Patents

Literature

83results about How to "Improve Manufacturing Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

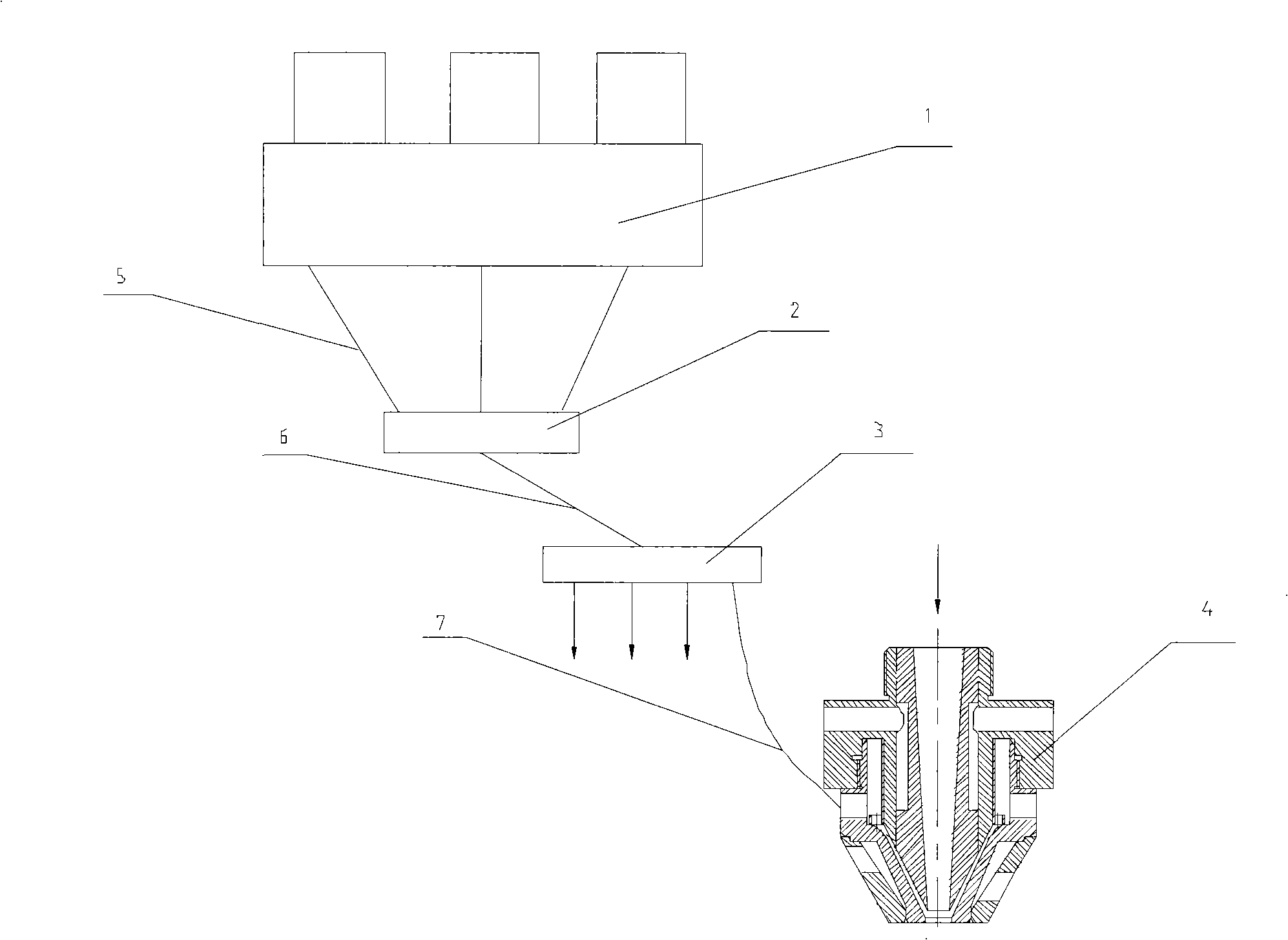

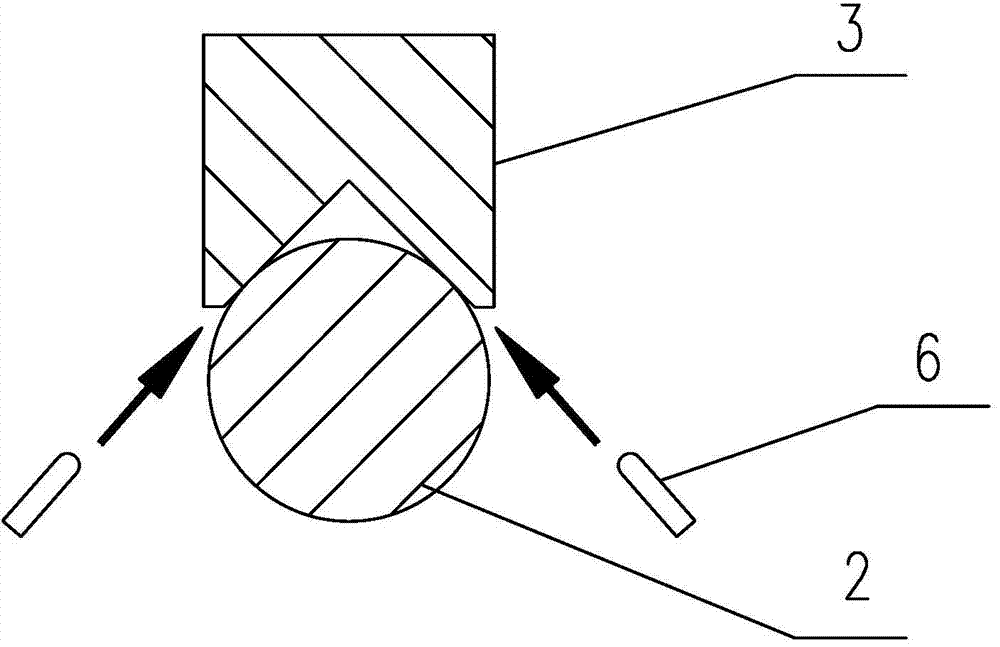

Coaxial powder feeding system for quickly molding and producing functional gradient material with laser

InactiveCN101342640AWell mixedImprove uniformityIncreasing energy efficiencyLaser beam welding apparatusNozzleRapid prototyping

The invention relates to a coaxial powder feeding system of laser rapid prototyping preparation function gradient material, comprising a powder inlet device, and the powder is absorbed and conveyed by carrier gas. The powder inlet device is communicated with a powder mixer through a first conveying pipe. The powder mixer is used for mixing the powder which has been conveyed. The mixed powder enters into a powder separate device through a second conveying pie. The powder separate device is used for separating the mixed powder into multi-path. The powder separate device is communicated with the powder inlet of a nozzle through a third conveying pipe. The nozzle makes the multi-path powder flock together in a molten pool formed by laser. The function gradient material is prepared under the cladding action of laser and powder. The mix of the powder is uniform. The coaxial powder feeding system has good power feeding property, which can realize the optimum processing, and at the same time, can be suitable for different processing distances. The powder utilization rate is high. The manufacturing accuracy is good. At the same time, the powder conveying distance can be adjusted with a certain scope, and so the coaxial powder feeding system can not be limited to the manufacturing space.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

