Patents

Literature

318results about How to "Clear pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital ink jet fabric-treating process

The present invention is digital ink jet fabric treating process, and belongs to the field of textile science and technology. The fabric pre-treating process for digital ink jetting and printing with water thinned pigment ink is suitable for fabric of cotton, hemp, silk, Dacron, polyester and cotton blend, acrylic fiber, etc.; and the treated fabric may be ink jetting printed with water thinned pigment ink in one digital ink jetting printer. After printing and proper heat treatment, may be produced printed product with clear pattern, bright color, and high fastness to resist water washing, friction and sunlight.

Owner:JIANGNAN UNIV

Method for manufacturing high-breathability non-woven wallpaper body paper and product

The invention discloses a method for manufacturing high-breathability non-woven wallpaper body paper and a product. The existing non-woven wallpaper has the disadvantages that the hand feel thereof is not soft enough, the principal plane stereoscopic impression is not strong and the opacity degree is low. The method of the invention comprises the following steps: beating plant fiber containing chemical wood pulp until the beating degree is 20-30OSR, and mixing with non-plant fiber containing chemical fiber; adding chemical addition agent into the mixed fiber; manufacturing the mixed fiber containing the chemical addition agent into body paper semi-finished products by utilizing a fourdrinier wire or inclined wire paper machine; mixing pigment, chemical addition agent and adhesive to form coating liquor, carrying out dip coating on the body paper semi-finished products inside or outside the machine; and drying and finishing the body paper subject to dip coating, and rolling the body paper to form finished paper of body paper, thus obtaining non-woven wallpaper which contains continuous fiber, has high breathability, and can be directly printed. The principal plane has natural lines; and the finished paper has the advantages of soft hand feel, good processability, excellent shape stability, rich color, distinct image and strong stereoscopic impression.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

Transfer printing type ultraviolet light curing ink composition, preparation method thereof and mobile phone casing using ink composition

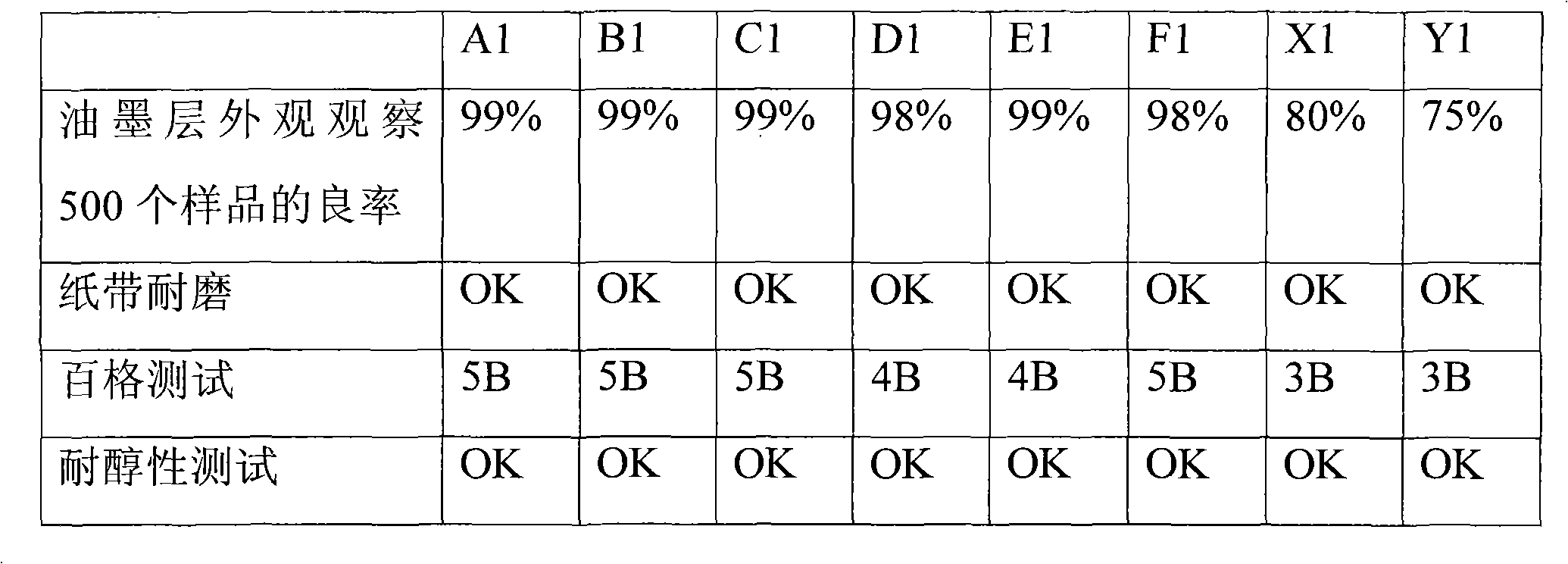

InactiveCN101993629AImprove adhesionClear patternInksTelephone set constructionsPolyesterAcrylic resin

The invention provides a transfer printing type ultraviolet light curing ink composition and a preparation method thereof. The ink composition comprises main body resin, a thinner, pigment and photoinitiators, and addition agents are included or not included, wherein the main body resin is polyester acrylate resin, modified acrylic resin, high-functionality-degree aliphatic urethane acrylate and hydroxy acrylic resin, the hydroxy acrylic resin is thermoplastic hydroxy acrylic resin, and the hydroxyl value content is between 45 and 70 mg KOH / g. The invention also provides a mobile phone casing using the ink composition, wherein the mobile phone casing sequentially comprises a substrate, a primer layer, a gloss oil layer and an ink pattern layer from bottom to top, and the ink pattern layer is obtained from the ink composition through transfer printing. When the transfer printing type ultraviolet light curing ink composition is adopted, the adhesive force between the ink layer and a contact layer can be enhanced, and in addition, when the surface of the contact layer is lower, the cured ink layer can effectively avoid the phenomenon of edge contraction.

Owner:BYD CO LTD

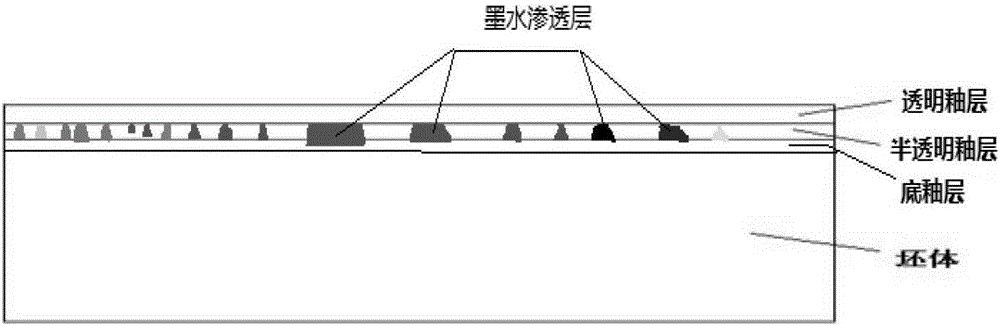

One-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects, and manufacturing method thereof

The invention relates to one-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects, and a manufacturing method thereof. According to the manufacturing method, a bottom green brick layer, a priming glaze slurry, a semitransparent glaze slurry, and a transparent glaze slurry are prepared respectively; the bottom green brick layer is subjected to following treatment respectively: a priming glaze layer is formed via priming glaze slurry pouring, jet printing of decorative patterns is carried out, a semitransparent glaze layer is formed via semitransparent glaze slurry pouring, and drying is carried out; obtained green bricks are printed with decorative patterns with ink-jet of penetrating ink and jet printing of a permeation promoter, and are allowed to stand for more than 5min; the obtained green bricks are printed with isolation glaze with water isolating performance via silk-screen printing, and are dried and cooled; the green bricks are coated with the transparent glaze slurry via pouring; the green bricks are subjected to one time sintering so as to obtain one-time sintered ink-jet penetrating porcelain tile semi-finished products with three-dimensional decorative effects; the semi-finished products are subjected to polishing via inelastic module technology so as to obtain the one-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects.

Owner:MONALISA GRP CO LTD

Curable resin composition for column spacer,column spacer, and liquid crystal display panel

InactiveUS20090128767A1Excellent developabilityImprove solubilityOrganic chemistryMixing methodsSolubilityLiquid-crystal display

It is an object of the present invention to provide a curable resin composition for a column spacer which has excellent developability and solubility and is capable of forming a clearly patterned column spacer without leaving a development residue at the time of pattern formation of the column spacer to be used in producing a liquid crystal display panel.The present invention is directed to a curable resin composition for a column spacer, which contains a compound having two or more polymerizable unsaturated bonds in a molecule, an alkali-soluble polymer compound, and a photo-reaction initiator, the compound having two or more polymerizable unsaturated bonds in a molecule being an oxide-modified compound having two or more polymerizable unsaturated bonds in a molecule.

Owner:SEKISUI CHEM CO LTD

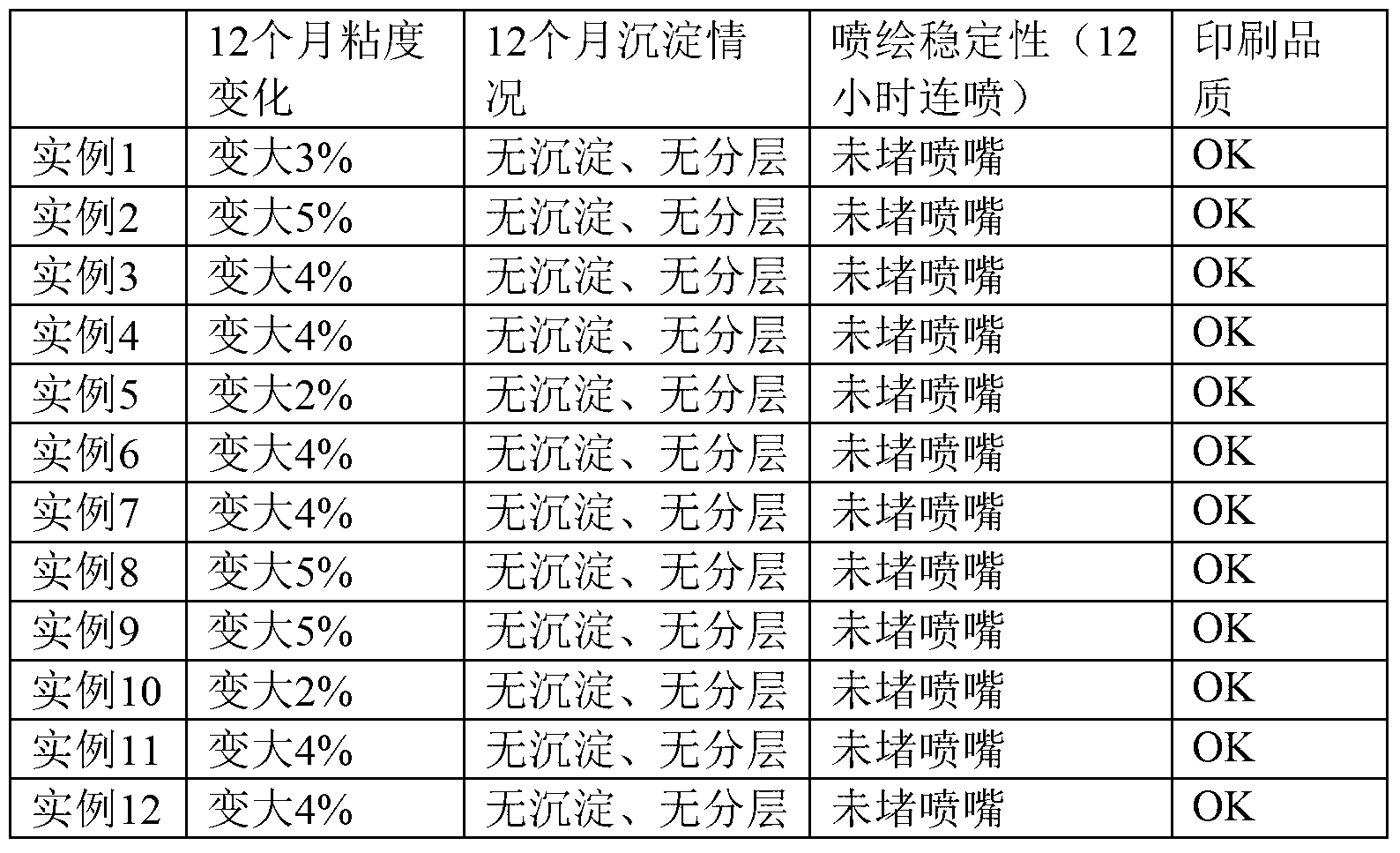

Digital inkjet thermal transfer printing water-based ink for textiles and preparation method of ink

