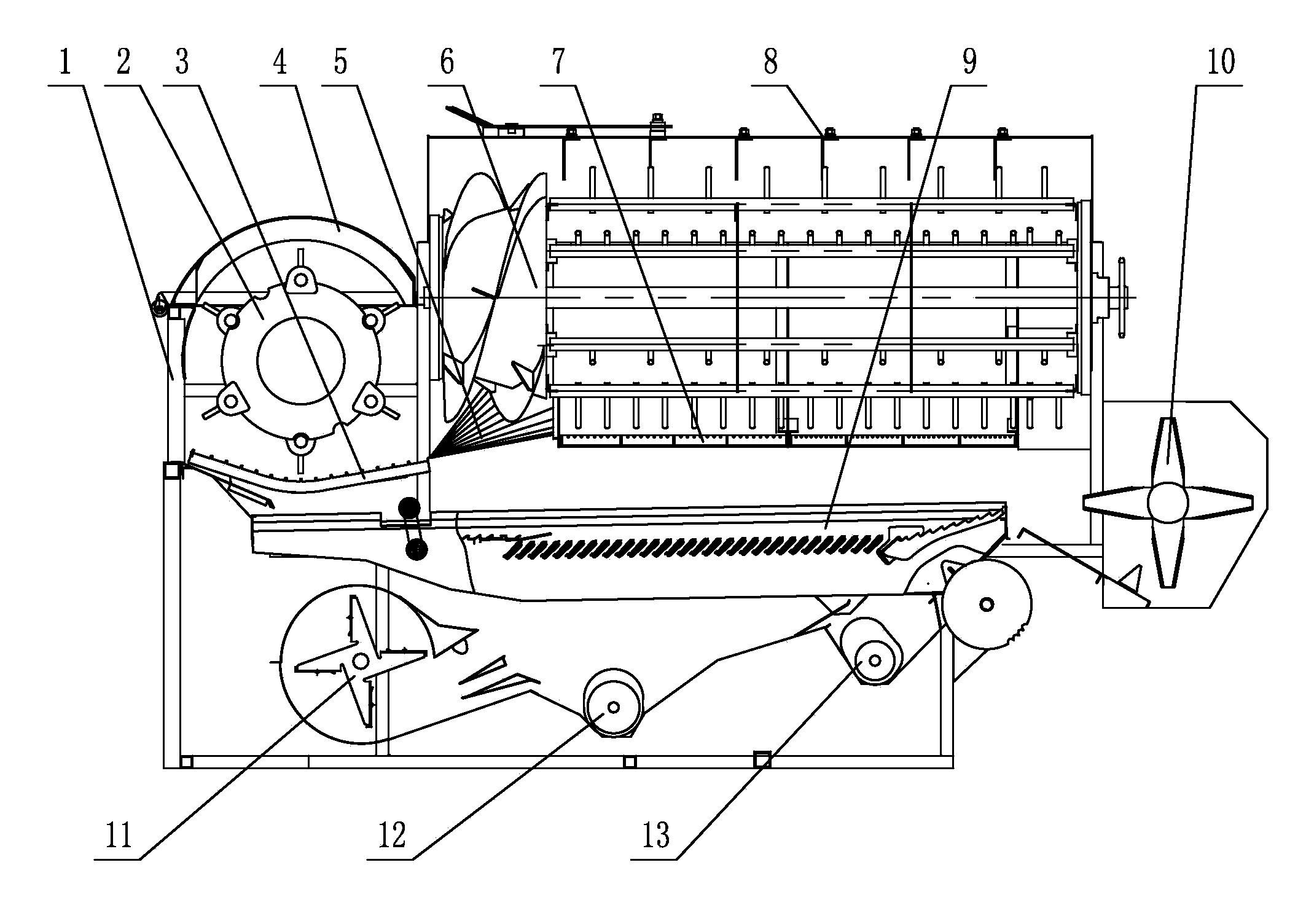

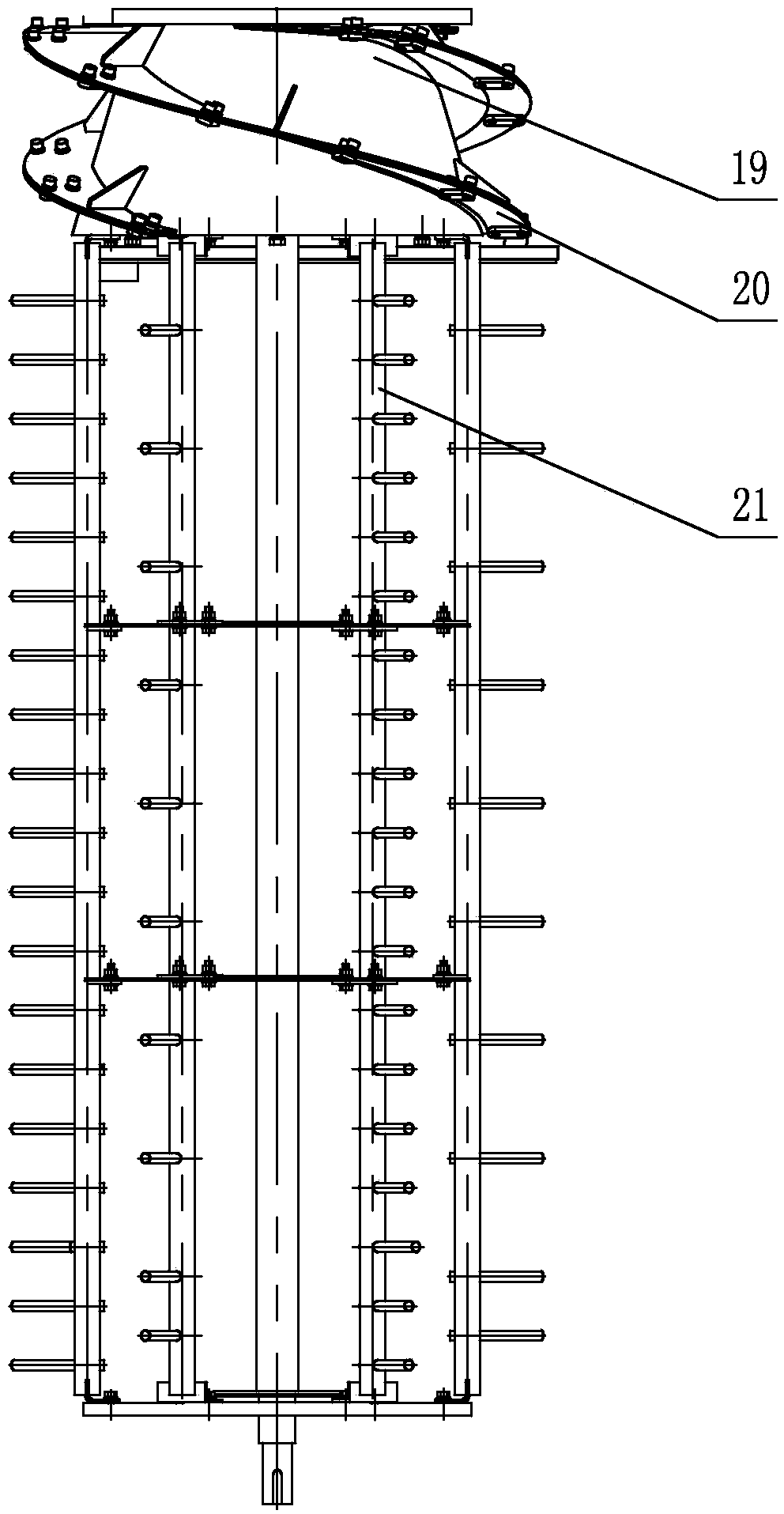

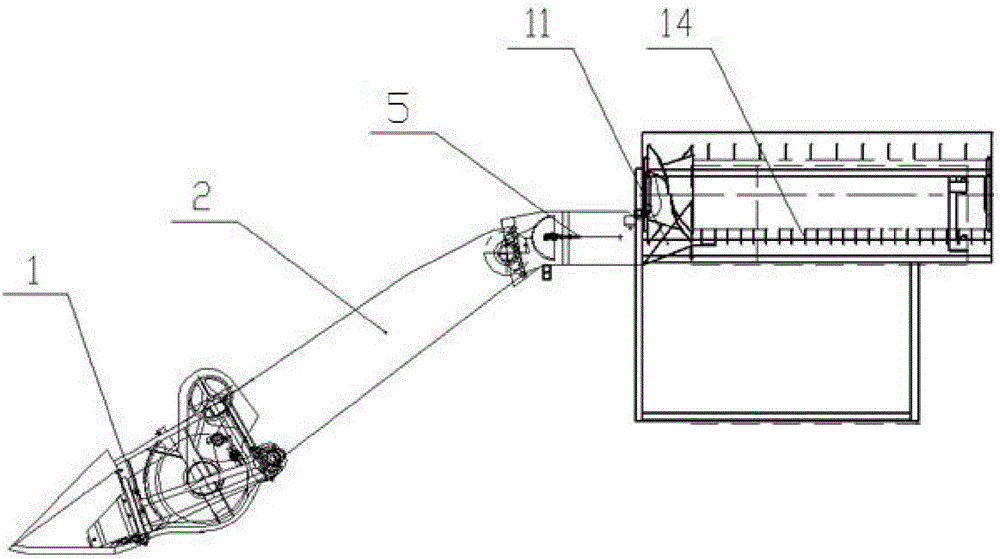

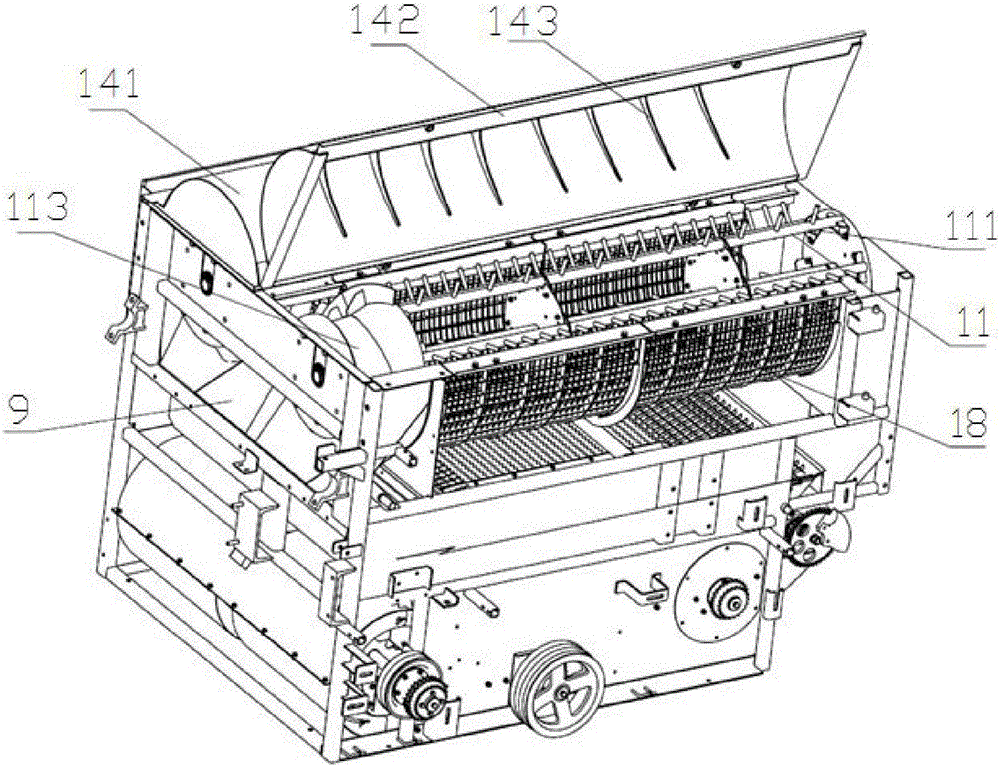

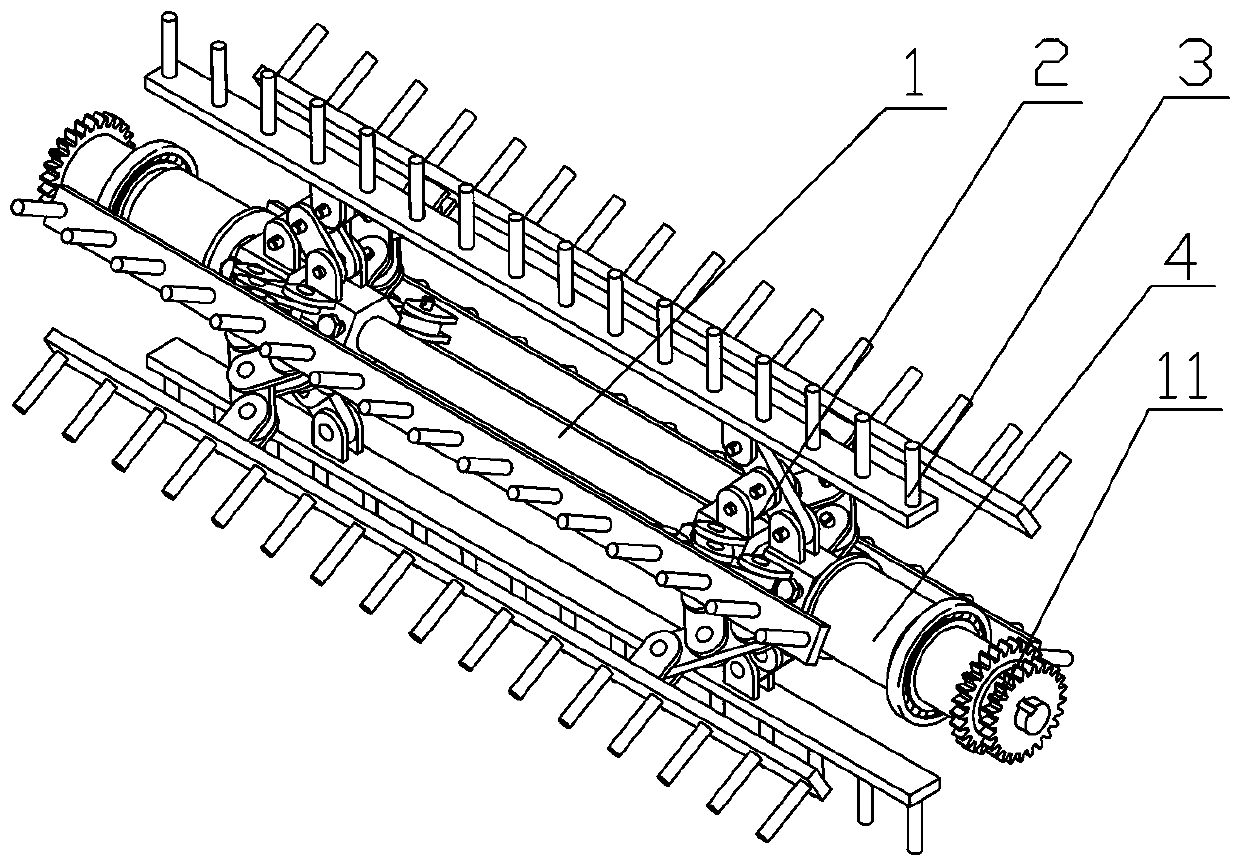

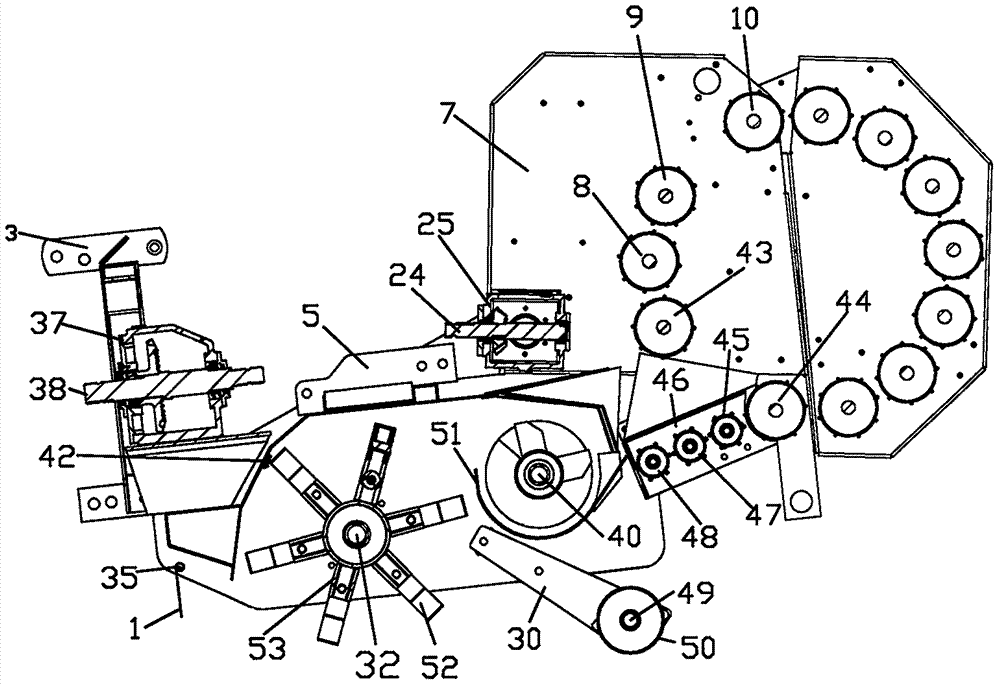

Threshing structure of L-shaped horizontal and longitudinal axial flow full-feeding combine harvester

InactiveCN103609250ALarge amount of feedImprove work efficiencyMowersThreshersTransverse axisEngineering

The invention relates to the technical field of agricultural machinery, in particular to a threshing structure of an L-shaped horizontal and longitudinal axial flow full-feeding combine harvester. The threshing structure comprises a threshing rack, a vibrating screen arranged on the threshing rack, an air blower and a middle conveyor connected on the upper portion of the front end of the threshing rack, a threshing drum communicated with the rear end of the middle conveyor is arranged on the threshing rack and comprises a horizontal axial flow drum and a longitudinal axial flow drum which are in communicated connection and perpendicular to each other to be L-shaped, two ends of the horizontal axial flow drum are connected with the middle conveyor and the longitudinal axial flow drum respectively, and the middle conveyor and the longitudinal axial flow drum are arranged on two sides of the horizontal axial flow drum respectively. The threshing structure is large in feeding quantity and high in operating efficiency during harvesting, connection of a threshing, cleaning and selecting drum and a discharging port of the middle conveyor is smooth and small in loss, crops in the horizontal axial flow drum are good in threshing, cleaning and selecting effect, and a notch board screen is large in separating area.

