Patents

Literature

423results about How to "Unique style" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

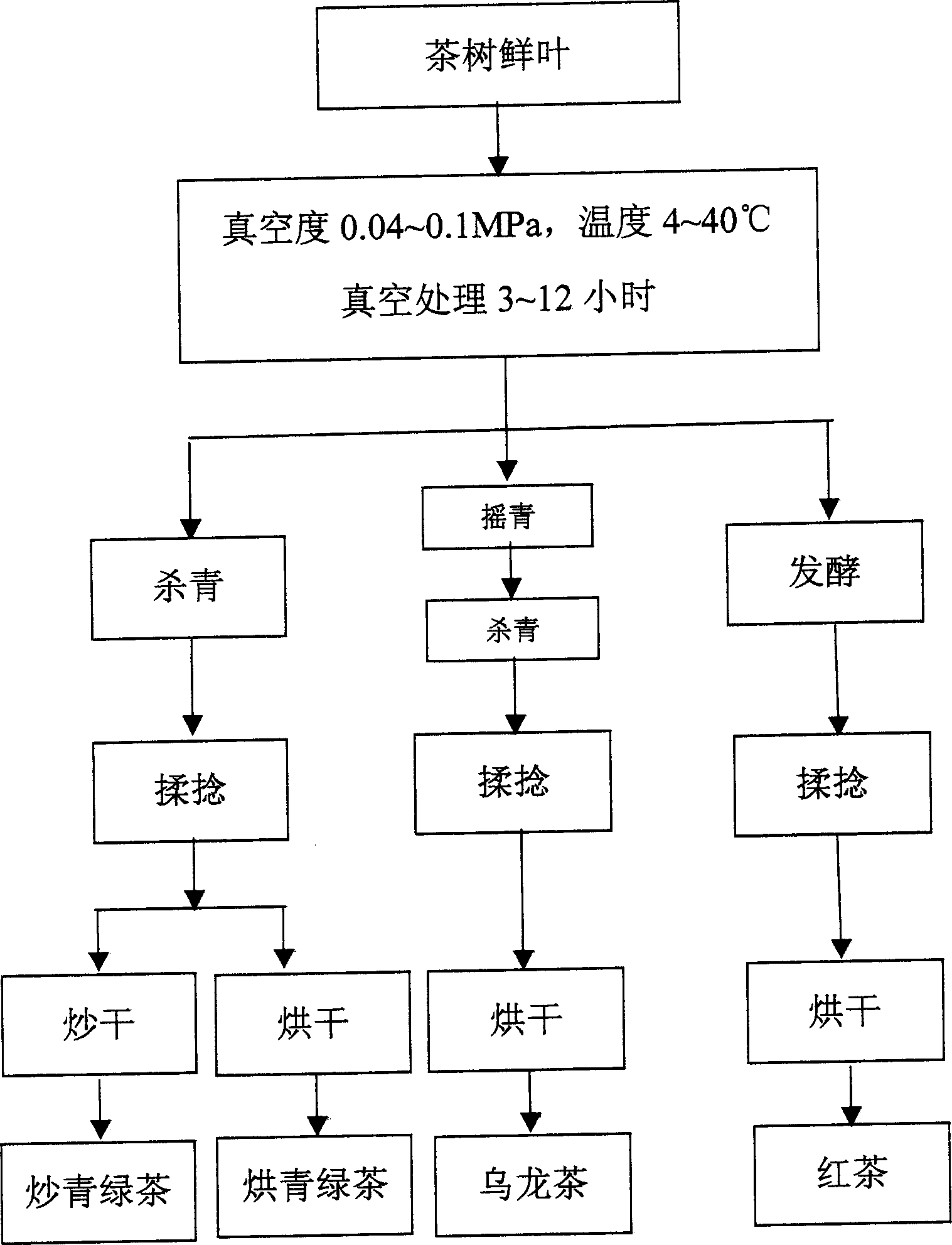

Tea processing method capable of increasing content of ª†-reanal

ActiveCN1545894AUnique styleIncreased gamma-aminobutyric acid contentPre-extraction tea treatmentConventional techniqueChemistry

The invention discloses a method for increasing gamma- reanal content in tea production, which comprises, vacuum treating the fresh tea leaves under the condition of, vacuum degree 0.04-0.1Mpa, temperature 4-40 deg. C, processing through the conventional techniques, the obtained gamma-reanal can reach 1.5-3.5mg / g.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

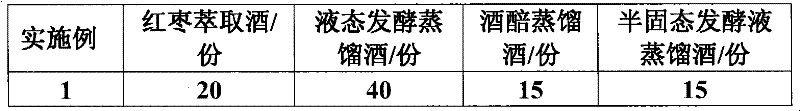

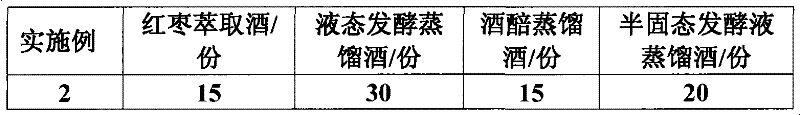

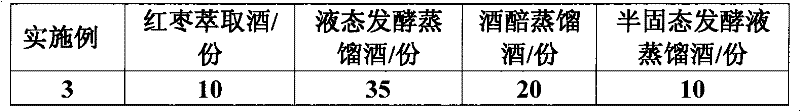

Red jujube health-care liquor and production process thereof

InactiveCN102051321AUnique flavorPromote circulationAnthropod material medical ingredientsAlcoholic beverage preparationAdditive ingredientChinese Jujube

The invention discloses red jujube health-care liquor and a production process thereof. Liquor, red jujubes, grape pips, roses and the like are selected as raw materials, and the red jujube health-care liquor is obtained by heat soaking, low-temperature soaking and repeated treatment of the raw materials. The red jujube health-care liquor is integrated with a plurality of functional raw materials, contains a plurality of effective ingredients such as general flavone, rhodioloside, crude polysaccharides and total saponins, and has multiple health-care efficacies of alleviating fatigue, enhancing immunity, promoting metabolism, promoting blood circulation, removing blood stasis, helping people maintain beauty and keep young, and removing chloasma. The red jujube health-care liquor is crystal and transparent, has unique flavor and health-care efficacy, and is suitable for long-term drinking. The product is clear, glossy, fragrant and pure and mild in taste, sweet and chill, refreshing and soft, and representative, and has a balanced body, long-lasting flavor and unique style. The production method is simple, raw materials used in preparing the red jujube health-care liquor are easy to obtain, and the red jujube health-care liquor is easy for popularization.