The invention discloses digital inkjet thermal transfer printing water-based ink for textiles and preparation method of the ink. The ink comprises the following raw materials in mass ratio: 5-15 parts of disperse dye, 5-10 parts of a dispersing agent, 0.1-0.5 part of a wetting agent, 5-25 parts of a cosolvent, 0.02-0.05 part of a preservative, 0.1-0.3 part of an antifoaming agent and 50-70 parts of deionized water. The digital inkjet thermal transfer printing water-based ink is prepared by using a method of effectively dispersing the disperse dye via a dispersing system and carrying out combined dispersion via a mechanical sand grinder and an ultrahigh-pressure homogenizer, and is suitable for the thermal transfer printing of textiles and the thermal transfer printing of plate materials such as aluminum plates coated with polyester; and the prepared water-based ink has the advantages of small particle size, uniformity in distribution, good stability, no nozzle blocking, rapidness in drying, bright color, clear patterns, high transfer rate, low cost and the like.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

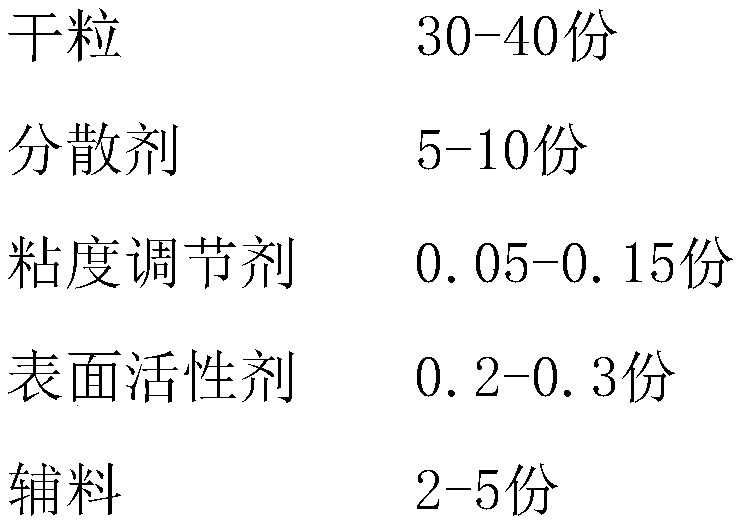

Ink-jet dry granular decorative ceramic tile and manufacturing method thereof

The invention relates to the technical field of ceramic tiles, in particular to an ink-jet dry granular decorative ceramic tile and a manufacturing method thereof. The manufacturing method includes the following steps: A. bottom glaze decoration; B. pattern decoration; C. drying for the first time; D. dry granular decoration; E. spraying a protective glaze; and F. calcining to obtain the product.The method for preparing the dry granular decorative ceramic tile has the advantages of simple operation steps, convenient control, simplified process flow, improved production efficiency, reduced production difficulty and production cost, so that the method is suitable for industrial large-scale production; by spraying with dry granular ink, spray printing can be carried out on a designated position on the surface of a blank body, so as to enable a spray printed texture to be accurately correspond to a pattern decorative texture, and thus the distribution uniformity and adhesion of dry granules on the surface of the blank body are improved, and the prepared ceramic tile product has clear and distinct patterns, low glaze gloss, good anti-skid effect, obvious dry granular feeling, strong stereoscopic impression, rich colors, stable physicochemical properties and wide temperature adaptation range.

Owner:JIANGXI HEMEI CERAMICS +3

Preparation method of patterned graphene conductive thin film

InactiveCN103236295AShort film forming timeHigh yieldConductive layers on insulating-supportsOther printing apparatusPrinting inkNanotechnology

The invention belongs to the field of a conductive thin film material and particularly relates to a preparation method of a patterned graphene conductive thin film. The preparation method comprises the following steps of: washing a flexible substrate and drying; utilizing plasmas to treat the flexible substrate; utilizing an intaglio printing process to print graphene oxide printing ink prepared by a Hummers method on the flexible substrate; then putting the flexible substrate into a drying box to be dried to obtain a graphene oxide thin film; and finally, carrying out reduction treatment on the graphene oxide thin film to prepare the patterned graphene conductive thin film. According to the preparation method disclosed by the invention, the patterned graphene conductive thin film is prepared by a manner of combining the graphene oxide printing ink with the intaglio printing process, so that the preparation method is short in film forming time, high in yield and low in production cost; large-scale batch production can be realized; and the prepared patterned graphene conductive thin film is good in flexibility, high in conductivity and high in pattern definition.

Owner:SHANGHAI NORMAL UNIVERSITY

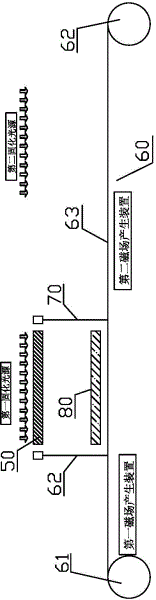

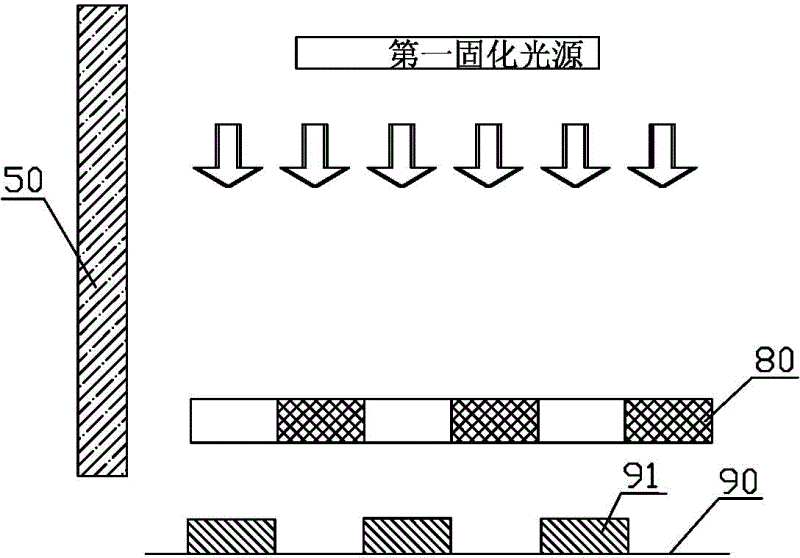

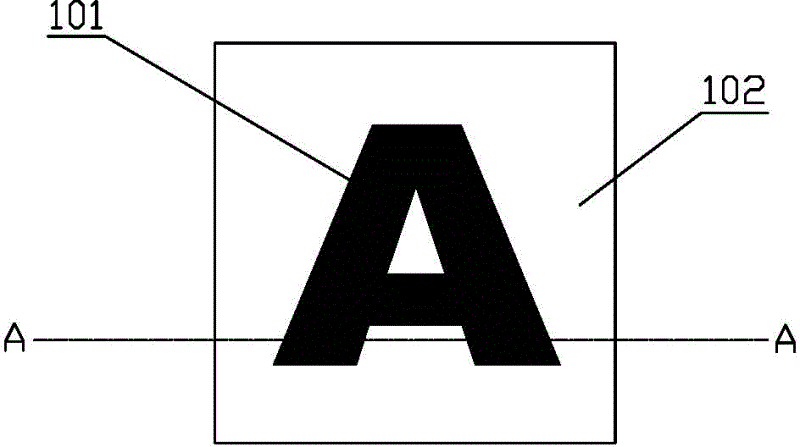

Production method of pattern in magnetic pigment fragment-containing coating layer and production device thereof

ActiveCN102616042AClear patternReduce manufacturing costPattern printingOther printing apparatusEngineeringPigment

The invention relates to a device for producing a pattern in a magnetic pigment fragment-containing coating layer, which comprises two magnetic field generators, two solidified light sources, a light barrier, a baffle plate and a base material transmitter, wherein the base material transmitter comprises two wheel shafts arranged at two ends, and a feed belt which takes the two wheel shafts as shaft drive, one magnetic field generator, one solidified light source, the other magnetic field generator and the other solidified light source are sequentially arranged along with the direction from one wheel shaft to the other wheel shaft, and the surface of the feed belt is provided with a base material which is coated or printed with the magnetic pigment fragment-containing magnetic ink coating layer. The visually-changed safe pattern disclosed by the invention belongs to a first-line and second-line anti-counterfeiting synthesis technique, the true and false can be visually identified without any tools, and the magnetism of the pattern can be detected by magnetism detecting equipment as well; and the anti-counterfeiting ink which symmetrically changes by means of light and shade (color) along with the change of the visual angle is high in preparation difficulty, the effect is very hard to imitate, and the fidelity effect is extremely high.

Owner:甄健

Hydraulic transfer film and process for producing hydraulic transfer product therewith

InactiveUS20060073342A1Excellent surface propertyImprove surface propertiesLiquid surface applicatorsDecorative surface effectsComposite materialRadiation exposure

An object of the present invention is to provide a hydraulic transfer film which has a transfer layer capable of forming a cured resin layer having excellent surface properties on a hydraulic transfer body and is less likely to cause blocking, a method for producing a hydraulic transfer film, capable of forming a clear decorative layer on a curable resin layer, and a method for producing a hydraulic transfer body having excellent surface properties and a clear pattern. The present invention provides a hydraulic transfer film comprising a water-soluble substrate film, a hydrophobic transfer layer including a curable resin layer which can be cured by at least one of irradiation with radiation and heating provided on the substrate film, and a peelable film provided on the transfer layer; a method for producing a hydraulic transfer film, which comprises laminating a film comprising a substrate film and a curable resin layer provided on the substrate film with a film comprising a peelable film and a decorative layer provided on the peelable film by dry lamination; and a method of producing a hydraulic transfer body using the hydraulic transfer film.

Owner:DAINIPPON INK & CHEM INC

Nano composite modified melamine-formaldehyde abrasion-resisting resin and preparation method thereof

InactiveCN102219884AImprove stabilityExtended shelf lifeNon-fibrous pulp additionPaper/cardboardMelamine formaldehydeNano al2o3

The invention discloses a nano composite modified melamine-formaldehyde abrasion-resisting resin and a preparation method thereof. The resin is mainly prepared from a mixture of nano alumina and nano silica, melamine, water, formaldehyde, a stabilizer and an alcohol substance by process steps of mixing, warming polycondensation and cooling discharging. The production method of the modified melamine-formaldehyde abrasion-resisting resin prepared by using the method is very simple and product property is stable; and decorative paper impregnated with the resin still remains the patterns of the surface of the original paper. The resin can be used for the production of impregnated glue film paper facing artificial boards and impregnated paper laminated wood floors, and the wear resistance of the resin reaches 4000 turns.

Owner:FUJIAN AGRI & FORESTRY UNIV

Matte brick and preparation method

The invention discloses a preparation method of a matte brick. The preparation method comprises the steps: preparing ground glaze, decorative patterns and surface glaze on the surface of a green bodysequentially, then performing drying and firing, performing polishing by using a matte grinding block and a fiber grinding block sequentially, and performing wax so as to obtain the matte brick finished product. The matte brick with a glossiness of 28-36 degrees is prepared through adoption of a reasonable surface glaze formula and a polishing technology, and the decorative patterns have good color and clear patterns, so that the brick is more similar to natural marble; and light reflection and light pollution are reduced through the brick, and broad application prospects are achieved.

Owner:肇庆乐华陶瓷洁具有限公司

Asbestos-free clutch facing used in vehicle and manufacture method therefor

InactiveCN101033786AImprove performanceHigh strengthFriction liningHeat treatedTemperature and pressure

The invention discloses a kind of none asbestos clutch facing used in cars and its production technology. The recipe of the component is that: E-glass fiber 30~50%, fragrance fiber 1~4%, polyacrylonitrile fiber 0.6~1.2%, the oil of cashew shell friction-type mix 3~6%, oil coke blacking 3~5%, particle graphite 5~8%, zinc oxide 0.2~1%, calcium sulfate 5~15%, heavy calcium carbonate 10~20%, flour acrylonitrile butadiene rubber 15~25%, anti-aging protective TMQ 0.2~0.5%, curing accelerator MBTS 0.2~0.5%, the oil of cashew shell resin modified 6~12%. Banburying mix the component told above in proportions at the proper temperature then make up pellicle by smelting and at last rolls in with the E-glass fiber then forms different ordinance blanks by winding. The blanks confect by heat pressing at the proper temperature and pressure then make into production by grinding and drilling holes. It has the merits like that: high strength, good ductility and stabilize coefficient of friction and so on.

