Preparation method of novel insulated rubber tape

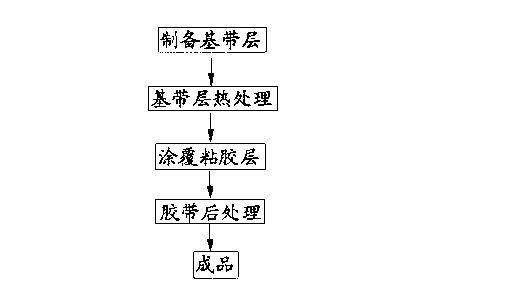

An insulating tape, a new type of technology, applied in the directions of adhesives, film/sheet adhesives, textiles, etc., can solve the problems of reducing the performance of insulating tapes, reducing the bonding strength between layers, easy to break, etc., to improve the practical value. , The preparation process is simple and the process arrangement is reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Concrete preparation process is as follows:

[0018] a) Prepare the base belt layer, the percentage ratio of each component in the base belt layer is: 25% glass fiber, 55% polyester fiber, 15% viscose fiber, 5% spandex; wherein, the glass fiber is made of glass fiber monofilament The diameter of the glass fiber monofilament is about 14um, and the diameter of each glass fiber is about 0.16mm; the polyester fiber is made of polyester filament FDY, the specification is 180D, and the diameter is about 0.06mm; the viscose fiber is made of viscose strong Filament, the specification is 300D, the diameter is about 0.1mm;

[0019] The base belt layer is a blended woven fabric, and its preparation process mainly includes: yarn blending, spinning, bobbin, twisting, weaving, singeing, shaping, etc.; the warp yarn in the woven fabric is a blended yarn line of polyester and spandex, The diameter of a single strand is about 0.1mm; the weft yarn is a blended yarn of glass fiber and vi...

Embodiment 2

[0024] Concrete preparation process is as follows:

[0025] a) Prepare the base belt layer, the percentage ratio of each component in the base belt layer is: 30% glass fiber, 55% polyester fiber, 10% viscose fiber, 5% spandex; among them, the glass fiber is made of glass fiber monofilament The diameter of glass fiber monofilament is about 12um, and the diameter of each glass fiber is about 0.14mm; the polyester fiber is made of polyester filament FDY, the specification is 200D, and the diameter is about 0.08mm; the viscose fiber is made of viscose strong Filament, the specification is 300D, the diameter is about 0.12mm;

[0026] The base belt layer is a blended woven fabric, and its preparation process mainly includes: yarn blending, spinning, bobbin, twisting, weaving, singeing, shaping, etc.; the warp yarn in the woven fabric is a blended yarn line of polyester and spandex, The diameter of a single strand is about 0.12mm; the weft yarn is a blended yarn line of glass fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com