Patents

Literature

606results about How to "Good elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant polymer thickening agent for oil field fracturing fluid as well as preparation method and application of thickening agent

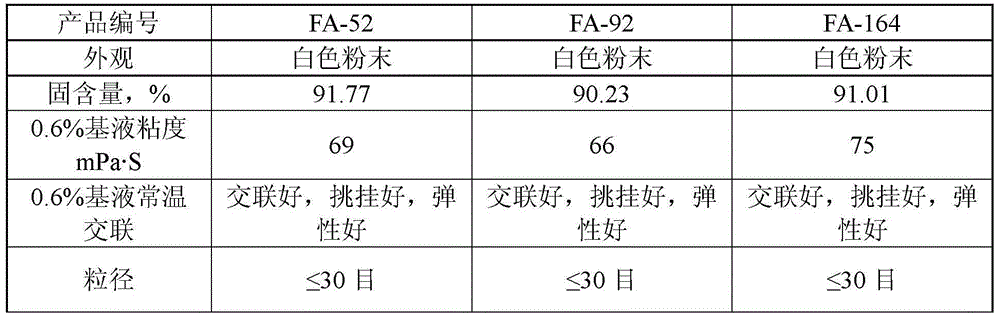

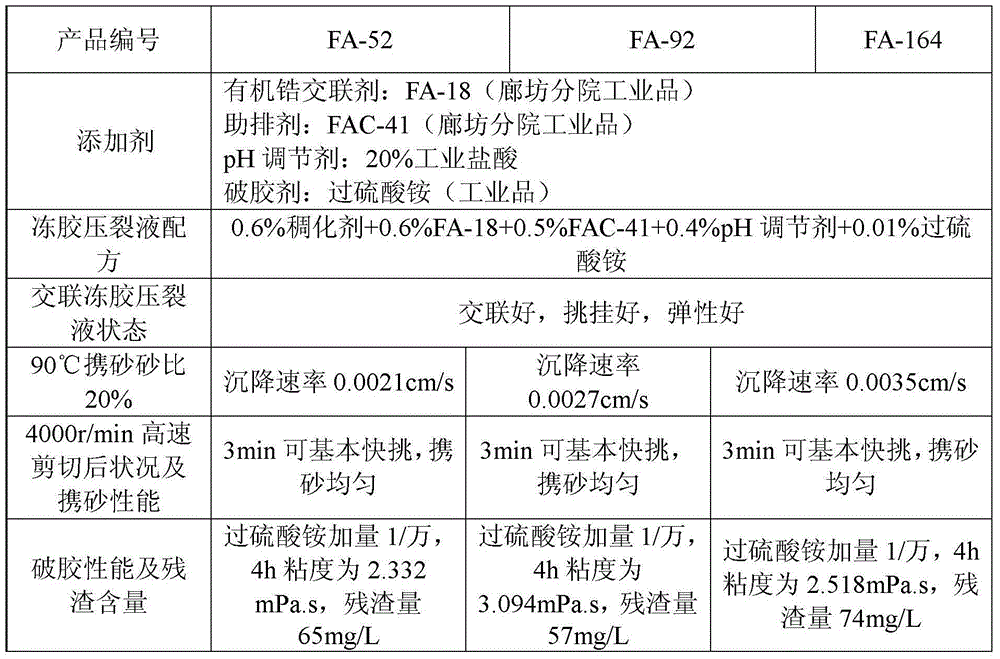

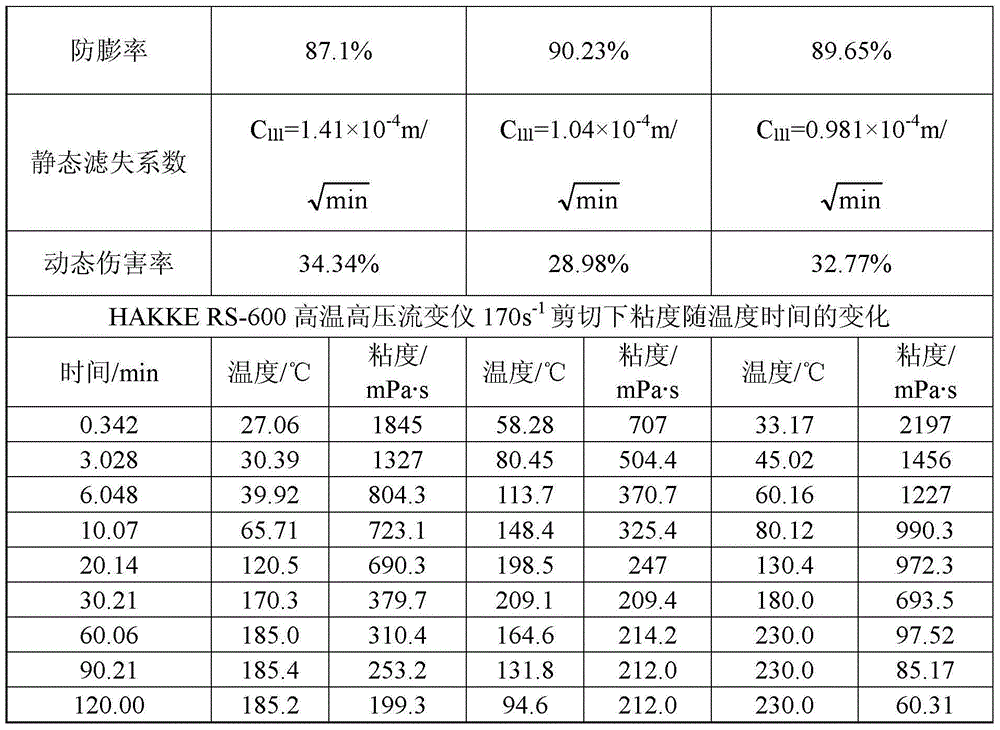

ActiveCN104449643AGood elasticityStrong ability to carry sandDrilling compositionSalt resistanceCarrying capacity

The invention discloses a high-temperature-resistant polymer thickening agent for an oil field fracturing fluid as well as a preparation method and application of the thickening agent. The preparation method of the thickening agent comprises the following step: polymerizing acrylamide, other olefin monomers, an initiating agent and a chain transfer agent in an aqueous solution by virtue of a solution process, wherein the weight ratio of acrylamide to the other olefin monomers to water is (10-20):(6-18):(62-84); and the other olefin monomers are selected from one or more, preferably two or three, of anionic olefin monomers, cationic olefin monomers or non-ionic olefin monomers. According to the high-temperature-resistant polymer thickening agent disclosed by the invention, free radicals are generated by using an aqueous solution catalyst process so as to ensure that the monomers are subjected to ternary polymerization or quaternary polymerization to form the anionic high molecular polyacrylamide polymer with the molecular weight of 4,000,000-8,500,000. After the thickening agent is crosslinked with a crosslinking agent, the thickening agent can be used for tolerating high temperature of more than 210 DEG C, and has the advantages of good crosslinked gel elasticity, strong sand carrying capacity, anti-shearing performance, salt resistance, no residues and the like.

Owner:PETROCHINA CO LTD

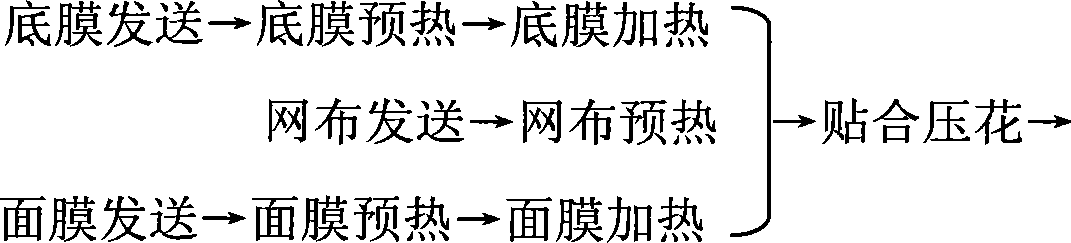

High strength ultrafine fiber simulation composite lether and its manufacturing method

The present ivnention relates to a high-strength ultrafine fibre imitation leather. It is made up by using sea-island ultrafine fibre base cloth through processes of impregnating with polyurethane, extracting treatment and after-finishing. The described base cloth is a double-layer or more than double-layer composite base cloth formed from sea-island composite fibre woven fabric and non-woven fabric which are combined together by means of needling process or cohesive process, then said invention makes the composite base cloth undergo the processes of impregnating with polyurethane, hardening, extracting 'sea' component in the solvent capable of removing 'sea' component from sea-island fibre to obtain semifinished product, widening forming, mellowing, dyeing, grinding or sticking film so as to obtain the invented product.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

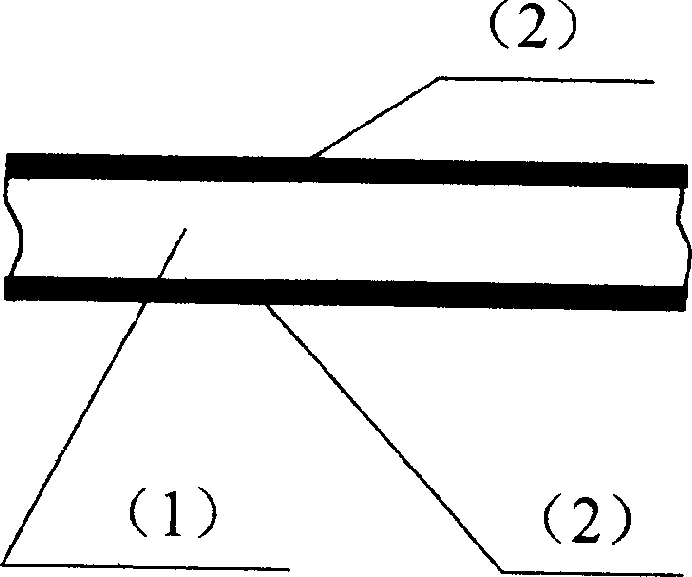

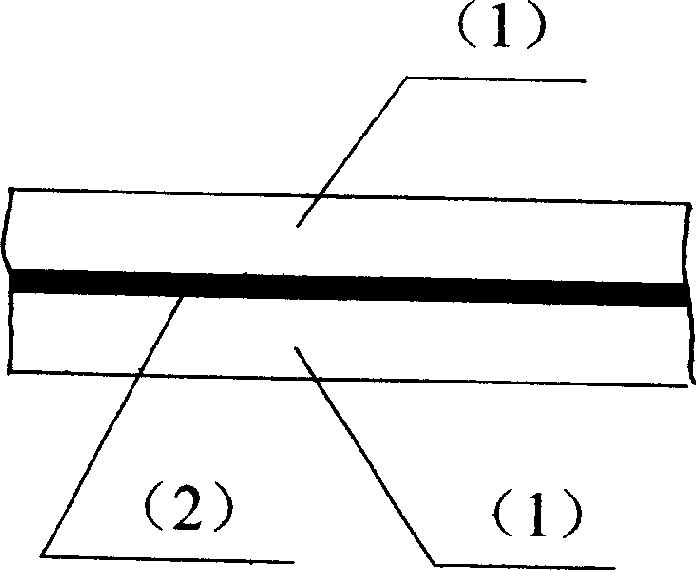

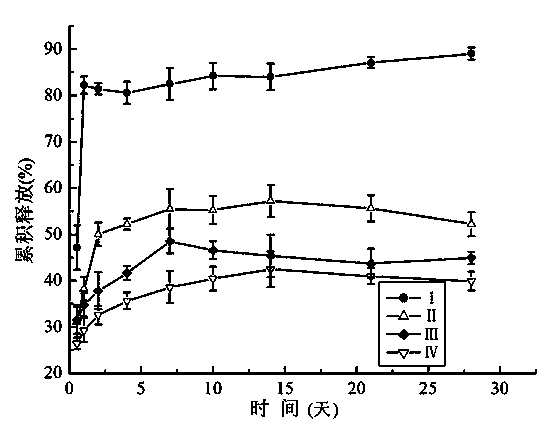

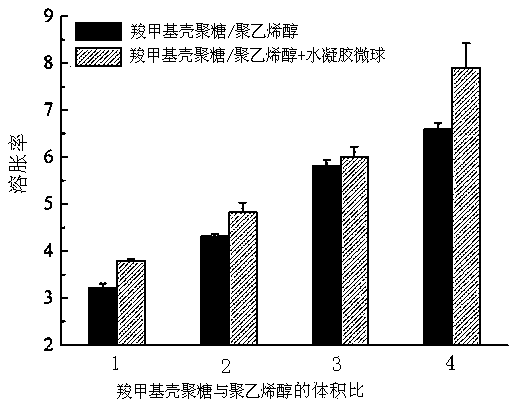

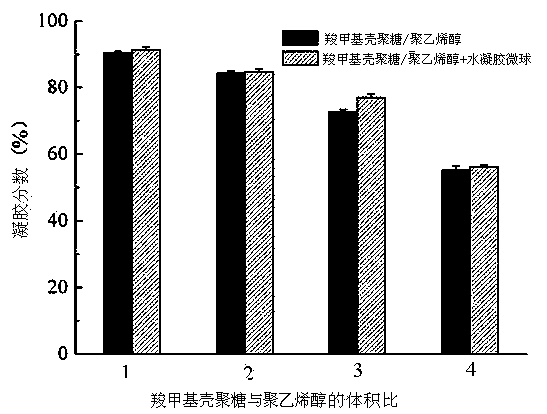

Medicinal sustained-release hydrogel as well as preparation method and application thereof

ActiveCN103467755AGood elasticityPrevent Adhesive WoundsAerosol deliveryOintment deliveryChemistryPolyvinyl alcohol

The invention discloses medicinal sustained-release hydrogel as well as a preparation method and an application thereof. Monodisperse medicament-containing calcium alginate microspheres are prepared by adopting a high-pressure electrostatic sessile drop method, to realize direct encapsulation of growth factors and keep the activity of medicaments; and the medicament-carrying calcium alginate microspheres are put into the netlike structure of the hydrogel to realize sustained release of the medicaments. The matrix of the hydrogel contains carboxymethyl chitosan and polyvinyl alcohol, the volume ratio of the carboxymethyl chitosan solution to the polyvinyl alcohol solution is n: (6-n), 0<n<=4, and the release rate of the medicaments is controlled through different volume ratios.