Owner:福建冠良汽车配件工业有限公司

Thermal-sublimation water-based intaglio printing ink and preparation method thereof

InactiveCN102585606AGood storage stabilityClear patternTransfer printing processInksOrganic solventPolymer science

The invention discloses thermal-sublimation water-based intaglio printing ink and a preparation method thereof. The thermal-sublimation water-based intaglio printing ink is composed of components in percentage by weight: 15-35% of disperse dye size, 24-50% of an N-vinylamide-acrylic ester copolymer emulsion, 0.3-2.5% of a thickening agent, 0.1-2% of an antifoaming agent, 0.1-3% of a neutralizer, 0.1-0.5% of a preservative and 10-42% of de-ionized water. The thermal-sublimation water-based intaglio printing ink has high heat resistance; and transferred printing paper is not adhered to a cloth material in a transfer printing process. The thermal-sublimation water-based intaglio printing ink also has excellent storage stability; patterns printed on various transferred printing paper are clear; the printing patterns transferred onto dacron, nylon cloth material and textile have clear profiles without any friction ghosting and transfer ghosting and are bright in color; and color fastness complies with wearing requirements. The thermal-sublimation water-based intaglio printing ink has no any toxic organic solvent residue, can be diluted with water and is good for safe production and environment protection.

Owner:SUN YAT SEN UNIV +1

Novel floor and manufacturing method thereof

The present invention is one new type of floor board and its production process. The floor board is produced with calcite powder or limestone powder, granular waste PVC plastic, PVC resin and dibutyl ester or dioctyl ester in certain weight proportion, and through drying in a drying apparatus for 5-7 min, adding paraffin, stearic acid and other assistants in certain amount into the drying apparatus and drying for other 10-15 min, pelletizing in a pelletizer, extruding into hollow or solid floor board base in a floor board forming machine, cooling, cutting, blocking hole, tenoning, polishing, dedusting, and adhering floor film. The floor board has clear patterns, and is waterproof, fireproof and environment friendly.

Owner:吕富

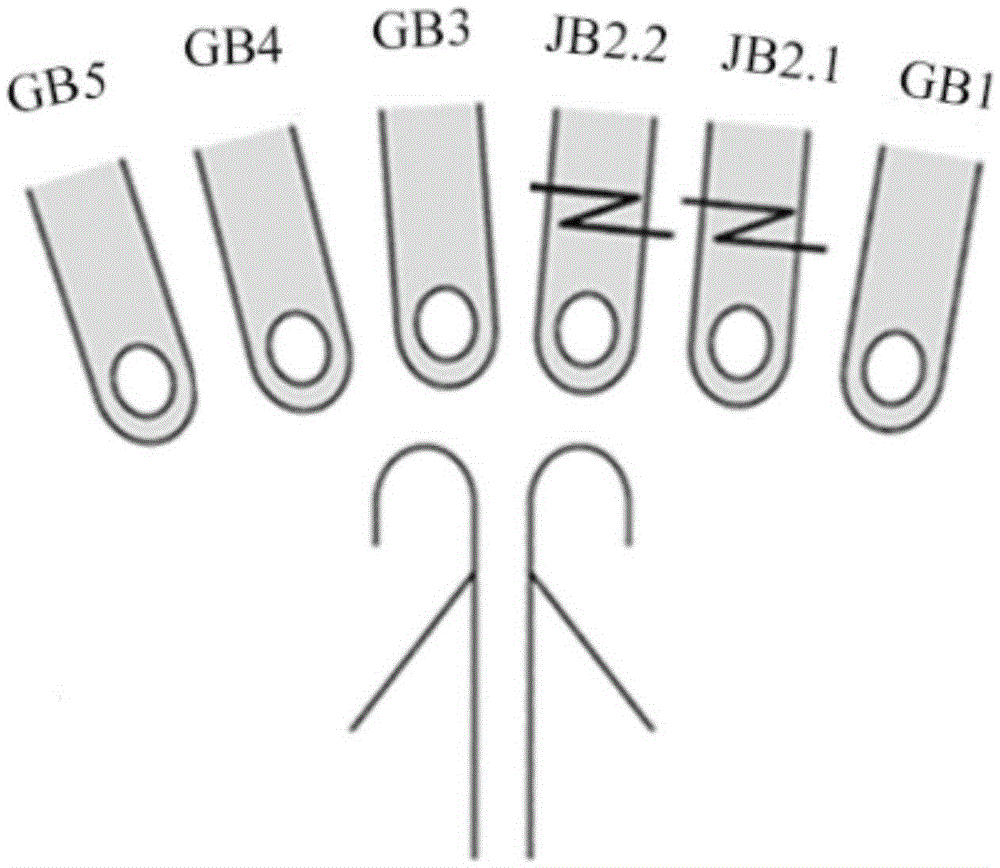

Production method of two-needle bed baseless jacquard sandwich fabric

ActiveCN105386230AIncrease elasticityClear patternOrnamental textile articlesWarp knittingEngineeringBed sheets

The invention relates to a production method of a two-needle bed baseless jacquard sandwich fabric. The production method is characterized by comprising the following steps that 1, a pattern of the baseless jacquard sandwich fabric is determined; 2, guide bars of a two-needle bed single jacquard warp knitting machine sequentially comprise two half-gauge front needle bed jacquard guide bars, an interval yarn guide bar and two back needle bed ground guide bars; the front needle bed jacquard guide bars penetrate into jacquard yarn, the interval yarn guide bar penetrates into interval yarn, and the back needle bed ground guide bars penetrate into back needle bed ground yarn; 3, in the weaving process, the two jacquard guide bars conduct symmetrical reversed yarn laying to form a jacquard surface fabric, the back needle bed ground guide bars conduct yarn laying and looping on back needle bed to form a base layer fabric, yarn laying and looping are conducted on the interval yarn alternatively on the front needle bed and the back needle bed to connect the jacquard surface fabric with the base layer fabric, and the baseless jacquard sandwich fabric is obtained. According to the production method of the two-needle bed baseless jacquard sandwich fabric, the baseless jacquard sandwich fabric which is rich in pattern, light, thin and good in stability can be obtained.

Owner:JIANGNAN UNIV

High air permeability non-woven base wallpaper and products thereof

The invention discloses high air permeability non-woven base wallpaper. The traditional non-woven wallpaper has the defects of insufficient flexibility, poor paper surface third dimension and lower opacity. The high air permeability non-woven base wallpaper comprises the following components in percent by mass of 20-72 percent of plant fiber, 10-40 percent of non-plant fiber, 10-30 percent of pigment, 2.5-10 percent of adhesive and 0.1-1.5 percent of chemical addition agent, wherein the mass percent of the components is 100 percent in sum; the plant fiber contains chemical wood pulp, the non-plant fiber contains chemical fiber, and the pigment contains at least one inorganic pigment or organic pigment with covering function. The non-woven wallpaper contains the long fiber, can be directly printed, and has the advantages of high air permeability, natural grains in paper surface, soft hand feel of finished paper, good processing property, better shape stability, good printing effect, rich color, clear pattern and strong three dimension.

