Patents

Literature

269results about How to "Process arrangement is reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

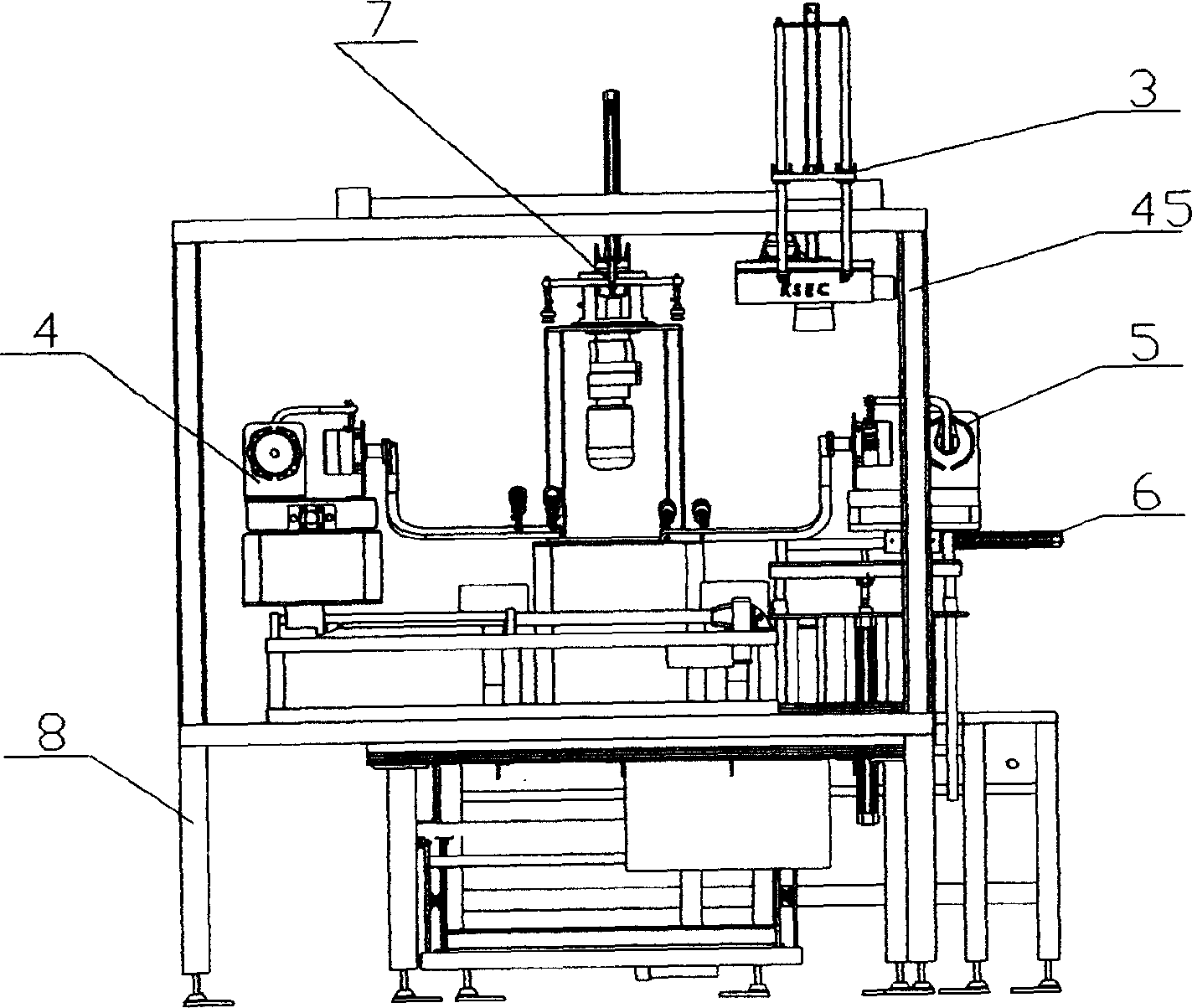

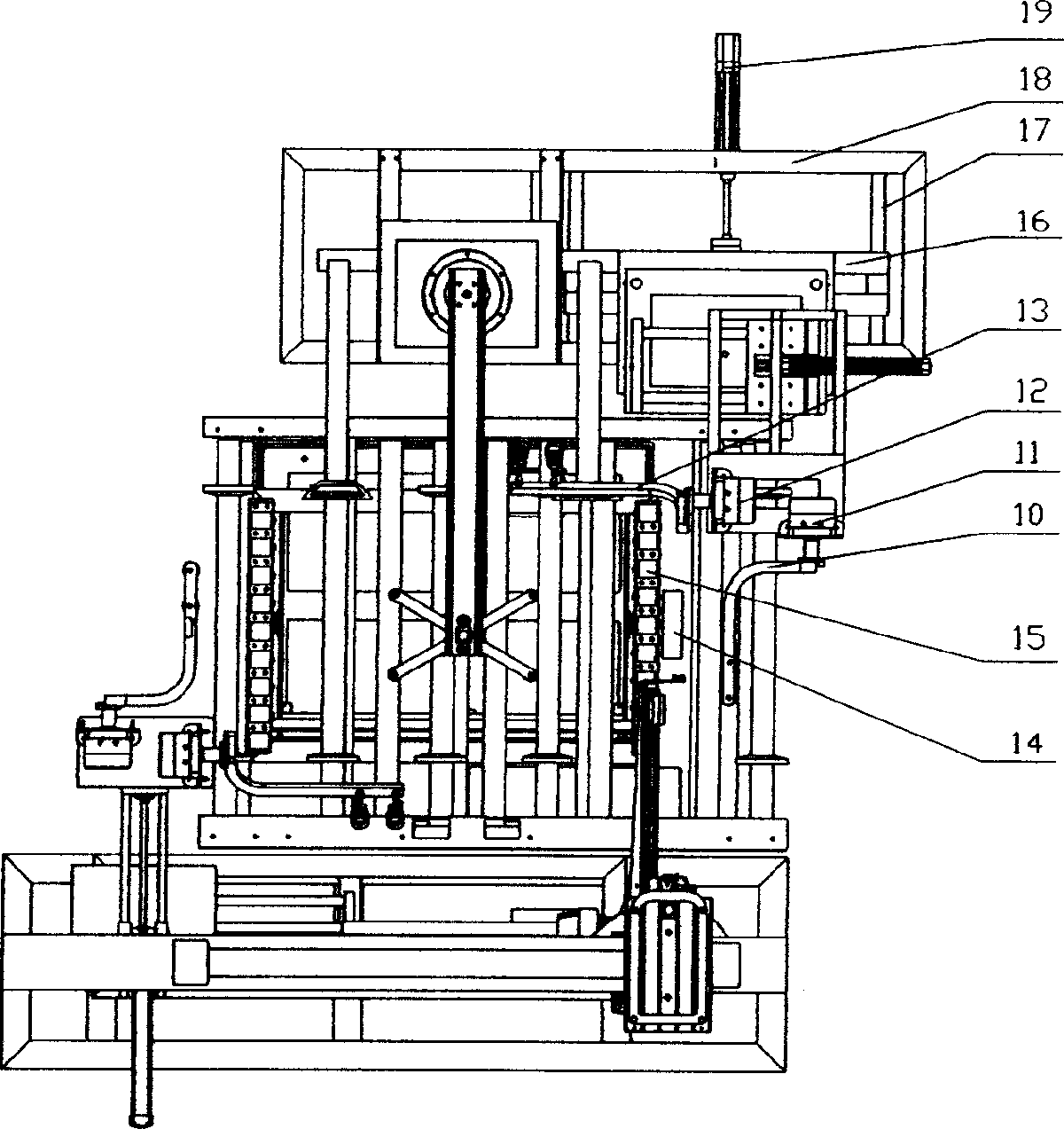

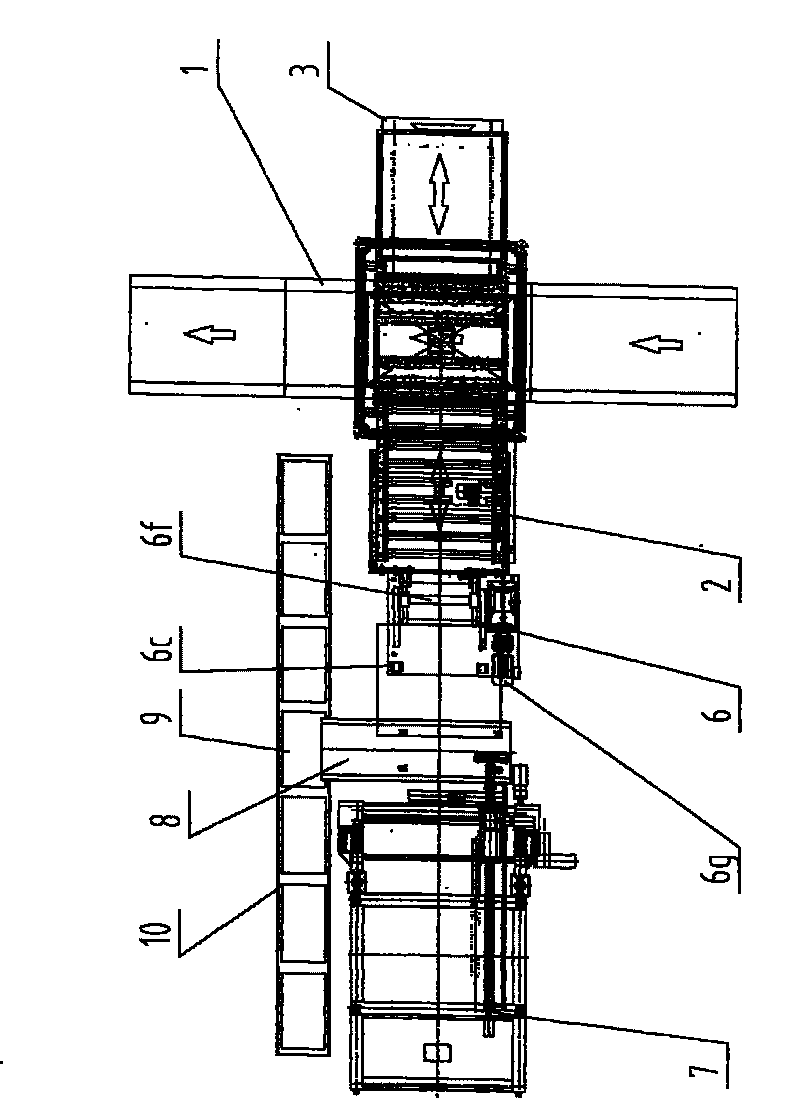

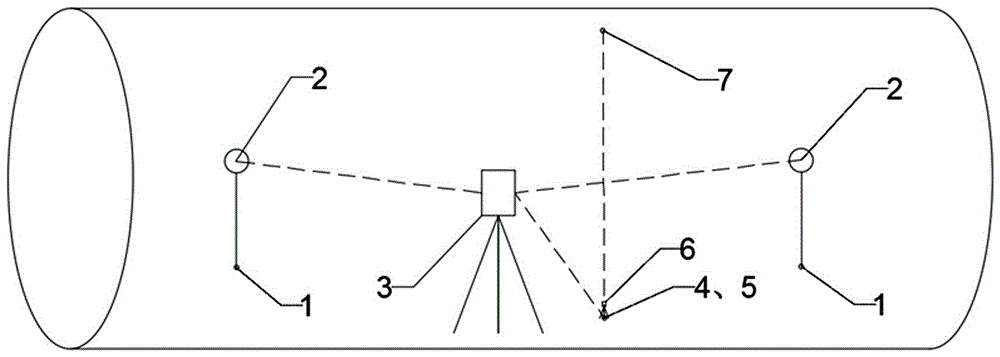

Automatic de-stacking and stacking technology and system for putting currency-box into and out of bank exchequer

ActiveCN1923644AQuick and easy palletizingPalletizing works accuratelyProgramme-controlled manipulatorControl devices for conveyorsStructural engineeringCartesian coordinate robot