Owner:山西悦卜林创业投资有限公司

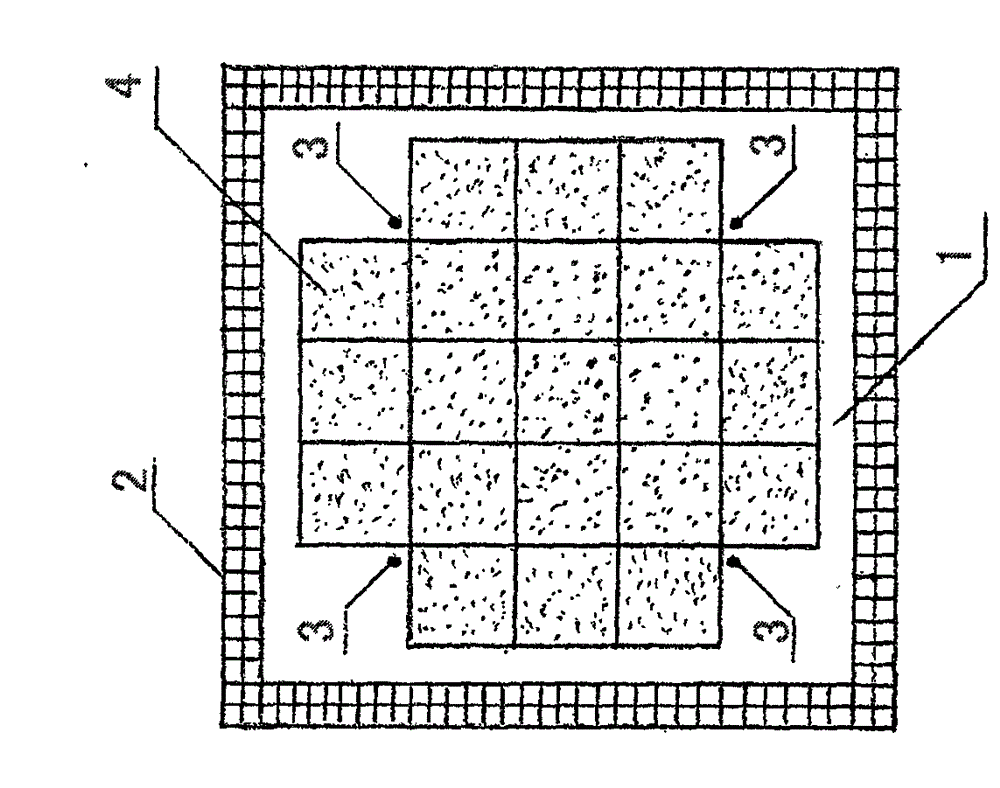

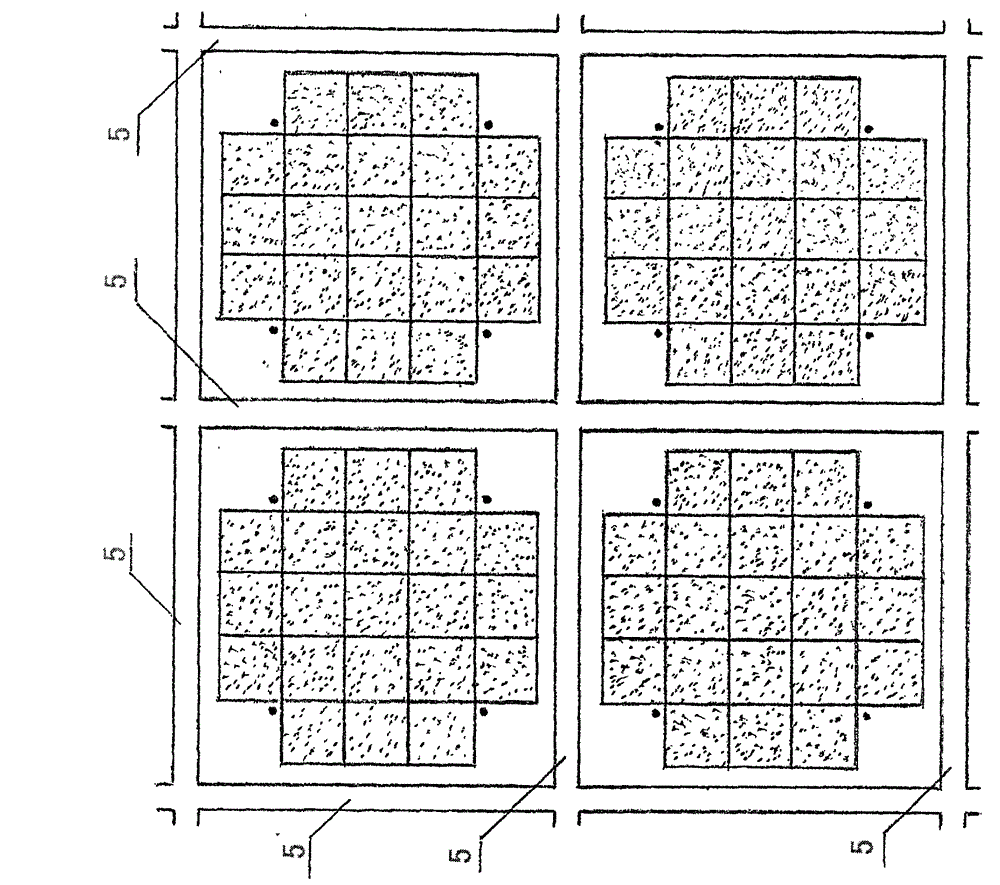

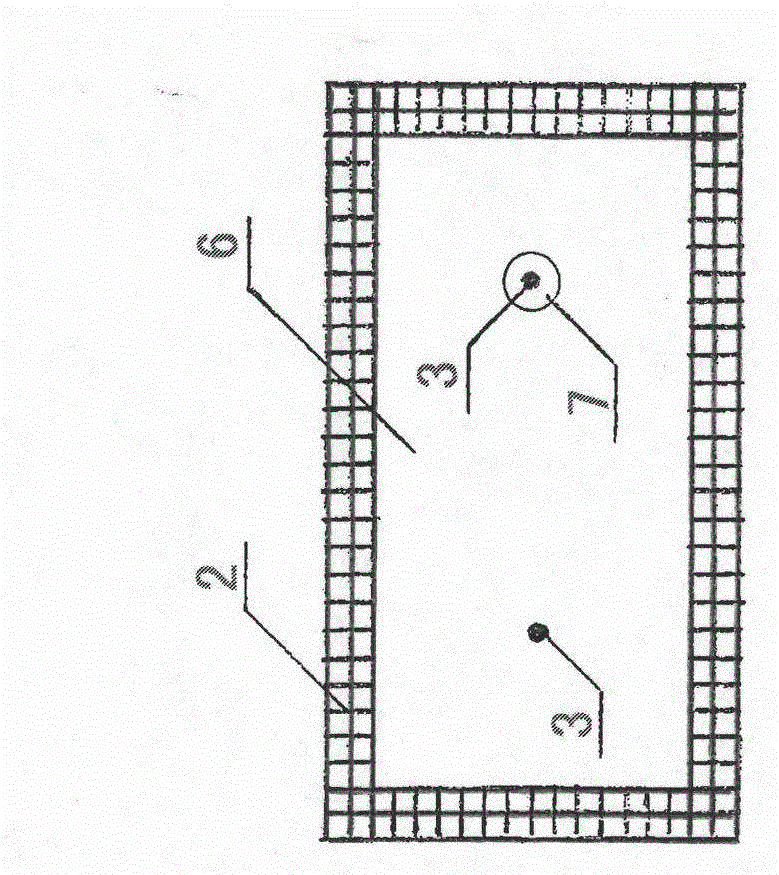

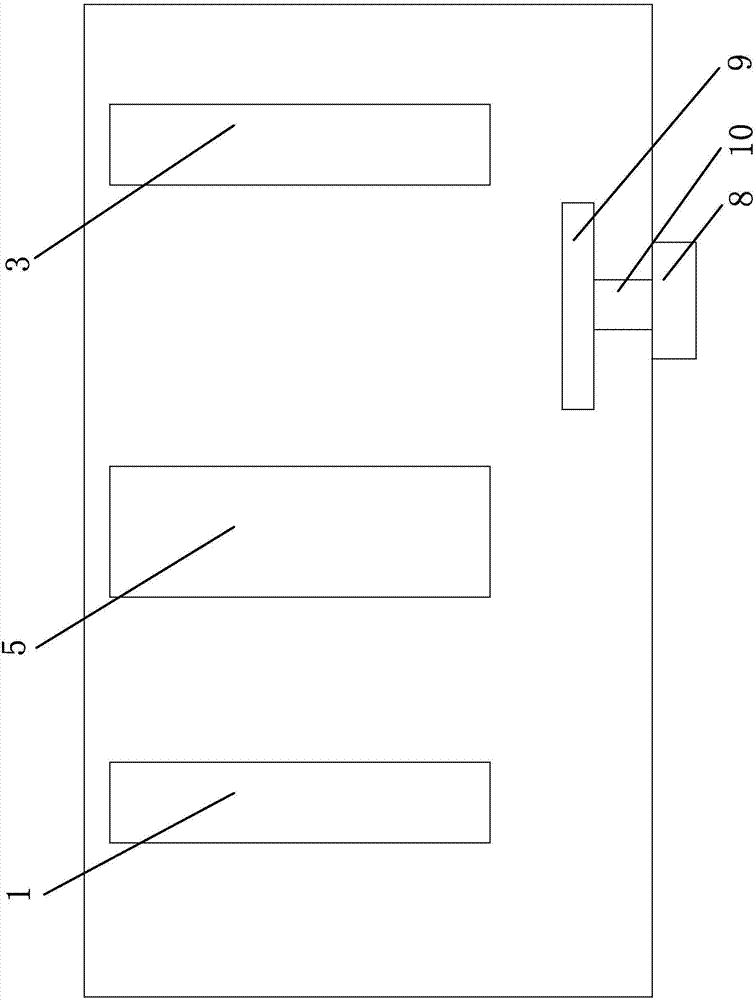

Method for integrating thermal insulation and decoration for small-sized assembled thermal insulation precast slab exterior insulation system

ActiveCN102912954ARich decoration types and color varietiesImprove the quality of decorationCovering/liningsLayered productsThermal insulationSurface plate

The invention belongs to a method for integrating thermal insulation and decoration for a small-sized assembled thermal insulation precast slab exterior insulation system. The method includes the following steps: firstly, pre-sticking exterior wall facing bricks on an outer side surface of a fine concrete panel in a plant; secondly, in the plant, forming the outer side surface of the fine concrete to be smooth in surface or forming concave-convex patterns with attractive appearances, then spraying coating on the outer side surface to form a coating decorative surface; thirdly, in a plant, producing a fine concrete panel through architectural concrete, then forming the outer side surface of the fine concrete panel to be smooth in surface or forming concave-convex patterns with attractive appearances, so as to form a architectural concrete decorative surface; and fourthly, forming beautiful decorative patterns of the vertical plane of an outer wall with small ornaments. Through the adoption of the method, the high-level precasting of the small-sized assembled thermal insulation precast slab can be realized, the decoration types, colors and patterns on the vertical plane of the outer wall can be greatly enriched, the decoration quality of the outer wall can be improved, and the decoration cost of the outer wall can be reduced.

Owner:马金颖

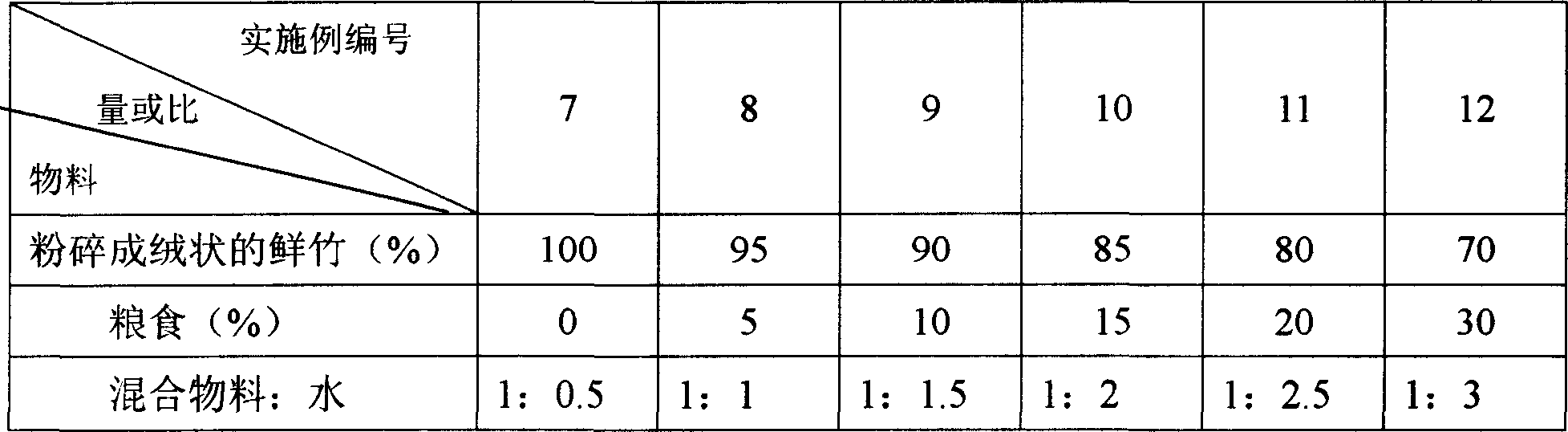

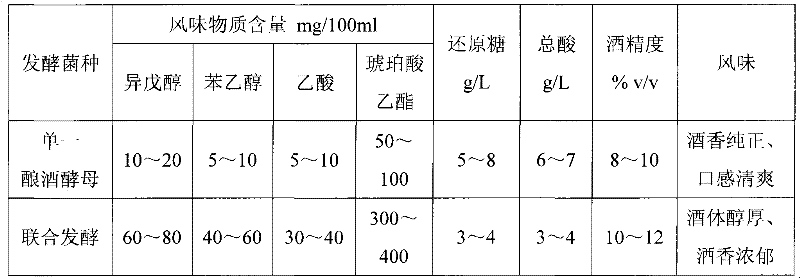

Method for making fresh-bamboo wine by fresh bamboo

This invention relates to a method for brewing fresh bamboo wine characterizing in including the following steps: cleaning and crushing fresh bamboo to villiform, taking the raw material in the proportion: fresh bamboo: 70-100%, food supplies: 0-30% then adding water in the weight proportion to material:1:0.5-3, adding bacilli amylase to braize and steam, adding sacchariferous agent to be sacchariferized for 20-30minutes under 58-62deg.C then adding seeding yeast to be fermented to prepare a health-care fresh bamboo wine.

Owner:罗福国

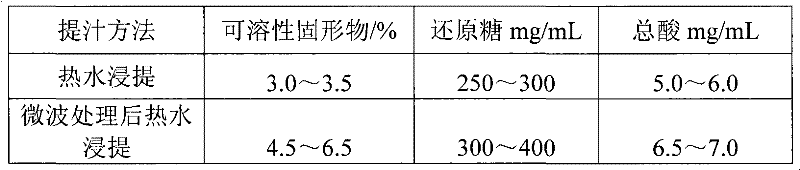

Brewing method of red date wine through multi-strain combined fermentation

InactiveCN102051310AImprove qualityGreat tasteAlcoholic beverage preparationMicroorganism based processesPichia pastorisFruit wine

The invention discloses multi-strain combined fermentation red date wine and a brewing method thereof, which belongs to the technical field of brewing. The red date wine is produced by taking red date as raw materials through such processes as pretreatment, digestion, enzymolysis, sterilization, fermentation, aging and clarification. The adopted Candida, Kloeckera, Hanseniaspora and Pichia pastoris move at the early stage of fruit wine fermentation generally, so that a great deal of aromatic substances and special flavor components can be generated, the quality of fruit wine is improved, and positive impact is generated on the total flavour of the red date wine. Non-brewing yeast and brewing yeast are accessed at different fermentation stages, the species and content of the flavor substances in the date wine can be increased through the combined fermentation of multiple strains, thereby improving the mouthfeel of the date wine and the quality of the date wine; the date wine has unique style, rich wine body, sweet and pure bouquet, fresh mouthfeel and typicality.

Owner:太原市汉波食品工业有限公司

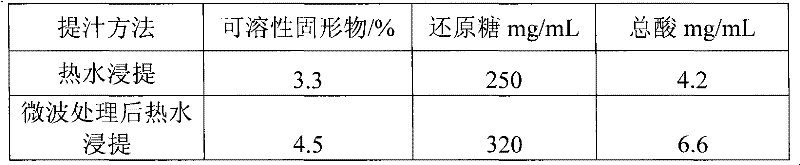

Discolouring fibers, discolouring coloured spun yarns and fabric, and processing method of fabric

InactiveCN103556492AImprove ionic bondingImprove dye uptakeWeft knittingBiochemical fibre treatmentYarnPolymer science

Owner:WUXI NATURAL GREEN FIBER TECH

Terylene ultra-flexible ike blanket and producing method thereof

InactiveCN101381926AUnique styleThe production method is scientific and reasonableWarp knittingDry-cleaning apparatus for textilesPolyesterWool

The invention discloses a polyester super-soft Aike flannelette blanket and a production method thereof. The blanket is made by using polyester yarn or polyester-cotton composite yarn in the specification that DTY single-fiber fineness is between 0.59 and 0.77 dtex as velvet yarn raw material and using FDY83-111dtex as base yarn, wherein according to the weight percentage, the polyester yarn or polyester-cotton composite yarn accounts for 80 to 85 percent, and the FDY100D / 48F accounts for 15 to 20 percent. The blanket has the advantages of unique plush style, environmental protection, moth repellency, mold prevention, granular feeling, artificial wool effect, warmth retention, light weight, fluffiness and comfortable feeling, and can fully meet the demands of markets and consumers. The production method is scientific, reasonable and suitable to be popularized and applied in the manufacture of broad-width blankets.

