Light wine and brewing process thereof

A wine and dry white wine technology, applied in the field of wine preparation, can solve the problems of mellow wine body, lack of sense of structure, inability to carry out under high pressure, insufficient nutrients and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

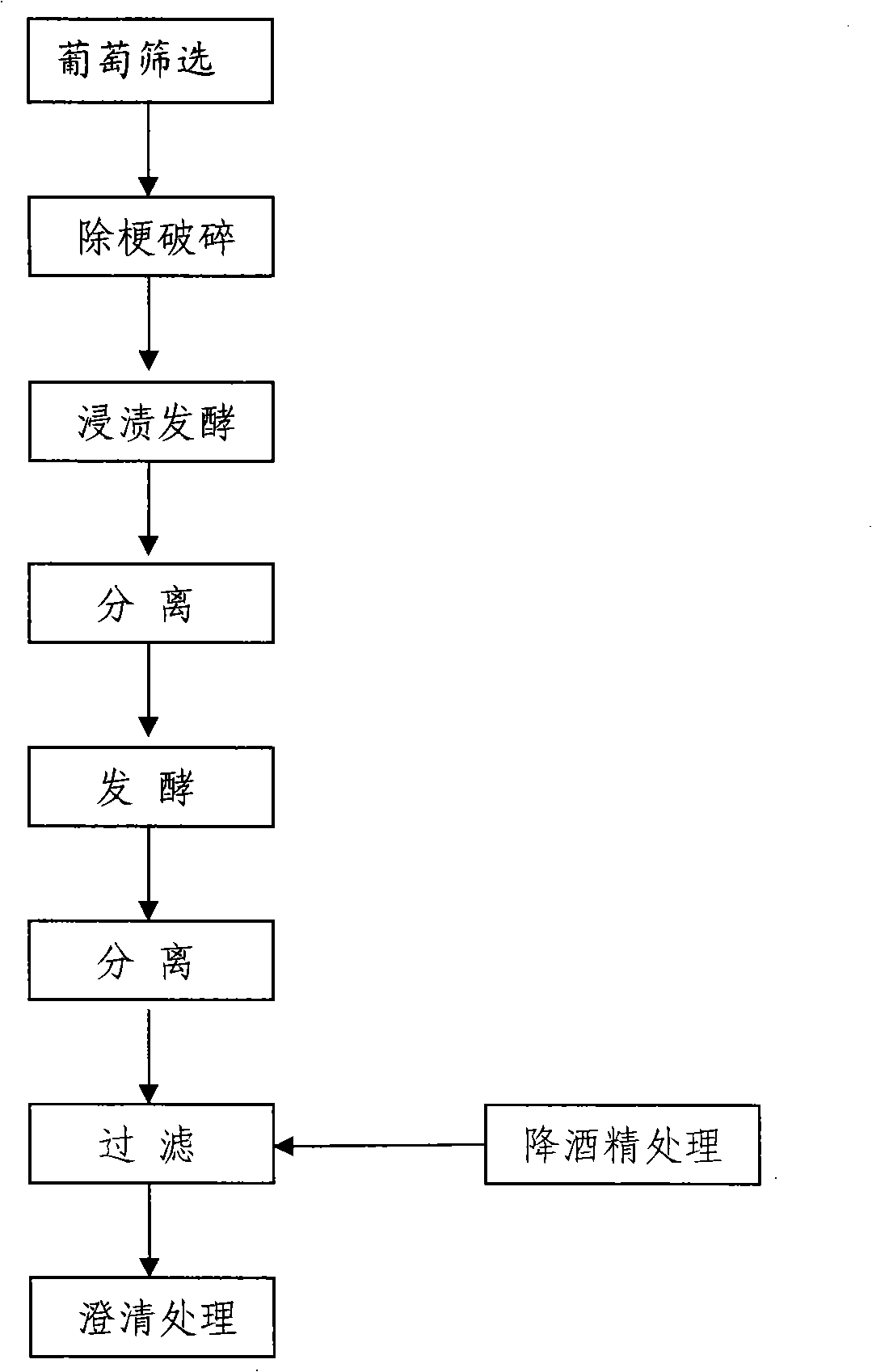

[0043] Embodiment 1: the brewing process of low-alcohol dry red wine

[0044] Such as figure 1 As shown in the process flow chart, the brewing of low-alcohol dry red wine includes the following steps:

[0045] a. Famous wine grapes such as Cabernet Sauvignon, Gernischt, Merlot or Gamay are planted, and there are strict and standardized cultivation methods, all adopting the advanced "single-stem and double-arm" viticulture mode. This viticulture mode is borrowed from the advanced foreign countries It is an original creation based on advanced viticulture technology and combined with the climate characteristics of East China. Lower yield control improves grape quality.

[0046] b. In order to ensure the quality of the wine, the grapes are selected and crushed within 12 hours after picking. The crushing of grapes adopts a special partial crushing process. Only part of the grapes are crushed, and whole grapes are used for fermentation. Whole grapes account for about 10%-30%. The...

