Patents

Literature

65results about "Apparel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

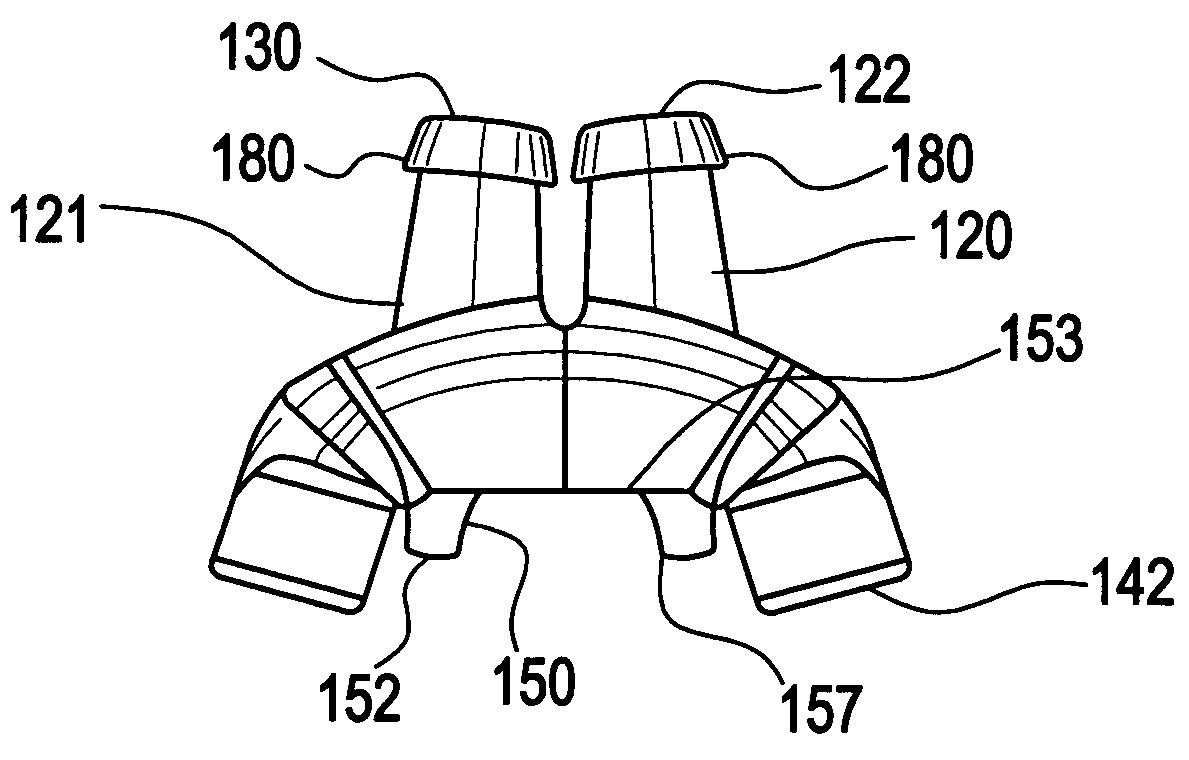

