Patents

Literature

102results about "Animal fibre deburring machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing, processing and post-processing down filler

ActiveCN102995331AImprove bulkIncrease warmthAnimal fibre deburring machinesLiquid/gas/vapor removalCold airDust control

The invention discloses the technical field of production, processing and post-processing of down filler and discloses a method for producing, processing and post-processing a down filler. The method comprises the following steps of: spraying, namely reprocessing washed finished product down produced by using a common production process, pumping the finished product down into a spraying machine by using a suction fan, then, spraying while stirring, and continuing to stir after the spraying is finished; attachment and fixation, namely pumping the sprayed wet down into a fixed box by using the suction fan, blowing by using hot air for 15-30 minutes, and stirring; drying, namely sucking the air-dried down in the fixed box into a dryer through a connecting pipeline in three times, drying and sterilizing for 20-30 minutes; cooling and dust removal, namely sucking the dried down to a cooling and dust removal machine through the connecting pipeline, stirring, blowing by using cold air, and meanwhile, screening impurities; and down discharging and packaging, namely bagging the cooled and dust-removed down to obtain a finished product. The product provided by the invention is rapid to dry, easy to tidy, good in filling powder and warmth retention property, less in possibility of being affected with damp and capable of effectively inhibiting the bacterial growth.

Owner:ZHEJIANG SAMSUNG DOWN CO LTD

Device and method for improving cleanness and bulkiness of water-washed down

ActiveCN102011198AImprove cleanlinessPrevent spoilageAnimal fibre deburring machinesMicroorganismEngineering

The invention discloses a device and method for improving cleanness and bulkiness of water-washed down. The device comprises an iron-removing tank, a neck and head feather-removing tank, a dust-removing tank, a down bulking tank and an exhaust fan. The device is characterized in that the iron-removing tank, the neck and head feather-removing tank, the dust-removing tank and the down bulking tank are sequentially communicated with each other, an exhaust tube is arranged on the dust-removing tank and the down bulking tank, the iron-removing tank, the neck and head feather-removing tank, the dust-removing tank and the down bulking tank form an airtight airflow channel, water-washed down sequentially enters each tank body under the action of wind force so that iron impurities, neck and head feather and dust in the water-washed down are sequentially removed, and finally the bulking treatment is carried out on the water-washed down. The device greatly improves the cleanness of the water-washed down, eliminates slight smell of dark feather as well as microorganisms in the water-washed down and avoids the deterioration of the water-washed down; and by carrying out bulkiness enlargement to the water-washed down, the device not only increases the handfeel and the comfortableness of clothes, but also reduces the cost of the clothes.

Owner:广东鸿基羽绒制品有限公司

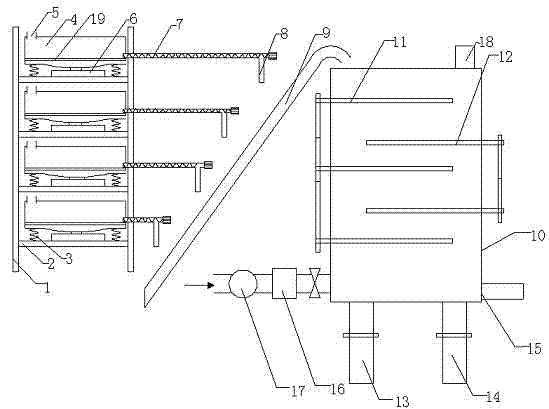

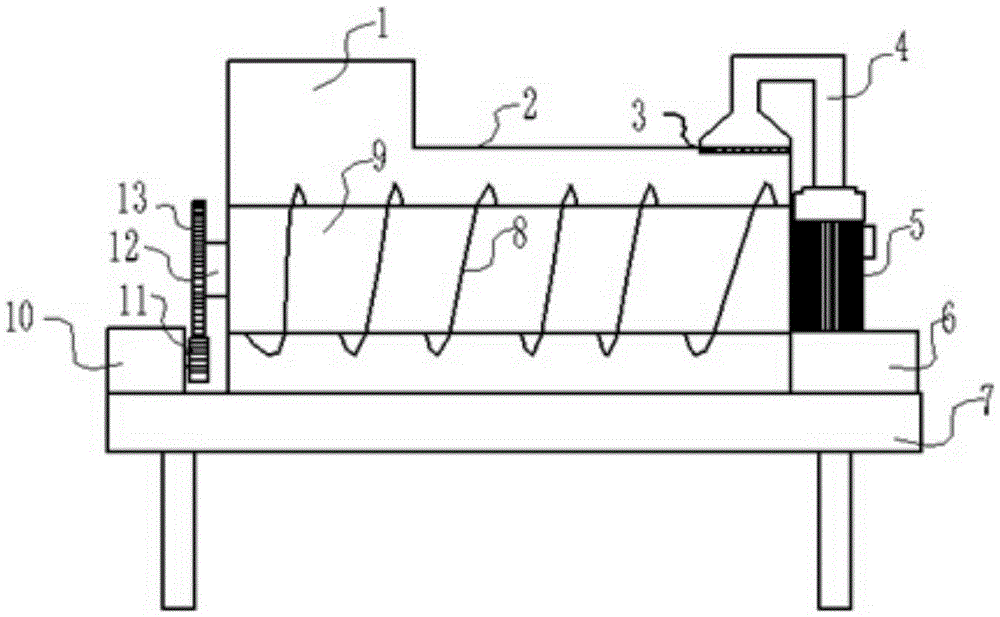

Wool washing device

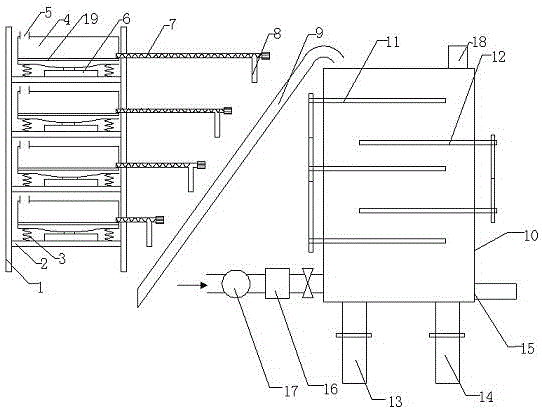

ActiveCN104499059ASimple structureReasonable designAnimal fibre deburring machinesWool fibre washing/scouringEngineeringAir blower

The invention discloses a wool washing device comprising impurity removing equipment and washing equipment. The impurity removing equipment comprises a support frame, a plurality of support plates are arranged on the support frame, a vibrating box is arranged on each support plate through vibrating springs, a spiral discharge pipeline is connected to one side of each vibrating box for discharging, a lifting conveyor belt is arranged on one side of the impurity removing equipment, a cabinet used for carrying materials conveyed by the lifting conveyor belt is arranged on one side of the lifting conveyor belt, a plurality of left stirring rods and a plurality of right stirring rods are inserted in the cabinet, a wool outlet is formed in one side of the lower end of the cabinet, a heater is connected with the other side of the lower end of the cabinet through a pipeline and a valve, and an air blower is connected to one side of the heater. The wool washing device has the advantages that the wool washing device is simple in structure, reasonable in design, small in occupied space and convenient to operate, wool can be cleaned up by the device, and steps such as soaking, washing, spin-drying and drying are completed in the same cabinet.

Owner:吴江市鼎裕纺织有限公司

Apparatus automatically extracting down feather and extracting method

ActiveCN105154988AImprove detection efficiencyAchieve consistencyAnimal fibre deburring machinesAnimal materialTechnical standardMobile manipulator

Owner:湖南合源羽绒制品有限公司

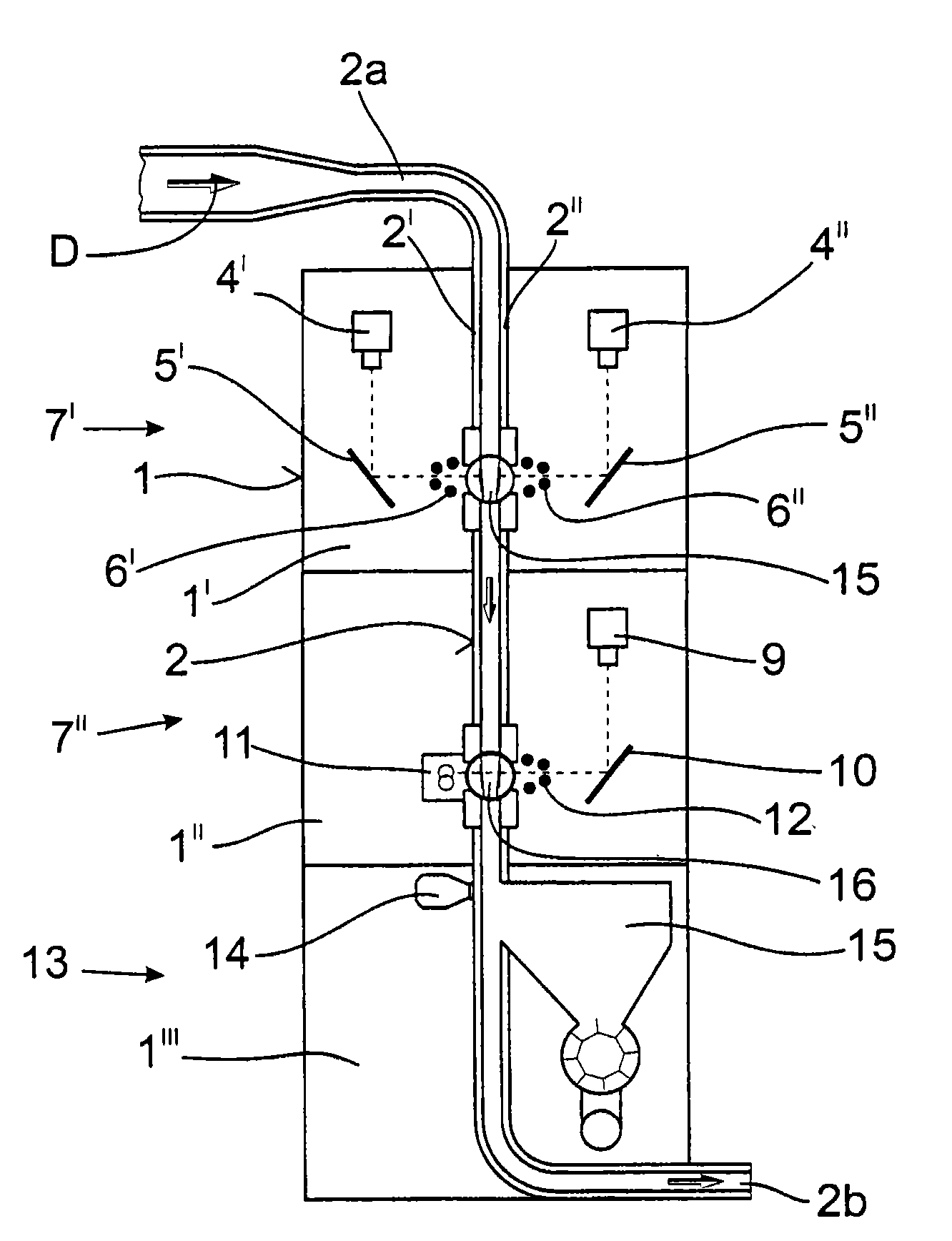

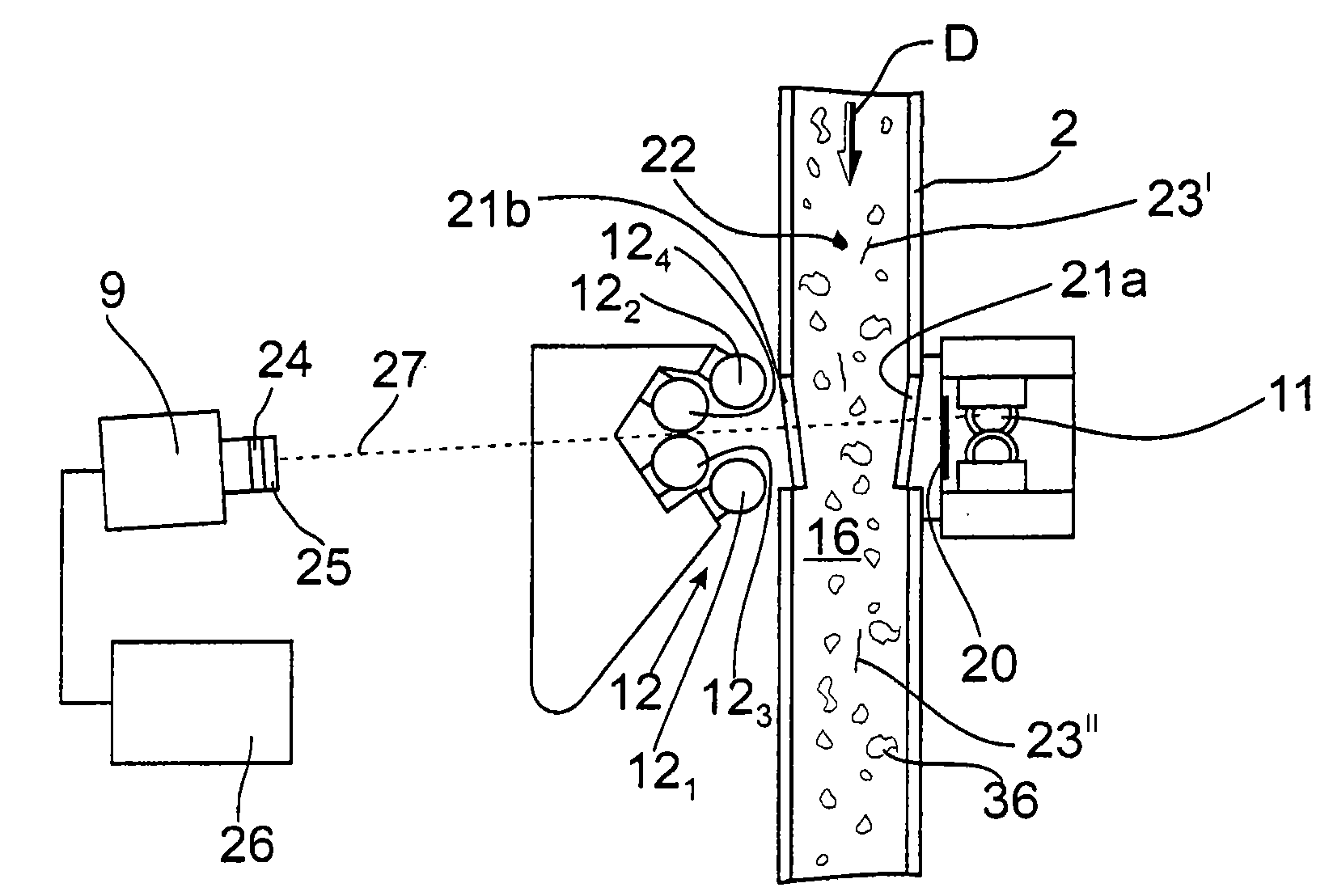

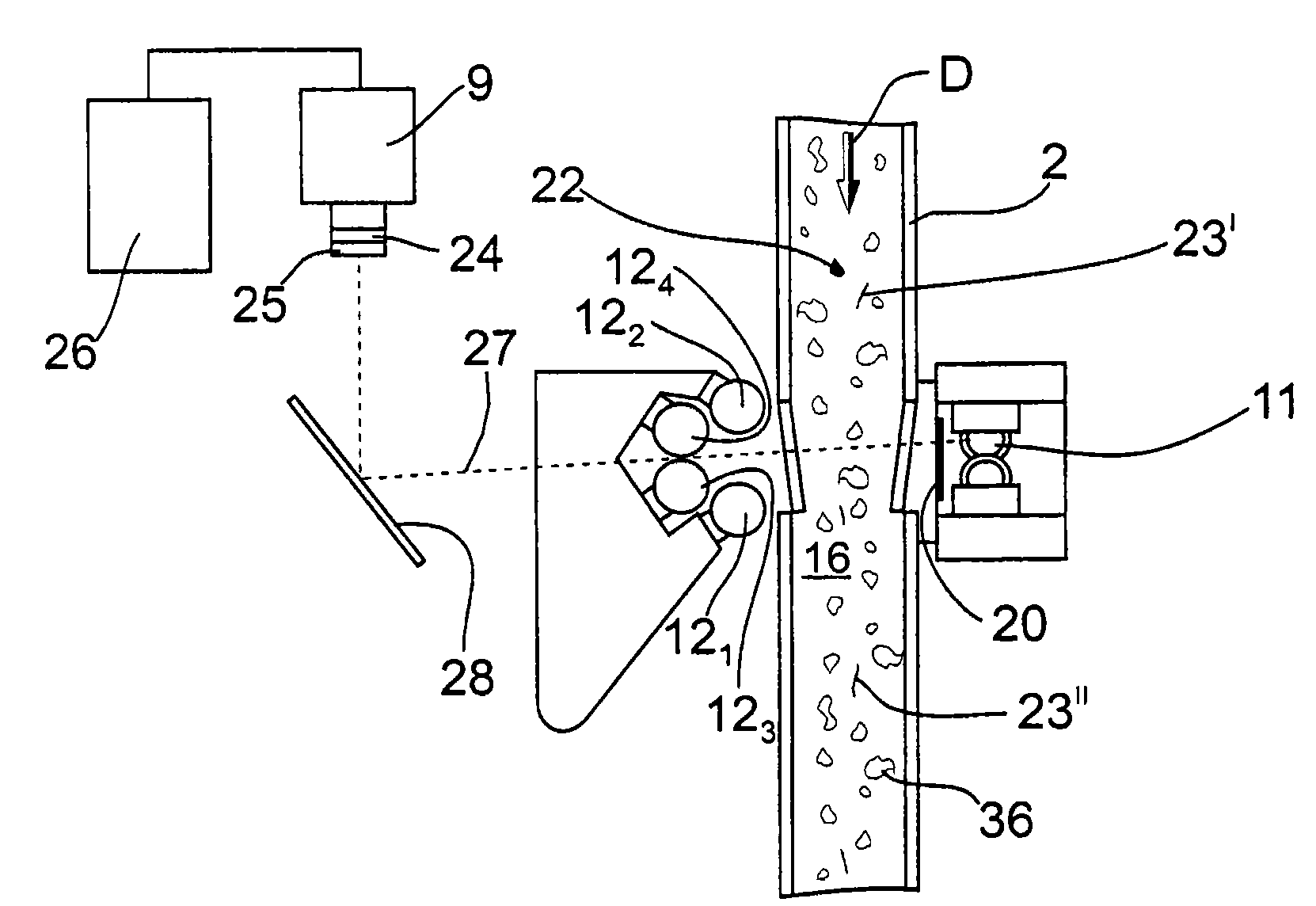

Apparatus in a spinning room preparation, ginning or the like installation for detection of foreign matter in fibre material

ActiveCN101634103ANo transient loss of claritySave installation spaceFibre cleaning/opening by air draught arrangementsSafety devices for fibre treatmentFiberForeign matter

Owner:TRUETZSCHLER GRP SE

Down feather processing technology

InactiveCN103484944AAvoid interferenceSorting went wellAnimal fibre deburring machinesWool fibre washing/scouringTruckMechanical engineering

The invention relates to a down feather processing technology. The down feather processing technology comprises the following steps of (1) selection, (2) suction, (3) washing, (4) dehydration, (5) drying, (6) cooling, (7) packing, (8) sorting, (9) static electricity elimination, (10) boxing and (11) truck loading. The down feather processing technology has the advantages of being reasonable in step setting, facilitating manufacture and the like, smooth performing of down feather processing can be ensured, and static electricity interference on down feather can be avoided.