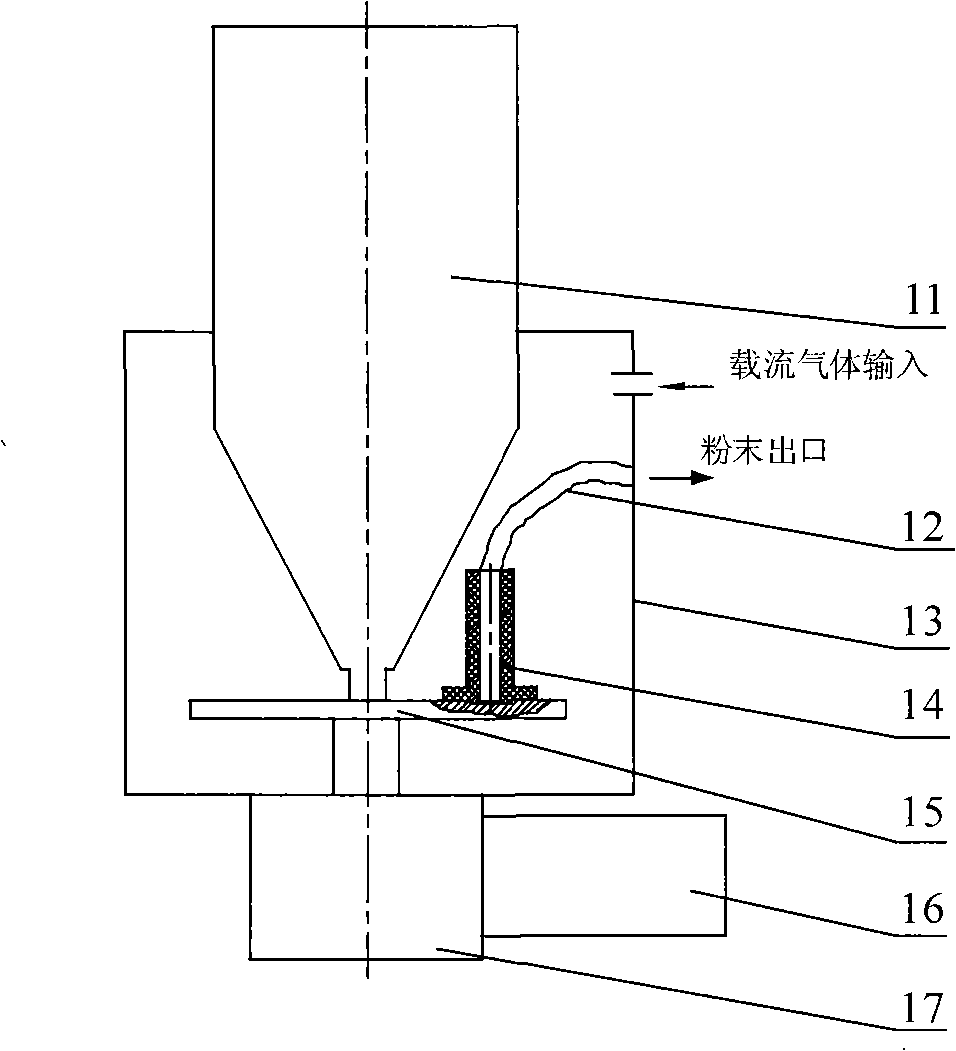

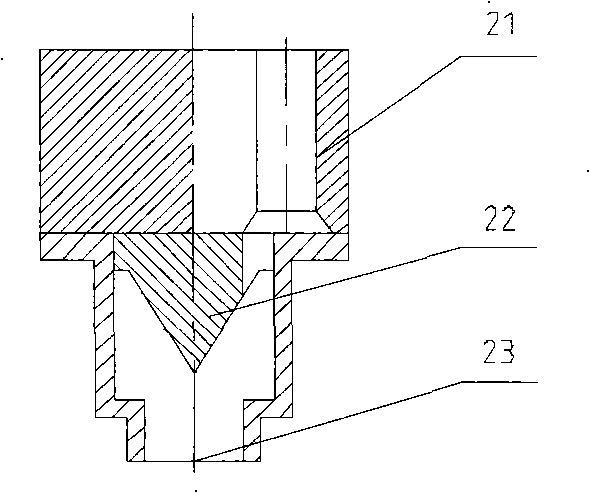

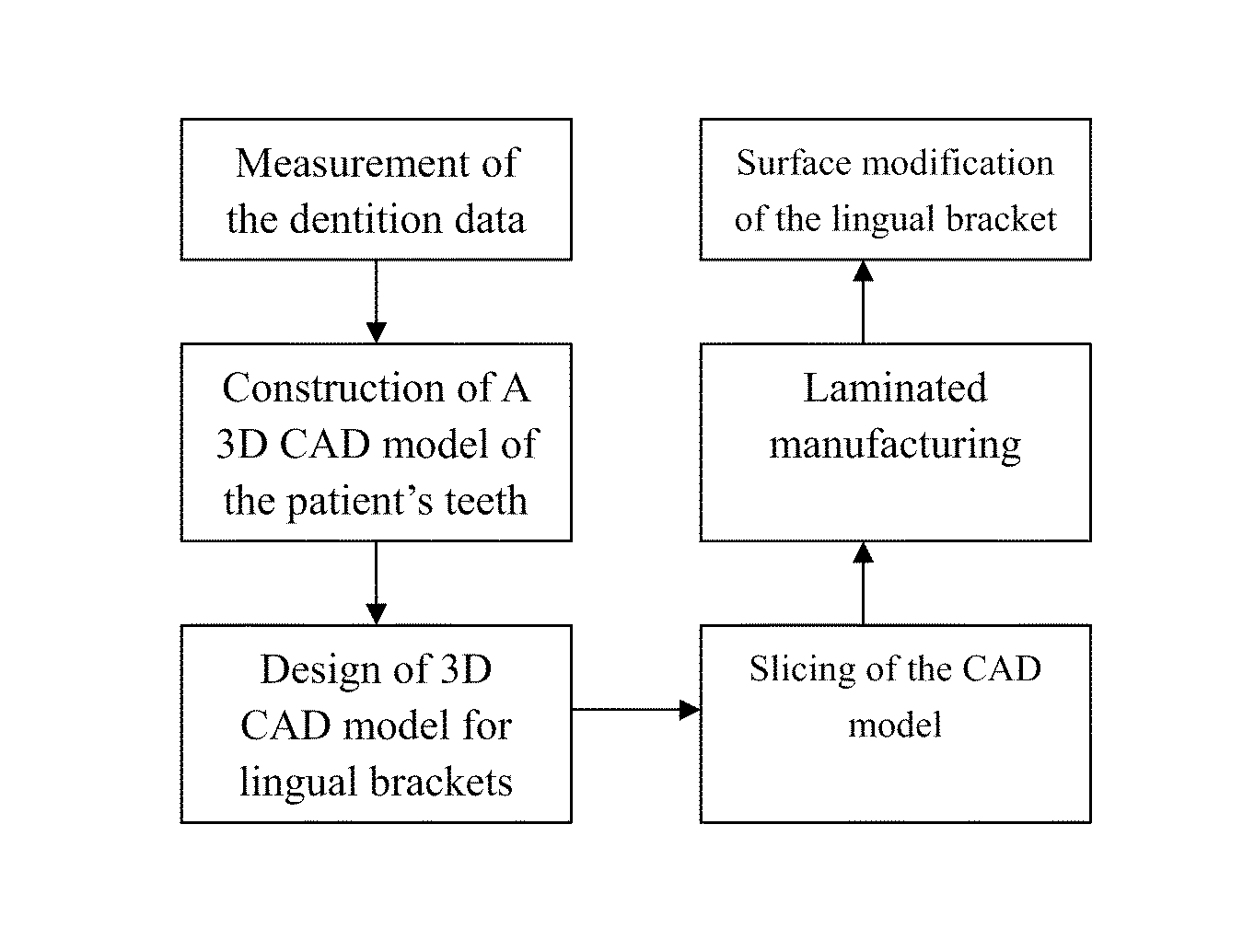

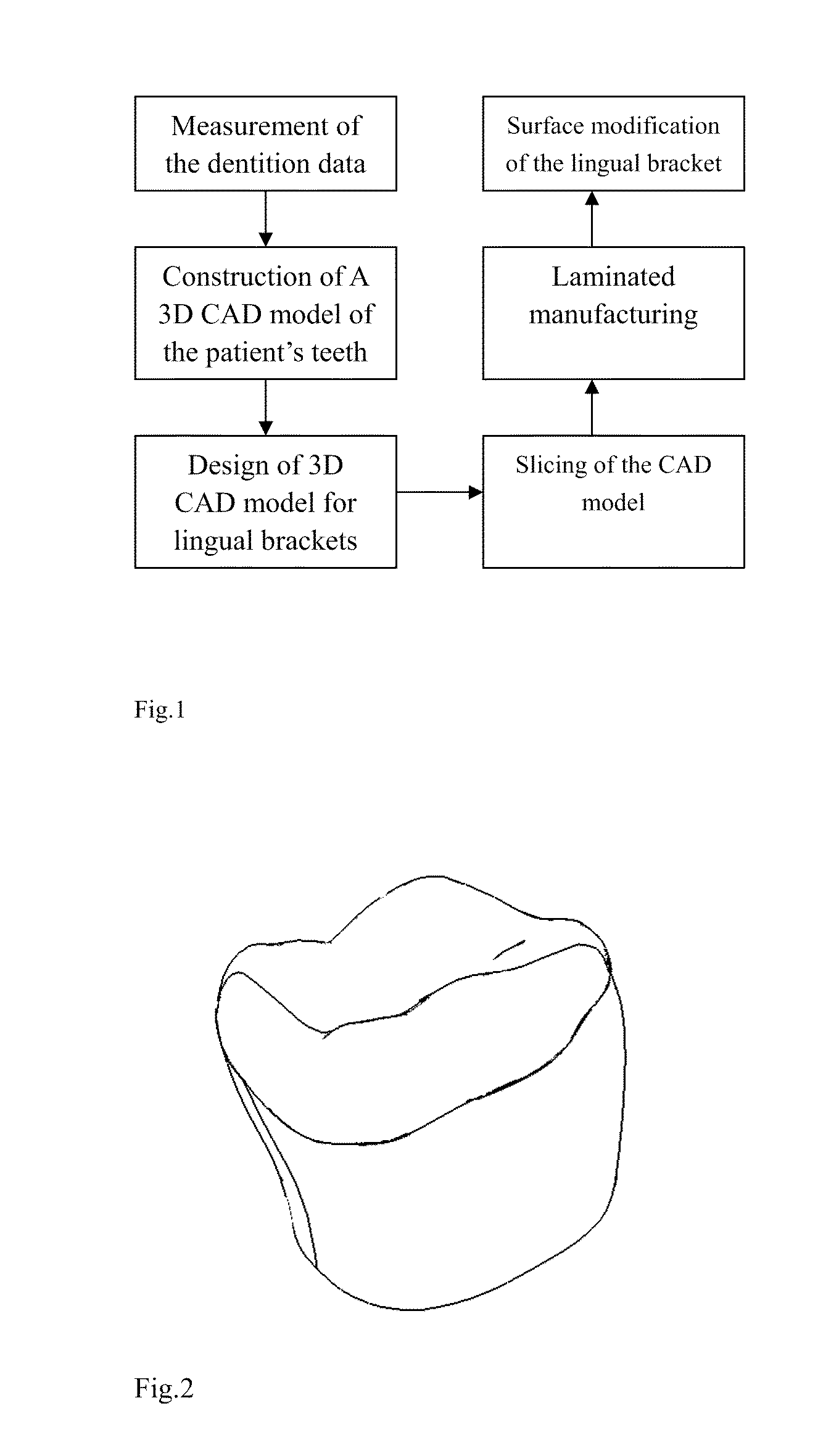

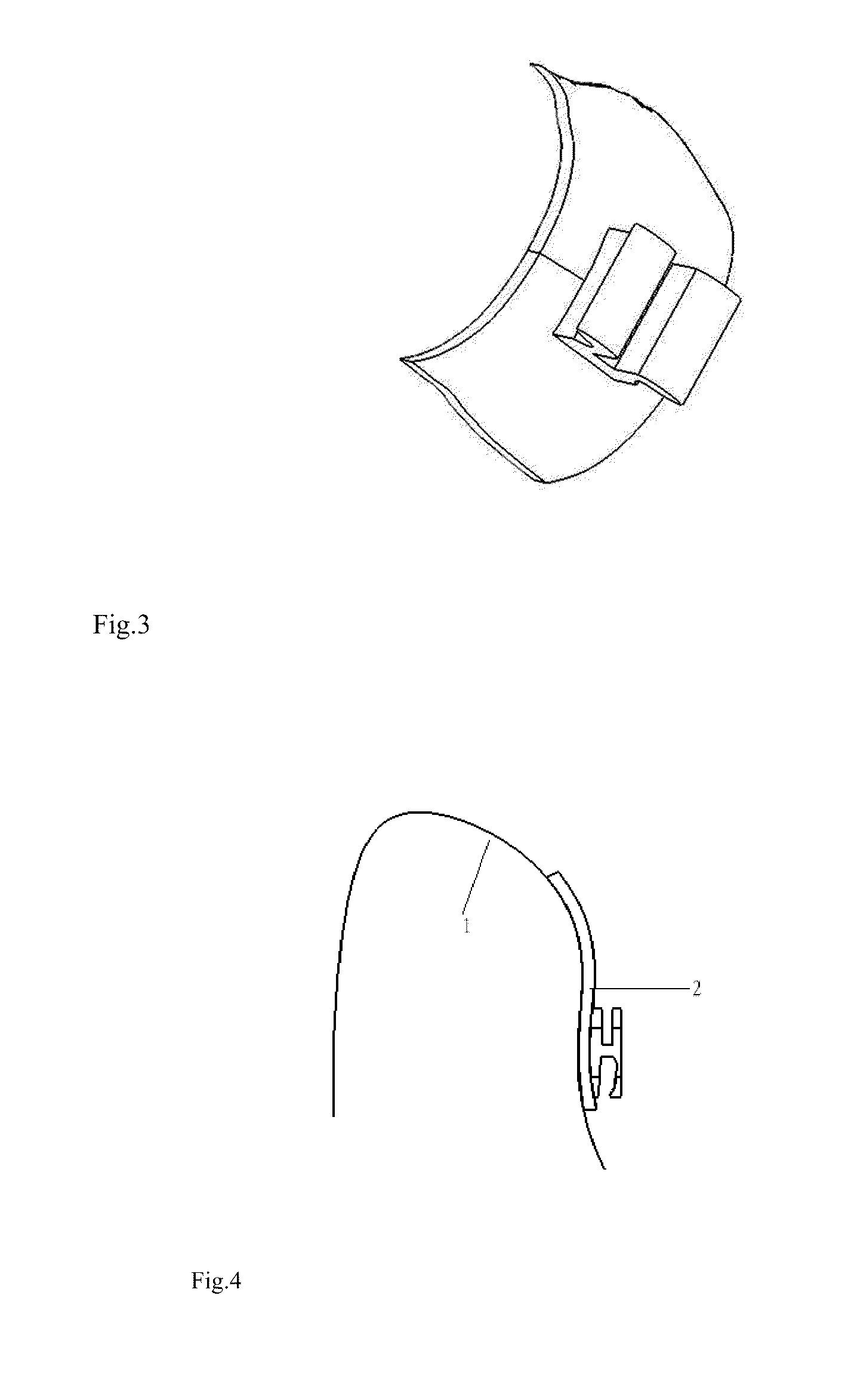

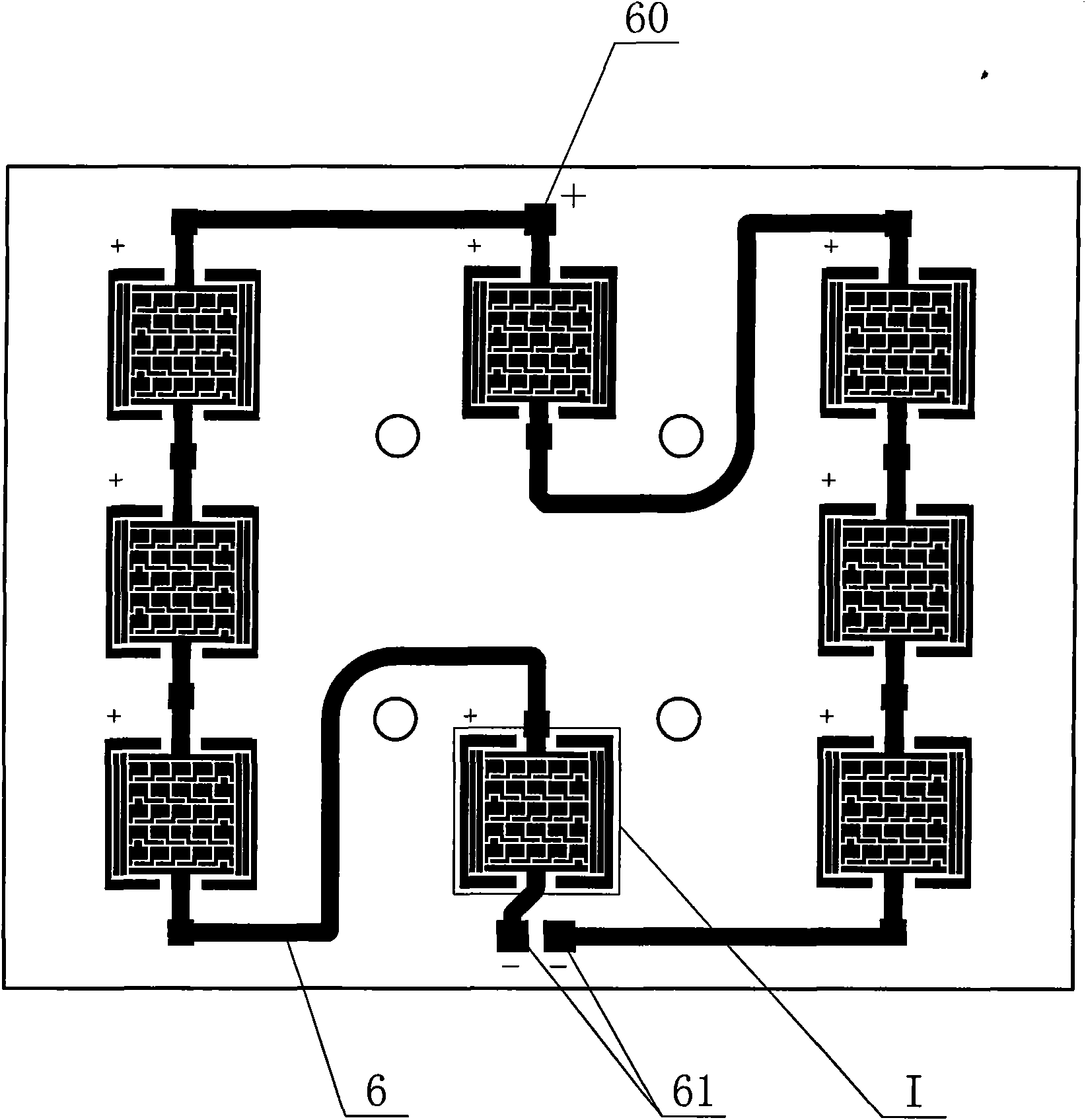

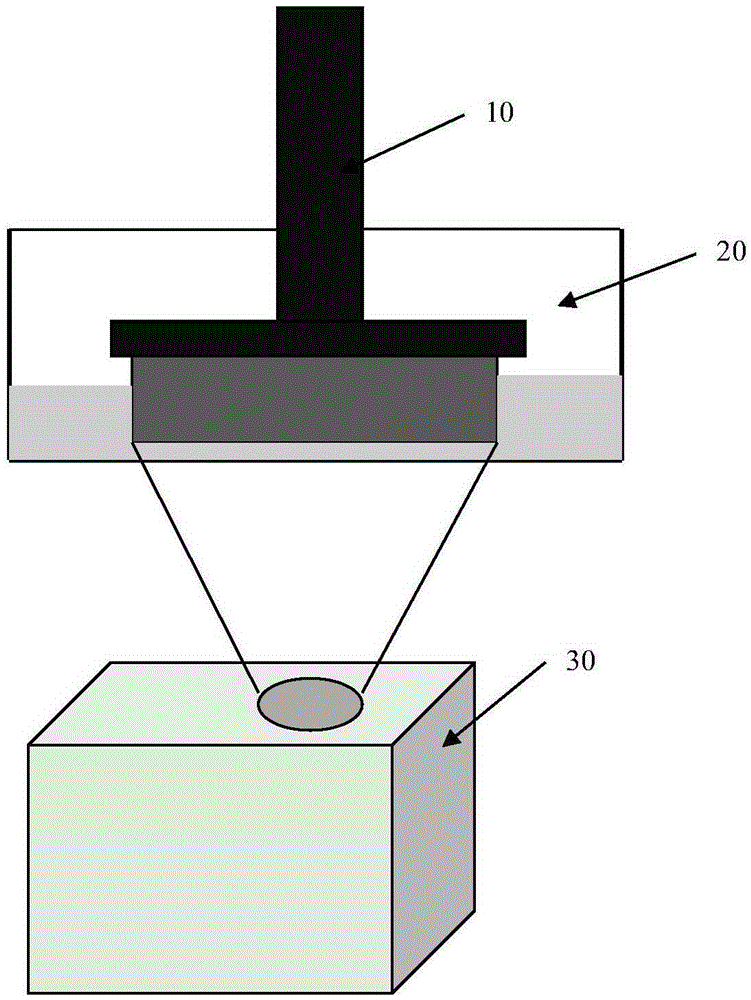

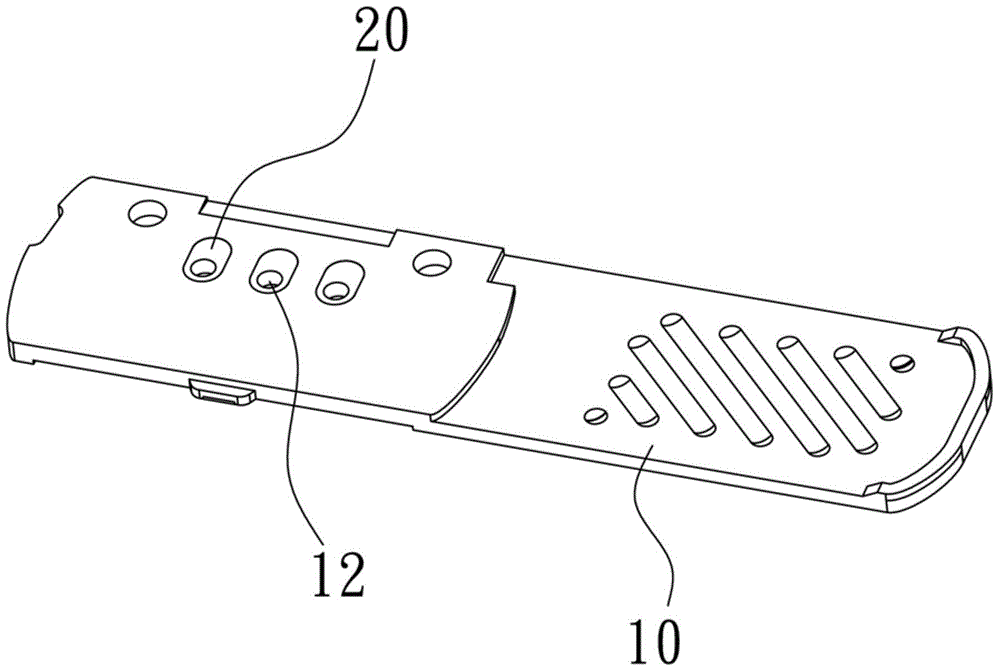

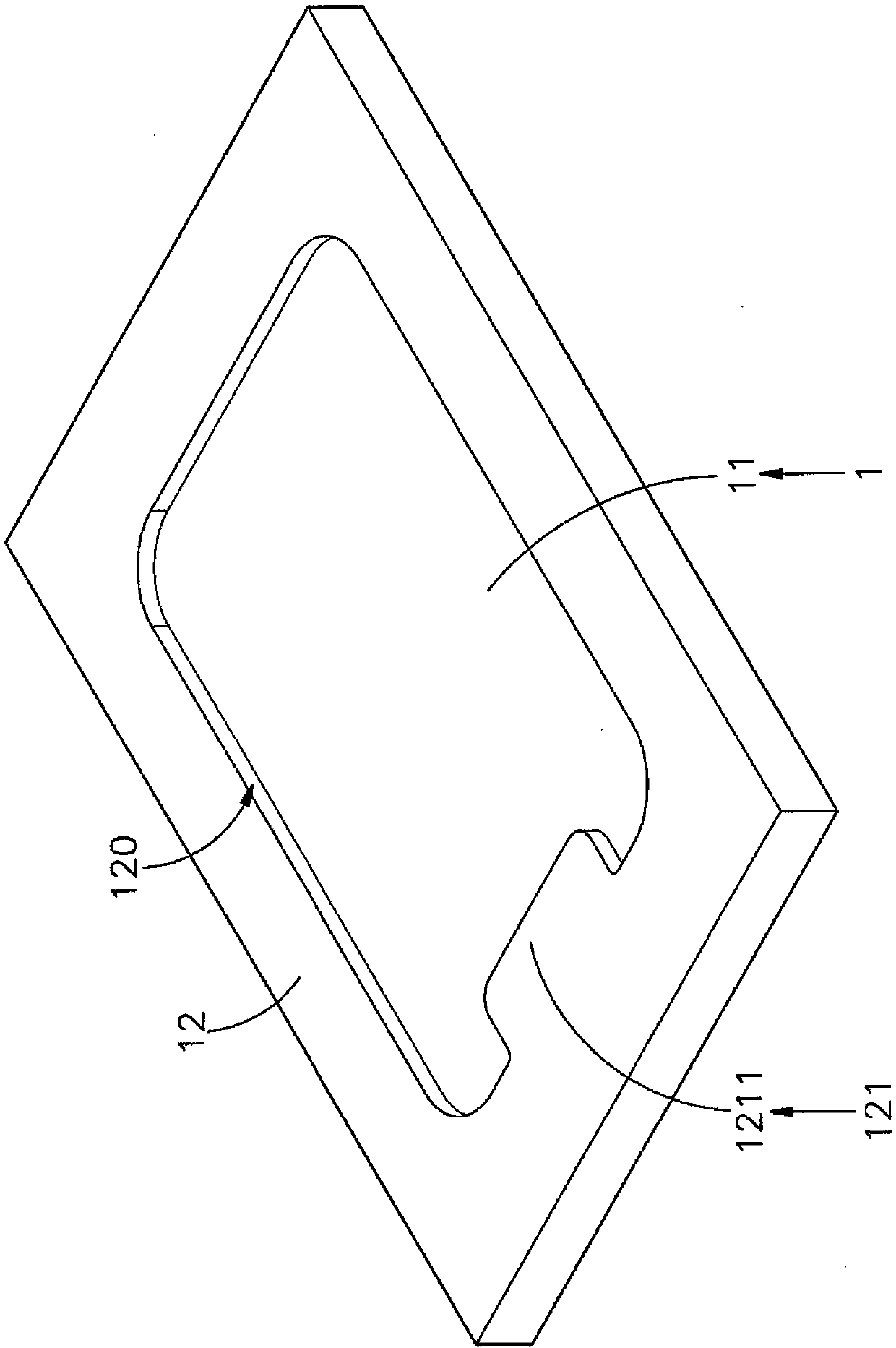

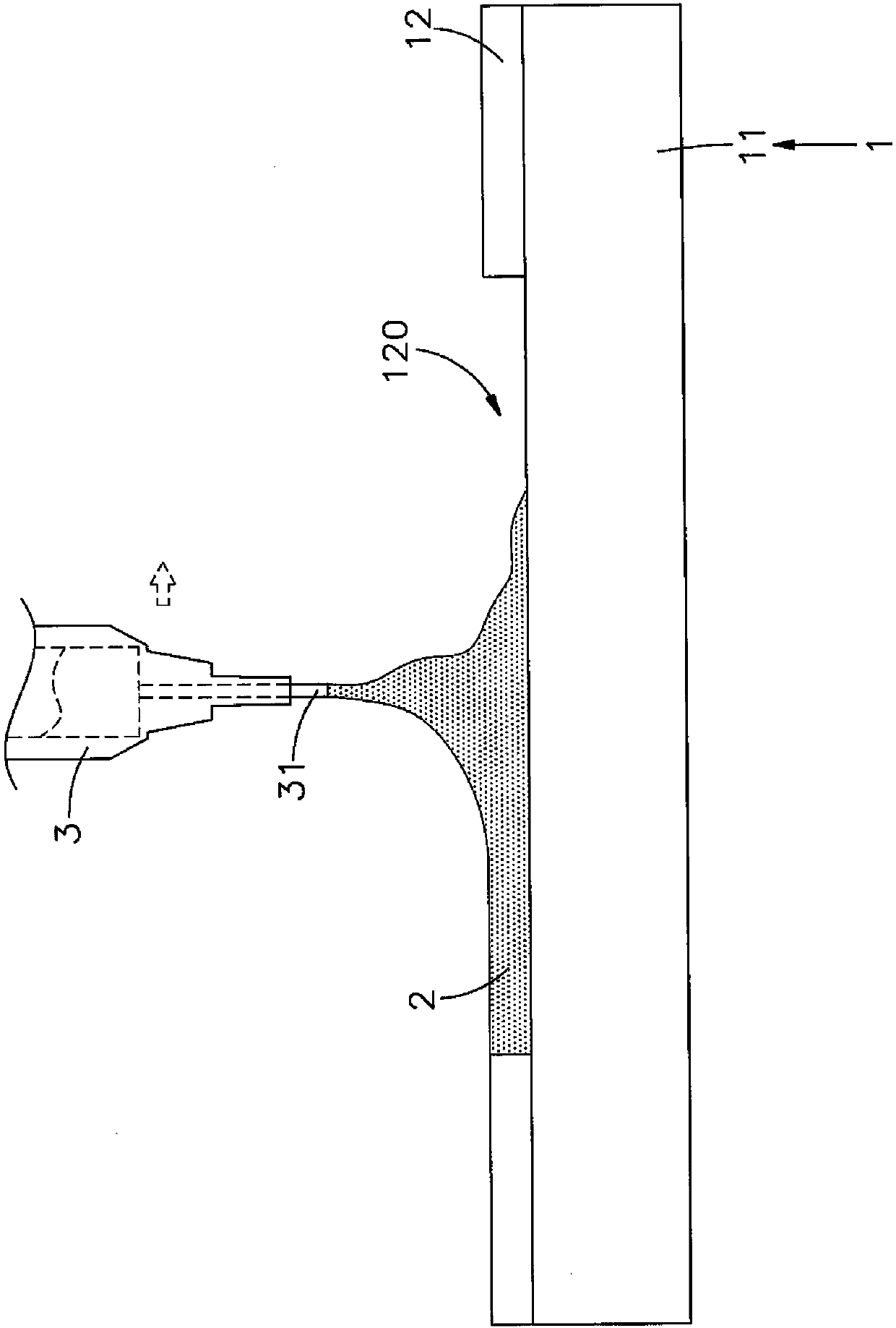

Direct manufacturing method of selective laser melting of customized tongue-side orthodontic support grooves

ActiveUS20100324715A1Improve Manufacturing AccuracyImprove accuracyAdditive manufacturing apparatusBracketsSelective laser meltingEngineering

This invention has provided a direct manufacturing methodology of customized lingual orthodontic brackets by selective laser melting. The procedure is as follows. First of all, measure the dentition data and construct the 3D CAD model of the teeth through reverse engineering. Then a single soleplate of the lingual bracket contacting the tooth surface, as well as the ideal slot position is designed based on the teeth features. The designed models are later imported into the SLM machine and used to produce the brackets with desired materials directly. This method can actualize customized manufacture with highly accuracy, producing highly matched brackets all at once. The invention not only saves time and cost, but also has wide adaptation range and is able to adopt various raw materials. Different raw materials can be utilized in one step to accommodate specific capacity requirement of different parts of the brackets.

Owner:SOUTH CHINA UNIV OF TECH

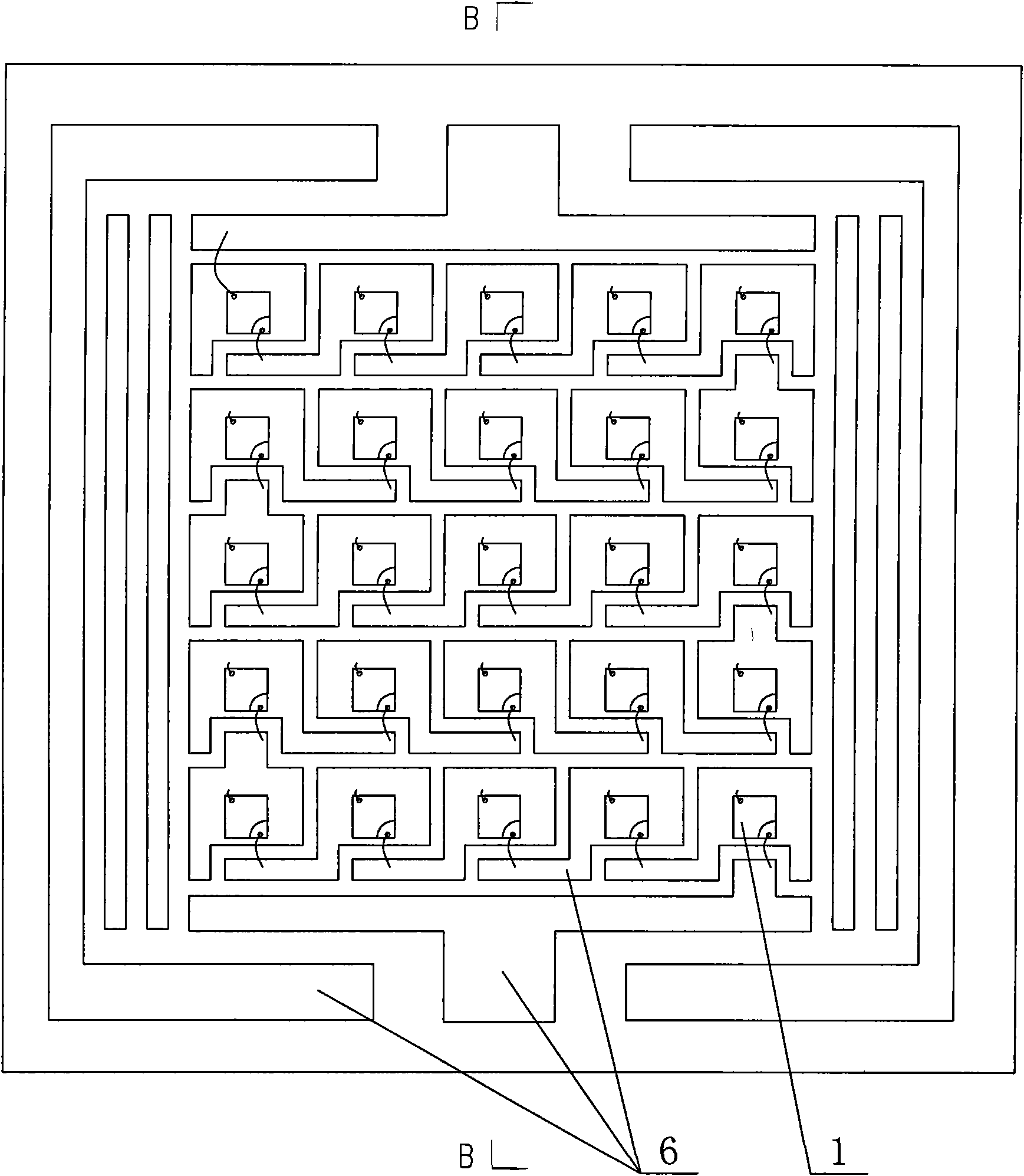

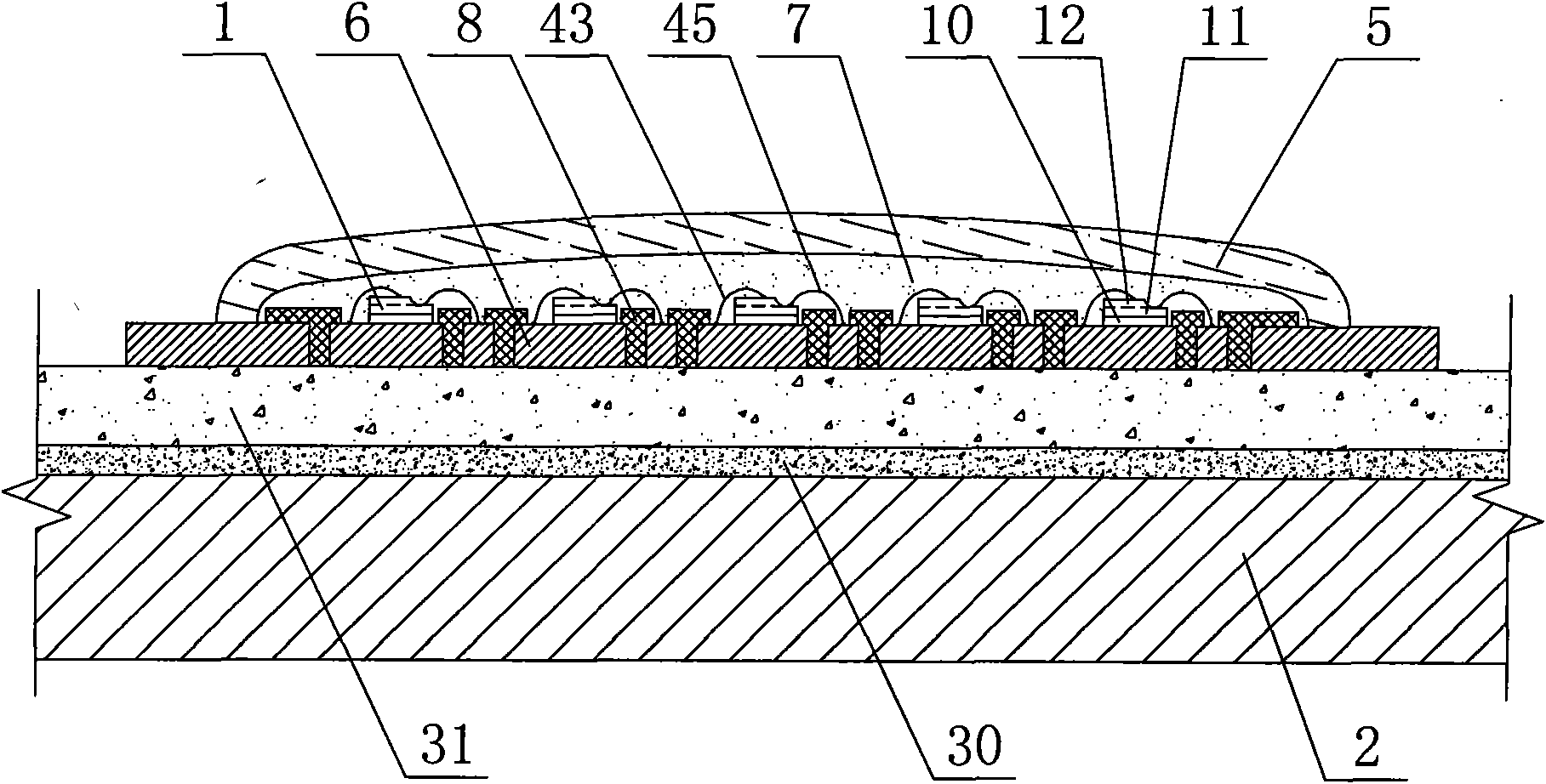

High-efficiency radiating LED illumination light source and manufacture method

InactiveCN101614333AImprove thermal conductivityPrecise thickness controlPoint-like light sourceElectric circuit arrangementsOptoelectronicsSilicon dioxide

The invention discloses a high-efficiency radiating LED illumination light source with low cost, good radiating effect, high production efficiency and high manufacture precision and a manufacture method. The high-efficiency radiating LED illumination light source comprises LED bare chips (1) and a metal substrate (2), wherein a heat conduction insulating layer is deposited on the metal substrate (2); metal layers (6) are deposited on the heat conduction insulating layer; the metal layers (6)are covered by a welding prevention layer (8); the heat conduction insulating layer is combined by a silicon dioxide layer (30) or a silicon nitride (31) or the combination of the silicon dioxide layer (30) and the silicon nitride (31); a preset circuit connection and a preset figure are formed on each metal layer (6) according to the serial connection and parallel connection relation of the LED bare chip (1); the LED bare chips (1) are divided into a plurality of groups and are mounted on each metal layer (6) normally or inversely; and the LED bare chips (1) in each group and the LED bare chips in the plurality of groups are connected through the metal layers (6) to form circuits. The manufacture method comprises the steps of pretreatment of the metal substrate, formation of the heat conduction insulating layer, the metal layers and the welding prevention layer as well as the encapsulation of the LED bare chips.

