High-efficiency radiating LED illumination light source and manufacture method

A technology for LED lighting and a manufacturing method, which is applied in the manufacturing field of the high-efficiency heat-dissipating LED lighting source, can solve the problems of complex process, high cost, low production efficiency, etc., and achieves excellent thermal conductivity, reduced heat dissipation base, and high manufacturing process precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

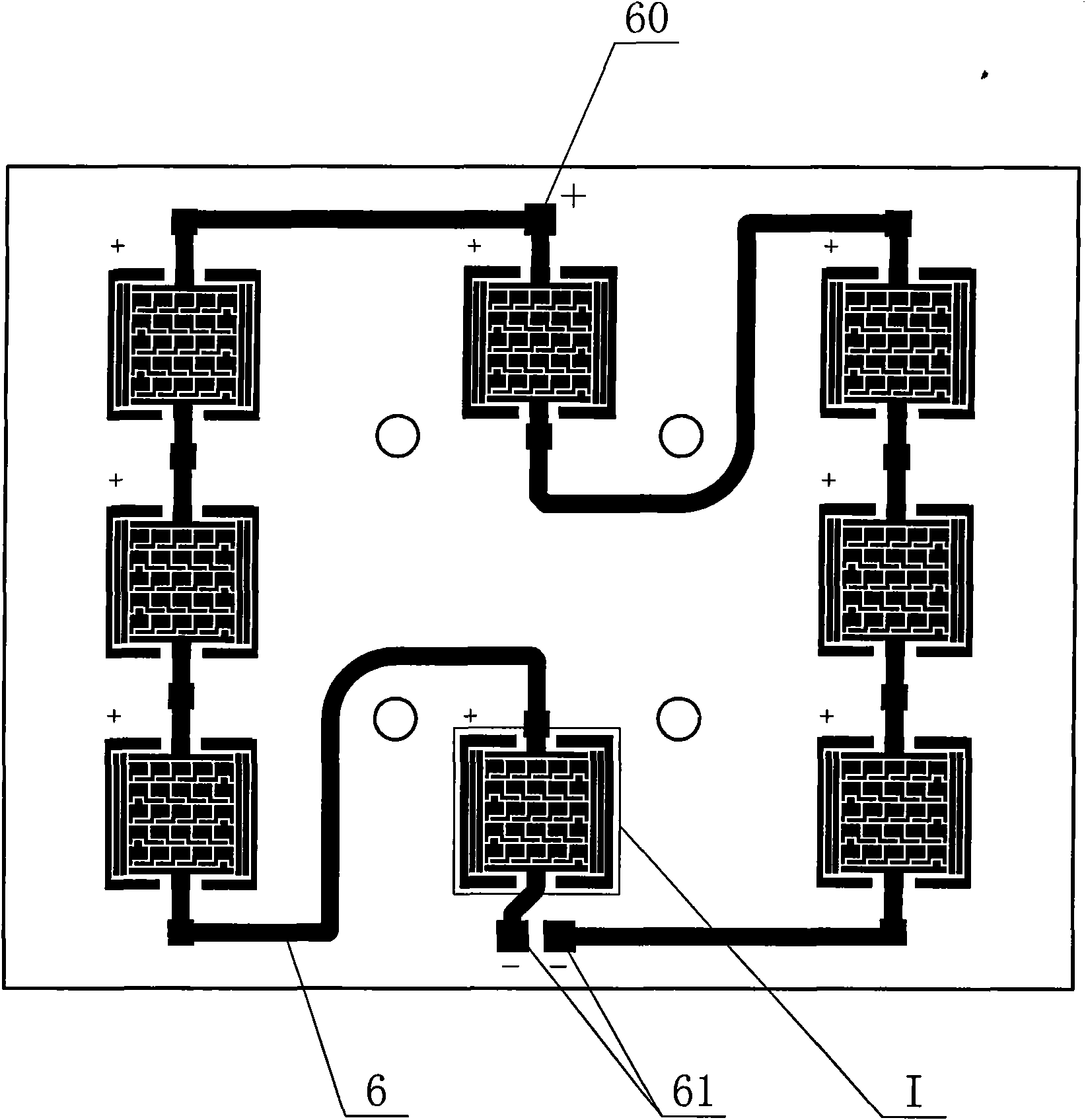

