Patents

Literature

372results about "Wool fibre washing/scouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

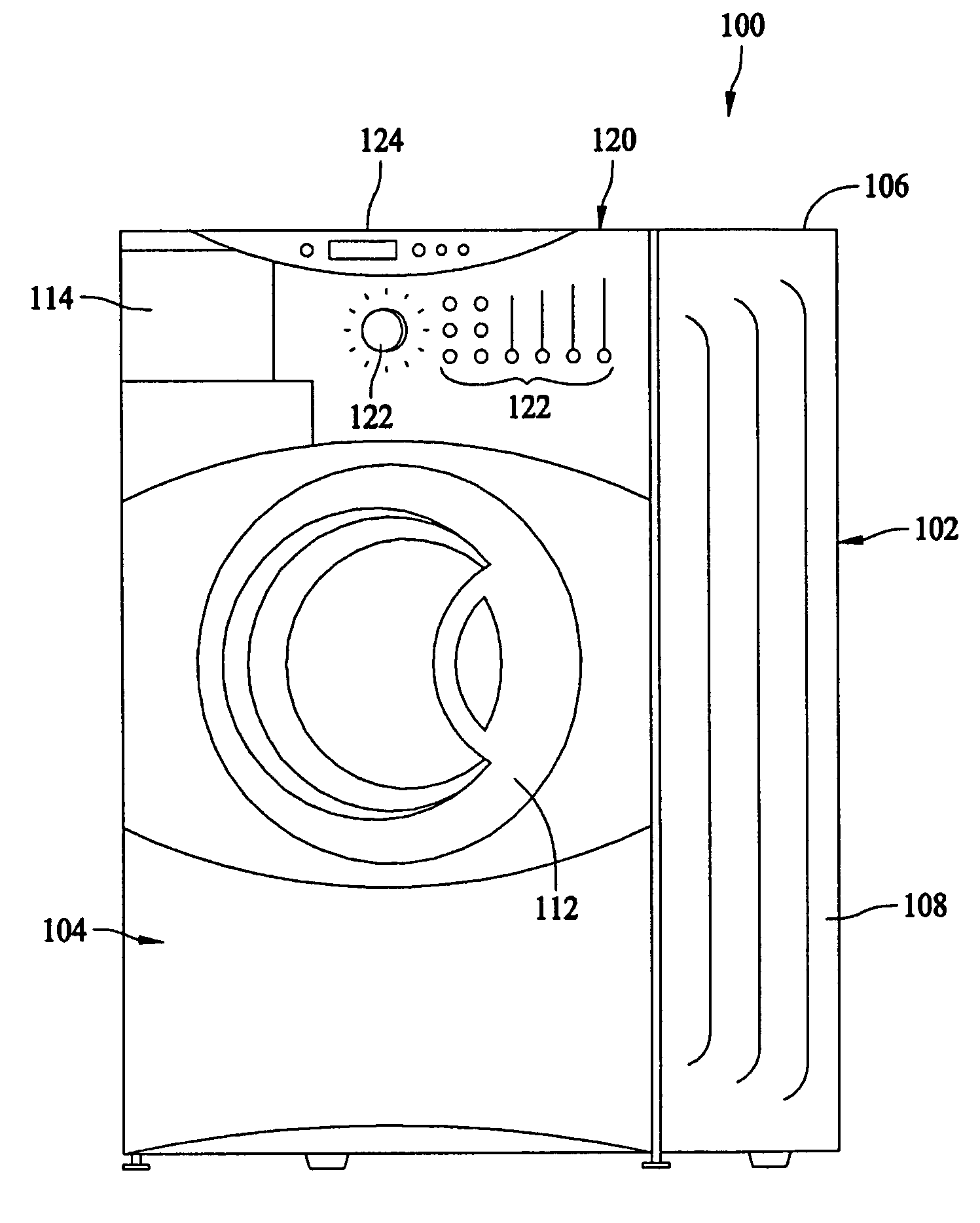

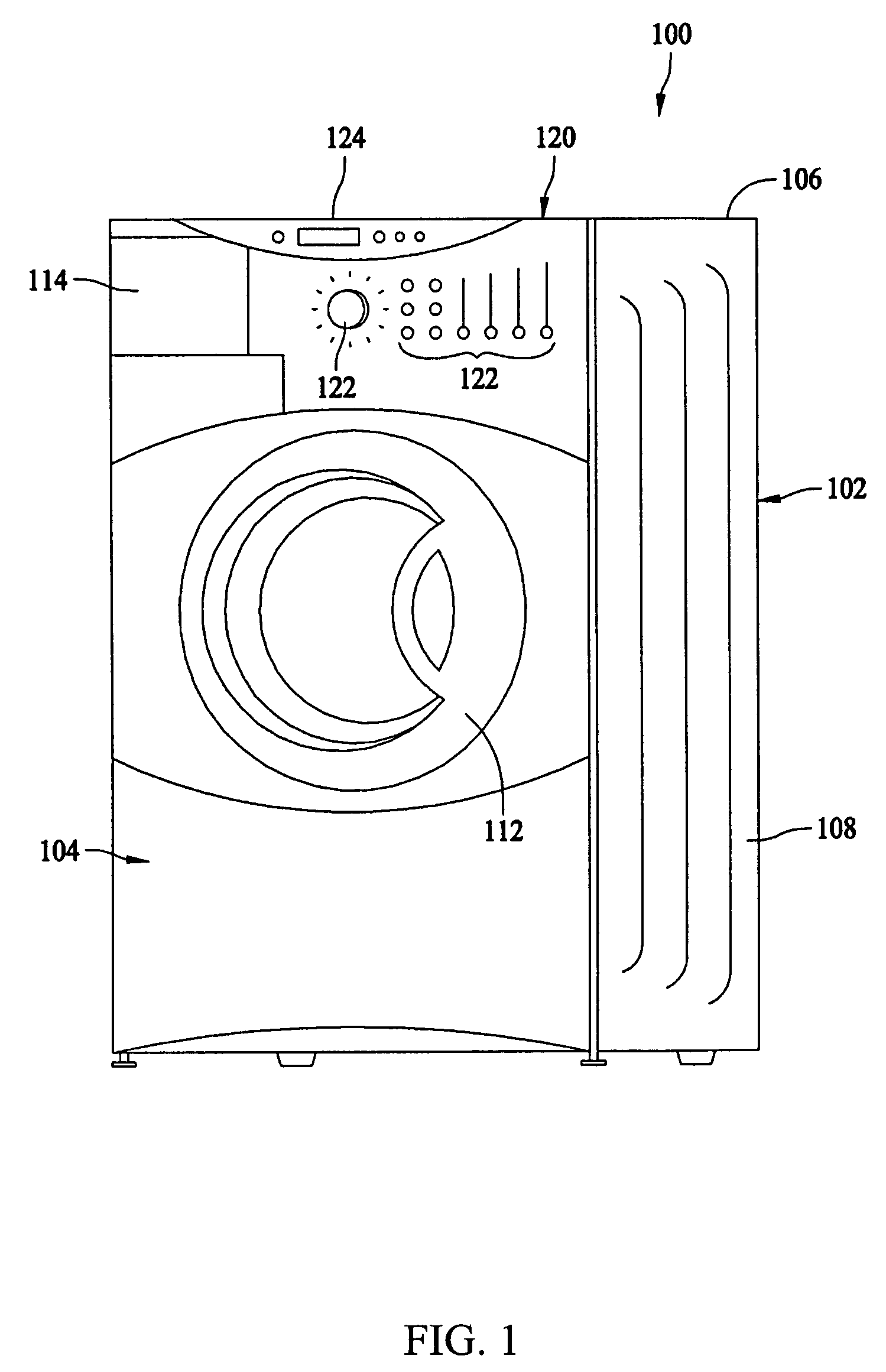

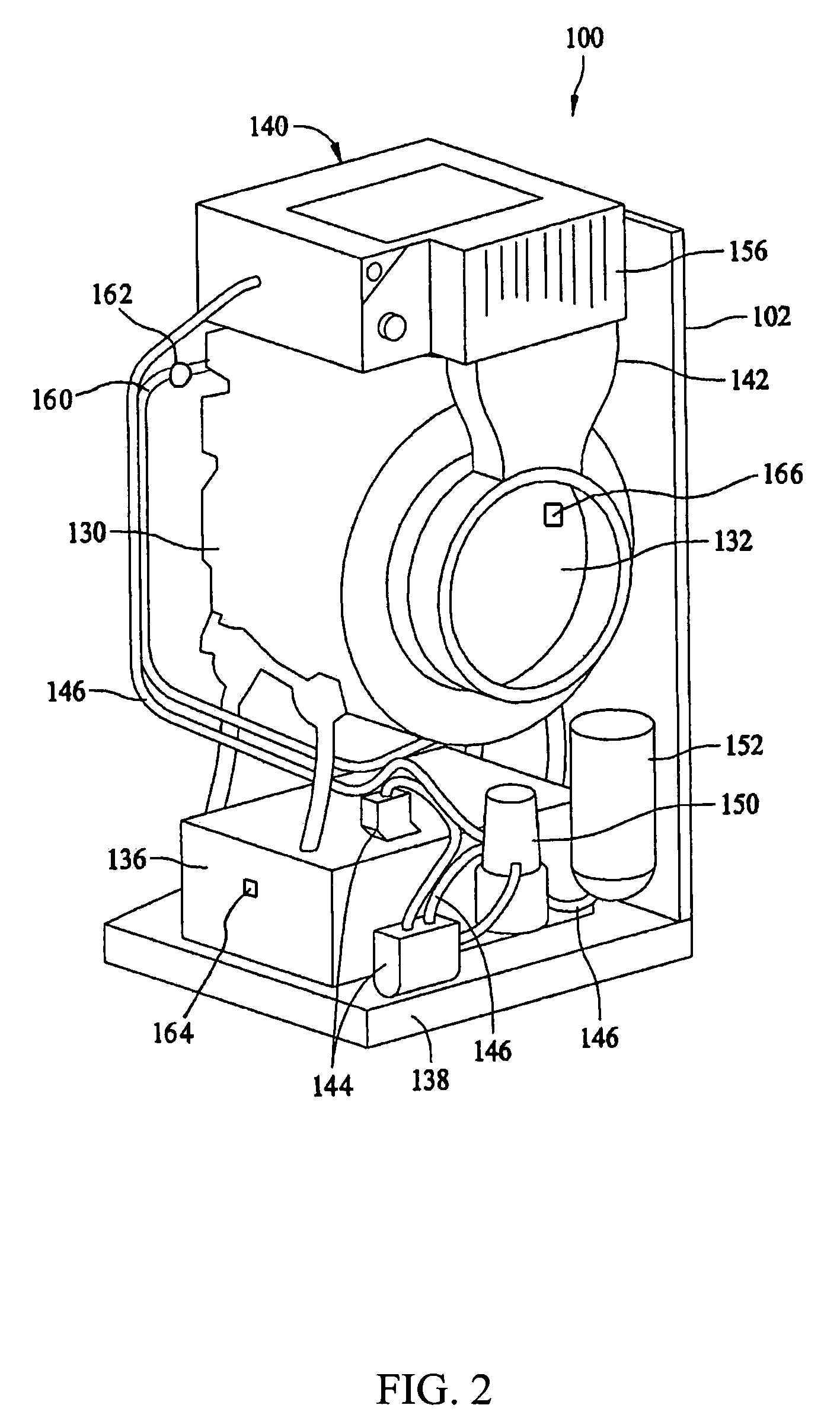

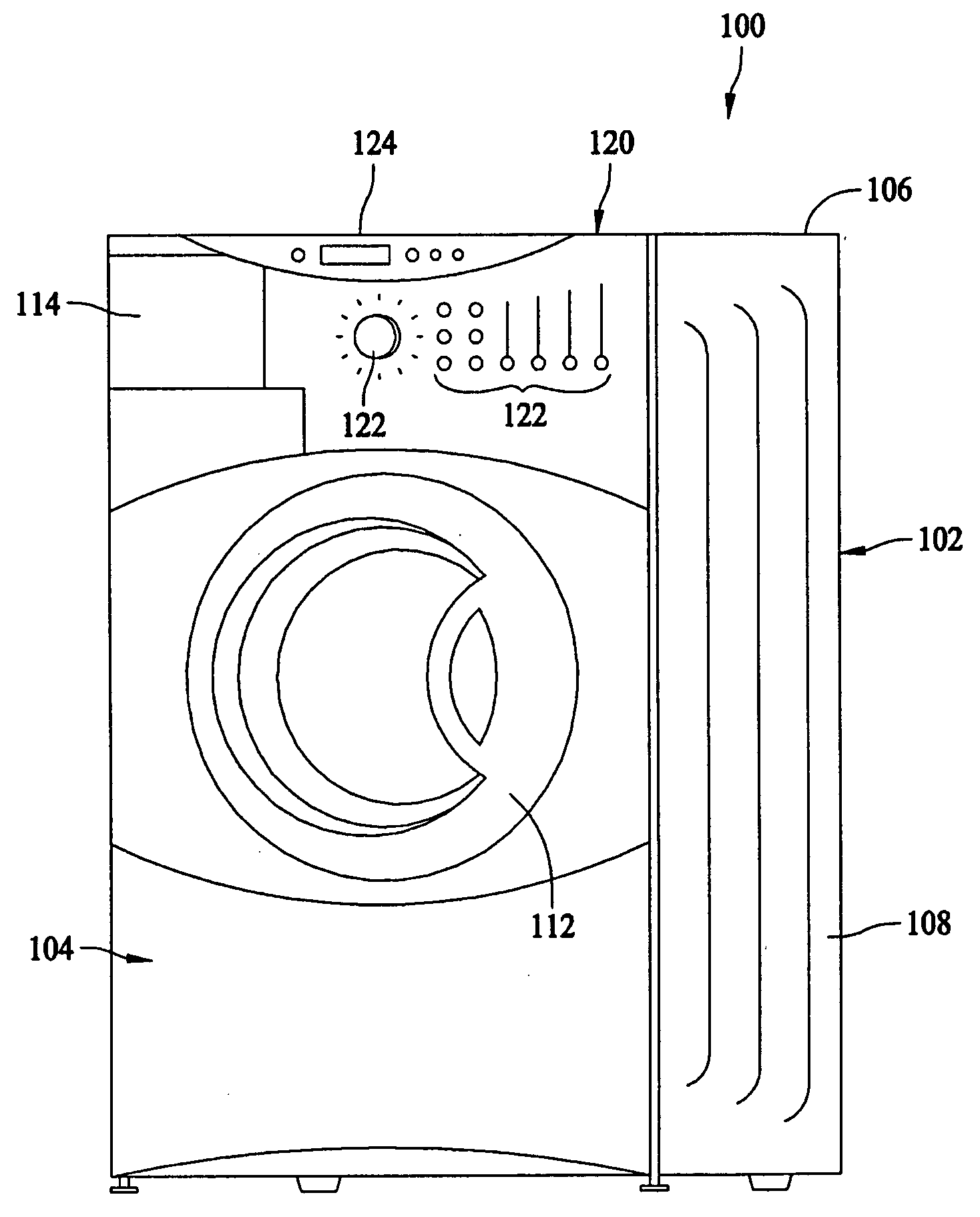

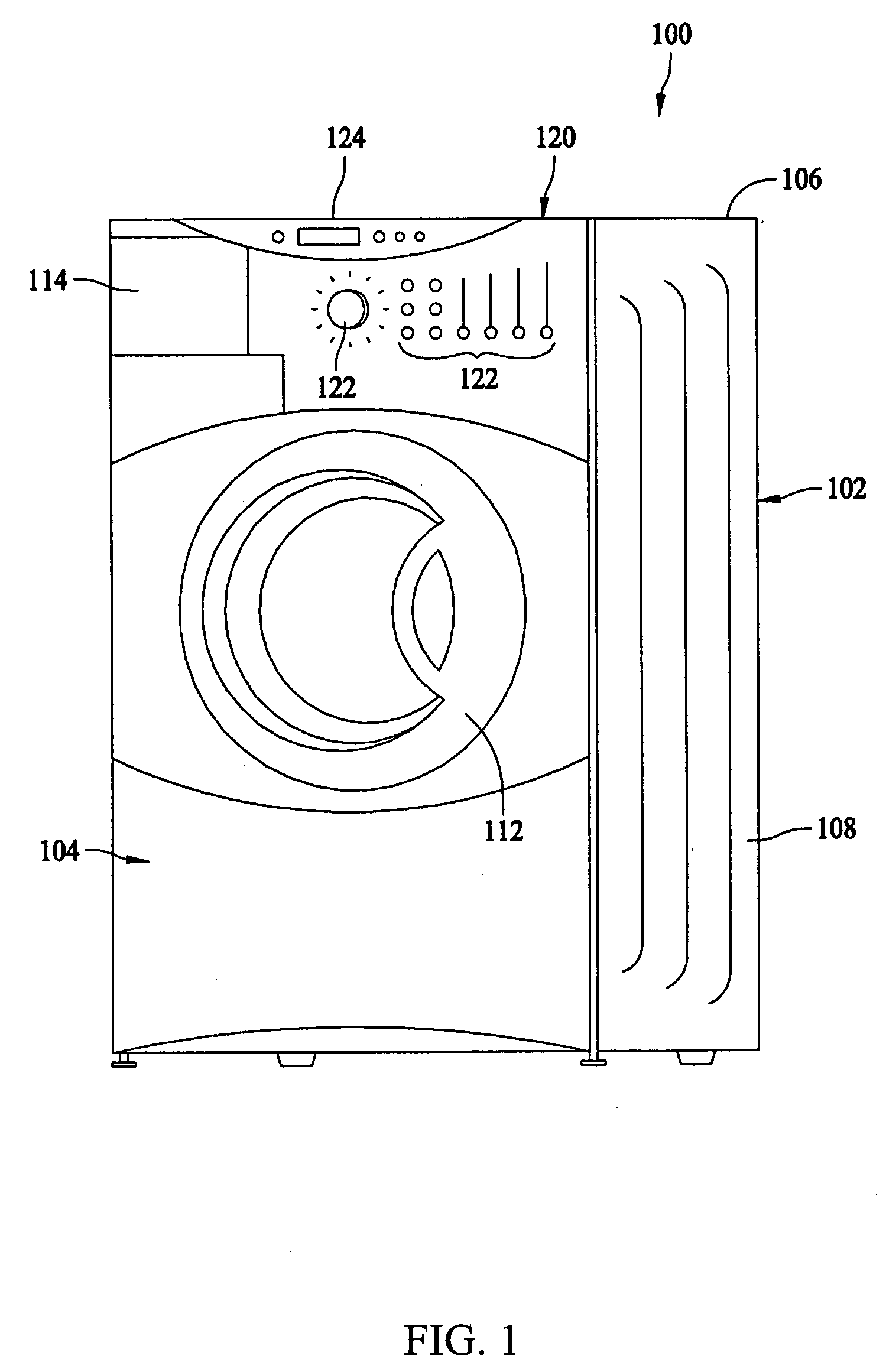

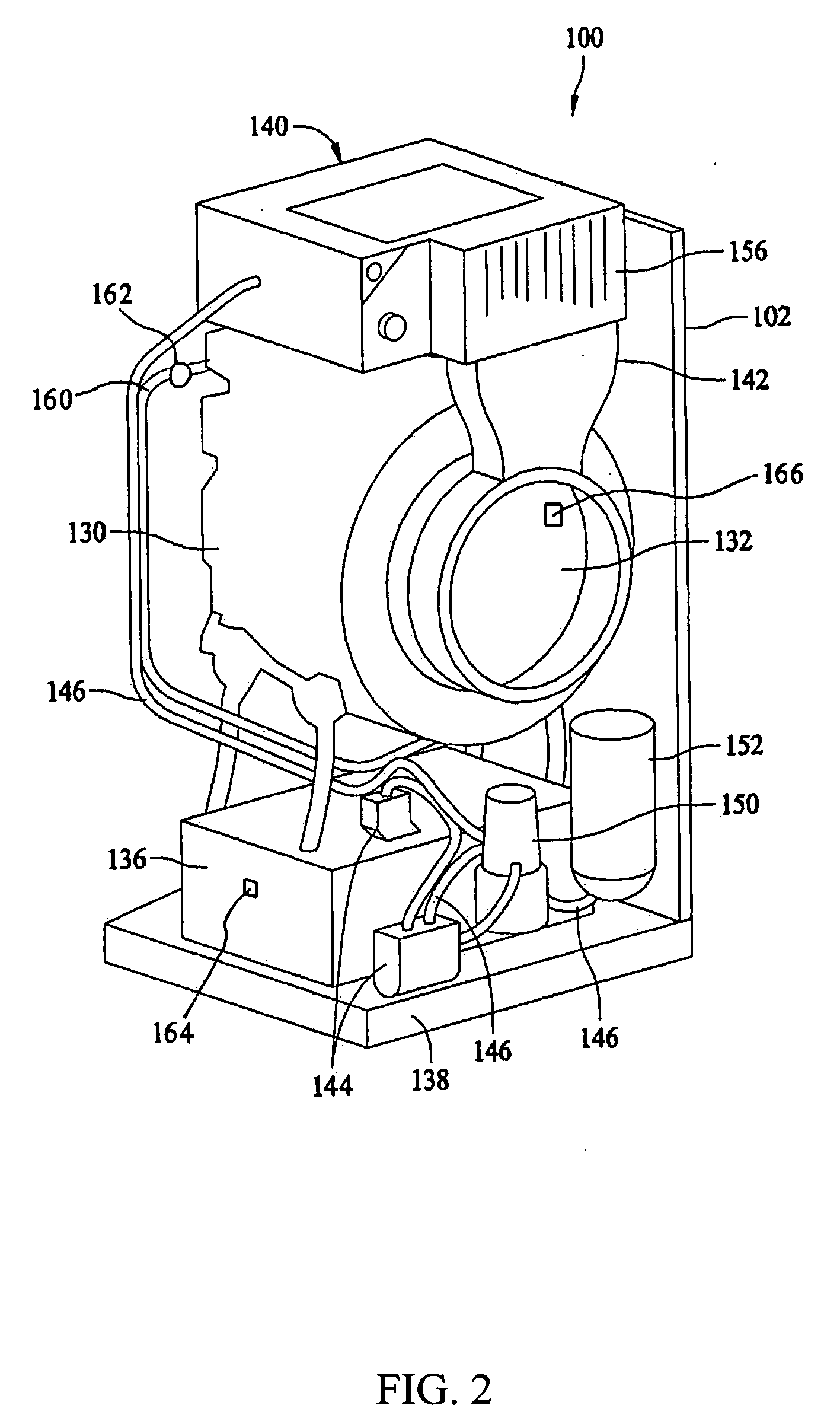

Methods and apparatus for monitoring a washing machine

A control system for a home appliance includes a cabinet, a wash tub positioned within the cabinet and configured to receive laundry therein, and a fill device configured to deliver liquid into the tub. The control system includes a first detecting component configured to detect an amount of the liquid delivered into the wash tub, a second detecting component configured to detect a liquid level in the wash tub, and a controller operatively coupled with the detecting components. The controller is configured to receive signals from the detecting components and calculate an amount of the laundry positioned within the wash tub based on the received signals.