Owner:NANTONG DONGSHENG AIKE HOME TEXTILE

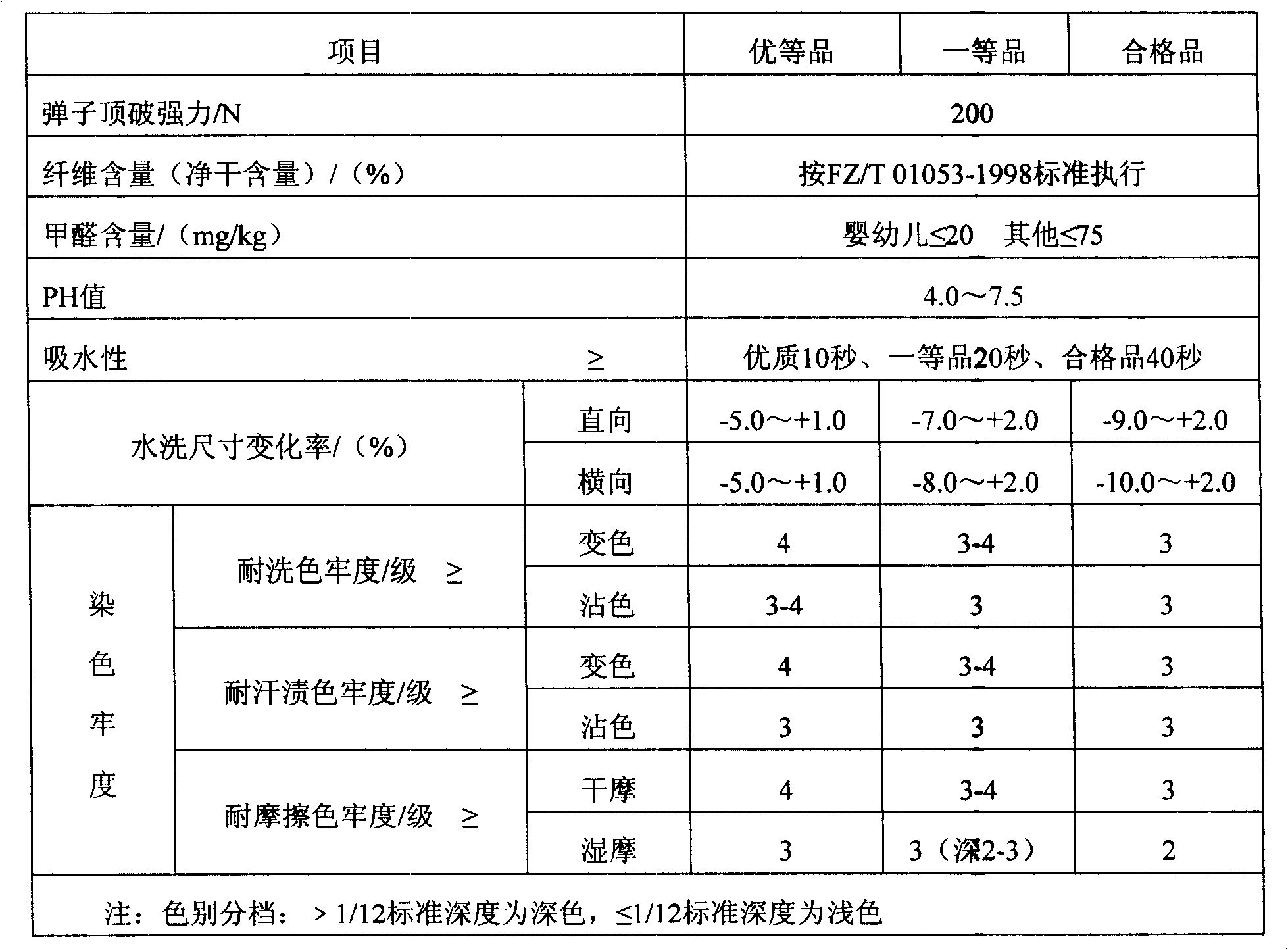

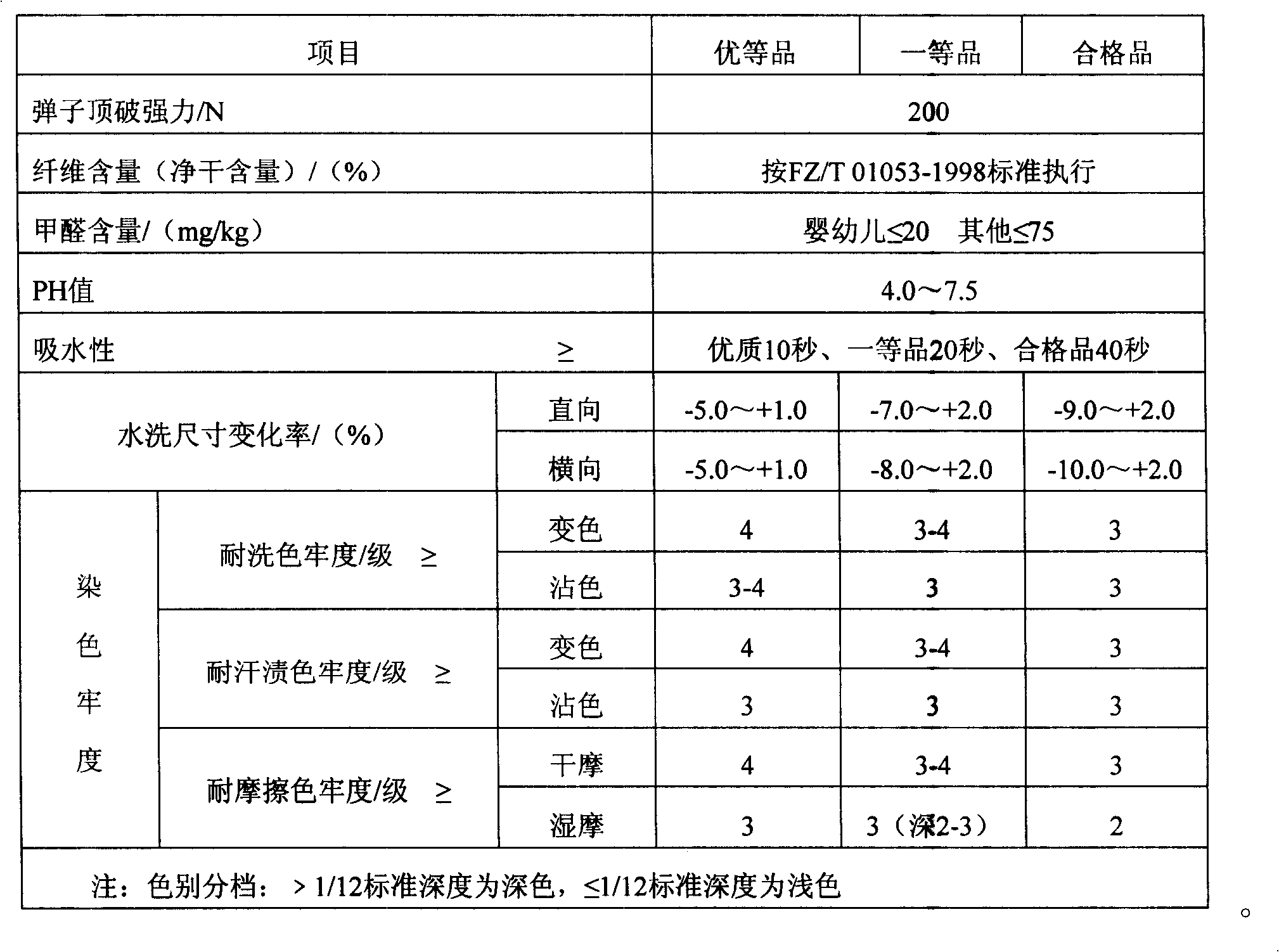

Terylene superfine warp-knitting soft and cleaning silk face fabric and production method thereof

InactiveCN101289779AUnique styleSoft touchWarp knittingHeating/cooling textile fabricsPolyesterHigh density

The invention discloses polyester ultrafine tricot soft silk fabrics and a method for producing the same. The invention is characterized in that: the polyester ultrafine tricot soft silk fabrics are prepared by adoption of 0.5 to 0.56 dtex of polyester silk or polyester-nylon composite silk as raw materials of chenille yarns and adoption of 75 to 150 D of polyester as bottom silk, wherein, the weight percent of the polyester silk or the polyester-nylon composite silk is between 55 and 75 percent and the weight percent of 75 to 150 D of the polyester is between 25 and 45 percent. The fabrics are unique in style and reach the appearance style of soft silk; the products have soft feel, high flexibility, high water absorptivity and oil absorption ability, high density and high specific surface area, can meet the demand of cleaning high-grade products, are green and environment-friendly and do not contain substances which are harmful to the human body. Simultaneously, the products have few production procedures, short period, high efficiency and high qualification rate.

Owner:SHANGHAI JINLE TEXTILE DECORATIONS

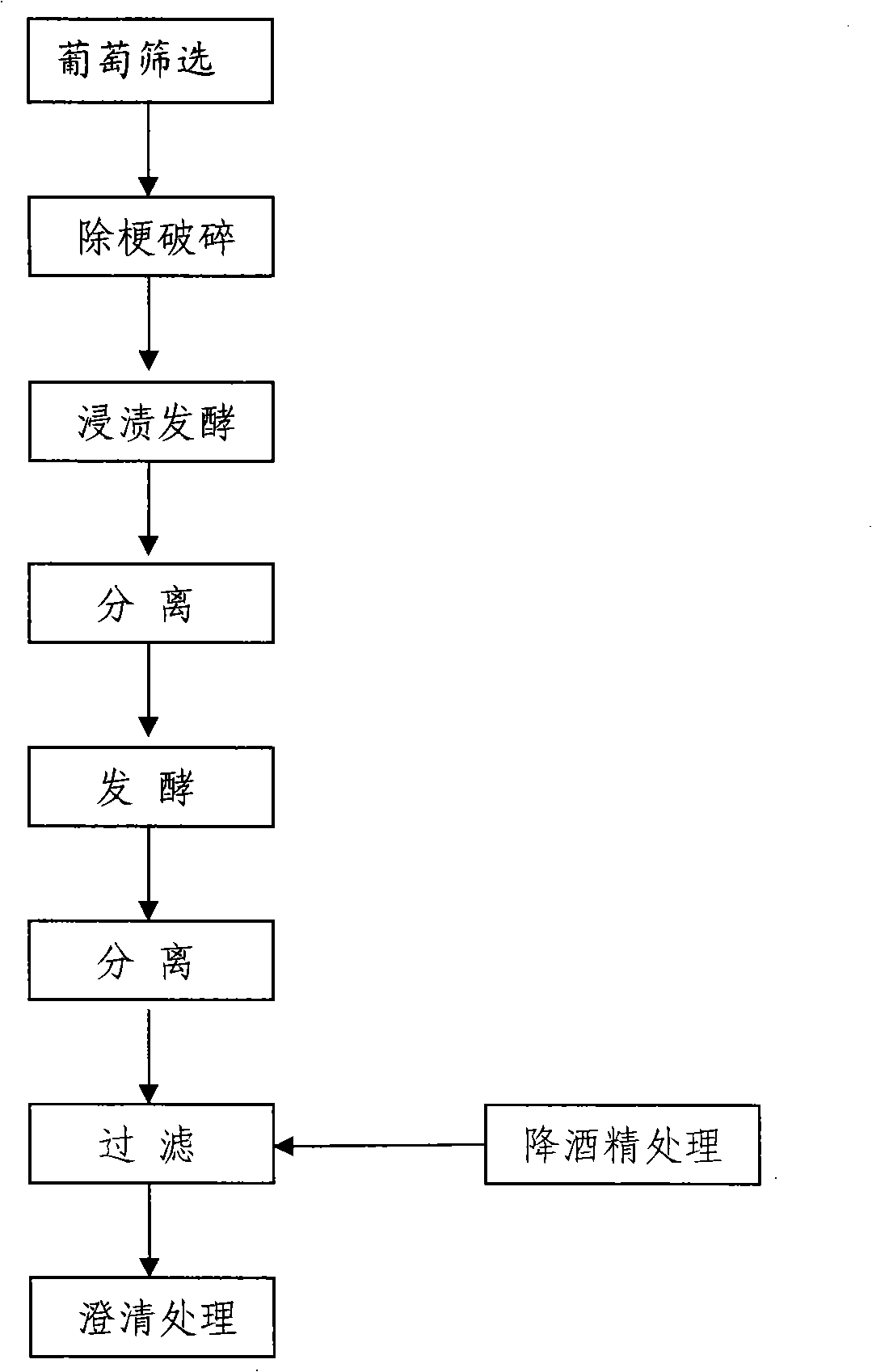

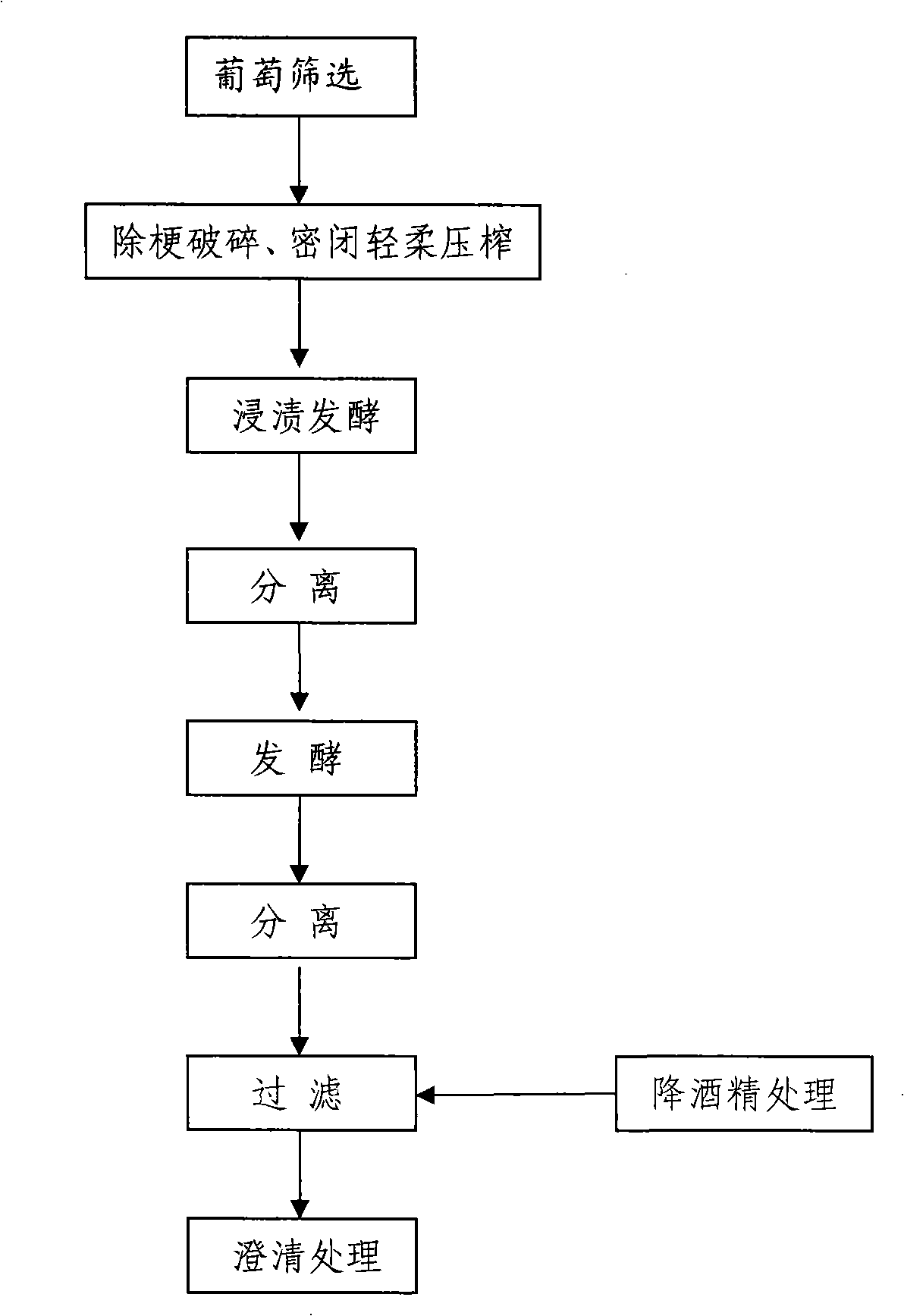

Light wine and brewing process thereof

The invention provides a low alcohol grape wine and the brewing technology thereof, belonging to the technical field of grape wine preparation. The aim of the invention is to provide a brewing technology of high concentration low alcohol (8-10 percent of alcohol degree) grape wine. Under the premise that the grape wine made by the brewing technology meets the technical indicators of high concentration and low alcohol, the brewing technology does not influence the flavor and the characteristics of the grape wine.

