Patents

Literature

73results about "Lubricating devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

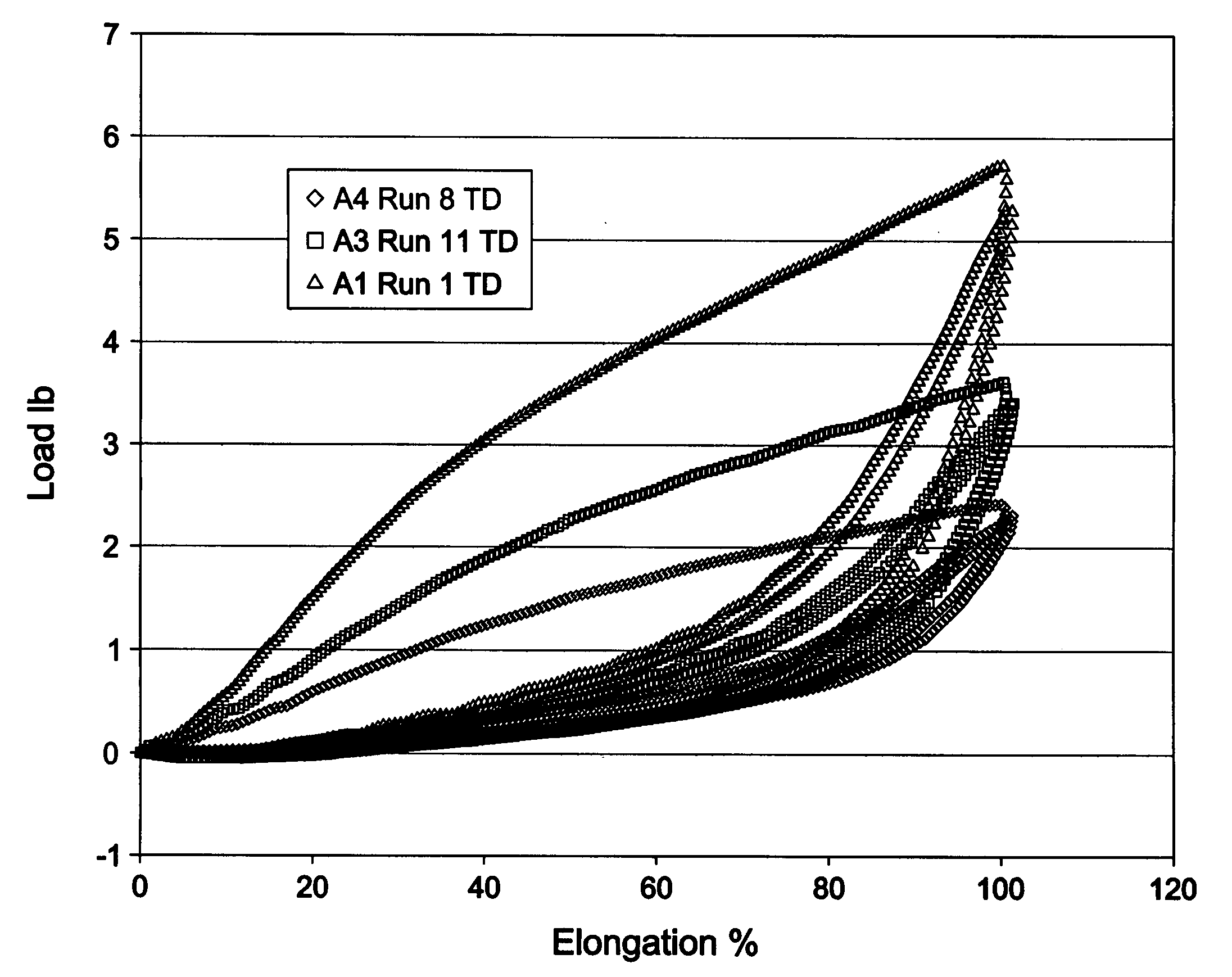

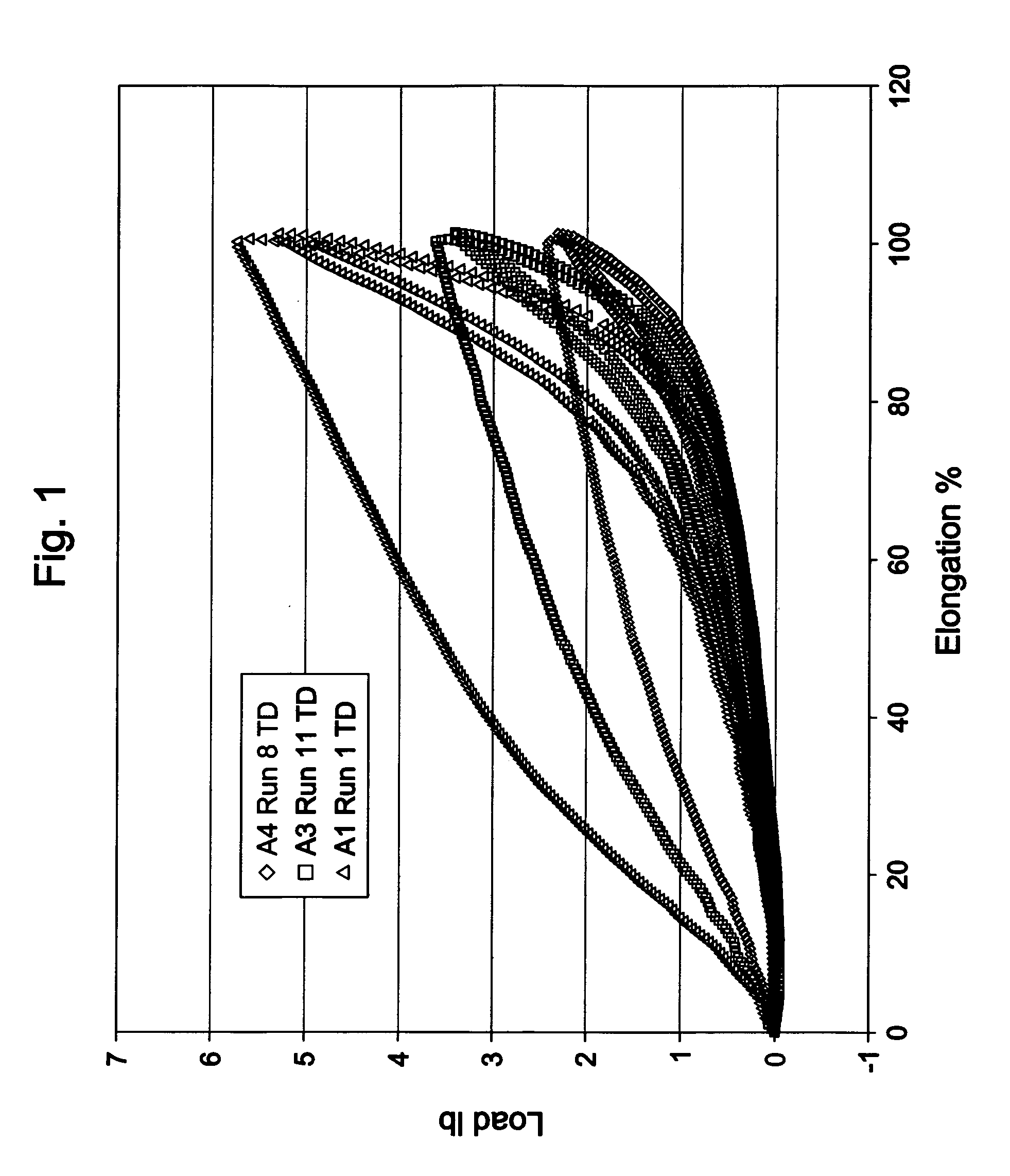

Spunbond fibers and fabrics from polyolefin blends

The invention described relates to a polyolefin blend composition suitable for spunbond fiber or filament compositions, and to fabric compositions and composite constructions therefrom, said blend comprising a) from 60-98 wt % of at least one random propylene copolymer having a comonomer content of from 8 to 25 wt % and a crystalline melting point (Tm) as determined by differential scanning calorimetry (DSC) of from about 40° C. to about 110° C.; and b) from 2-40 wt % of at least one substantially isotactic polypropylene homopolymer or copolymer comprising one or more C2 and / or C4-C8 comonomer, having a crystalline melting point (Tm) as determined by DSC greater than or equal to 120° C. The blends of the present invention typically have a melt flow rate (MFR) of from 100 g / 10min to about 500 g / 10min.

Owner:EXXONMOBIL CHEM PAT INC

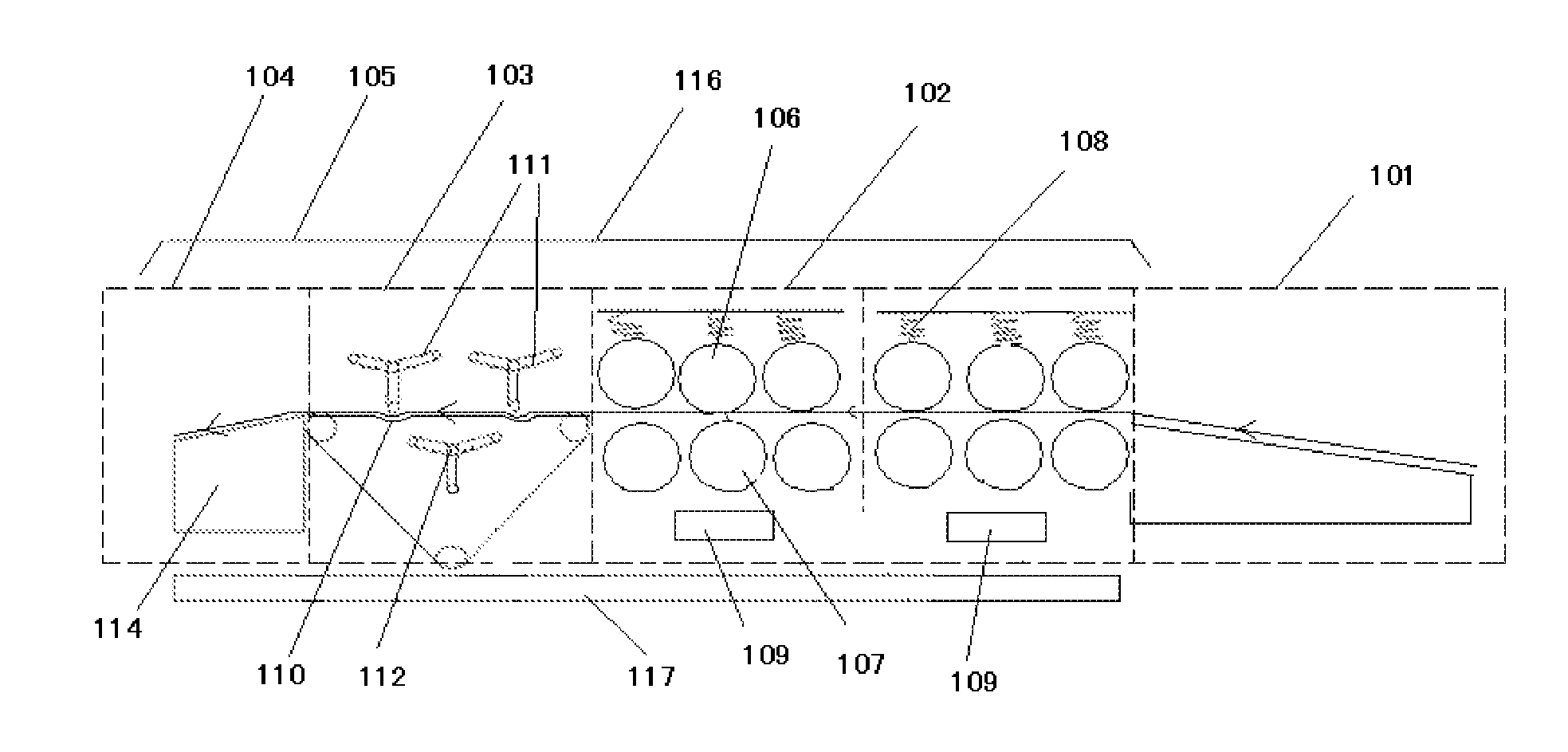

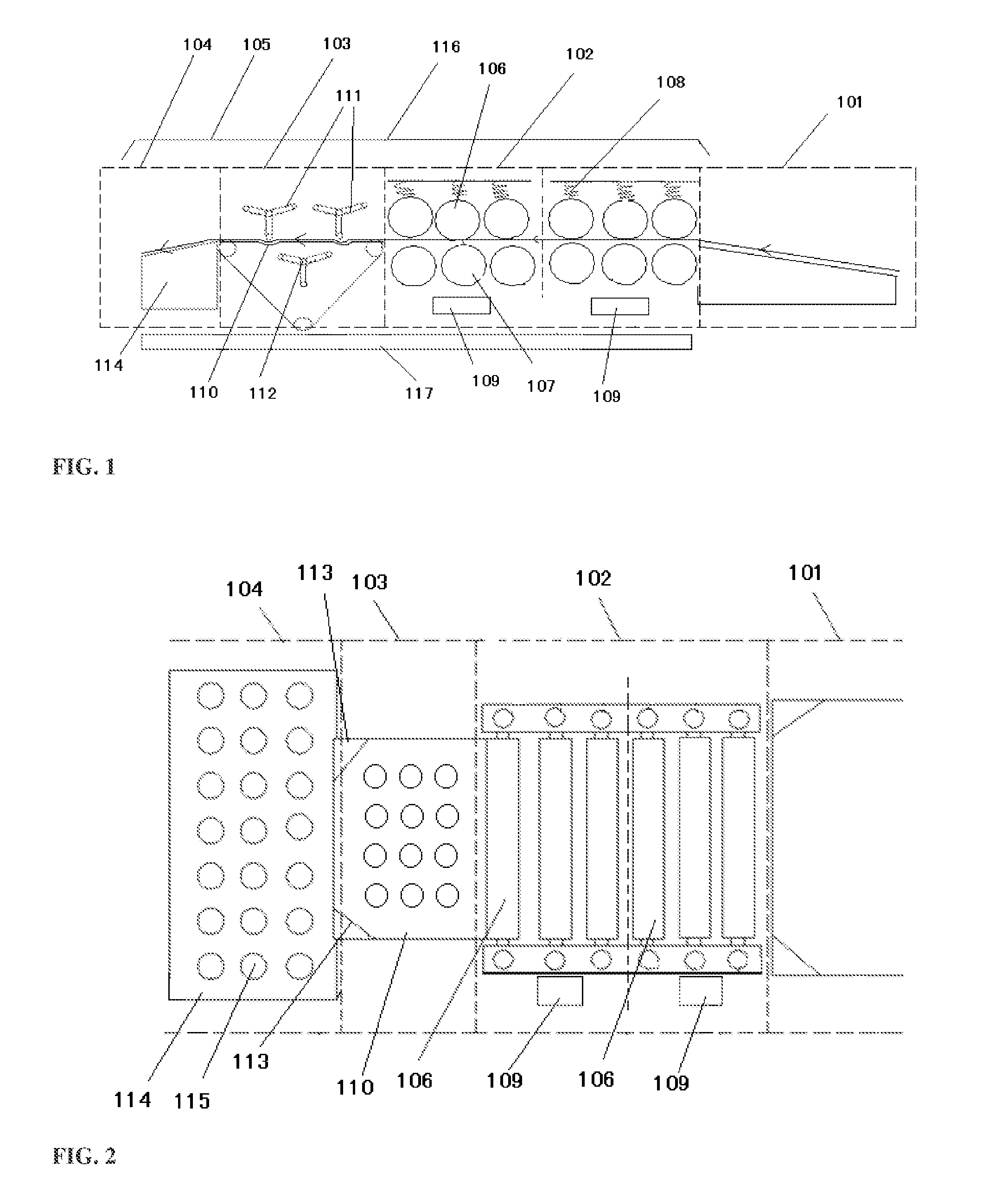

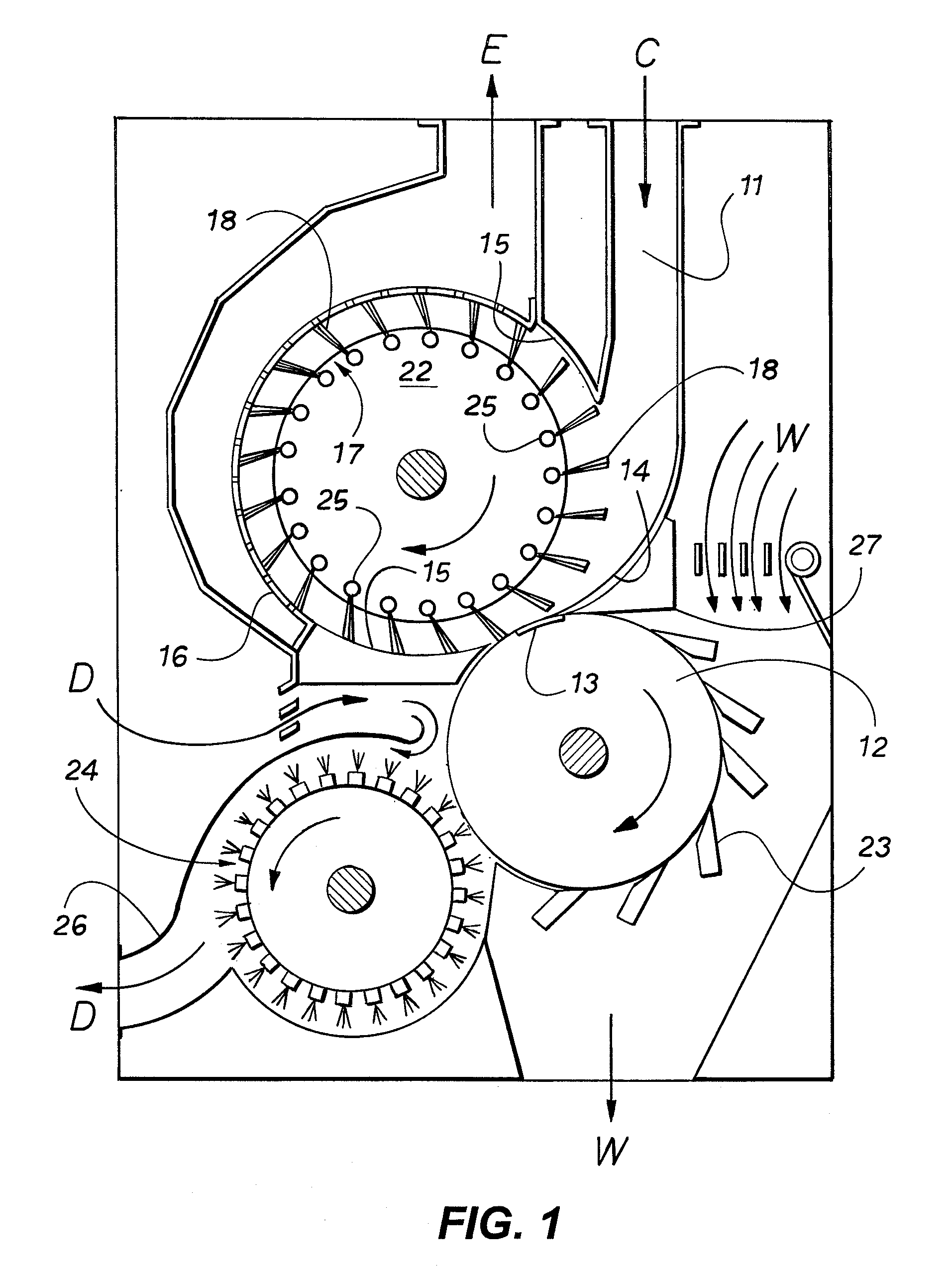

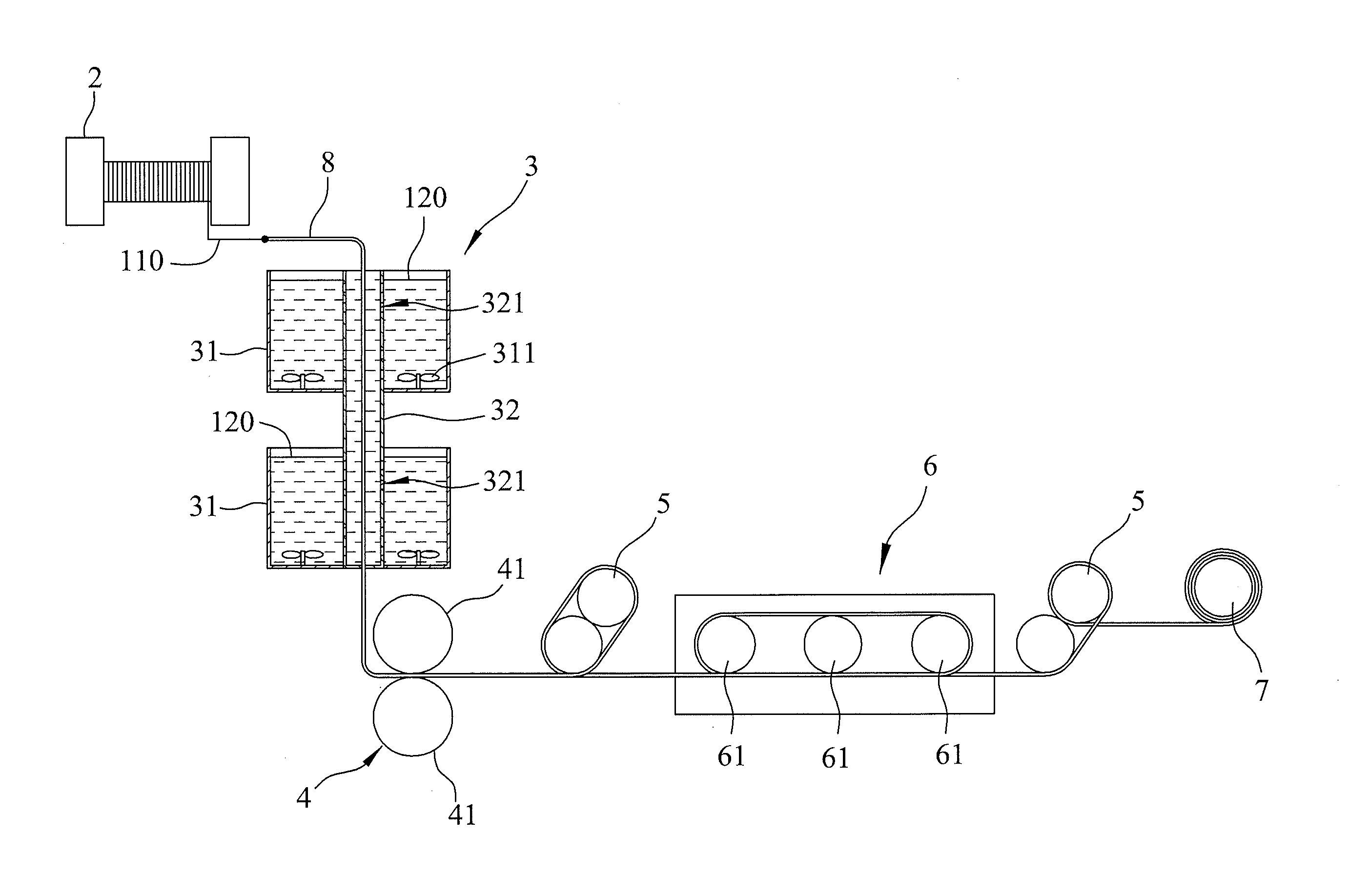

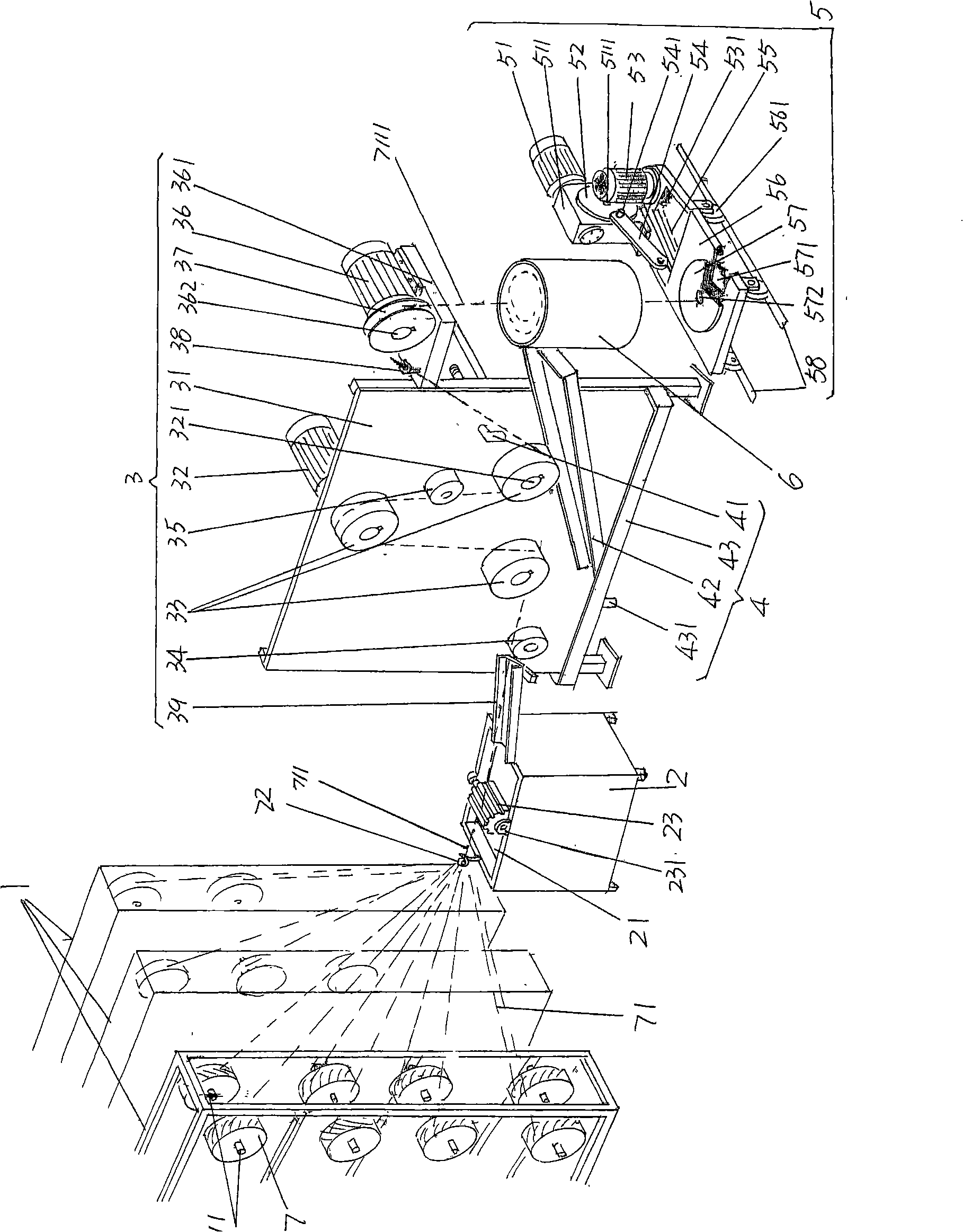

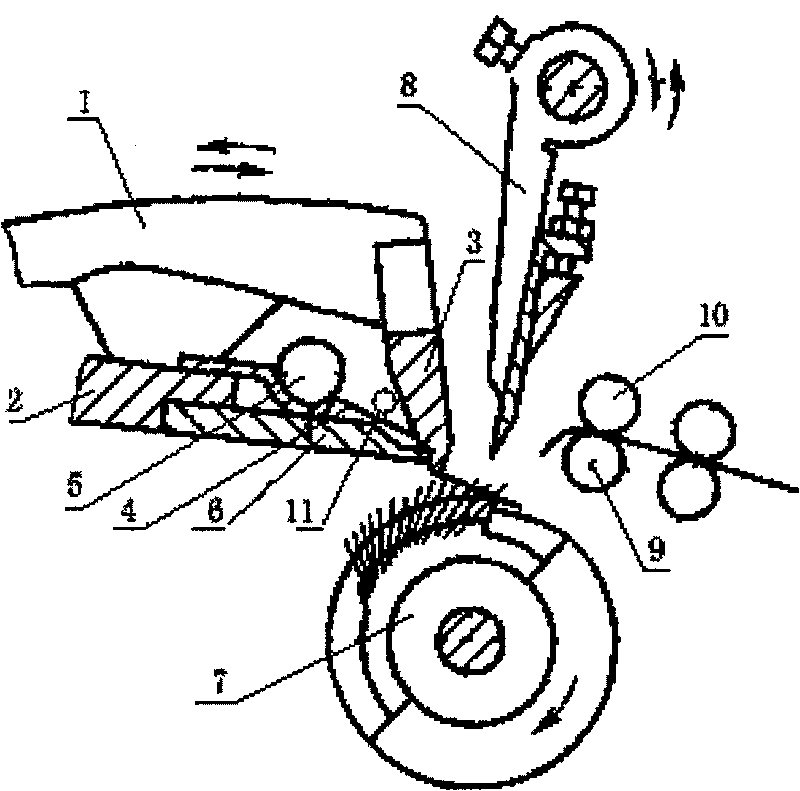

Processing Line of Bast Fiber

ActiveUS20120324677A1Improve fiber separation indexImprove biochemistry degumming uniformityMechanical impurity removalLubricating devicesCardingEngineering

A processing line of bast fiber is provided. The processing line is comprised of various devices for carding, cutting, degumming, high temperature washing, separating and water washing, softening, drying, batching and applying oil, permeating and reconditioning, stretching-breaking carding, and combing and sorting. The processing line of bast fiber can improve production efficiency, and improve the yield of long hemp fibers. Moreover, the produced fiber has stable quality and is convenient for post-processing.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