Owner:安徽万利达羽绒制品有限公司

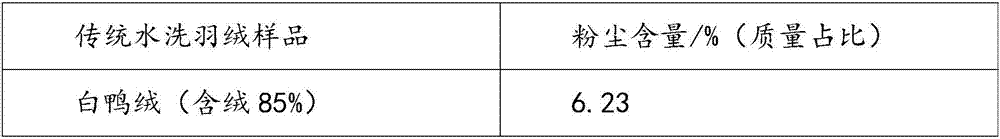

Feather down washing technology for reducing dust, matched dehydration device and control method thereof

ActiveCN107164806AEfficient removalLow costAnimal fibre deburring machinesDrying solid materials without heatAntistatic agentEngineering

The invention discloses a feather down washing technology for reducing dust. The technology comprises the steps that 1, a fixed quantity of feather down to be cleaned is weighed and placed into the matched dehydration device; 2, medicaments are added into the matched dehydration device, and the feather down is started to be cleaned; 3, dust is removed from the feather down; 4, the feather down is dehydrated; the medicaments added in the step 2 are a feather down detergent and a non-ionic anti-static agent; the upper portion of the feather down in the step 3 is covered with a layering dense grid in a pressed mode, water is injected so as to enable the water level to be higher than the feather down, and dust on the water surface is removed. On the basis of the novel matched dehydration device, the feather down washing technology formula and parameters and the procedures of dehydration, drying, feather sorting, wool extracting and pile splicing are optimized and adjusted, the equipment cost is low, use is convenient, and under the condition of combining the novel technology, dust inside feather down can be effectively removed.

Owner:GUQI FEATHER & DOWN PLC

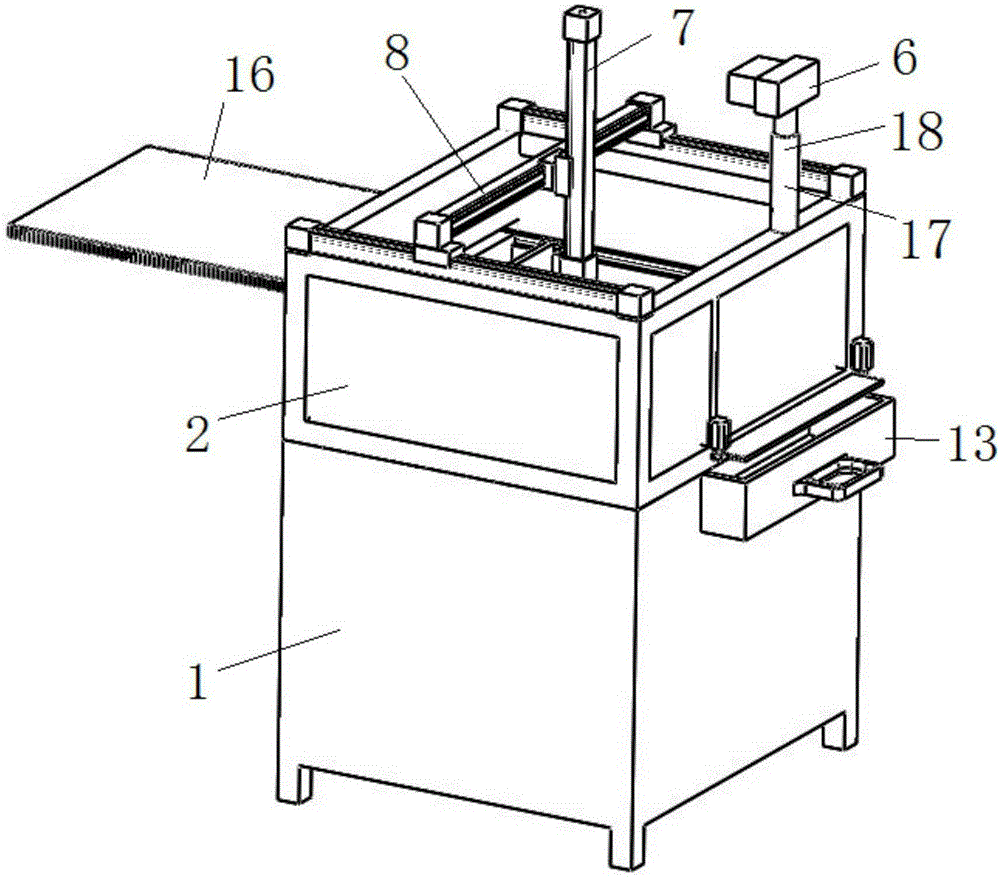

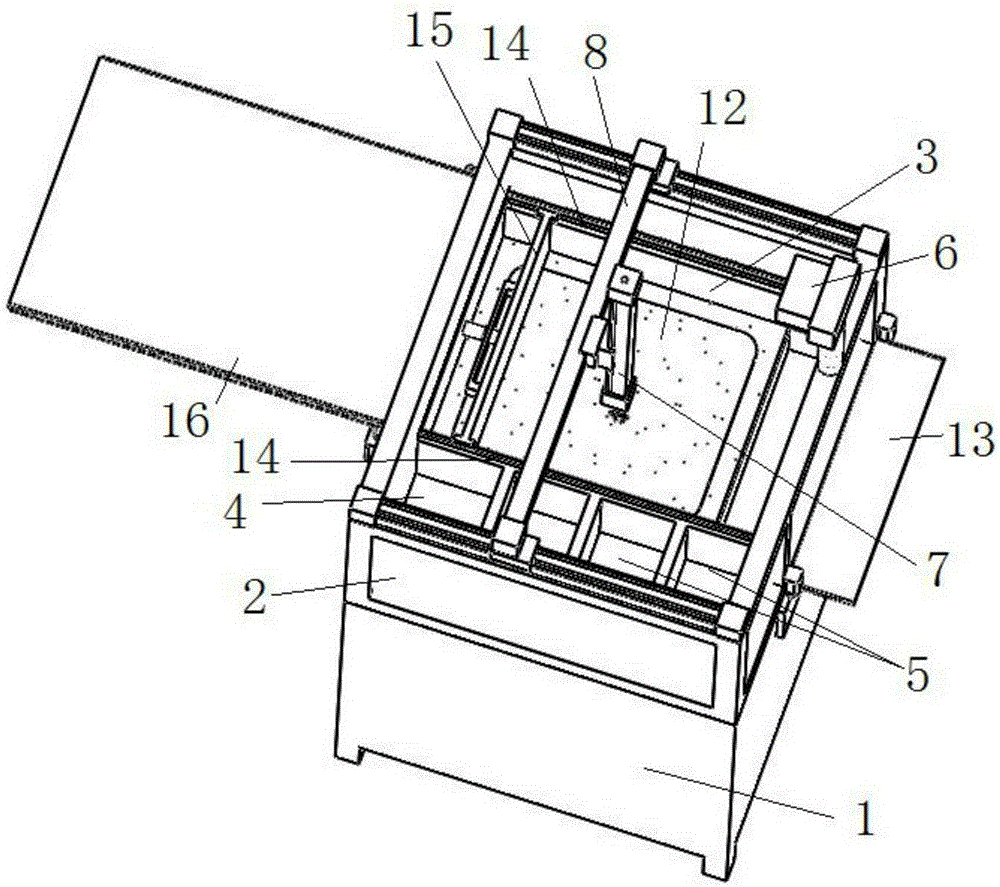

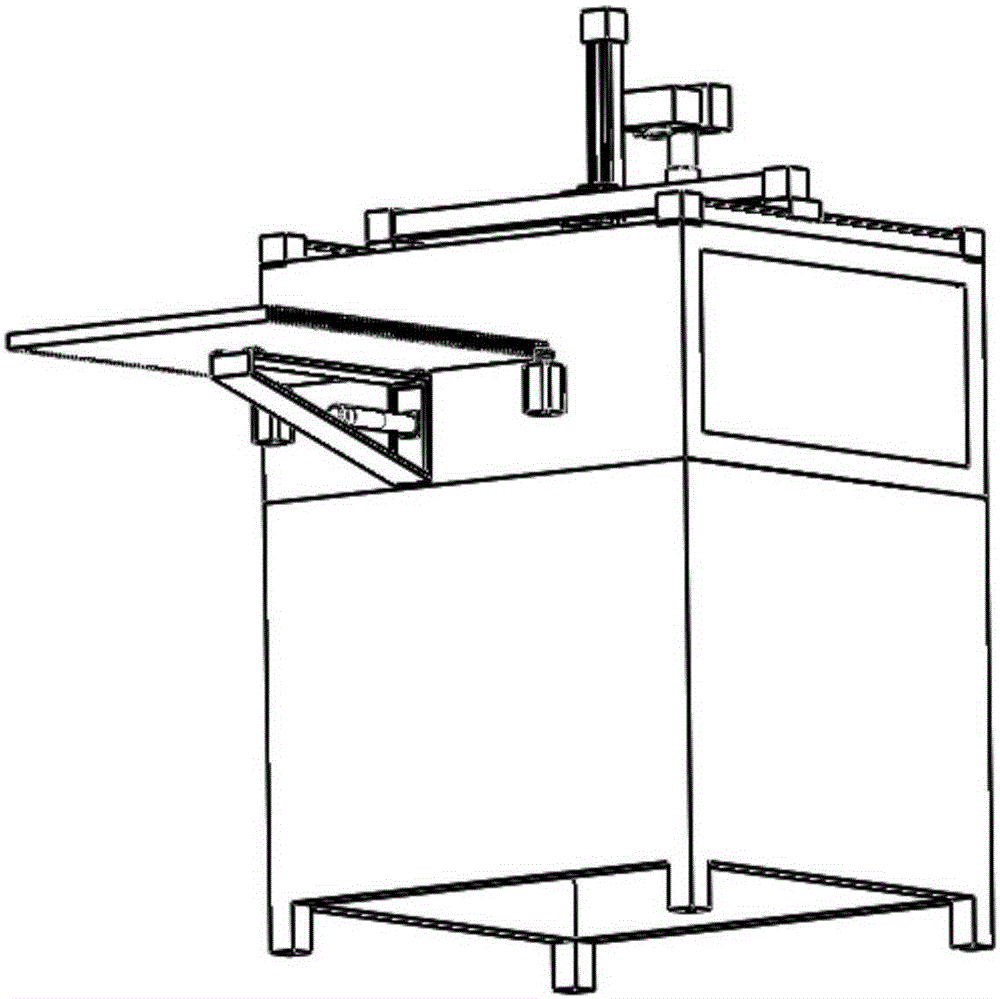

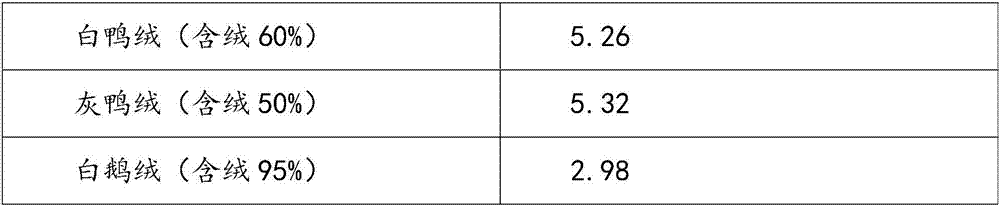

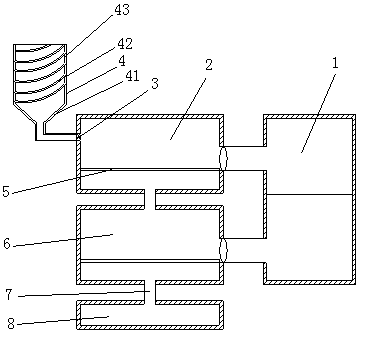

Ultrasonic washing and baking system for wool

InactiveCN107130303AEasy to cleanAvoid cloggingSievingAnimal fibre deburring machinesCooking & bakingMegasonic cleaning

The invention relates to an ultrasonic washing and baking system for wool. The ultrasonic washing and baking system is mainly used for solving the problem in the prior art that the washing is unclean. By adopting the technical scheme that the ultrasonic washing and baking system for the wool, provided by the invention, comprises a feeding device, a cleaning device and a rinsing and drying device, wherein the feeding device comprises a plurality of vibration screening units which are of trapezoidal arrangement, each vibration screening unit comprises material frames, which are arranged obliquely, a miscellaneous material layer located at the bottom of the material frames, and vibration springs and a vibration motor which are located at the bottom of the miscellaneous material layer, the cleaning device comprises a charging opening which is in seamless flexible connection with a discharging opening of the last material frame, a washing chamber communicating with the charging opening, and a washing solution tank and a precipitation tank II which separately communicate with the washing chamber, an ultrasonic vibrating box is arranged in the washing chamber, and the rinsing and drying device comprises a rinsing and drying chamber, which communicates with the bottom of the washing chamber, and a clean water tank communicating with the rinsing and drying chamber, the problem is better solved, so that the ultrasonic washing and baking system can be applied to wool cleaning.