Owner:青岛华东葡萄酿酒有限公司

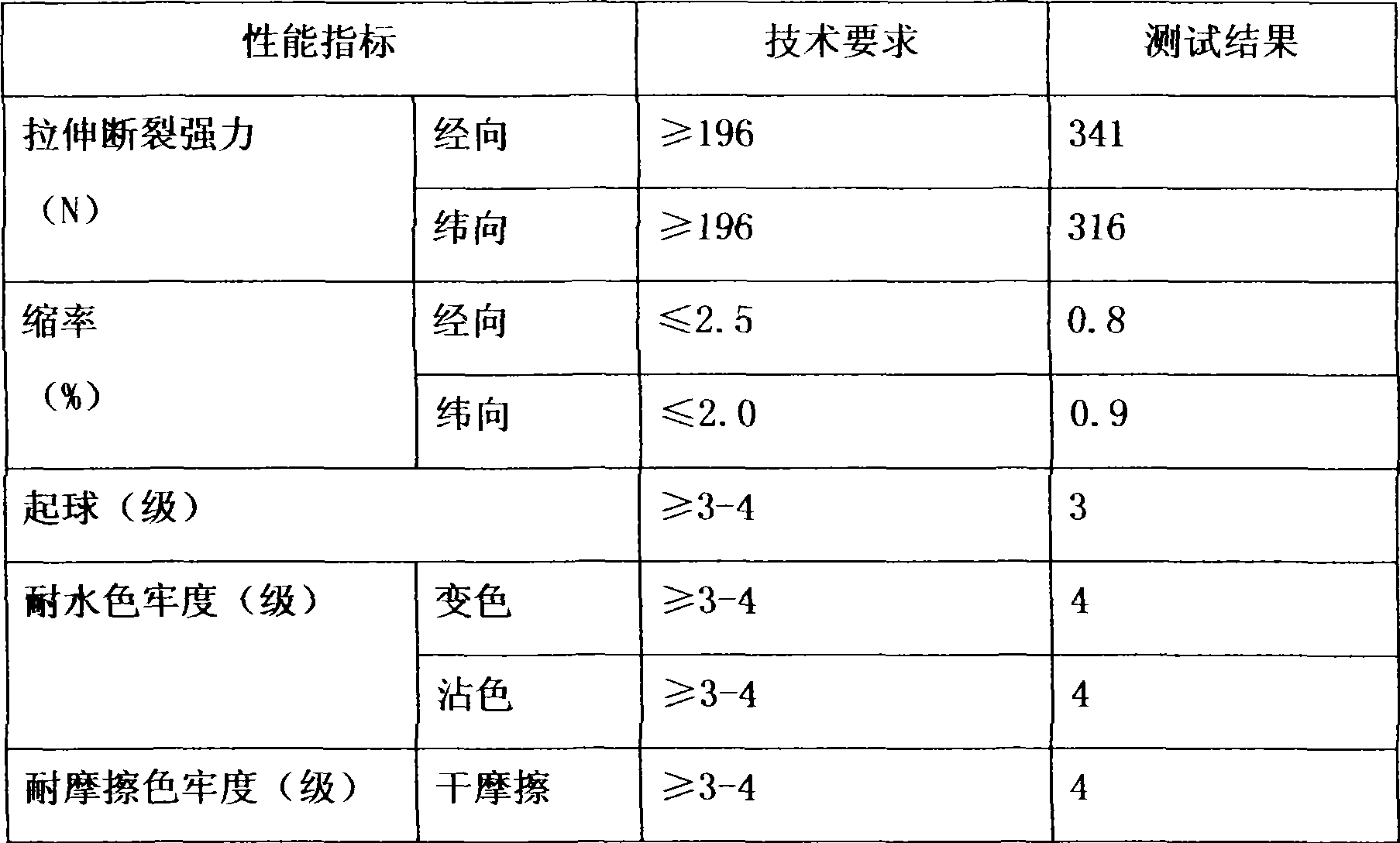

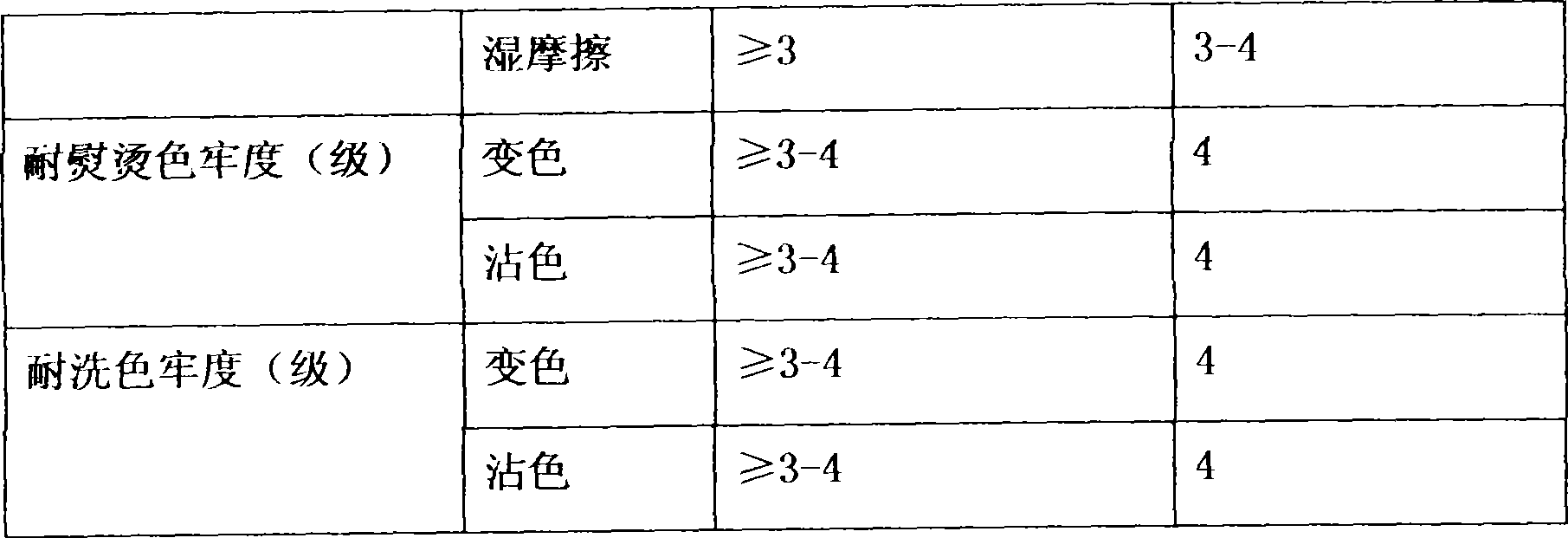

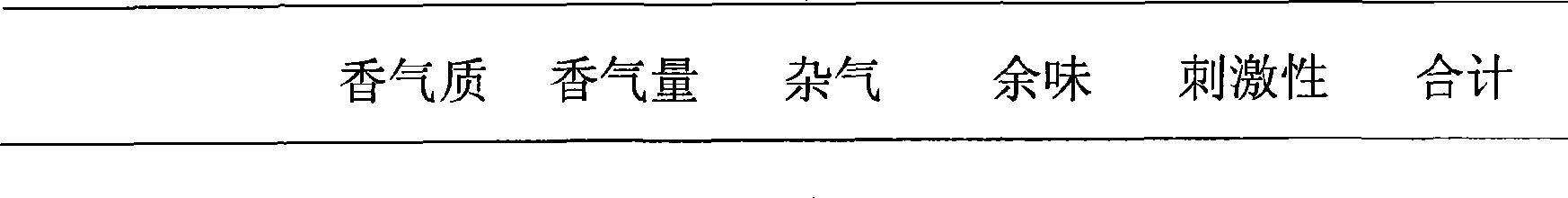

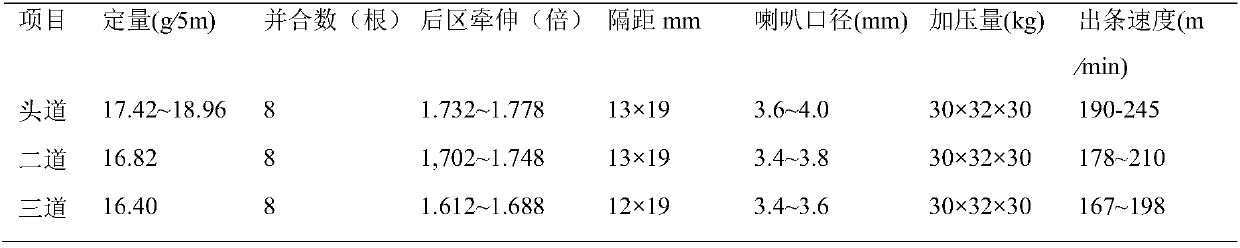

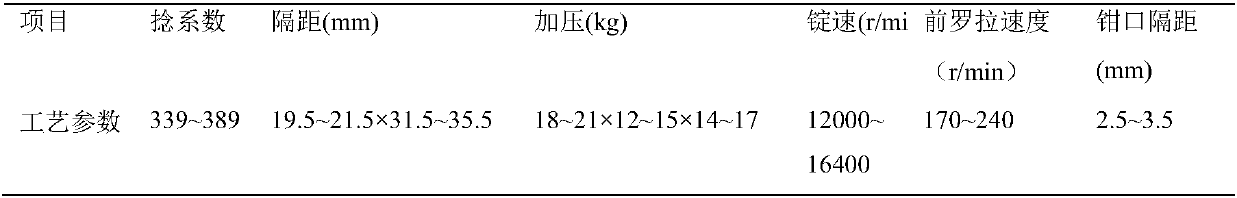

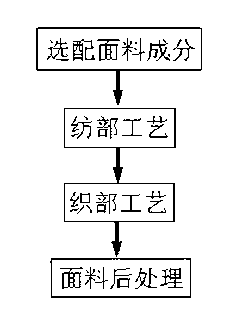

Method for producing sheep and rabbit hair combing elastic fabric

InactiveCN101418519AImprove spinnabilityIncreased scale angleBiochemical fibre treatmentWoven fabricsTextile technologyFiber

The invention discloses a method for producing a wool and rabbit hair combing elastic fabric and belongs to the field of textile technology. The method comprises raw material selection, a spinning process, a weaving process and fabric afterfinishing. The method is characterized in that before the spinning process, rabbit hair fiber is subjected to enzyme treatment, water washing and drying for spinning preparation; and the wool and the rabbit hair fibers are spun into wool and rabbit hair combed yarn through adopting the combination of combing spinning and semi-combing spinning; and the wool and rabbit hair combed yarn is interwoven to form the wool and rabbit hair combing elastic fabric. The method aims at the disadvantages that the rabbit hair fiber has poor spinnability and is easy to moult, creatively adopts oxidase to carry out pretreatment on the rabbit hair fiber in order to increase the angle of squama of the rabbit hair fiber, increase the friction coefficient of the surface of the rabbit hair fiber, have good spinnability and effectively improve the phenomena that a rabbit hair textile moults. The quality and added value of the product are greatly improved, and the product has good utility value and potential economic and social benefits.

Owner:SHAOXING UNIVERSITY

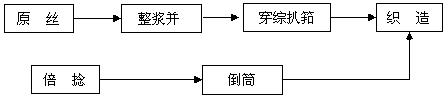

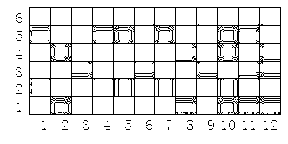

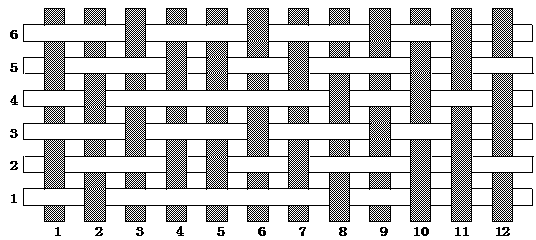

Rayon three-dimensional lattice shell fabric and production process thereof

The invention discloses a rayon three-dimensional lattice shell fabric and a production process thereof. The shell fabric comprises organzine and tram. The organzine is dacron black silk. The tram comprises first tram and second tram. The first tram is superfine denier fiber and the second tram is lustrous dacron filament. The rayon three-dimensional lattice shell fabric production process comprises organzine processing, tram processing and weaving, wherein organzine process steps comprises beam warping, starching, warp rebeaming and drafting scrabbling reed; and tram process steps comprises spooling, two-for-one twisting and rewinding. The process combines a specific fabric style and a novel type fiber advantage, product property is optimized, and stability of the product quality is improved. Products which are produced by the process are smooth, light in weight, exquisite in handle, good in air permeability, good in drapability and capable of being used as high-grade garment materials.