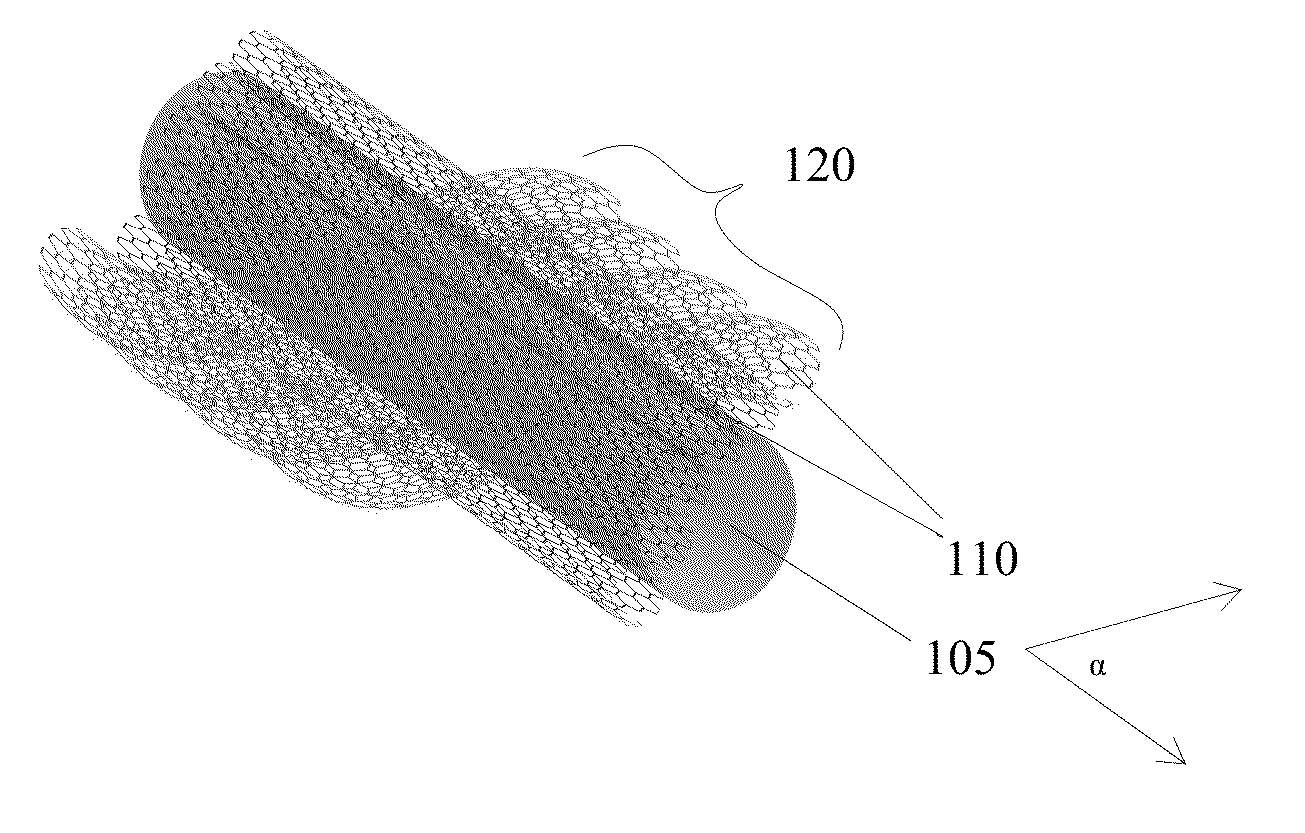

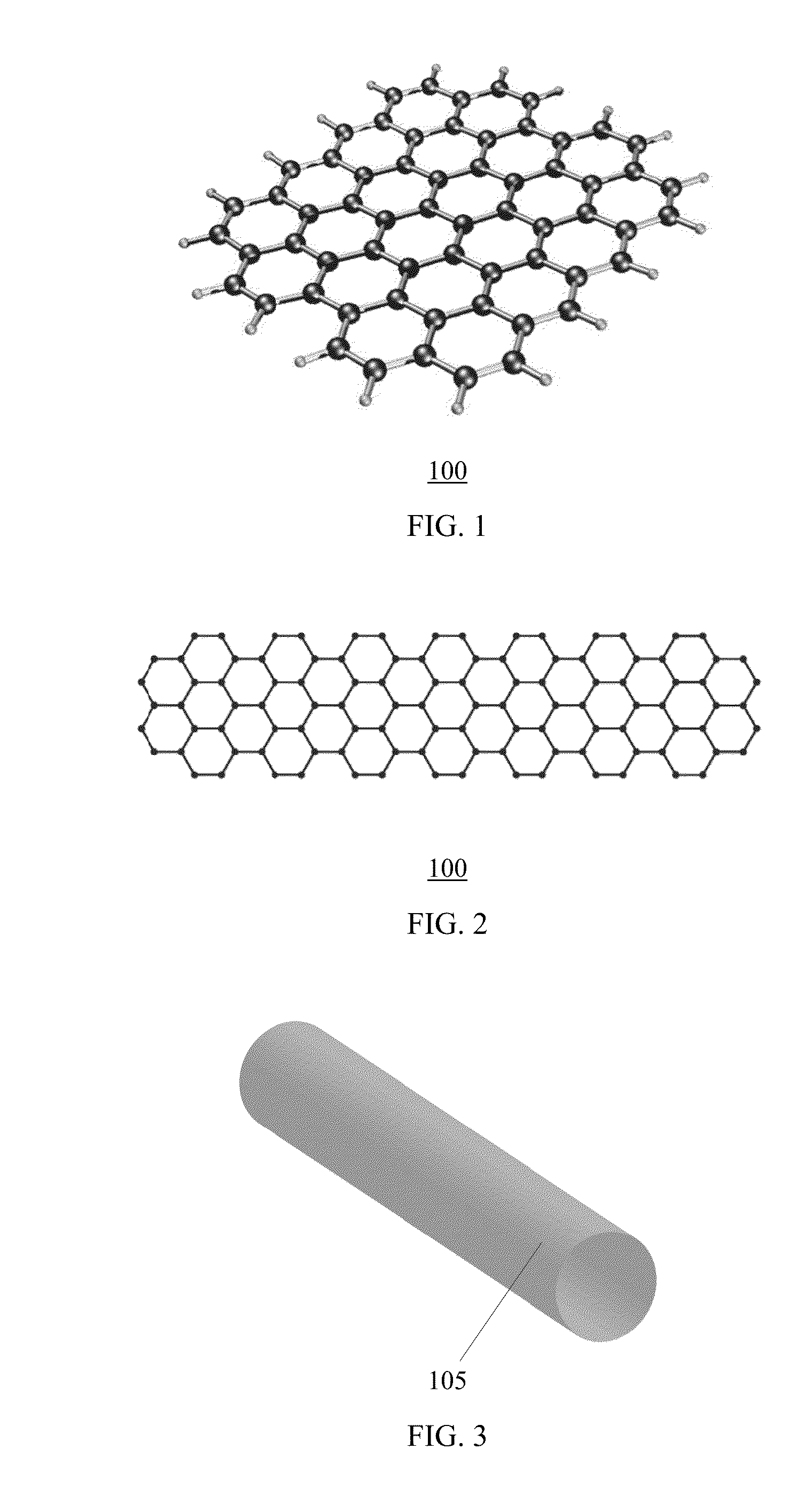

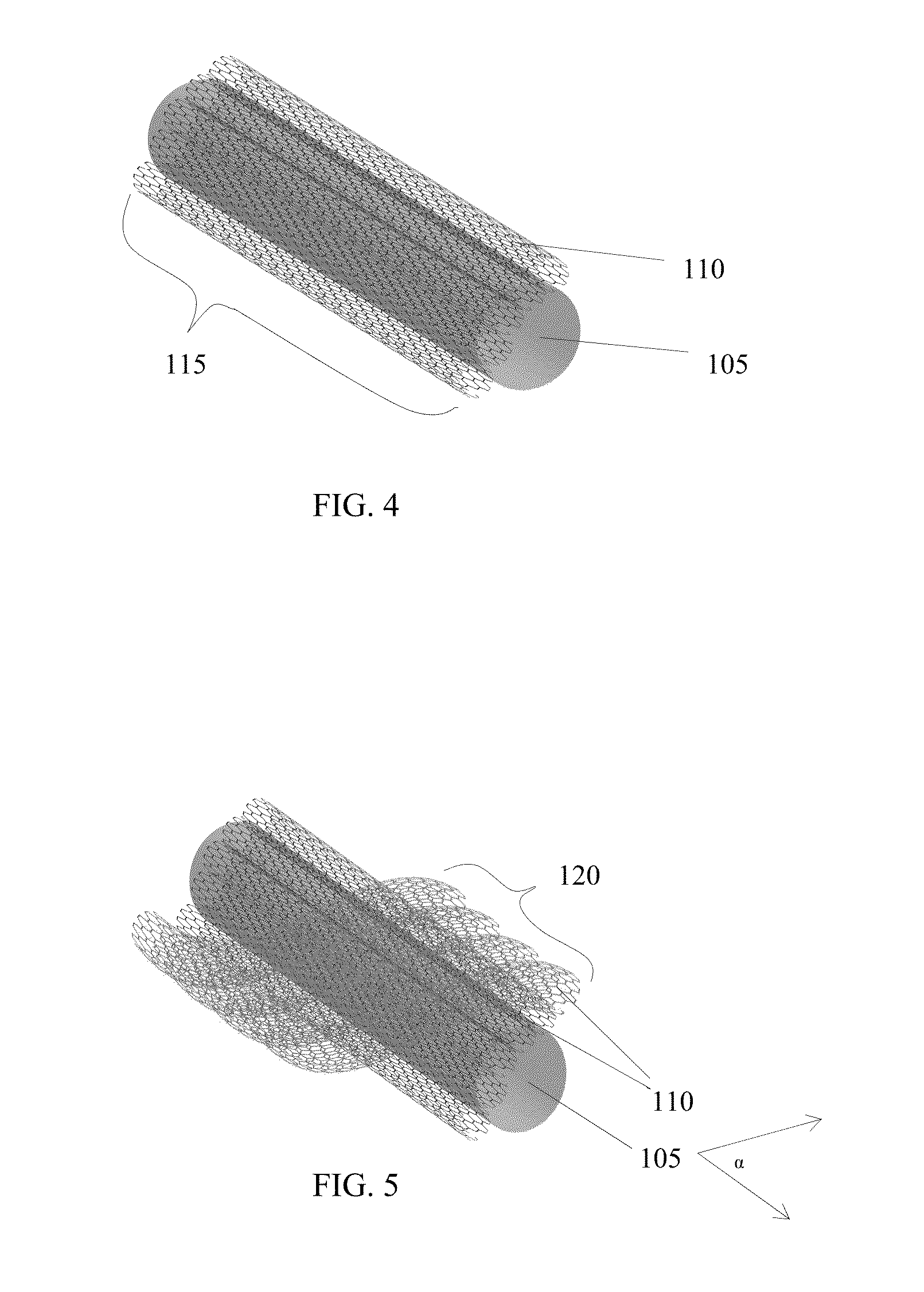

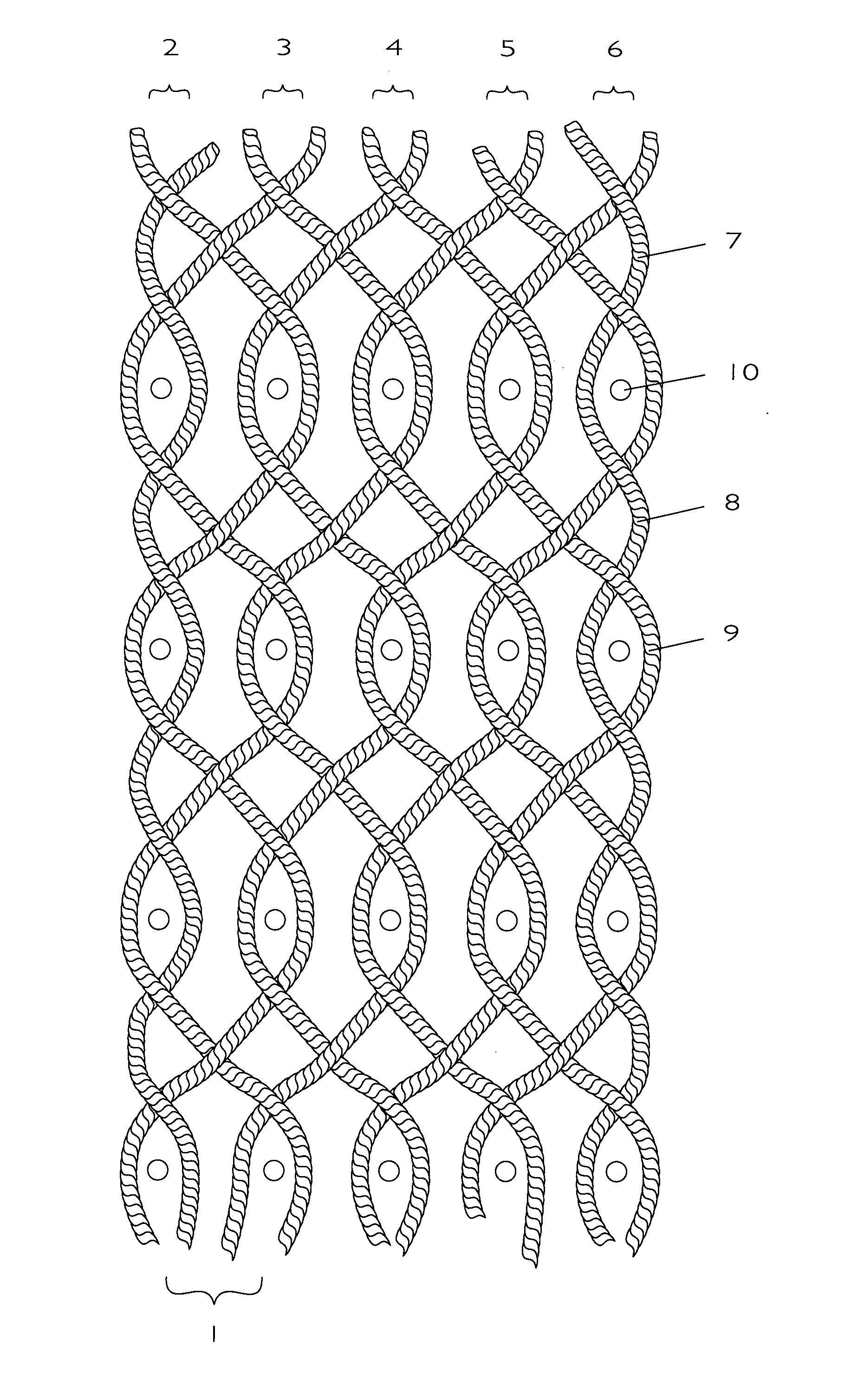

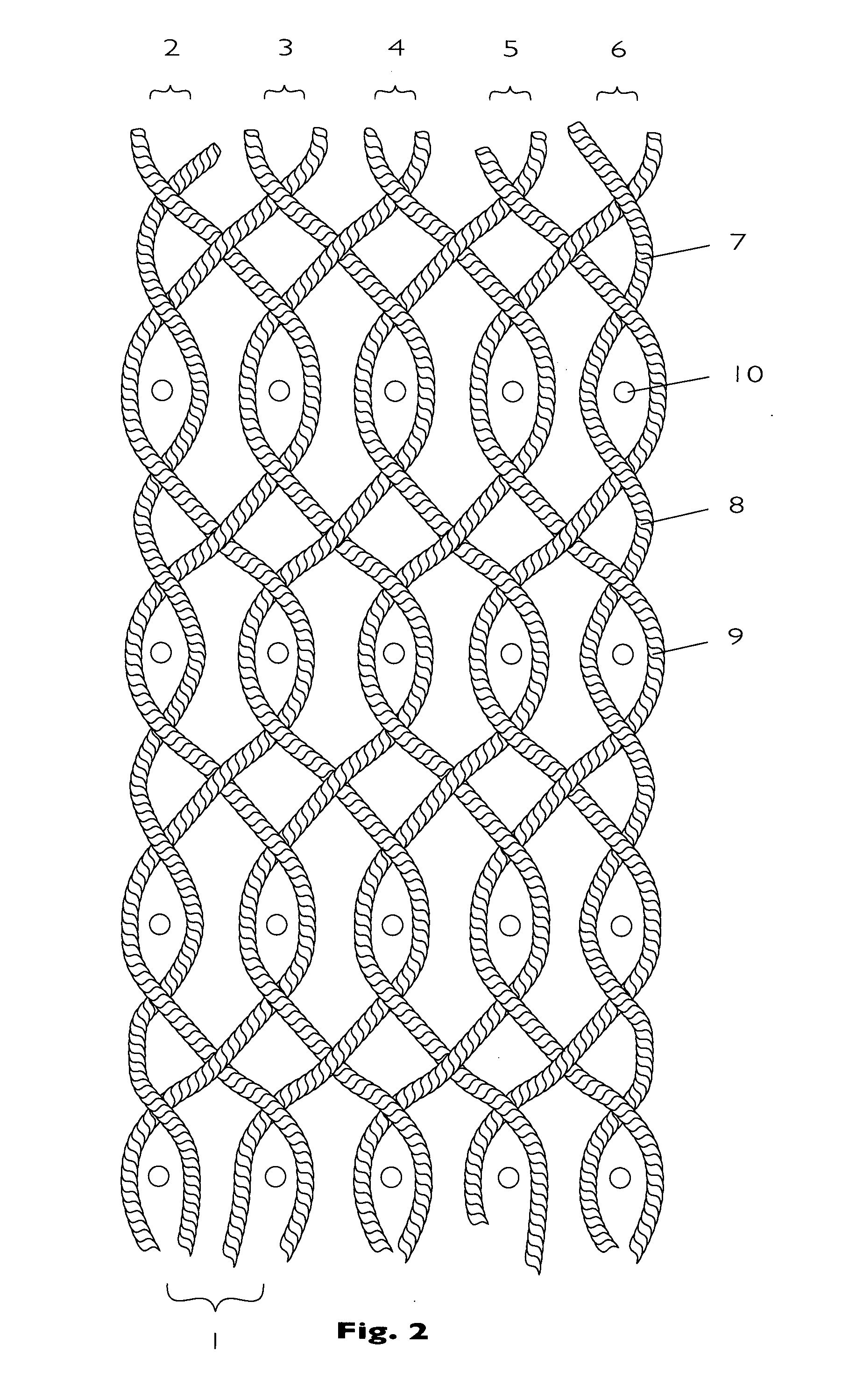

Graphene-Based Threads, Fibers or Yarns with Nth-Order Layers and Twisting and Methods of Fabricating Same

InactiveUS20140050920A1High strengthHigh tensile strengthMaterial nanotechnologyLubricating devicesYarnFiber

A representative embodiment includes a graphene-based fiber comprising: a starting strand; and a plurality of coatings of aligned graphene comprising: a first coating of aligned graphene axially offset at a first angle from an axis of the starting strand; a second coating of aligned graphene over the first coating and axially offset at a second angle from the axis of the starting strand; and at least one next coating of aligned graphene over a preceding coating and axially offset at a next angle from the axis of the starting strand. Another embodiment includes a plurality of intertwined and twisted graphene-based fibers. In various embodiments, the graphene may be graphene ribbons or carbon nanotubes or both. The graphene ribbon includes a plurality of aligned and overlapping graphene flakes in a polymer. Methods of fabrication are also disclosed.

Owner:NTHDEGREE TECH WORLDWIDE

Aramid fiber and carbon fiber blended yarn and production method thereof.

InactiveCN101864631ALow densityHigh temperature resistantLubricating devicesYarnYarnVibration attenuation

The invention discloses aramid fiber and carbon fiber blended yarn formed by blending aramid fiber and carbon fiber in a mass part ratio of 1:1. The production method of the aramid fiber and carbon fiber blended yarn adopts the aramid fiber and carbon fiber as raw materials in the mass ratio of 1:1 and comprises the following steps of: firstly, preprocessing the aramid fiber and the carbon fiber, i.e. preadding an oiling agent to release static electricity; and sequentially carrying out the working procedures of blending, blowing, carding, drawing, roving, spinning and self-winding to make the aramid fiber and carbon fiber blended yarn. By adopting the aramid fiber and carbon fiber blended yarn and the production method thereof, the blended yarn has the performances of low density, resistance of high temperature, corrosion, friction and aging, high vibration attenuation property, electric and thermal conduction and optical penetration, low heat expansion coefficient, electromagnetic shielding property by non-magnet, and the like.

Owner:江阴市海江纱厂有限公司

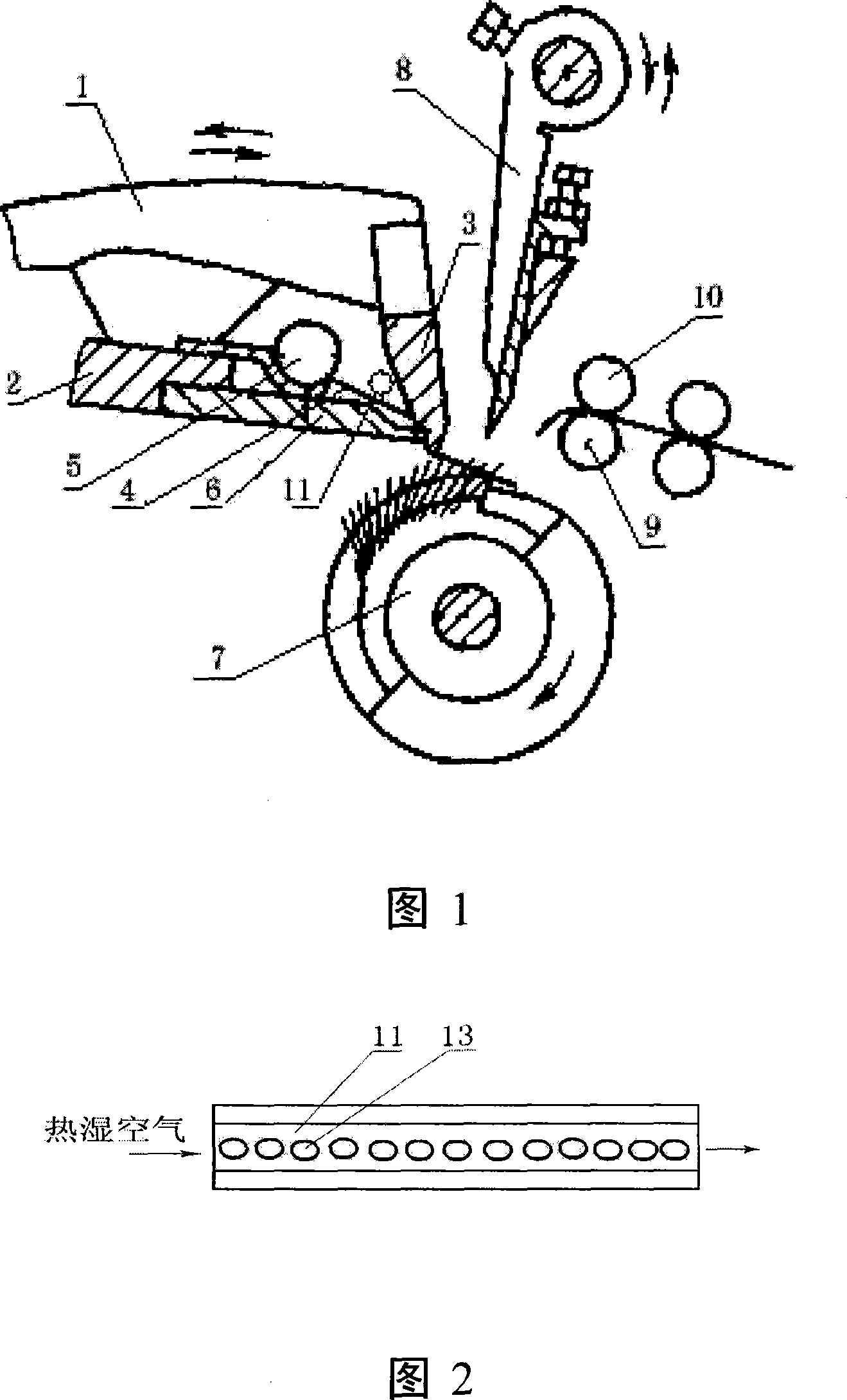

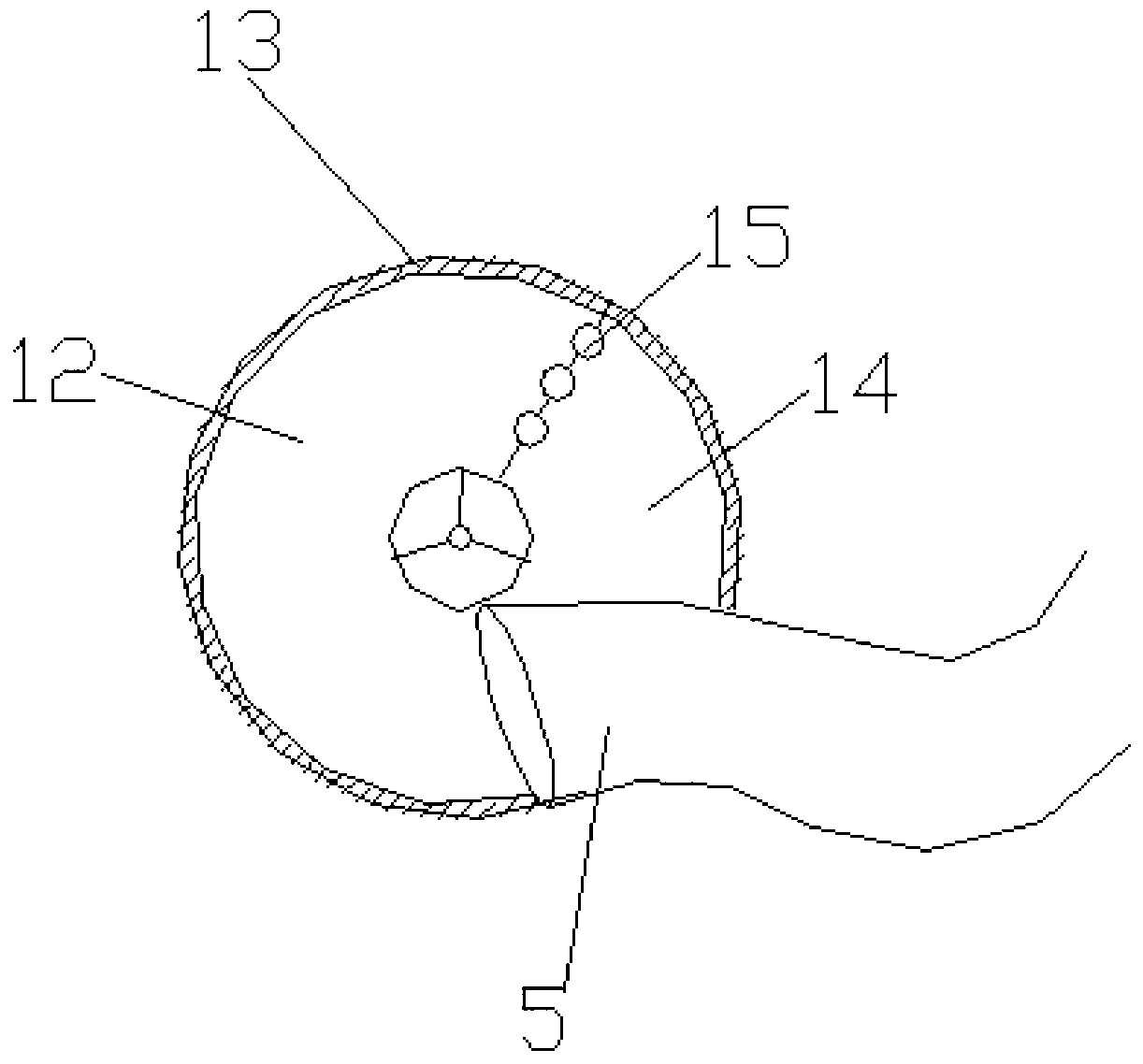

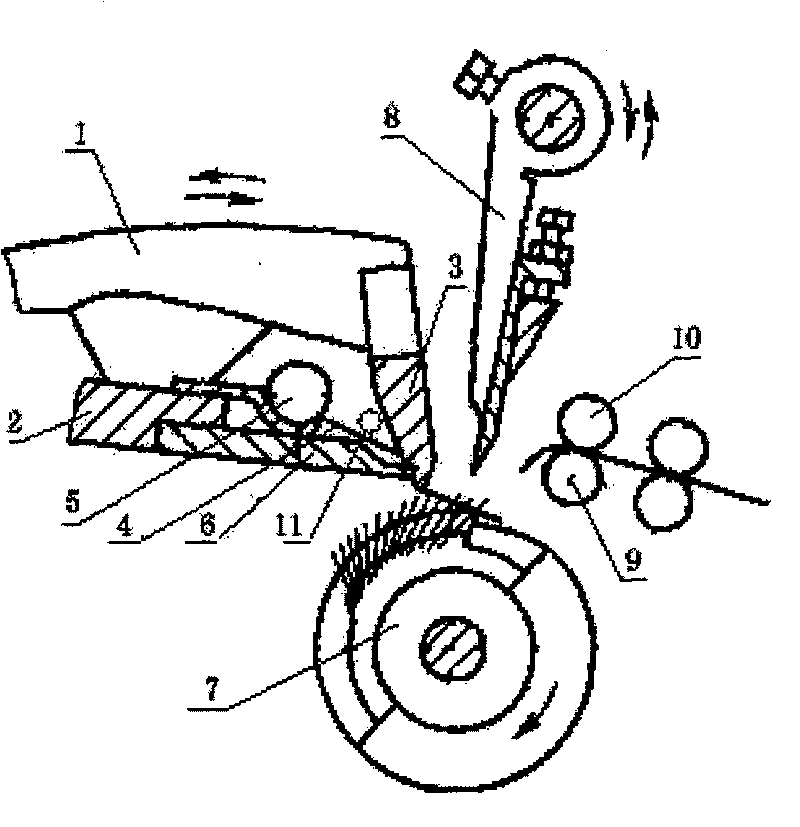

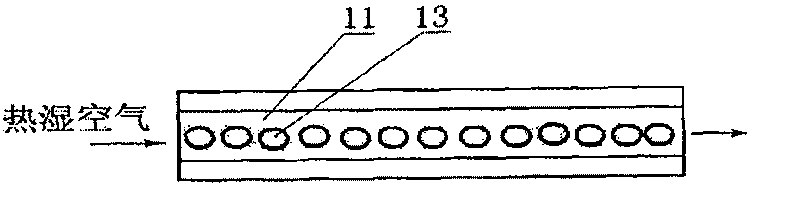

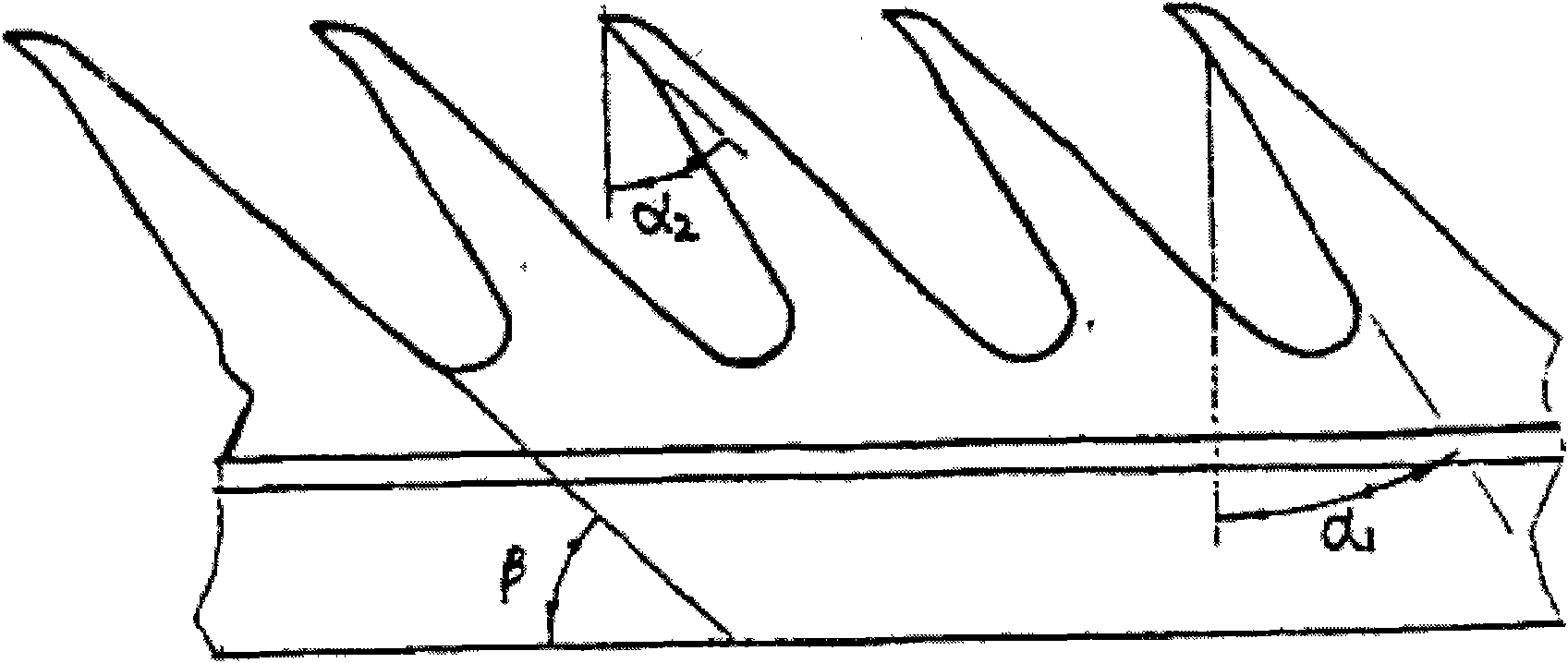

Combing machine heat moist treatment nipper plate mechanism

InactiveCN101215738ANot easy to damageReduce long fiber contentLubricating devicesCombing machinesFiberCavity wall

The invention provides a nipper mechanism which is applied in a combing machine, which belongs to the textile processing technical field. The nipper mechanism of the combing machine comprises a nipper frame which is provided with a lower nipper, an upper nipper arm which is provided with an upper nipper, a feed roller, a feed table and a heat-wet processing device, the heat-wet processing device is a hollow circular pipe element, a row of air discharging holes which are evenly arrayed are opened on the cavity wall, the circular pipe element is fixedly installed on the lower nipper or the upper nipper, the axial cord of the heat-wet processing device and the axial cord of the feed roller are in parallel, the heat-wet processing device is externally connected with a heat-wet air generating device, the feed roller and the feed table are externally connected with a heating device. The flexibility of fiber is improved through heat-wet process of the heat-wet processing device and heating process of the feed roller and the feed table, the frictional force between fibers is reduced, and impurities removing and fiber straightening and paralleling effect of a combing machine is distinctively increased, and fiber damage is reduced.