Owner:曾联

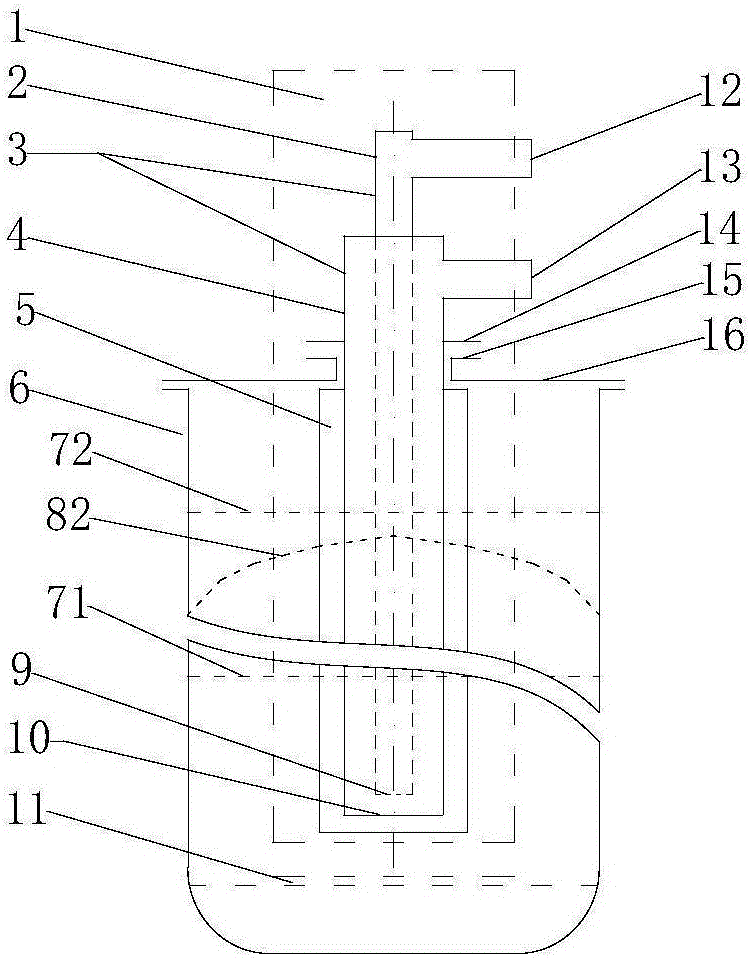

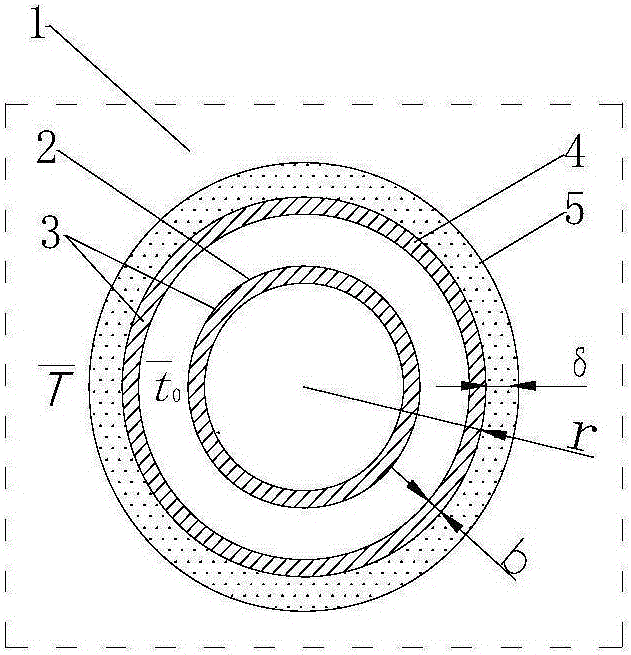

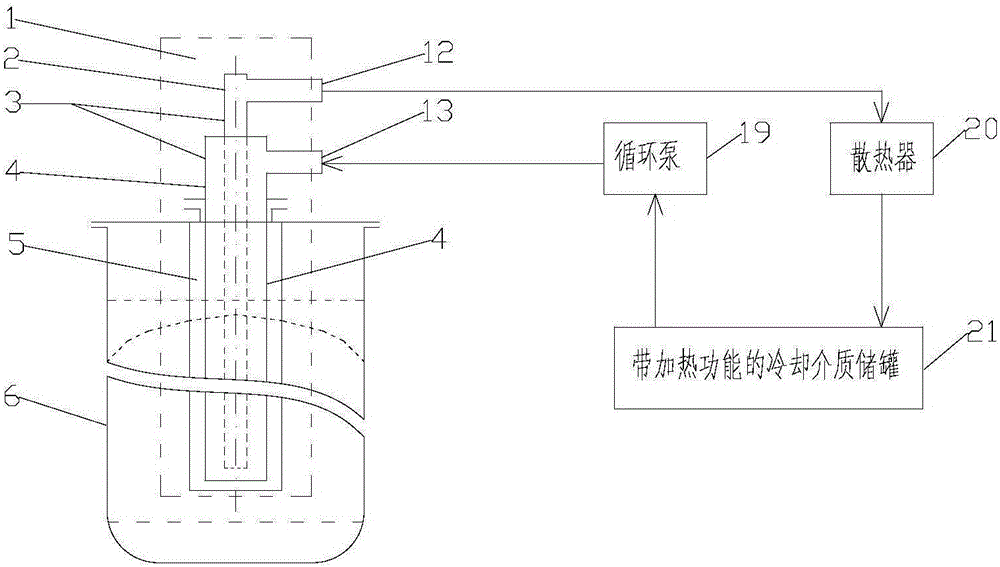

Tubular heat exchanger with inert coating layer and application to titanium sponge production

ActiveCN105925820AIncrease productivityImprove reduction efficiencyStationary tubular conduit assembliesTitanium tetrachlorideMagnesium

The invention discloses a tubular heat exchanger with an inert coating layer and application to titanium sponge production. The tubular heat exchanger can be used for quickly rejecting heat generated from a magnesiothermic reduction reaction and gathered in a liquid magnesium central area, so that the titanium tetrachloride feeding amount can be multiplied; meanwhile, the inert coating layer on the surface of the tubular heat exchanger always remains in a solidification state, thereby preventing formation, deposition and attachment of a titanium crystal on the metal surface of the tubular heat exchanger, and preventing bonding of a titanium lump and the metal surface of the tubular heat exchanger; and after the reduction is finished, the coating layer is melted and drops off, and a cavity is formed in the axis position of the titanium lump, so that the titanium sponge distillation period can be shortened by half or above. By adoption of the tubular heat exchanger provided by the invention, the titanium sponge production efficiency is multiplied, the power consumption cost is greatly reduced, and a prerequisite is provided for further enlargement of a furnace profile.

