Down feather cleaning machine

A washing machine and down technology, which is applied in the field of down washing machines, can solve the problems of uneven feeding of down raw materials, inability to remove down impurities, etc., and achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

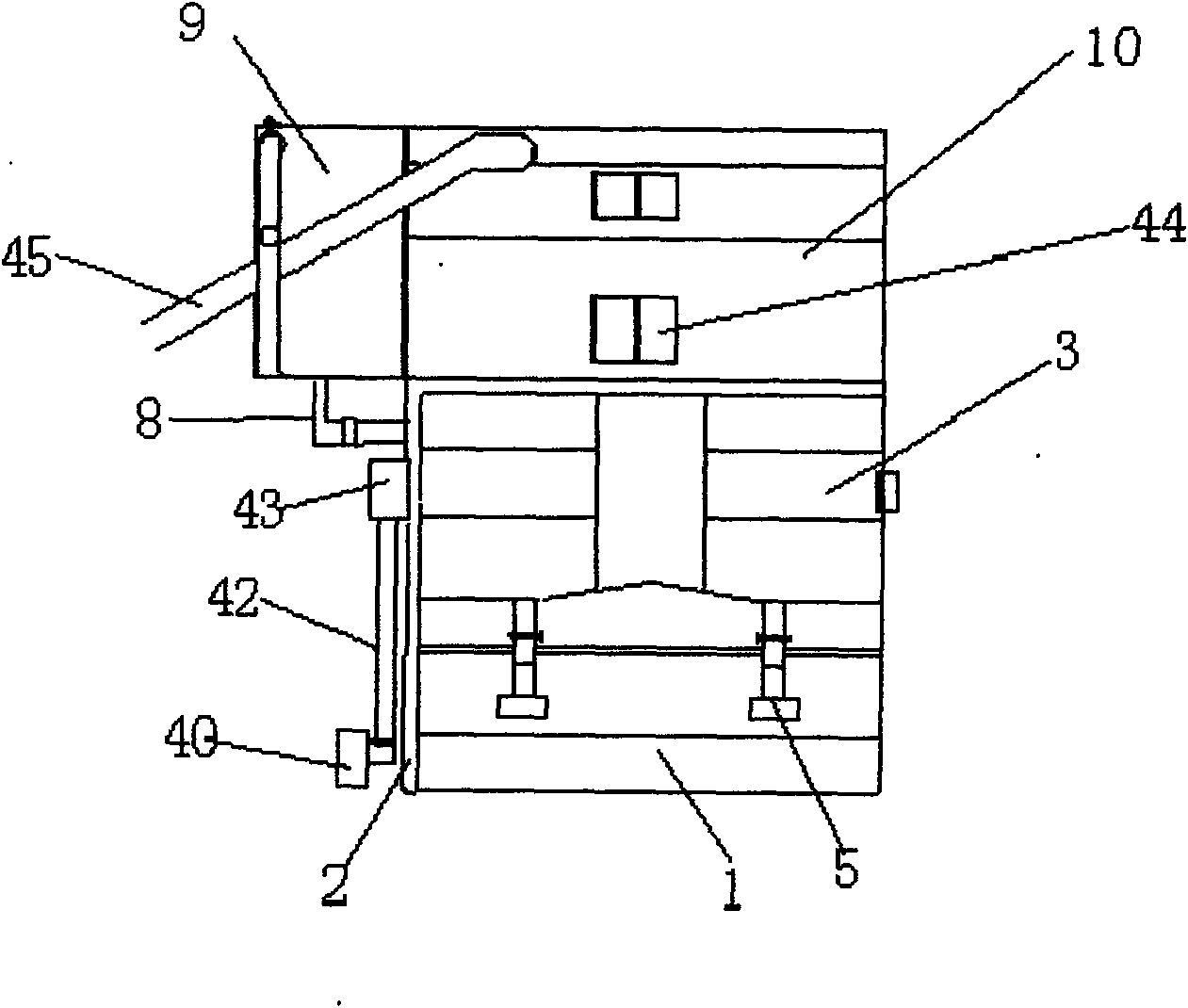

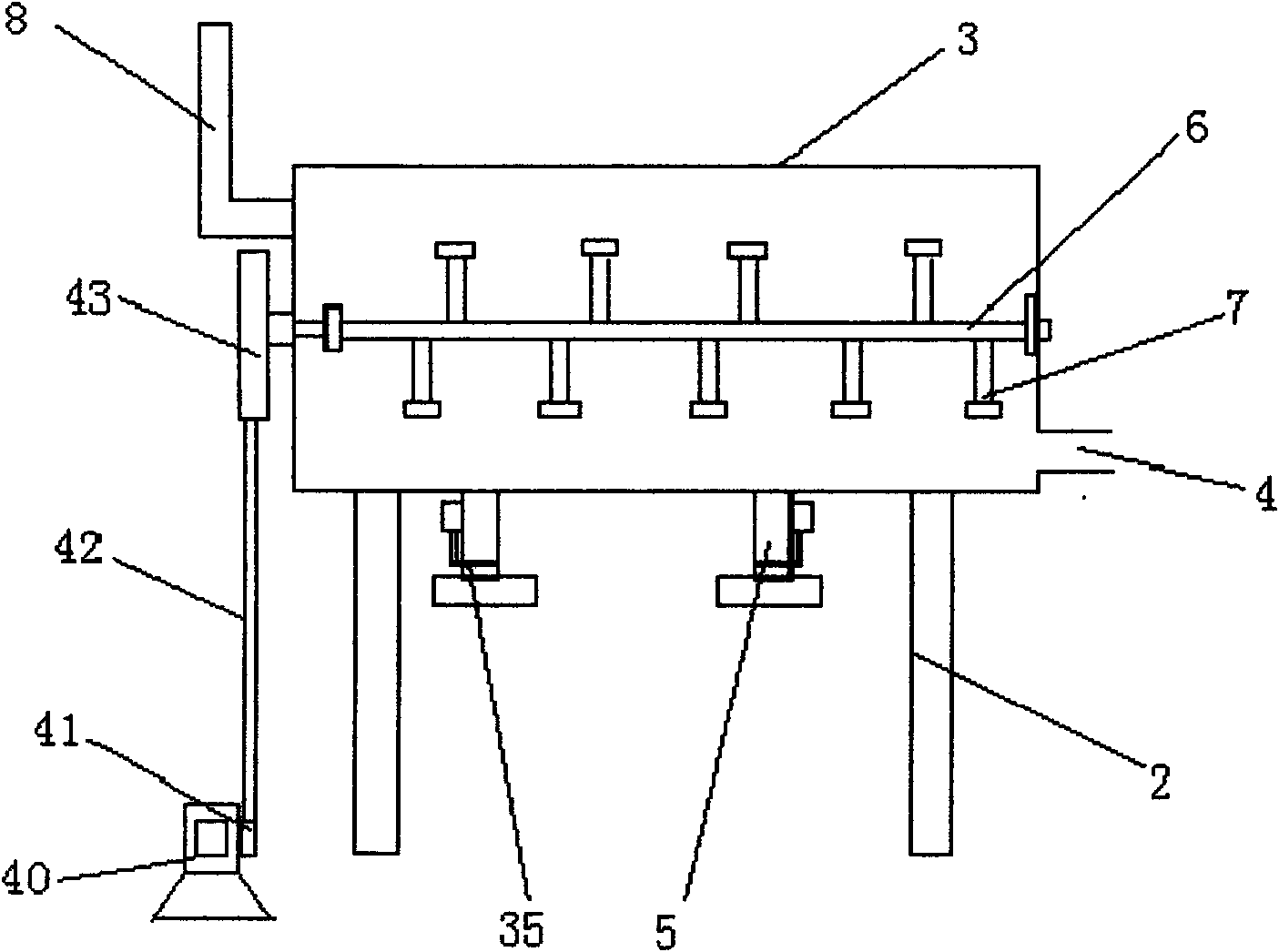

[0025] Example 1, such as Figure 1 to Figure 6 As shown, a down cleaning machine includes a down cleaning device, the down cleaning device is fixedly arranged on a sink 1, and the down cleaning device includes a cleaning chamber 3 arranged on the support 2 of the sink 1, the described The upper part of the cleaning chamber 3 is provided with a discharge port 4, the lower part of the cleaning chamber 3 is provided with a drain outlet 5, and the inside of the cleaning chamber 3 is provided with a rotating shaft 6 driven by a driving device, and the driving device is provided on the output end of the variable speed motor 40. The driving pulley 41; the rotating shaft 6 is rotated by the belt 42 driving the pulley 43. Stirring rods 7 are evenly distributed on the rotating shaft 6, and the upper part of the cleaning chamber 3 is also provided with a water inlet 8, and the water inlet 8 is connected to the water tank 9 on one side of the cleaning chamber, and it is characterized in ...