Owner:JIANGSU DESHUN TEXTILES

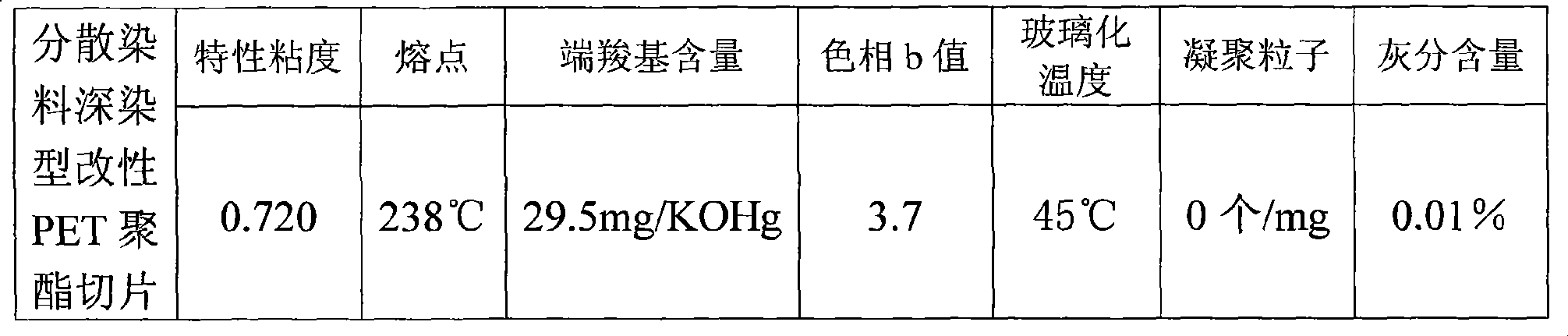

Novel dual-color side-by-side composite polyester fiber

InactiveCN101440538AHigh color fastnessConducive to weavingFilament/thread formingConjugated synthetic polymer artificial filamentsDisperse dyeYarn

The invention relates to a novel two-color parallel type composite polyester fiber, which is a novel two-color parallel type composite fiber of common semi-dull PBT and modified PET polyester, and is characterized in that on a composite spinning device, a parallel type composite fiber spun by double screws has a peanut type fiber cross section, and the ratio of the PBT polyester to the modified PET polyester is 50:50. The specifications of the spun fibers are 100D / 36f and DTY of 150D / 72f, and the modified PET polyester used in spinning is disperse dye normal pressure deep-dyeing type polyester; the spun fiber after treatment has the same elasticity with polyurethane core spun yarn performances. With the disperse dye normal pressure deep-dyeing type polyester, the composite polyester fiber has excellent dyeing property and can effectively generate two-color effect. Besides, because two grooves are formed on the surface of the fiber, the fiber has the functions of moisture absorption and perspiration to certain extent.

Owner:邹祖林

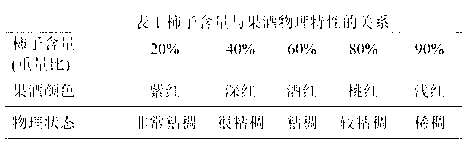

Red composite persimmon fruit wine and preparation method thereof

ActiveCN103232924AUnique styleTo make up for the shortcomings of light yellow tasteAlcoholic beverage preparationMicroorganism based processesFruit wineVitis vinifera

The invention discloses a red composite persimmon fruit wine and a preparation method thereof. According to the invention, persimmon and at least one selected from the group consisting of grape, Hylocereus polyrhizus, mulberry and myrtle are subjected to pulping and fermentation so as to prepare an old wine composite persimmon fruit wine or a blended composite persimmon fruit wine; the other fruits endow the persimmon fruit wine with new colors and flavors and compensate for the disadvantages of thin taste and a yellow color of a single persimmon fruit wine. The composite persimmon fruit wine is bright red or claret, has a unique style, is greatly popular among consumers and has wide market prospects and a great commercial value.

Owner:李阳 +1

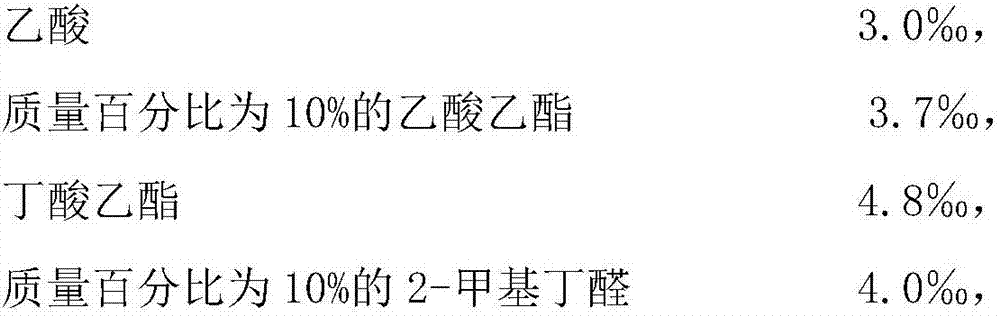

Production process of novel yellow Maojian tea

ActiveCN104186725AIncrease fermented aromaGreat tastePre-extraction tea treatmentTea flavoringFermentationChemistry

The invention relates to a production process of novel yellow Maojian tea. The production process comprises the procedures of material sorting, withering, rolling, primary heap-yellowing, primary drying (namely fixation by hot wind), secondary heap-yellowing, secondary rolling, secondary roasting, and drying. The production process of the novel yellow Maojian tea has the beneficial effects of unique style and simple process, and is easy to handle and beneficial to popularization and application; the procedure of moist heat heap-yellowing after the fixation during the preparation of traditional yellow tea is changed into a procedure of enzymatic yellowing before the fixation in the process disclosed by the invention, and the withering procedure is added; fermentation-type fragrance, fresh taste and sweet aftertaste of the traditional yellow tea are preserved, the fragrance of the yellow tea is greatly enhanced by virtue of the yellowing procedure, and a novel product with the unique style is produced; the internal and external qualities of the traditional yellow tea are adequately embodied, the concept of people that the traditional yellow tea is weak in fragrance and taste is changed, and fixation procedure by a roller is changed into the fixation procedure by the hot wind and a primary heaping process, so that the working efficiency is greatly improved. Therefore, the production process of the novel yellow Maojian tea is very valuable and is suitable for being generalized and applied.

Owner:HUNAN JUSN YINZHEN TEA IND

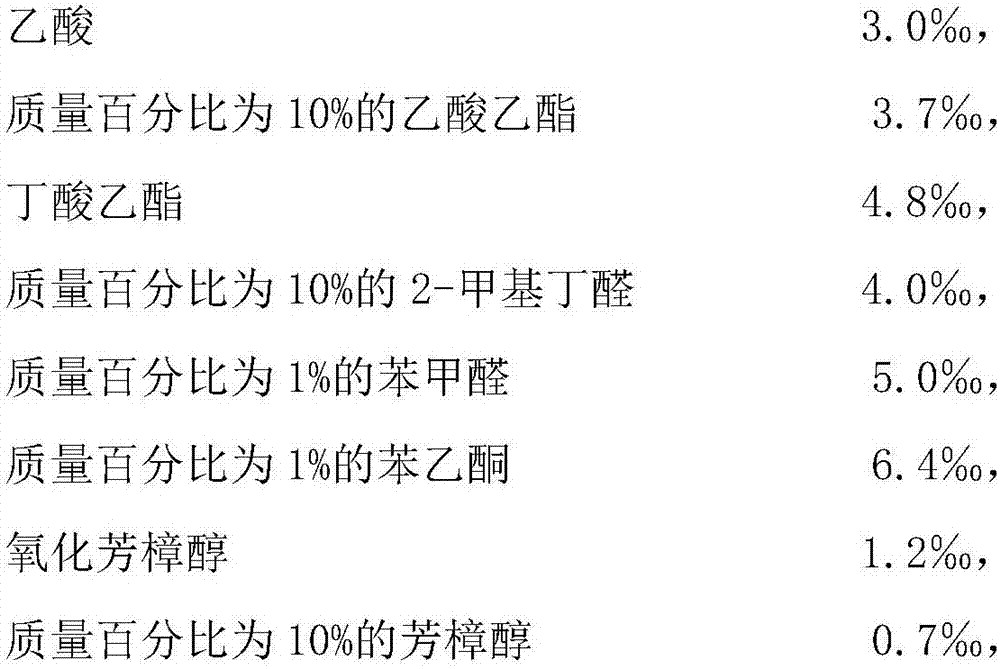

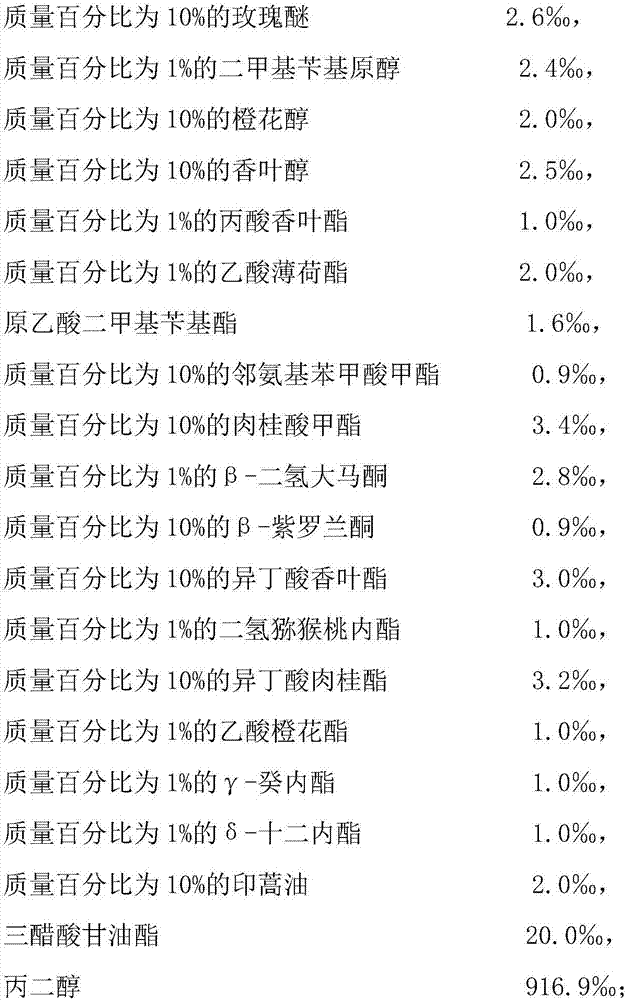

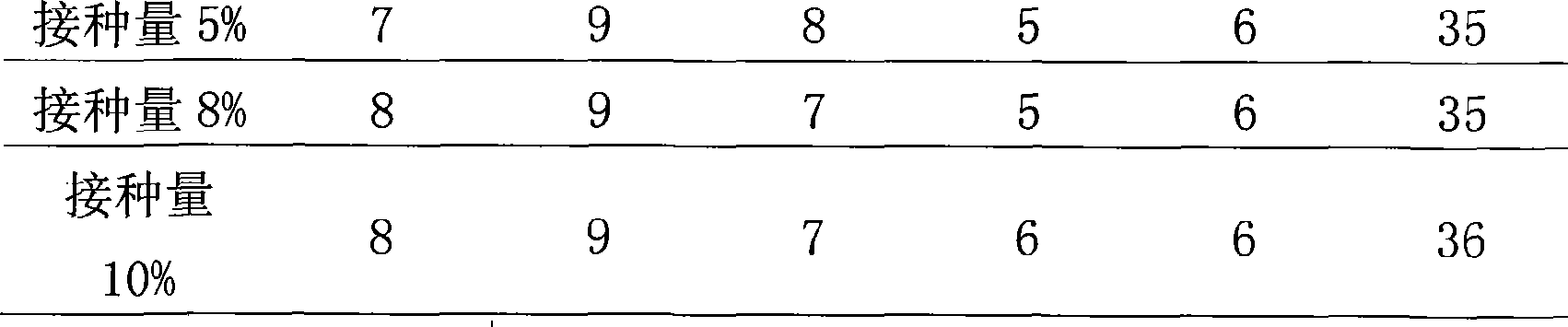

Preparation method of grapey flavoring essence for tobacco

InactiveCN107164093AFull of aromaUnique styleTobacco preparationEssential-oils/perfumesDihydroactinidiolideChemistry

The invention discloses a preparation method of a grapey flavoring essence for tobacco. The preparation method comprises the following steps: (1) preparing raw materials; (2) uniformly mixing propylene glycol, acetic acid, ethyl acetate, ethyl butyrate, 2-methylbutylaldehyde, benzaldehyde, acetophenone, linalool oxide, linalool, rose oxide, dimethyl benzyl carbinol, nerol, geraniol, geranyl propionate, menthyl acetate and beta-ionone; (3) adding imethylbenzylcarbinyl acetate, methyl anthranilate, methyl cinnamate, beta-damascone, nerolyl acetate, geranyl isobutyrate, dihydroactinidiolide and cinnamyl isobutyrate to a material obtained in step 2; 4, adding gamma-decalactone, delta-dodecalactone, Davana oil and glyceryl triacetate to obtain a material obtained in step 3, and uniformly mixing the added substances and the material; and (5) aging a material obtained in step 4. The grapey flavoring essence for tobacco has the sweet flavor of grapes, and also ahs full flavor and unique style.