Owner:王进民

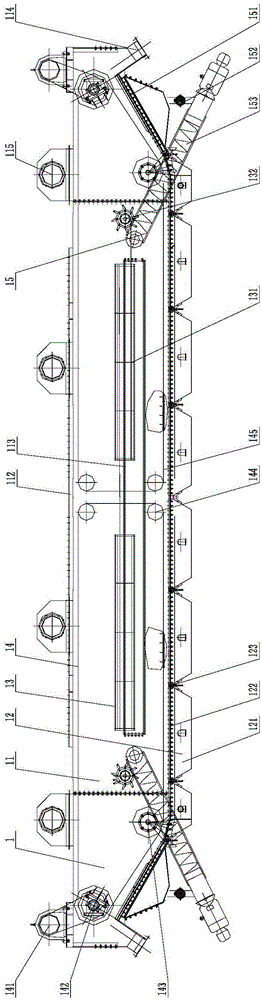

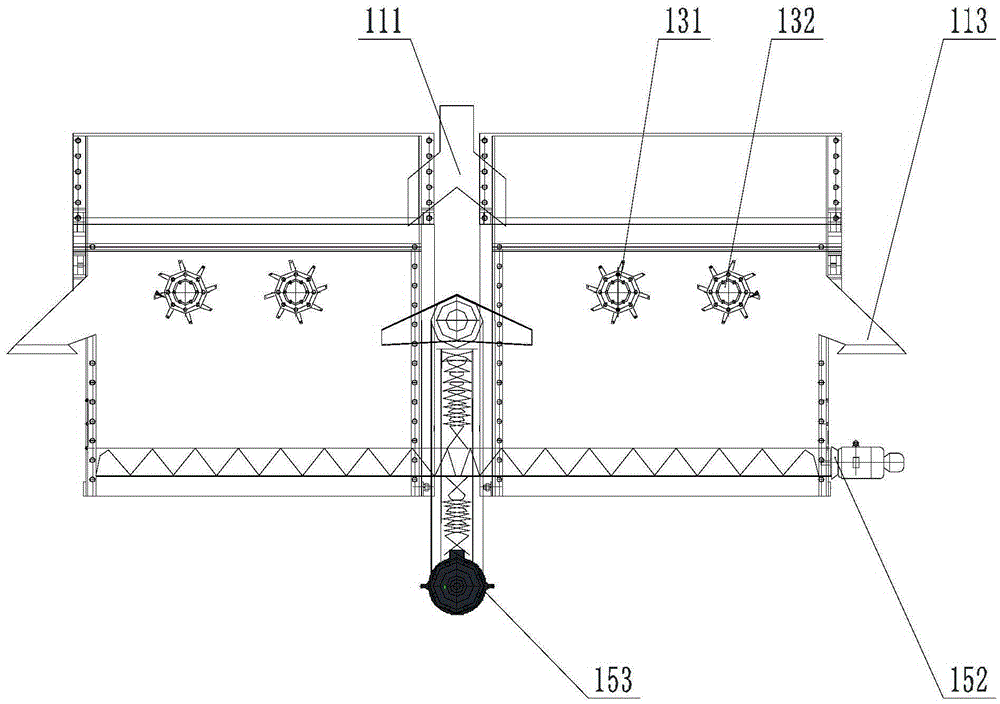

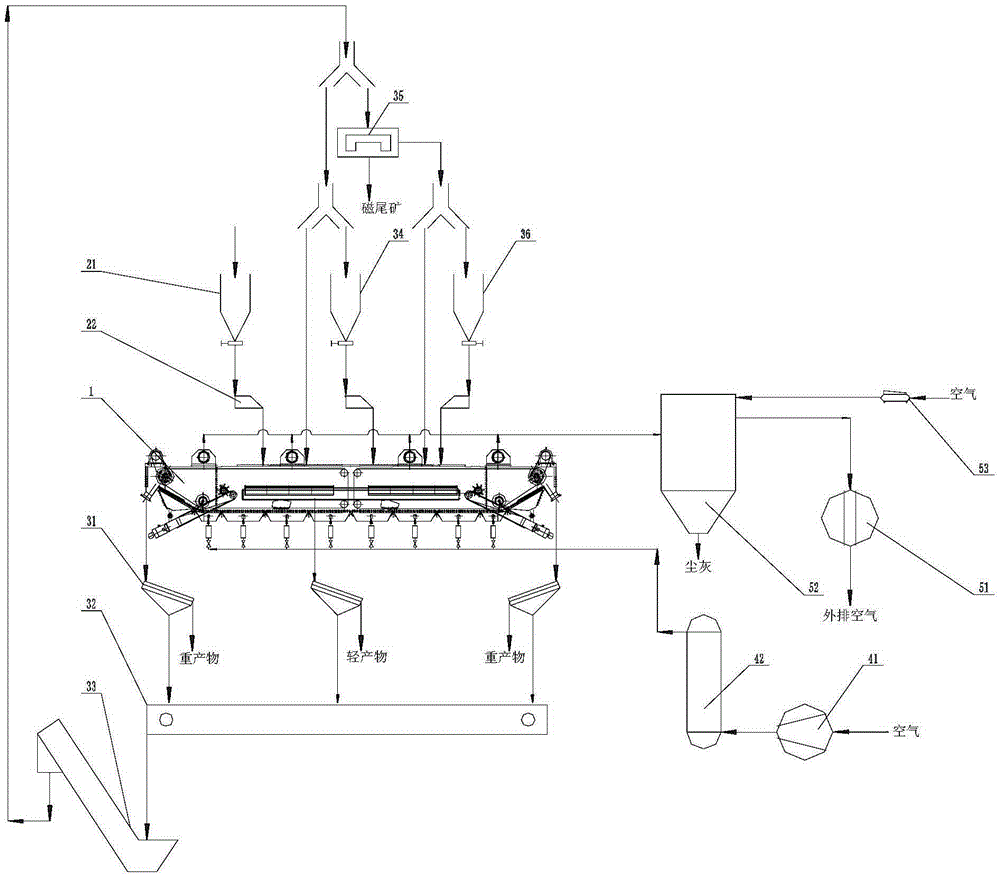

Large dry dense medium fluidized bed separation machine and separation system

ActiveCN105381950AReduce circulationReduce the carrying loadGas current separationPressure stabilizationFluidized bed

The invention discloses a large dry dense medium fluidized bed separation machine and a separation system. The separation machine mainly comprises a separation machine bed body, an air distribution device, a float discharge device, a sediment discharge device, a quick dense medium circulating device and the like. The separation system comprises a raw material feeding system, the large dry dense medium fluidized bed separation machine, a medium purifying and recycling system, an air supply system, a dust removal system, a control system and the like. The air supply system is mainly provided with a roots blower, a pressure stabilization air storage tank and the like. The raw material feeding system comprises a raw material bin and a feeder. The medium purifying and recycling system mainly comprises a sculping screen, a medium scraper conveyer, a medium bucket elevator, a circulating medium bin, a magnetic separator, a magnetic material bin and the like. The dust removal system mainly comprises an induced draft fan, a dust remover, an air compressor and the like. The separation machine is large in handling amount, high in separation precision, small in medium circulating amount, reliable in running and easy to maintain. The separation system is reasonable in layout, compact in structure, large in handling capacity, good in separation effect and low in capital construction and running cost.