Owner:WUHAN TEXTILE UNIV

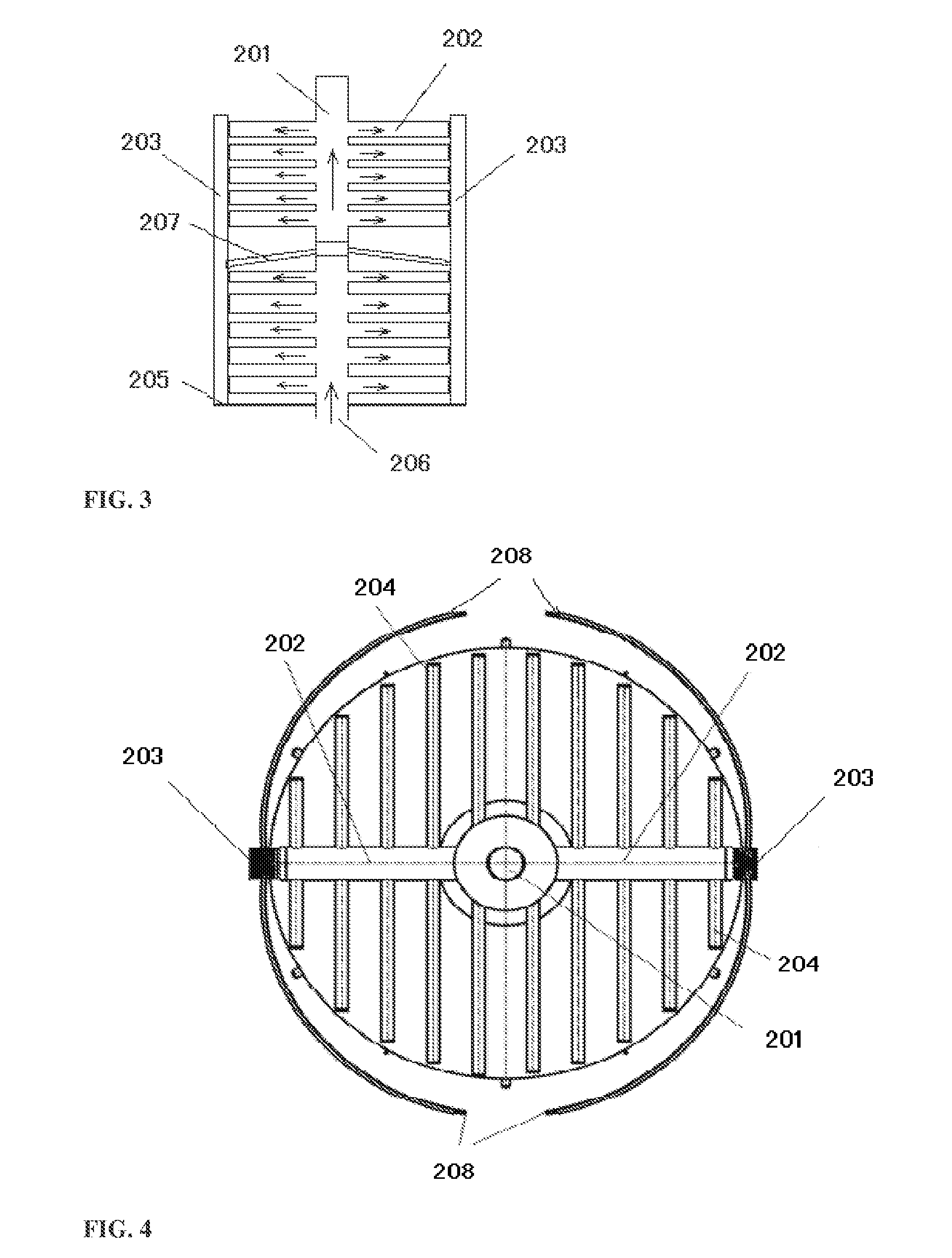

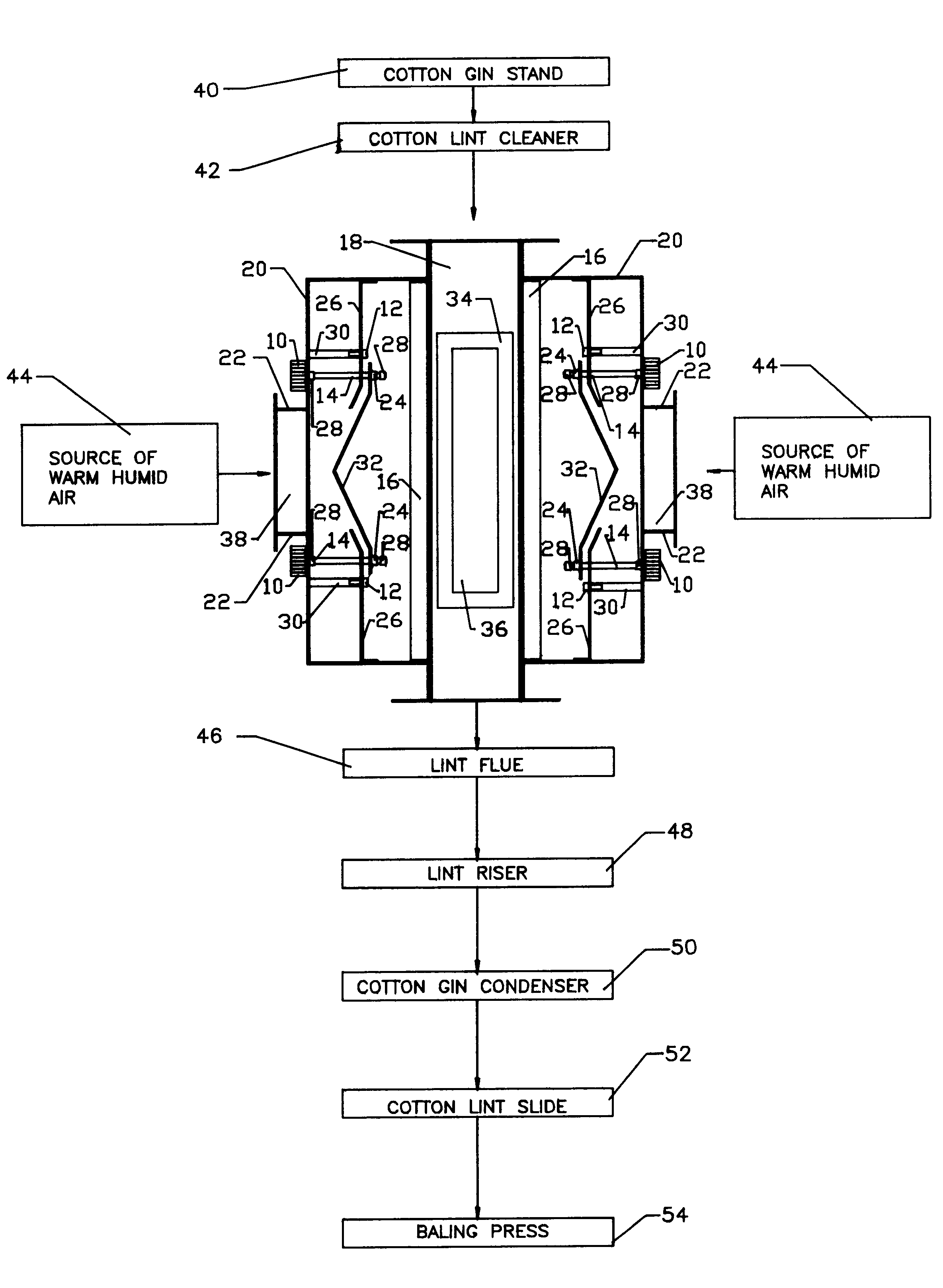

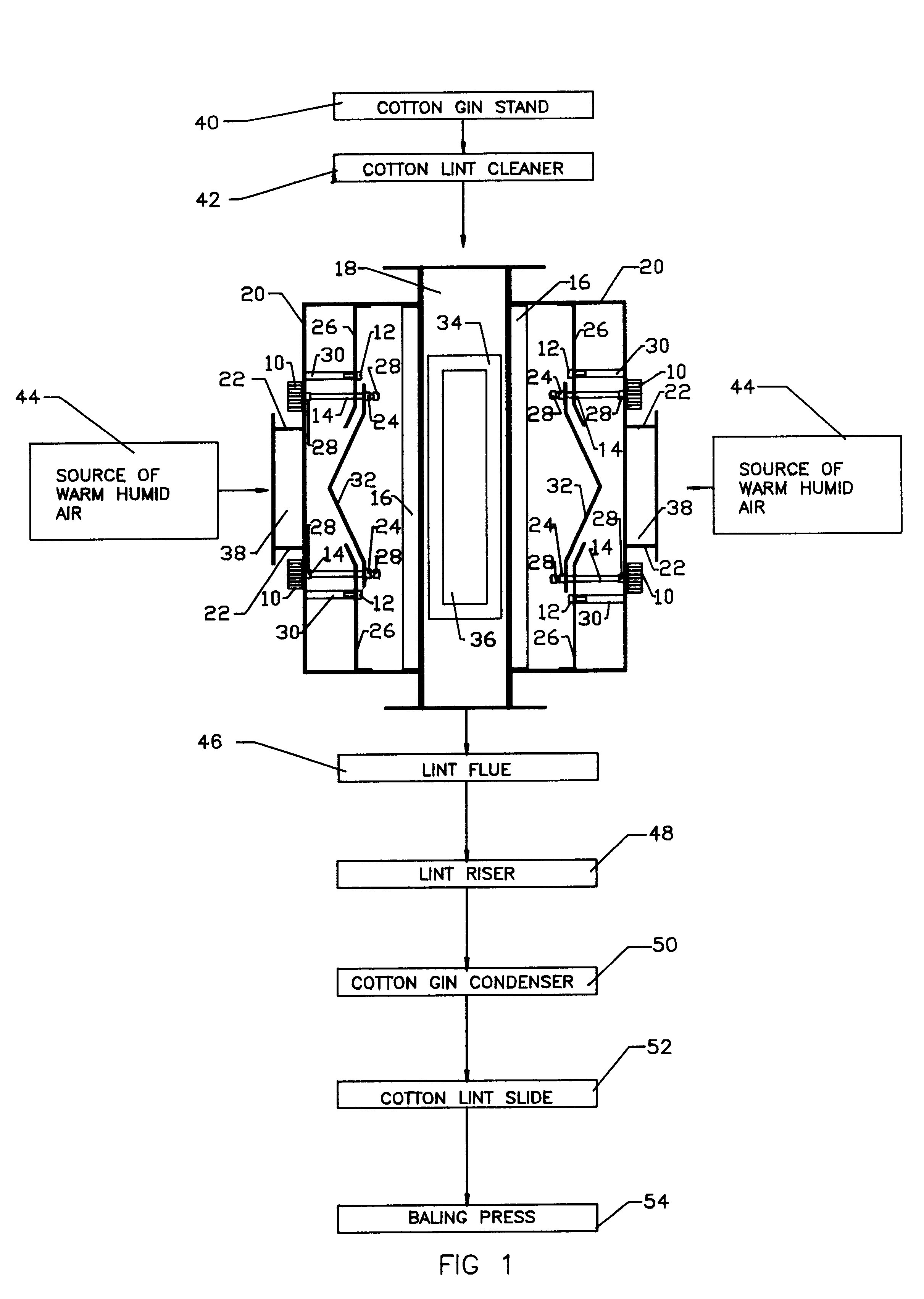

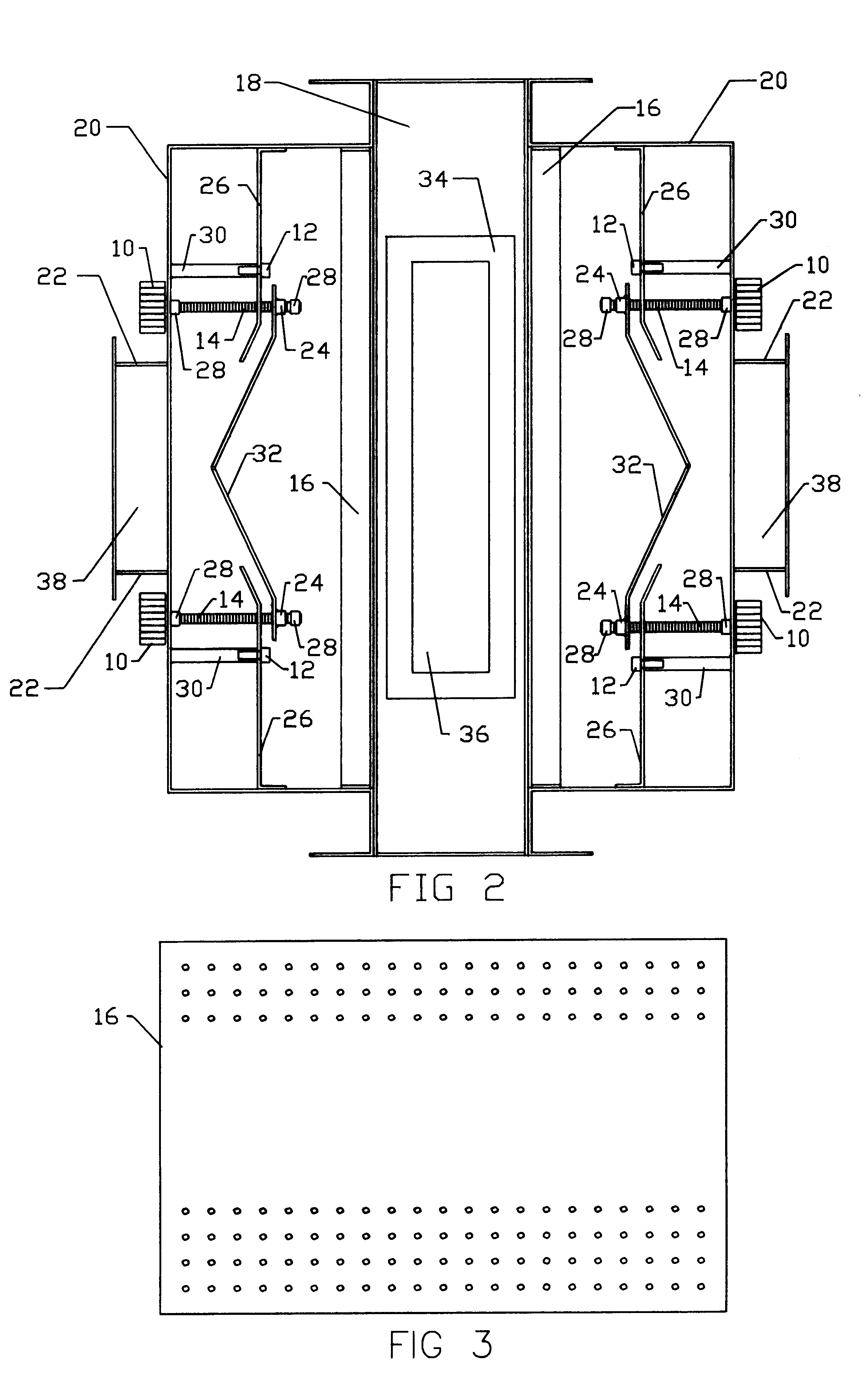

Fiber moisture cell for humidifying cotton and method

InactiveUS6237195B1Save resourcesEnergy efficiencyLubricating devicesVegetable fibre separation from seedsFiberEngineering

Apparatus for humidifying lint cotton in a cotton gin that has a cell arranged for receiving a fiber mass from a lint cleaner and controlling the movement of the fiber over a moist air inlet panel. Warm humid air introduced through an adjustable air inlet panel passes through the moist air inlet panel and, thus, through the cotton under negative pressure raising the moisture content of the fiber mass. The movement of the fiber mass thru the cell is controlled by the amount of warm moist air flowing under pressure through the moist air inlet screen.

Owner:SHOEMAKER THOMAS R

Method for treatment of spider silk-filament for use as thread or a composition in the manufacture of cosmetic, medical, textile or industrial applications such as bio-artificial cell tissue or skin based on (recombinant) spider silk

InactiveUS20150056256A1Reduced pathological immune responseImprove scalabilityCosmetic preparationsElectric discharge heatingAntioxidantMagnetite Nanoparticles

A method for the treatment of spider silk filament for use as a thread or composition in the manufacture of cosmetic, medical, textile, and industrial applications, wherein the spider silk filament, derived from genetically modified organisms, is treated with at least one component selected from the group consisting of vitamins, hormones, antioxidants, chelating agents, antibiotics, preserving agents, fragrances, dyes, pigments, magnetic nanoparticles, nanocrystals, cell adhesion enhancers, thermal insulators, shrinkage agents and cosmetic, medical or dermatological active substances. Textile fabrics obtained by this method are stronger, bio-compatible, bio-degradable and have a higher thermal conductivity. Treated spider silk filament can also be applied in an oil-in-water or water-in-oil protective cream that is hypoallergenic and ensures a firmer skin.

Owner:ESSAIDI JALILA

Apparatus and method for dry forming a uniform non-woven fibrous web

Owner:BIAX FIBERFILM CORP

Blending and opening device

ActiveCN103290536AReduce labor intensityPass smoothlyLubricating devicesContinuous processingState of artFiber bundle

The invention relates to the technical field of wool top processing equipment, in particular to a blending and opening device which comprises a first automatic sucking device, a second automatic sucking device, an opener, an automatic oil filling tank and a plurality of delivery pipes. The blending and opening device has the advantages that fibers can be directly sucked into the opener from the ground by the aid of the first automatic sucking device without being manually placed into the opener, accordingly, the efficiency is high, the labor intensity of workers is low, fibers which are processed by the opener can be automatically sucked into the automatic oil filling tank by the aid of the second automatic sucking device, both the first automatic sucking device and the second automatic sucking device have impurity removal functions, and the quality of later-period finished products is greatly improved; manual blending in the prior art can be replaced by the automatic oil filling tank, so that the labor intensity of the workers is greatly reduced, a uniform blending effect is realized, cohesive force of fiber bundles is increased, the fibers can smoothly pass a carding device, a spinning device and the like advantageously, and twisting, end breaking and the like are reduced.

Owner:浙江中鼎纺织股份有限公司

Composites comprising collagen extracted from sarcophyton sp. coral

Isolated composites are disclosed comprising collagen fibers isolated from a Sarcophyton sp. coral. An exemplary composite comprises as a first component a bundle of collagen fibers, the collagen fibers being isolated from a Sarcophyton sp. coral, and a second component selected from the group consisting of a polysaccharide, a polypeptide, polylipid, a synthetic polymer, a metal and a mineral, wherein the bundle of collagen fibers comprise woven fibers, twisted fibers, braided fibers, knitted fibers, tied fibers, or sutured fibers. Uses thereof and method of generating are also disclosed.

Owner:RAMOT AT TEL AVIV UNIV LTD

Process for manufacturing blended wool yarns

The invention relates to the field of textile technology, in particular to a process for manufacturing blended wool yarns. The process is characterized in that usage boundaries on various traditional spinning devices are broken, and reconfiguration, modification and adjustment are creatively carried out, so that rove staple fibers are spun into separate-count semi-worsted yarns. Yarns are spun by a drafting method, blending and carding of raw wool yarns and doubling drafting of cotton yarns are assimilated, accordingly, colors of spun yarns are uniform, fibers are blended uniformly, surfaces of the yarns are smooth, and the yarns feel fluffy and soft. According to the scheme, the process has the advantages that the process is adaptable to a wide range of raw materials, counts of the yarns can be high or low, the technology is easy to popularize, equipment investment is low, and occupied factory area is small.

Owner:刘自忠

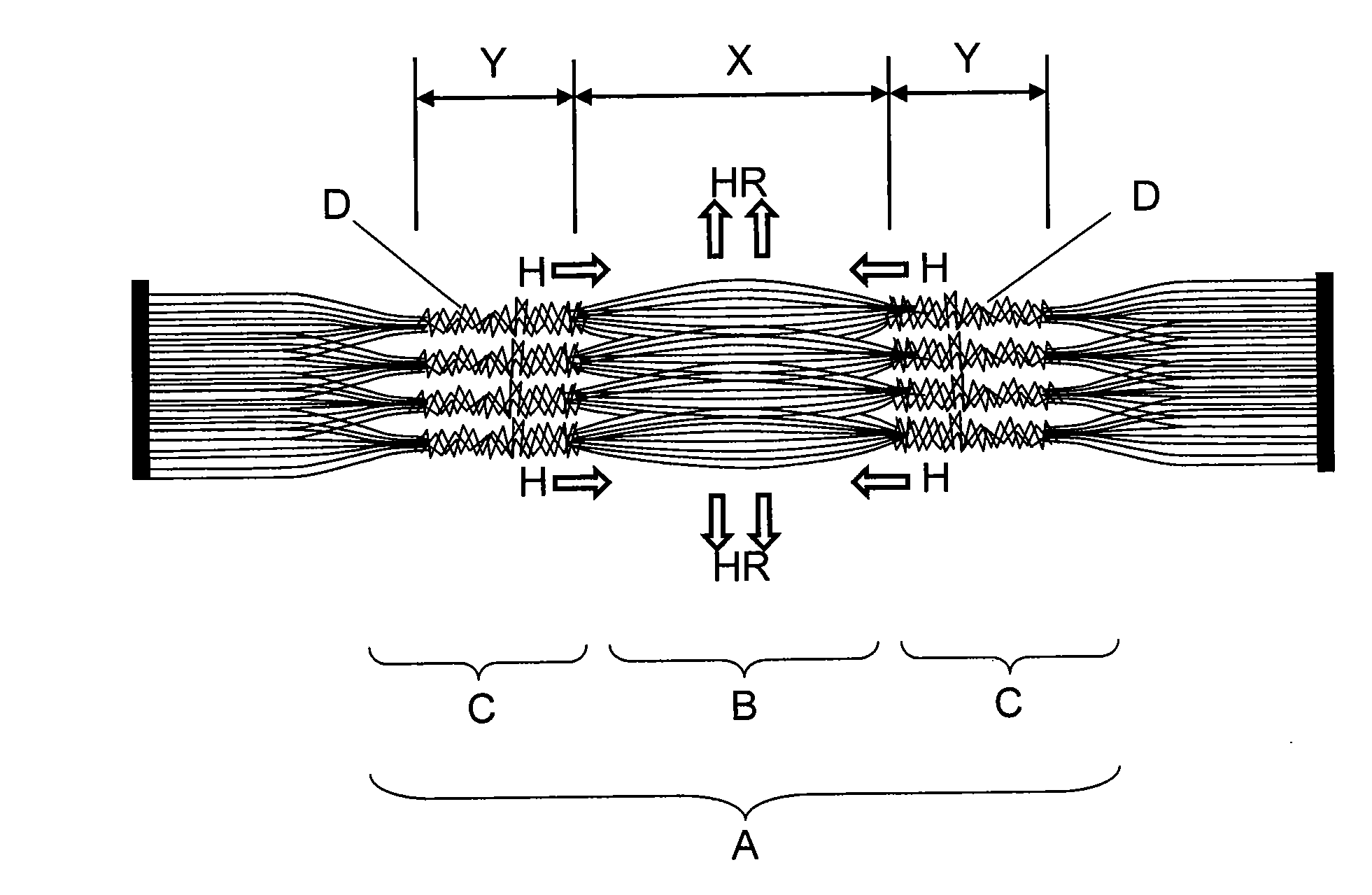

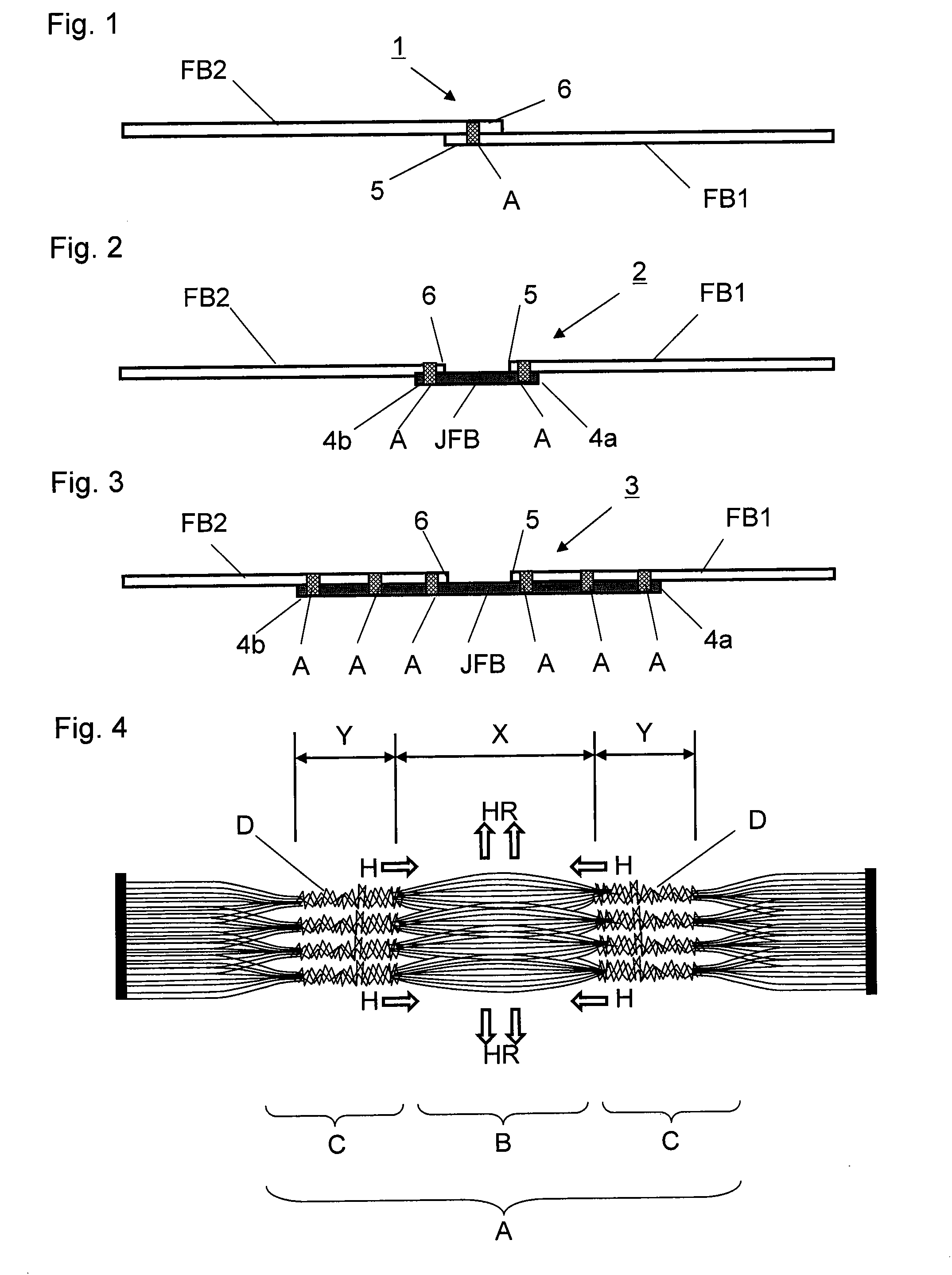

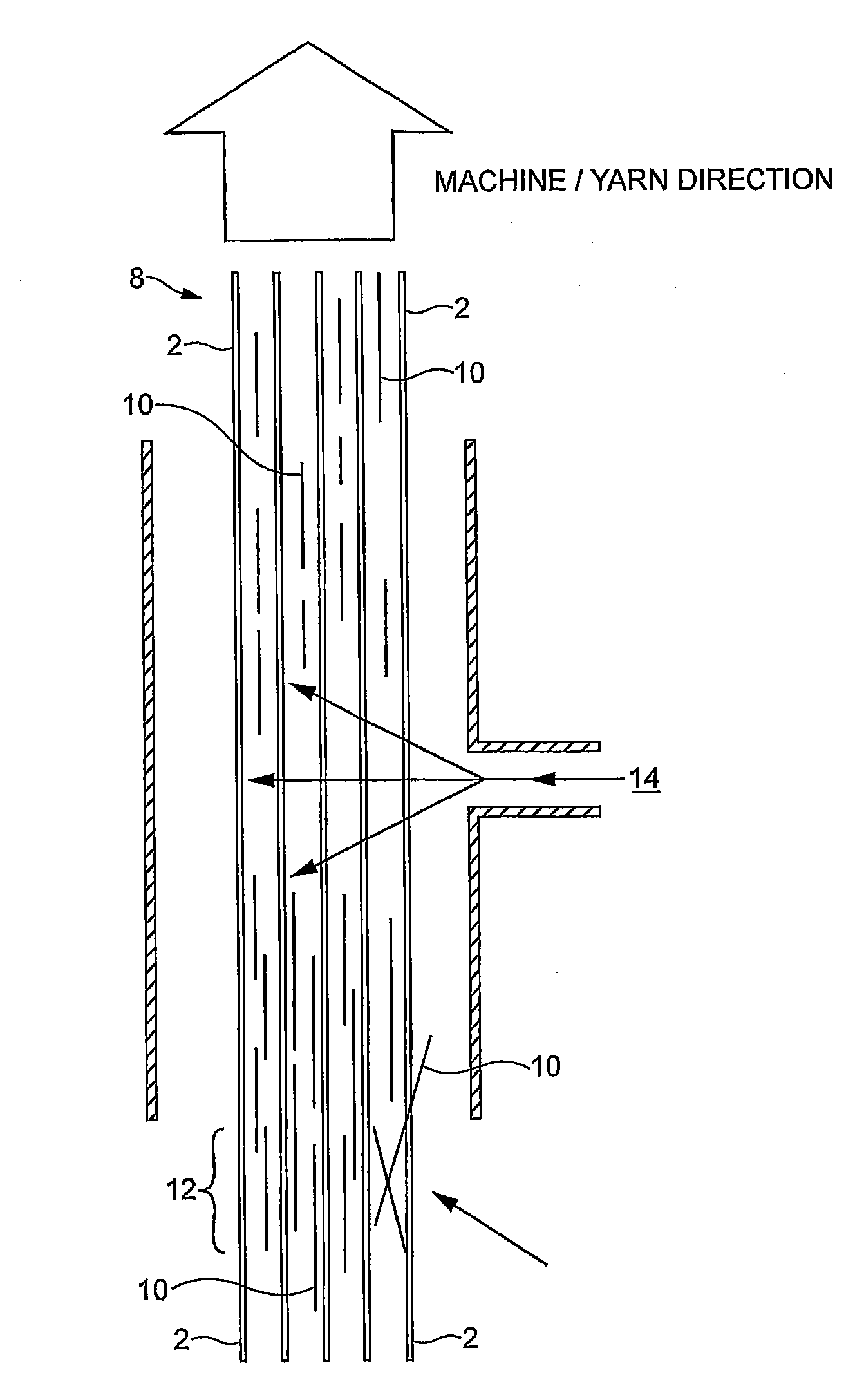

Fiber bundle with pieced part, process for producing same, and process for producing carbon fiber

InactiveUS20110217228A1Avoid heat buildupRealize heat dissipationLubricating devicesLayered productsFiber bundleMaterials science

A fiber bundle which has a pieced part formed by jetting a pressurized fluid against a fiber-bundle overlap is formed either by directly superposing the ending part of a fiber bundle composed of many fibers on the beginning part of another fiber bundle composed of many fibers or by superposing the end part and the beginning part on a jointing fiber bundle composed of many fibers, whereby the many fibers of the fiber bundles are interlaced with one another to thereby piece up the fiber bundles. The pieced part comprises an opened-fiber part in which the fibers have been opened and interlaced-fiber parts respectively located on both sides thereof, each interlaced-fiber part being composed of a plurality of constituent interlaced parts located apart in the width direction for the fiber bundle.

