Patents

Literature

501results about How to "Quick cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

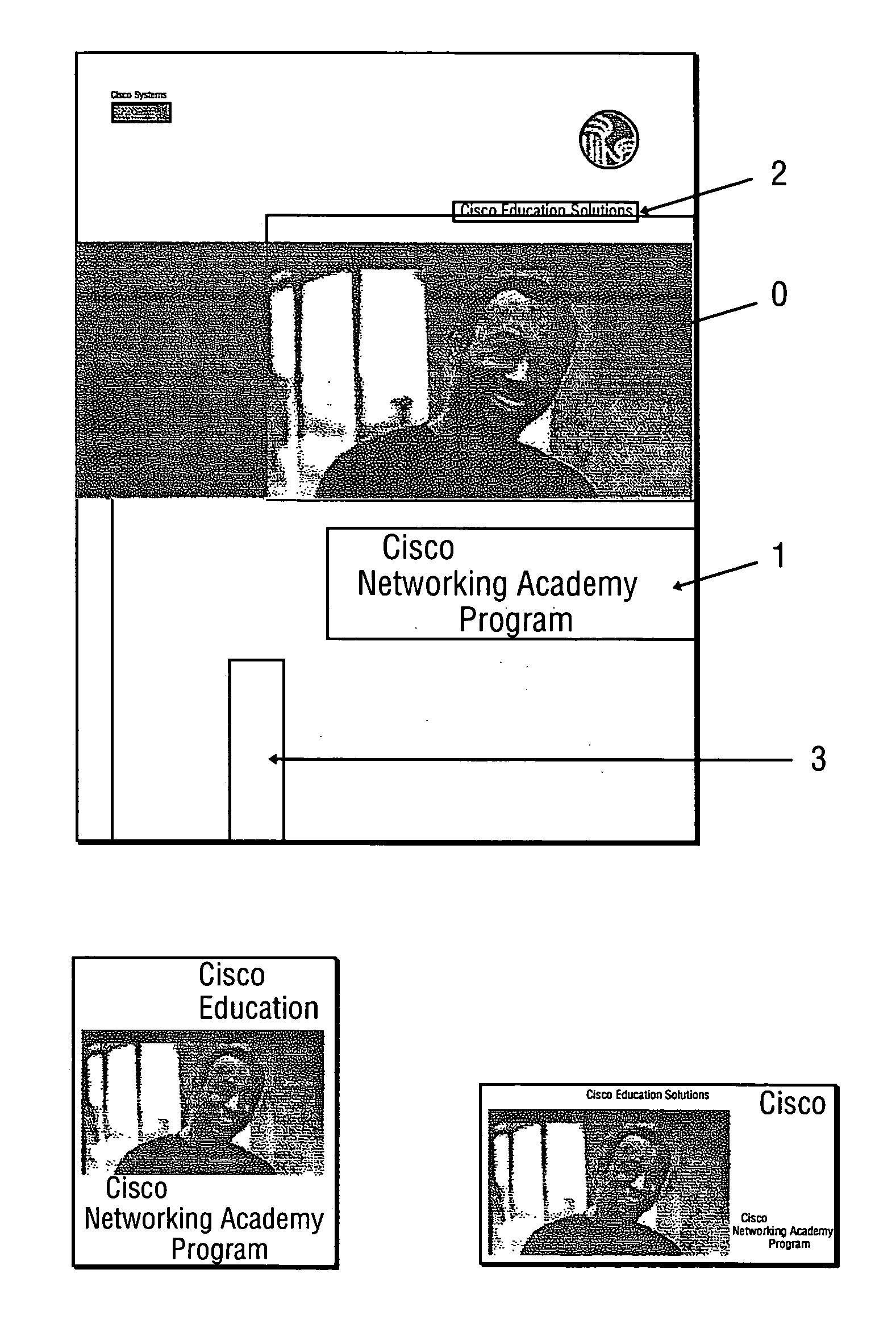

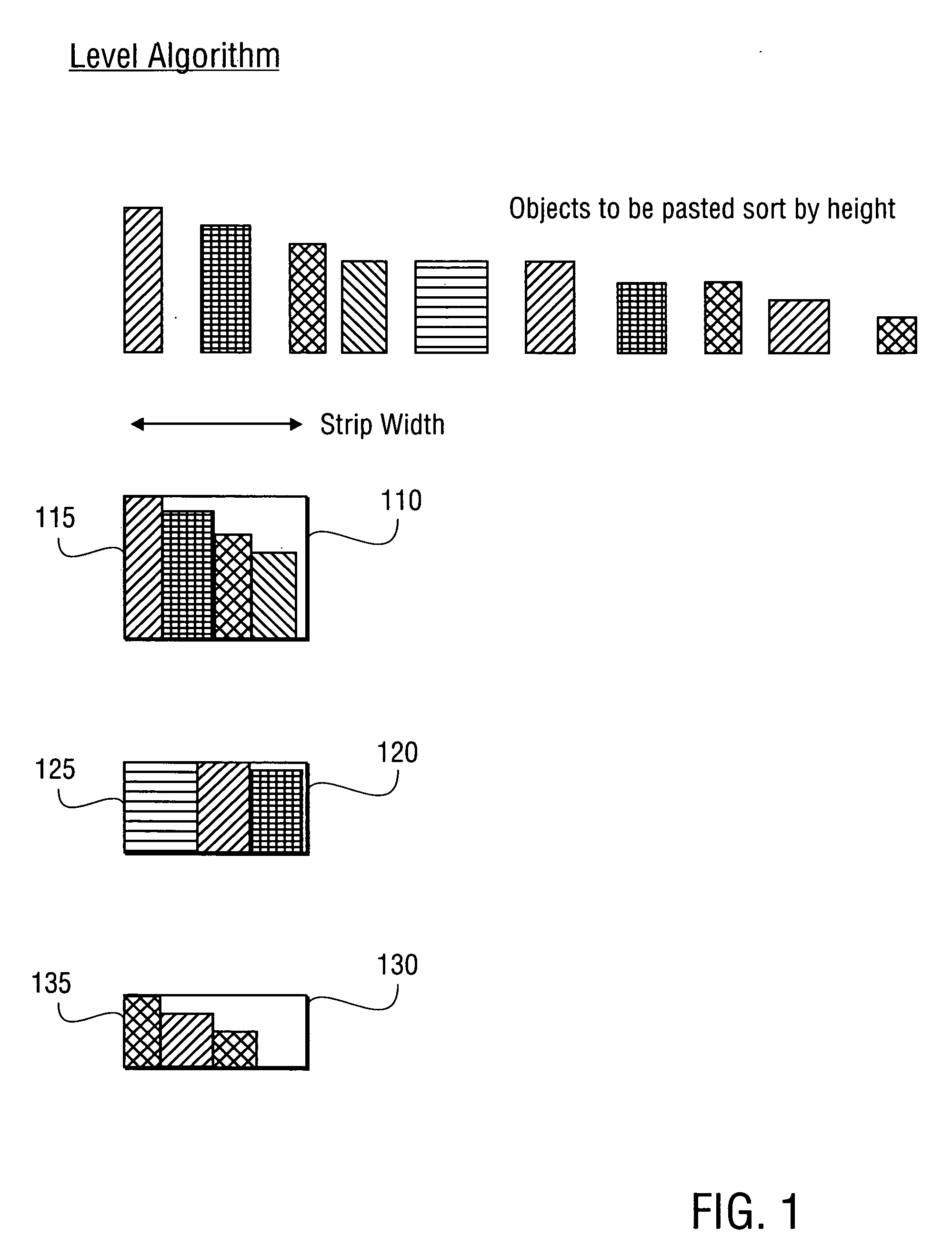

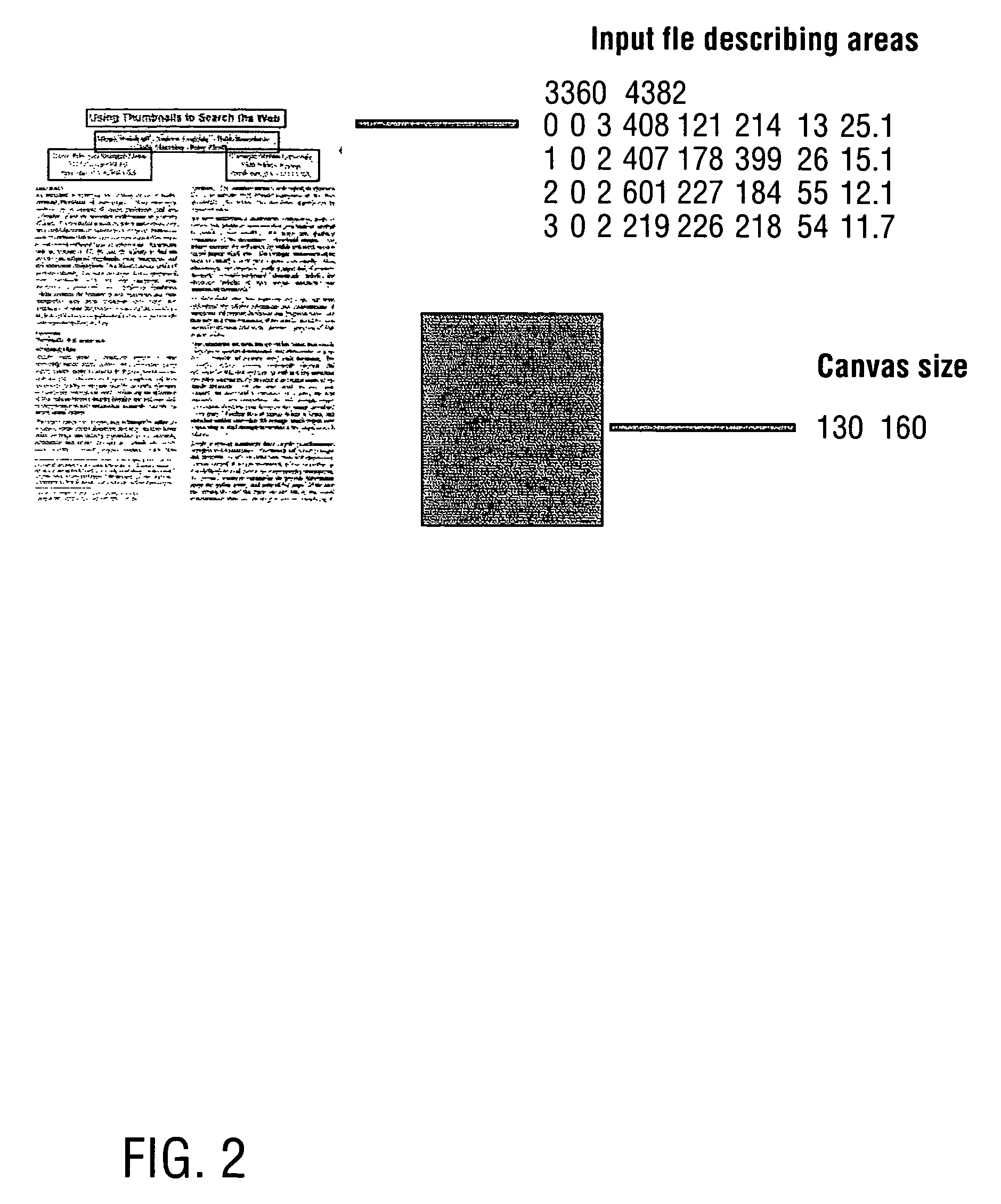

Resolution sensitive layout of document regions

InactiveUS20040145593A1Quick costHigh distortionDigital data information retrievalCharacter and pattern recognitionImage resolutionDocumentation

Owner:RICOH KK

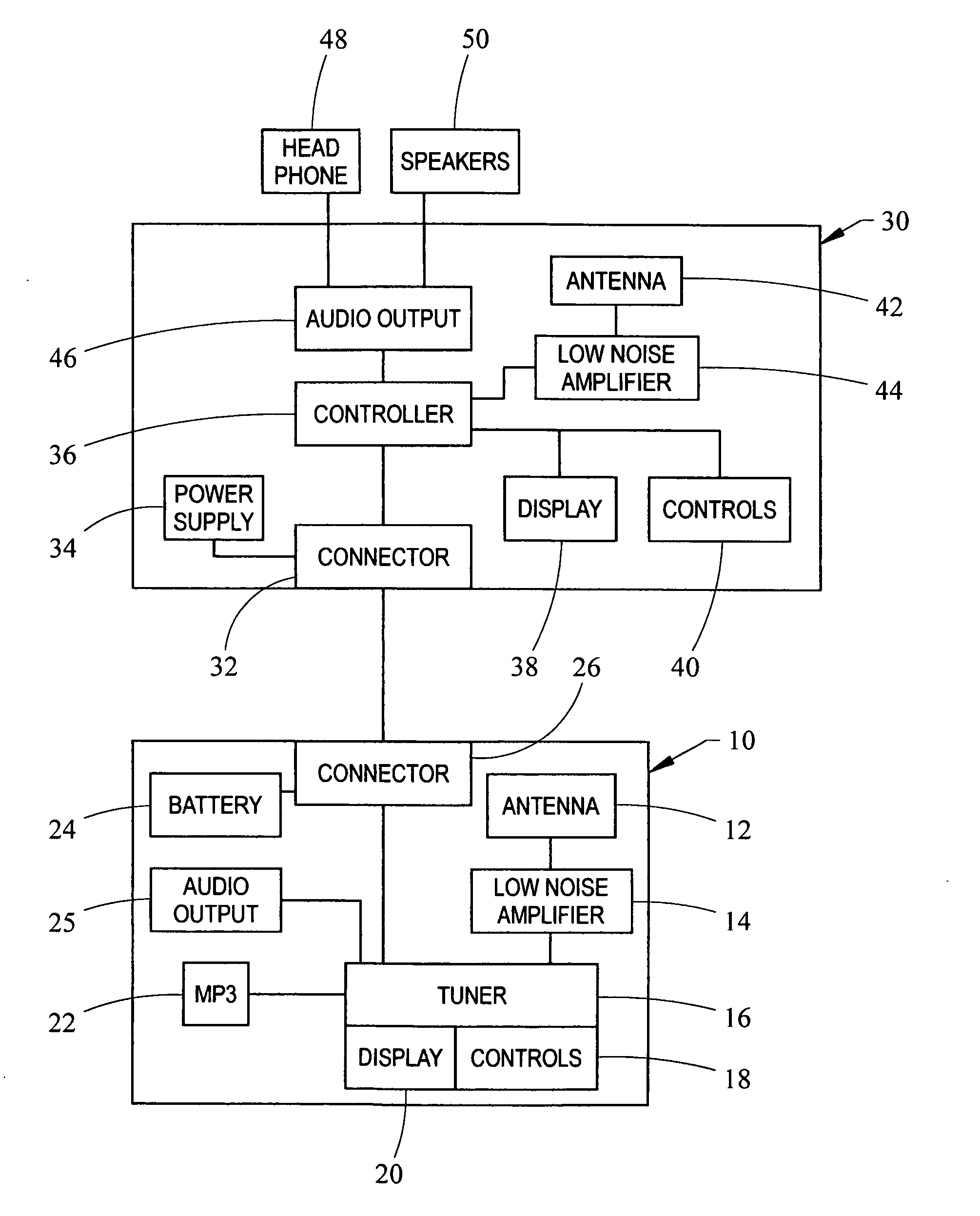

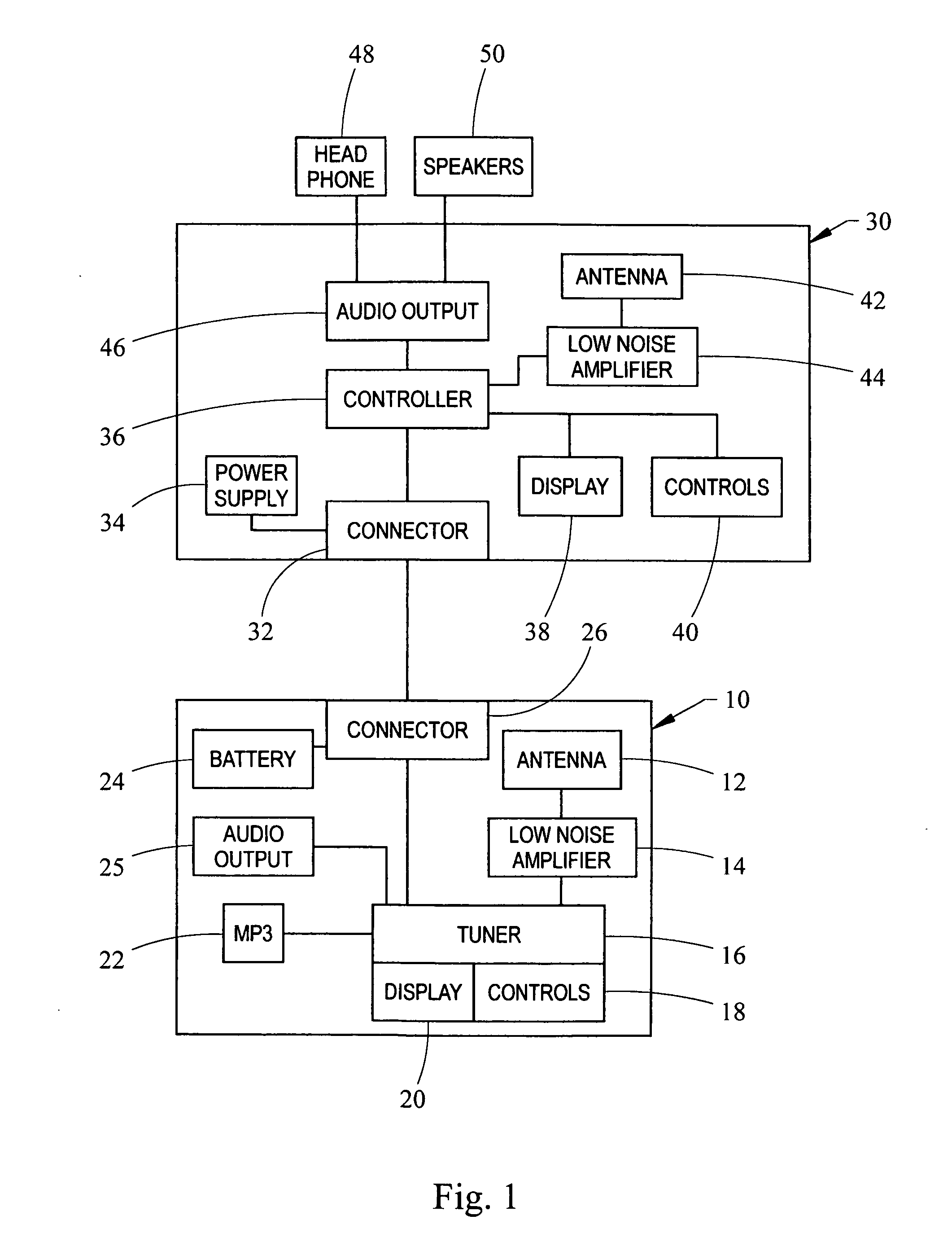

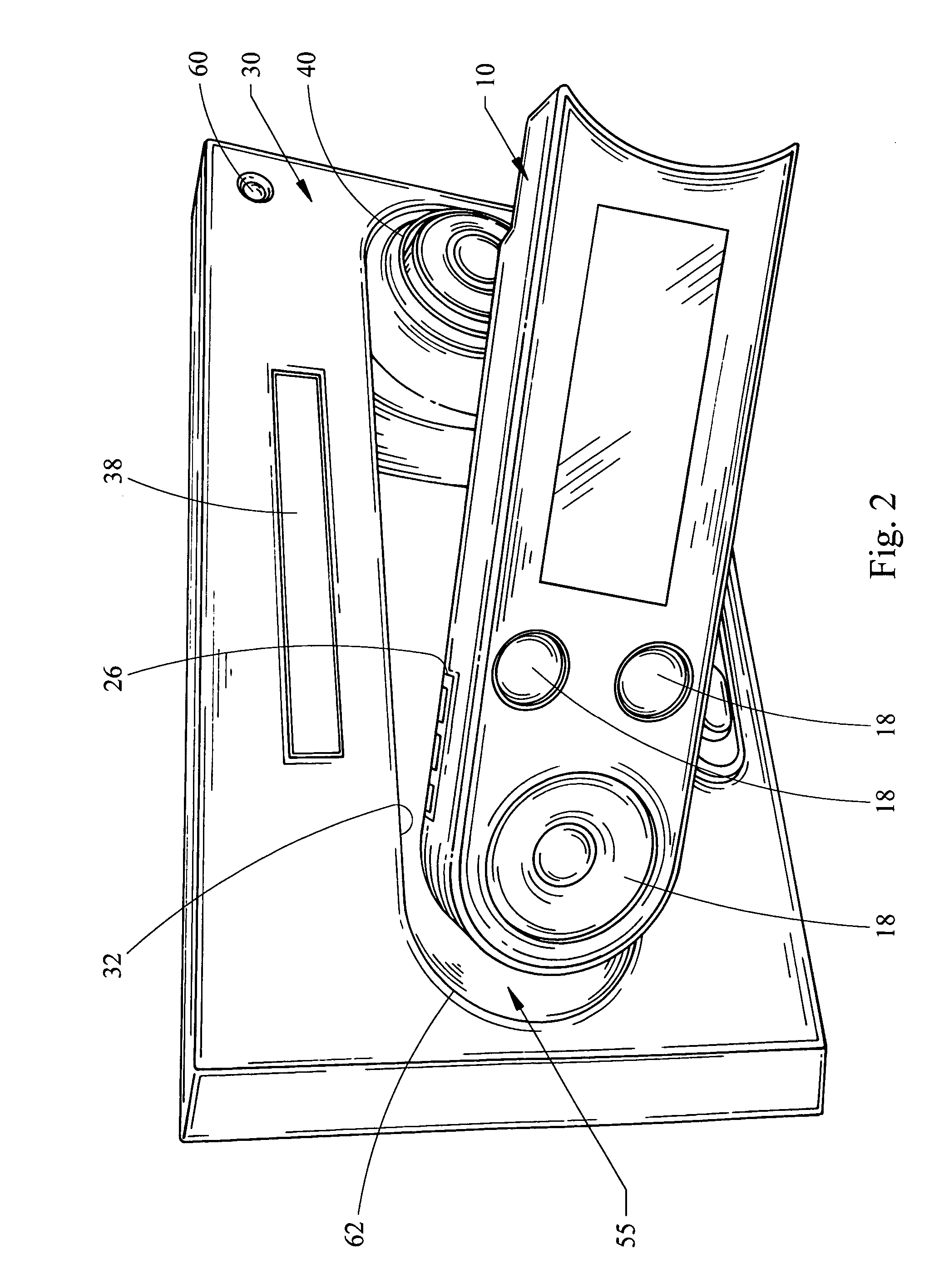

Dockable portable satellite receiver

InactiveUS20060094349A1Maximize limited memory spaceLow costSatellite broadcast receivingBroadcast transmission systemsTelecommunications linkAudio power amplifier

A portable satellite receiver includes a tuner, an antenna, and an amplifier. The portable satellite receiver has a protective housing enclosing the tuner, antenna, and amplifier. The portable satellite receiver is configured to interface with an accessory device through a communication link such that the accessory device receives audio signals from the portable satellite receiver over the communication link.

Owner:VISTEON GLOBAL TECH INC

Bio-organic fertilizer

InactiveCN104774054ALow costQuick costBio-organic fraction processingOrganic fertiliser preparationSnow moldMicrobial agent

The invention discloses bio-organic fertilizer, and belongs to the technical field of organic fertilizer. The proportion by weight of all raw materials of the bio-organic fertilizer is dried chicken manure : edible mushroom : compound microbial agent : corn flour or rice bran : functional strain = 110-140 : 390-360 : 0.1-0.5 ; 0.1. The compound microbial agent comprises mould, bacillus, lactic acid bacteria, actinomycetes and saccharomycetes. The strains are efficient viable bacteria. Each gram of the compound microbial agent comprises the number of the mould ranges from 5 hundred million to 8 hundred million, the number of the efficient viable bacteria of bacillus ranges from 12 hundred million to 15 hundred million, and the number of the actinomycetes ranges from 10 hundred million to 12 hundred million and the saccharomycetes of 15 hundred million to 18 million. According to the bio-organic fertilizer, the chicken manure and mushroom dregs serve as main materials, and the high-quality organic fertilizer can be fermented quickly by adding the compound microbial agent and the functional strain.

Owner:YONGZHOU WANXIDENG AGRI DEV

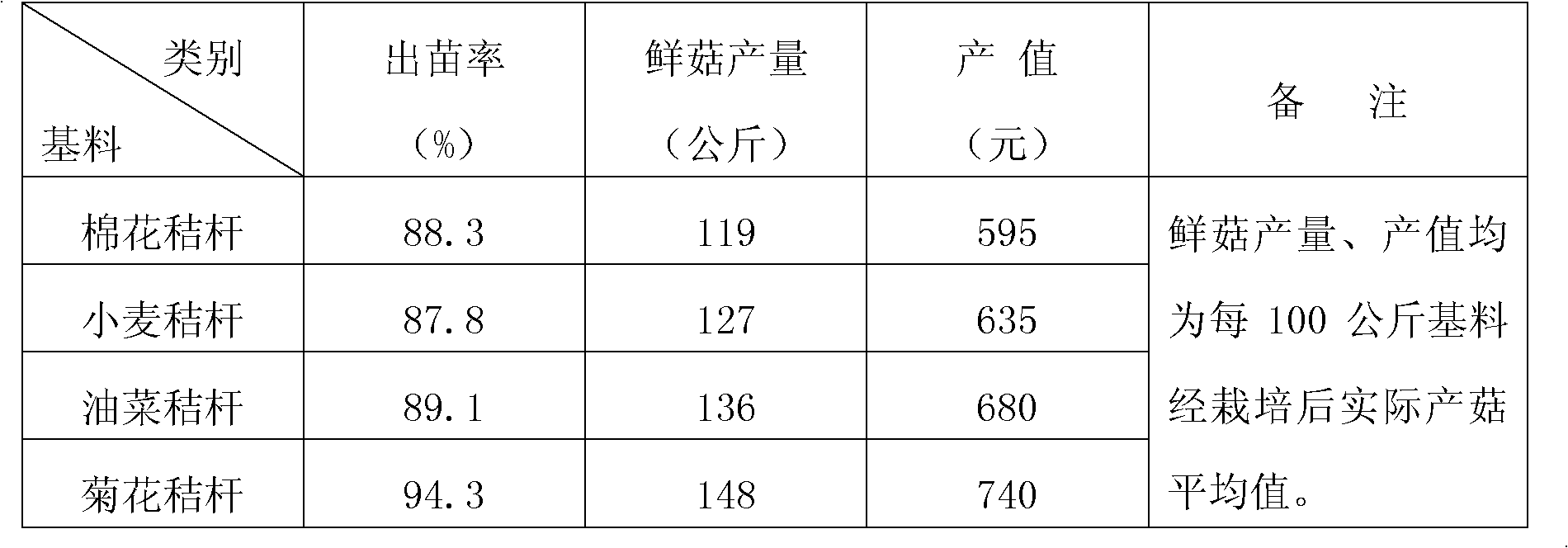

Culture base material for cultivating shiitake by using chrysanthemum straws and method for cultivating shiitake by using culture base material

InactiveCN102329171AStrengthen multi-level value-added resourcesIncrease yield efficiencyBio-organic fraction processingOrganic fertiliser preparationBiotechnologyChrysanthemum cinerariifolium

The invention discloses a culture base material for cultivating shiitake by using chrysanthemum straws. Chrysanthemum straw chips which are subjected to fermentation treatment are taken as a raw material, and auxiliary materials which have the effect of adjusting nutrition balance are added. The culture base material comprises the following components in percentage by weight: 77 percent of chrysanthemum straw chips, 15 percent of wheat bran, 5 percent of corn meal and 3 percent of bean cake. The chrysanthemum straw chips are treated by a fermentation treatment method and can be taken as a raw material of a culture medium when snowflake-shaped substances overgrow on the chrysanthemum straw chips. The pH value of the culture base material is kept at 6.5+ / -0.1. The invention also discloses a method for cultivating the shiitake by using the culture base material for cultivating the shiitake by using the chrysanthemum straws. The method comprises the steps of mixing materials, bagging, sterilizing, inoculating, growing mycelia, culturing, performing shiitake fruiting management, harvesting and the like. The problems about the improvement of the nutrient of the culture base material by treating the chrysanthemum straws, high-yield cultivation and management are solved.