Owner:HAIER US APPLIANCE SOLUTIONS INC

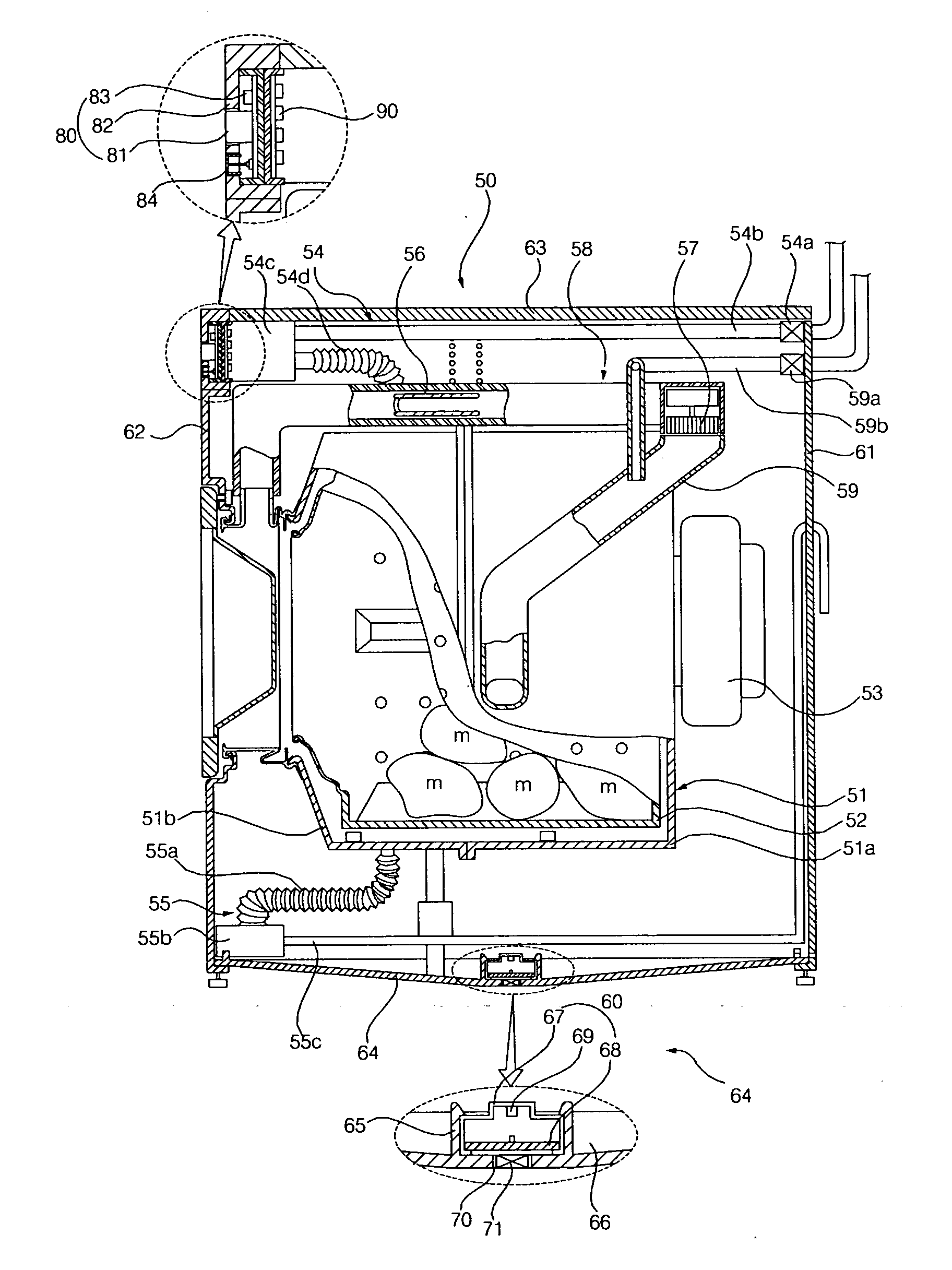

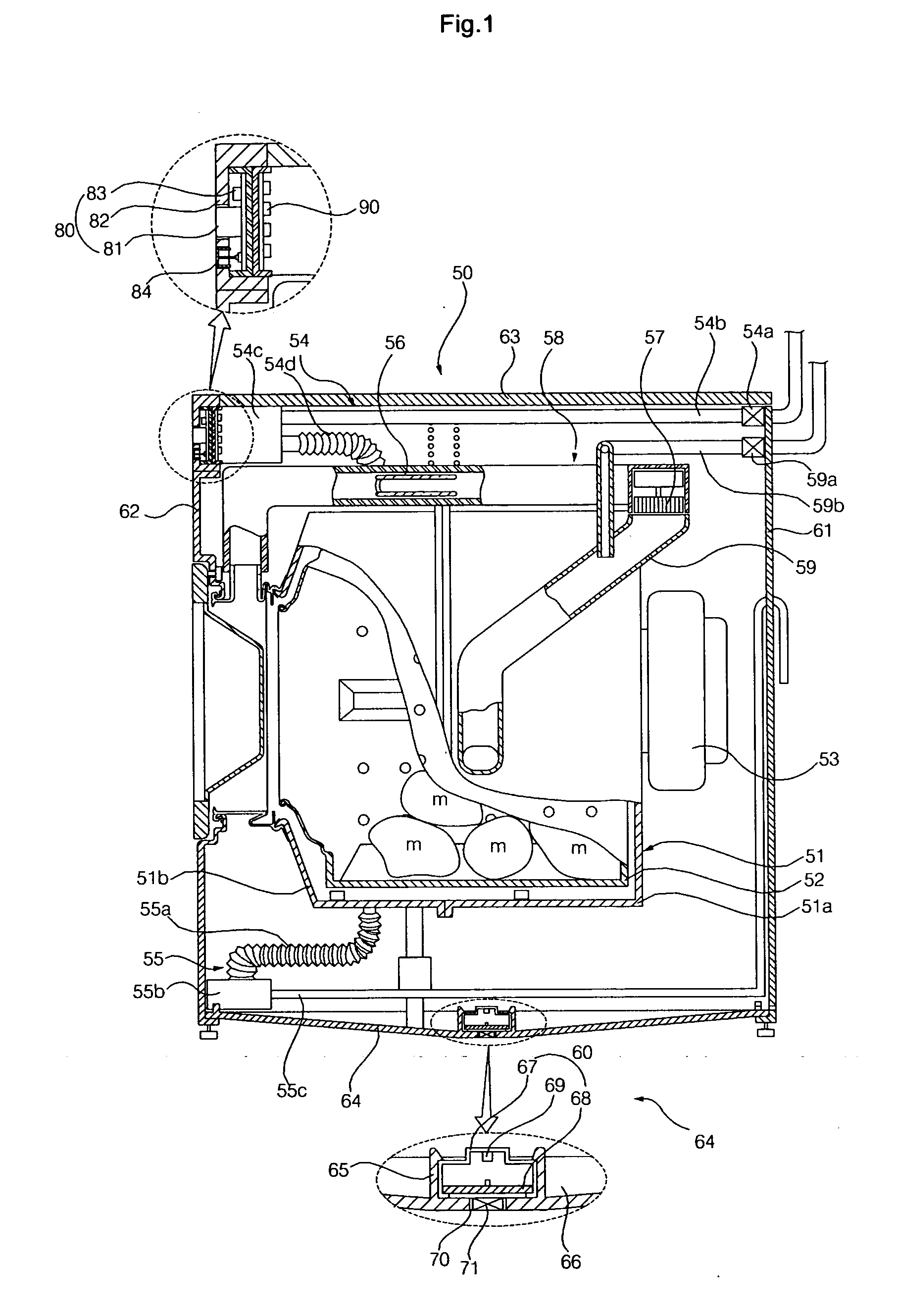

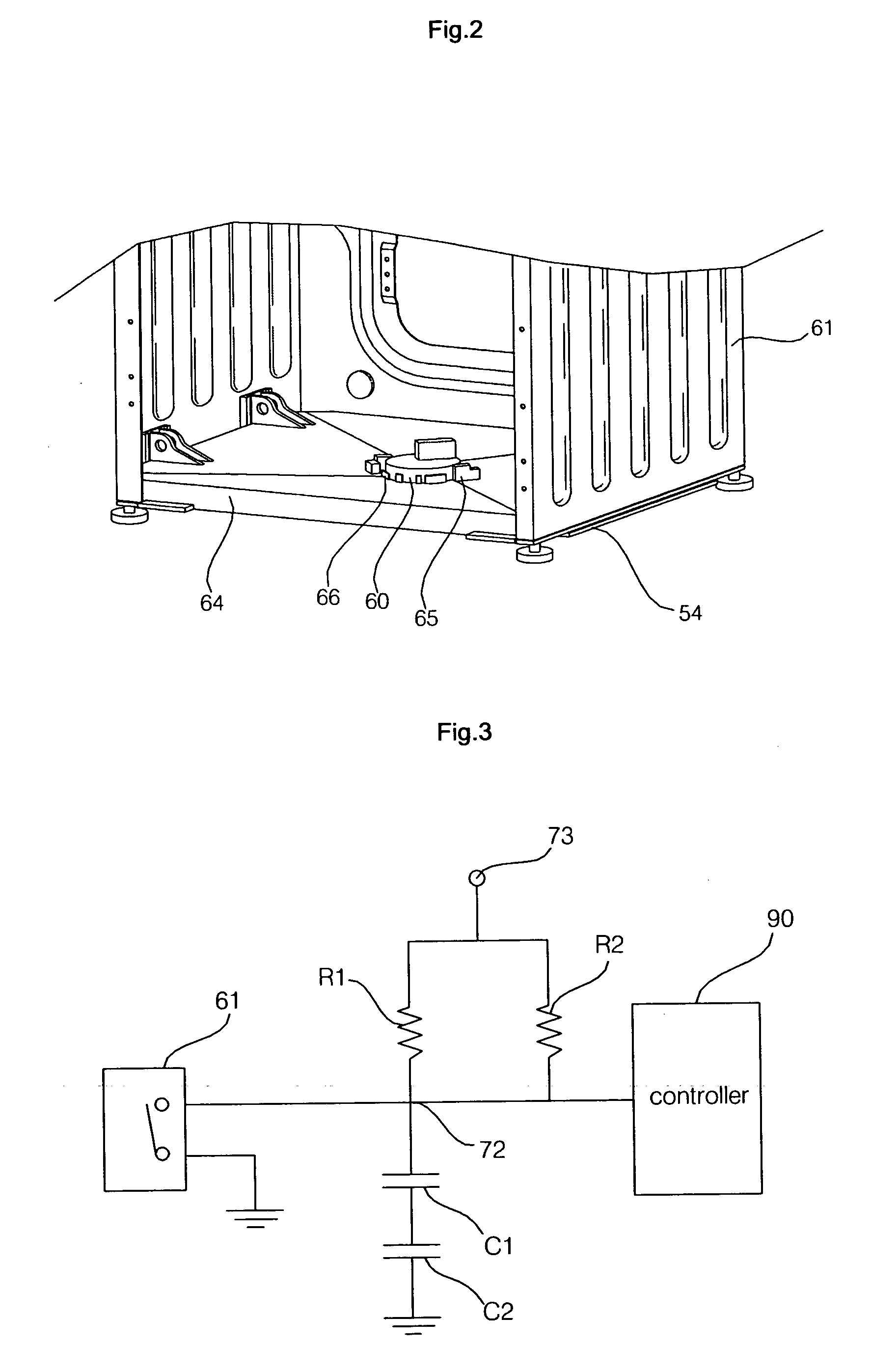

Laundry treatment apparatus and leakage controlling method thereof

InactiveUS20070101512A1Undesired interruptionAvoid accidentsOther washing machinesWool fibre washing/scouringWater leakLaundry

A laundry treatment apparatus and a controlling method thereof are disclosed. The laundry treatment apparatus includes a leakage detecting device detecting washing water leaking to the lower side of a casing, an auxiliary power supply recharged when a main electric power is supplied, and a controller controlling the auxiliary electric power supply according to the detection by the leakage detecting device. According to the leakage controlling method, since the external electric power inputted to the laundry treatment apparatus is interrupted and the auxiliary power supply is recharged during the supplying of the main electric power to the laundry treatment apparatus when the leakage is detected, an electric leakage and other accidents can be prevented, and an informing device is controlled by the auxiliary power supply so that the leakage can be measured.

Owner:LG ELECTRONICS INC

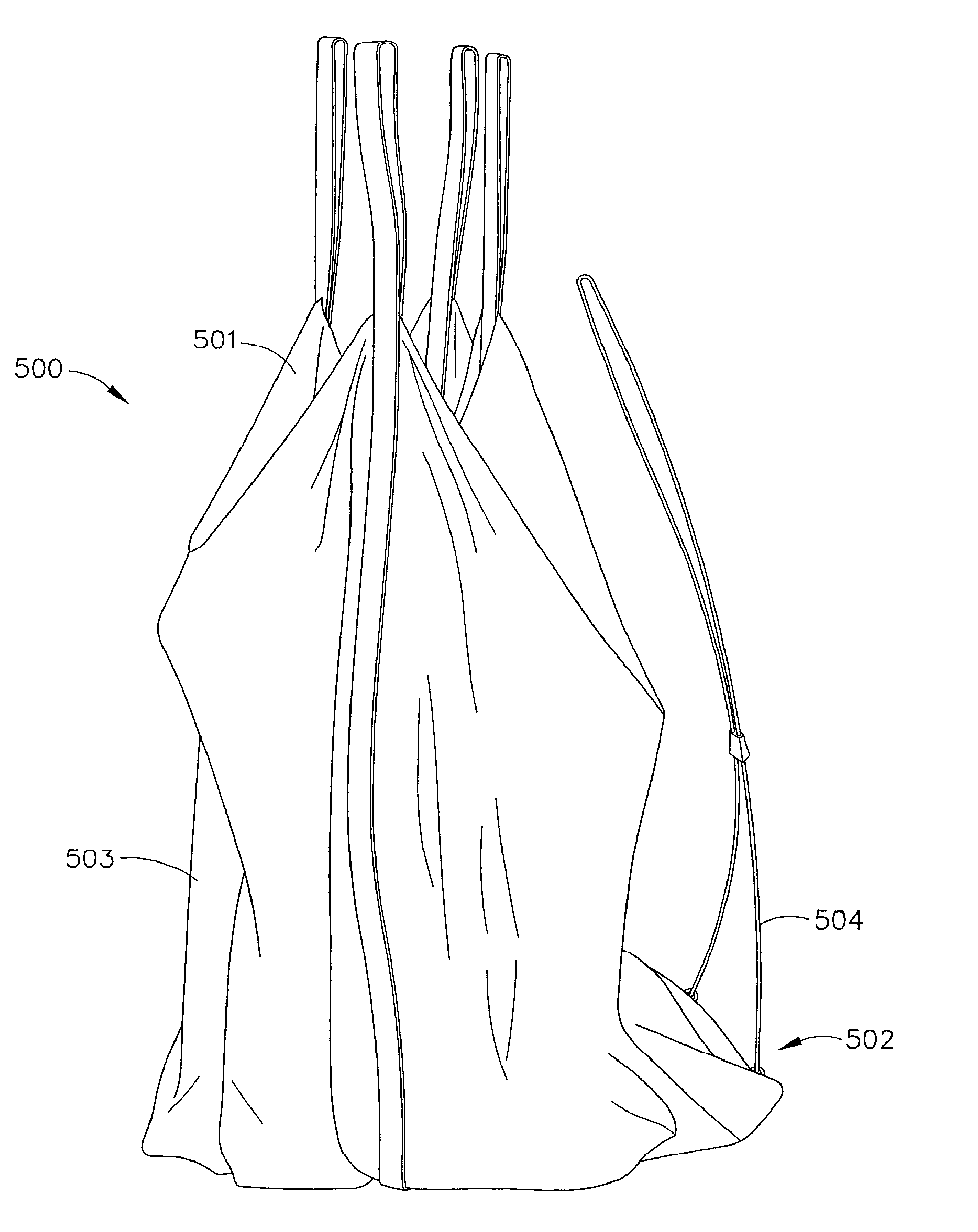

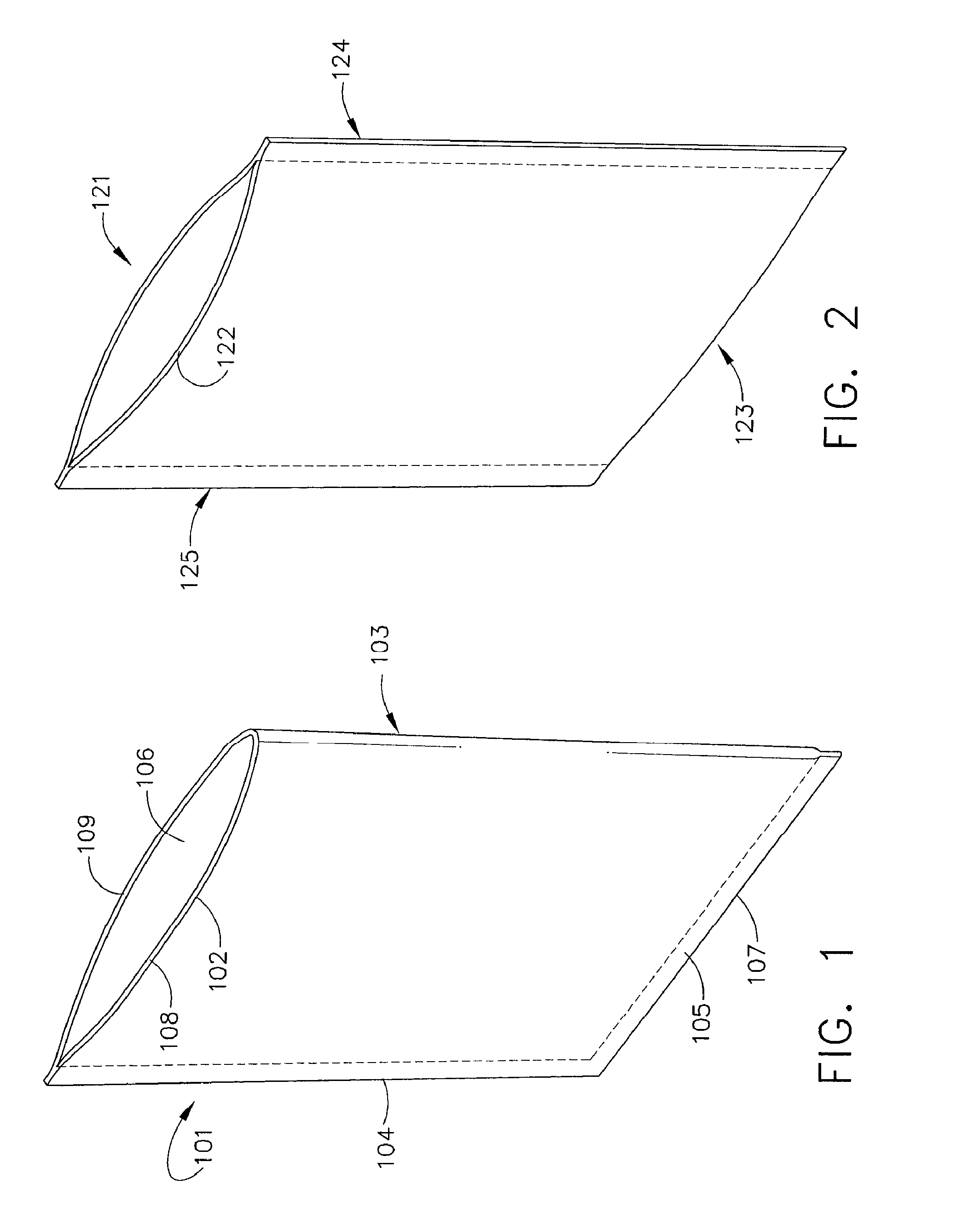

Fabric bag for use in fabric care processes

InactiveUS6857296B2Reduce noiseImprove performanceDry-cleaning apparatusWool fibre washing/scouringPliabilityEngineering

The present invention relates to improved bag-type containers for use in a non-immersion fabric care process for dry clean only fabrics. The outer shell of the bags are made from fabric such that the bags resist melting at higher temperatures than conventional non-fabric plastic bags and / or the bags are more pliable and / or supple than conventional non-fabric plastic bags and / or the bags retain more of their pliability and / or suppleness than conventional non-fabric plastic bags after being subjected to heat and / or the bags produce less noise during use than the conventional non-fabric plastic bags and / or the bags retain their shape and / or resist wrinkling during use better than the conventional non-fabric plastic bags. The bags of this invention are used in fabric care or “refreshment” processes are conducted in a hot air environment, preferably dryers, in the presence of a cleaning / refreshment composition.

