Terylene camouflage waterproof cloth

A polyester cloth and camouflage technology, applied in the chemical industry, can solve problems such as balling, easy fluffing, poor cohesion, etc., and achieve the effects of wide application fields, good elasticity, good light aging resistance and hydrolysis stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

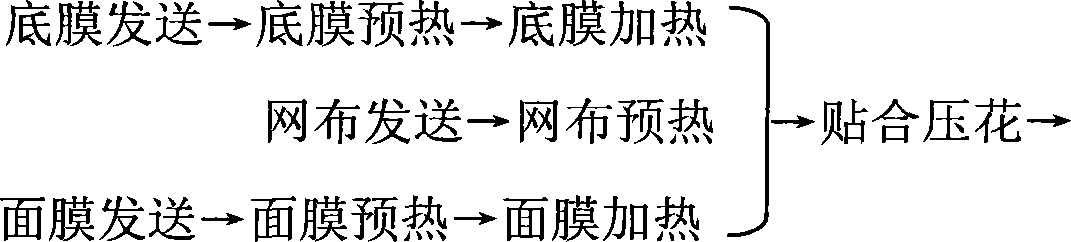

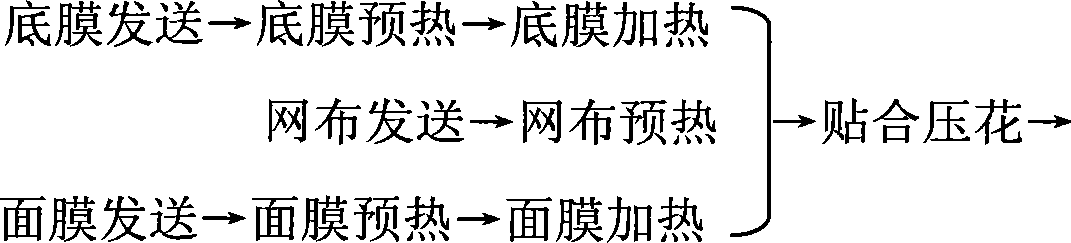

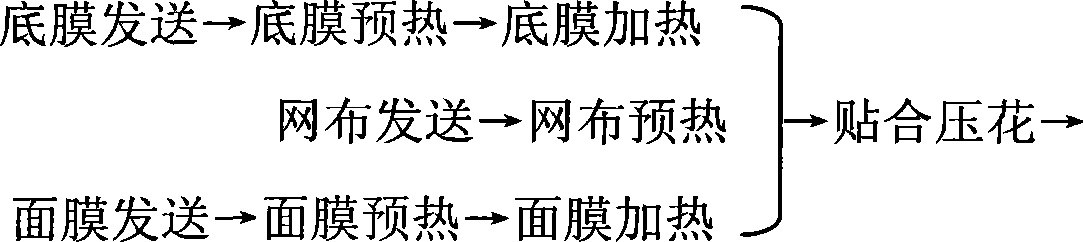

Method used

Image

Examples

Embodiment 1

[0022] PVC film calendering process: automatic feeding → high-speed mixing (mixer) → banburying (internal mixer) → refining A (milling machine) → refining B (milling machine) → filtering (filter) → calendering ( Four-roll calender) → embossing (embossing roller) → cooling → coiling (coiler) → packaging; the process parameters of the calendering process are: low speed mixing time: 20S; high speed mixing time: 280S; 10,000 horsepower confidential Refining time: 240S, A refining temperature: 175±5°C; B refining temperature: 160±5°C; filter temperature: 155±5°C; side roll temperature: 185±5°C; upper roll temperature: 178±5°C; lower roll Temperature 166±5℃; middle roller temperature: 175±5℃; gravity roller temperature: 168±5℃;

[0023] The coating process is: base fabric delivery → base fabric ironing → coating → drying → cooling → coiling; process parameters: base fabric ironing temperature 100°C; drying temperature in zone one: 120±5°C; zone two Drying temperature: 140±5°C; thre...

Embodiment 2

[0030] PVC film calendering process: automatic feeding → high-speed mixing (mixer) → banburying (internal mixer) → refining A (milling machine) → refining B (milling machine) → filtering (filter) → calendering ( Four-roll calender) → embossing (embossing roller) → cooling → coiling (coiler) → packaging; the process parameters of the calendering process are: low speed mixing time: 20S; high speed mixing time:

[0031] 280S; 10,000-horsepower machine internal mixing time: 240S, A refining temperature: 175±5°C; B refining temperature: 160±5°C; filter temperature: 155±5°C; side roll temperature: 185±5°C; upper roll temperature: 178±5°C 5°C; lower roll temperature: 166±5°C; middle roll temperature: 175±5°C; gravity roll temperature: 168±5°C;

[0032] The coating process is: base fabric delivery → base fabric ironing → coating → drying → cooling → coiling; process parameters: base fabric ironing temperature 80°C; drying temperature in zone one: 120±5°C; zone two Drying temperature:...

Embodiment 3

[0039] PVC film calendering process: automatic feeding → high-speed mixing (mixer) → banburying (internal mixer) → refining A (milling machine) → refining B (milling machine) → filtering (filter) → calendering ( Four-roll calender) → embossing (embossing roller) → cooling → coiling (coiler) → packaging; the process parameters of the calendering process are: low speed mixing time: 20S; high speed mixing time: 280S; 10,000 horsepower confidential Refining time: 240S, A refining temperature: 175±5°C; B refining temperature: 160±5°C; filter temperature: 155±5°C; side roll temperature: 185±5°C; upper roll temperature: 178±5°C; lower roll Temperature 166±5℃; middle roller temperature: 175±5℃; gravity roller temperature: 168±5℃;

[0040] The coating process is: base fabric delivery → base fabric ironing → coating → drying → cooling → coiling; process parameters: base fabric ironing temperature 90°C; drying temperature in zone one: 120±5°C; zone two Drying temperature: 140±5°C; three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com