Owner:HUBEI UNIV FOR NATITIES

Brewing process of red raspberry health wine and uses thereof

The invention relates to a method for brewing high-acid low-sugar small berry fruit wine, in particular to a method for brewing raspberry wine using raspberry as a fermenting material and an application for carrying out the same. The method comprises the following steps of: crushing rinsed raspberry fruits which are free of insects and unrotten, adding pectinase and cellulose during crushing to perform zymohydrolysis, and adding white granulated sugar; performing primary acidity regulation by adopting potassium tartrate; adding Saccharomyces cerevisiae into fruit juice to perform primary fermentation, and performing back flow and solid-liquid separation after the primary fermentation; adding active aster flavor yeast into the fruit juice which is performed with the solid-liquid separation to perform secondary fermentation, esterifying the fermented fruit juice and reducing the acidity naturally, performing the solid-liquid separation to receive filtrate, namely raspberry brut, and receiving the raspberry wine which is the aged brut. The method uses two yeasts with different fermentation functions for brewing to acquire the raspberry fruit wine with soft taste and full-bodied ester flavor, and maintains special flavor peculiar to the raspberry fruits, nutrient contents in the raspberry, oxidation resistance and other biological functions.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Brewing method for wolfberry dry red wine

The invention relates to a brewing method for wolfberry dry red wine. The brewing method for wolfberry dry red wine is a method for brewing wolfberry dry red wine by taking fresh wolfberry as a raw material and combining double-fermentation with an oak barrel aging technology. The brewing method is characterized by comprising the following steps: by taking the fresh wolfberry as the raw material, cleaning and crushing the raw materials, preparing the raw materials into pulp fermented mash by adopting belt low-temperature dipping, adding wolfberry fruit wine yeast to carry out primary fermentation under a low-temperature condition, getting primarily fermented wine by squeezing, adding concentrated wolfberry juice into the wine to carry out secondary fermentation to obtain secondarily fermented wine, and then aging the secondarily fermented wine in an oak barrel to prepare the wolfberry dry red wine. According to a trial, the wolfberry dry red wine brewed by adopting the brewing method has full-bodied wolfberry flavor, elegant alcohol flavor and coordinated oak flavor, is harmonious and soft in body, unique in flavor and rich in nutrition.

Owner:宁夏红枸杞产业有限公司

Sandwich jam roasted sausage and processing method thereof

InactiveCN104013025AFull of nutritionUnique styleFood coatingFood preparationBiotechnologyCarrageenan

The invention discloses a sandwich jam roasted sausage which comprises an outer skin and an inner stuffing in the outer skin, wherein the outer skin is prepared from the following components in parts by weight: 65-75 parts of pig lean meat, 25-35 parts of pig prime condition, 20-30 parts of chicken breast meat, 8-12 parts of cassava modified starch, 3-5 parts of table salt, 7-9 parts of whit sugar, 0.002-0.004 part of sodium nitrite, 0.3-0.5 part of carrageenan, 0.1-0.3 part of composite phosphate, 0.1-0.3 part of pork essence, 0.3-0.5 part of five spice powder, 35-45 parts of ice water, and 0.001-0.003 part of a fumigant. The inner stuffing is prepared from the following components in parts by weight: 30-40 parts of strawberry jam, 6-10 parts of white granulated sugar, 0.4-0.6 part of an acidity regulator and 12-16 parts of raw potato powder. The sandwich jam roasted sausage is abundant in nutrition, unique in pattern and good in taste.

Owner:SHANDONG JIASHIBO FOOD

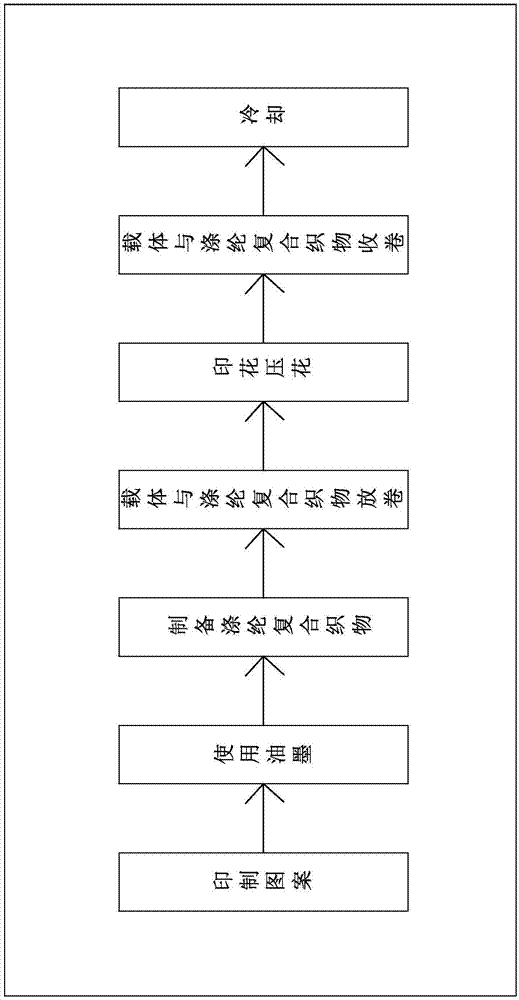

Printing and embossing synchronous forming method and device for polyester compound fabric

InactiveCN107323062AClear patternStrong sense of textureLamination ancillary operationsTransfer printing processPolyesterPrinting ink

The invention provides a printing and embossing synchronous forming method and device for polyester compound fabric and belongs to the technical field of the textile industry. The printing and embossing synchronous forming method for the polyester compound fabric comprises the steps as follows: a, printing of patterns; b, use of printing ink; c, preparation of the polyester compound fabric; d, unwinding of a carrier and the polyester compound fabric; e, printing and embossing; f, winding of the carrier and the polyester compound fabric; g, cooling. The product produced with the method has clear lines and has the topping style, meanwhile, one-step forming of heat transfer printing and embossing of the fabric is realized, the production process is simplified, and the cost is saved. The printing and embossing synchronous forming device for the polyester compound fabric comprises a rack, wherein the rack is provided with an inlet and an outlet, a film unwinding roller and a fabric unwinding roller are arranged at the inlet, the film unwinding roller and the fabric unwinding roller are arranged in an upper-lower manner, and a film winding roller and a fabric winding roller are arranged at the outlet. The forming device has the advantage that the product quality and the production efficiency are improved.

Owner:ZHEJIANG PIYI TEXTILE

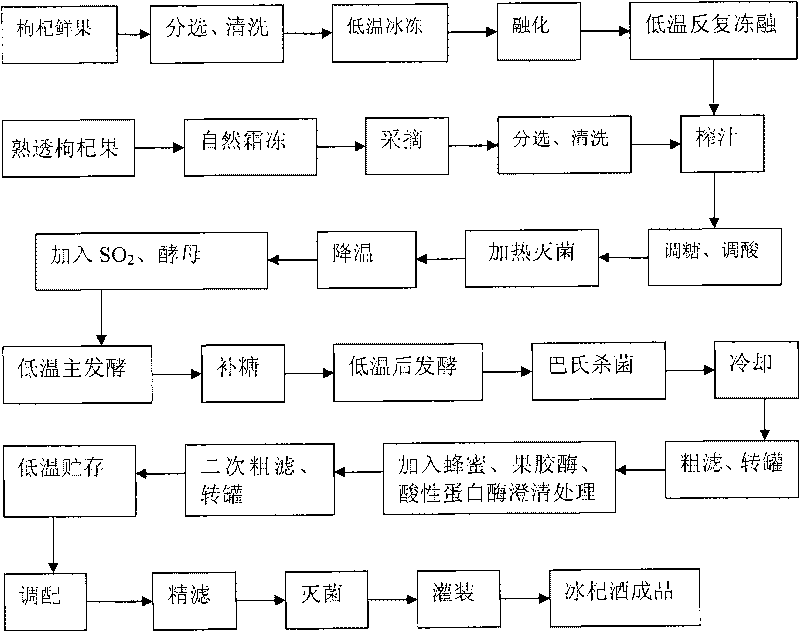

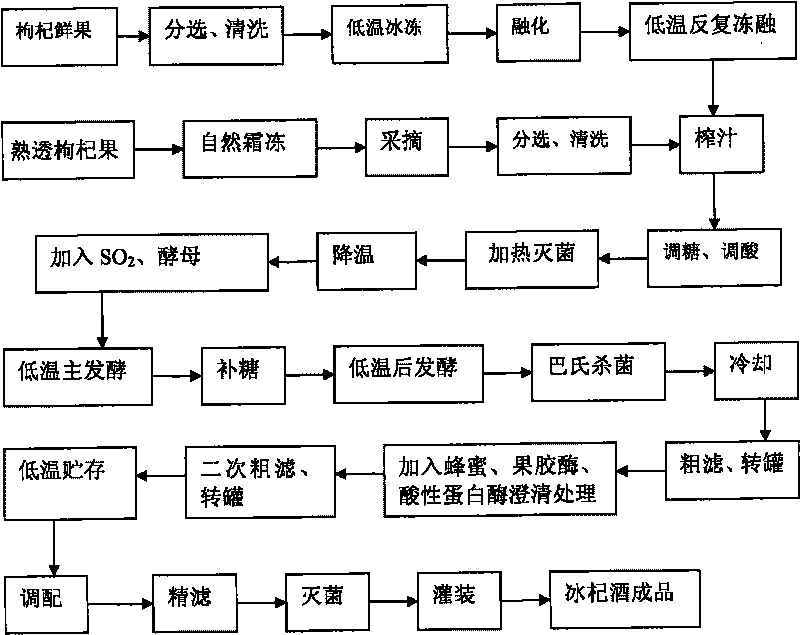

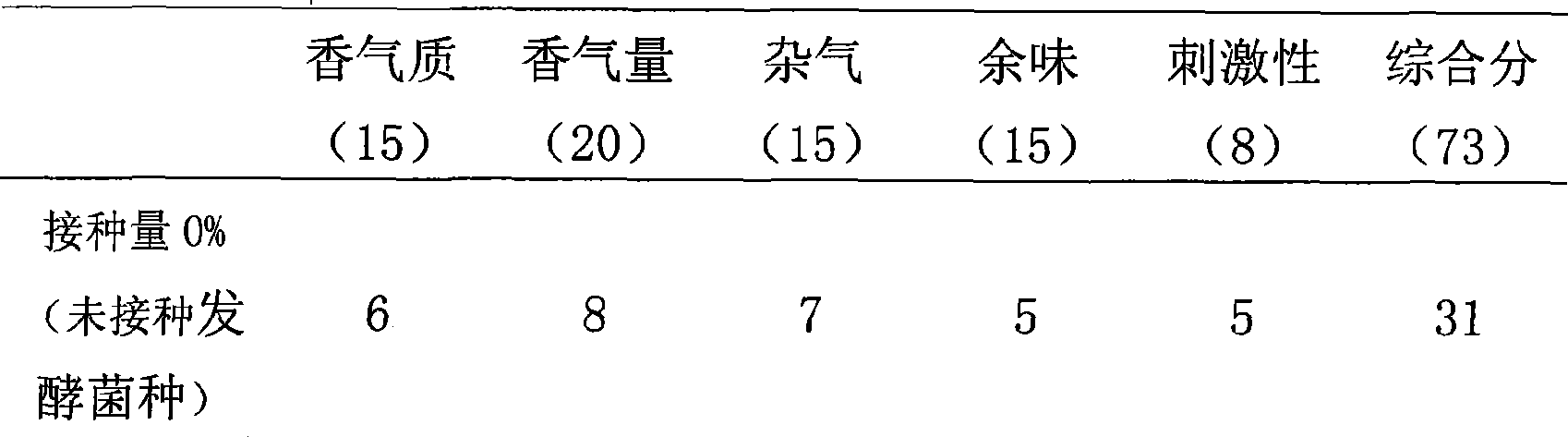

Ice medlar wine and brewing method thereof

InactiveCN101701172AIncreased polysaccharide contentElegant and pleasant wine aromaAlcoholic beverage preparationMicroorganism based processesProteinase activityFreezing thawing

The invention discloses an ice medlar wine brewed by taking medlar fruits as raw materials and a brewing method thereof. The invention is characterized in that a brewing process combining a natural frosting technology, a low-temperature repeat freeze-thawing technology and a microbe low-temperature long-term fermentation technology are employed and honey, pectase and acid protease are adopted to prepare the ice medlar wine by the processing steps of settling, fining and stable treatment. A medlar natural freezing method comprises the following steps of: naturally frosting fresh medlar fruits before picked from trees in late fall at the temperature of minus 6-minus 10 DEG C, and then picking, sorting and washing; a medlar repeat freeze-thawing method comprises the following steps of: carrying out low-temperature freezing and thawing at the temperature of minus 10-minus 15 DEG C for many times after squashy medlar is picked and sorted; the ice medlar fruits are prepared into the ice medlar wine by juicing, repeat fermenting, settling, low-temperature storing and curing, blending, sterilizing and filling. The ice medlar wine brewed by using the method has elegant and cheerful aroma and intense medlar fragrance; the wine body is harmonious and soft and has various nutrient components; and the quality of the ice medlar wine is obviously superior to that of the ice medlar wine brewed with common methods.

Owner:LIAONING SANQING AGRI DEV

Pomegranate fruit vinegar drink and production process thereof

InactiveCN102551163ABright and transparent colorUnique styleVinegar preparationFood preparationHydroxycitric acidPueraria

The invention aims to provide a pomegranate fruit vinegar drink and a production process thereof aiming at nutrient components of pomegranates and a drink form of fruit vinegar by using the conventional local specialty, namely the national geographical indication product (Lintong pomegranates). The pomegranate fruit vinegar drink can retain the original nutrient components of the Lintong pomegranates and has health-care and food therapy functions. The drink comprises pomegranate raw juice, pomegranate puree, pomegranate puree vinegar, water, honey and sugar, and can also comprise one of black tartary buckwheat or kudzuvine root, or a combination of the black tartary buckwheat and the kudzuvine root. Food additives such as citric acid, aspartame, potassium sorbate, sunset yellow, a flavoring essence and the like can also be added into the drink. The production process comprises the following steps of: selecting a raw material, namely pomegranates; cleaning and husking; rinsing; removing residual skins and diaphragms; crushing and juicing; adding active dry yeast; performing alcoholic fermentation; separating and taking wine; adjusting ingredients; performing acetic fermentation; sealing and aging; adding the water, the honey, the sugar and the like; adding the additives; filtering; filling; sterilizing; and thus obtaining a finished product.