Owner:ZHEJIANG WINBON SPECIALTY PAPER +1

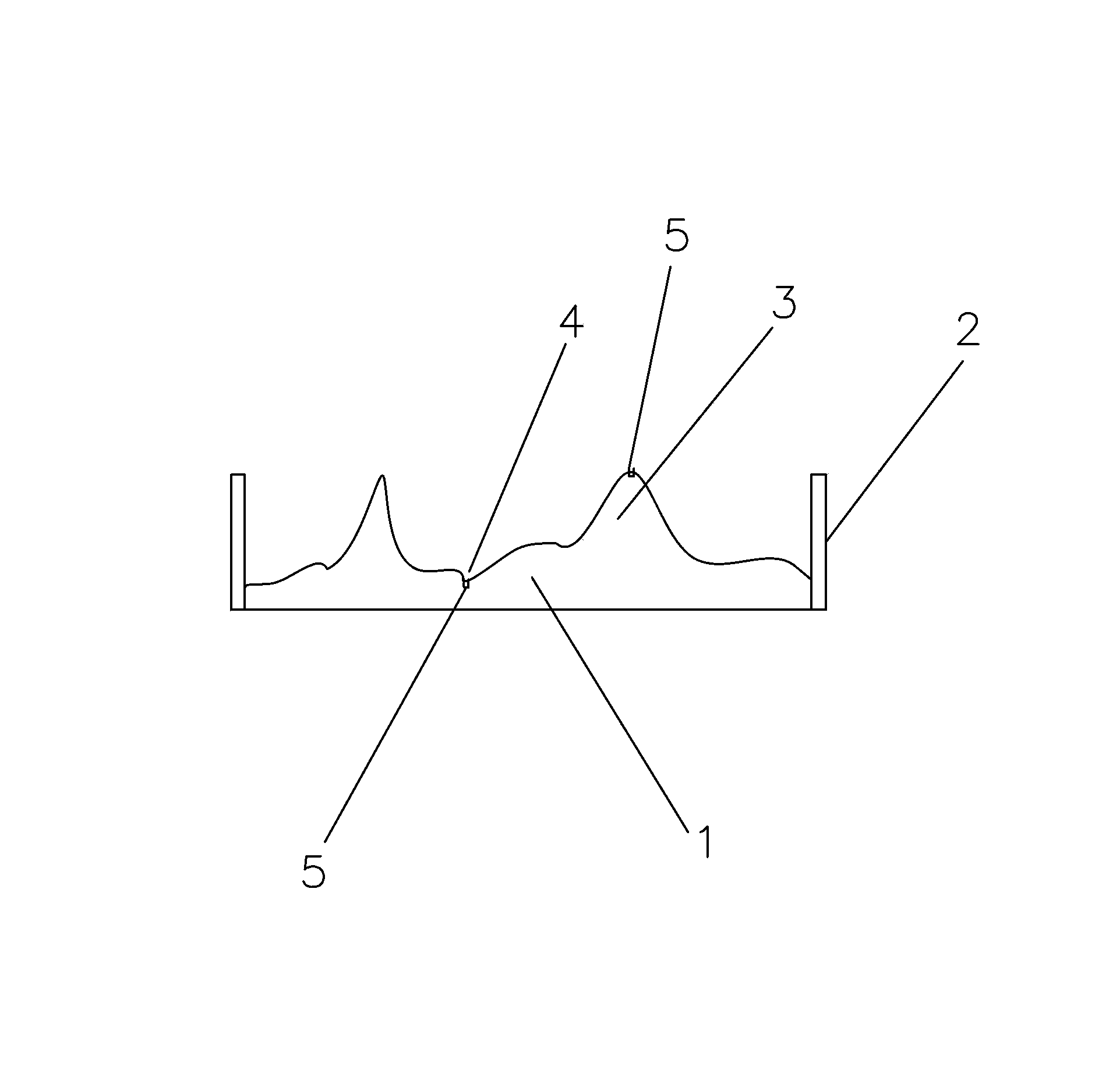

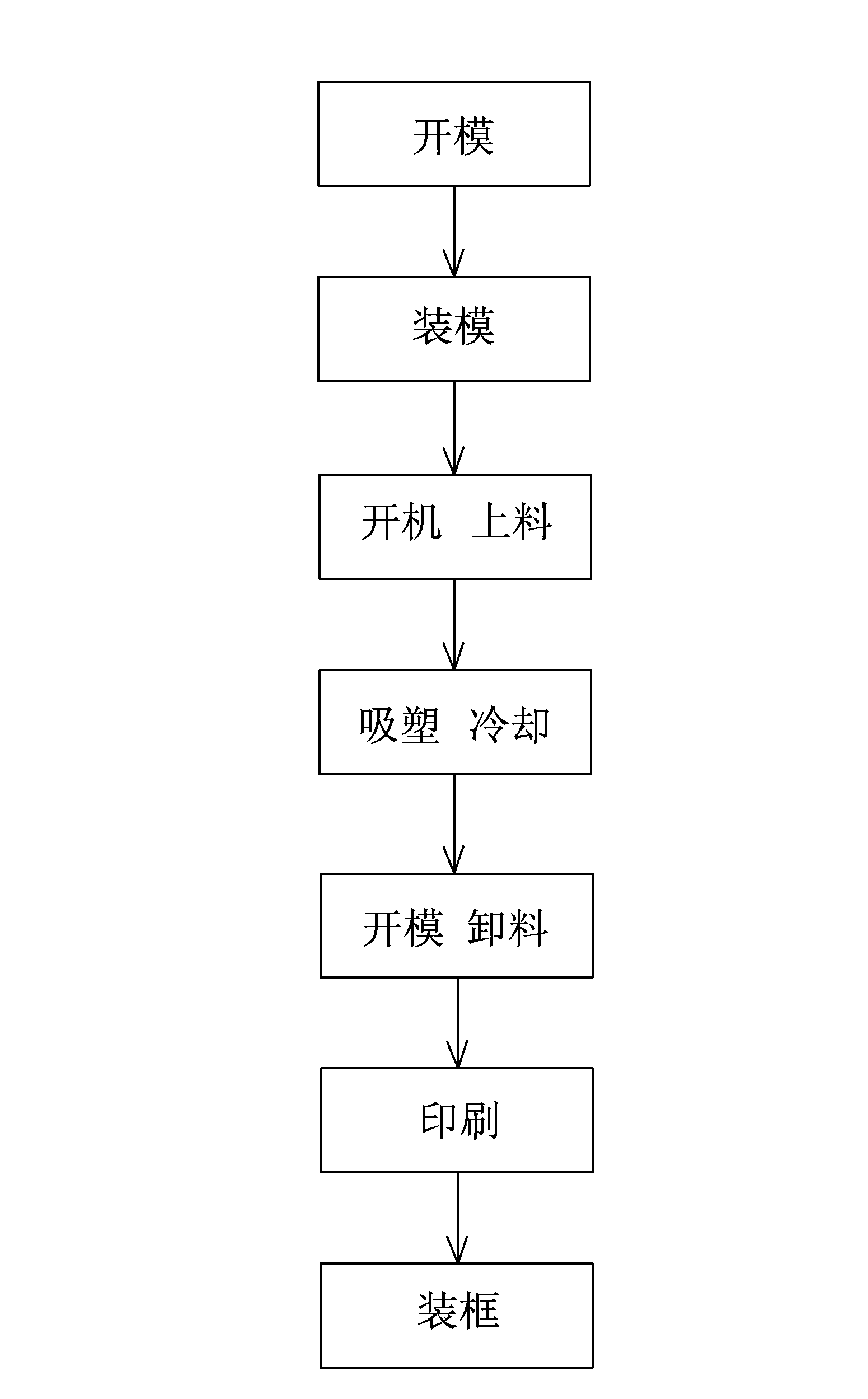

Three-dimensional topographic map model and forming process thereof

InactiveCN103390368AStable structureExtended service lifeEducational modelsPlastic forming machineTopographic map

The invention discloses a three-dimensional topographic map model which comprises a three-dimensional topographic map model body and a framework. The three-dimensional topographic map model body is made of plastic materials and formed in an integrated mode, and different colors are printed on the surface of the three-dimensional topographic map model body to distinguish different altitudes. The framework is of a rectangular structure, and the three-dimensional topographic map model body is arranged in the framework. Due to the facts that the three-dimensional topographic map model body is made of the plastic materials and formed in the integrated mode and the different colors are printed on the surface of the three-dimensional topographic map model body to distinguish the different altitudes, the three-dimensional topographic map model is firm and durable, and attractive in appearance. According to the forming process of the three-dimensional topographic map model, mould opening is carried out according to the shape of the three-dimensional topographic map model, the three-dimensional topographic map model is plastic molded in an integrated mode through a mould of a plastic forming machine instead of a manual splicing method, therefore, firmness of the three-dimensional topographic map model is improved, meanwhile, production efficiency is improved, and manufacturing cost is saved.

Owner:苏州育龙科教设备有限公司

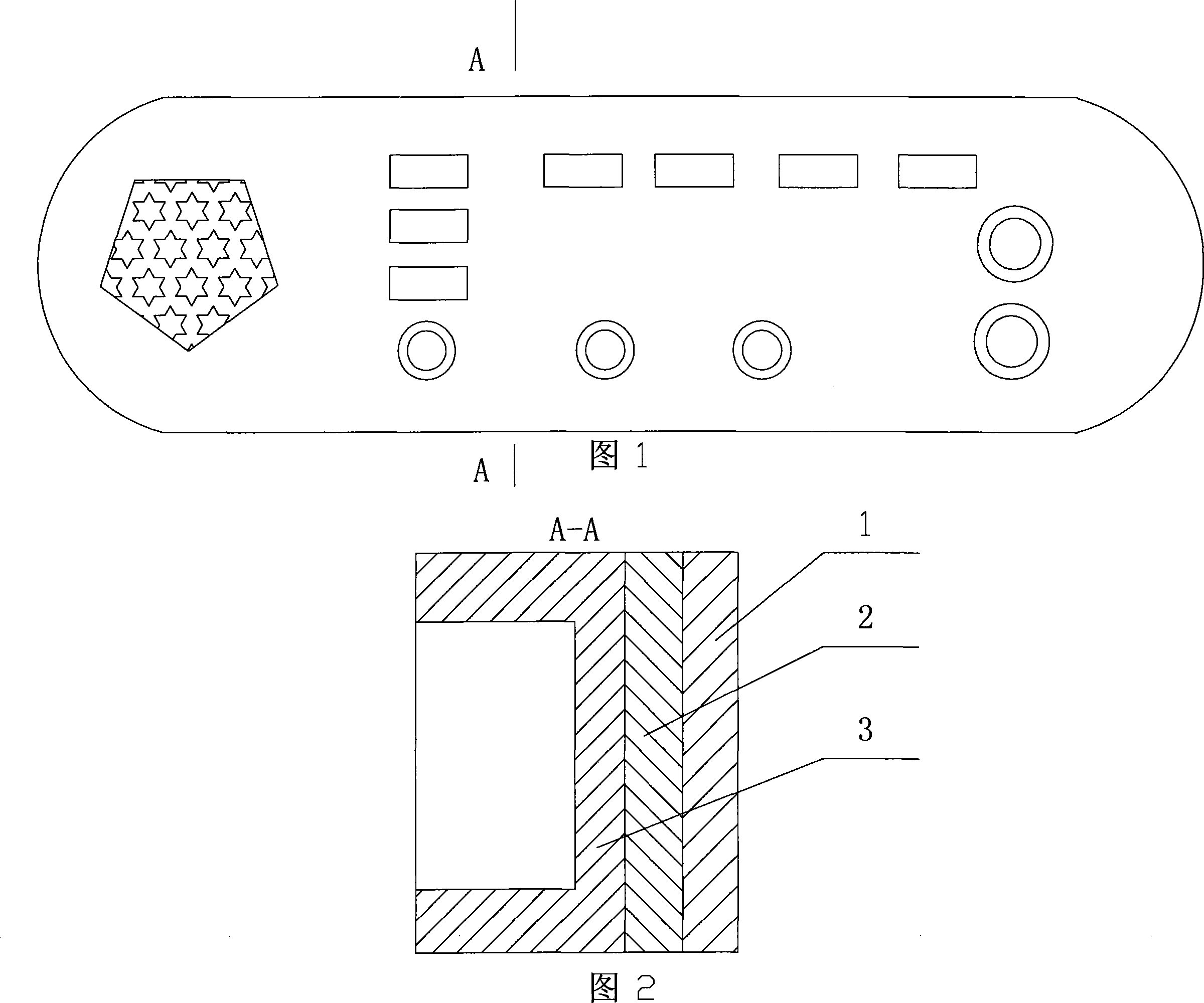

Manufacturing method of glasses rack sheet material

ActiveCN102478716AClear patternPattern wear-resistantLamination ancillary operationsCellulosic plastic layered productsLiquid stateRoom temperature

The invention relates to the technical field of glasses rack sheet material and especially relates to a manufacturing method of a glasses rack sheet material. The manufacturing method comprises the following steps: (1) preparing at least two layers of raw material of the glasses rack sheet material, wherein at lest one raw material layer has patterns; (b) piling the raw material layers prepared in the step (a) in an enclosed die successively and heating the die to 180-250 DEG C under vacuum condition to melt each raw material layer into liquid state and form layered slurry during heating of the die; (c) disposing the die treated in the step (b) into a refrigeration machine, cooling the die to 50-65 DEG C, taking out the die from the refrigeration machine for standing and cooling the die to a room temperature to coagulate each raw material layer into glasses rack sheet material; (d) cutting and processing the glasses rack sheet material prepared from the step (c). The manufacturing method of the present invention is simple, easily operated and with a short manufacturing period; the prepared glasses rack sheet material has intelligible pattern and wear resistance.

Owner:重庆丽海眼镜有限公司

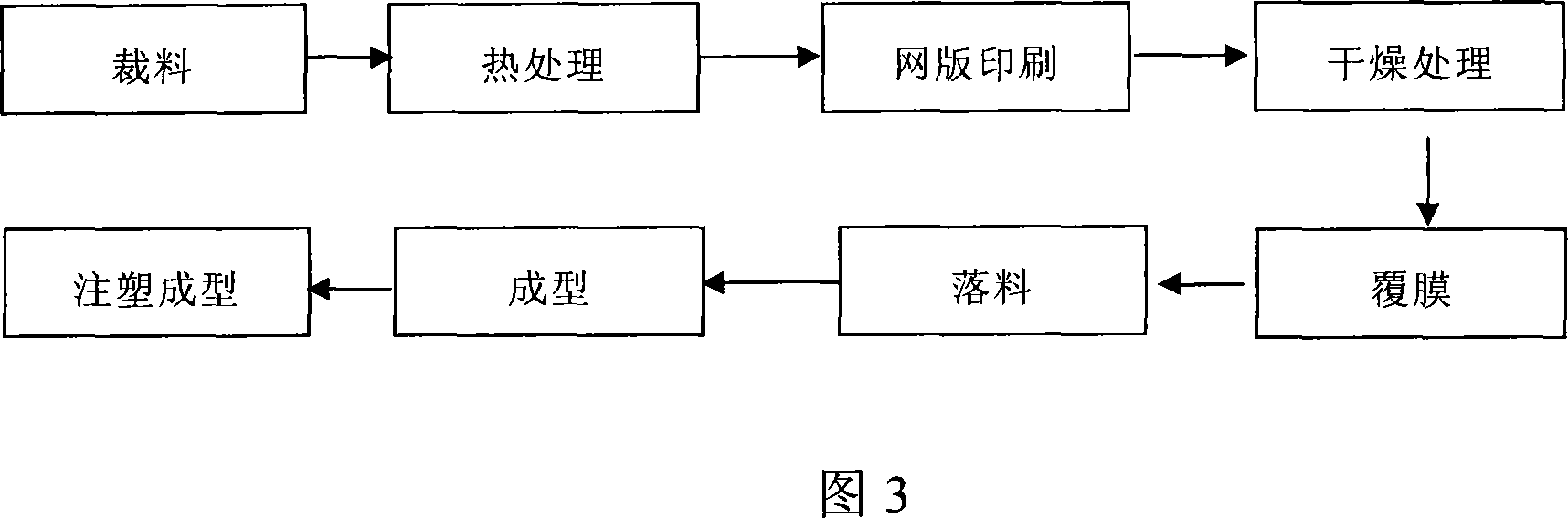

Surface decoration and process for making the same

InactiveCN101200156ABulb uniformAvoid cumbersome stepsSynthetic resin layered productsSpecial ornamental structuresScreen printingGraphics

The invention relates to a surface decoration piece (IMD) and the production process of the surface decoration piece, which is in particular widely used in the information technology products, household appliances, electronic products, personal computers, car accessories and so on and belongs to the technical field of injection molding decoration. The invention is characterized in that the screen-printing of ink patterns is adopted on the reverse side of a transparent sheet. The ink pattern is disposed between the injection molding layer sheet and the formed transparent sheet, which is integrated through the drying, cutting, molding and the injection molding. With the invention, the production time can be shortened and the costs can be reduced with the improvement of product quality and the enhancement of the scratch resistance of the products. With strong solvent resistance, excellent three-dimensional sense, the patterns are clear with excellent anti-light and moisture proof performance. The graphic, logo and color can be changed at any time without the need to replace the die. The convex bubbles of the function keys are uniform with good feel, in which the life expectancy can be up to one million times. The printing precision of the products with three-dimensional shapes is accurate and the error is small.