Owner:IRON OUT INC DBA SUMMIT BRANDS

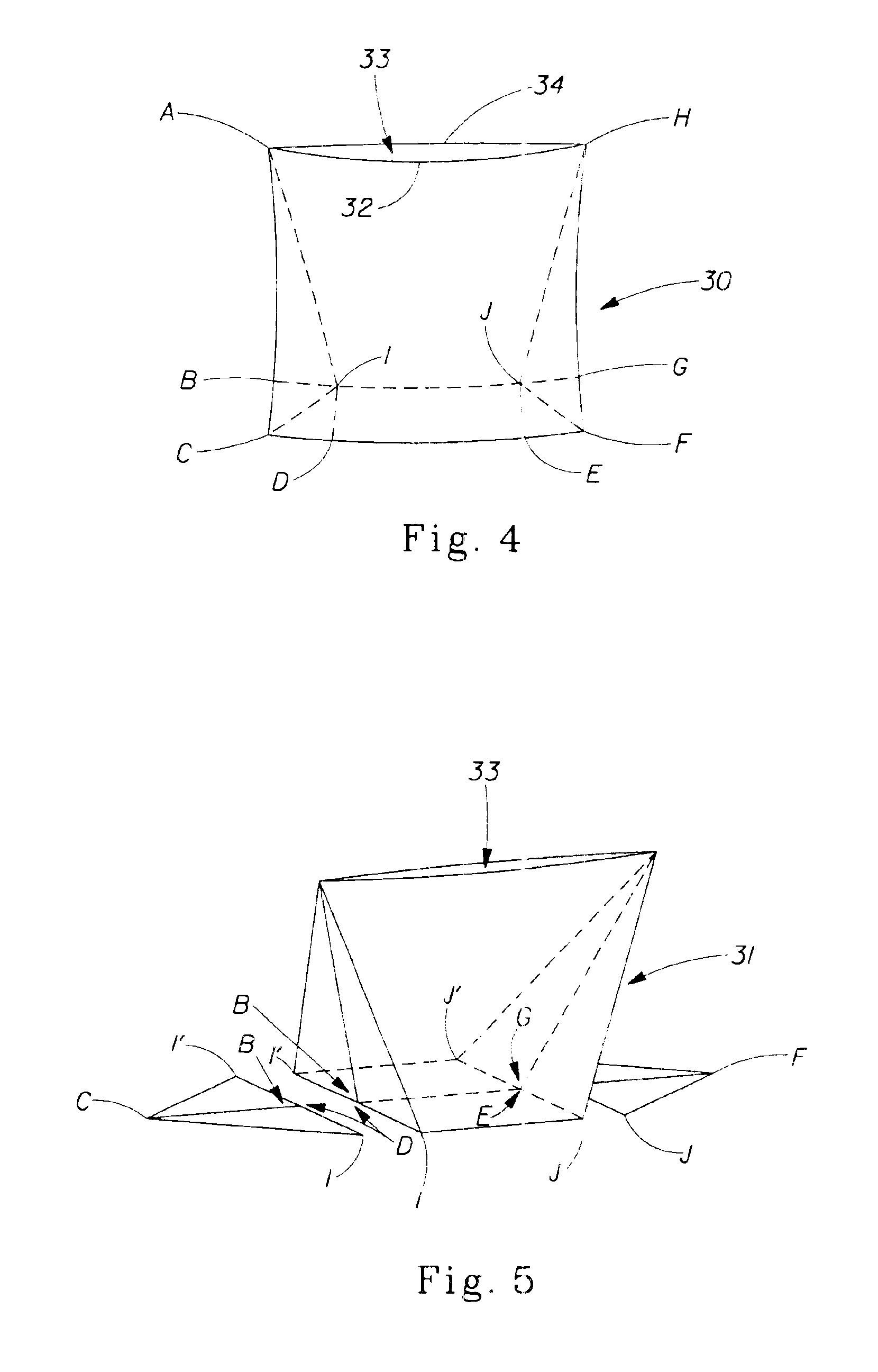

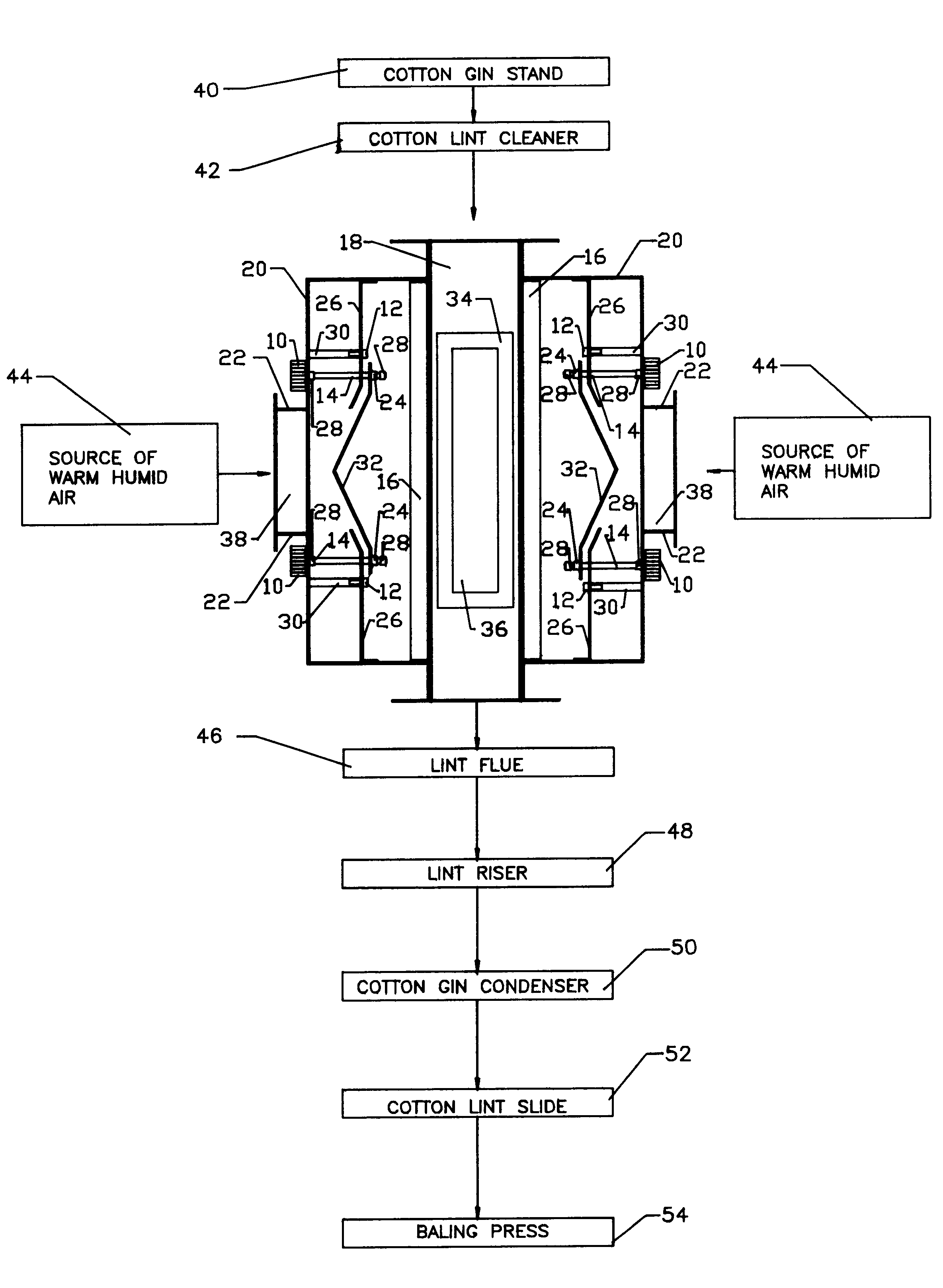

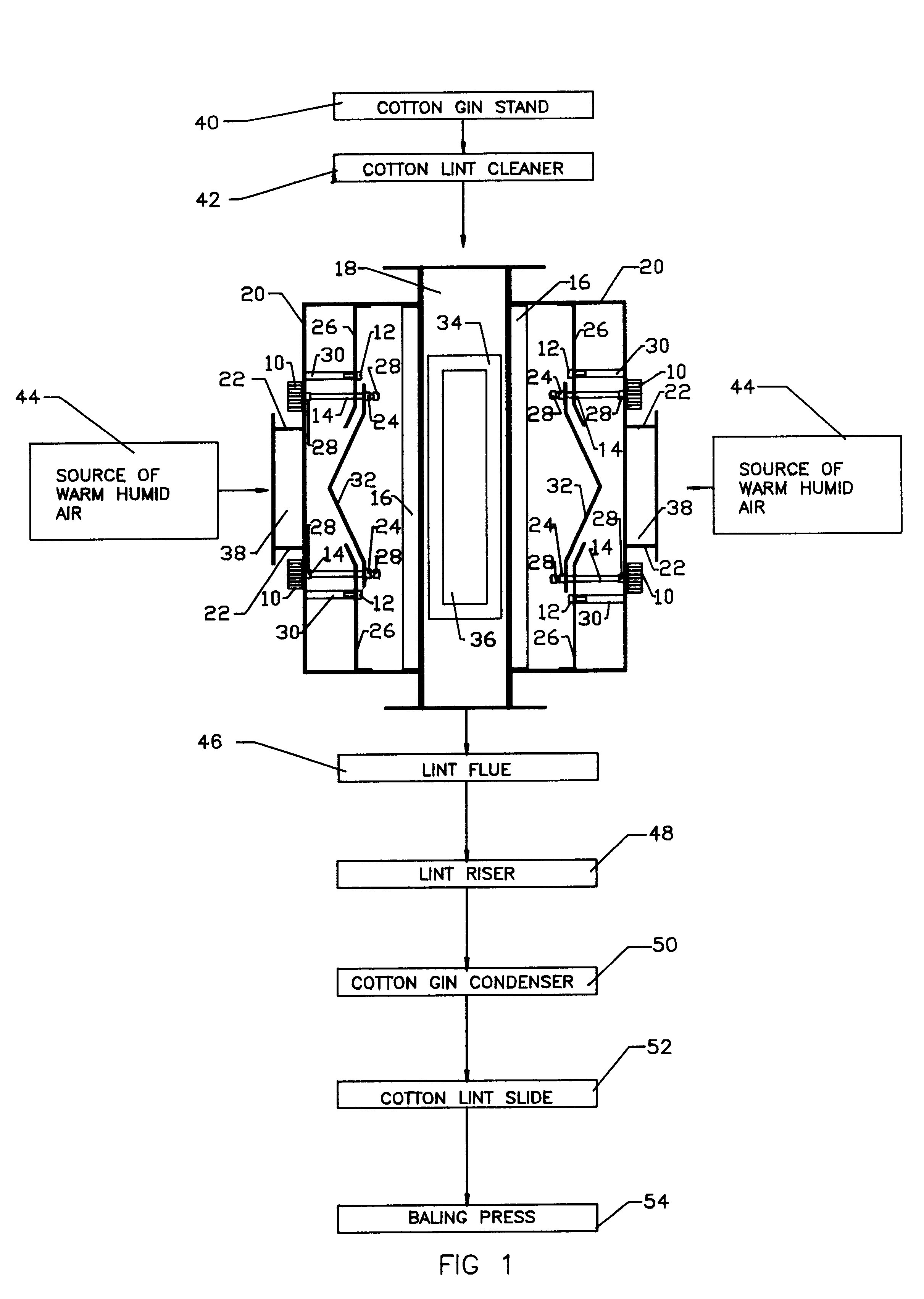

Fiber moisture cell for humidifying cotton and method

InactiveUS6237195B1Save resourcesEnergy efficiencyLubricating devicesVegetable fibre separation from seedsFiberEngineering

Apparatus for humidifying lint cotton in a cotton gin that has a cell arranged for receiving a fiber mass from a lint cleaner and controlling the movement of the fiber over a moist air inlet panel. Warm humid air introduced through an adjustable air inlet panel passes through the moist air inlet panel and, thus, through the cotton under negative pressure raising the moisture content of the fiber mass. The movement of the fiber mass thru the cell is controlled by the amount of warm moist air flowing under pressure through the moist air inlet screen.