Owner:安徽省庆元堂徽菊股份有限公司

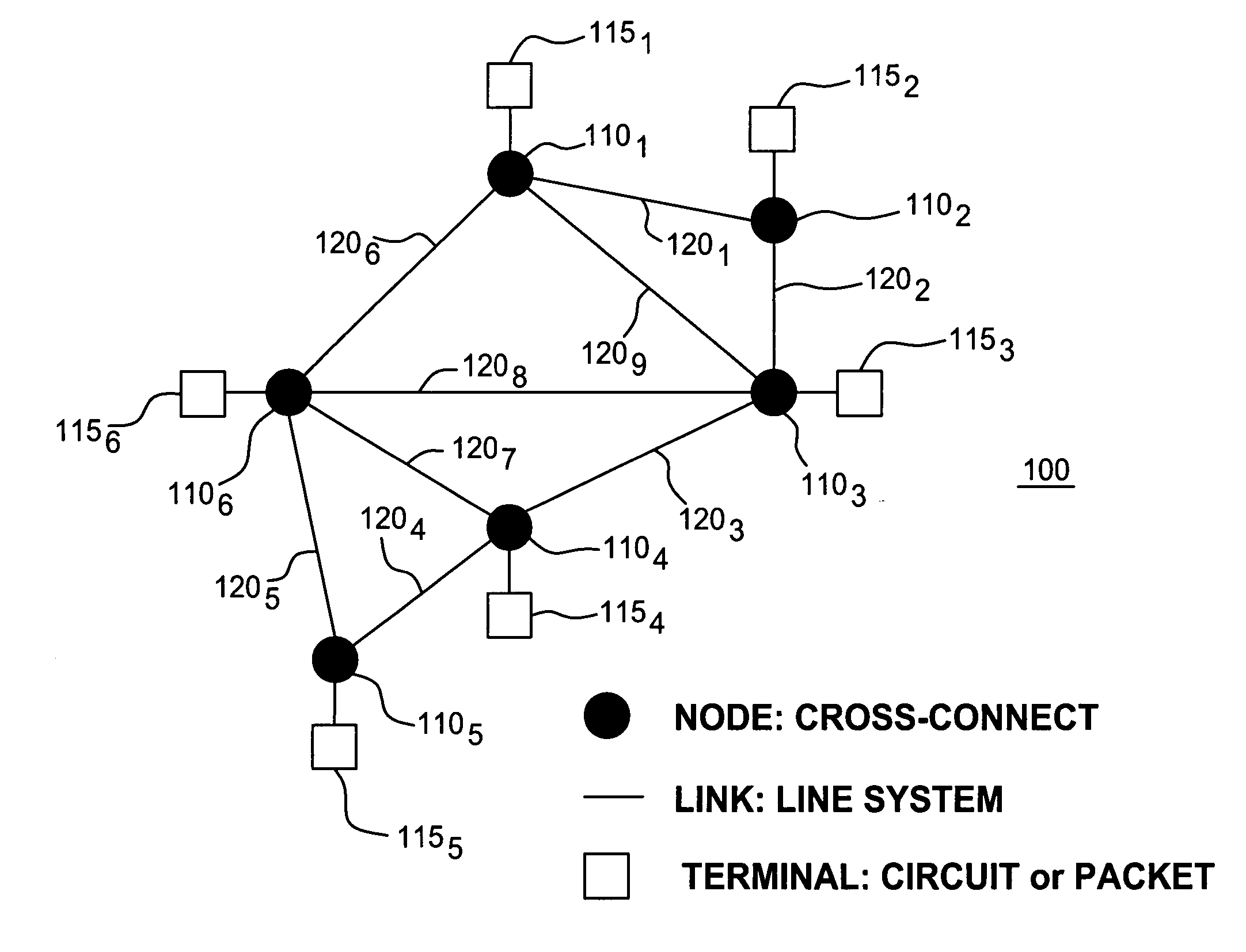

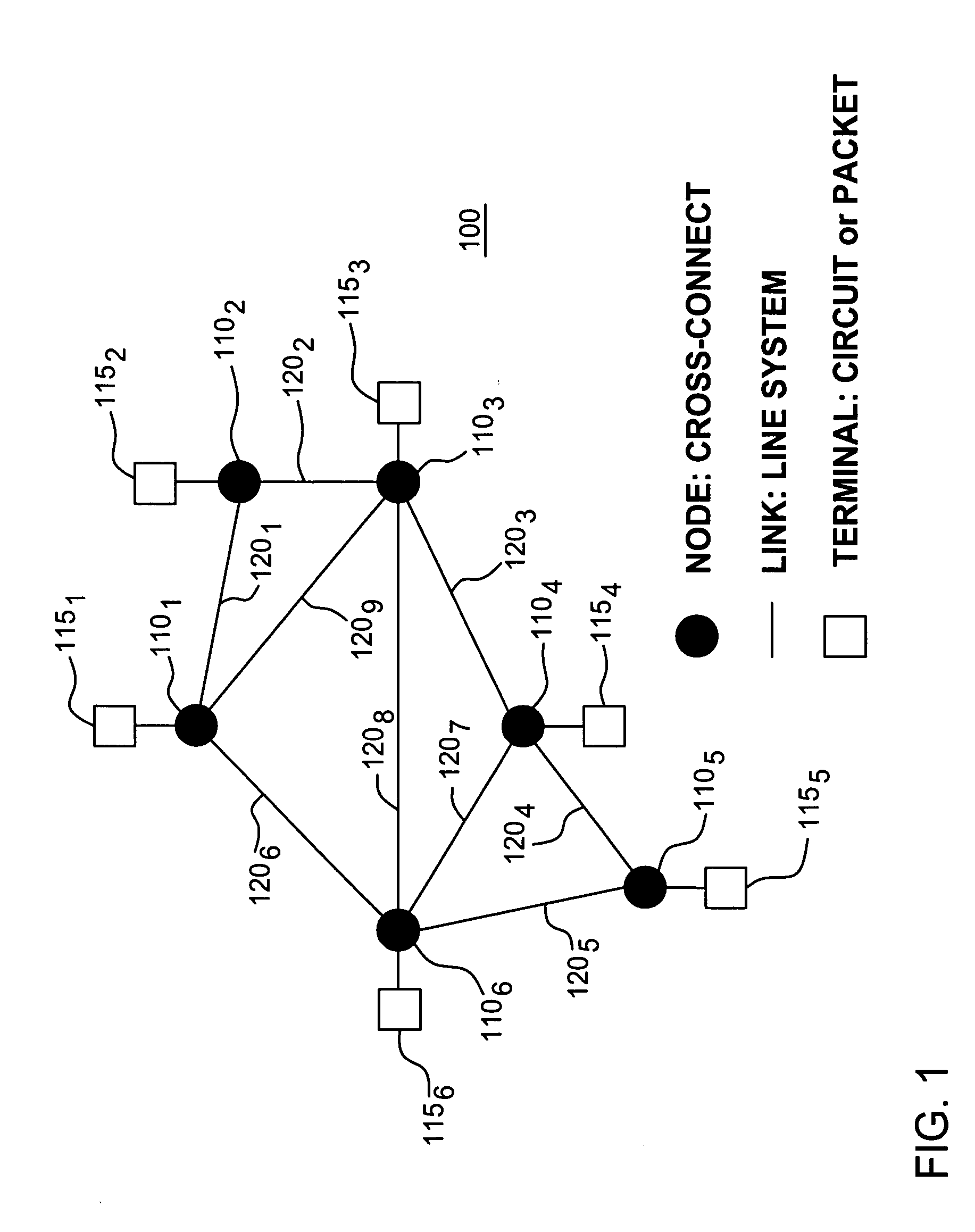

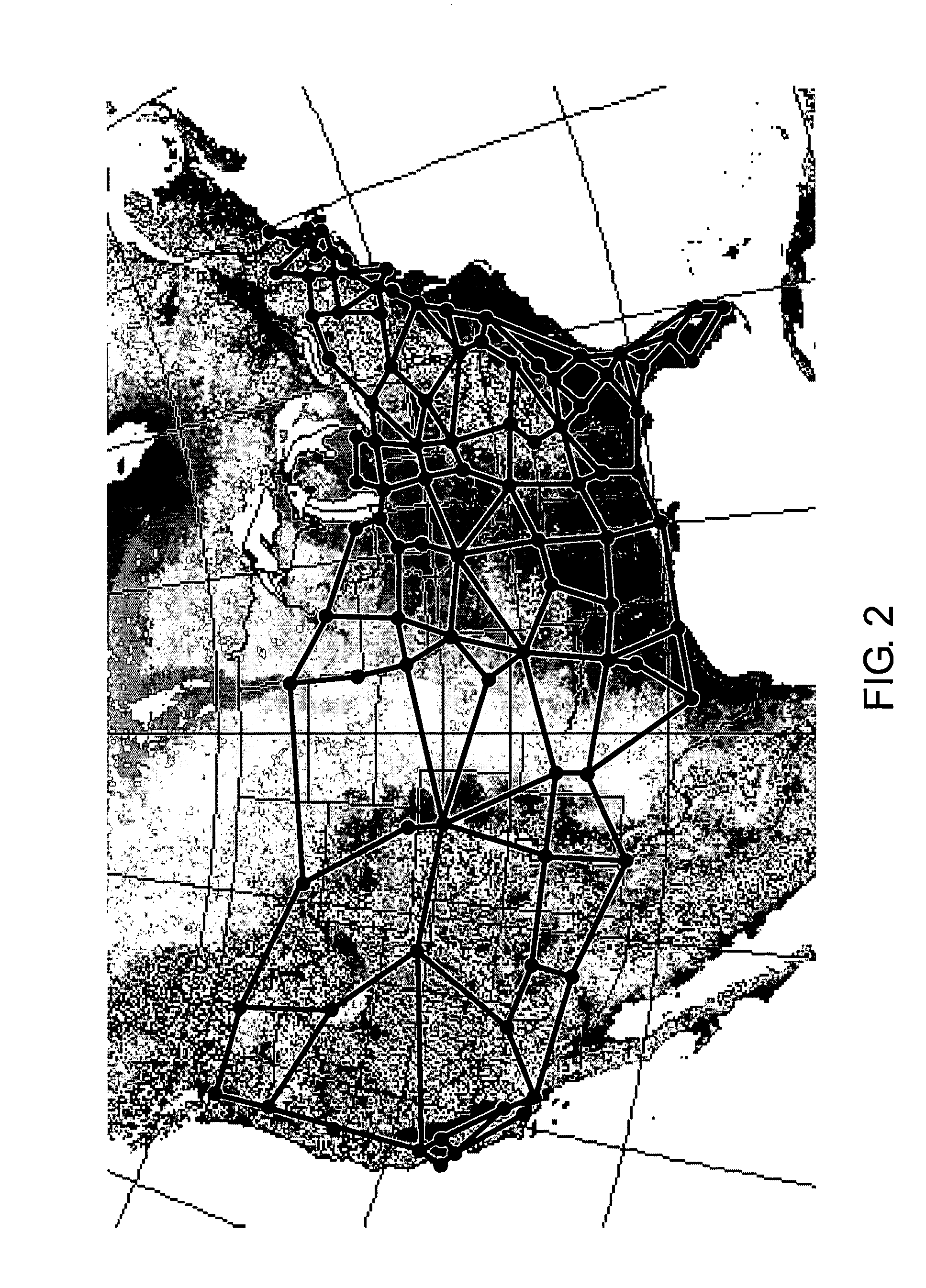

Network global expectation model for multi-tier networks

InactiveUS20050197993A1Quick costRapidly needWavelength-division multiplex systemsFuzzy logic based systemsSensitivity analysisNetwork cost

In the Network Global Expectation Model, expectation values evaluated over the entire network are used as a multi-moment description of the required quantities of key network and network element (NE) resources and commensurate network costs. The Network Global Expectation Model naturally and analytically connects the global (network) and local (network element) views of the communication system, and thereby may be used as a tool to gain insight and very quickly provide approximate results for the preliminary evaluation and design of dynamic networks. Further, the Network Global Expectation Model may serve as a valuable guide in the areas of network element feature requirements, costs, sensitivity analyses, scaling performance, comparisons, product definition and application domains, and product and technology roadmapping. The network is arranged as a multiple tier network of nodes in order to apply the analysis methods of the Network Global Expectation Model. The analytical method is developed to include non-uniform demands on the network.

Owner:LUCENT TECH INC

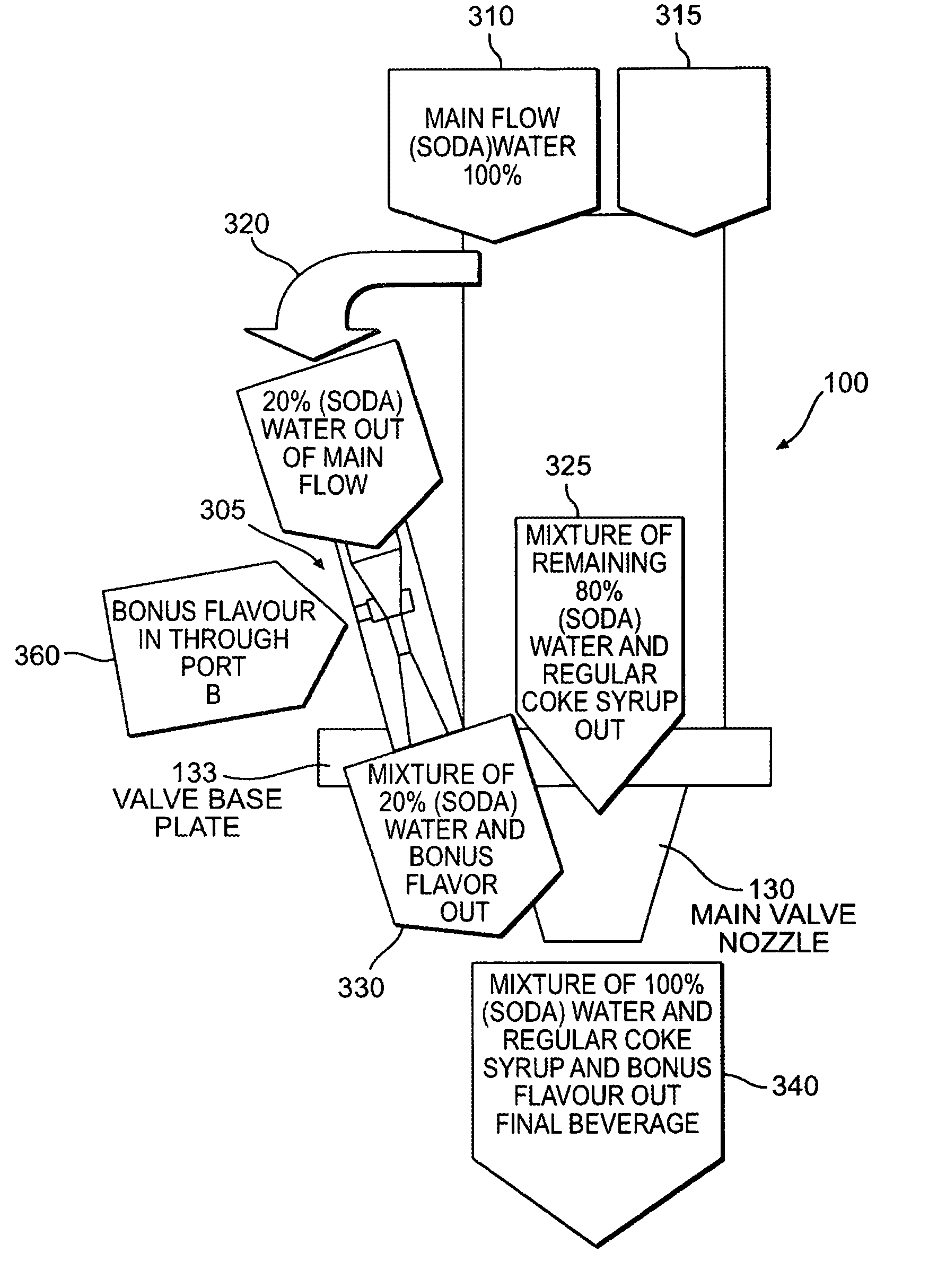

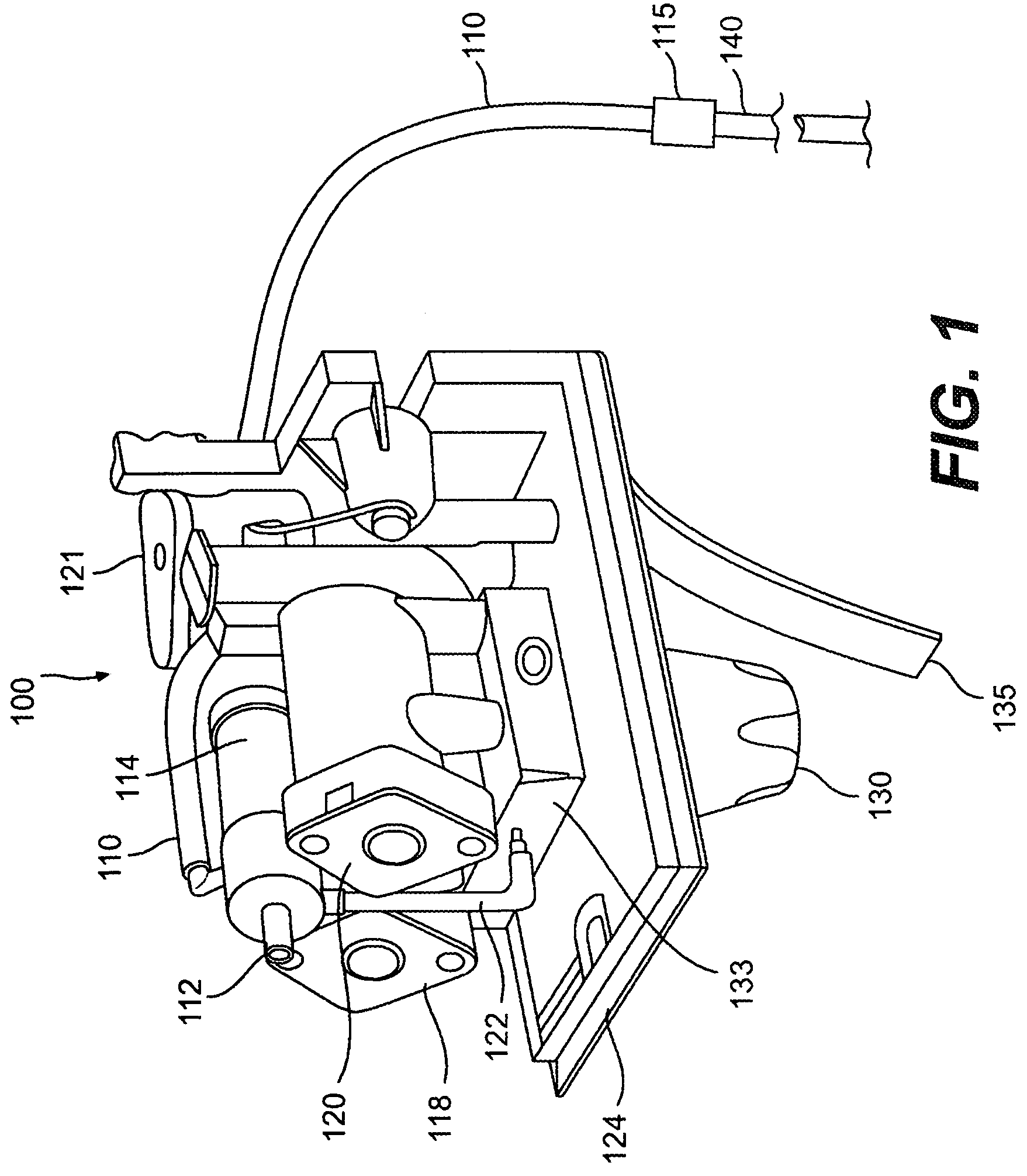

Liquid dispensing device

InactiveUS7048148B2Affect levelPrevent backflowMixing methodsLiquid transferring devicesEngineeringHigh pressure

A drink dispensing head incorporating a Venturi valve to utilize the motive force of a high pressure liquid to draw a low pressure liquid into the dispensing head without the need for a pumping means. A Venturi valve incorporated into a remote valve structure for adding a bonus flavor to a regular beverage dispenser without altering the existing valve structure.

Owner:THE COCA-COLA CO

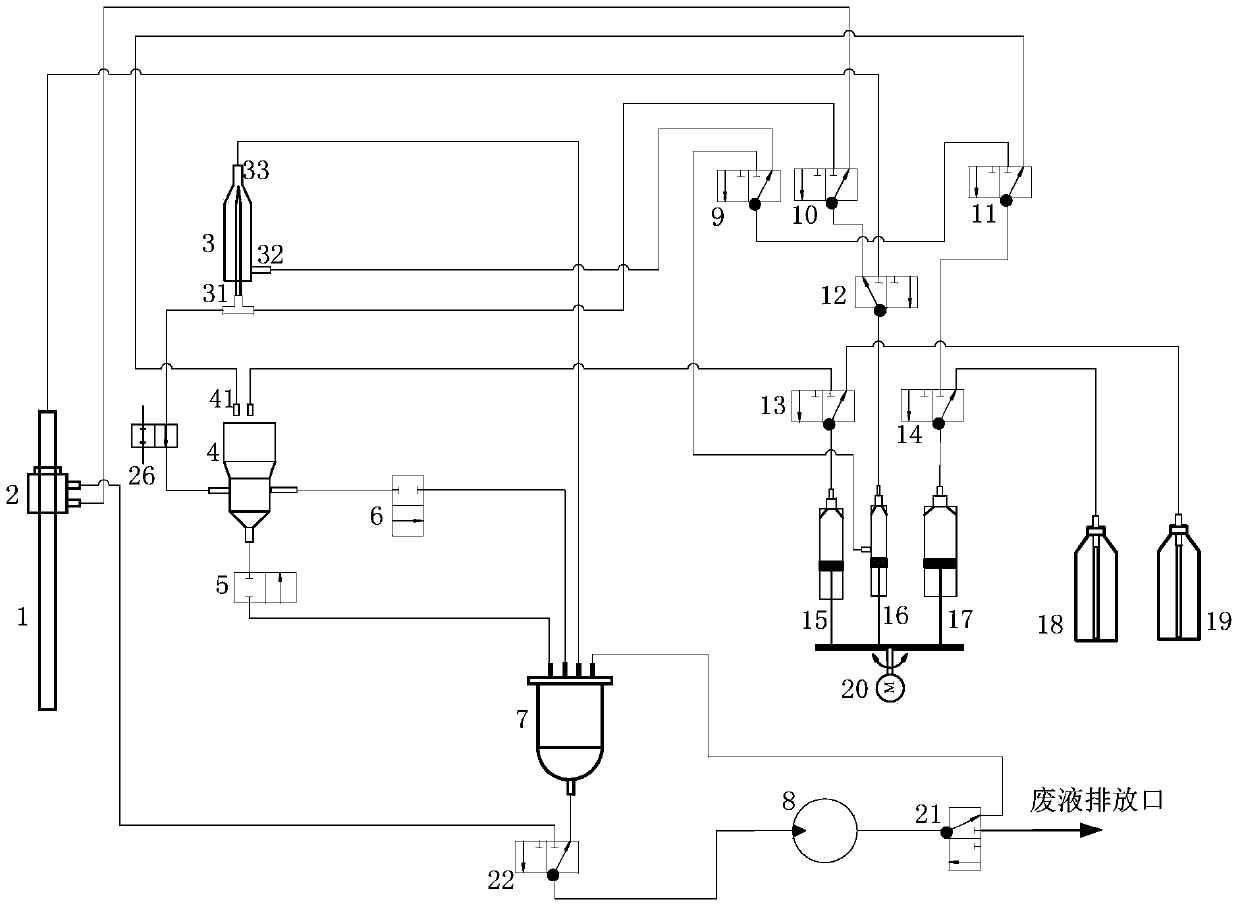

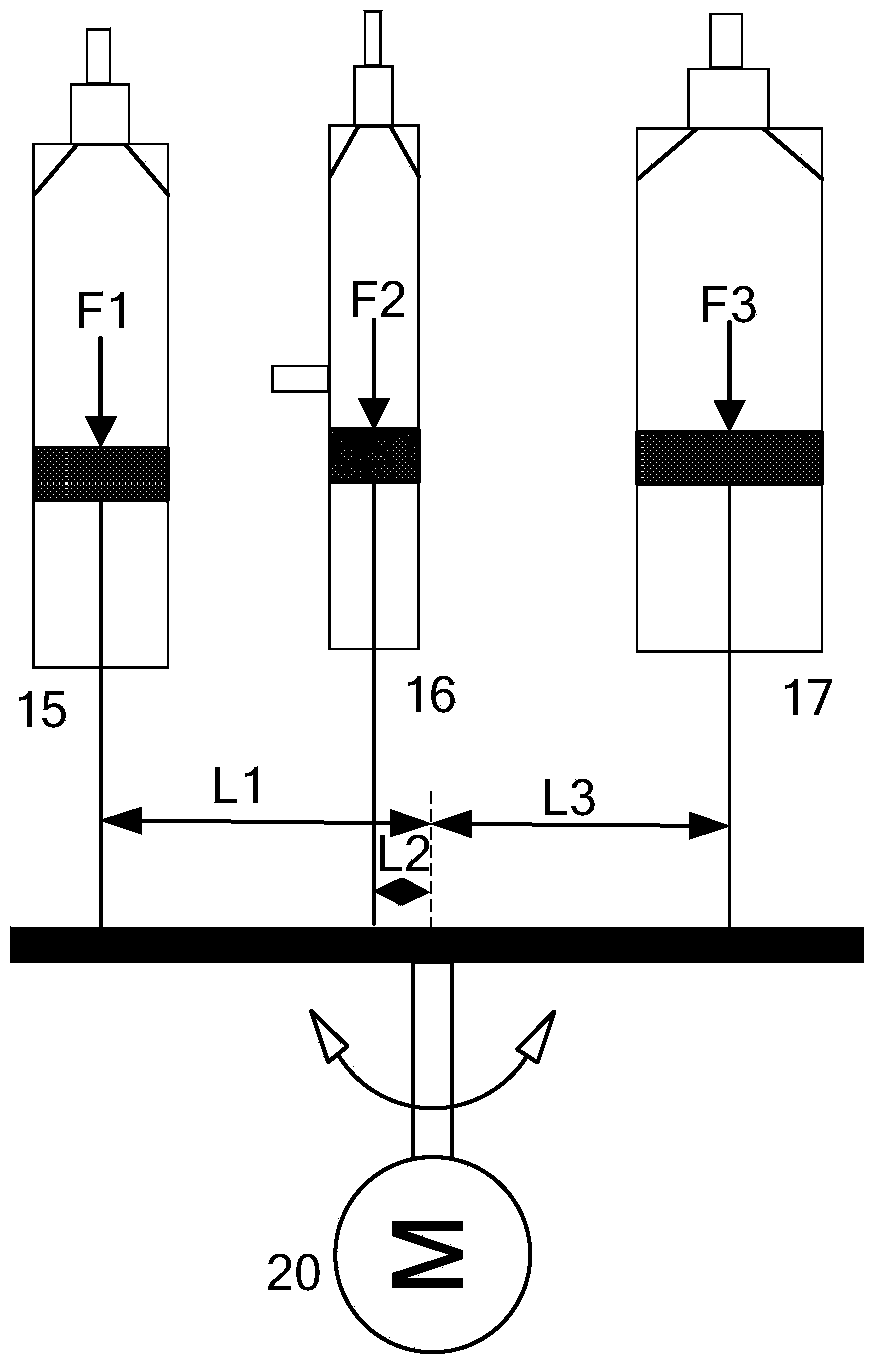

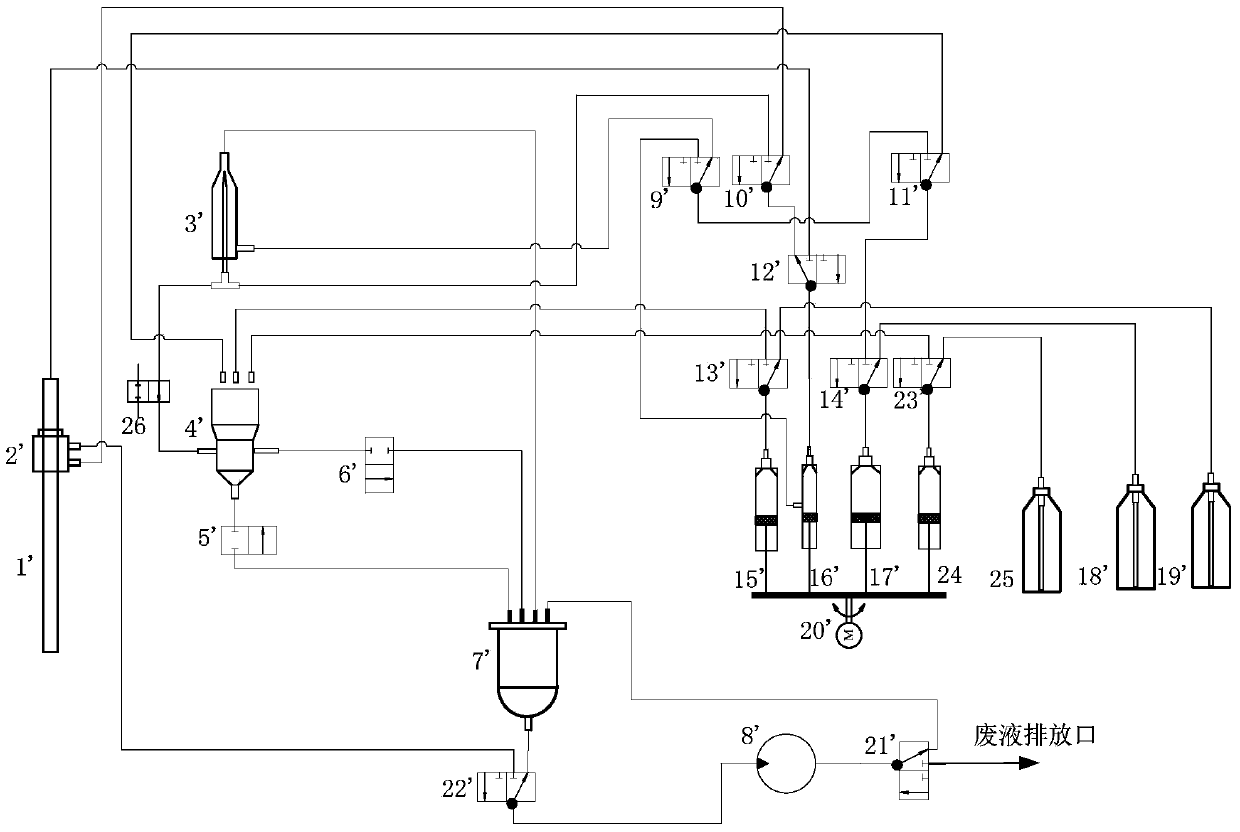

Fluid system of flow cytometer and flow cytometric detection method

The invention discloses a fluid system of a flow cytometer and a flow cytometric detection method. The fluid system comprises a sampling needle, a sampling needle cleaning device, a flowing chamber, a reaction tank, a hemolytic agent syringe, a sample syringe, a diluent syringe, a diluent bottle, a hemolytic agent bottle and a motor, wherein the sample syringe is respectively communicated with the sampling needle, the reaction tank, the flowing chamber, the sampling needle cleaning device and the diluent syringe, the diluent syringe is respectively communicated with the diluent bottle, the flowing chamber and the reaction tank, the hemolytic agent syringe is respectively communicated with the hemolytic agent bottle and the reaction tank, and the hemolytic agent syringe, the sample syringe and the diluent syringe are all driven and controlled by the motor. According to the invention, driving motors for a plurality of syringes are integrated into one, arrangement of the syringes satisfies moment balance, integral rigidity and inertia are improved, gap instability of the driving motor can be buffered, a more stationary sample flow can be obtained, and thus, detection precision of the flow cytometer is improved.