Owner:JIANGSU SHUANGYING TEXTILE TECH

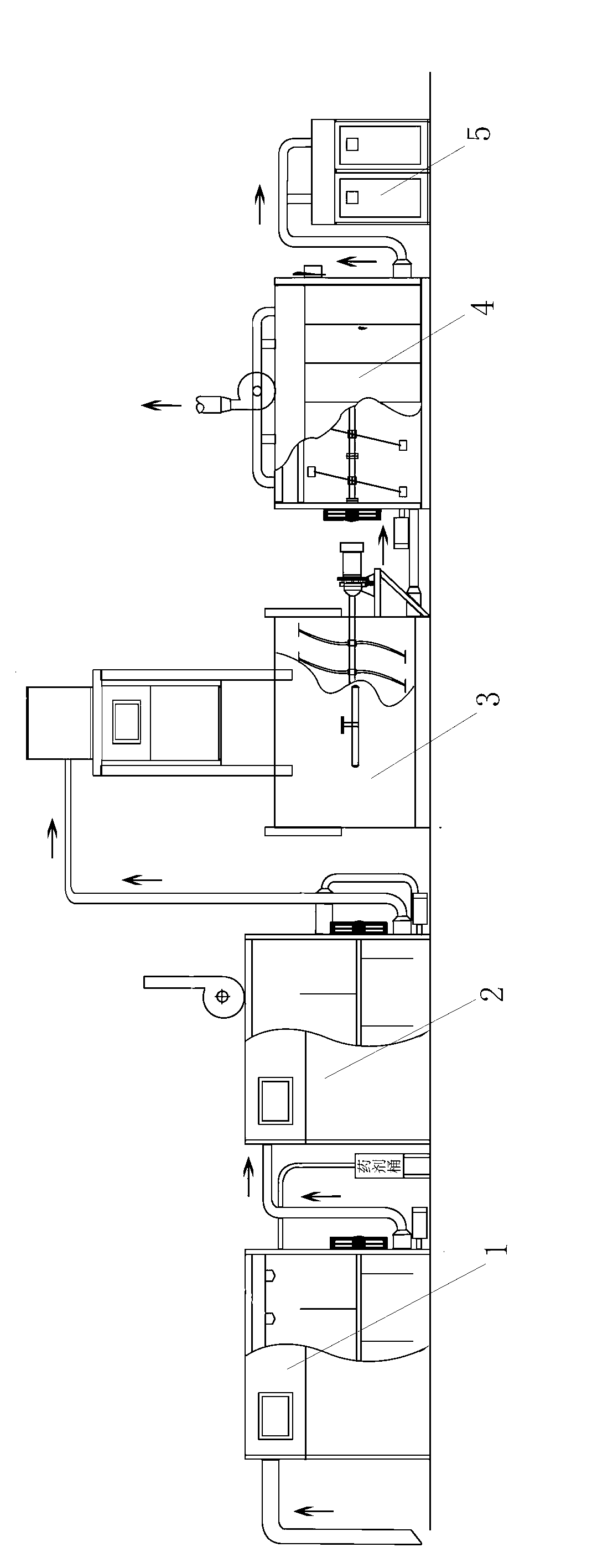

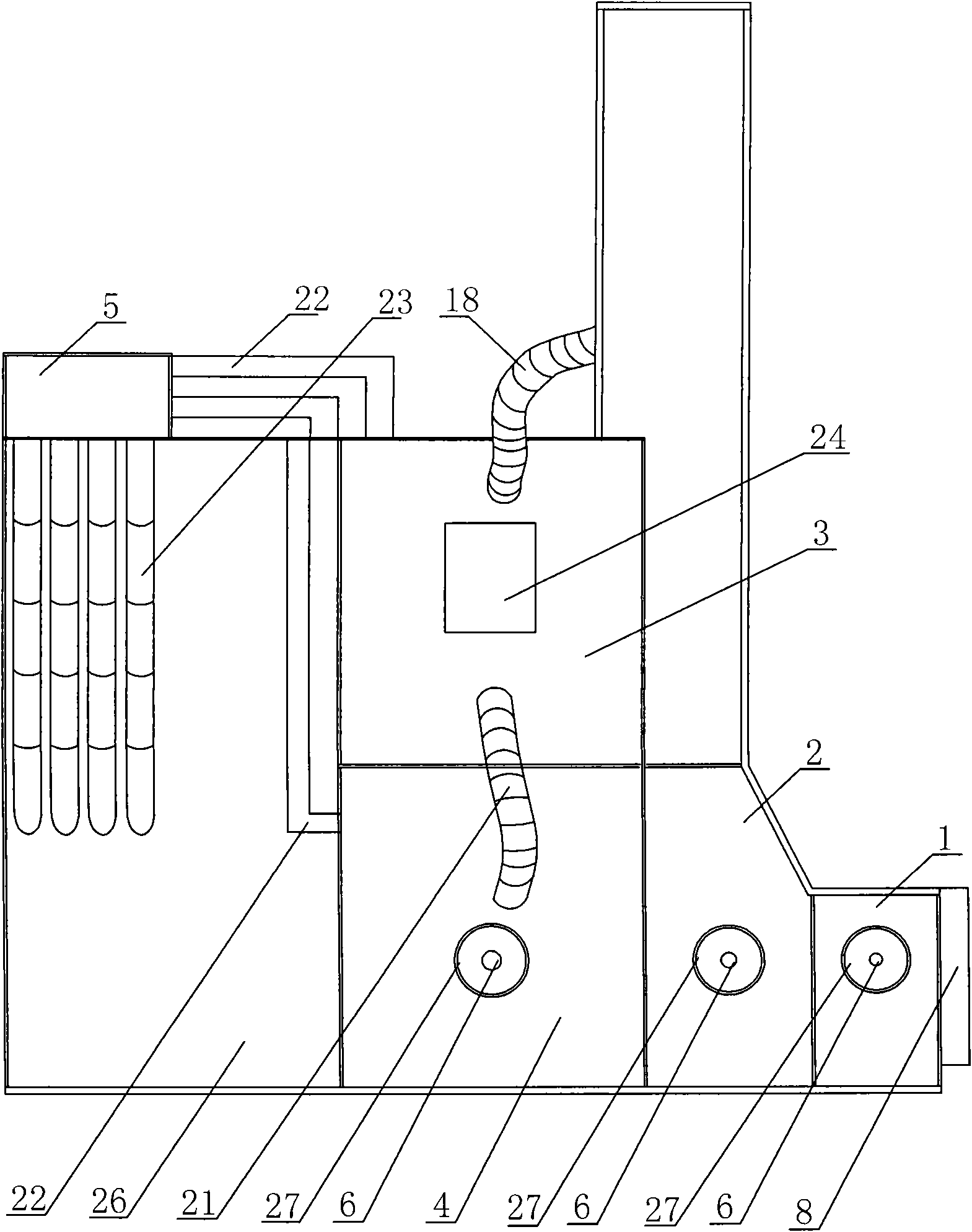

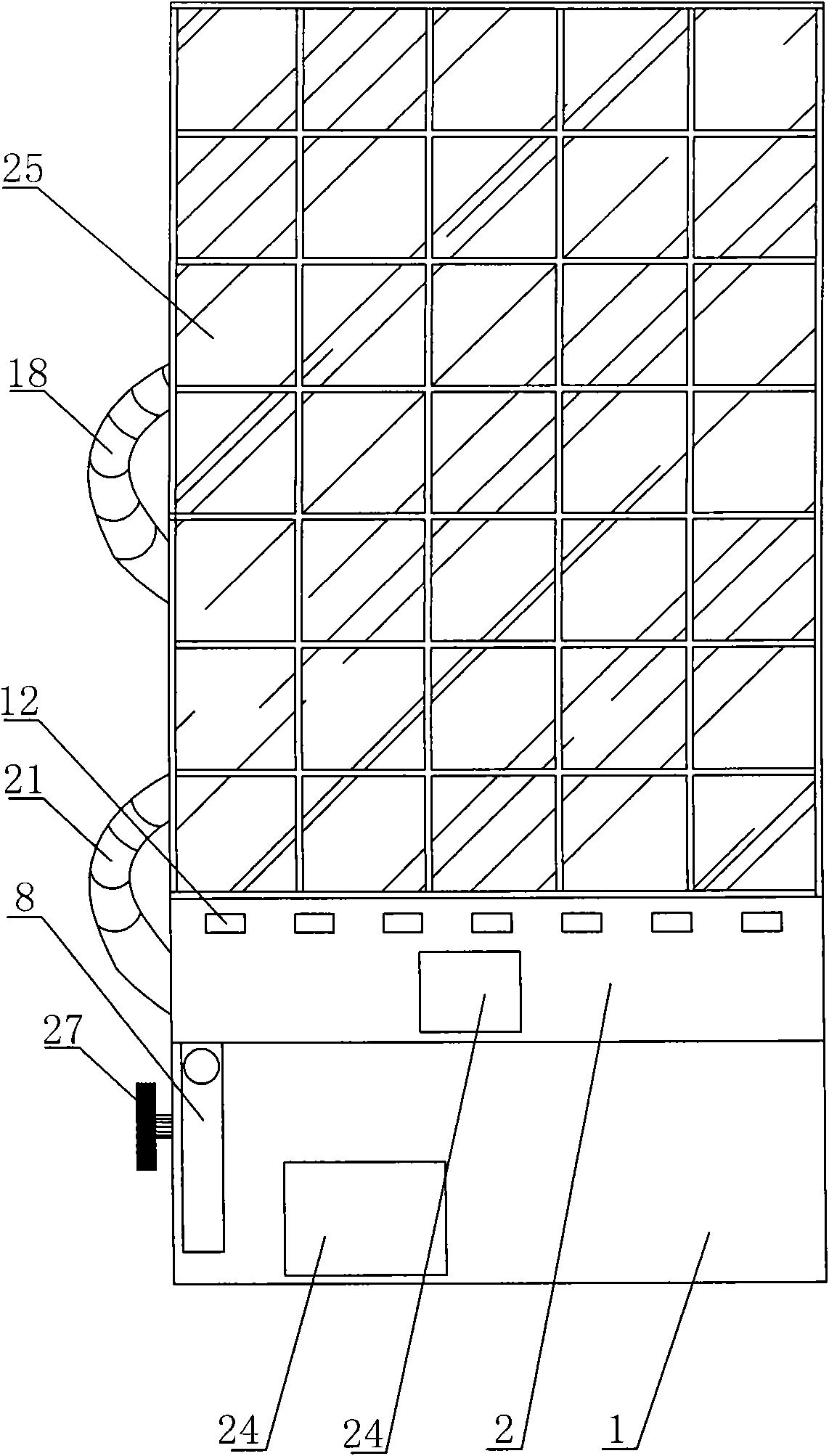

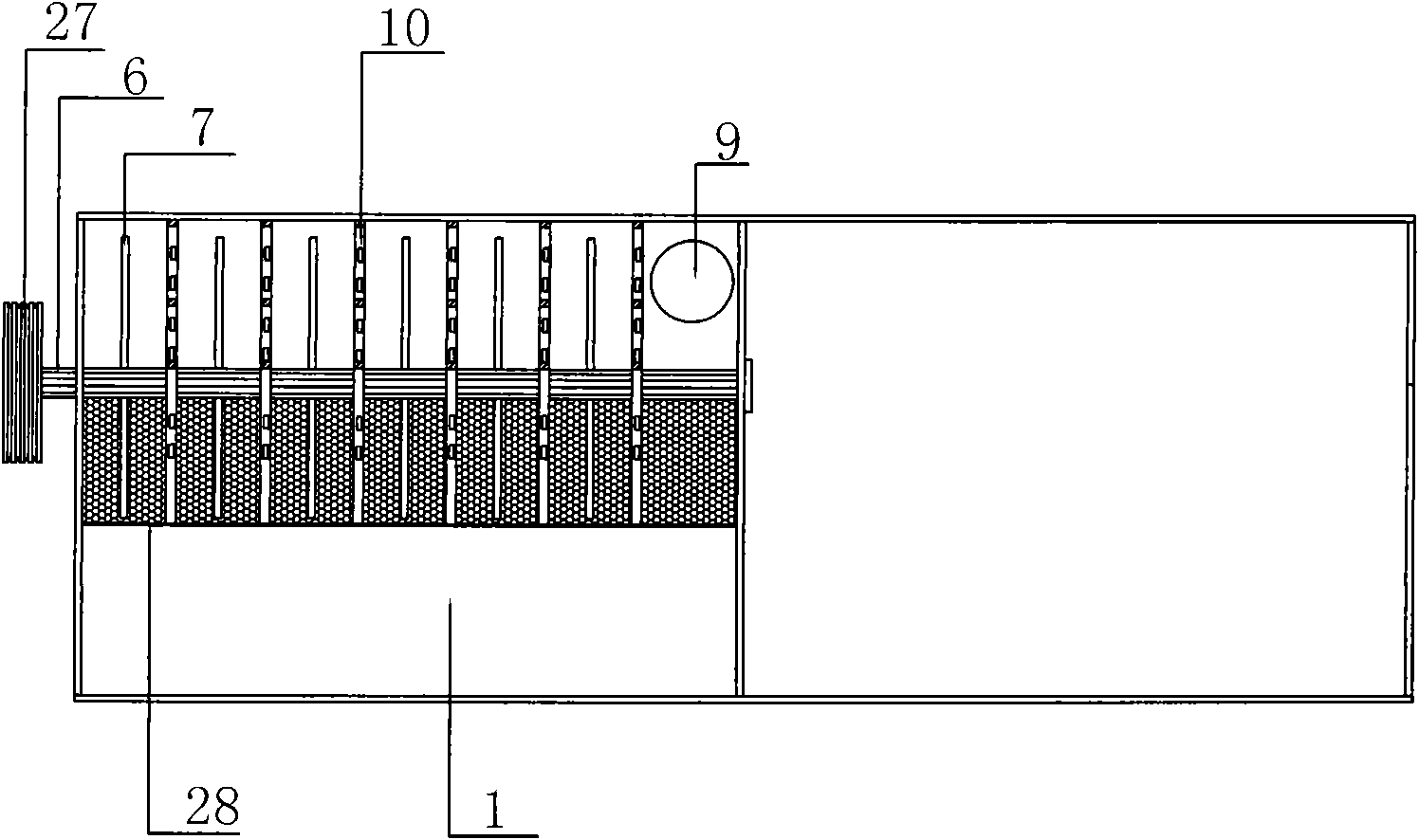

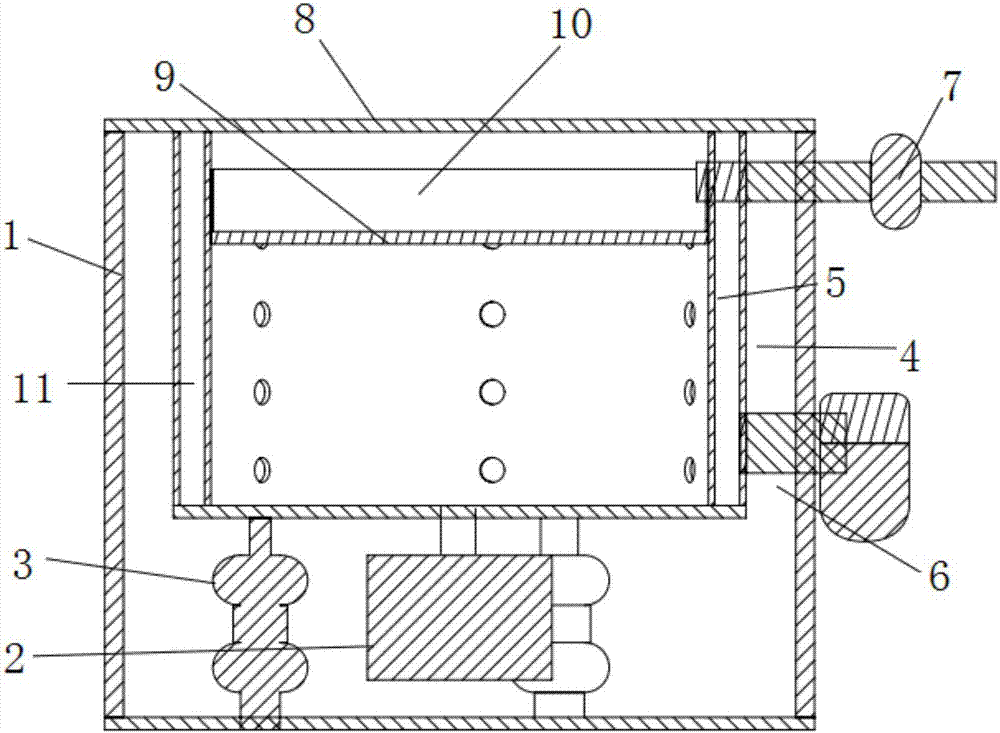

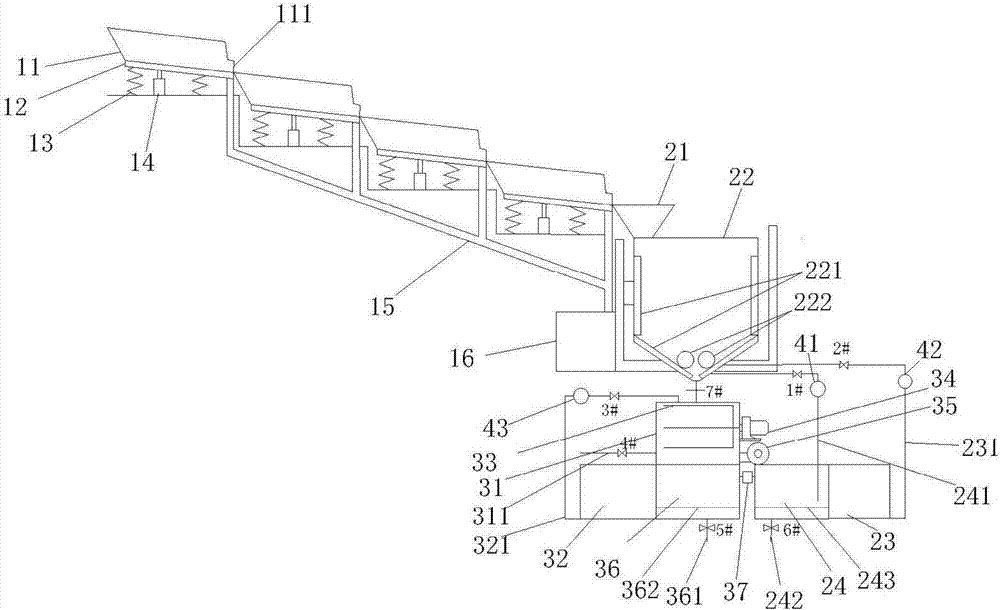

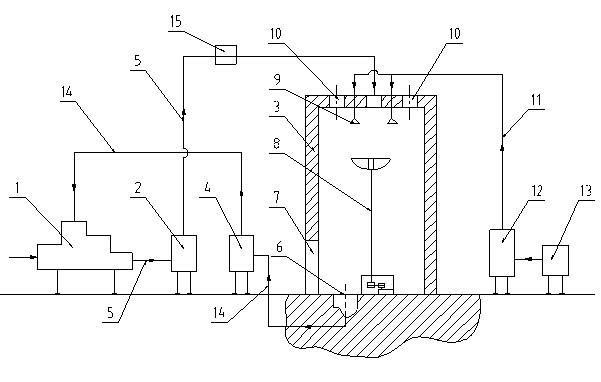

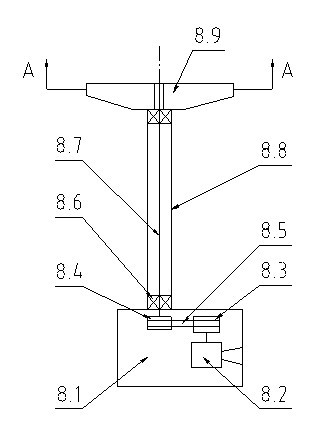

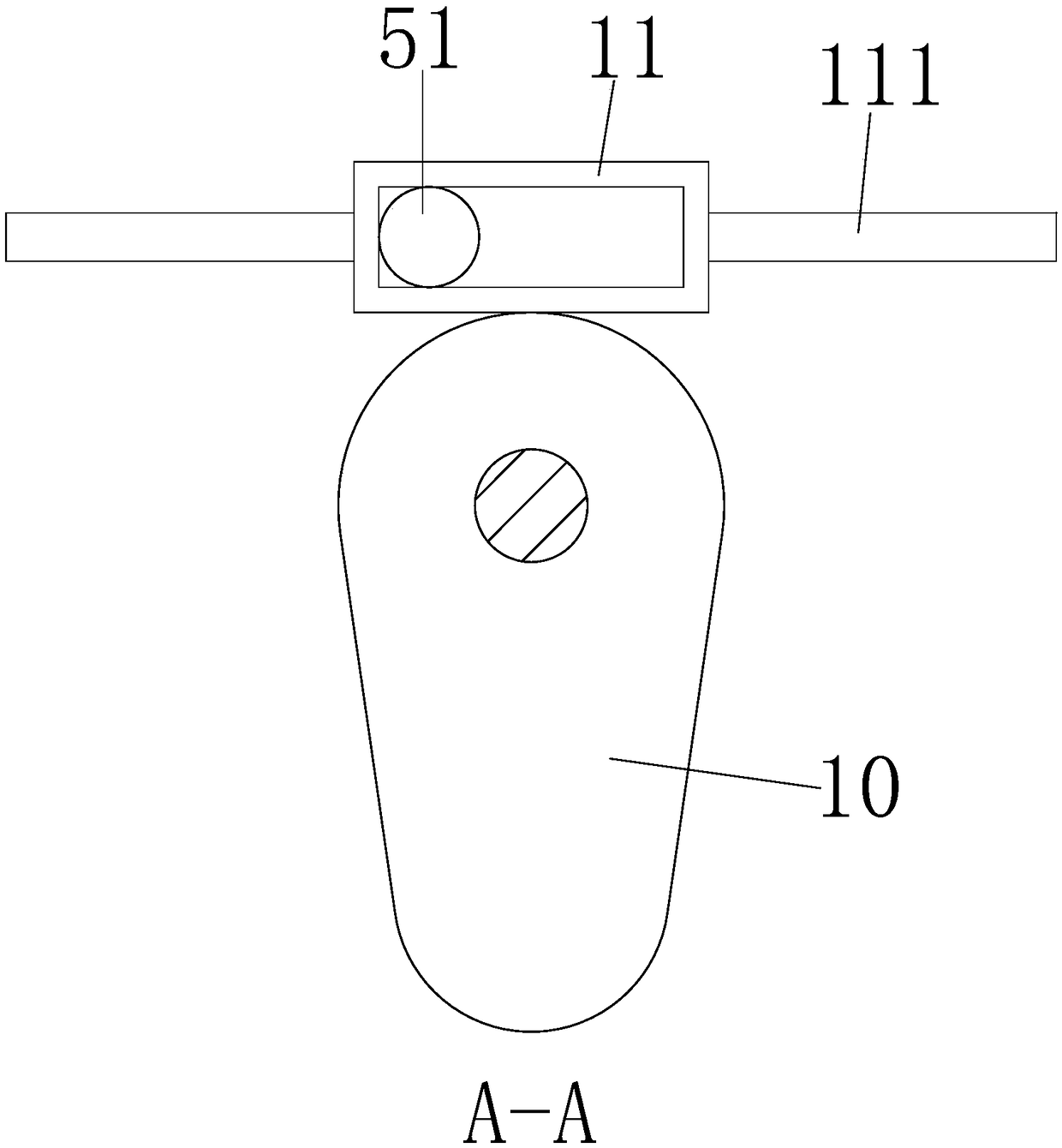

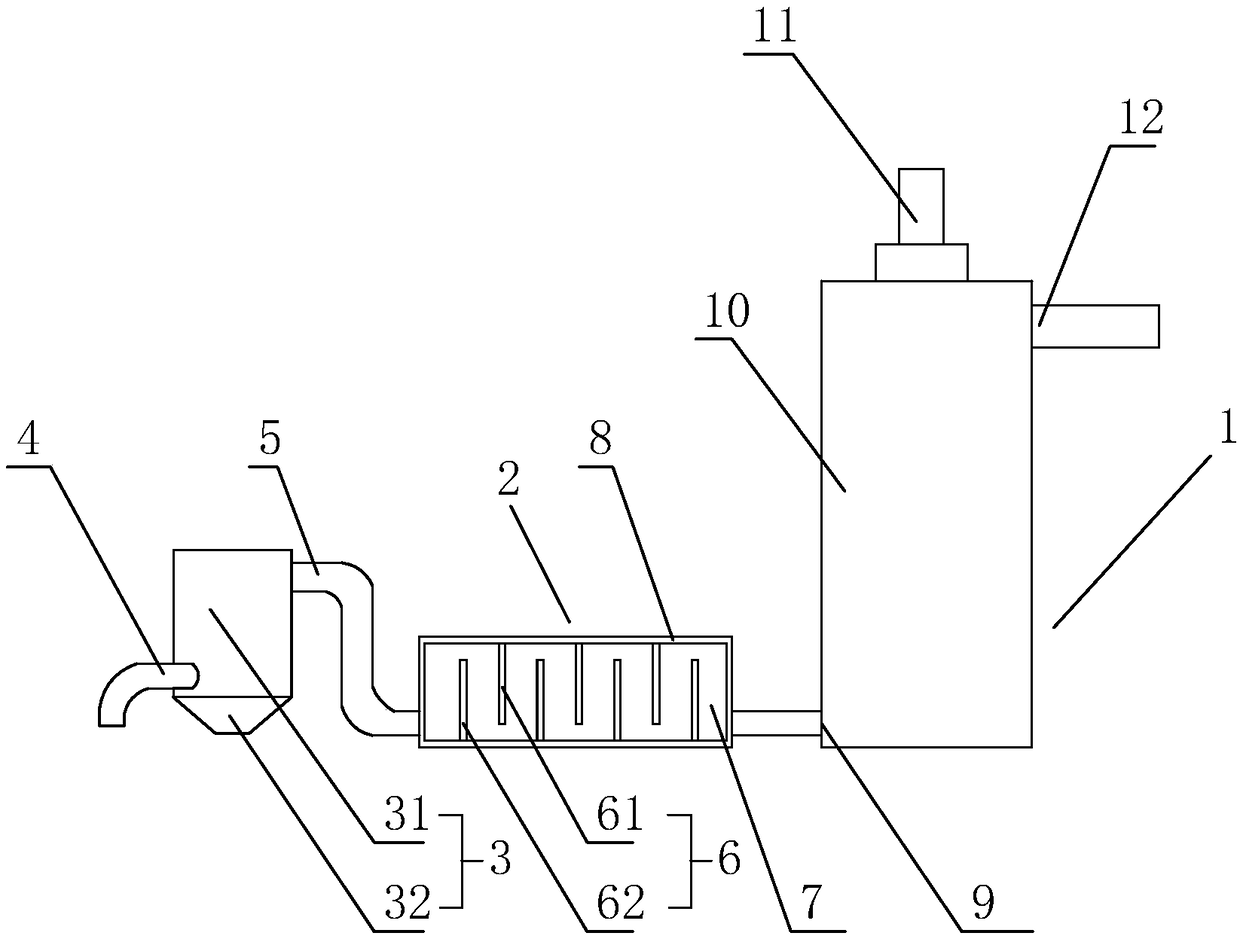

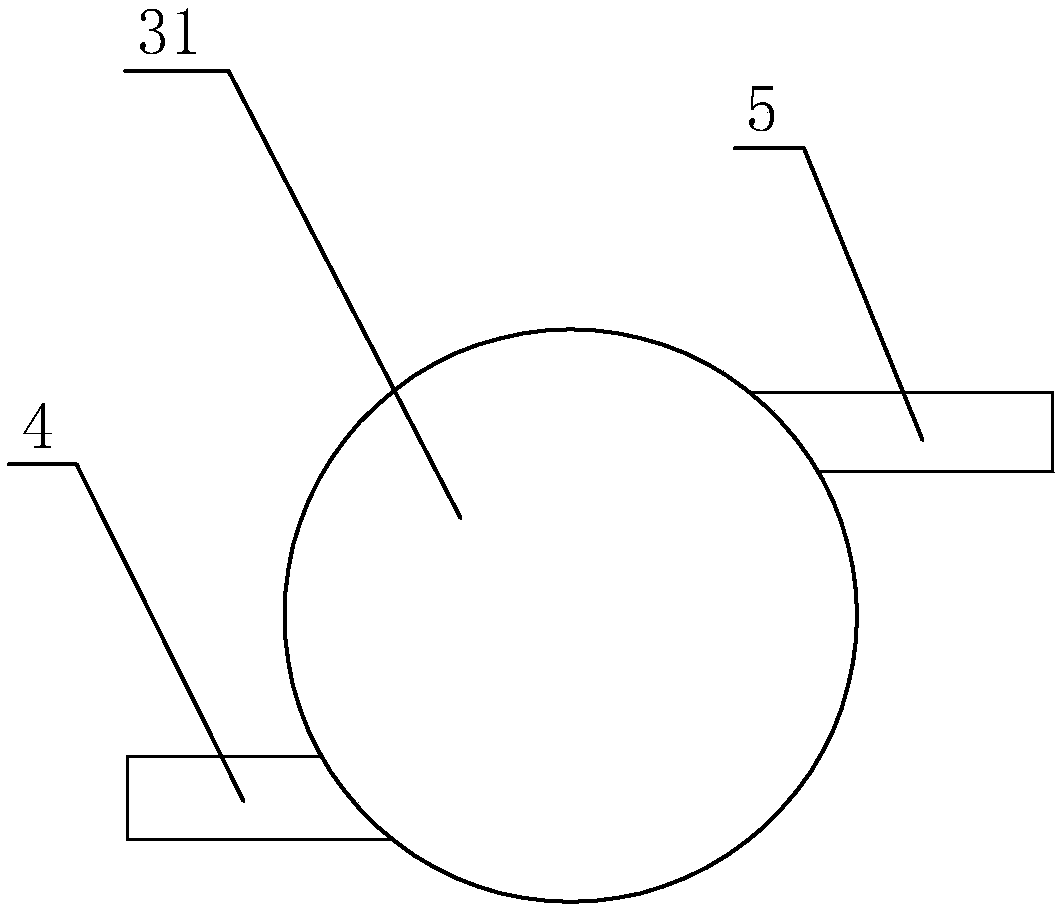

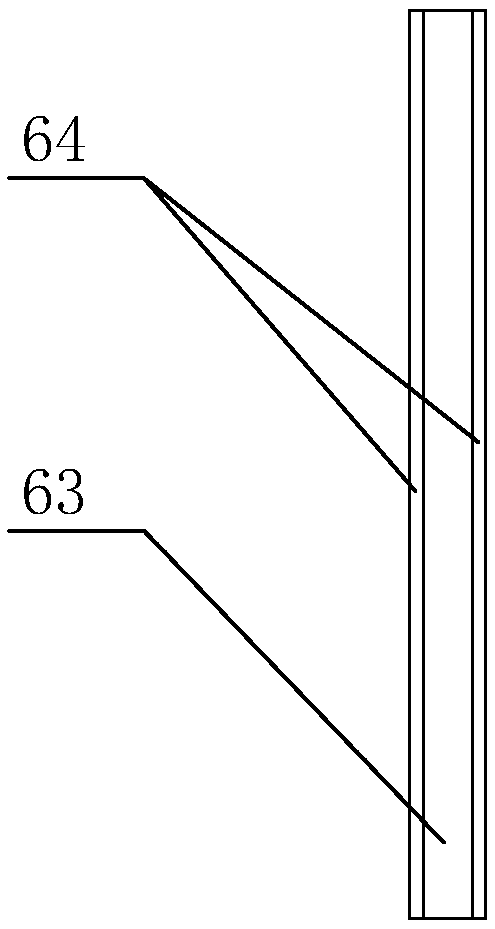

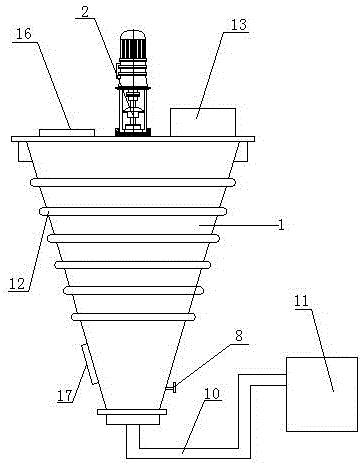

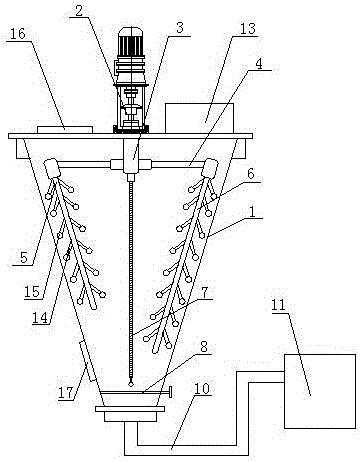

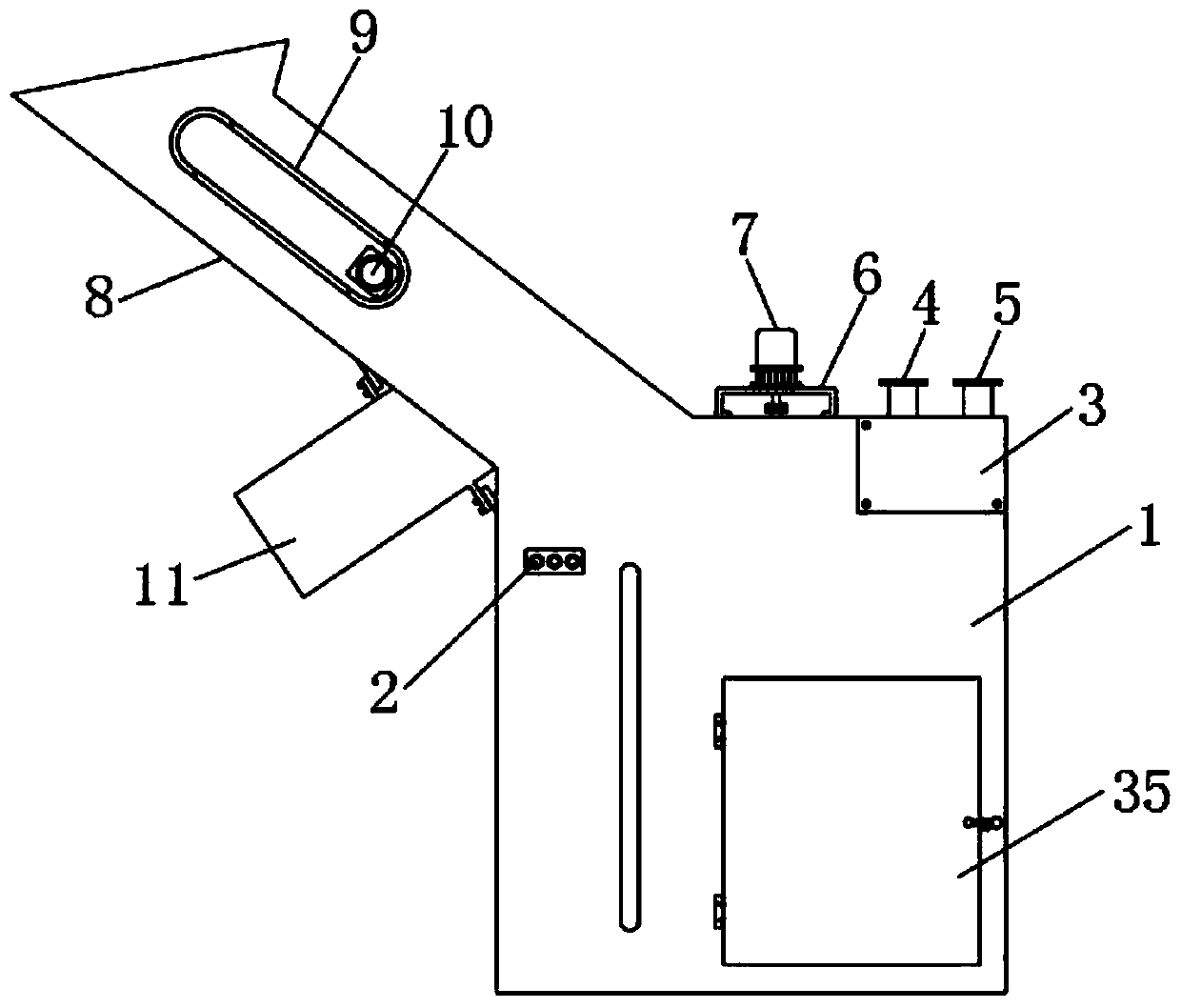

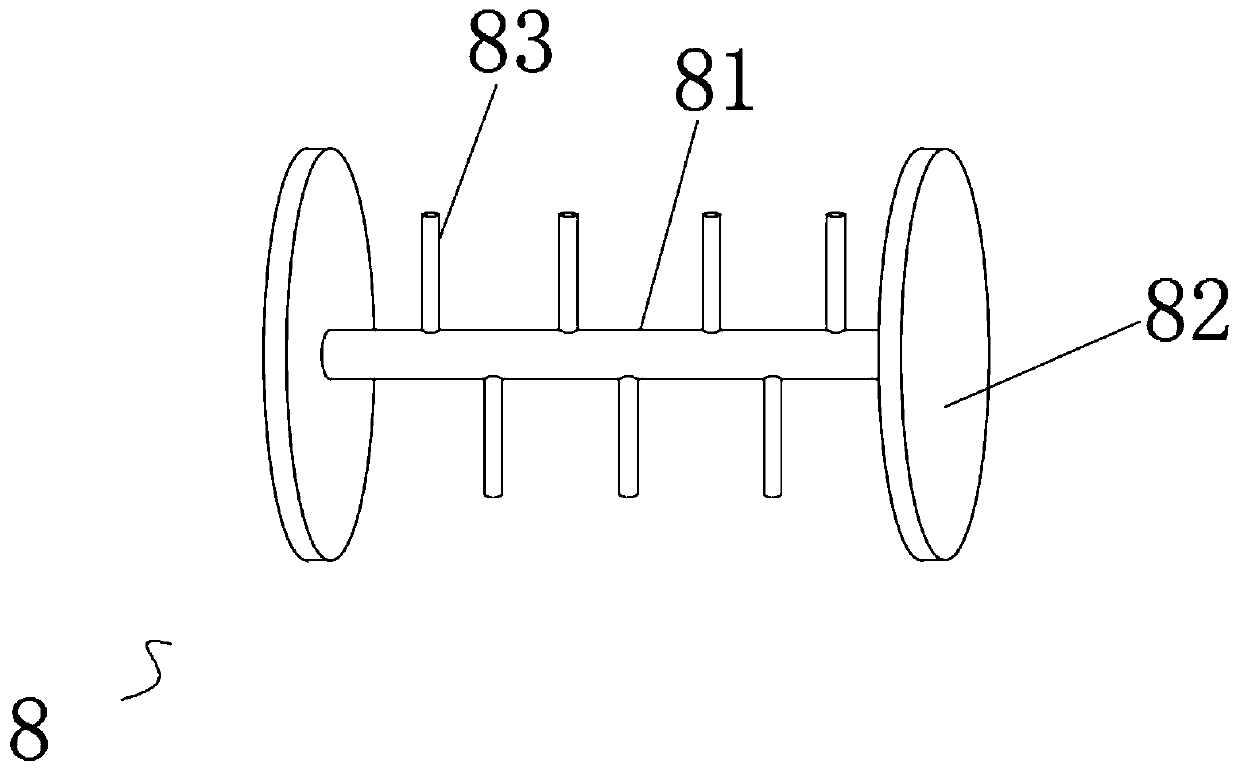

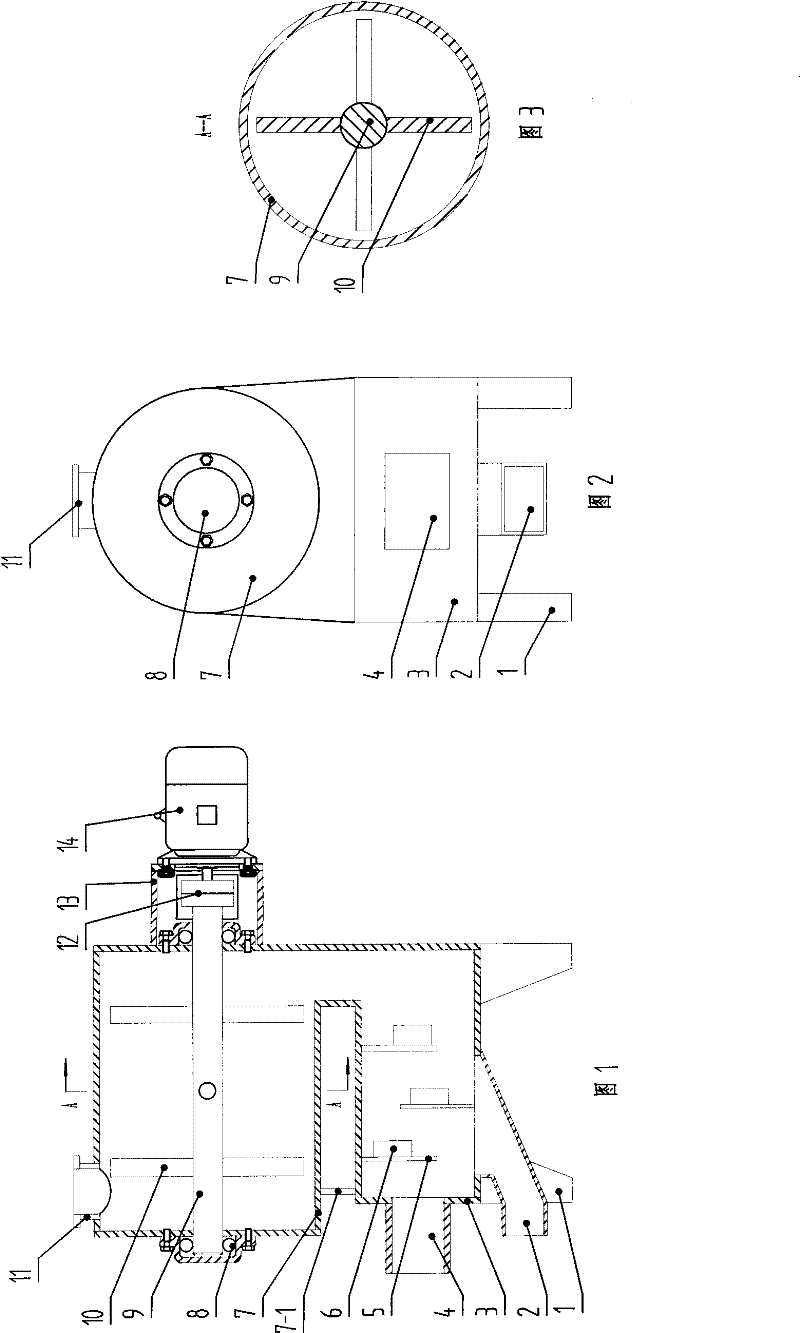

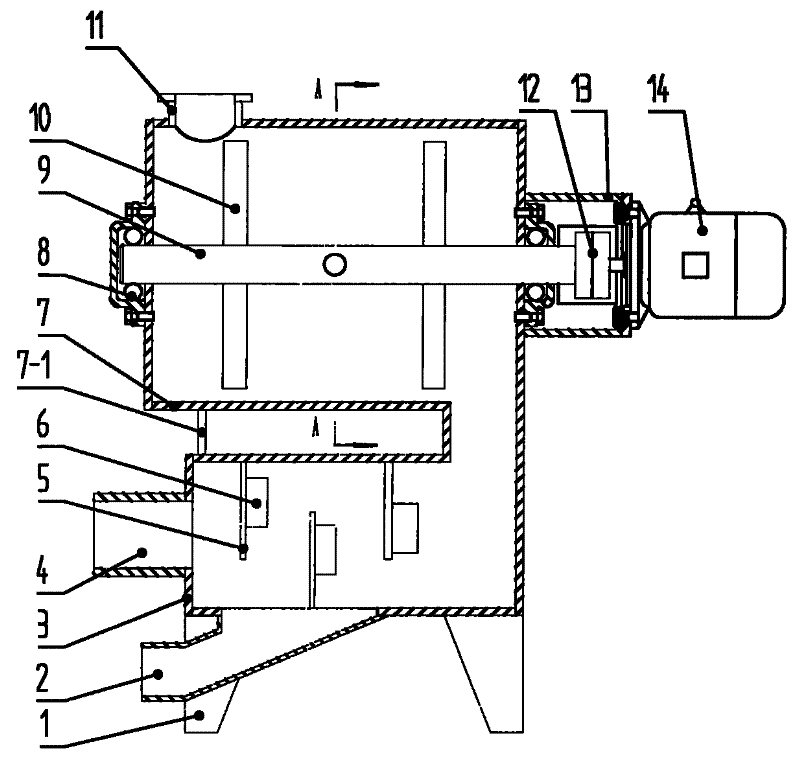

Novel fiber mixing system

ActiveCN102586895AOpen fullyWell mixedLubricating devicesAnimal fibre deburring machinesFiberSpray nozzle

The invention relates to a novel fiber mixing system. The novel fiber mixing system comprises a fiber mixing machine (1), a fiber delivering fan (2) and a fiber mixing cabin (3), which are sequentially connected through a fiber delivering air pipe I (5), wherein a fiber sucking fan (4) is arranged between the fiber delivering fan (2) and the fiber mixing cabin (3); a ground air suction inlet (6) is formed in the bottom of the fiber mixing cabin (3); the ground air suction inlet (6), the fiber sucking fan (4) and the fiber mixing machine (1) are sequentially connected through a fiber delivering air pipe II (14); a fiber loosening device (8) is arranged in the fiber mixing cabin (3); a plurality of oil feeding agent spraying nozzles (9) are arranged above the fiber loosening device (8); anda plurality of air pressure release outlets (10) are formed in the top of the fiber mixing cabin (3). The novel fiber mixing system can fully loosen and mix fibers and automatically feed oil, and hasa good fiber mixing effect; a large amount of labor is saved; and the production efficiency is improved.

Owner:JIANGSU ZHENXIN IND

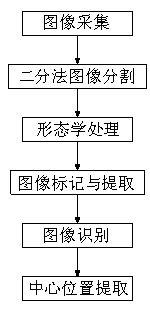

Multifunctional different color down picker for feather processing

InactiveCN109082712AImprove clarityShorten comparison timeAnimal fibre deburring machinesState of artImaging processing

The invention relates to a multifunctional different color down picker for feather processing. The picker comprises an automatic different color down separation system which comprises a raw material supplying device, an image collection processing device and a down picking separation device; the raw material supplying device comprises a feeding cavity which comprises a cylindrical feeding upper section and a conical feeding lower section; the image collection processing device comprises an image collection room, a high-speed camera and an image processing system; the feeding lower section is arranged on one side of the image collection room, an air blower is arranged at the connecting part of the feeding lower section and the image collection room, the image processing system is arranged on the outer wall of the image collection room, the image collection room is of a falling tower structure, and the inner wall of the falling tower structure is white. Accordingly, the raw material supplying device, the image collection processing device and the down picking separation device are integrated, by means of the microgravity theory, the down static collection definition is improved, andthe problems that in the prior art, the different color down picking quality is not up to standard, and the picking efficiency is low are solved.

Owner:WEST ANHUI UNIV +2

High automation and informatization down feather processing method

InactiveCN104153005AImprove cleanlinessIncrease elasticitySucessive textile treatmentsAnimal fibre deburring machinesControl systemProcess engineering

The invention discloses a high automation and informatization down feather processing method and relates to the technical field of down feather processing. The method includes the nine technology steps of material selection, dust removing, washing, dewatering, drying, cooling, packaging, sorting and boxing. In the technology method, a central control system is adopted for intelligently controlling all the steps in the production machining process, so that most of manual operation is omitted, labor cost is reduced, working efficiency is improved, the automation production capacity is improved, and the informatization degree is high. In the actual production process, through strict control over parameters of all the steps and sterilization on down feather by the adoption of chitin assistants, the cleanliness of down feather finished products is improved, and the produced down feather is high in elasticity, white, free of peculiar smell and good in hand feeling and anti-bacterial, anti-virus and mildew-resistance performance and has a very good health care function.

Owner:ANHUI LION GOOSE PROD

A wool washing device

ActiveCN104499059BDry to achieveAchieving stirringAnimal fibre deburring machinesWool fibre washing/scouringEngineeringAir blower

Owner:吴江市鼎裕纺织有限公司

Dust removal type down feather sterilization and drying equipment

InactiveCN107976009AAvoid flyingEasy to disassembleDrying solid materials with heatAnimal fibre deburring machinesAir pumpEngineering