Owner:薛巍

Half-dry rice noodle and preparation method thereof

ActiveCN105410624AMuscular strengthGood elasticityFood ingredient as mouthfeel improving agentLoss ratePowder mixture

The invention discloses a half-dry rice noodle and a preparation method thereof. The half-dry rice noodle comprises the following raw materials: rice, a starch mixture, a fresh fruit and vegetable paste mixture and a fruit and vegetable powder mixture and is prepared by the following steps of fermentation and preprocessing of the rice, mixing of all raw materials, twin-screw extrusion forming, aging, re-steaming, washing and cutting oof noodles, measuring and packing, post-sterilization, cooling and the like. The half-dry rice noodle prepared by the invention has the advantages of smooth and bright appearance, strong gluten power, good elasticity, natural flavor, long shelf time, clear finished product soup and the like, the breaking rate is controlled to be lower than 2%, and the loss rate of cooking is controlled to be lower than 4%. According to the half-dry rice noodle and the preparation method thereof, the problem of the existing rice noodle of single nutrition is solved; the ingredients rich in protein and vitamins are added in the formula, so that the product has comprehensive nutrients; in addition, any preservative, brightening agent and thickening agent are not added in the product, so that the product prepared by the preparation method has excellent taste and is nutrient and healthy.

Owner:GAEA GEM RICE

Method for fabricating soft knitting face fabric from cotton

InactiveCN101003936ADimensionally stableDoes not reduce strengthFabric breaking/softeningBiochemical fibre treatmentAgricultural engineeringSizing

The present invention discloses a processing method of flexible cotton knitted face fabric. Said processing method includes the following several steps: weaving, enzymatic washing, kiering and bleaching, dyeing, oversoftening, dewatering, opening, drying, sizing and pre-shrinking.

Owner:浙江盛泰服装集团股份有限公司

Sponge calcium alginate medical dressing, and preparation method

The invention discloses a sponge calcium alginate medical dressing and a preparation method thereof and belongs to the technical field of medicines. The sponge calcium alginate medical dressing is formed by the following steps of: performing freeze drying on blended solution of sodium alginates with different molecular weights and forming, crosslinking and curing by using calcium ions and treating by using a softening agent. The sponge calcium alginate medical dressing has high flexibility, elasticity, air permeability, abrasive resistance, water absorption, biocompatibility and degradability a good barrier property, and the function of stopping bleeding, is easy to remove, has a flat and crackless surface, can substitute a sponge calcium alginate nonwoven medical dressing, can be used for treating various skin traumas such as wounds, wound surfaces of burns, and the like, prevents bacterial infection, promotes tissue repair and accelerates wound heating. Compared with the sponge calcium alginate nonwoven medical dressing, the sponge calcium alginate medical dressing has the advantages of simple production process, low cost and the like and helps to reduce the medical cost of a patient.

Owner:山东康康新材料科技有限公司

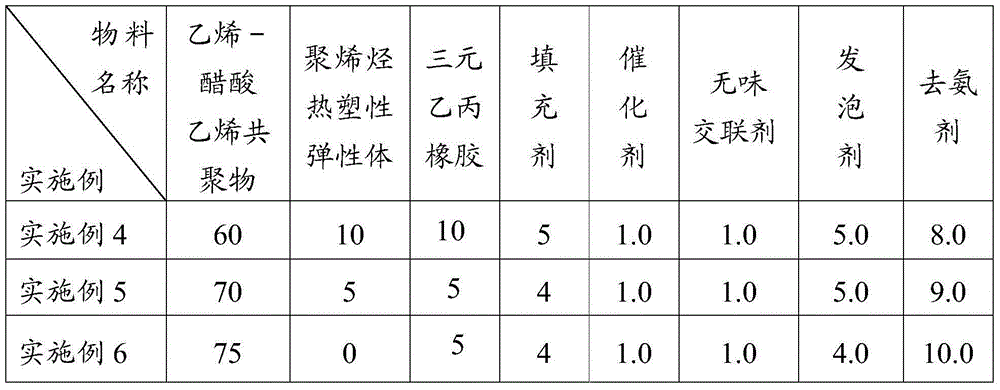

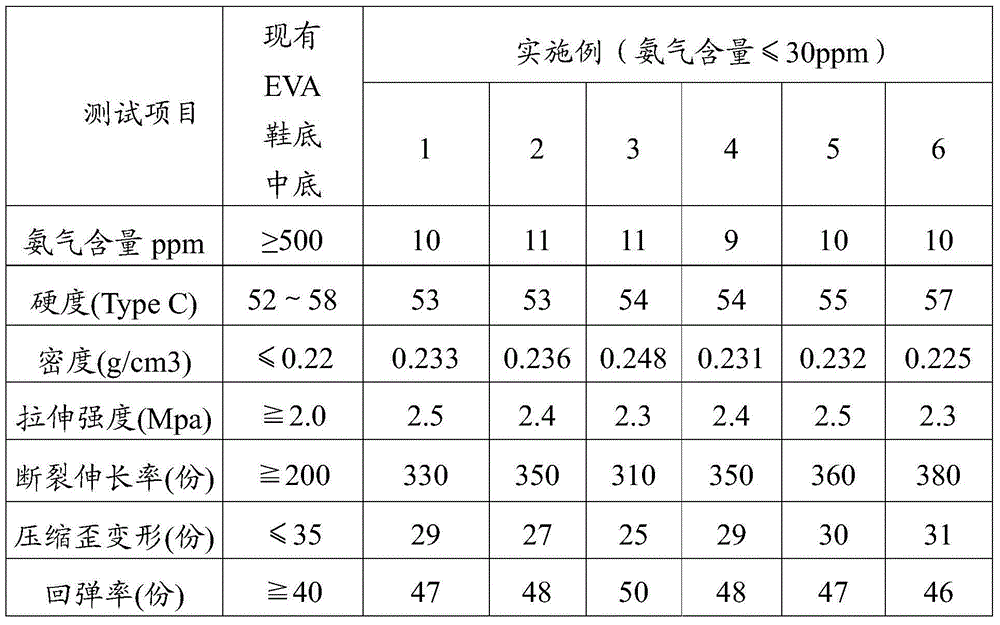

EVA composite foam material and preparation method thereof

The invention provides an EVA composite foam material and a preparation method thereof. The EVA composite foam material comprises the following components in parts by weight: 50-90 parts of an ethylene-vinyl acetate copolymer, 0-30 parts of a polyolefin thermoplastic elastomer, 0-30 parts of ethylene propylene diene monomer, 0-20 parts of a filler, 0.7-2.5 parts of a tasteless crosslinking agent, 1-8 parts of a foaming agent and 5-10 parts of a deammoniation agent. The EVA composite foam material is free of ammonia gas flavor and peculiar smell, good in elasticity and good in physical property. The preparation method of the EVA composite foam material comprises the following steps: (1) weighing the components of the EVA composite foam material; (2) pouring all the components excluding the tasteless crosslinking agent, the deammoniation agent and the foaming agent into an internal mixer for mixing; (3) adding the crosslinking agent, the deammoniation agent and the foaming agent into the mixed materials for mixing; (4) pouring the obtained mixture into a granulator for granulation and then foaming to obtain the EVA composite foam material free of ammonia flavor.

Owner:ANTA CHINA

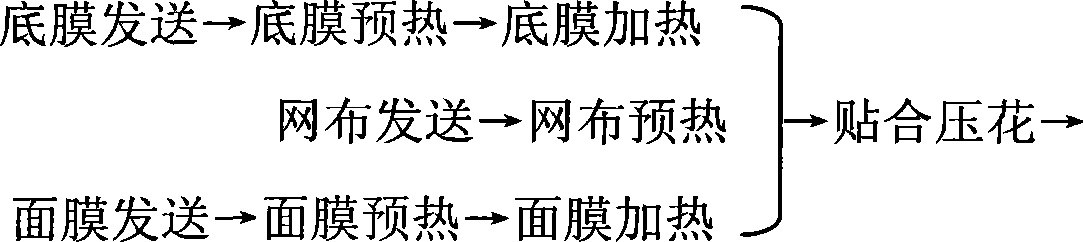

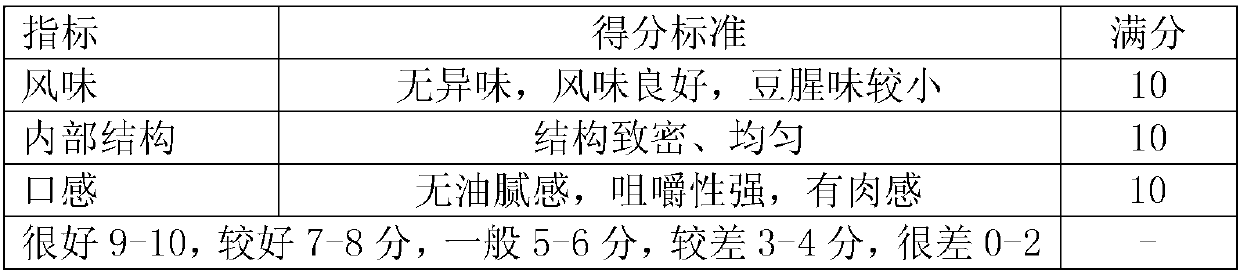

Terylene camouflage waterproof cloth

ActiveCN101225611AHigh strengthGood elasticityLamination ancillary operationsLaminationCamouflageEngineering

The invention provides a terylene camouflage waterproof cloth, which is made by the following steps: 170 T terylene cloth is printed with camouflage patterns, then is double-face coated with special PU soft glue, and then is hot-conglutinated with PVC surface material. The terylene camouflage waterproof cloth has the advantages of high strength, good elasticity, desirable resistance to tension and good flexibility, as well as favorable waterproof performance, which are all seen in the PVC surface material; furthermore, the terylene camouflage waterproof cloth has the capacity for being made into garments as of the terylene fabric, and the fabric cloth thus manufactured has the functions of good strength, waterproof performance, resistance to ageing and sea water; therefore, the fabric cloth can be applied to manufacture underwater operation suits or waterproof articles, and enjoy a great variety of application fields.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Woollen sweater and production thereof

The invention discloses a knitted sweater and the production technology thereof. The raw material of the knitted sweater is yarn blended with spun silk, Modal fiber, milk fiber and cashmere. The weight ratio of the spun silk ranges from 50 to 60 percent, that of the Modal fiber ranges from 20 to 30 percent, that of milk fiber ranges from 10 percent to 15 percent and that of cashmere is between 5 to 15 percent. The production technology for knitted silk comprises (1) selection of raw white yarn, (2) dyeing, (3) rewinding, (4) panel knitting, (5) linking, (6) stitches, (7) hand sewing, (8) rinsing, (9) drying and (10) ironing. The knitted sweater has natural wrinkle resistance, higher hygroscopicity and warmth, and soft handfeel.

Owner:周婉

Green plum fruit jelly and preparation method thereof

The invention relates to a green plum fruit jelly and a preparation method thereof, wherein the green plum fruit jelly is characterized in that the green plum fruit jelly is prepared from fresh green plum fruit, green plum juice, compound gelatinizing agent, sugar, acid, and water; the green plum fruit jelly comprises the following raw materials according to mass percent: 1-5 wt% of green plum juice, 5-7 wt% of green plum fruit, 25-30 wt% of white sugar, 0.1-0.4 wt% of citric acid, 6-8 wt% of compound gelatinizing agent, and rest of water; the jelly has the characteristics of suitable sour and sweet, smooth mouthfeel, good elasticity and rich nourishment; therefore, the green plum fruit jelly is popular with consumers.