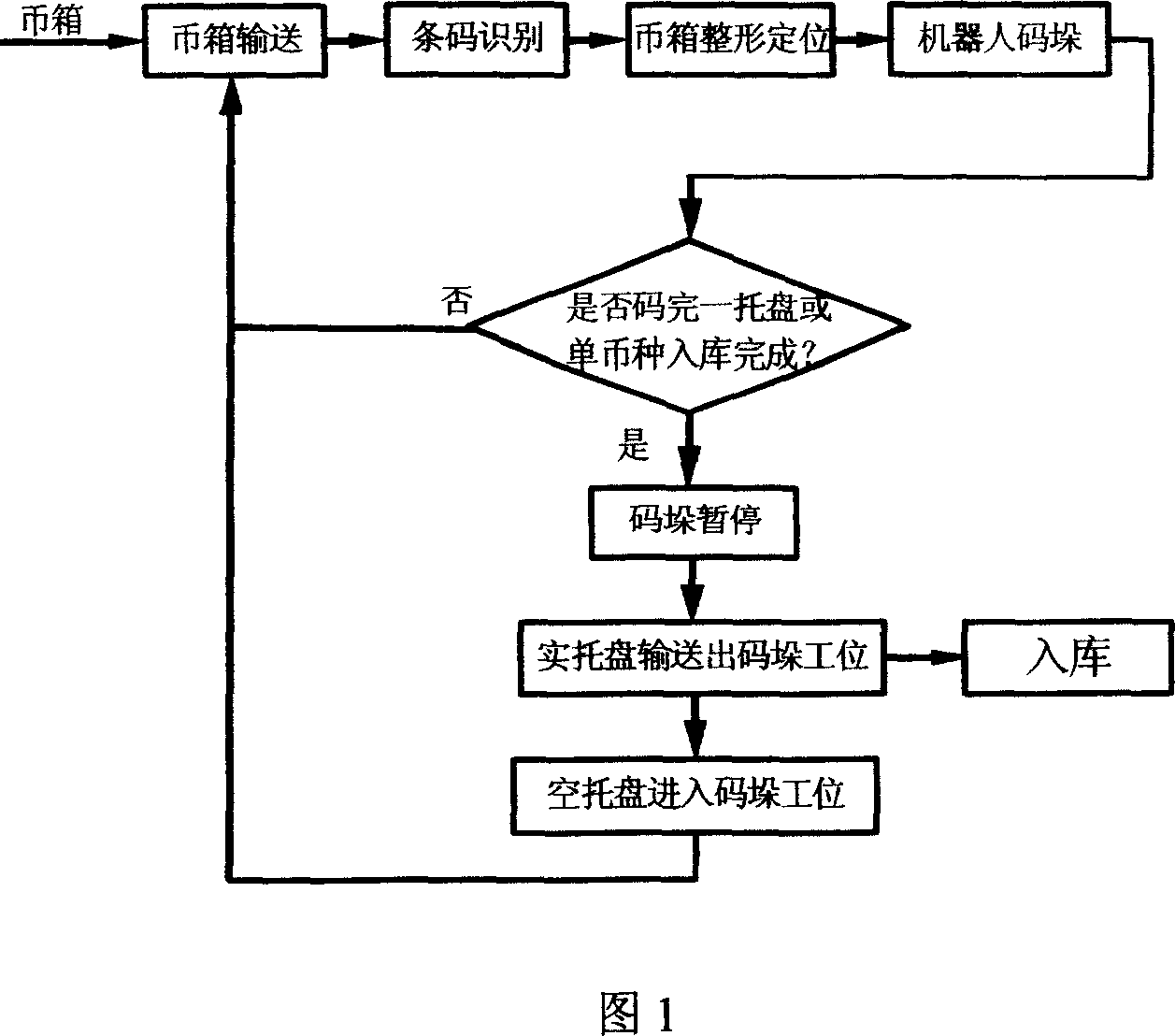

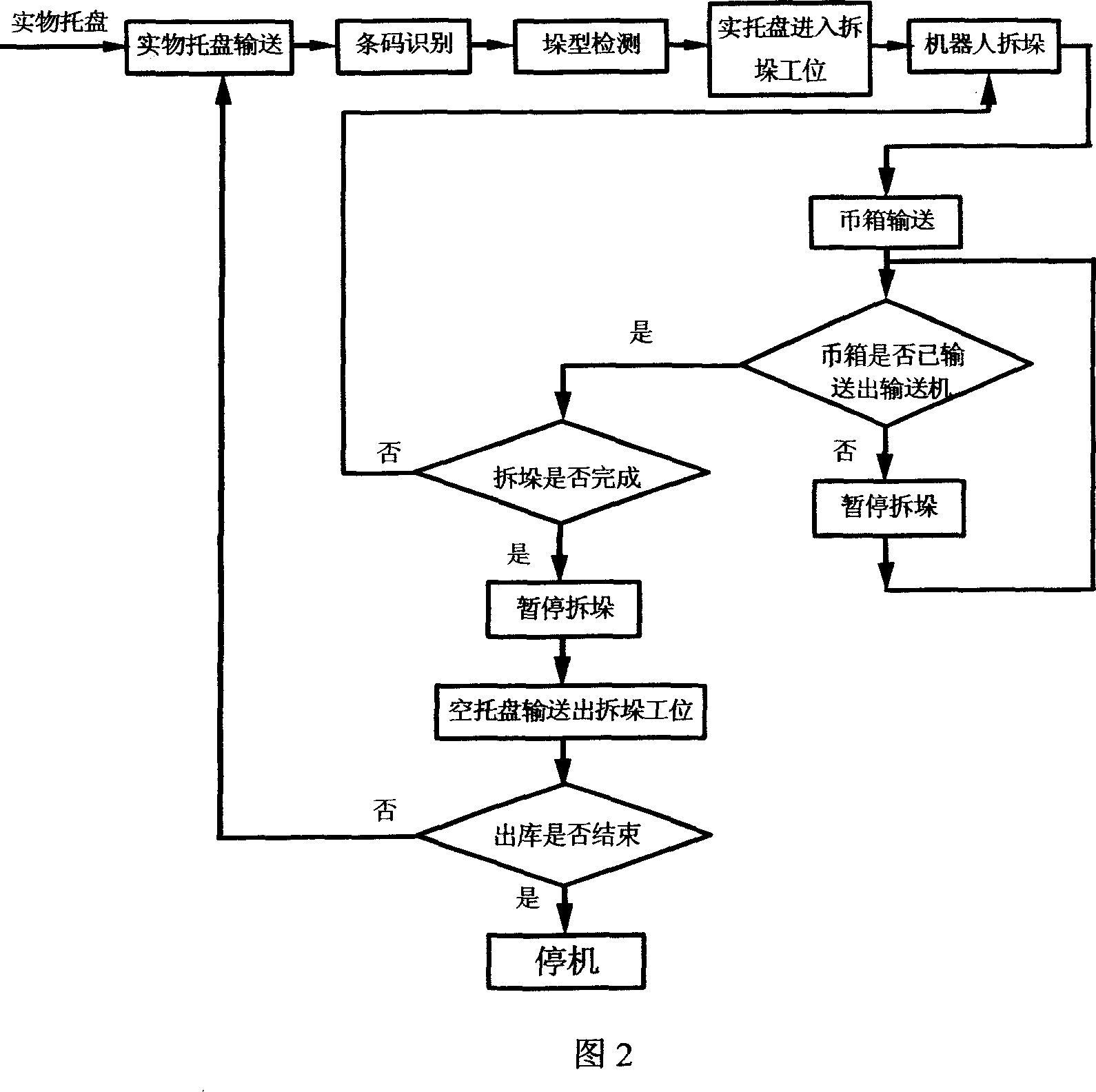

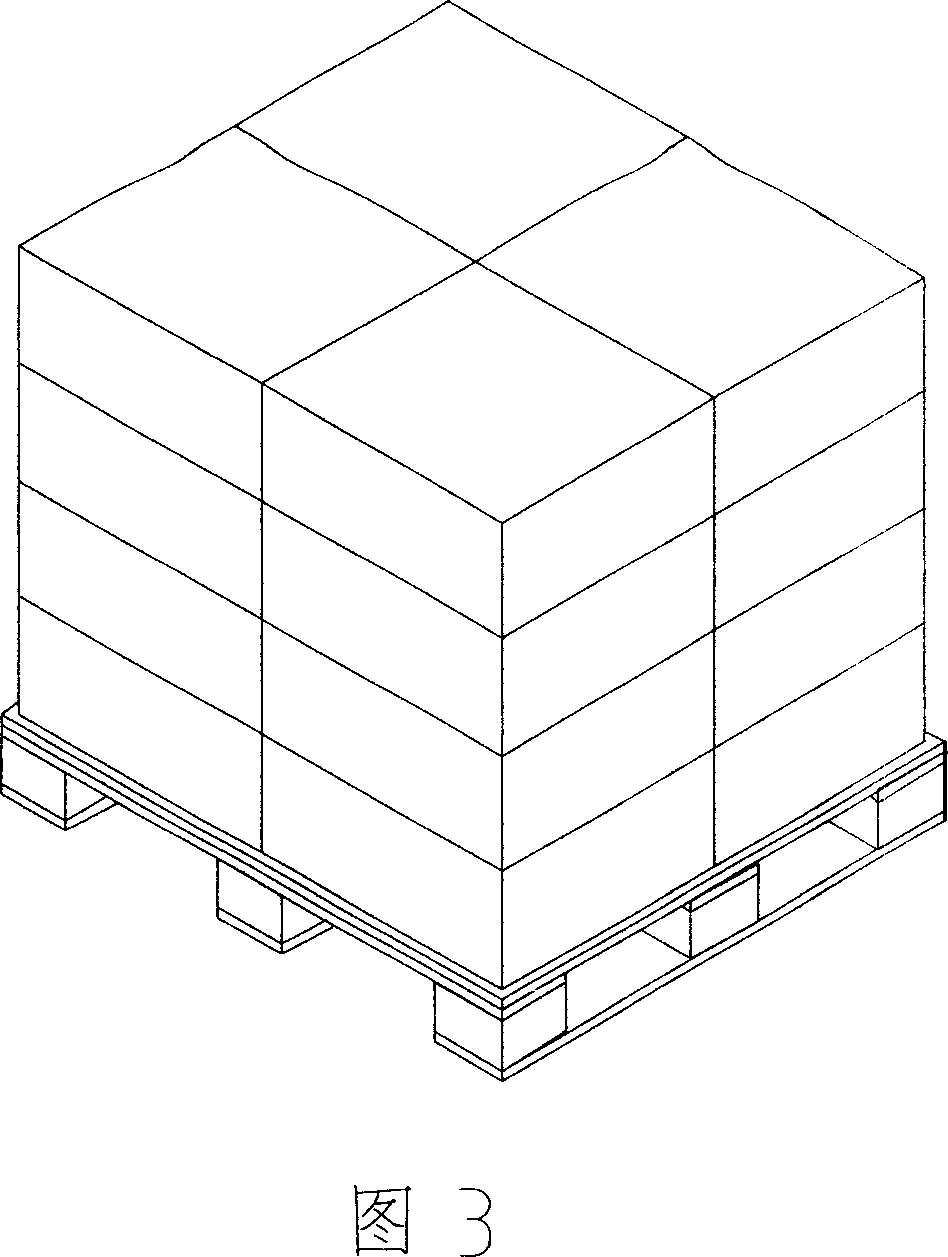

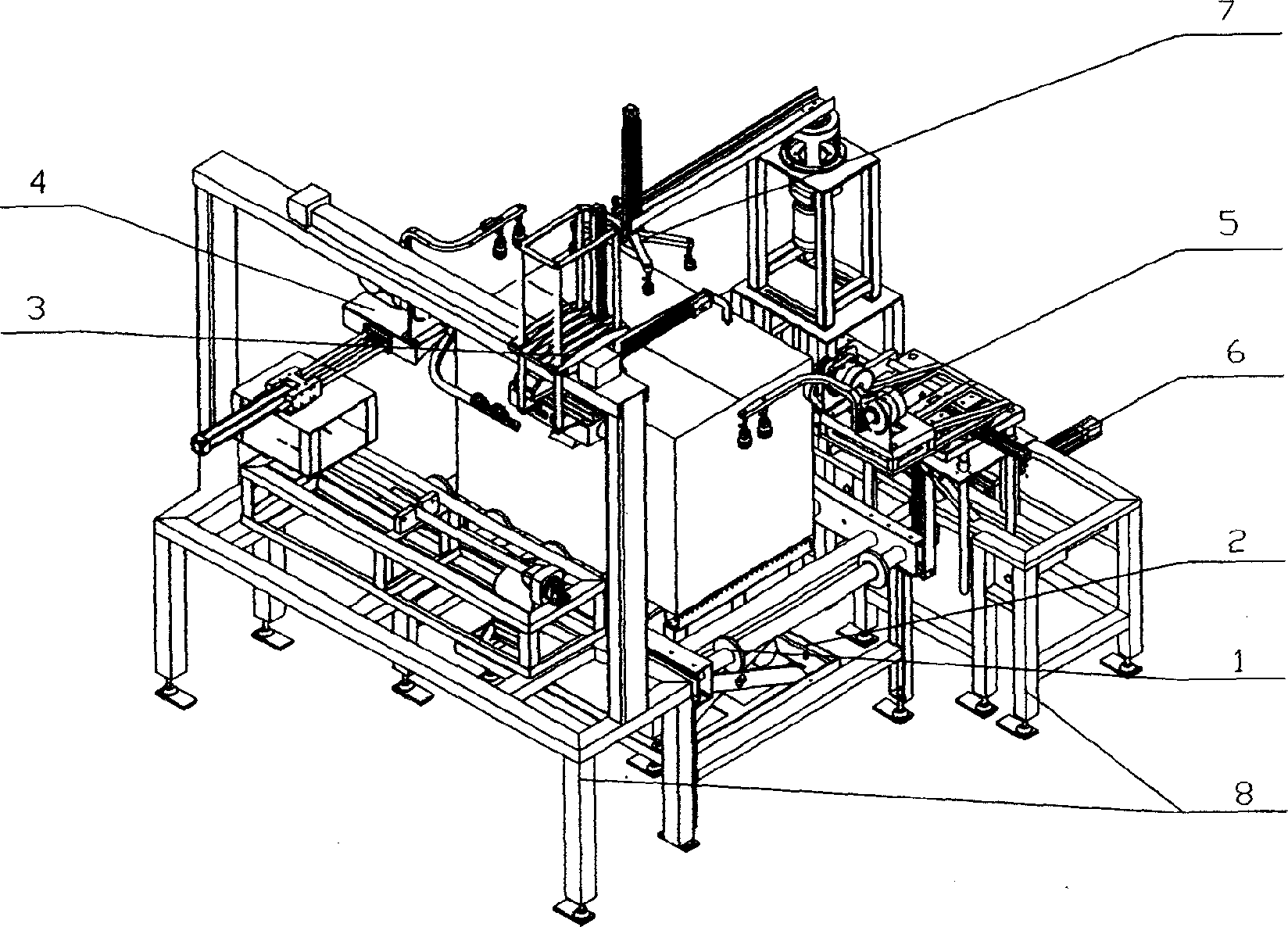

The automatic de-stacking and piling process and system for entry and exit of money case in the bank exchequer comprises of the entry piling and exit de-stacking; the system comprises of a Cartesian coordinate robot (5) and the fixture (6) at the bottom, with the transverse conveyer (1) and money box conveyer (10) equipped at the lower part of the robot sequentially. Inside the transverse conveyer and under the robot's piling and de-stacking position, there locates an alighting conveyer (12), whose outlet has an vertical conveyer (14) perpendicular to the transverse conveyer that has an check sensor (29) (19) on it. Above or the side of the transverse conveyer and the money box conveyer, separately locate the bar code scanner (13) (9) and the side of money box conveyer close to the robot has a money box regularizing and positioning device and a check sensor (15), (17). It can use the same system to realize the automatic de-stacking and piling operation of money boxes, automatic hand over of money box's entry and exit of the exchequer with high automation level, small occupant area, and quick and accurate de-stacking and piling.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

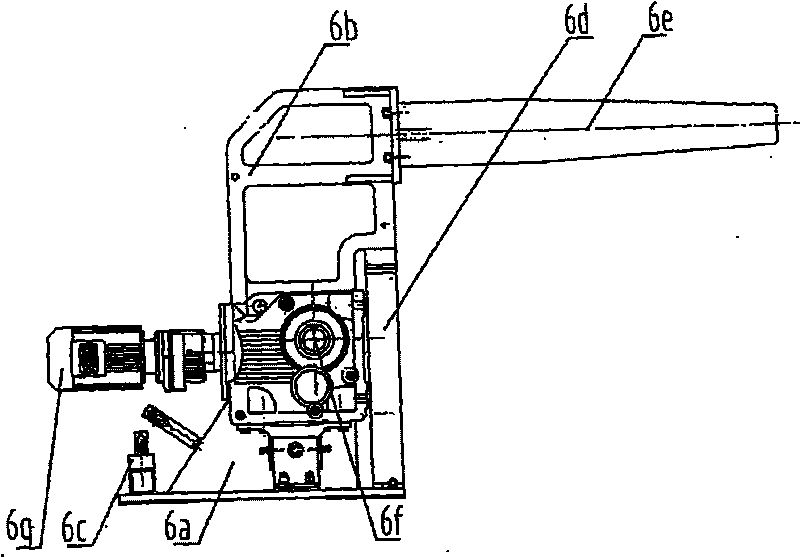

Full automatic opening method and device for paper box

ActiveCN1616305AProcess arrangement is reasonableImprove work efficiencyArticle unpackingCartonPulp and paper industry

The automatic paper box opening process includes the following steps: detecting, dismantling and recovering packing belt on the paper box; and turning the cover. The device used in the said process includes paper box package dismantling and recovering unit, front cover turning unit and back cover turning unit set along the paper box conveying line. The present invention can complete the number detection, locating, shearing and fast recovering of packing belt on the surface of paper box, the turning of paper box cover and removing the upper lining inside the paper box automatically and successively, is suitable for paper boxes of different sizes and has high work efficiency.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