The invention discloses a dust removal type down feather sterilization and drying equipment. The dust removal type down feather sterilization and drying equipment comprises a sterilization and dryingdevice body, heaters and upper baffles, wherein an inlet is formed in the upper end of the sterilization and drying device body. Sterilization lamps are arranged on the inner wall of the sterilizationand drying device body, a dust suction box is arranged below the sterilization lamps, a dust suction opening is formed above the dust suction box, the bottom end of the dust suction opening is connected with a dust suction pipeline, a first air pump is installed on the dust suction pipeline, a handle is fixed on the right wall of the dust suction box, rolling wheels are arranged at the bottom endof the dust suction box, the sterilization and drying device main body is arranged outside the heaters, air injection pipes are arranged on the bottom surface of the interior of the sterilization anddrying device body, a discharge port is formed below the inner sides of the air injection pipes, and the discharge port is formed in the upper baffles. The dust removal type down feather sterilization and drying equipment is provided with the dust suction box, so that the sterilizing, dust removal and drying of down feather is combined, and the dust suction box can adsorb impurities in the down feather.

Owner:ANHUI LION GOOSE PROD

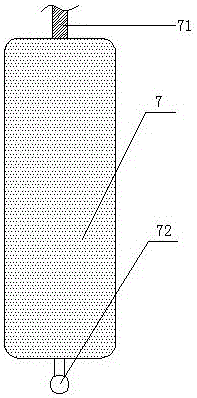

Down feather dust separating method

ActiveCN105734680ADust content meets the requirementsHarm reductionGas current separationAnimal fibre deburring machinesEngineeringAir blower

The invention discloses a down feather dust separating method.The method includes the steps that firstly, a separating device is made to idle, and a numerical value X monitored by a pipeline dust detector is recorded; a down feather raw material is put into a down feather raw material storage chamber of the separating device, an air blower and a dust collector are started, down feathers and small-particle dust in the down feather raw material storage chamber penetrate through a first filter screen along with airflow and then enter a down feather dust separating chamber, and large-particle impurities are separated out; then, the down feather raw material continues to float along with airflow, and small-particle dust enters a dust monitoring chamber through a second filter screen and is sucked out of the dust monitoring chamber by the dust collector to be recycled; when a numerical value monitored by the pipeline dust detector is smaller than or equal to the original recorded numerical value X, it is judged that separation is completed, and down feathers in the down feather dust separating chamber are qualified.According to the method, impurities and dust in down feathers are constantly separated out and recycled by using the air blower to provide power and utilizing the mobility of air in cooperation with the first filter screen and the second filter screen, and the procedure is simple; besides, the concentration of dust can be monitored, and separation quality is guaranteed.

Owner:广东鸿基羽绒制品有限公司

Down feather storage device with size being changed conveniently

InactiveCN108146782AEasy to change sizeEasy to storeAnimal fibre deburring machinesShock-sensitive articlesSoftware engineeringDown feather

The invention discloses a down feather storage device with the size being changed conveniently. The down feather storage device comprises a storage chamber main body, rotating vanes, a push plate andfixing screws. The upper portion of the storage chamber main body is provided with rotating rods. The upper portions of the rotating rods are fixedly provided with motors. The right sides of the motors are provided with a feeding opening, the upper portion of the feeding opening is provided with a rotating shaft, the upper portion of the rotating shaft is fixedly provided with a fixing cover. Thelower portions of the rotating vanes are provided with the rotating rods, heating wires are arranged below the rotating vanes, a sucking pipe is fixed below the heating wires, and the right side of the sucking pipe is provided with a draught fan. The right side of the draught fan is fixedly provided with a discharging opening, the left side of the discharging opening is provided with a fixing spring, the left side of the fixing spring is provided with a transverse plate, and a vibrator is arranged below the transverse plate. The down feather storage device with the size being changed conveniently is provided with a first storage chamber, a second storage chamber and a third storage chamber, and therefore the height and size of the whole device can be changed through the first storage chamber, the second storage chamber and the third storage chamber.

Owner:ZHANJIANG ZIJIN DOWN PROD

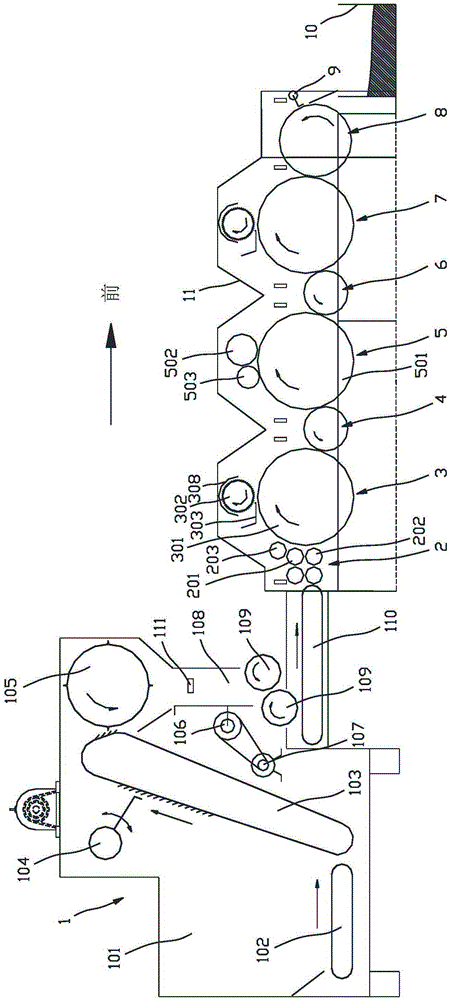

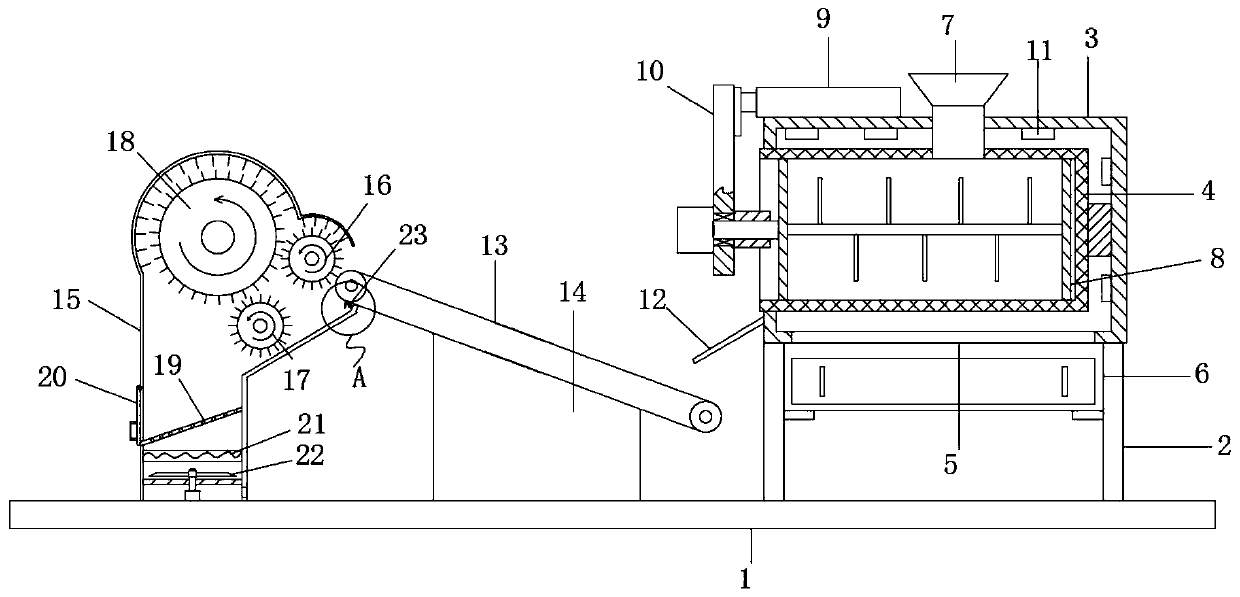

Grass impurity removing machine for wool

InactiveCN105386129AEasy to cleanLess impuritiesAnimal fibre deburring machinesEngineeringSheep wool