Owner:无锡市红光标牌有限公司

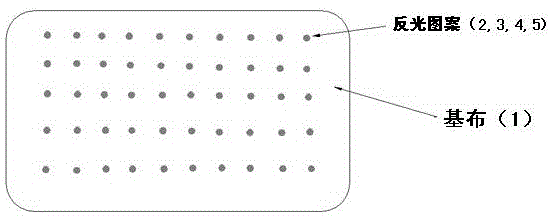

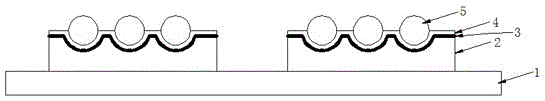

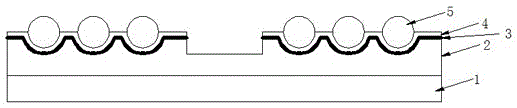

Fancy reflective fabric and production method thereof

ActiveCN105286146AClear patternHas a warning effectLamination ancillary operationsPolyureas/polyurethane adhesivesEngineeringTextile

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

Antifreezing speed-sealing film and preparation method thereof

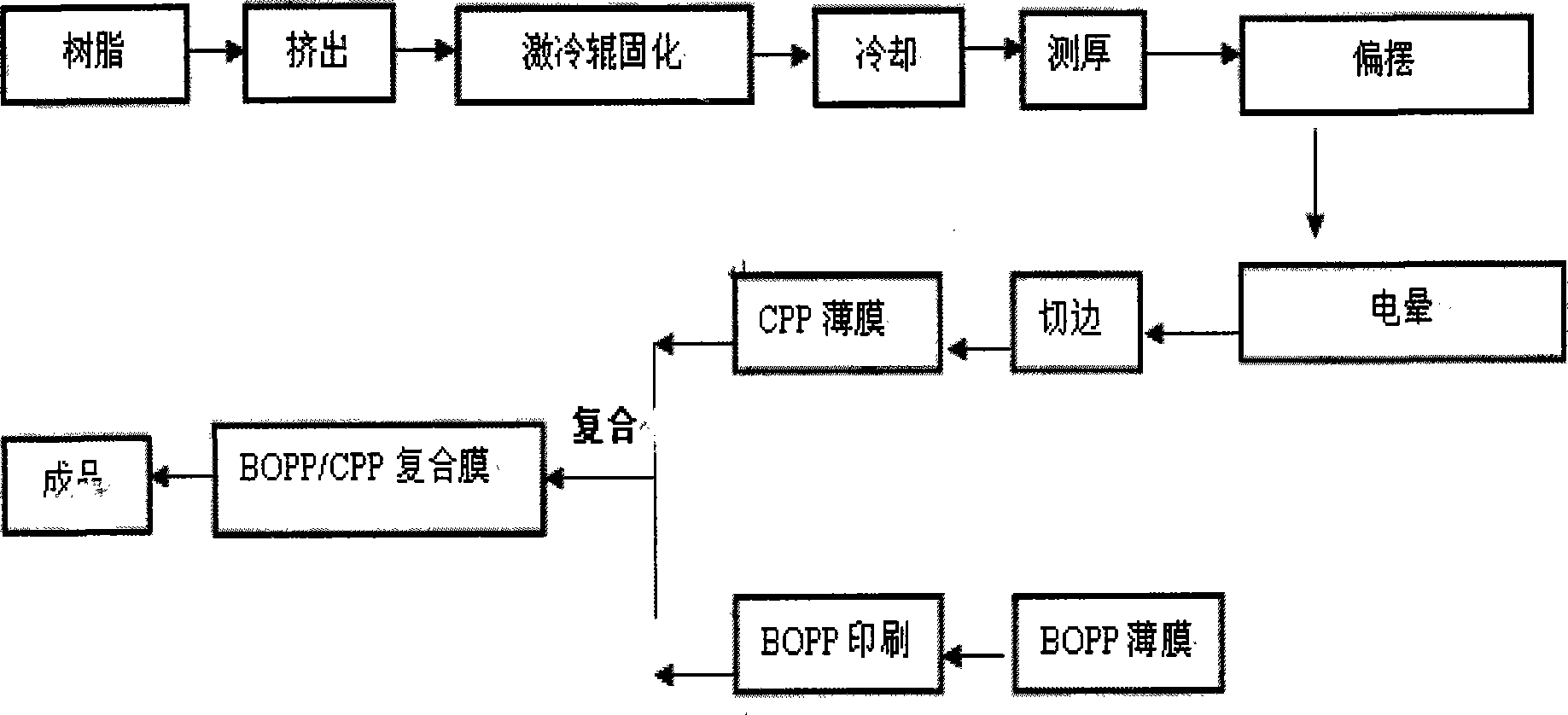

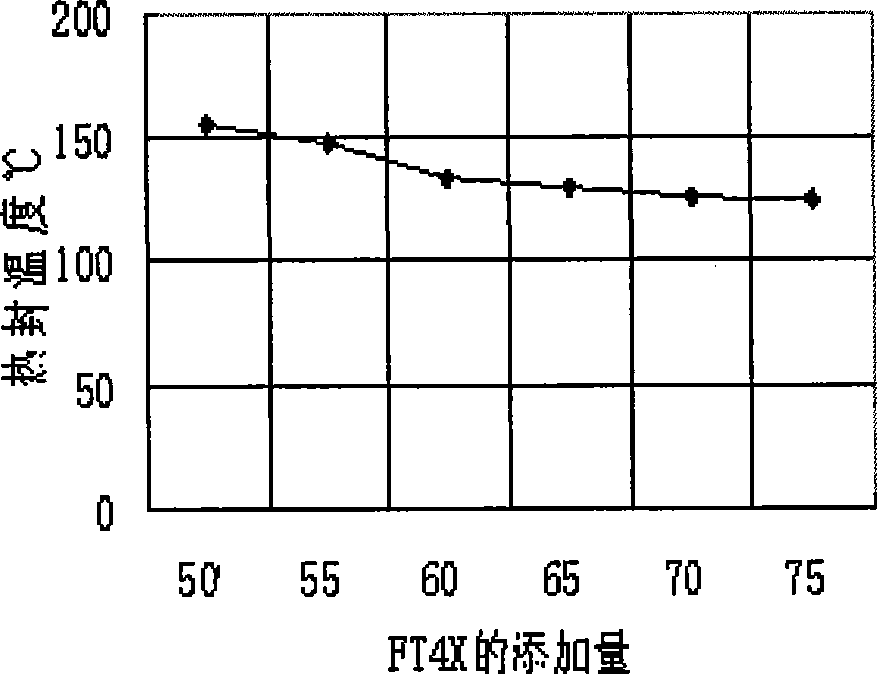

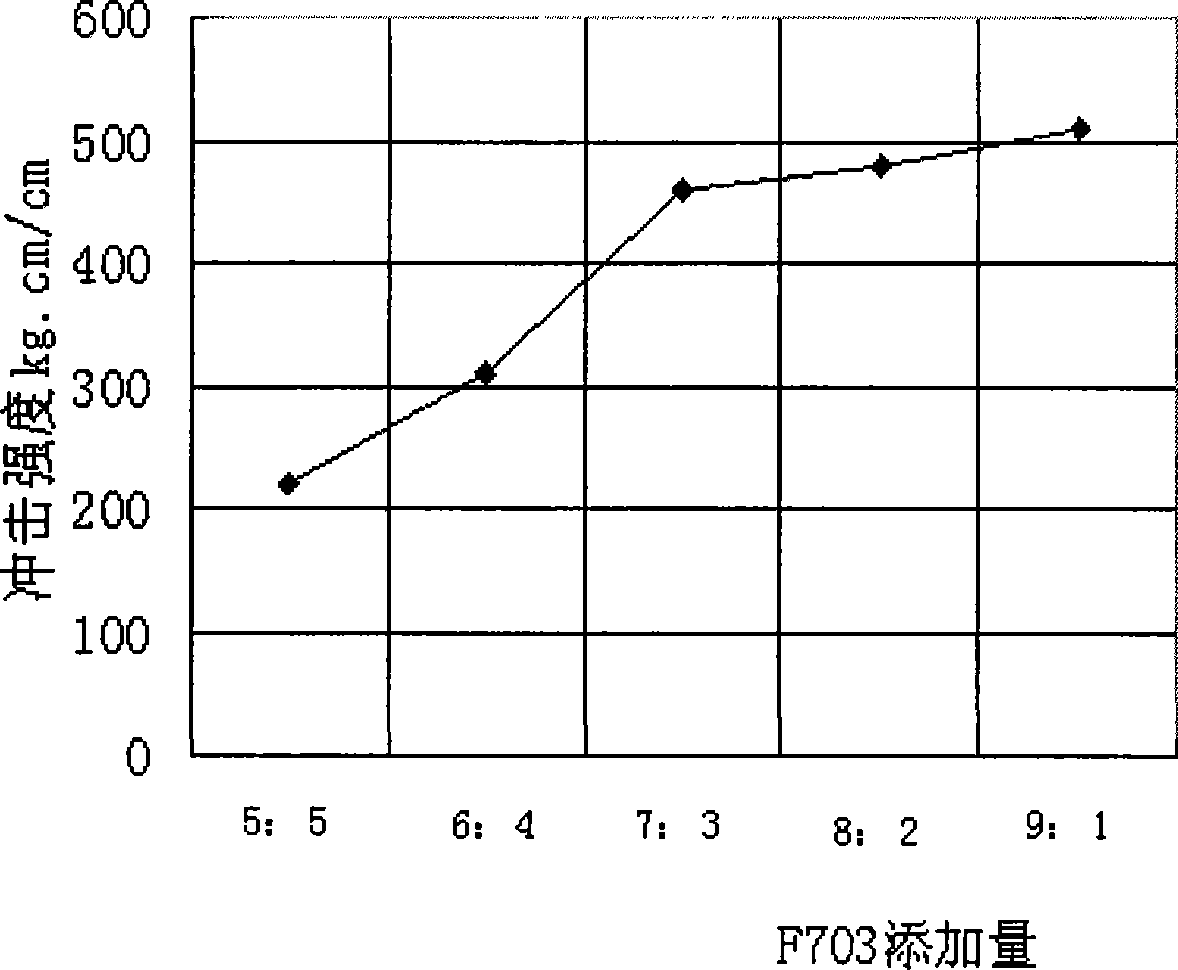

The invention discloses an anti-freezing film capable of being quickly sealed and a preparation method thereof. The film is formed by composition of biaxial tension polypropylene and a polypropylene film, wherein the polypropylene film consists of a corona layer, an intermediate layer and a heat-sealing layer; the heat-sealing layer comprises metallocene three-element blocking polypropylene, an ethylene elastomer, an antitackiness agent and a slip agent the weight ratio of which is 50-86.5: 18-20: 1-2: 1-1.5. The preparation method comprises the following steps in turn: a step of extrusion, a step of solidifying a sharp cooling roller, a step of cooling, a step of thickness measurement, a step of corona, a step of swing, a step of edge cutting, a step of composition of BOPP and CPP and a step of forming a spiral-wound film through cutting. Compared with the prior art, the anti-freezing film capable of being quickly sealed has the characteristics of good anti-freezing property, cold resistance and mechanical performance, obvious shock resistance effect and penetration resistance effect, low initial sealing temperature, short heat-sealing time and high sealing intensity, and is suitable for a modern quick automatic packaging unit.

Owner:HUANGSHAN NOVEL

Method for processing coloured foreign fiber burnt-out fabric

InactiveCN101440551AClear patternStrong three-dimensional senseDouble pile fabrics splittingPattern makingEngineeringBurning out

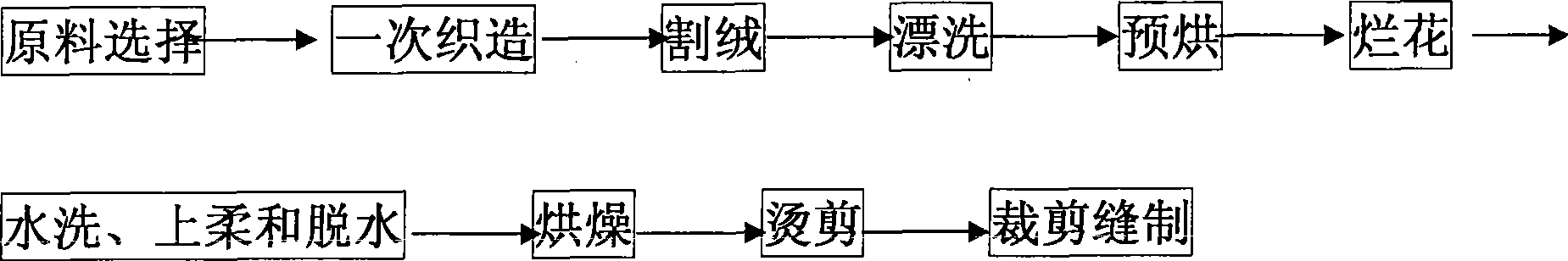

The invention provides a method for processing color foreign fiber burnt-out fabric. The method comprises the following steps: material selection; first weaving; pile cutting; rinsing; pre-drying; burnt-out print; water washing, softening and dewatering; drying; scalding-shearing; and tailoring. The method is characterized in that: the material selection comprises the selection of covering weave material and the selection of ground weave material; and, the covering weave material is frame spinning purified cotton yarn or viscose glue cotton blended yarn, and the ground weave material is colored terylene filament, wherein the colored terylene filament is 23 to 40 mass percent, and the frame spinning purified cotton yarn or viscose glue cotton blended yarn is 60 to 77 mass percent. The method has the advantages that: because the colored terylene filament is selected as the ground weave, and the frame spinning purified cotton yarn or viscose glue cotton blended yarn is selected as the covering weave, after burnt-out print, the fabrics can achieve the effects of clear pattern, reasonable three dimensional appeal and dusky gentleness; moreover, the fabrics also have good softness and ideal heat insulating ability.