Owner:LABIXIAOXIN (FUJIAN) FOOD INDUSTRY CO LTD

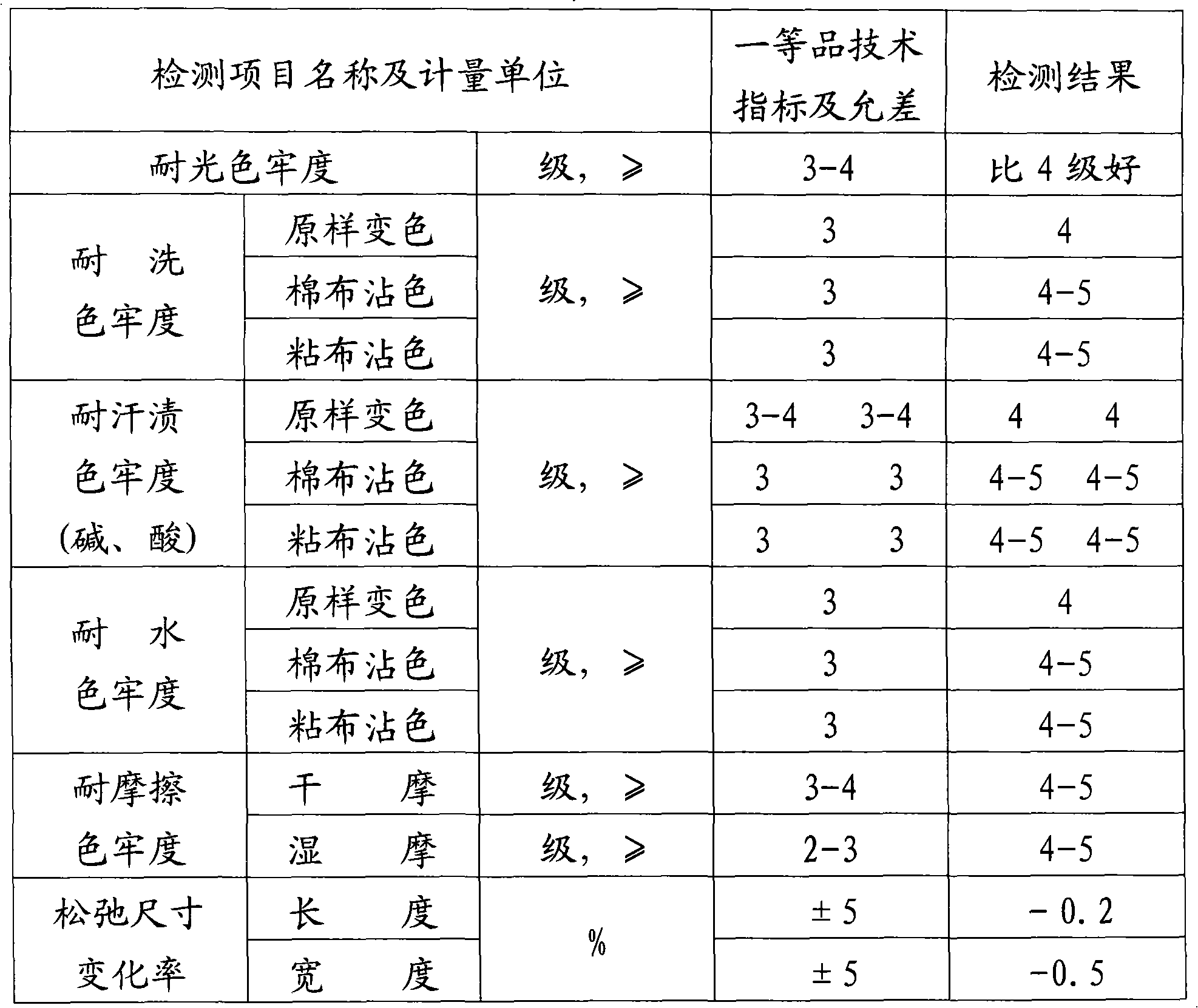

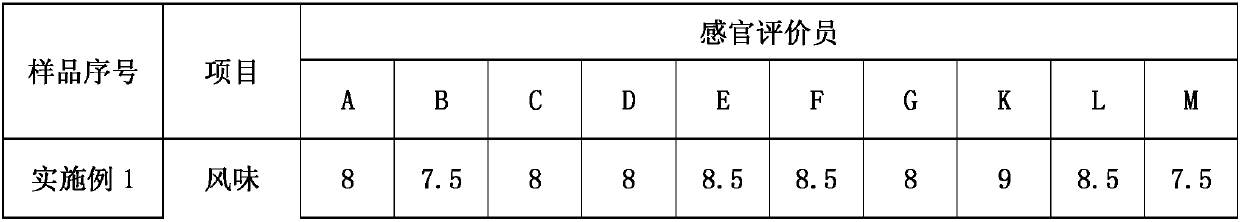

Vegetarian meat steak containing soybean protein and preparation method thereof

The invention discloses a vegetarian meat steak containing soybean protein and a preparation method thereof. The vegetarian meat steak blank body is prepared from following raw materials in parts by weight: 10-20 parts of textured soybean protein, 3-10 parts of soybean protein isolate, 2-10 parts of amylum, 2-8 parts of vital wheat gluten, 2-9 parts of vegetable oil, 0-3 parts of salt, 0-1 part ofmonosodium glutamate, 30-130 parts of water, 0-0.6 part of white pepper, 0-0.6 part of five spice powder, 0-0.8 part of chive powder and 0-0.8 part of fresh ginger powder. According to the vegetarianmeat steak containing the soybean protein and the preparation method thereof, the vegetarian meat steak prepared by the raw materials and the preparation method is crispy outside and soft inside, theinner structure is good, chewiness and intense shredded meat feeling are achieved, requirements of modern catering for healthy food are met, and taste and delicacy are achieved.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

Potato vermicelli and processing method thereof

The invention discloses potato vermicelli and a processing method thereof. Raw materials of the potato vermicelli comprise, 42-50% of potato starch, 18-25% of cassava starch, 10-15% of corn starch, 0.5-1.0% of licorice root powder, 0.5-1.5% of gluten powder, 3-8% of vegetable edible oil, 0.2-0.6% of a thickening agent, 0.1-0.5% of an emulsifier, 0.8-1.5% of gravy salt, and the balance of water. During preparation, gravy salt and gelatinized starch are added to pulp, a microwave treatment is performed, food grade gluten powder, a thickening agent, an emulsifier and other auxiliary materials are added to uniformly stir, and flour milling, drying and other steps are performed to process into the potato vermicelli, wherein the prepared potato vermicelli has characteristics of cooking resistance, no strip breaking, good toughness, good taste, no alum addition, green and health. According to the present invention, the potato starch, the cassava starch, the corn starch and the licorice root powder are added, such that prepared potato vermicelli is rich in various nutrients of cereals, and has characteristics of good taste, low production cost, and easy promotion.

Owner:王惠莹

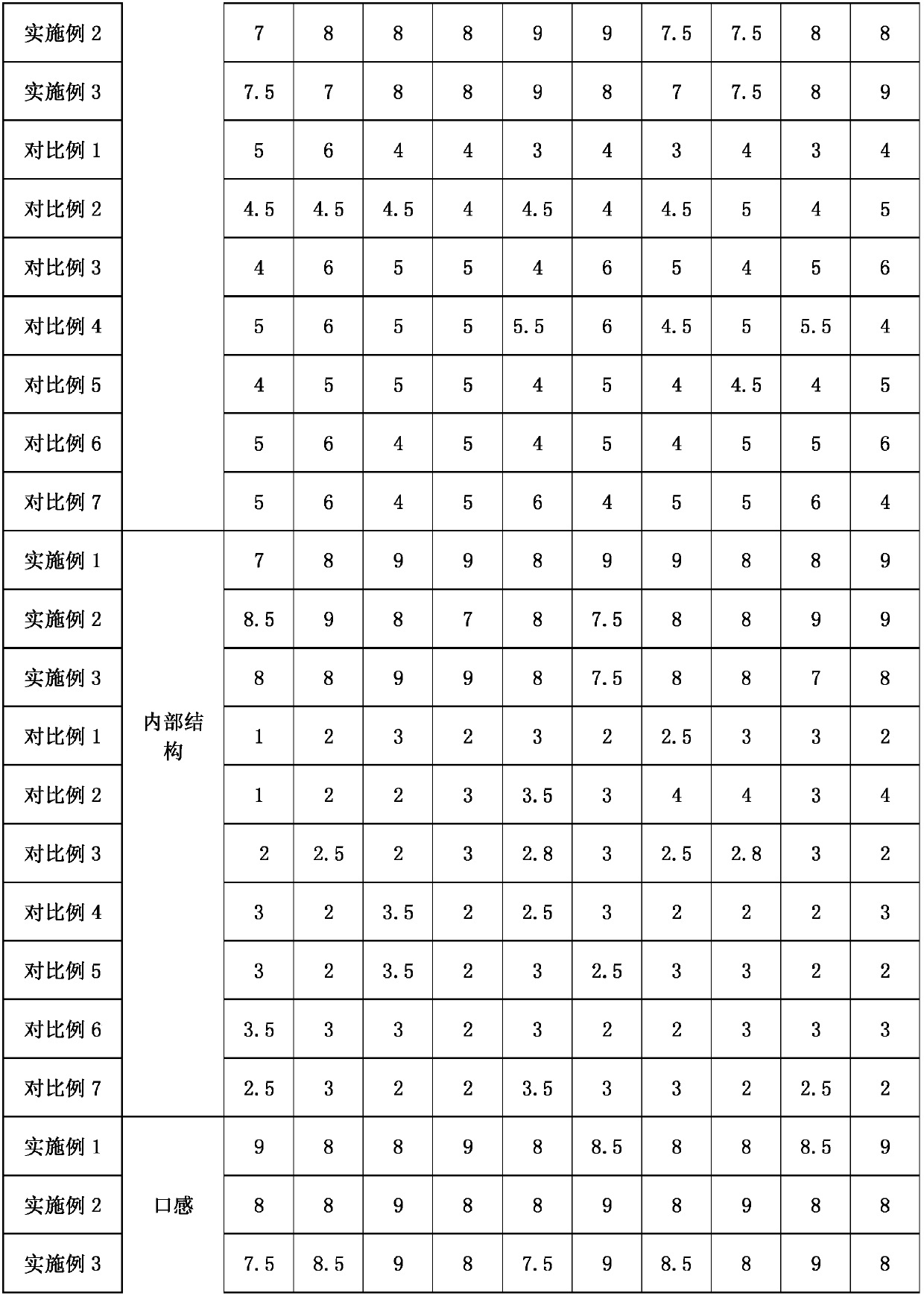

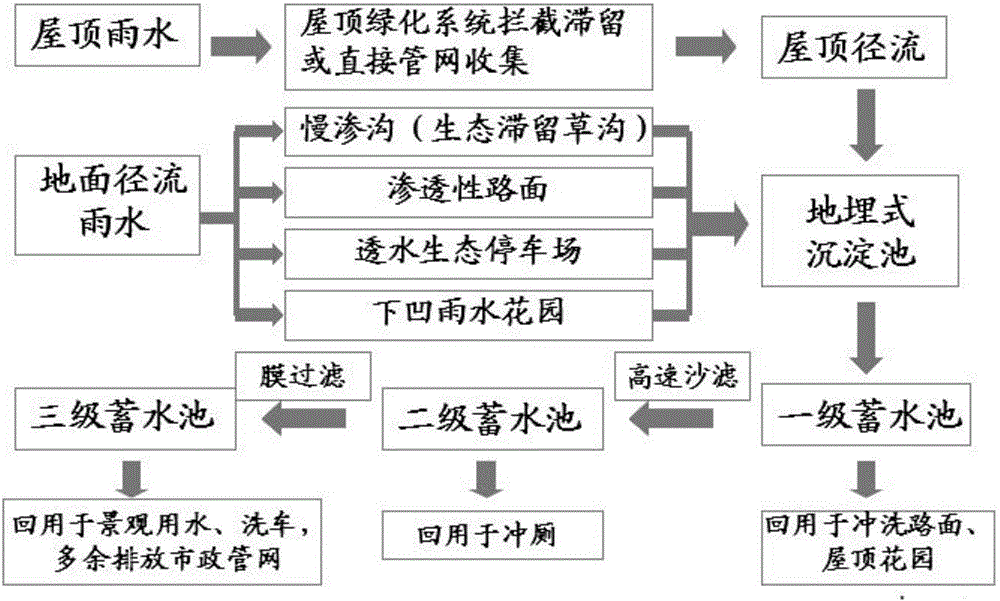

Rainwater collecting and recycling method and system

InactiveCN106400885AWith "interceptWith absorptionFatty/oily/floating substances removal devicesGeneral water supply conservationNatural disasterCollection system

The invention discloses a rainwater collecting and recycling method. The method comprises the following steps: collecting rainwater into a buried sedimentation tank by virtue of a roof rainwater collection system and a surface runoff rainwater collection system, so as to form primary stored water; introducing 50-60% of the primary stored water in the upper layer of the sedimentation tank into a primary reservoir by virtue of a water pump, so as to form secondary stored water; introducing 50-60% of the secondary stored water in the upper layer of the primary reservoir into a secondary reservoir by virtue of a water pump, so as to form tertiary stored water; and introducing 80-90% of the tertiary stored water in the upper layer of the secondary water reservoir into a tertiary reservoir by virtue of a water pump, so as to form quaternary stored water. The method provided by the invention has functions of 'intercepting', 'absorbing', 'maintaining', 'purifying' and 'releasing' the rainwater, and the like, so that novel urbanized municipal facilities have excellent 'elasticity' in such aspects as adapting to environmental change, responding to natural disasters and the like. The method is energy-saving and environment-friendly.

Owner:浙江伟达园林工程有限公司

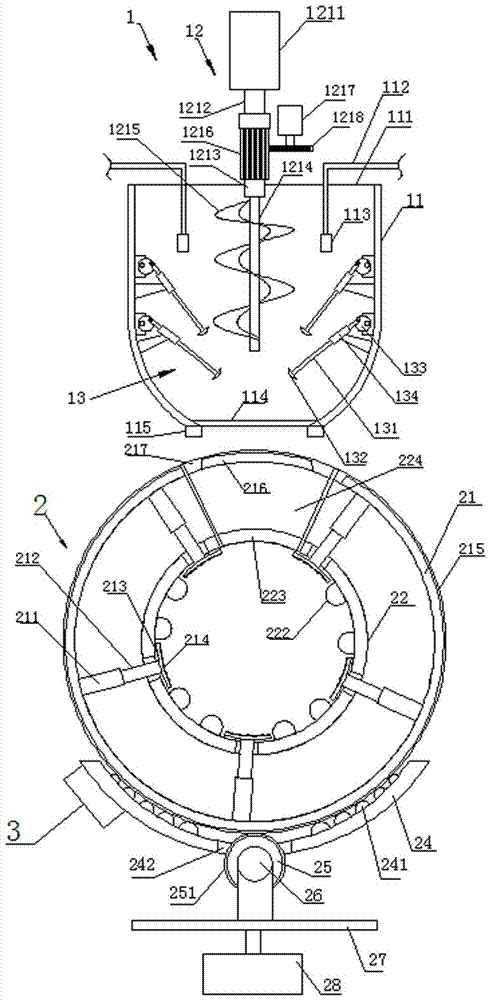

Cooperative dough forming and dough kneading machine

InactiveCN107006551AGood elasticityFast processingMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsHollow cylinderEngineering

The invention relates to a combined dough kneading machine, which comprises a kneading device and a kneading device arranged in sequence; The beating device; the beating device includes a plurality of rods for telescopic movement and towards the center of the bottom of the cylinder; the dough kneading device includes a first hollow spherical roller arranged under the cylinder and a fixed distance sleeved in the first hollow The second hollow spherical drum in the spherical drum; the inner wall of the first hollow spherical drum is evenly equipped with a plurality of cylinders and kneading rods driven by the cylinders; the second hollow spherical drum is provided with a plurality of dough The through hole through which the rod penetrates; the inner wall of the second hollow spherical roller is provided with a plurality of protrusions at intervals; the lower part of the first hollow spherical roller is provided with an arc-shaped supporting plate that cooperates with the lower part of the first hollow spherical roller.

