Preparation method of multi-functional fabric

A multi-function, fabric technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of complex fabric structure design, unstable fabric functionality, unreasonable raw material preparation, etc., to achieve excellent antibacterial, mildew, and good perspiration Hygroscopicity, implement scientific and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

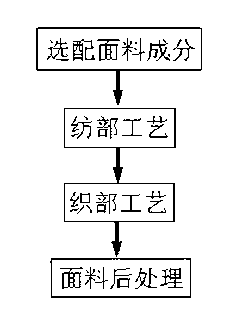

[0020] The specific preparation process of the fabric is as follows:

[0021] a) Optional fabric composition, the main components of the fabric are bamboo fiber, holy hemp fiber and tencel, the blending ratio of the fabric composition is: bamboo fiber 60%, holy hemp fiber 20%, tencel 20%; the fabric composition The fineness is: bamboo fiber 1.67dtex, holy hemp fiber 1.67dtex, tencel 1.38dtex.

[0022] b) Spinning process, which mainly includes the following steps: 1) Tencel and Shengma fiber are blended into silk through the cleaning and carding process; 2) Bamboo fiber is spun into silk through the cleaning and carding process; 3 ) Tencel, Shengma blended silk and bamboo fiber silk are made into blended yarn through three processes of drawing, coarse sand and spun yarn. Among them, the cleaning process adopts a short process, appropriately reduces the speed of each beater, and uses carding instead of beating to reduce fiber damage and neps; the carding process reasonably sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com