Owner:SHOEMAKER THOMAS R

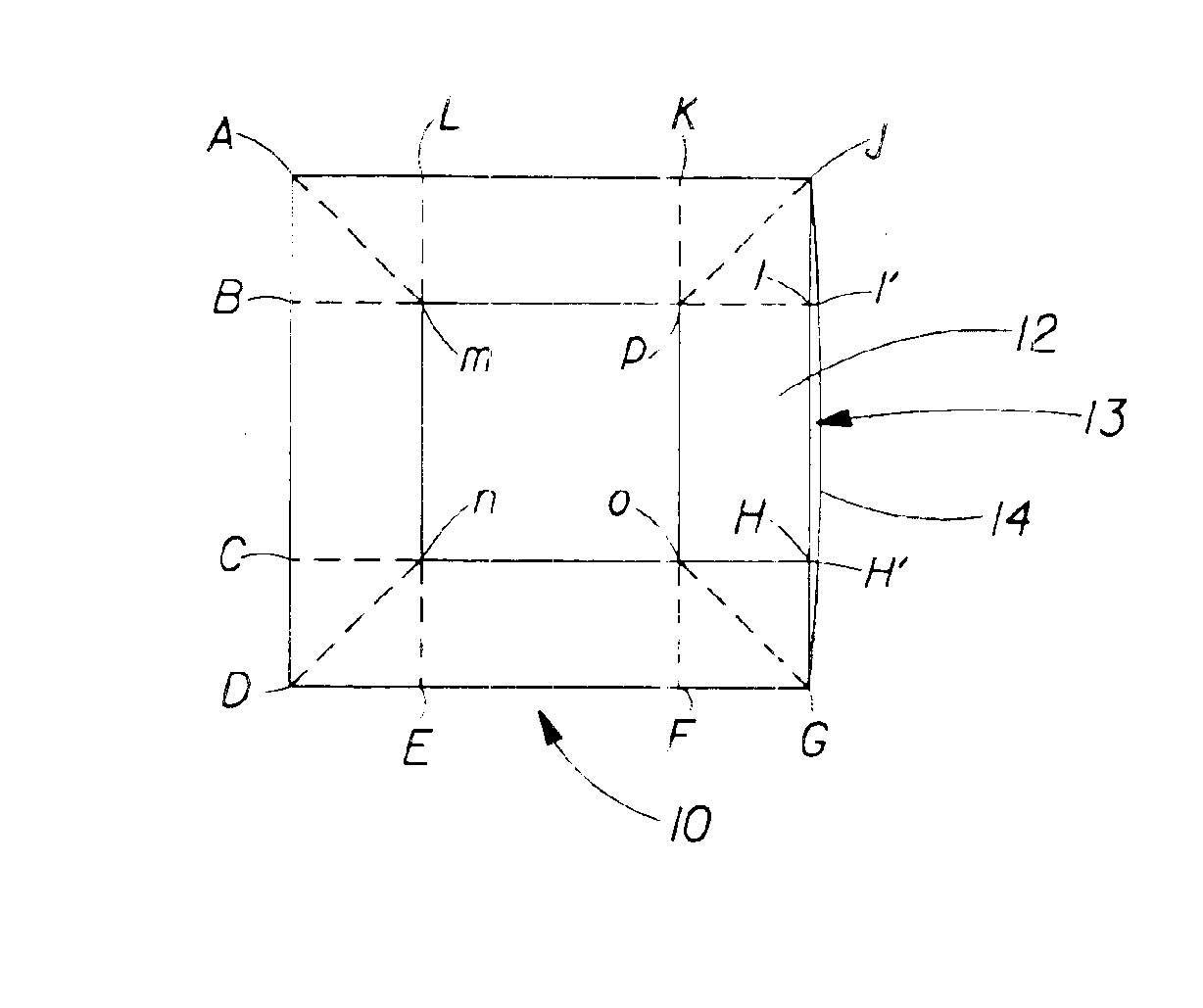

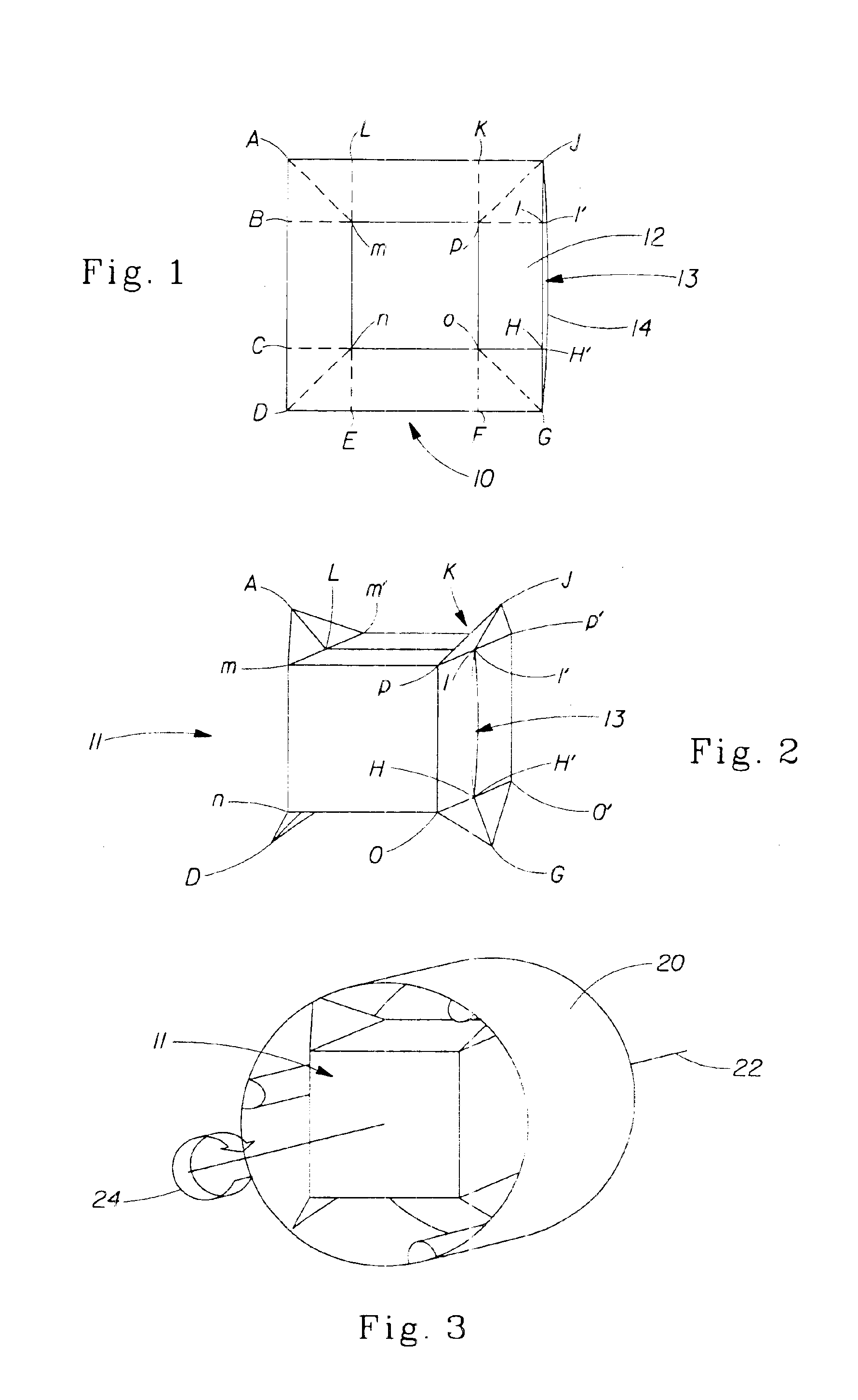

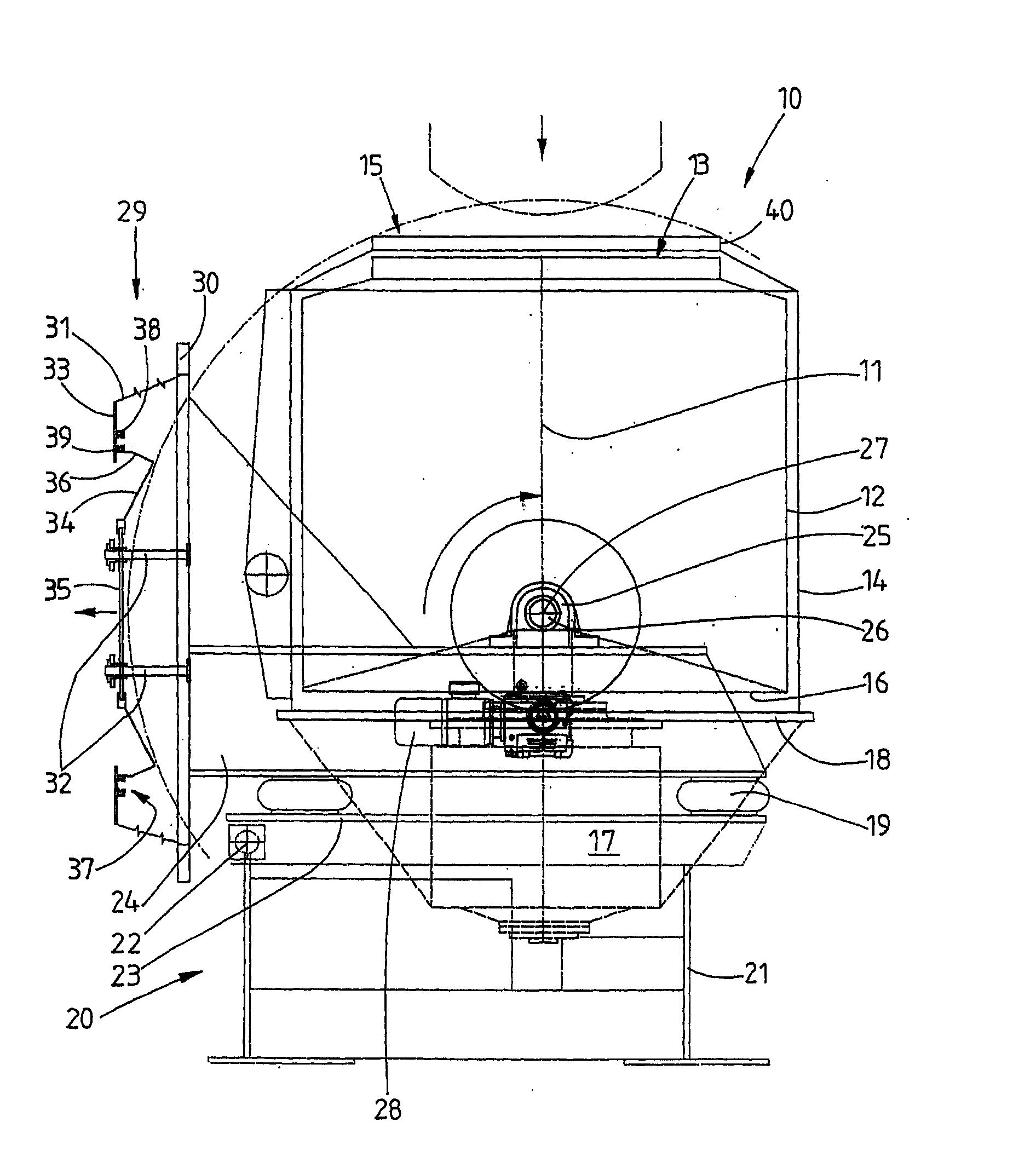

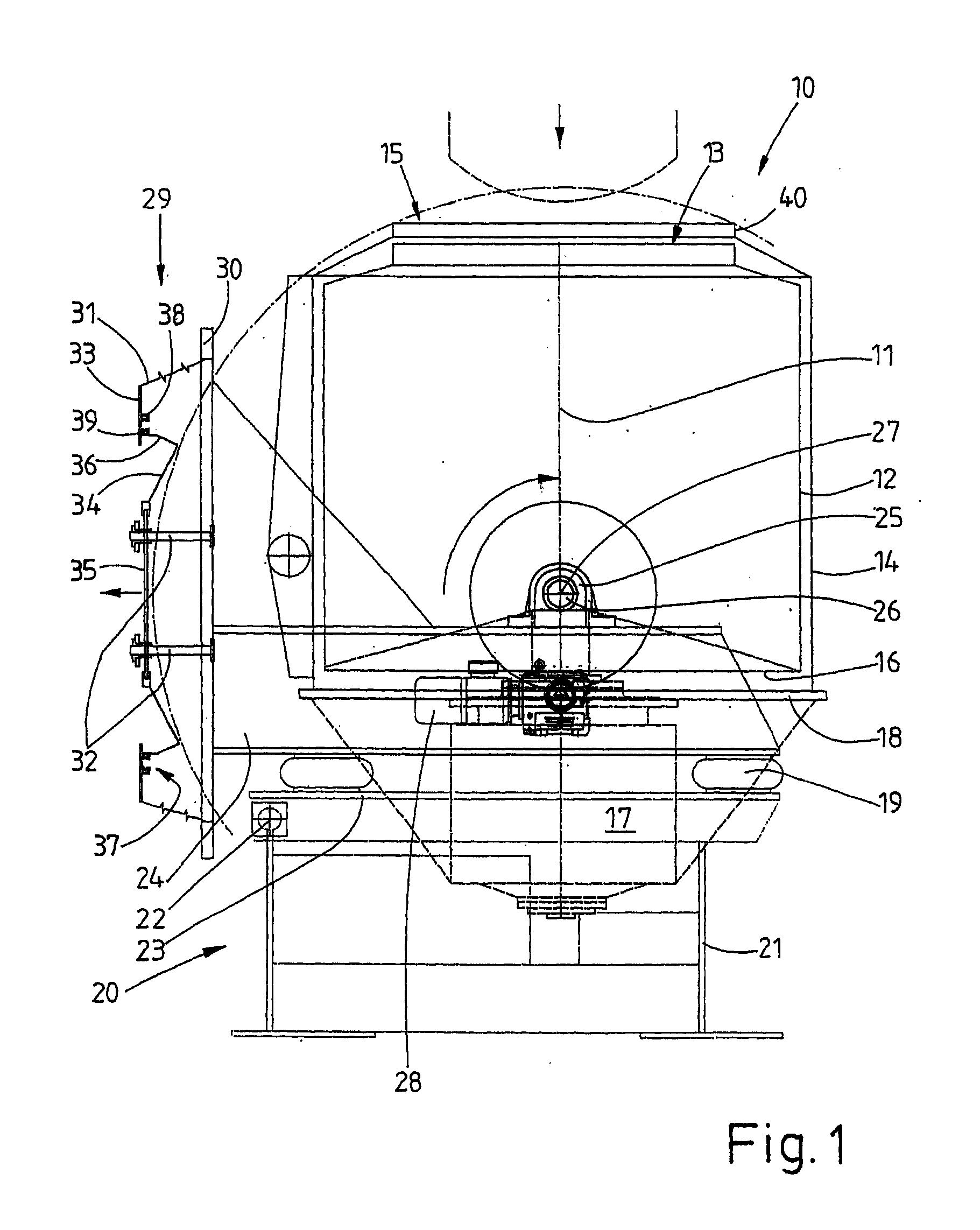

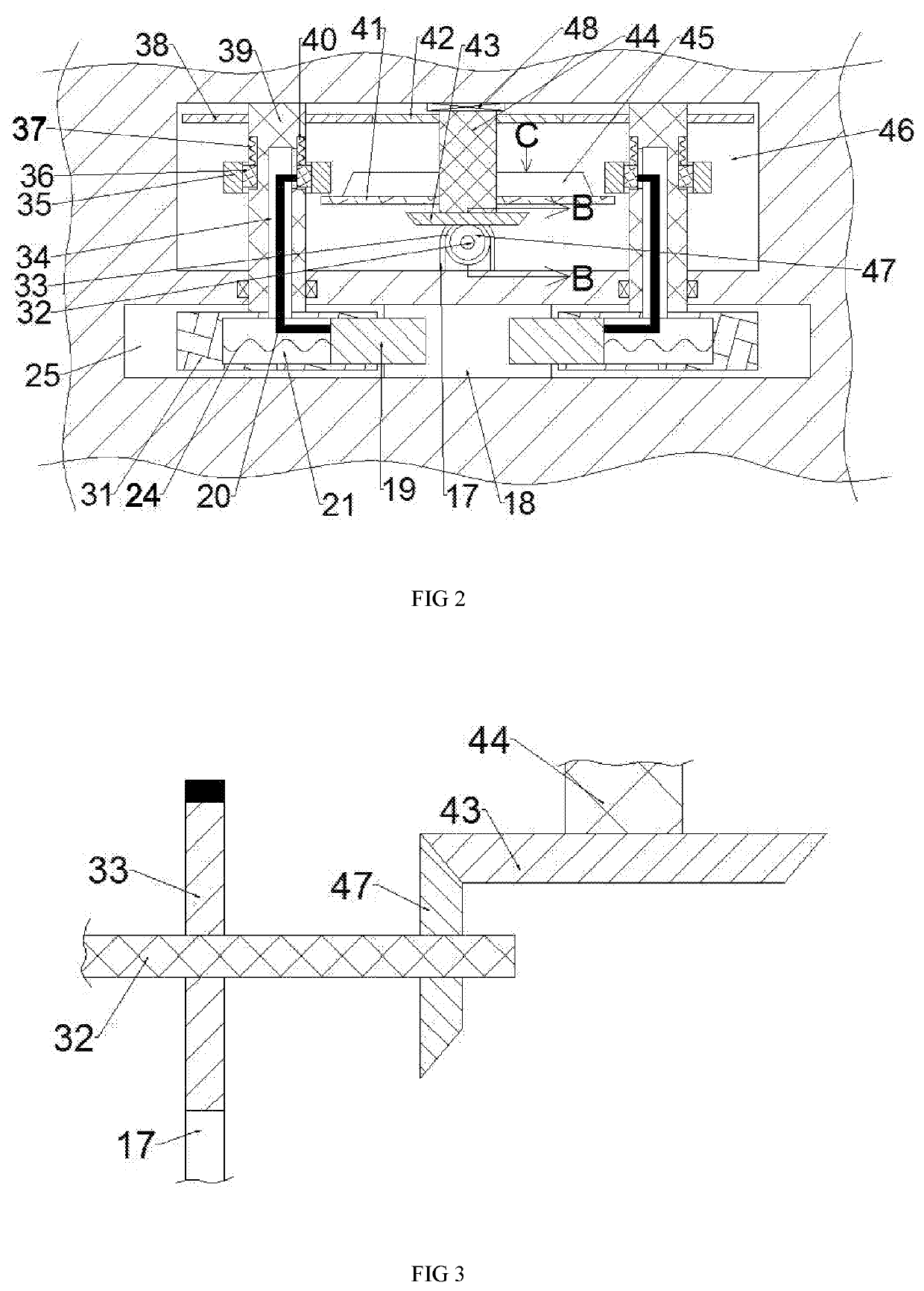

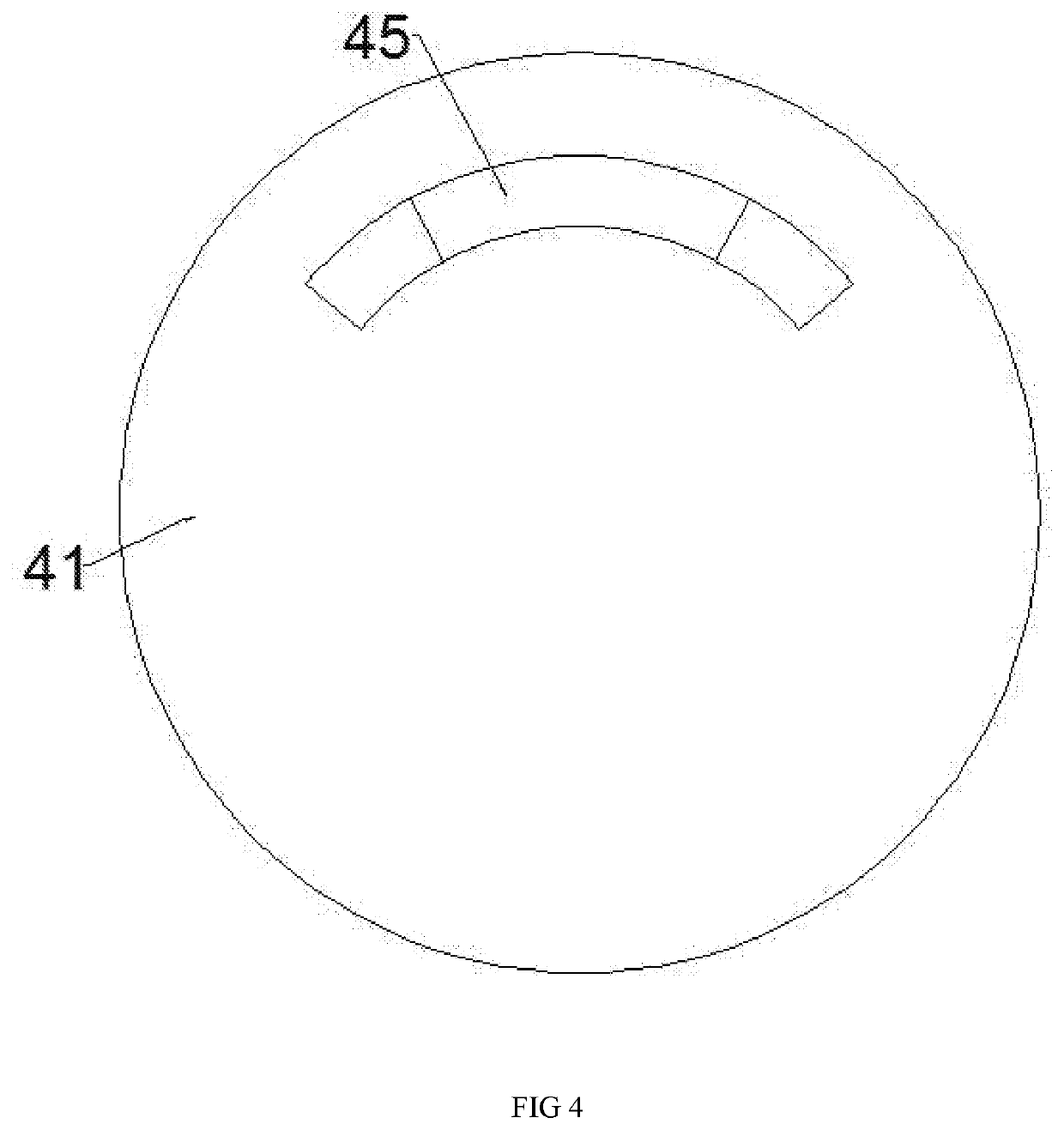

Device and method for wet treating laundry

InactiveUS20070151042A1Avoid small quantitiesSimple designWool fibre washing/scouringOther washing machinesEngineeringLaundry

The washer-extractor (41) having only a single front-end opening (13) of the drums (12, 14). This opening (13) is used for loading and also unloading. The openings (13, 15) can be closed by a door (46). The door (46) can be separated from the drums (12, 14). In addition, the door (46) does not co-rotate when the inner drum (12) is rotationally driven for washing and spinning the laundry. A washer-extractor (41) of this type is characterized by its simple design and by a reliable sealing effected by the door (46), particularly when the washer-extractor (41) is arranged in the dividing wall (43).

Owner:KANNEGIESSER GMBH CO HERBERT

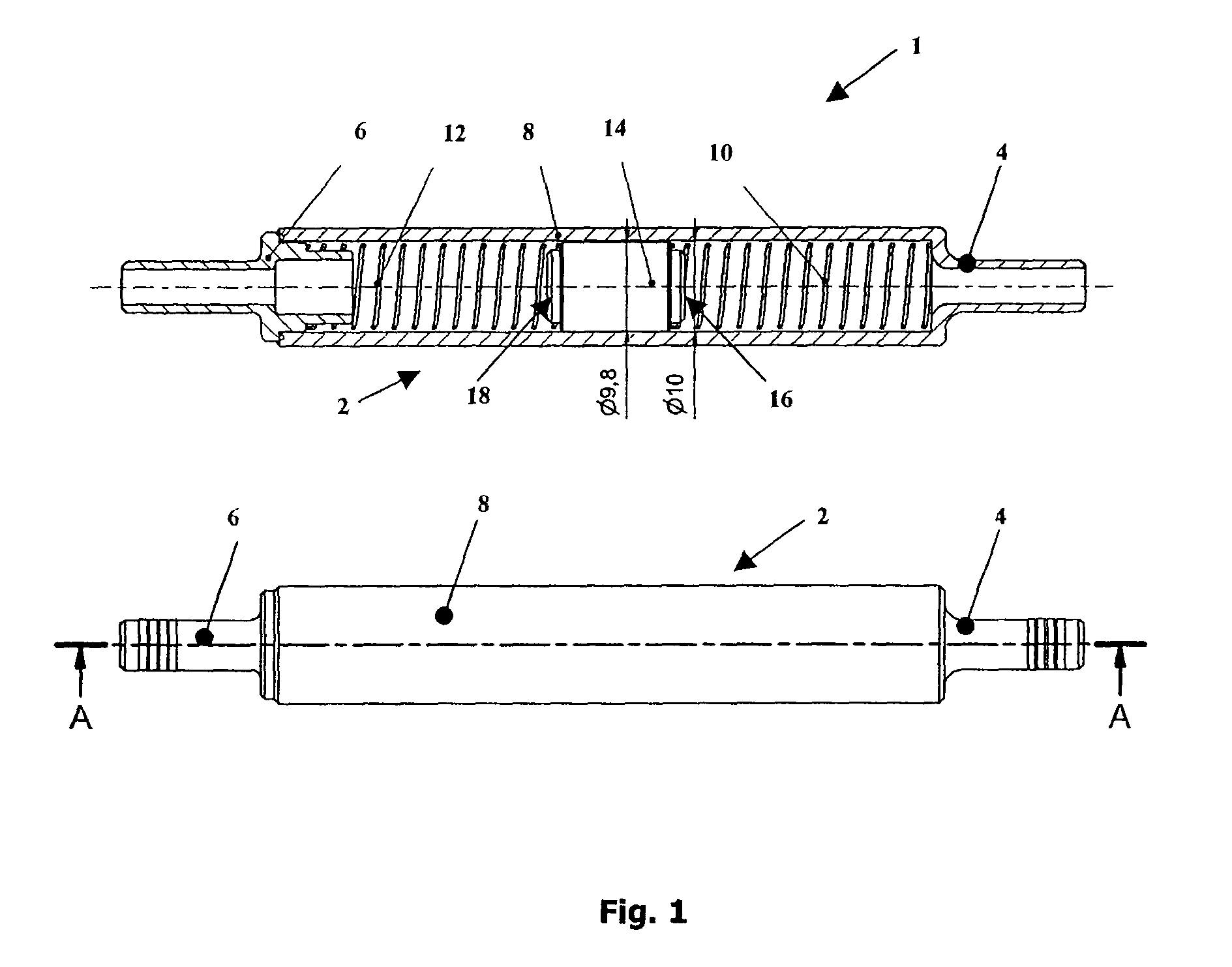

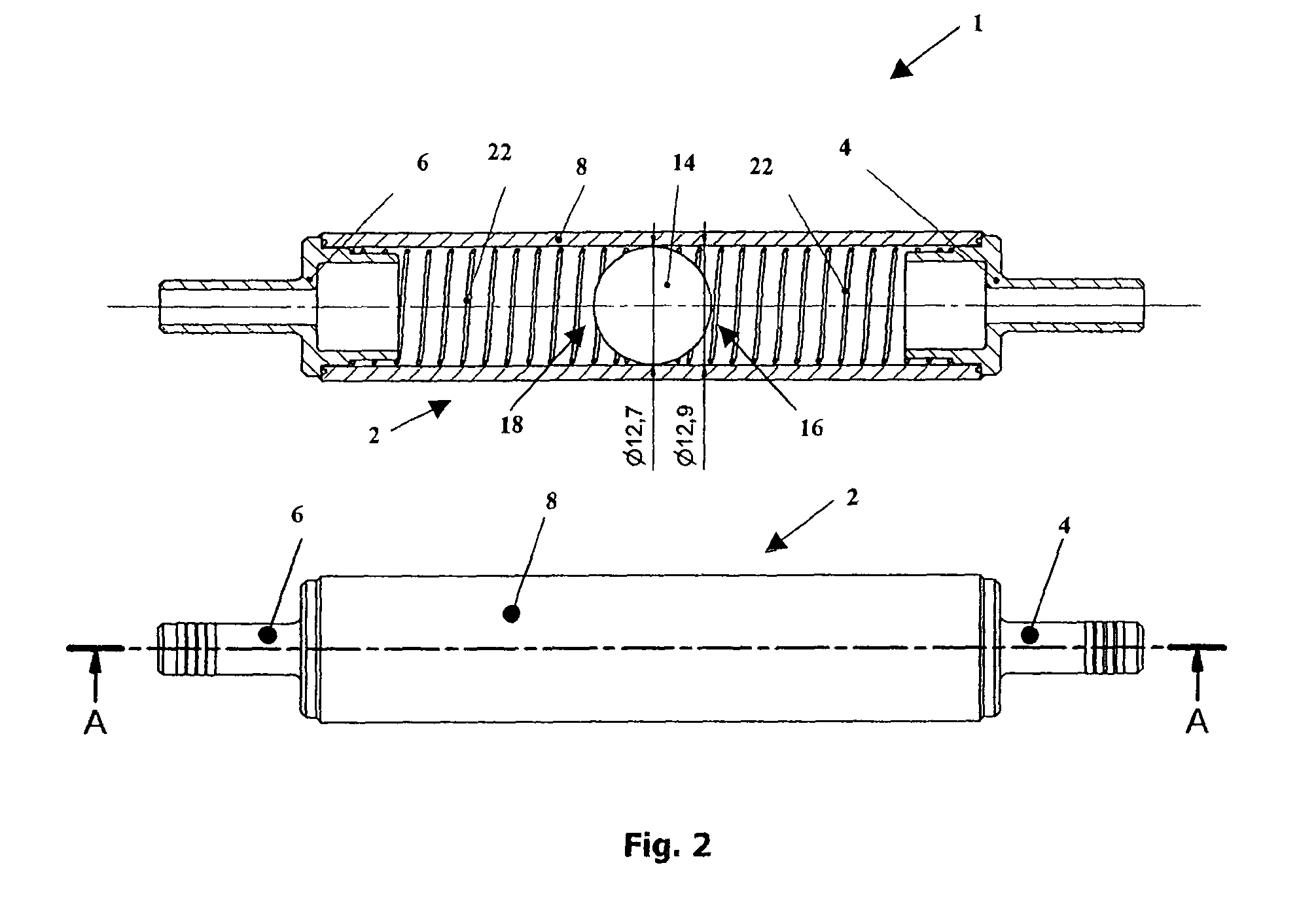

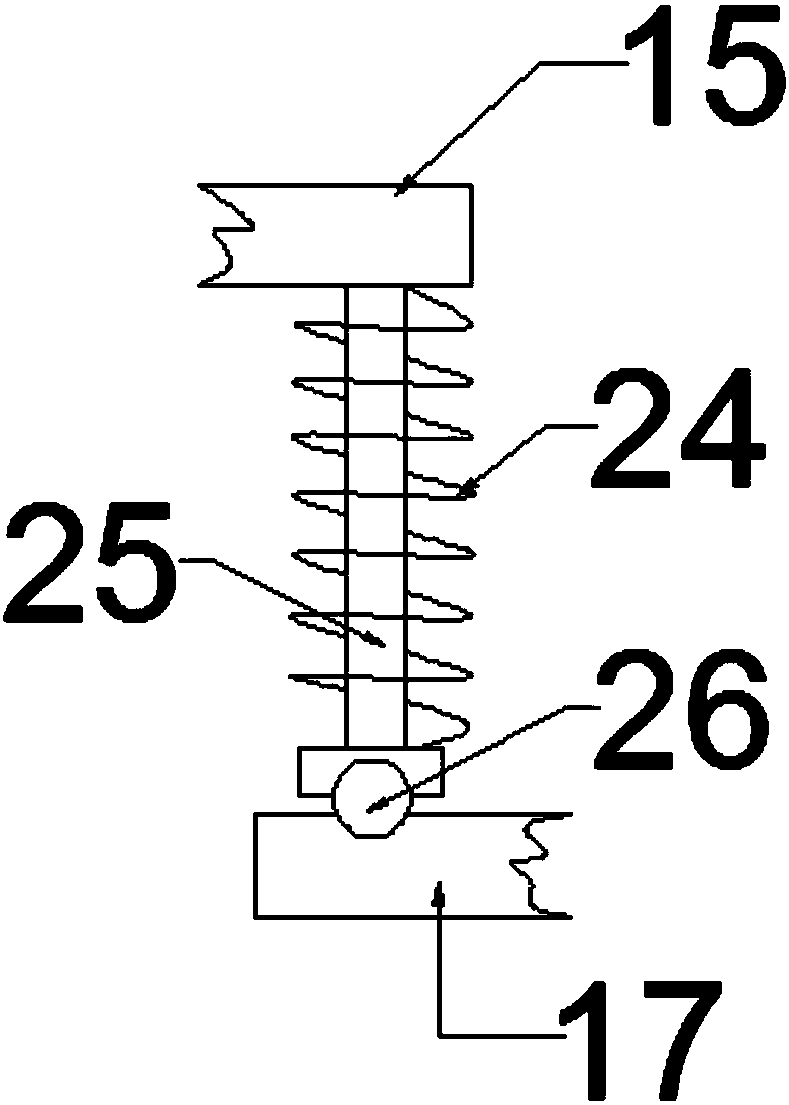

Device for detecting the unbalance of a rotatable component of a domestic appliance

InactiveUS7926313B2Precise and simpleReduce usageWool fibre washing/scouringOther washing machinesSpring forceEngineering

Owner:EMZ HANAUER

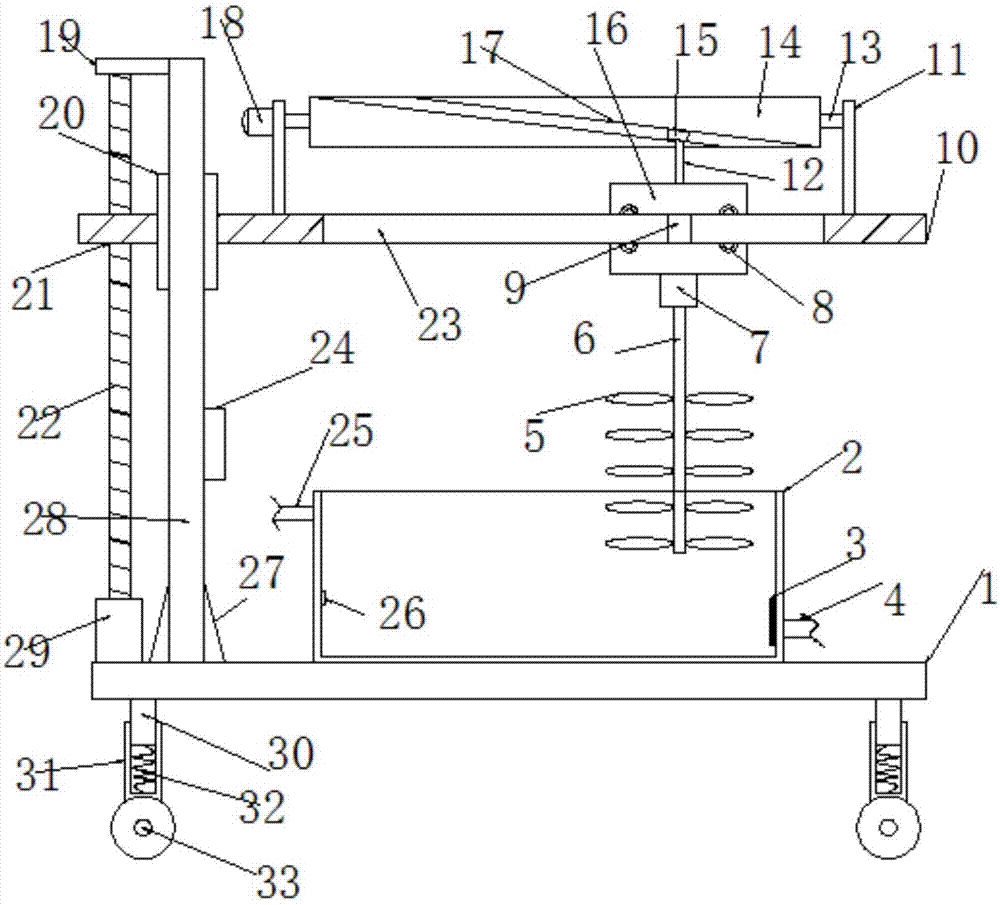

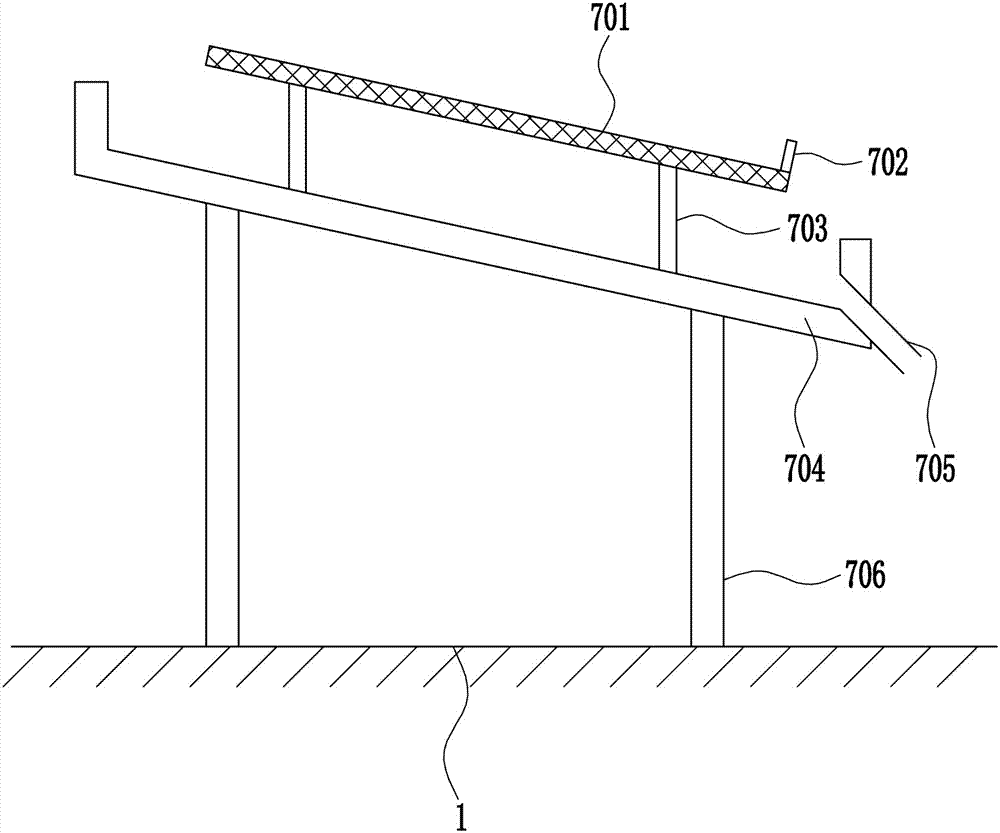

Wool cleaning device for animal husbandry

PendingCN107385519ASimple structureReasonable structureWool fibre washing/scouringClimate change adaptationAnimal scienceAnimal husbandry

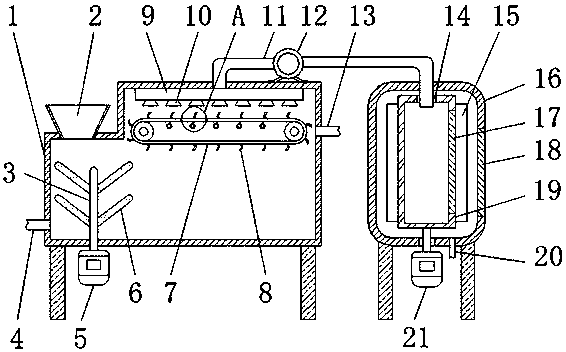

The invention discloses a wool cleaning device for the animal husbandry. The wool cleaning device comprises a base. A cleaning box is fixed to the upper end of the base, an opening is formed in the upper end of the cleaning box, a water inlet pipe is arranged on the left upper side of the cleaning box, a drain pipe is arranged on the right lower side of the cleaning box, a filter plate is arranged at an inner port of the drain pipe, a lifting support column is vertically arranged at the left upper end of the base, and a plurality of reinforcing ribs are arranged between the outer side of the lower end of the lifting support column and the base, so that the mechanical properties of the lifting support column can be improved; the lifting support column is provided with a rectangular cross section, a lifting plate is penetratingly arranged on the lifting support column, and a lifting sleeve with a rectangular cross section is arranged on the lifting plate and is arranged on the lifting support column in a slide fit manner. The wool cleaning device has the advantages that the wool cleaning device is simple and reasonable in structure and convenient to carry, a stirring shaft and stirring blades can move in the left-right directions during cleaning, and accordingly cleaning effects can be improved; the lifting plate can be lifted when materials are fetched in late periods, the stirring shaft and the stirring blades can be taken out of the cleaning box, and accordingly the wool cleaning device is beneficial to improving the material fetching efficiency and high in practicability.

Owner:内蒙古沃尔绒业有限公司

Methods and apparatus for monitoring a washing machine

A control system for a home appliance includes a cabinet, a wash tub positioned within the cabinet and configured to receive laundry therein, and a fill device configured to deliver liquid into the tub. The control system includes a first detecting component configured to detect an amount of the liquid delivered into the wash tub, a second detecting component configured to detect a liquid level in the wash tub, and a controller operatively coupled with the detecting components. The controller is configured to receive signals from the detecting components and calculate an amount of the laundry positioned within the wash tub based on the received signals.