Owner:NANKER GUANGZHOU SEMICON MFG

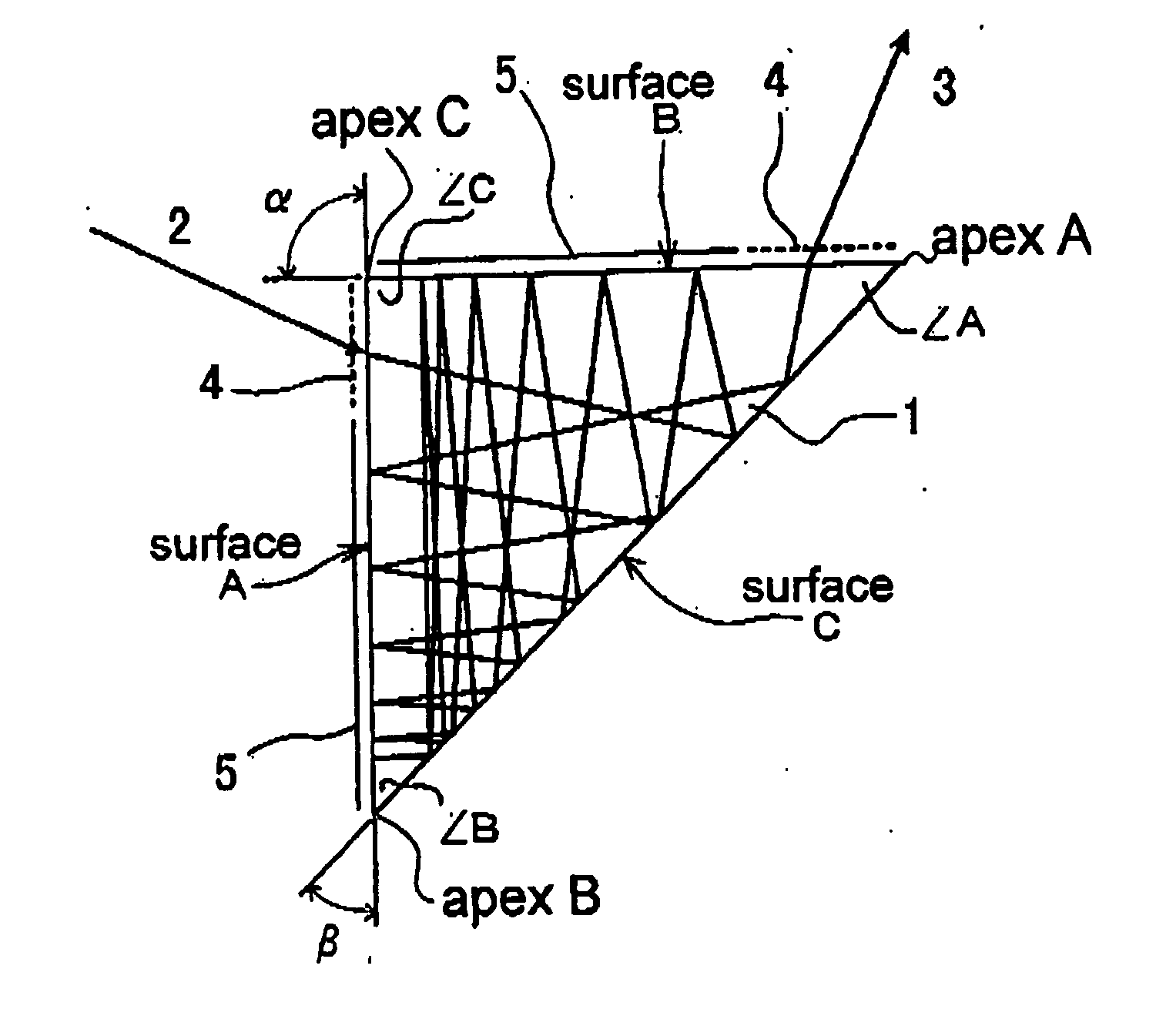

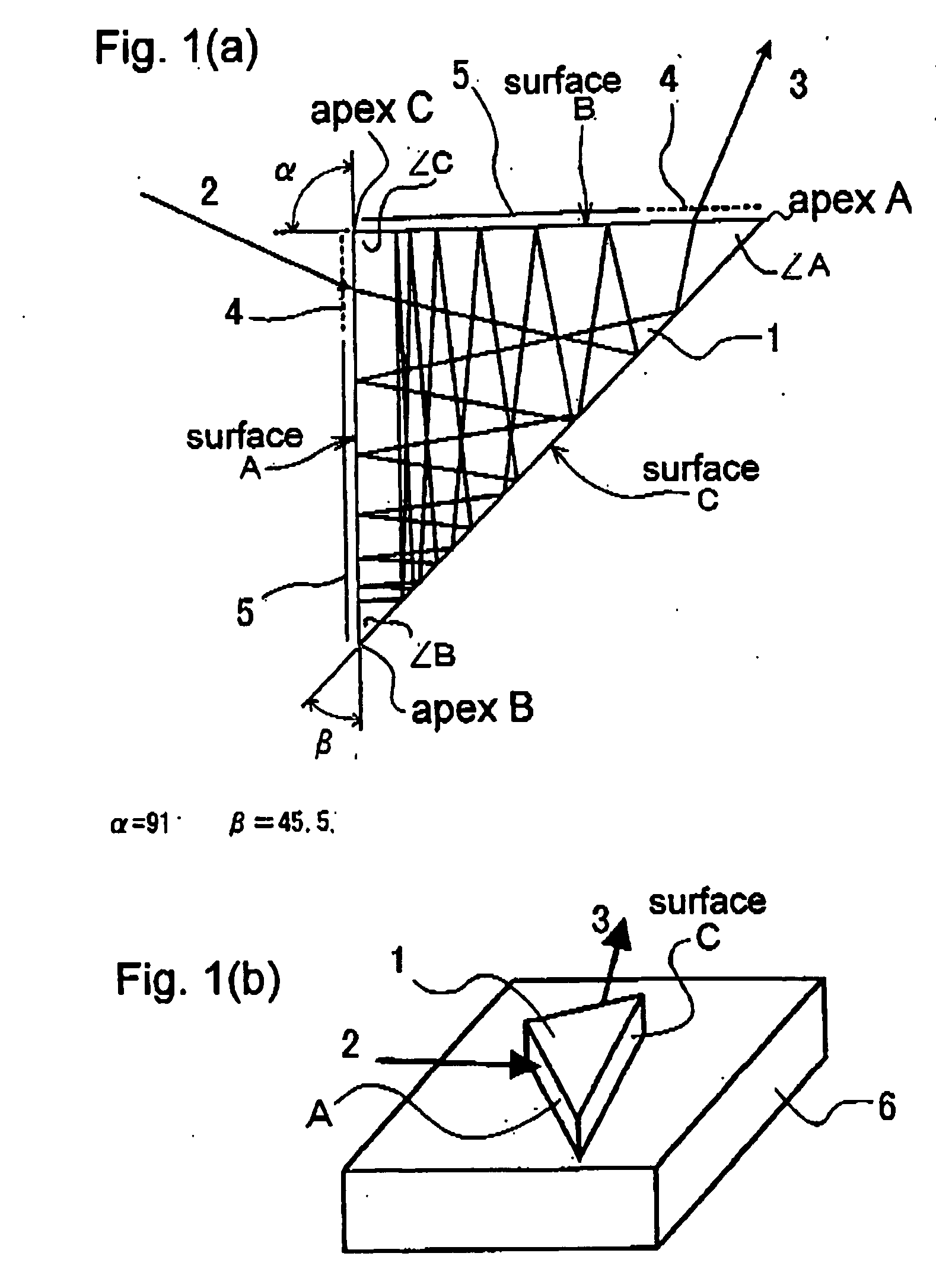

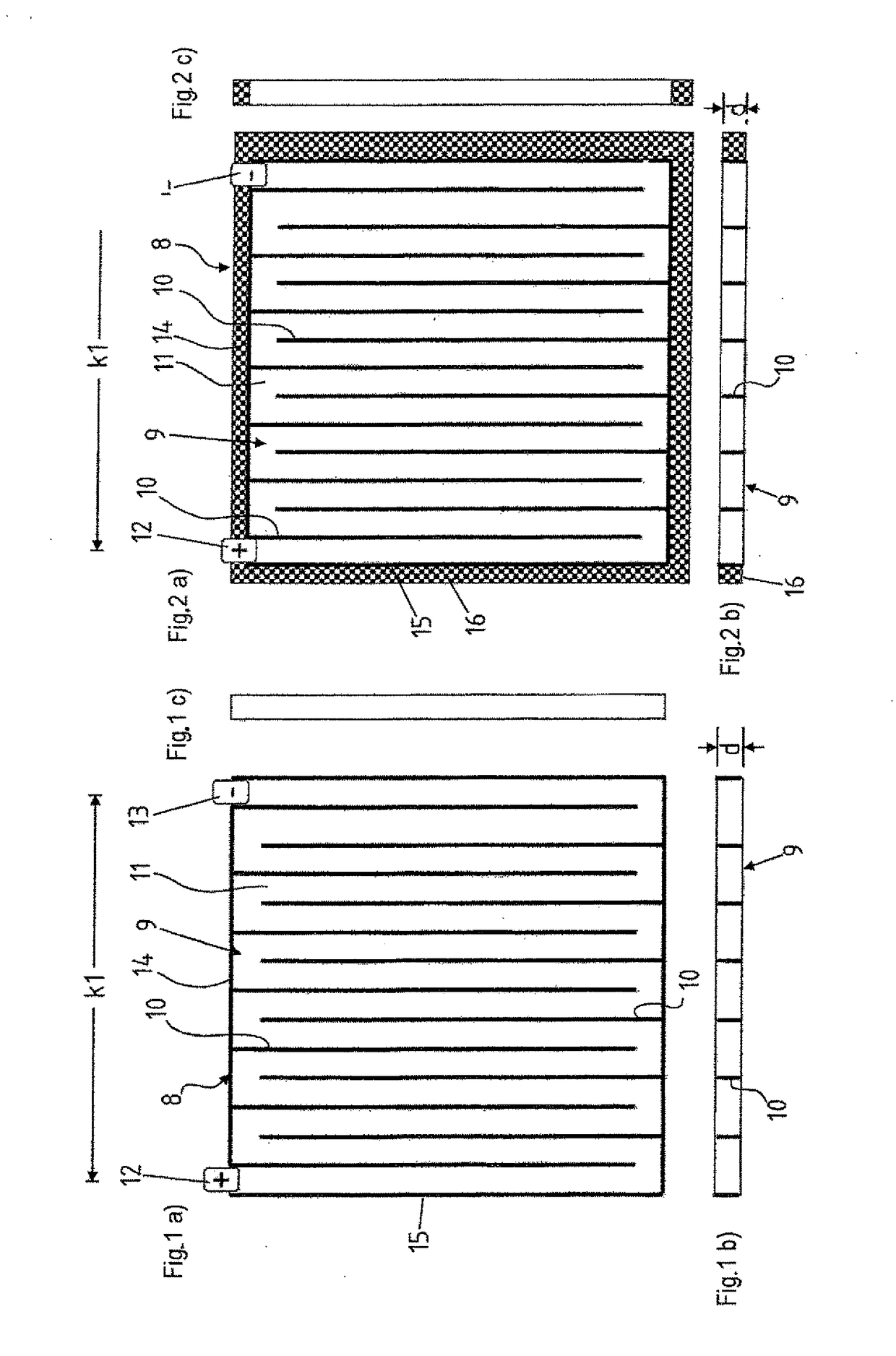

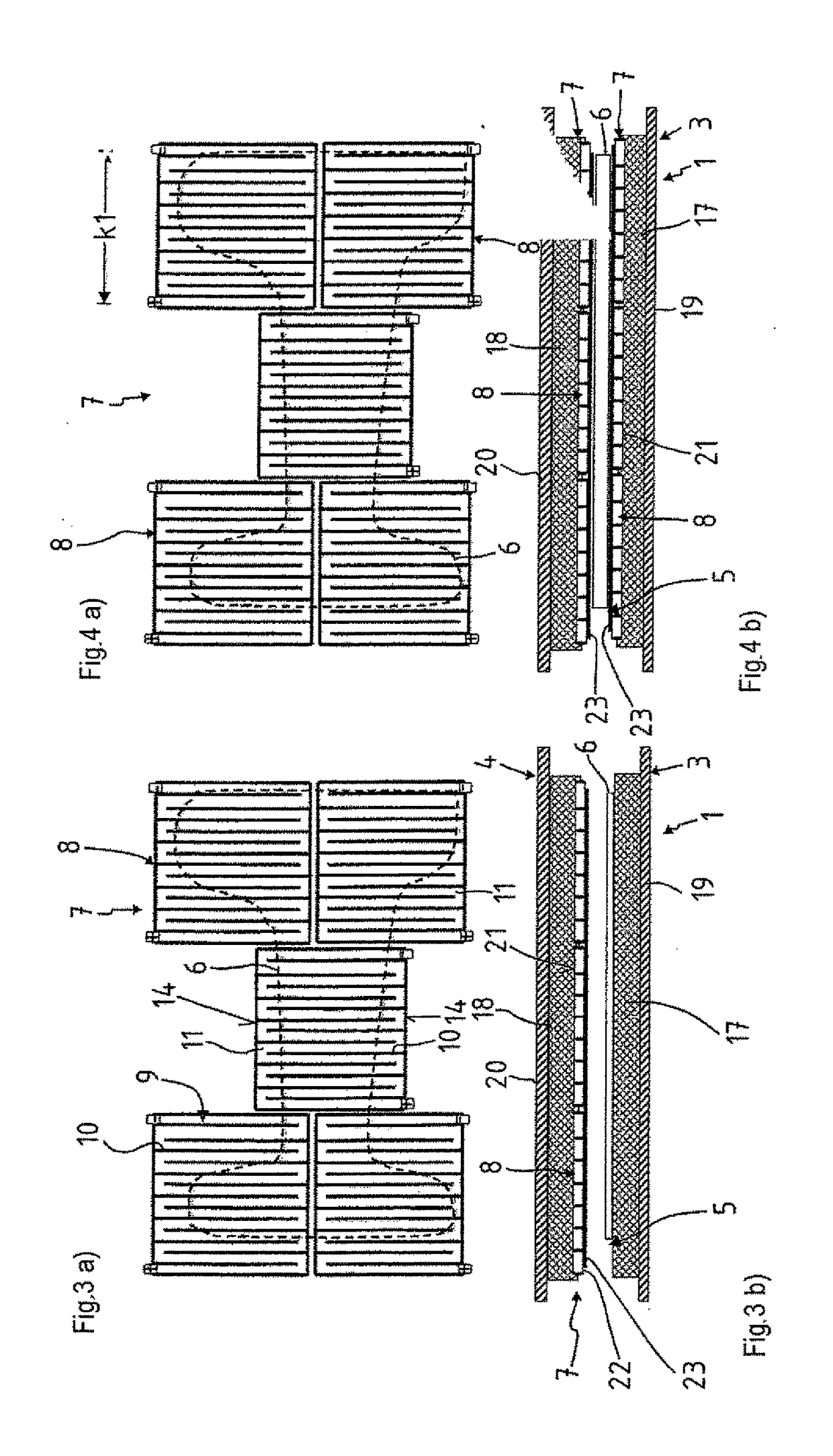

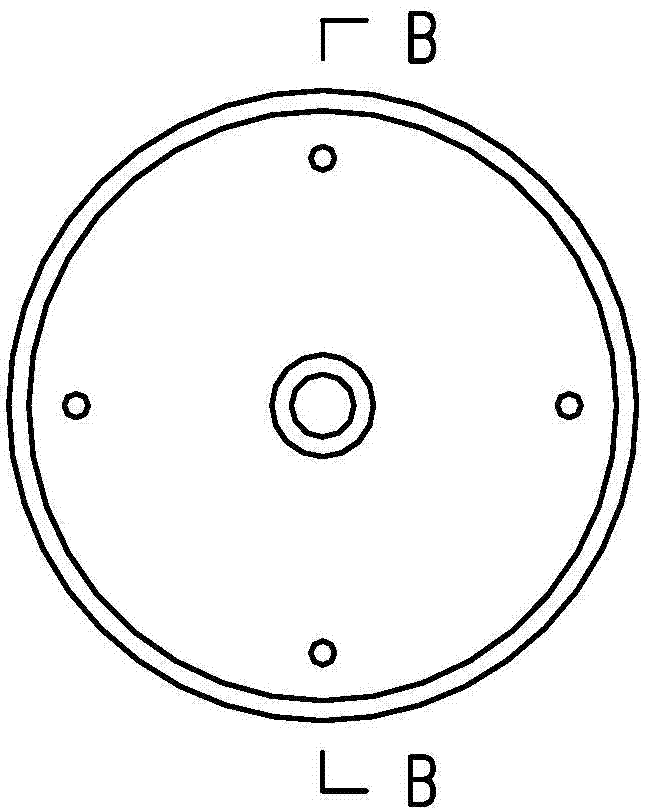

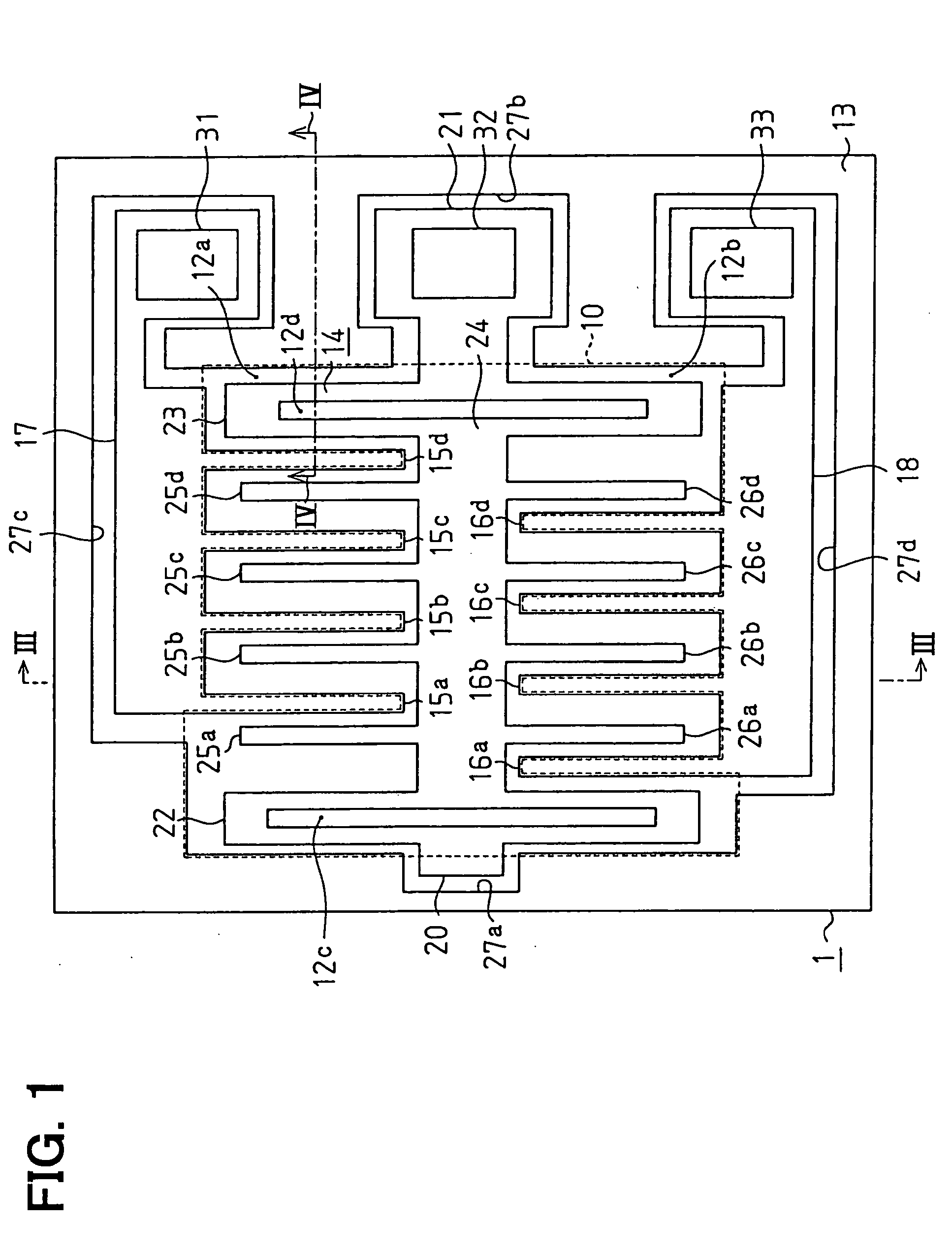

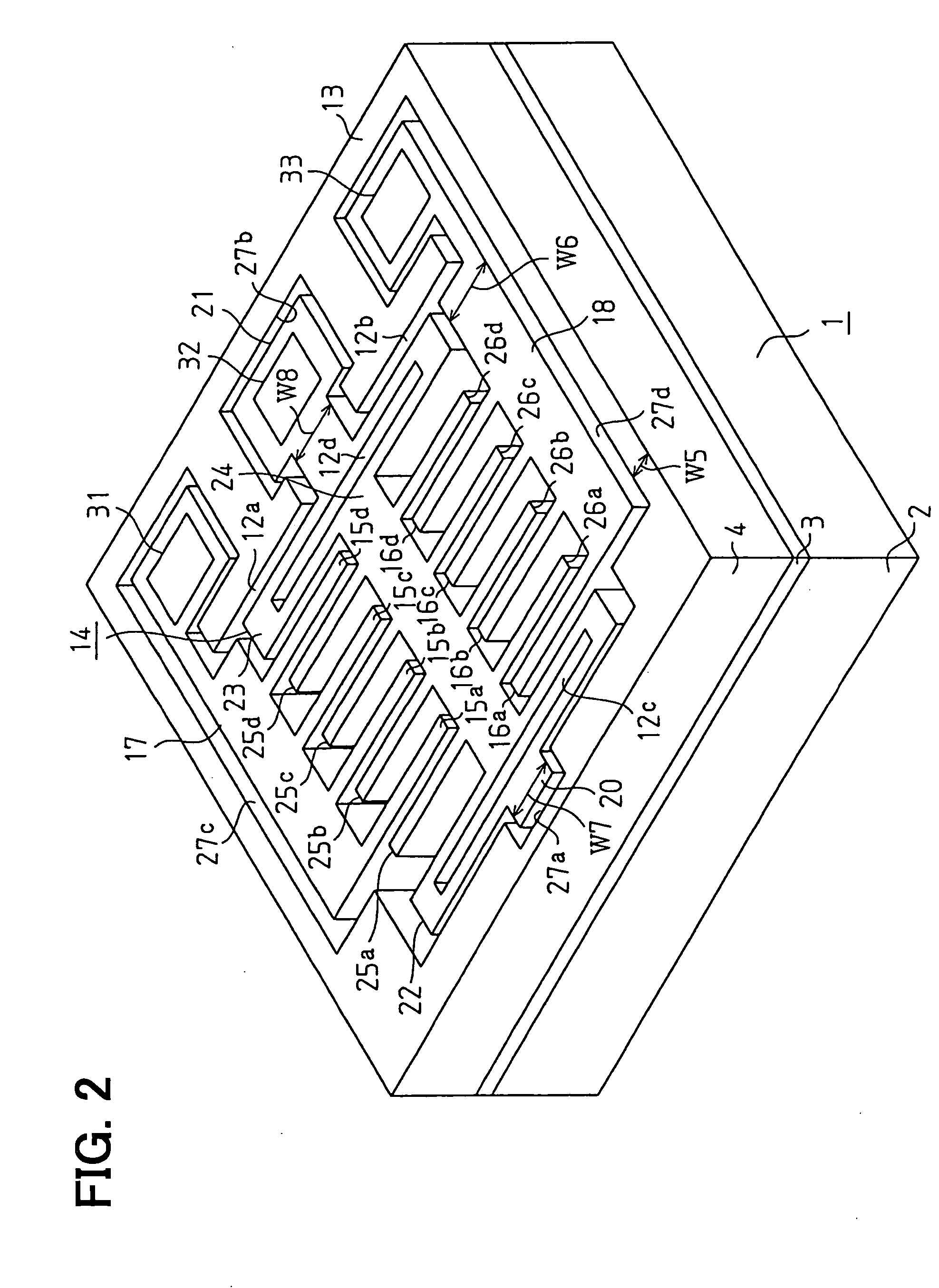

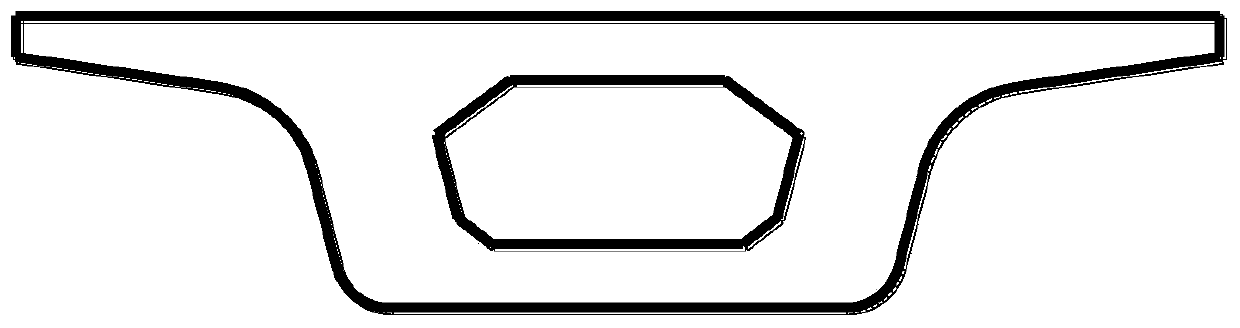

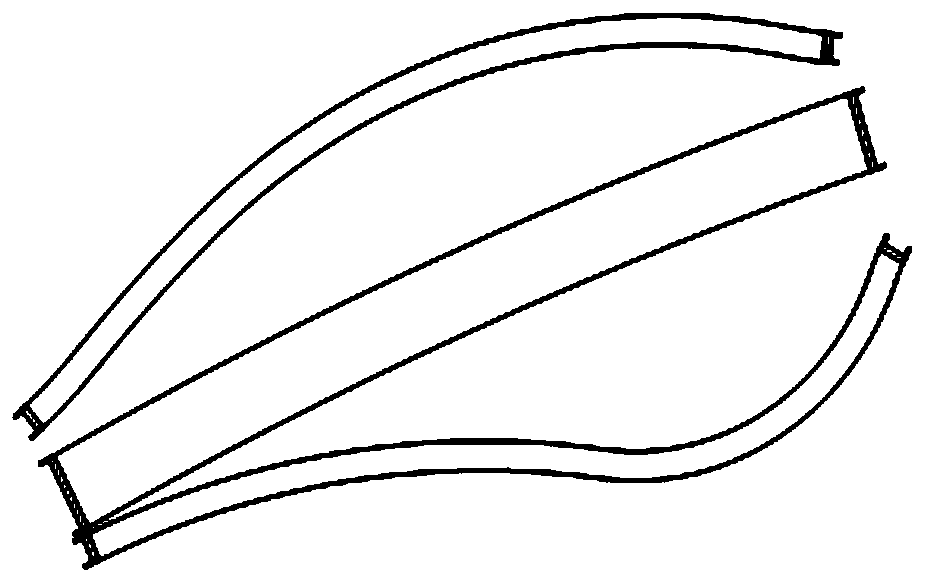

Slab type solid-state laser medium and slab type nonlinear optical medium each using light path formed by multiple reflection caused by three reflecting surfaces

InactiveUS20050195879A1Eliminating spatial hole burningIncrease productionOptical resonator shape and constructionLaser arrangementsLight beamNonlinear optical

A slab type solid-state laser medium furnished on side faces thereof with three reflecting surfaces, provided therein with a light path for optical amplification attained by multiple reflection on the reflecting surfaces, wherein the three reflecting surfaces comprises Surface C serving as a surface on which an incident laser beam reflects first in the solid-state laser medium, Surface B serving as a surface on which the beam reflected on Surface C is subsequently reflected and Surface A serving as a remaining surface, and wherein when Surface Ac and Surface Bc respectively denote imaginary surfaces forming reflected images of Surface A and Surface B relative to Surface C and when Angle C denotes an angle of intersection between Surface A and Surface B or extended surfaces thereof, Angle A denotes an angle of intersection between Surface B and Surface C or extended surfaces thereof and Angle B denotes an angle of intersection between Surface C and Surface A or extended surfaces thereof, Angle C is larger than each of Angle A and Angle B and the incident laser beam is injected into the solid-state laser medium so that the light path formed for the optical amplification in the solid-state laser medium is equivalent to a light path in which the injected beam repeating reflection between Surface A and Surface Bc has been folded back at Surface C, whereby the light path is capable of producing unit reflections on Surface C, Surface B, Surface C and Surface A sequentially in the order mentioned and inducing a multiplicity of the unit reflections. Otherwise, for the purpose of inducing a nonlinear optical effect, a slab type nonlinear optical device similar in shape to the solid-state laser medium is used in the place of the solid-state laser medium.

Owner:NAT INST OF INFORMATION & COMM TECH

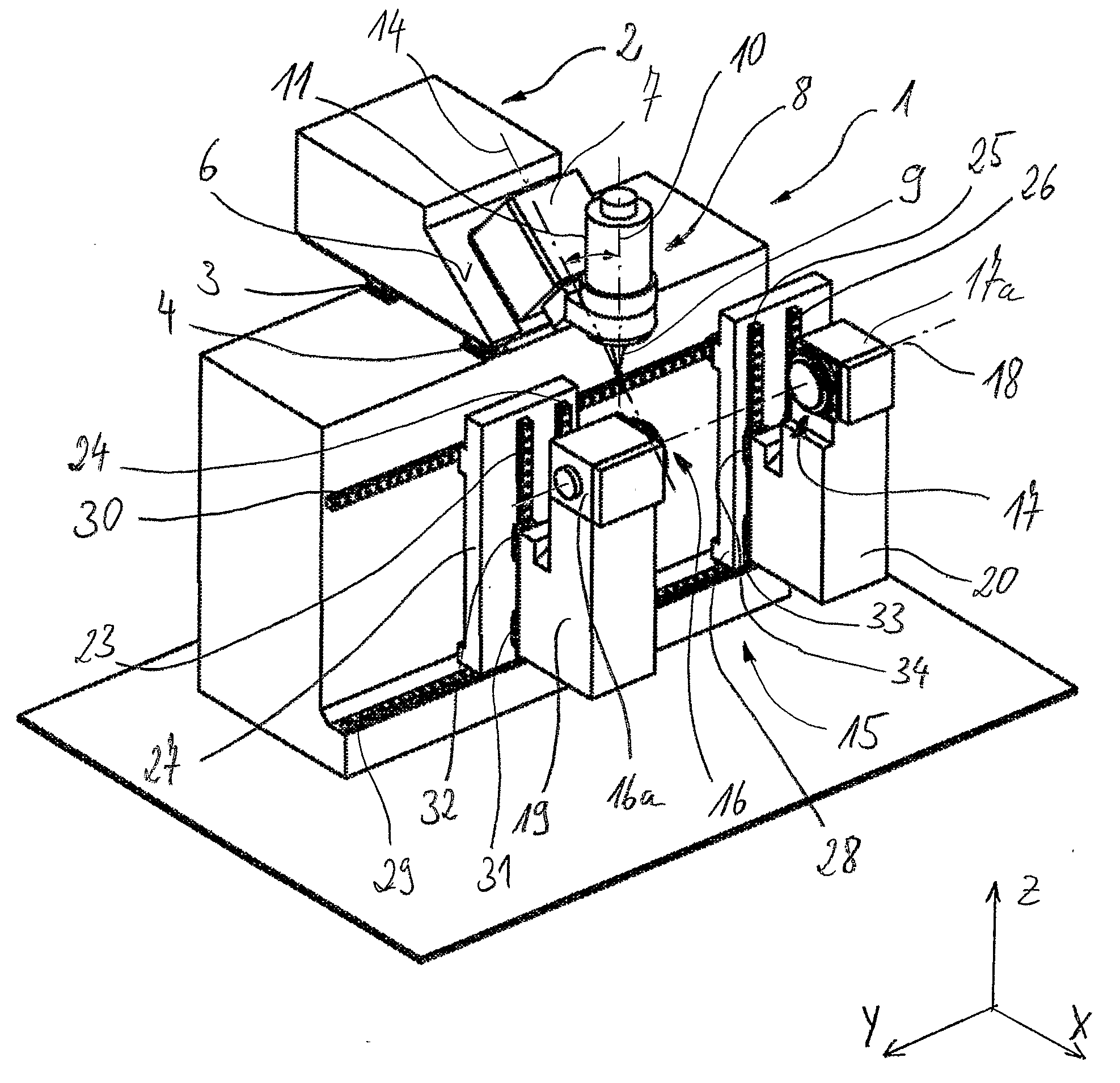

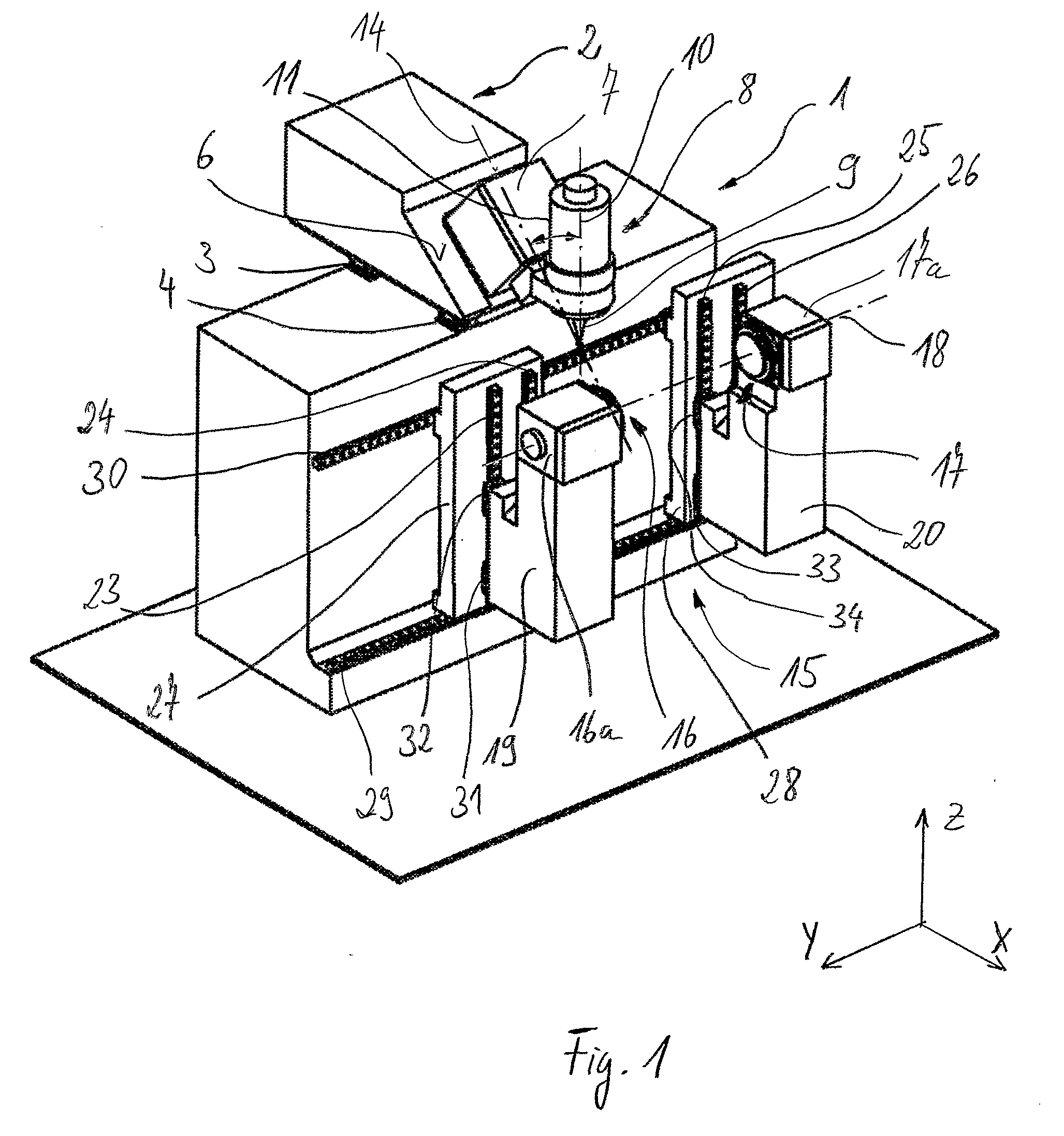

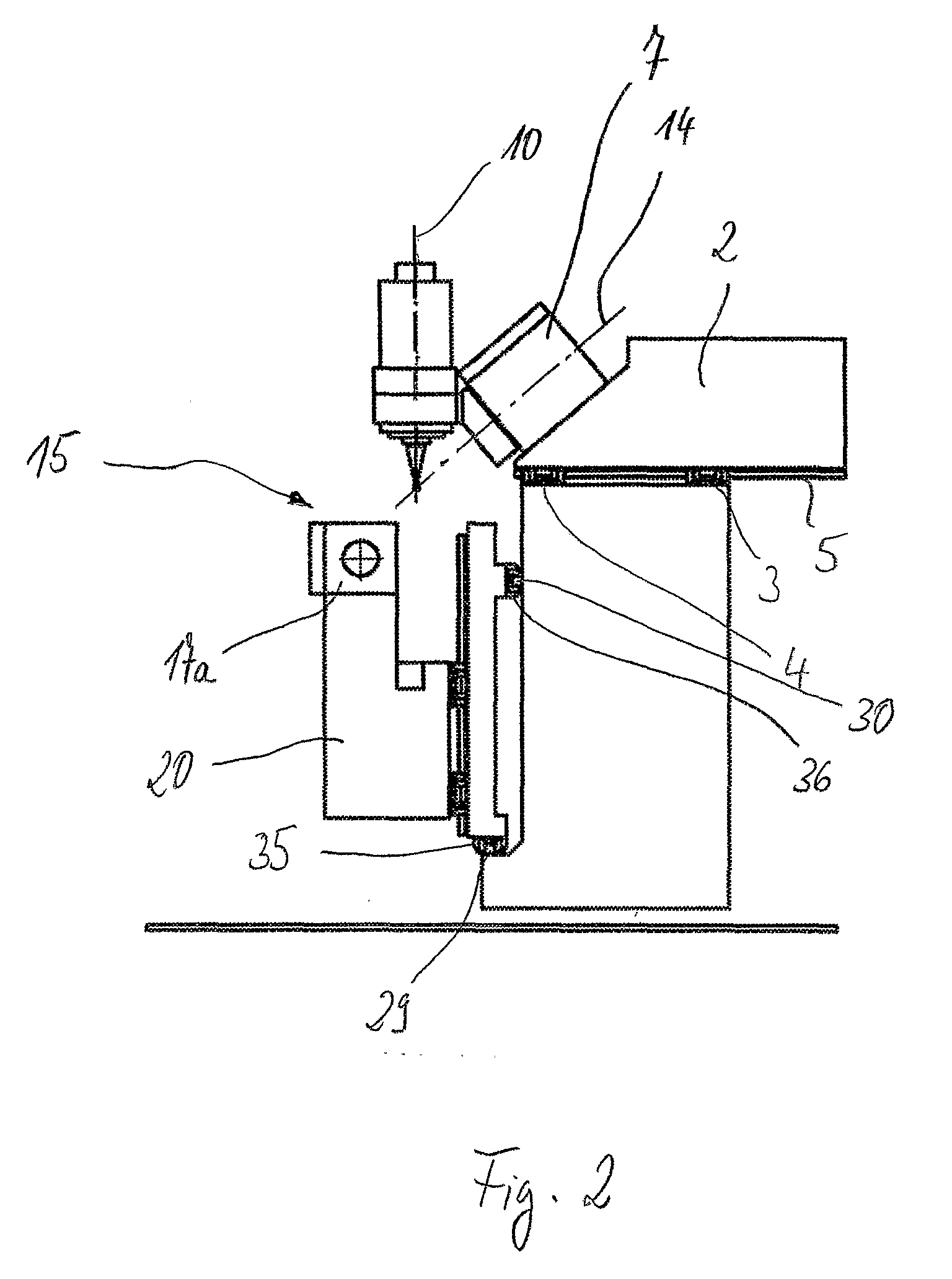

Machine Tool with Two Clamp Points on Separate Carriages

InactiveUS20080213057A1Improve Manufacturing AccuracyImprove rigidityTailstocks/centresAttachable milling devicesEngineeringRelative motion

The invention relates to a machine tool for milling workpieces, provided with at least two linear displacement axes and at least one pivot axis for carrying out relative movements between a tool and the corresponding workpiece with a workpiece mounting in which a workpiece may be clamped between two clamping points, whereby one of the linear displacement axes is provided as workpiece axis of the workpiece mounting, by means of which the workpiece may be linearly driven, which is furthermore provided with a tool holder for mounting a cutting machining tool, driven in rotation about a tool axis by means of a tool drive. The same conditions are achieved for workpieces of greatly different length for a highly accurate production, whereby two physically separate carriages (27, 28) for the workpiece mounting are provided, on each of which one of the clamping points (16, 17) is arranged and which both may be linearly driven along the same workpiece axis independently of each other.