Owner:SHENZHEN DYMIND BIOTECH

Short-flow preparation method of minor-caliber nickel-based alloy thin-wall tubes

InactiveCN102463272AIncrease productivityShort labor intensityExtrusion control devicesAlloyMaterials science

The invention relates to a short-flow preparation method of minor-caliber nickel-based alloy thin-wall tubes, belonging to the technical field of processing non-ferrous metal material tubes, mainly comprising the following steps that: (1) centrifugal casting technology is carried out to prepare nickel-based alloy tube billets, wherein, the ratio of outer diameters and inner diameters of the tube billets is 0.4-0.6; (2) the hot extrusion temperature of nickel-based alloy tubes is 1000-1250 DEG C, and the extrusion ratio is 5-16; (3) LG / LD and other series of cold pilger mills or drawing machines are used for carrying out multi-pass cold processing to reduce the tube diameter and reduce the wall thickness, so as to obtain thin-wall tubes; and (4) intermediate annealing, final annealing and final tube straightening are carried out. The method has the advantages of short flow, low labor intensity, laborsaving shaping, low cost, and high production efficiency. The prepared minor-caliber nickel-based alloy thin-wall tubes have high additional values. The method is suitable for large scale production, and has remarkable economic benefits and social benefits.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

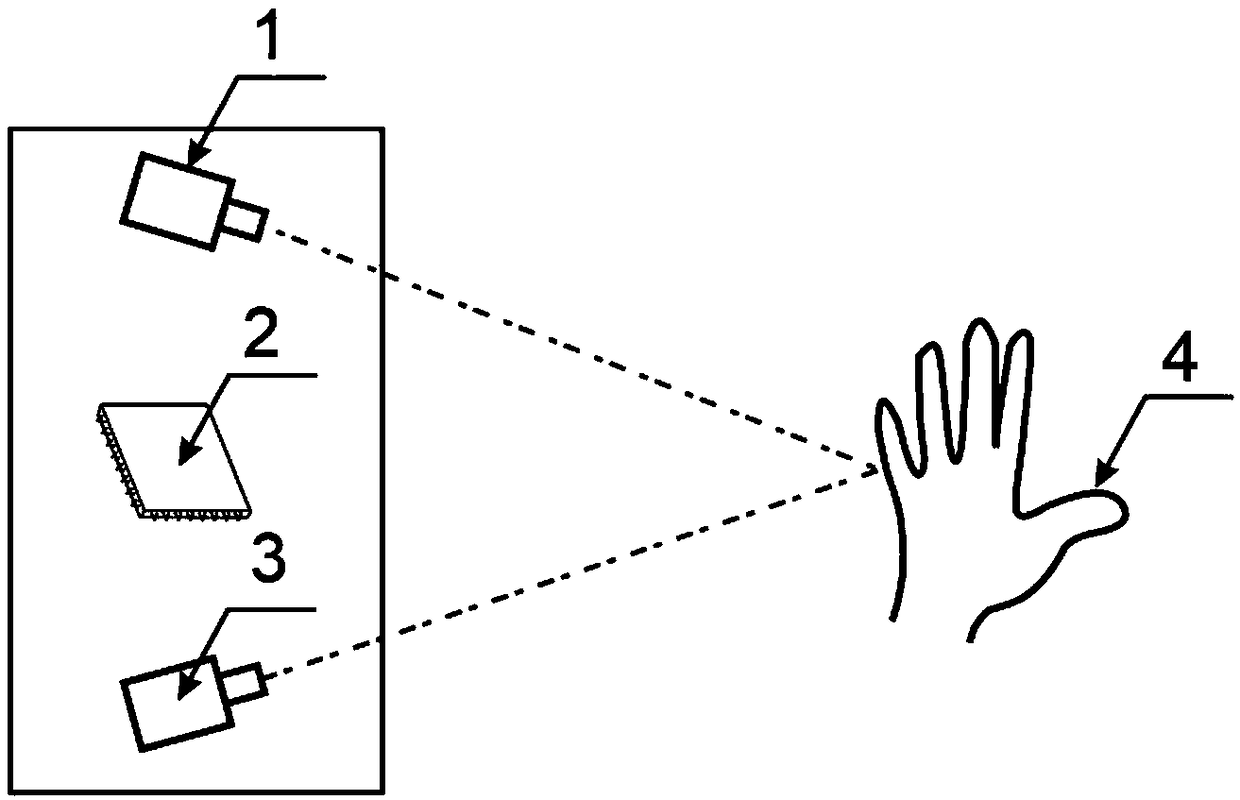

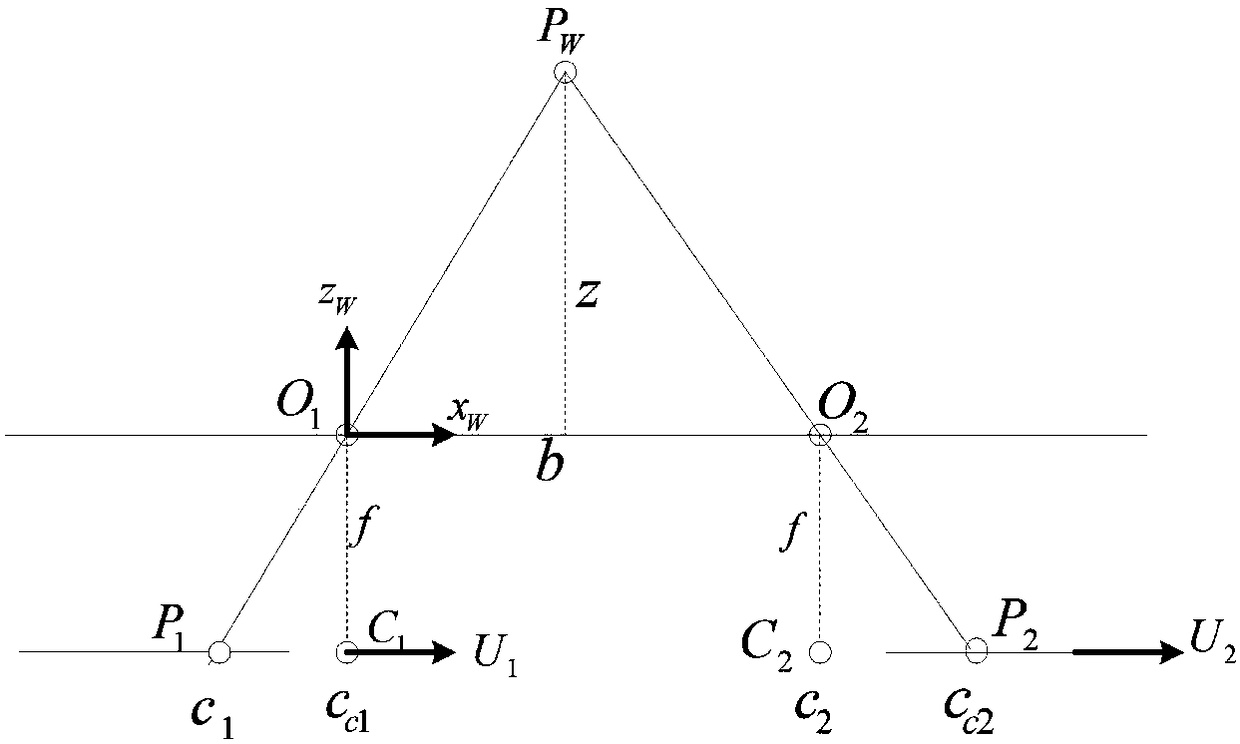

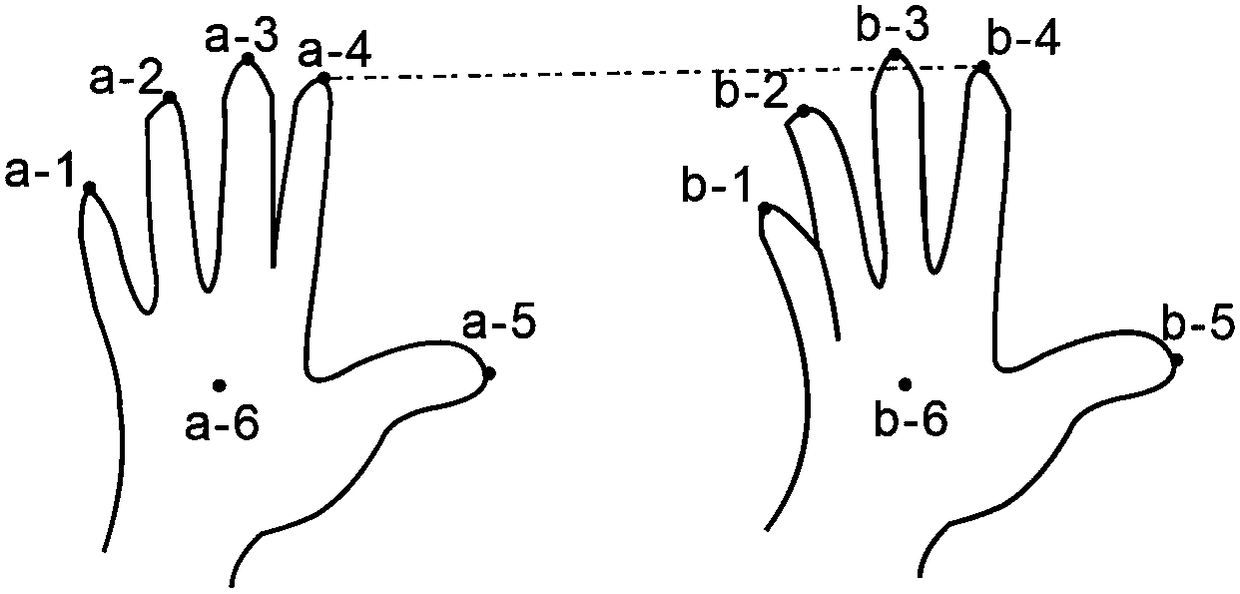

Three-dimensional dynamic gesture recognition method based on deep learning

InactiveCN108256504AQuick extractionSolve the rare matching problemImage analysisThree-dimensional object recognitionVisual perceptionComputer science

The invention provides a three-dimensional dynamic gesture recognition method based on deep learning and stereoscopic vision, which has low cost, high precision, high speed and good timeliness. The deep learning method can be used to quickly extract feature points of a gesture area, meeting the requirement on real-time dynamic three-dimensional reconstruction, and solving the problem that the stereoscopic vision technique has matching difficulty. The method using the stereoscopic vision technique has lower cost than structured light scheme, depth camera scheme and other schemes. By providing sparse reconstruction for feature points, calculation quantity is greatly decreased at the premise of no precision loss. Trajectory recognition speed and precision are increased for a feature point tracing method; a trajectory defining scheme based on feature points also decreases trajectory recognition and matching difficulties.

Owner:SUZHOU DEKA TESTING TECH CO LTD

Cermet composition and method for preparing cermet coat on metal surface

A metal-ceramic composition and coating it on metal surface are both disclosed herewith. It consists both parts of mixed powders containing Cr, B, Si, Fe, Al, La rare-earth oxides and Ni, and carbide materials, TiC or WC. It is coated as following: mixing metal-ceramic composition with polyvinyl alcohol or ethyl estate as binding agent to be slurry, coating it onto metal surface, drying, and firing in gas protecting furnace or vacuum furnace to obtain metal-ceramic coated metal parts. It is available to various shaped parts with different materials, and reduces energy consumption.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

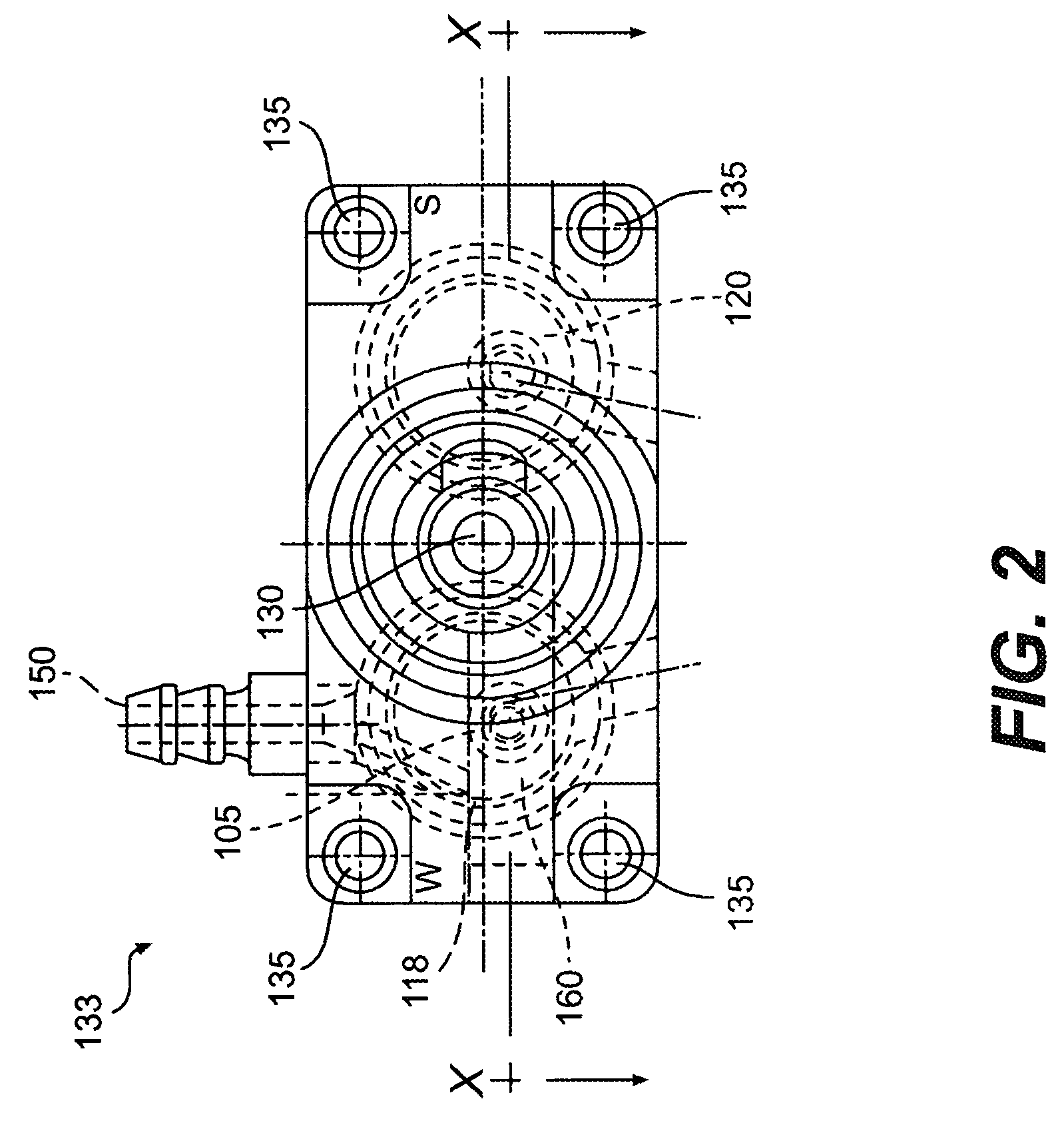

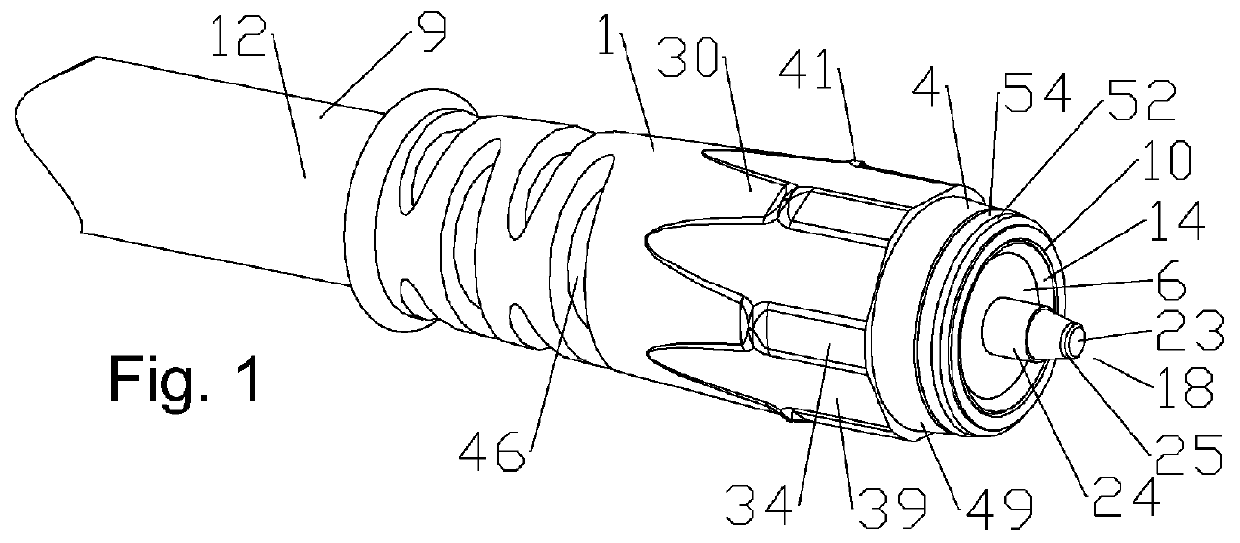

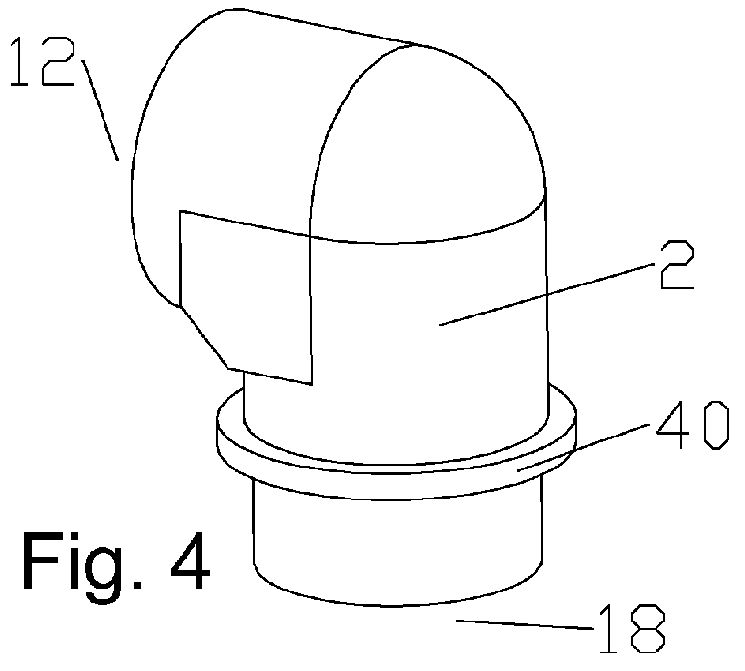

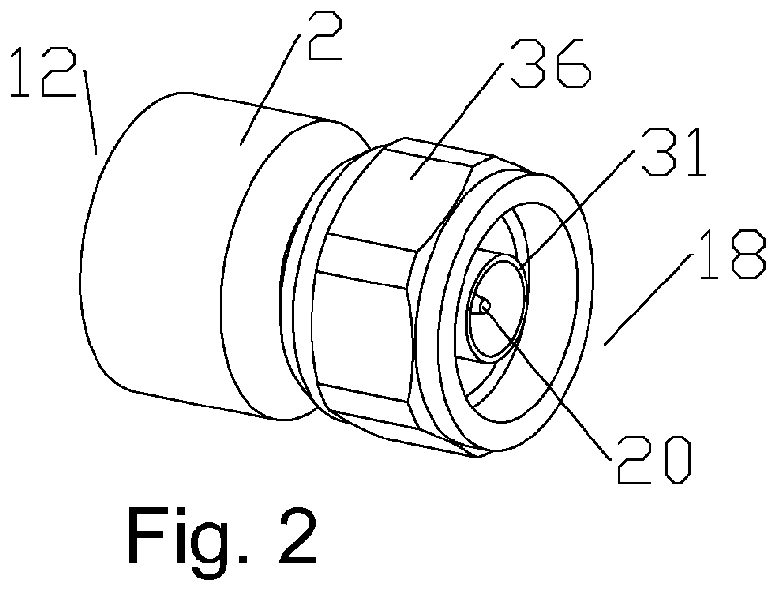

Method and aparatus for radial ultrasonic welding interconnected coaxial connector

ActiveUS20120129384A1Cost-effectiveLower potentialContact member manufacturingElectrically conductive connectionsCoaxial cableElectrical conductor

A coaxial connector assembly for interconnection with a coaxial cable with a solid outer conductor is provided with a monolithic connector body with a bore. A mating surface with a decreasing diameter toward a connector end is provided on an outer diameter of the connector body proximate the connector end. An overbody may be provided overmolded upon a cable end of the connector body. An interface end may be seated upon the mating surface, the interface end provided with a desired connection interface. The interface end may be permanently coupled to the mating surface by a molecular bond interconnection. In a method of interconnection, the interface end is coupled to the mating surface by application of radial ultrasonic welding.