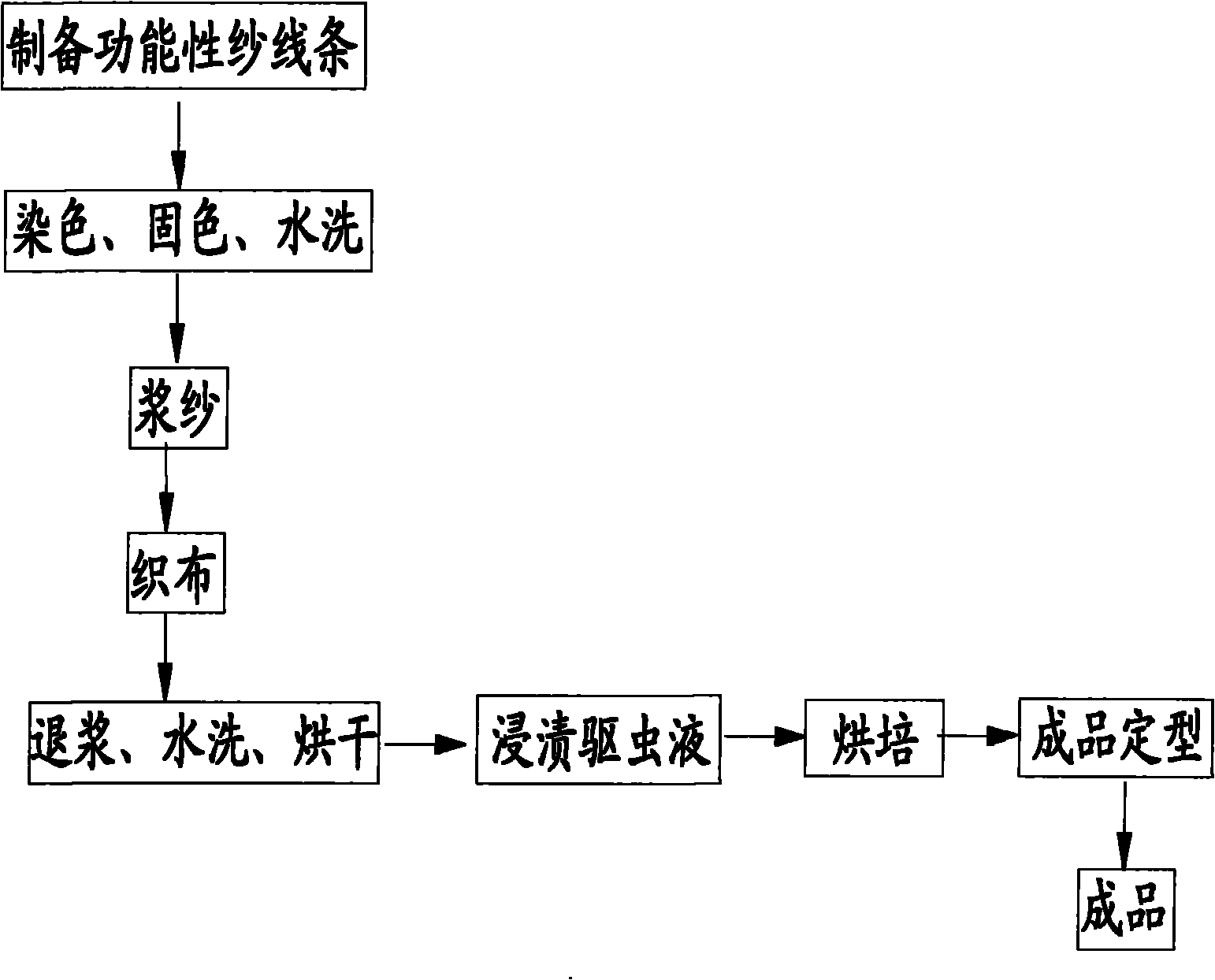

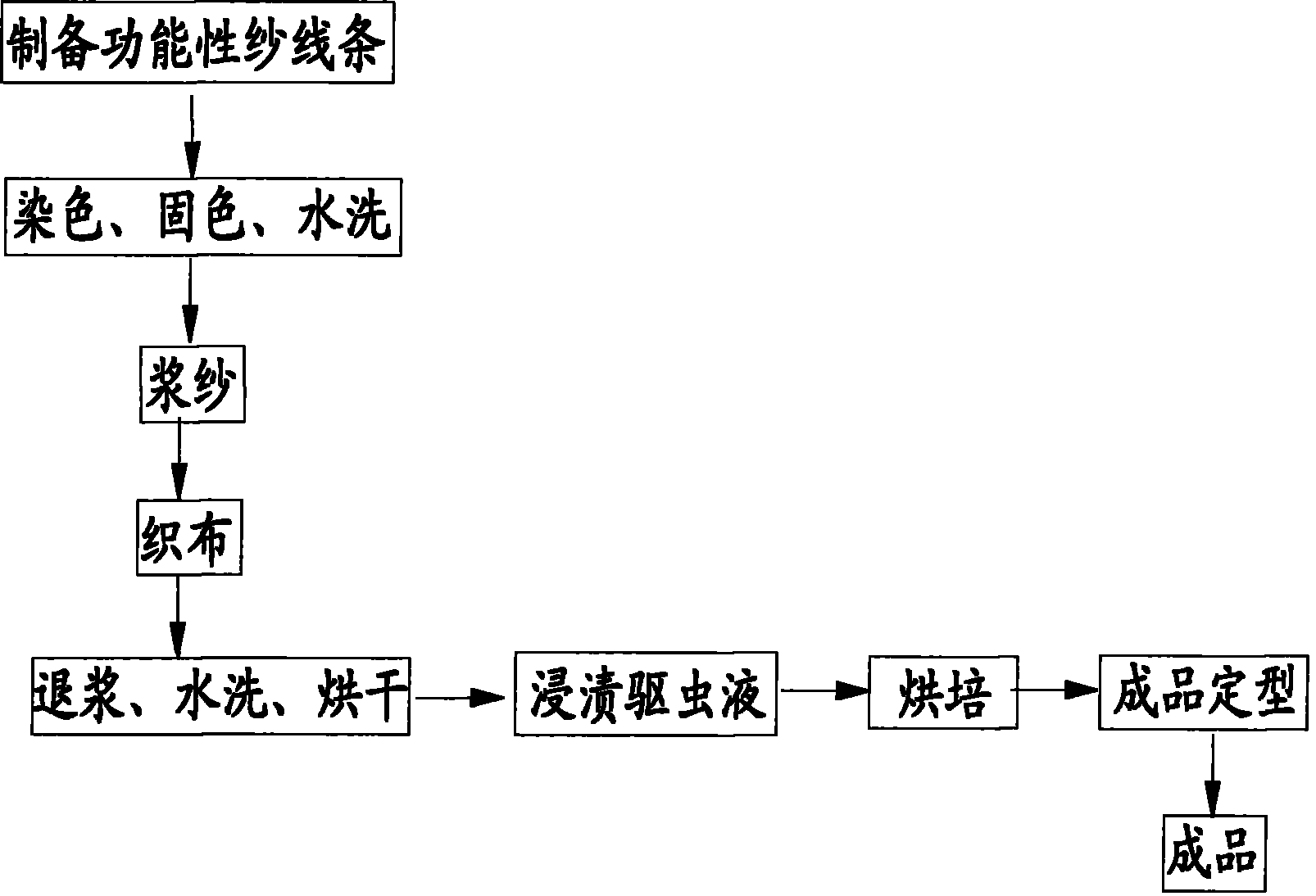

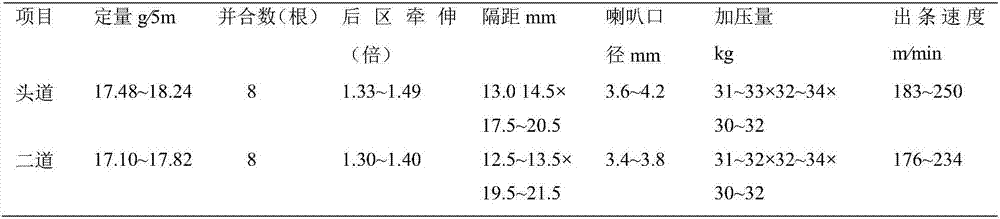

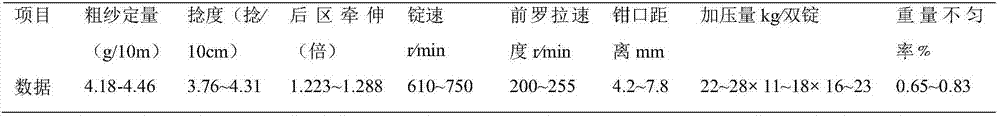

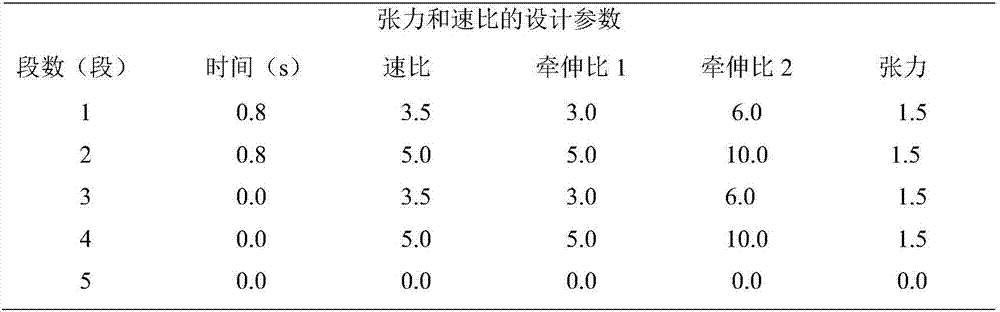

Insect-repelling antibacterial fabric manufacture process

InactiveCN102168341AImprove the bactericidal effectImprove insect repellent effectWeft knittingCarbon fibresYarnHigh resistance

The invention provides an insect-repelling antibacterial fabric manufacture process. The manufacture process comprises the following steps: (a) preparing functional yarns: (b) dyeing, fixing color, and washing with water; (c) sizing; (d) waving; (e) desizing, washing with water and oven-drying; (f) soaking in an insect-repelling solution; (g) drying; and (h) shaping. The insect-repelling antibacterial fabric manufacture process disclosed by the invention is reasonable, and the manufactured fabric has a good sterilizing and insect-repelling effect to prevent bites of insects, such as mosquitoes, flies, fleas and bedbugs. In addition, the fabric has the advantages of high resistance to abrasion and wash, long service life, no adverse effects to a human body due to the adoption of natural materials and wide application market.

Owner:CHANGSHU HUABO WOOLEN TEXTILE

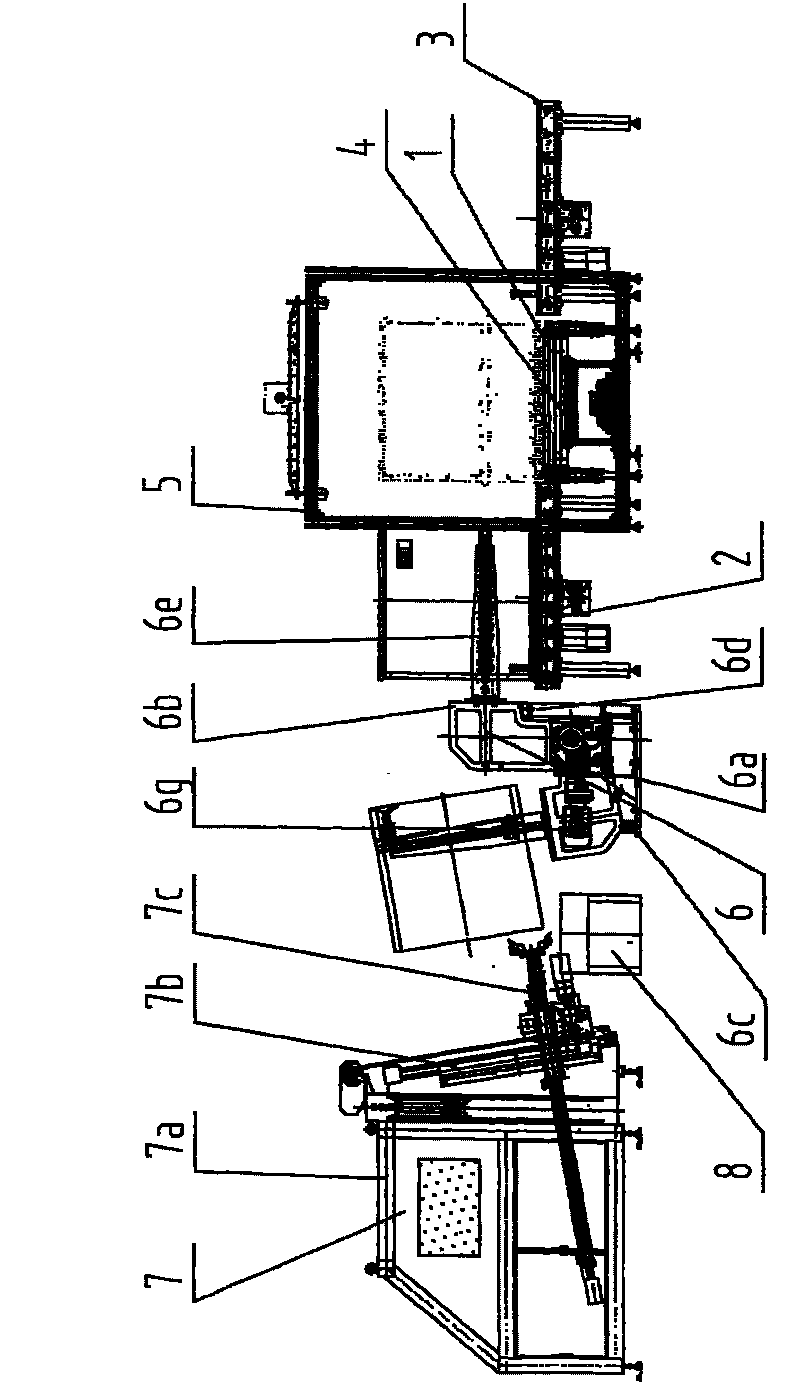

Process and system for automatically cleaning tobacco boxes

ActiveCN101722164ASatisfy classification and recyclingImprove production efficiencyProgramme-controlled manipulatorHollow article cleaningEngineeringCleaning station