Owner:林娜娜

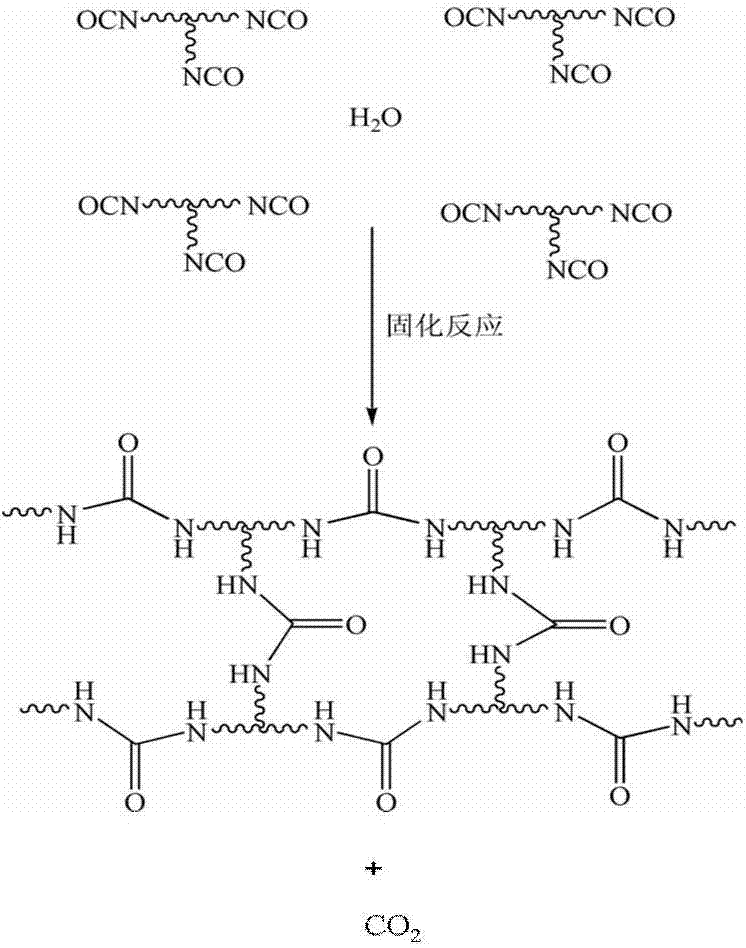

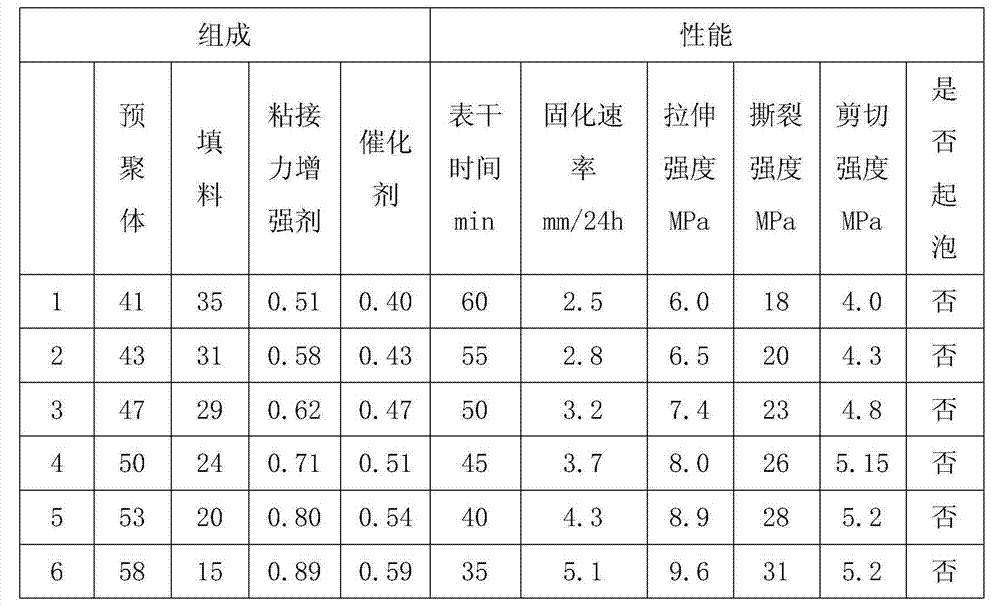

Hardly-foamed one-component polyurethane sealant

ActiveCN103897650AGood elasticityHigh strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistryPlasticizer

The invention relates to a hardly-foamed one-component polyurethane sealant, belonging to the technical field of sealants. The sealant is prepared from the following raw materials in parts by weight: 30-60 parts of a polyurethane pre-polymer, 0-50 parts of a filling material, 0-30 parts of a plasticizer, 0.2-0.9 part of a catalyst and 0.3-1 part of a bonding force enhancer. The sealant has stable storage and good workability, is not easy to foam even under a high-humidity and high-temperature environment, has good mechanical properties and strong bonding force after curing, and is particularly suitable for the elastic bonding of glass and metal base materials.

Owner:ZHENGZHOU UNIV

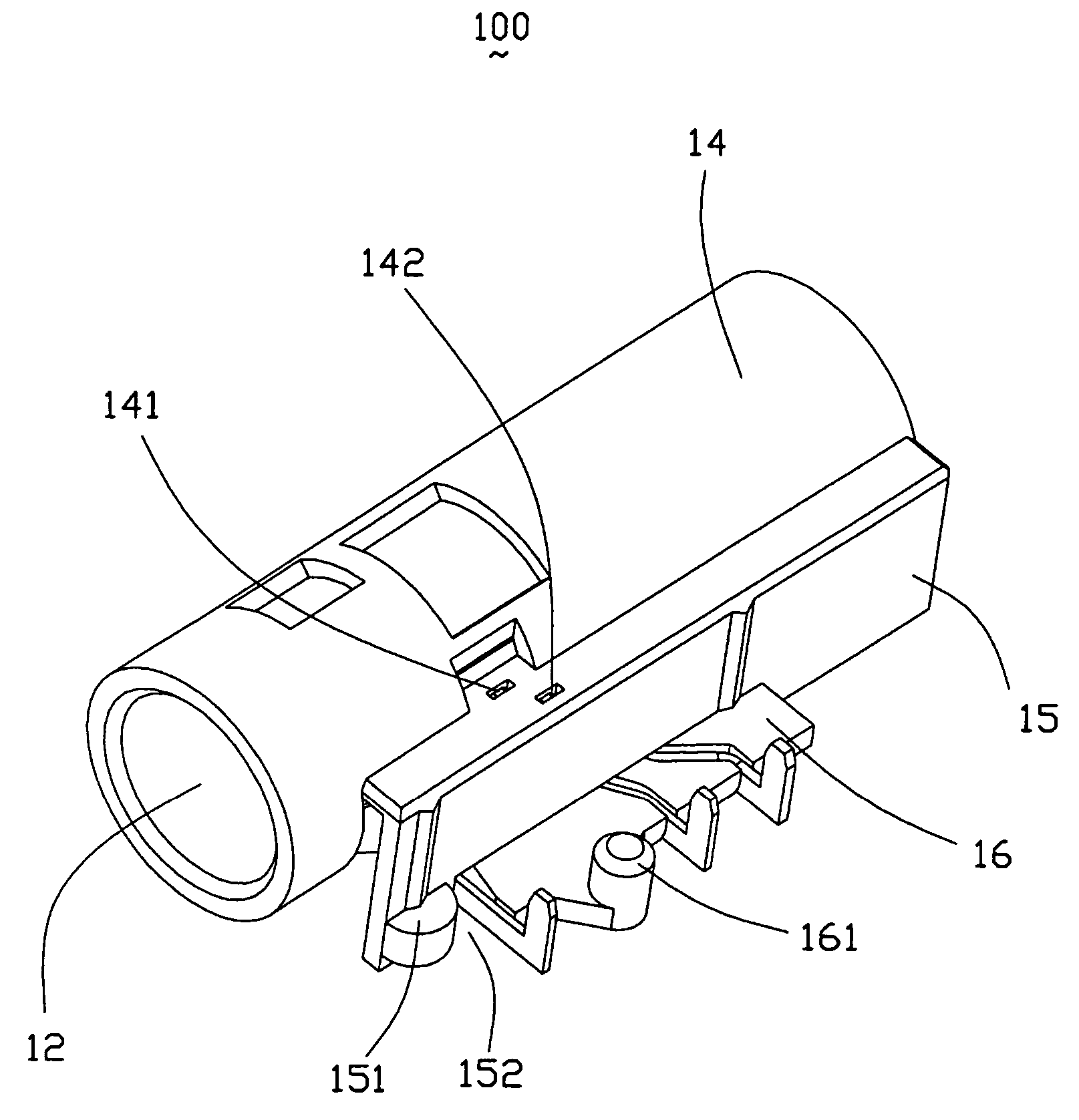

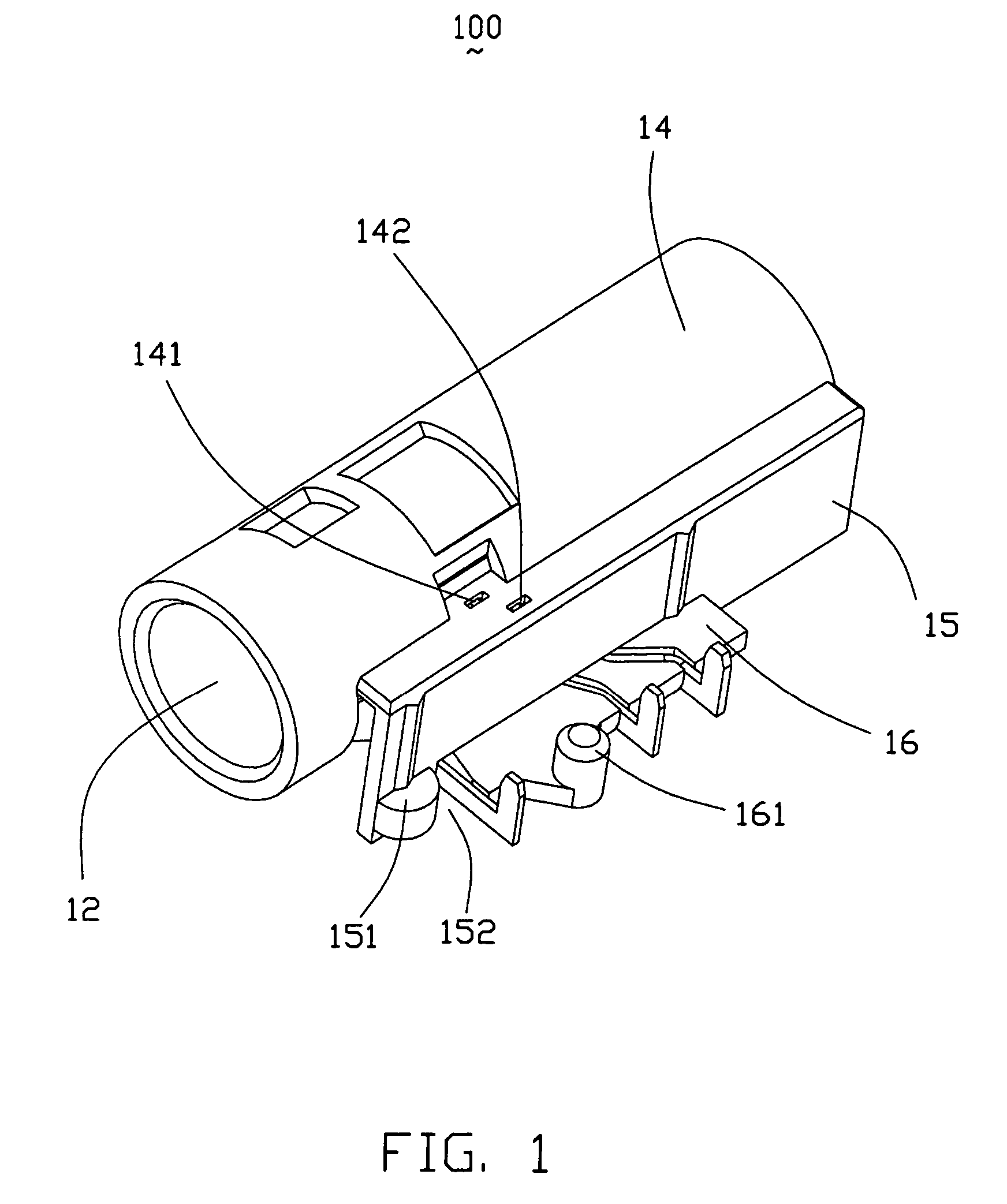

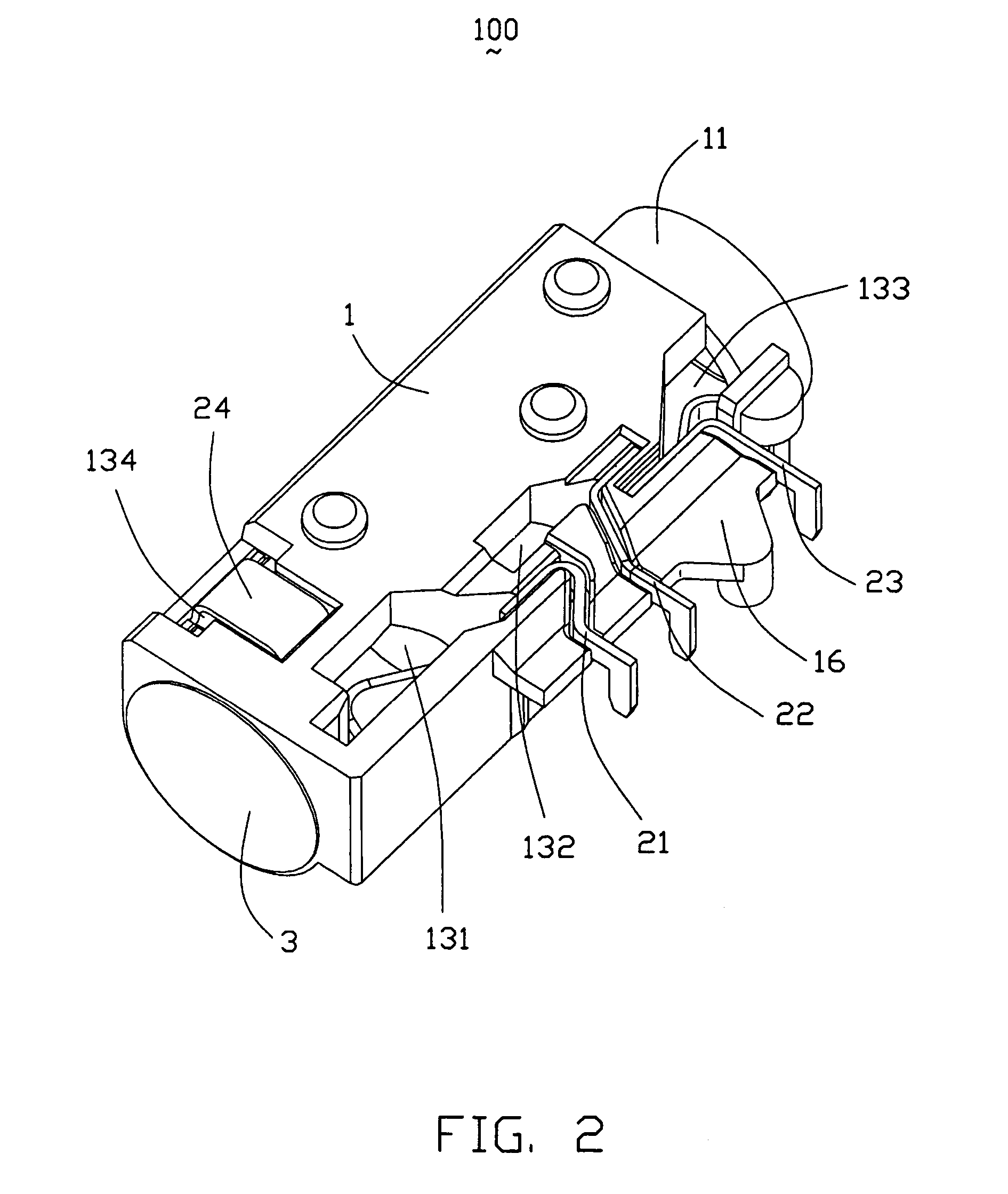

Miniature audio jack connector with improved contact arrangement

InactiveUS7341491B2Good elasticityFirmly connectedCoupling device detailsTwo-part coupling devicesMating connectionMating plug

A miniature audio jack connector (100) for electrically connecting a mating plug (5) includes an insulative housing (1), a number of contacts (2) retained in the housing. The housing defines a plug-insertion hole (12) in a longitudinal direction thereof. The contacts include a second contact (22) and a third contact (23). The second contact includes a second retaining portion (220) and a second elastic arm (221) extending into the plug-insertion hole. The third contact includes a third retaining portion (230) and a third elastic arm (231) extending opposite to the second elastic arm. The second and third retaining portions (220, 230) overlap each other along the longitudinal direction of the housing (1), thereby lengthening the elastic arms (221, 231) of the contacts (22, 23) to be reliable connecting with the mating plug.