Owner:CHINA UNIV OF MINING & TECH

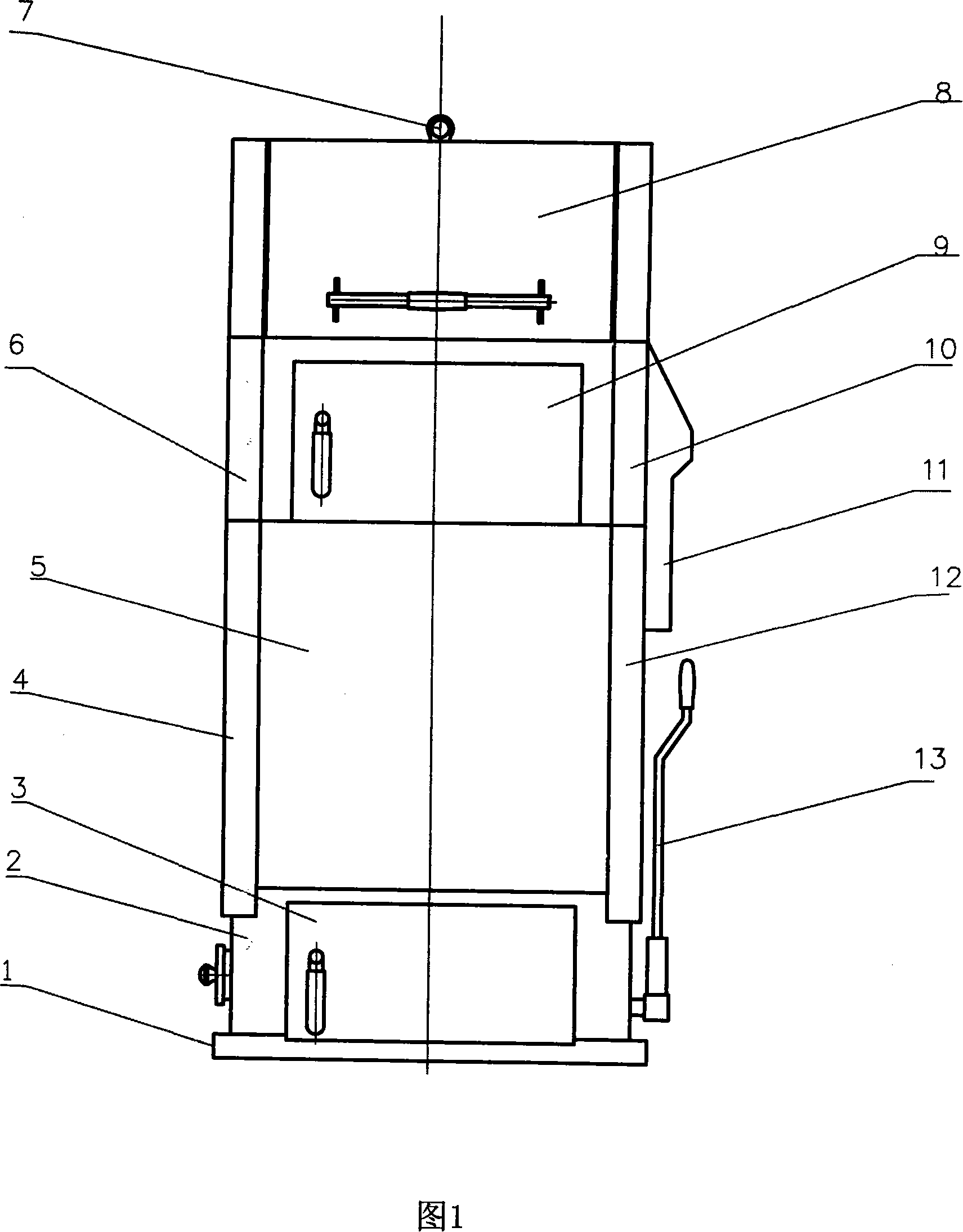

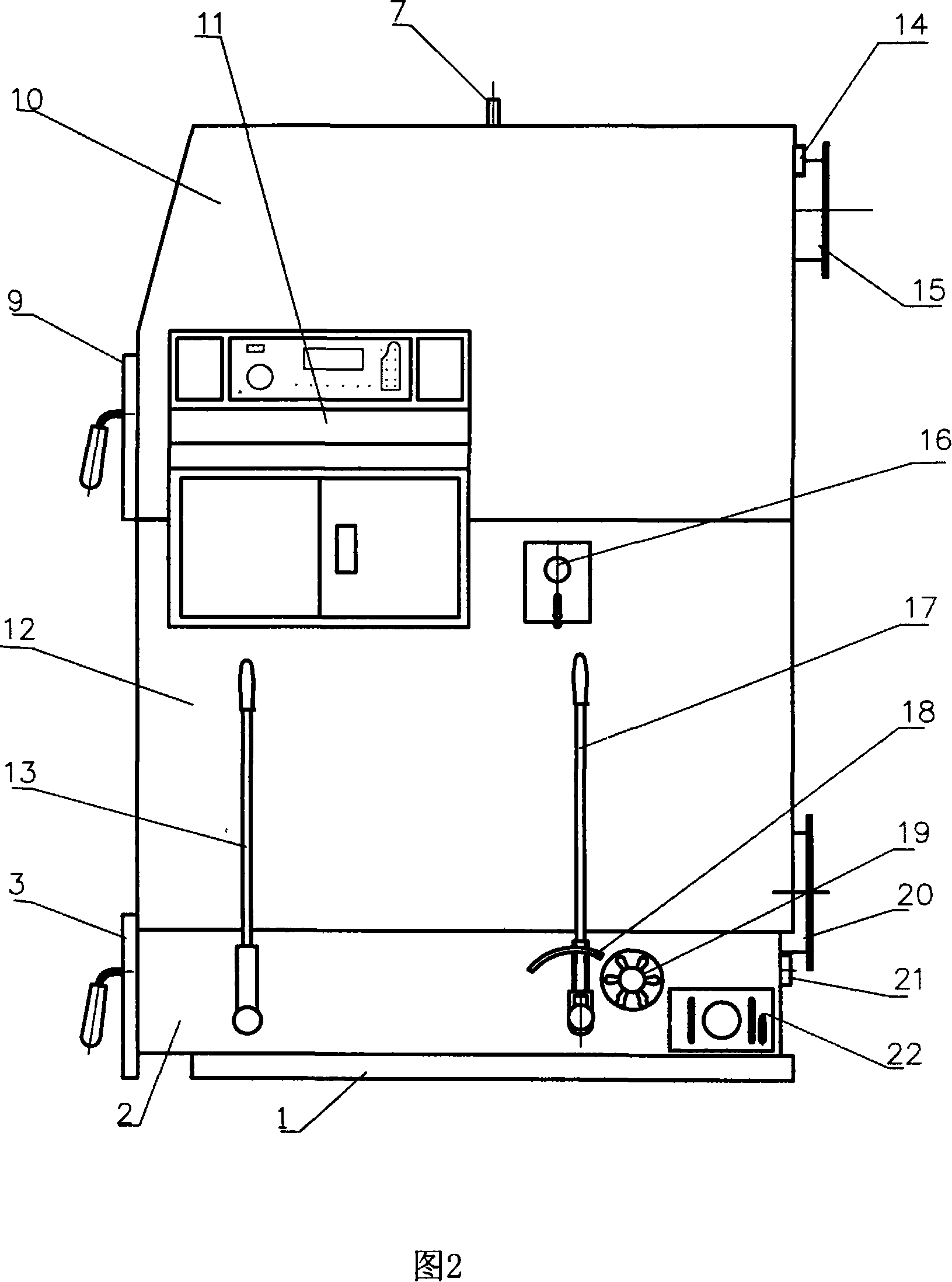

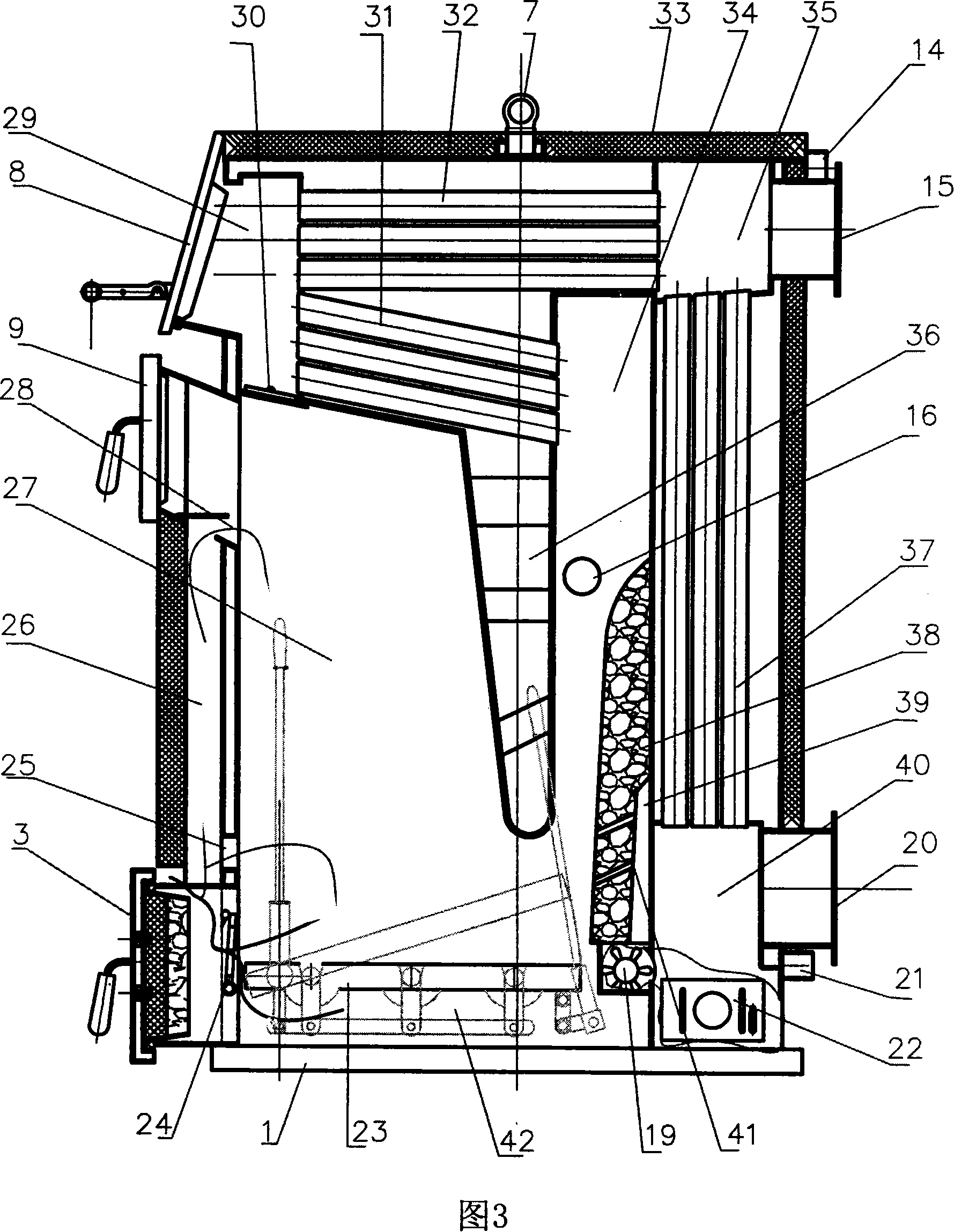

Biomass gasification automatic-control boiler

InactiveCN101122417AReduce the overall heightReduce generationSolid bar grateSolid fuel combustionAutomatic controlCombustion chamber

The invention discloses a biomass gasification automatic control boiler. A furnace is arranged above an ash removal grate. A secondary combustion chamber is arranged above the back of the ash removal grate. The middle is equipped with a fireproof plate with a sandwich structure. A flue gas channel is arranged between the lower end of the fireproof plate and the ash removal grate. Sandwich water jackets, which are mutually communicated, are arranged on the periphery and the top of the furnace, the fireproof plate and the secondary combustion chamber. A primary air is supplied into the furnace from a plurality of directions of the furnace. A secondary air is supplied into the secondary combustion chamber through a secondary air channel and a ventilating hole on a spoiler. An upper settling chamber is arranged above the furnace, which is communicated with the secondary combustion chamber through a fire tube. In addition, a settling and flue conversion chamber and a lower settling chamber, which are communicated through a fire tube is arranged above the furnace. The ash removal grate is a lifting grate, which can rotate around an anterior location pin and is used to adjust the height of the opening arranged between the lower end of the fireproof plate and the ash removal grate. A microcomputer control device can automatically control the operation of the boiler according to the set requirements. Using biomass fuels and coals, the invention has the advantages of high efficiency and low emission, which accords with the requirements of environmental protection and energy saving.

Owner:SHANDONG DUOLE HEATING EQUIP

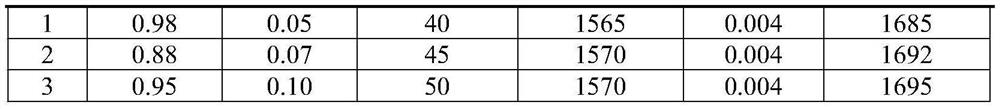

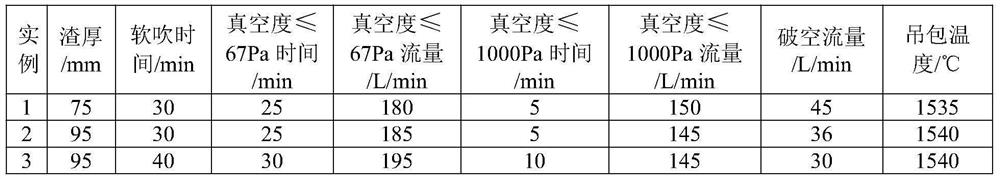

Smelting method of electrode bar base material for non-protective-atmosphere electroslag remelting of H13 steel

The invention discloses a smelting method of an electrode bar base material for non-protective-atmosphere electroslag remelting of H13 steel, and belongs to the field of ferrous metallurgy. The smelting method of the electrode bar base metal for non-protective-atmosphere electroslag remelting of the H13 steel comprises the steps of electric furnace steelmaking, LF furnace refining, VD vacuum degassing, pouring and the like. According to the smelting method, by increasing the content of [Al] in the steel, adjusting the composition of the LF slag, and adjusting a VD argon soft blowing system to be proper, the content of inclusions in the molten steel can be effectively reduced, and the cleanliness of the electrode bar base material is improved. By the adoption of the electrode bar base material prepared through the method, secondary oxidation of molten steel in the electroslag remelting process can be avoided, so that the content of oxidation-system inclusions in the H13 steel manufactured through non-protective-atmosphere electroslag remelting is reduced, and the quality of steel obtained after non-protective-atmosphere electroslag remelting is improved. The problems that an existing electrode bar base material used for non-protective-atmosphere electroslag remelting of the H13 steel is low in cleanliness and prone to secondary oxidation in the non-protective-atmosphere electroslag remelting process can be effectively solved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

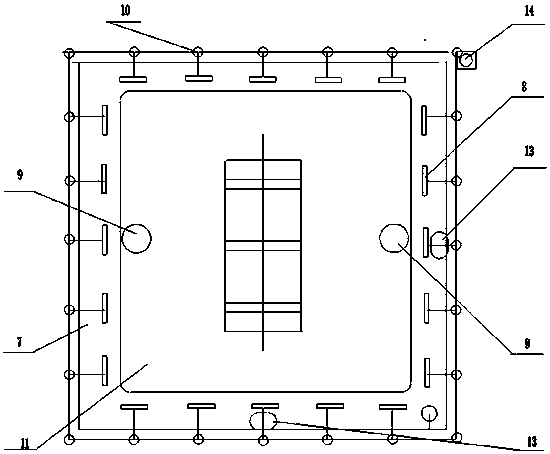

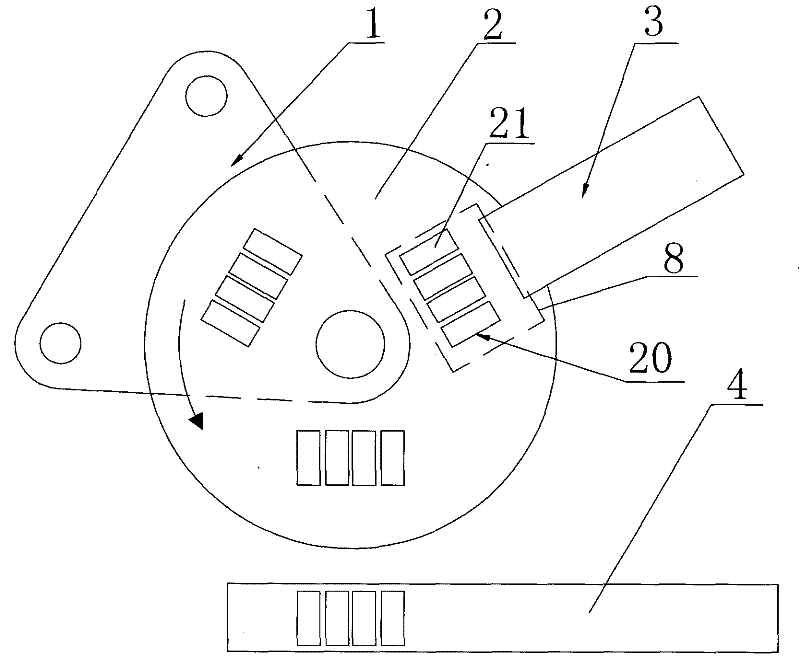

Rotary three-station bidirectional building material pressing machine

InactiveCN102205551ALarge amount of feedConsistent sizeFeeding arrangmentsBrickMechanical engineering

The invention discloses a rotary three-station bidirectional building material pressing machine. A three-station rotating disk rotates around a circle center; three groups of die frames are uniformly distributed on the three-station rotating disk at intervals; a lower die capable of moving in a longitudinal direction is positioned at the lower end of each group of die frame; a demoulding and stacking system comprises a demoulding and stacking device and a brick output conveyor; the demoulding and stacking device is used for demoulding a pressed building material and automatically stacking thebuilding material onto the conveyor tidily to be conveyed; the initial state of the three-station rotating disk is static; in the initial state, a material inlet of a feeding machine is opposite to one group of die frame, and the other group of die frame is positioned in a pressing region of the bidirectional pressing machine; the demoulding and stacking device of the demoulding and stacking system is opposite to the third group of die frame; and the rotating direction of the three-station rotating disk is from the feeding machine to the bidirectional pressing machine, and the single rotatingangle is 120 degrees. With the rotation of the three-station rotating disk, the feeding machine, the bidirectional pressing machine and the demoulding and stacking system perform feeding, pressing, demoulding, stacking and transmission on the three groups of die frames in real time, so the production speed is increased greatly.