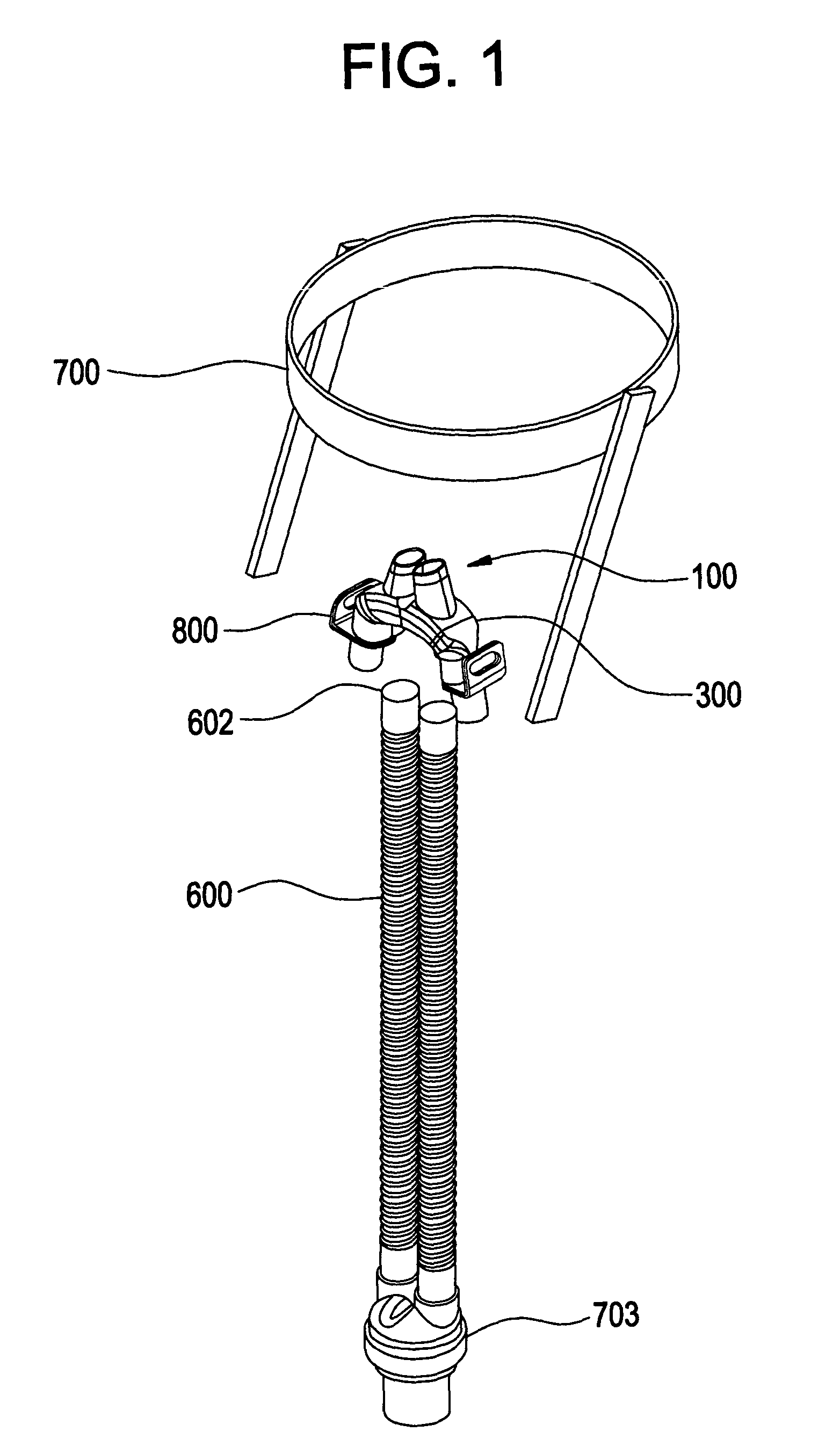

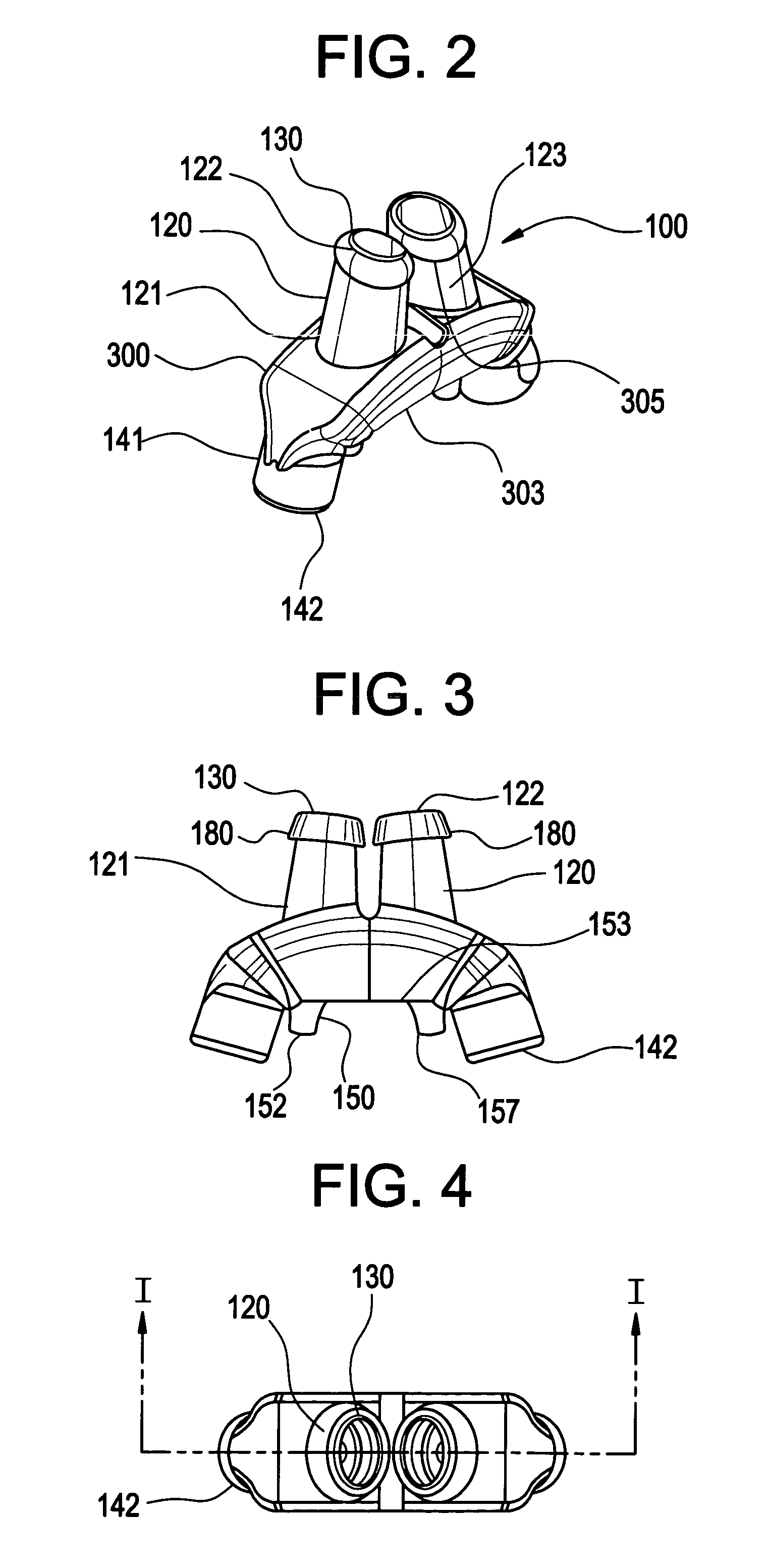