Owner:HAIER US APPLIANCE SOLUTIONS INC

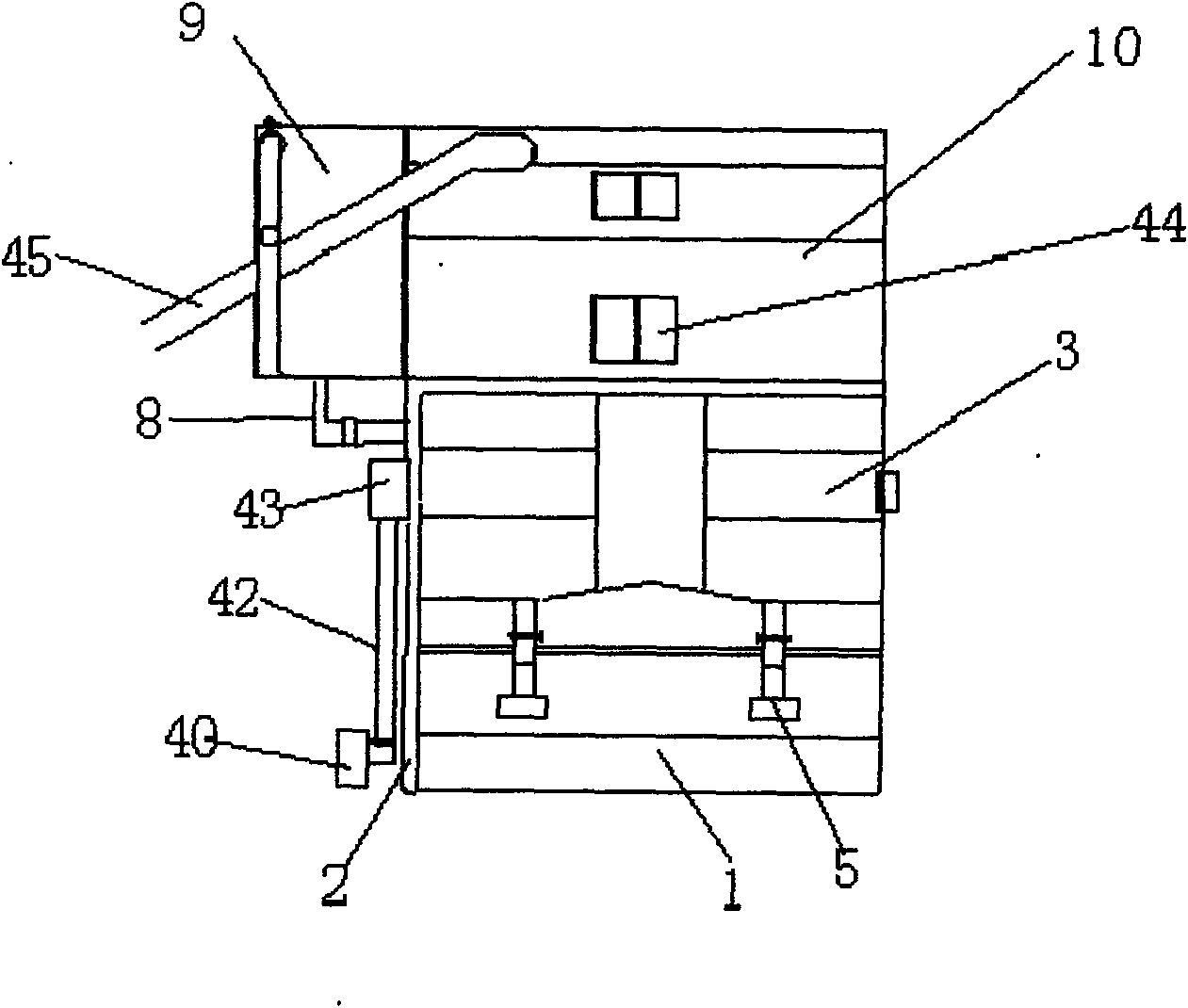

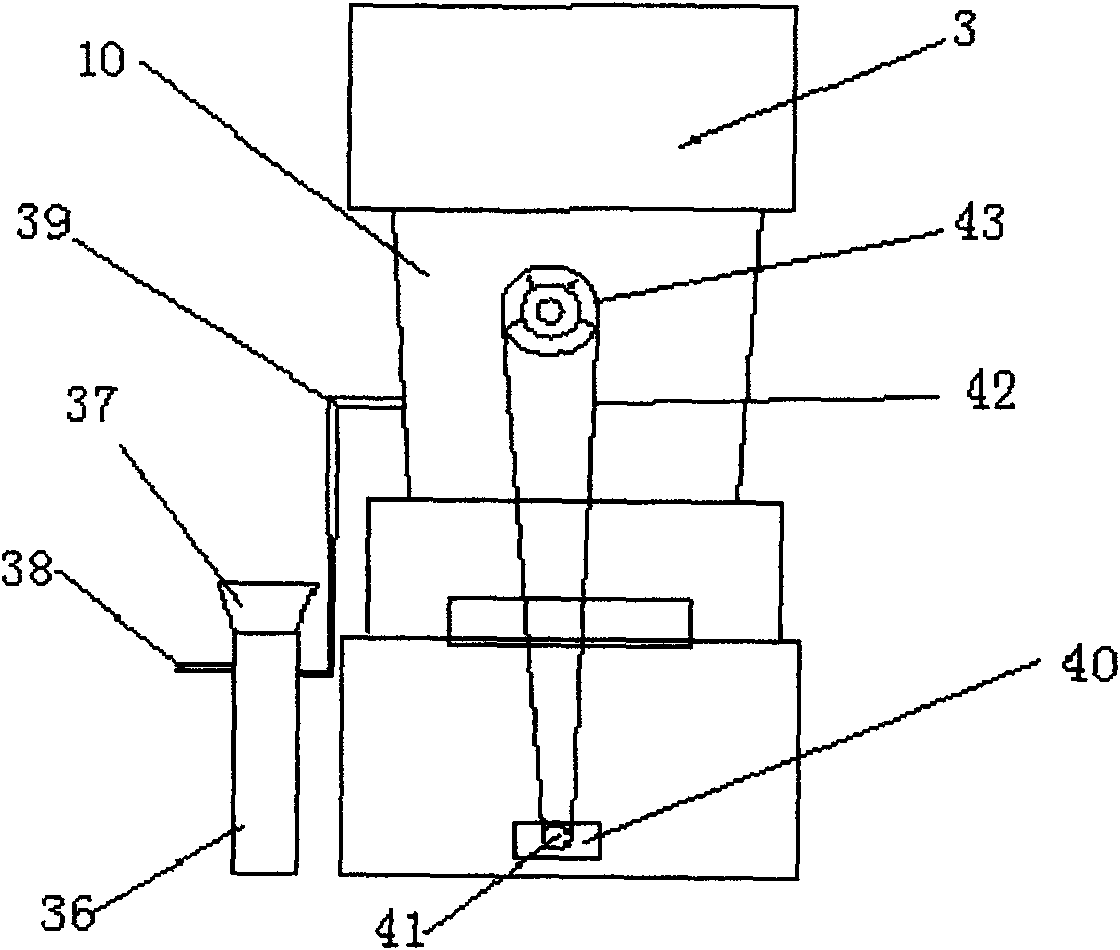

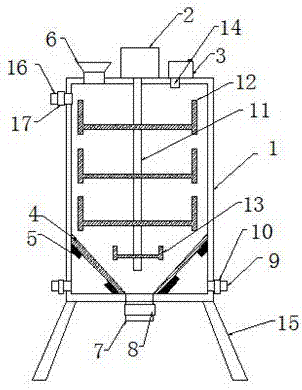

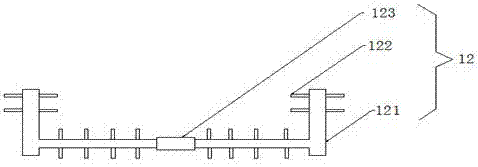

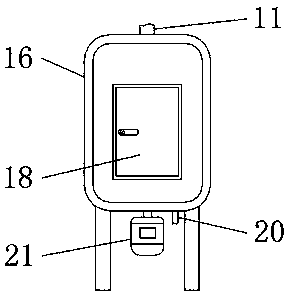

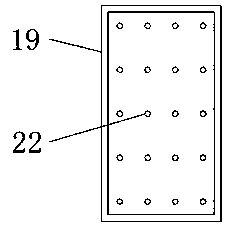

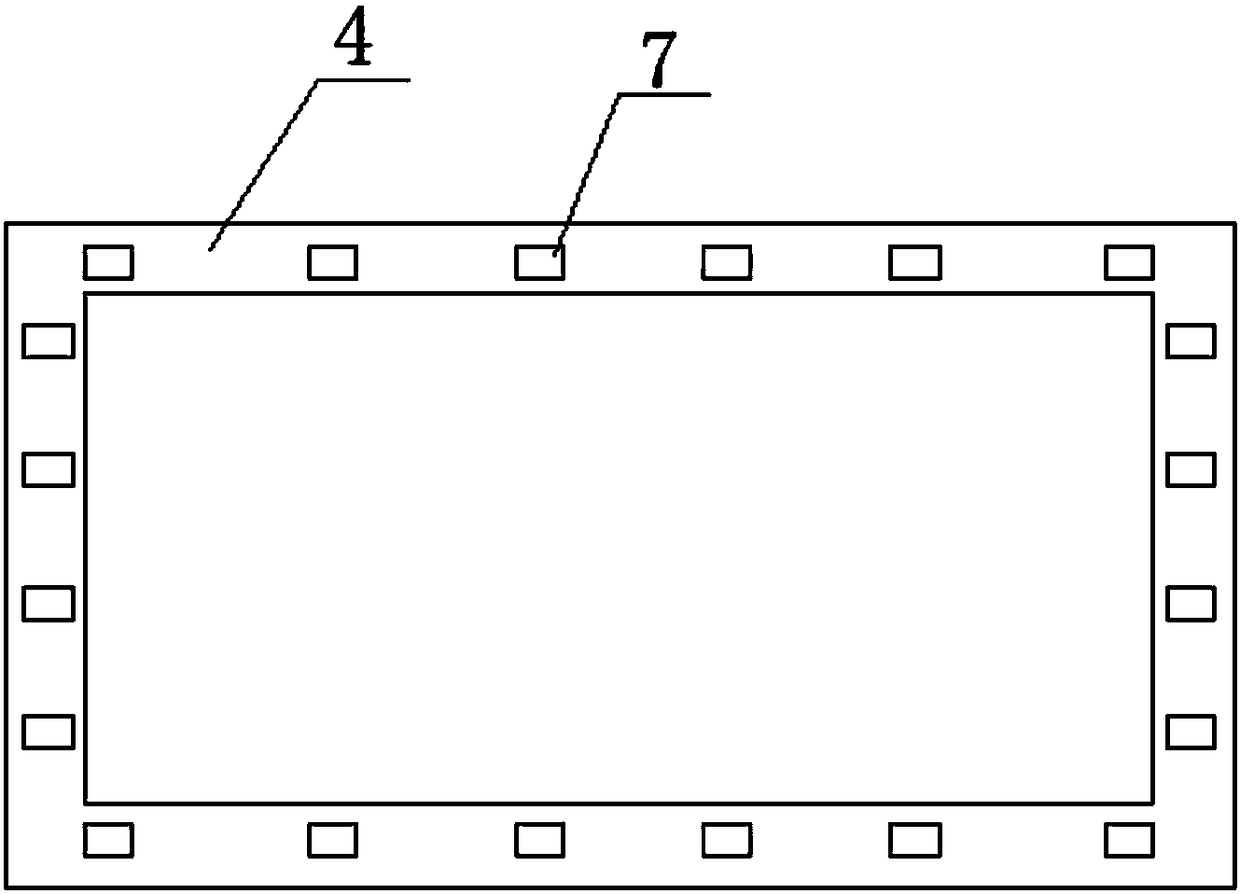

Wool cleaning equipment for animal husbandry

ActiveCN106283205AExtended service lifeIncrease salesWool fibre washing/scouringEngineeringAnimal husbandry

The invention relates to wool cleaning equipment and in particular to wool cleaning equipment for animal husbandry. The technical problem to be solved by the invention is to provide wool cleaning equipment for animal husbandry with the advantages of good cleaning effect and high cleaning speed. In order to solve the technical problem, the wool cleaning equipment for animal husbandry, provided by the invention, comprises a bottom plate, a cleaning pool, a water outlet pipe, a valve, a right rack, a fixing block, a top plate, a sliding rail, a slide block, a moving plate, a rotating motor, a small belt pulley, a first rotating shaft and the like, wherein the left side of the top of the bottom plate is connected with the cleaning pool in a bolted connection manner; the water outlet pipe is arranged at the bottom of a left wall of the cleaning pool; the valve is arranged on the water outlet pipe; and the right rack is welded at the right end of the top of the bottom plate. According to the invention, the effects of good cleaning effect and high cleaning speed are achieved, the wool cleaning equipment is simple in structure and convenient to operate, the labor amount of herd owners is saved, the working efficiency is improved, and the cleaning effect is good, so that the wool quality is high.

Owner:吴波

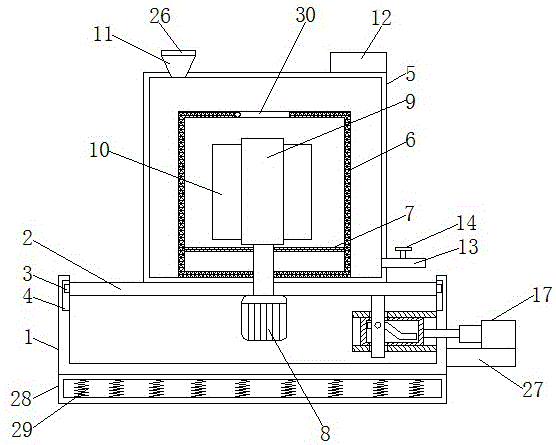

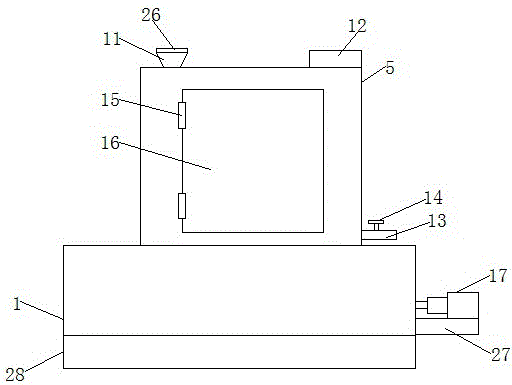

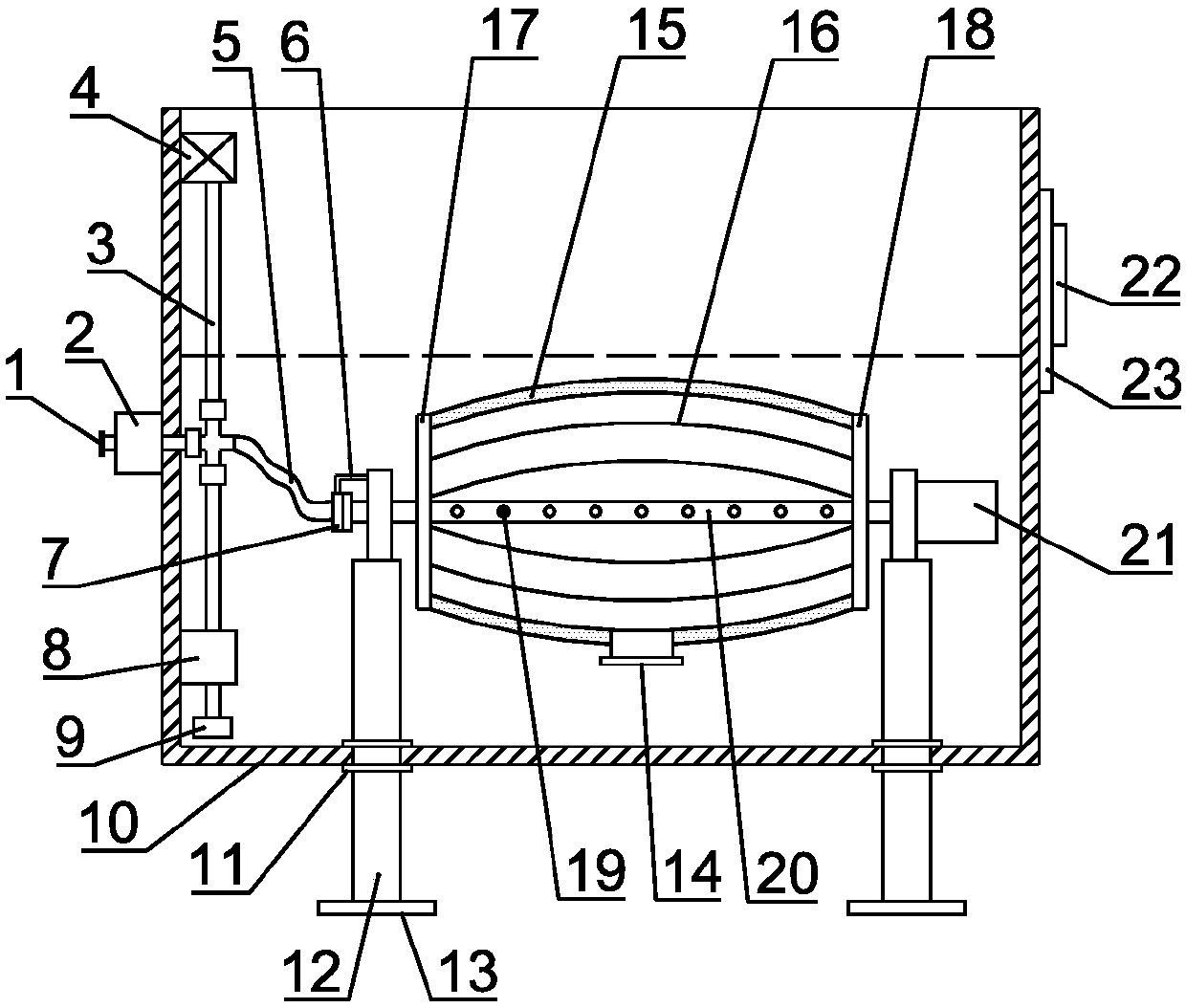

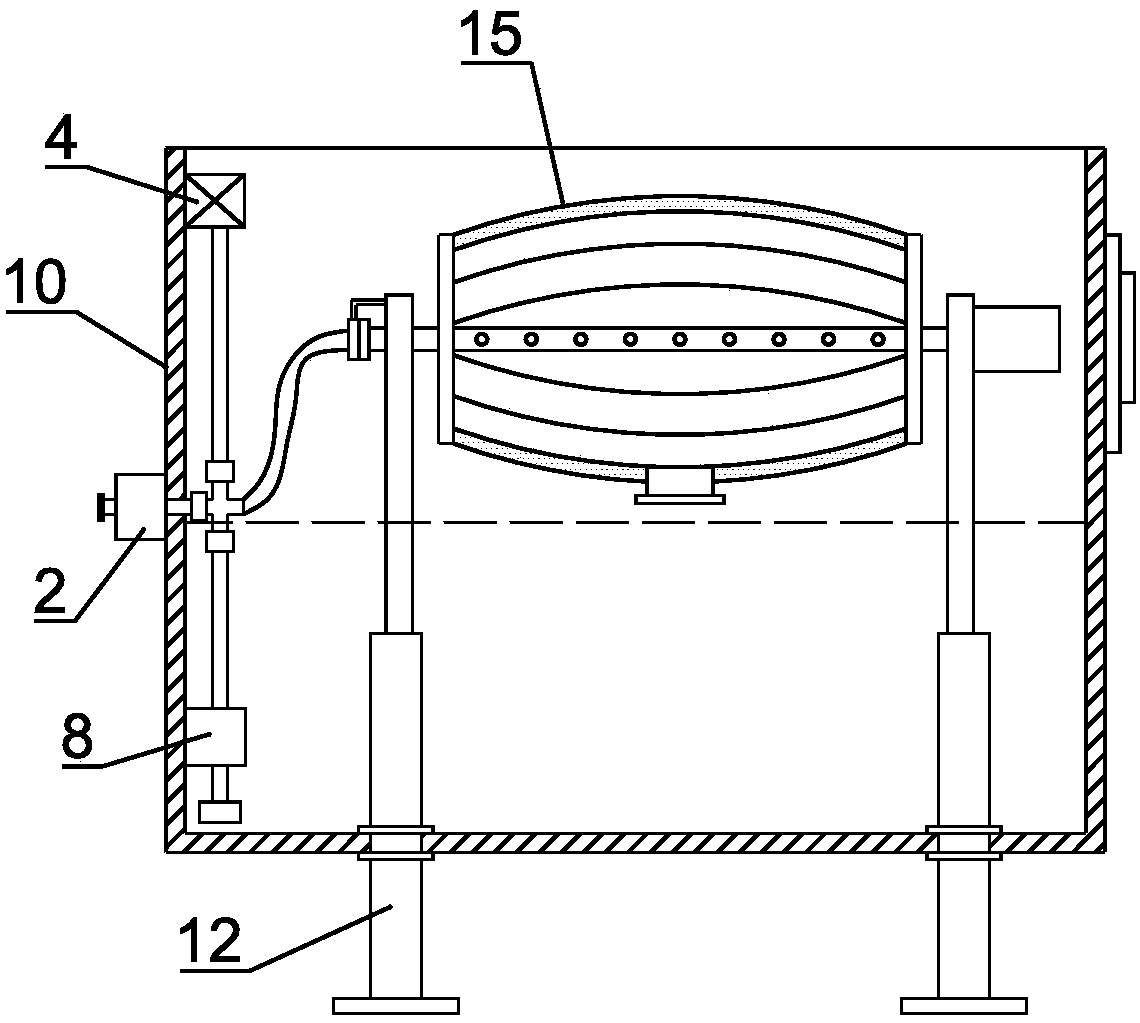

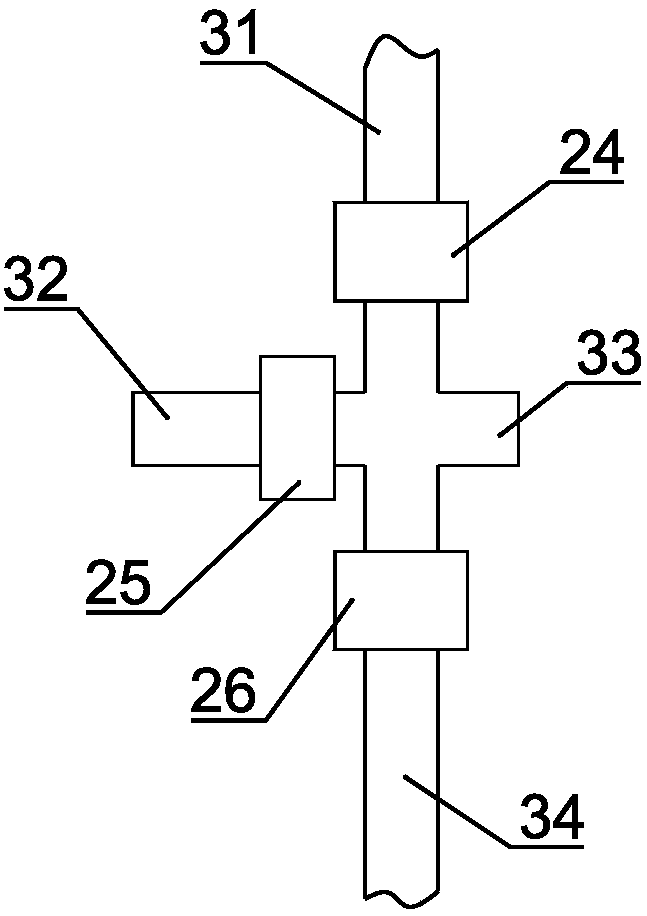

Cleaning equipment capable of dewatering for down feather processing

InactiveCN107841794AImprove efficiencyReduce labor intensityWool fibre washing/scouringBiochemical engineeringDown feather

The invention discloses cleaning equipment capable of dewatering for down feather processing, and belongs to the field of down feather processing equipment. The cleaning equipment capable of dewatering for down feather processing comprises an outer barrel and an inner barrel, wherein the inner barrel is arranged in the outer barrel; an end cap is arranged on the top of the outer barrel; an elasticsupporting device is arranged on the lower side of the outer end of the guide rod; a throw-drying motor is arranged in the center of the bottom end of the outer barrel; an output shaft of the throw-drying motor penetrates through the outer barrel and is fixedly connected with the center of the bottom end of the inner barrel; a stirring motor is fixedly arranged in the center of the upper end surface of the end cap; an output shaft of the stirring motor is connected with a stirring shaft; the stirring shaft is vertically arranged in the inner barrel; stirring blades are arranged on the stirring shaft; mounting plates are symmetrically arranged on the outer side of the outer barrel in the left-right direction; a supporting rod is vertically arranged on the upper side of each mounting plate;a water outlet tube is arranged in the right lower direction of the outer barrel; and a water outlet valve is arranged on the water outlet tube. The cleaning equipment is reasonable in structure andconvenient to operate; cleaning and throw-drying can be integrated; and the cleaning efficiency is high.