Owner:湖南思为科技开发股份有限公司

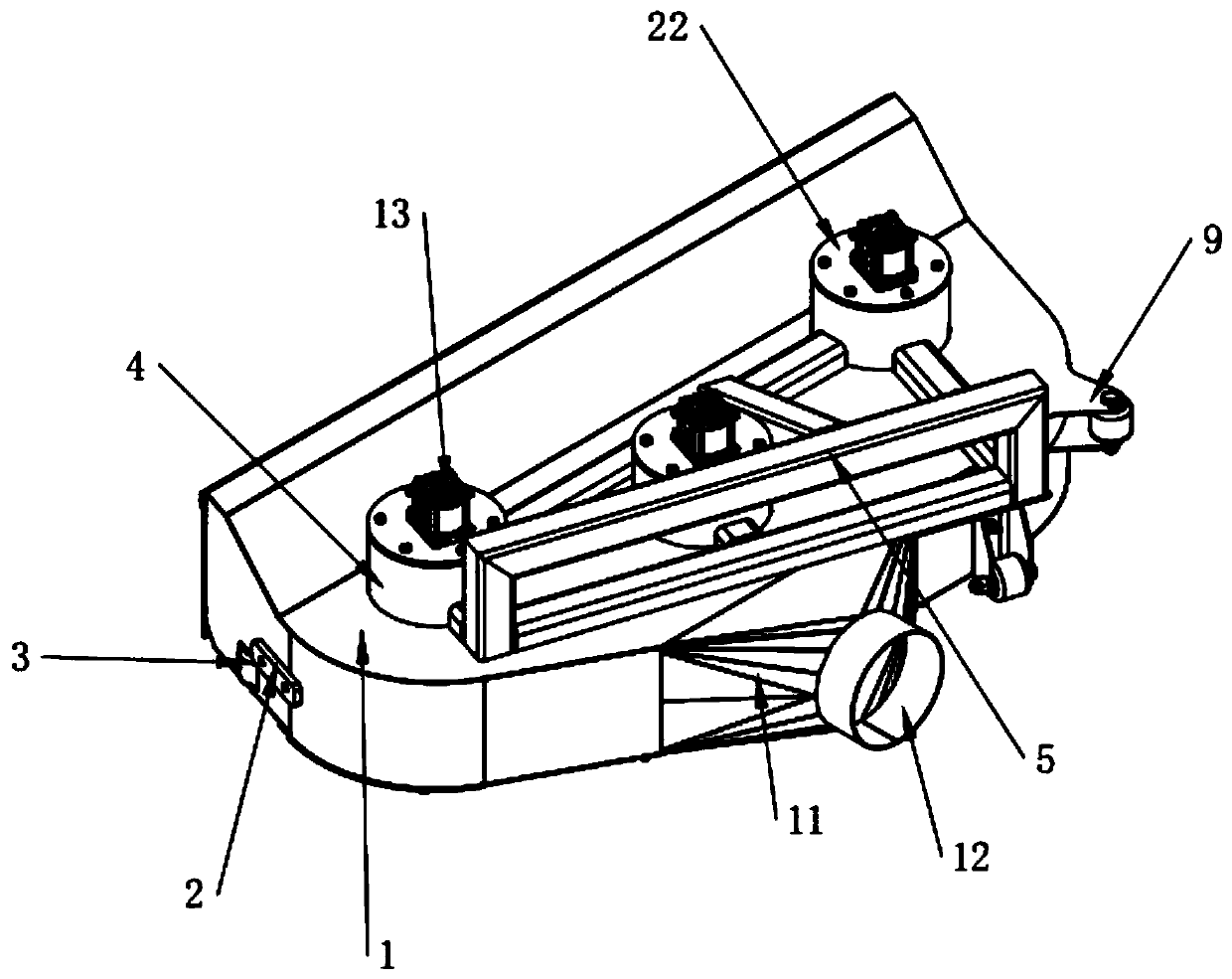

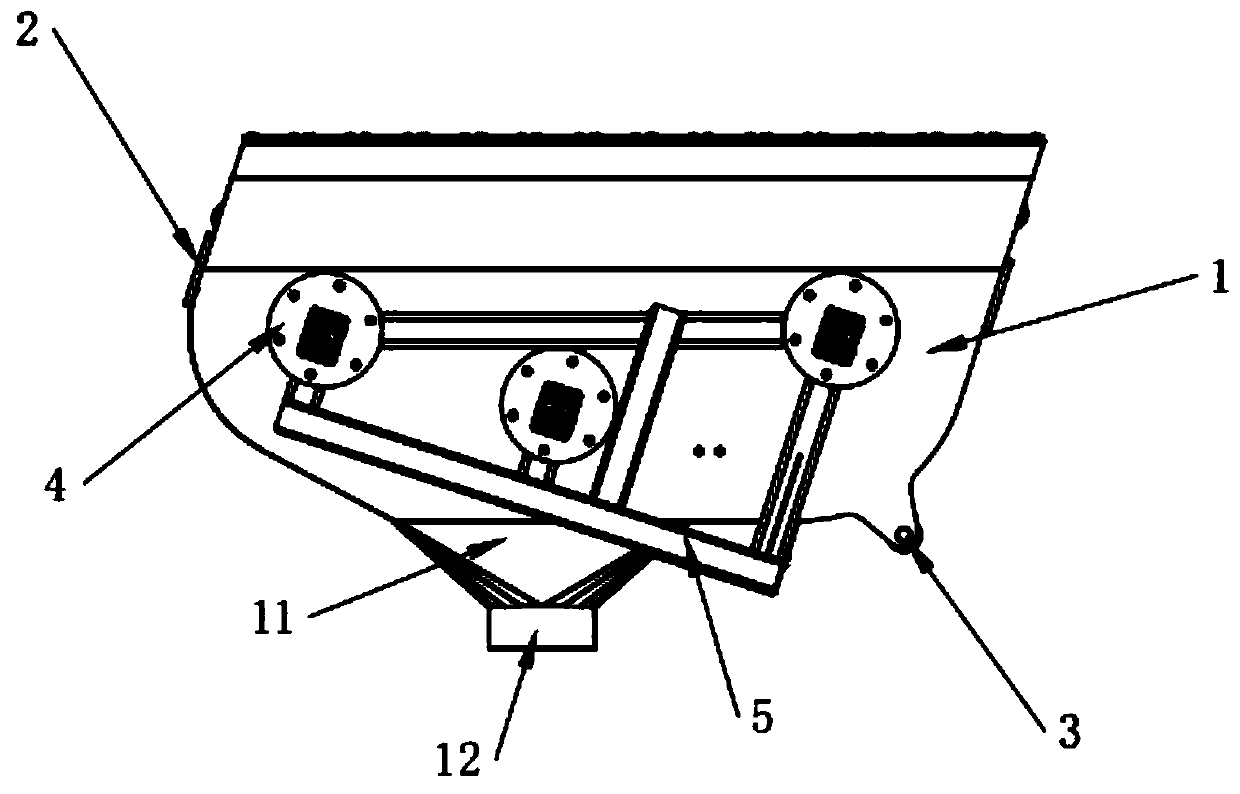

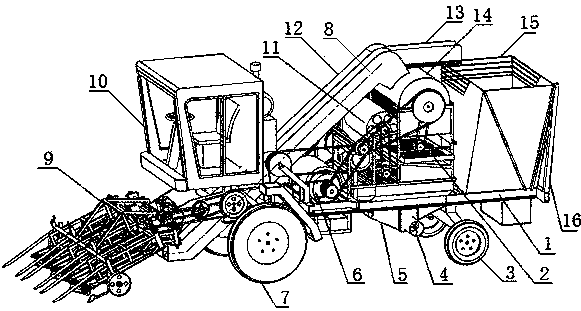

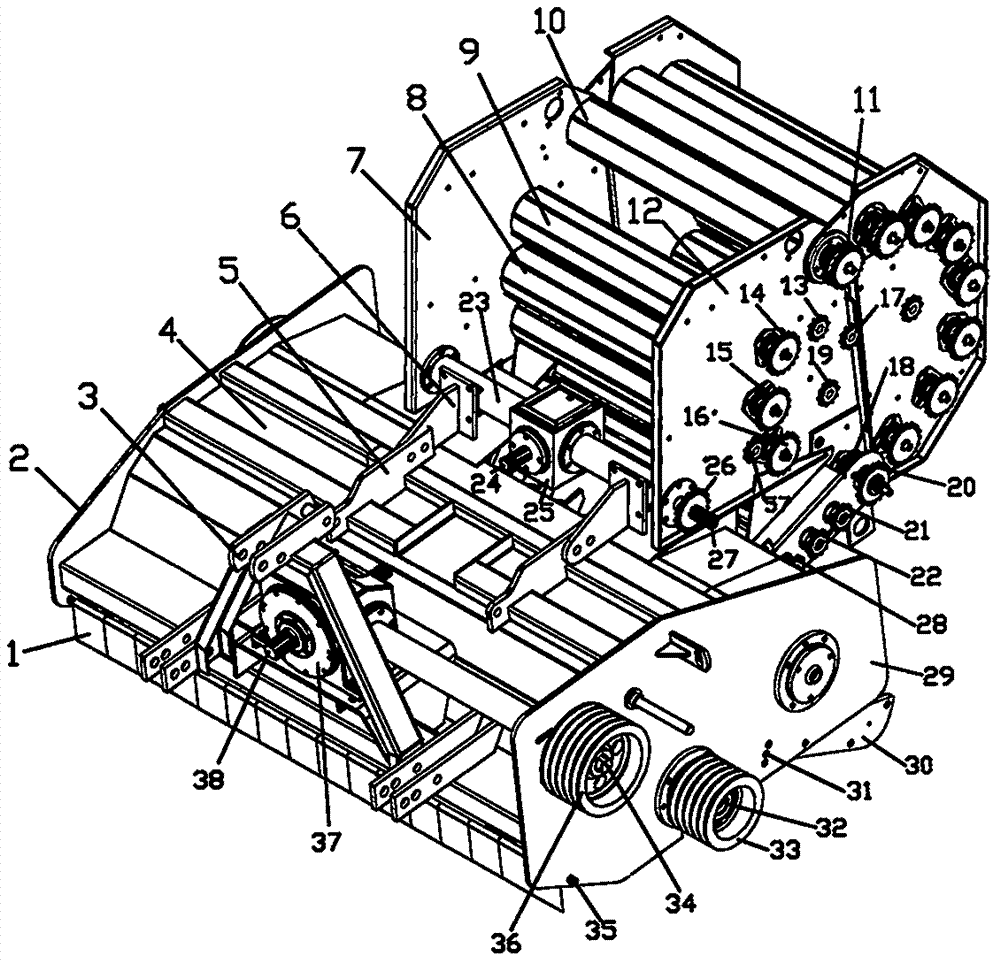

Three-ridge six-row peanut seedling and fruit integrated combined harvesting machine

PendingCN108124576ALarge amount of feedGood fruit picking performanceDigger harvestersSprocketEngineering

The invention discloses a three-ridge six-row peanut seedling and fruit integrated combined harvesting machine which is composed of a walking system, a fruit pulling system and a fruit picking system,wherein the walking system comprises a machine frame, driving wheels are arranged on the two sides of the front end of the machine frame, and walking wheels are arranged on the two sides of the rearend of the machine frame; the fruit pulling system is arranged at the front end of the machine frame and comprises a support, three groups of six seedling righting rods are arranged at the front end of the support and are used for righting the peanut seedlings, three groups of clamping chain wheels are arranged under the seedling righting rods side by side, three groups of six shovel blades are arranged under the clamping chain wheels, and a seedling clipper is arranged at the rear end of the support; the fruit picking system is composed of a seedling lifting device, a root lifting device, a grass collecting box and a fruit picker, and the seedling lifting device, the root lifting device, the grass collecting box and the fruit picker are all arranged on the machine frame. The three-ridge six-row peanut seedling and fruit integrated combined harvesting machine has the beneficial effects that once three-ridge six-row peanut seedling and fruit combined harvesting is utilized to achieve afull process of peanut digging, seedling and root shearing and separation and fruit picking; a feeding quantity is large, fruit picking performance is good, a peanut breaking rate is low, peanut seedlings and nuts are integrally harvested, and a work efficiency is high; the harvesting machine is especially suitable for large parcel or farm operation.

Owner:SHANDONG YUAN QUAN MACHINERY

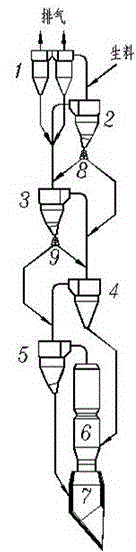

Novel dry-method cement kiln preheating and precalcining system and method

ActiveCN104880092AIncrease the solid-gas ratioImprove heat transfer efficiencyPreheating chargesWaste heat treatmentCement kilnMaterial Separation

The invention discloses a novel dry-method cement kiln preheating and precalcining system and method. The system comprises multiple stages of preheaters, wherein an air inlet pipe of each stage of preheater is communicated with an air outlet of the next stage of preheater, the preheaters are sequentially connected in this way until the last stage of preheater, an air inlet pipe of the last stage of preheater is communicated with the top of a calciner, the bottom of the calciner is communicated with a kiln tail smoke chamber, a fine material separating device is mounted at a discharge port at the bottom of at least one of the preheaters except the last stage of preheater, a discharge pipe of each fine material separating device is divided into two ways, one way of each discharge pipe is communicated with the air inlet pipe of the corresponding stage of preheater, and the other way of each discharge pipe is communicated with the air inlet pipe of the next stage of preheater. The system and the method have the benefits as follows: the at least one fine material separating device is additionally mounted below the at least one preheater requiring material separation, and material separation quantities and cycling times can be controlled; the air flow temperature of an outlet of the system can be decreased under the condition that the original preheater stages are not increased; the solid-air ratio can be increased through fine material separation and cycling heat exchange, the heat exchange efficiency is improved, and the yield is increased.

