Biomass fuel block production method and equipment

A technology of biomass fuel and straw, which is applied in the fields of biomass fuel live mold molding machine and biomass fuel production system, biomass fuel block production, and straw extrusion machine, which can solve low production efficiency, mold wear, and work energy consumption advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

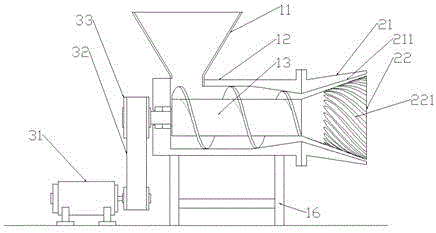

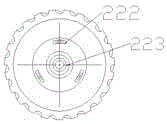

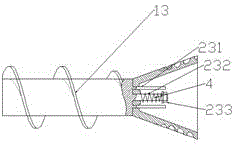

[0047] Embodiment 2 Biomass fuel living mold molding machine

[0048] See Figure 4-7 , Biomass fuel live mold molding machine, including body 5, biomass fuel extruder, mold fixing and blocking device, demoulding mechanism, movable mold 8, track 9, heat preservation and shaping chamber 3;

[0049] Biomass fuel extrusion machine, including machine base 6, hopper 61, feeding bin 62, feeding hydraulic cylinder 71, forming bin 63, forming hydraulic cylinder 72, dense extrusion hydraulic cylinder 73, and heating device;

[0050] The feeding bin 62 is fixed on the machine base 6, and the hopper 61 communicates with the feeding bin 62 above the feeding bin 62;

[0051] One side of the feeding bin 62 is provided with a feeding extrusion channel, and the feeding hydraulic cylinder 71 drives the feeding pressure head 711 to move horizontally in the feeding extrusion channel, and the feeding pressure head 711 is rectangular;

[0052] The forming chamber 63 is on the other side of the...

Embodiment 3

[0067] Embodiment 3 Biomass fuel production system

[0068] See Figure 7 , a biomass fuel production system, which includes: a straw cutting machine, a straw extrusion rubbing machine, and a biomass fuel living mold forming machine in sequence.

[0069] The straw extruding machine is the straw extruding machine described in embodiment 1; the biomass fuel forming machine is the living mold forming machine for biomass fuel described in embodiment 2.

[0070] When using the biomass fuel block production system, use a straw cutting machine to cut the cut length of 0.5-3.5cm; use a straw extrusion machine to squeeze and rub the cut straw into filaments or flakes; The live mold forming machine compresses and molds the straw.

Embodiment 4

[0071] Embodiment 4 A kind of method of producing biomass fuel block

[0072] 1) Cut the straw into 0.5-3.5cm pieces;

[0073] 2) Squeeze and knead the straw into silk or flakes with a straw extrusion machine;

[0074] 3) Heating to 190°C-230°C, filling the mold by hydraulic extrusion;

[0075] 4) Keep the movable mold filled with biomass fuel in the heat preservation bin for 2-5 minutes at a temperature above 170°C to finalize the shape and demould;

[0076] 5) The hot mold after demoulding, immediately proceed to the next round of filling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com