Owner:周子宸

Fermentation optimization method of tobacco essence

ActiveCN101449854ASimple production processUnique styleTobacco preparationTobacco treatmentInorganic saltsFlavor

The invention discloses a fermentation and optimization method for tobacco flavors, which takes tobacco residual materials as raw materials, such as tobacco stems, tobacco dusts and secondary tobacco leaves, the tobacco residual materials are put into a fermentor, sugar and inorganic salt, tobacco flavor bottom materials, and water are added in to regulate pH value and a fermentation medium is obtained, and well-known preserving strain, micrococcus luteus ACCC11001, is selected as liquid fermentation strain and is fermented under certain fermentation conditions. The tobacco flavors after fermentation culture not only can maintain characteristic fragrance contained in original flavors, but also can ensure auxiliary fragrance obtained by fermentation to combine perfectly with the characteristic fragrance, and compared with the original flavors, the grade of the fragrance is improved obviously and the fragrance smells more elegant. The production process of the invention is simple, convenient and easy for extension, thus being provided with greater development and application value.

Owner:YINGTAN HUABAO FLAVORS & FRAGRANCES

Sparerib sauce base material, production method and application thereof

InactiveCN102763832AThe ribs are pure and rich in flavorRich tasteFood preparationMonosodium glutamateLean meat

The invention discloses a sparerib sauce base material, a production method and application thereof. The base material comprises pig bone essence, pig lean meat, animal protease, yeast extract, hydrolyzed plant protein powder, refined pig oil, monosodium glutamate, edible glucose, edible refined salt, I+G, white granulated sugar, soybean protein powder, mixed spices, maltodextrin, taurine, modified starch, BHT, potassium sorbate, and pig lean meat essence. The preparation method comprises the steps of (1) mincing pig lean meat into minced meat; (2) cooking the minced meat, and milling with colloid mill to obtain minced meat liquid; (3) performing enzymatic hydrolysis on the minced meat liquid; (4) deactivating enzyme; (5) adding other components into the enzymolysis liquid, and stepwise heating under stirring; and (6) stopping reaction to obtain the base material. The base material has the advantages of pure and thick fragrance of sparerib, rich and unique flavor, mellow mouth feeling, and lasting aftertaste. The base material can be used for producing sparerib sauce.

Owner:FUJIAN XINMA INDAL

Health care type composite fancy yarn and manufacturing method thereof

The invention provides a health care type composite fancy yarn and a manufacturing method thereof. The fancy yarn includes two core yarns, one decorative yarn, and one fixing yarn; with the two core yarns as a main body, the decorative yarn is feed at the speed more than 1.10-1.28 times the speed of the core yarns so as to clamp the decorative yarn between the core yarns and the fixing yarn; and performing twisting to form the fancy yarn. The health care type composite fancy yarn has a special shape and a unique three-dimensional fancy effect, is different in style, is clear in pattern, is fluffy in hand feeling, is changeable, can generate a flashing effect after different colors of fibers are merged, is unique in appearance effect, and is novel in structure; the yarn has a significant concave-convex three-dimensional feeling, is unique in style, is flexible and diverse in shape, is rich in color, is flexible in color matching, is various in pattern type, is bright in vision sense, ischangeable, is comfortable in touch sense, is excellent in hygroscopicity, air permeability and elasticity, and is beautiful in appearance; and various fabrics and high-grade products made of the health care type composite fancy yarn are high in technical content, and can prevent untoward effects after contacting human bodies.

Owner:ZHONGYUAN ENGINEERING COLLEGE

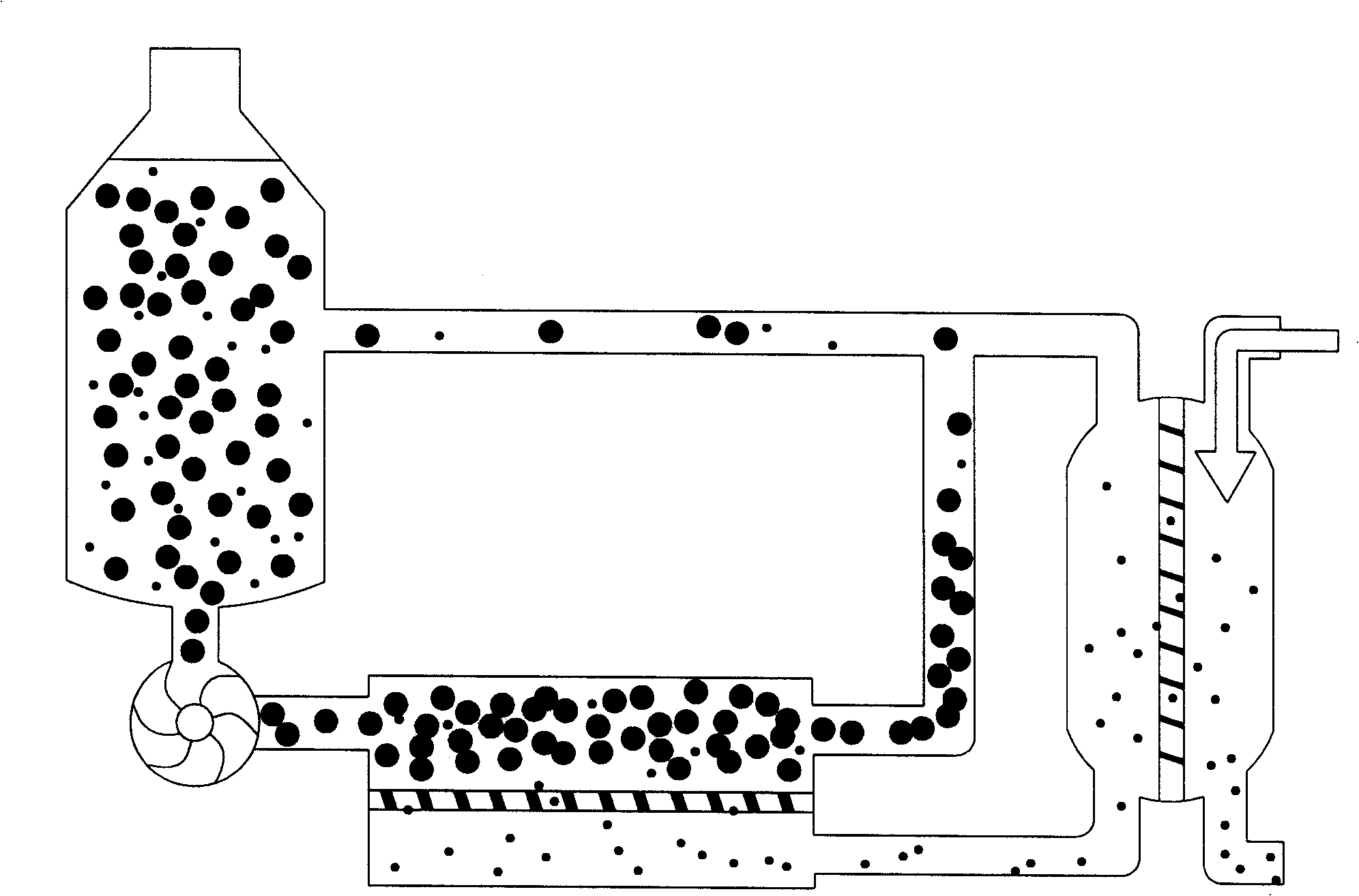

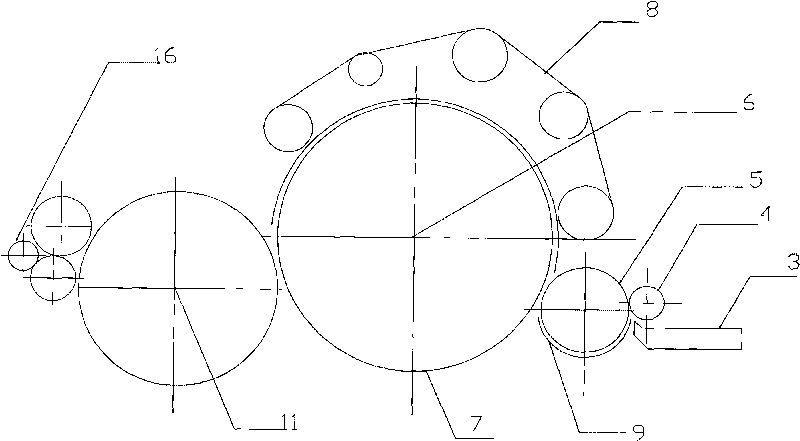

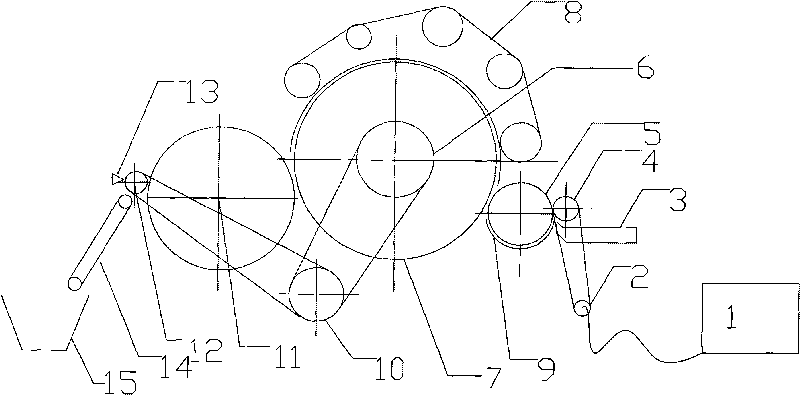

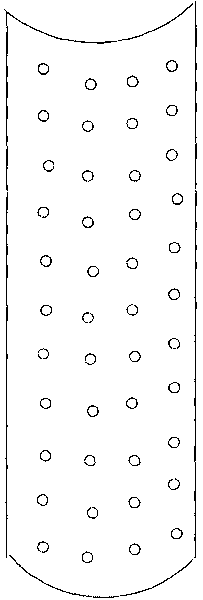

Production device of fiber color points and spinning method of color point yarns

The invention provides a production device of fiber color points and a spinning method of color point yarns, and improves the common cotton spinning machinery, i.e. adding a cotton feeding system on various carding machines, simultaneously being dispensed with a cotton stripping device, installing a stripping and conveying device, configuring all the technological parameters (e.g. transmission rate, cutting die, doffer space and the like) of the carding machines, and being reformed into a device capable of producing various fiber color points. The spinning method utilizes the production device, selects the kind and the dosage of an adhesive suitable for the fiber to produce color points with different size specifications, different tightness and extensive color change according to different fiber types during the production process of the color points.

