Feather down washing technology for reducing dust, matched dehydration device and control method thereof

A technology of dehydration equipment and a control method, which is applied in the field of feather cleaning, can solve problems such as easy generation of dust, low work efficiency, and impact on human health, and achieve the effect of dust removal and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

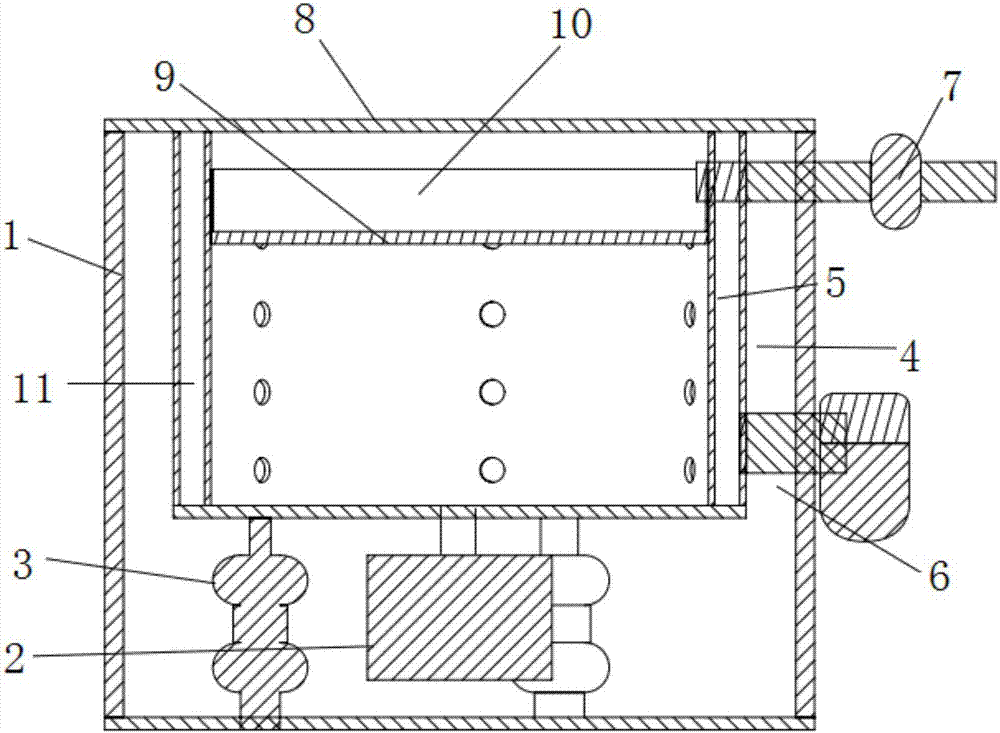

Image

Examples

Embodiment Construction

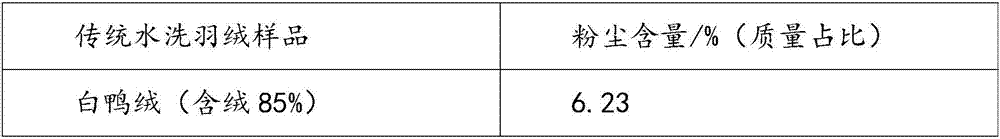

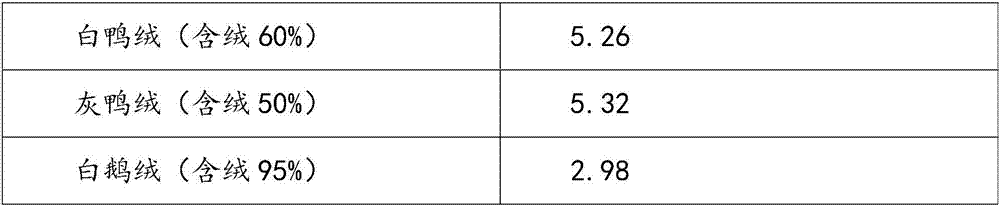

[0027] Test analysis of traditional water-washed down dust:

[0028] The weighing method is used to calculate the dust content. The test method is as follows: Accurately weigh a certain quality of feather down that has been washed with traditional techniques and place it in the down pre-treatment box. Stainless steel mesh; equilibrate for 12 hours in an environment with a temperature of 20±2°C and a relative humidity of 65±2%, weigh the down, and then use a hair dryer to blow the four sides of the stainless steel mesh at a distance of 10cm for 3 minutes on each side. Continue to balance in an environment with a temperature of 20±2°C and a relative humidity of 65±2% for 12 hours, and then weigh the feather and down; It is the mass of feather down dust. Repeat the operation and calculate the average value to obtain the dust content of different down samples, and the results are shown in Table 1.

[0029] Table 1 Dust content of different down samples in traditional water washi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com