The invention relates to a process and a system for automatically cleaning tobacco boxes. The process comprises the following steps of: conveying the tobacco boxes to a cleaning system, detecting the bottom of the boxes by a visual detector (5) to judge whether the tobacco boxes need cleaning or not, and identifying the positions of residual materials in the boxes; directly sending the tobacco boxes not needing cleaning out of the cleaning system, and conveying the tobacco boxes needing cleaning to a tobacco box turning station; turning the tobacco boxes by 90 to 150 DEG by a tilter (6) so that openings face a cleaning robot (7); stretching a cleaning claw (7c-2) of the cleaning robot (7) into the boxes for cleaning, cleaning the residual materials to a residual material belt conveyor (8), and then conveying the residual materials to a recycling box (9); turning and resetting the cleaned tobacco boxes by the tilter, and sending the tobacco boxes back to a visual detector station for rechecking; and sending the tobacco boxes qualified in the rechecking out of the cleaning system, and conveying unqualified tobacco boxes to the tilting station again for secondary cleaning or directly conveying the unqualified tobacco boxes to a manual cleaning station for cleaning. The process and the system can complete automatic cleaning of the tobacco boxes for storing shredded leaves and sliced leaves.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

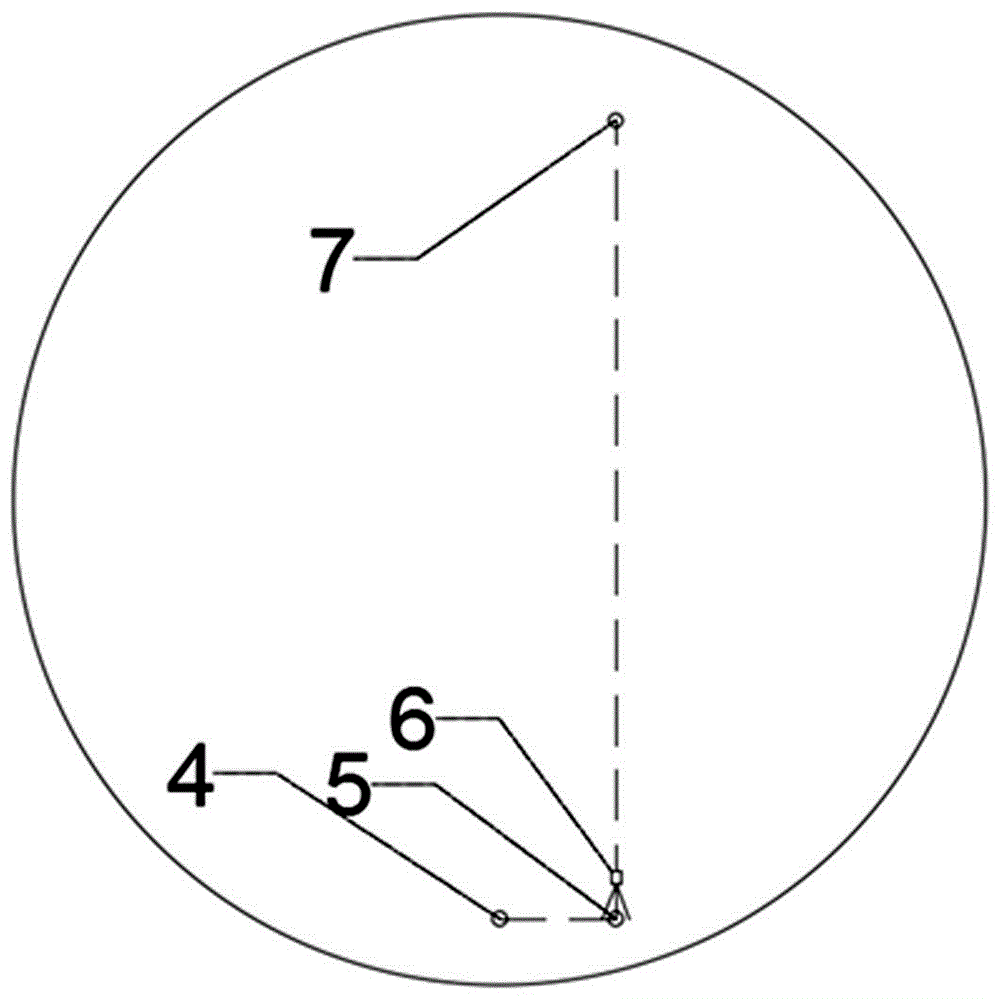

Trackless construction method for subway rigid catenary system

ActiveCN106585427ASolve the problem of delaysImprove construction efficiencyTrolley linesSocial benefitsEconomic benefits