Owner:CHANGSHU SHENHUA KNITTING

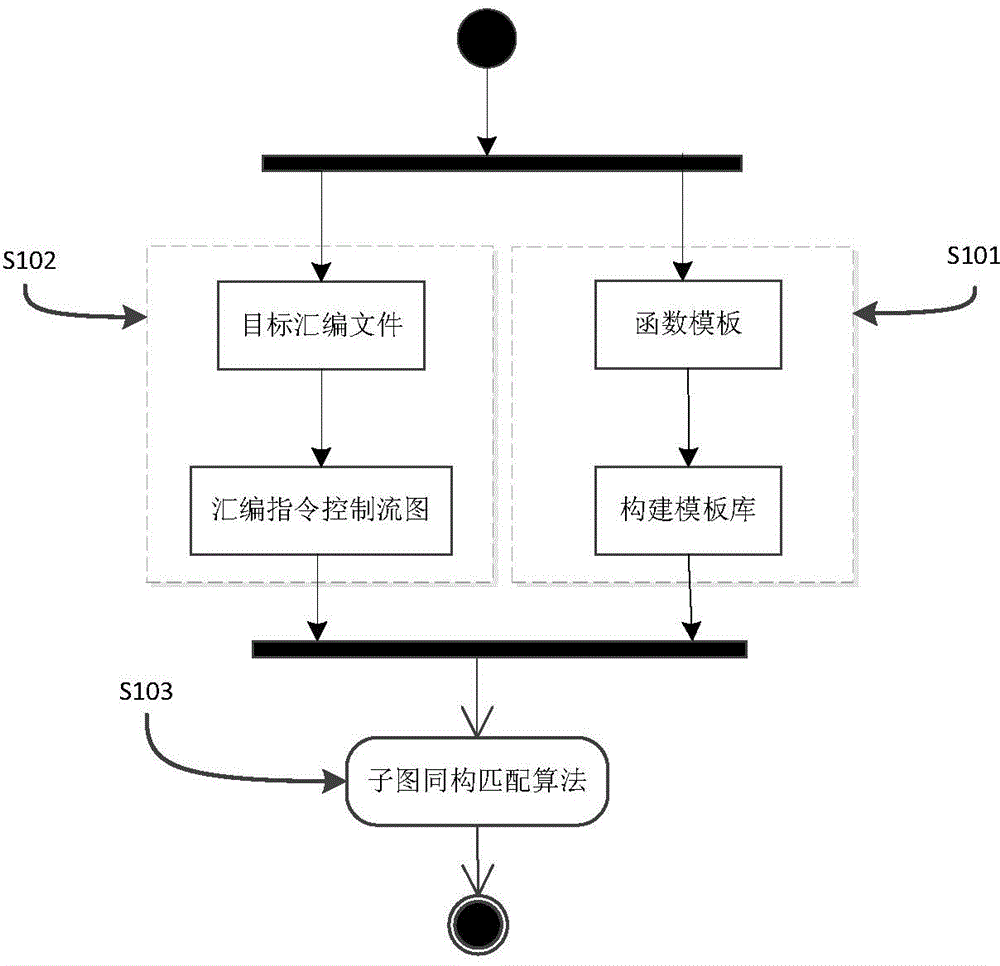

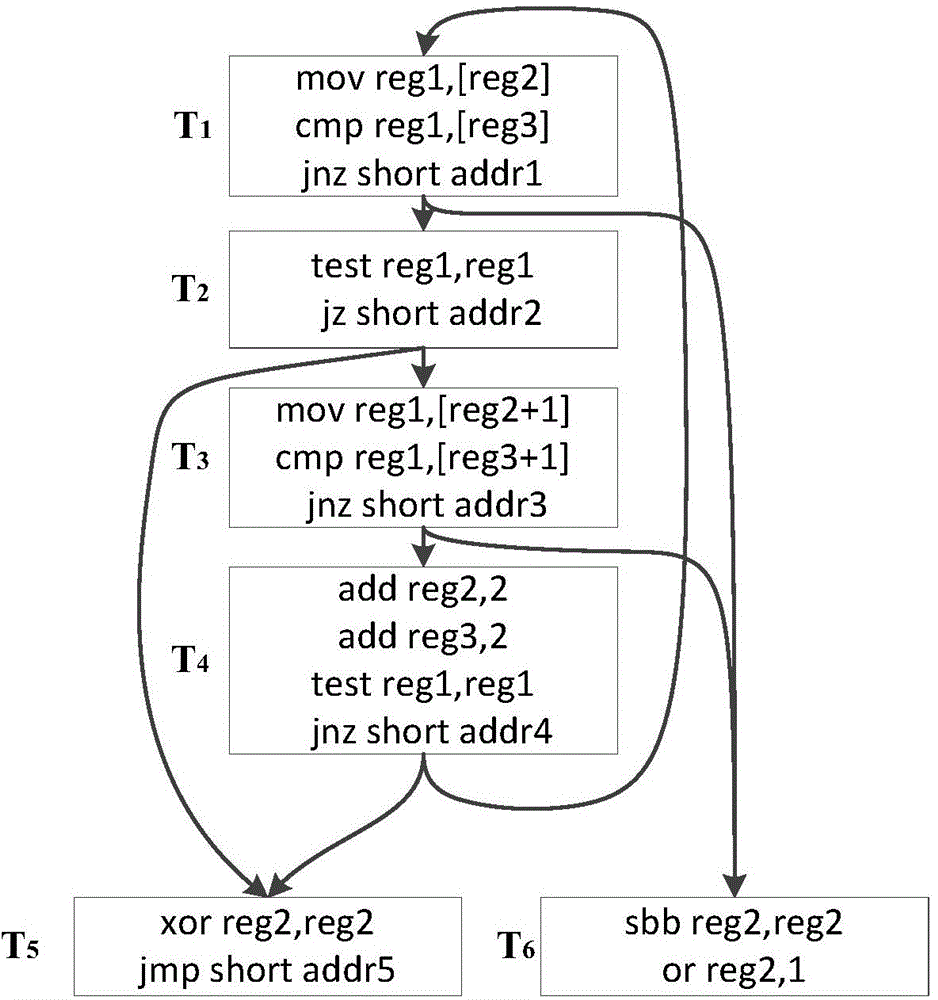

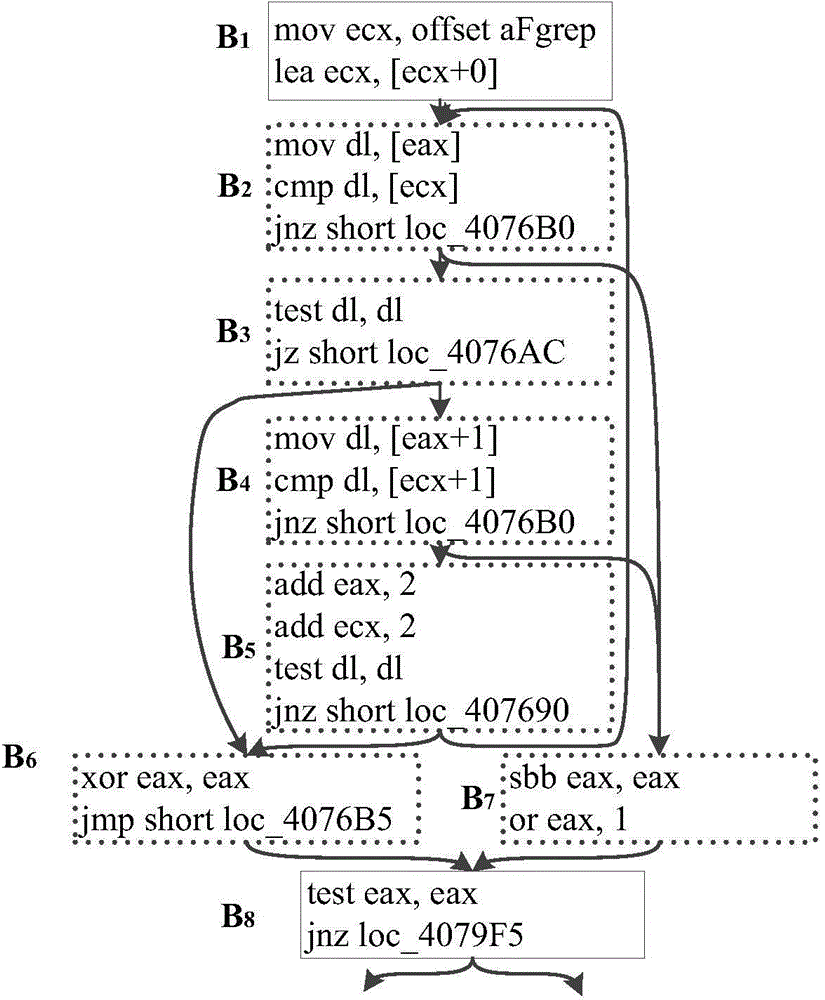

Intrinsic function recognition method based on sub-graph isomorphism matching algorithm in decompilation

InactiveCN104915211ARealize automatic identificationEfficient identificationSpecific program execution arrangementsTheoretical computer scienceInline expansion

The invention discloses an intrinsic function recognition method based on a sub-graph isomorphism matching algorithm in decompilation, and belongs to the technical field of decompilation. According to the method, an intrinsic function template library is established, sub-graph isomorphism matching is conducted on intrinsic function templates and target assembling files generated through decompilation on the basis of a control flow diagram, and intrinsic functions which are subjected to compiler optimization and inline expansion in target programs of the target assembling files are positioned. According to the intrinsic function recognition method, inline intrinsic functions in the decomplation process can be recognized automatically, meanwhile, the templates and prototypes of the intrinsic functions are analyzed, the function names, returned values, returned value types and function parameters of the intrinsic functions are recovered, and thus the purpose of promoting the semantics of the inline intrinsic functions is achieved. More type information is provided for type analysis in decompilation through the promoted inline intrinsic functions, the complexity of data flow analysis and control flow analysis is lowered, the level of abstraction of intermediate codes is improved, and the readability of decompilation results is enhanced.

Owner:XI AN JIAOTONG UNIV

Flashing light wool-simulating hemp-simulating surfacing material and process technique thereof

InactiveCN101109125AImprove comfortSpecial glossHeating/cooling textile fabricsDyeing processPolyesterPolymer science

The invention discloses a sparkling fur- / hemp-imitated shell fabric and the processing process for the shell fabric. Wherein, a warp and a weft are woven together, the warp takes blend yarn of bamboo fiber and polyester microfiber as raw materials, the weft uses blended yarn of sparkled and various color from modified polyester and viscose as raw materials. The invention is soft, of good drapability, highly resistant to wear, with good air permeability, resistance to static, good resilience and antibiotic property.