Owner:TORAY IND INC

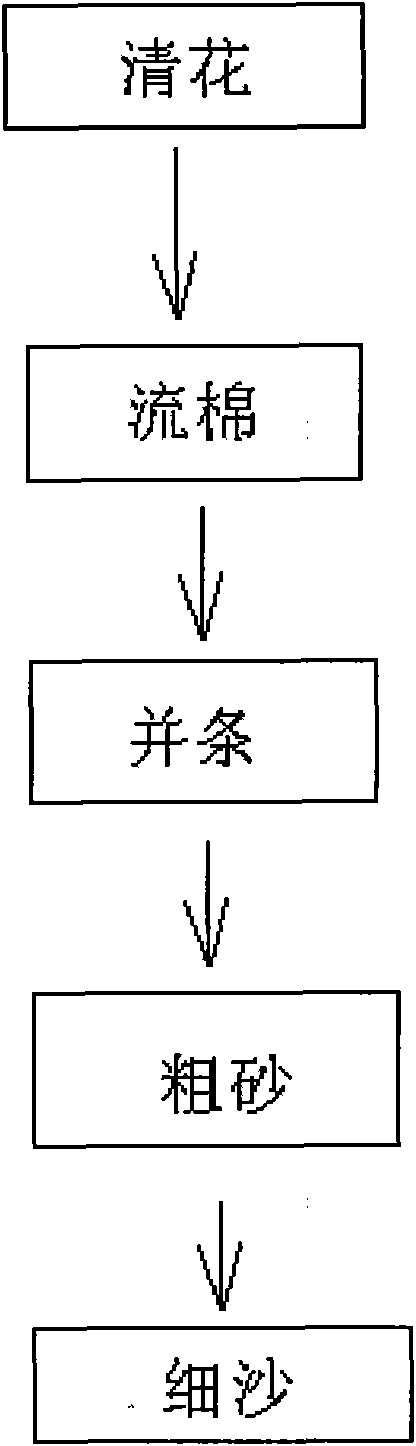

Method for producing ramie cotton blended yarn by using cotton-spinning equipment

This invention discloses a method for producing gunny-cotton blend yarn with a cotton spinning device including the following steps: pretreatment of fine dry gunny, cleaning cotton, combing cotton, fine combing, merging slivers, roving, spinning and winding process, which is advantaged that hemp yarn number is high reaching to 60-80 British yarn with 55-80% hemps, dry yarn is increased greatly and faults are reduced greatly.

Owner:CHANGSHANZHAOZHOU TEXTILE

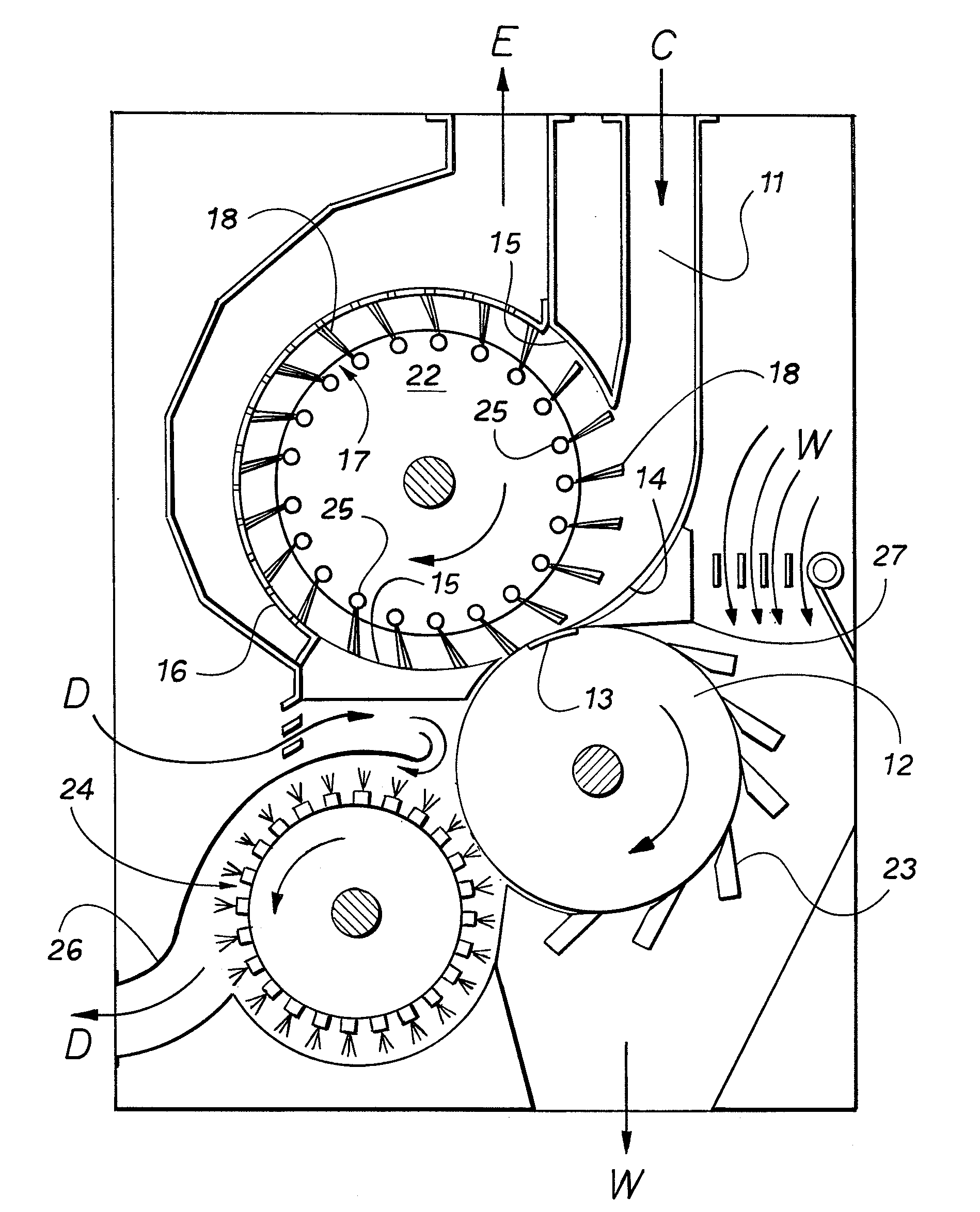

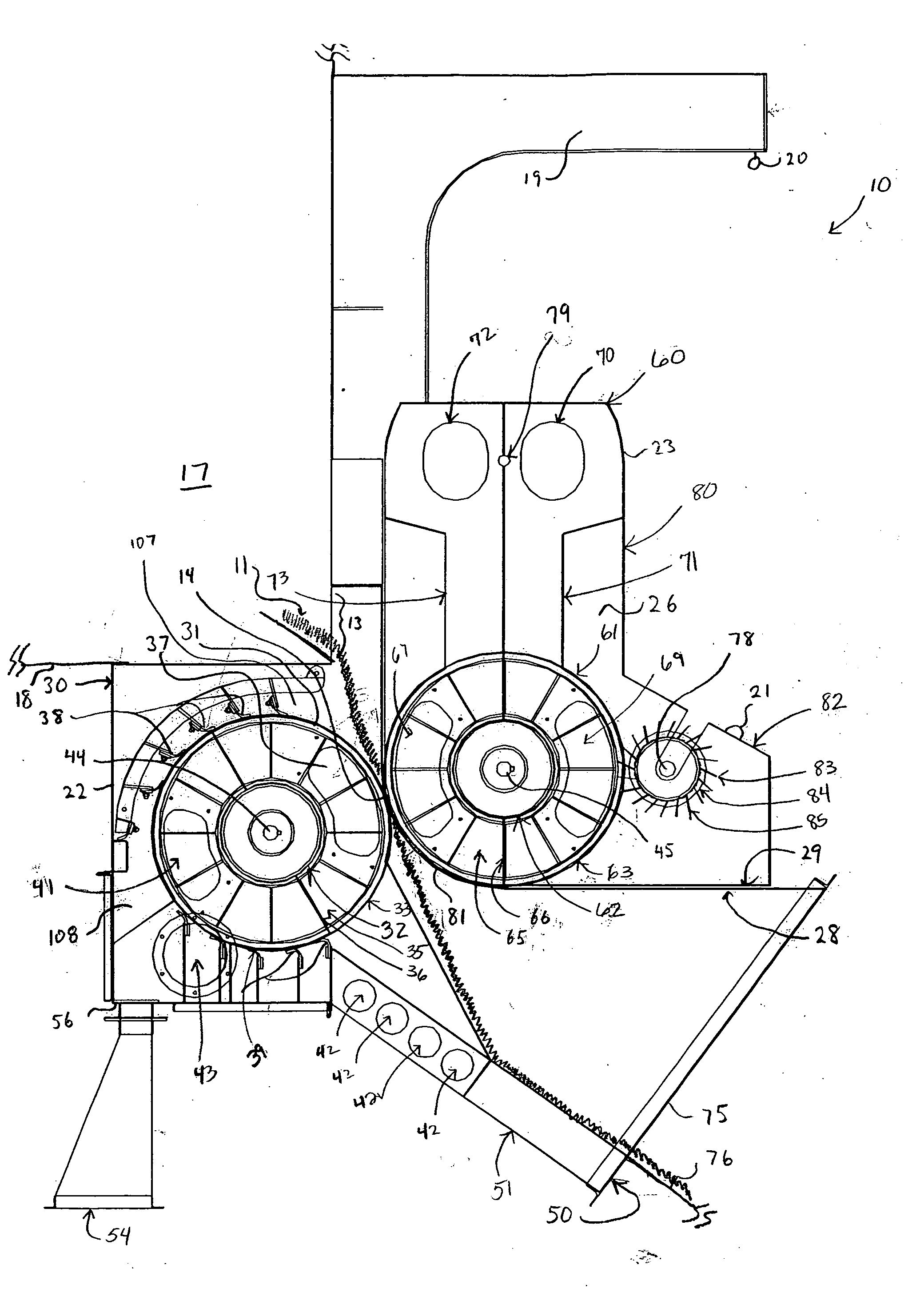

Method and Apparatus for Separating Foreign Matter From Fibrous Material

ActiveUS20090172918A1Simple methodEliminate needMechanical impurity removalLubricating devicesForeign matterFiber

An apparatus for cleaning foreign matter from separated tufts of fiber uses a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and deliver the tufts to a toothed cleaning cylinder which passes beneath a plurality of cleaning bars. The open reel utilizes brush like outer surfaces to sweep tufts of fiber from the housing back into the air stream adjacent the cleaning cylinder.

Owner:LUMMUS INDS

Producing yarn

ActiveUS20110098147A1Inhibition formationMaintain good propertiesLubricating devicesLayered productsThermoplastic elastomerAramides

A process for the production of a yarn is disclosed, the process comprising providing a bundle comprising continuous filaments of a thermoplastic polymer, contacting the bundle with a sliver comprising fibres of a heat resistant material to form a mixed bundle, and applying a gas jet to the mixed bundle to distribute the fibres of the heat resistant material in the bundle. Also disclosed are yarns comprising filaments of a thermoplastic polymer and fibres of a heat resistant material, wherein the fibres are distributed between and among the filaments. Preferably, the heat resistant material is a non-thermoplastic polymer, especially an aramid. Yarns according to the invention find use in technical fabrics especially transmission belts.

Owner:HEATHCOAT FABRICS LTD

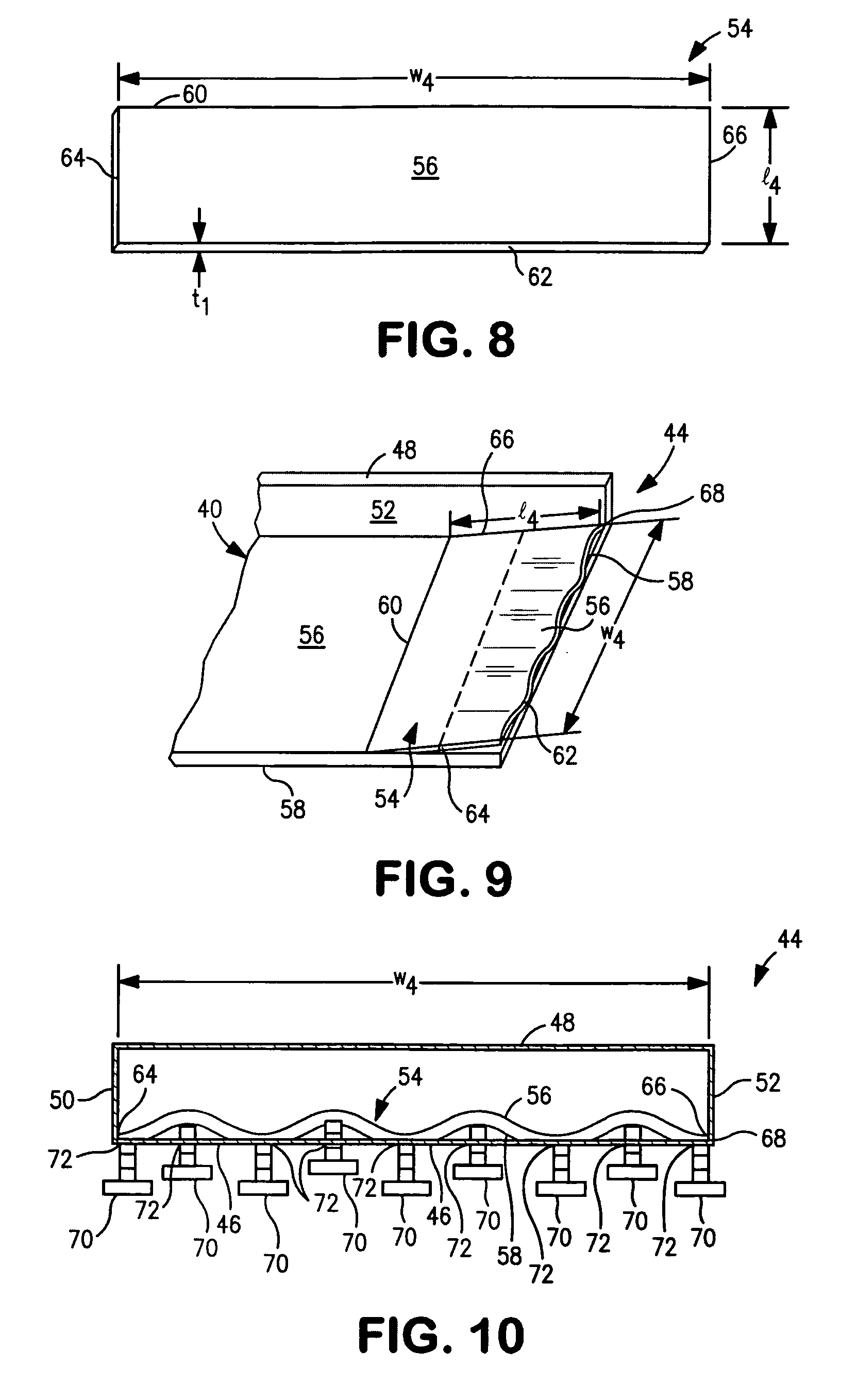

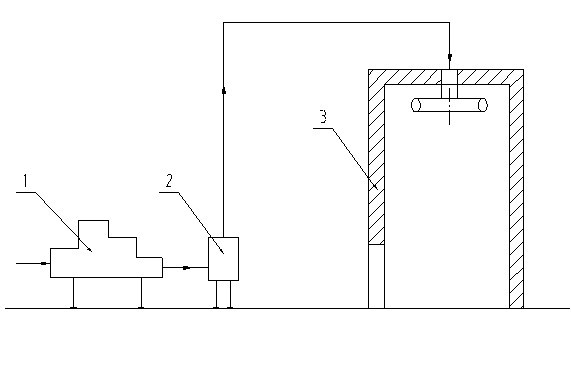

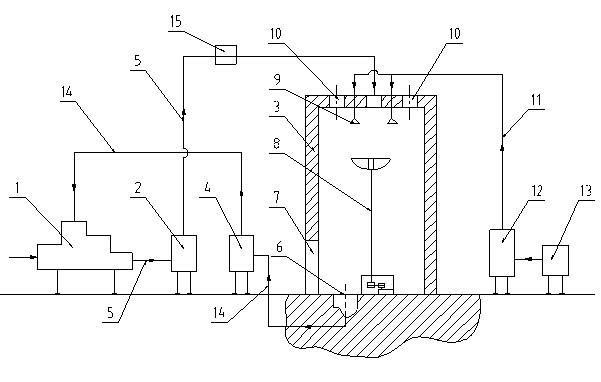

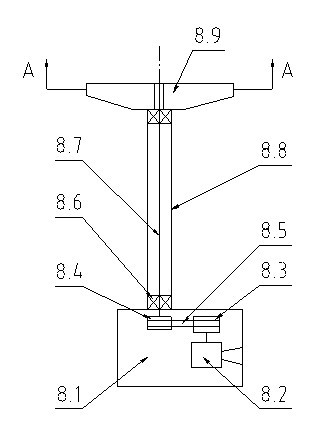

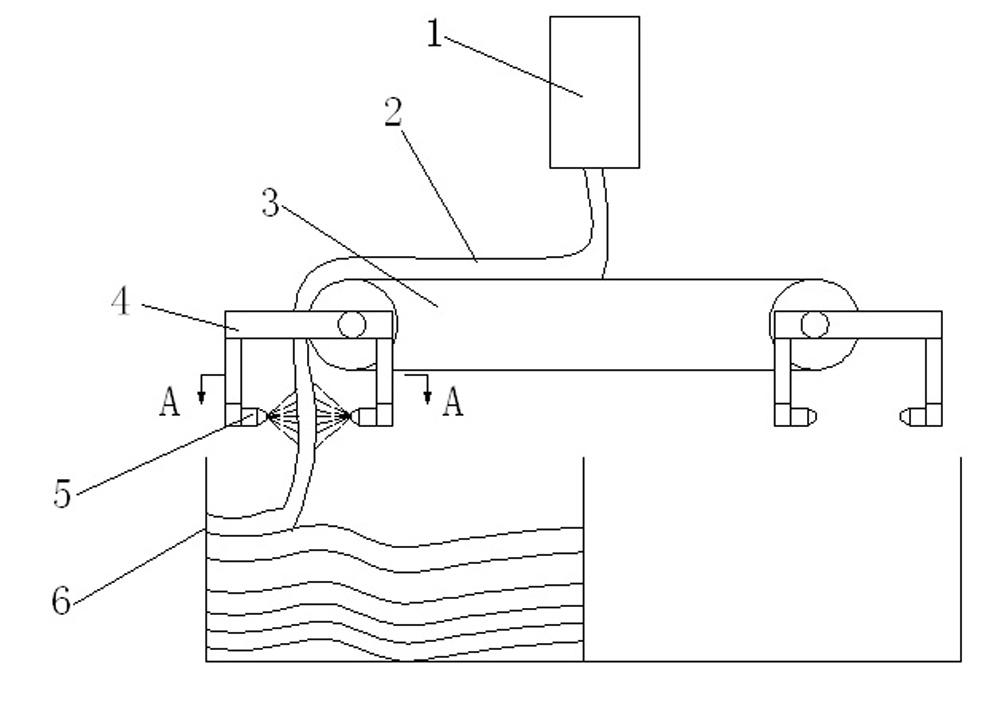

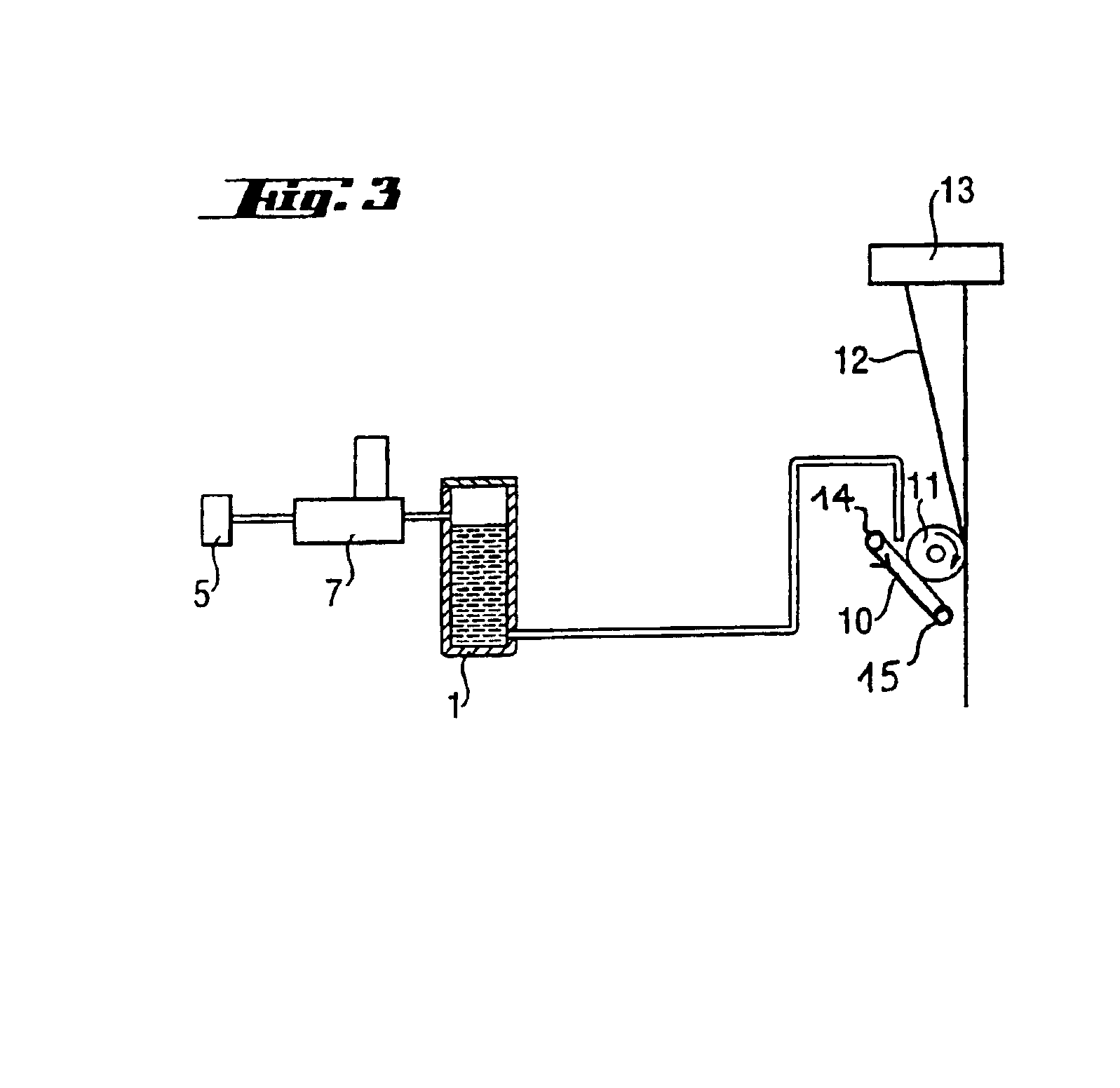

Novel fiber mixing system

ActiveCN102586895AOpen fullyWell mixedLubricating devicesAnimal fibre deburring machinesFiberSpray nozzle

The invention relates to a novel fiber mixing system. The novel fiber mixing system comprises a fiber mixing machine (1), a fiber delivering fan (2) and a fiber mixing cabin (3), which are sequentially connected through a fiber delivering air pipe I (5), wherein a fiber sucking fan (4) is arranged between the fiber delivering fan (2) and the fiber mixing cabin (3); a ground air suction inlet (6) is formed in the bottom of the fiber mixing cabin (3); the ground air suction inlet (6), the fiber sucking fan (4) and the fiber mixing machine (1) are sequentially connected through a fiber delivering air pipe II (14); a fiber loosening device (8) is arranged in the fiber mixing cabin (3); a plurality of oil feeding agent spraying nozzles (9) are arranged above the fiber loosening device (8); anda plurality of air pressure release outlets (10) are formed in the top of the fiber mixing cabin (3). The novel fiber mixing system can fully loosen and mix fibers and automatically feed oil, and hasa good fiber mixing effect; a large amount of labor is saved; and the production efficiency is improved.

