Double-layer knitting stitch type fleece and making method thereof

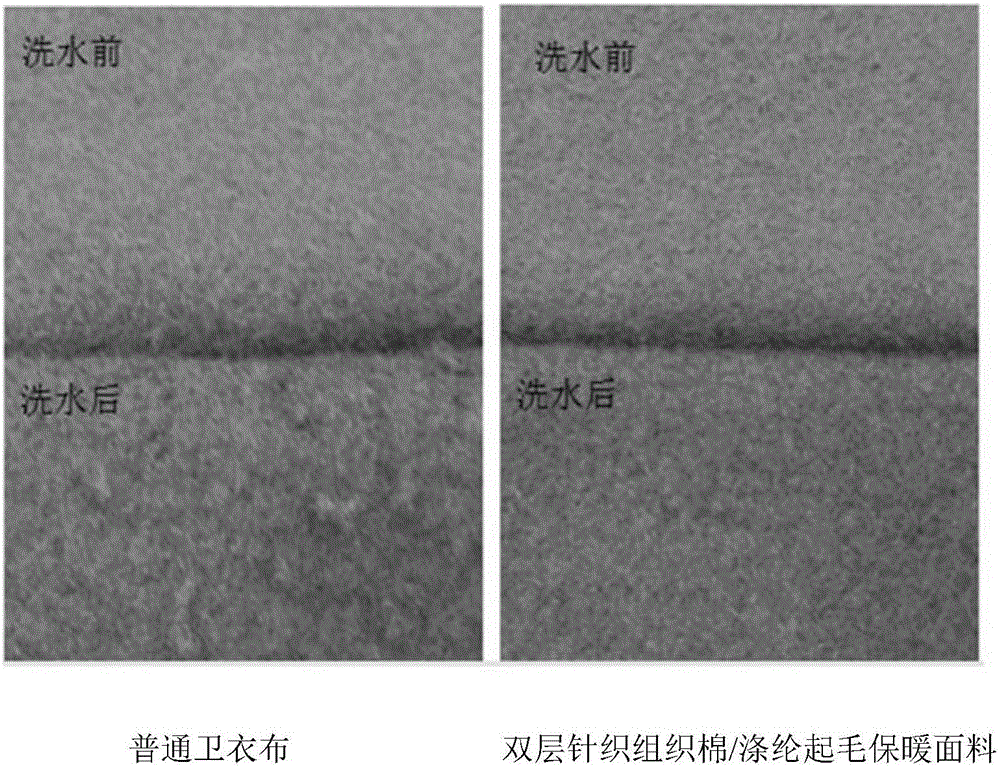

A manufacturing method and double-layer technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of easy pilling, poor elasticity, and single structure of the wool surface, and achieve the effect of fluffy hand feeling and excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

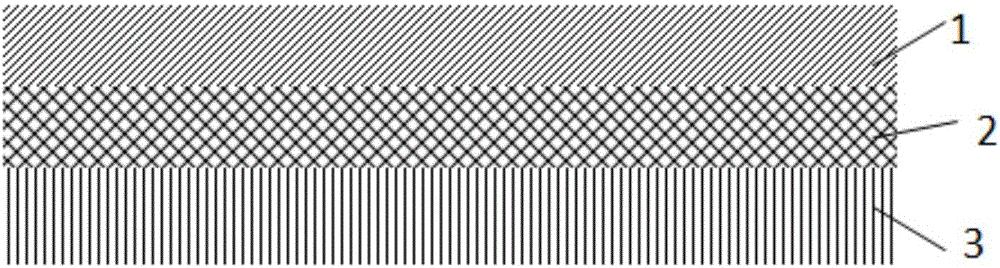

[0046] This embodiment provides a kind of double-layer knitting tissue raised fabric, the structure of this fabric is as follows: figure 1 As shown, it includes surface cloth (1), middle layer (2) and bottom layer cloth (3), wherein, surface layer cloth (1) adopts 100% ring-spun cotton yarn with 30 lbs, and its twist coefficient is 3.7; bottom layer cloth (3 ) adopts 20 English count polyester-cotton blended yarns (60% cotton / 40% polyester), and its twist coefficient is 3.5; the middle layer (2) adopts 75D / 72F polyester filaments.

[0047] The manufacture method of the present embodiment double-layer knitting organization raised fabric is:

[0048] The model used: 18G large circular knitting machine, the machine speed is 20r / min, the distance between the tube opening is 1.0cm, and the yarn feeding tension is 8cN. The large circular knitting machine is equipped with a FEED machine with a positive yarn feeding device.