Owner:COMMSCOPE TECH LLC

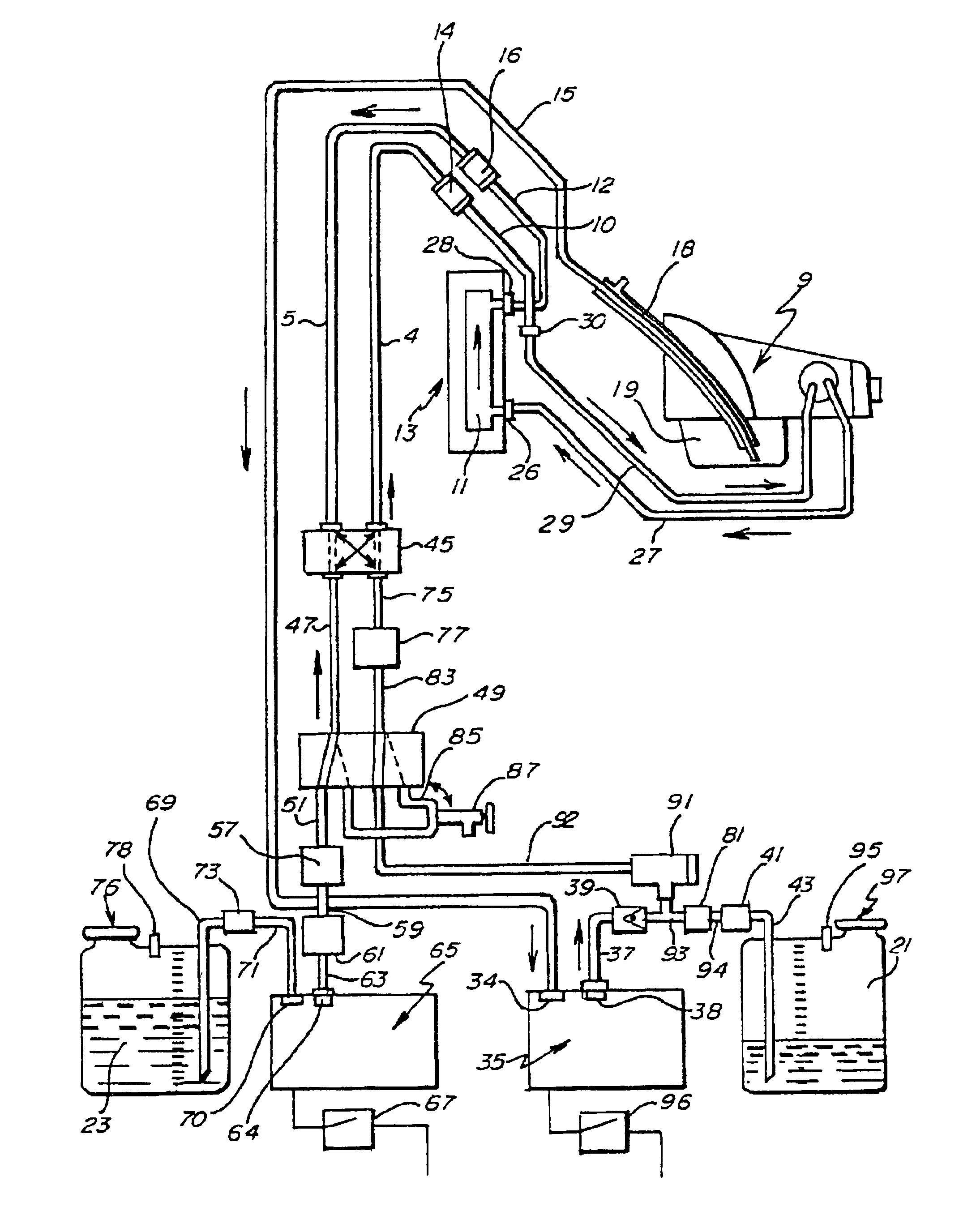

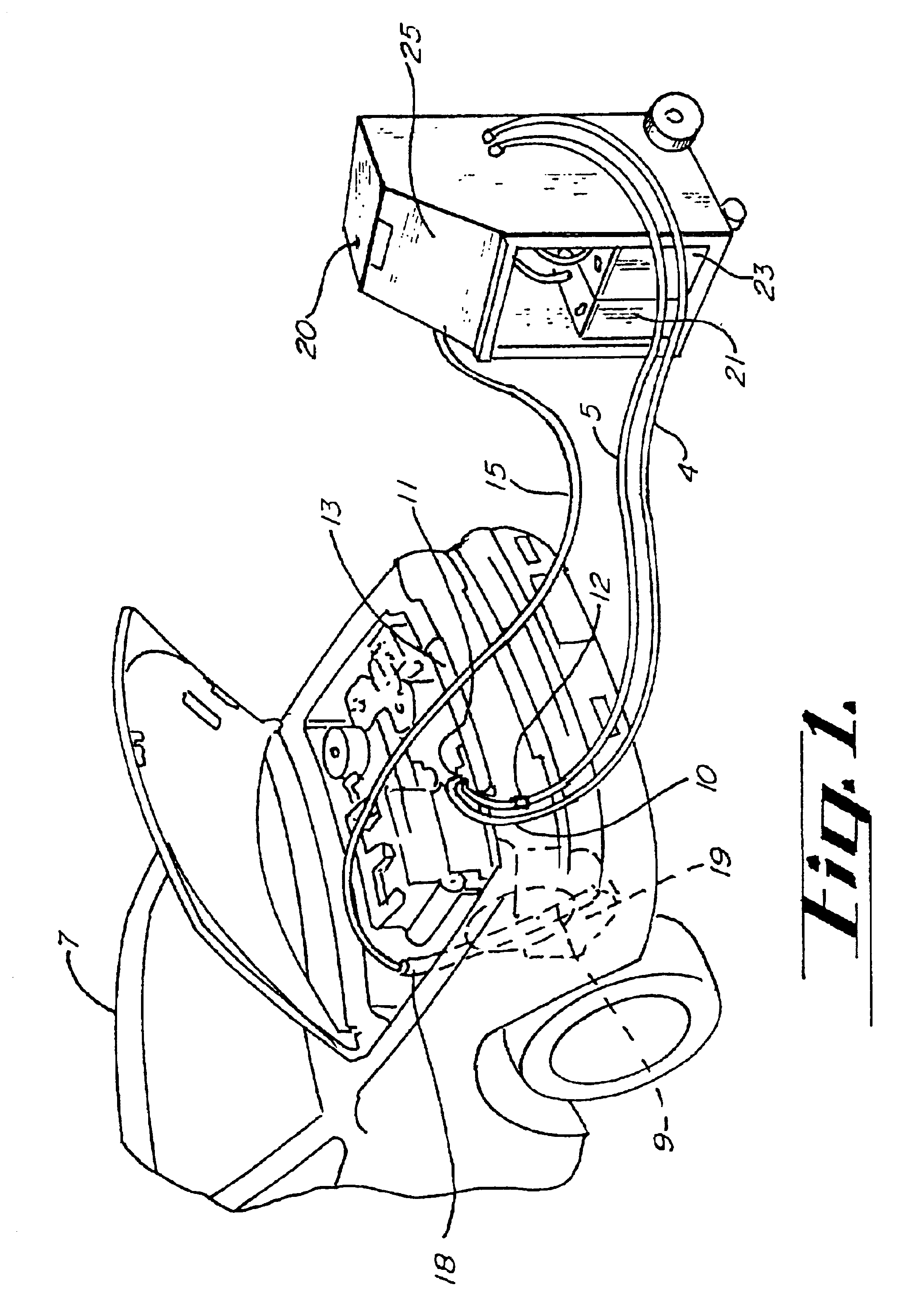

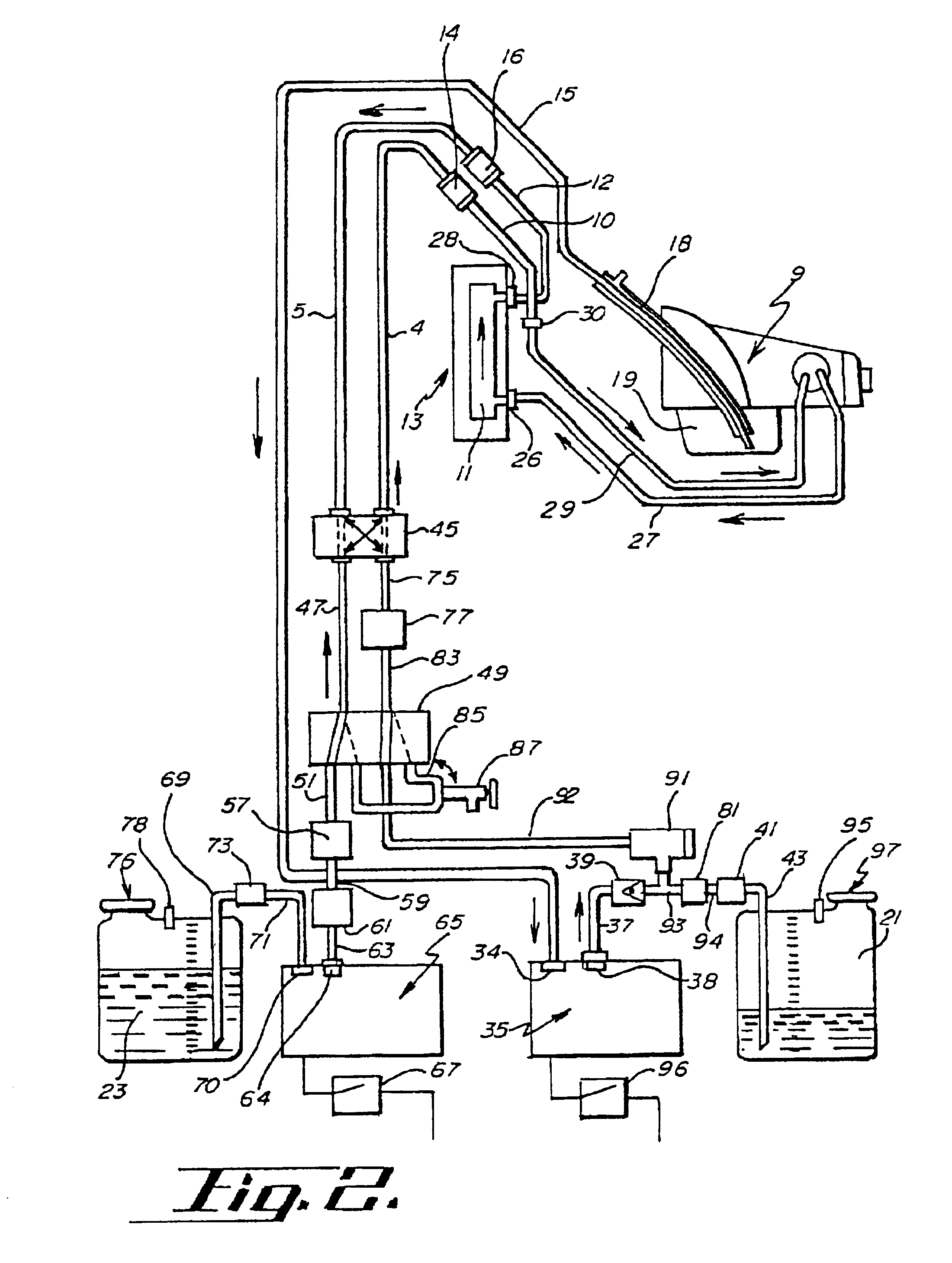

Complete fluid exchange system for automatic transmissions

InactiveUS6779633B2Highly effectiveEasy to operateCrankshaftsLiquid fillingAutomatic transmissionAutomotive industry

An improved system for changing the fluid of vehicular automatic transmissions and the like, which has the capability to provide a complete fluid exchange faster and with less usage of fresh fluid in a manner that is easier to operate. This is accomplished by the system's unique capability to extract used fluid and replace it with fresh fluid at a faster, balanced rate than before possible in prior art. This is accomplished by decreasing or removing restriction from the exhausting of the used fluid and introducing fresh fluid at more than one locus. The unique, novel capability of the invention to use a dual use pan access tube to combine a static change with a dynamic change, and to introduce fresh fluid into the transmission from two different loci instead of one as in all prior art, allows the fluid exchange to be completed in a shorter time with less use of fluid. These improvements increase the commercial utility and value of complete fluid changing in automatic transmissions and should extend its commercial viability as a routine maintenance procedure in the vehicular or automotive industry.

Owner:VIKEN JAMES P

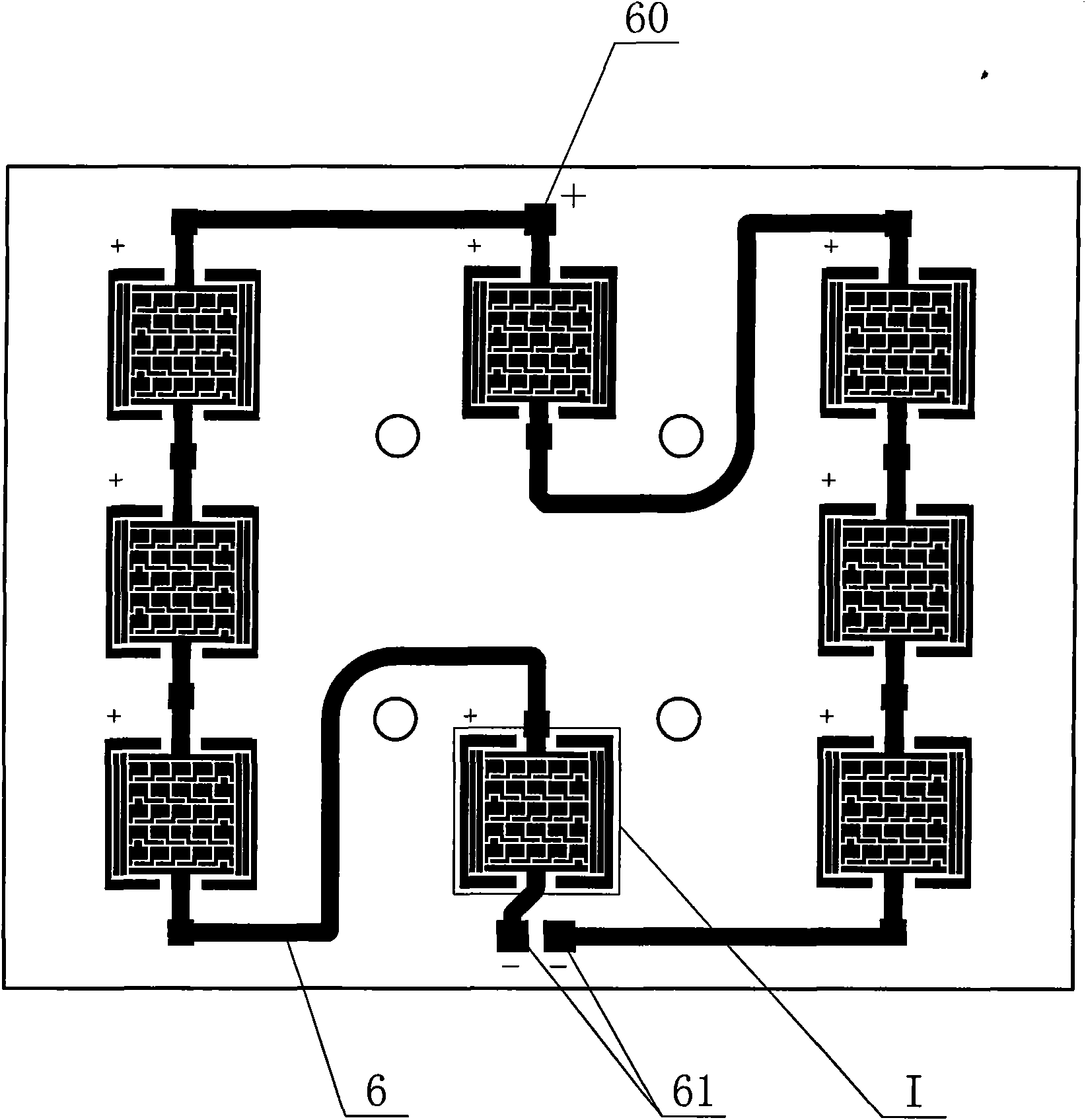

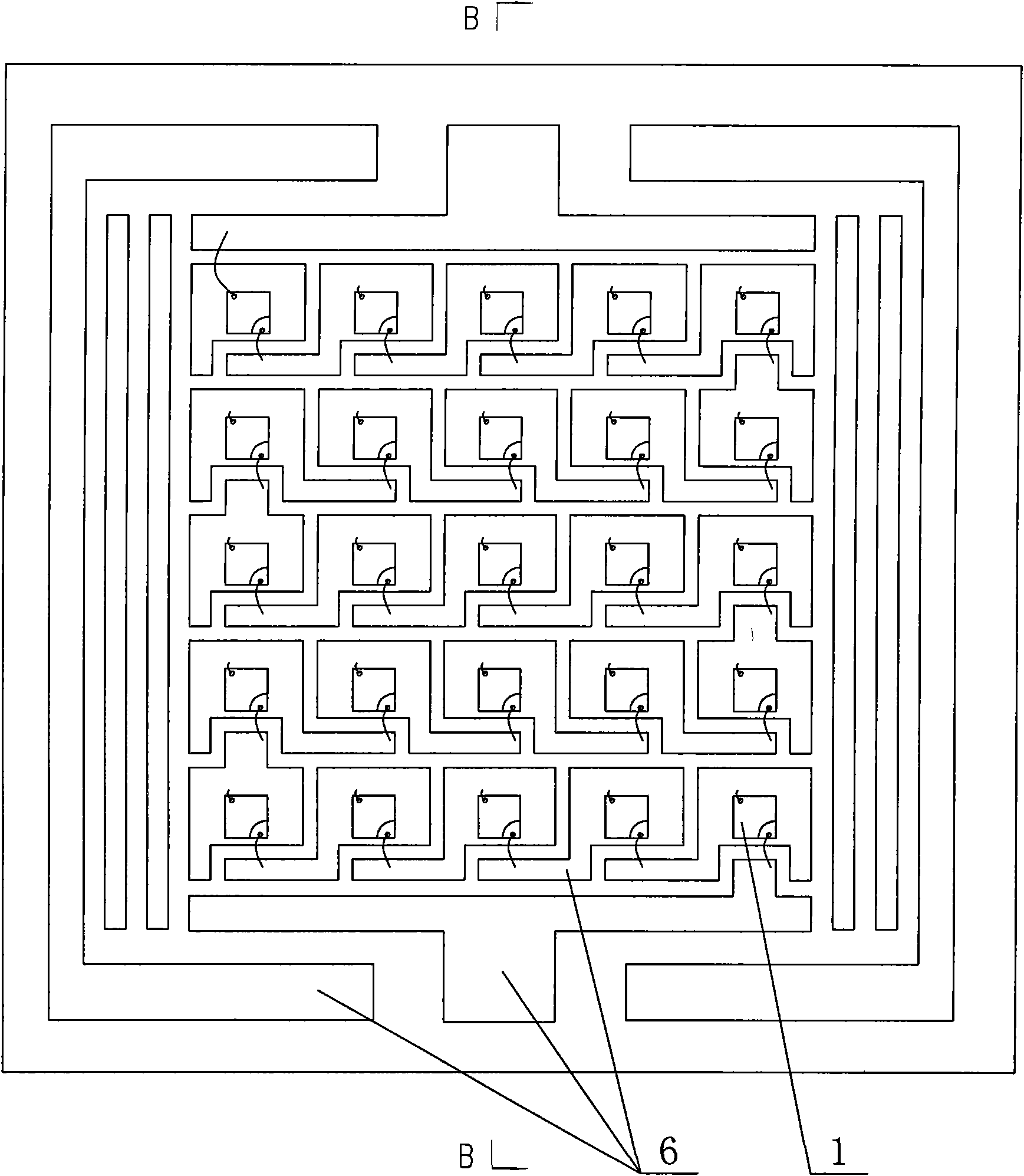

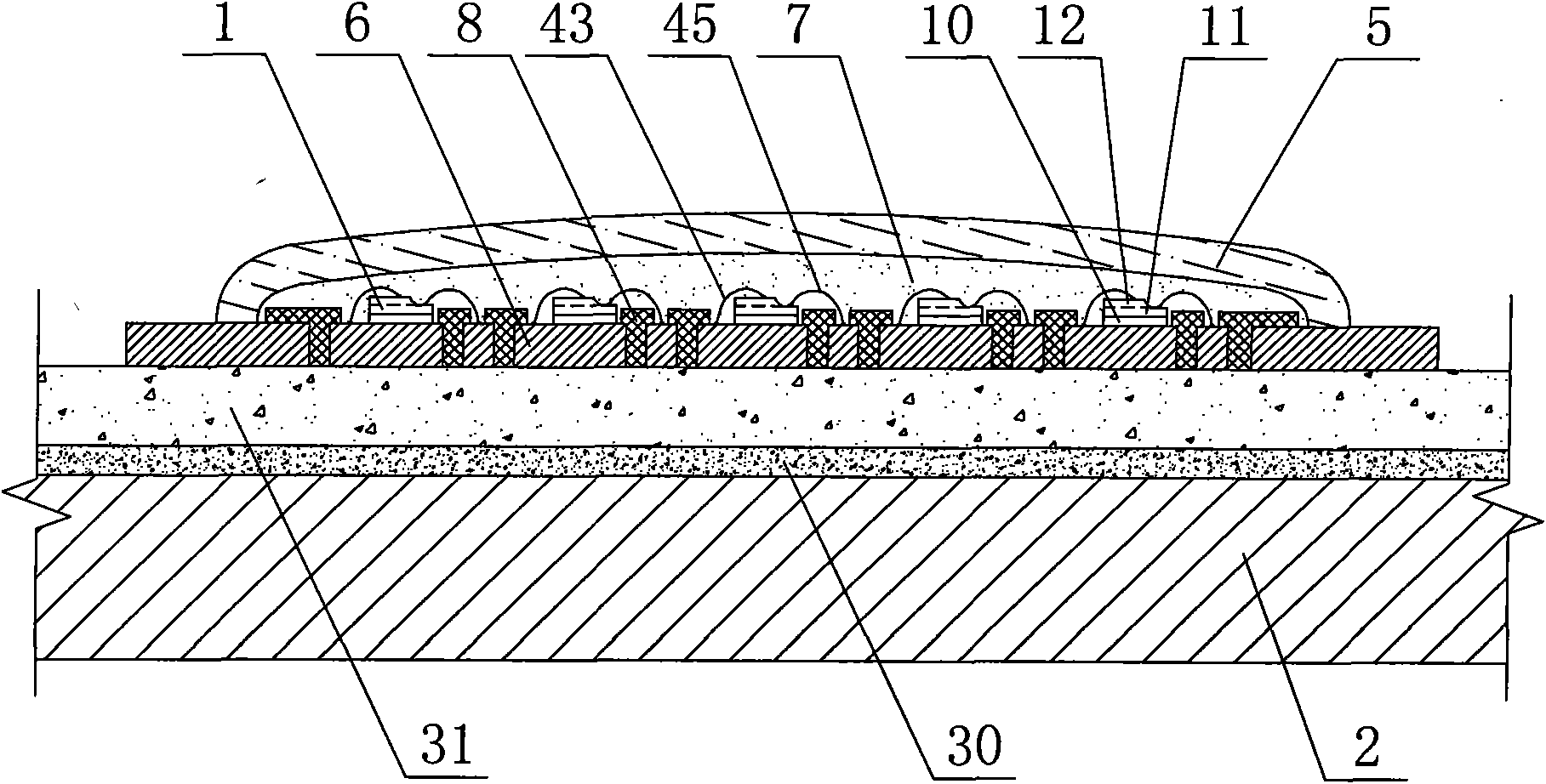

High-efficiency radiating LED illumination light source and manufacture method

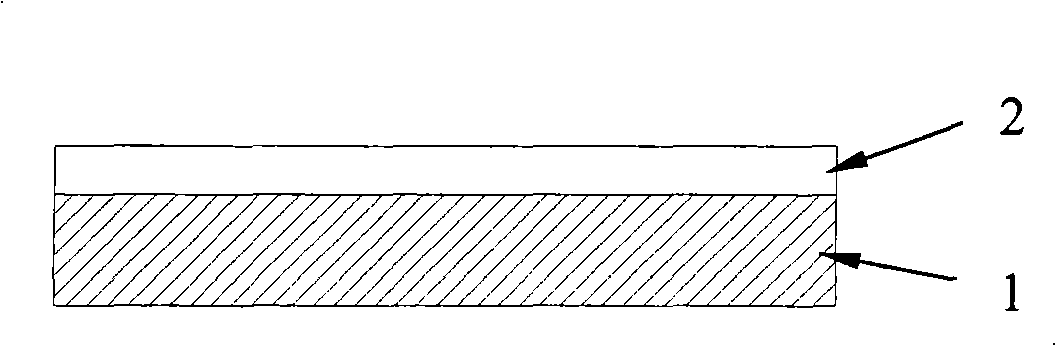

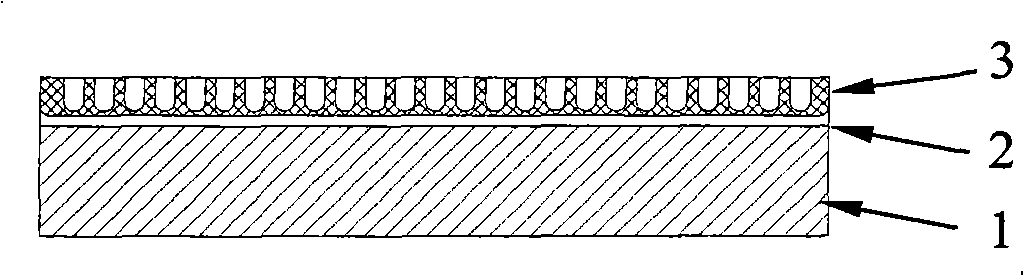

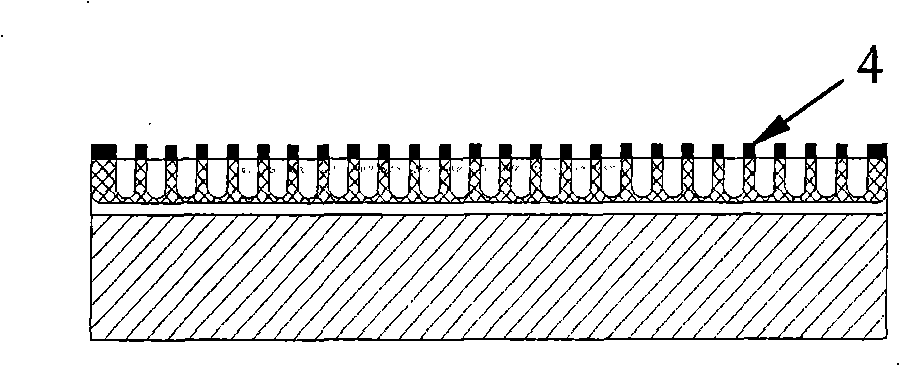

InactiveCN101614333AImprove thermal conductivityPrecise thickness controlPoint-like light sourceElectric circuit arrangementsOptoelectronicsSilicon dioxide

The invention discloses a high-efficiency radiating LED illumination light source with low cost, good radiating effect, high production efficiency and high manufacture precision and a manufacture method. The high-efficiency radiating LED illumination light source comprises LED bare chips (1) and a metal substrate (2), wherein a heat conduction insulating layer is deposited on the metal substrate (2); metal layers (6) are deposited on the heat conduction insulating layer; the metal layers (6)are covered by a welding prevention layer (8); the heat conduction insulating layer is combined by a silicon dioxide layer (30) or a silicon nitride (31) or the combination of the silicon dioxide layer (30) and the silicon nitride (31); a preset circuit connection and a preset figure are formed on each metal layer (6) according to the serial connection and parallel connection relation of the LED bare chip (1); the LED bare chips (1) are divided into a plurality of groups and are mounted on each metal layer (6) normally or inversely; and the LED bare chips (1) in each group and the LED bare chips in the plurality of groups are connected through the metal layers (6) to form circuits. The manufacture method comprises the steps of pretreatment of the metal substrate, formation of the heat conduction insulating layer, the metal layers and the welding prevention layer as well as the encapsulation of the LED bare chips.

Owner:NANKER GUANGZHOU SEMICON MFG

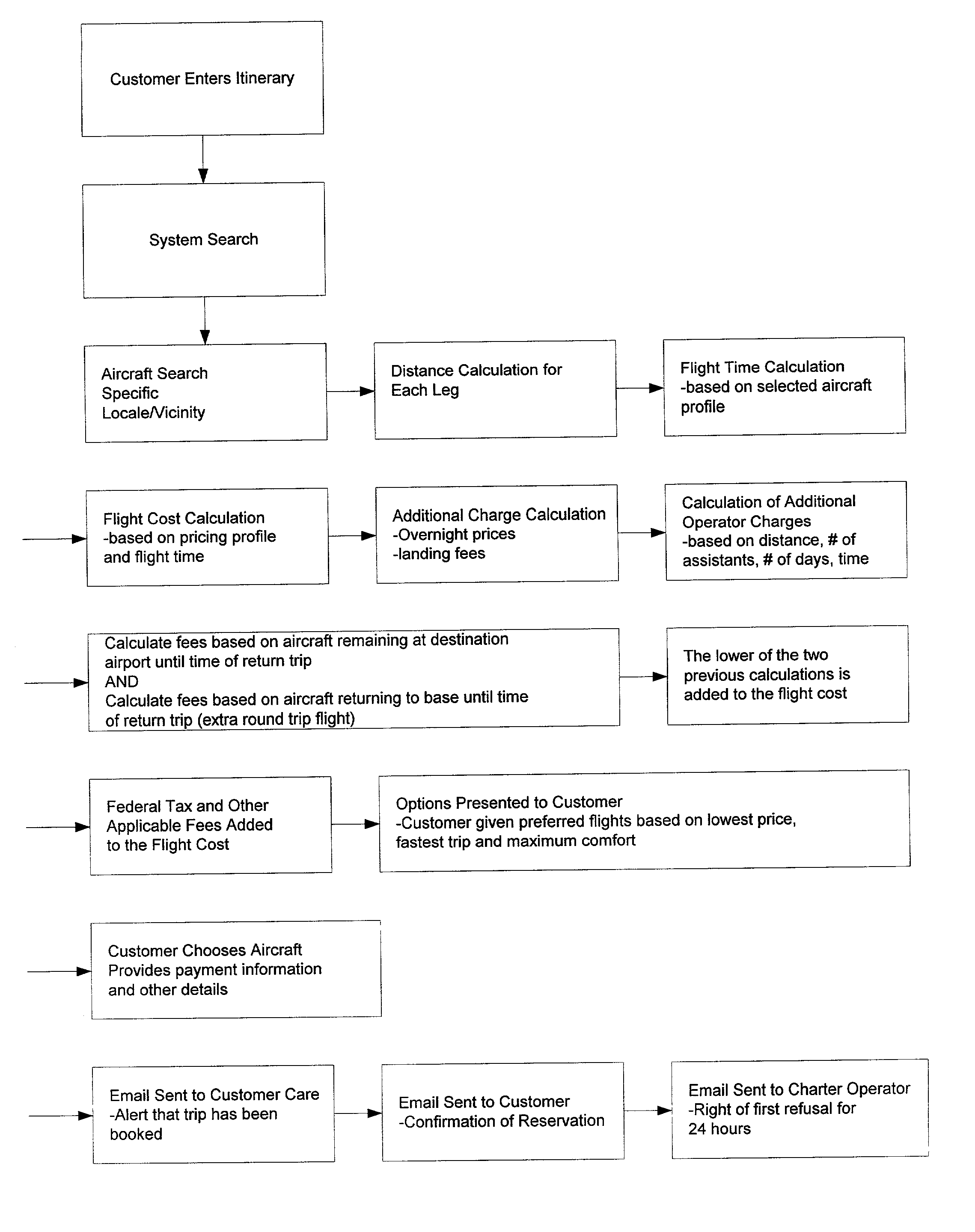

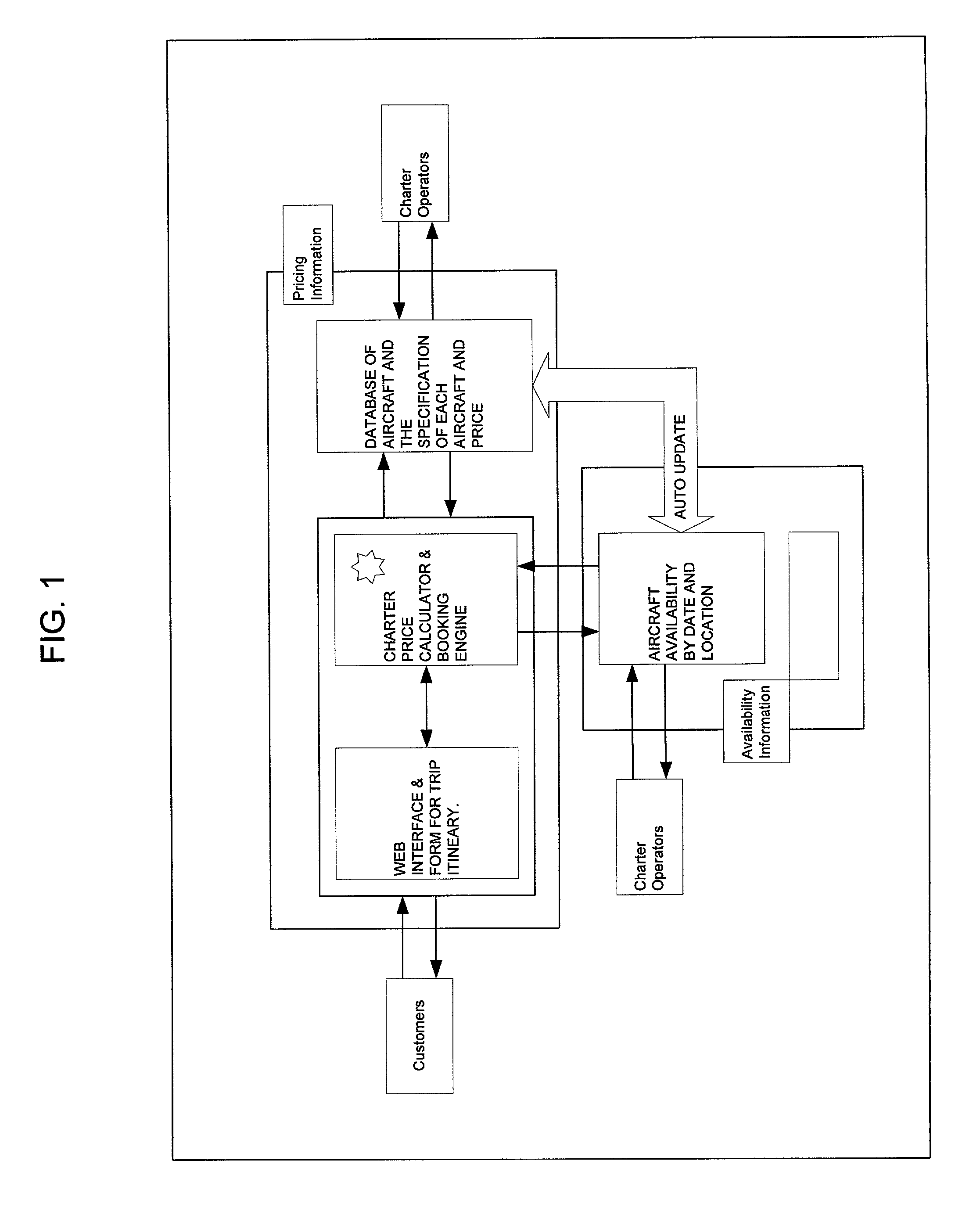

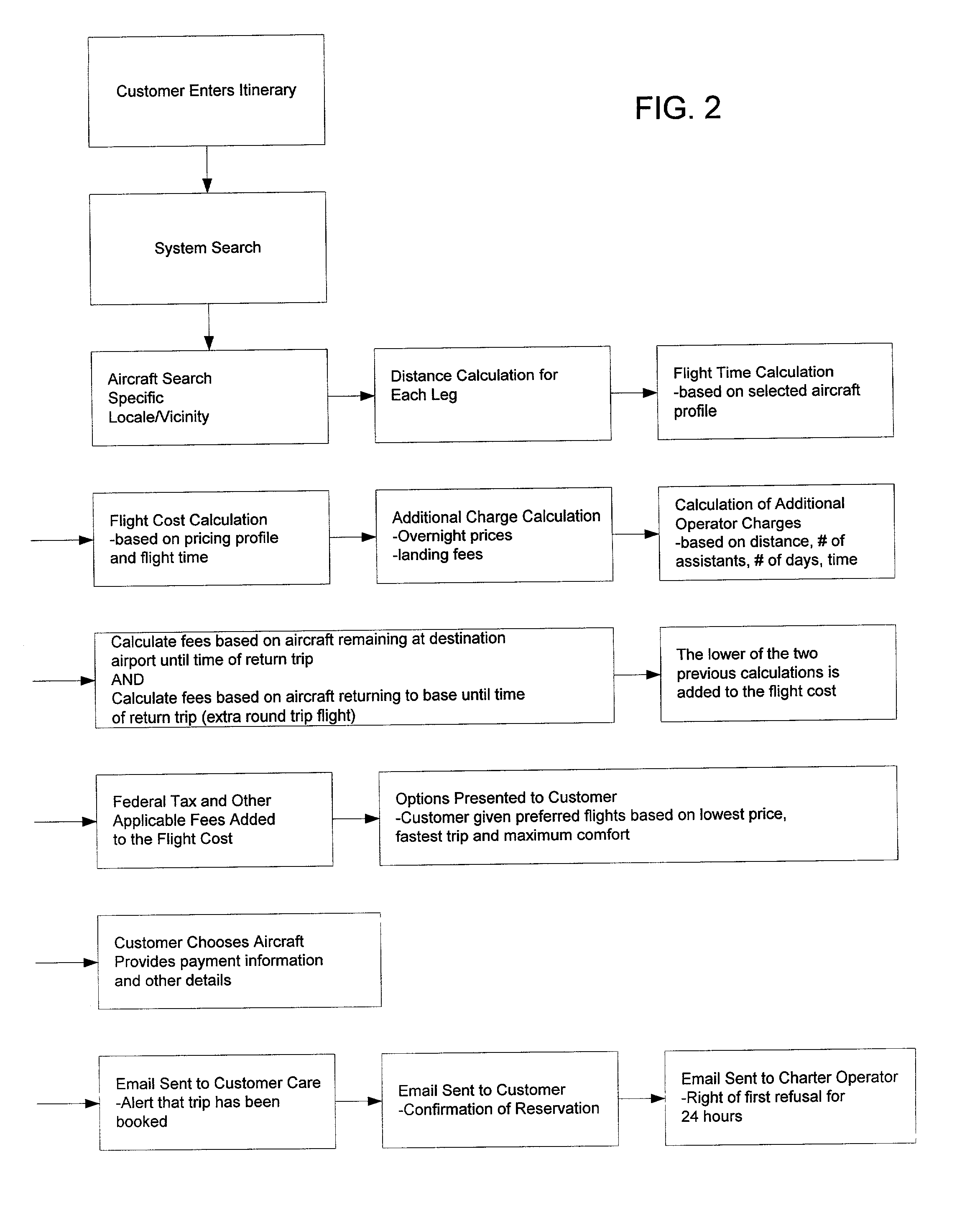

Method and system for reserving air charter aircraft

InactiveUS7124089B2Quickly and easily reserveQuick costReservationsPoint-of-sale network systemsAerospace engineeringLayover

The present invention is a method and system for pricing and reserving charter aircraft. In a preferred embodiment, itinerary information is received, via computer, from a user and is compared with information contained in maintained databases to identify charter aircraft suitable for accommodating the user. The system then determines a charter price by calculating total charter prices for each of the suitable charter aircraft. Several factors including flight costs, relocation costs, repositioning costs and layover costs are considered in calculating the total charter prices. Finally, the total charter prices are preferably selectively categorized and transmitted, via computer, to the user who is then able to complete the reservation process. In another preferred embodiment, lowest charter prices are transmitted to the user for alternative charter aircraft travel. In another preferred embodiment, users can engage in either a reverse auction or a real-time auction for available charter aircraft travel.