The invention belongs to the field of textile machinery, and particularly discloses a grass impurity removing machine for wool. The grass impurity removing machine for the wool comprises a feeding mechanism, a first grass impurity removing mechanism, a first transferring roll, a loosening mechanism, a second transferring roll, a second grass impurity removing mechanism, a doffer and a stripping mechanism which are sequentially arranged from back to front. Primary clearing is performed on grass impurities mixed in the sheep wool through the first grass impurity removing mechanism, the sheep wool is transferred to the loosening mechanism through the first transferring roll, combing and loosening are performed on the sheep wool which is transferred by the first transferring roll through the loosening mechanism, the sheep wool is transferred to the second grass impurity removing mechanism through the second transferring roll, secondary clearing is performed on the grass impurities mixed in the sheep wool through the second grass impurity removing mechanism, and finally the sheep wool is condensed into a net through a doffer and then stripped into a fallen wool box through the stripping mechanism to be used in the next process. Through the processes of primary grass impurity removing, transferring and weed throwing, combing and loosening, transferring and weed throwing and secondary grass impurity removing, the impurities mixed in the sheep wool are effectively reduced, and the machine is beneficial for meeting the requirements of the next combing process.

Owner:SHANDONG UNIV OF SCI & TECH

Dust removing device for down processing

ActiveCN108823641ASolve the easily damaged downSolve efficiency problemsAnimal fibre deburring machinesEngineeringThrough transmission

The invention relates to the technical field of down processing auxiliary devices, in particular to a dust removing device for down processing. The device comprises a base plate, a dust removing box arranged on the base plate and a down collecting box located at one side of the dust removing box; a feeding port is formed in the upper portion of the dust removing box, a plurality of air-blowing separation mechanisms are arranged on the side wall of the dust removing box, a discharging port is formed in the portion, below the air-blowing separation mechanisms, on the side wall of one side of thedust removing box, a vibrating screen is hinged to the lower portion of the discharging port, an intermittent turning mechanism is connected to the vibrating screen and connected with the air-blowingseparation mechanisms through transmission mechanisms, and the dust collecting box is arranged at the portion, below the intermittent turning mechanism, of the bottom of the dust removing box. The dust removing device solves the problems that by means of an existing dust removing device, down is easily damaged, the working efficiency is low, and the service life of the device is shortened. In addition, the dust removing device is compact and simple in structure and convenient to operate and maintain.

Owner:安徽万利达羽绒制品有限公司

Efficient down feather iron removal and impurity removal device

PendingCN109252225ARemove completelyEasy to cleanAnimal fibre deburring machinesIron removalEngineering

The invention discloses an efficient down feather iron removal and impurity removal device. The device comprises a longitudinal iron removal cylinder. The longitudinal iron removal cylinder comprisesan outer cylinder, a rotating shaft, a stirring rod, a magnet frame, a magnet and a driving motor are arranged inside the outer cylinder, a feeding inlet is formed in the lower portion of the outer cylinder, a discharging outlet is formed in the upper portion of the outer cylinder, a transverse iron removal box is connected to the front portion of the feeding inlet, the transverse iron removal boxcomprises a box body, a plurality of magnetic plates are arranged inside the box body, the magnetic plates include the upper magnetic plates and the lower magnetic plates, the multiple upper magneticplates and the multiple lower magnetic plates are sequentially and alternately arranged, and a broken line shaped air flue is formed inside the box body through the upper magnetic plates and the lower magnetic plates. Non-iron impurities in down feather can be removed while the iron removal effect can be improved, and the overall impurity removal and iron removal processing efficiency is improved.

Owner:嘉善新天鹅羽绒制品有限公司

Down feather dust removing device

InactiveCN108914210AAvoid adsorptionAvoid cloggingAnimal fibre deburring machinesAir movementSuction force

The present invention discloses a down feather dust removing device. The down feather dust removing device comprises a dust removing machine body and a dust removing roller; the dust removing roller is arranged in the dust removing machine body; a first fan box is welded onto one end outer surface of the dust removing roller; and a first fan is arranged in the first fan box. In the invention, thedust removing roller is arranged, the dust removing roller rotates in the horizontal direction, second fans accelerates air movement and blow down feather and dust in the dust removing roller to allowthe down feather and the dust to flutters with the air, small holes are formed in a surface of the dust removing roller, and dust is blown out of the dust removing roller and located in the dust removing machine body; dust suction openings are formed above the dust removing roller, the dust removing openings generate suction forces through a self-priming pump to suck the dust into the dust collecting box, and then dust removal can be achieved; when the dust removing roller rotates, the down feather is prevented from being attached onto an inner wall of the dust removing roller to block the small holes; the dust blowing-out and suction efficiency can be improved, and the dust removal efficiency can be improved.