Owner:成都建筑材料工业设计研究院有限公司

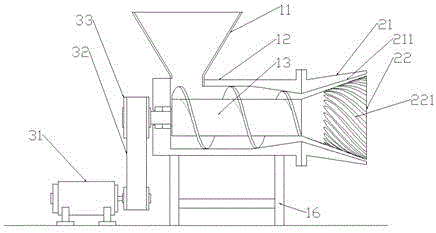

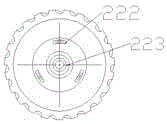

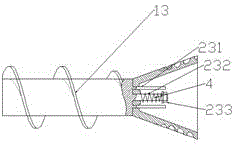

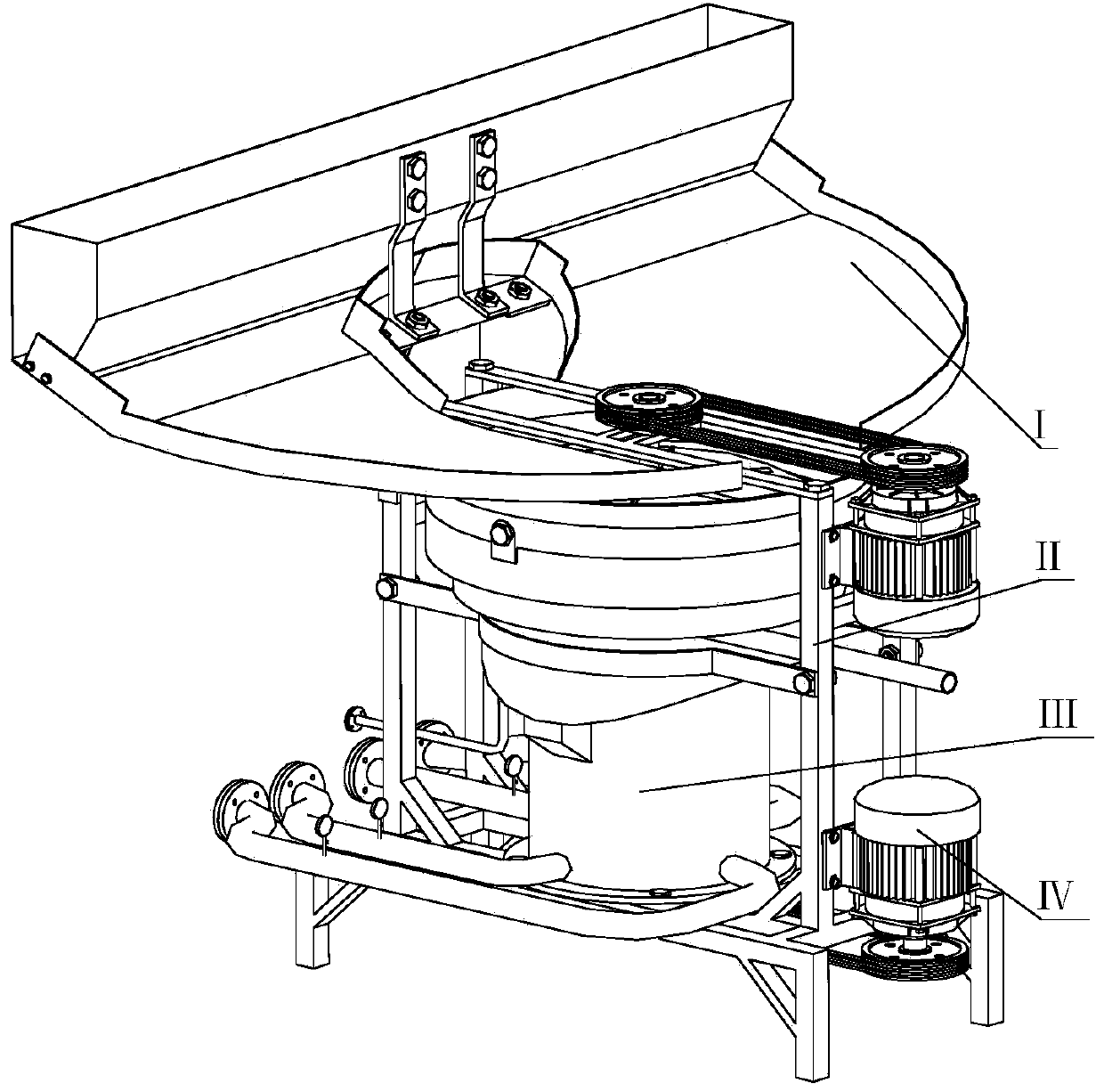

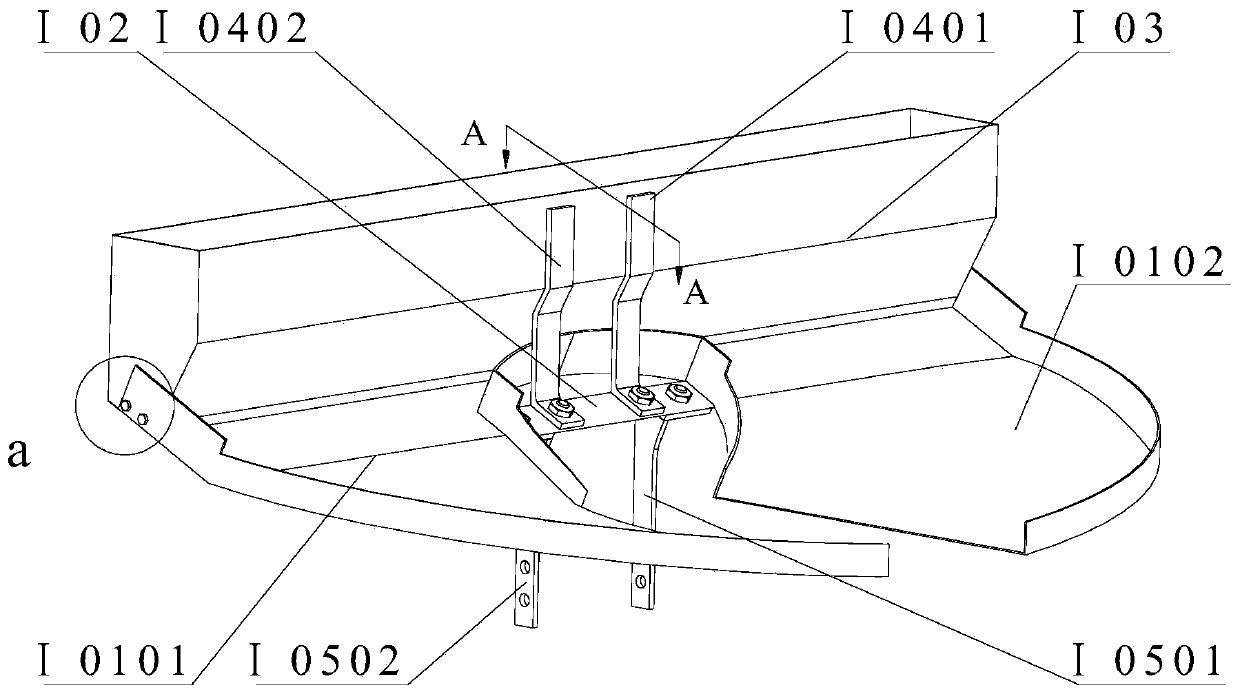

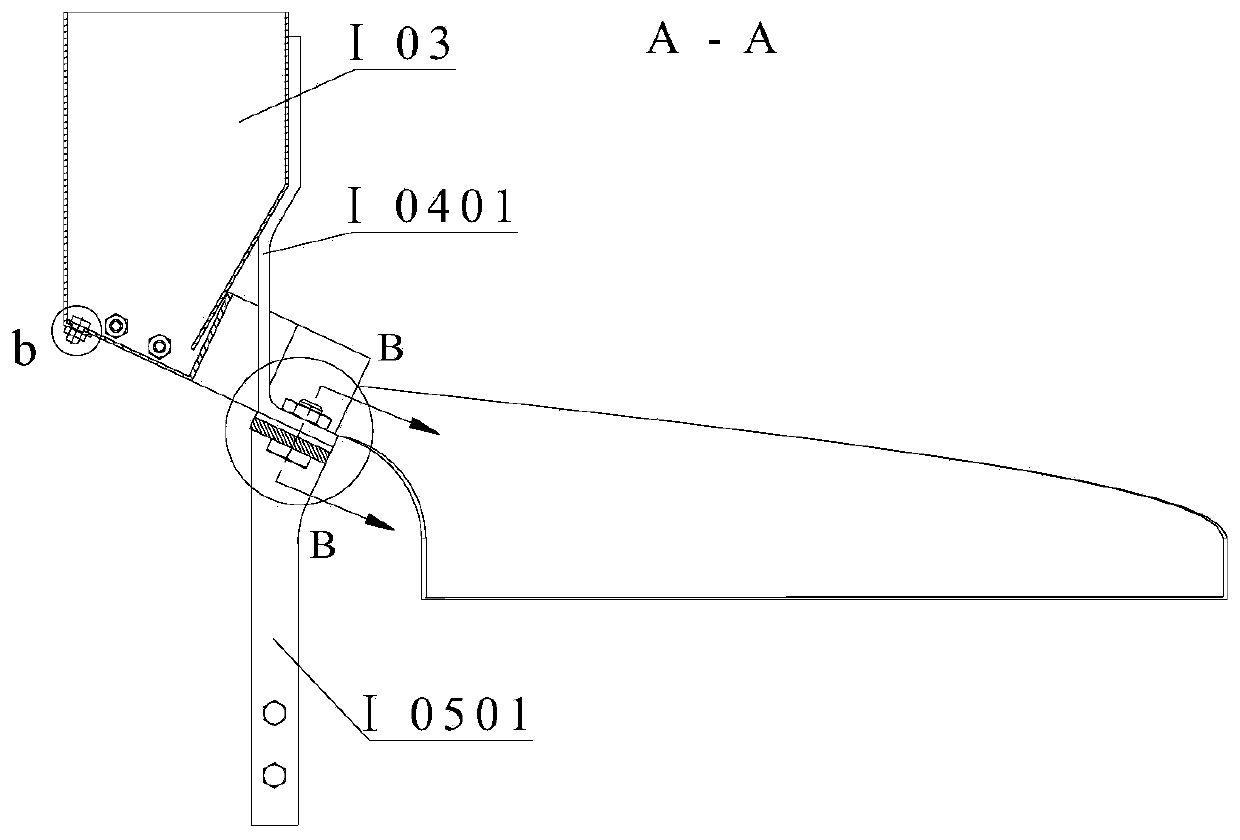

Same-cavity integrated vertical walnut shell high-speed multi-stage superfine grinding device and method

ActiveCN111450970ALarge amount of feedLarge amount of processingGrain treatmentsMechanical engineeringMaterials science

The invention discloses a same-cavity integrated vertical walnut shell high-speed multi-stage superfine grinding device and method. The same-cavity integrated vertical walnut shell high-speed multi-stage superfine grinding device comprises a double-channel sliding type feeding device and a same-cavity integrated vertical grinding device body, the same-cavity integrated vertical crushing device body comprises a material raising disc and a same-cavity integrated vertical crushing barrel body, a first-stage coarse crushing area, a second-stage fine crushing area, a third-stage pneumatic impact micro-crushing area and a fourth-stage jet mill superfine crushing area are arranged in the same-cavity integrated vertical crushing barrel body, walnut shells falling through the double-channel slidingtype feeding device are evenly raised into a wedge-shaped gap of the first-stage coarse crushing area through the material raising disc to be coarsely crushed, the second-stage fine crushing area achieves fine crushing on the coarsely crushed materials through a two-stage wedge-straight-through gradually-shrinking gap, the third-stage pneumatic impact micro-crushing area impacts the walnut shellfine crushed particles at a high speed, the walnut shell fine crushed particles are impacted and violently rubbed under carrying of high-speed airflow to be crushed, in the four-stage jet mill superfine grinding area, micro-particle grading is achieved through arc-shaped blades, and micro-particles meeting the particle size condition are sucked out through negative pressure attraction.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

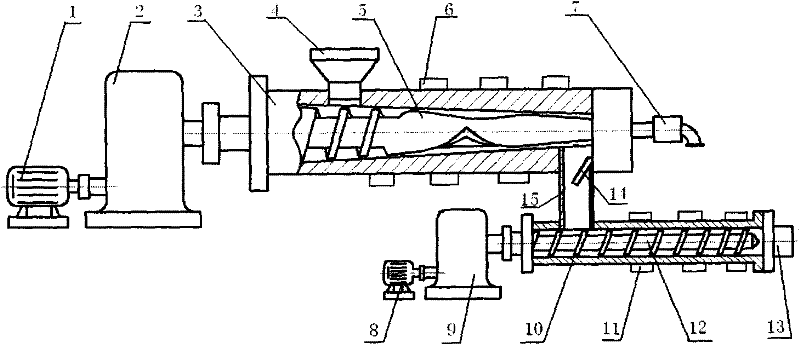

Full-feeding combined harvesting threshing device

ActiveCN104025813AIncreased conveying and threshing capabilitiesLarge amount of feedThreshersEngineeringSieve

The invention relates to a full-feeding combined harvesting threshing device which comprises a body. A front transverse tangential-flow drum, a transitional guide plate and a rear longitudinal axial-flow drum are sequentially mounted on the body, a front grid concave sieve is arranged below the front transverse tangential-flow drum, a rear grid concave sieve is arranged below the rear longitudinal axial-flow drum, a swing type vibrating sieve is mounted below the front grid concave sieve and the rear grid concave sieve, a fan, a primary auger and a secondary auger are mounted below the swing type vibrating sieve, and a stem cutting device is mounted at the rear of the swing type vibrating sieve. The full-feeding combined harvesting threshing device is characterized in that the transverse center line of the front transverse tangential-flow drum and the axial center line of the rear longitudinal axial-flow drum are positioned on the straight line; a plurality of punched holes are uniformly formed in the transitional guide plate. The rear longitudinal axial-flow drum comprises threshing toothed bars and a feeding head, the feeding head is mounted at the ends of the threshing toothed bars, and three spiral blades are arranged on the circumferential surface of the feeding head. The full-feeding combined harvesting threshing device has the advantages that the conveying and threshing abilities can be improved, the feeding quantity can be increased, and the loss ratio can be reduced.

Owner:WUXI COMBINE HARVESTER

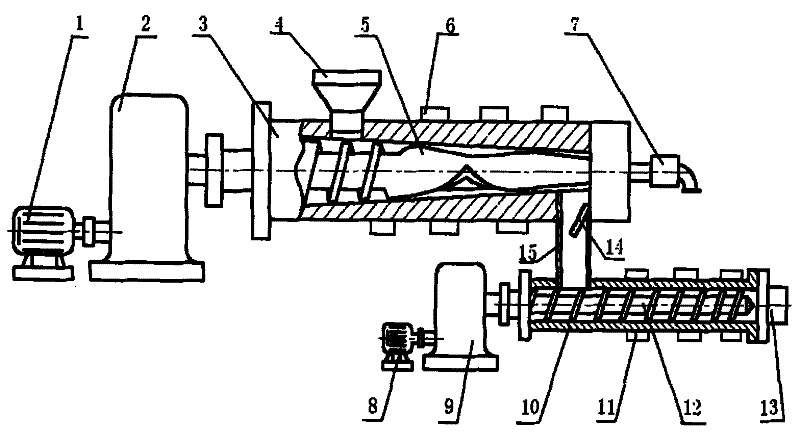

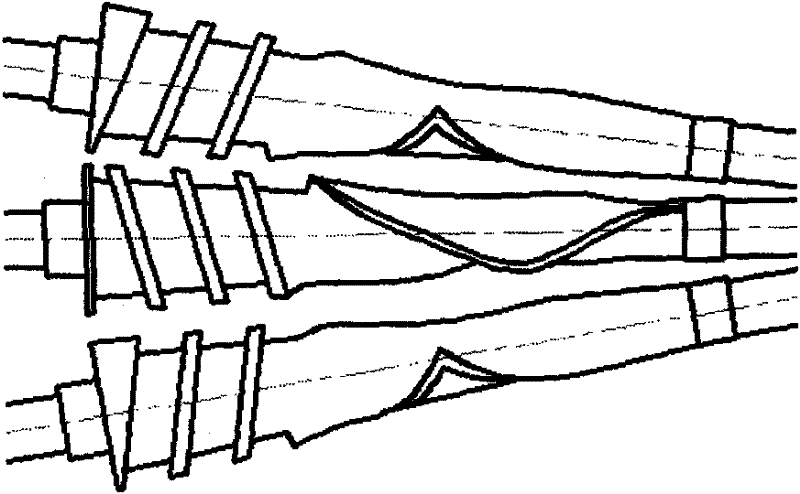

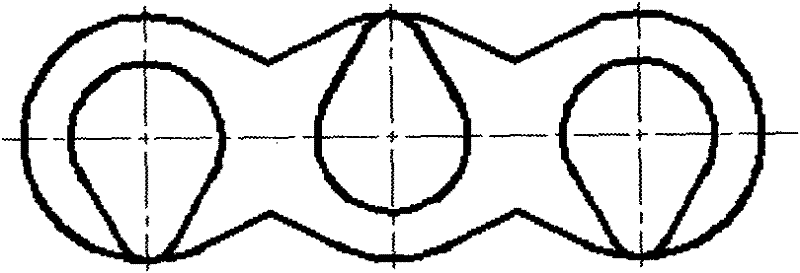

Conical tri-rotor continuous mixing unit with rotors in linear arrangement

InactiveCN102228817AEnhanced axial transportImprove the mixing effectRotary stirring mixersCamElectrical and Electronics engineering

The invention provides a conical tri-rotor continuous mixing unit with rotors in linear arrangement, mainly comprising a mixing part and an exhausting part and a single-order or dual-order mode is adopted in the unit. The mixing part mainly comprises a charging device, a cylinder, conical rotors, a heating and cooling device and a driving device; the central lines of the three conical rotors for mixing are in the same plane and form fixed cone angles in linear arrangement in installation; the outer diameter outlines of the three rotors are tapered and each motor is provided with a charging segment and a mixing segment; the charging segment is of a spiral conveyance structure; and for a conical surface vertical to the outer outlines of the rotors, the mixing segment is of a cam shape, S shape or quadrangular rotor shape and the like. When the single-order mode is adopted, a spiral structure is adopted at the tail ends of the rotors so as to form a pressure to transmit materials to a machine head; and when the dual-order mode is adopted, mixing materials enter into the next-order screw extruder by a valve to form a pressure to transmit the materials to the machine head. For the two modes, the machine head suitable for a cavity is utilized to carry out pelleting or molding, and for the purpose of intensifying the pressure, a melt pump can be connected with the machine head. The three rotors can rotate at the same speed or different speeds, and when the three motors rotate, multiple shearing areas, stretching areas and kneading areas are formed, thus the materials among the rotors are exchanged frequently, thereby improving the plasticating performance, the melting performance and the dispersion performance effectively, shortening the processing time and improving the yield. The mixing unit is used for mixing, pelleting and other processes in processing rubbers, coatings, propellants, explosives, paper pulps, plastics, foods, pharmacy, feeds and the like.