Owner:STARRAGHECKERT

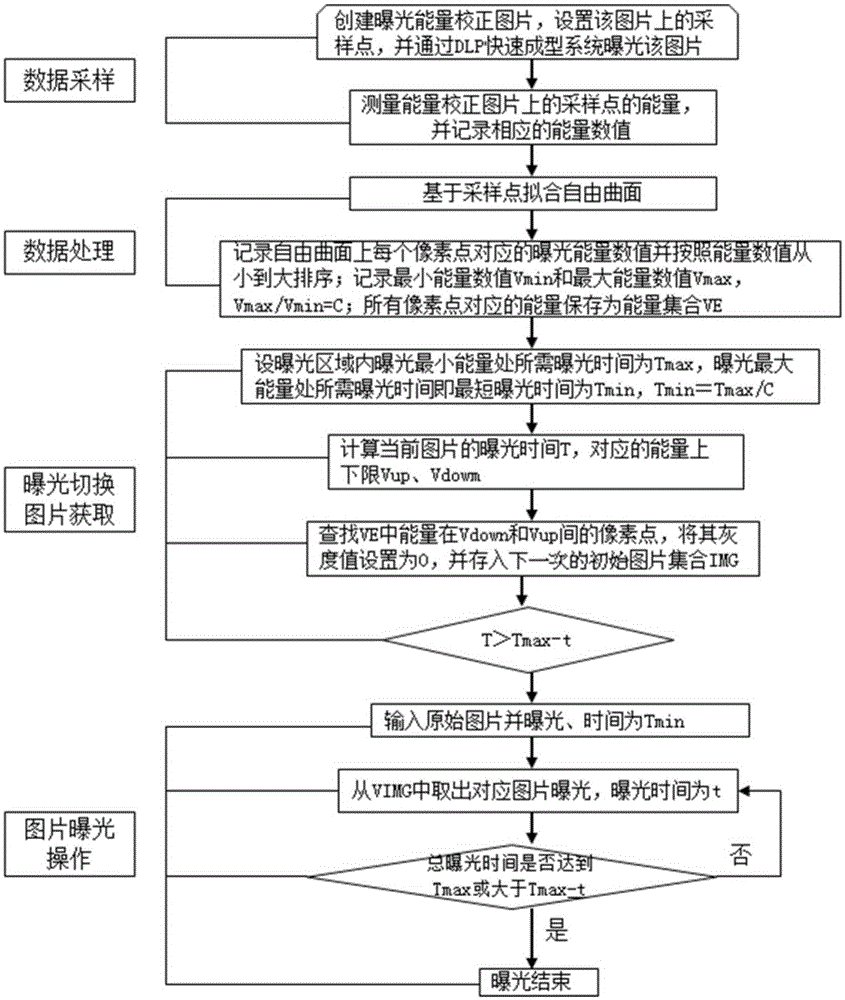

Method for homogenizing DLP exposure energy

ActiveCN105425546AAvoid direct manipulationImprove Manufacturing AccuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusCamera lensLight energy

The invention provides a method for homogenizing DLP exposure energy. The method includes the following steps that step 1, in data sampling, an exposure energy correcting picture is obtained, and light energy determining equipment is utilized for measuring a light energy value of a sampling point on a picture sample; step 2, in data processing, surface fitting processing is performed on the energy value of the sampling point, and statistics is performed on exposure energy corresponding to all pixel points of the picture; step 3, in the process of obtaining an exposure switching picture, an exposure switching picture set VIMG is generated; step 4, in picture exposure operation, time lengths of exposure time of all the pixel points are adjusted. Direct operation on energy is avoided, and the energy is homogenized easily, conveniently and rapidly through adjusting exposure time; the problem that because of an optical machine or lens or other hardware, exposure energy is not homogenized is solved, the manufacturing precision of a DLP face exposure rapid forming system is improved, the yield of the DLP face exposure rapid forming system is increased, an even printing effect under a full format is achieved, the yield of the system is greatly increased, the manufacturing precision of the DLP rapid forming system is improved, and the yield of the DLP rapid forming system is increased.

Owner:HANS LASER TECH IND GRP CO LTD

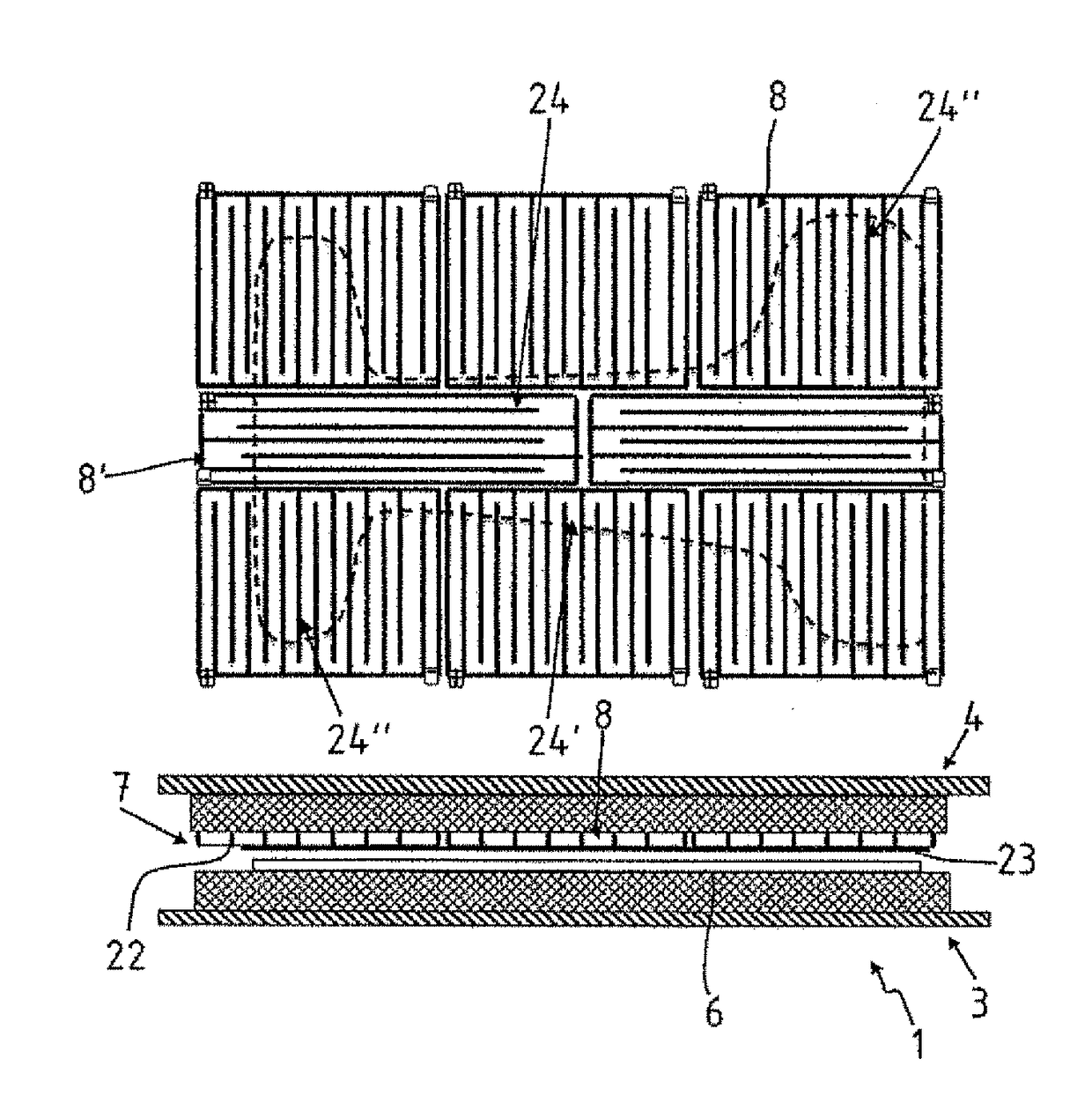

Hot forming line and method for producing hot formed sheet metal products

InactiveUS20170066030A1High strengthImprove Manufacturing AccuracyShaping toolsMetal-working feeding devicesProduction lineElectrical resistance and conductance

A hot forming line for producing hot formed and press hardened sheet metal products made from metal plates includes a heating station and a forming station. The heating station has a bottom tool and an top tool between which a metal plate is received. The metal plate is heated in the heating station by indirect resistance heating. The heat is generated outside the metal plate and is transmitted by heat conduction into the metal plate itself. For this the bottom tool and / or the top tool has an electric resistance heating with at least one surface heating element. The surface heating element is a heating plate with a plate body made of an electrically conductive material, wherein the plate body is configured as heat conductor. For this the plate body is slotted and is for example provided with a slot, which extends over the thickness of the plate body.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

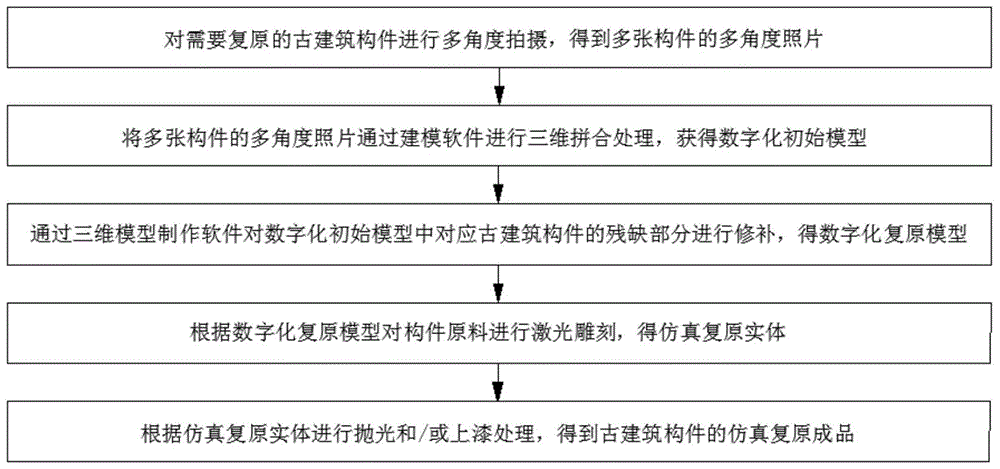

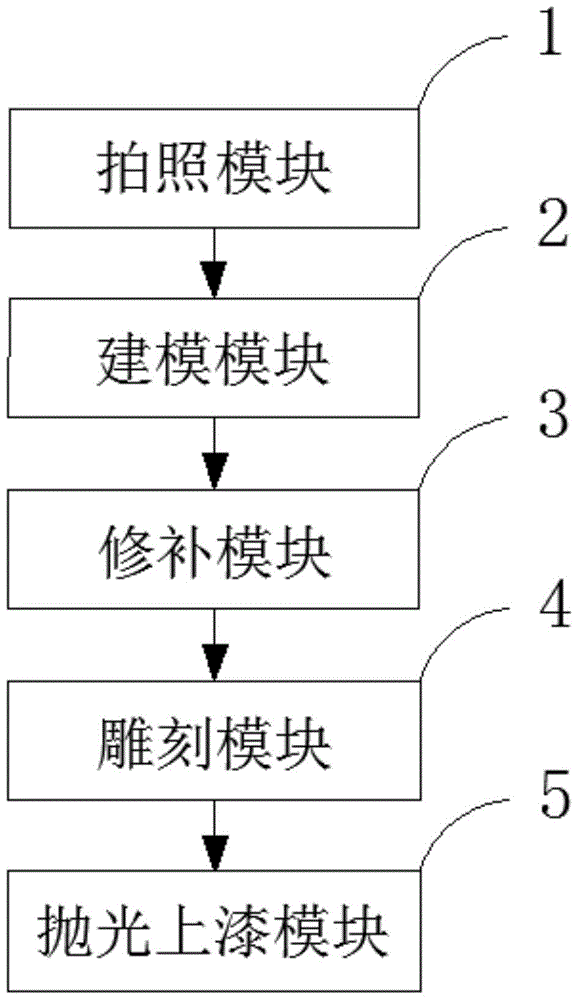

Simulation recovery system and method of historic building component

InactiveCN105741347AReduce manufacturing costImprove repair efficiency3D-image rendering3D modellingModeling softwareLaser engraving

The invention relates to a simulation recovery system and method of a historic building component. The method comprises the following steps: carrying out multi-angle shooting on the historic building component which needs to be recovered to obtain a plurality of multi-angle photos of the historic building component; carrying out three-dimensional split processing on the plurality of multi-angle photos of the historic building component through modeling software to obtain a digitized initial model; through three-dimensional model manufacture software, repairing the missing part of the corresponding historic building component in the digitized initial model to obtain a digitized recovery model; according to the digitized recovery model, carrying out laser engraving on the raw materials of the historic building component to obtain a simulation recovery entity; and according to the simulation recovery entity, carrying out polishing and / or painting processing to obtain a simulation recovery finished product of the historic building component. Compared with the prior art, the simulation recovery system and method can show texture characteristics and colors, is low in manufacture cost, is free from the restriction of height where the historic building component is positioned, and can meet bath quick surveying and mapping and simulation recovery requirements of the historic building.

Owner:GUILIN UNIV OF ELECTRONIC TECH

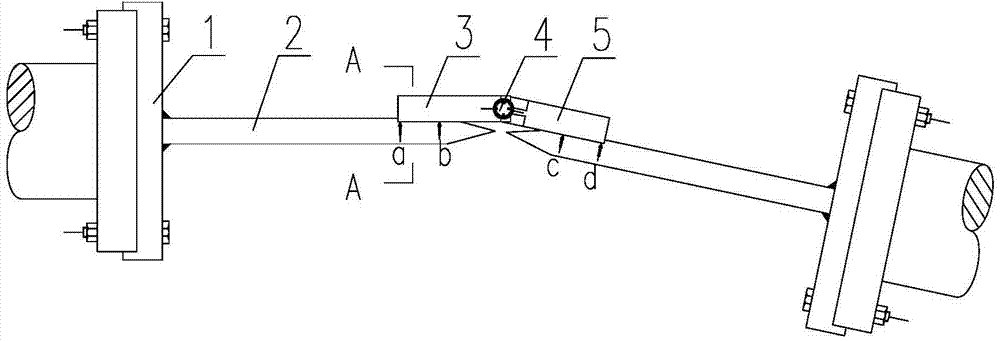

Manufacturing method for zigzag shafting alignment tool

ActiveCN103542797AIntuitive measurement resultsImprove Manufacturing AccuracyAngles/taper measurementsSteel barShaft alignment

The invention discloses a manufacturing method for a zigzag shafting alignment tool, and relates to the field of alignment of zigzag shafting. The manufacturing method includes respectively manufacturing a pair of alignment pointers between an input shaft and an output shaft, wherein the input shaft and the output shaft are adjacent and an included angle is formed between the both, and each alignment pointer is a mechanical member formed by welding of a flange and a straight steel bar with a tapered tip; manufacturing a set of alignment right-angle ruler comprising a first right-angle ruler arm, an angle indicating bolt and a second right-angle ruler arm, wherein a screw hole is formed at the ruler arm end of each of the first right-angle ruler arm and the second right-angle ruler arm, the angle indicating bolt penetrates the screw hole to fix the first right-angle ruler arm and the second right-angle ruler arm together, and the first right-angle ruler arm and the second right-angle ruler arm rotate around the angle indicating bolt which displays included angle between the first right-angle ruler arm and the second right-angle ruler arm. By the method, both angle and offset can be measured, measuring results are visual, measuring accuracy is high, construction is simple and convenient, the tool is convenient to demount, and production efficiency can be improved.

Owner:WUCHANG SHIPBUILDING IND

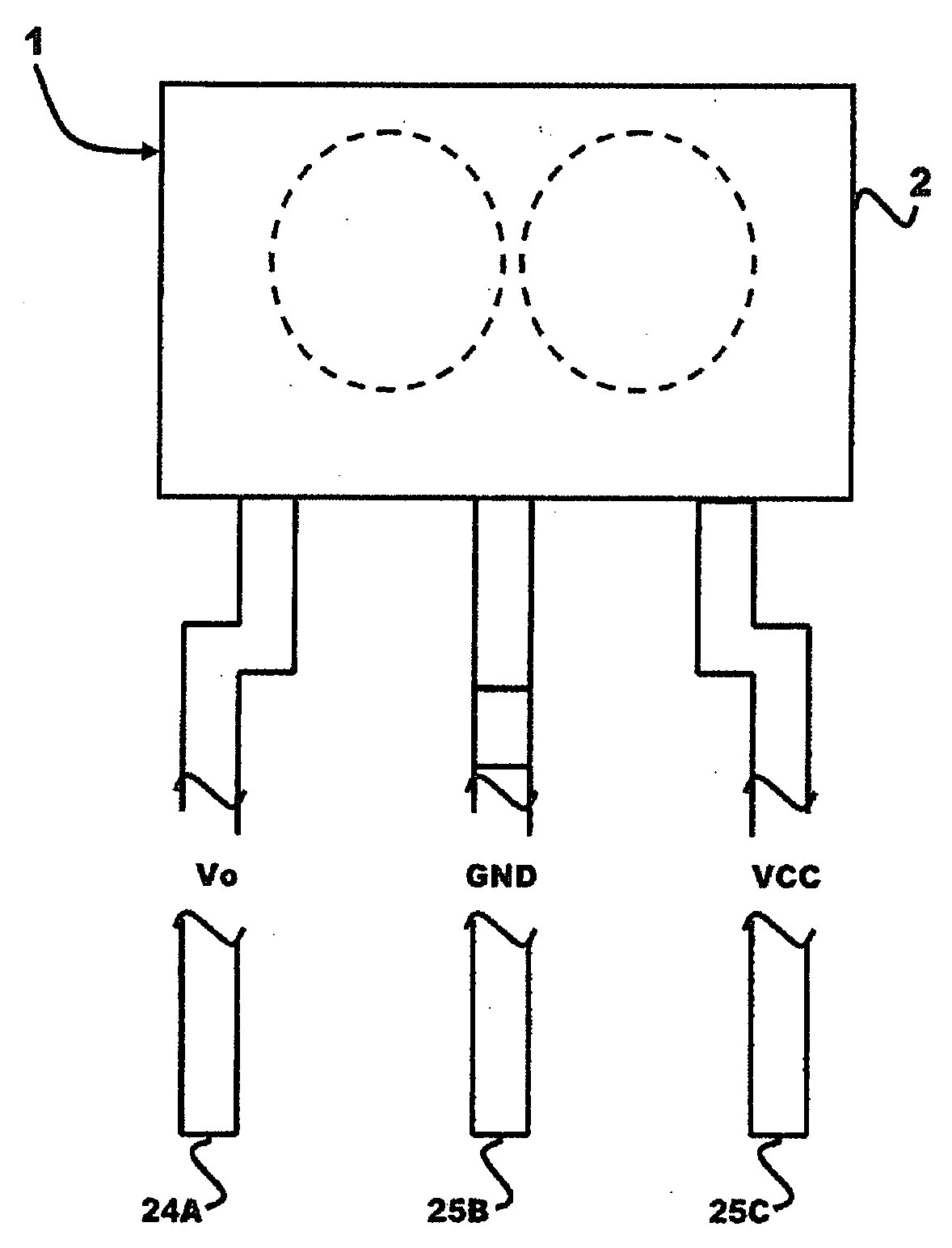

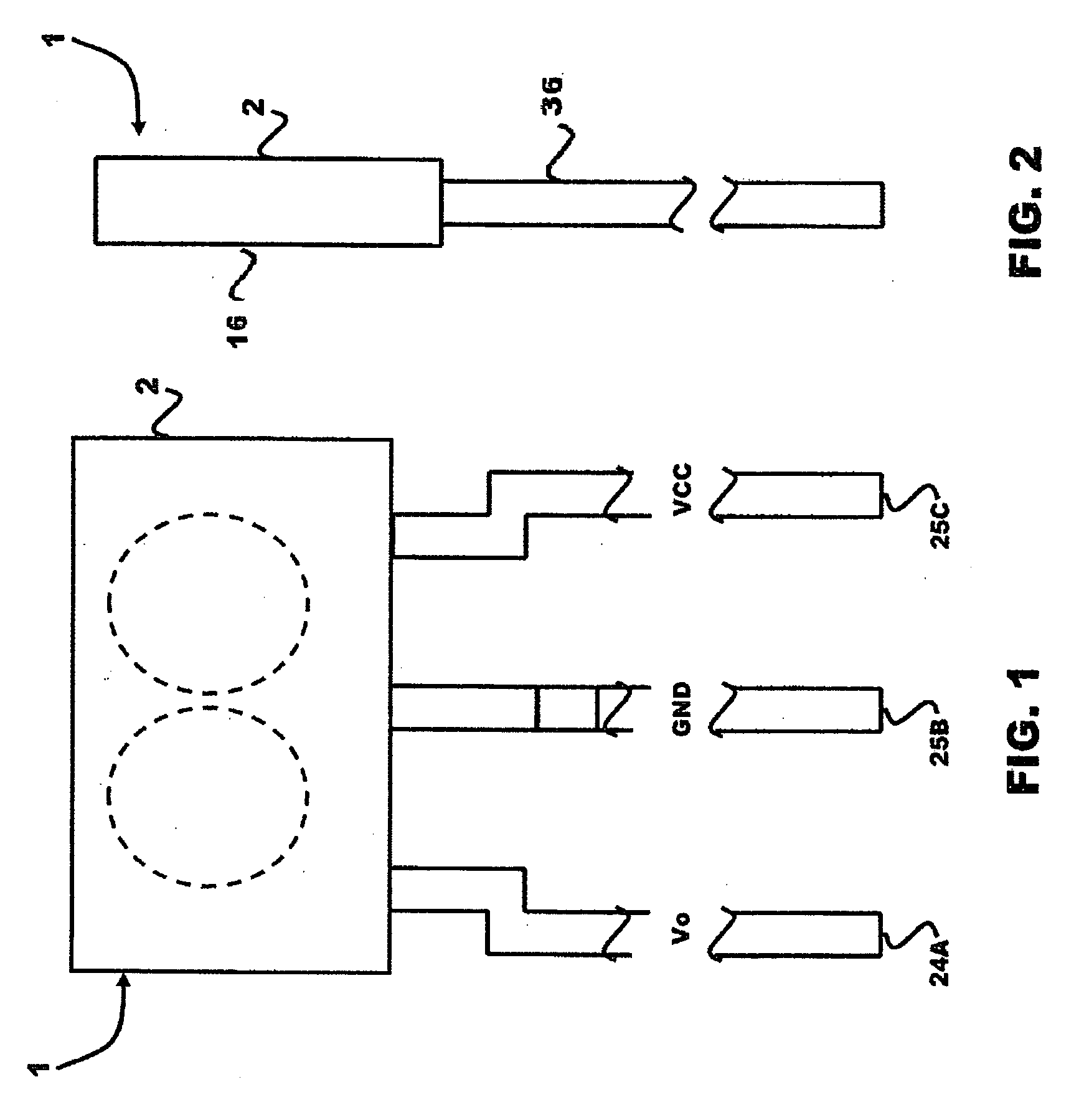

Low-cost compact bar code sensor

ActiveUS20080048037A1Improve Manufacturing AccuracyLarge working distanceMirrorsTelevision system scanning detailsVertical-cavity surface-emitting laserDetector circuits

A barcode sensor package has an optical emitter circuit and an optical detector circuit which are formed as one or more integrated optical circuits disposed in a housing which has a reading surface and one or more apertures located between the optical emitter and detector circuits. The optical emitter circuit has an emitter die, such as a vertical cavity surface emitting laser (VCSEL), for emitting a light beam and a diffraction optical element disposed on the emitter die for focusing the light beam to a bar code. The optical detector circuit has a photodetector die, such as a phototransistor, for detecting reflective light and another diffraction optical element disposed on the photodetector die for guiding light reflected from the bar code to the detector. The diffraction optical elements are fabricated by patterning optical layers, deposited on respective emitter and detector dies, using photolithograph or a direct write process.

Owner:HONEYWELL INT INC

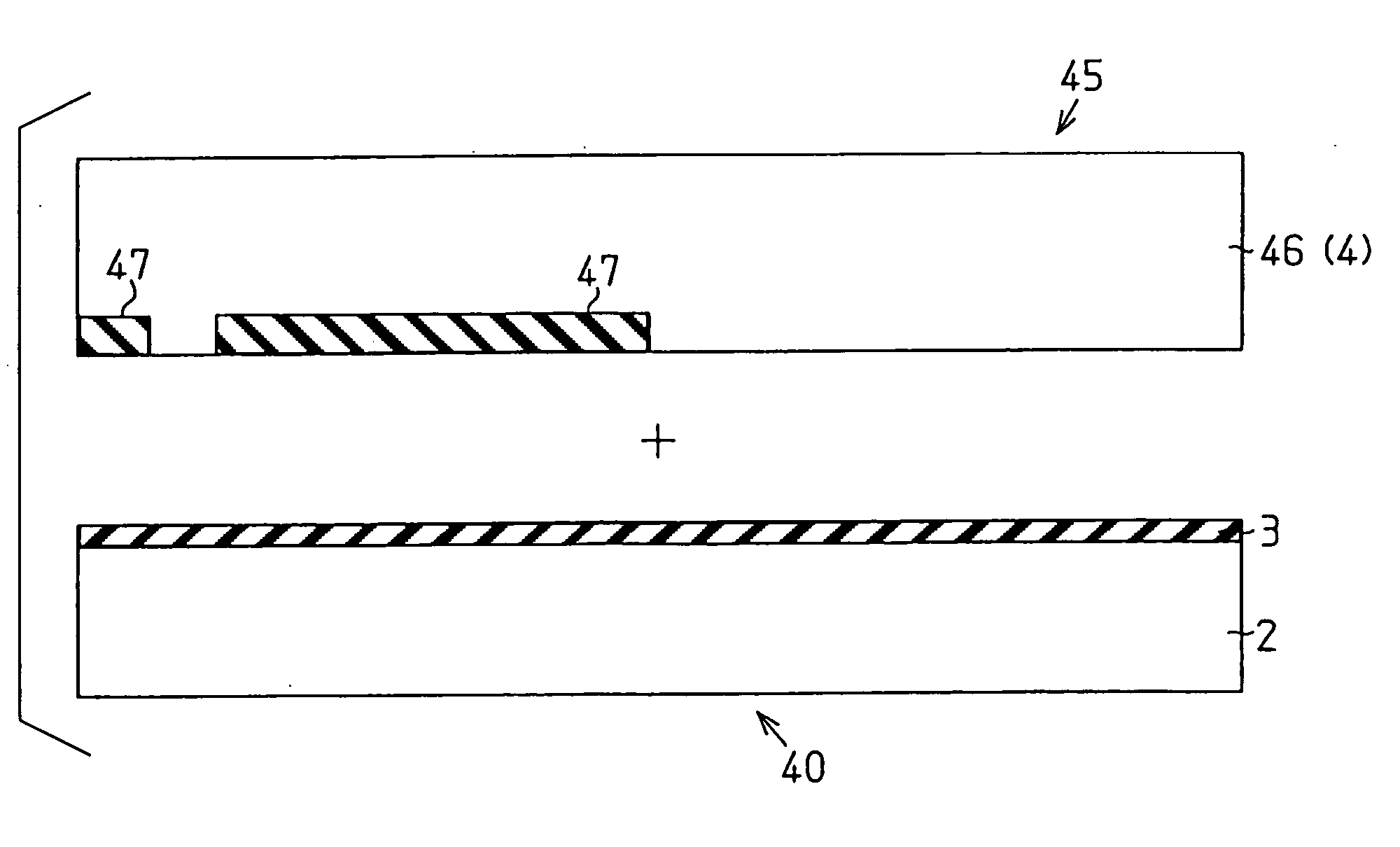

Method for manufacturing semiconductor physical quantity sensor

InactiveUS20060008936A1Improve Manufacturing AccuracyDesign degree of of largeSemiconductor/solid-state device manufacturingAcceleration measurementEngineeringSemiconductor

A method for manufacturing a semiconductor physical quantity sensor is provided. The sensor includes a multi-layered substrate, a cavity, a groove, a movable portion and a fixed portion. The multi-layered substrate includes a support substrate, an embedded insulation film, and a semiconductor layer. The method includes the steps of: preparing the multi-layered substrate having a sacrifice layer embedded in the semiconductor layer so that the sacrifice layer is disposed at a cavity-to-be-formed portion; forming the groove from the semiconductor layer to reach the sacrifice layer; and selectively etching the sacrifice layer from a bottom of the groove to form a cavity.