Owner:季元吉

Down feather cleaning machine

InactiveCN102115916AEasy to collectWool fibre washing/scouringApparelEngineeringMechanical engineering

The invention discloses a down feather cleaning machine, comprising a down feather cleaning device fixedly arranged on a draining pool. The down feather cleaning device comprises a cleaning cavity arranged on a support of the draining pool, the upper part of the cleaning cavity is provided with a discharge opening, a feed opening is communicated with a feed pipe, the lower part of the cleaning cavity is provided with a water outlet, the cleaning cavity is internally provided a rotation shaft rotating under the drive of a driving device, stirring rods are uniformly distributed on the rotation shaft, and the upper part of the cleaning cavity is further provided with a water inlet connected with a water tank on one side of the cleaning cavity. The down feather cleaning machine is characterized in that the upper part of the cleaning cavity is further connected with a feed device. A down feather loosening device is arranged below distribution openings of an outer cavity, the outer cavity is internally provided with a down feather hair loosening device, and the lower part of an air compartment is connected with an oscillating mechanism. The down feather cleaning machine can be used for evenly and smoothly conveying down feathers inside a feed conveying pipeline into processing equipment as required and also can be used for removing impurities and dust inside the down feathers so as to enable the down feather to be cleaner.

Owner:广东羽顺羽绒制品有限公司

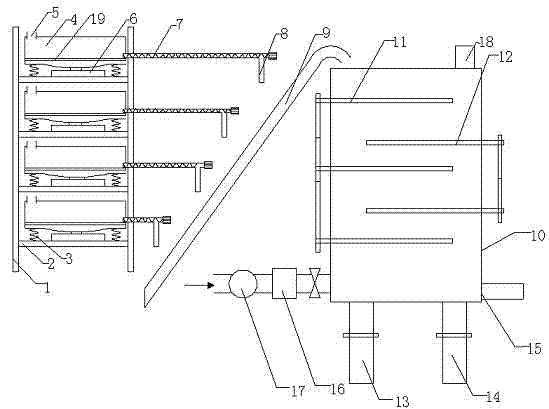

Wool washing device

ActiveCN104499059ASimple structureReasonable designAnimal fibre deburring machinesWool fibre washing/scouringEngineeringAir blower

The invention discloses a wool washing device comprising impurity removing equipment and washing equipment. The impurity removing equipment comprises a support frame, a plurality of support plates are arranged on the support frame, a vibrating box is arranged on each support plate through vibrating springs, a spiral discharge pipeline is connected to one side of each vibrating box for discharging, a lifting conveyor belt is arranged on one side of the impurity removing equipment, a cabinet used for carrying materials conveyed by the lifting conveyor belt is arranged on one side of the lifting conveyor belt, a plurality of left stirring rods and a plurality of right stirring rods are inserted in the cabinet, a wool outlet is formed in one side of the lower end of the cabinet, a heater is connected with the other side of the lower end of the cabinet through a pipeline and a valve, and an air blower is connected to one side of the heater. The wool washing device has the advantages that the wool washing device is simple in structure, reasonable in design, small in occupied space and convenient to operate, wool can be cleaned up by the device, and steps such as soaking, washing, spin-drying and drying are completed in the same cabinet.

Owner:吴江市鼎裕纺织有限公司

Cleaning machine for down by means of vibration cleaning

ActiveCN106567135AReduce economic consumptionEasy to cleanWool fibre washing/scouringEngineeringWater tanks

The invention provides a cleaning machine for down by means of vibration cleaning and relates to the field of down processing. The cleaning machine for down by means of vibration cleaning comprises a base; the base is provided transversely with a movable plate therein; two sides of the movable plate are fixedly connected with first slide blocks; two sides of the inner wall of the base are provided with first slideways matching with the first slide blocks; the top part of the movable plate is fixedly connected with a water tank; the top part of the water tank extends to the outside of the base; the bottom of the inner wall of the water tank is fixedly connected with a leakage net cage; a leakage net is transversely and fixedly connected to the inside of the leakage net cage; the top part of the leakage net cage is movably connected with a movable cover plate; a motor is fixedly connected to the middle shaft of the movable plate bottom; the rotating shaft of the motor successively passes through the movable plate, the leakage net cage and the leakage net and extends to the top of the leakage net. The cleaning machine for down by means of vibration cleaning has good cleaning effect and high efficiency, reduces economic consumption for users and saves time and labor.

Owner:临沂广源土地发展有限公司

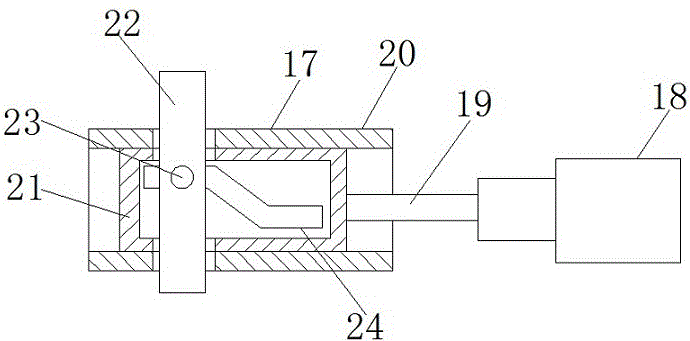

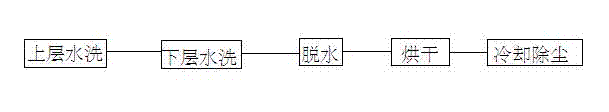

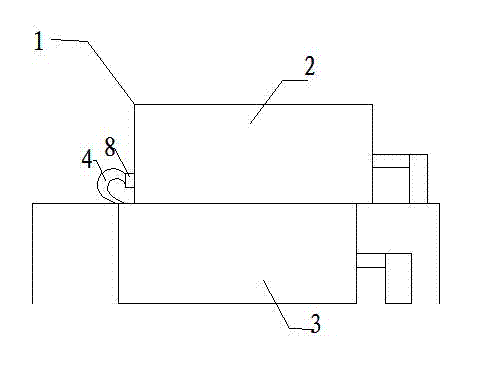

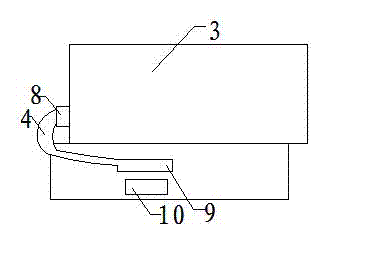

Preparation equipment for high-quality down feather and method thereof

InactiveCN102787367AImprove cleanlinessQuick killWool fibre washing/scouringHeatPulp and paper industryPollution

The invention provides preparation equipment for high-quality down feather and method thereof. The preparation equipment comprises a dehydrator and a cooling dust remover, as well as a double-layered washing machine including both an upper layer washing machine box body and a lower layer washing machine box body, and further comprises a dryer with a steam pipeline inserted therein, wherein a plurality of steam holes are formed in the steam pipeline. The preparation method comprises the following steps: (1) washing in the upper layer; (2) washing in the lower layer; (3) dehydrating; (4) drying; and (5) cooling and removing dust. According to the invention, as the washing machines in the upper and the lower layers are adopted for washing, the cleanliness of down feather is improved; as the dryer adopts the steam and stuffy drying manners in the drying process, sulfurous acid in feathers can be quickly reduced to bacillus for killing, and secondary pollution is avoided; and 100KG raw materials can be washed in only 85 minutes, and the weight productivity within 12 hours can reach 750KG, so that the production efficiency is high.

Owner:江苏欣隆羽绒有限公司

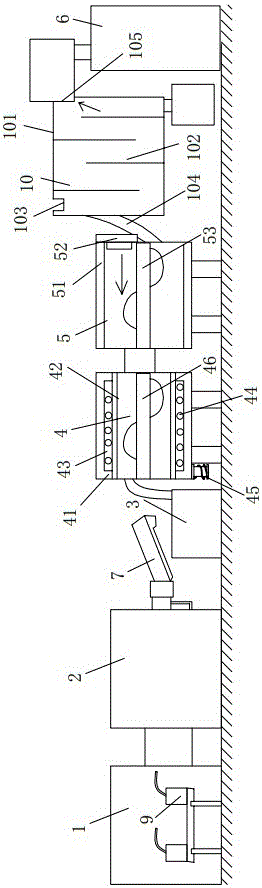

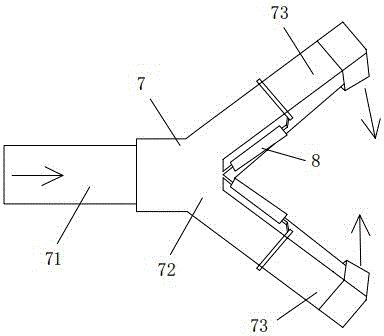

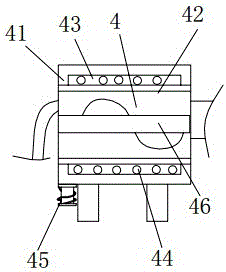

Down processing production line and down processing technology using same

ActiveCN106591958AWon't hurtEasy to operateWool fibre washing/scouringProduction lineProcess engineering

The invention discloses a down processing production line and a down processing technology using the same. The down processing production line comprises a cold water down washing machine, a hot water down washing machine, a centrifugal dehydrator, a steam drying device, an air-cooled cooling machine, a down sorting machine and a down collection device which are connected in sequence. The hot water down washing machine delivers down and water therein to the centrifugal dehydrator through a homogenous flow device, wherein the homogenous flow device comprises a drainage pipe, a three-way pipe and two discharging pipes. The centrifugal dehydrator is arranged below the discharging pipes. The steam drying device comprises an inner drum and an outer drum, a steam heating cavity is arranged between the inner drum and the outer drum, and a steam heating device is arranged in the steam heating cavity and is used for controlling steam heating quantity of the steam drying device through a control valve arranged outside the outer drum. The full-automatic efficient down processing production line and the down processing technology using the same have the advantages that down processing efficiency is improved, and fluffy and soft down is produced.

Owner:ANHUI FANGXIANG DOWN & FEATHER PROD CO LTD

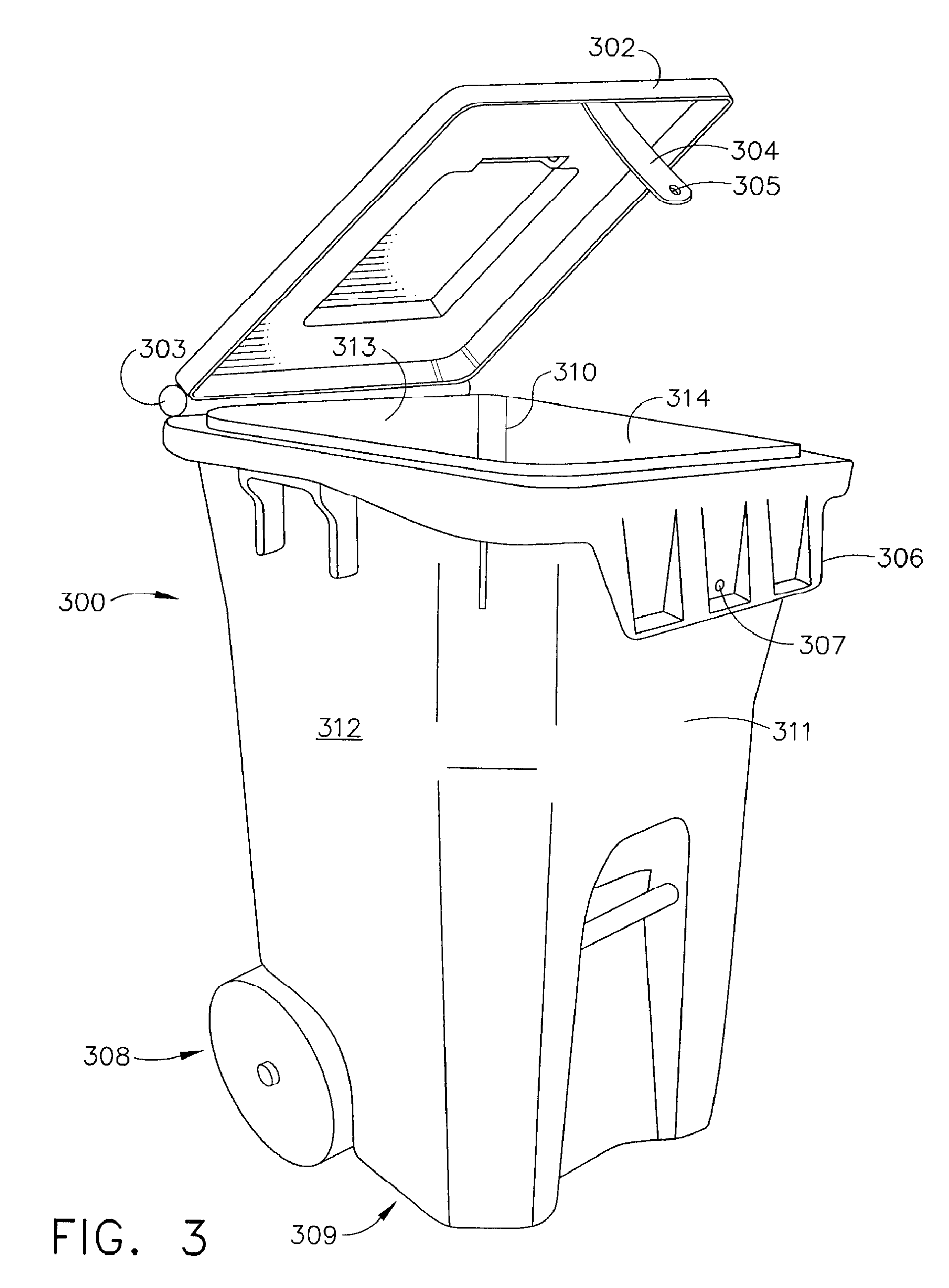

Method of collecting, transporting and cleaning soiled textiles

A method of collecting soiled textiles to be cleaned, comprising the steps of providing a container having an open end, a closed end, and sides extending therebetween, providing a sling having an open end, a second end, and sides extending therebetween disposed in and supported by said container, providing a water soluble bag having an open end, a closed end, and sides extending therebetween and made of a plastic film having a thickness of at least 1.3 mils, wherein said bag dissolves in water at a temperature of 165° F. in less than about 250 seconds, does not dissolve in water at a temperature of 85° F. in 7 days, being capable of containing at least 175 lbs. of soiled textiles, and having a capacity of at least 50 gallons, wherein said bag is disposed in and supported by said sling, and wherein soiled textiles deposited in said container are contained in said bag.

Owner:CINTAS CORP SERVICES INC

Novel wool cleaning device

The invention discloses a novel wool cleaning device, which comprises a box body, a deceleration motor, a filter screen and a rotating rod. The deceleration motor is fixedly installed at the center of the outer surface of the top of the box body. The feed port, the deceleration motor is fixed with a detergent liquid storage box on the side away from the feed port, the bottom side wall and the bottom of the box are provided with relative inclined filter screen fixing seats, and the rotating rod The first stirring rod and the second stirring rod are welded, the upper side wall of the box is provided with a water inlet, and the bottom side wall of the box is opened with a corresponding water outlet, and the water outlet is arranged on the filter screen In the closed space formed with the box body, a material outlet is opened at the middle of the bottom of the box body and between the opposite filter screens. The invention has the advantages of simple structure, ingenious conception and high working efficiency, and can fully agitate and clean the wool.

Owner:SUZHOU CHENCAI TEXTILE RES & DEV

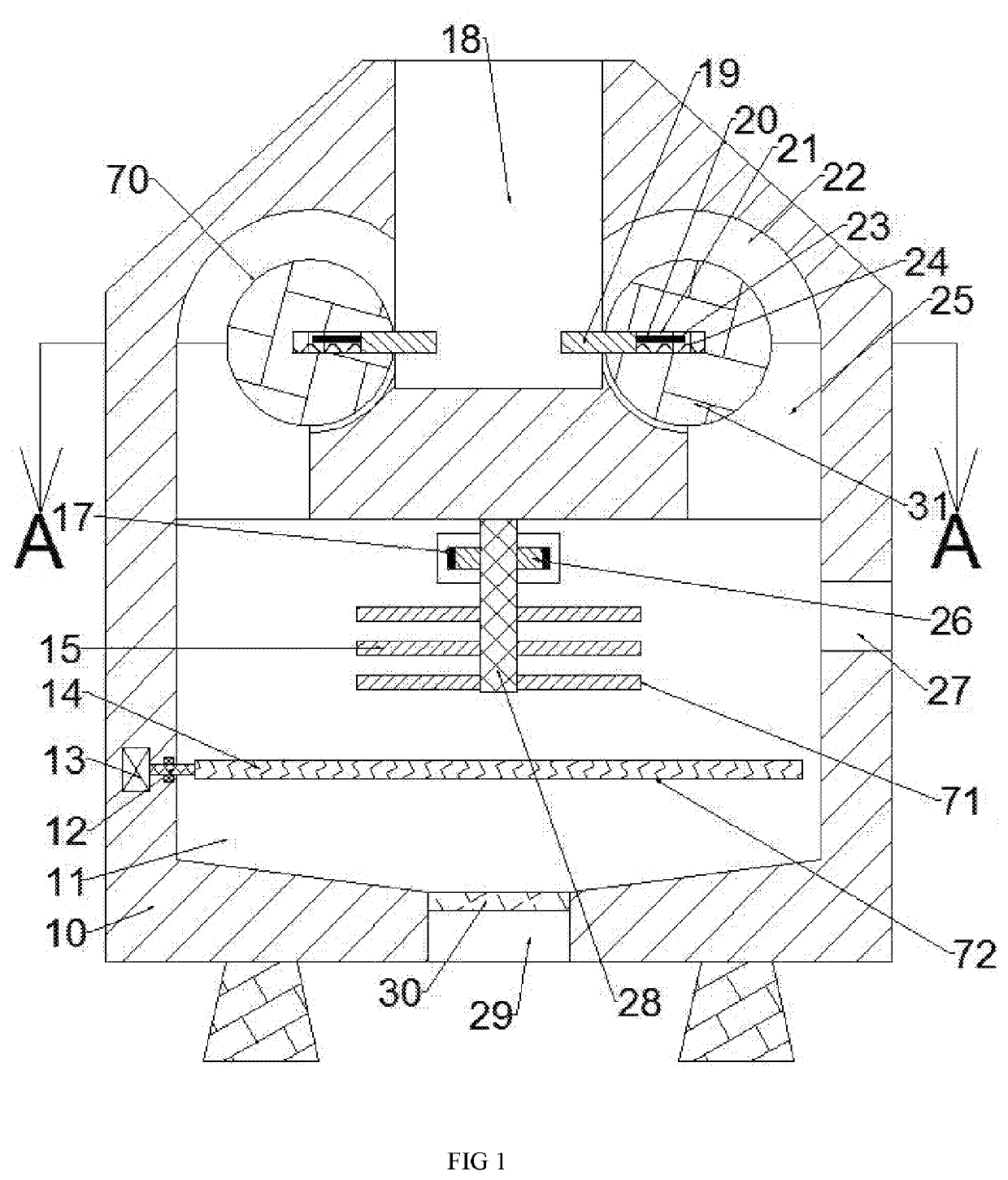

Woolen wool washing apparatus for chemical fiber production

InactiveUS20200181803A1Improve washing efficiencyImprove washabilityWool fibre washing/scouringAnimal materialFiberLaundry washing machine

The invention discloses a wool raw wool washing device for chemical fiber production, which includes a washing machine. The washing machine is provided with a working cavity. A front end wall of the working cavity is provided with a storage cavity with an upward opening. The wool raw wool is installed in the washing machine. Two dispersing mechanisms are symmetrically arranged in the working cavity in the storage cavity, and the dispersing mechanism includes a connecting shaft rotatably connected to the rear wall of the working cavity. A rotating wheel is fixed at the front end of the connecting shaft. The connecting shaft is provided with a collar that can slide back and forth, and the rotating wheel is provided with a slidable dispersing rod. The rotation of the connecting shaft can drive the rotating wheel to rotate, and the device can disperse the raw wool in the lump. After washing into small balls, it has a high washing efficiency, and by dispersing into small balls, it helps to discharge the stones and branches in the wool, and has a good washing effect. The overall mechanical linkage of the device is relatively good, High, more energy efficient.

Owner:WANG MING

Processing technology of down feather

InactiveCN107268278AImprove bulkReduce dust contentWool fibre washing/scouringDry-cleaning apparatus for textilesCross-linkPulp and paper industry

The invention provides a processing technology of down feather, and the processing technology comprises the following steps: (1) adding the down feather, water, a degreasing agent and a detergent into a water washing machine for degreasing and water washing of the down feather; (2) after rinsing, adding a cross-linking agent and a filler to the water washing machine, and rotating the water washing machine; (3) adding a softener and an acaricide into the water washing machine, rotating the water washing machine for 20-60 minutes, adjusting pH value to 3-6, then rotating the water washing machine for 10-30 minutes, wherein 2-4g by mass of the softener are added into 1l of the water; (4) dehydrating until the water content of the down feather is 45-60%; and (5) using hot steam for steam drying and sterilization of the down feather treated by the step (4), wherein a healthy tranquilizer and a flavor agent are added into the high temperature steam. The dust content of the down feather is greatly reduced, the fluffy degree of the down feather is improved, and the down feather has sedative fragrance, and has the additional functions of health care and tranquilizing.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Production process of cashmere quilt

InactiveCN105386289ASoft touchSuede plumpNon-ionic surface-active compoundsWool fibre washing/scouringProcess engineeringEngineering

The invention discloses a production process of a cashmere quilt. The production process includes the four steps of cashmere pretreatment, cashmere carding, carding bio-treatment and cashmere quilt processing. The step of cashmere pretreatment includes the concrete substeps that firstly, impurity removal is performed, wherein a cashmere opening duster is used for performing dusting and willower treating impurity removal on cashmere; secondly, washing and drying are performed, wherein firstly, the cashmere subjected to impurity removal in the first step is soaked in a neutral detergent for 30-45 min and then lightly rubbed to be washed, and secondly, the washed cashmere is soaked in a home-made detergent for 45-60 min and then lightly rubbed to be washed. The cashmere quilt is soft in handfeel, plump in suede and bright in color, and the weight of the cashmere quilt is small and reaches a high level of cashmere products; besides, the production process is simple, and cost is substantially reduced.

Owner:安徽首农毛业有限公司

Cleaning and drying device conveniently removing impurities for down feather production and processing

ActiveCN108168222AFacilitate subsequent processingProcessing effectDrying solid materials without heatWool fibre washing/scouringEngineeringWater pipe

The invention discloses a cleaning and drying device conveniently removing impurities for down feather production and processing. The cleaning and drying device includes a cleaning device, a water inlet pipe, a stirring rod, a transmission belt, a suction opening, a fan, a first water outlet, a protective cover, a protective door, an air-tight door, a spin-dry revolving drum, a second air hose anda blowpipe; the upper of the cleaning device is provided with a feed inlet, the lower of the feed inlet is provided with a rotating rod, the water inlet pipe is located below the left side of the cleaning device, and the cleaning device is internally connected with a first motor through the rotating rod; and the stirring rod is located at the outer side of the rotating rod, the second air hose isarranged in the transmission belt which is provided with through holes, and the through holes are connected with scraping plates. According to the cleaning and drying device conveniently removing theimpurities for the down feather production and processing, the cleaning device is arranged to clean down feather, subsequent processing can be prevented from affection due to impurities in the down feather, and the cleaning of the down feather is facilitated.