Owner:洪桂焕

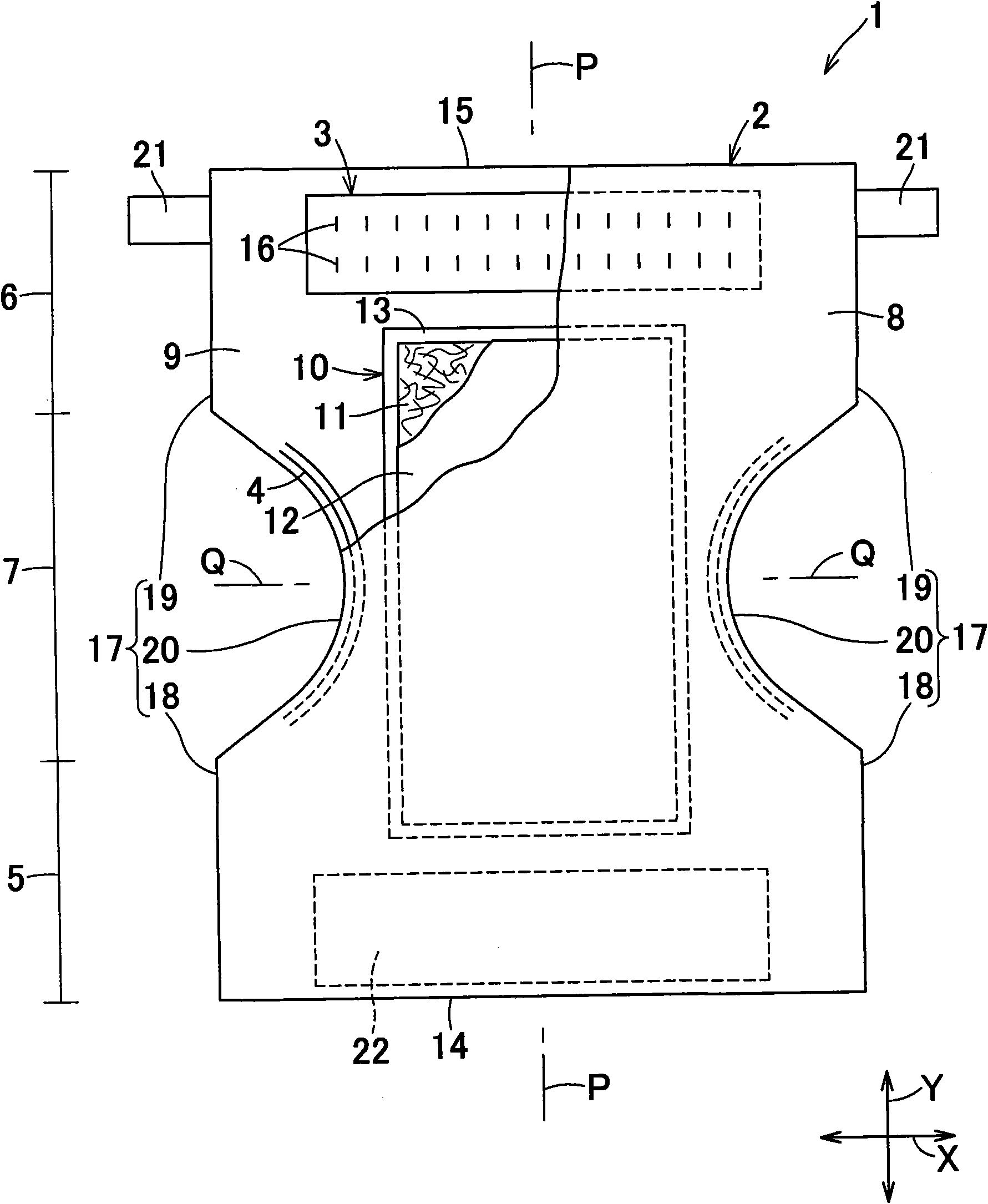

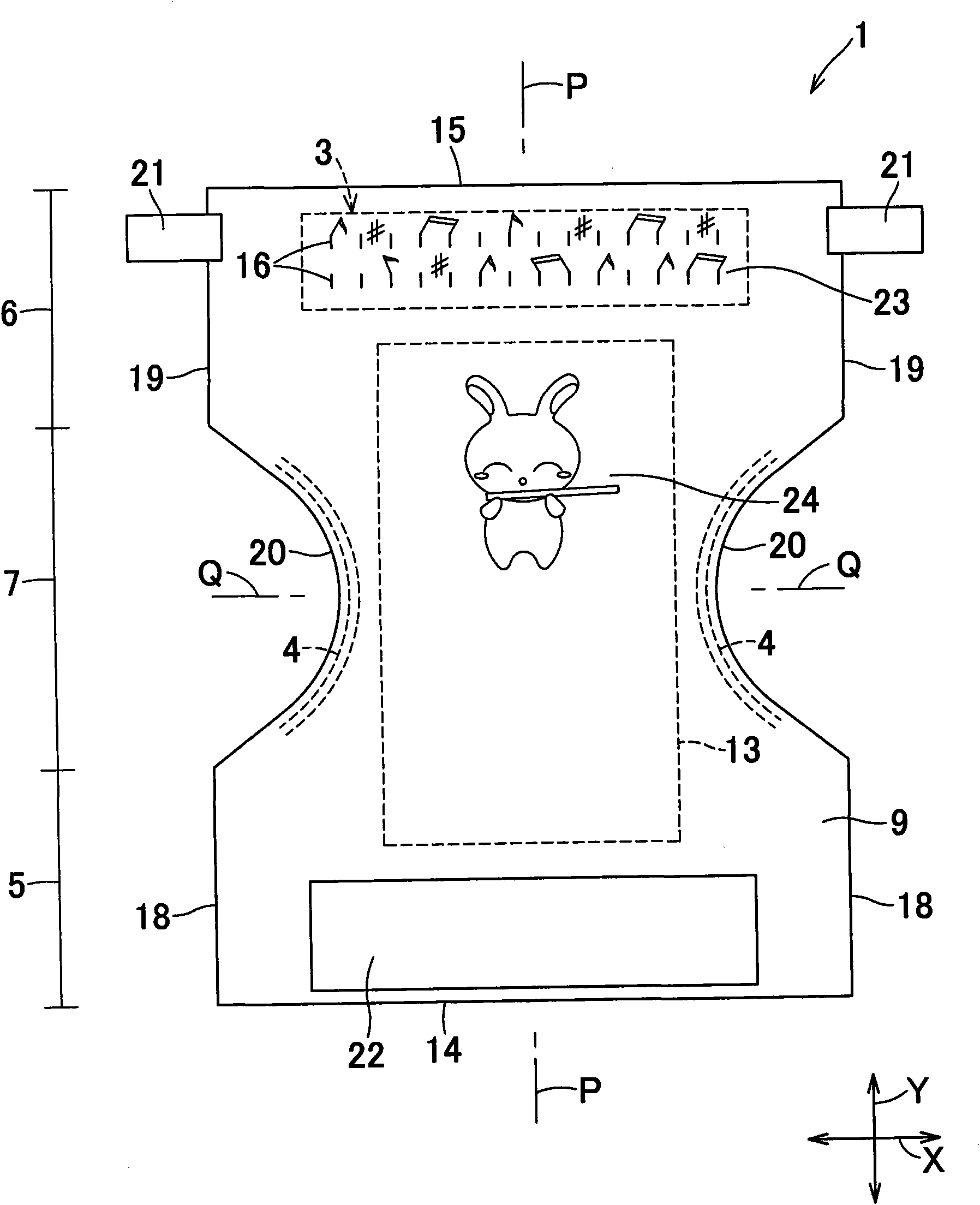

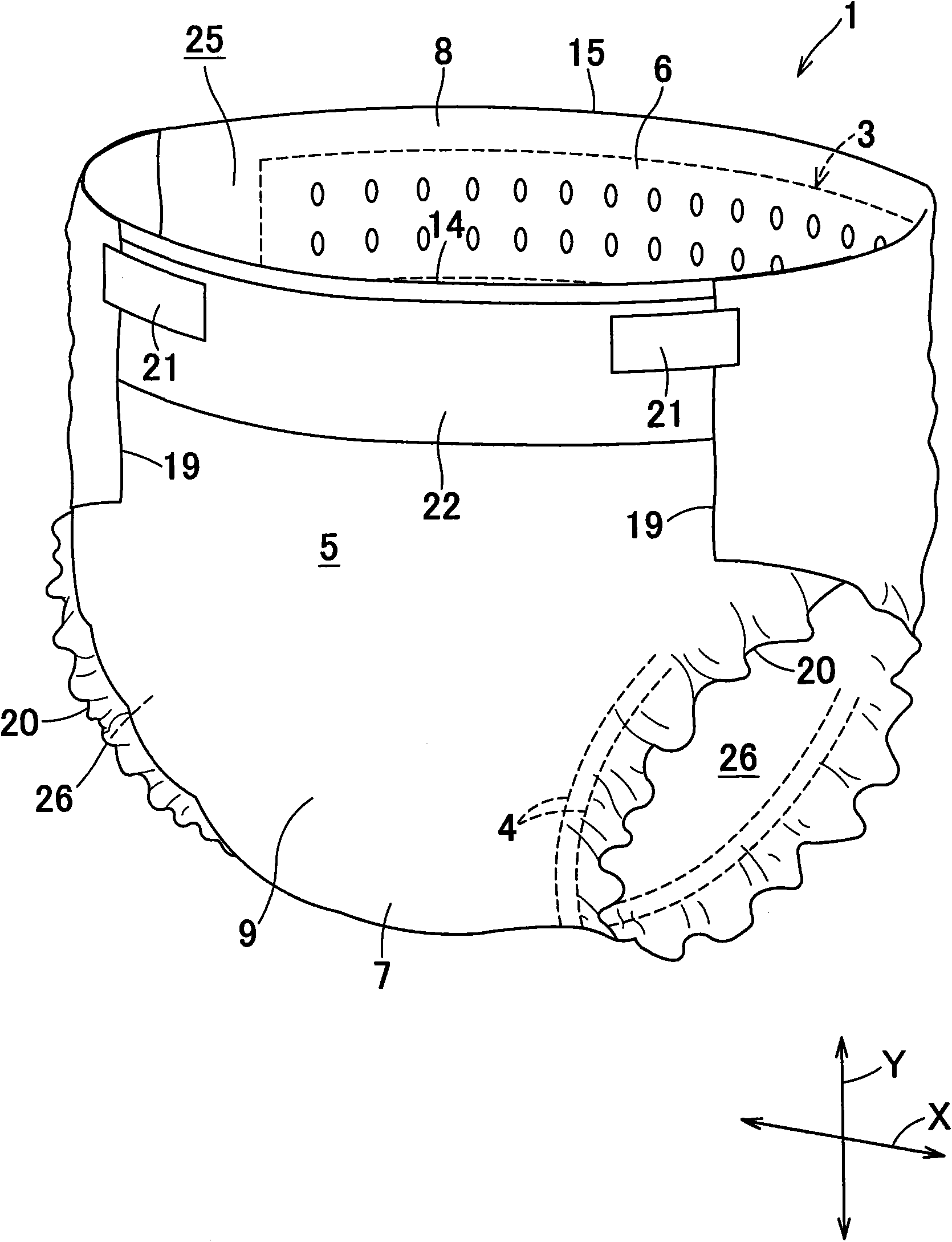

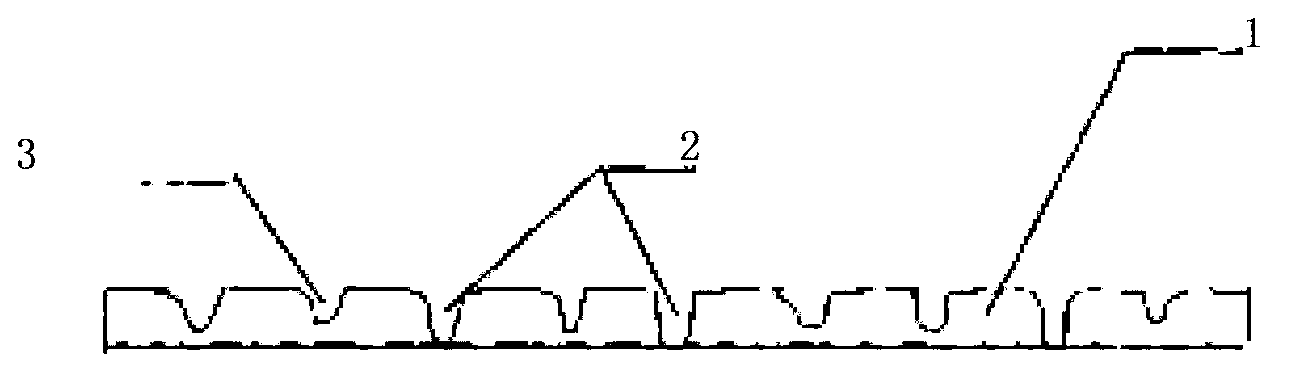

Absorbent article

InactiveCN102014823AHelp intellectual developmentFacilitate dialogueAbsorbent padsBaby linensEngineeringCrotch

An absorbent article which can make a wearer sight a changed design particularly at a diaper change. A waist elastic element (3) is set on a diaper (1) in a stretched state in a rear waist region (6) of the diaper (1), and the elastic element (3) is provided with plural slits (16) which run in the longitudinal direction (Y) and pass through in the thicknesswise direction. When the diaper (1) is worn, the waist elastic element (3) is stretched, so that the slits (16) form openings (27). In a first design area (23) present on the periphery of the slits (16), stems and tails are so printed as to fit the slits (16). When the slits (16) are widened to form the openings (27), the openings (27) are recognized as heads to form notes. In an area spread from the first design area (23) to a crotch region (7), a second design area (24) is formed and a picture of an instrument-playing character is printed in the area (24). Thus, the diaper can make a wearer feel as if the notes appearing in the first design area (23) came from the instrument.

