Hardly-foamed one-component polyurethane sealant

A technology of polyurethane sealant and polyurethane prepolymer, applied in the field of sealant, can solve problems such as easy foaming, and achieve the effects of good elasticity, excellent bonding performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

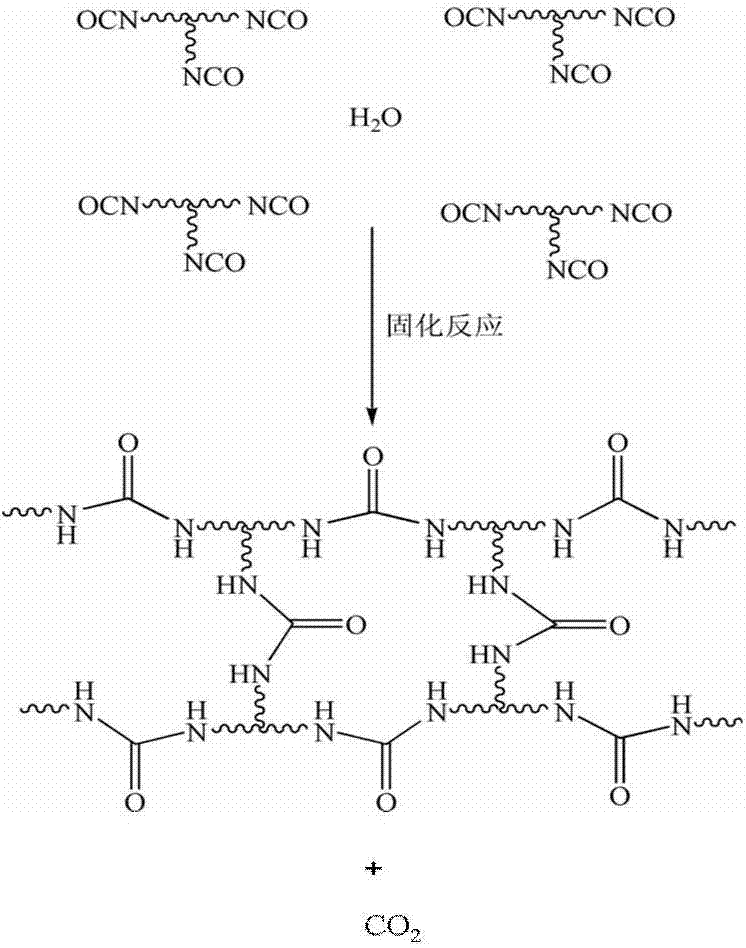

Method used

Image

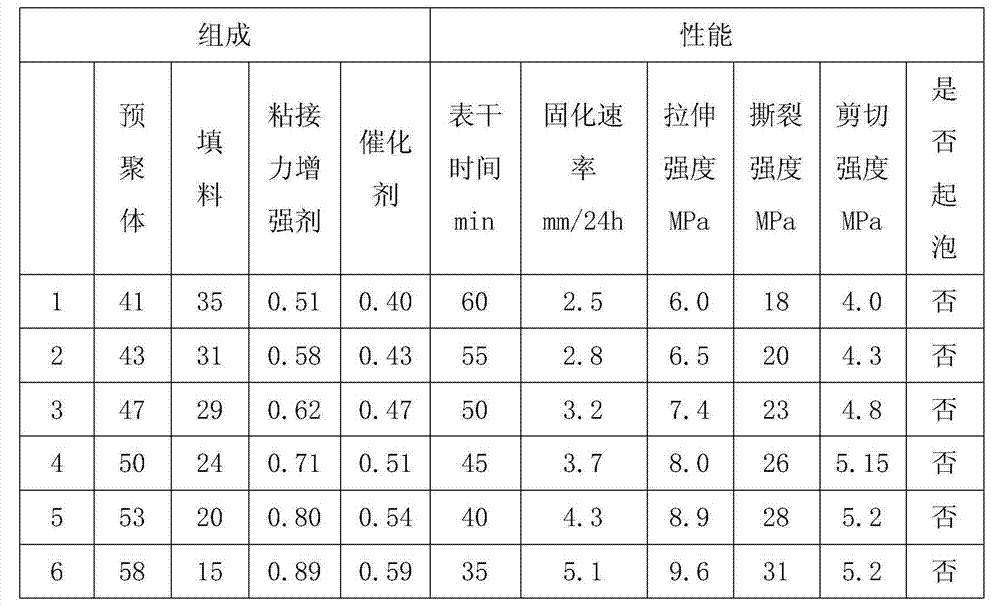

Examples

Embodiment Construction

[0027] In the following text, the invention will now be described more fully, illustrating various embodiments. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

[0028] The polyether polyol mixture (PPG polyether with a molecular weight of 2000, a functionality of 2, and an E0-terminated propylene oxide polyether with a molecular weight of 6000, a functionality of 3, and a mass ratio of 1:2) and a plasticizer Put it into the reaction kettle, under the conditions of 110~130℃ and vacuum degree of -0.098 MPa, dehydrate until the water content is less than 500ppm, then cool down to about 50℃, add polyisocyanate MDI, nitrogen protection, stirring, control the reaction temperature 75~ React at 90°C for 1.5 hours to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com