Owner:DENSO CORP

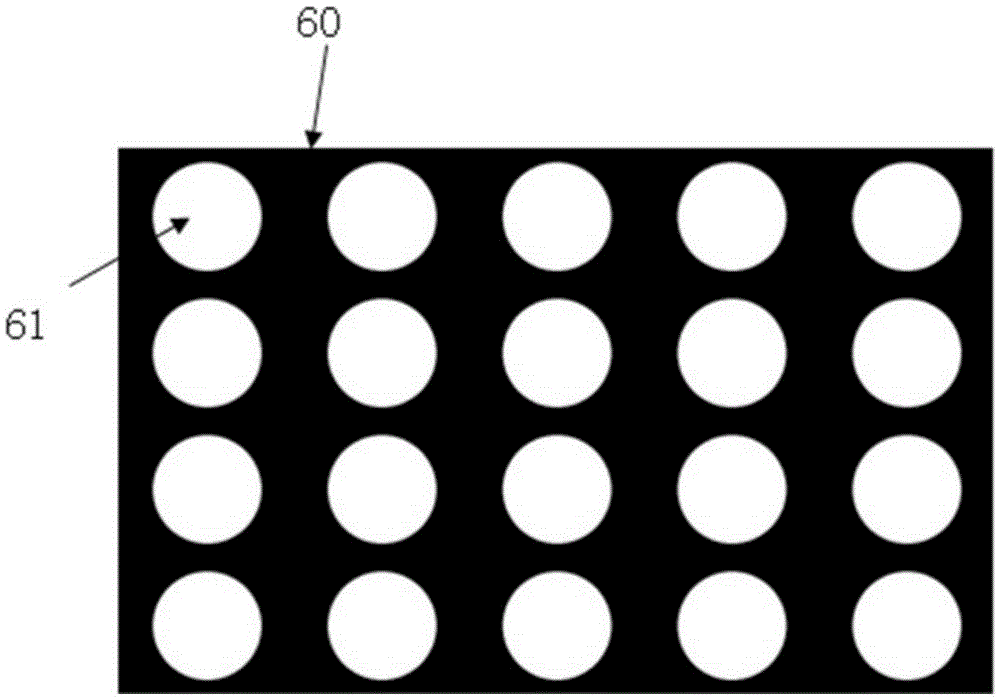

Array substrate, display pane and manufacturing method thereof, and display device

ActiveCN109671738AEvenly filledAvoid performance failureSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThinning

The invention discloses an array substrate, a display panel and a manufacturing method thereof and a display device. The array substrate comprises a substrate and a pixel defining layer. The surface array of the substrate has a plurality of pixel grids, the pixel defining layer is disposed on the substrate, the pixel defining layer defines a plurality of pixel grids arranged in an array, the pixeldefining layer further comprises a plurality of thickness thinning regions, and the thickness thinning regions are suitable for guiding flow of the package layer. According to the array substrate provided by the embodiment of the invention, the pixel defining layer is laid on the substrate, is configured to define a plurality of pixel grids and comprises the plurality of thickness thinning regions, when the substrate is filled with the package layer, the thickness thinning regions can guide the flow direction of the package layer so as to allow the filling of the package layer to be uniform and avoid the condition of the excessive filling or non-full filling of the package layer to cause the conditions of failure or poor performances of the performances of the OLED.

Owner:BOE TECH GRP CO LTD

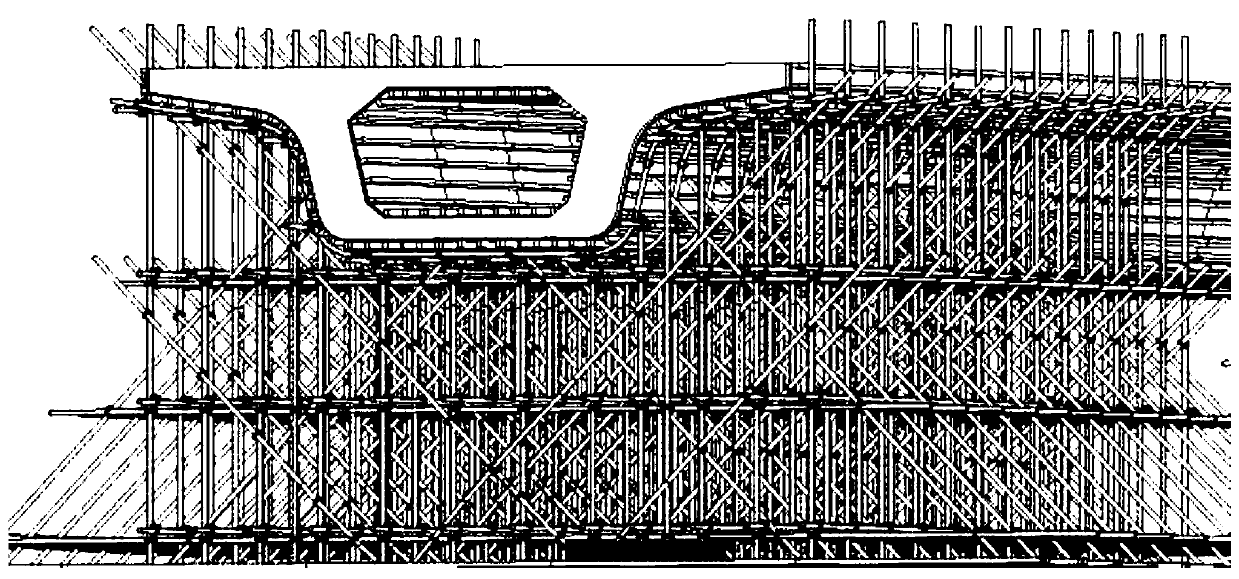

Method for processing crystallizer copper pipe with upper and lower installation spigots

The invention discloses a method for processing a crystallizer copper pipe with upper and lower installation spigots. The method comprises the specific steps that (1) each side of a copper pipe semi-finished product which is formed through extrusion are respectively reserved with 1-2millimeters as a machining allowance according to the length dimension of a finished product; (2) a mounting plate of a combination fixture is fixed on an operating platform of a numerical control machine tool; (3) the copper pipe is installed and fixed through the combination fixture; (4) a lower end spigot mounting surface, a lower opening end face, an external chamfer and an internal chamfer are machined on the copper pipe; (5) an upper end spigot mounting surface is machined on the copper pipe; and (6) an upper opening end face and an upper opening annular groove are machined on the copper pipe. According to the method, the method which is continuously used by a conventional machining method and takes the external surface of the copper pipe as a basis reference for various machining surfaces is changed, and the surface of an inner cavity of the copper pipe is used as the basis of machining; and moreover, processes are reasonable in arrangement, and tools are appropriately used, so that the machining quality can be ensured.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

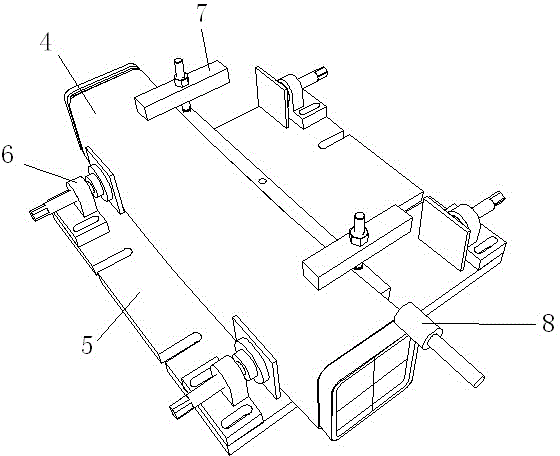

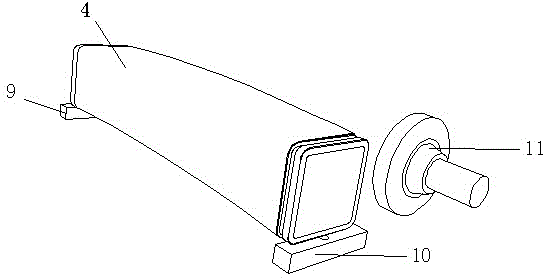

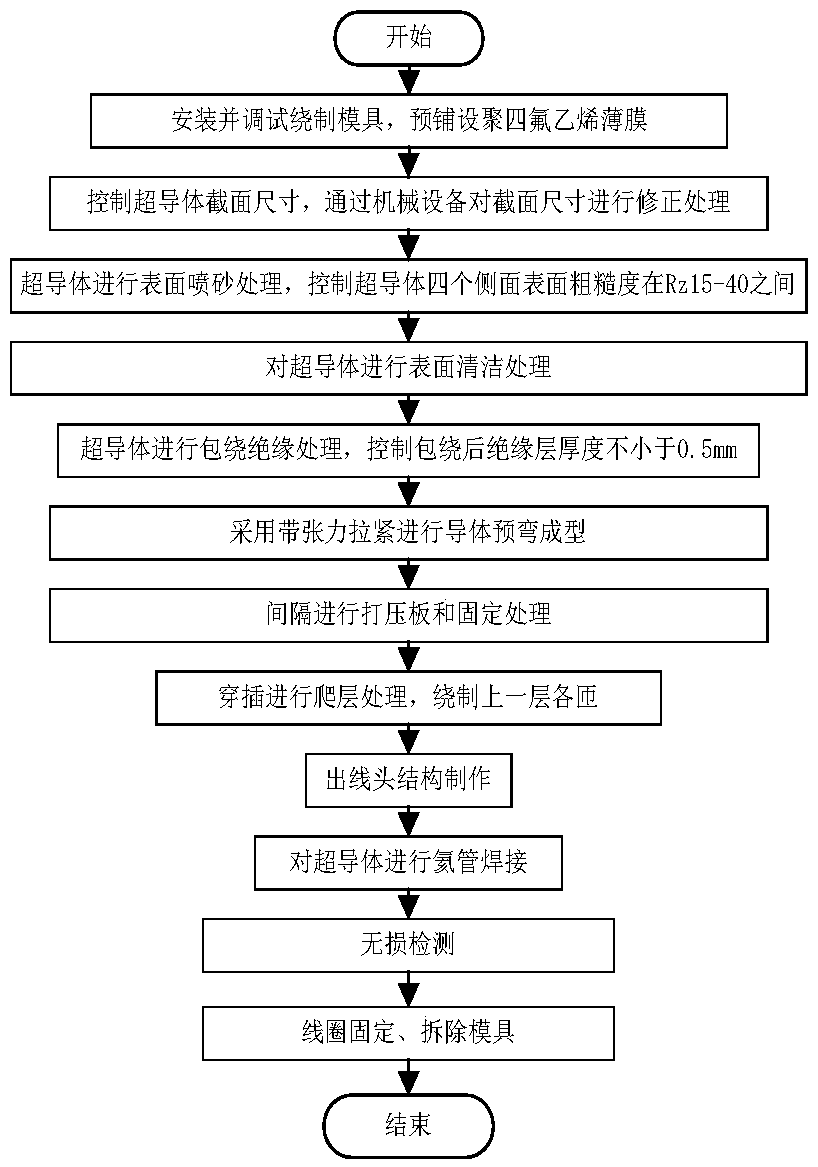

A superconduction CICC cylindrical coil winding process

ActiveCN109273244AGuarantee statusGuaranteed efficiencySuperconducting magnets/coilsCoils manufactureNon destructiveWinding machine

The invention discloses a super conduction CICC cylindrical coil winding process The following steps are included: conductor cross-section size processing, conductor surface treatment, conductor insulation treatment, conductor strip tension winding forming treatment, climbing layer treatment, enthalpy inlet and outlet tube welding processing, joint processing, non-destructive testing processing, final coil unmolding and fixing treatment, Completion of the winding of the entire coil The invention can rapidly wind the high-precision CICC cylindrical coil, and has the advantages of synergistic effect of each step mechanism, high efficiency, high precision, convenient size control, and high application prospect in the winding of the cylindrical coil by using the belt tension winding machine.

Owner:合肥聚能电物理高技术开发有限公司

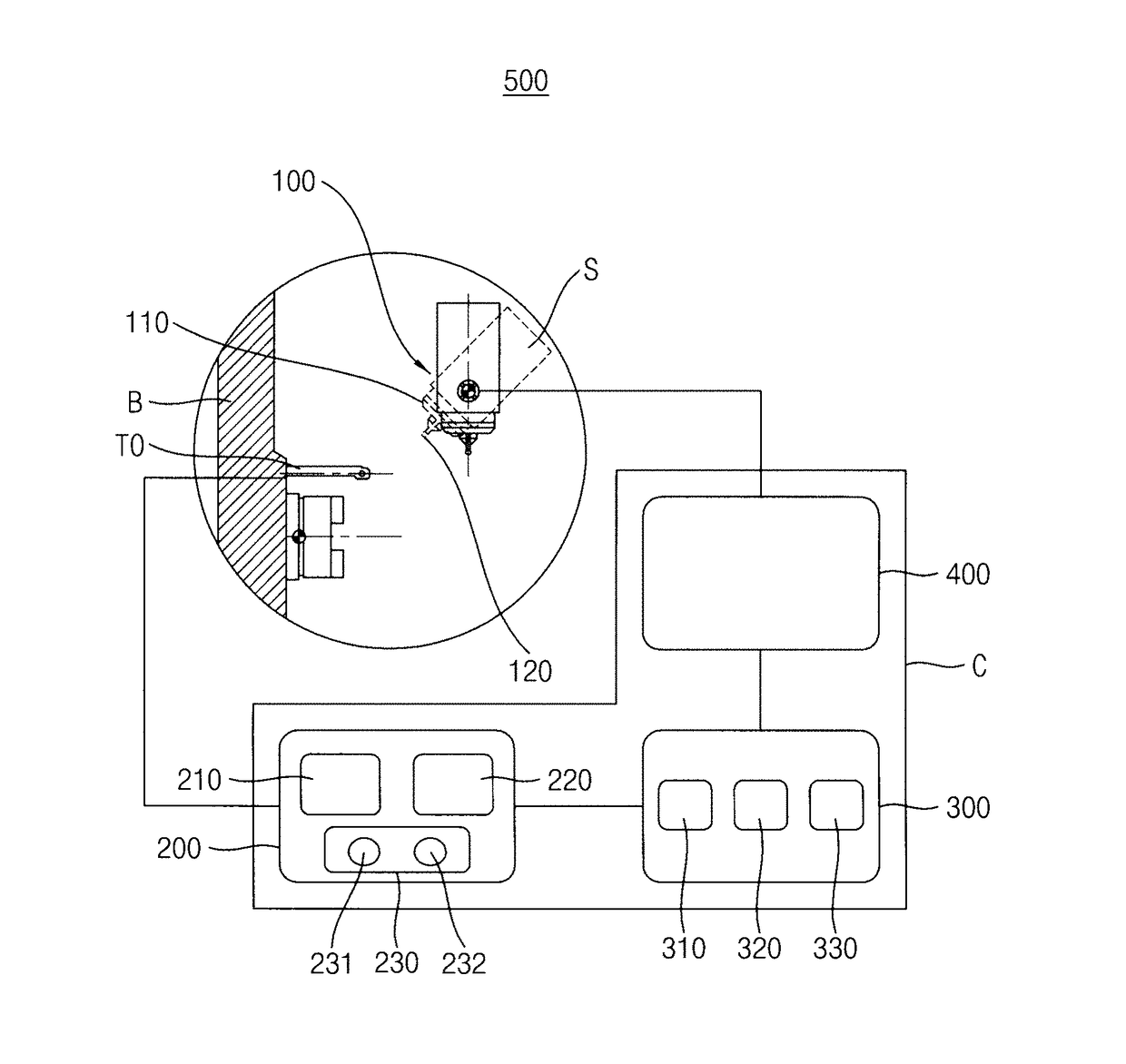

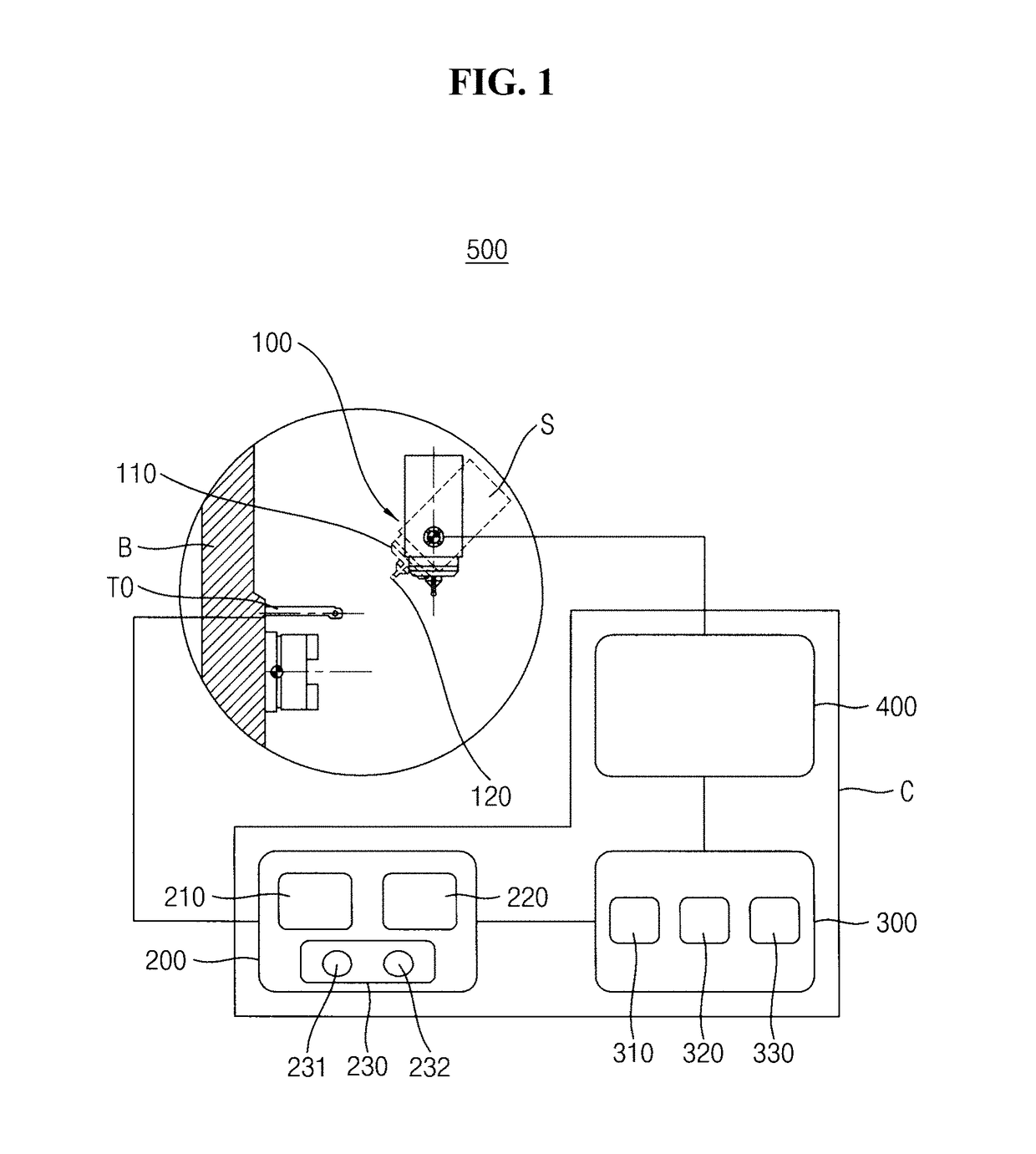

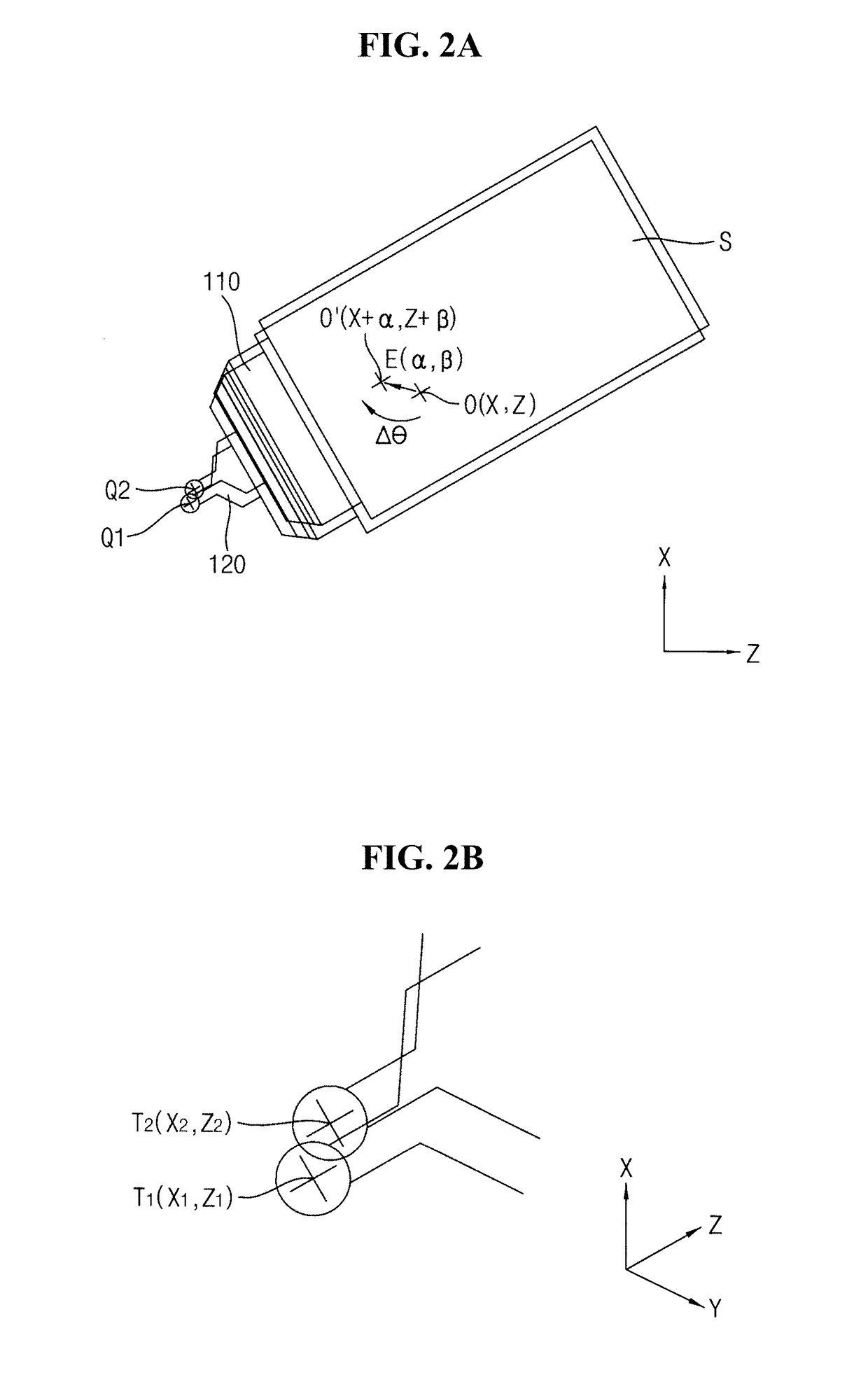

Position controller for controlling a rotation center of a tilting head

ActiveUS20170357237A1Eliminate errorsImprove Manufacturing AccuracyAutomatic control devicesNumerical controlControl theory

Disclosed is a position controller for a tilting head in a machining center. The position controller includes an offset attachment having a body combined to the tilting head and a spherical contact secured to the body, an offset detector built in the machining center such that the offset detector move out into a process area of the machining center and automatically detects a tool offset from a contact point with the spherical contact, a storing unit individually storing first and second tool offsets by respective rotation positions of the tilting head, and an operator generating a transform offset of the first tool offset by a rotational transform and a center error vector from the transform offset and the second tool offset. Accordingly, the center error of the tilting head is automatically detected and corrected in the machining center.

Owner:DN SOLUTIONS CO LTD

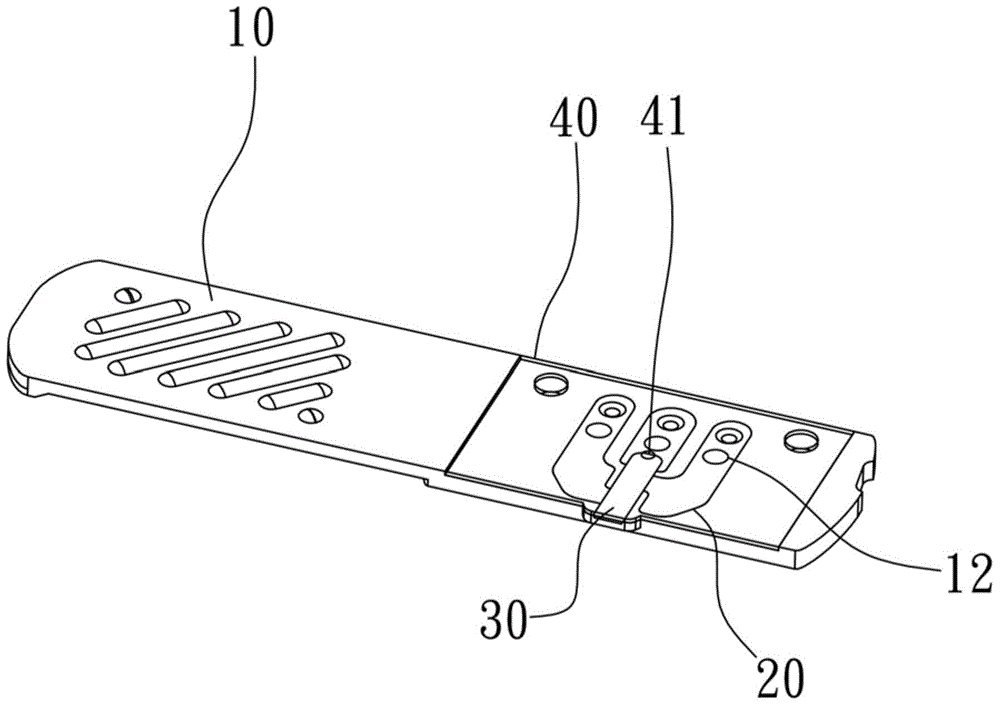

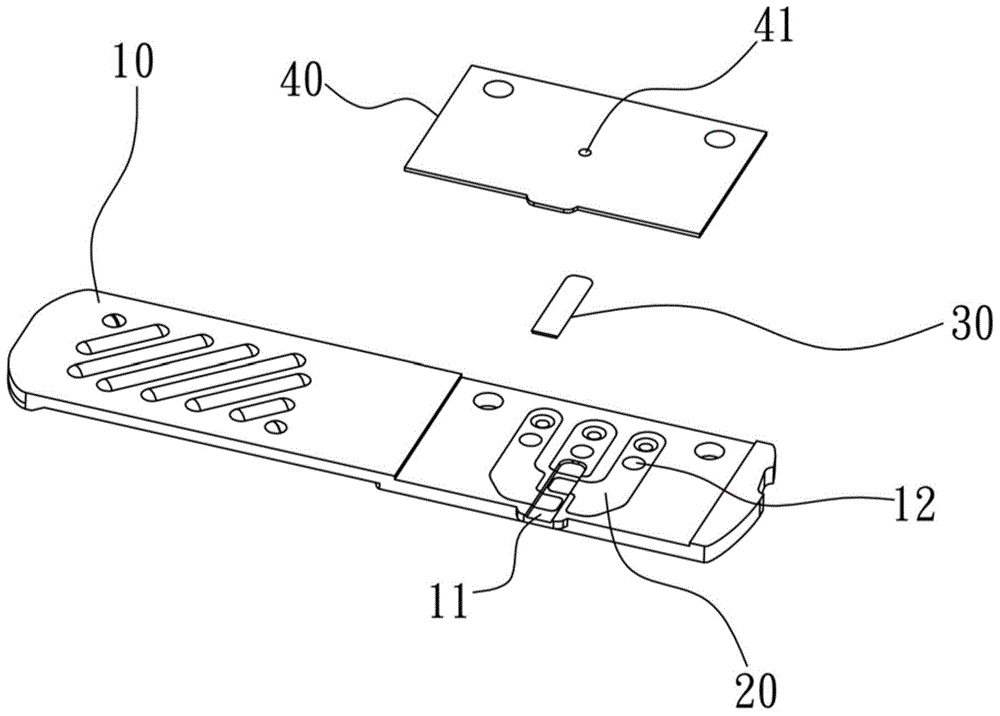

Electrochemical sensing test piece and making method thereof

ActiveCN105092662AImprove Manufacturing AccuracyLow costLiquid/solution decomposition chemical coatingMaterial electrochemical variablesElectricityChemical reaction

The present disclosure illustrates an electrochemical test strip and manufacturing method thereof. In the embodiment, a manufacturing process which is not complex and has well precision and convenience is provided to manufacture the electrochemical test strip for testing human body fluid. A surface metallization layer serves as a conductive signal transmission medium, so that the manufacturing cost can be reduced, and the material can be recovered by dissolving the metal in surface metallization.