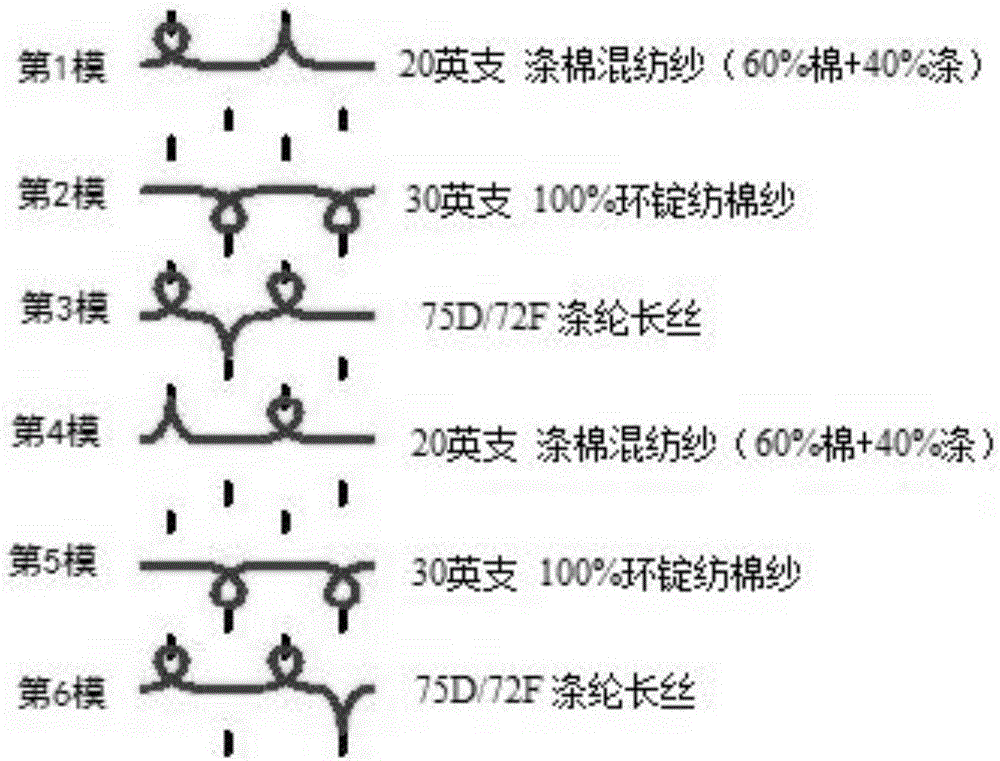

[0049] Double-sided knitting with a plain weave six-patter...

Embodiment 2

[0061] This embodiment provides a kind of double-layer knitting tissue raised fabric, the structure of this fabric is as follows: figure 1 Shown, comprise surface layer cloth (1), middle layer (2) and bottom layer cloth (3), wherein, surface layer cloth (1) adopts 26 British counts 100% ring-spun cotton yarn, and its twist coefficient is 3.6; Bottom layer cloth (3 ) adopts 16 British count polyester-cotton blended yarns (60% cotton / 40% polyester), its twist coefficient is 3.5, and the middle layer (2) adopts 100D / 144F polyester filaments.

[0062] The manufacture method of the present embodiment double-layer knitting organization raised fabric is:

[0063] The model used: 18G large circular knitting machine, the machine speed is 20r / min, the distance between the tube opening is 1.0cm, and the yarn feeding tension is 8cN. The large circular knitting machine is equipped with a FEED machine with a positive yarn feeding device.

[0064] Double-sided knitting with eight-mode pique...

Embodiment 3

[0076] This embodiment provides a kind of double-layer knitting tissue raised fabric, the structure of this fabric is as follows: figure 1 Shown, comprise surface layer cloth (1), middle layer (2) and bottom layer cloth (3), wherein, surface layer cloth (1) adopts the cotton yarn of 30 pounds 100% ring spinning, twist coefficient is 3.7; Bottom layer cloth (3 ) adopts polyester-cotton blended yarn (60% cotton / 40% polyester) of 26 English count twist coefficients of 3.6, and the middle layer (2) is 75D / 72F polyester filament.

[0077] The manufacture method of the present embodiment double-layer knitting organization raised fabric is:

[0078] The model used: 18G large circular knitting machine, the machine speed is 20r / min, the distance between the tube opening is 1.0cm, and the yarn feeding tension is 8cN. The large circular knitting machine is equipped with a FEED machine with a positive yarn feeding device.

[0079] Double knitting with pique ten-mode weave, such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com