Owner:陈素珍

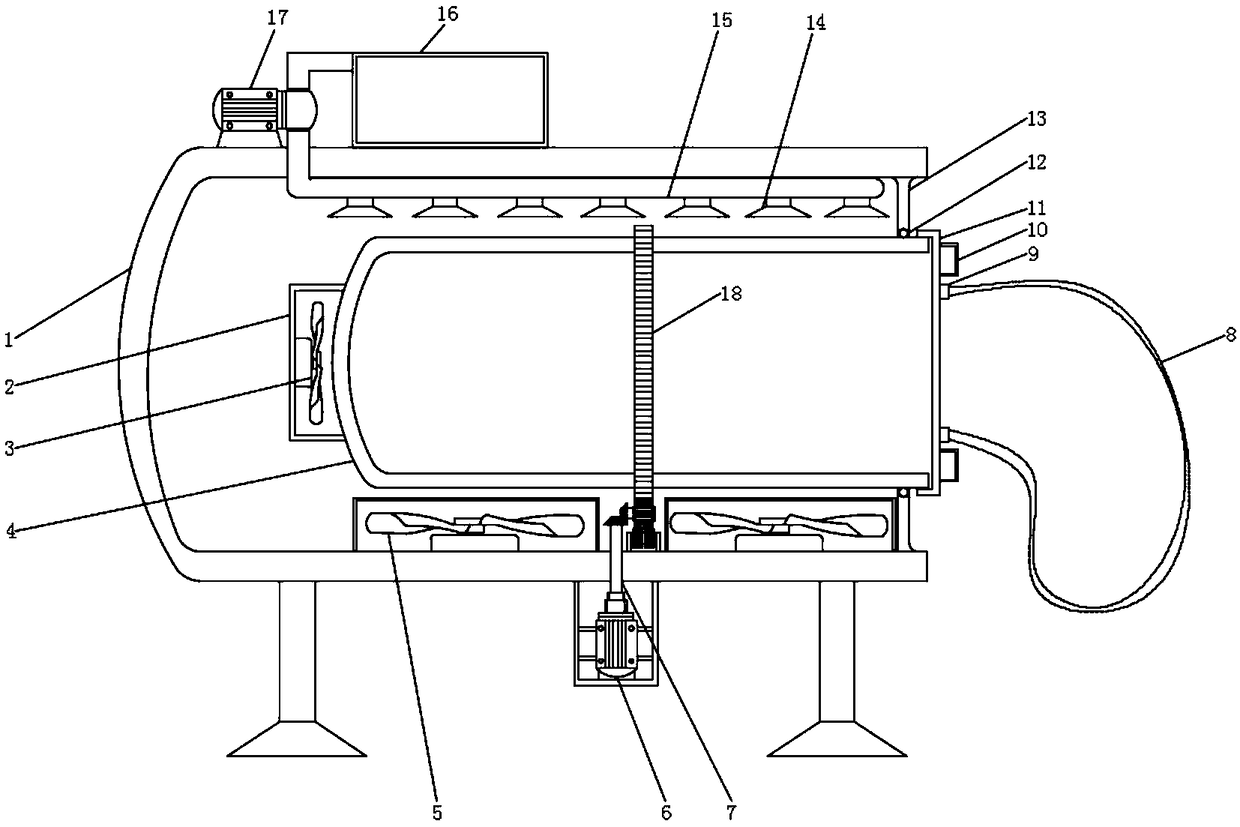

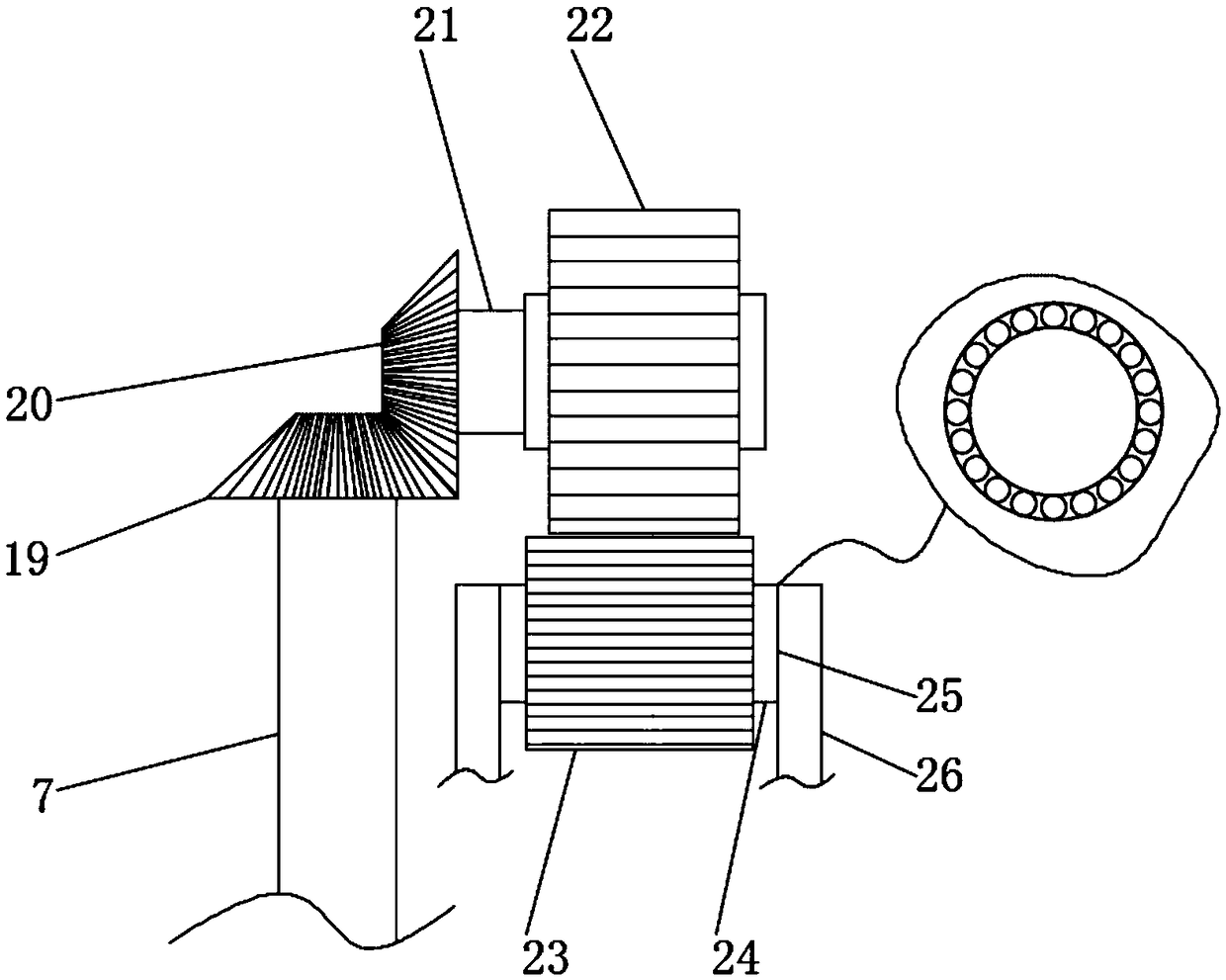

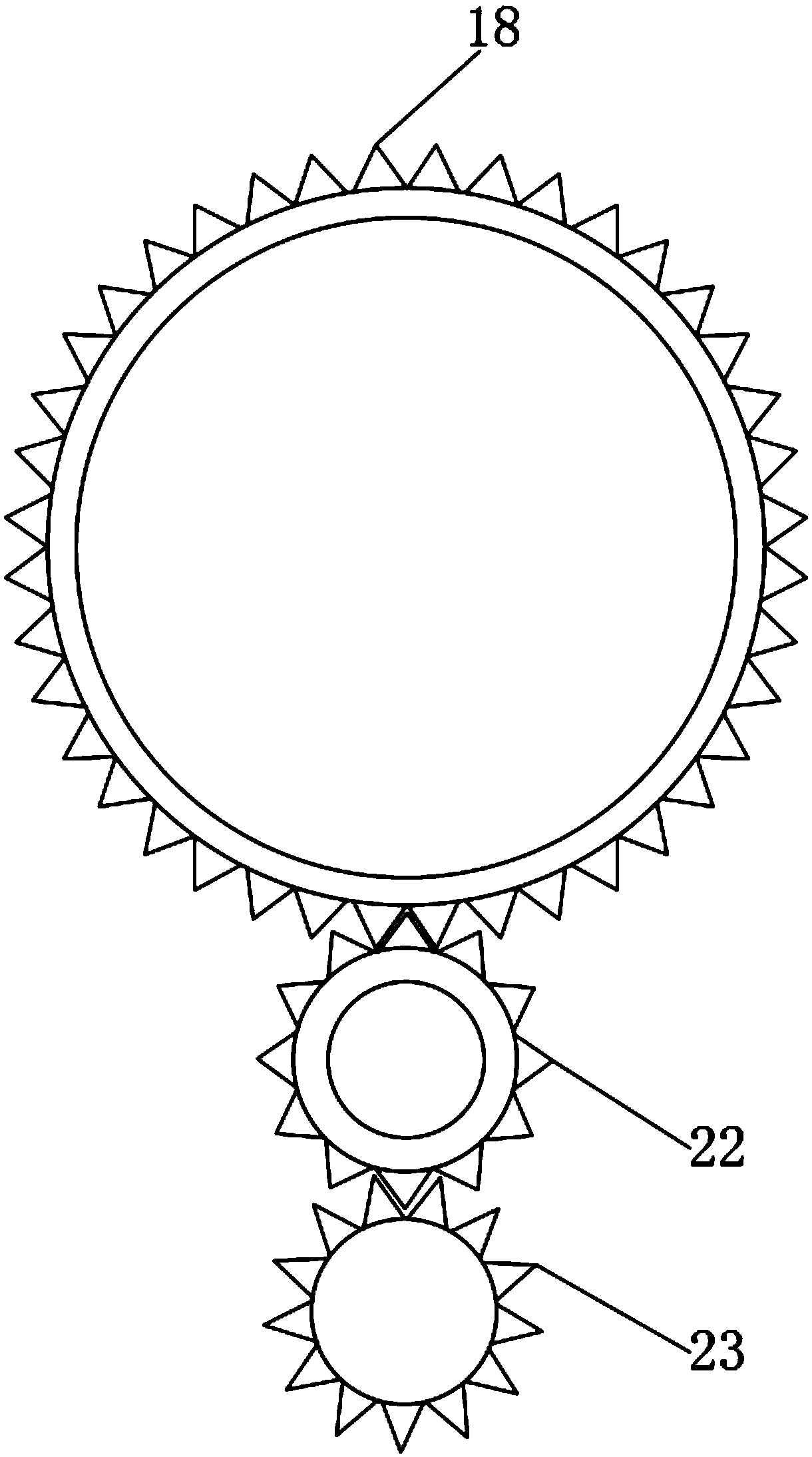

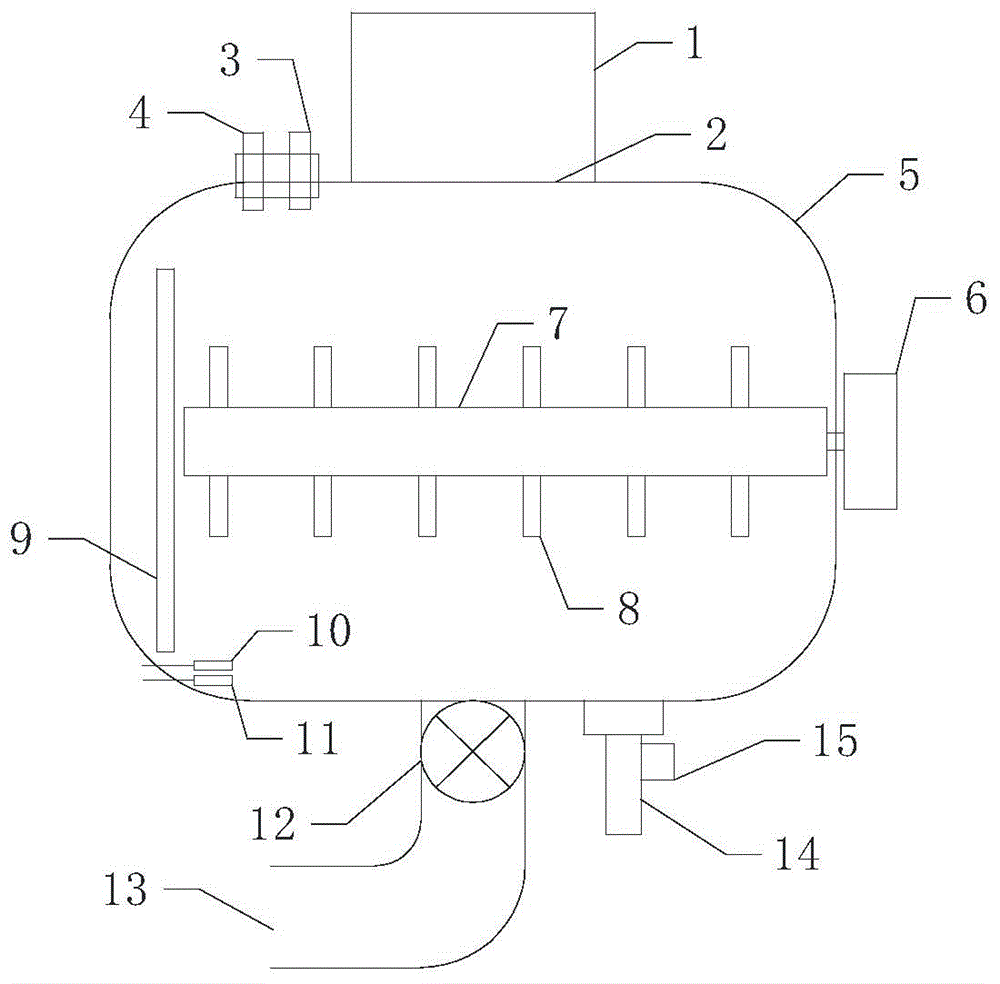

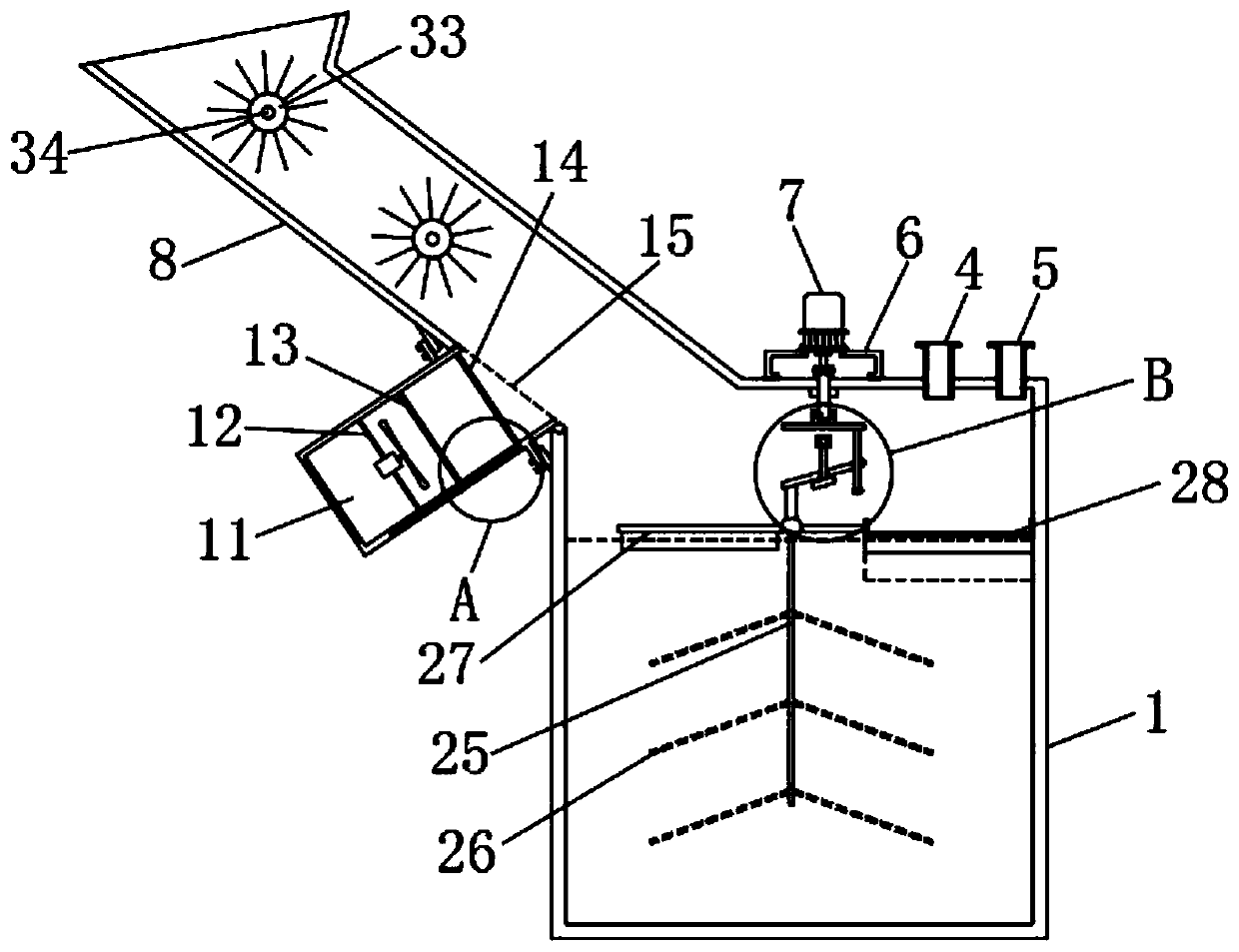

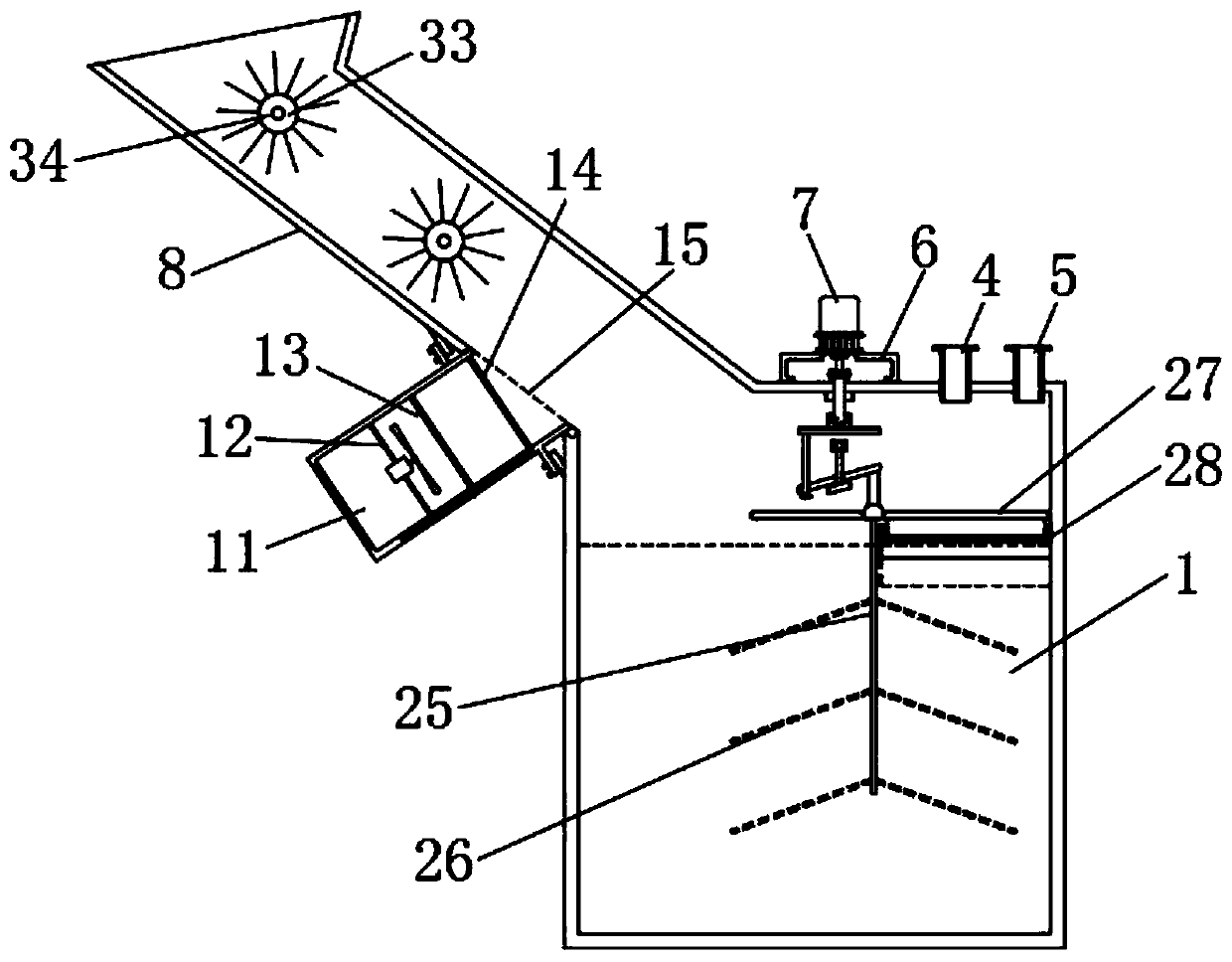

Full-automatic down feather water-washing device

InactiveCN104805510AImprove efficiencyQuality improvementAnimal fibre deburring machinesWool fibre washing/scouringWater dischargeBiochemical engineering

The invention provides a full-automatic down feather water-washing device. The device comprises a tank body, wherein a down feather raw material feeding hole, a water feeding hole and a detergent feeding hole are formed in the top of the tank body; a capacitive material level sensor, a BOD (Biochemical Oxygen Demand) or biochemical oxygen consumption probe and a COD (Chemical Oxygen Demand) probe are arranged in the tank body; the bottom of the tank body is provided with a water discharging pipe and a down feather discharging hole; a control valve is arranged on the water discharging pipe; an air sucking fan is arranged in the down feather discharging hole and is close to the tank body. The full-automatic down feather water-washing device provided by the invention can be used for realizing full automation of a water washing device by arranging the capacitive material level sensor, the BOD probe and the COD probe in the tank body, so the down feather washing efficiency and quality are enabled to reach a relatively high level.

Owner:ANHUI SANXIANG DOWN +2

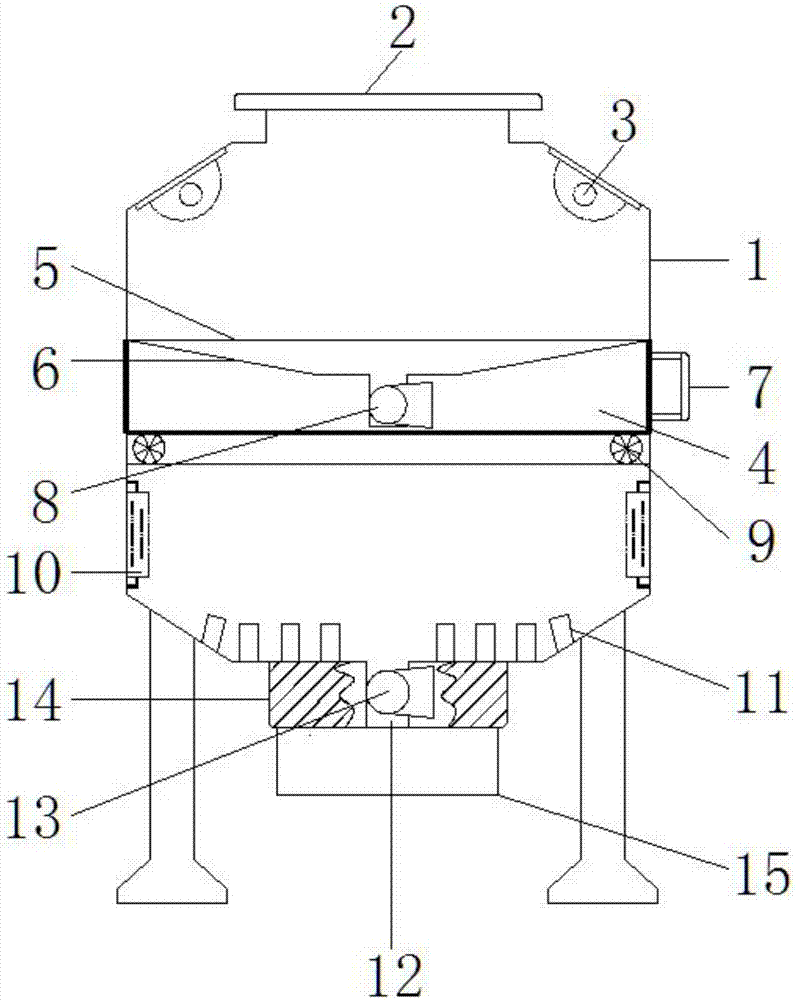

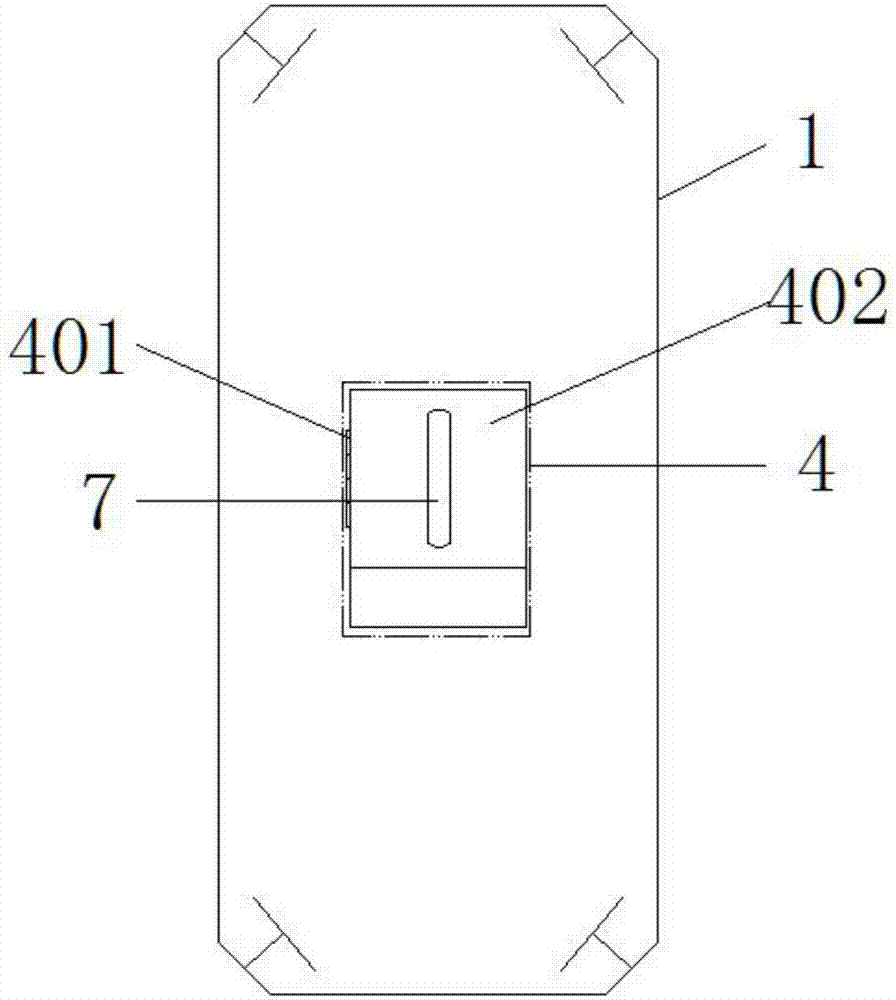

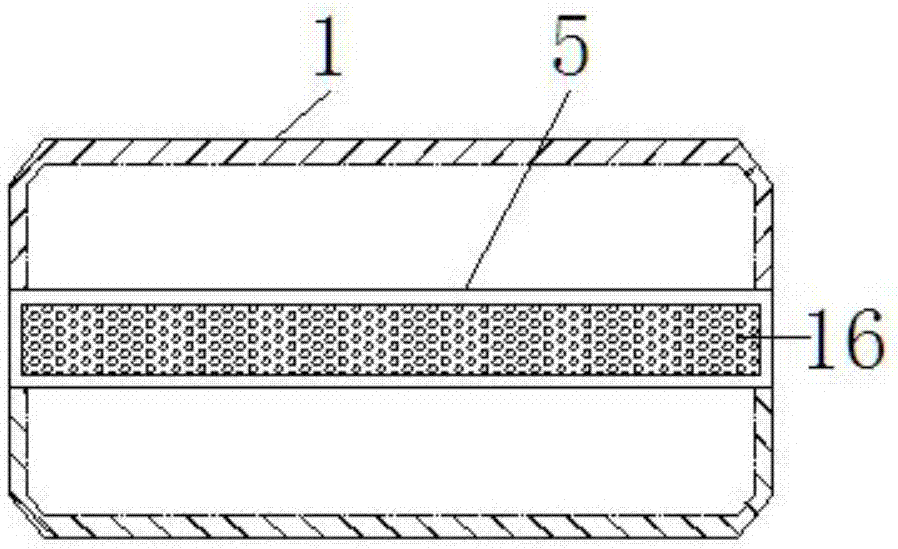

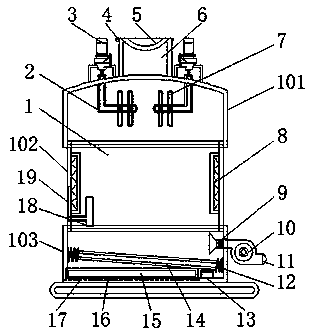

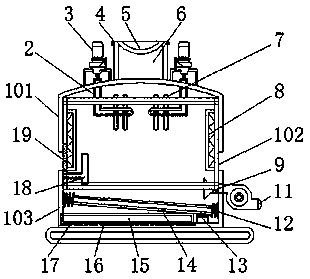

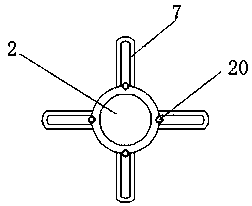

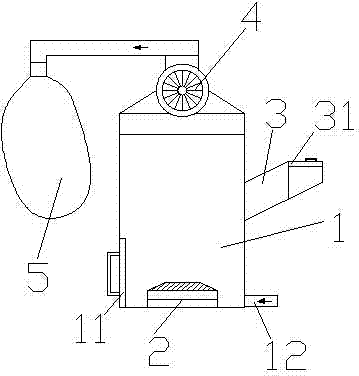

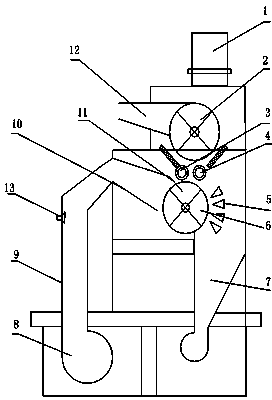

Rabbit wool unhairing device

InactiveCN104499060AHigh densityAnimal fibre deburring machinesWool fibre washing/scouringEngineeringWool

The invention discloses a rabbit wool unhairing device which comprises a base box, a feeding port and an air incoming passage. The air incoming passage is connectedly arranged at the bottom of the base box, the feeding port is arranged in the middle of one side of the base box, a rotating wave wheel is arranged below the inside of the base box, a negative pressure fan is arranged at the top of the base box, an air outlet of the negative pressure fan is connectedly provided with a wool discharging pipeline, and a rabbit wool collecting