Owner:UNI CHARM CORP

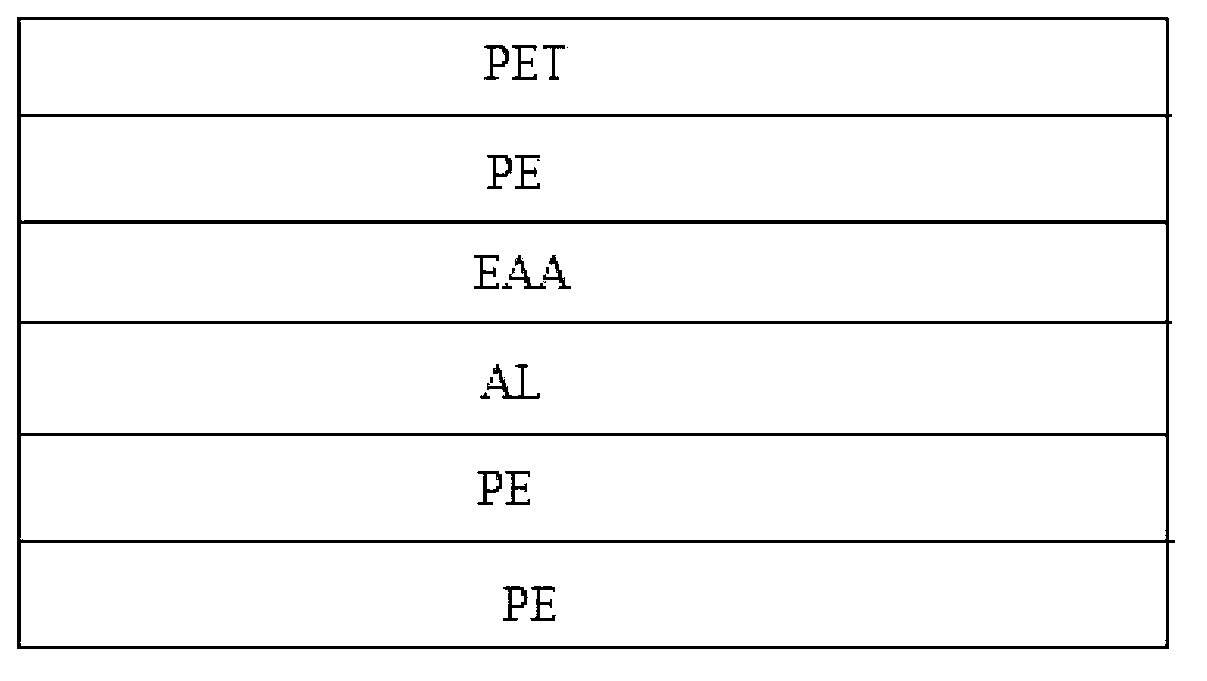

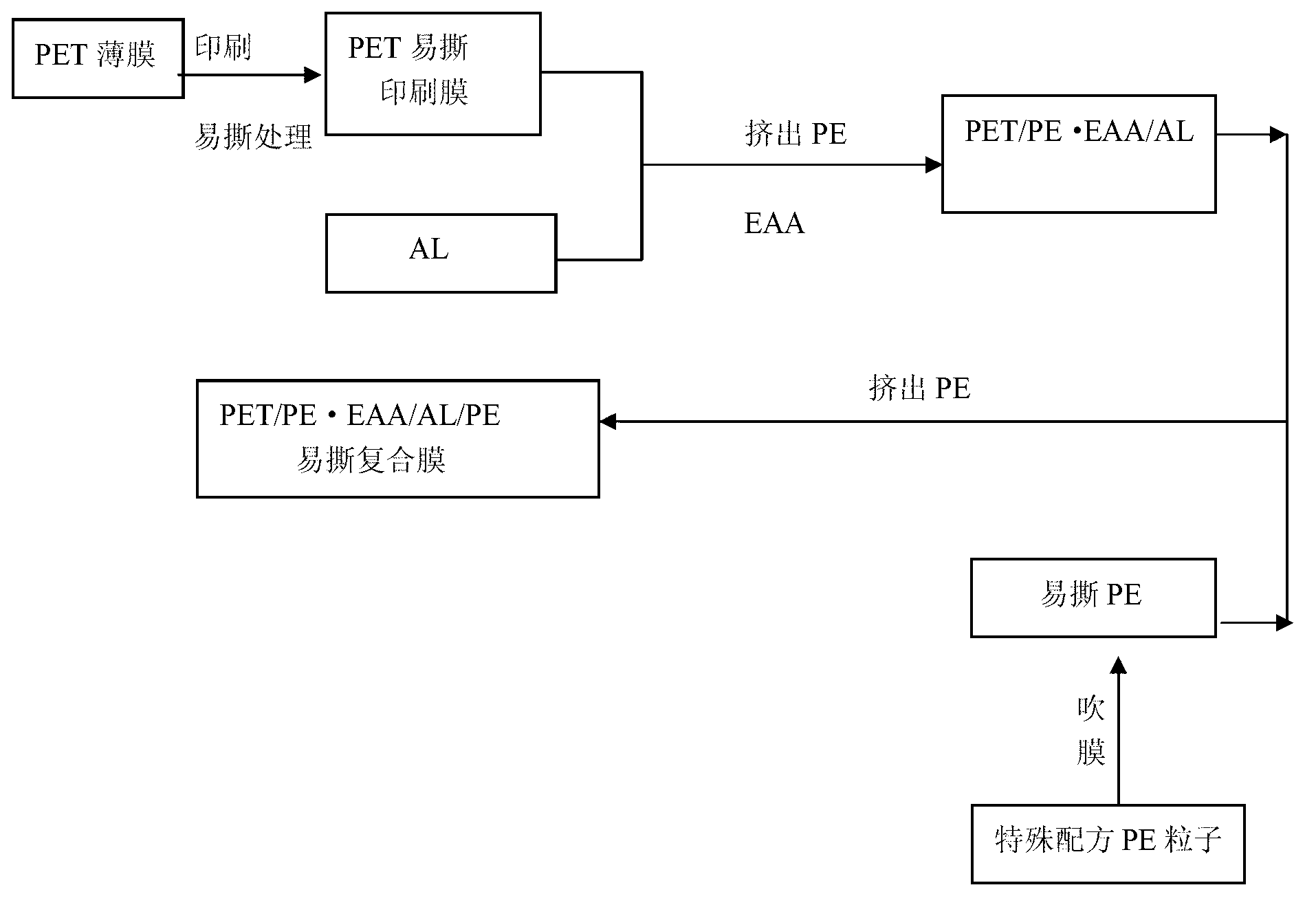

Shredded composite packaging film in arbitrary direction and preparation method thereof

ActiveCN103192564AImprove integrityIntegrity guaranteedSynthetic resin layered productsMetal layered productsEthyleneComposite structure

The invention discloses a shredded composite packaging film in arbitrary direction, and the shredded composite packaging film is of a PET / PE.EAA / AL / PE / PE (poly(ethylene terephthalate) / polyethylene.ethylene acrylic acid / aluminum / polyethylene / polyethylene) composite structure compounded by three layers of base materials with different performances. The shredded composite packaging film comprises an outer layer, PET, a first protective layer, PE.EAA, a barrier layer, an AL foil, a second protective layer, PE, an inner layer and PE. The invention further discloses a preparation method of the shredded composite packaging film in arbitrary direction. The shredded composite packaging film has the advantages of good shelf effect, excellent barrier property, strong packaging tightness without a gap, and excellent protecting effect; the grade of the product can be improved; the quality guarantee period of a packaging content can be ensured; and the packaging integrity can be kept in transporting and moving processes.

Owner:HUANGSHAN NOVEL

Method for producing patterned nano-fiber

InactiveCN101463532AEasy to useReliable process principleFilament/thread formingNon-woven fabricsZinc Acetate DihydrateFibrous layer

The invention relates to a technique adopting electrostatic spinning technology to prepare patterned nanofibre, comprising the steps: zinc acetate is dissolved in de-ionized water, and the zinc acetate solution and alcohol are slowly dripped into PVP solution under the stirring condition and stirred for two hours at the room temperature, so that zinc acetate / PVP precursor electrostatic spinning solution which is uniform and transparent is prepared and contained in a spinning solution container provided with a spray head where hemispherical solution beads are formed; the metal spray head is connected with anode of a power supply, a fiber gathering unit is placed just under the spray head and is connected with cathode of the power supply; the power supply is turned on, the voltage is increased by 20kV for 60s and then reduced, and electrified jet current is sprayed out from the spray head to form fibrous layer sediment without fixed orientation in a fiber collecting device. The technique principle is reliable, the technical process is simple, spinning quality is easy to control, patterning is clear, the spinning patterns can be flexibly selected, and the using effect of spinning cloth can be improved.

Owner:QINGDAO UNIV

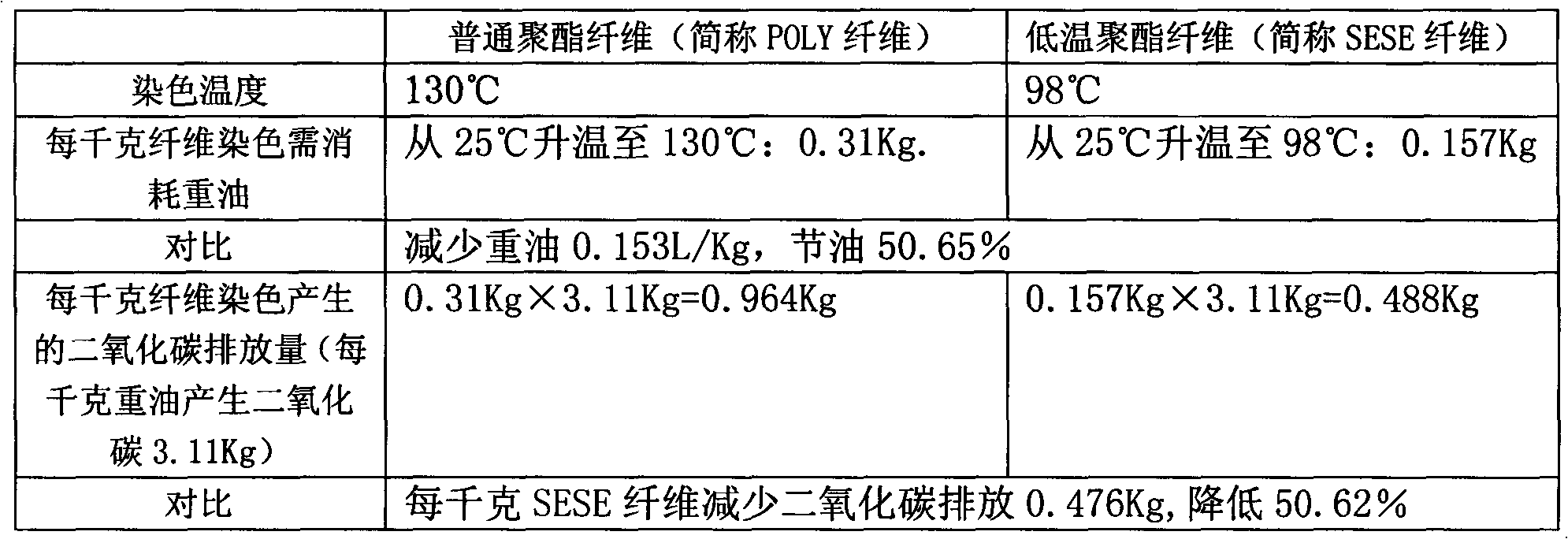

Method for producing low-temperature polyester fiber double-color strip fabric

The invention relates to a method for producing low-temperature polyester fiber double-color strip fabric. By the method, the production process flow of the strip fabric is optimized, energy resources are saved to the greatest extent and the emission of carbon dioxide is reduced. The method comprises the following steps of: 1, performing a weaving process, namely weaving grey cloth on a double-sided circular knitting machine by selecting a low-temperature polyester fiber yarn and a positive ion yarn as upper face yarns and an ordinary polyester fiber yarn as a bottom face yarn according to double-sided acrylic cloth; and 2, performing dyeing and finishing processes, namely removing oil from the grey cloth, placing in a vat, throwing disperse dye stuff and positive dye stuff in a dye vat, dyeing in a bath, raising the temperature of dye liquid in the dye vat from room temperature to between 96 and 99 DEG C, preserving temperature for 40 to 60 minutes, reducing and washing for 20 to 30 minutes at the temperature of between 60 and 80 DEG C, taking the cloth out, dewatering, drying, forming and obtaining a finished product.

Owner:佛山市妙湛纺织科技有限公司

Manual technique for fabricating blue printed true silk, and protection sgainst dyeing paste dedicated to manual blue printing

An indigo dyeing technology for the white silk fabric includes such steps as laminating 10-20 layers of tough paper with tung oil, drying in the air, fixing the 2-3 gummed plate together, drawing pattern, chiselling to become through pattern, grinding, putting the chiselled plate on white silk fabric, coating anti-dyeing slurry, drying the fabric in the sun, immersing in warm water at 30-50 deg.C for softening it, dyeing with plant indigo by immersion method, rinsing, drying and rolling. Said anti-dyeing slurry is prepared from soybean powder, lime powder, water and soybean oil.

Owner:吴莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com