Owner:KUANG HONG PRECISION

Manufacturing technology of spline shaft

InactiveCN101596675AMeet usabilityFulfil requirementsOther manufacturing equipments/toolsCylindrical grindingMaterials science

The invention provides a manufacturing technology of a spline shaft and has the following characteristics: manufacturing a blank, adjusting the sizes of the excircle and the length, the size of the excircle is Phi 27.5 and the size after processing is Phi 27; hardening and tempering the altered blank, focally controlling the layout of workpieces in the heating process and the oil introducing manner in the hardening and tempering process, adopting the dedicated tooling and fixture to prevent deformation, controlling the straightness accuracy to be less than 0.3; punching central holes at two ends of the blank which is hardened and tempered to place on a cylindrical grinding machine, grinding until the excircle size is Phi 27.5; milling the splines on a spline milling machine after mass grinding to an extent that the surface is smooth and level after milling. The technology leaves out two working procedures, improves efficiency when lowering the cost simultaneously. Integrated with various proposals, the technology is workable and scientific.

Owner:诸城市同翔机械有限公司

Equipment and method for preparing high-performance aluminum alloy material based on genome high-flux technology

PendingCN111336809AGrain refinementImprove performanceStirring devicesCrucible furnacesHigh fluxMaterials science

The invention discloses equipment and a method for preparing a high-performance aluminum alloy material based on a genome high-flux technology. The equipment comprises an element box assembly, a feeding hopper mechanism and smelting devices, wherein the element box assembly is mounted at one end of the equipment, a funnel cooperating with the element box assembly and a moving device capable of moving horizontally and vertically are arranged on the feeding hopper mechanism, so that a plurality of horizontally arranged element boxes are placed into the smelting device of the next station throughvertical movement of the moving device after obtaining elements, at least one smelting device is horizontally arranged at the lower part of the equipment, and the smelting devices are composed of heating parts and stirring parts. By means of the equipment and method, multiple aluminum alloy material components made of different materials can be proportioned at a time, mechanical automation is completely achieved, and the characteristics of being high in proportioning precision and repeatability, high in smelting temperature field consistency and the like are achieved; and high-throughput preparation of the aluminum alloy can also be realized, and preparation of genome aluminum alloy samples of various batches can be carried out in various environments.

Owner:苏州慧金新材料科技有限公司

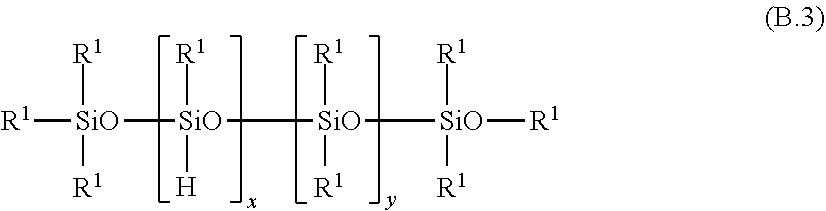

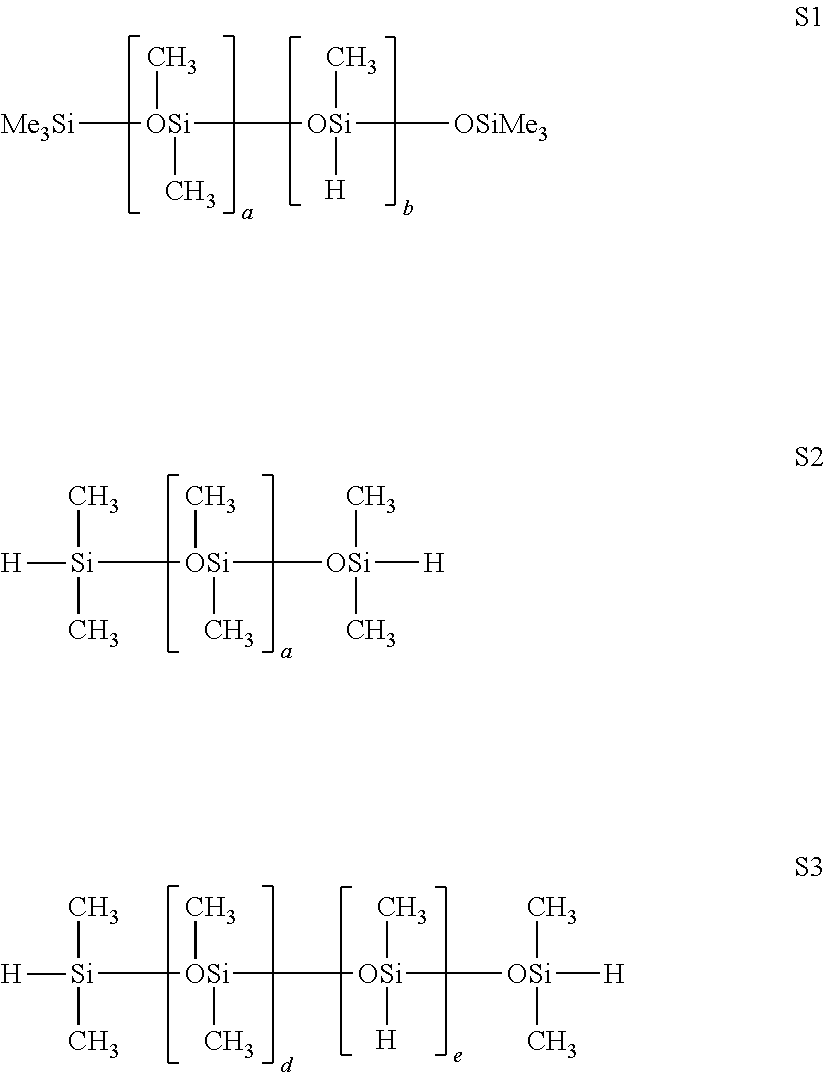

Method for manufacturing a silicone elastomer article using a 3D printer

PendingUS20200108548A1Improve Manufacturing AccuracyManufacturing platforms/substratesManufacturing heating elementsPolymer scienceComputer printing

The invention relates to an additive manufacturing method for producing a three-dimensional elastomer silicone article. The elastomer silicone article is built up layer by layer by printing a silicone composition crosslinkable by addition reactions comprising at least one organopolysiloxane-polyoxyalkylene copolymer with a 3D printer selected from an extrusion 3D printer or a material jetting 3D printer.

Owner:ELKEM SILICONES FRANCE SAS +4

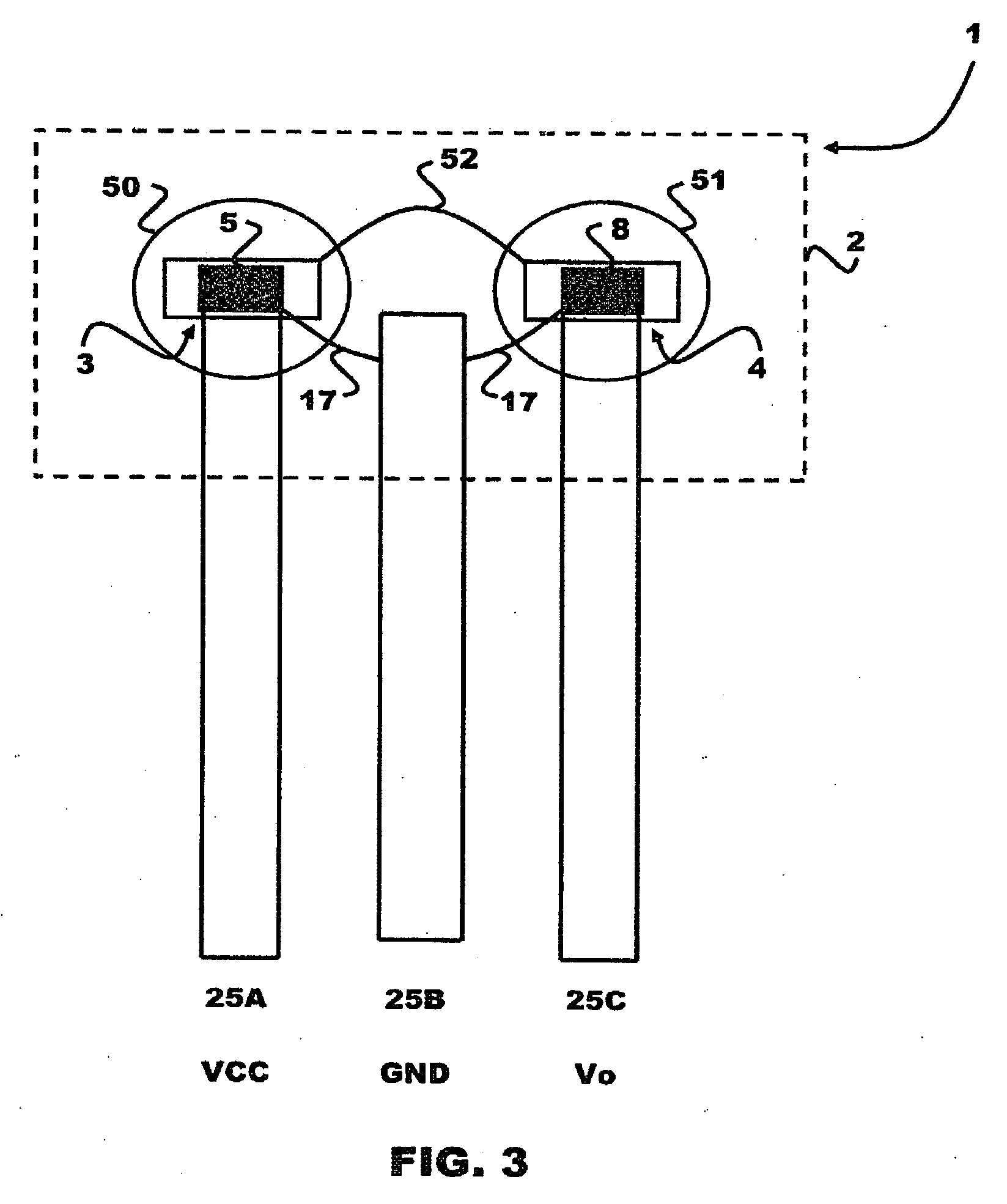

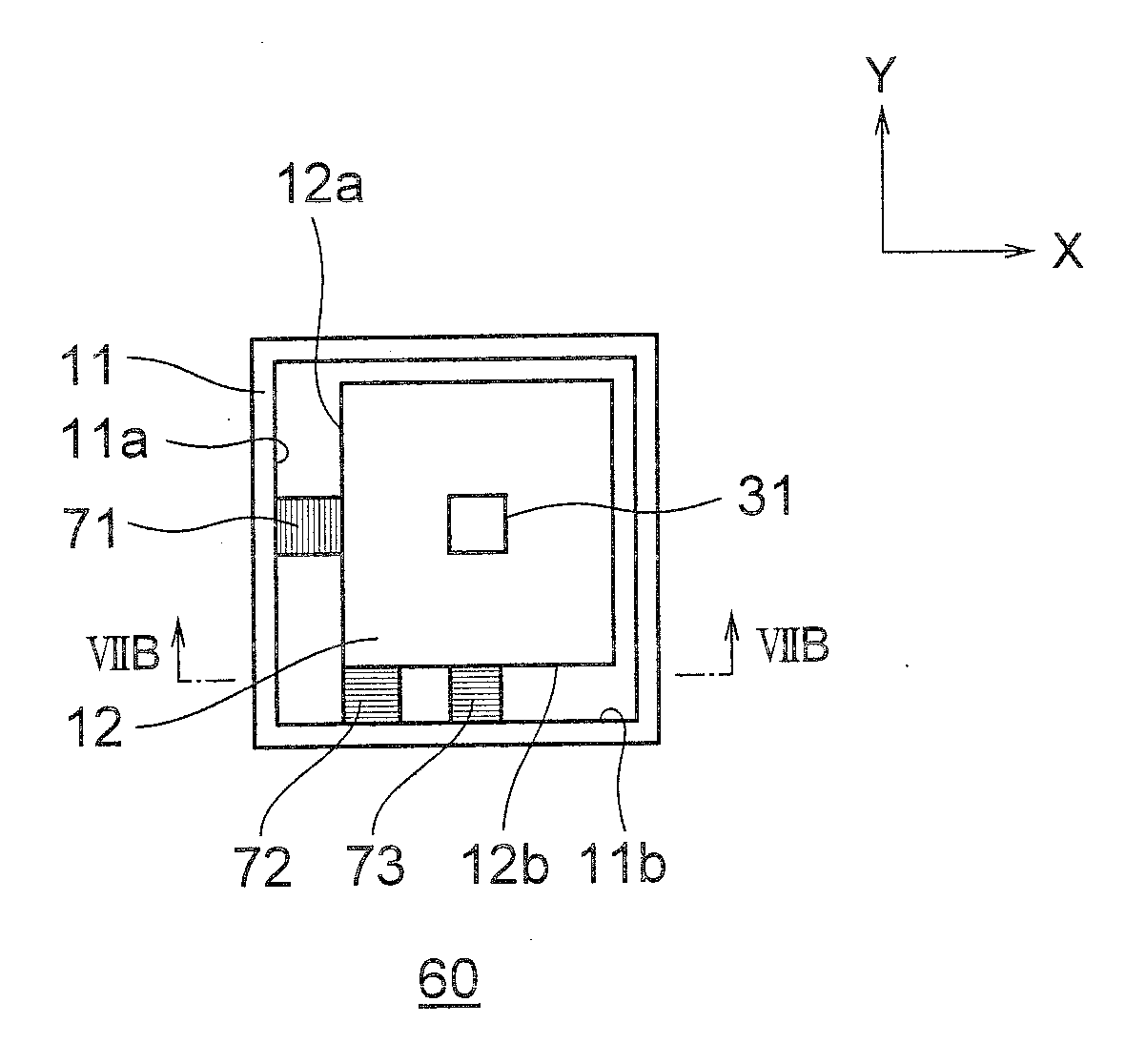

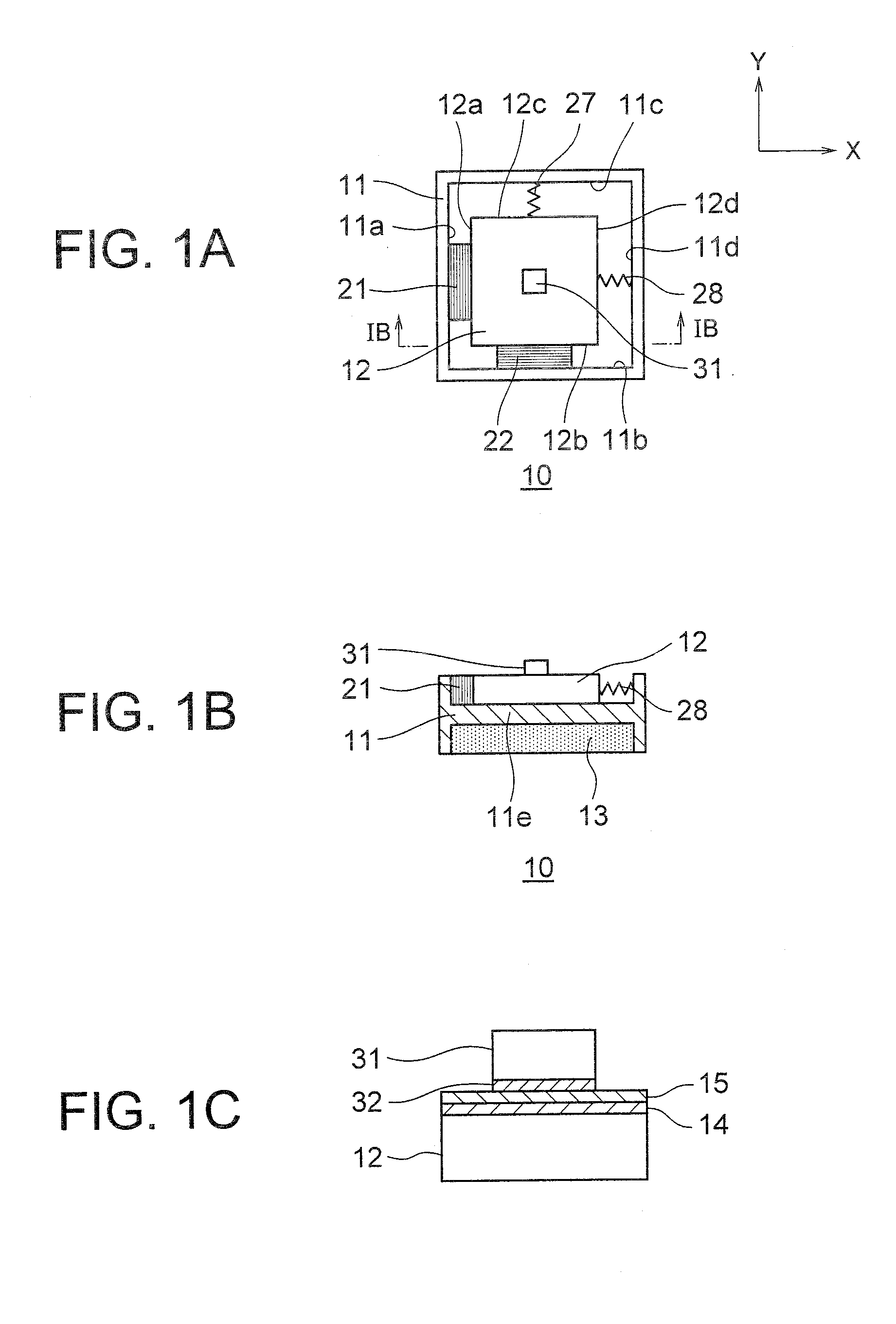

Inertial drive actuator

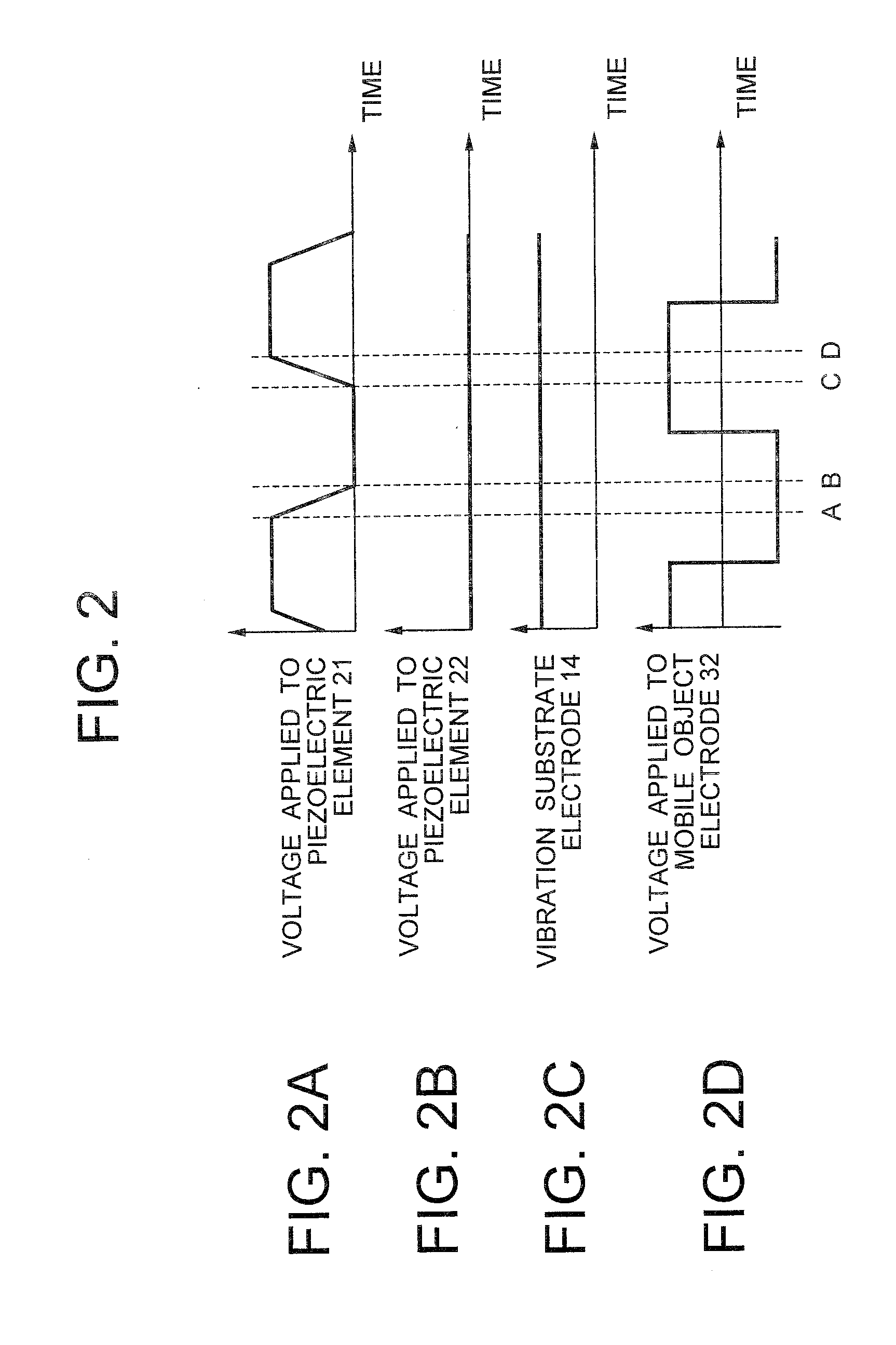

InactiveUS20090302711A1Improve Manufacturing AccuracySmall-sizing easyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesMobile objectSizing

There is provided an inertial drive actuator in which, a small-sizing is easy, including a first displacement generating mechanism of which, one end is adjacent to a fixed member, and a first displacement is generated in the other end thereof, a second displacement generating mechanism of which, one end is adjacent to the fixed member, and which generates a second displacement in the other end thereof, a driving mechanism which applies a voltage for displacing the first displacement generating mechanism and the second displacement generating mechanism, a vibration substrate which is connected to the other end of the first displacement generating mechanism and the other end of the second displacement generating mechanism, and which is displaceable in a plane in which, there exist a direction of the first displacement and a direction of the second displacement, a mobile object which is disposed to be facing the vibration substrate, and which moves with respect to the vibration substrate by an inertia with respect to a displacement of the vibration substrate, and a friction controlling mechanism which changes a frictional force between the mobile object and the vibration substrate.

Owner:OLYMPUS CORP

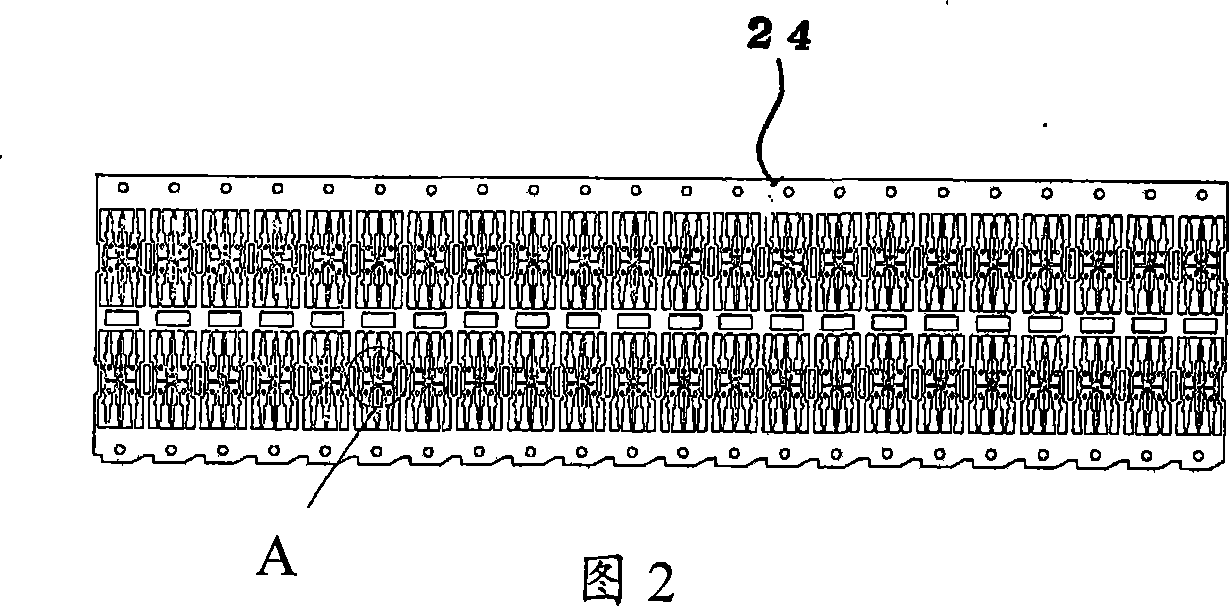

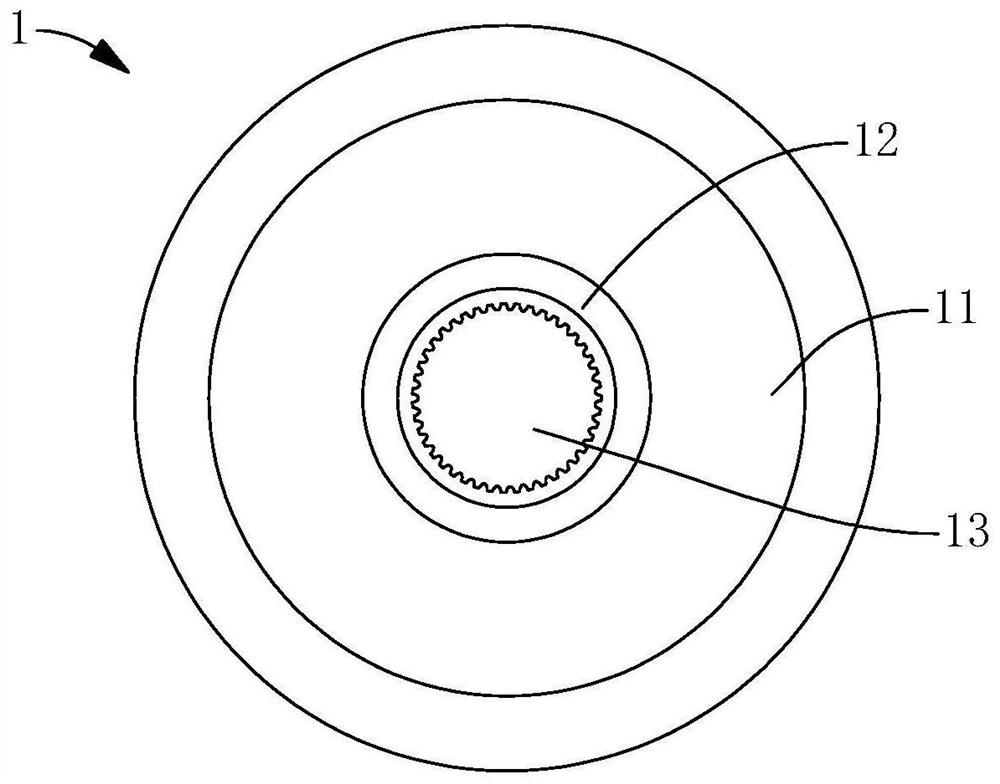

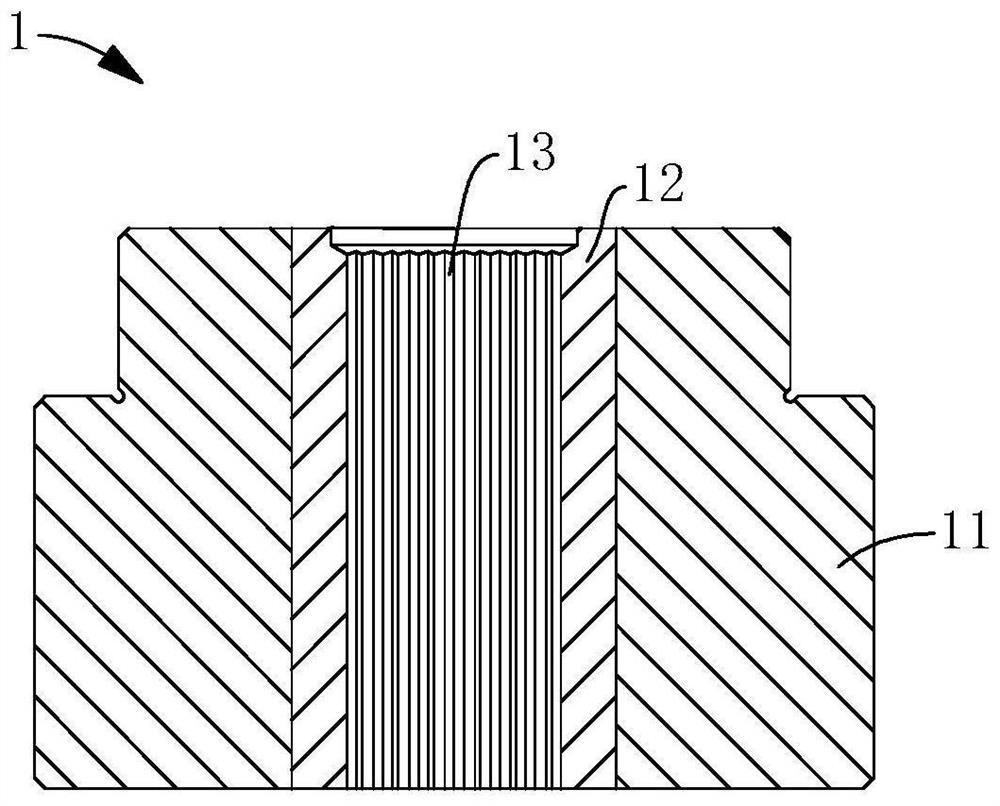

LED manufacturing method

ActiveCN101388424AWon't looseNo situationSolid-state devicesSemiconductor/solid-state device manufacturingMetallic materialsElectroplating

The invention is applied to the production method of an LED, and provides a production method of an LED on a tape type copper metal material sheet. The method comprises the following steps: forming a tape type copper metal material sheet, continuously punching circuits on the tape type copper metal material sheet to form a holder of circuit pattern for placing a diode crystal and electric terminals, plating multi-layer metal on the surface of the holder, continuously spraying metal and molding on the holder to form a protective body for an appointed pattern, providing a groove structure on the upper surface of the protective body, fixing the diode crystal on a holder which is located on the bottom of the groove structure of the protective body, and connecting the electrode terminals of the diode crystal and the terminal contacts of the holder through metal wires. The invention can improve the problem of LED production precision, makes production accurate and easy, and effectively reduces cost.