bag is arranged at the tail end of the wool discharging pipeline. By the above mode, the characteristic that rabbit wool is light in weight is utilized, the rabbit wool constantly tumbles and flies under action of the rotating wave wheel and compressed air, and the rabbit wool which is light in weight flies to the top and is collected into the rabbit wool collecting bag under action of the negative pressure fan; rabbit hair and sundries are larger than the rabbit wool in density, thereby hovering at the bottom of the base box under action of gravity.

Owner:ZHANGJIAGANG CHAFTA TEXTILE TECH

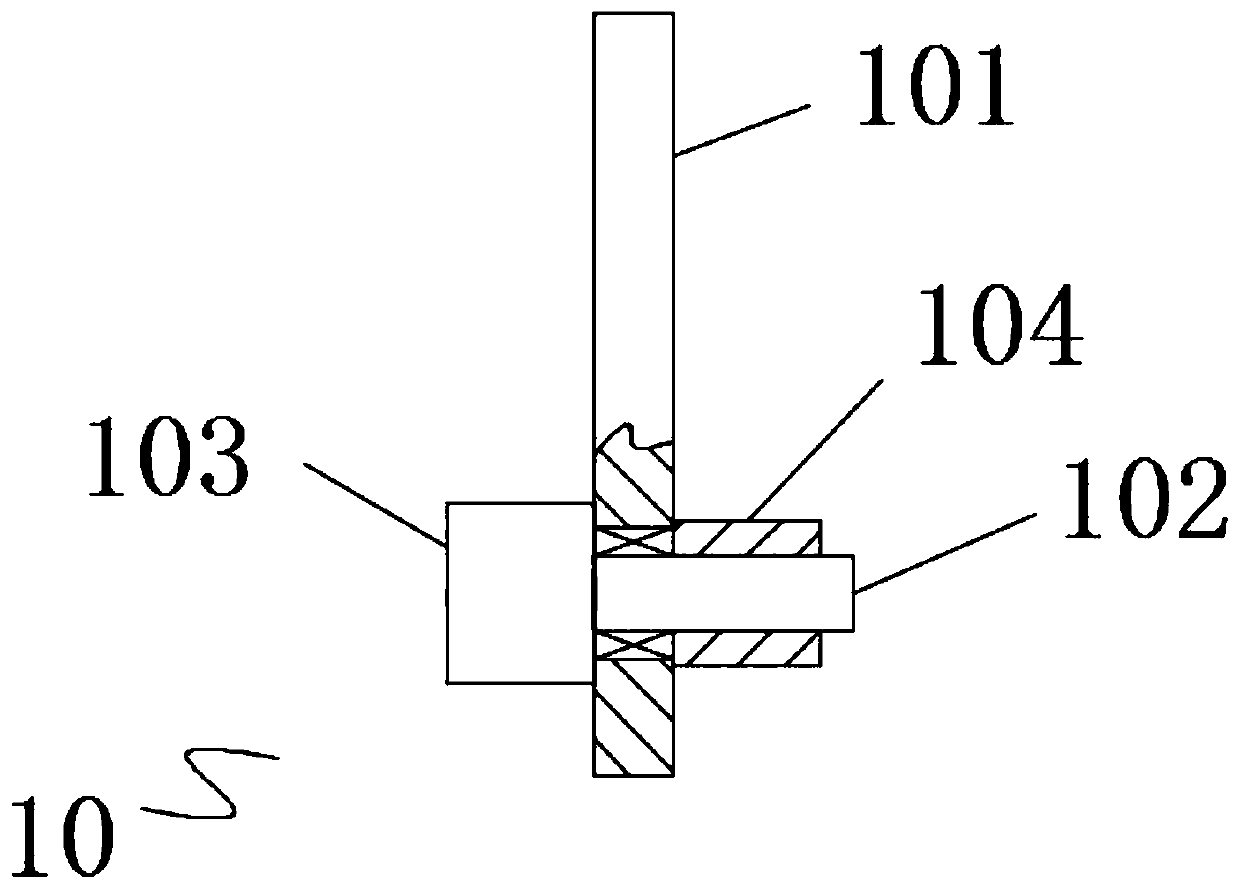

PLC-based feather and down separation system

InactiveCN104611789AReduce usageSimple and fast operationAnimal fibre deburring machinesFibre separationAutomatic controlSeparation system

Owner:ANHUI LION GOOSE PROD

Down de-dusting and de-ironing apparatus

InactiveCN105040112AAvoid damageGuarantee healthy useAnimal fibre deburring machinesPush and pullDrive shaft

The invention discloses a down de-dusting and de-ironing apparatus comprising a de-dusting case. A transmission mechanism and a feeding port are arranged at the top portion of the de-dusting case, and a discharging port is arranged on the side surface of the de-dusting case. The down de-dusting and de-ironing apparatus is characterized in that the top portion of the de-dusting case is communicated with a compressed air system; the bottom portion of the de-dusting case is connected to a dust collector through a dust collection pipe; multiple layers of steam pipes are wound on the periphery of the de-dusting case from top to bottom; the de-dusting case is internally provided with a transmission shaft fixedly connected to the bottom end of the transmission mechanism; a cross joist is transversely and fixedly connected to the transmission shaft; a first stirring shaft and a second stirring shaft are respectively arranged at the left end and the right end of the cross joist; a magnetic board I is vertically and downwardly in threaded connection with the transmission shaft; a push-and-pull type sieve plate is arranged at the bottom inside the de-dusting case; and a cross magnetic board II is arranged on the sieve plate. The beneficial effects of the down de-dusting and de-ironing apparatus are that the apparatus is simple in structure and low in manufacturing cost, is convenient to use, has good de-dusting and de-ironing effects, can thoroughly disinfect the down, can reduce processes, and can conveniently discharge the down.