Owner:FLEXJET LLC

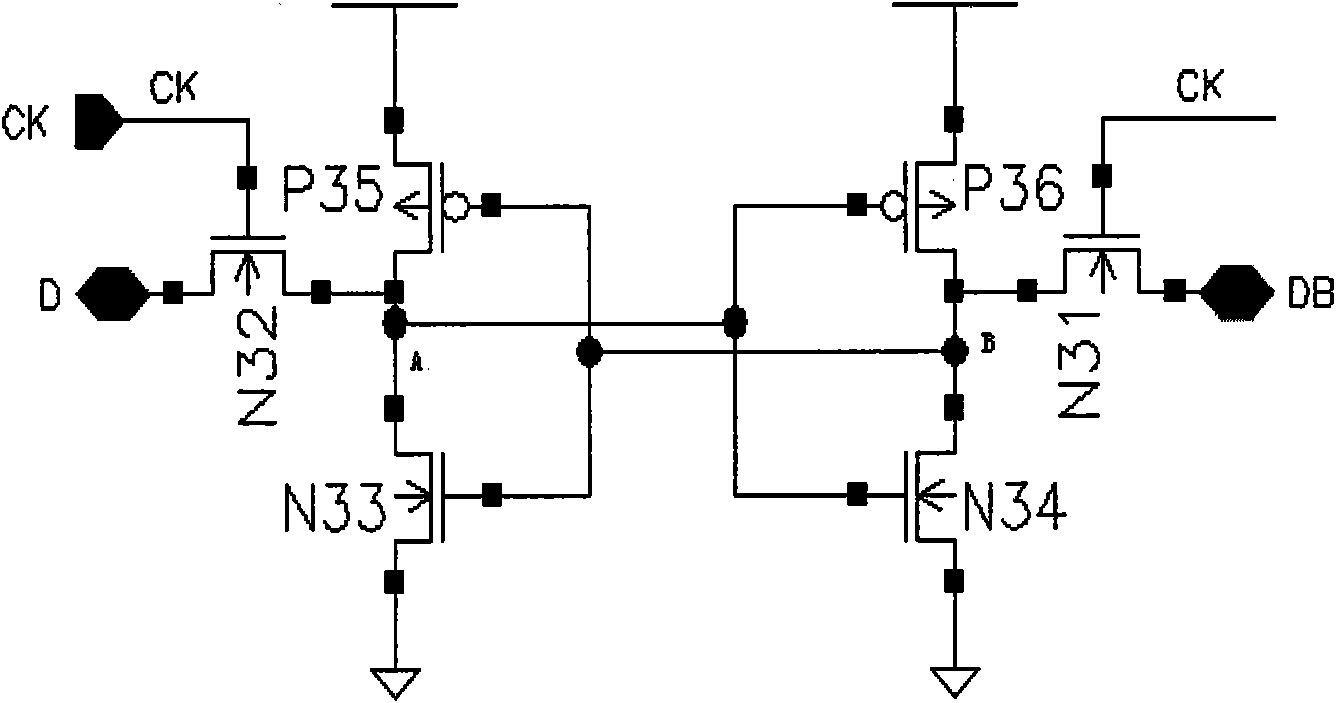

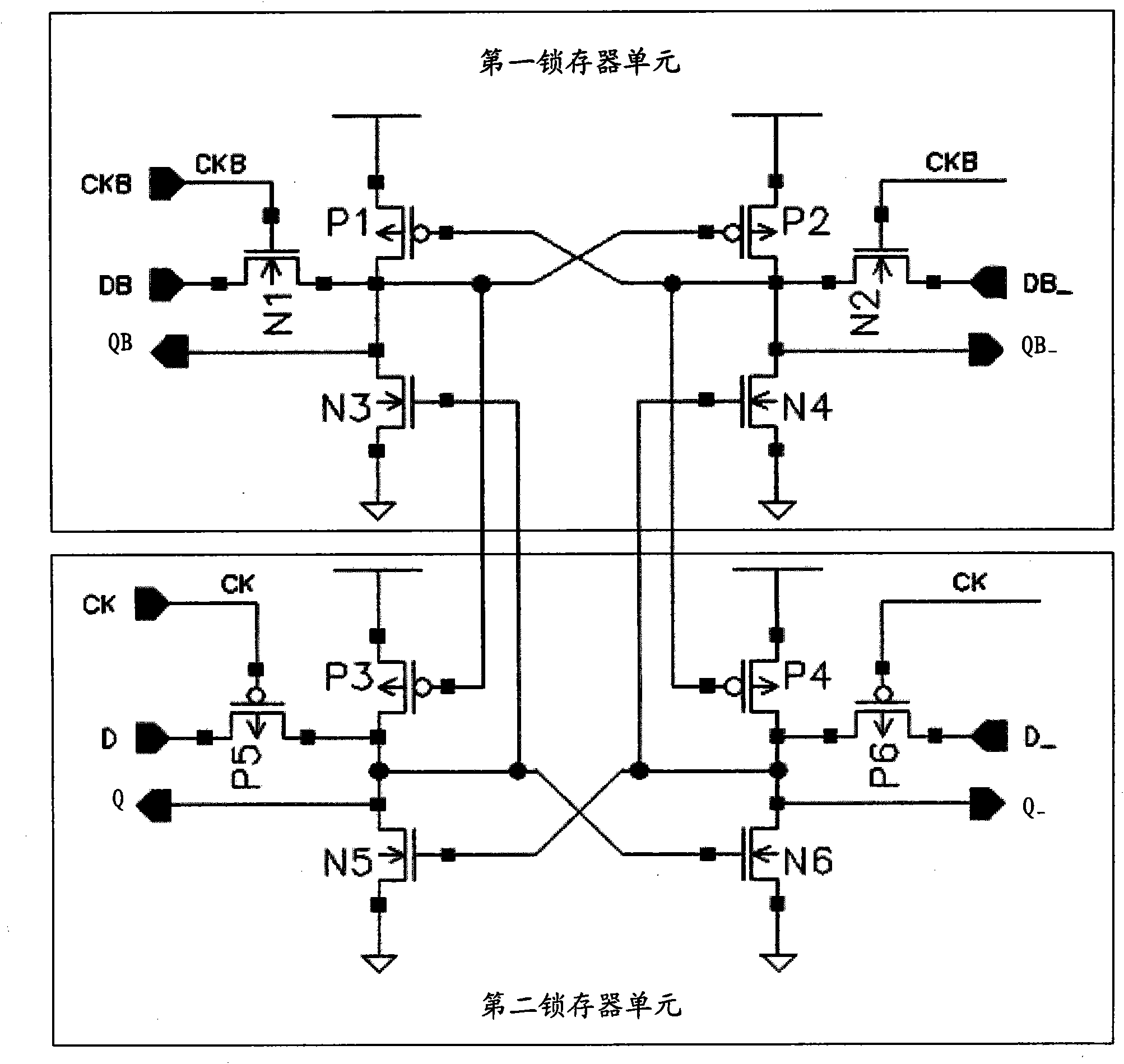

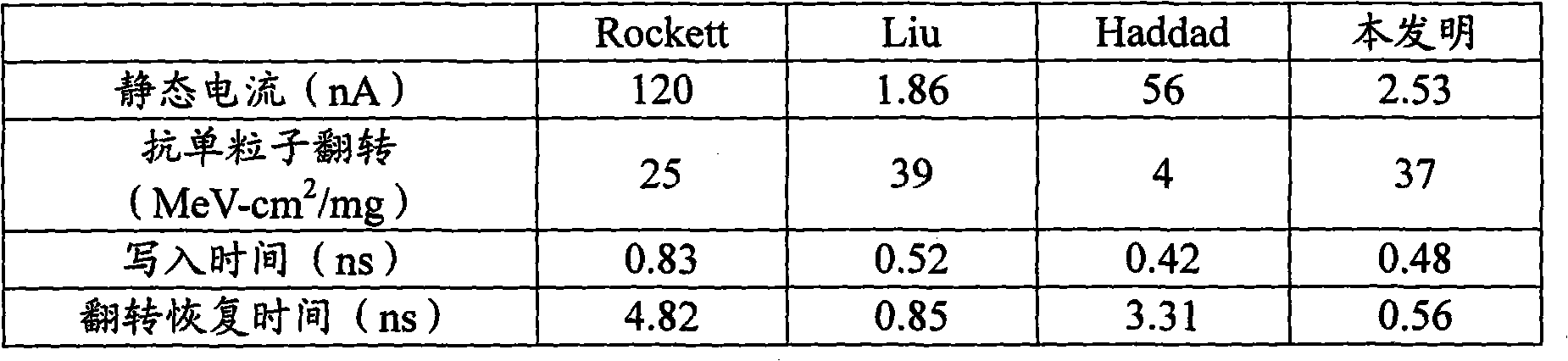

High-speed low-power consumption latch device capable of resisting SEU (single event upset)

The invention is suitable for the field of semiconductor devices and provides a high-speed low-power consumption latch device capable of resisting SEU (single event upset). The latch comprises a first latch unit and a second latch unit, which are cross-coupled, wherein a clock signal of the first latch unit is opposite to the clock signal of the second latch unit; a data signal of the first latch unit is opposite to the data signal of the second latch unit; when a stored data value at a sensitive point of the first latch unit upsets, the stored data value at the sensitive point of the first latch unit is recovered by the second latch unit through feedback; and when the stored data value at the sensitive point of the second latch unit upsets, the stored data value at the sensitive point of the second latch unit is recovered by the first latch unit through feedback. In the invention, a redundancy storage node is introduced in the high-speed low-power consumption latch device capable of resisting SEU under a common process condition, and when a node upsets, the voltage of the node can be recovered from other nodes through feedback.

Owner:SHENZHEN STATE MICROELECTRONICS CO LTD

Agricultural organic fertilizer and preparation method thereof

The invention discloses agricultural organic fertilizer. The agricultural organic fertilizer consists of the following raw materials in percentage by weight: 30-45 parts of fowl manure, 15-25 parts of cow dung, 12-25 parts of pig manure, 10-13 parts of peat soil, 15-20 parts of straw ash, 8-10 parts of sawdust, 2-4 parts of formic acid, 5-8 parts of animal bone meal, 6-8 parts of egg shell powder, 3-5 parts of gypsum powder, 2-4 parts of calcium hydrogen phosphate and 0.5-0.8 part of an EM inoculant. Furthermore, the invention discloses a preparation method of the agricultural organic fertilizer. The agricultural organic fertilizer, compared with the prior art, has the following advantages that the agricultural organic fertilizer overcomes shortcomings of chemical fertilizer and conventional agricultural fertilizer, and realizes comprehensive treatment of waste to turn waste into wealth; and the agricultural organic fertilizer can protect soil. The organic fertilizer preparation method is simple and easy to operate, relatively short in fermentation time, wide in raw material source, low in cost, and quite remarkable in both social benefit and economic benefit.

Owner:合肥科友生物科技有限公司

Modified double-component epoxy resin paint

InactiveCN1704454AReduce volatilityLow viscosityEpoxy resin coatingsAntimony trioxideSilicon dioxide

The invention relates to a modified double-component epoxy resin paint, wherein the raw materials of the main ingredients includes bisphenol A epoxy resin, multiple functional group glycide amine epoxy resin and filler selected from silicon dioxide, titanium oxide, antimony trioxide, zinc oxide and calcium carbonate, the raw material of the curing agent includes modified aliphatic polyamines, organic diatomaceous soil and methyl ethylene glycol.