Owner:HON HAI PRECISION IND CO LTD

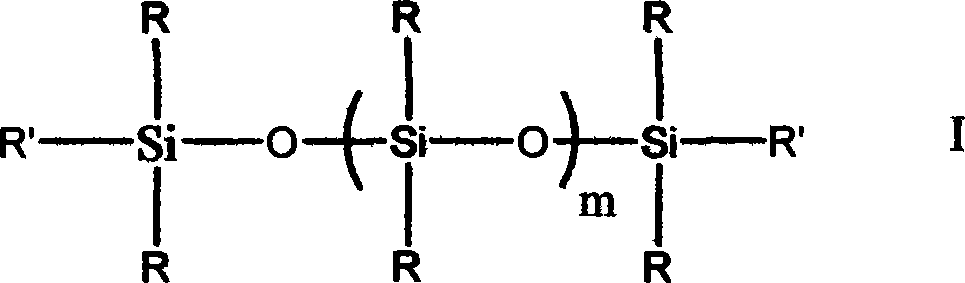

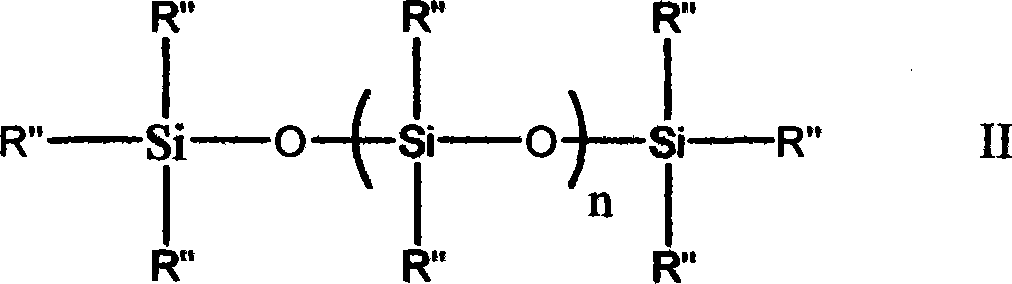

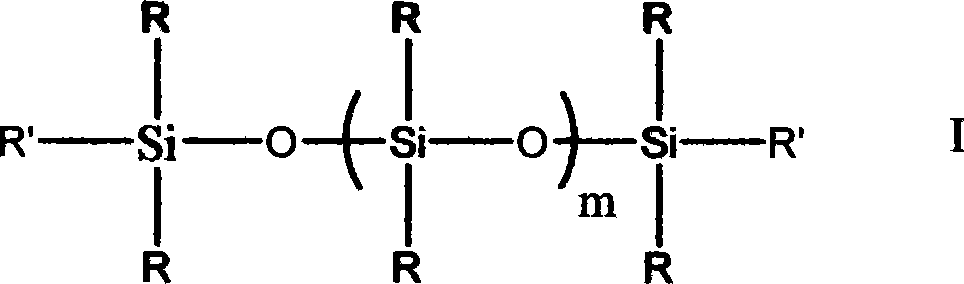

High elasticity silica-gel breast prosthesis filler and preparation thereof

The invention discloses a high elastic silicon gel filling material for breast implants. An A component and a B component are mixed, and cross-linking agents are added into the mixing of the A component and the B component to form the gels with a semi-interpenetrating network structure through catalytic cross bridging; the A component is a linear siloxane polymer with a general formula I and the B component is a linear siloxane polymer with a general formula II. The filling material of the invention preferably solves the problems of low elasticity, unnatural hand feeling and uneasy regulation of softness and shape maintenance of common gels of breast implants by using the semi-interpenetrating network structure, thus obtaining the gels with natural characteristics and like body fat; the breast implants filled with the gels has good elasticity, soft and natural hand feeling and can keep better natural shapes after being implanted into human bodies.

Owner:SHANGHAI KANGNING MEDICAL DEVICE

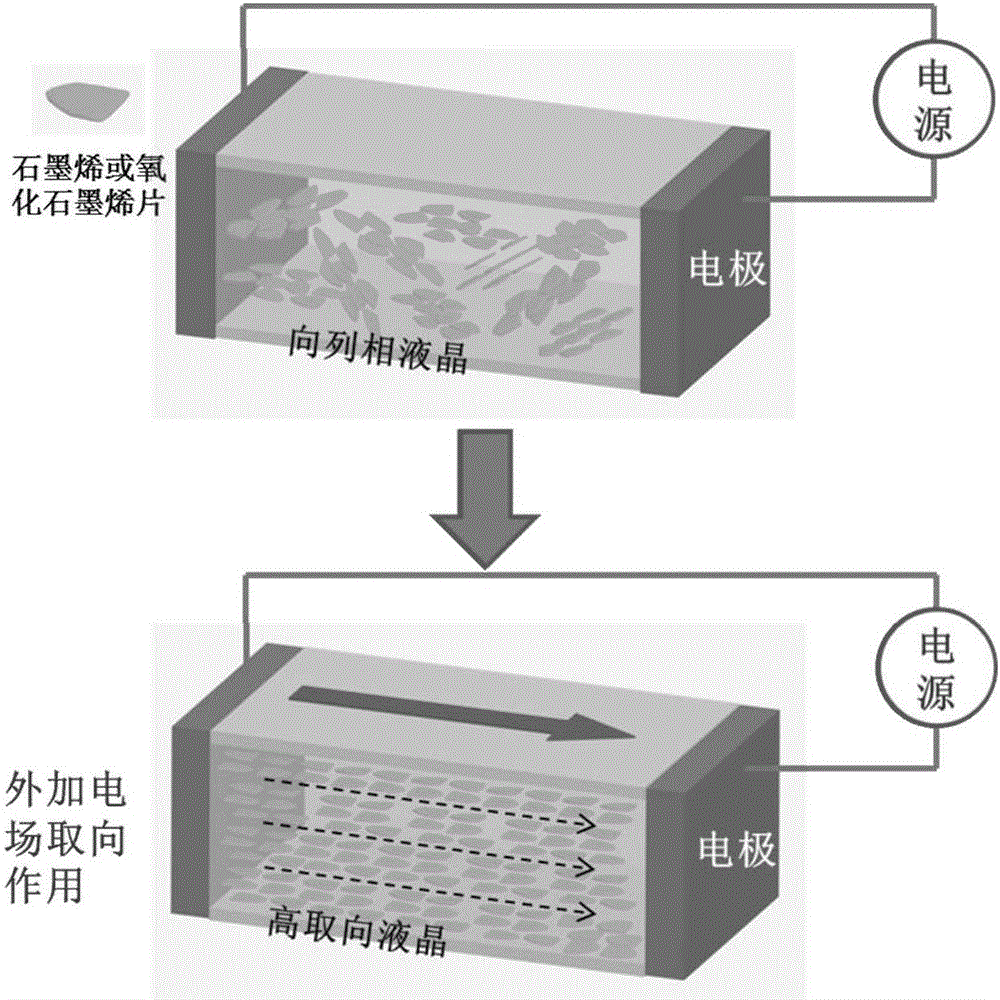

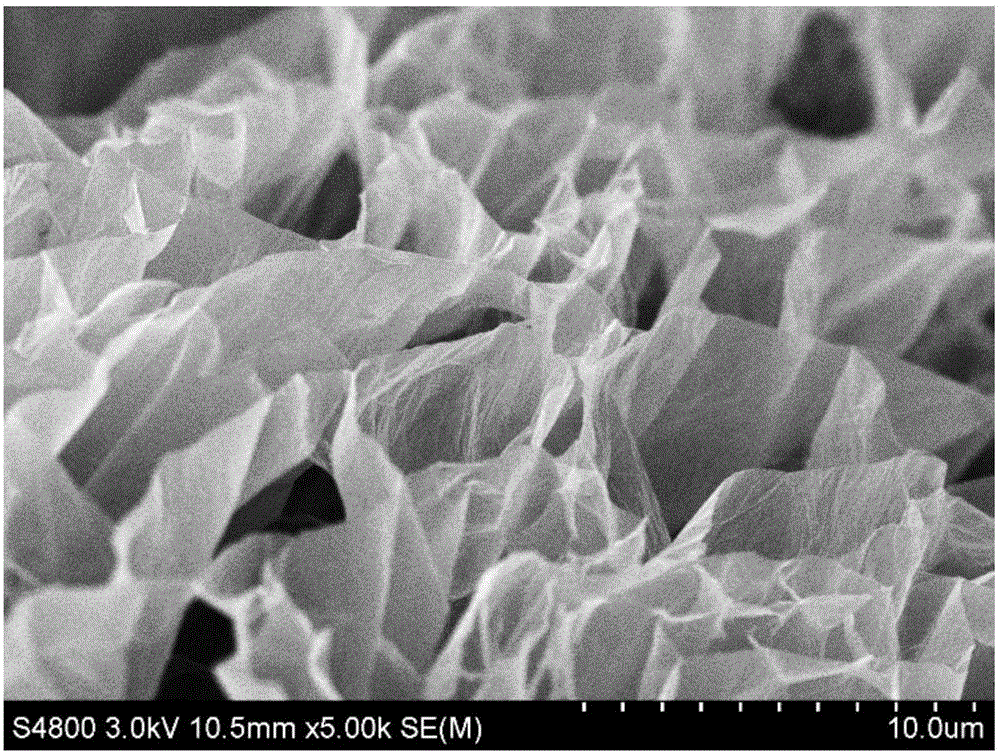

Method for preparing high orientation graphene aerogel

ActiveCN106044752ASimple and efficient operationGood elasticityCeramicwareCvd grapheneSupercritical drying

The invention discloses a high orientation graphene aerogel and a preparation method thereof. The method comprises the steps of first preparing a dispersion liquid of graphene or graphene oxide, placing the dispersion liquid of graphene or graphene oxide in a container with an electrode, obtaining a high orientation graphene or graphene oxide dispersion liquid through an additional electric field orientation method, continuing to maintain an electric field effect, performing freeze freezing in liquid nitrogen, and obtaining the high orientation graphene aerogel after freeze drying or supercritical drying. The high orientation graphene aerogel is high in porosity, pores have a very high degree of orientation in an electric field direction, the pore size is controllable, and the high orientation graphene aerogel can be used for electrode materials of batteries and super capacitors, electron field emission sources, heat insulating and radiating materials, adsorbing materials, high flux water filter materials and catalyst carriers and the like.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Sugar-free gel soft candy and its production

The invention is concerned with a kind of sugarless gel soft candy and its produce method. It relates to gelatin, food grade Pullulan, sorbitol, maltitol, isomaltitol, Erythritol, sour material, flavoring essence, natural edible pigment and water. Mix gelatin and Pullulan to get liquid of glue, dissolve sorbitol, maltitol, isomaltitol and Erythritol to get sirup, and mix the liquid of glue and sirup to get mixed material liquid. Add sour material, flavoring essence and natural edible pigment into the mixed material liquid, pour, mold and dry till with 12 to 20 percent of water to get the production. The added stuffs have good effect to agglomerate with good elasticity for the compound using of gelatin and Pullulan. The production is not easy to becoming into the crystal for using sorbitol, maltitol and isomaltitol. This invention has great importance for the new production technology field for sugarless gel soft candy.