Owner:江苏欣隆羽绒有限公司

Down feather washing process

InactiveCN109183160ADoes not affect loftImprove qualityAnimal fibre deburring machinesWool fibre washing/scouringWarm waterEngineering

The invention discloses a down feature washing process, which comprises the following steps: coarse sorting; fine sorting; dust removal treatment; initial washing with cold water; fine washing with warm water; rinsing treatment; dehydration; drying treatment; cooling; and classification and packaging. Overall, the down feature washing process has a good impurity removal effect and a good down feature cleaning effect, can save water, and can produce high-quality down features.

Owner:HENAN PENGDA DOWN PROD

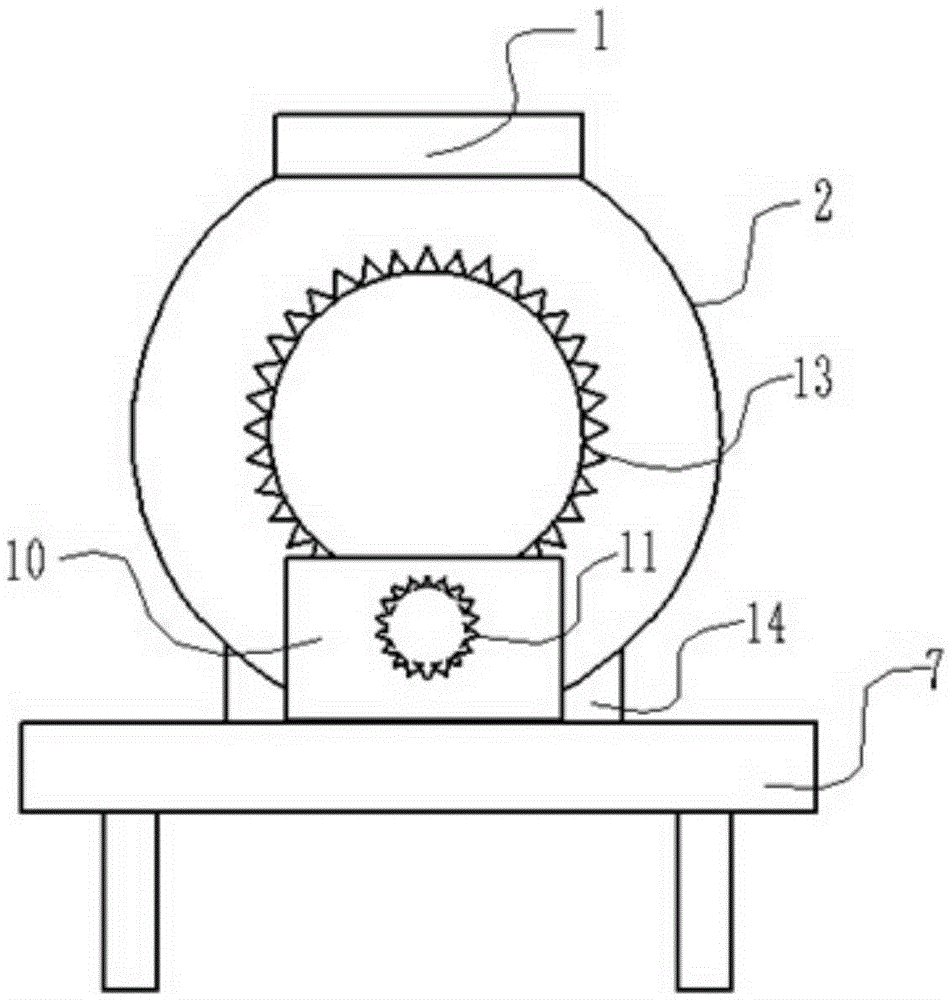

Wool cleaning machine

InactiveCN104005092AEfficient removalGuaranteed cleaning efficiencyAnimal fibre deburring machinesEngineeringPre treatment

The invention discloses a wool cleaning machine. The wool cleaning machine comprises a dust cage, and an air pipe arranged above the dust cage; a wool feeding pipeline is arranged at a feeding port of the dust cage, and while a discharging port is formed in the bottom part of the dust cage; a wool shifting roller and a wool pressing roller are arranged at the lower surface of the discharging port of the dust cage; a wool cleaning device consisting of a rack drum and a smoits removing cutter is arranged under the wool pressing roller, wherein the smoits removing cutter is circumferentially arranged outside the rack drum; a clearance is formed between the smoits removing cutter and the rack drum; a wool arranging plate is arranged at the front end of the upper part of the rack drum; a smoits removing box is arranged below one lower side of the rack drum, close to the smoits removing cutter; a wool outlet pipeline is arranged at one side of the rack drum, corresponding to the smoits removing cutter; a rear wind shield is arranged on the wool outlet pipeline. With the adoption of the wool cleaning machine, smoits in preliminarily-purified wool can be effectively removed, the fine removal of smoits in wool can be realized by the wool pretreatment process, and thus the smoits removal quality is improved, the wool cleaning efficiency is ensured, and the cost is also saved.

Owner:ZHENGZHOU COTTON & JUTE ENG TECH & DESIGN RES INST

Down feather dedusting device for textiles

InactiveCN105386128ASmooth transmissionImprove qualityAnimal fibre deburring machinesDrive shaftEngineering

The invention relates to the textile field, in particular to a down feather dedusting device for textiles. By the adoption of the device, dust in down feather can be removed completely and effectively, so that the quality of down feather is improved. The device comprises a box body, wherein a feed inlet is formed in the box body, a roller is arranged inside the feed inlet, stirring blades are arranged on the roller, and the roller is connected with the stirring blades in a welded mode; a motor, a first transmission gear, a second transmission gear and a main driving shaft are arranged on the box body, the first transmission gear is meshed with the second transmission gear, and the roller connected with the main transmission shaft is made to rotate through the motor connected with the first transmission gear; a filter screen is arranged on the box body and connected with a dust suction pipe, the dust suction pipe is connected with an air blower, and a dust collection box is arranged at the lower end of the air blower. The device is simple in structure, convenient to use and suitable for various places.

Owner:SUZHOU BUWU JIAXIANG TEXTILE TECH CO LTD

Environment-friendly wool flock cleaning and impurity removing device and process thereof

InactiveCN110965134AGuaranteed cleanlinessEasy to operateAnimal fibre deburring machinesWool fibre washing/scouringWoolProcess engineering

The invention discloses an environment-friendly wool flock cleaning and impurity removing device and a process thereof. The device comprises a cleaning box, a control button, a first motor, a second motor and a fan; a first guide wheel is connected to the outer surface of the front end of the cleaning box through a hinge; a sealing plate and a fixing frame are fixed on the upper surface of the cleaning box by bolts, and the fixing frame is arranged at the left side of the sealing plate; a first charge pipe and a second charge pipe are welded on the upper surface of the sealing plate in a penetrating mode, and the second charge pipe is arranged at the right side of the first charge pipe; and a feeding pipe is welded on the outer surface of the cleaning box. According to the environment-friendly wool flock cleaning and impurity removing device provided by the invention, by setting a swash plate, a connecting disk rod, a cleaning plate and a slag discharging groove, a stirring shaft drives a stirring rod to scatter wool, and meanwhile, the swash plate moves up and down and rotates on the connecting disk rod, so that the stirring shaft can drive the cleaning plate to clean floating sundries and discharge from the slag discharging groove, so that mixed liquor can be kept in a clean state, and meanwhile, the floating sundries can be recycled, which is more environmentally friendly.

Owner:湖州练市富腾绒毛有限公司

Cashere and wool opening device and opening operation method

InactiveCN111549399AImprove purityImprove opening efficiencyAnimal fibre deburring machinesFibre cleaning/opening by toothed membersPlant fibreCarbonization

The invention belongs to the technical field of wool opening devices and discloses a cashmere and wool opening device which comprises a bottom plate; a bracket is arranged on the right side of the topend of the bottom plate; an outer box is arranged at the top end of the bracket; the left end of the outer box is opened; the outer box is internally provided with a net barrel; and the left end of the net barrel penetrates through an opening formed in the left side of the outer box. By adopting the cashmere and wool opening device disclosed by the invention, through combination of the arranged components such as the outer box, the net barrel, a stirring delivery mechanism, a transmission mechanism and an ultrasonic generator, carbonized plant fibers in wool can be broken and are separated from the wool, so that the purity of the wool is improved; by arranging an electric push rod to be connected with the transmission mechanism, the wool after impurity removal can be sent to an opening device through conveying equipment; the wool can be subjected to opening treatment through multiple arranged licker-ins, so that the wool opening efficiency is improved; drying treatment on the opened wool can be performed through arranged electric heating wire and heat dissipation fan; and wool residues adhered to the conveying equipment can be scraped through arranged elastic scraping mechanism.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

Aftertreatment processing method for waterproof down

InactiveCN108823647AImprove waterproof performanceImprove bulkAnimal fibre deburring machinesAnimal materialComputer scienceSizing

The invention discloses an aftertreatment processing method for waterproof down. The method comprises steps as follows: step 1), down addition: a washed finished down product is added to a down storage box, and down is enabled to pass an iron removing device through quantitative feeding; step 2), spraying: the down is extracted from the down storage box, chemical spraying is performed through thequantitative feeding, and stirring is performed during spraying; step 3), dehumidification and sizing: the down enters a dehumidification stage after being stirred, and excessive water in a spraying device is dried by a fan; step 4), drying: the down is sucked into an oil heat conduction drying device by the fan and is dried through the quantitative feeding; step 5), cooling and dedusting; step 6), secondary cooling; step 7), down discharge and packaging. According to the scheme, the down subjected to waterproof treatment is provided with a protecting nanofilm and has excellent waterproof performance, filling power is improved, and heat retention property of the down is improved; besides, the down has certain dampproof and antibacterial functions, and is protected from breeding bacteria and producing peculiar smell due to dampness.

Owner:LIUQIAO GROUP

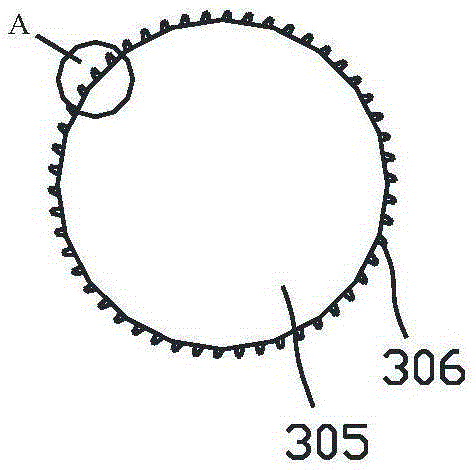

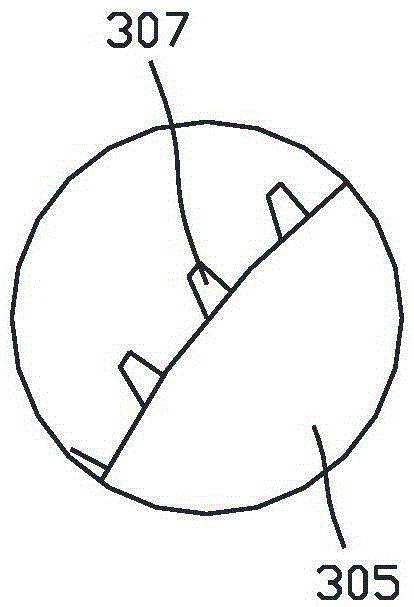

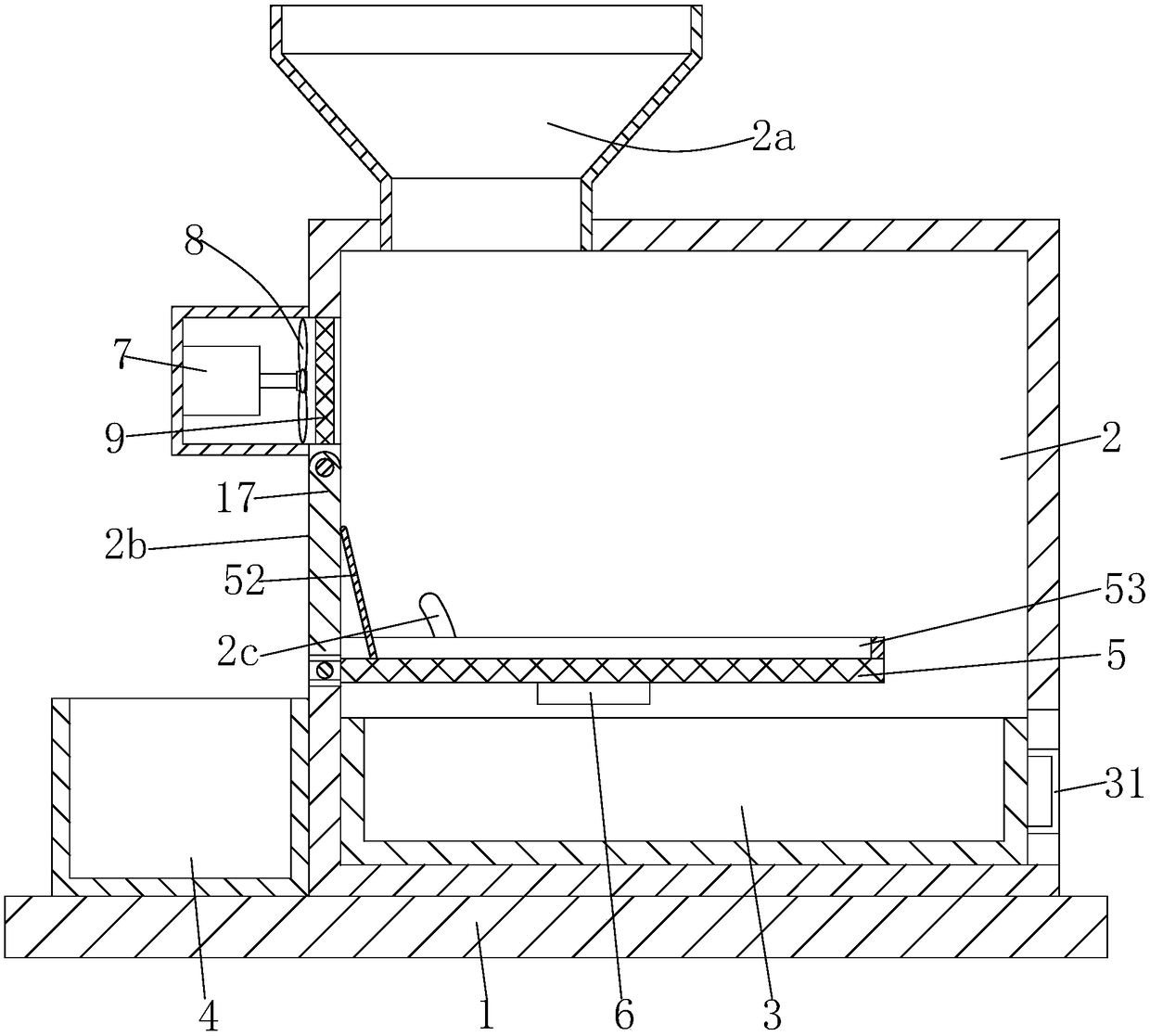

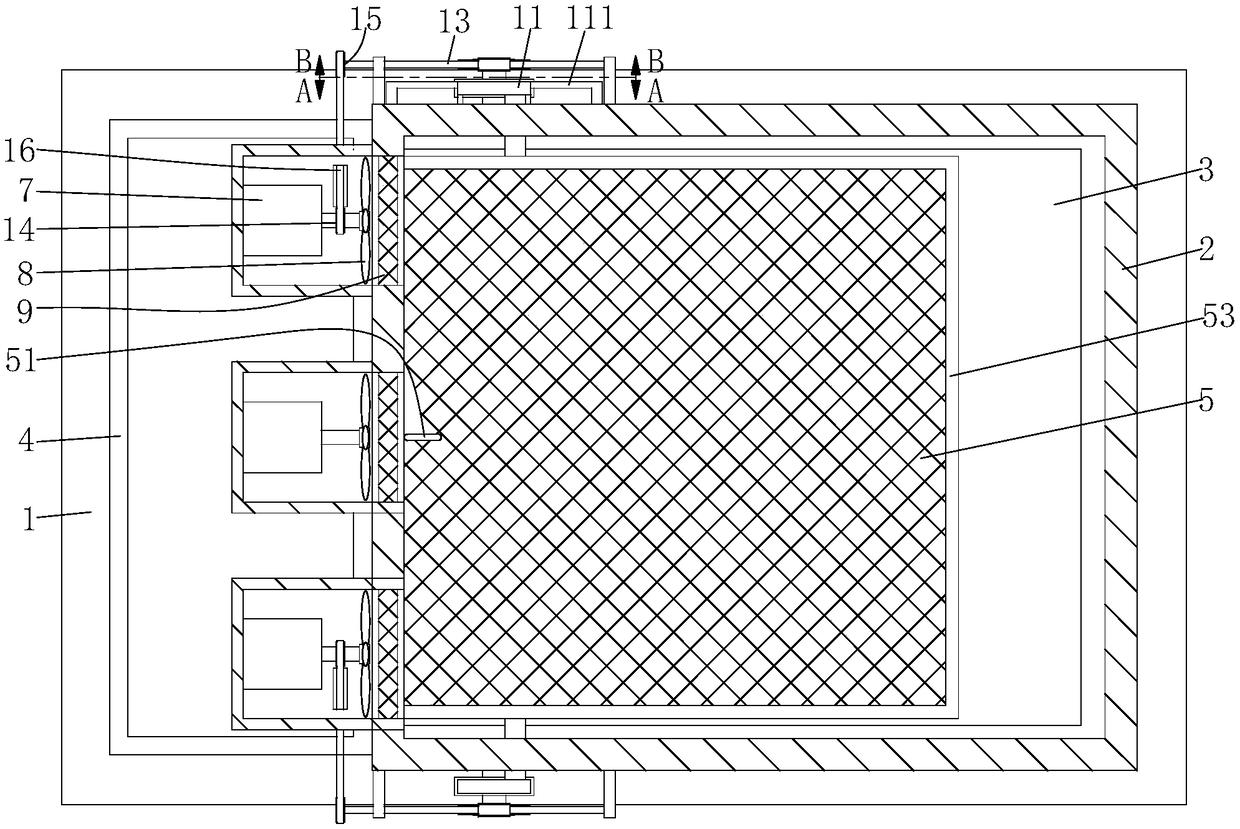

Iron removal machine from down

InactiveCN101333689BQuality improvementImprove work efficiencyAnimal fibre deburring machinesAnimal materialIron removalEngineering

Owner:徐州腾宇羽绒设备有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com