Owner:BEIJING UNIV OF CHEM TECH

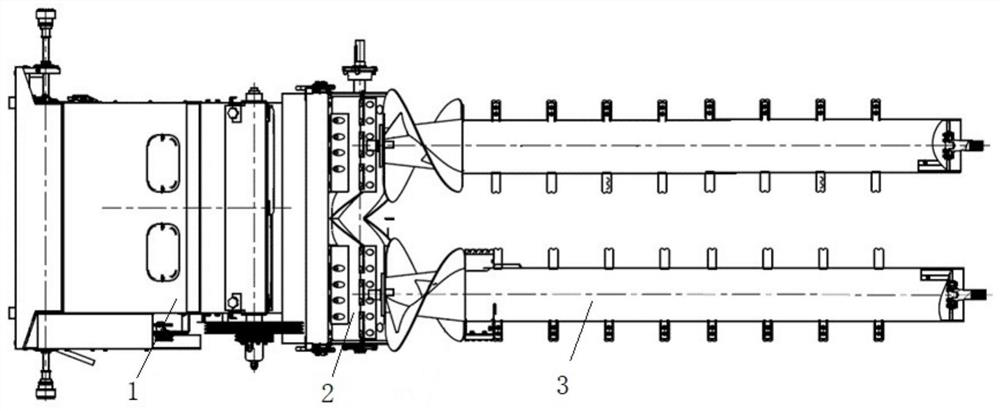

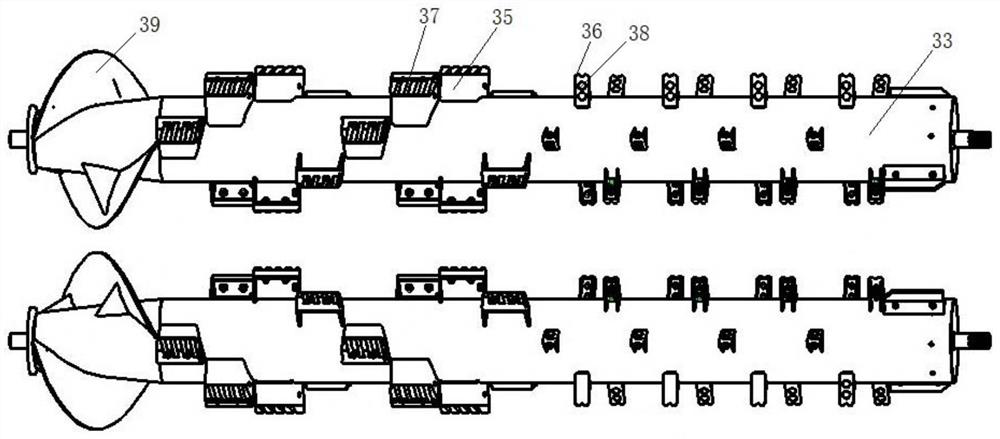

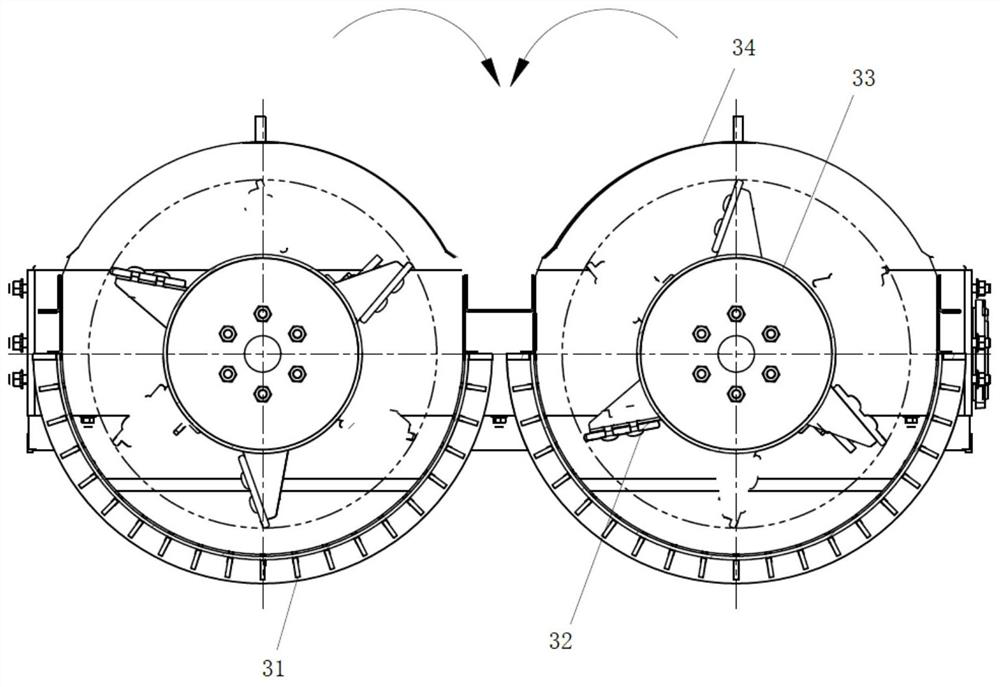

Forced acceleration feeding double-longitudinal-axial-flow threshing and separating device and combine harvester thereof

PendingCN113557855AStrong threshing and separation abilitySatisfy the Harvest RequirementsMowersThreshersAgricultural scienceAgricultural engineering

The invention relates to a forced acceleration feeding double-longitudinal-axial-flow threshing and separating device and a combine harvester thereof. The threshing and separating device comprises a forced acceleration feeding roller and a longitudinal double-axial-flow roller; the forced acceleration feeding roller is transversely arranged and rotates forwards, and the longitudinally-arranged double-axial-flow roller is longitudinally arranged behind the forced acceleration feeding roller. According to the forced acceleration feeding double-longitudinal-axial-flow threshing and separating device, the forced acceleration feeding roller and the longitudinal double-axial-flow roller are combined, forced acceleration feeding plays a role in auxiliary feeding of the roller, the forced acceleration feeding double-longitudinal-axial-flow threshing and separating device can adapt to large-particle and small-particle crops, harvesting requirements of large-feeding-amount crops such as rice, wheat, oilseed rape, beans, corn and coarse cereals can be met, the threshing and separating device has the technical effects of high harvesting efficiency, high grain threshing and separating capacity, low grain breakage rate and lower threshing and separating power consumption.

Owner:HENAN RICHUANG GENERAL MACHINERY MFR

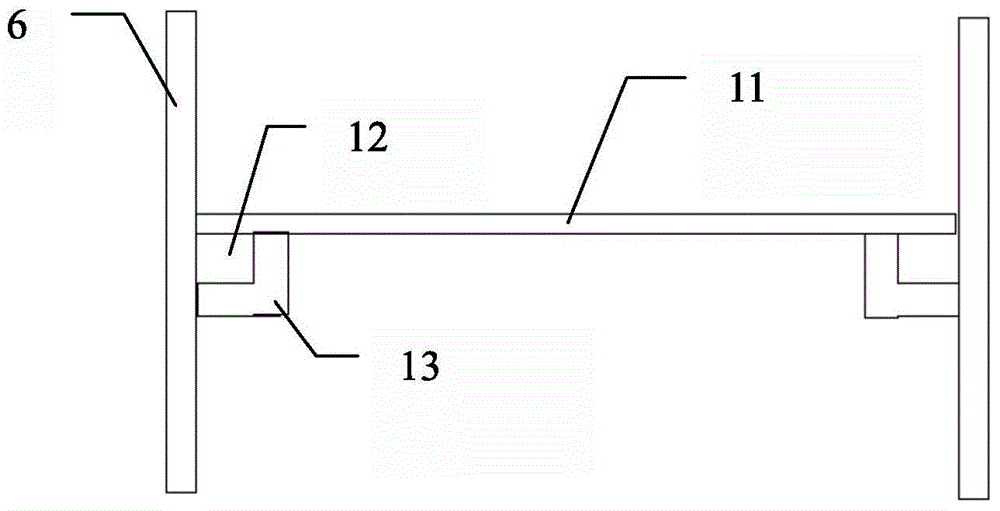

High pressure double-layer filtering device for steel rolling sludge treatment

InactiveCN104128033AImprove work efficiencyImprove filtering effectMoving filtering element filtersEngineeringHigh pressure

The invention discloses a high pressure double-layer filtering device for steel rolling sludge treatment. By disposing a plurality of demountable meshes in flexible connection with baffle plates between driving rollers on the upper surface of a filtering mechanism, and equipping the meshes with a small aperture, on the one hand, a strong supporting effect can be achieved on a filtering belt, the feeding amount per unit time is increased by over 10%, and on the other hand, an effective two-stage filtration effect can be realized on to-be-treated sludge so as to enhance the filtration effect, and clogging of a filtrate collecting device can be effectively avoided. At the same time, by adding a magnetic material capable of performing adsorption at flexible joints of the meshes and the baffle plates, the connection fastness of the meshes and the baffle plates is enhanced, and separation of the meshes from the baffle plates can be effectively avoided when the feeding amount on the filtering belt is great. In addition, by setting the filtrate collecting device as an inverted conical structure, adsorption of filtrate in the filtrate collecting device can be effectively reduced.

Owner:佛山市高明和盈金属材料有限公司

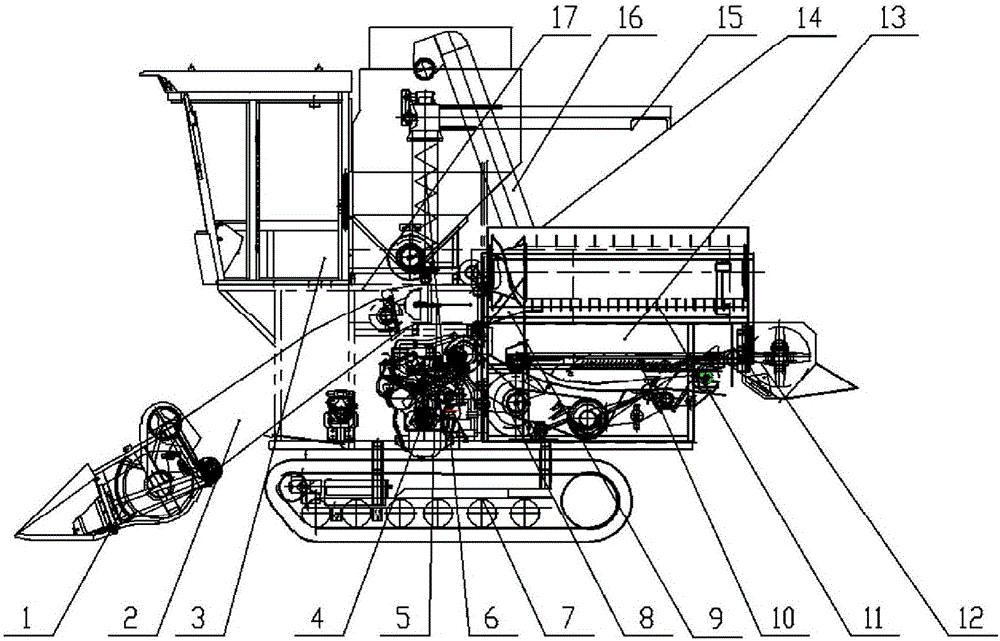

Grain combine harvester

The present invention provides a grain combine harvester comprising a header body, a chassis, a first bridge, a threshing chamber and threshing rollers. The header body is arranged at the front end of the chassis, the threshing chamber is arranged at the rear end of the chassis, the header body communicates with the threshing chamber by the first bridge, the threshing rollers are arranged in the threshing chamber, the first bridge is connected with the threshing rollers by a second bridge, and the first bridge is hinged to the second bridge. The grain combine harvester adopts double bridges and double threshing rollers and combines a crawler chassis to provide the grain combine harvester with large feed amount, fast harvesting speed, high efficiency of threshing and selection and good universality by reasonable layout and matching.

