Optical band artificial composite structure material made by AAO template

A technology of artificial composite and structural materials, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve the effects of easy mass production, short processing cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. But the following examples are only limited to explain the present invention, and the protection scope of the present invention should include the whole content of claim, and promptly can realize the whole content of claim of the present invention to those skilled in the art through following embodiment.

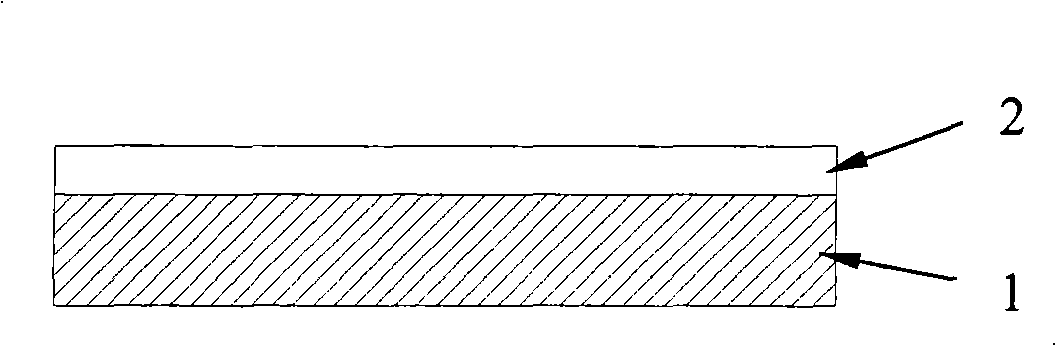

[0034] Such as figure 1 Shown, the schematic diagram of making the first step of the present invention; at first select a piece of silicon substrate 1, and its surface is polished, then sputter-deposits a layer of high-purity aluminum film with a thickness on the order of microns on the polished silicon substrate 1 surface 2;

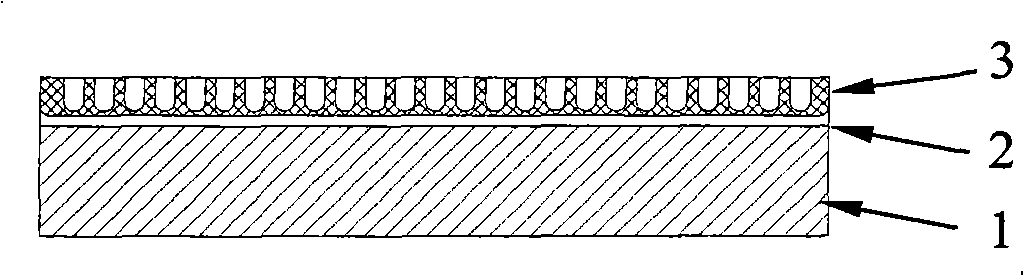

[0035] Such as figure 2 Shown, the production schematic diagram of the second step of the present invention; Adopt electrochemical two-step anodic oxidation method on the surface of high-purity aluminum membrane 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com