Manufacturing method for high-wear-resisting wave spring

A wave spring, high wear resistance technology, applied in the field of bearing springs, can solve the problems of unsatisfactory service performance and life, easy to generate noise, low wear resistance, etc., achieve good comprehensive mechanical properties, reduce wear, wear resistance, etc. Outstanding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

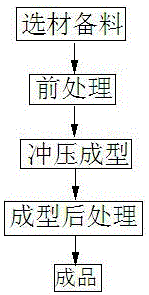

Image

Examples

Embodiment 1

[0016] The specific preparation steps of the high wear-resistant wave spring mentioned in the present invention are as follows:

[0017] a) Material selection and preparation. The raw material of the wave spring is an alloy spring steel plate with a thickness of 0.3-0.35mm. The main components and percentage ratios of the alloy spring steel plate are: C 0.55%, Mn 9%, Cr 4.5 %, Ni 0.7%, Si 0.5%, Cu 0.35%, Al 0.12%, Mo 0.22%, Ti 0.025%, Pd 0.11%, Ce 0.01%, and the rest is Fe; the impurity P content is controlled below 0.03%, and the impurity The content of S is controlled below 0.03%;

[0018] b) Pretreatment, the pretreatment process is spheroidizing annealing treatment, the treatment process is as follows: first, the steel plate is slowly heated to 750°C-760°C in the furnace; then, it is kept at this temperature for 4.5 hours; then, the steel plate is Cool to about 550°C; finally, take out the steel plate and air cool to room temperature;

[0019] c) Stamping processing, usi...

Embodiment 2

[0022] The specific preparation steps of the high wear-resistant wave spring mentioned in the present invention are as follows:

[0023] a) Material selection and preparation. The raw material of the wave spring is an alloy spring steel plate with a thickness of 0.3-0.35mm. The main components and percentage ratios of the alloy spring steel plate are: C 0.6%, Mn 10%, Cr 5 %, Ni 0.6%, Si 0.4%, Cu0.3%, Al 0.13%, Mo 0.2%, Ti 0.025%, Pd 0.01%, Ce 0.01%%, the rest is Fe; the content of impurity P is controlled below 0.03% , the content of impurity S is controlled below 0.03%;

[0024] b) Pretreatment, the pretreatment process is spheroidizing annealing treatment, the treatment process is as follows: first, the steel plate is slowly heated to 760°C-770°C in the furnace; then, it is kept at this temperature for 4 hours; then, the steel plate is Cool to about 550°C; finally, take out the steel plate and air cool to room temperature;

[0025] c) Stamping processing, using automatic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com