The invention belongs to the technical field of construction of subway vehicle power supply. In order to solve technical problems of subway rigid catenary system construction of large operation interference, long construction period and low working efficiency, the invention provides a trackless construction method for a subway rigid catenary system. The trackless construction method for the subway rigid catenary system comprises the following steps of step 1, calculating a catenary system suspension point; step 2, measuring and positioning the rigid catenary system suspension point; step 3, suspending, assembling and calculating the rigid catenary system; and step 4, suspending, assembling, mounting and rechecking the rigid catenary system. The invention is advantaged in that the positioning point position and the clearance height are determined before track laying, the construction efficiency is increased, the construction cost is saved, a problem that construction period delay is caused because the construction of the catenary system depends on a steel rail is solved, the gap in the domestic trackless construction technique of the urban subway rigid catenary system is filled and good economic benefit and social benefit are obtained.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Comfortable skin-care warming health-care hollow porous yarn, and preparation method and application thereof

The invention provides a preparation method and application of a comfortable skin-care warming health-care hollow porous yarn. The comfortable skin-care warming health-care hollow porous yarn is formed by firstly blending and then processing such six hollow fibers (one or more fibers) as fine staple cotton fibers, seashell fibers (or Amicor antibiotic fibers or Cleancool fibers), water-soluble polyvinyl short fibers (or water-soluble polyvinyl filaments), kawo kawo fibers ( or Viloft fibers or Prolivon fibers or antibiotic hollow polyester fibers or Porel hollow fibers or Poral hollow fibers or micropore polyester fibers) and the like. The product has a body temperature adjustment effect, keeps a human body to always feel comfortable, is good in stiffness, feels soft and smooth, is good in drapability, unique in appearance and good in wrinkle resistance, enables a wearer to feel comfortable and is fluffy in texture, thereby being suitable for production of high-grade knitting machine woven fabrics, cold-proof underwear, bedding articles and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

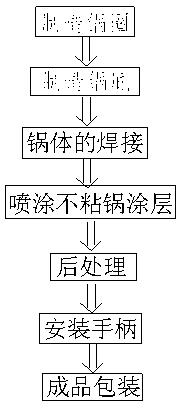

Manufacturing method of high-performance wok

InactiveCN103300706AHigh strengthImprove thermal conductivityCooking vesselsArc welding apparatusAdditive ingredientEngineering

The invention discloses a manufacturing method of a high-performance wok, which comprises the following steps: a) casting a wok ring, b) manufacturing a wok bottom, c) welding a wok body, d) spraying a non-stick coating, e) conducting post-treatment, f) mounting a handle, and g) packaging a finished product. The invention discloses the manufacturing method of the high-performance wok, which is reasonable in procedure arrangement and moderate in cost; the wok bottom of the high-performance wok is in a multilayer composite structure; the interlayer bonding properties are stable; the wok body is made of cast iron; the whole wok body is high in strength, stable in performance and long in service life; the wok has prominent heat-conduction, wear-proof, anticorrosion and non-stick performances, and the advantages of an iron pan; good nutritional ingredients of food can be ensured; and the wok is beneficial to human health.

Owner:CHANGSHU JINHAO MACHINERY

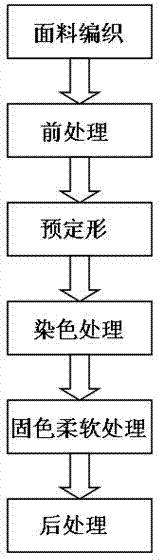

Dyeing and finishing process for lace fabric

InactiveCN102851875AShiny brightProcess arrangement is reasonableFabric breaking/softeningHeating/cooling textile fabricsWear resistantEngineering

The invention provides a dyeing and finishing process for a lace fabric. The dyeing and finishing process comprises the following steps: a) weaving of a fabric; b) pre-processing; c) pre-shaping; d) dyeing treatment; e) dye fixation and mellowing; and f) post-processing. The dyeing and finishing process revealed in the invention has the following advantages: process procedures are reasonably arranged; implementation of the process is scientific and simple; the prepared lace fabric can permanently keep bright sheen, is washable and durable, wear-resistant and non-fading, and has a high market value compared to products of a same kind.

Owner:KUSN CHENGYU ELECTROMECHANICAL TECH

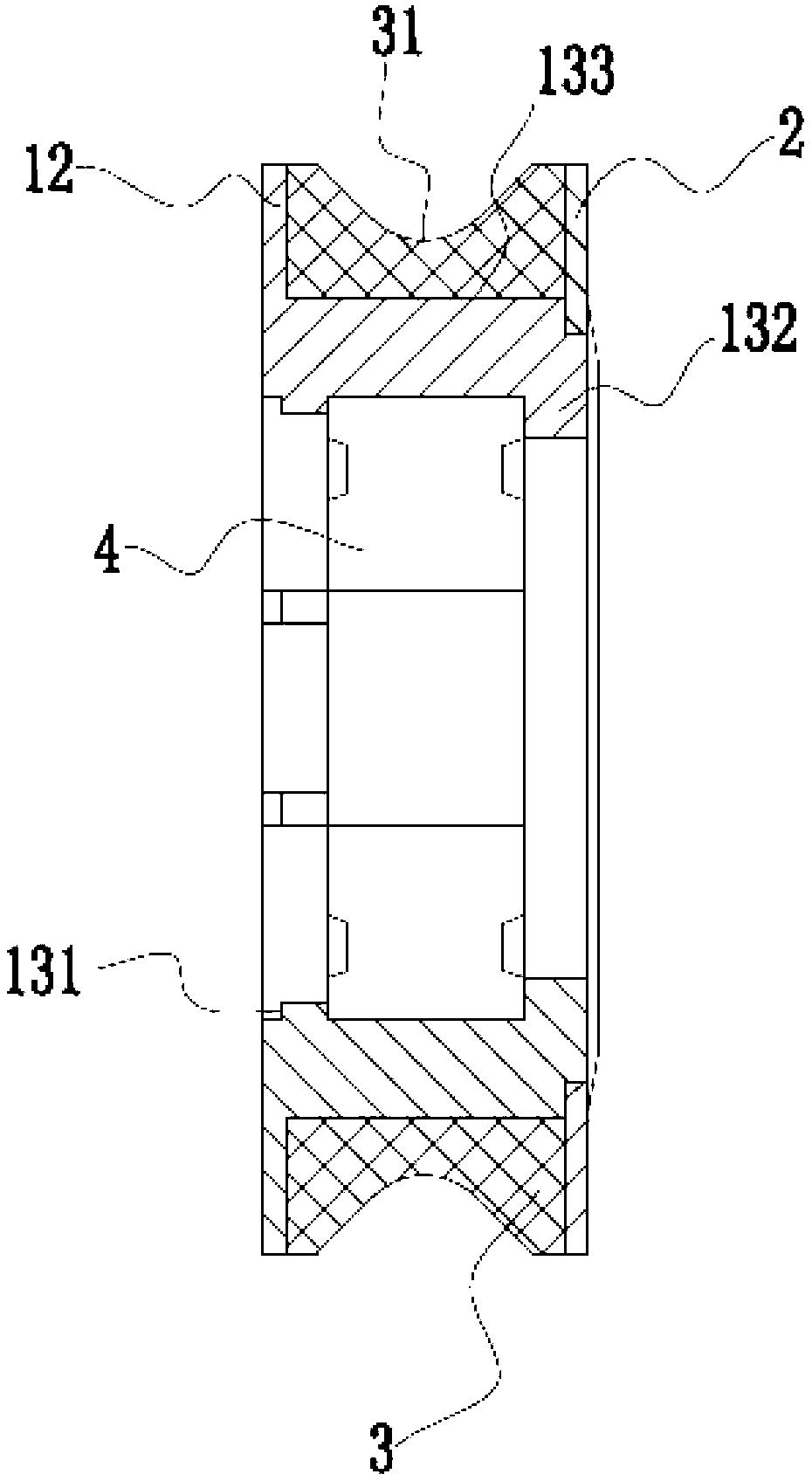

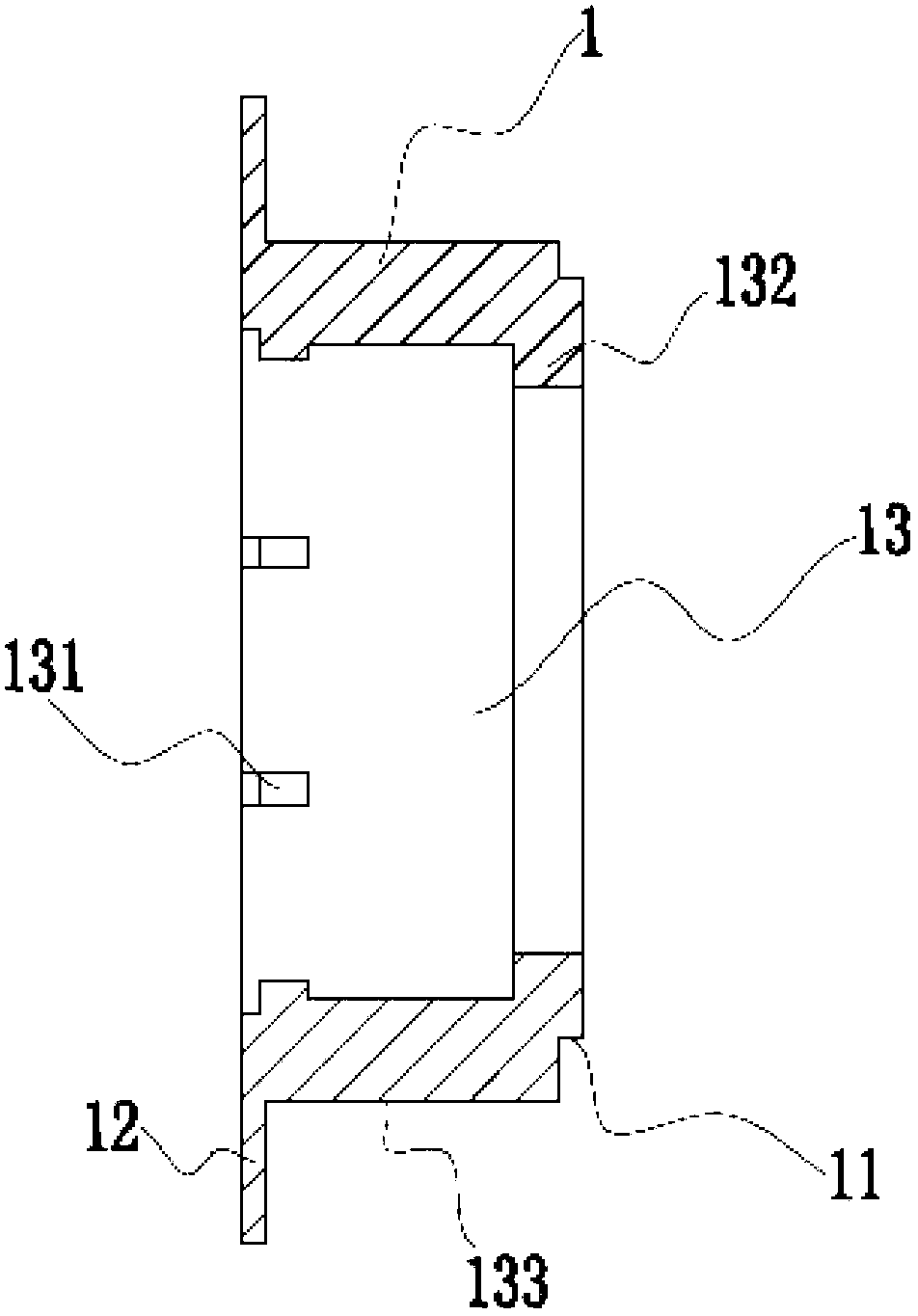

Fire-proof wheel and production technology thereof

InactiveCN102705356AImprove fire protectionImprove connection stabilityShaft and bearingsElevatorsElevator systemWork performance