Owner:广东广纺检测技术股份有限公司

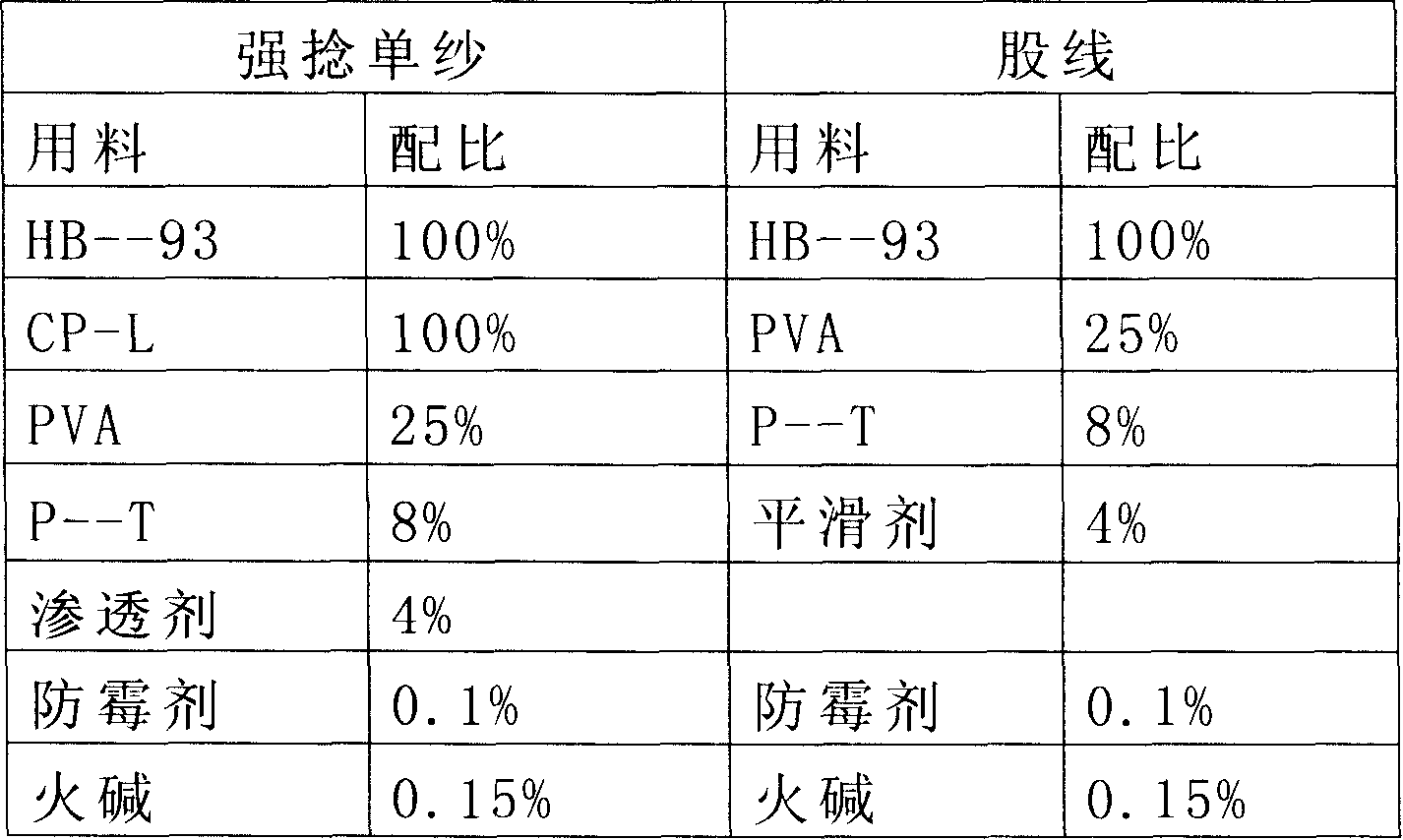

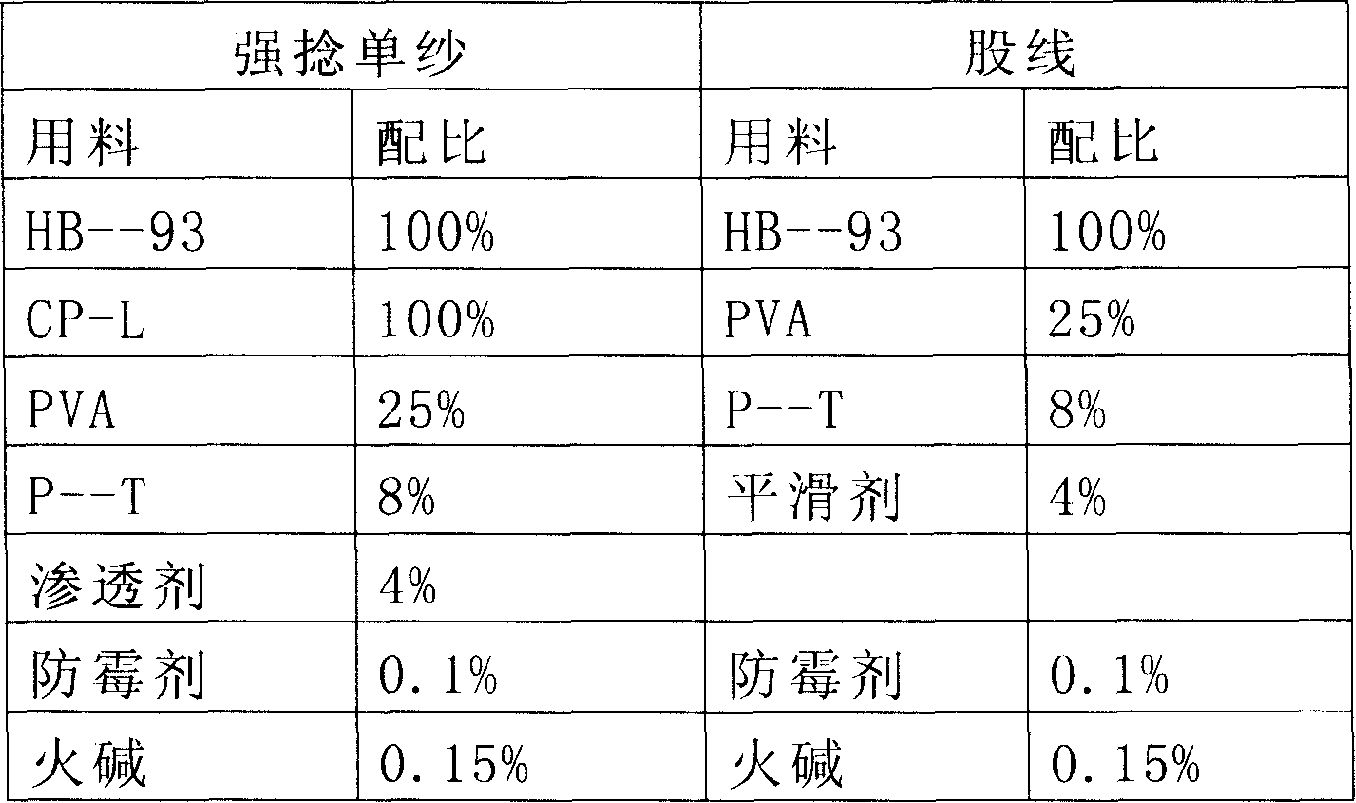

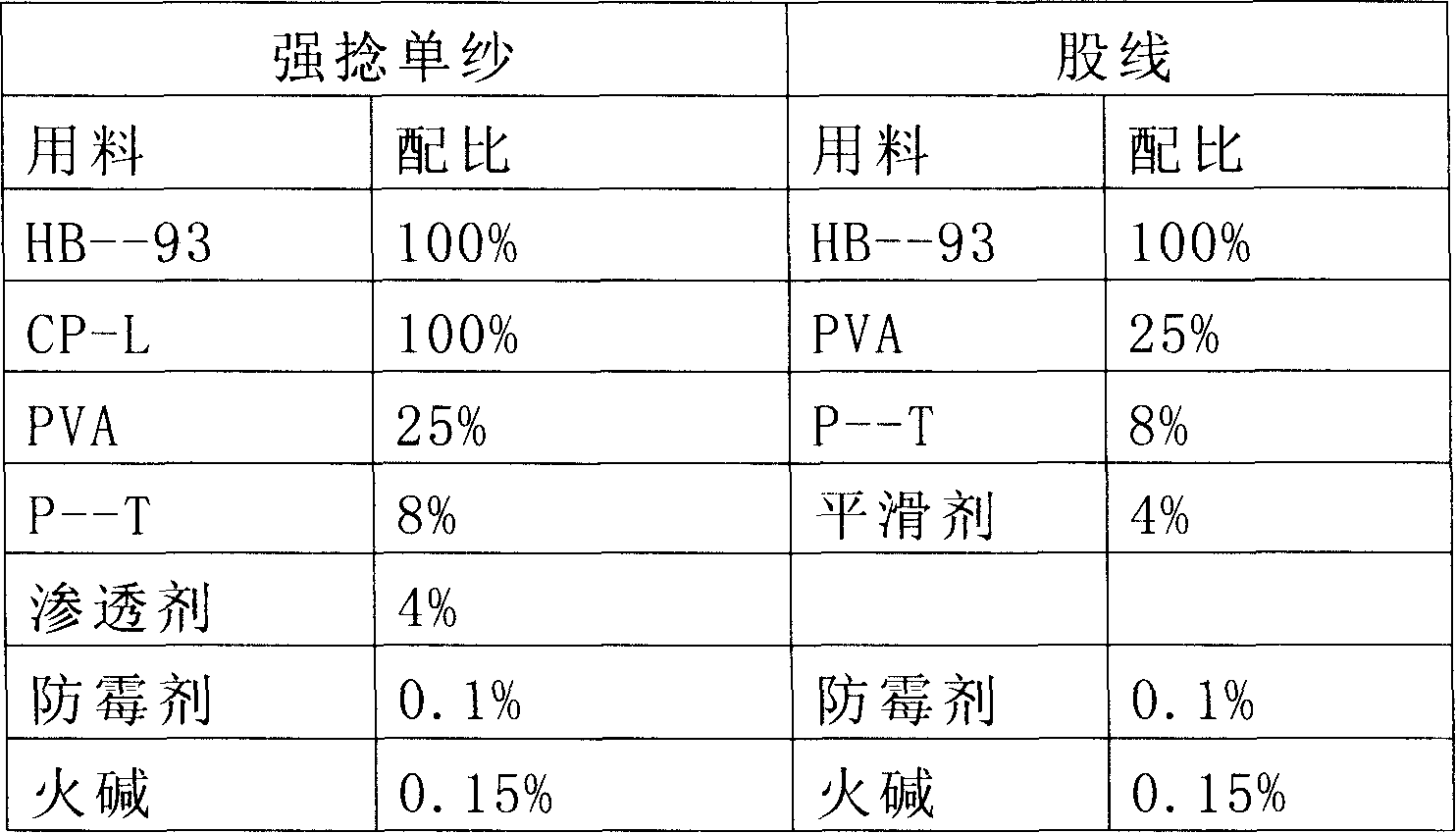

High count single yarn double-sided mercerized fabric and processing method thereof

InactiveCN102926114AHigh strengthImprove dye uptakeMercerising of indefinite length fabricsWeft knittingYarnSilk cloth

The invention discloses a high count single yarn double-sided mercerized fabric and a processing method of the high count single yarn double-sided mercerized fabric, and belongs to the field of textile fabric processing. The technical scheme of the high count single yarn double-sided mercerized fabric and the processing method the high count single yarn double-sided mercerized fabric comprises special spinning, yarn processing, double-sized fabric weaving and fabric after-treatment. The special spinning means that a high-strength high-count yarn is manufactured by the adoption of special cotton collocation and the implementation of strong twisting on the special cotton collocation and the yarn processing. The double-sided fabric weaving means that the double-sided fabric is woven by a double-sided machine with high stitch length of 40 stitches or more than 40 stitches. The fabric after-treatment means that a finished production fabric is manufactured by singeing, mercerizing and sizing of the fabric. The high count single yarn double-sided mercerized fabric and the processing method of the high count single yarn double-sided mercerized fabric is characterized in that high-strength high-count yarns manufactured by adopting the special spinning method, and weaving requirement of high stitch distance double-sided machine strength is met. The high count single yarn double-sided mercerized fabric and the processing method of the high count single yarn double-sided mercerized fabric produce high-quality high count single yarn double-sided fabrics, and the fabrics are light and elegant, and comfortable, and have a silky and smooth touch, and the luster of the fabrics is soft and bright, and the fabrics are the best in double-sided fabrics.

Owner:WUXI NATURAL GREEN FIBER TECH

Preparation method of multi-functional fabric

InactiveCN103132204AStrong odor absorptionGood perspiration and moisture absorptionWoven fabricsMoisture absorptionEngineering

The invention discloses a preparation method of a multi-functional fabric, and the multi-functional fabric is manufactured through a unique preparation method. The preparation method includes the following steps: a. selecting and matching of fabric components, b. spinning, c. weaving, and d. post-processing of the fabric. The preparation of the multi-functional fabric has the advantages that procedure arrangement is reasonable, the method is carried out scientifically and effectively, and fabric manufactured through the preparation method have the functions of ultra-strong smell-absorbing capacity, good moisture absorption and sweat discharge quality, and excellent health functions such as antibiosis, mildew-proof, acarid resistance and acarid killing. Further, the fabric is unique in style, and is ideal fabric in manufacture of high quality clothing and household textiles.

Owner:KUSN ZHOUSHI TOWN JISHENG CLOTHING FACTORY

High-denier high-density double-weft cloth and manufacturing technique thereof

The invention relates to a high count high density weft backed fabric and a manufacturing technique thereof, wherein, the fabric adopts weft backed weave structure; end spacing of the fabric is 240 ends per inch and weft density of the fabric is 240 picks per inch; warp threads adopt JC100 purified cotton folded yarns and weft yarns adopt JC80 purified cotton yarns. The manufacturing technique for the fabric is to adopt special technological methods in procedures like warping, slashing, denting, weaving and so on, thereby product quality is guaranteed, and quality and grade of products are obviously improved. By adoption of weft backed structure for weaving the high count high density fabric, the invention has the advantages of double-faced satin displayed on fabrics, bright luster of cloth covers, smooth hand feeling, refined grain and unique style; by adoption of 100 percent long stapled cotton, the invention has the characteristics of high count high density, flat and refined textile surface and good style of fabric covers.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Method for producing Chinese wolfberry jam from Chinese wolfberry pomace from wine brewing

InactiveCN105595274ARealize comprehensive utilizationFragrantLactobacillusStrepto/lacto-coccusEnzymatic hydrolysisAdditive ingredient

The invention relates to a Chinese wolfberry jam and a production method thereof, especially a method for producing Chinese wolfberry jam by using Chinese wolfberry pomace from wine brewing as a raw material. The method combines a composite enzymatic hydrolysis and a lactobacillus fermentation technology. The method is characterized by comprising the steps of: using Chinese wolfberry pomace from wine brewing as the raw material, removing seeds, cleaning, beating, carrying out enzyme treatment, adjusting the components, inoculating lactobacillus, and fermenting to produce soluble dietary fiber; improving the taste, adjusting the sugar content and acidity, and then homogenizing and sterilizing to prepare the Chinese wolfberry jam. The method utilizes the pomace leftover from the Chinese wolfberry deep processing industry, innovates the technology, and provides the Chinese wolfberry jam with rich nutrients, agreeable sweet-sour taste, strong aroma and delicate taste.

Owner:宁夏红中宁枸杞制品有限公司

Pure cotton heavy twist striated fabric and preparation technique thereof

The invention relates to a purified cotton hard twisted stripe and a manufacturing technique thereof, wherein, the stripe adopts combined weave of 5 / 2 kettsatin and 1 / 1 plain weave; end spacing of the stripe is 450.5 ends per ten centimeters and weft density of the stripe is 301 picks per ten centimeters; warp threads adopt JC7.3Tex single yarns with a twist number of 210 twists per ten centimeters and JC7.3Tex x 2 folded yarns; compound yarns are used for closely weaving satin weaves, and hard twisted single yarns are used for weaving plain weaves; fabrics are of thick and thin variable stripe effect; weft yarns adopt JC9.7Tex single yarns with a twist number of 240 twists per ten centimeters. In the aspect of the manufacturing technique, special technological methods are adopted in procedures like warping, slashing, denting, weaving and so on, thereby product quality is guaranteed, and quality and grade of products are obviously improved. Because the stripe adopts the combined weave of the 5 / 2 kettsatin and the 1 / 1 plain weave, the invention has the advantages of bright luster of cloth covers, smooth hand feeling and refined grain; because the compound yarns are used for closely weaving satin weaves and the hard twisted single yarns are used for weaving plain weaves, the fabrics are of thick and thin variable stripe effect and the style is unique.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com