Owner:SHENZHEN SUNSCREEN CO LTD +1

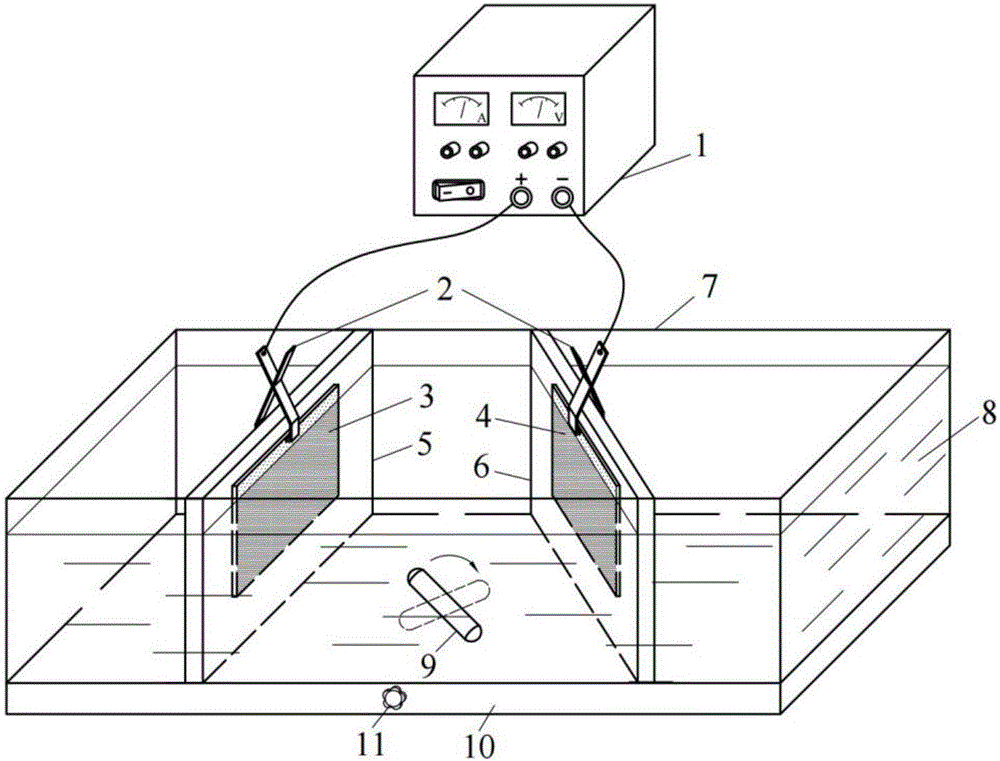

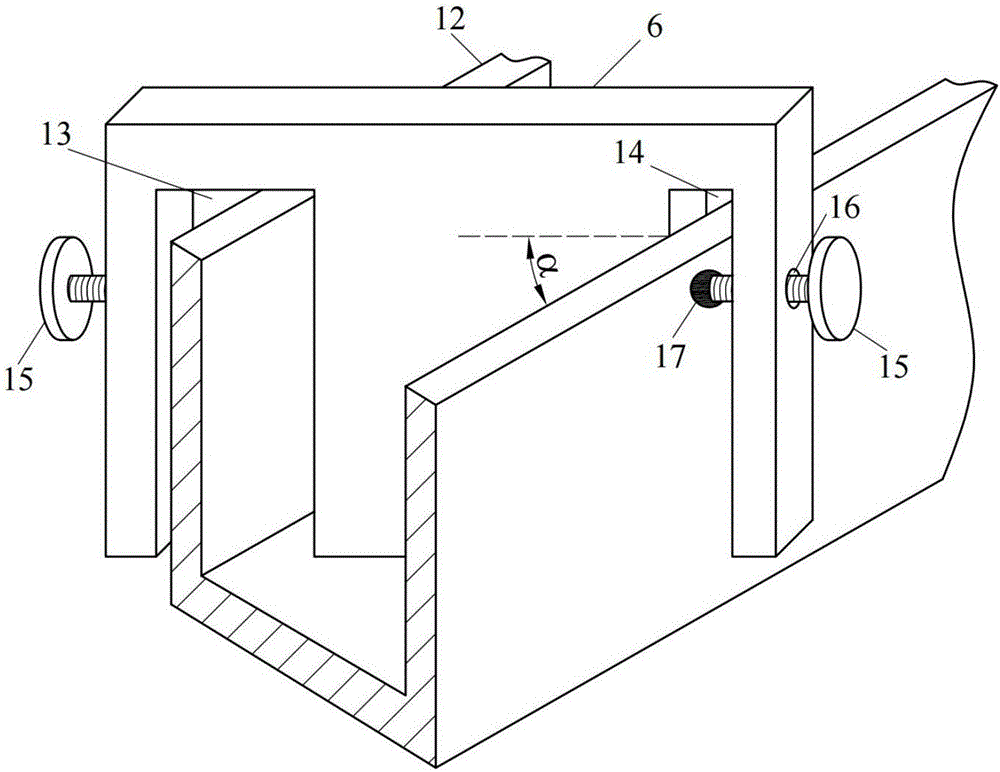

Preparation device of structure type infiltration gradient surface

The invention discloses a preparation device of a structure type infiltration gradient surface. The preparation device comprises an electroplating power supply, an electroplating bath, an anode plate and a cathode plate; the electroplating bath contains an electroplating solution; the anode plate and the cathode plate are soaked into the electroplating solution; the anode plate is connected with an anode of the electroplating power supply; the cathode plate is connected with a cathode of the electroplating power supply; the anode plate and the cathode plate are arranged at a set inclination angle; and the distance between the anode plate and the cathode plate changes in a continuous gradient manner in the arrangement direction of the anode plate and the cathode plate. According to the preparation device, the anode plate and the cathode plate are fixed in the electroplating solution at the set angle, and electroplating electric current continuously changes in the electrode arrangement direction, so that the structure type infiltration gradient surface of which the metal grain sizes and density change in a gradient manner is formed on the cathode plate; the structure type infiltration gradient surface is simple in preparation process, simple in structure, and is easy to realize; and by controlling electroplating parameters, the distance and the arrangement angle between the anode plate and the cathode plate, chemical components of the anode plate, and the like, various infiltration gradient surfaces meeting the practical industrial requirements can be prepared.

Owner:淳华氢能源科技(湖南)有限公司 +1

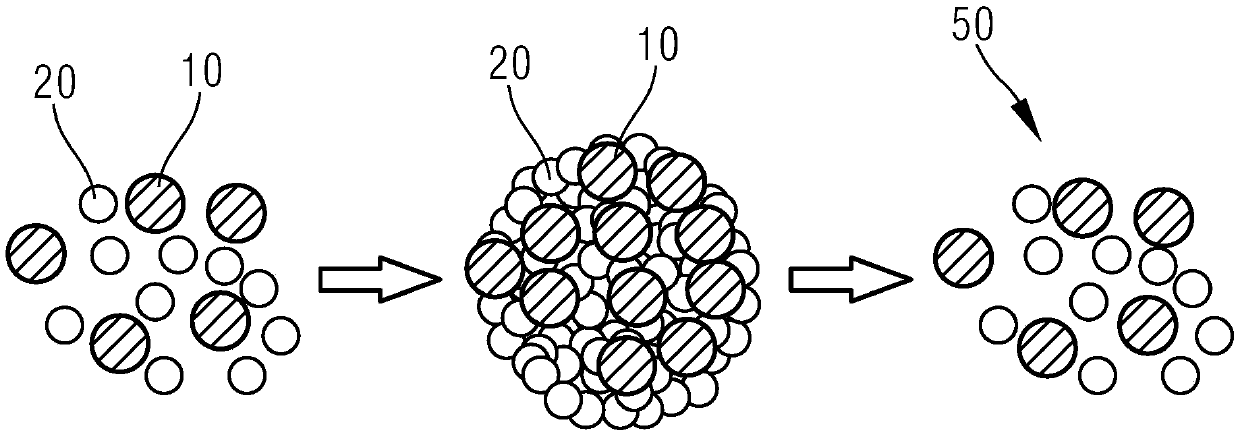

3D printing metal powder, 3D printing method and method for preparing 3D printing metal powder

InactiveCN110893465AImprove mechanical propertiesFunction increaseAdditive manufacturing apparatusIncreasing energy efficiency3d printNanoparticle

The invention provides 3D printing metal powder, a 3D printing method and a method for preparing 3D printing metal powder. The method for preparing the 3D printing metal powder comprises the followingsteps: decomposing metal basic powder into a metal powder matrix by a mechanical grinding process; adding reinforced particles in the metal basic powder matrix and mixing the metal powder matrix andthe reinforced particles; adding a binder and bonding the metal powder matrix and the reinforced particles by the binder and through a spray drying process so as to obtain disperse particles, whereinthe size of the disperse particles is more than those of the metal powder matrix and the reinforced particles; and removing the binder from the disperse particles by a sintering process so as to obtain 3D printing metal composite powder. Uniform reinforcement can be guaranteed and the mechanical property and the function of the nanoparticles can be improved; and furthermore, the internal microcracks of the metal powder added with the nanoparticles can be reduced.

Owner:SIEMENS AG

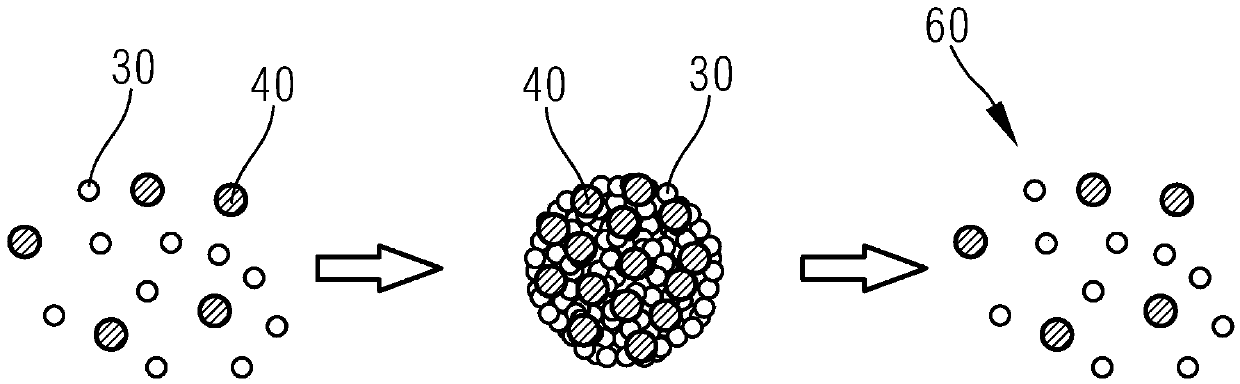

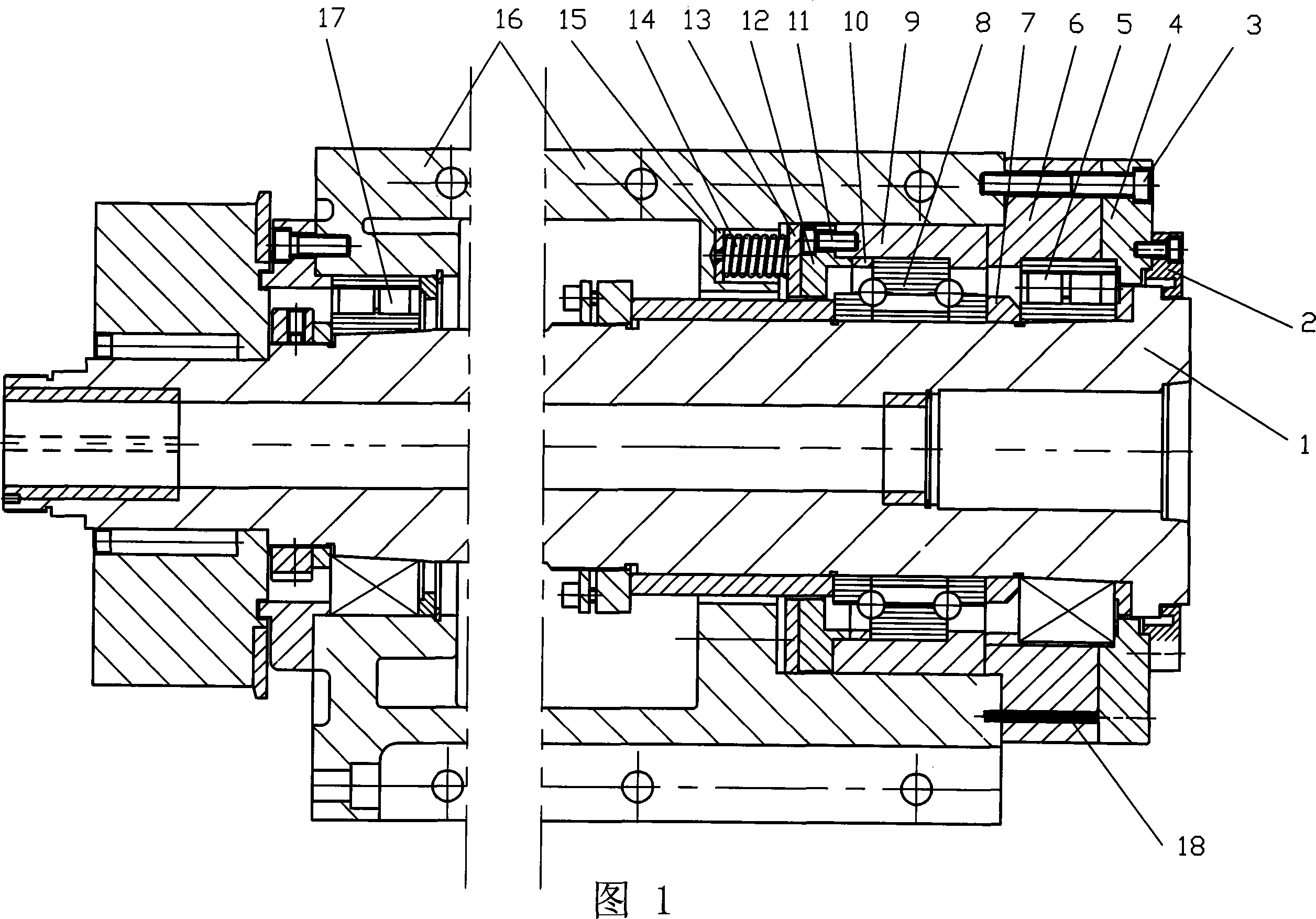

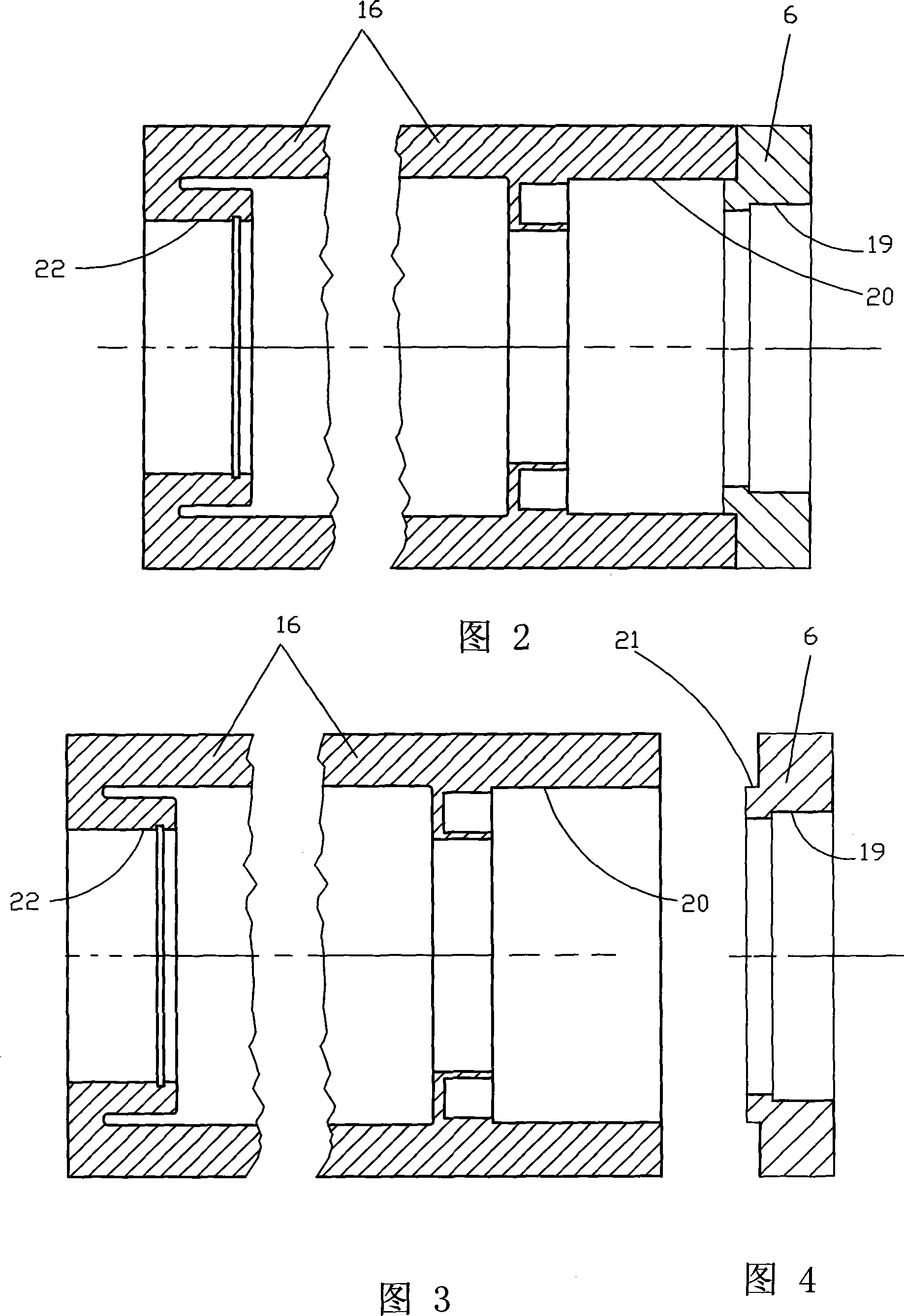

Process for improving the accuracy of manufacturing of precision boring head

InactiveCN101112722AImprove manufacturing precisionImprove Manufacturing AccuracyMeasurement/indication equipmentsBoring headsEngineeringMechanical engineering

A method improving the manufacture precision of precision boring head includes the steps that the secondary aging treatment is carried out after the roughing process is carried out to a main shaft box body (16); the half-precision process is carried out to the main shaft box body (16), and a front bearing hole (20) and a rear bearing hole (22) are preserved with the processing allowance ranging from 0.05 mm to 0.06 mm; after the inspection is approved, the main shaft box body (16) is finish machined into the finished products according to the design requirement; the hole diameter of the front bearing hole (20) is actually measured; a spigot external round (21) on a front bearing sleeve (6) is matched and grinded according to the actually measure values; the geometric tolerance of the internal hole (19) of the front bearing sleeve (6) is actually measured, and the manual grinding disposal is adopted when the actually measured numerical values are oversize in the fourth step to reach the design requirement; a positioning pin (18) is adopted for positioning between the main shaft box body (16) and the front bearing sleeve (6). By adopting the method, when all work pieces are processed, the problems produced are timely and reasonably solved, and the integration manufacture precision of the precision boring is improved, and the boring process of the high precision work pieces can be satisfied.