Owner:ZHANJIANG ZIJIN DOWN PROD

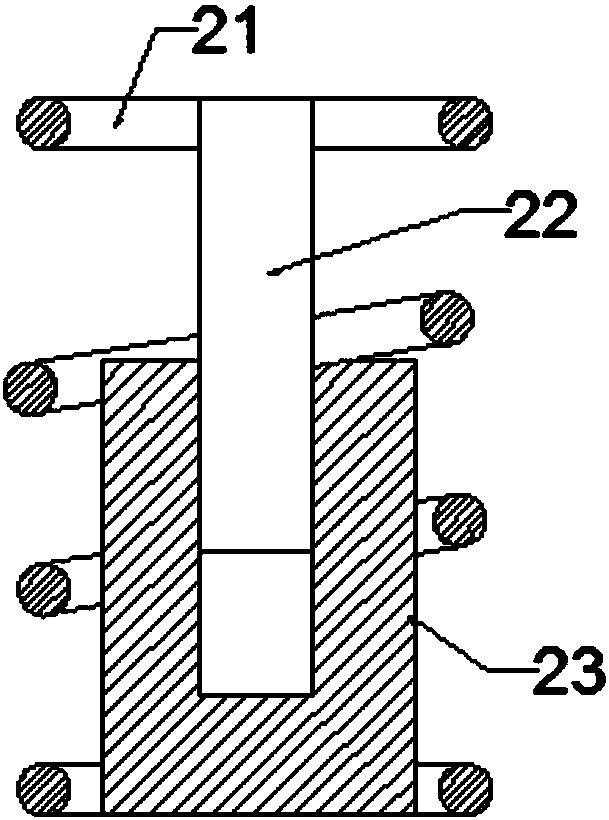

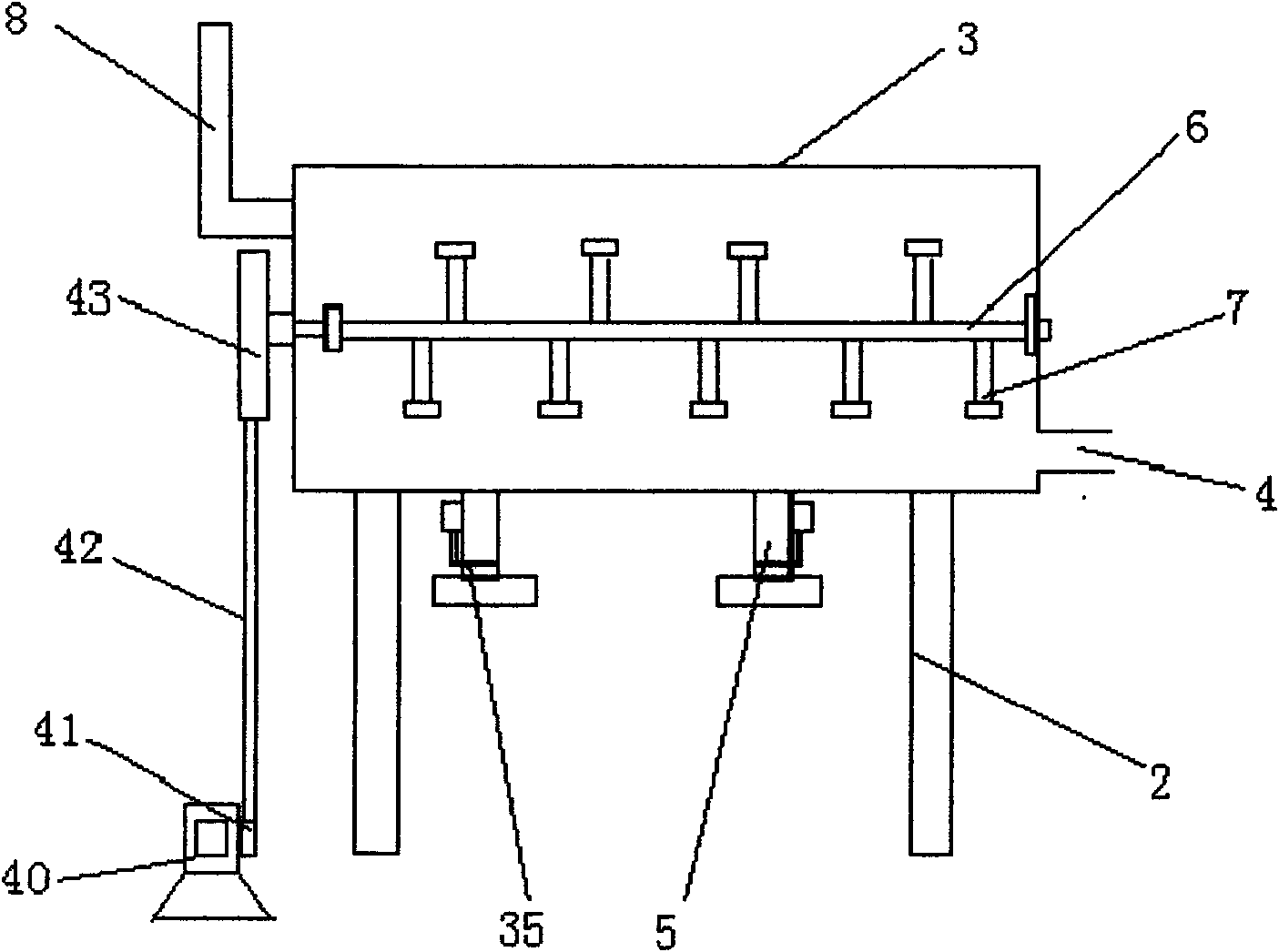

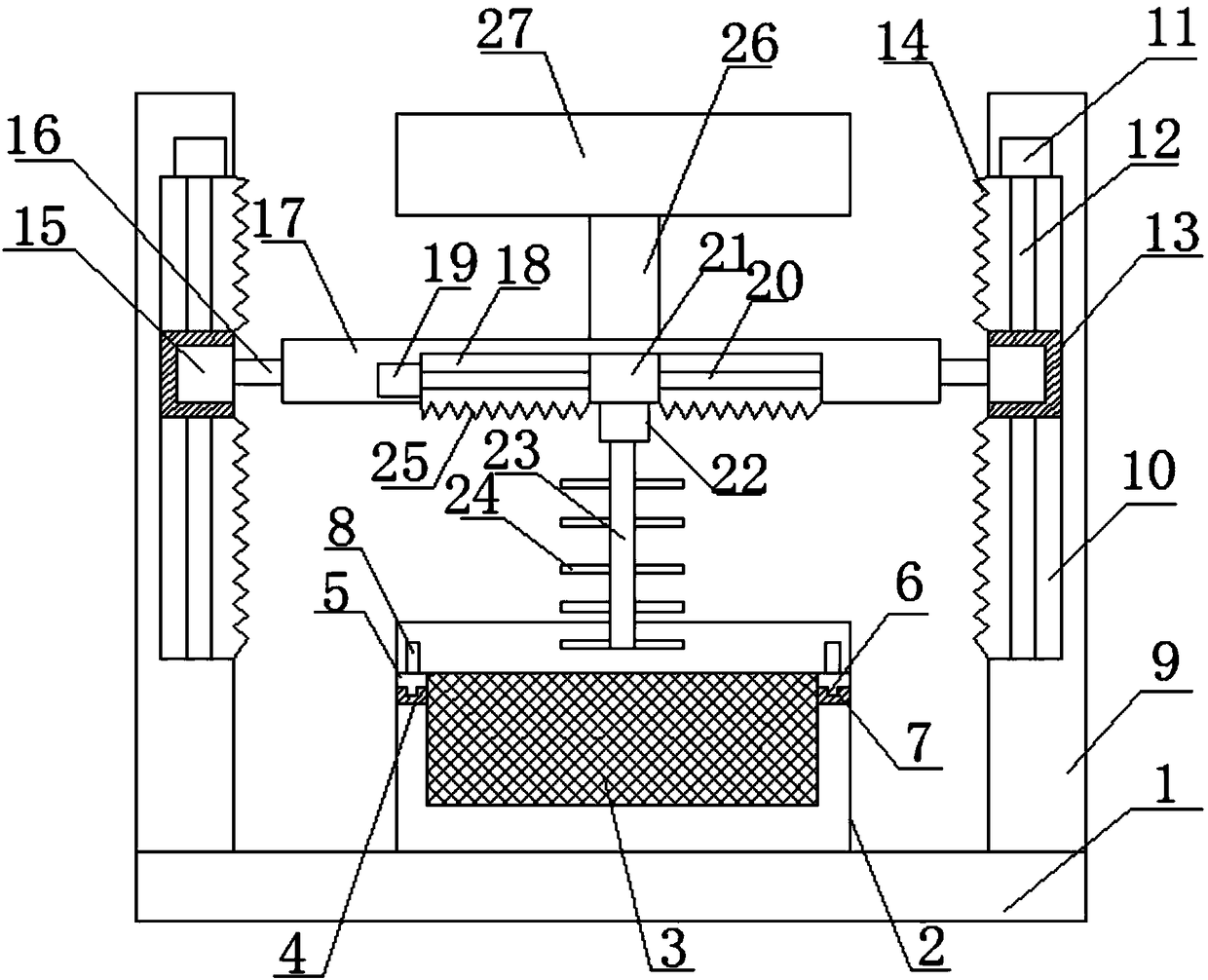

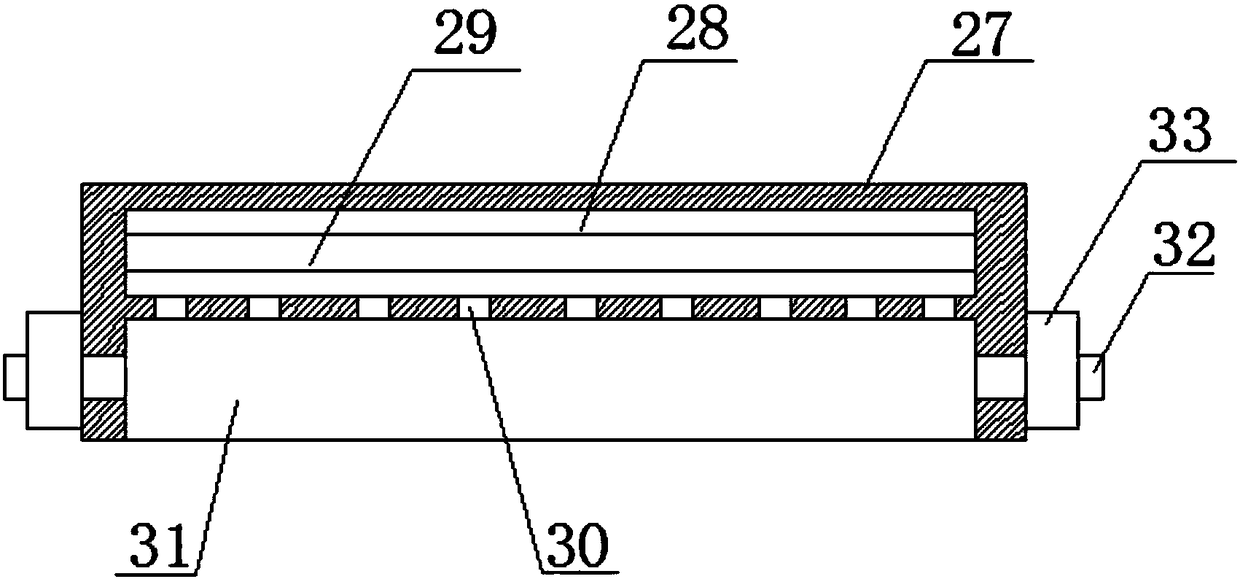

Conveniently-used wool cleaning device for animal husbandry

ActiveCN108546998AWon't cause random flyingEasy to collectWool fibre washing/scouringLiquid/gas/vapor removalAnimal husbandryThreaded rod

The invention discloses a conveniently-used wool cleaning device for animal husbandry. The device comprises a base, wherein the upper side of the base is symmetrically provided with supporting columnsat the left and right, the inner side of each supporting column is provided with a lifting chamber, the upper end of each lifting chamber is provided with a first motor, an output end of each first motor is provided with a first threaded rod, each first threaded rod is provided with a lifting seat, a second motor is arranged in each lifting seat, output ends of the two second motors are providedwith rotating columns, a supporting plate is arranged between the two rotating columns, the lower side of the supporting plate is provided with a moving cavity, the left end of the moving cavity is provided with a third motor, an output end of the third motor is provided with a second threaded rod, the second threaded rod is provided with a moving seat, the lower side of the moving seat is provided with a fourth motor, an output end of the fourth motor is provided with a stirring rod, the stirring rod is provided with a plurality of stirring blades, the upper side of the supporting plate is provided with a supporting rod, and the upper end of the supporting rod is provided with a sealing cover. The conveniently-used wool cleaning device for the animal husbandry has the advantages of simplestructure, convenient use, good cleaning effect, high efficiency and high practicability.

Owner:淮安逸之文企业管理有限公司

Yarn spinning technology for multi-fiber semi-worsted melange yarn and yarn

InactiveCN104878490AImprove insulation effectIncrease elasticityWool fibre washing/scouringAnimal materialCardingWorsted

The invention relates to a yarn spinning technology for multi-fiber semi-worsted melange yarn and the yarn prepared with the technology. The technological steps of the yarn mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise mercerized wool fiber, nylon fiber, viscose fiber and cashmere wool fiber. The problems of high probability of water shrinkage and pilling of wool are solved with a more environment-friendly method, meanwhile, nylon, cashmere wool and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are increased; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

Down feather washing technology

InactiveCN104153006AReduce usageDoes not affect loftSucessive textile treatmentsWool fibre washing/scouringWarm waterDeodorant

The invention discloses a down feather washing technology. The technology includes the following steps that first, down feather is added; second, primary washing is performed through cold water; third, fine washing is performed through warm water; fourth, rinsing is performed through cold water; fifth, drying is performed so that fat-extracted down feather can be obtained. According to the washing technology, industrial sodium carbonate, detergent and deodorant are added in the washing process, the washing effect is good, dust extraction, fat extraction and deodorization are integrated, the technology is convenient and fast to perform, water consumed for washing down feather is reduced by 30% or so under the condition that the whiteness, the fluffy degree, the cleanness and the oxygen consumption amount are not influenced, the washing efficiency is improved, no harm happens to a human body, and the technology is safe and reliable.

Owner:ANHUI XIAZHEN GRP

Down feather processing technology

InactiveCN103484944AAvoid interferenceSorting went wellAnimal fibre deburring machinesWool fibre washing/scouringTruckMechanical engineering

The invention relates to a down feather processing technology. The down feather processing technology comprises the following steps of (1) selection, (2) suction, (3) washing, (4) dehydration, (5) drying, (6) cooling, (7) packing, (8) sorting, (9) static electricity elimination, (10) boxing and (11) truck loading. The down feather processing technology has the advantages of being reasonable in step setting, facilitating manufacture and the like, smooth performing of down feather processing can be ensured, and static electricity interference on down feather can be avoided.

Owner:安徽万利达羽绒制品有限公司

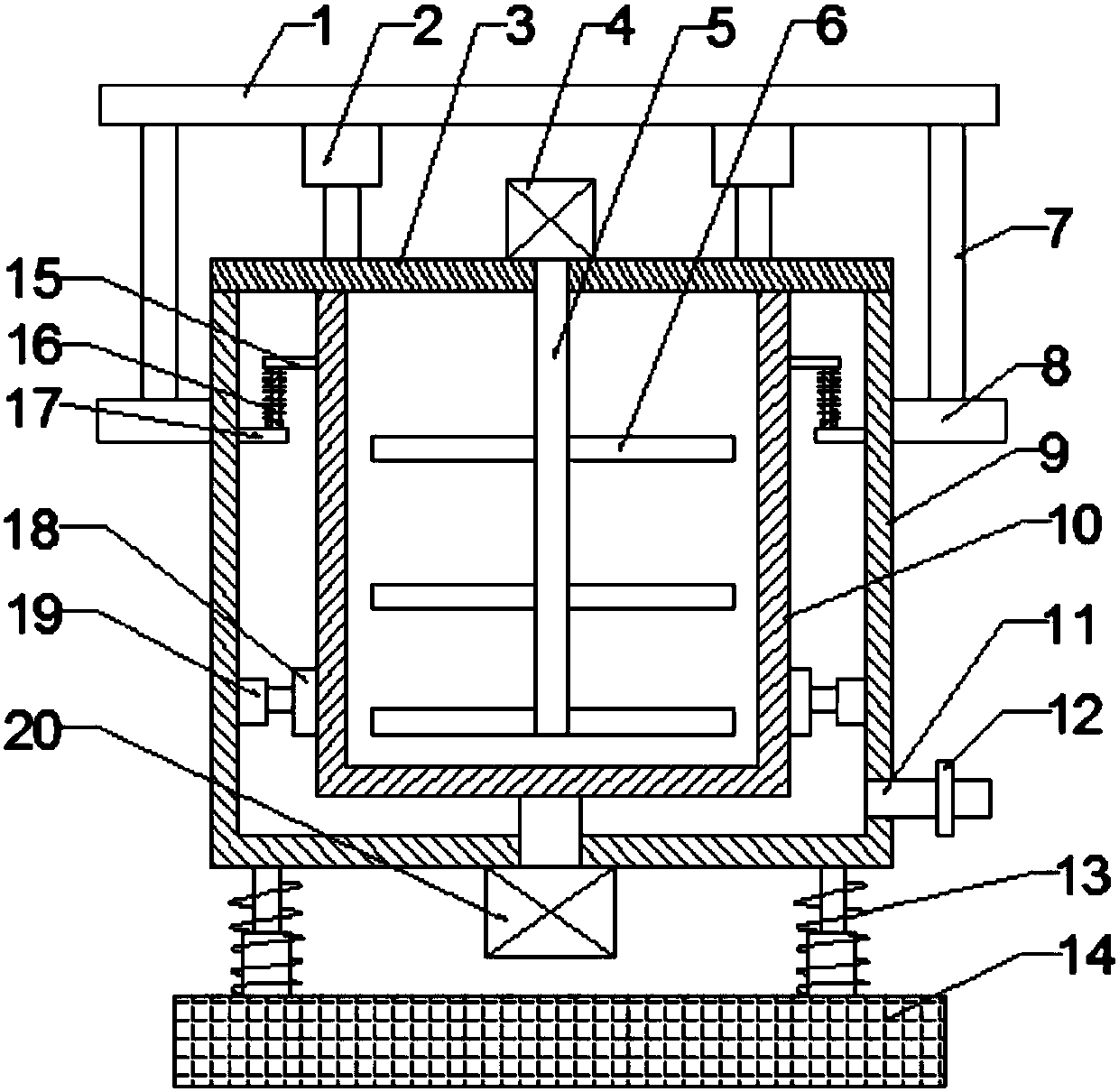

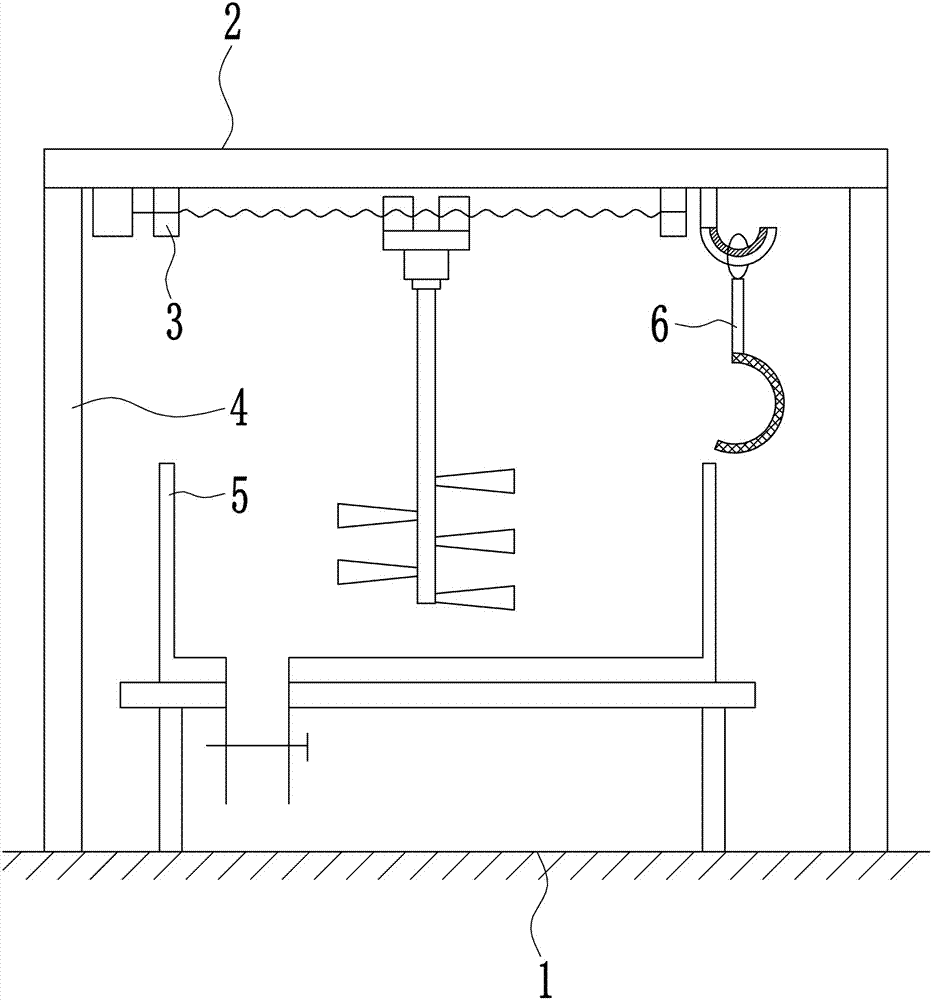

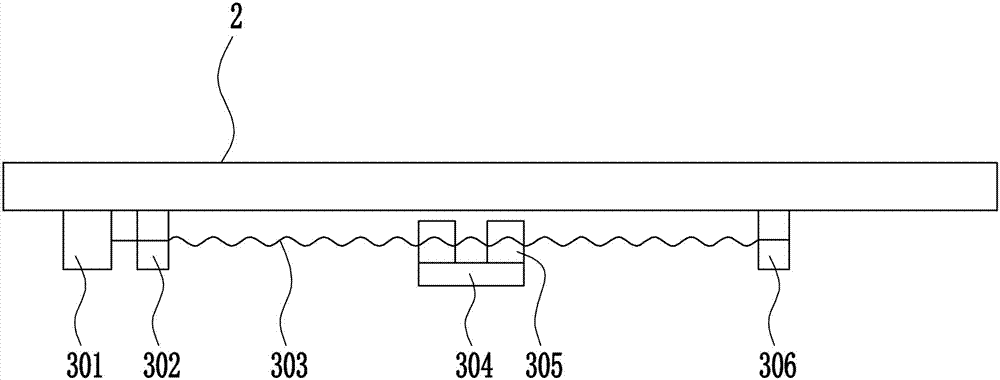

Wool cleaning device for stock farming

The invention relates to a cleaning device and especially relates to a wool cleaning device for stock farming. The technical problem to be solved by the invention is to provide the wool cleaning device for stock farming. In order to solve the technical problem, the wool cleaning device for stock farming provided by the invention comprises a top plate; brackets and the cleaning device are arranged on the ground; the cleaning device is located between the brackets on the left and right sides; the top plate is arranged at the top of the brackets; a moving device is arranged at the bottom of the top plate; the bottom of the moving device is connected with the top of the upper part of the cleaning device. According to the invention, a better cleaning function for the wool is achieved, the wool can be thoroughly cleaned, water in the cleaned wool can be effectively extruded, the wool can be conveniently dried and the working efficiency is high.

Owner:故城县诚泽养殖有限公司

Wool finishing device for animal husbandry

The invention discloses a wool finishing device for animal husbandry, which comprises a box body. A processing net cylinder is arranged inside the box body. Left and right fixing plates are respectively installed at the left and right ends of the processing net cylinder. A central tube is installed in the inner middle of the barrel, telescopic cylinders are installed on the left side of the left fixed plate and the right side of the right fixed plate, a four-way pipe is installed on the left side inside the box, and a hot air blower is installed at the end of the first branch , a lifting pump is also installed on the fourth branch, the end of the second branch is connected with the water outlet of the booster pump, the end of the third branch of the four-way pipe is connected with a communication hose, and the other end of the communication hose passes through the rotary joint It is connected with the left end of the central tube, and the right end of the central tube is also equipped with a driving motor. The invention achieves the effects of good cleaning effect and fast speed, can be dried quickly, has a simple structure, is convenient to operate, saves the labor of the herdsman, and makes the wool better in quality and better in sales.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

Environment-friendly processing method for down feather with antibacterial, deodorizing and healthcare functions

ActiveCN105506751AImprove cleanlinessFeel goodWool fibre washing/scouringAnimal materialBacterial virusDeodorant

The invention provides an environment-friendly processing method for down feather with antibacterial, deodorizing and healthcare functions. The environment-friendly processing method comprises the following process steps: (1) preparing materials; (2) roughly washing; (3) dewatering; (4) drying; (5) classifying; (6) removing dust and sand; (7) finely washing, namely washing and bleaching; (8) dewatering; (9) drying and sterilizing; (10) cooling, removing sand and removing iron; and (11) packaging and warehousing. In implantation of the environment-friendly processing method, an environment-friendly enzyme down feather detergent is used, so that the cleaning capability is better, and various bacterial viruses in the down feather can be removed effectively; the antibacterial effect lasts longer, and bacteria are not easy to propagate after long-term use; the environment-friendly enzyme down feather deodorant is also added, so that the stench of the down feather can be removed; the down feather has antibacterial, deodorizing and healthcare functions, the down feather has good hand feeling and good elasticity, and does not have peculiar smell; the environment pollution caused by the wastewater discharged after washing is greatly reduced; moreover, the environment-friendly enzyme down feather detergent and deodorant are prepared by processing fruit peels, plants and kitchen garbage; waste is changed into treasure; the pollution of the environment caused by the waste fruit peels, plants and the kitchen garbage is also reduced.