Owner:广东富味健康科技有限公司

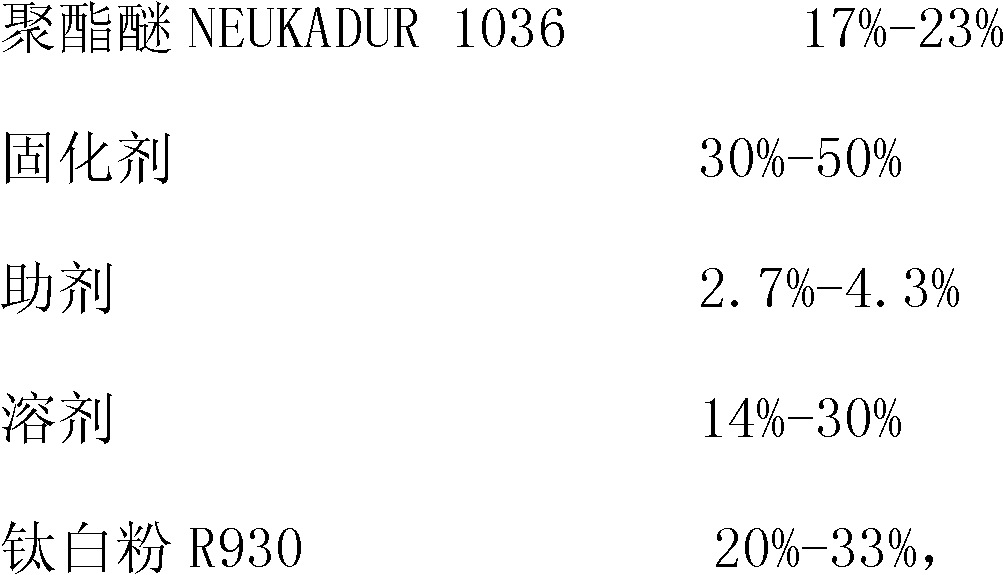

Coating for blades of wind generation set

InactiveCN102585677AHigh surface hardnessGood elasticityPolyurea/polyurethane coatingsChemistryPliability

The invention discloses a coating for blades of a wind generation set, which is formed by polyurethane NEUKAPOL 1007, polyester ether NEUKADUR 1036, curing agents, auxiliaries, auxiliaries and titanium dioxide powder R930. Double-component polyurethane NEUKAPOL 1007 and double-component polyester ether NEUKADUR 1036 are chosen, the chosen polyurethane and polyester ether are low-viscosity resin with high hydroxyl values (respectively being 550-590 and 160-170), the resin is very small in molecular weight and can form coating films with high cross-linking density, the coating films have extra high surface hardness and excellent elasticity, bending resistance, elasticity and physical and mechanical performance and can avoid stress concentration, and therefore the coating films formed by the coating have good tensile strength, tearing strength and stone striking resistance, and service life of the wind generation set is ensured.

Owner:JIANGSU MARINE VICTORY COATING

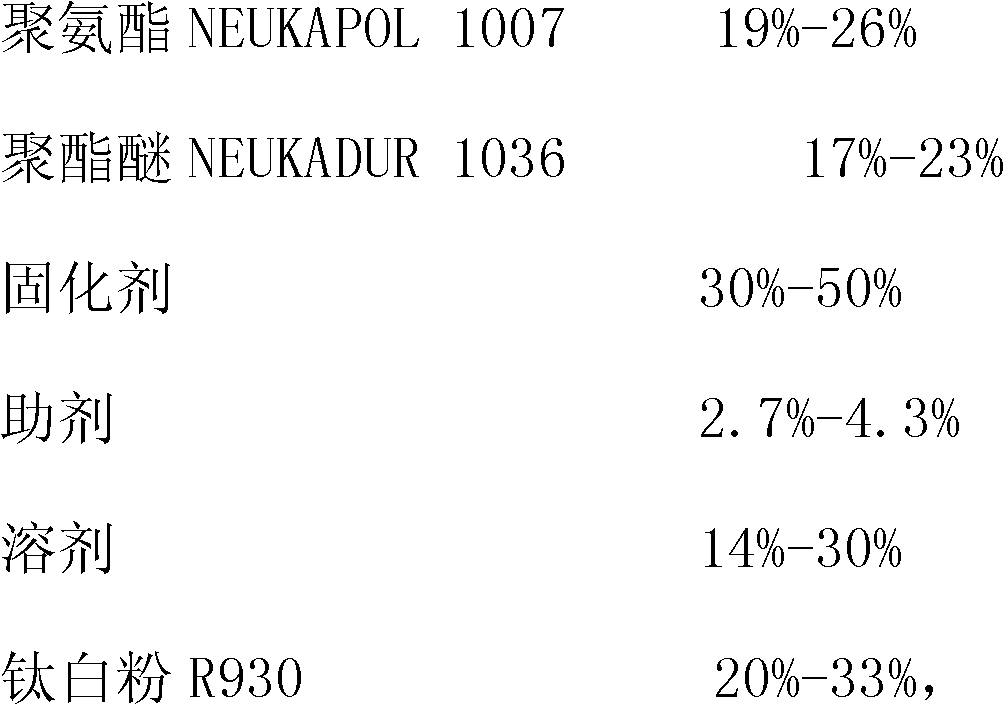

Production method for PTT (Poly Trimethylene terephthalate)/PET (Poly Ethylene Terephthalate) side-by-side composite elastic short fibers

InactiveCN104593886ASoft touchGood elasticityHeating/cooling textile fabricsMelt spinning methodsPoly ethyleneLarge capacity

The invention discloses a production method for PTT (Poly Trimethylene terephthalate) / PET (Poly Ethylene Terephthalate) side-by-side composite elastic short fibers. The production method comprises the following steps of (1) compositing a raw material a, namely, modified PET and a material b, namely, PTT in a large-capacity two-channel composite spinning assembly after respectively passing through crystallizing and drying equipment, melting and extruding equipment and a spinning manifold, obtaining a strand with a side-by-side shape, and then obtaining a PTT / PET side-by-side composite elastic short fiber precursor c after spinning, circular blowing cooling, oiling, rolling and falling into a barrel; (2) feeding the precursor c into a packaging machine for packaging after bundling, drafting, oiling, tension heat setting, oiling, mechanical rolling, relaxation heat setting and cutting. According to the production method disclosed by the invention, since the special composite spinning manifold, the large-capacity two-channel composite spinning assembly and a multi-roller tension heat setting instrument device are adopted, the PTT / PET side-by-side composite elastic short fiber prepared by the production method has moderate elasticity, excellent hand feeling and good stretch elastic recovery.

Owner:福建省海兴凯晟科技有限公司

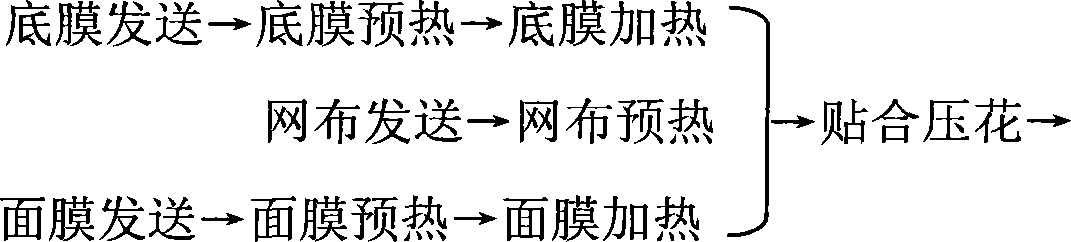

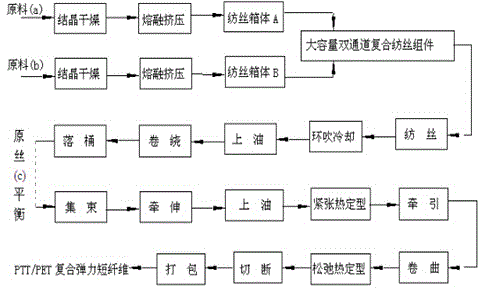

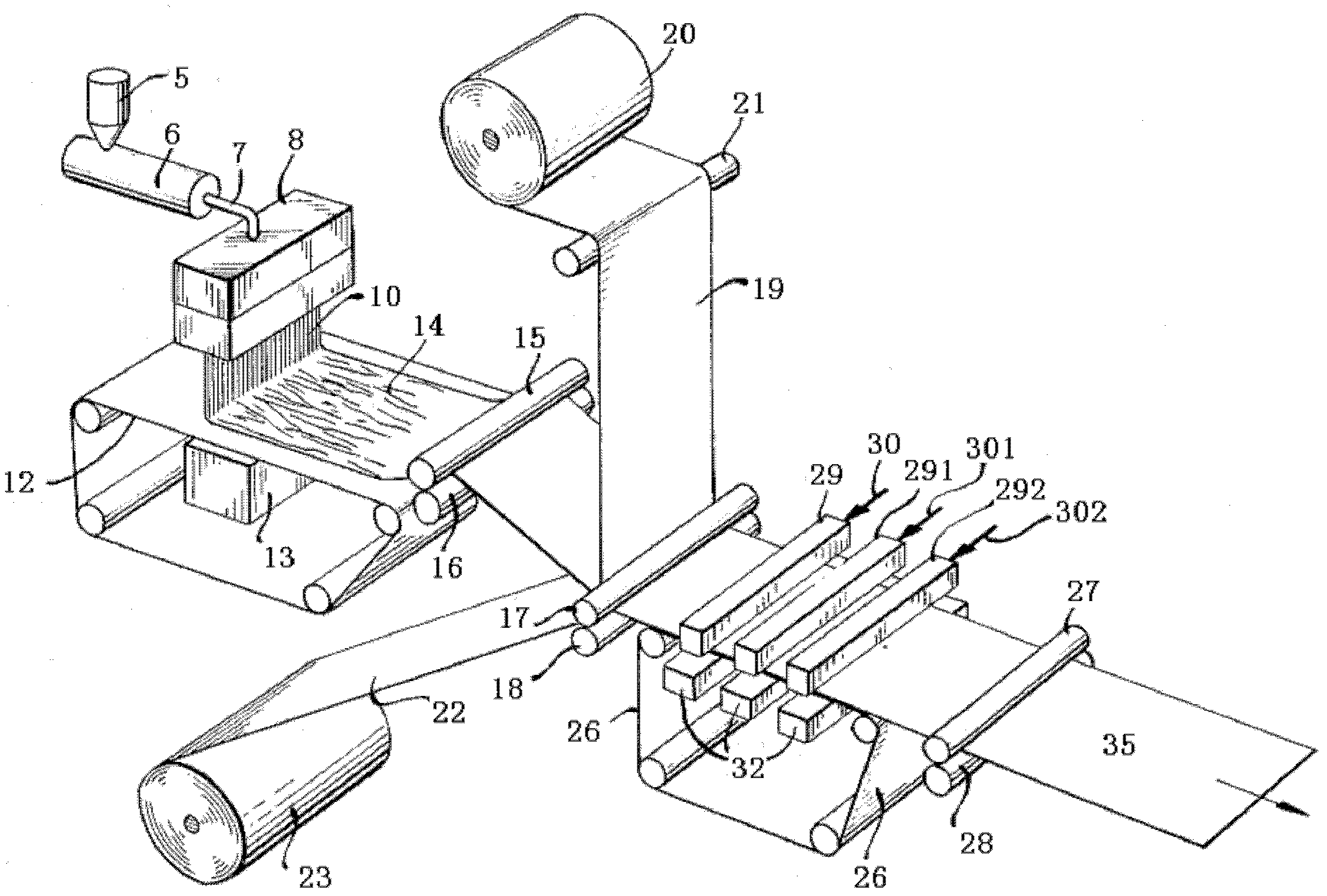

High-elasticity non-woven fabric and manufacturing equipment thereof

InactiveCN102501484AGood elasticityIncrease elasticitySynthetic resin layered productsLaminationFiber layerWoven fabric

The invention relates to a non-woven fabric and the manufacturing field of the non-woven fabric, and particularly relates to a high-elasticity non-woven fabric and manufacturing equipment of the high-elasticity non-woven fabric and manufacturing equipment. The non-woven fabric contains a middle fiber layer, an upper surface layer and a lower surface layer, and is characterized in that the middle fiber layer is formed by a thermoplastic polyurethane elastic body through a hot melting method; the upper and lower surface layers are made of wool fibers and / or wood pulp fibers. According to the high-elasticity non-woven fabric and the manufacturing equipment of the high-elasticity non-woven fabric, the manufacturing equipment comprises a hot melting device, a first transporting device, a gluing device, a high-pressure device and a molding device. The non-woven fabric woven by the equipment has the advantages of good elasticity, distinct gradation and convenience for manufacturing.

Owner:CHENGDU CAIHONG ENVIRONMENTAL PROTECTION TECH

Two-component polyurethane foaming agent and preparation method thereof

The invention relates to the technical field of sealing materials, in particular to a two-component polyurethane foaming agent and a preparation method thereof. Since curing of a one-component polyurethane foaming agent requires absorbing water vapor in air for reaction, and the curing time is longer, the curing reaction is slower if the humidity of the air is lower, and the dependency on the environment is higher. The two-component polyurethane foaming agent is prepared from two components of a component A and a component B, wherein the component A is prepared from polyol, a foaming agent, a catalyst, a surfactant and a flame retardant; the component B is prepared from isocyanate, the foaming agent and a foam stabilizer. The two-component polyurethane foaming agent provided by the invention is fast in curing speed, low in environment dependency, large in density and good in elasticity, and can meet the requirements of building industry. The invention also relates to the preparation method of the two-component polyurethane foaming agent.

Owner:苏州健能新材料科技有限公司

Silicone sponge and preparation method and usage thereof

Disclosed herein are a silicone sponge and preparation method and use thereof. More particularly, disclosed is a silicone sponge comprising a polyurethane sponge impregnated with a silicone solution, preparation method thereof and functional products made from the silicone sponge. The silicone sponge has excellent air permeability and elasticity, and various useful properties.

Owner:DONG SUNG SILICONE

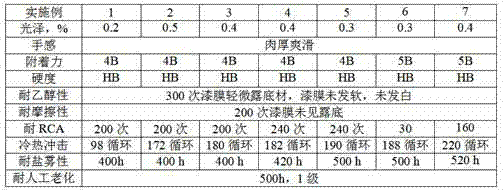

Water-based elastic rubber paint and preparation method thereof

ActiveCN104231901AGood elasticityEthanol scrub resistancePolyurea/polyurethane coatingsSolventIsocyanate

The invention relates to a water-based elastic rubber paint and a preparation method thereof and belongs to the technical field of paint. The water-based elastic rubber paint comprises, by weight, components A and component B, the components A include 30-40 parts of waterborne polyurethane emulsion, 0.3-0.6 part of water-based dispersing agents, 3-6 parts of color paste, 3-5 parts of extinction powder, 5-10 parts of elastic powder, 2-5 parts of hand feeling auxiliaries, 0.2-0.5 part of wax powder, 0.2-0.4 part of flatting agents, 0.1-0.3 part of defoaming agents, 1-2 parts of hydrated magnesium silicate, 0.5-1 part of neutralization agents, 1-2 parts of cosolvent and 5-10 parts of deionized water, the component B includes hexamethylene diisocyanate (HDI) hydrophilic isocyanate, and the weight ratio between the components A and the component B is (8-12) :1. According to the water-based elastic rubber paint and the preparation method thereof, pure waterborne system raw materials are used for preparing the water-based elastic rubber paint, the water-based elastic rubber paint is excellent in hand feeling elasticity and resistant to ethyl alcohol scrubbing and RCA paper tape friction and can be rubbed by RCA paper tapes for 200 times.