Owner:JIANGSU ZHENXIN IND

Cotton conditioning device

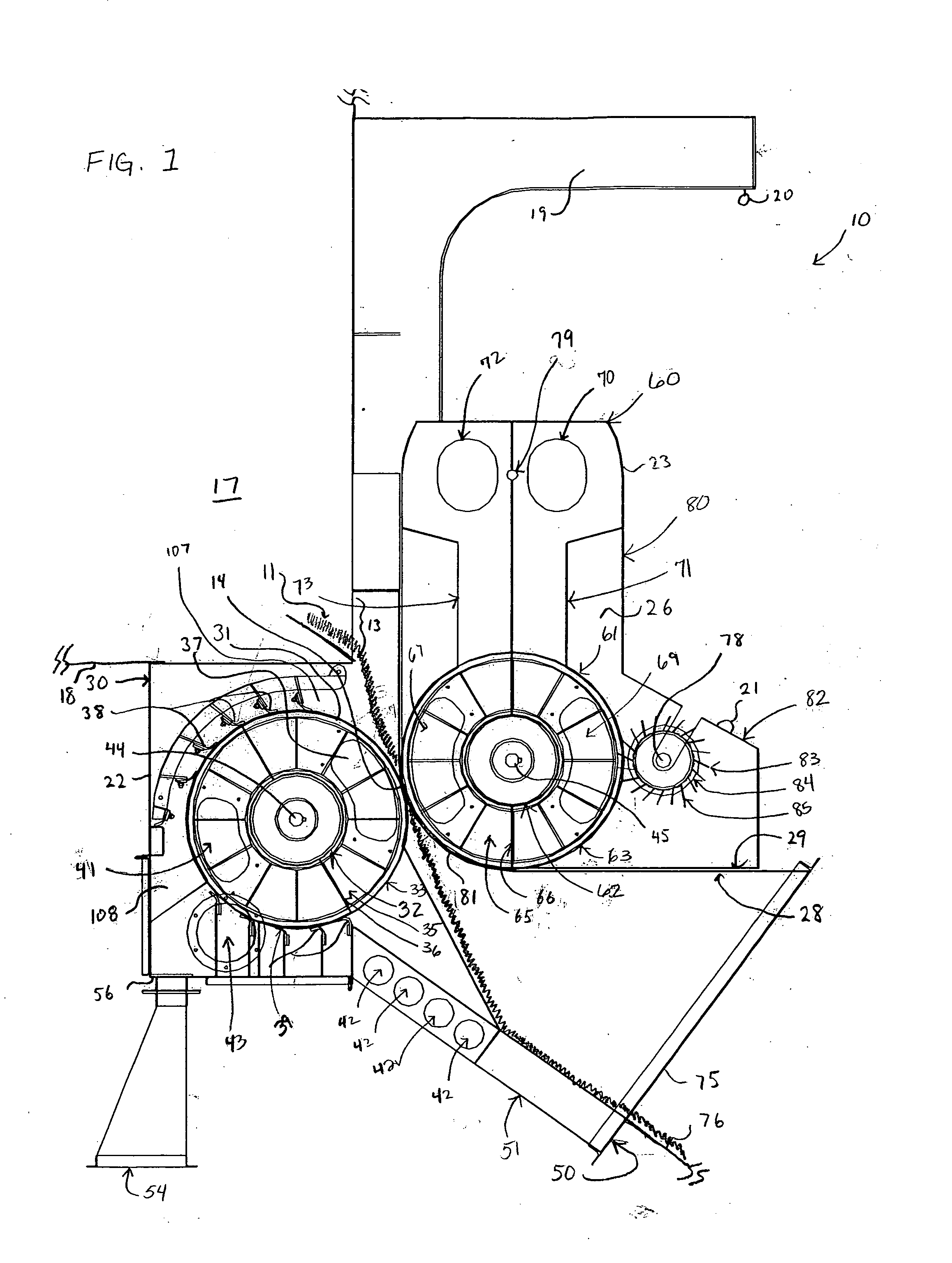

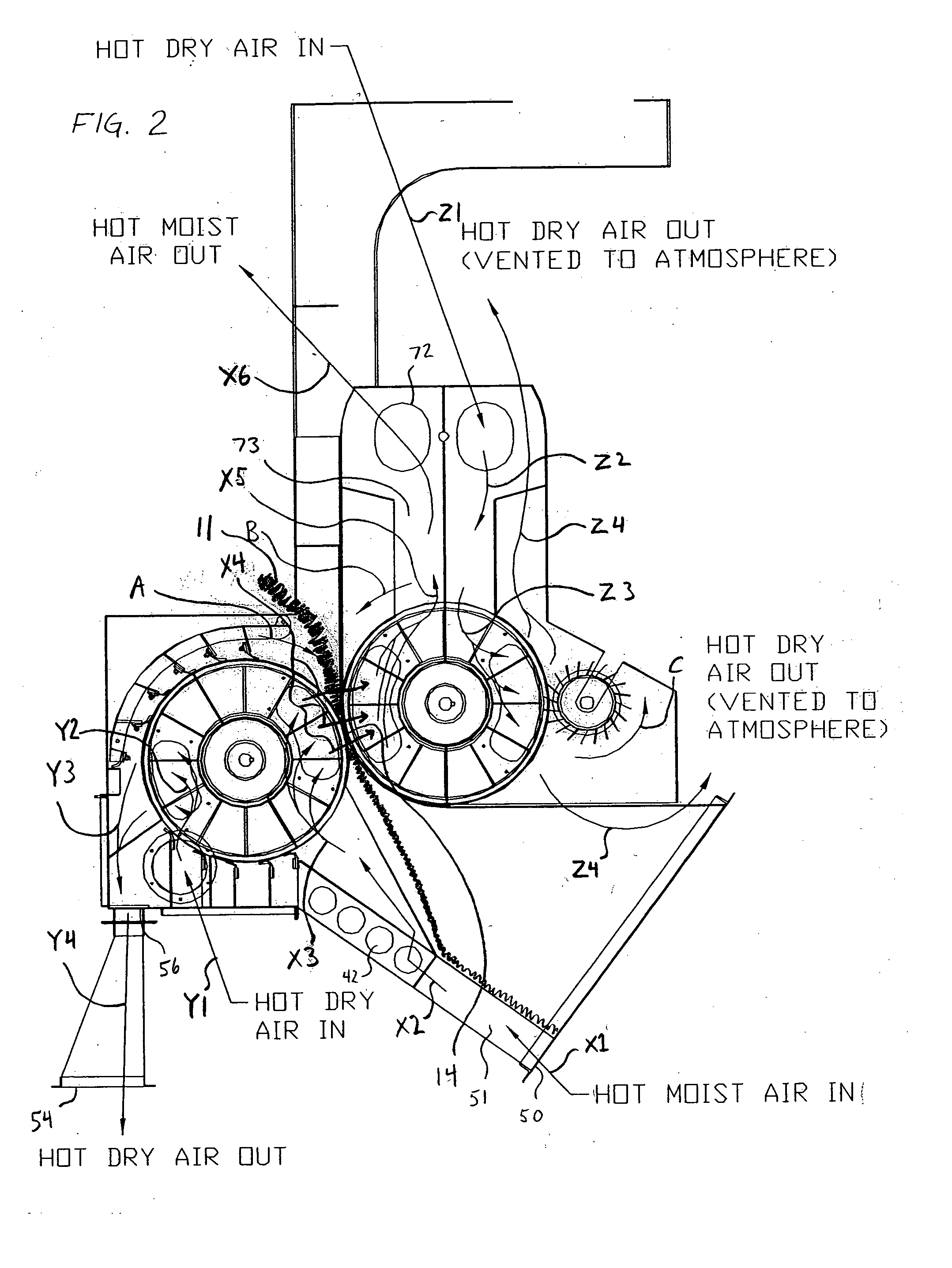

ActiveUS20080005869A1Effectively and efficiently adds moisture to lint cottonReasonable priceLubricating devicesLap forming devicesFiberEngineering

The present invention related generally to a device for adding moisture to fibrous material such as cotton. The conditioning device receives a continuous cotton batt from a battery condenser. The continuous cotton batt is fed between two opposing drums. Hot moist air is fed into one drum and drawn out of the perforated surface of the drum, through the batt as it is being compressed between the two drums, and into the other drum. The opposing drums are internally compartmented by a plurality of longitudinal staves, each compartment being covered by a corresponding segment of the perforated surface. Hot dry air is fed into the compartments of the drums when the corresponding segment of the surface is not carrying the cotton batt in order to dry the surface of the drum and clear the perforations of any lint that might have been retained on the surface.

Owner:CHEROKEE FABTION

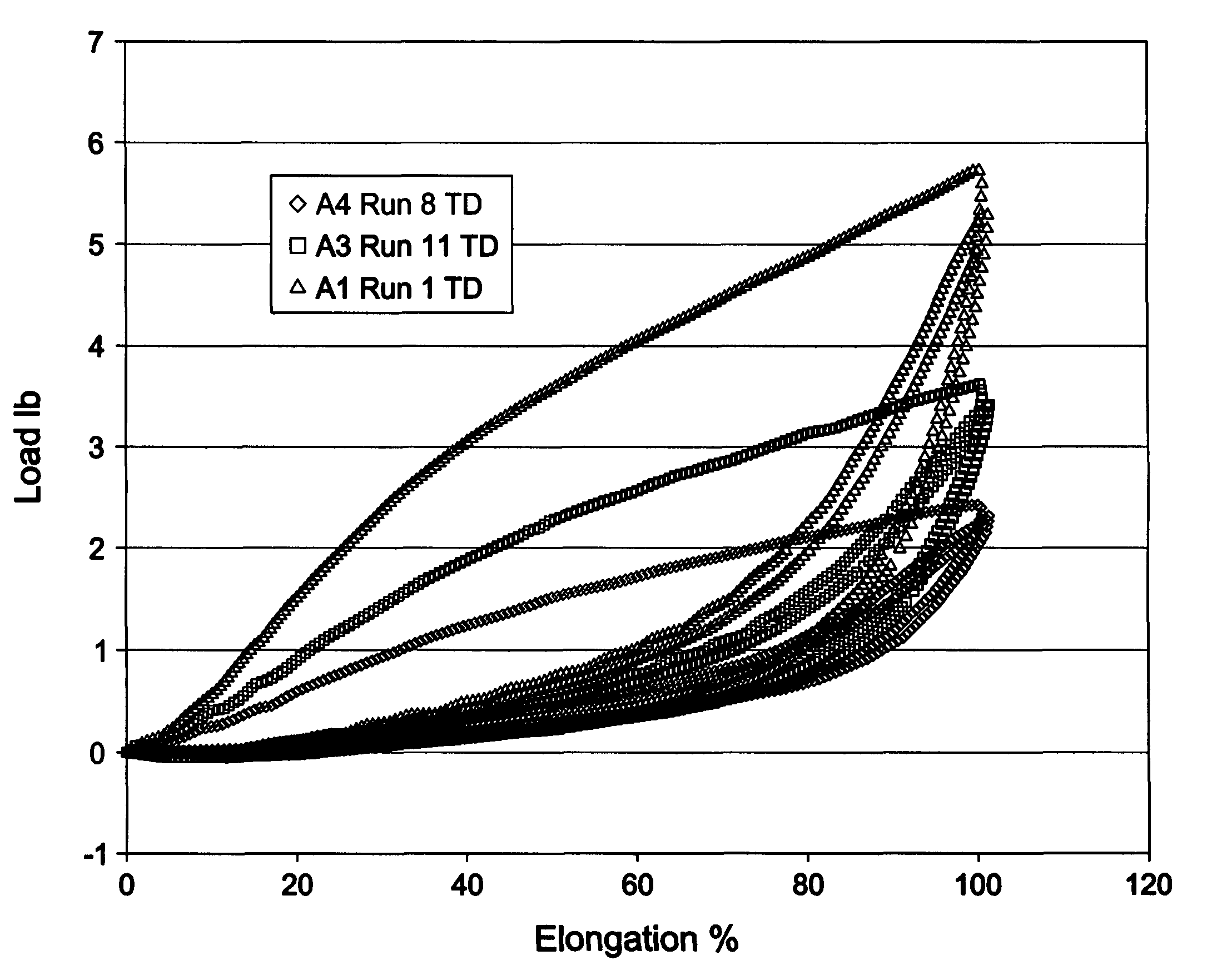

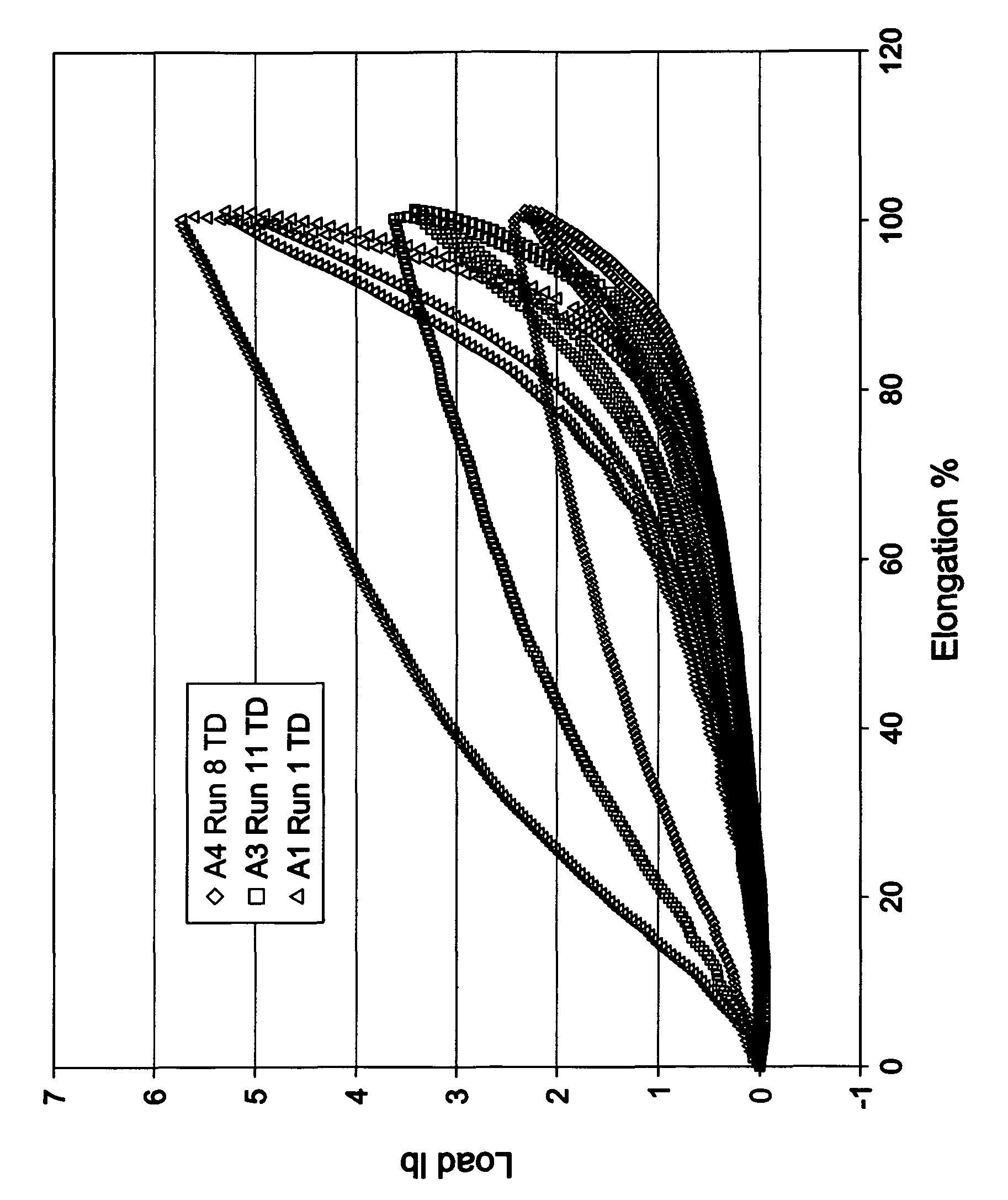

Spunbond fibers and fabrics from polyolefin blends

The invention described relates to a polyolefin blend composition suitable for spunbond fiber or filament compositions, and to fabric compositions and composite constructions therefrom, said blend comprising a) from 60-98 wt % of at least one random propylene copolymer having a comonomer content of from 8 to 25 wt % and a crystalline melting point (Tm) as determined by differential scanning calorimetry (DSC) of from about 40° C. to about 110° C.; and b) from 2-40 wt % of at least one substantially isotactic polypropylene homopolymer or copolymer comprising one or more C2 and / or C4-C8 comonomer, having a crystalline melting point (Tm) as determined by DSC greater than or equal to 120° C. The blends of the present invention typically have a melt flow rate (MFR) of from 100 g / 10 min to about 500 g / 10 min.

Owner:EXXONMOBIL CHEM PAT INC

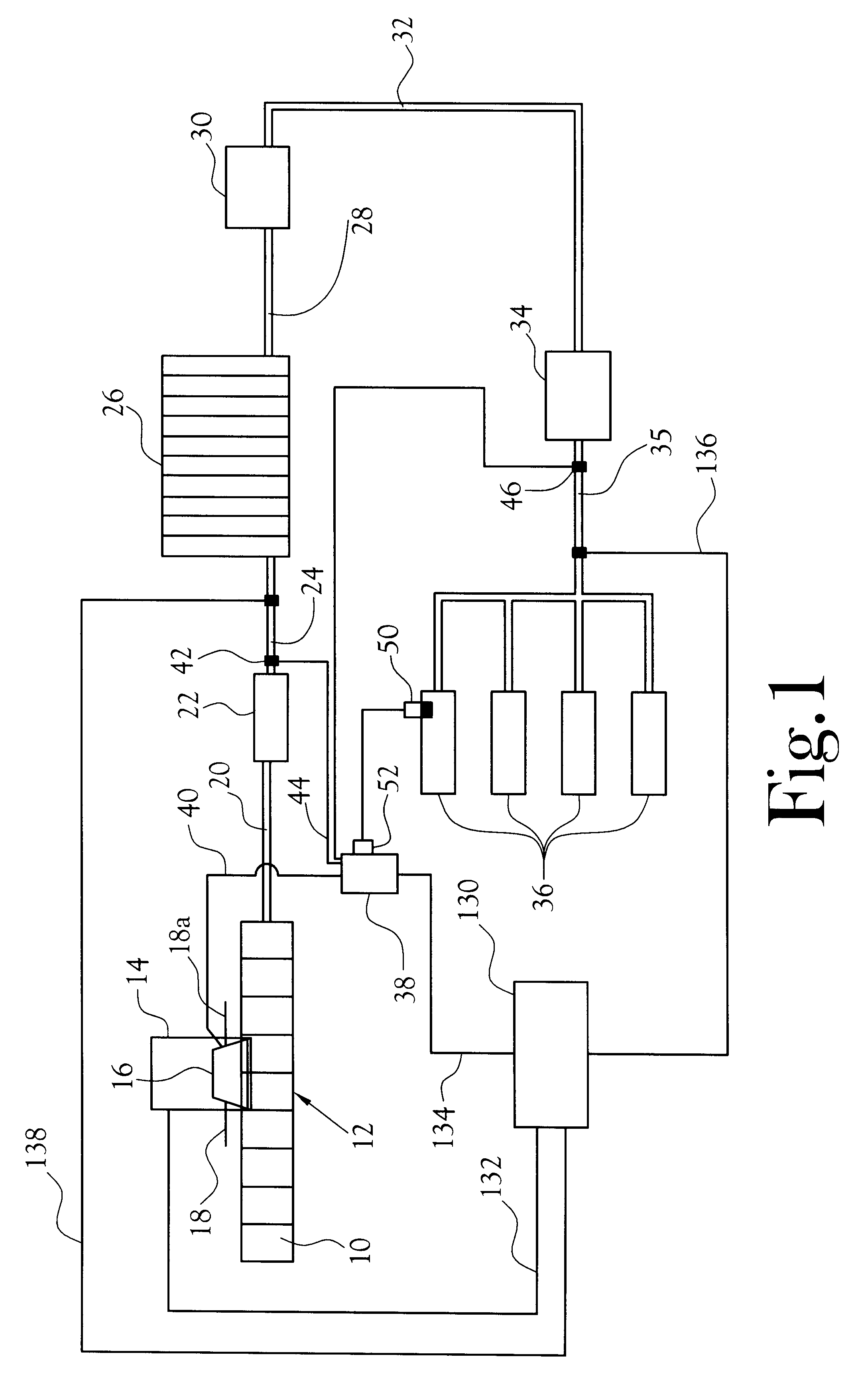

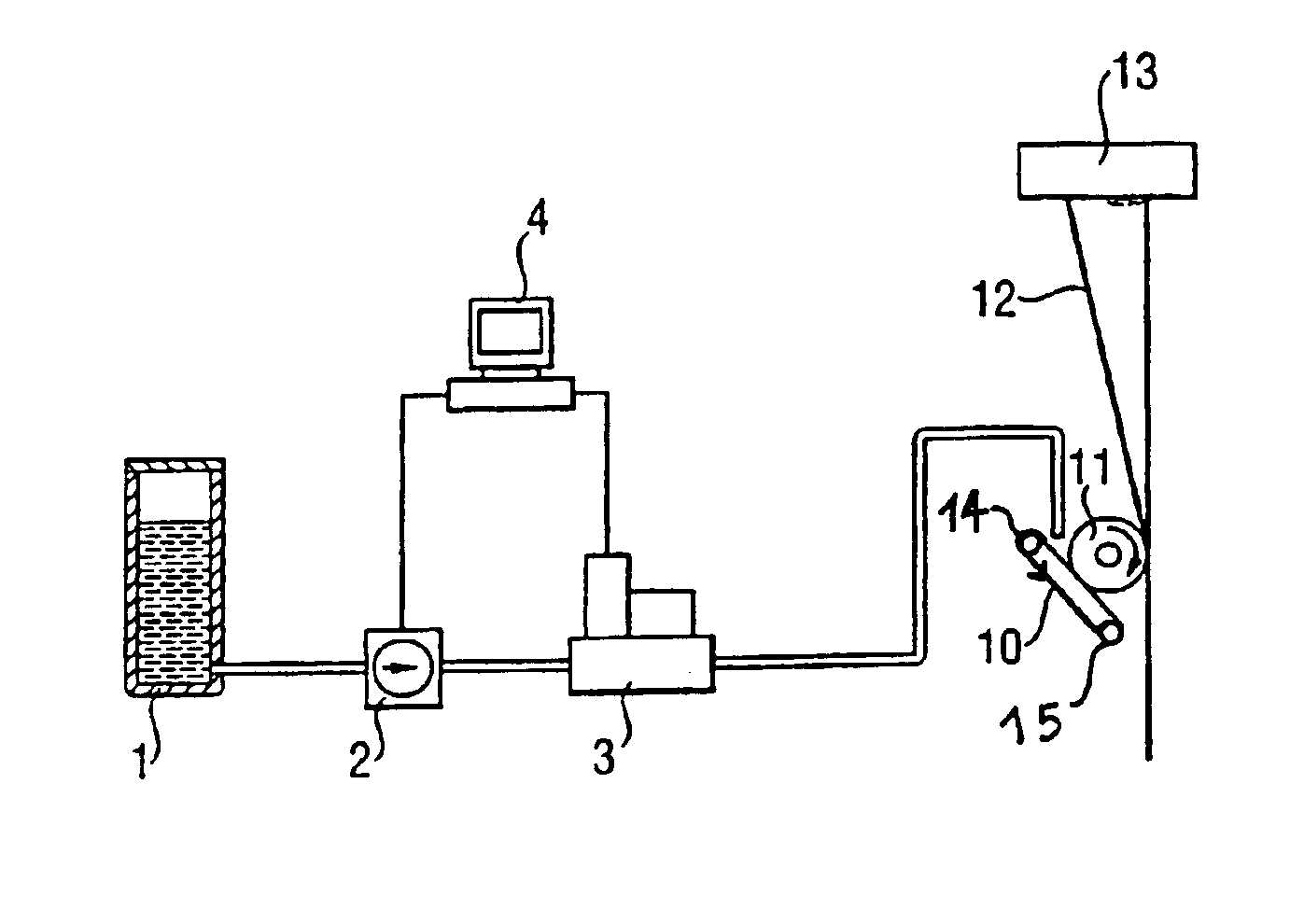

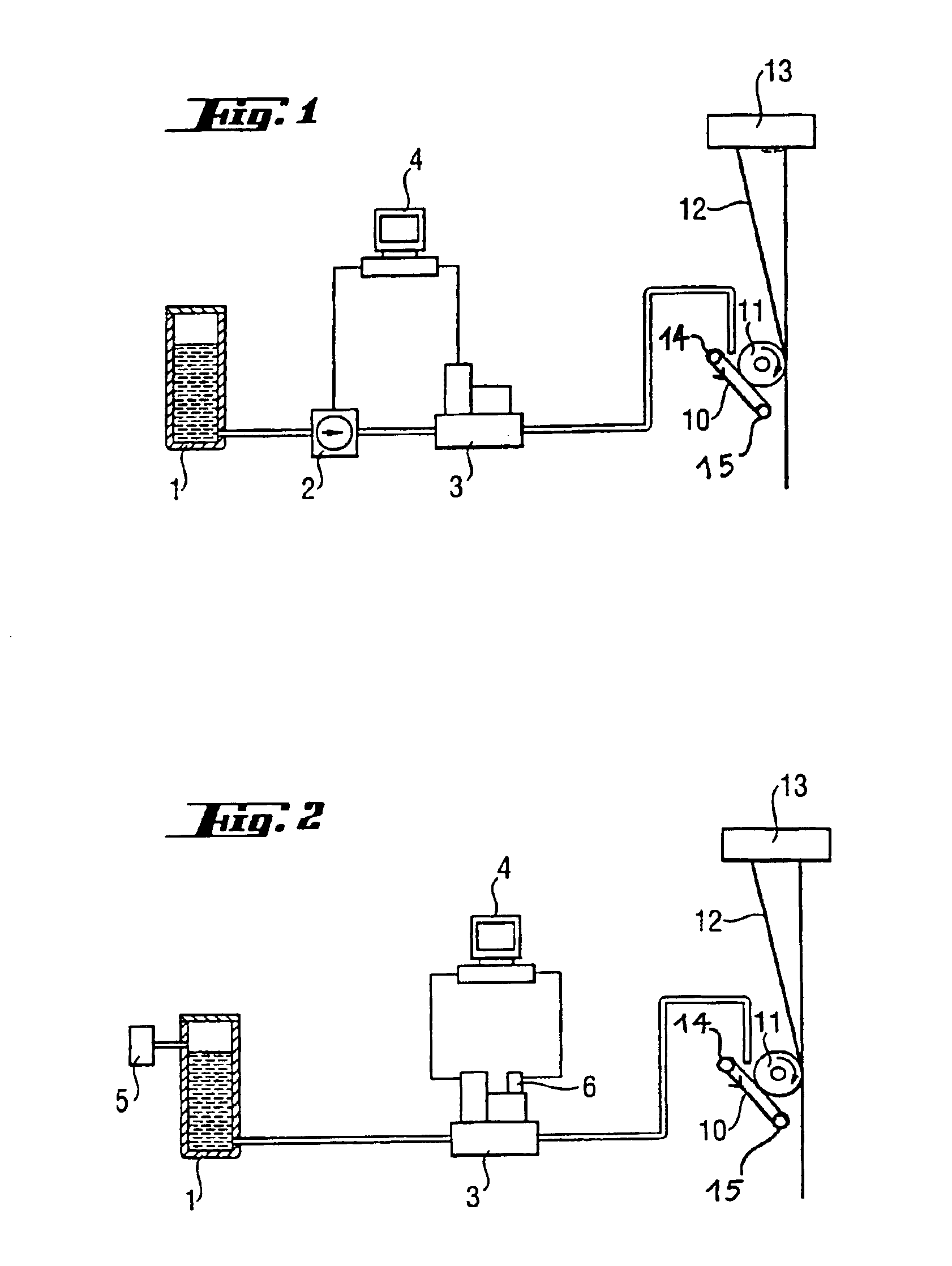

Method and apparatus for conditioning textile fibers

A method and apparatus are provided for conditioning of textile, e.g. cotton, fibers as they are removed from bales for processing. A source of a conditioning liquid and a source of pressurized air are each in flow communication with a plurality of atomizing nozzles secured to a reciprocating fiber take-off device located above a plurality of aligned bales of fibers. As the removal apparatus moves back and forth across the upper surface of each bale, the nozzles dispense conditioning liquid directly onto the exposed upper surface of each bale. The fibers are thereafter entrained in an air flow for transport to further processing station(s). Within the stream of airborne fibers, one or more sensors detect the moisture content and / or other physical property(ies) of the fibers and sends an appropriate signal to a controller that individually controls the rates of flow of water to those spray nozzles associated with the entrained fibers and the rate of flow of conditioning liquid to the nozzles associated with the take-off device. Control of the flow of air and conditioning liquid provides for retention of conditioning liquid in a quiescent state at the exit of each conditioning agent spray nozzle in position to be substantially instantaneously uniformly sprayed in a fan-pattern onto the exposed surface of the bales. Further the control of the present invention minimizes any spray of the conditioning liquid beyond the end bales of the aligned bales of fibers.

Owner:COTTON CONDITIONERS

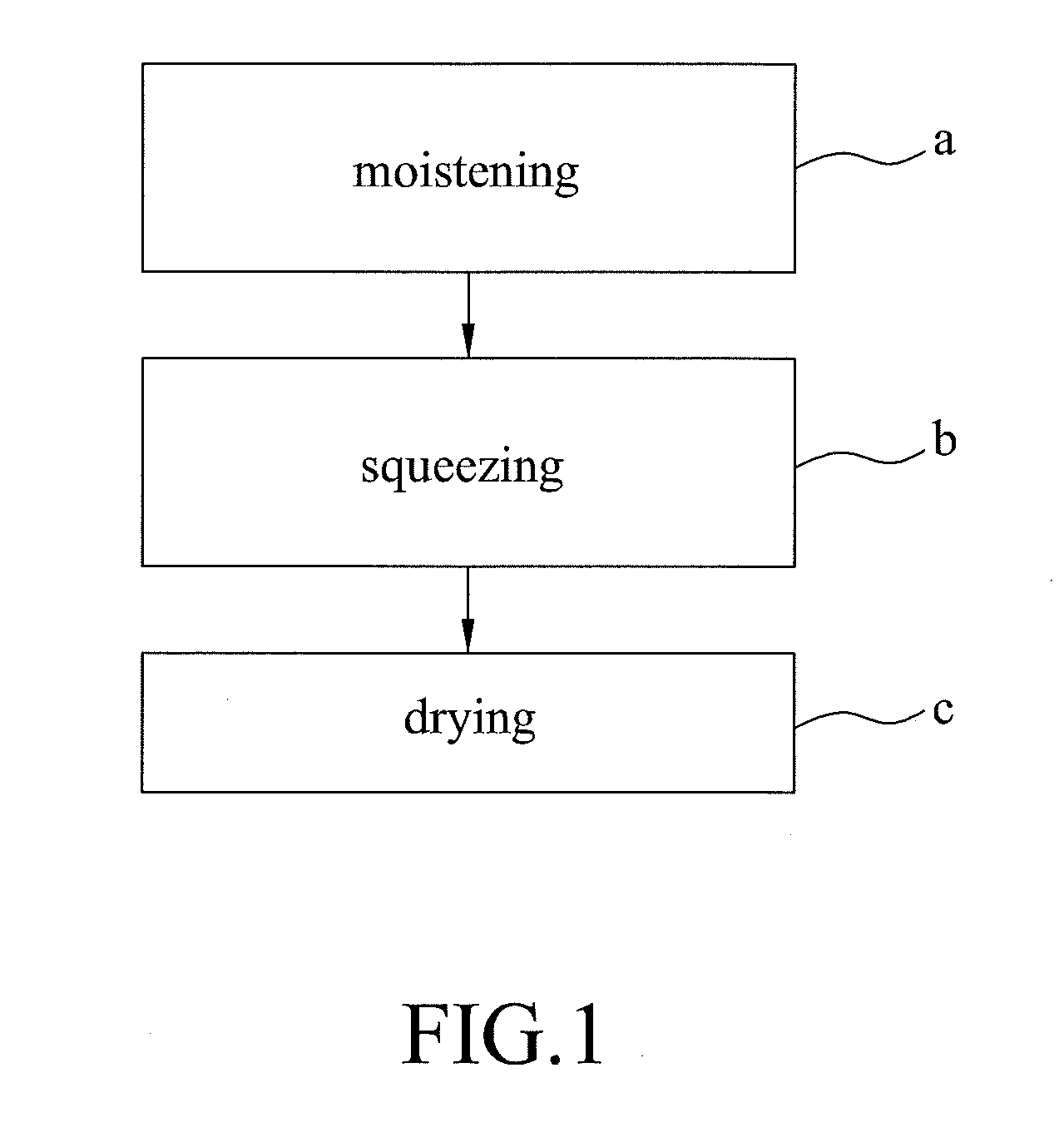

Method for fabricating a conductive yarn and conductive yarn fabricated by the method

InactiveUS20140318857A1Improve conductivityShorten the processing periodMaterial nanotechnologyLubricating devicesPolymer scienceElectrically conducting yarn

A method for fabricating a conductive yarn includes the steps of: moistening a preformed yarn with a conductive slurry to prepare the preformed yarn absorbed with the conductive slurry; and drying the preformed yarn absorbed with the conductive slurry. The conductive slurry includes a conductive nanometer structure, a solvent, and a resin component. The conductive nanometer structure has an aspect ratio sufficient to permit binding of the conductive nanometer structure to the preformed yarn.