The invention discloses a fire-proof wheel and a production technology of the fire-proof wheel. The fire-proof wheel comprises a wheel main body and a bearing which are made of metal materials. The wheel main body comprises a retaining ring and a wheel core which is provided with a through hole. One end of the wheel core is provided with a folded side, and the other end of the wheel core is provided with a first limiting step. The retaining ring is fixedly sleeved on the first limiting step. One end of the inner wall of the through hole of the wheel core is provided with a second limiting step, and the other end of the inner wall of the through hole of the wheel core is provided with a certain quantity of riveting points which are distributed in an annular shape. The bearing is fixed between the riveting points and the second limiting step. A Teflon ring is sleeved on the outer surface of the wheel core, and the Teflon ring is located between the retaining ring and the folded side. The fire-proof wheel provided by the invention comprises the wheel core and a baffle which are made of metal materials, so that the fire-proof function of the surface of the wheel is good; compared with the design of the polyurethane ring in the prior art, the Teflon ring is not influenced by high temperature, the use stability is high, and the work performance is good, so that the fire-proof wheel is quite suitable for fire elevator systems.

Owner:NINGBO HUALING ELEVATOR PARTS

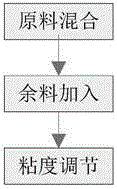

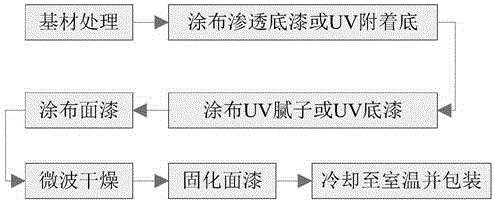

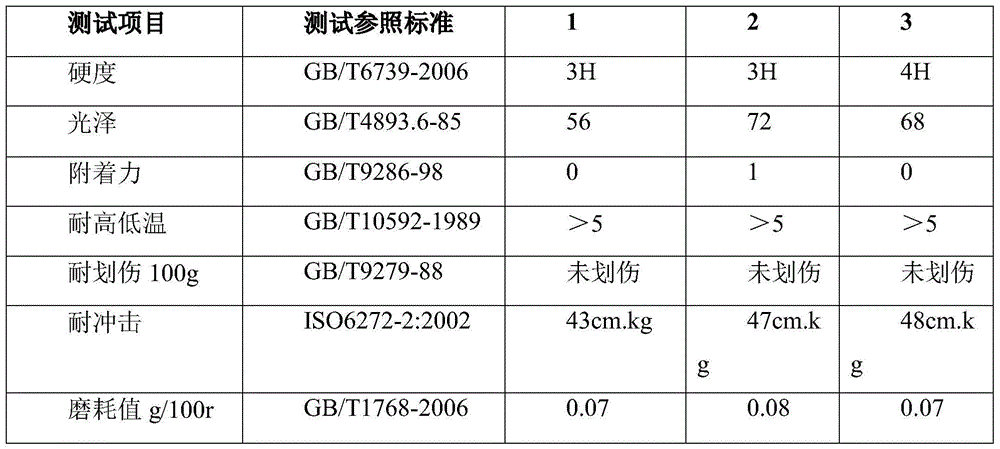

Aqueous UV wood paint, preparation method and application technology thereof

InactiveCN105860792AInhibition releaseGuaranteed to be environmentally friendlyPretreated surfacesPolyurea/polyurethane coatingsHardnessWear resistance

The invention discloses an aqueous UV wood paint. The aqueous UV wood paint comprises the following components: 20-40% of aqueous polyurethane resin, 20-60% of aqueous UV resin, 0.2-0.6% of an antifoaming agent, 0.2-0.8% of a leveling agent, 0.2-0.8% of a wetting agent, 0.2-0.8% of a thickening agent, 0.2-0.8% of an initiator, 0.2-0.8% of a dispersant, 0.2-0.8% of matting powder, 5-40% of water, and 0.2-0.5% of a handfeel auxiliary agent. The invention also discloses a preparation method of the aqueous UV wood paint and an application technology thereof. The aqueous UV wood paint has the advantages of good environmental protection performance, strong adhesive force, high hardness, good wear resistance and coin scratching-resistant performance. The preparation method has the advantage of simple operation, by employing a microwave drying method, the drying speed is fast, drying requirement of a thicker coating can be satisfied, the production efficiency is high, and the aqueous UV wood paint is quit suitable for industrial production.

Owner:HUNAN BANFERT NEW MATERIALS TECH

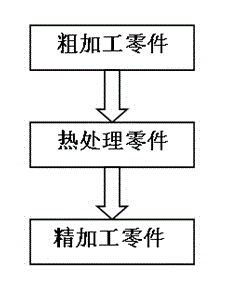

Thin-walled part machining method

InactiveCN104959786ASolve processing deformationImprove machining accuracyMachining deformationProcessing accuracy

The invention provides a thin-walled part machining method. A thin-walled part is an aluminum alloy thin-walled cavity part. The machining method comprises the first step of rough part machining, the second step of thermal processing of the part and the third step of fine part machining. According to the thin-walled part machining method, the machining method is reasonable in procedure arrangement and high in working efficiency; the problem of machining deformation of the part is effectively solved, and the machining precision and the surface quality of the part are greatly improved.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

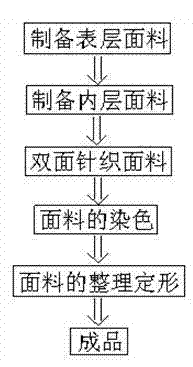

Cool moisture-absorbing sweat-releasing fabric production method

InactiveCN102899794AMoisture wicking hasWith icy coolingWeft knittingBiochemical fibre treatmentMoistureCivil engineering

The invention provides a cool moisture-absorbing sweat-releasing fabric production method which includes steps of a), producing surface fabric; b), producing inner fabric; c), performing double-side knitting to the fabrics; d), dyeing the fabrics; and e) setting the fabrics. The cool moisture-absorbing sweat-releasing fabric production method is reasonable in procedure arrangement and easy and convenient; and the fabrics produced by the method are cool, comfortable, soft and smooth and have moisture-absorbing and sweat-releasing effects, and accordingly are perfect fabrics for making outdoor sports wears for summer.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

Moisture-absorption and sweat-discharge fiber spunlaced nonwoven fabric and preparation method thereof

InactiveCN107419438AImprove performanceLong-lasting and stable effectNon-woven fabricsPolyesterViscose

The invention relates to an antibacterial health-care spunlaced faric, in particular to a preparation method and application of a moisture-absorption and sweat-discharge fiber spunlaced nonwoven fabric. The moisture-absorption and sweat-discharge fiber spunlaced nonwoven fabric is prepared from, by weight, 10-70% of moisture-absorption and sweat-discharge fiber (including Coolmax, Coolplus, Cooldry and Topocool), 0-50% of pearl fiber, 0-50% of mint fiber, 0-60% of antibacterial viscose fiber (or viscose fiber) and 0-60% of antibacterial polyester fiber or polyester fiber. The moisture-absorption and sweat-discharge fiber spunlaced nonwoven fabric has the advantages that the developed moisture-absorption and sweat-discharge fiber spunlaced nonwoven face towel base fabric has the effects of disinfection, cleaning, maintenance, moisturizing nourishing and the like and also has the effects of corrosion prevention, inflammation diminishing, hygiene, health care and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Mint fiber spunlace non-woven mask substrate and preparation method thereof

The invention relates to an antibacterial healthcare spunlace fabric, in particular to a preparation method and application of a mint fiber spunlace non-woven mask substrate. The mint fiber spunlace non-woven mask substrate is prepared from, by weight, 10-100% of mint fiber, 0-90% of copper ammonia fiber, 0-90% of pearl fiber, 0-90% of viscose and 0-90% of polyester fiber. The mint fiber spunlacenon-woven mask substrate has the advantages that the developed mint fiber spunlace non-woven mask substrate is soft in touch and good in adsorption, has the water wetting and lightsome skin feeling and has the efficient anti-aging, anti-radiation, anti-bacterial and anti-oxidative effects, and the mask substrate has the functions of preserving moisture, activating cells, supplying oxygen and the like, and achieves the nourishing, nutritional and healthcare effects on the skin.