Owner:BEIJING HANTECH BUILDING MATERIALS TECH

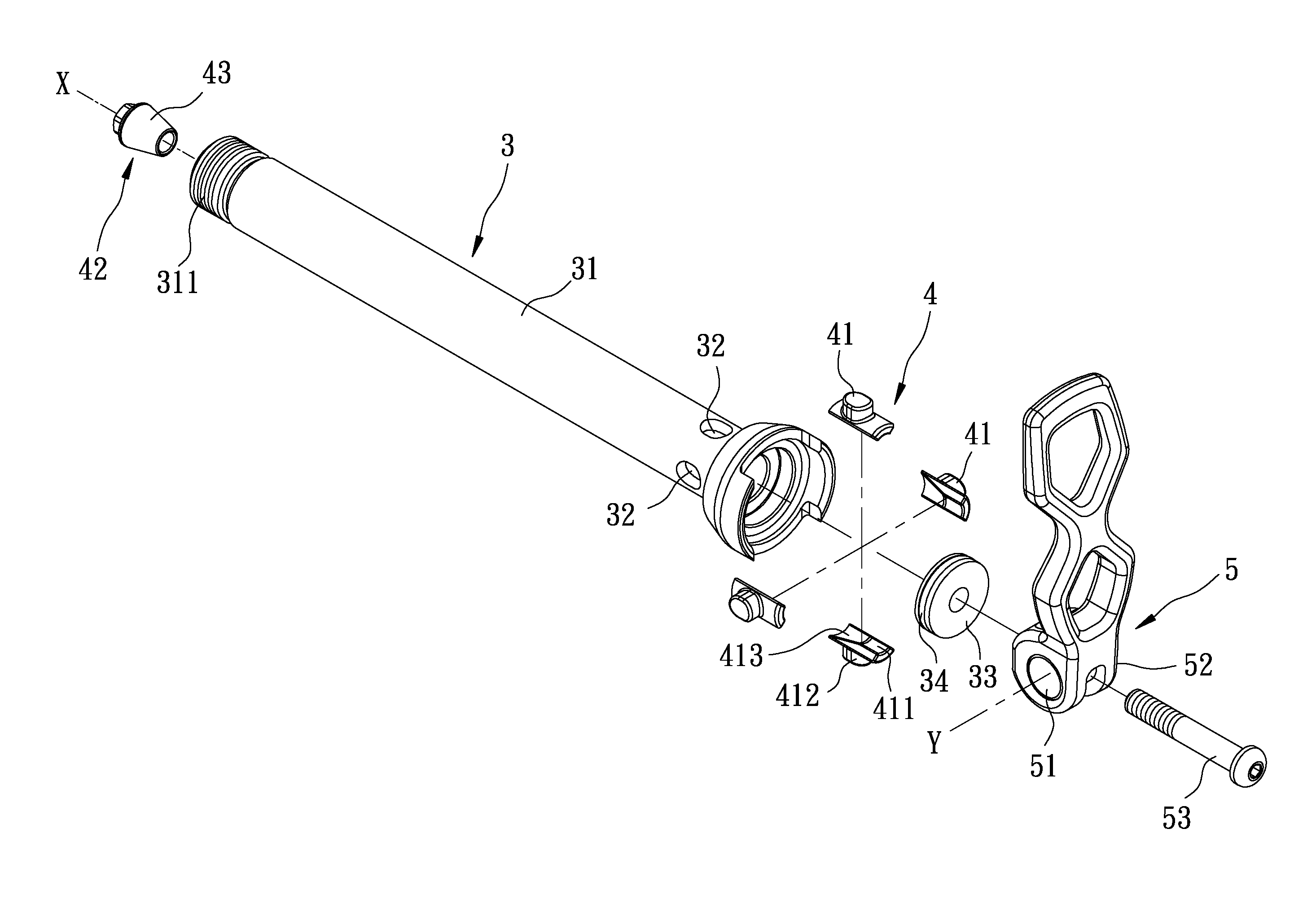

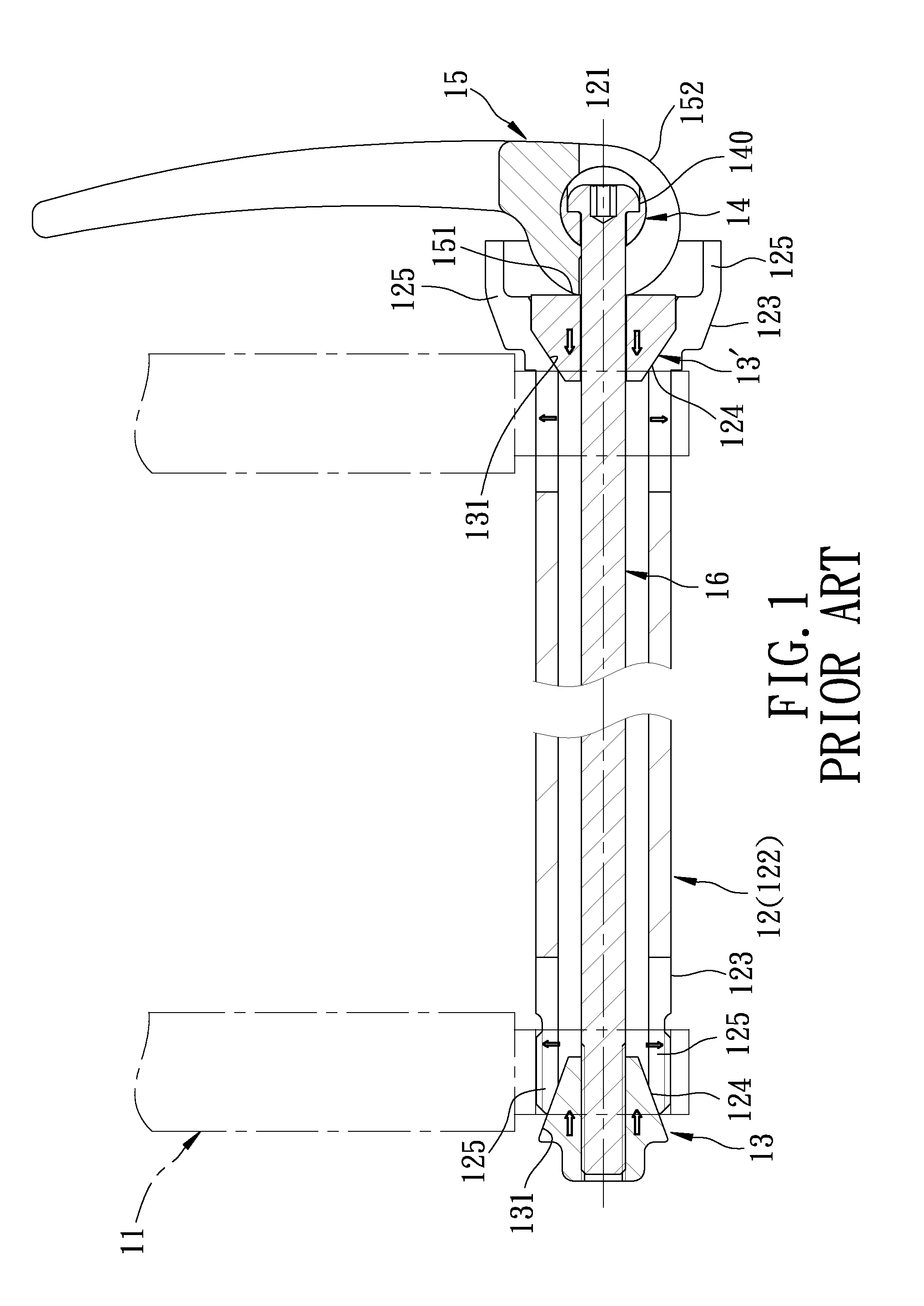

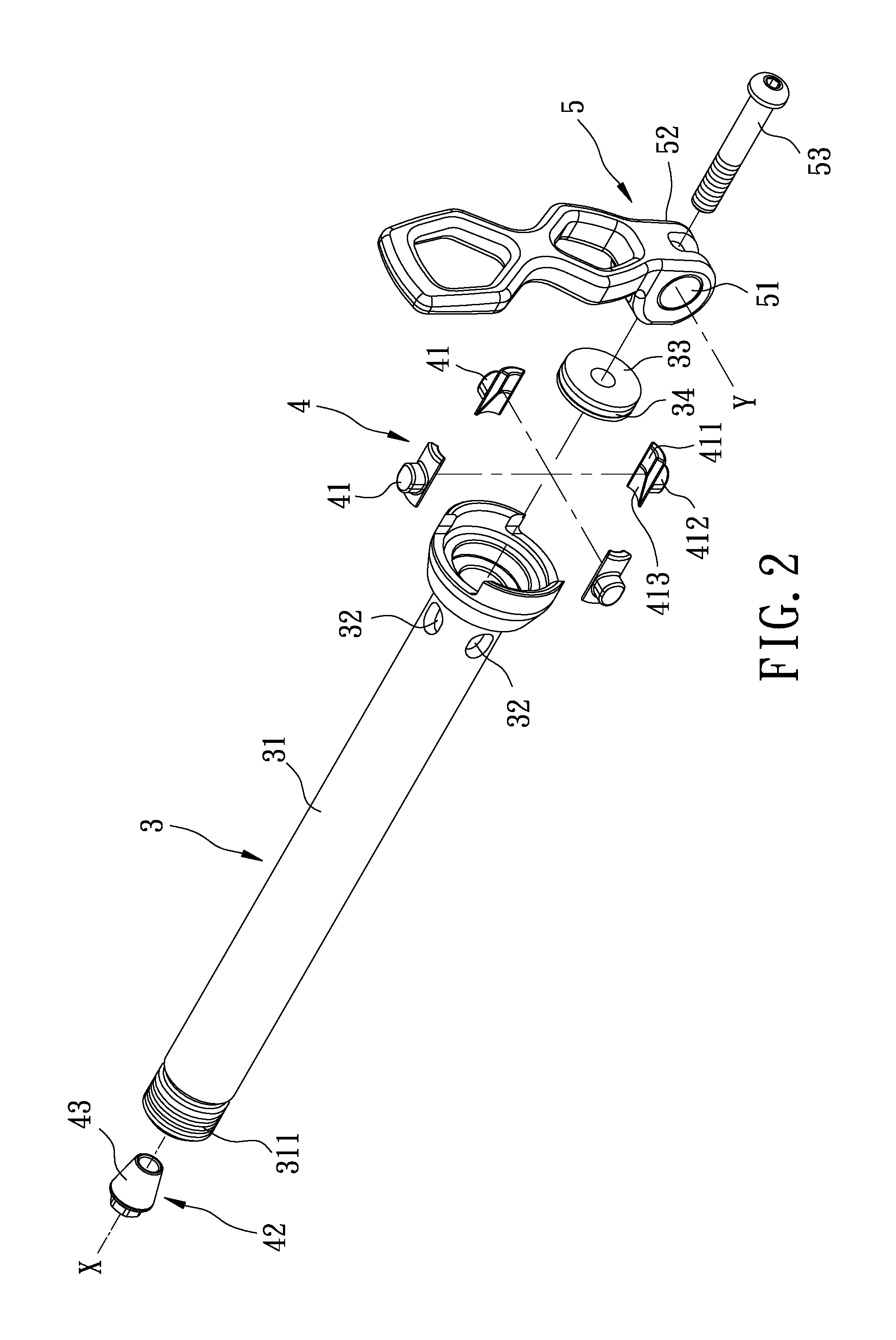

Quick release devices

Owner:APROTECH

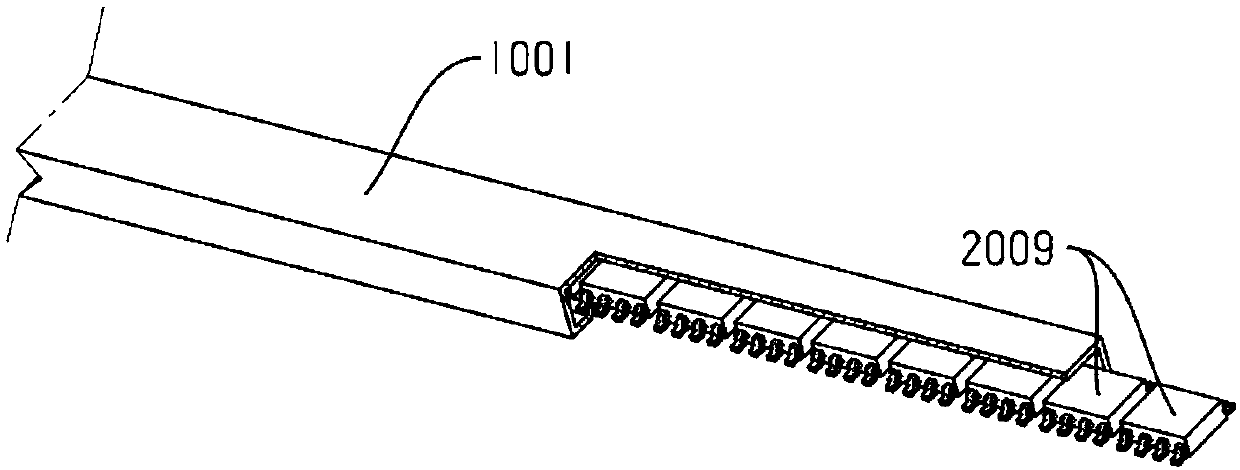

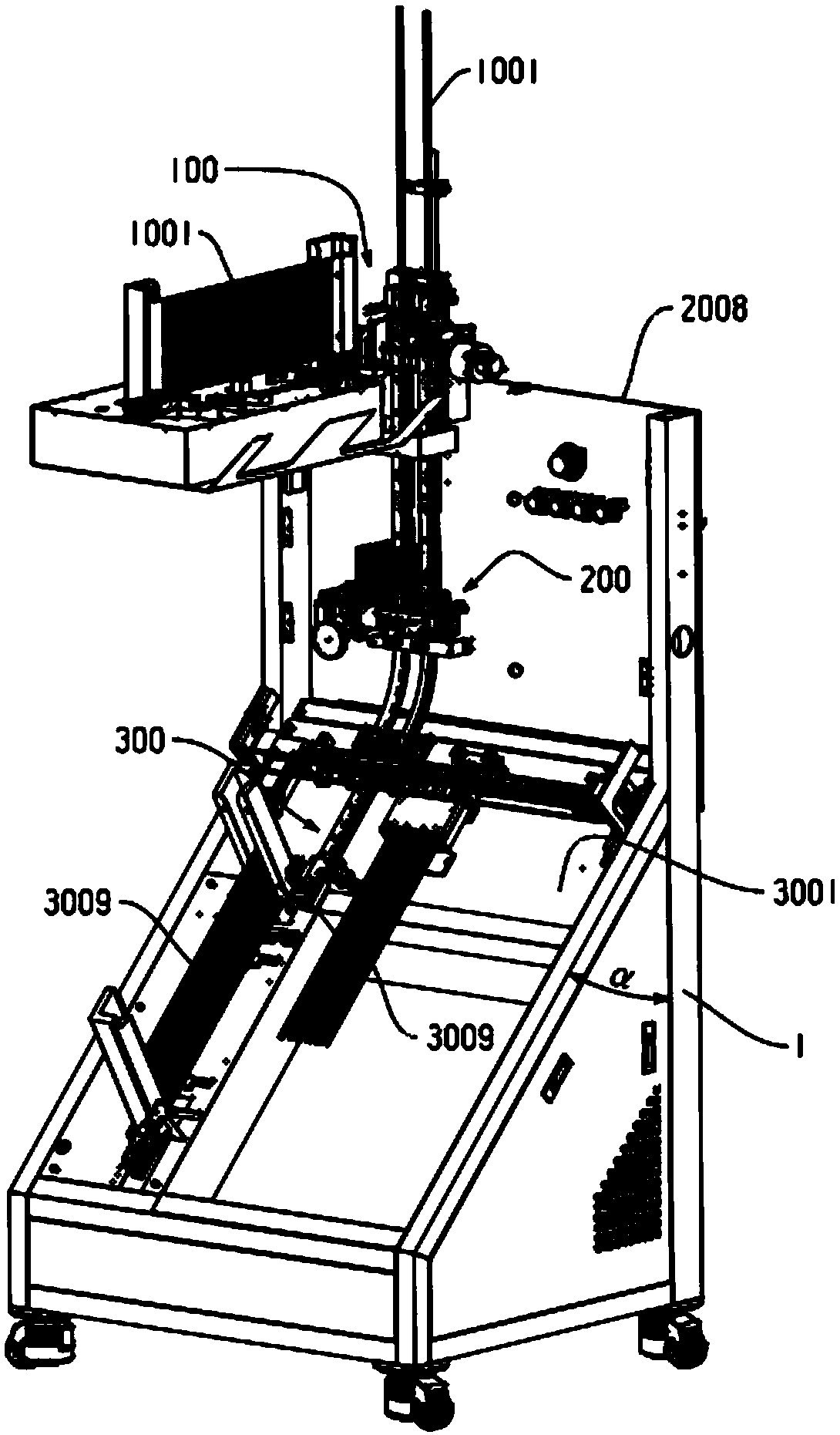

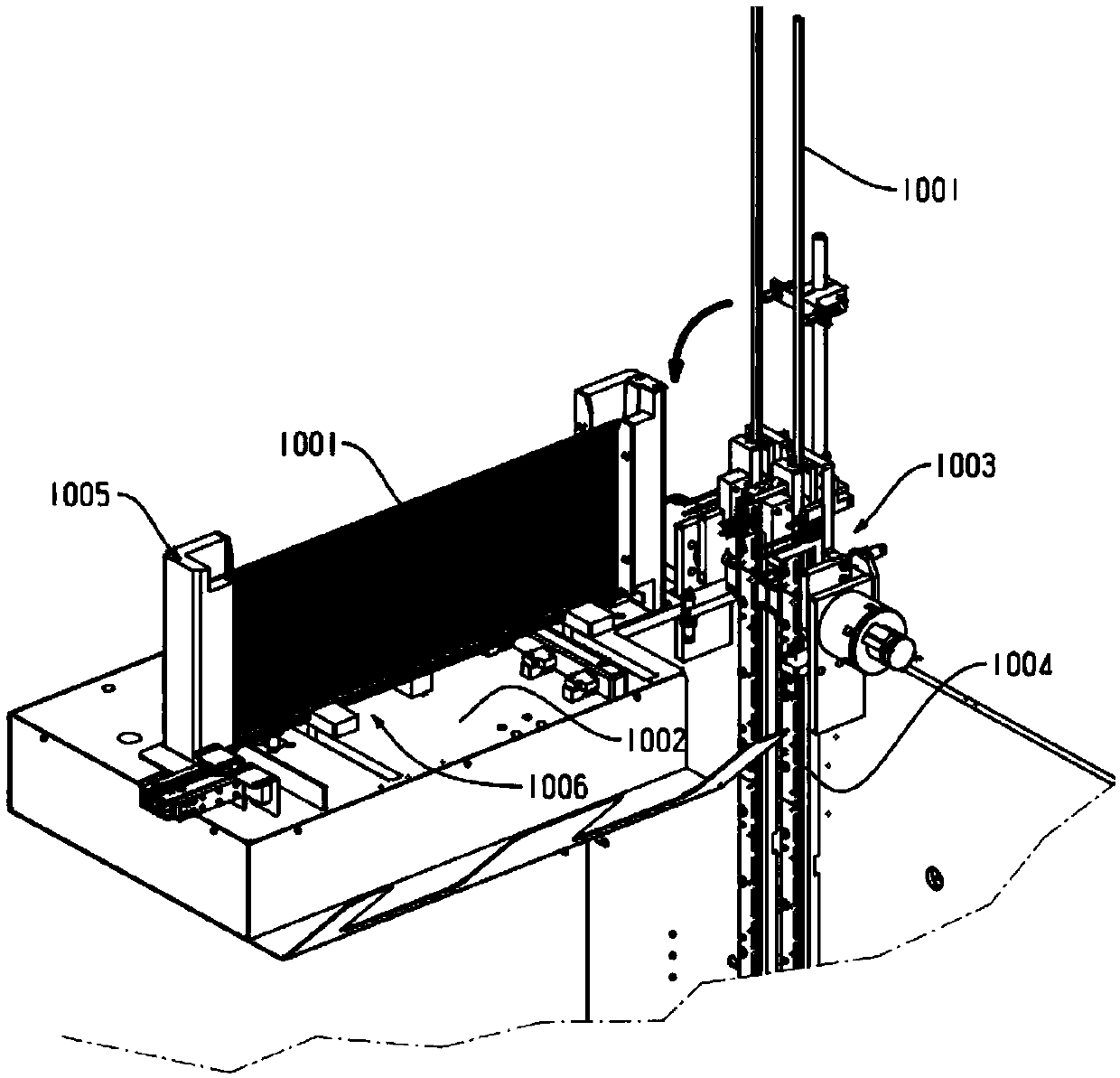

Automatic IC testing and sorting device

The invention discloses an automatic IC testing and sorting device. The device comprises a feeding device, a testing device and a sorting and storing device which are arranged on a machine frame; andthe machine frame comprises a first mounting plate and a second mounting plate, wherein the first mounting plate is vertically arranged, and the second mounting plate is connected with the bottom of the first mounting plate and is obliquely arranged. An IC material tube is clamped on the feeding device, IC chips which are not tested in the IC material tube are supplied to the testing device for testing through the feeding device, after the testing is finished, the chips are classified through the sorting and storing device and are stored in a plurality of empty material tubes. According to thedevice, a clamping mechanism with the IC material tube clamped is turned over, so that the IC material tube is changed into a vertical state, and the IC chips in the IC material tube slide out and get to a vertical material channel; the IC chips can be controlled by a blocking and pressing mechanism to be fed to the testing device one by one, testing chucks clamp the IC chips and push the IC chips to a testing PCB for testing, the IC chips are received through a material receiving table after the test is completed and are classified and placed to a first material storing mechanism or a second material storing mechanism, so that the speed of sorting and storing is increased, and the labor cost is saved.

Owner:昆山宇辰光通自动化科技有限公司

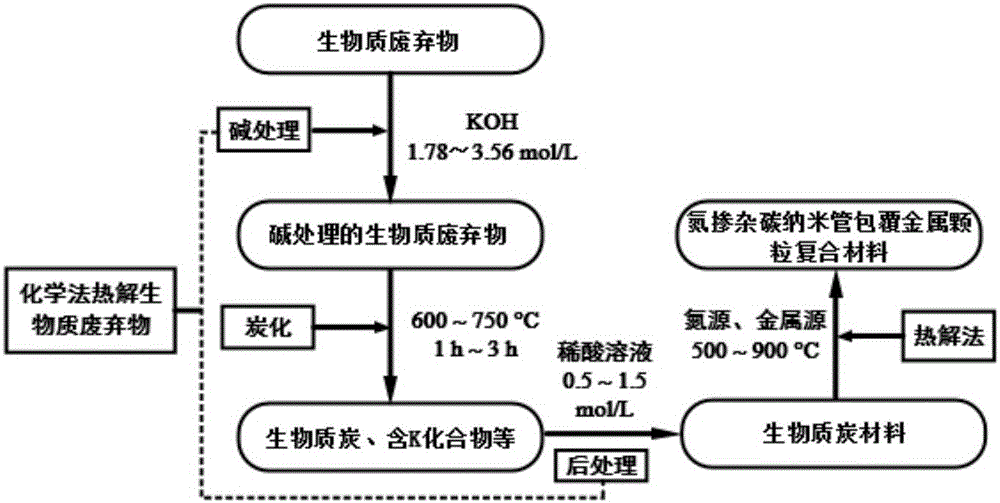

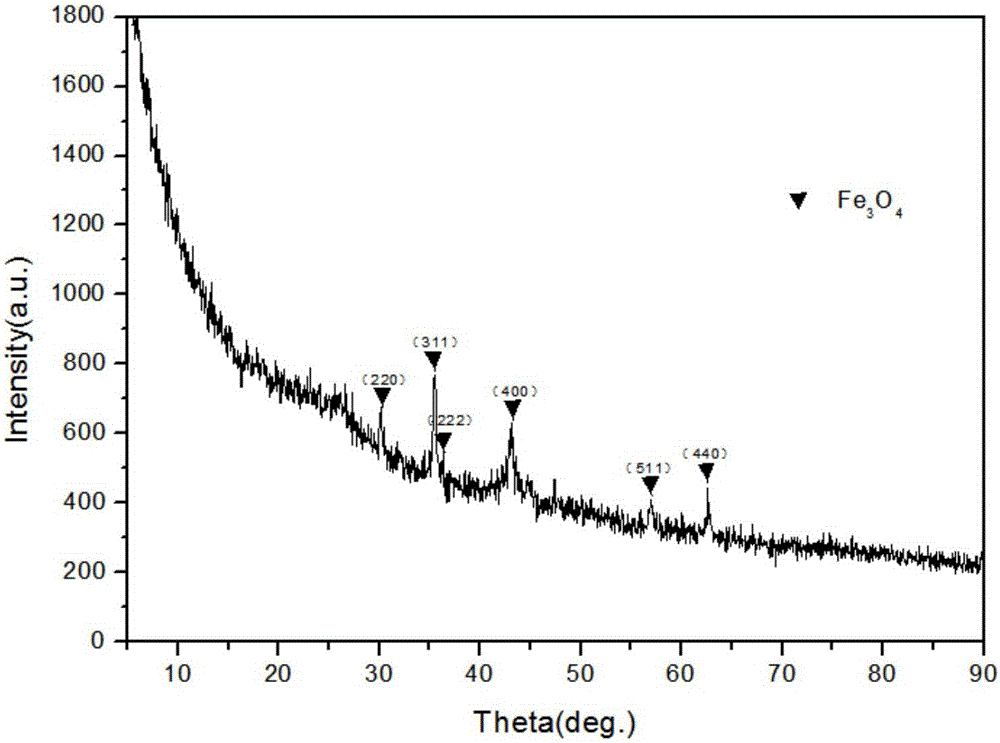

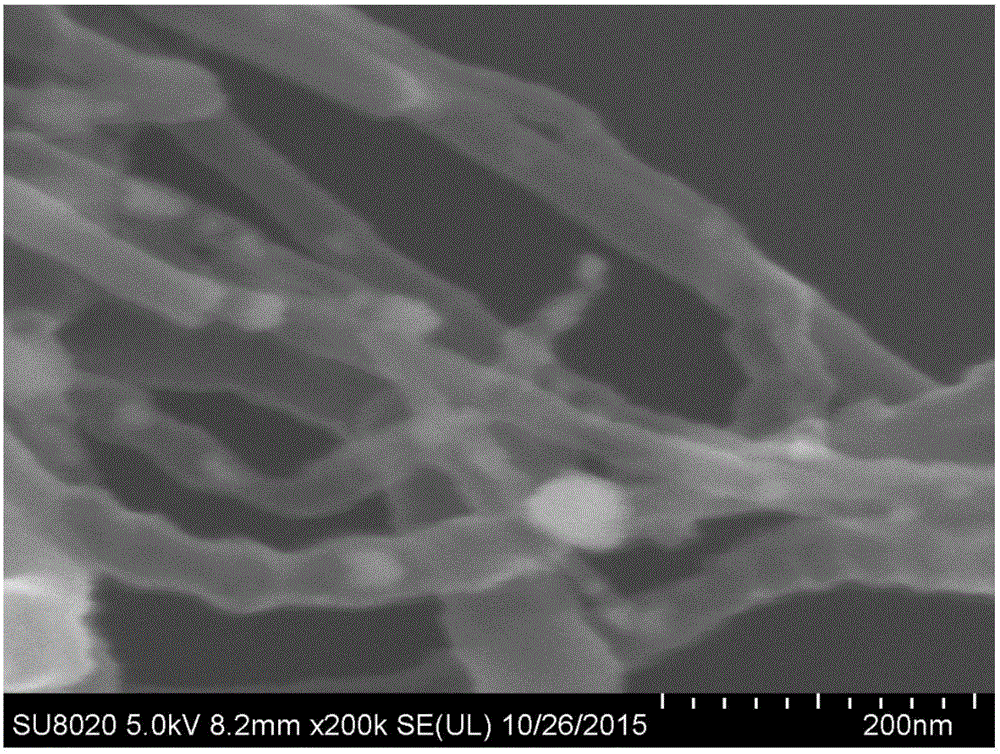

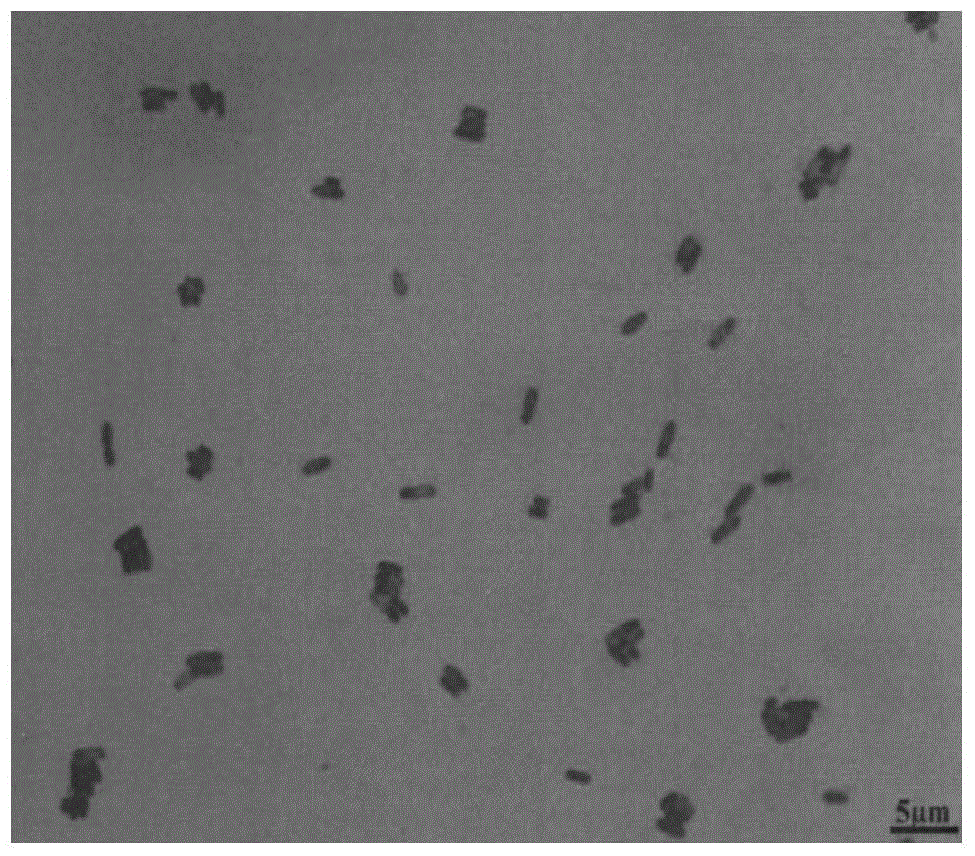

Method for using biomass waste for preparing nitrogen-doped carbon nanotube coated metal particle composite material

ActiveCN105772708AGood dispersionImprove stabilityTransportation and packagingMetal-working apparatusCarbon layerDispersity

The invention discloses a method for using biomass waste for preparing a nitrogen-doped carbon nanotube coated metal particle composite material. The method includes the following steps that firstly, the biomass waste and KOH are evenly mixed in deionized water, an obtained heterogeneous mixture is carbonized under the protection of inert gas, and biomass charcoal is obtained; and then, the biomass charcoal, a nitrogenous nonmetallic compound and water-soluble divalent metal salt are evenly mixed in methyl alcohol, the obtained heterogeneous mixture is subjected to pyrolysis under the protection of the inert gas, and therefore a target product is obtained. By the adoption of the method, a two-step pyrolysis technology is adopted for achieving growth of carbon nanotubes, and dispersion of metal nanoparticles and formation of a cooperative acting mechanism are promoted; the stability of the composite material is reinforced through the structure of carbon nanotube coated metal nanoparticles; the surface activity and dispersity of a carbon layer are improved through in-situ decoration of the nitrogen element; and the contact and active site point number is increased through the formation of a rich pore structure and the high specific surface area.

Owner:安徽皖瑞能源科技有限公司

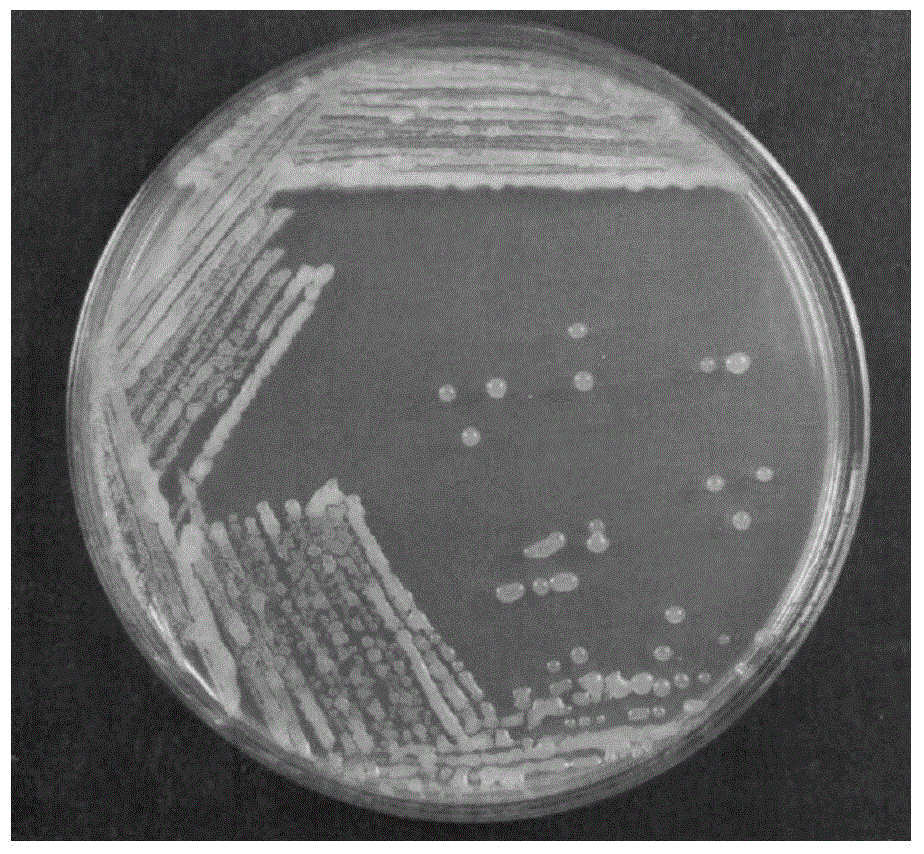

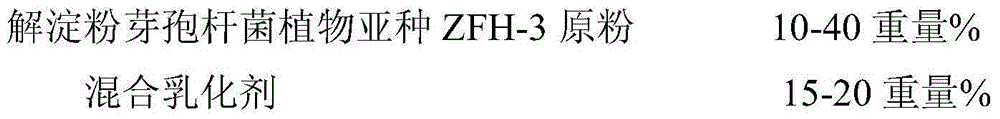

Bacillus amyloliquefaciens plant subspecies ZFH-3 microbial agent and application thereof

ActiveCN104630121AStrong growth adaptabilityEasy to colonizeBiocideBacteriaPathogenBacillus amyloliquefaciens

The invention relates to a bacillus amyloliquefaciens plant subspecies ZFH-3 microbial agent and application thereof and belongs to the field of plant protection and disease prevention and treatment. The microbial agent per g contains 2*10<10>-1.2*10<11>cuf bacillus amyloliquefaciens plant subspecies ZFH-3 living spores, and the ZFH-3 strain is classified and named Bacillus amyloliquefaciens subsp.Plantarum, wherein the collection number is CGMCC No. 9884. The agent has a remarkable inhibiting effect on various pathogens of crops, shows a relatively good preventing and treating effect on prevention and treatment of soil-borne diseases and can effectively prevent and treat soil-borne diseases of vegetables, so that the loss is damaged and the field efficacy is over 59%. The microbial agent is non-toxic and safe to human bodies, replaces chemical agents for preventing and treating soil-borne diseases, conditioning soil and promoting plant growth, and has a good application prospect.

Owner:GUANGDONG GEOLONG BIOTECH

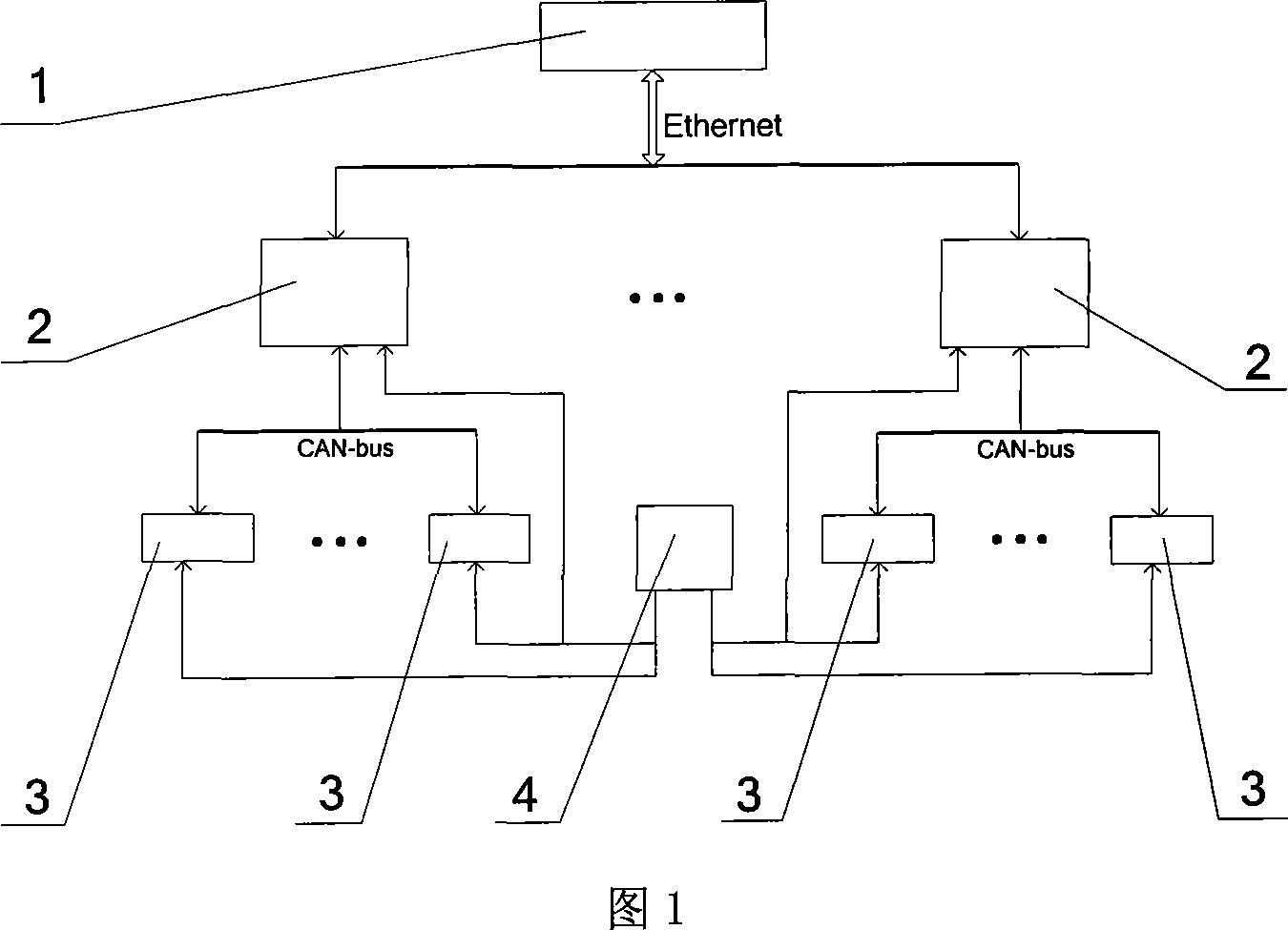

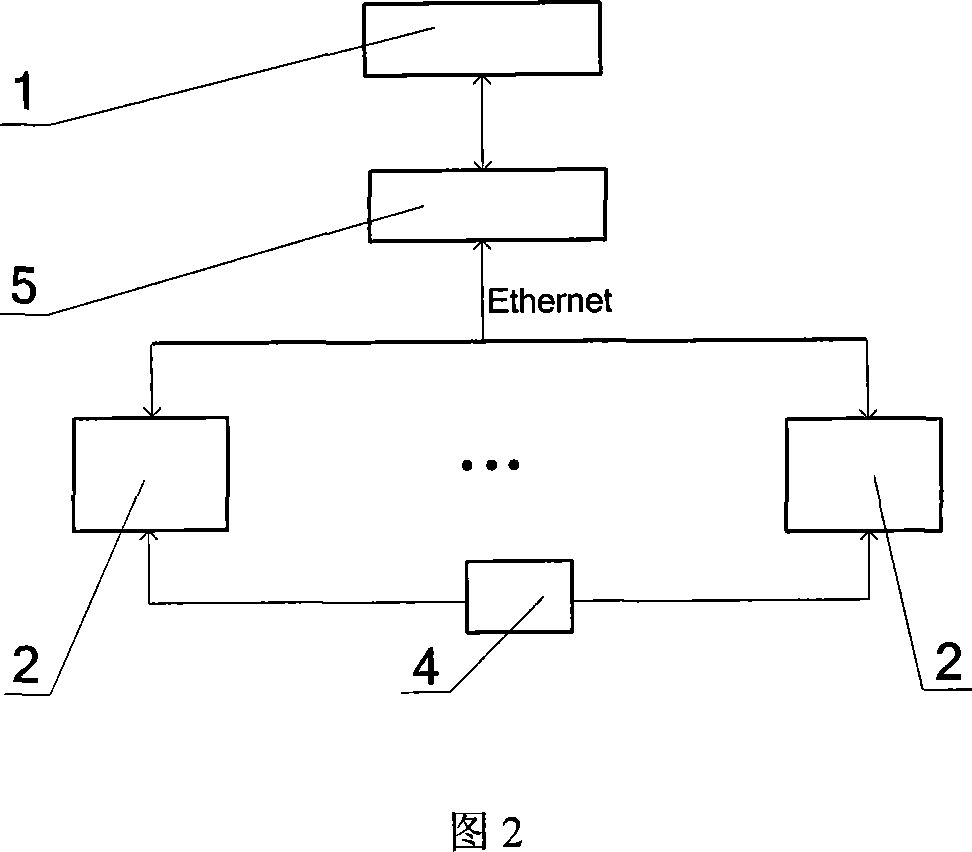

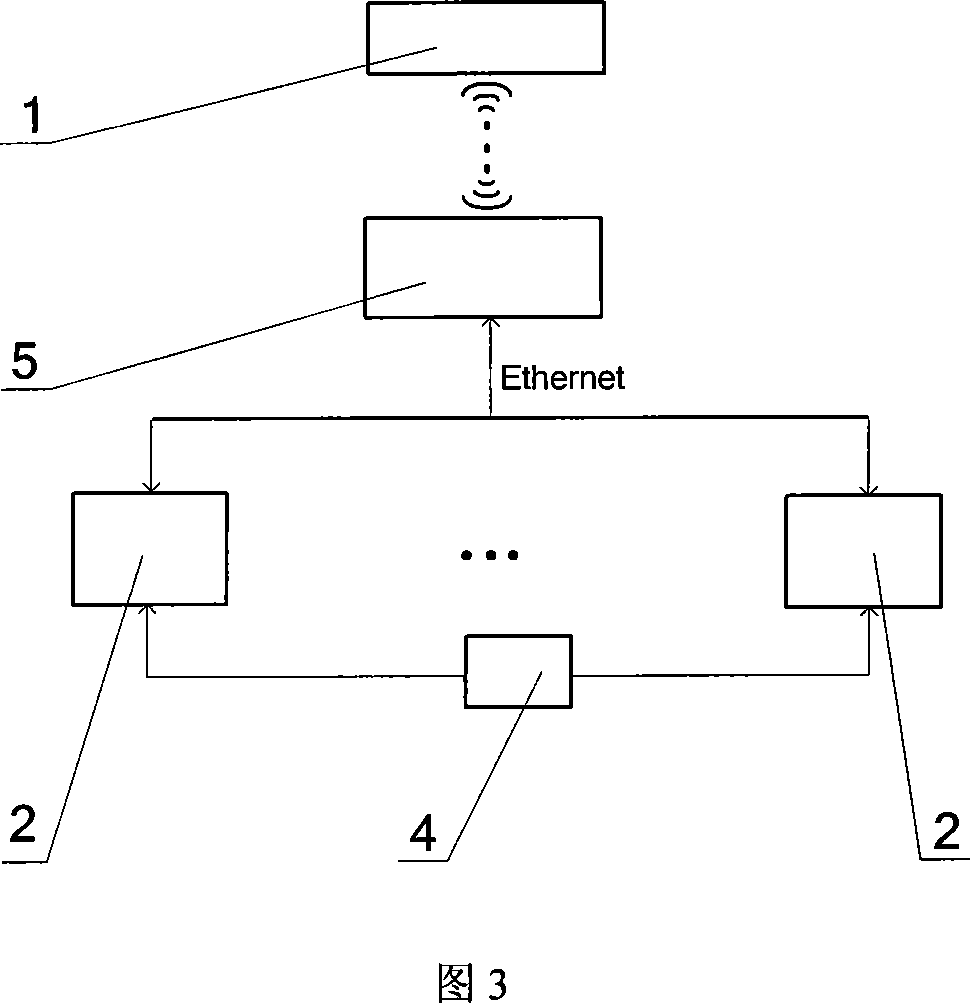

Distribution multiple freedom robot controlling system

InactiveCN101045297AIncrease opennessSimple structureProgramme-controlled manipulatorModularityMulti degree of freedom

A distributed control system for one or more multi-freedom robots features that an industrial computer is connected via Ethernet to one or more multi-freedom robot movement plan controllers A, which is connected via CAN-bus to one or more DSP-based modular robot' s individual joint controllers B, and a DC power supply is connected with one or more said controller A and controllers B.