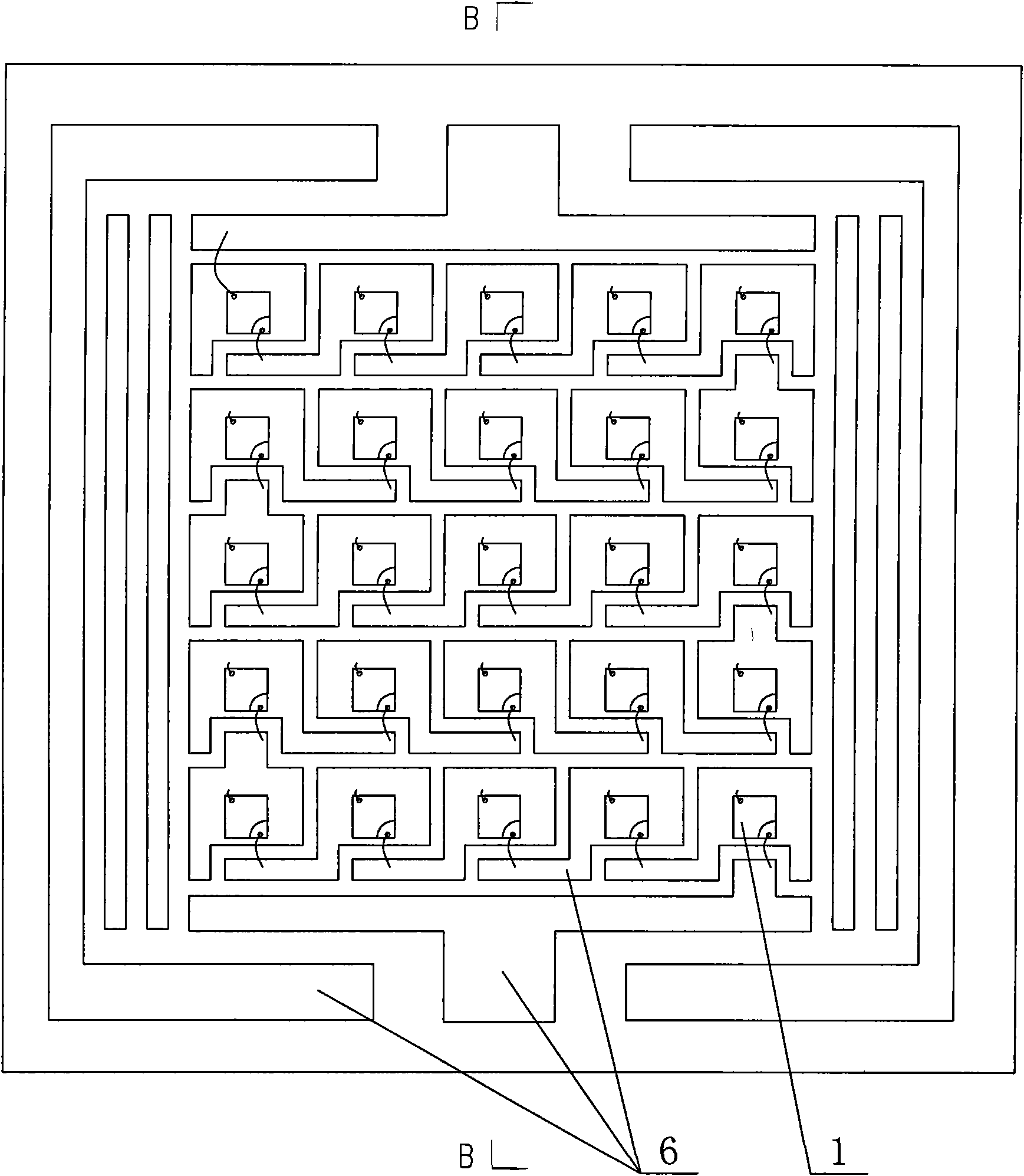

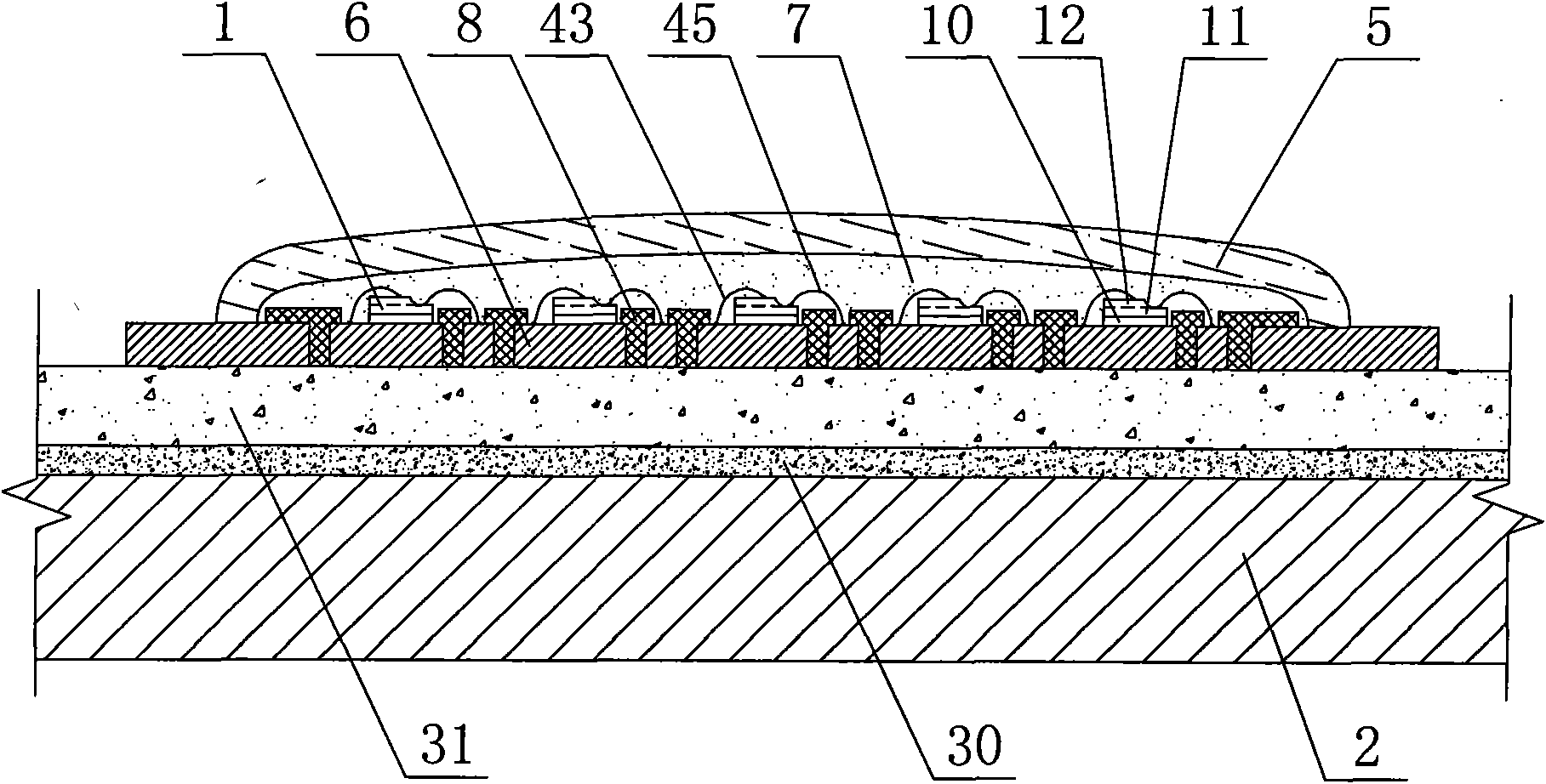

[0032] Such as Figure 1 ~ Figure 3 As shown, the high-efficiency heat dissipation LED lighting source of this embodiment is a light source applied to industrial and mining lamps with 220V alternating current, including an LED bare chip 1 and a metal substrate 2, the LED bare chip 1 is a two-electrode chip, and the LED bare chip 1 includes a substrate 10, an N-type epitaxial layer 11, and a P-type epitaxial layer 12, and the substrate 10 is aluminum oxide (sapphire, Al 2 o 3 ) substrate, of course, the substrate 10 can also be a substrate of other materials such as gallium arsenide (GaAs) or silicon carbide (SiC), and the metal substrate 2 is an aluminum substrate with a thickness of 2 mm. Of course, copper can also be used. Substrate, the thickness of the metal substrate 2 can be 1-3mm, the upper surface of the metal substrate 2 is deposited with a thermally conductive insulating layer, and a metal layer 6 is deposited on the thermally conductive insulating layer, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com