Owner:ZHONGYUAN ENGINEERING COLLEGE

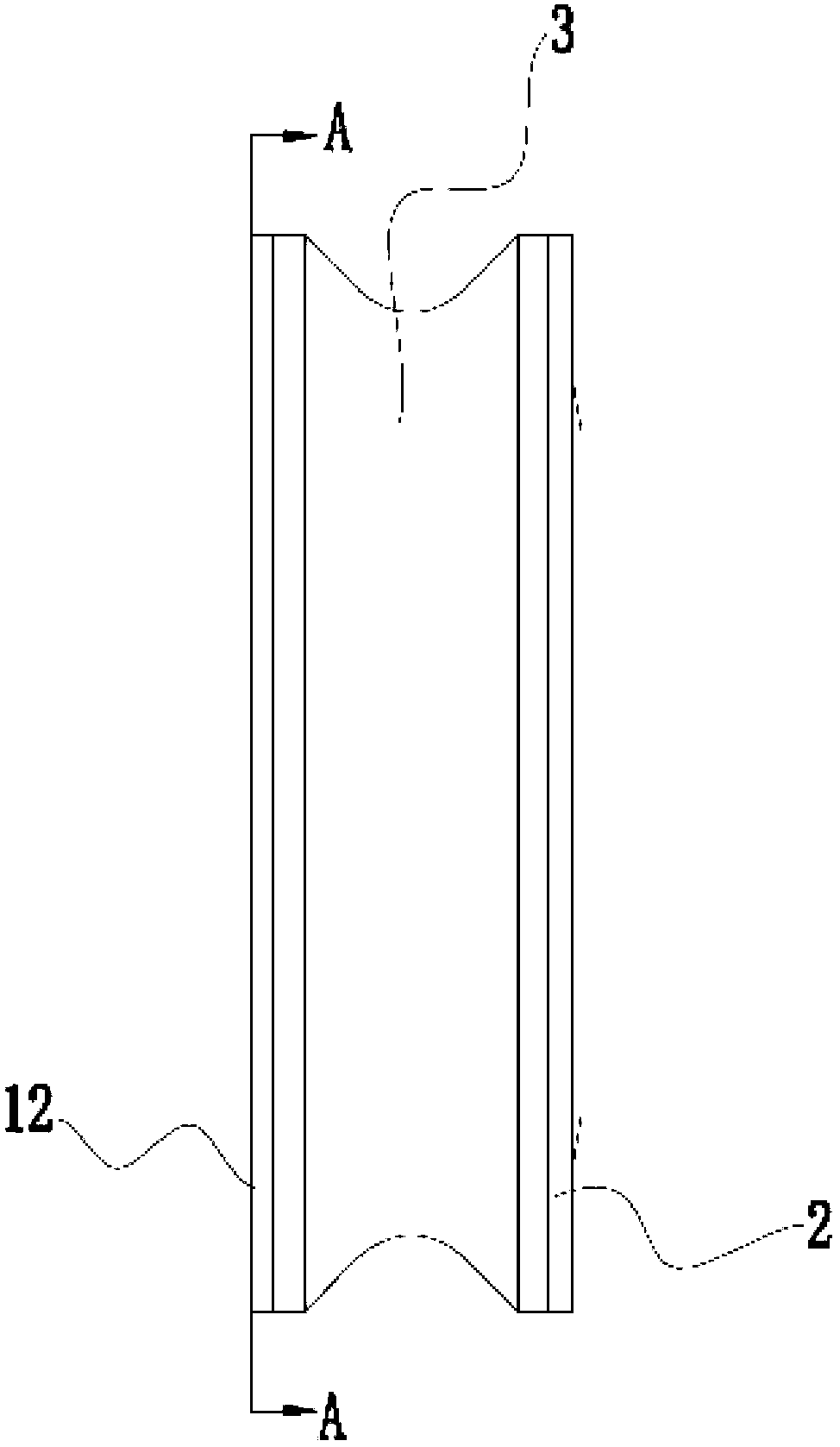

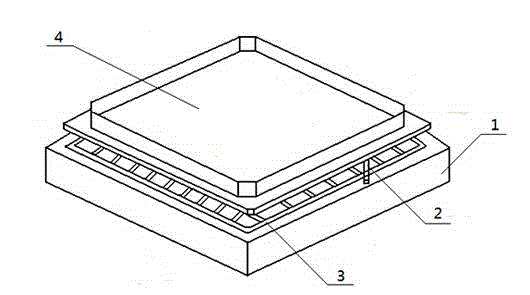

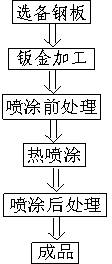

Manufacturing method of panel of microwave oven chamber

The invention discloses a manufacturing method of a chamber panel of a microwave oven. The manufacturing method comprises the steps as follows: a), steel plate preparation; b), sheet-metal working; c), spraying pretreatment, d), thermal spraying and e), spraying post-treatment. According to the manufacturing method of the chamber panel of the microwave oven, the process arrangement is reasonable, the implementation is simple and convenient, and the manufactured chamber panel has stable microwave reflecting capacity; and at the same time, a surface ceramic material is excellent in aspects of oil resistance, corrosion resistance and high temperature resistance, the chamber panel is convenient to clean, the service life is long, and the practical performance is excellent.

Owner:KUNSHAN RONGAO WEIJIE TRADE

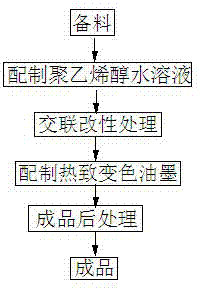

Preparation method of novel thermochromic printing ink

The invention provides a preparation method of a novel thermochromic printing ink. The preparation method comprises following steps: a) material preparation; b) preparation of a polyvinyl alcohol aqueous solution; c) crosslinking modification processing; d) preparation of the thermochromic printing ink; and e) finished product postprocessing. The invention discloses the preparation method of the novel thermochromic printing ink. Procedures of the preparation method are reasonable; operation is convenient; cost is moderate; and the prepared novel thermochromic printing ink possesses excellent covering performance and wear resistance, is brilliant in color and is high in color changing sensitivity, and is especially suitable to be used for fields such as food anti-counterfeit labels and temperature-sensitive packaging materials.

Owner:SUZHOU ZHONGYA INK

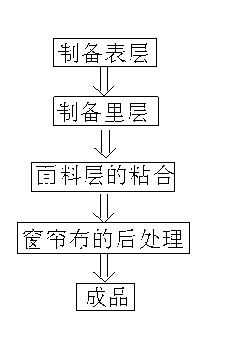

Preparation method of novel soundproof curtain fabrics

InactiveCN102991094AUnique structureGood effectLamination plant layoutLaminationSurface layerHome environment

The invention discloses a preparation method of novel soundproof curtain fabrics. The preparation method comprises the following steps: a) preparing a surface layer; b) preparing an inner layer; c) bonding a fabric layer; and d) carrying out post-processing on a curtain fabric. According to the preparation method of the novel soundproof curtain fabrics, disclosed by the invention, the process arrangement is reasonable, the implementation is convenient and fast, and the cost is moderate; the prepared curtain fabric is unique in structure, stratified in soundproof effect, remarkable in effect, elegant in appearance, and soft in texture, can build a relatively quiet and comfortable home environment for people, and has a board market prospect.

Owner:TAICANG SUYEE INFORMATION TECH

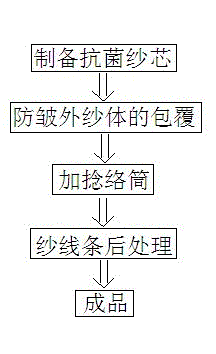

Preparation method of anti-wrinkling and antibacterial compound yarn strip

The invention discloses a preparation method of an anti-wrinkling and antibacterial compound yarn strip. The preparation method comprises the following steps of: (a) preparing an antibacterial yarn core; (b) coating an outer anti-wrinkling yarn strip; (c) twisting and spooling; and (d) performing post-treatment on the yarn strip. The preparation method of the anti-wrinkling and antibacterial compound yarn strip disclosed by the invention is reasonable in procedure arrangement, is easy and convenient to implement, and is appropriate in cost; an outer yarn body has excellent coating performance and has elasticity, so that prepared fabric cloth has an easy-care function; and the yarn core has a remarkable antibacterial effect, and the antibacterial effect is more durable under the coating of the outer yarn body.

Owner:SUZHOU XUNXIAN TEXTILE TECH CO LTD

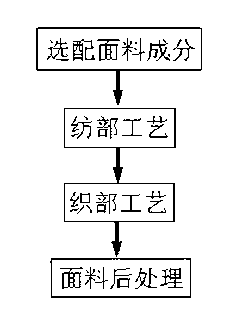

Preparation method of multi-functional fabric

InactiveCN103132204AStrong odor absorptionGood perspiration and moisture absorptionWoven fabricsMoisture absorptionEngineering

The invention discloses a preparation method of a multi-functional fabric, and the multi-functional fabric is manufactured through a unique preparation method. The preparation method includes the following steps: a. selecting and matching of fabric components, b. spinning, c. weaving, and d. post-processing of the fabric. The preparation of the multi-functional fabric has the advantages that procedure arrangement is reasonable, the method is carried out scientifically and effectively, and fabric manufactured through the preparation method have the functions of ultra-strong smell-absorbing capacity, good moisture absorption and sweat discharge quality, and excellent health functions such as antibiosis, mildew-proof, acarid resistance and acarid killing. Further, the fabric is unique in style, and is ideal fabric in manufacture of high quality clothing and household textiles.

Owner:KUSN ZHOUSHI TOWN JISHENG CLOTHING FACTORY

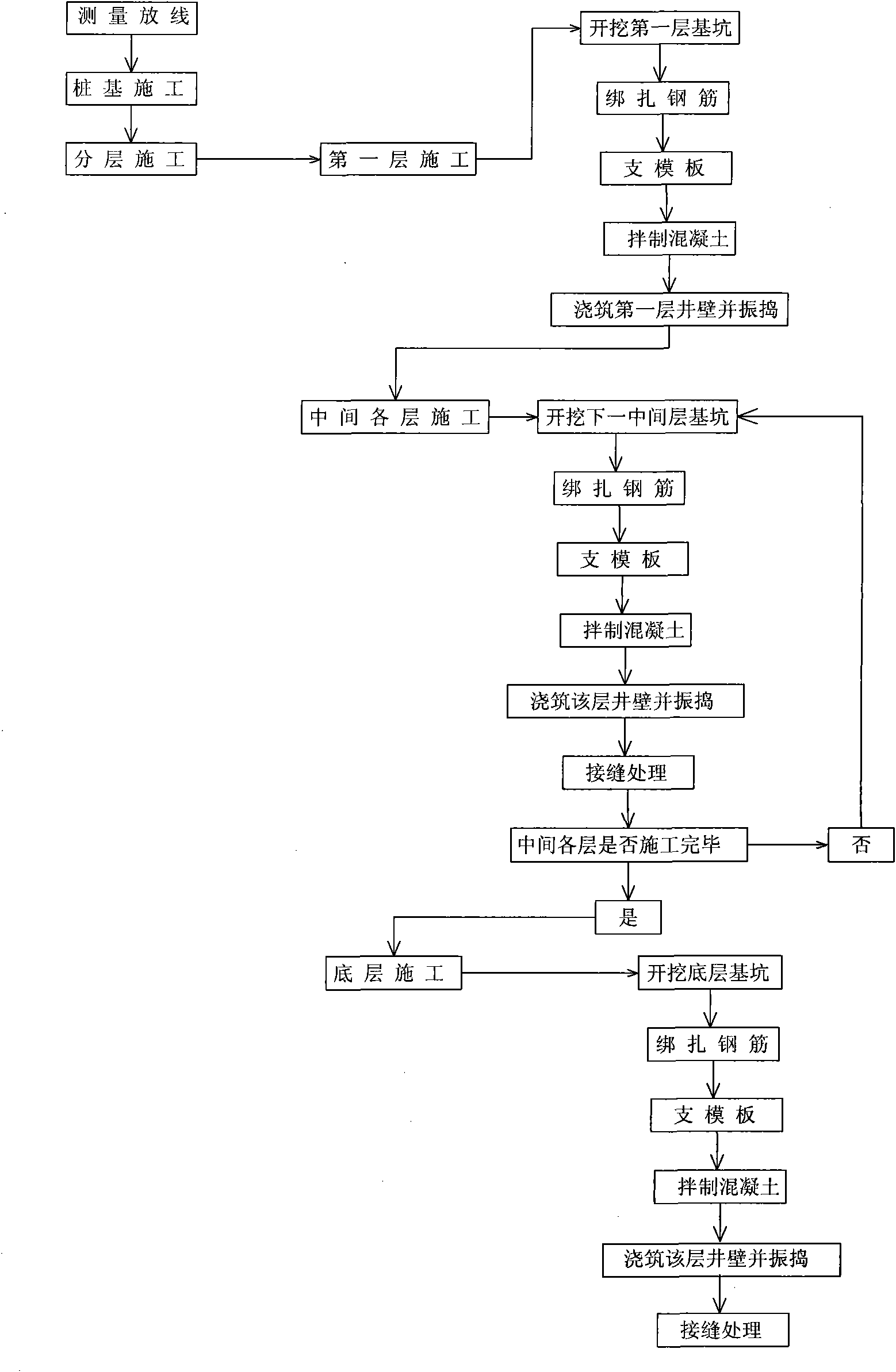

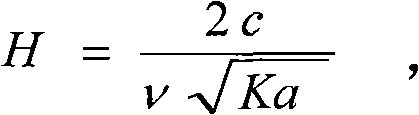

Suspension type construction method of top pipe shaft

InactiveCN101638898ASolve the problem of lateral deformationReduce the impactArtificial islandsUnderwater structuresEarthquake resistanceEngineering

The invention discloses a suspension type construction method of a top pipe shaft. The suspension type construction method is characterized by comprising the following construction steps: firstly, measuring and laying at the position of the shaft; secondly, pipe foundation construction: pressing at least four engineering piles into the ground and distributing the engineering piles along the periphery of the shaft; and thirdly, layered construction, namely excavating a foundation pit in a layering manner and casting the shaft wall in a layering manner, wherein the size and the position of the foundation pit are the same as the shaft; and the third step comprises three substeps in sequence: the first substep is the construction of a first layer, namely the uppermost layer, excavating the first layer and carrying out casting to the shaft wall of the uppermost layer; the second substep is the construction of all the layers in the middle, downward continuously excavating in a layer manner and carrying out casting to the shaft wall layer by layer; and the third substep is construction of the bottom layer, excavating the bottommost layer and casting the shaft wall and the shaft bottom ofthe layer. The suspension type construction method creates the construction method of inversely casting the shaft wall from top to bottom, shortens the construction period, does not need to arrange asupporting structure additionally in construction, solves the problem of lateral deformation of the original maintaining wall and improves the earthquake resistance of the shaft.

