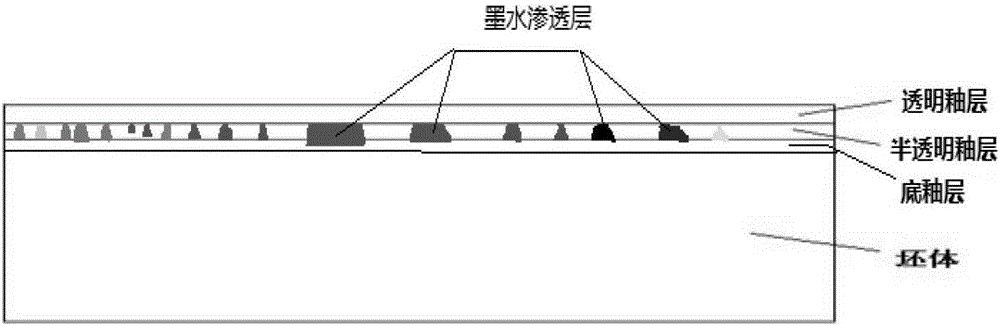

One-time sintered super-flat ink-jet penetrating porcelain tiles with three-dimensional decorative effects, and manufacturing method thereof

A technology of decorative effect and manufacturing method, which is applied in the field of manufacturing super-flat inkjet ink-bleeding porcelain tiles in one time, can solve the problems of poor three-dimensional effect, blurred patterns, color difference, etc., and achieve clear patterns and chemical corrosion resistance Strong, good anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] 1: Preparation of bottom glaze: In order to match the color development of ordinary ceramic ink, calcium, magnesium, barium and other raw materials are not added to the glaze slurry. Its formula is as follows: 41 parts of potassium feldspar, 14 parts of albite, 10 parts of kaolin, 10 parts of burnt clay, 8 parts of alumina, 5 parts of quartz, 10 parts of zirconium silicate, additive A: 0.5 parts, additive B: 4 parts. The chemical composition analysis of additive A is SiO 2 2.01%, Al 2 o 3 2.89%, Fe 2 o 3 0.03%, TiO 2 93.05%, CaO0.03%, MgO0.09%, K 2 O0.02%, Na 2 O0.06%, balance is 1.35% impurity. The chemical composition analysis of Additive B is SiO 2 94.41%, Al 2 o 3 0.14%, Fe 2 o 3 0.05%, TiO 2 0.05%, CaO0.08%, MgO0.06%, K 2 O0.04%, Na 2 O0.21%, balance is 4.59% impurity. The chemical composition analysis of the bottom glaze is SiO 2 56.5%, Al 2 o 3 24.6%, Fe 2 o 3 0.23%, TiO 2 0.66%, CaO0.32%, MgO0.17%, K 2 O4.7%, Na 2 O2.6, ZrO6.4%, the bala...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com