Owner:ZOOMLION HEAVY MASCH CO LTD

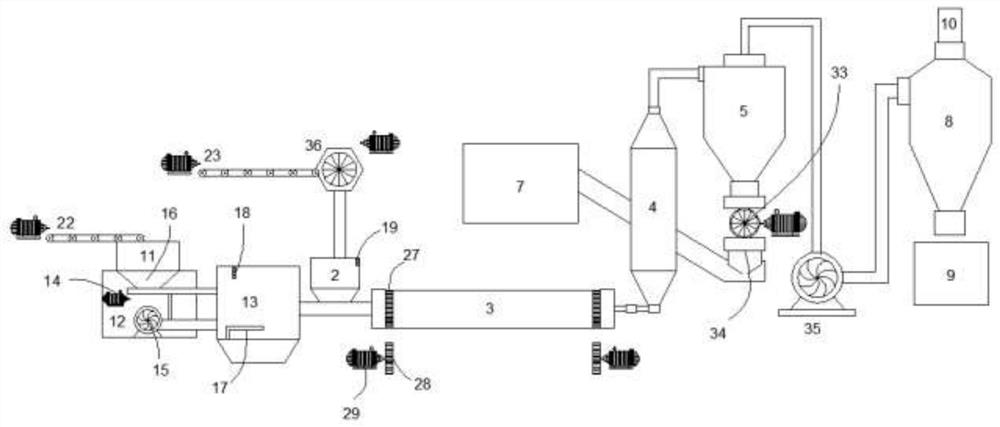

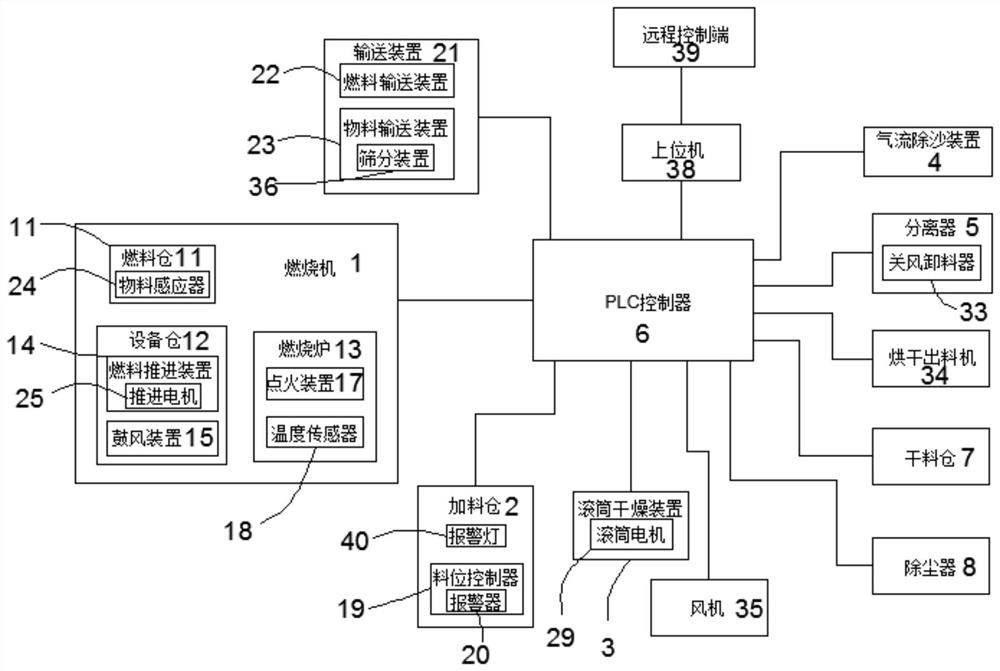

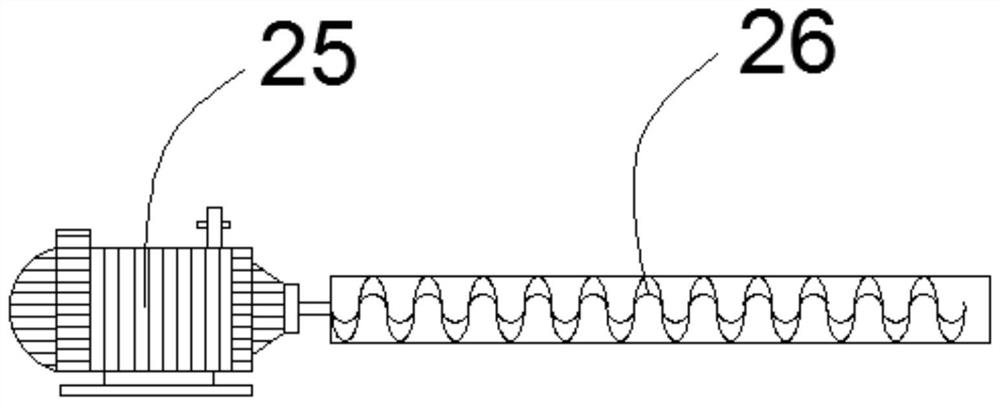

Multifunctional intelligent drying system and drying process

PendingCN112762680ALarge amount of feedReduce supplyDrying safety systemsDrying solid materialsCombustorDrum drying

The invention provides a multifunctional intelligent drying system and a drying process. The system comprises a combustor, a feeding bin, a roller drying device, an airflow sand removing device, a separator and a PLC, all of which are connected in sequence. The separator is connected with a dry material bin and a dust remover. The PLC is connected with the above mechanisms. The combustor comprises a fuel bin, an equipment bin and a combustion furnace, the fuel bin is located above the equipment bin, a fuel propelling device and a blower device are arranged in the equipment bin, and the fuel propelling device is connected with a discharging port of the fuel bin. The fuel propelling device and the blower device are respectively connected with the combustion furnace through pipelines, and an ignition device and a temperature sensor are arranged in the combustion furnace. A material level controller is arranged in the feeding bin and provided with an alarm, and an alarm lamp is arranged outside the feeding bin. The drying system further comprises a conveying device, the conveying device comprises a fuel conveying device and a material conveying device, the fuel conveying device is connected with the fuel bin, and the material conveying device is connected with the feeding bin.

Owner:吉林市恒远机制木炭有限公司

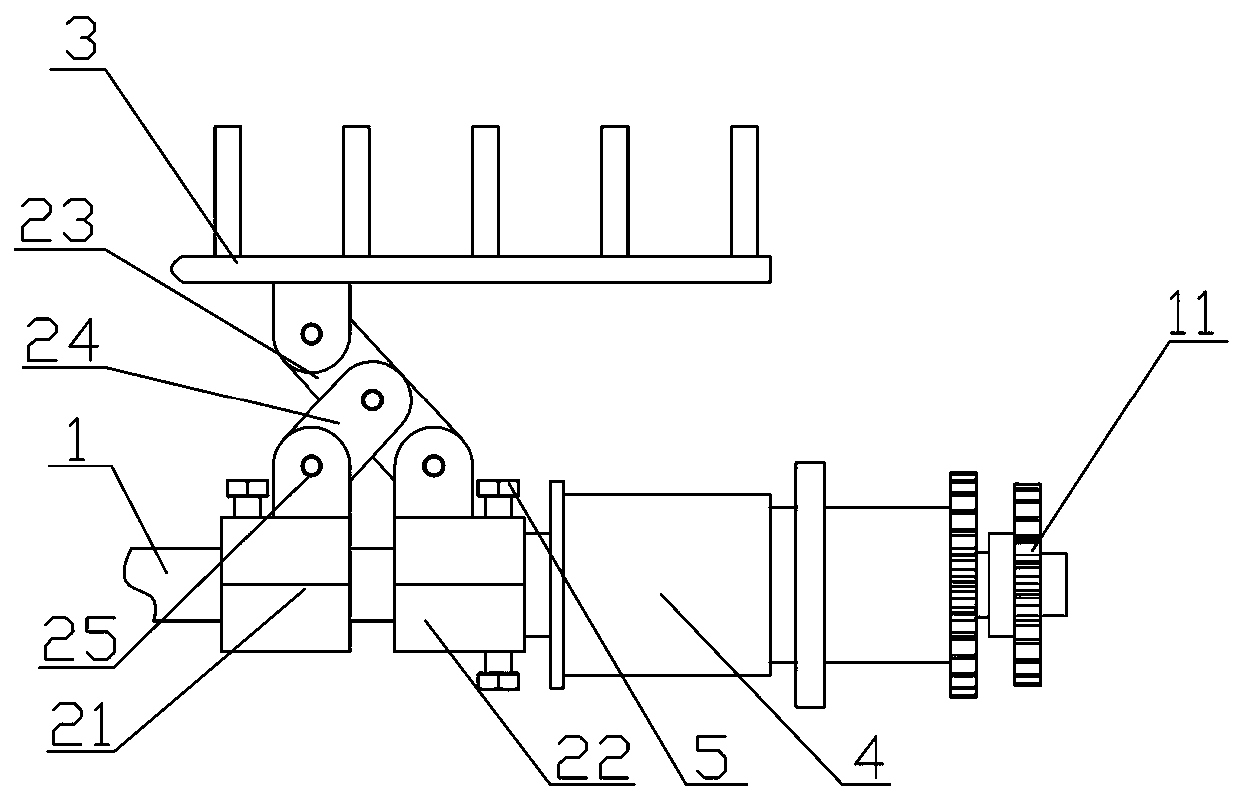

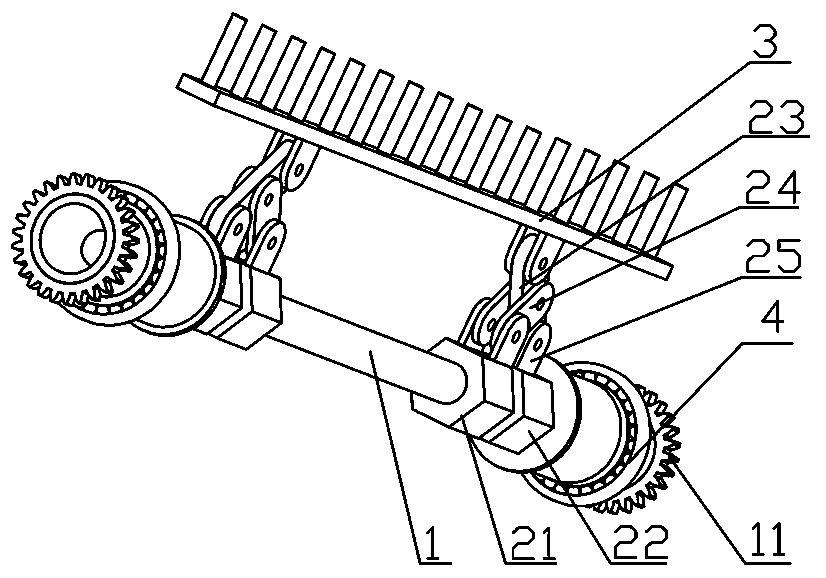

A threshing drum with adjustable threshing gap

The invention discloses a threshing drum adjustable in threshing gap. The threshing drum comprises a spindle, a gap adjusting mechanism, a toothed rod and a gap control mechanism. The gap adjusting mechanism and the gap control mechanism are mounted on the spindle, the tail end of the gap adjusting mechanism is connected with the toothed rod, and the gap adjusting mechanism can adjust the toothedrod for radial motion; the gap control mechanism is connected with the gap adjusting mechanism and can control a sliding element of the same for axial sliding, and a spindle driving chain wheel is arranged at one end of the spindle. A threshing drum structure with a spoke and a threshing toothed rod is reformed, the gap adjusting mechanism is used to replace the spoke, and the gap control mechanism is added, so that threshing gap can be adjusted at proper time, the problem of blockage of the threshing drum can be solved effectively, and the threshing drum is wide in application range.

Owner:HUNAN AGRICULTURAL UNIV

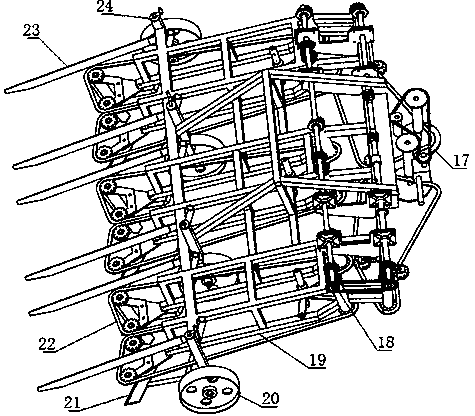

Forced feeding device of round baler

InactiveCN107980333AImprove work efficiencyIncrease profitCrop conditionersMowersAgricultural engineeringSprocket

The invention discloses a forced feeding device of a round baler. The device includes a left vertical plate and a right vertical plate, the left vertical plate is fixedly connected with a first side plate and an upper cover plate, and the right vertical plate is fixedly connected with a second side plate and the rear end of the upper cover plate; a left protection plate is arranged on the left vertical plate, the left protection plate and the first side plate are connected with the rear end of the upper cover plate, a right protection plate is arranged on the right vertical plate, and the right protection plate and the second side plate are connected with the rear end of the upper cover plate; a first feeding roller, a second feeding roller and a third feeding roller are rotatably connected in parallel between the left vertical plate and the right vertical plate; the third feeding roller is connected with a material-collection and discharge hole, the first feeding roller is connected with a straw bale inlet, the first feeding roller, the second feeding roller and the third feeding roller are fixedly connected with a first feeding chain wheel, a second feeding chain wheel and a third feeding chain wheel respectively, and the first feeding chain wheel, the second feeding chain wheel and the third feeding chain wheel are in drive connection with a fifth chain wheel. The forced feeding device makes straw feeding mandatory, and the work efficiency is improved.

Owner:河南省颍骏机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com