Owner:ZHENGZHOU MUNICIPAL ENG CORP +1

Sarcandra glabra fiber spunlaced nonwoven mask base cloth and preparing method thereof

The invention relates to anti-microbial and health-care spunlaced cloth, in particular to a preparing method and application of sarcandra glabra fiber spunlaced nonwoven mask base cloth. The sarcandra glabra fiber spunlaced nonwoven mask base cloth is prepared from, by weight, 10-100% of sarcandra glabra fiber, 0-90% of viscose and 0-80% of polyester fiber. The sarcandra glabra fiber spunlaced nonwoven mask base cloth has the advantages of having health care functions of resisting and inhibiting bacteria, cleansing the skin and strengthening the constitution, protecting and nourishing the skin, moisturizing the skin and the like, being skin friendly, high in hygiene, capable of effectively promoting metabolism, preventing skin ageing, and having a great protective effect on the human body; meanwhile, the nonwoven mask base cloth is good in hygroscopicity, wet permeability and breathability, and has the functions of preserving moisture, activating cells, supplying oxygen and the like, and has the effects of conducting nourishing, supplementing and health care on the skin and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Silk-ramie fiber spunlace non-woven facial mask base fabric and preparation method thereof

The invention relates to an antibacterial health care spunlace fabric, in particular to a preparation method and application of a silk-ramie fiber spunlace non-woven facial mask base fabric. The silk-ramie fiber spunlace non-woven facial mask base fabric is prepared from the following raw materials including, by weight, 10-100% of silk-ramie fibers, 0-50% of real silk fibers, 0-50% of natural silk fibers, 0-90% of viscose fibers, and 0-70% of polyester fibers. The advantages of the silk-ramie fiber spunlace non-woven facial mask base fabric are that the silk-ramie fiber spunlace non-woven facial mask base fabric can clean skins, retain moisture, and protect skins, is high in sterilizing rate, is nonirritating, has a moisture preservation, cell activating, and oxygen supplying function, and can nourish and care skins.

Owner:ZHONGYUAN ENGINEERING COLLEGE

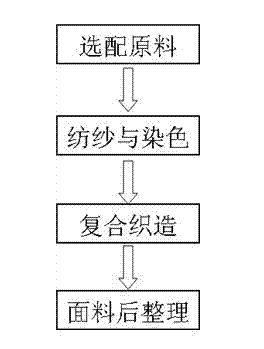

Method for preparing multifunctional fabric

InactiveCN102776683AProcess arrangement is reasonableScience of preparationWeft knittingYarnDyeingMultiple function

The invention provides a method for preparing a multifunctional fabric. The preparation method comprises the following steps: a) selecting and preparing raw materials; b) spinning and dyeing; c) composite weaving; and d) after finishing of the fabric. The invention discloses the method for preparing the multifunctional fabric; the preparation method is rational in procedure arrangement, scientific and effective in preparation links and simple to perform; the prepared fabric not only has the excellent functions of efficient anti-bacterium, heat preservation and health care, but also has the better properties of moisture absorption, no sweat, wear resistance and softness; and therefore, the multifunctional fabric is an ideal fabric of which underclothes and shirts are made.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

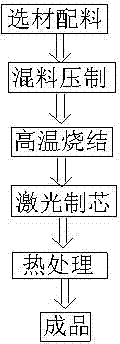

Manufacturing method of high-performance wire-drawing die core

InactiveCN103480848AImprove mechanical propertiesProper selectionDrawing mandrelsCemented carbideMechanical property

The invention discloses a manufacturing method of a high-performance wire-drawing die core. The manufacturing method comprises the following steps that a), material selecting and compounding are conducted; b), material mixing and pressing are conducted; c), high-temperature sintering is conducted; d) laser core manufacturing is conducted; e) heat treatment is conducted. The manufacturing method of the high-performance wire-drawing die core is reasonable in procedure arrangement, easy and convenient to implement, and modest in cost, the material of the die core is selected and compounded reasonably, pressing, sintering, heat treatment and other procedures are arranged orderly and proper to implement, the comprehensive mechanical property of the die core is improved to the maximum degree, and particularly abrasion-resistance performance reaches the property level of cemented carbide.

Owner:SUZHOU YIQUN MOLD

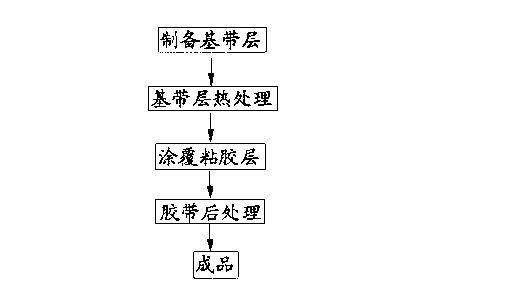

Preparation method of novel insulated rubber tape

InactiveCN103275640AHigh strengthIncrease elasticityFilm/foil adhesivesHeating/cooling textile fabricsFiberElectrical tape

The invention discloses a preparation method of a novel insulated rubber tape. The preparation method comprises the following steps of: a) preparing a base band layer; b) thermally treating the base band layer; c) coating an adhering layer; and d) post-treating the tape. The invention discloses the preparation method of the novel insulated rubber tape. The preparation method is reasonable in step arrangement and simple and convenient in preparation process. The base band layer in the tape has unique fiber constitution and structure, so that the prepared tape has more excellent strength, elasticity and insulating performance. Meanwhile, the tape is moderate in thickness, and the sealing and insulating demands can be satisfied by winding the tape by two layers generally, therefore, the practical value of the tape can be effectively enhanced.

Owner:KUNSHAN HANBAO TAPE TECH

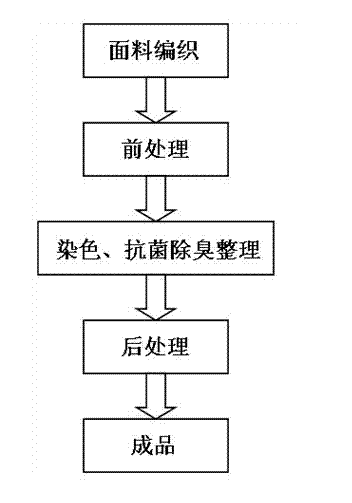

Bacterium-resisting/deodorizing/finishing technology for towel shell fabric

InactiveCN102851898AProcess arrangement is reasonableImplement process scienceFibre typesTwo or more solvent application treatmentEngineeringEnergy source

The invention provides a bacterium-resisting / deodorizing / finishing technology for towel shell fabric, which comprises the following steps: a) knitting shell fabric; b) pre-treating the shell fabric; c) dyeing, bacterium-resisting / deodorizing / finishing the shell fabric; and d) after-treating the shell fabric. A bacterium-resisting / deodorizing / finishing technology for towel shell fabric is disclosed by the invention and is characterized by reasonable work procedure arrangement, scientific, simple and convenient implementation; a bath-drying / bacterium-resisting / deodorizing / finishing technology is used, thus, the inhibition efficiency of the towel shell fabric reaches to more than 99.9%; in addition, a technology process is shortened, energy source is saved, and cost is reduced.

Owner:KUSN CHENGYU ELECTROMECHANICAL TECH

Comfortable skin-protection health-care parallel spinning wrap soft yarn and preparing method thereof

The invention relates to health-care yarn, in particular to comfortable skin-protection health-care parallel spinning wrap soft yarn and a preparing method and application thereof. The comfortable skin-protection health-care parallel spinning wrap soft yarn is novel composite yarn and is mainly provided with unidirectional wrap composite soft yarn and bidirectional cross wrap composite soft yarn and comprises core yarn, outer wrap yarn and rough yarn, wherein water-soluble polyvinyl alcohol staple fiber filament is adopted by the outer wrap yarn; polymer filament is adopted by the core yarn; the rough yarn is one or more of fine staple cotton fiber and original-color or color pearl fiber. The health-care parallel spinning wrap soft yarn is novel composite yarn and has the advantages of being bright in dyed color, rich in color, high in color fastness, tender in luster, good in moisture absorption and the like, fabric processed through the health-care parallel spinning wrap soft yarn has the performance of being soft in texture, excellent in elasticity, high in water absorption, large in water storage capability, good in moisture absorption and rapid moisture-permeability, good in breathability, good in moisture permeability, good in comfort, good in heat retention and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Multifunctional health-care porous elastic big-belly yarn and preparation method thereof

The invention relates to a preparation method and application of a multifunctional health-care porous elastic big-belly yarn. The multifunctional health-care porous elastic big-belly yarn is prepared from two core yarns, two fixed yarns and a decorative yarn, wherein the fixed yarns are core-spun yarns obtained by carrying out blended processing on silver fibers, copper fibers, soft silk fibers and DOW-XLA elastic fibers; the core yarns are blended hollow yarns obtained by carrying out blended processing on Porel fibers, hollow polyester fibers and provilion; the decorative yarn is a blended rough yarn obtained by carrying out blended processing on nettle fibers, apocynum fibers and alpaca wool fibers. The multifunctional health-care porous elastic big-belly yarn not only has a special form, but also is rich in yarn colors, multiple in shapes and ever-changing; products developed by using the multifunctional health-care porous elastic big-belly yarns are natural and environment-friendly, have the health care functions of resisting bacteria and eliminating inflammation, protecting skin and keeping fitness, absorbing moisture and releasing sweat, deodorizing and resisting aging, and the like, are good in comfortableness, and do not cause adverse effects when being contacted with a human body; the multifunctional health-care porous elastic big-belly yarn is mainly used for various textiles such as yarn-dyed female lines, knitted fabrics, tweed, coarse worsted fabrics, decorative articles, hand knitted fabrics and shawls.

Owner:ZHONGYUAN ENGINEERING COLLEGE

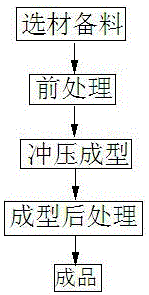

Manufacturing method for high-wear-resisting wave spring

InactiveCN106077258AImprove mechanical propertiesImprove wear resistanceLow internal friction springsManufacturing technologyEngineering

The invention discloses a manufacturing method for a high-wear-resisting wave spring. The manufacturing method includes the following steps that firstly, materials are prepared; secondly, pretreatment is conducted; thirdly, stamping forming is conducted; and fourthly, forming aftertreatment is conducted. The manufacturing method for the high-wear-resisting wave spring is disclosed and is reasonable in process arrangement, the manufacturing technology is easy and convenient to implement, cost is moderate, the manufactured wave spring has good comprehensive mechanical performance, the wear-resisting performance is particularly outstanding, the abrasion loss of the spring in the compressed process can be effectively reduced, and the good use performance and the long service life of the spring are ensured.

Owner:SUZHOU CITY HUQIU DISTRICT HUSHUGUAN SPRING FACTORY

Method for preparing cool blended and knitted fabric

InactiveCN104382268AThin structureComfortable to wearHeating/cooling textile fabricsWoven fabricsYarnEngineering

The invention discloses a method for preparing a cool blended and knitted fabric. The method comprises the following steps: (a) raw material selection; (b) yarn spinning; (c) weaving; (d) dying; (e) after-finishing. The method has the advantages of being reasonable in arrangement of work procedures, simple and convenient in preparation process and easy to realize. The prepared fabric is thin in structure and comfortable in wearing, has good effects of heat conduction, heat dissipation and cooling, and is an ideal fabric for making summer clothes.

Owner:CHANGSHU JINYU FIBER PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com