Owner:JIANGSU HUAXIA PAINT MAKING

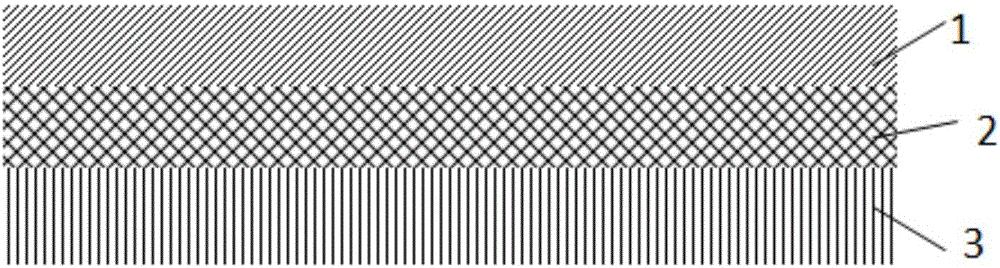

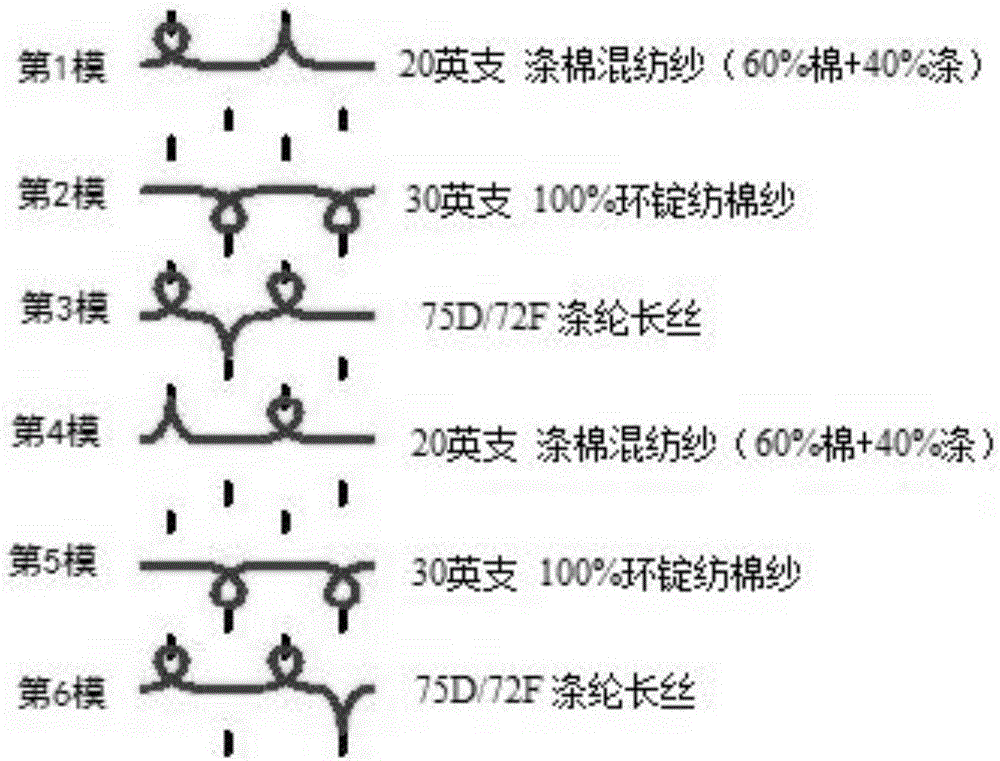

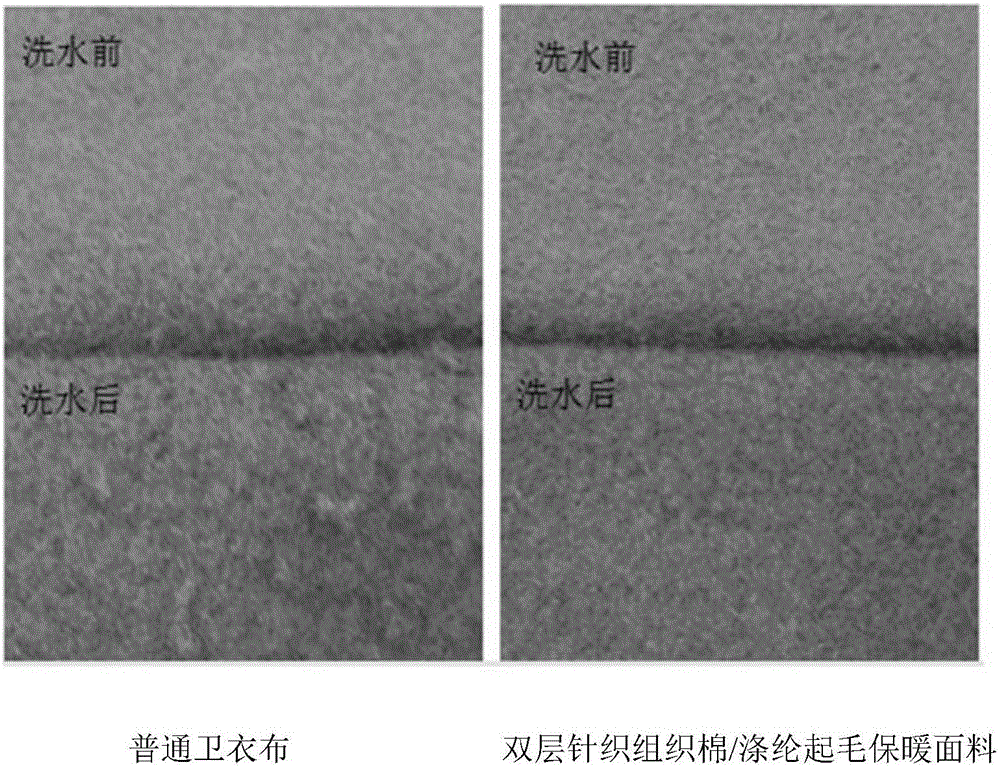

Double-layer knitting stitch type fleece and making method thereof

The invention provides double-layer knitting stitch type fleece and a making method thereof. The double-layer knitting stitch type fleece comprises a surface layer, a middle layer and a bottom layer, wherein the surface layer is made of cotton yarn or cotton blended yarn, the middle layer is made of dacron or nylon, the bottom layer is made of dacron or blended yarn, the surface layer is connected with the bottom layer through the middle layer, and the bottom layer is subjected to fluffing finishing. The invention further provides the making method of the double-layer knitting stitch type fleece. The making method comprises the steps of forming the surface layer and the bottom layer with the knitting double-layer weaving method, connecting the surface layer and the bottom layer into a whole by means of the middle layer to form knitting double-layer gray fabric, and conducting functional after treatment on the knitting double-layer gray fabric to obtain the double-layer knitting stitch type fleece.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Undercarriage faulty airplane safe landing gear

The invention discloses an undercarriage faulty airplane safe landing gear. The undercarriage faulty airplane safe landing gear comprises a landing plate provided with a traction mechanism and a sliding mechanism arranged below the landing plate. An elastic steel sheet with the M-shaped cross section is arranged on the upper portion of the landing plate. A flexible energy relief layer is arranged on the elastic steel sheet. A compensation air bag is arranged in a cavity between the landing plate and the elastic steel sheet. An airplane position automatic correction device is arranged in a concave position in the middle of the elastic steel sheet. The undercarriage faulty airplane safe landing gear has the advantages of being high in anti-seismic buffering capacity, capable of accurately and conveniently conducting positioning, flexible and adjustable in airplane landing position, low in cost, and capable of being popularized and applied conveniently.

Owner:马新攀

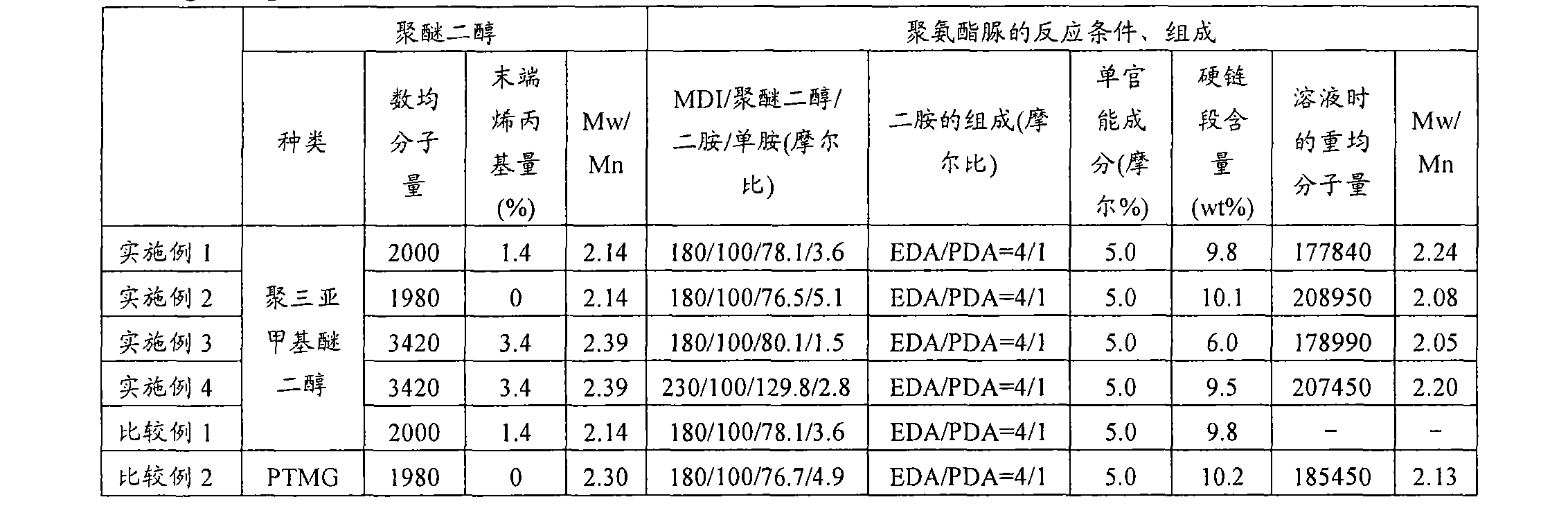

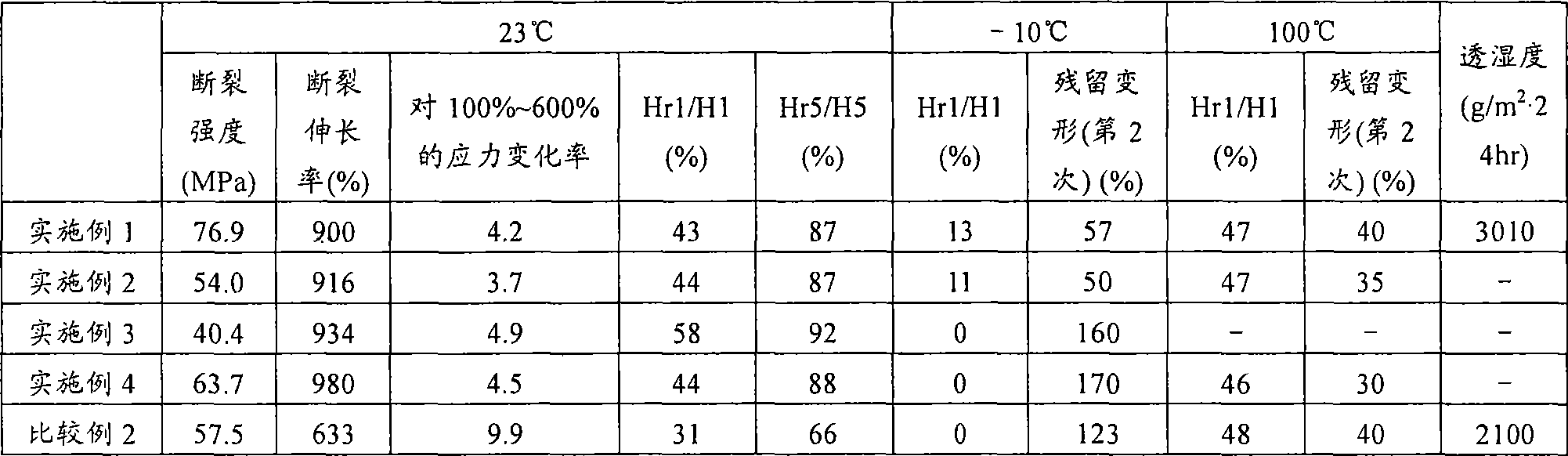

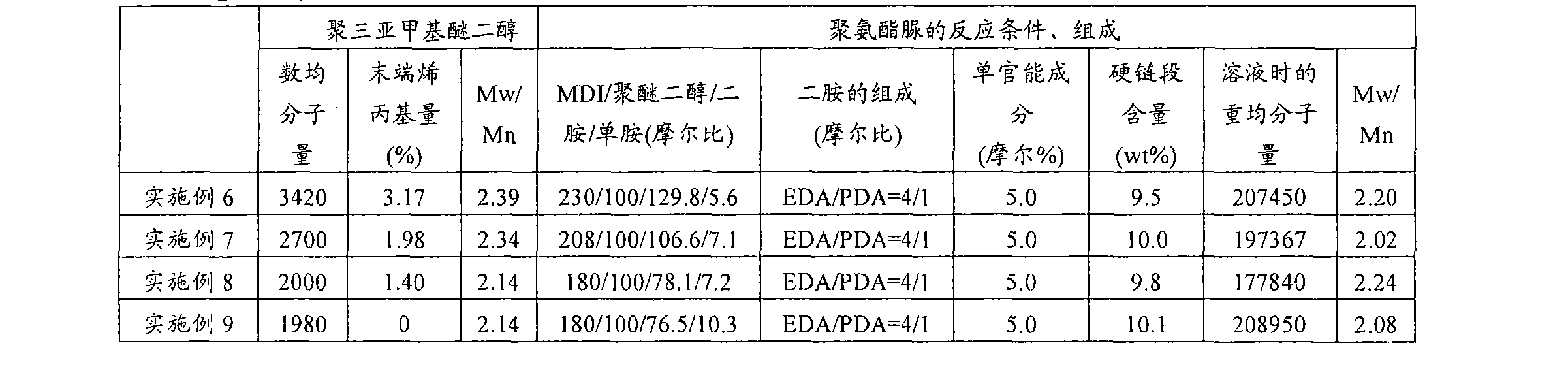

Method for producing polyurethane and use of polyurethane produced by the same

InactiveCN101484496AGood elasticityHigh elongation at breakMonocomponent polyurethanes artificial filamentFiberPolyurethane elastomer

Disclosed are a polyurethane and a polyurethaneurea which are extremely useful for polyurethane elastic fibers, synthetic / artificial leathers and highly functional polyurethane elastomers such as TPU. Specifically disclosed is a method for producing a polyurethane from a polyether polyol (a) obtained by a dehydration condensation reaction of a polyol and containing an 1,3-propanediol unit, a polyisocyanate compound (b) and a chain extender (c) in the co-presence of an aprotic polar solvent. Also specifically disclosed are a polyurethane produced by the method, and a film and a fiber composed of such a polyurethane.

