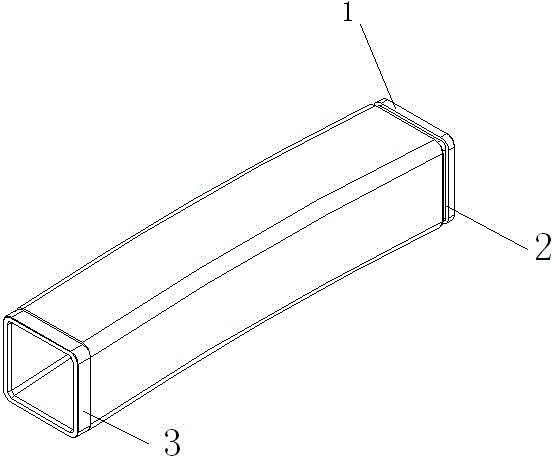

Method for processing crystallizer copper pipe with upper and lower installation spigots

A technology of mold copper tube and processing method, which is applied in the field of processing and manufacturing mold copper tubes of continuous casting machines, can solve the problems that the processing quality of copper tubes is difficult to meet the design requirements, and the quality difference is large, so as to improve production efficiency and The effects of economic benefits, product performance improvement, and installation accuracy requirements guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A kind of processing method of the crystallizer copper tube that has up and down installation notch of the present invention, its specific steps are:

[0021] (1) Cut off the redundant parts at both ends of the extruded copper tube semi-finished product on a sawing machine, and process the upper and lower ends of the plane on a general-purpose machine tool. quantity;

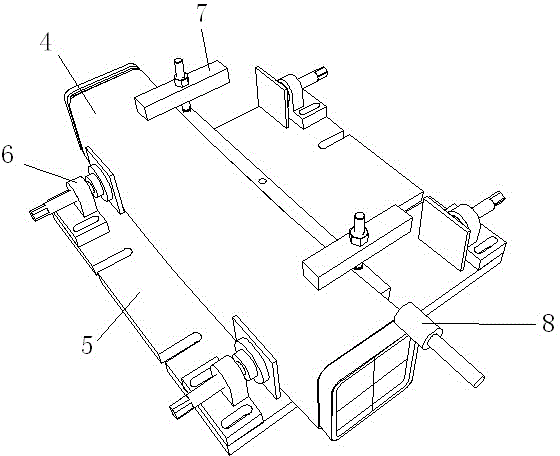

[0022] (2) Fix the mounting base plate 5 of the combined fixture on the workbench of the CNC machine tool, and keep each side of the combined fixture base plate parallel or perpendicular to the coordinate axis of the machine tool;

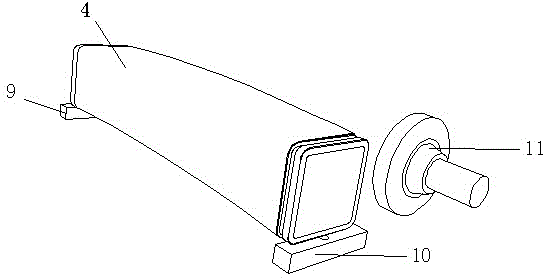

[0023] (3) Install and fix the copper tube 4 with a combined fixture: when the copper tube 4 is installed on the combined fixture, the arc surface of the copper tube is placed sideways, and the straight face of the copper tube 4 is placed on the plane of the bottom plate 5 of the combined fixture, The protruding amount of both ends relative to the fixture is equal, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com