Owner:ASIATIC FIBER CORP

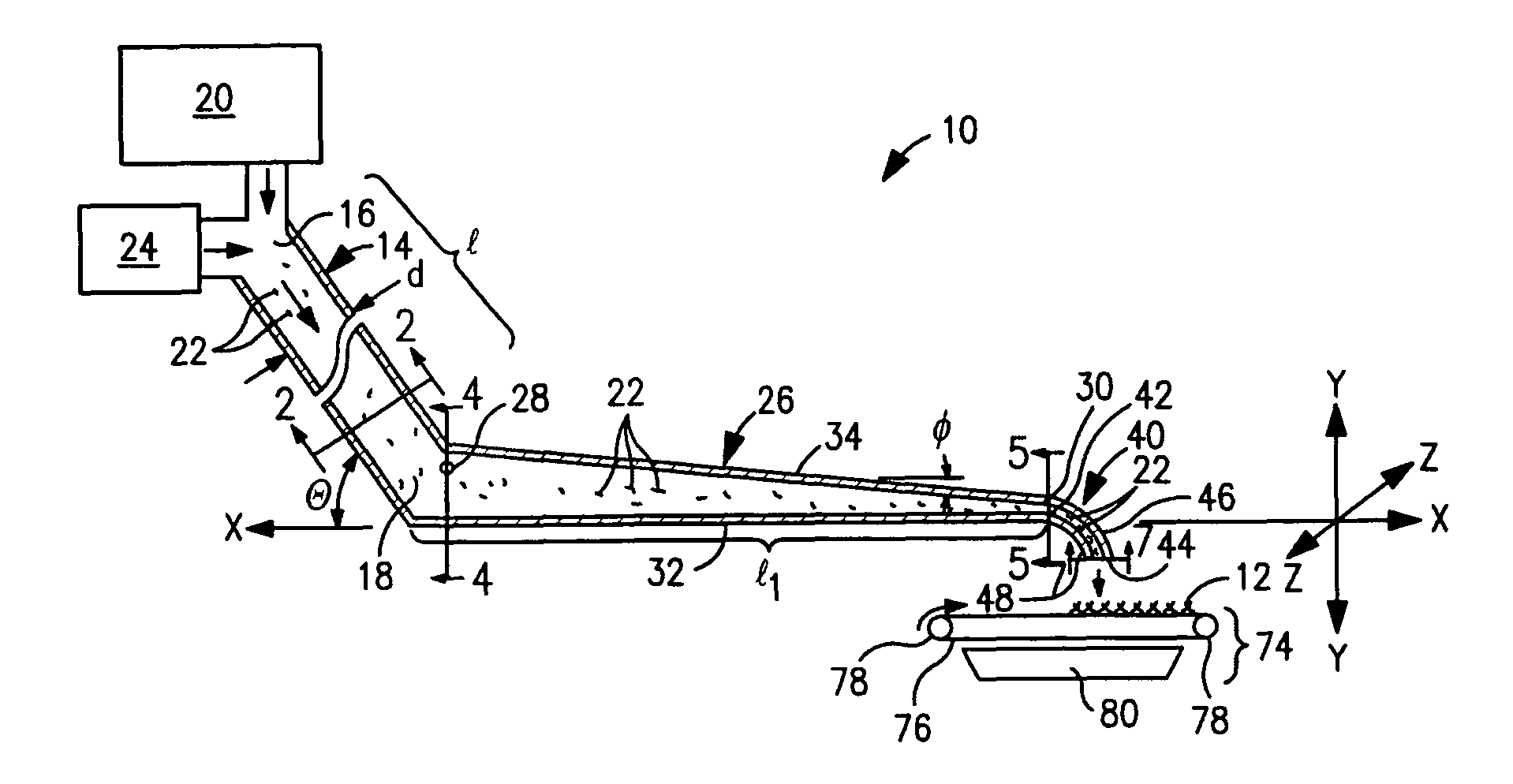

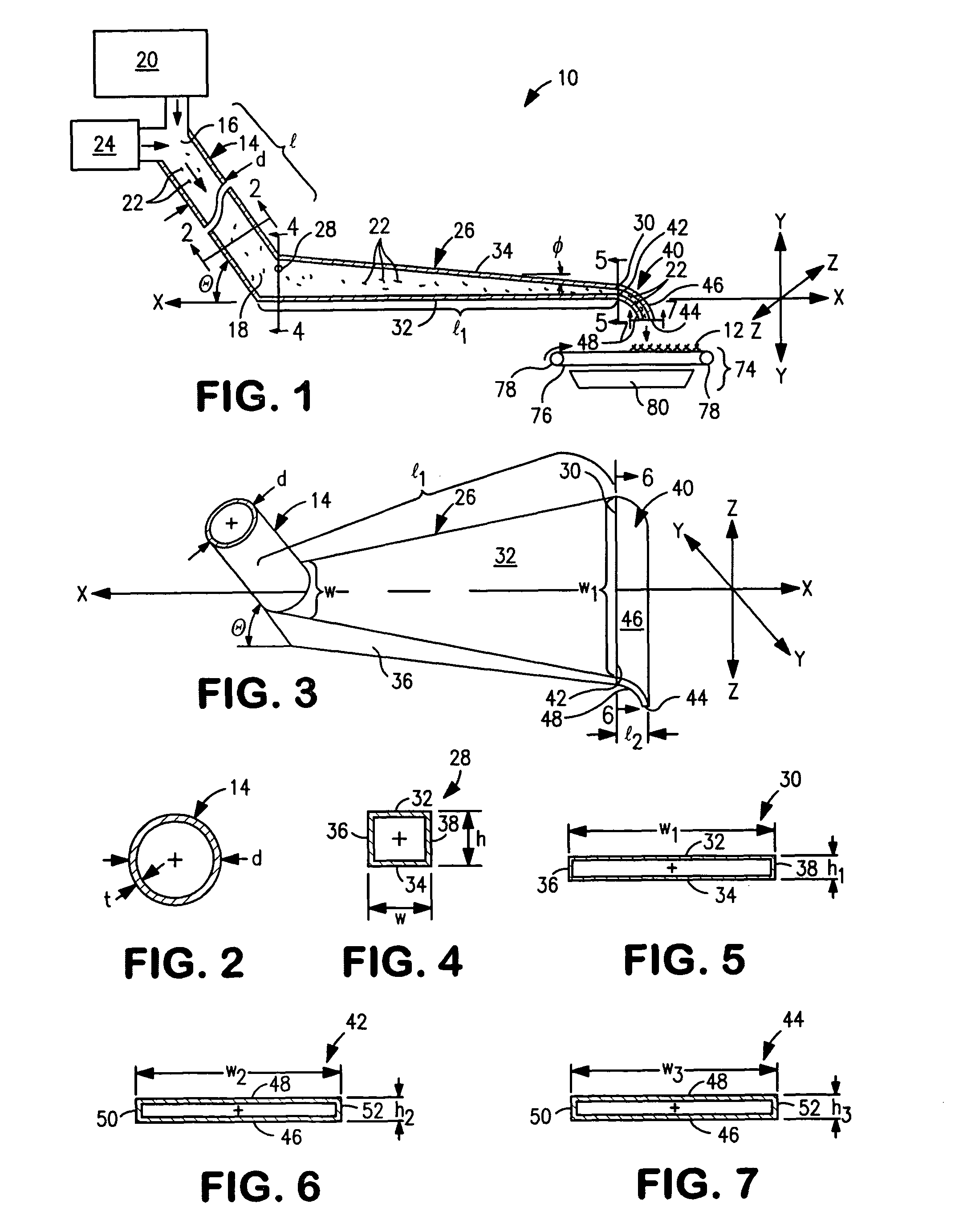

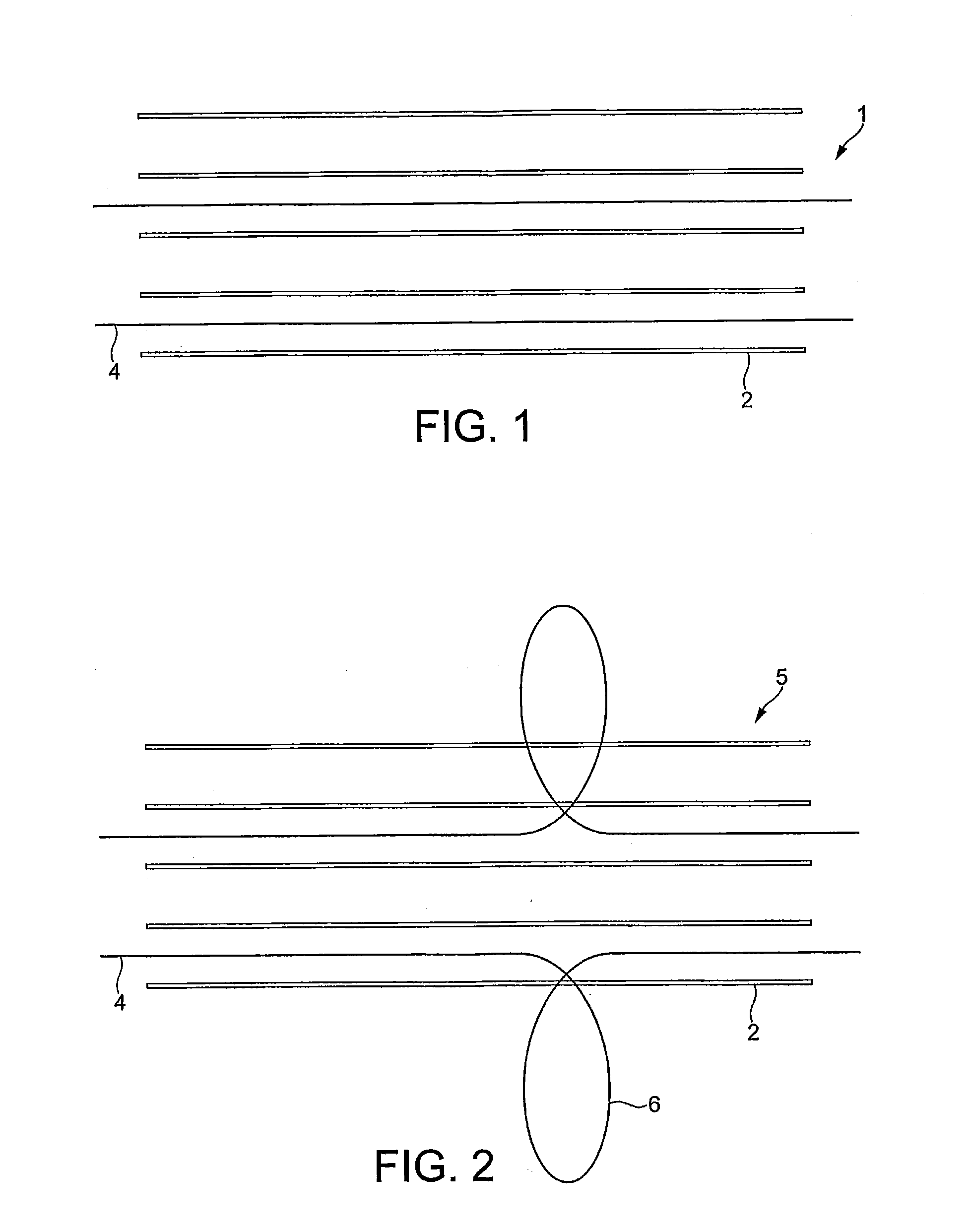

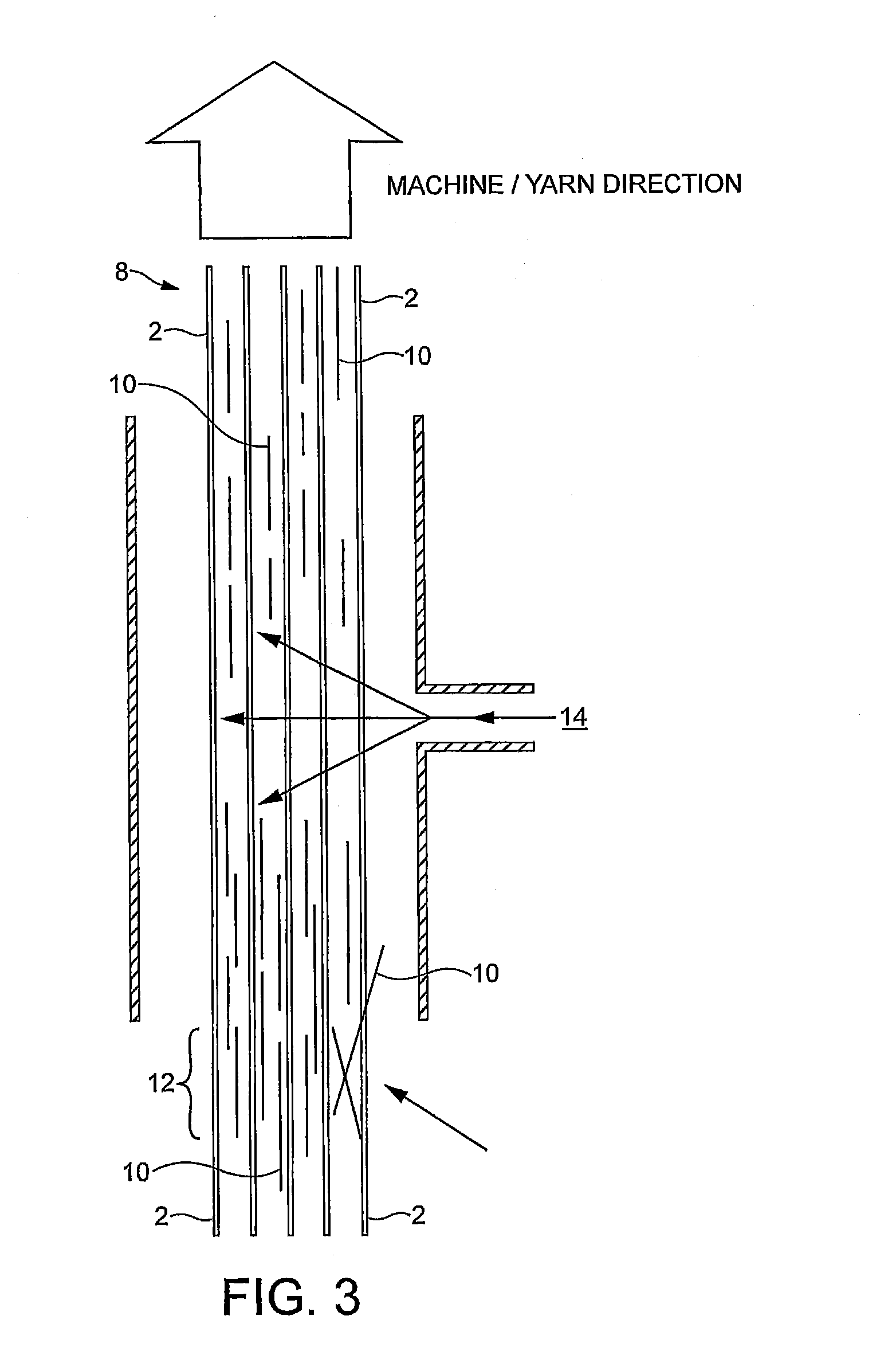

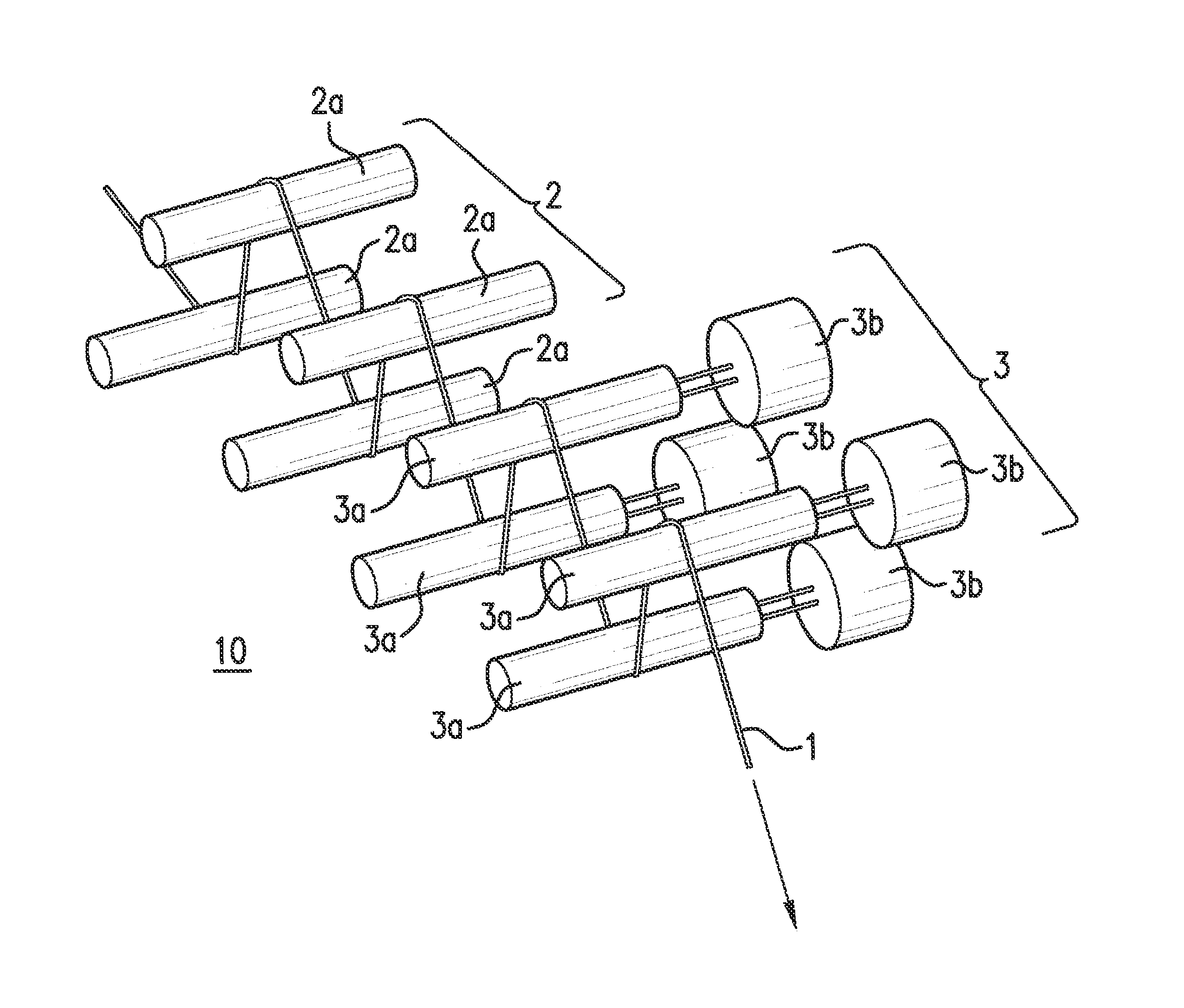

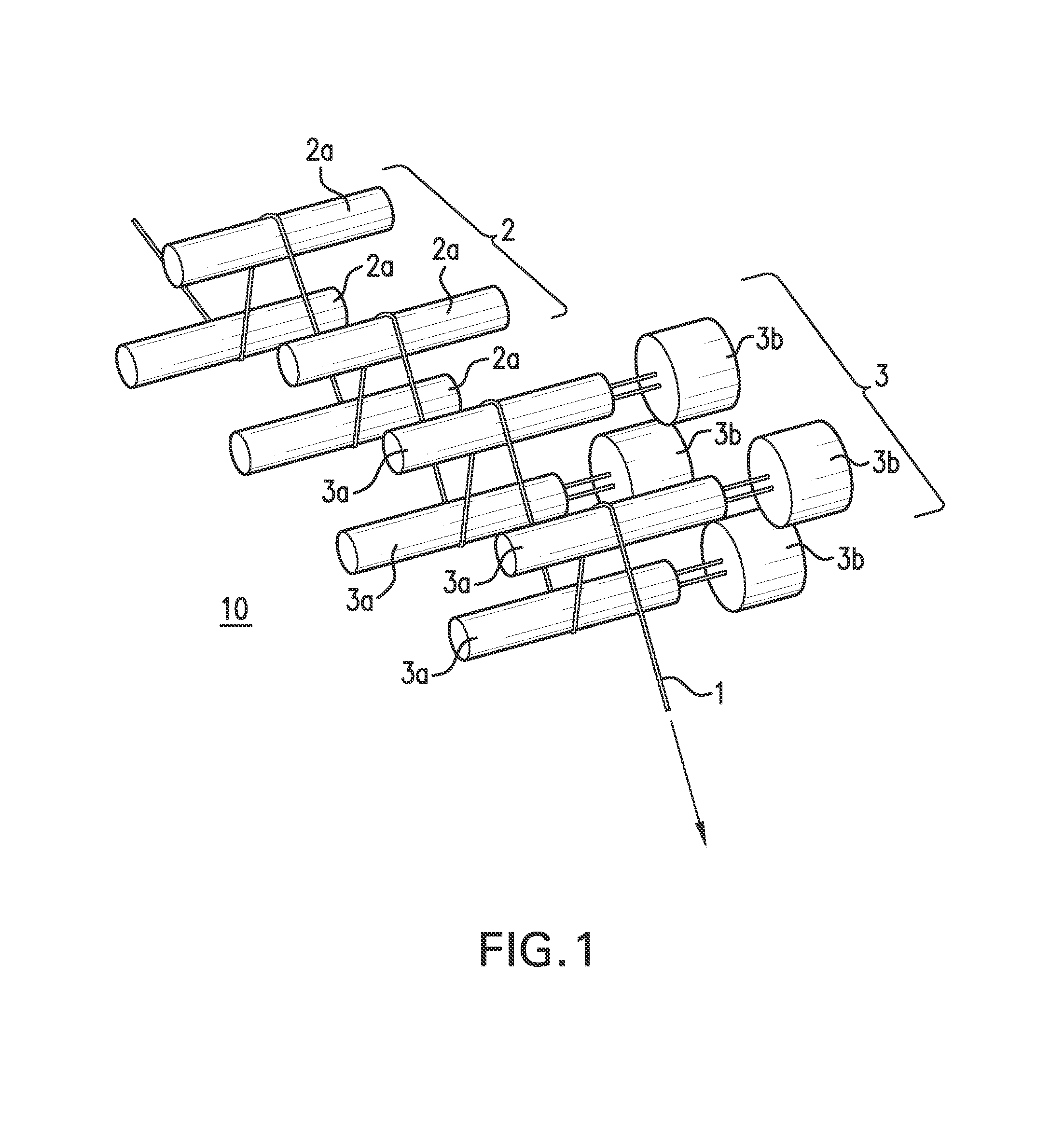

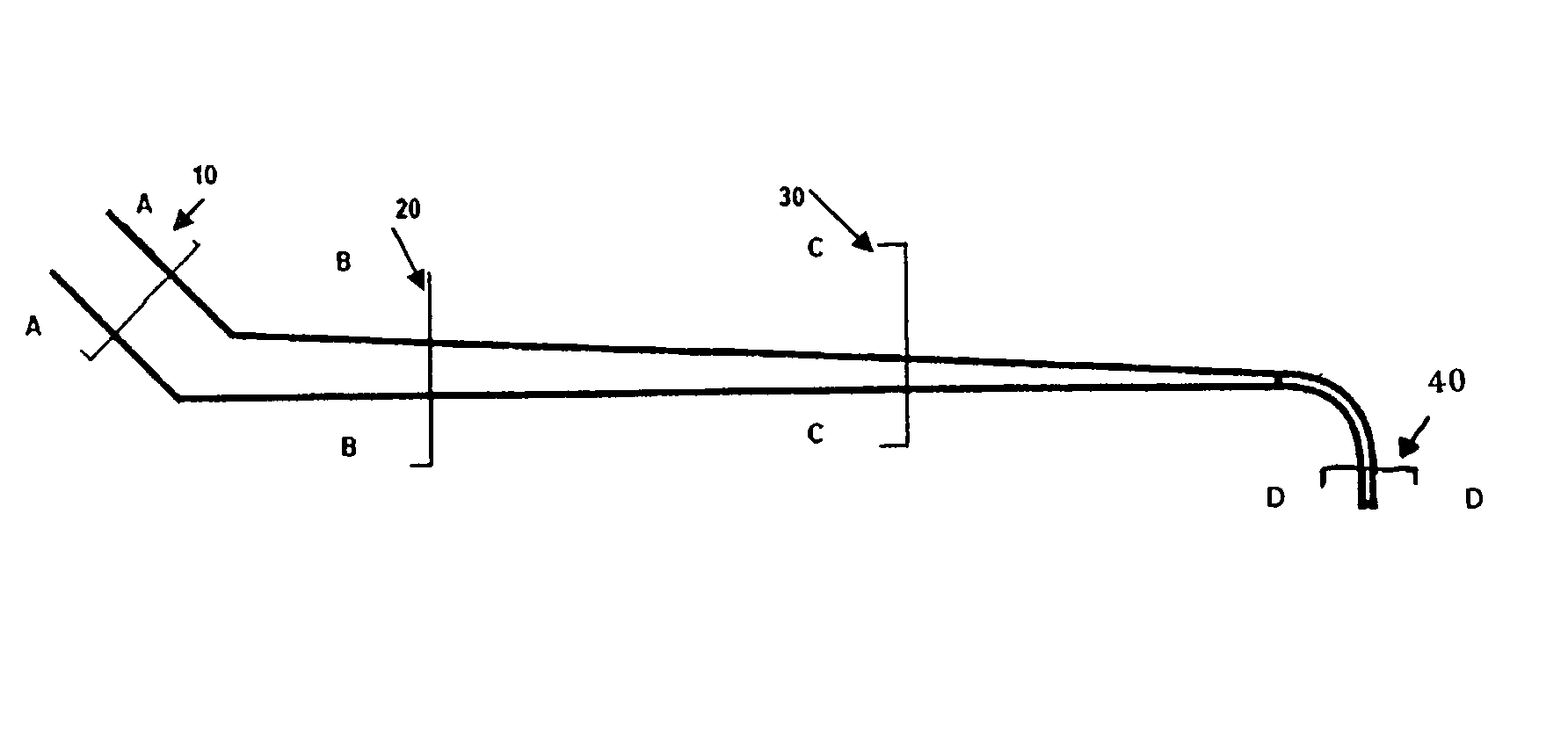

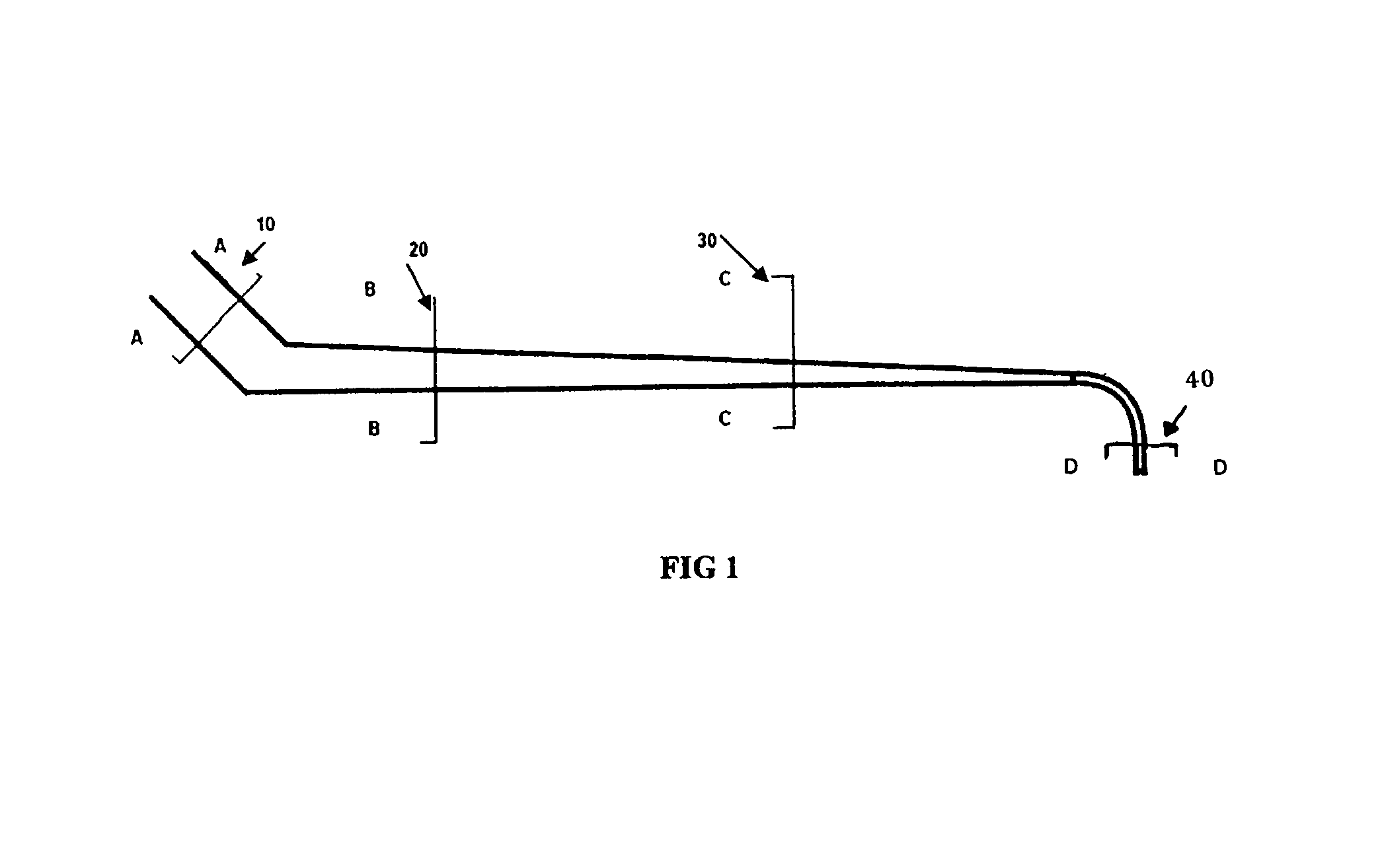

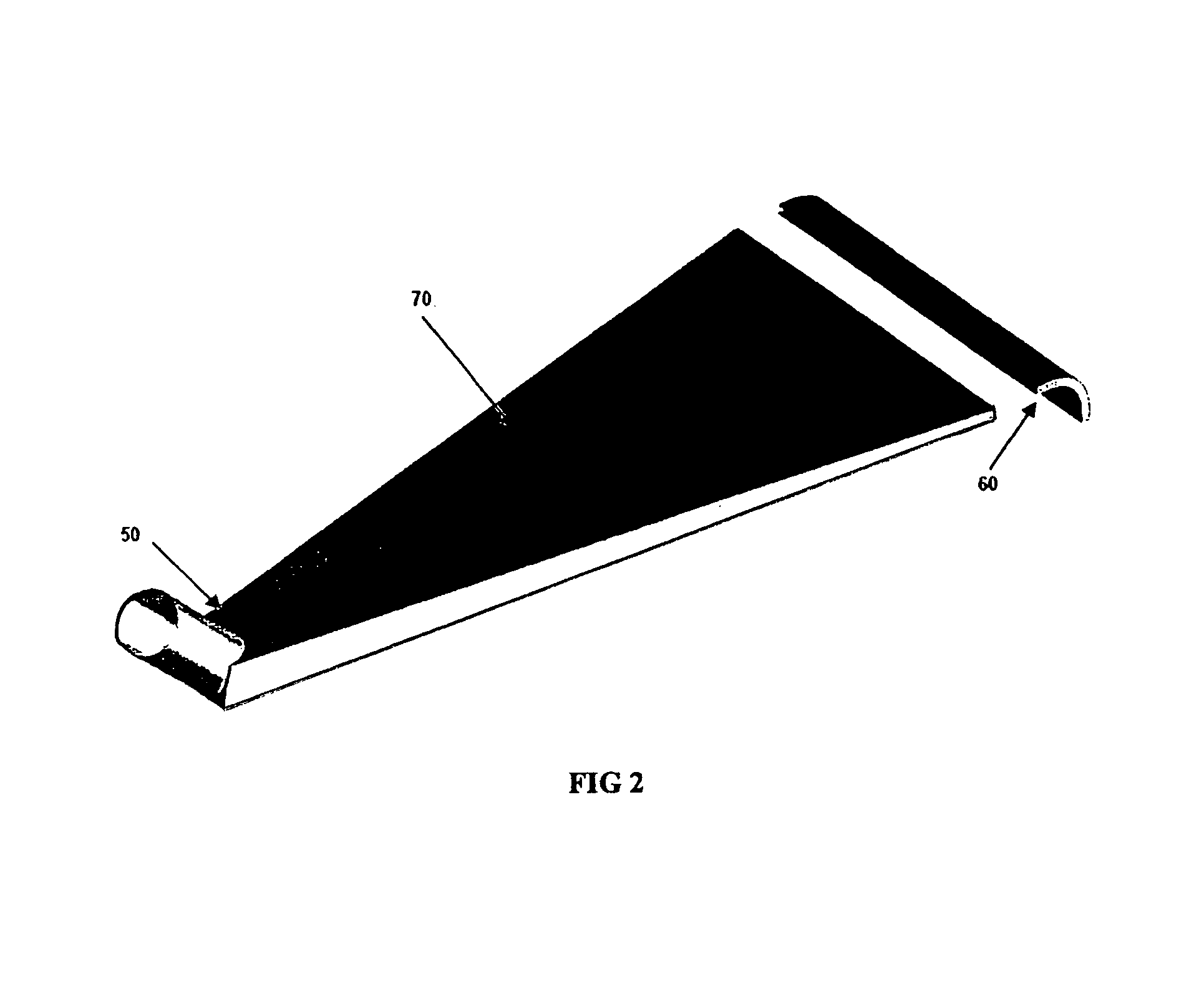

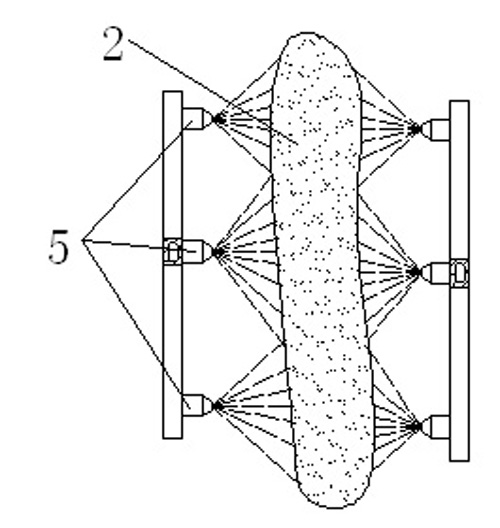

Apparatus and methods for spreading fiber bundles for the continuous production of prepreg