Owner:WUHAN UNIV OF SCI & TECH

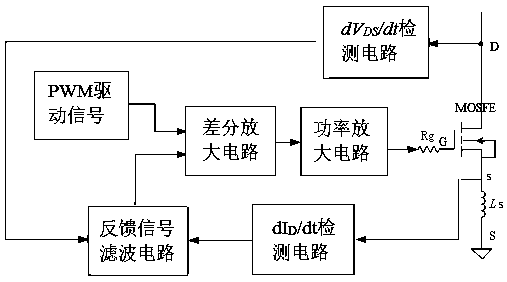

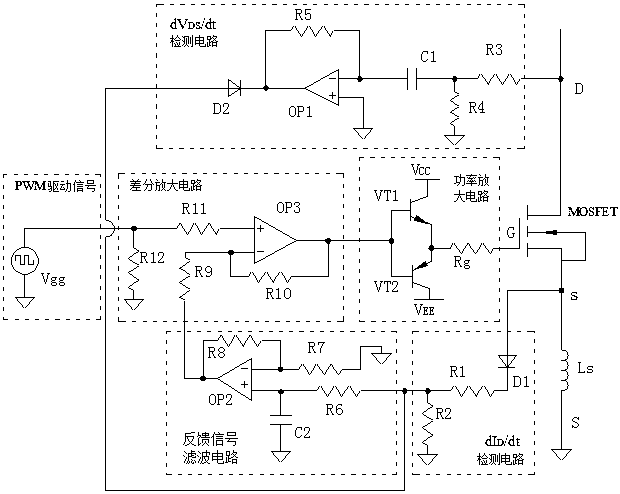

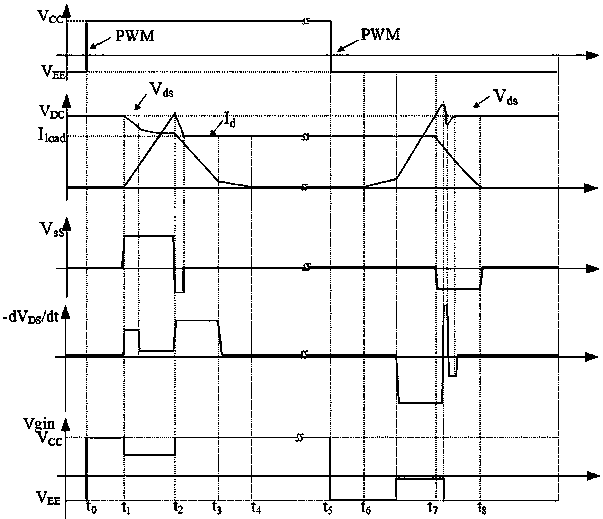

Active driving circuit for SiC power device of electric vehicle motor controller

InactiveCN110401331ASimple structureLow costTransistorEfficient power electronics conversionElectric vehicleDrain current

The present invention provides an active driving circuit for a SiC power device of an electric vehicle motor controller. The active driving circuit comprises a dID / dt detecting circuit, a dVDS / dt detecting circuit, a feedback signal filtering circuit, a differential amplifying circuit and a power amplifying circuit. The differential amplifying circuit is connected with the gate of a SiC power device through the power amplifying circuit, the differential amplifying circuit is connected with a pulse generator Vgg to input a PWM drive signal; the feedback signal filtering circuit is connected with the differential amplifying circuit, the dID / dt detecting circuit is connected between the source of the SiC power device and the feedback signal filtering circuit, and the dVDS / dt detecting circuitis connected between the drain of the SiC power device and the feedback signal filtering circuit. The drain current change rate and the drain-source voltage change rate are directly fed back to the drive signal input end to modulate the drive signal, the current rising phase in the turn-on process and the voltage rising phase of the turn-off stage are independently controlled, a simple simulationcircuit is adopted to achieve, and therefore, the active driving circuit for the SiC power device of the electric vehicle motor controller is high in applicability, simple in implementation, low in cost and good in control effect.

Owner:HUNAN UNIV +1

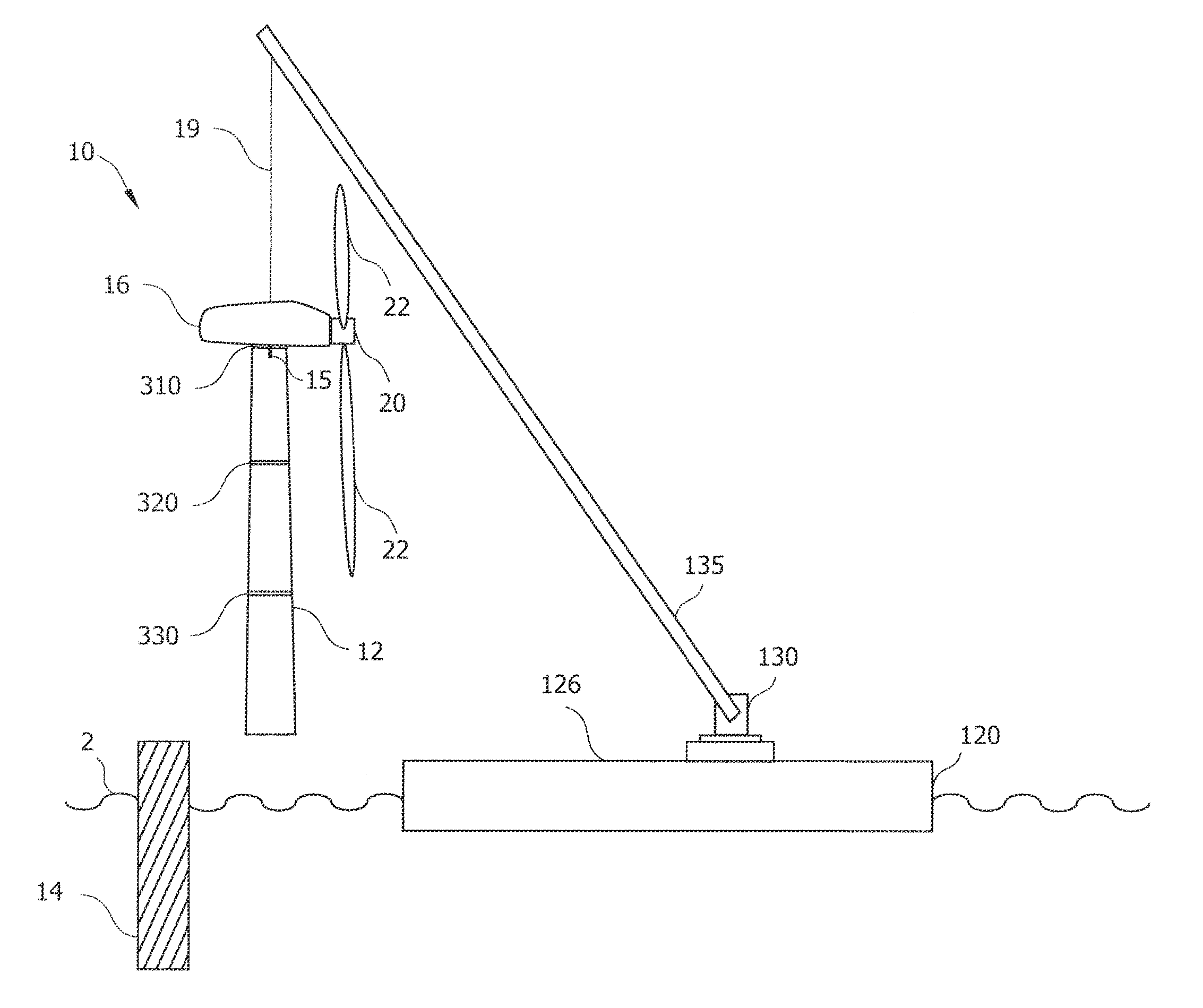

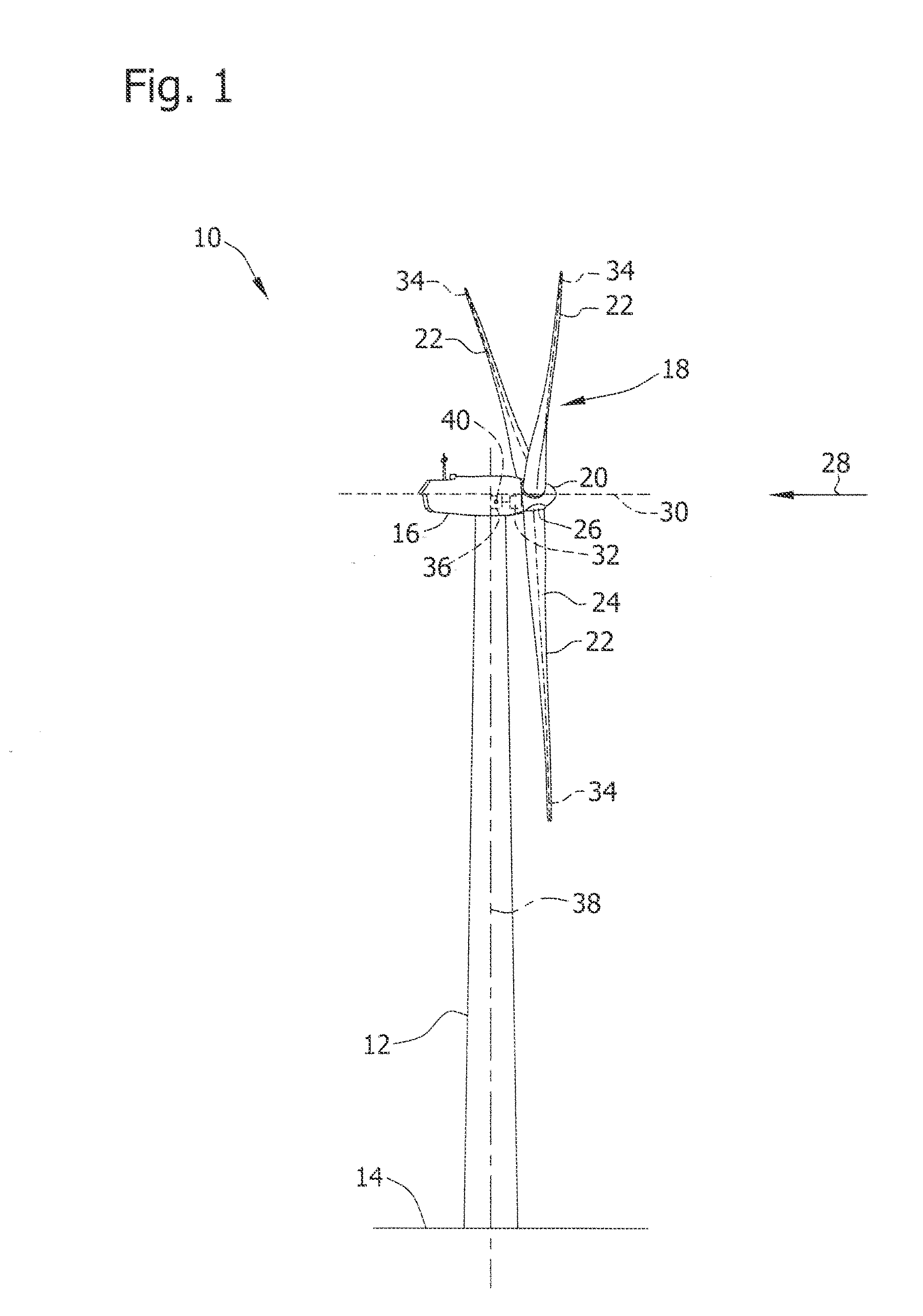

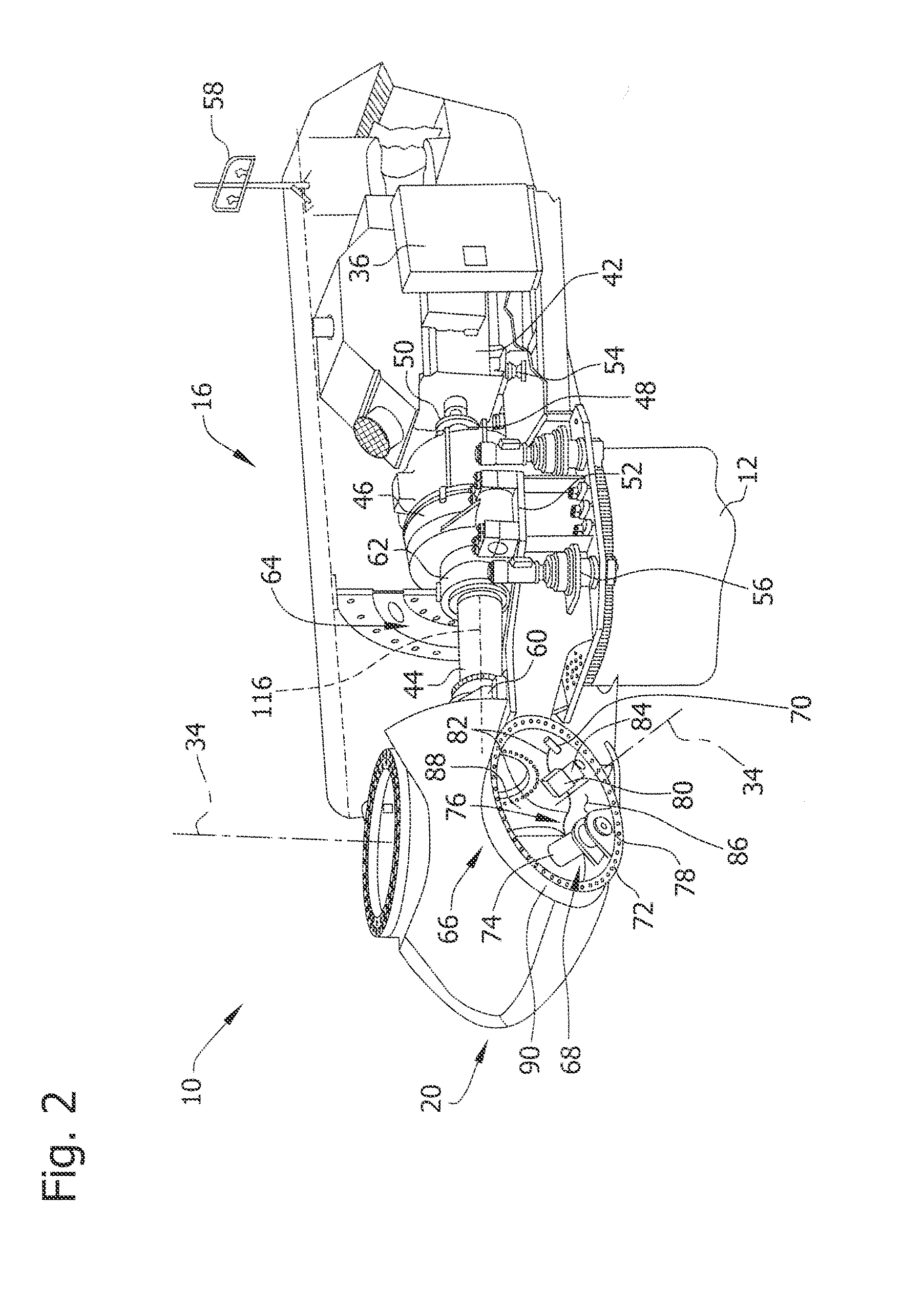

Hoisting nacelle and tower

According to the present disclosure, a method for hoisting one or more tower sections (12, 25) of a wind turbine (10) or one or more tower sections (12, 25) of a wind turbine (10) preassembled to a nacelle (16), wherein the one or more tower sections (12, 25) include an uppermost flange (310, 320, 330, 340), is provided. The method includes: attaching one or more linking elements (19) to the one or more tower sections (12, 25) at or below the uppermost flange (310, 320, 330, 340); and hoisting the one or more tower sections (12, 25) of a wind turbine (10) or one or more tower sections (12, 25) of a wind turbine (10) preassembled to the nacelle (16) using a hoisting machine (130) that is connected with the one or more tower sections (12, 25) by the one or more linking elements (19).

Owner:GENERAL ELECTRIC CO

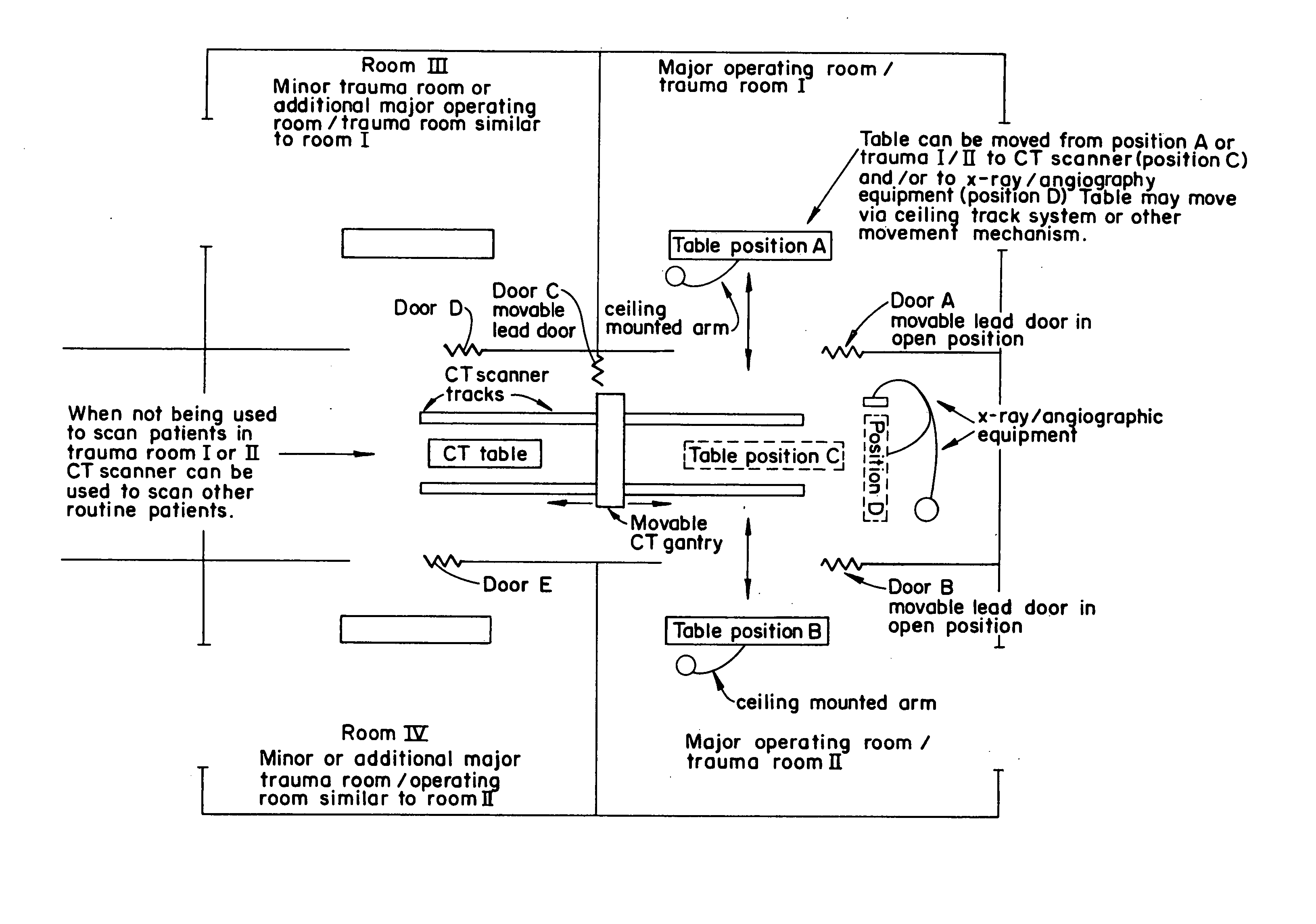

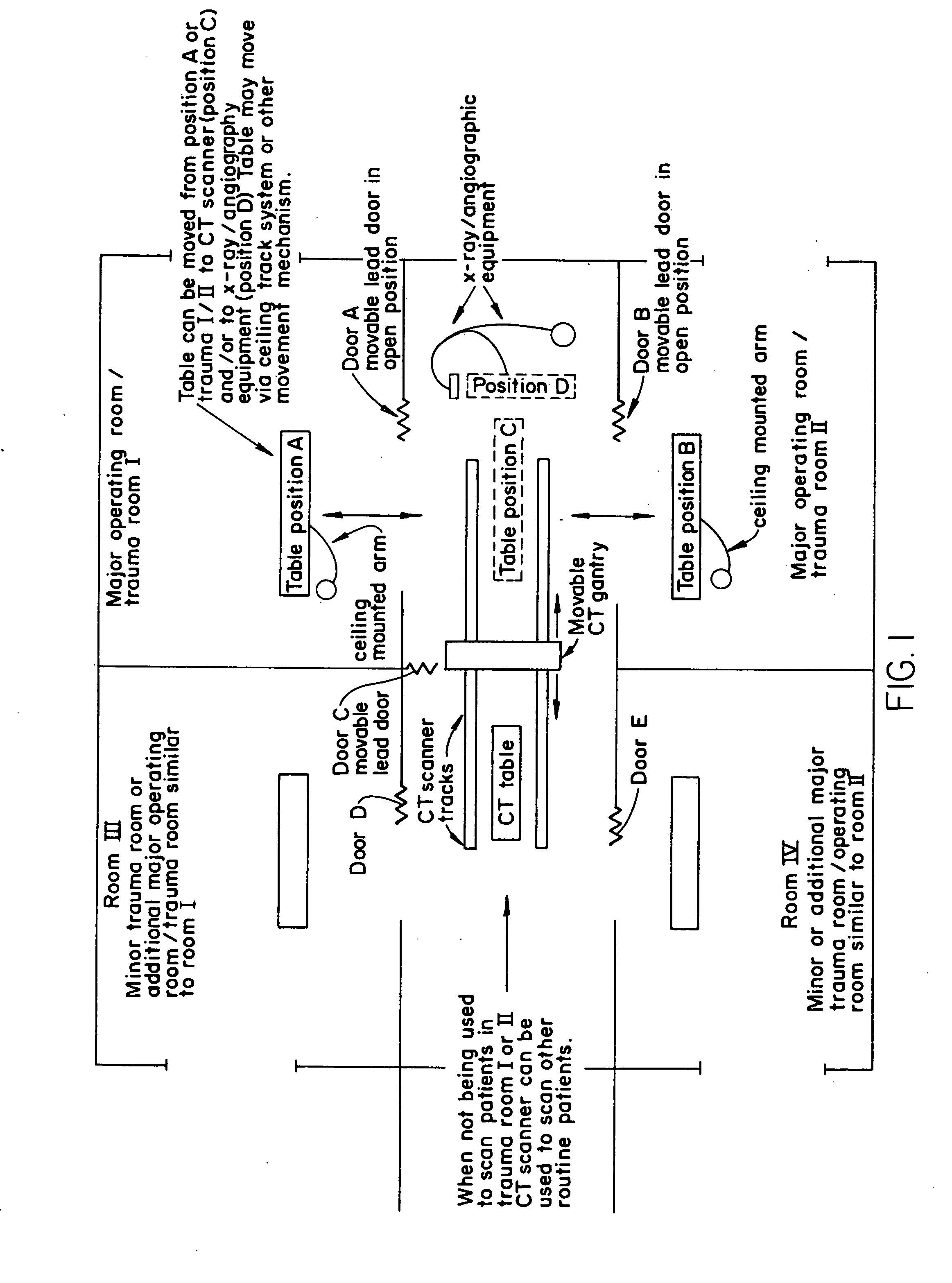

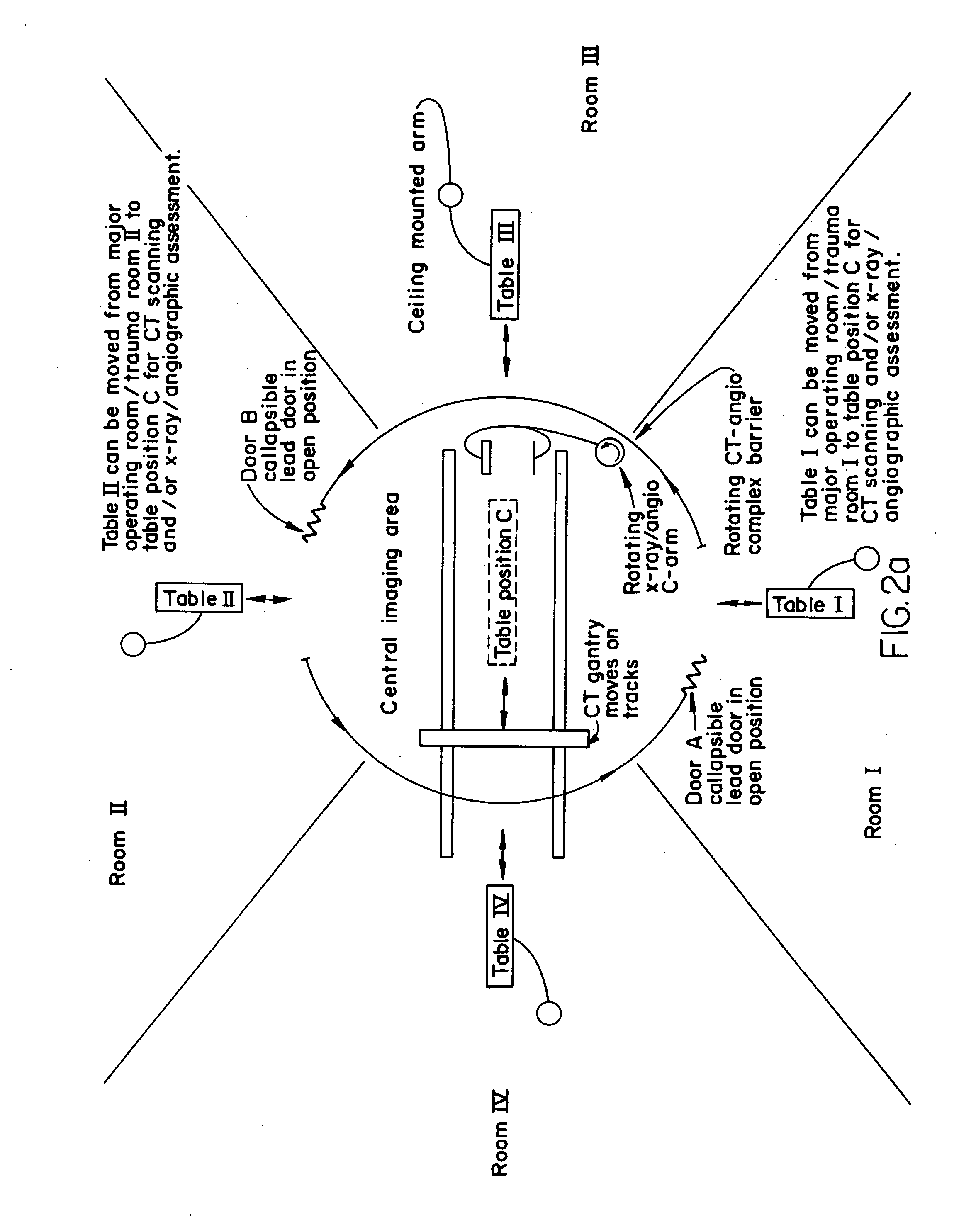

Multi-functional medical facility with diagnostic, therapeutic and interventional capabilities