Owner:DALIAN HUAGEN MACHINERY

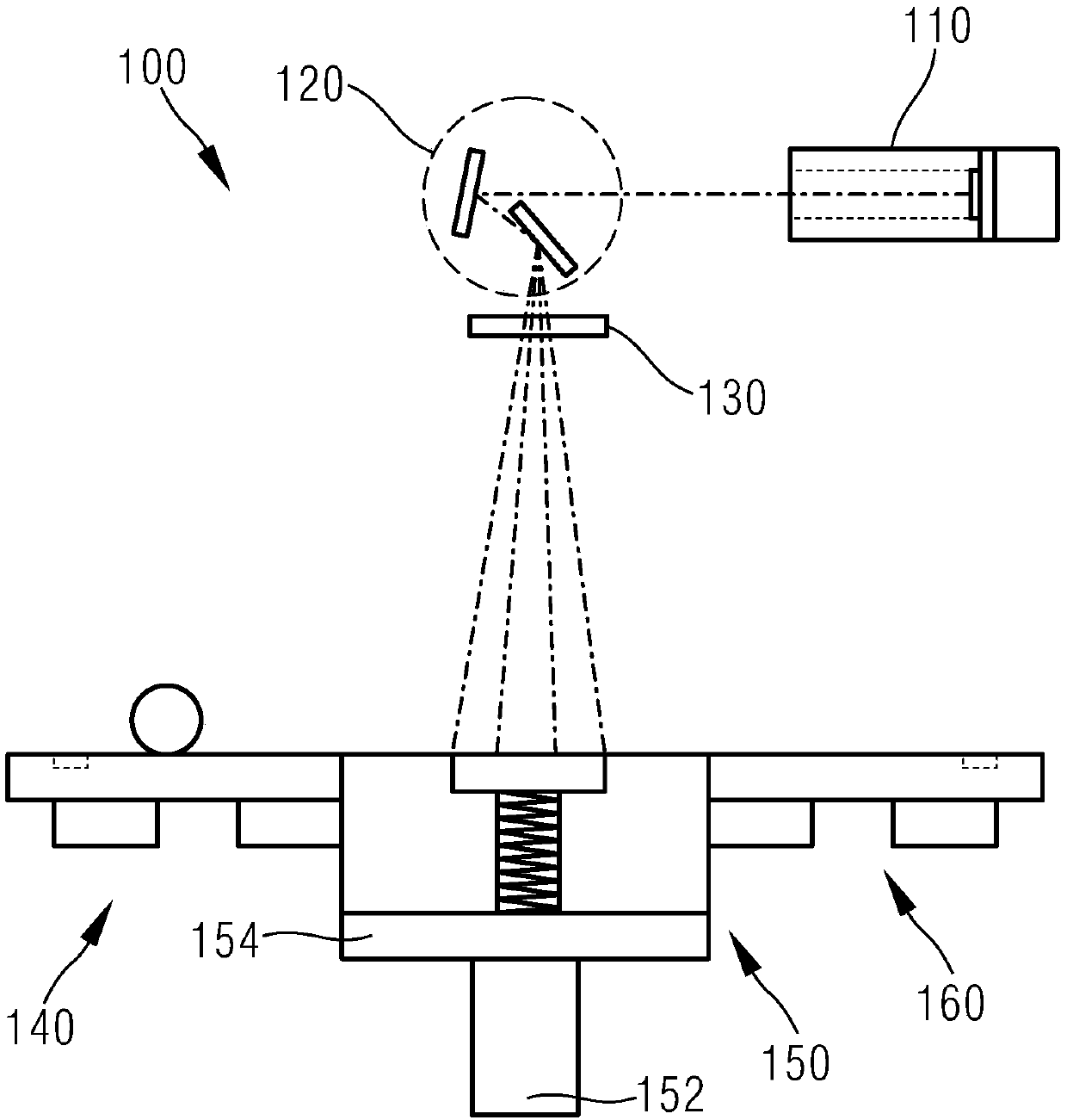

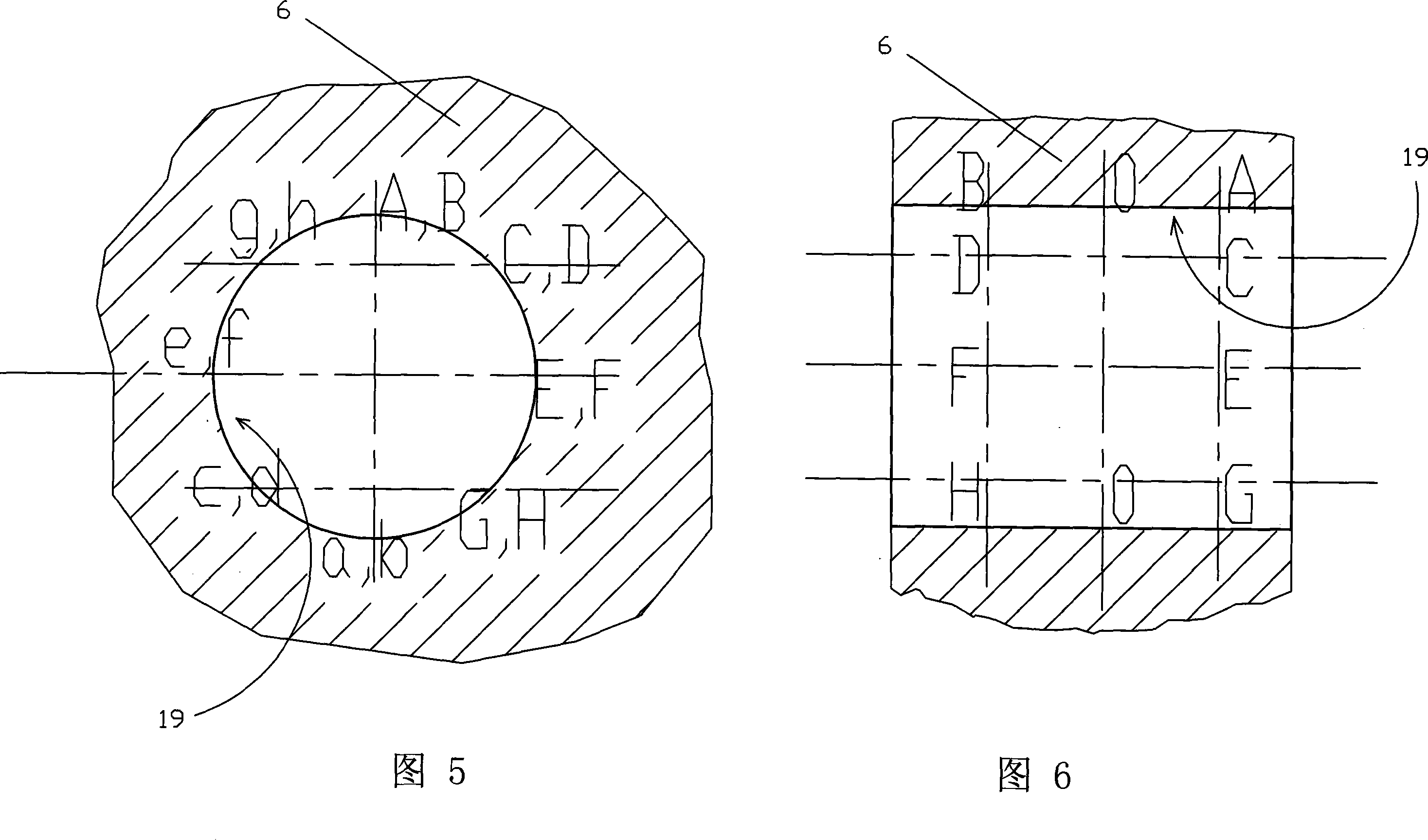

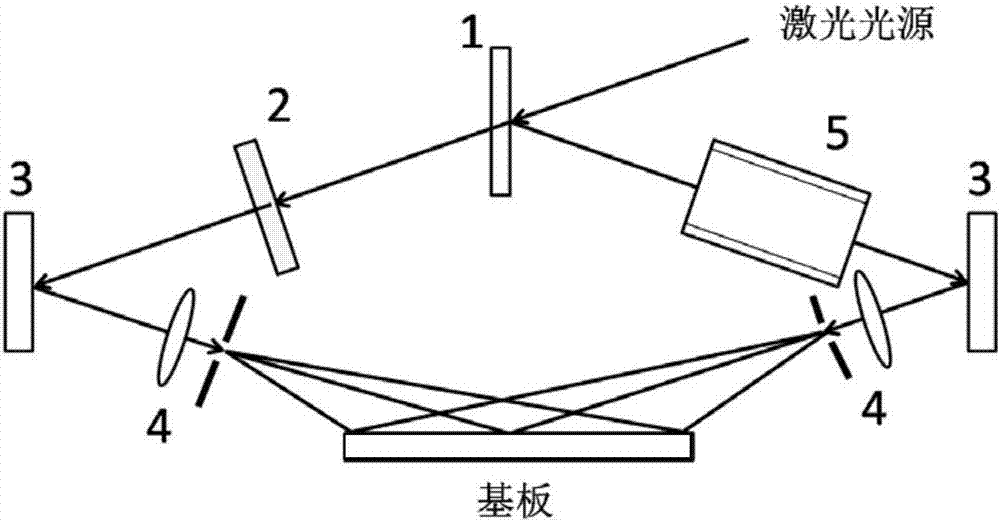

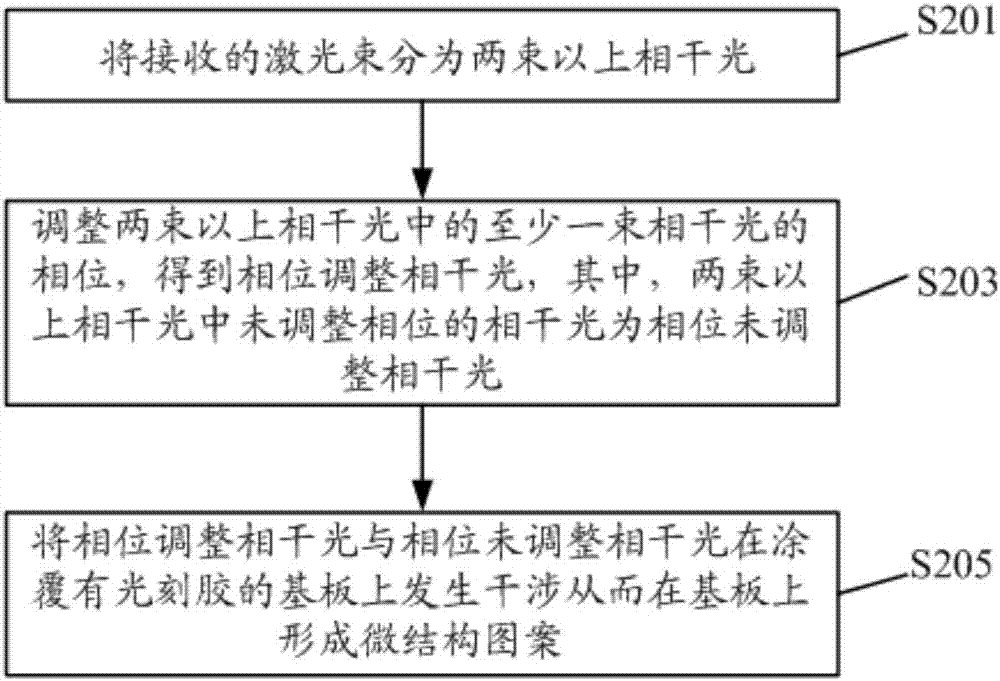

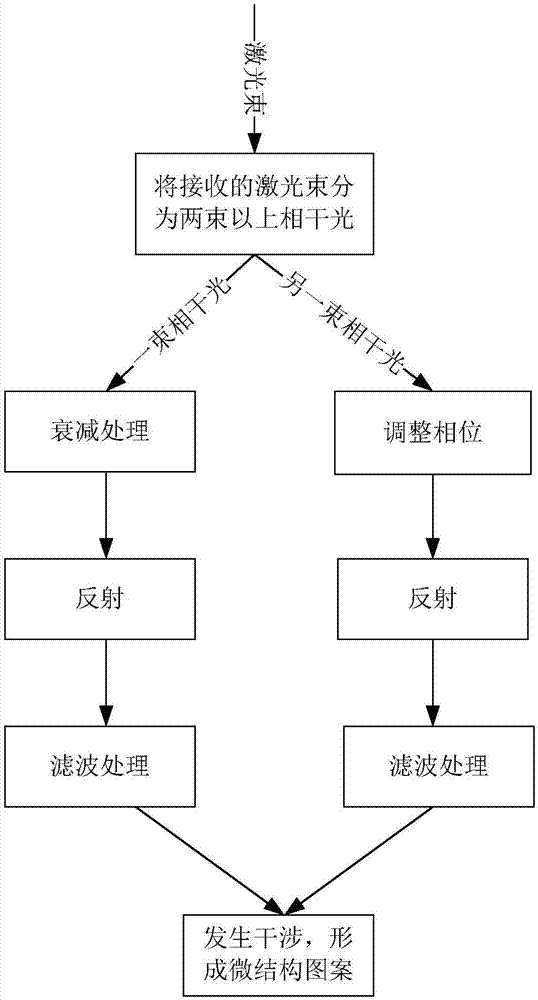

Photoetching instrument and microstructure pattern photoetching method used in preparation of metamaterial

PendingCN107290939AImprove Manufacturing AccuracyIncrease light intensityPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam splitterLaser interference

The invention discloses a photoetching instrument and microstructure pattern photoetching method used in preparation of a metamaterial. The photoetching instrument comprises a beam splitter and a pockels box, wherein the beam splitter is used for dividing a received laser beam into more than two beams of coherent light and outputting the coherent light, the pockels box is used for receiving and adjusting a phase of at least one first coherent light of the two beams of coherent light and outputting the at least one first coherent light after the phase is adjusted, and the at least one first coherent light output from the pockels box and second coherent light which is output from the beam splitter and is not received and adjusted by the pockels box are intervened with each other on a substrate so as to form a microstructure pattern on the substrate. With the adoption of a periodic pattern formed by laser interference, the manufacturing process can be simplified; and by employing the pockels box to adjust optical path different, the light intensity of the coherent light at an interference position is high to form an interference pattern, accurate moving of the interference pattern is achieved, the preparation efficiency is improved, and the manufacturing accuracy of the pattern is also improved.

Owner:KUANG CHI INST OF ADVANCED TECH

Equal-thickness moulding surface splitting casting superplastic forming/diffusion connection forming mould and preparation method thereof

ActiveCN107096890AQuality assuranceGuaranteed accuracyFoundry mouldsFoundry coresHigh pressureConnection form

The invention belongs to the field of aeronautical manufacturing engineering / aircraft assembly and provides an equal-thickness moulding surface splitting casting superplastic forming / diffusion connection forming mould and a preparation method thereof. The superplastic forming / diffusion connection forming mould comprises two parts of an upper mould body and a lower mould body; the upper mould body and the lower mould body are composed of a moulding surface part and a bracket part correspondingly; and the four parts are machined correspondingly. Guiding pin mounting plates are located in the middles of the two opposite side faces of the upper and lower mould moulding surfaces; hanging columns are arranged on the two sides of the guiding pin mounting plates; temperature measuring holes and air feeding / discharging holes (9) are formed in the side faces of the upper and lower mould moulding surfaces; and lightening grooves are formed in the upper surface of an upper mould bracket and penetrate through the whole bracket part. According to the superplastic forming / diffusion connection forming mould and the preparation method thereof, accuracy of the dimension and moulding surface can be kept under the high temperature and high pressure conditions, the manufacturing precision of superplastic forming / diffusion connection parts is improved, thus the shapes of the superplastic forming / diffusion connection parts meet the assembly requirements, the service life of the mould is prolonged, and the production cost is reduced.

Owner:SHENYANG AIRCRAFT CORP

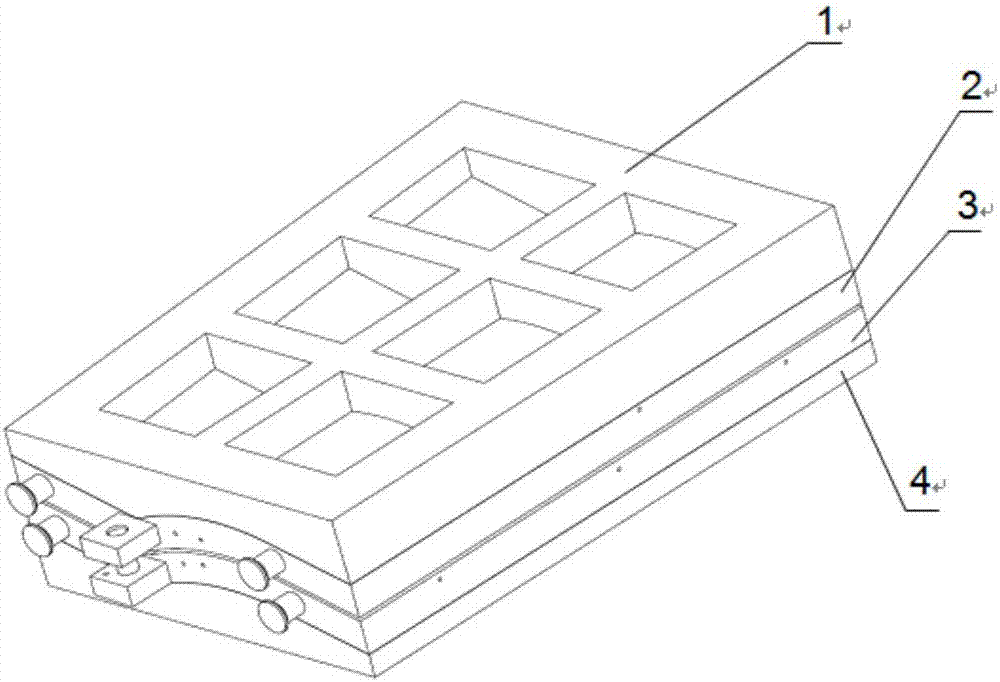

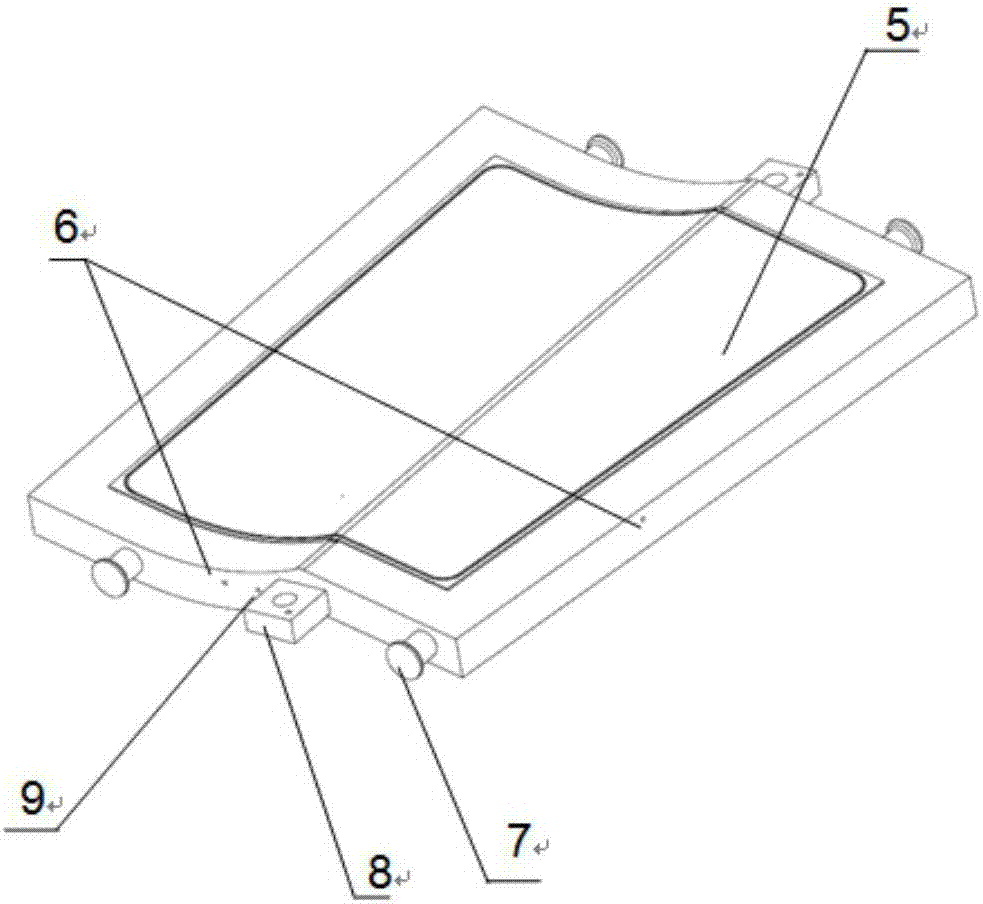

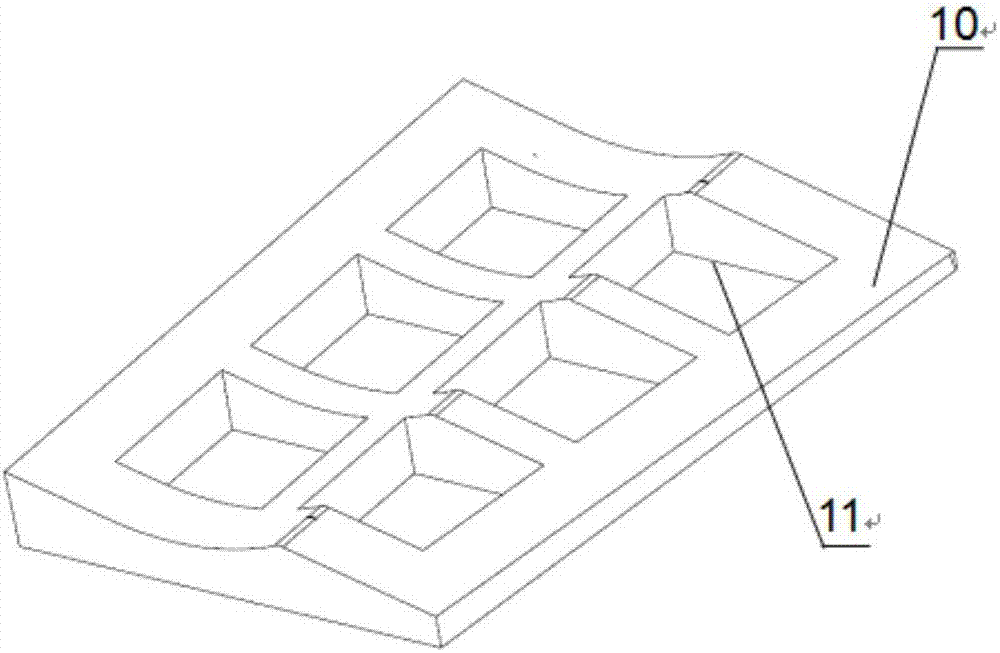

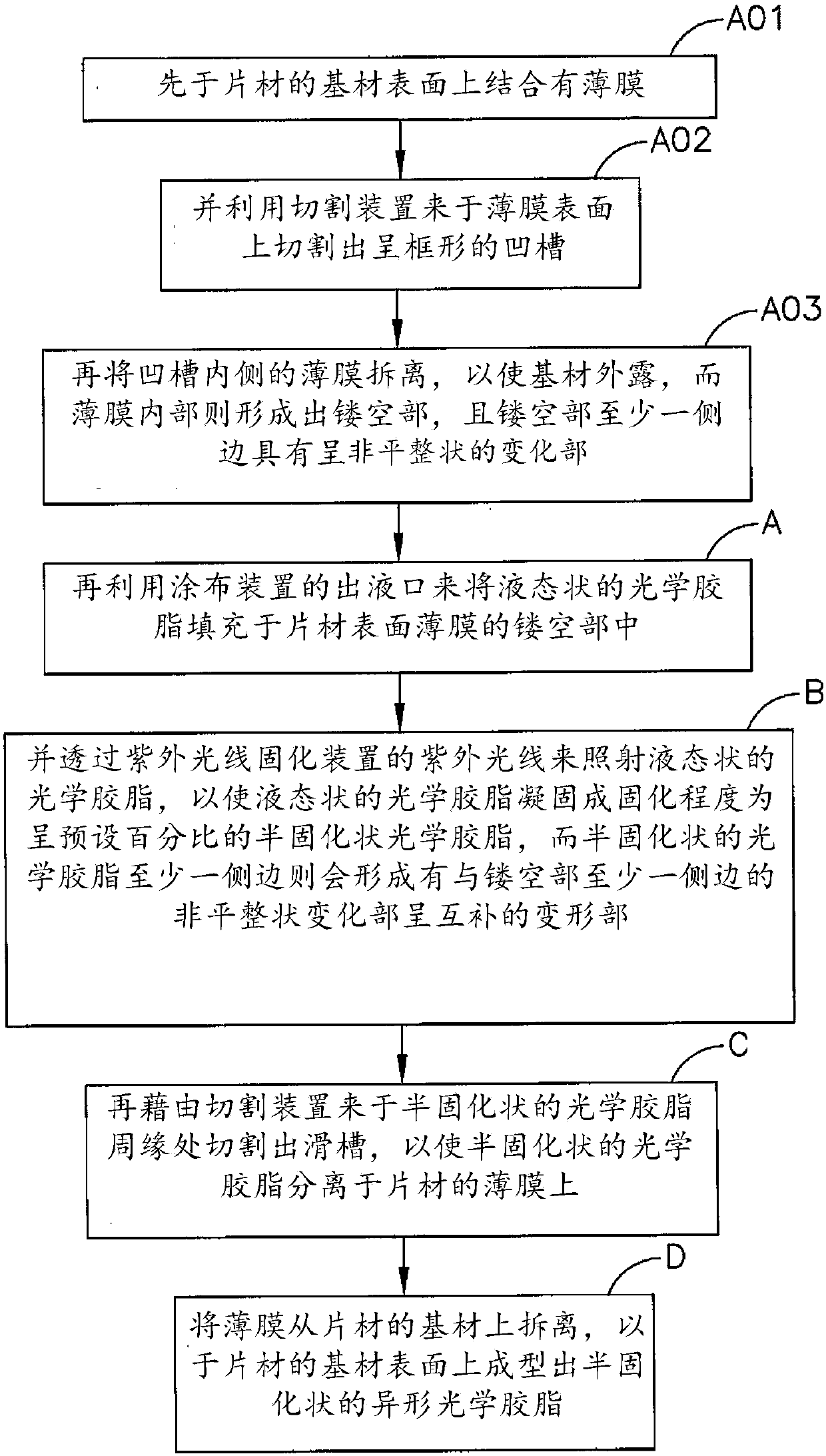

Forming method of special-shaped optical clear resin

ActiveCN110027147AImprove Manufacturing AccuracyImprove pass rateOptical articlesLiquid stateEngineering

The invention discloses a forming method of special-shaped optical clear resin, in particular to the method of forming semi-cured special-shaped optical clear resin by utilizing a sheet material. A coating device can be used for filling a hollow part of a film on the surface of the sheet material with the liquid-state optical clear resin, the liquid-state optical clear resin is solidified into a semi-cured state through an ultraviolet ray curing device, the semi-cured optical clear resin is separated from the film through a cutting device, the film is continuously torn off from the surface ofa base material of the sheet material, and thus the semi-cured special-shaped optical clear resin can be formed on the surface of the base material of the sheet material. Through the manufacturing mode, the manufacturing accuracy and the qualification rate of the special-shaped optical clear resin can be improved, and the use of a mold can be reduced by using the film, so that the manufacturing process is simplified, and the effects of reducing the overall manufacturing time and cost are achieved.

Owner:USUN TECH CO LTD

Method for forming curved bridge based on BIM combined template support process

ActiveCN110348142AReduce wasteImprove Manufacturing AccuracyGeometric CADSpecial data processing applicationsRadianMaterials science

The invention discloses a method for forming a curve bridge based on BIM by adopting a combined template support process of a customized arc-shaped steel pipe and a flexible template. The method comprises the steps of BIM-based modeling, blanking, encoding, mold splicing and mold release oil brushing. Based on application of the BIM technology, steel pipe waste in the arc-shaped steel pipe manufacturing process is reduced, the manufacturing accuracy of the radian of each steel pipe is improved, and the method has the advantages that the operation procedure is simple, the construction period isremarkably shortened, the engineering cost is reduced, the construction speed is high, and the application range is wide.

Owner:LONGYUAN CONSTR GROUP

Self-locking nut machining method and self-locking nut

The invention discloses a self-locking nut machining method and a self-locking nut. The method comprises the steps that blanking is conducted, specifically, the periphery of a bar is cut by a preset thickness to reduce the outer diameter of the bar, and then the bar is cut into multiple sections of small bars; hot-press forming is conducted, specifically, the small bars are heated and softened, and then the small bars are put into a hot-pressing die to be stamped into cylinder structures with outer splines on the peripheries; solid solution and aging treatment is conducted, specifically, the cylinder structures are subjected to solid solution and aging treatment, so that the mechanical comprehensive performance requirements for parts are met, and the hardness HRC after solid solution and aging is 42-47; appearance and thread turning are conducted, specifically,the appearance is turned at first, and then threads are turned, or the threads are turned firstly, and then the appearance is turned; groove milling is conducted, specifically, a notch groove in one side of a workpiece is milled at first, and then a notch groove in the other side of the workpiece is milled; and end face grinding is conducted, specifically, the workpiece and a thread taper mandrel rod in close fit and threaded connection with the workpiece are fixed on a cylindrical grinding machine, and the two end faces of the workpiece are ground to be flat through a grinding wheel of the cylindrical grinding machine. By means of the method, the part machining cost is reduced, the qualification rate is increased, and the machining period is shortened.

Owner:AVIC POWER ZHUZHOU AVIATION PARTS MFG

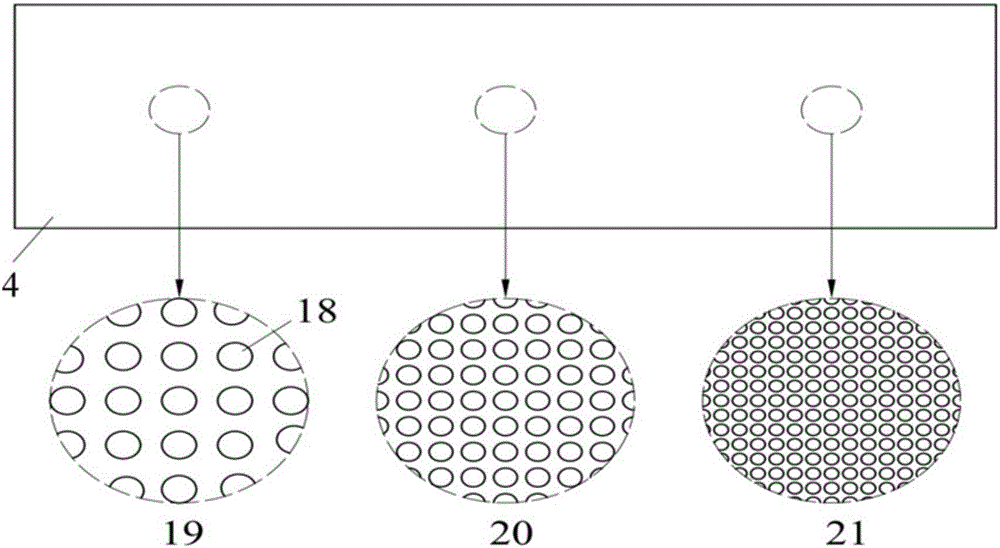

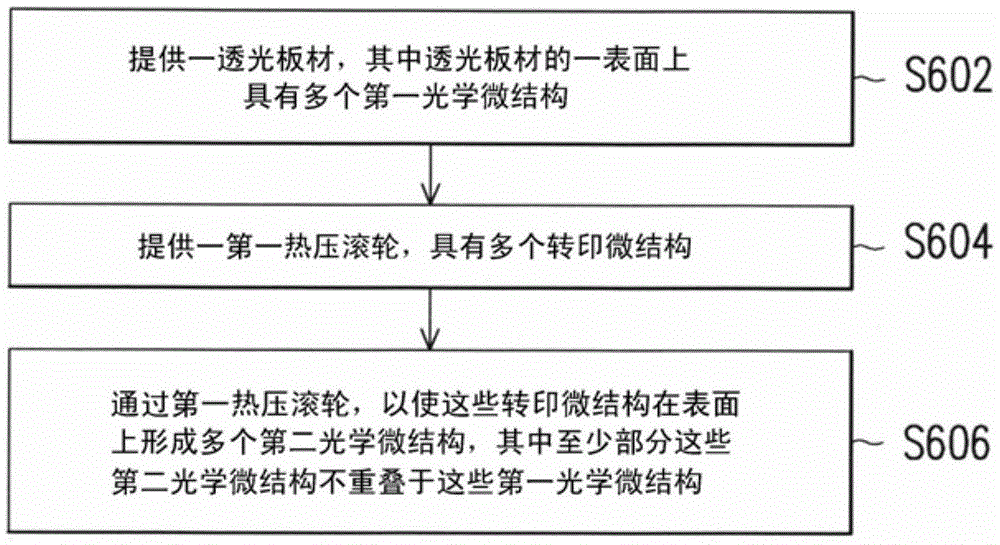

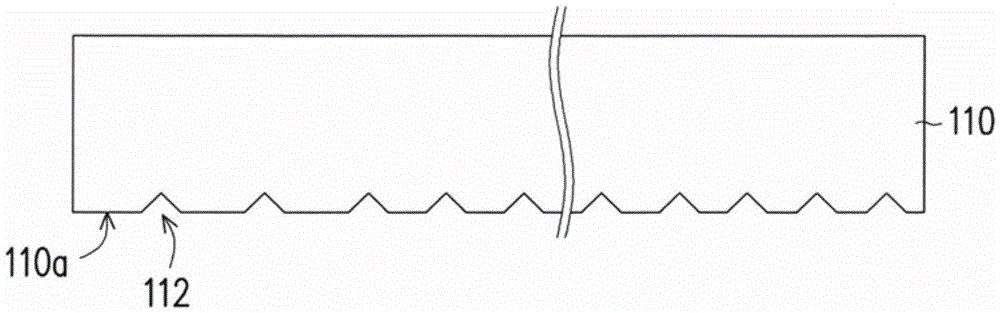

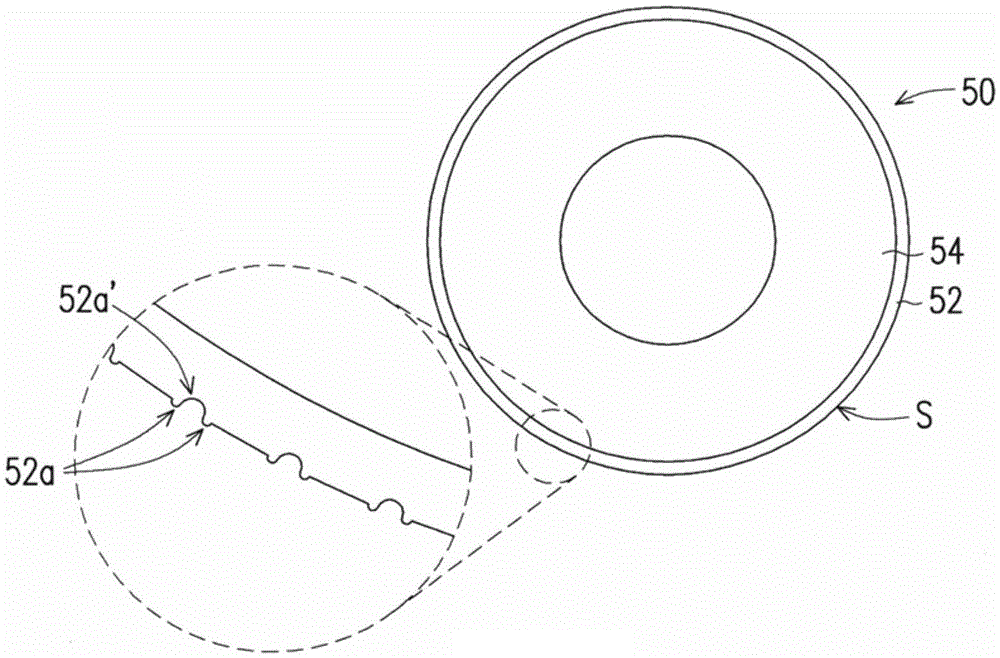

Manufacturing method of light guide plate

InactiveCN106371165AImprove Manufacturing AccuracyShorten development timeOptical articlesPlanar/plate-like light guidesLight guideEngineering

The invention discloses a manufacturing method of a light guide plate. A transparent plate is provided, wherein a surface of the transparent plate has a plurality of first optical microstructures. Then, a first hot pressing roller having a plurality of transfer printing microstructures is provided. A plurality of second optical microstructures are formed on the surface through the transfer printing microstructures by the first hot pressing roller. At least a part of the second optical microstructures is not overlapped with the first optical microstructures. Thus, not only the first optical microstructures with complex shapes can be precisely formed through the injection molding process, but also optical and display optimization toward the backlight module can be performed by the second optical microstructures with simple shapes, so as to save production time.

Owner:NANO PRECISION TAIWAN LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com