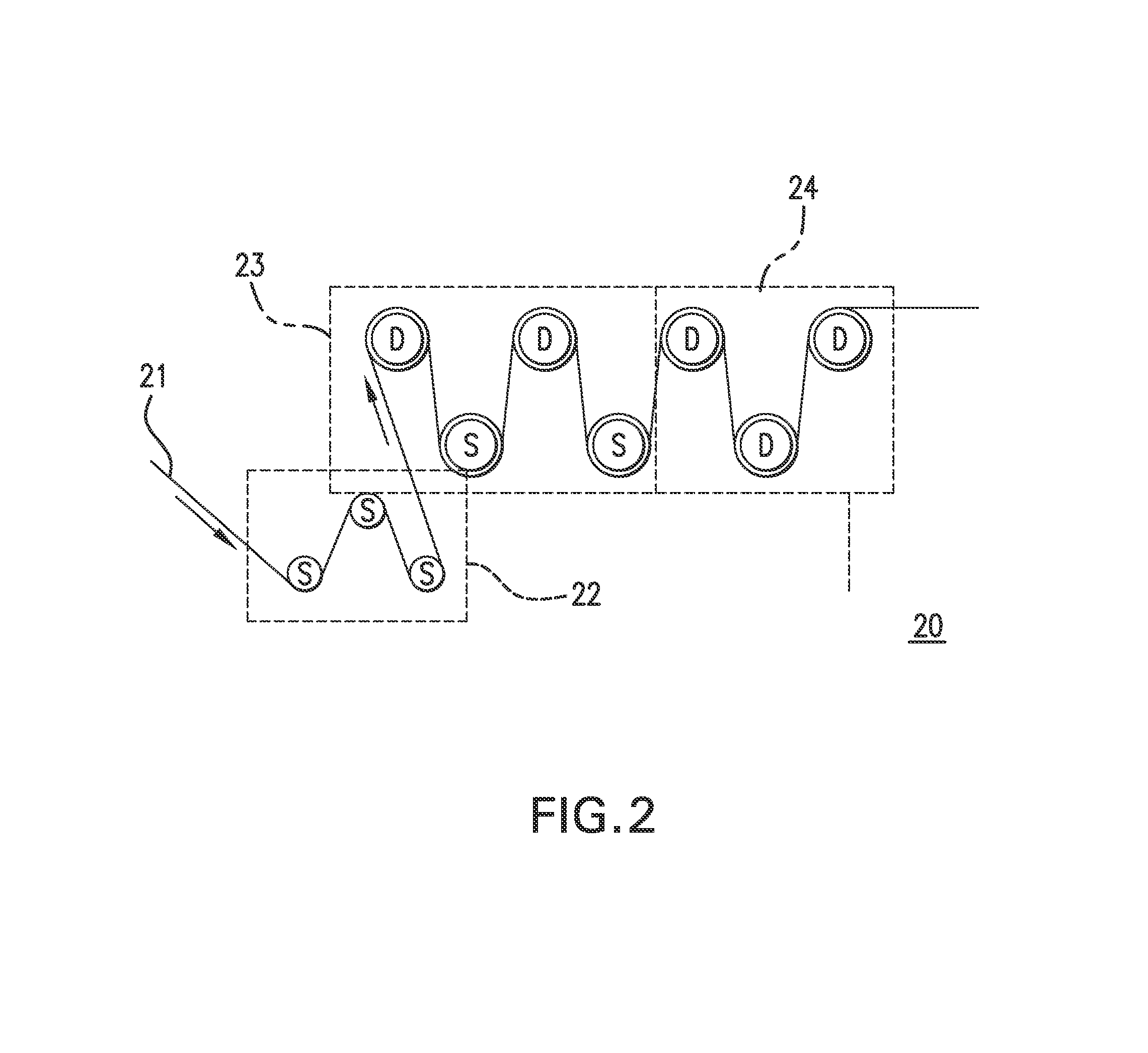

ActiveUS8490253B2Improve breathabilityReduce tensionLubricating devicesFibre mixingFiber bundleEngineering

Apparatus for producing spread fiber bundles by strategic use of tension control throughout the device and use of higher differential speeds between driven rollers and line speed of the running fiber bundle are provided herein, along with methods for producing spread fibers, prepregs, and articles of manufacture therefrom.

Owner:CYTEC TECH CORP

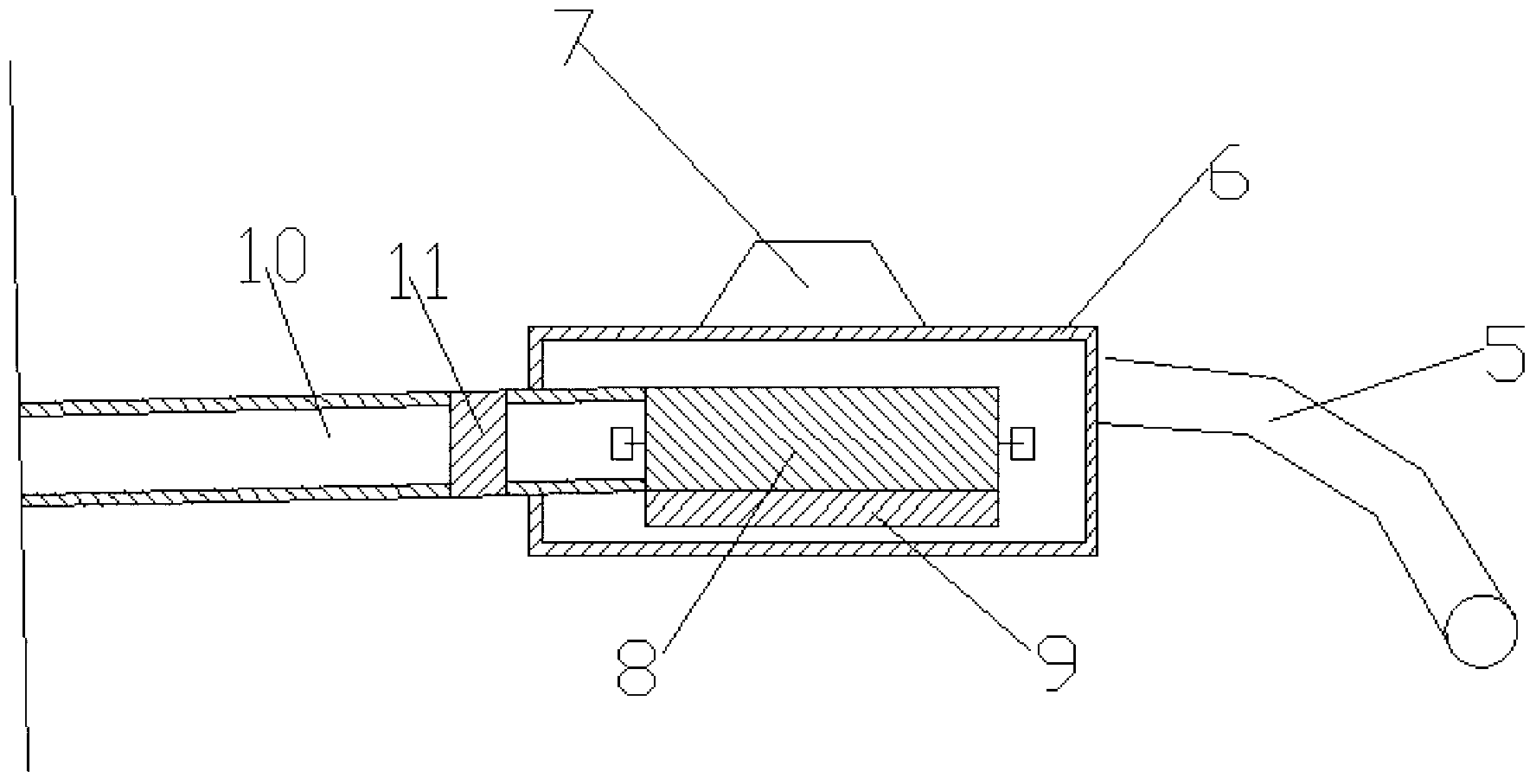

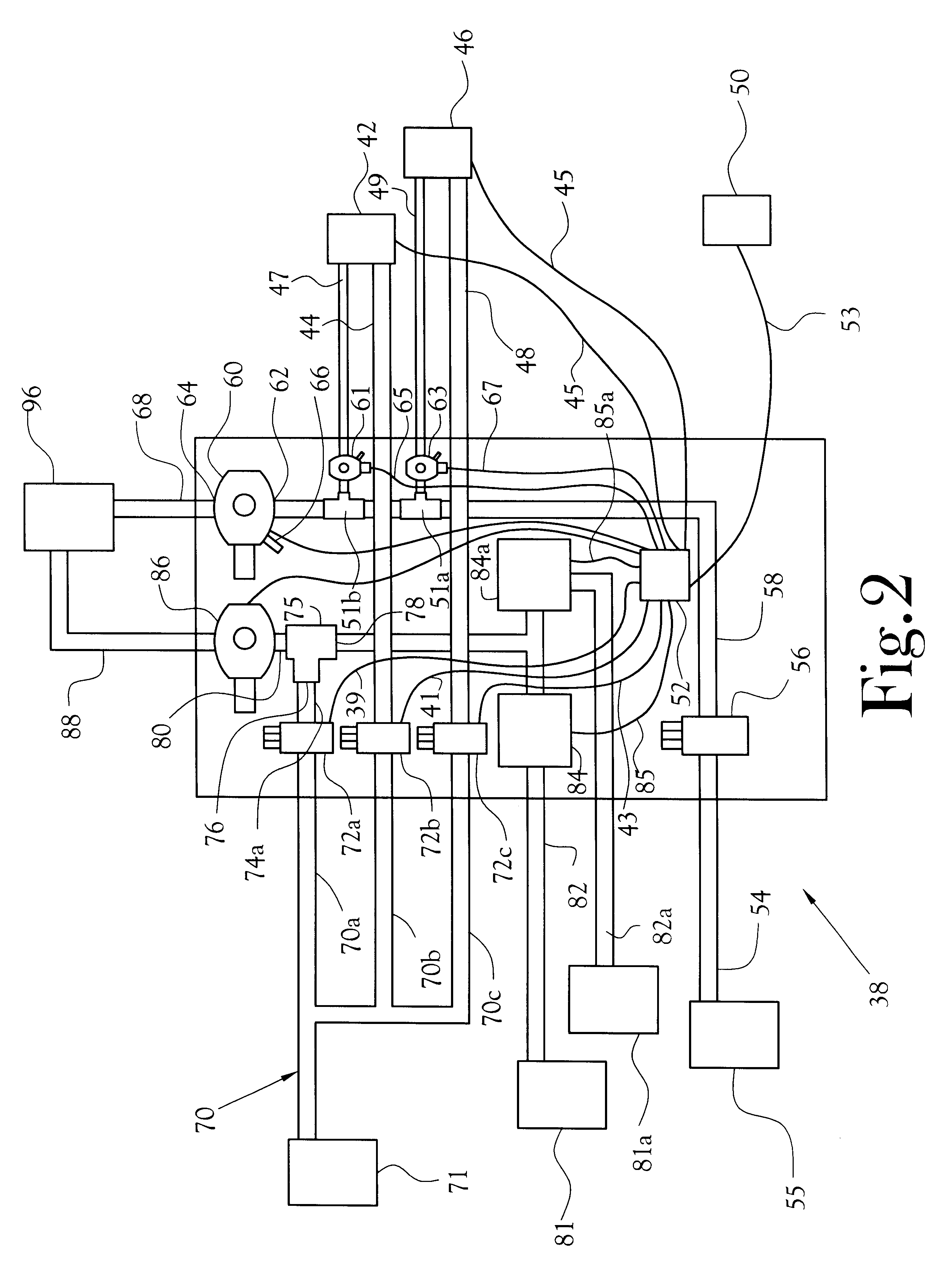

Fiber combining device

InactiveCN101525790AReduce manufacturing costSave resourcesLubricating devicesGearingFiberEngineering

The invention relates to a fiber combining device which belongs to the technical field of recovery devices for chemical fiber filaments. The device comprises a filament placing frame, an oil pan box, a filament bundle traction mechanism, a filament bundle cleaning mechanism, a filament storing container actuating mechanism and a filament storing container, wherein the filament placing frame corresponds to one end of the oil pan box, and a group of waste filament pan shafts are fixedly arranged on the filament placing frame at intervals; an oil storing pan is matched with the opening of the oil pan box, and a bundle collecting filament guide hook for collecting filaments released from the filament placing frame into a filament bundle is fixedly arranged at one end of the oil pan box; an oil wheel for applying oil to the filament bundle is arranged in the middle of the oil pan box and corresponds to the upper part of the oil storing pan; the filament bundle traction mechanism corresponds to the other end of the oil pan box; the filament bundle cleaning mechanism is arranged on the filament bundle traction mechanism; the filament storing container actuating mechanism is arranged at one end of the filament bundle traction mechanism; and the filament storing container is arranged on the filament storing container actuating mechanism. The device not only can save resources and protect the environment but also can reduce the production cost of manufacturers.

Owner:常熟市海欣复合材料有限公司

Combing machine heat moist treatment nipper plate mechanism

InactiveCN101215738BNot easy to damageReduce long fiber contentLubricating devicesCombing machinesFiberCavity wall

The invention provides a nipper mechanism which is applied in a combing machine, which belongs to the textile processing technical field. The nipper mechanism of the combing machine comprises a nipperframe which is provided with a lower nipper, an upper nipper arm which is provided with an upper nipper, a feed roller, a feed table and a heat-wet processing device, the heat-wet processing device is a hollow circular pipe element, a row of air discharging holes which are evenly arrayed are opened on the cavity wall, the circular pipe element is fixedly installed on the lower nipper or the uppernipper, the axial cord of the heat-wet processing device and the axial cord of the feed roller are in parallel, the heat-wet processing device is externally connected with a heat-wet air generating device, the feed roller and the feed table are externally connected with a heating device. The flexibility of fiber is improved through heat-wet process of the heat-wet processing device and heating process of the feed roller and the feed table, the frictional force between fibers is reduced, and impurities removing and fiber straightening and paralleling effect of a combing machine is distinctively increased, and fiber damage is reduced.

Owner:WUHAN TEXTILE UNIV

Apparatus for the uniform distribution of fibers in an air stream

An apparatus for the manufacture of an air laid web in which individual cellulose fibers or textile fibers or their blends can be conveyed and distributed by air uniformly to any desired width onto a forming zone composed of either a foraminous screen or a fibrous polymer matrix on top of a consolidating vacuum box.