Embodiment 2

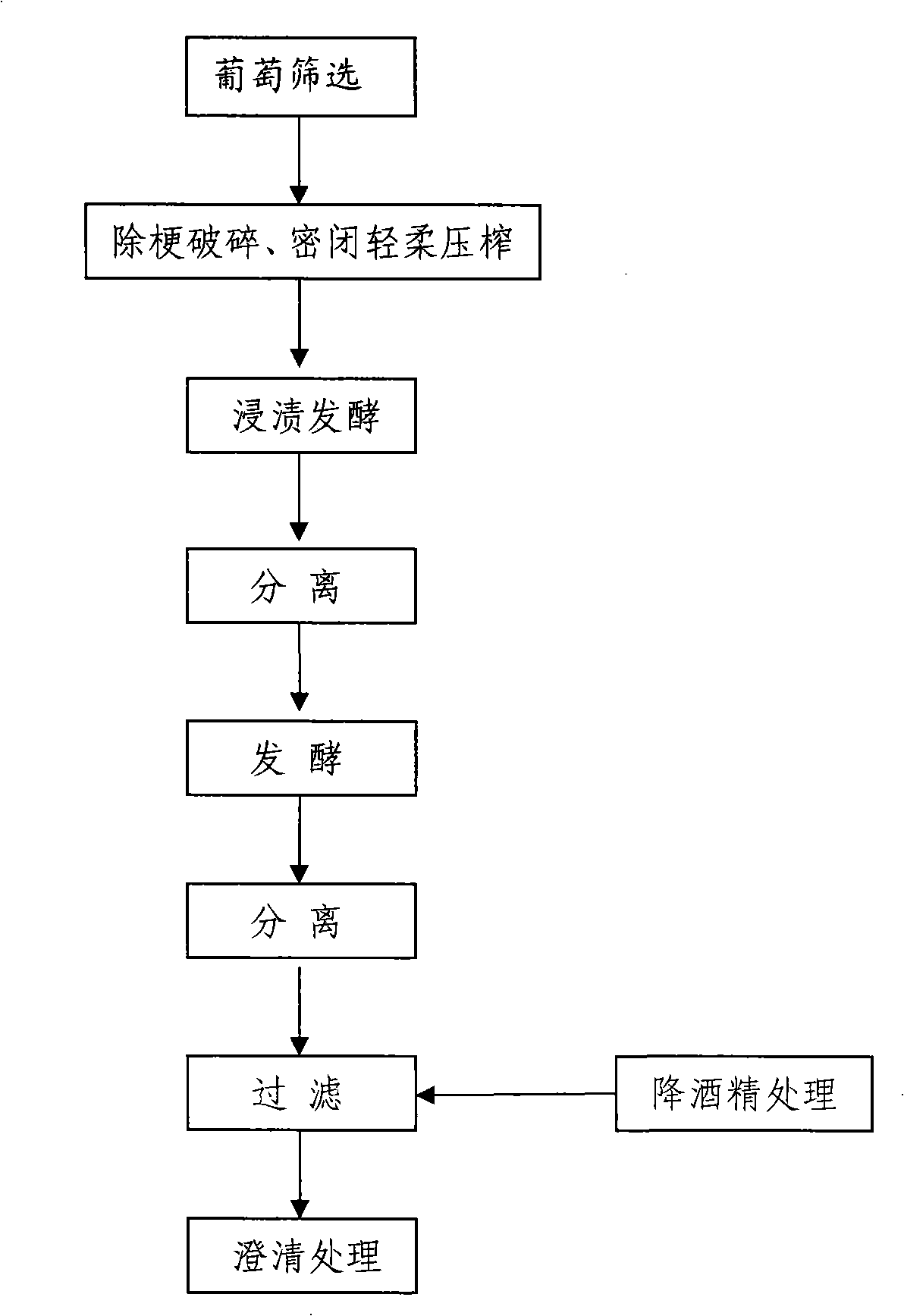

[0055] Embodiment 2: the brewing process of low-alcohol dry white wine

[0056] Such as figure 2 As shown in the process flow chart, the brewing of low-alcohol dry red wine includes the following steps:

[0057] a. Plant famous wine grapes Chardonnay, Riesling or Sauvignon Blanc, and have strict and standardized cultivation methods, all of which adopt the advanced "single-stem and double-arm" viticulture mode. This viticulture mode is borrowed from foreign advanced by Huadong Company Viticultural technology, and combined with the climate characteristics of East China, the original creation. Lower yield control improves grape quality.

[0058] b. In order to ensure the quality of the wine, the grapes are selected and crushed within 12 hours after picking. The crushing of grapes adopts a special partial crushing process. Only part of the grapes are crushed, and whole grapes are used for fermentation. Whole grapes account for about 10%-30%. The purpose is to obtain more peel ...

Embodiment 3

[0070] The physical and chemical properties of the low-alcohol wine brewed by any process in Example 1 or 2 are as follows: alcohol content is 8-10%, sugar content≤4g / L, acidity is 5-9g / L, dry extract 16-30g / L, free sulfur dioxide ≤50mg / L, total sulfur dioxide ≤250mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com