Owner:潮州市吴越羽绒有限公司

Automatic down feather water washing device and method

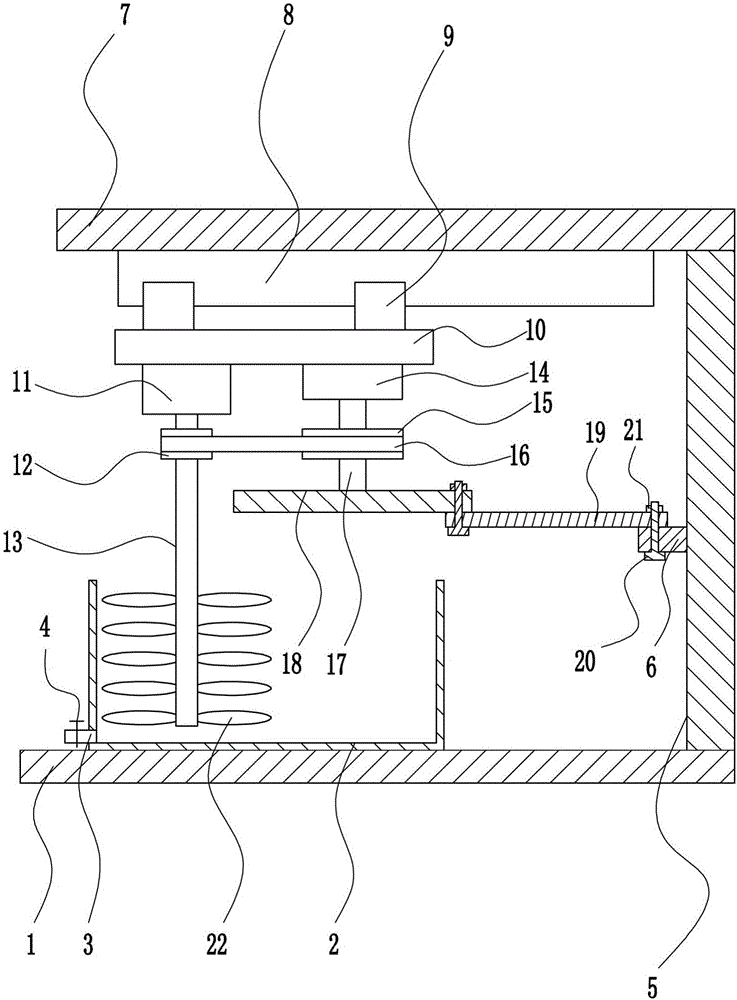

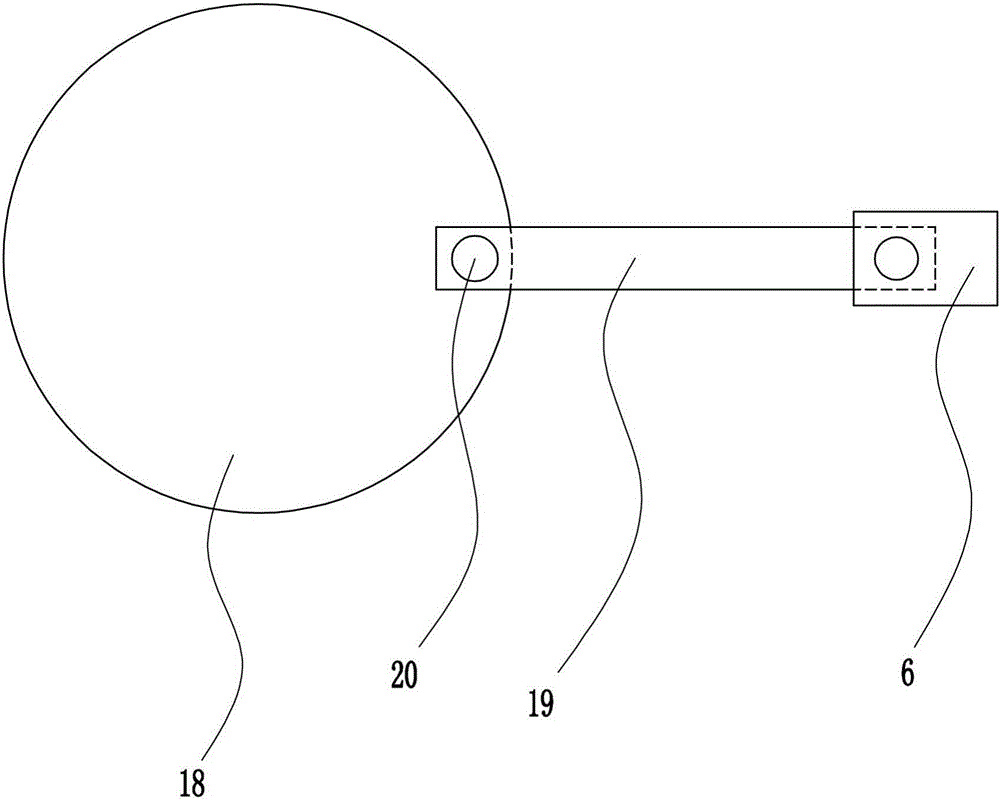

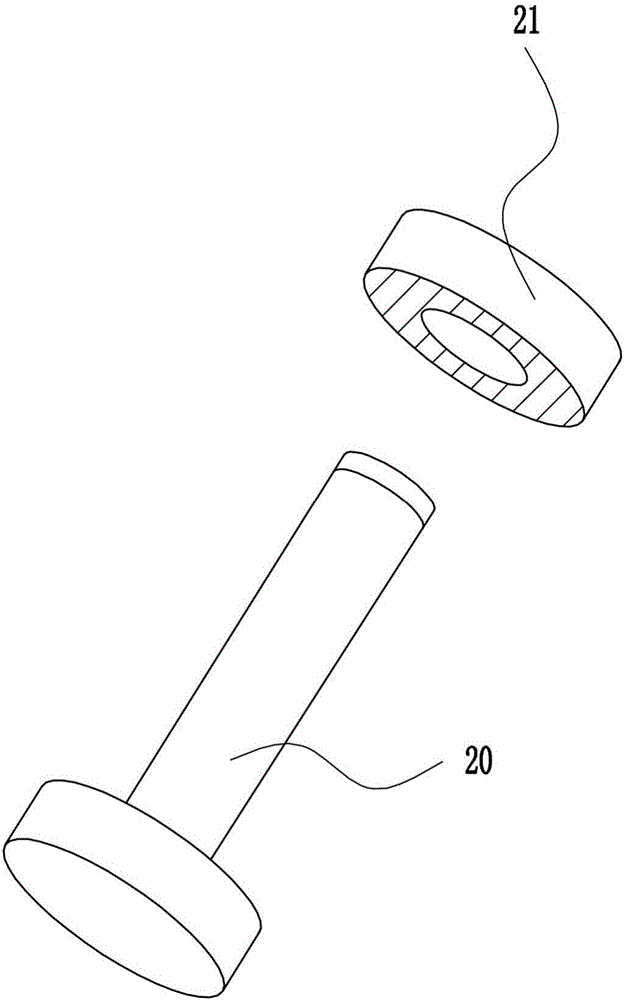

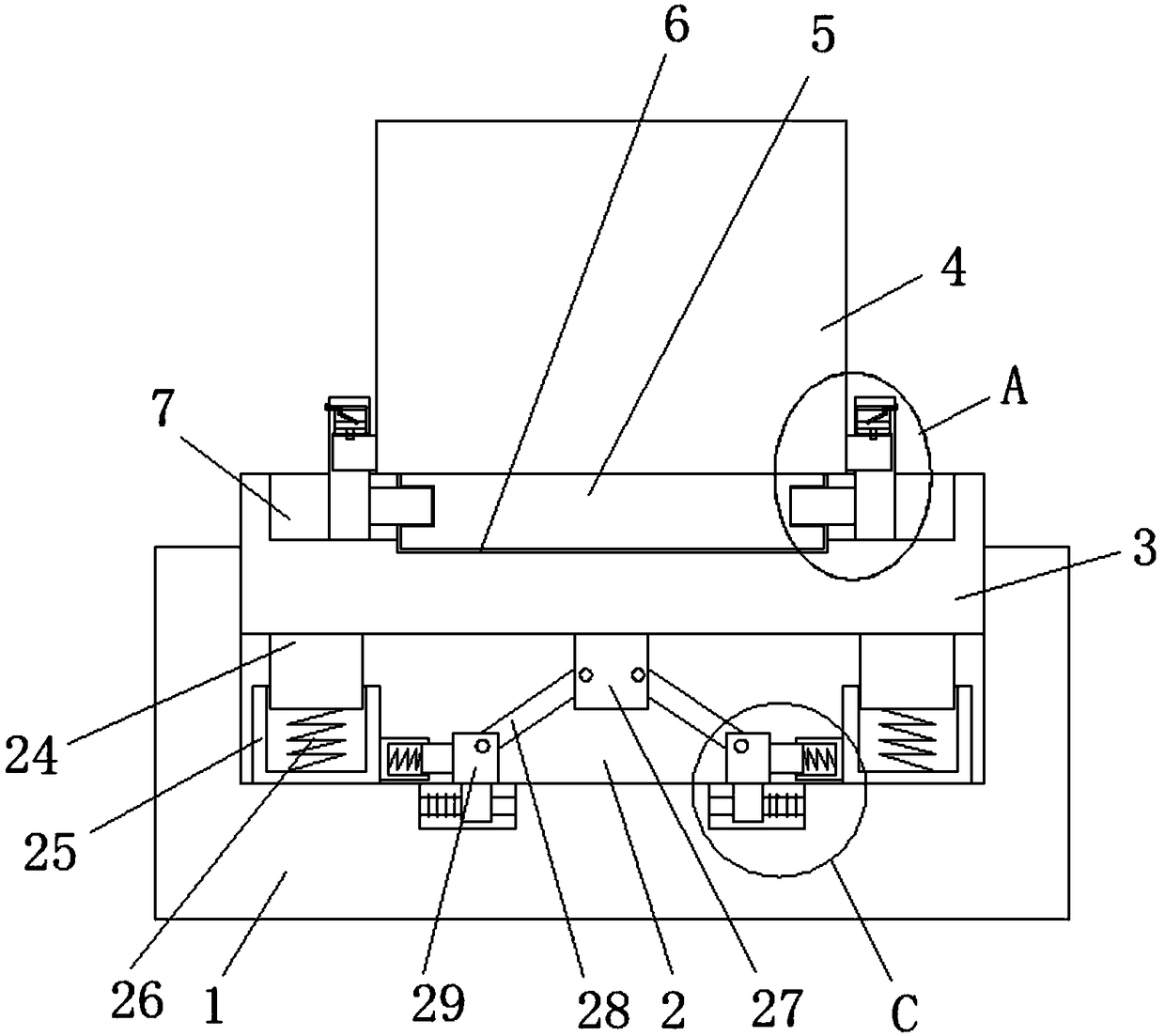

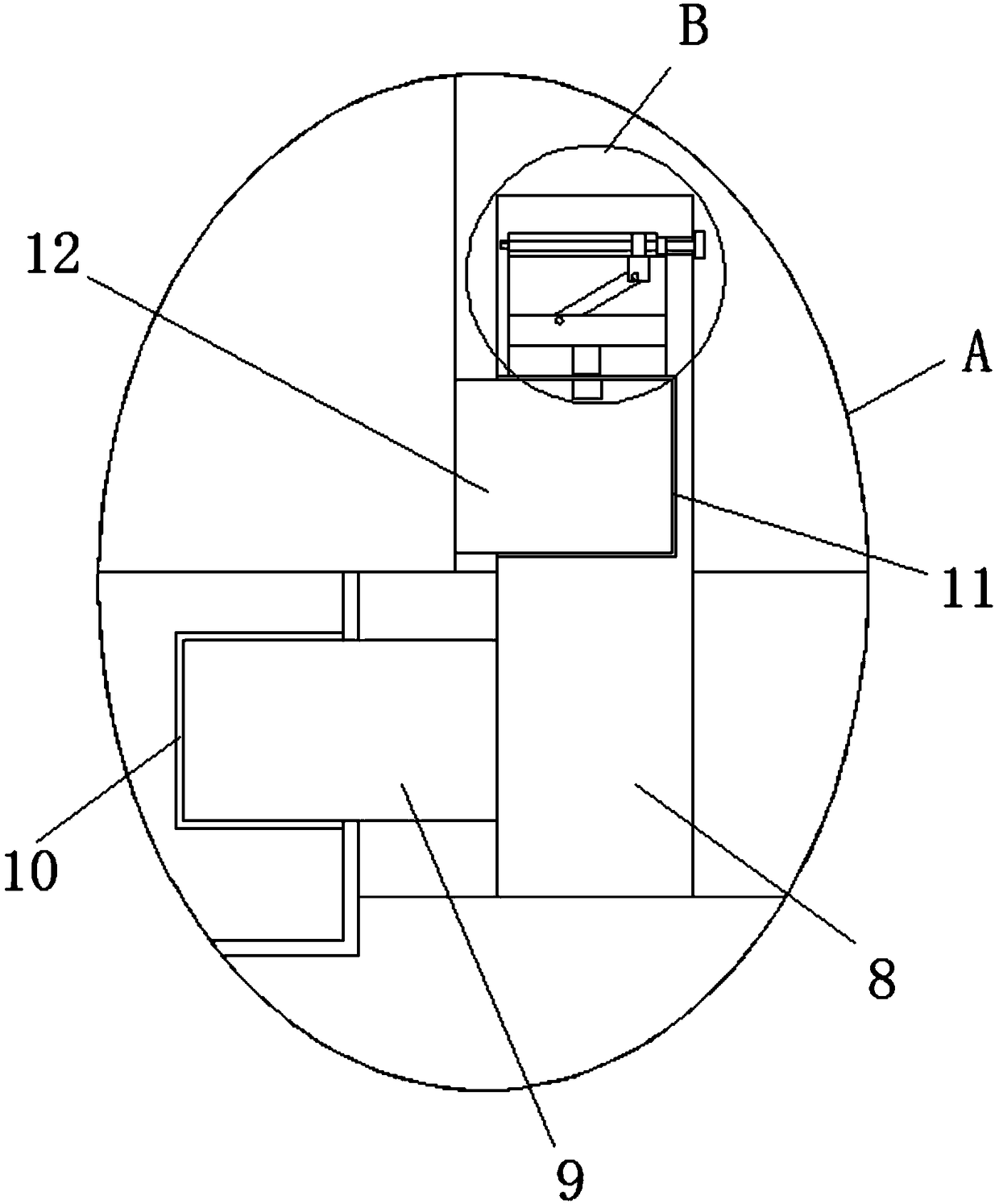

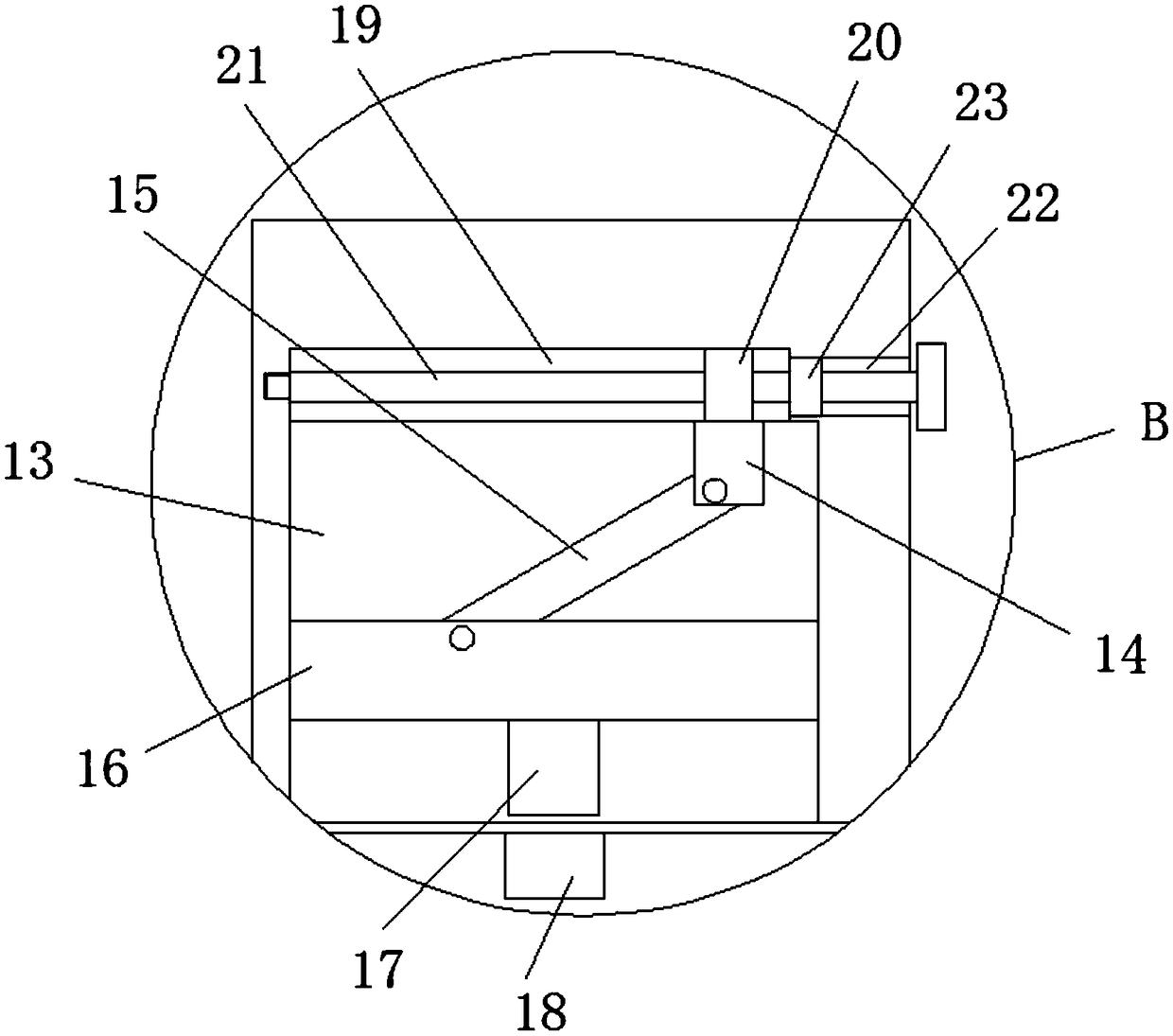

PendingCN108360075APlay the role of initial shock absorptionPlay a shock absorbing roleWool fibre washing/scouringClamp connectionMechanical engineering

The invention discloses an automatic down feather water washing device and method. The down feather water washing device comprises a base, the top of the base is provided with a mounting groove, the mounting groove is internally and slidably provided with a mounting plate, the top of the mounting plate extends into the upper portion of the base, the top of the mounting plate is provided with a water washing device body, the bottom of the water washing device body is fixedly provided with a placing block, the top of the mounting plate is provided with a placing groove, the placing block is in clamped connection with the placing groove, the inner walls of the two sides of the placing groove are both provided with moving grooves of which top portions are provided with openings, the moving grooves are internally and slidably provided with moving plates, the sides, close to each other, of the two moving plates are both fixedly provided with fixing blocks, and two sides of the placing blockare both provided with fixing grooves. The automatic down feather water washing device and method have the advantages that the water washing device body can be installed and fixed conveniently, damping of the water washing device body can be achieved conveniently, the noise can be reduced, the components and parts in the water washing device body can be protected conveniently, the structure is simple, and the use is convenient.

Owner:HENAN PENGDA DOWN PROD

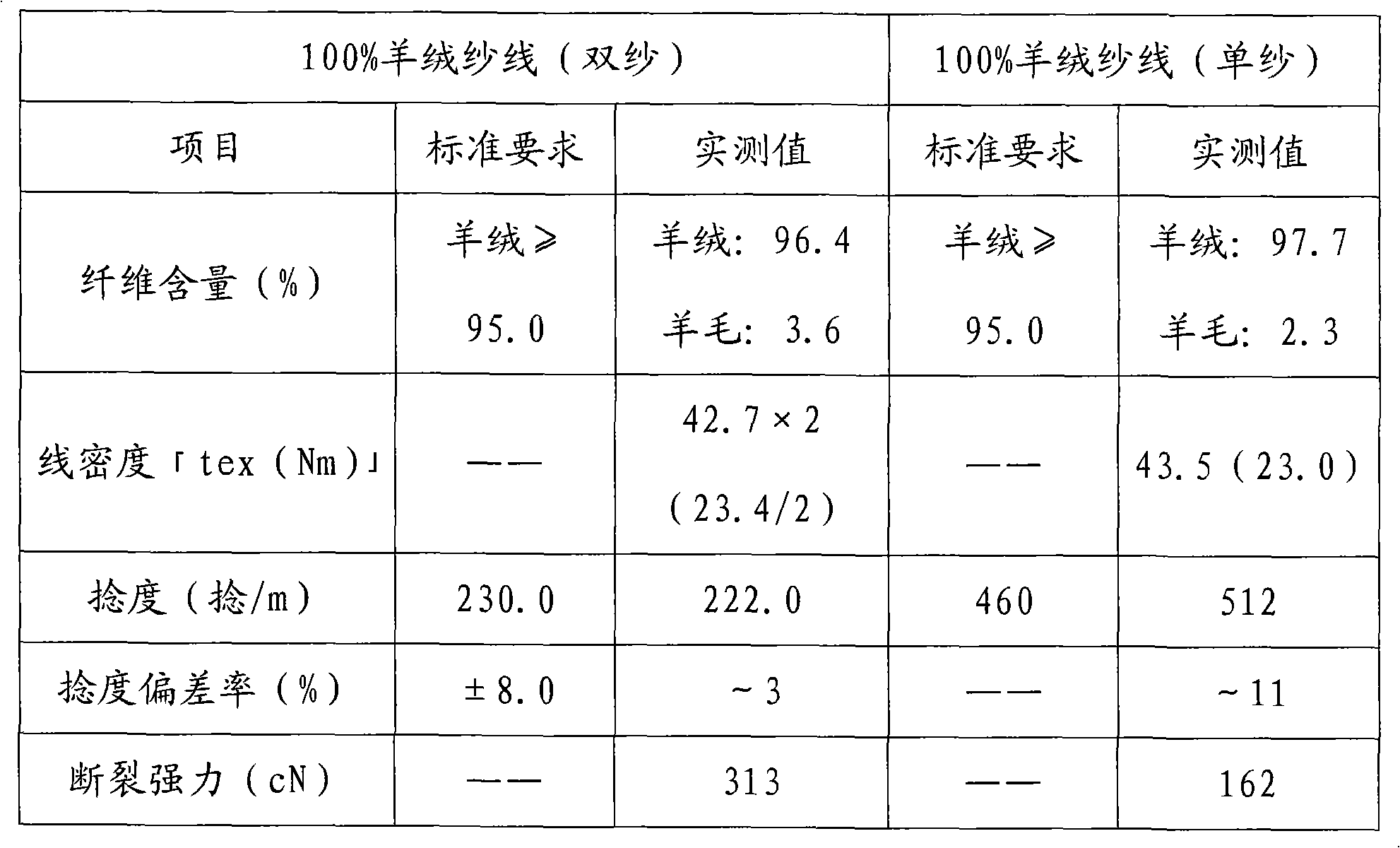

Cashmere yarn with high tensile stretch and production technology thereof

ActiveCN101586278AAvoid damageHigh elongation at breakFibre cleaning/openingWool fibre washing/scouringYarnSingle fiber

The invention belongs to the technical field of knitting yarns and production technology thereof, in particular relates to a cashmere yarn with high tensile stretch and production technology thereof. The production technology of the cashmere yarn with high tensile stretch includes the followings: in cashmere washing step, drying is carried out at the low temperature of 40 DEG C to 50 DEG C so as to reduce the power damage of cashmere single fiber; in carding step, the card clothing angle of cubing rolls of a carding machine is adjusted between 130 DEG and 150 DEG so that the striking point direction of cubing rolls is changed and the length damage of cashmere is reduced; in dying step, drying is carried out at the low temperature of 50 DEG C to 70 DEG C so as to further reduce the power damage of cashmere single fiber; in spinning step, the twist factor of the single yarn used is 90% to 98%. In the invention, drying is carried out at the low temperature of 40 DEG C to 50 DEG C both in cashmere washing step and in dying step, and the card clothing angle of cubing rolls of a carding machine is adjusted between 130 DEG and 150 DEG in carding step, thereby reducing the damage of cashmere to the maximum and guaranteeing high breaking elongation, rebound degree and force of cashmere.

Owner:湖州珍贝羊绒制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com