Owner:MITSUBISHI RAYON CO LTD

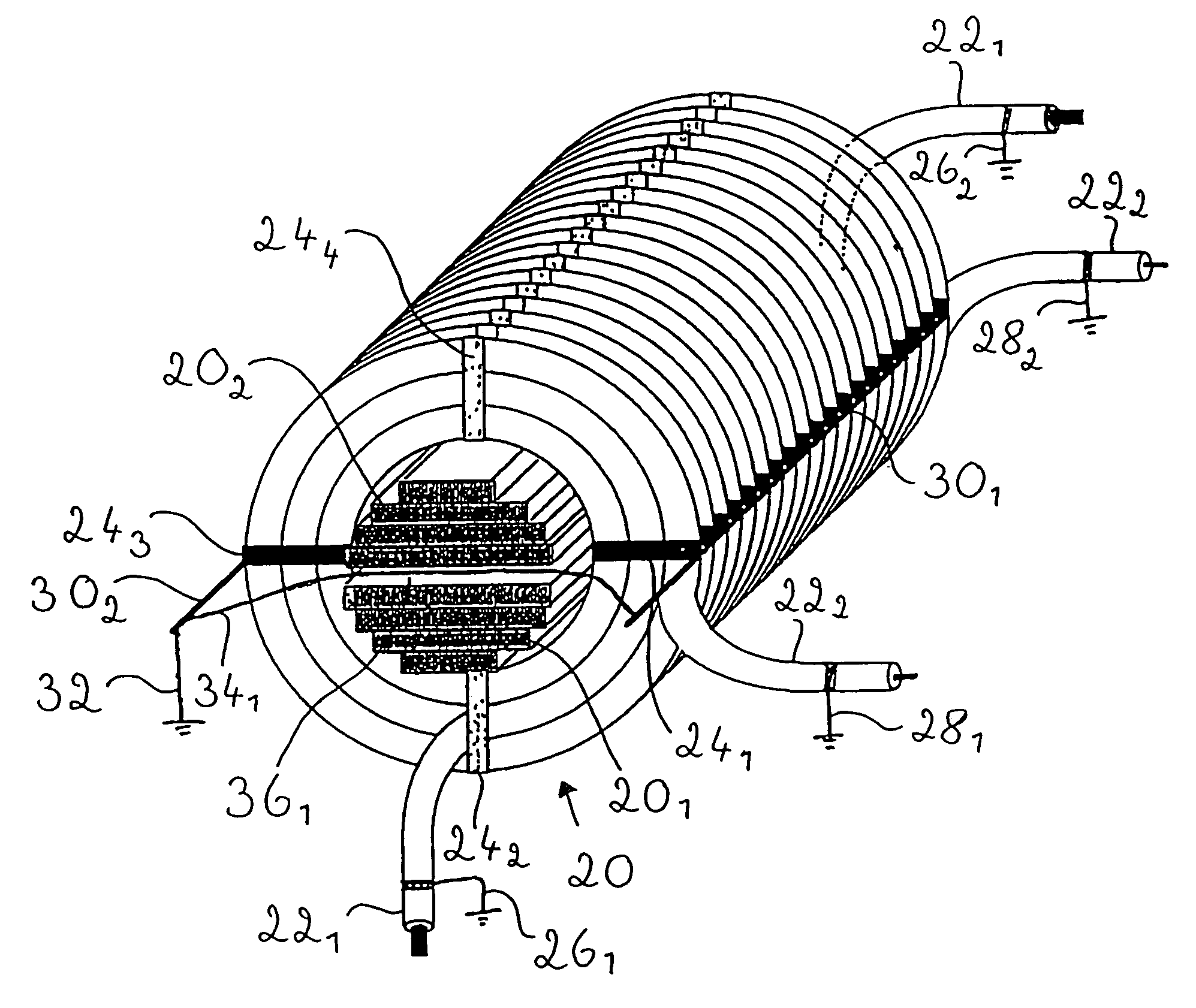

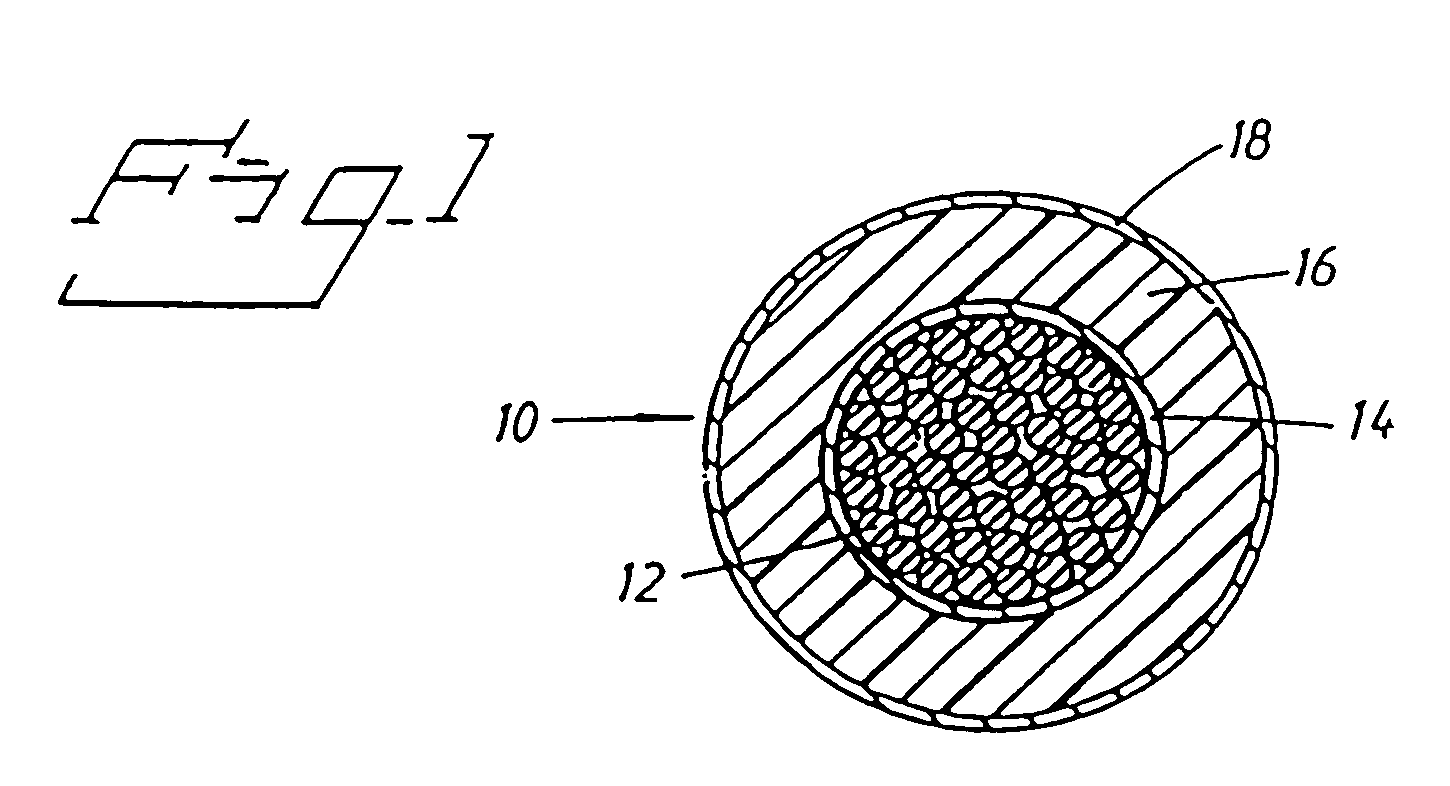

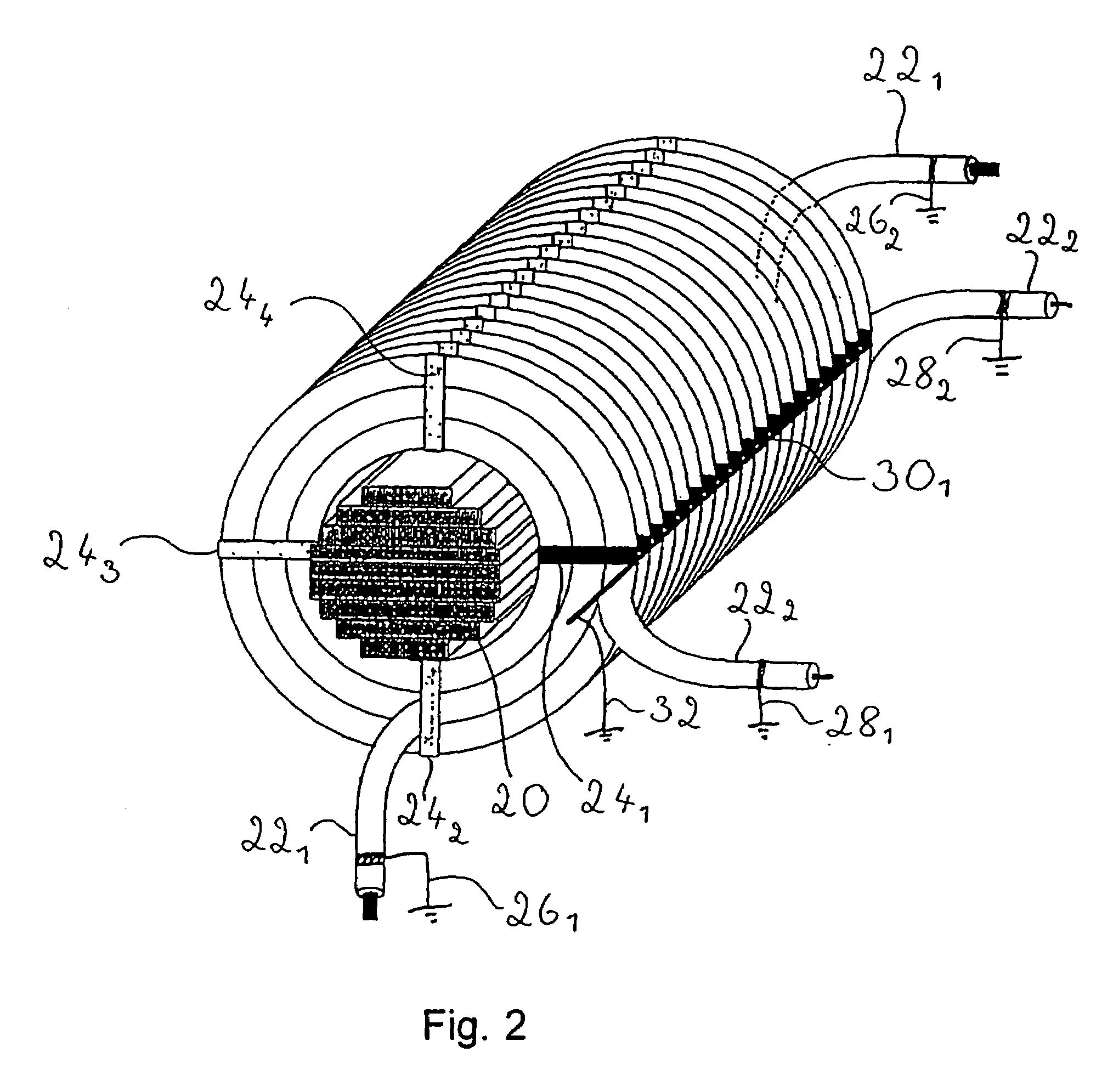

Power transformer/inductor

InactiveUS6970063B1Good elasticityShort construction timeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductorEngineering

The present invention relates to a power transformer / inductor comprising at least one winding. The windings are designed by means of a high-voltage cable, comprising an electric conductor, and around the conductor there is arranged a first semiconducting layer, around the first semiconducting layer there is arranged an insulating layer and around the insulating layer there is arranged a second semiconducting layer. The second semiconducting layer is earthed at or in the vicinity of both ends (261, 262; 281, 282) of each winding and furthermore one point between both ends (261, 262; 281, 282) is directly earthed.

Owner:ABB (SCHWEIZ) AG

Manufacturing method of packaging box plates

InactiveCN103786230AReduce weightGood elasticityNon-macromolecular adhesive additivesWood working apparatusSteel platesAgricultural crops

The invention discloses a manufacturing method of packaging box plates. The manufacturing method includes the steps of preparing materials, including the main material crop offcut; pouring wood chips, glue, and the crop offcut into a glue blender, and mixing well; laying, namely coating a veneer with a glue layer prior to laying the veneer on a steel plate, and making sure the glue side faces upside; placing the steel plate on a conveyor belt; evenly laying mixture on the veneer of the steel plate by a spreader; laying another veneer with the lower surface glued, on the mixture; pressurizing and solidifying, namely heating and pressurizing a laid plate blank in a hot press, at the temperature of 140-170 DEG C, holding the pressure for 6-10 minutes for solidification and forming; stripping and trimming, namely stripping the solidified plate and trimming the plate. Specifically, the materials include, by weight, 30-40% of the wood chips, 8-10% of the glue, and the balance of the crop offcut. The glue is dicyclopentadiene modified unsaturated polyester resin glue. Therefore, environment protection is achieved.

Owner:孟可星

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com