Embodiment 2

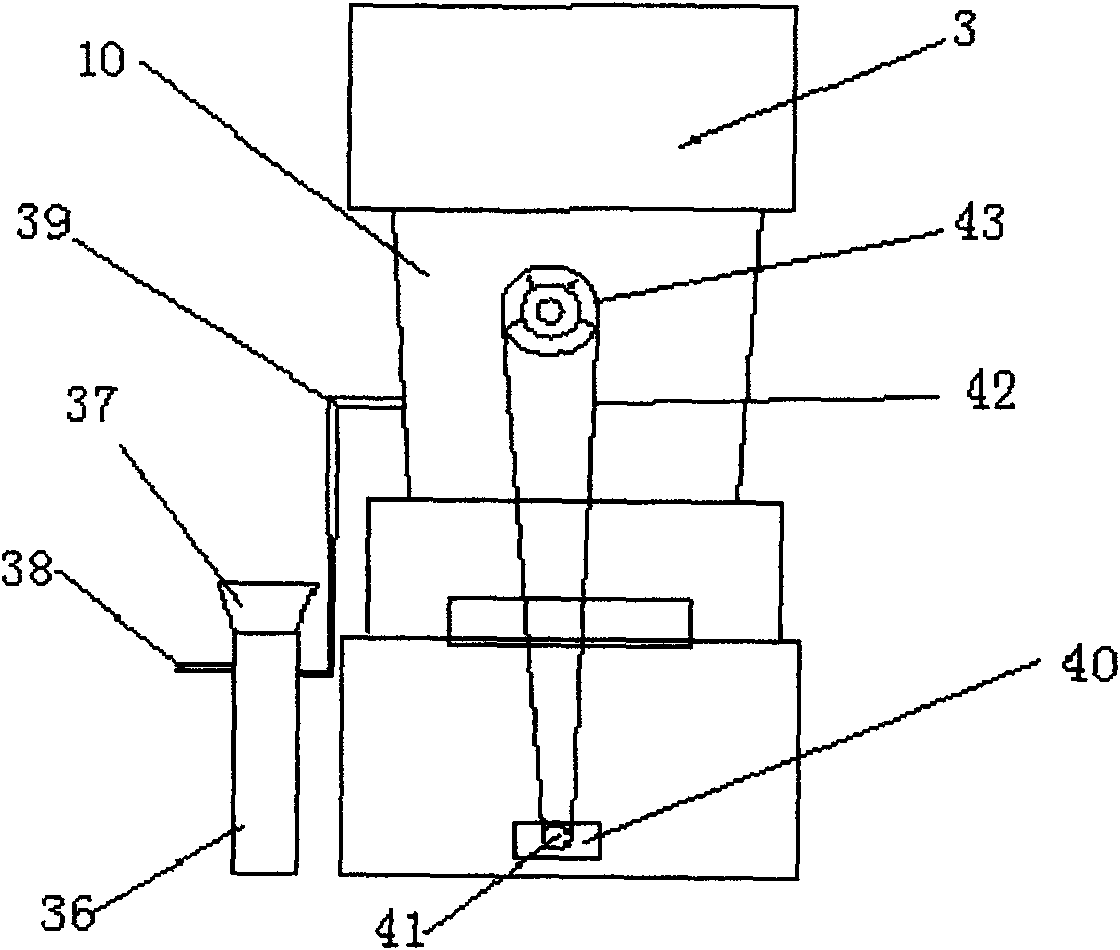

[0027] Example 2, such as Figure 4 to Figure 5 Shown, on the basis of embodiment 1. Further, the vibrating mechanism further includes a vibrating plate 19 connected to the air chamber 14, the lower part of the vibrating plate 19 is connected to the eccentric wheel 22 driven by the motor 21 on the frame 20, and the eccentric wheel 22 is connected to the vibrating plate through a connecting rod 23. The swing seat 24 on the 19 is also provided with a rocking bar 25 at the two ends of the vibrating plate 19, and one end of the rocking bar 25 is provided with a rocking bar bearing 26; 27 is arranged on the column 28 that is set on the frame 20.

[0028] Further, the outer cavity is provided with a device for making the down enter the material distribution port smoothly, and the described device for allowing the down to enter the material distribution port smoothly is a push rod 29 set through the outer cavity 10, and the push rod placed in the outer cavity 29. One end is connect...

Embodiment 3

[0029] Example 3, such as Figure 4 Shown, on the basis of embodiment 2. In order to make feeding smooth, the inside of the outer cavity is also provided with a feather loosening device. The feather loosening device includes a rotatable winch wheel 32 on which paddles 33 are evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com