Owner:BIAX FIBERFILM CORP

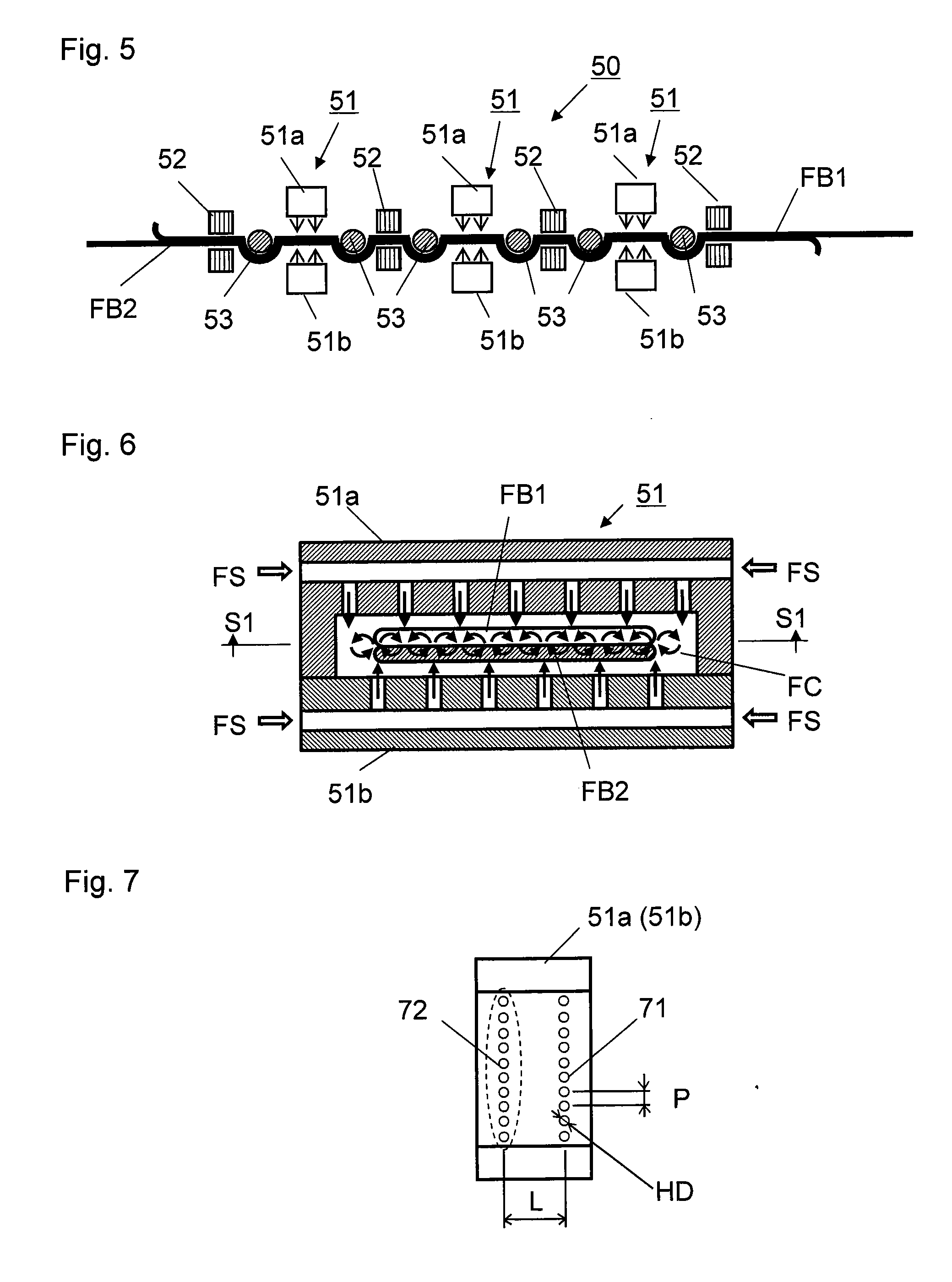

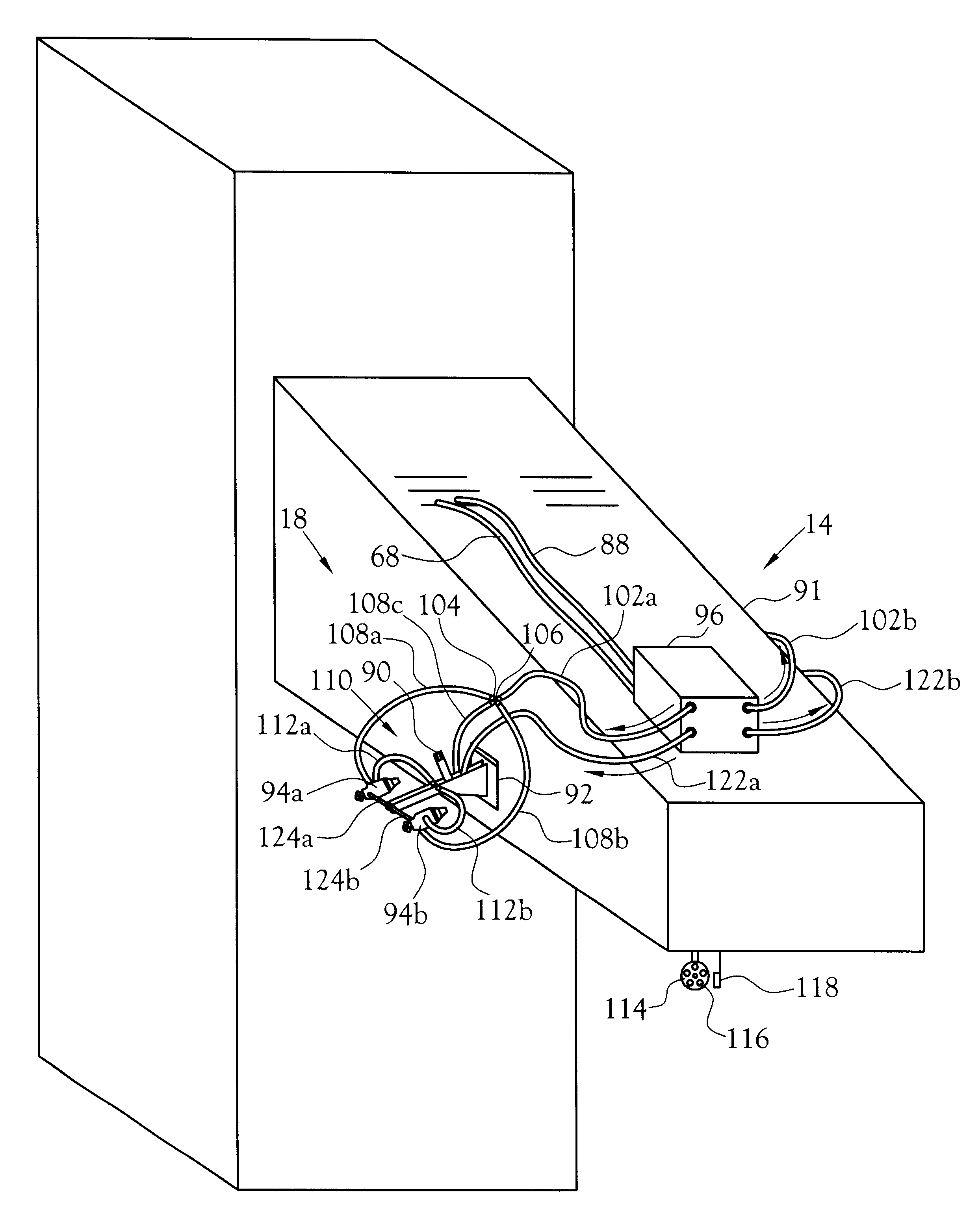

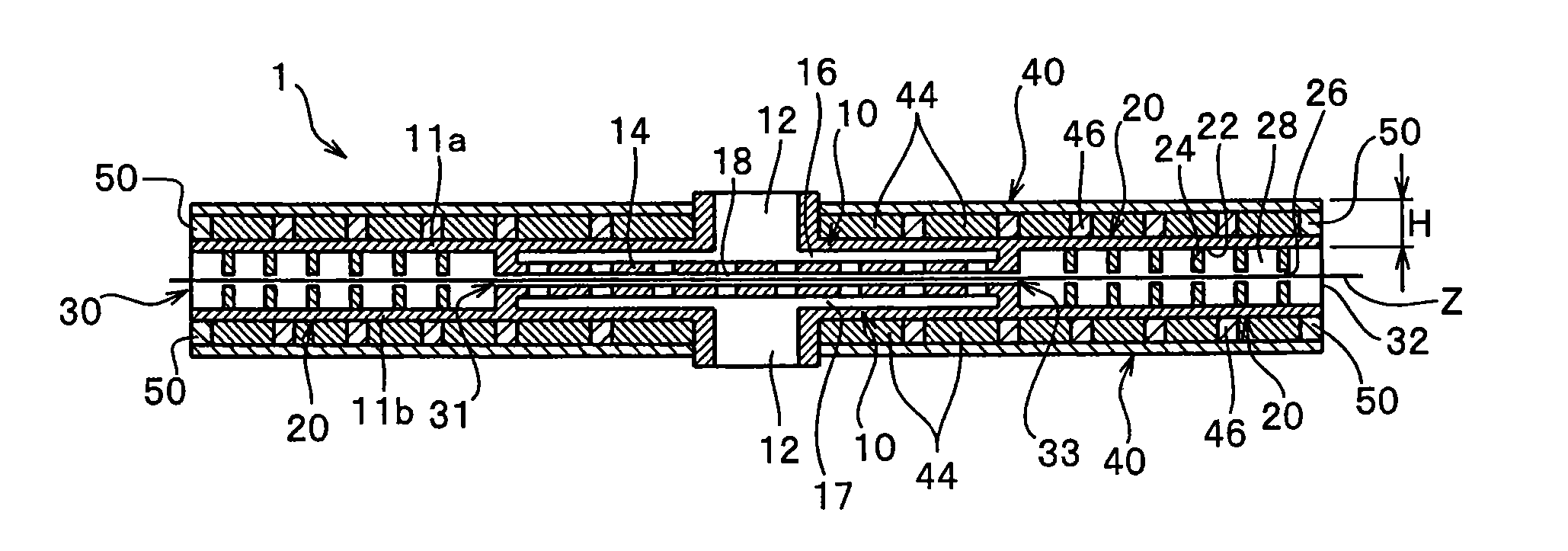

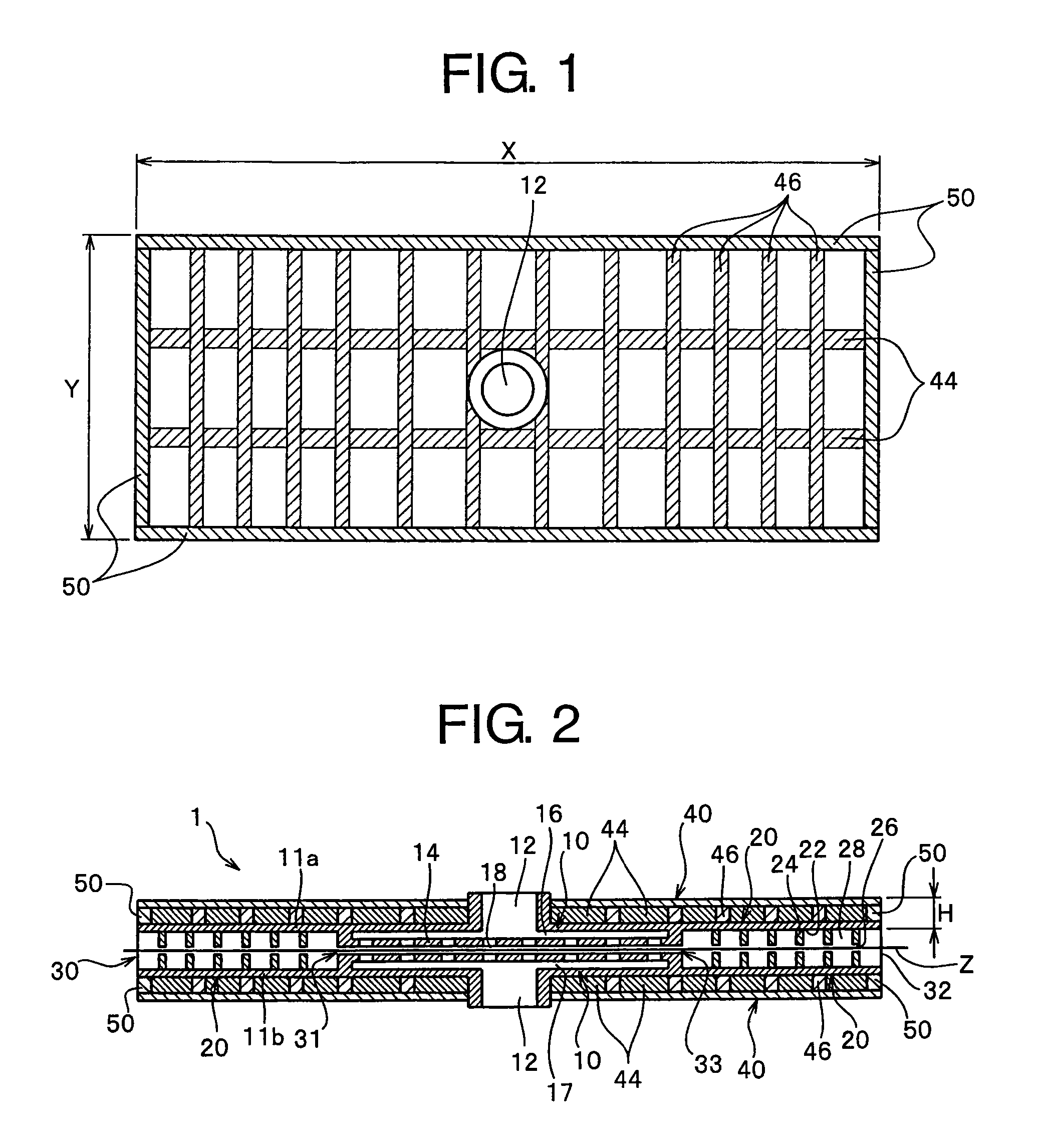

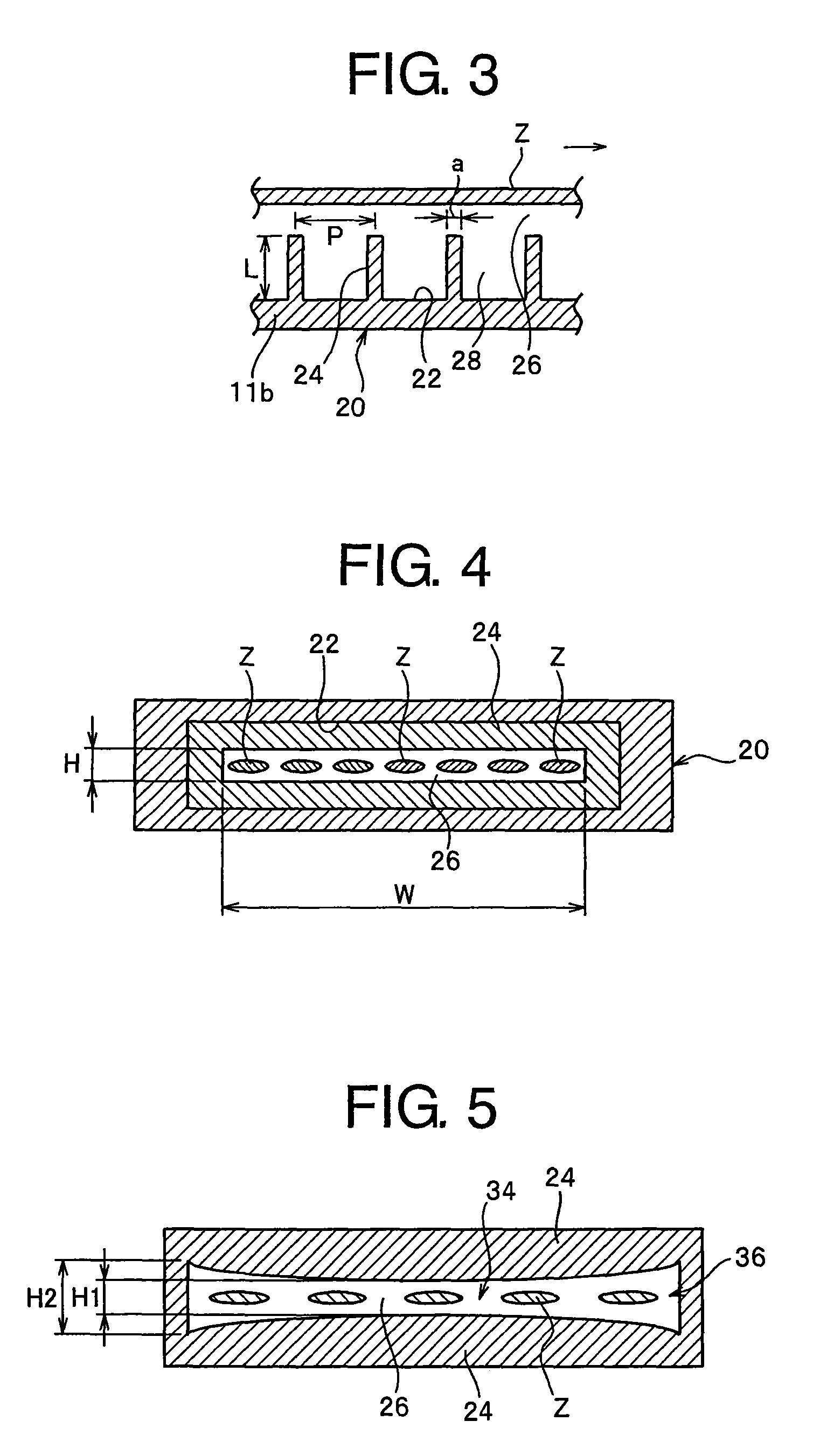

Apparatus for pressure steam treatment of carbon fiber precursor acryl fiber bundle and method for producing acryl fiber bundle

ActiveUS8839492B2Reduce thermal deformationEasy to solveLubricating devicesTextile treatment containersFiber bundleCarbon fibers

A pressure steam treatment apparatus according to the invention includes a pressure steam treatment chamber and labyrinth sealing chambers. The labyrinth sealing chambers are respectively arranged on a fiber bundle inlet and on a fiber bundle outlet of the steam treatment apparatus, having a running path of the fiber bundle in a horizontal direction and having plural labyrinth nozzles on top and bottom of the running path. The difference between a maximum value and a minimum value of the distance in the perpendicular direction of the top and bottom side labyrinth nozzles, of a pair of opposing labyrinth nozzles is 0.5 mm or smaller when the ambient temperature of the labyrinth sealing chamber is 140° C. This structure ensures that the energy cost can be reduced, the deformation of the apparatus and also, the raise of fuzz on the fiber bundle and fiber bundle breakage can be prevented at the same time.

Owner:MITSUBISHI CHEM CORP

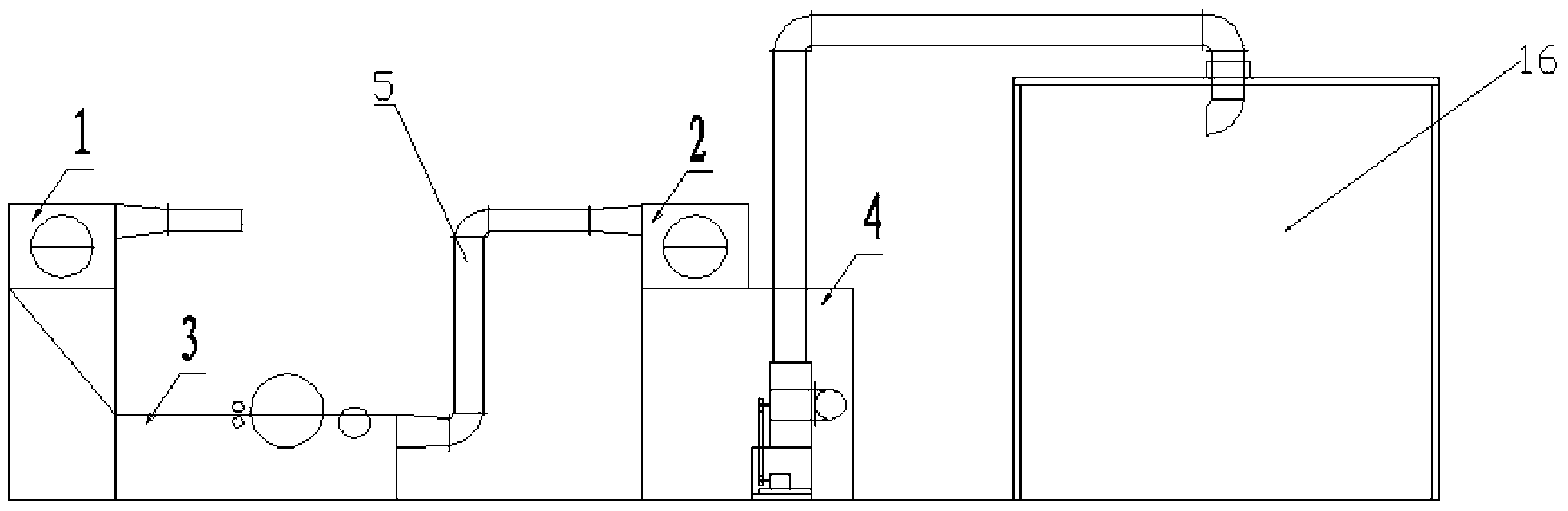

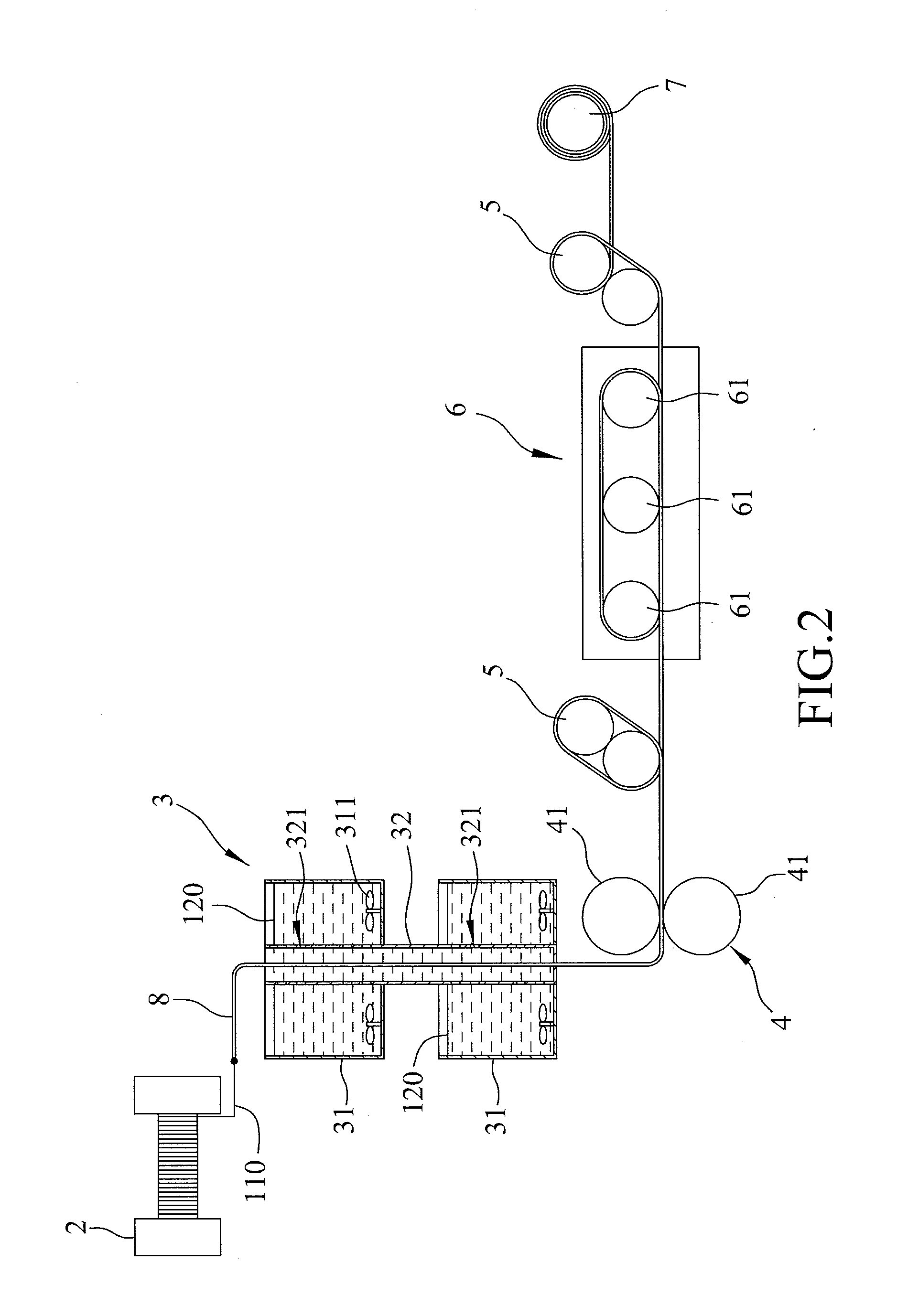

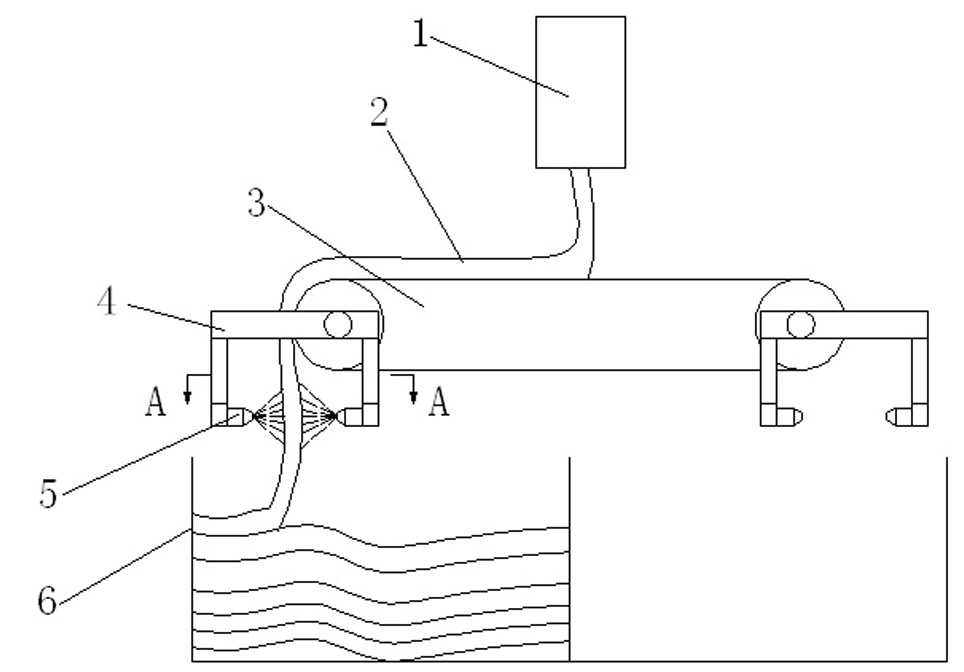

Oiling method and oiling device of wool lubricant during slivering process of cashmere

ActiveCN102134764AReasonable installation locationEasy to control moisture regainLubricating devicesMoisture regainConveyor belt

The invention relates to a cashmere processing device, in particular to an oiling method and an oiling process of wool lubricant during the slivering process of cashmere. The device comprises a cashmere condensing device and a conveyor belt which is mounted below the cashmere condensing device and can move left and right, and the device is characterized in that wool lubricant spray heads are fixedly mounted at two ends of the conveyor belt, and the horizontal height of the wool lubricant spray heads is lower than that of the conveyor belt. The oil injection way of the wool lubricant spray heads is changed from the vertical way to the horizontal way, thereby simultaneously spraying the wool lubricant to two sides of raw material during the falling process of the raw material, realizing uniform oiling and simultaneously ensuring that the moisture regain of the raw material achieves 25%-30%; furthermore, as the spray heads are mounted below the conveyor belt, the sprayed wool lubricant can not pollute the conveyor belt, the cashmere sliver preparation rate can be improved by 2 percent on the existing basis, and the quality of cashmere slivers is further improved.

Owner:宁夏新澳羊绒有限公司

Preparation method of chitin antibacterial fiber yarn and application in householde textile

The invention provides a preparation method of chitin antibacterial fiber yarns, comprising a cotton cleaning procedure, a cotton steaming procedure, a drawing procedure, a roving procedure and a spinning procedure. In all the procedures, spinning finishes is adopted, is formed by complex formulation of surfactant, antistatic agent and smooth agent, has the advantages of softness, favorable permeability and antistatic property, can be fast decomposed in water, and does not generate any negative influence on environment and dyeing finishing.

Owner:SHANGHAI SHUIXING HOME TEXTILE

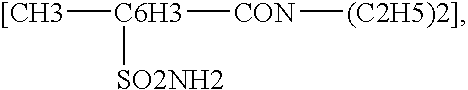

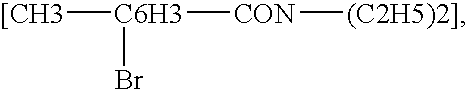

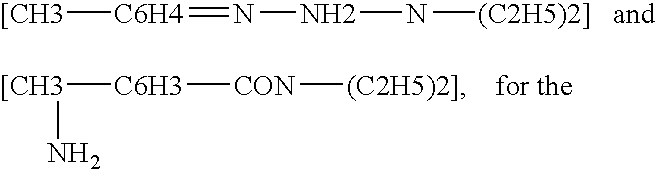

Covalent Conjugates of Cotton and Substitutes (Viscose, Modal Cotton) with Bioactive Substances Having Antiseptic, Sanitizing, Acaricidal and Insect Repellent Activity, and a Method for Obtaining Them

InactiveUS20090130187A1Improve sensory propertiesLubricating devicesBiochemical fibre treatmentViscoseEngineering

The present invention concerns covalent conjugates of cotton and substitutes (viscose, modal cotton) with bioactive substances having antiseptic, sanitizing, acaricidal and insect repellent activity, as well as a new process for obtaining aforesaid conjugates in common equipment of the textile industry, without compromising the marketable and organoleptic properties of the cotton and its substitutes treated in this manner. The conjugates obtained by the new process are characterized by a high stability, while maintaining in the long term the antiseptic, sanitizing, acaricidal and / or insect repellent activity imparted by the procedure described herein.

Owner:VOLPATO IVO +2

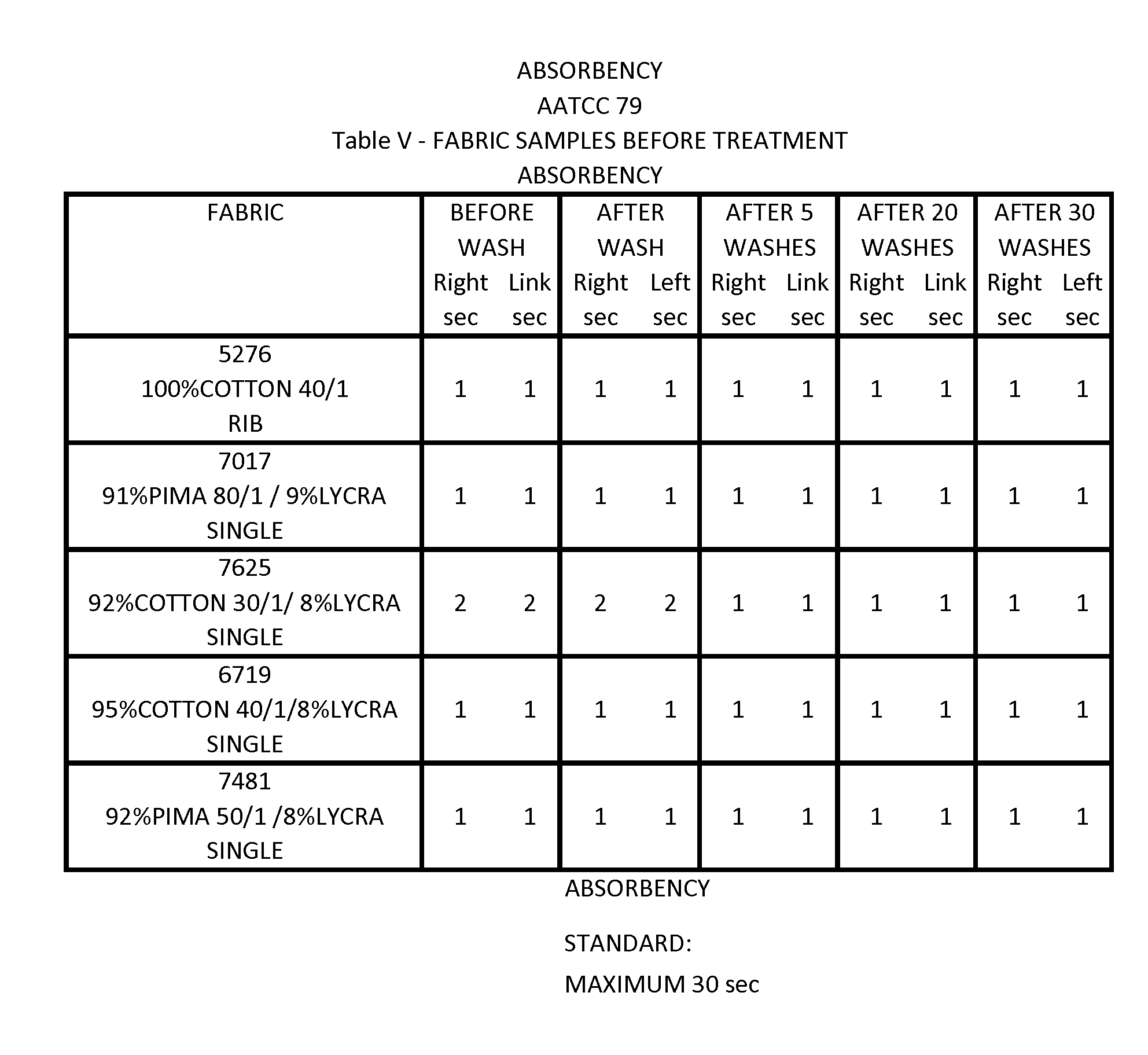

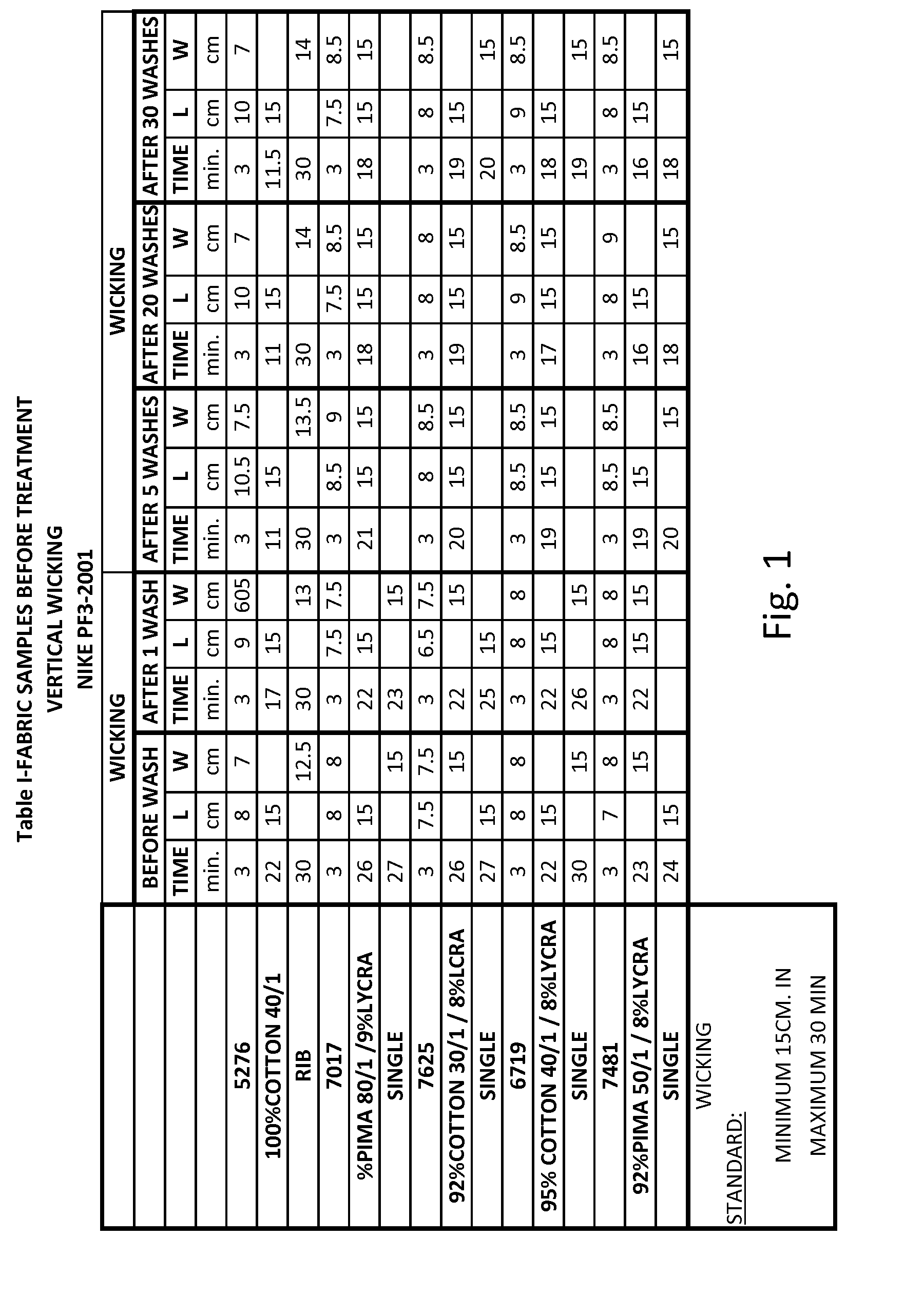

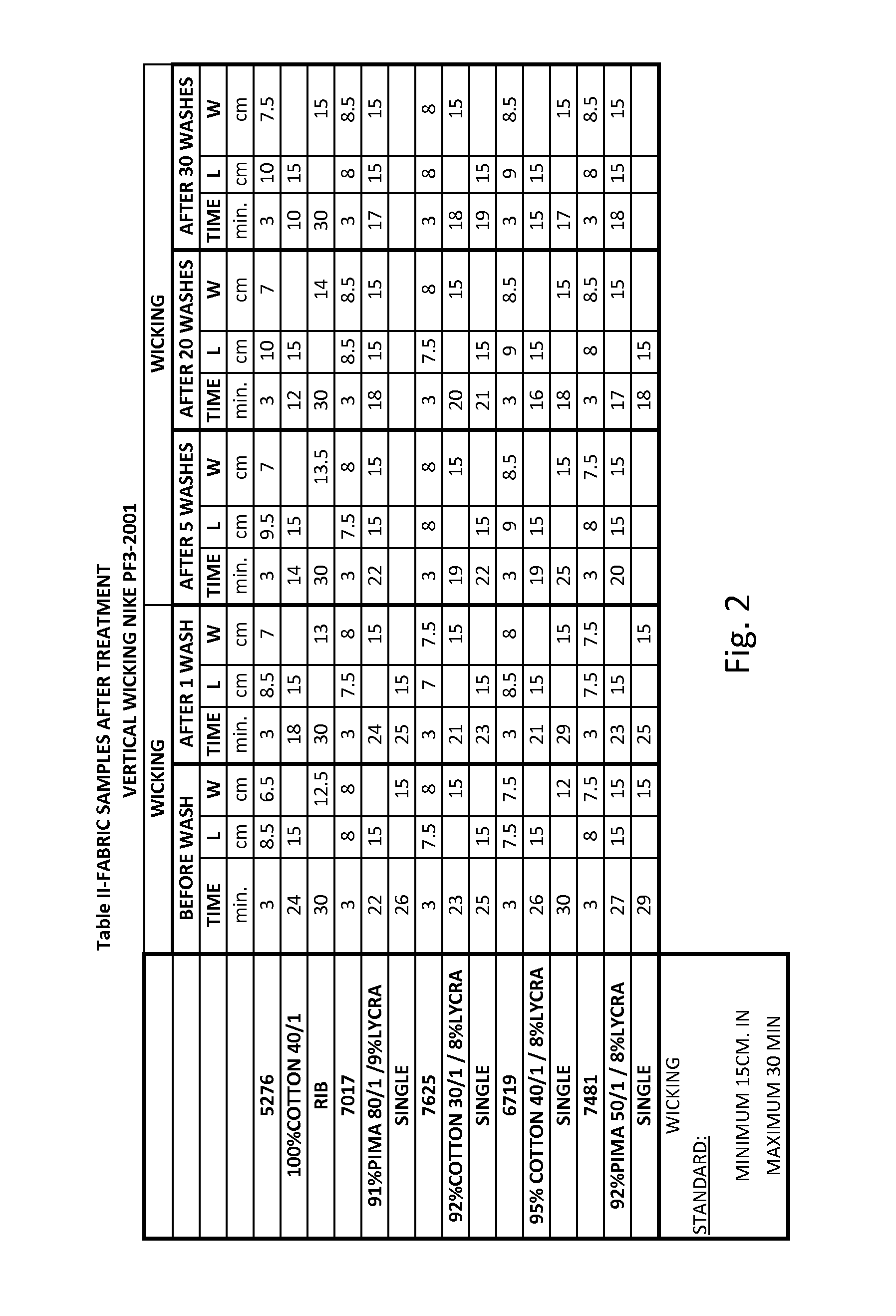

Moisture-management in hydrophilic fibers

ActiveUS20080128044A1Improved moisture-management performanceImprove performanceMechanical impurity removalLubricating devicesHydrophilizationPolymer science

Provided is a fabric having improved moisture-management performance and being resilient to repeated washing, as well as a process for manufacturing the fabric. The process, employing consecutive steps of hydrophilization and hydrophobization, includes defatting cotton or cellulose fibers and their coating with silicone nanoparticles.

Owner:DELTA GALIL INDUSTRIES

Method for making yarn and products comprising same

InactiveUS6884469B1Reduce lossAvoid stagnationLubricating devicesFilament/thread formingYarnThermoplastic

The invention relates to a process for manufacturing a continuous yarn, and the product obtained from such process. A multiplicity of continuous filaments are formed by the mechanical drawing of a multiplicity of streams of molten thermoplastic(s) flowing from the orifices of at least one fiberizing device. A mixture, in the liquid state, is deposited on the surface of at least some of the filaments before they are brought together into at least one yarn. An absorbent mat may be continuously impregnated, with at least some of said mixture being continuously taken up by means of a rotating roller in contact with said mat, and using a sizing roller, said mixture may be deposited on the filaments while they are being drawn.

Owner:SAINT GOBAIN VETROTEX FRANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com