InactiveUS20070033889A1Minimize patient discomfortEasy and efficient processingUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringCritically illElective surgery

A multi-functional medical facility permits emergent diagnostic imaging assessment, image guided therapeutic interventions, and open surgical procedures within the complex. The concept of bringing diagnostic and therapeutic imaging and operative equipment to the critically ill patient or the patient undergoing non-emergency, elective surgery, instead of bringing the patient to the equipment is a major clinical advantage that should improve efficiency, outcome and survival. An important economic advantage is that the components can be used separately and independently of each other, thus enabling them to also be used for routine emergency room (ER) work.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

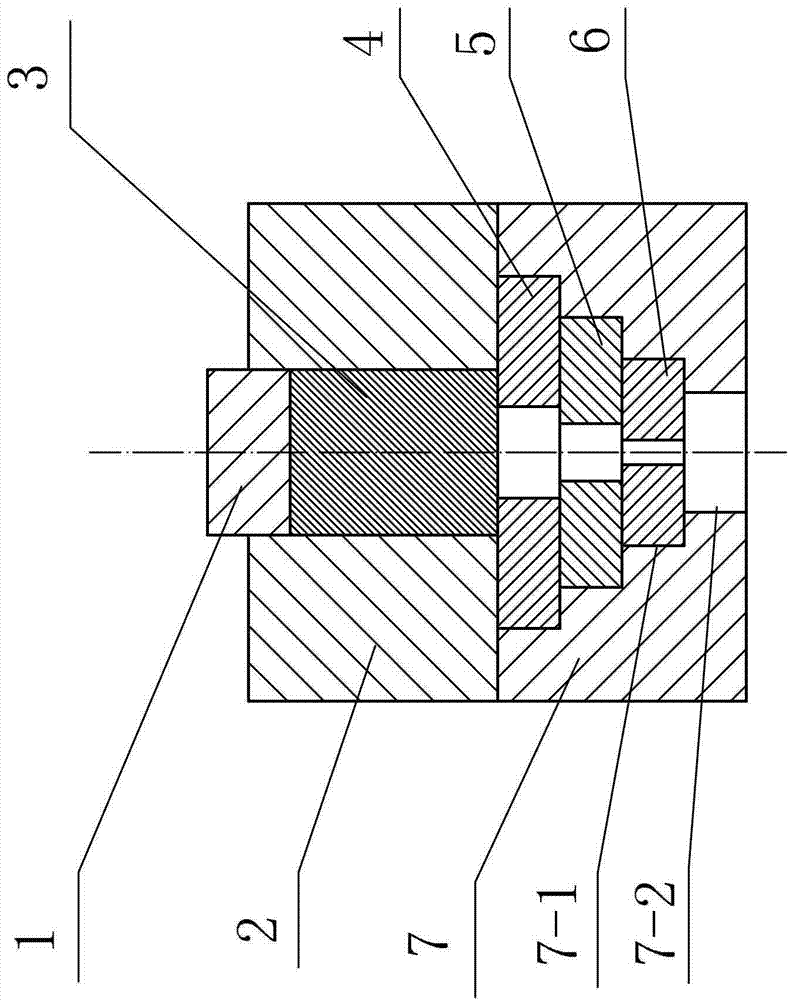

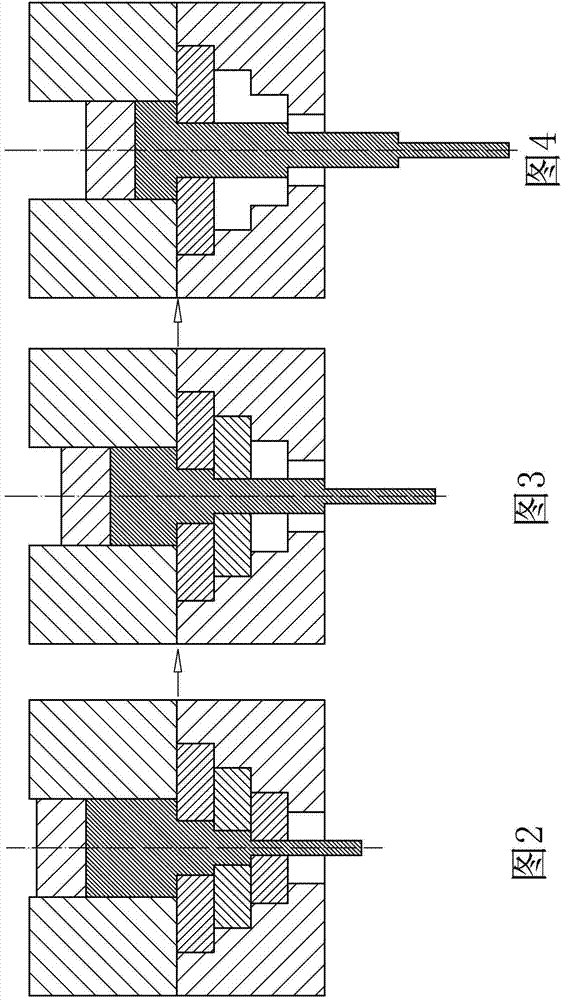

Modularized extrusion molding apparatus and method for section bar with order-variable cross sections

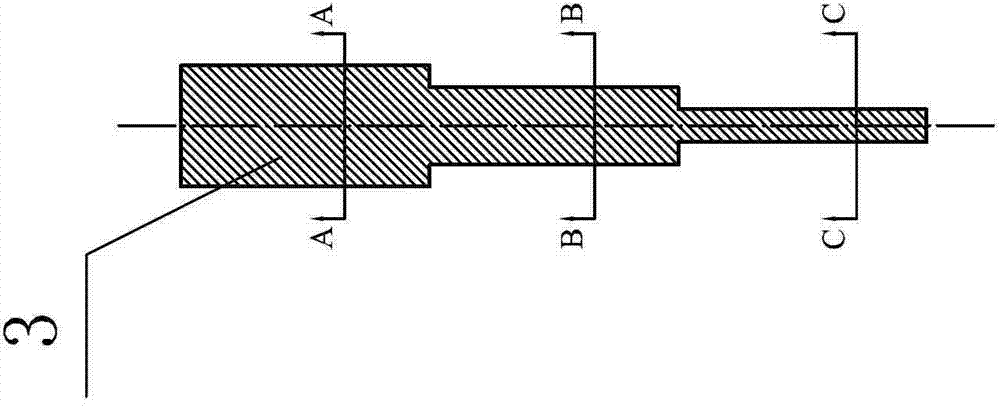

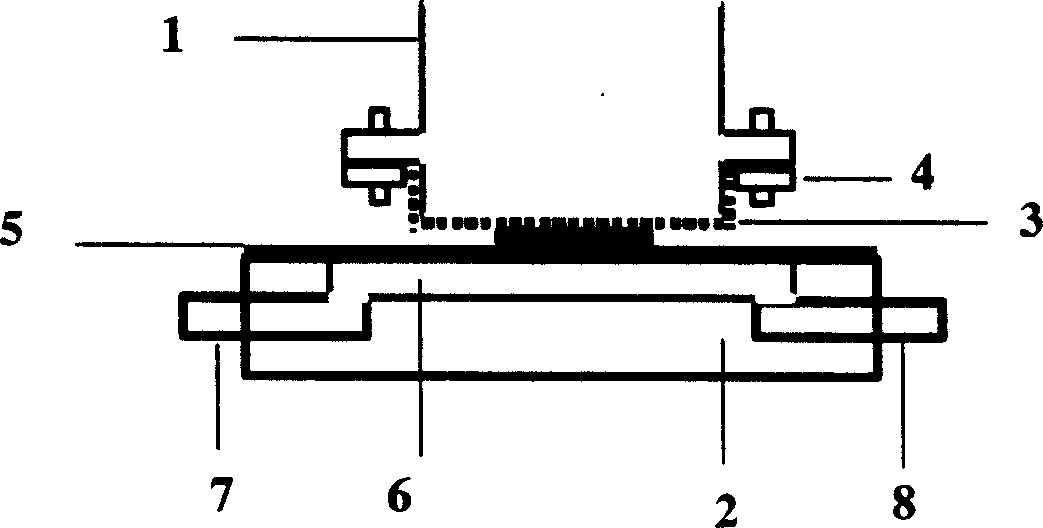

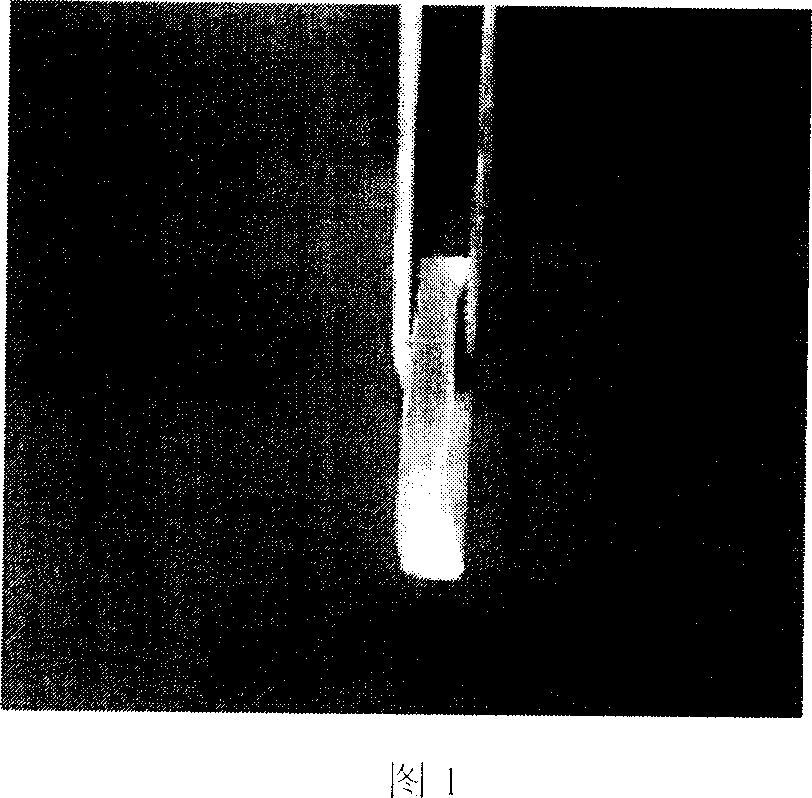

ActiveCN103480682ASolve technical problemsReduce the number of processesExtrusion diesExtrusion mandrelsProcess engineeringMechanical engineering

The invention provides a modularized extrusion molding apparatus and a modularized extrusion molding method for a section bar with order-variable cross sections, belonging to the field of extrusion processing technology. The invention overcomes the problems of numerous procedures, high process requirements, a substantial texture tendency and difficult implementation of conventional preparation methods for bars with different cross sections and defects like easy generation of folds and superposition of material interfaces, etc. during processing and preparation. The cavity of a first-order module, the cavity of a second-order module and the cavity of a third-order module of the apparatus are combined and form an axial step-like extrusion die cavity with a continuous order-variable surface. The method comprises the following steps: assembling the apparatus; and placing a blank material in an extrusion cylinder, putting in a punch, allowing the punch to descend so as to extrude the blank material from the die orifice of the first-order module, the die orifice of the second-order module and the die orifice of the third-order module, stopping descending of the punch, removing the third-order module, allowing the punch to go a distance downwardly, then stopping descending of the punch, removing the second-order module and allowing the punch to descend again so as to realize extrusion molding of the blank material. The invention has the following beneficial effects: the apparatus is simple, the number of production procedures is small, and the method can be easily implemented, popularized and applied in production.

Owner:福建祥鑫股份有限公司

Fabric moisture-penetrability testing device and testing method

InactiveCN1975416AReduce precisionReduce sensitivityInspecting textilesSurface/boundary effectTextile millSaturated water vapor

The invention relates to a testing device and the method for the fabric moisture-penetrability. The device is made up of the column canister, the base, the waterproof moisture film, the pressure ring and the testing board. The shallow groove is set on the base which the two ends are connected with the air inlet and the air outlet carved on the base two sides. The waterproof moisture film is the bottom of the column canister to form the saturate water vapor resource; the dry quick flowing N2 is the carrier to carry the water vapor through the fabric away. So it can measure the relative humidity of the N2 flow to get the moisture content of the fabric. The invention has the high precision and good repetition, the testing time is short and the cost is low; so the device can be used in the textile mill to control the product moisture-penetrability quality.

Owner:WUHAN TEXTILE UNIV

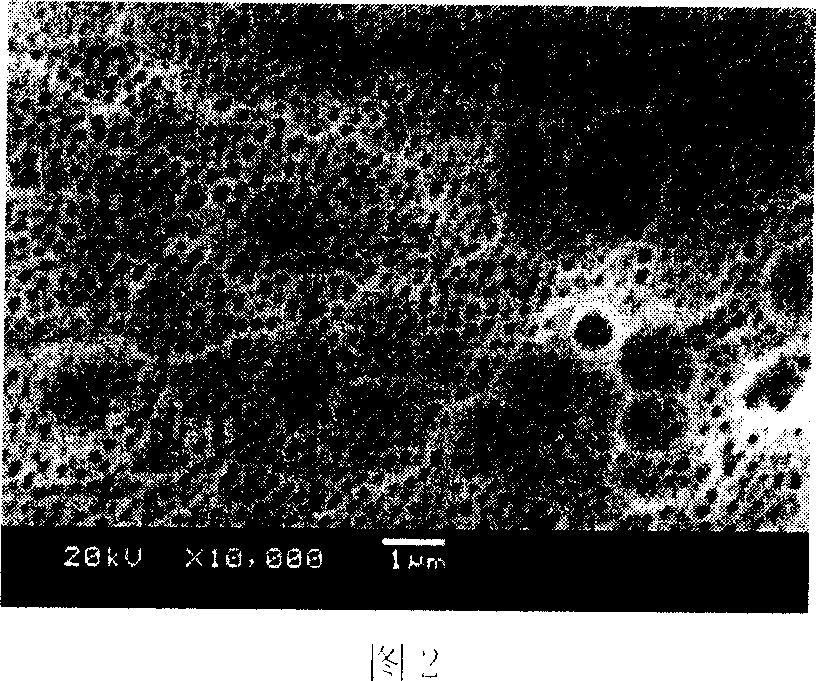

Toughness porous anodic aluminium oxide film and preparation method thereof

InactiveCN1920108AUniform pore size distributionImprove toughnessAnodisationPhosphoric acidCrystal cell

The invention provides the porous anode pellumina and preparing method. The porous anode pellumina is composed by hexagon crystal cells, the bore diameter range is 5-200nm, the bores are parallel, and the bore diameter is distributed homogeneously. The film has good tenacity. The method comprises the following steps: aluminium sheet degreasing, removing the surface oxidate with alkali, then carrying out chemical milling, using aluminum sheet as anode, platinum filament as cathode, carrying out electrolytic oxidation in acide, then film aluminium base is electrolyzed in the electrolytic solution of dilute hydrochloric acid and anhydrous ferric chloride, soaking the film in the phosphoric acid, and getting the product. The film can be used for separating film of hyperfiltration and microfiltration and form board for making functional material and nanometer line.

Owner:DALIAN UNIV OF TECH

Optical band artificial composite structure material made by AAO template

InactiveCN101306795APromote engineering applicationPrecise alignmentNanostructure manufactureMetallic aluminumMicrometer

A method for preparing optical band artificial composite structural materials by using an AAO template comprises the steps of selecting a polishing optical silicon chip, and depositing a layer of micrometer-grade aluminum film on the surface of the polishing optical silicon chip; preparing a porous alumina template with thickness less than 1 micrometer on the surface of the aluminum film by using an electrochemistry two-step anodic oxidation method; generating a single-channel nano-pore array AAO template; depositing a metal film layer on the single-channel nano-pore array AAO template by using a lateral vacuum deposition method; selecting an optical material substrate, and connecting one surface of the nano-pore array AAO template having the metal film layer with the substrate; removing the silicon chip; eroding the metallic aluminum film layer and the alumina barrier layer at the back side to form a two-channel pore array AAO template; and depositing a metal film layer on the other surface of the AAO template by using the lateral vacuum deposition method. The inventive method has the advantages of low cost, short processing cycle, large processing pattern area, and precise implementation of nanometer grade alignment between an upper metal grid layer and a lower metal grid layer; and has wide application prospect in fundamental research and practical applications of optical band artificial composite structural materials.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

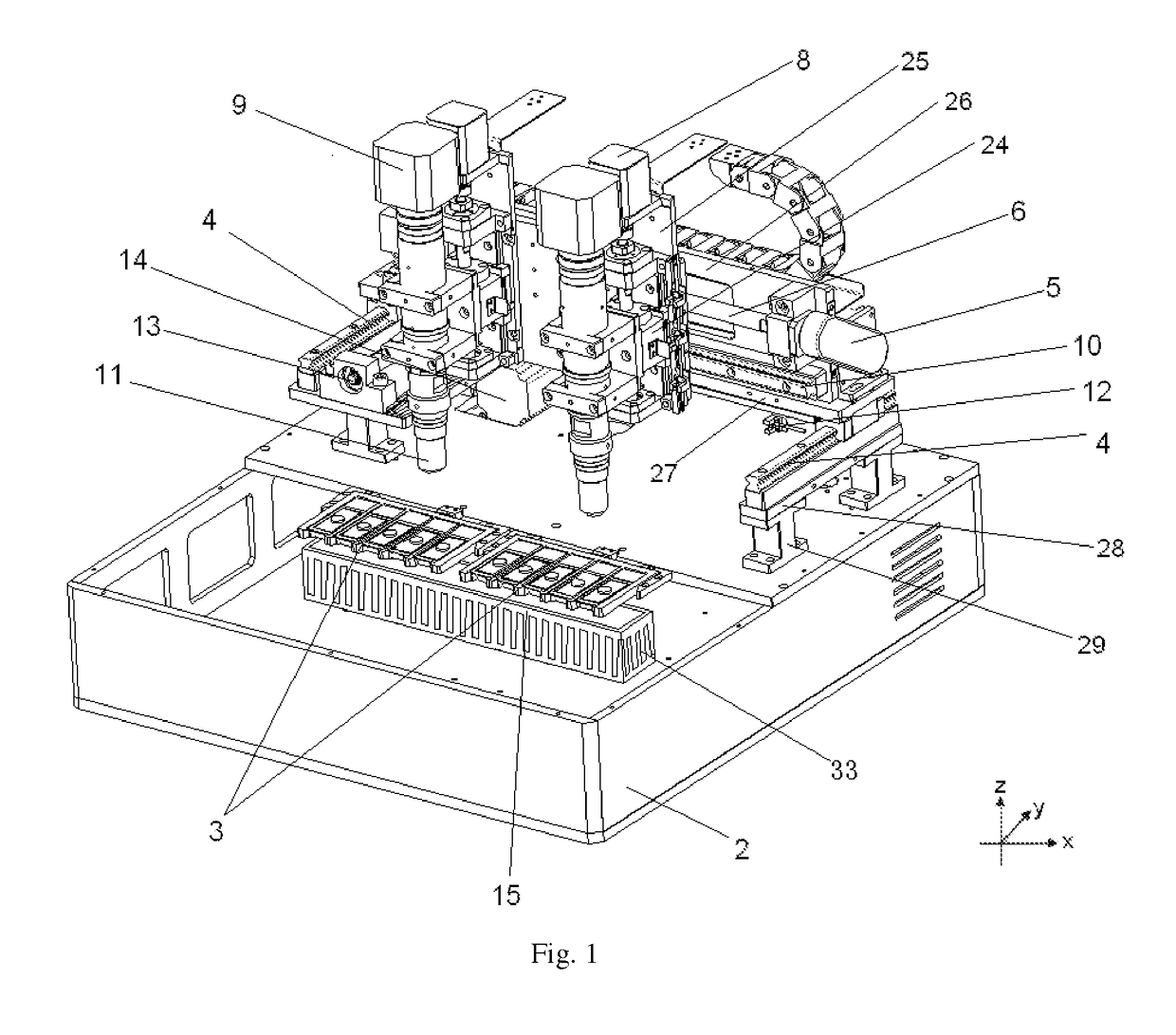

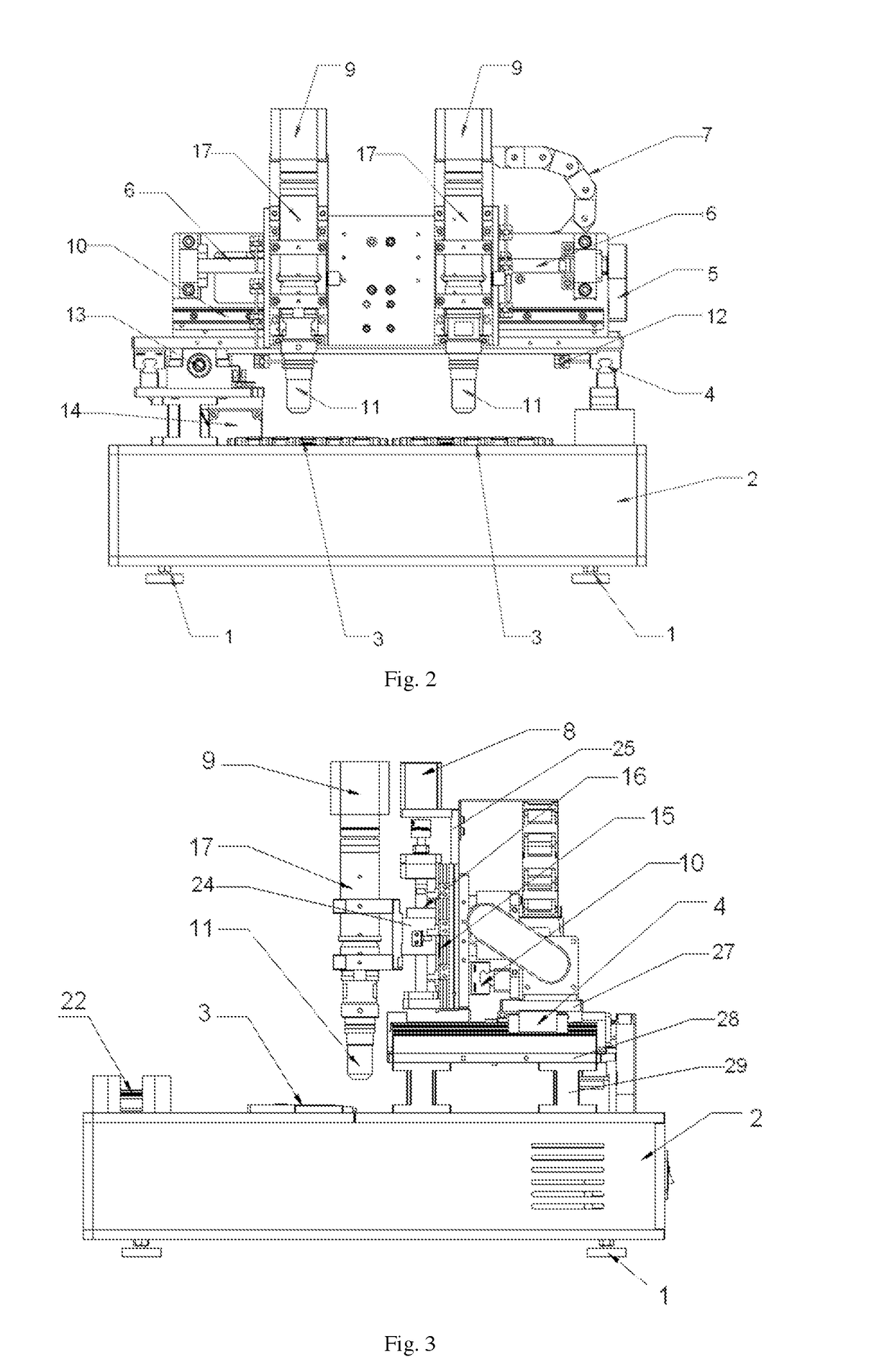

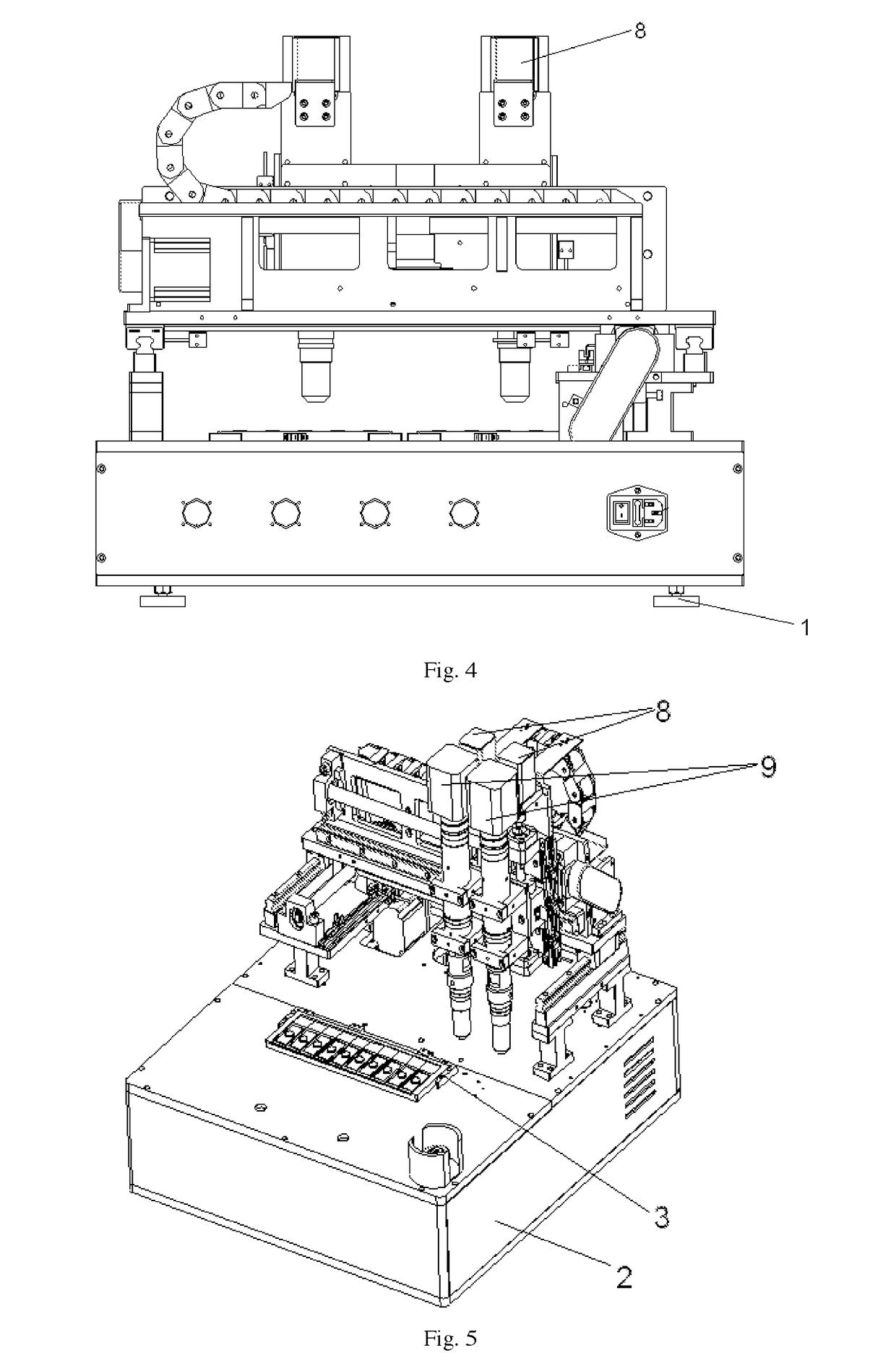

Fully Automatic Microscopic Scanner

ActiveUS20190033568A1Quick costOptimizationTelevision system detailsMicroscopesEngineeringLine array

A fully automatic microscopic scanner, comprising an image acquisition mechanism (IAM) with a line array camera. The IAM and the microscopic scanning mechanism can move along X / Y / Z axis under the action of a power control mechanism and the stage mechanism and the light source mechanism are fixed and not moved. The light source mechanism comprises a flat light source with a condenser and the flat light source area is greater than or equal to the total area of the tray. The light source mechanism comprises a cooling fan and a water cooling unit. It also comprises a general control mechanism and a laser pre-focus system connected to it. The invention also discloses a fully automatic microscopic scanner which links the microscopic scanning mechanism and the IAM with the light source mechanism. According to the present invention, flexible adjustment of lens can be achieved to make the lens move forwards and backwards, leftwards and rightwards and up and down. In addition, with the unique light source mechanism and laser pre-focus system, the stage and the light source are fixed and not moved during the scanning process so that real-time accurate and fast focusing might be fulfilled. In such a way, unlimitedly extended microscopic scanning range, improved scanning efficiency and improved quality of scanning can be accomplished.

Owner:LI XINYU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com