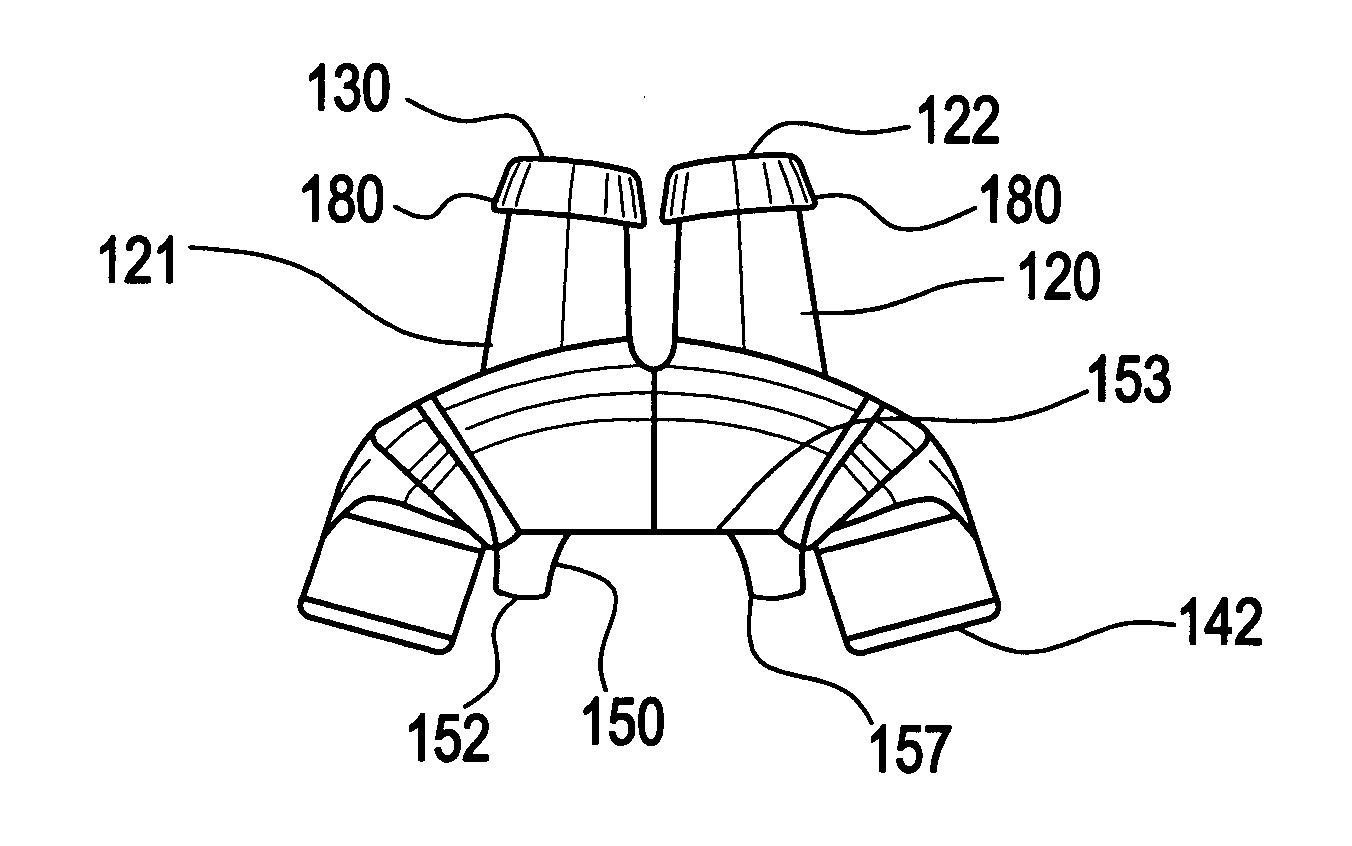

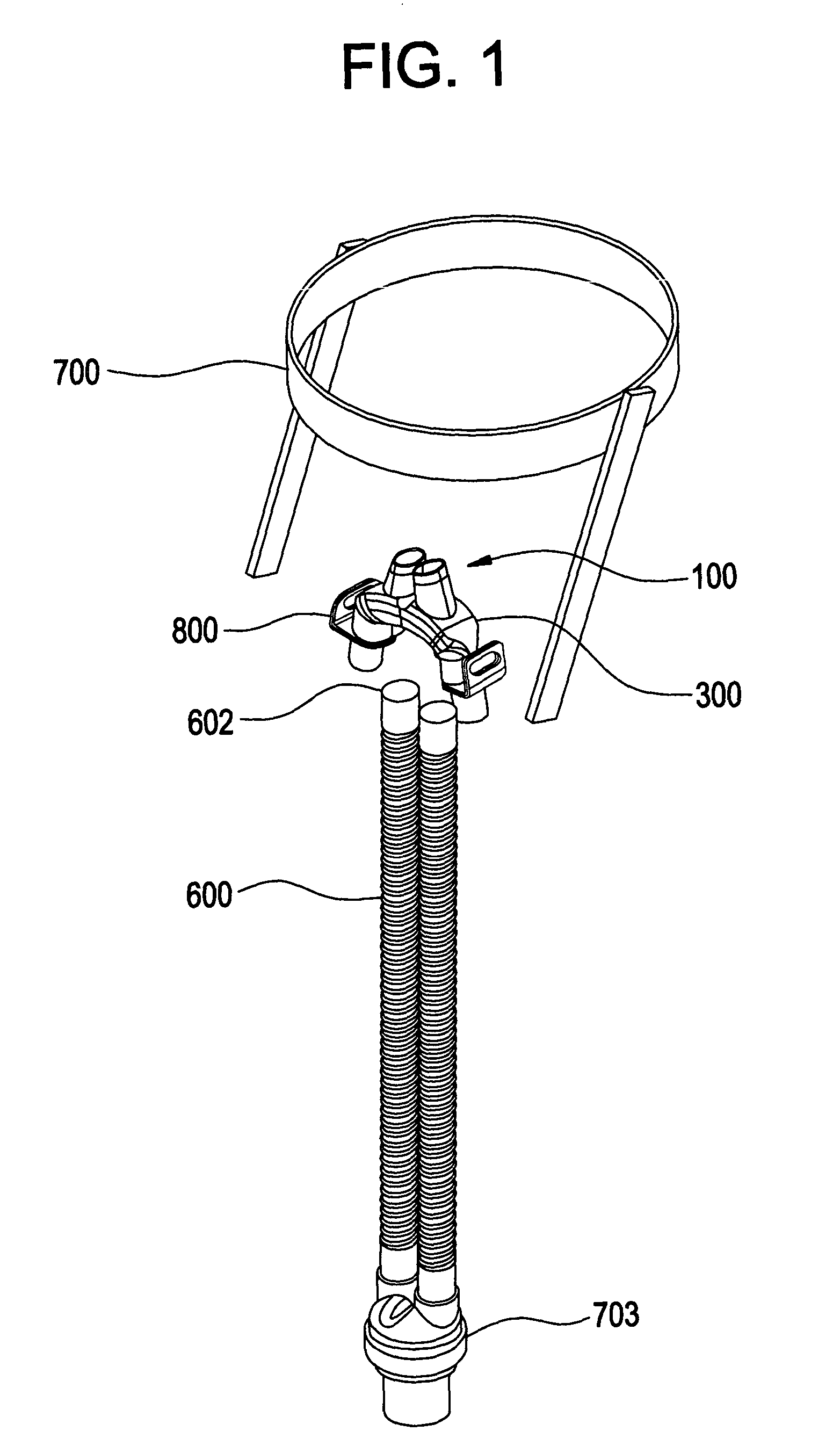

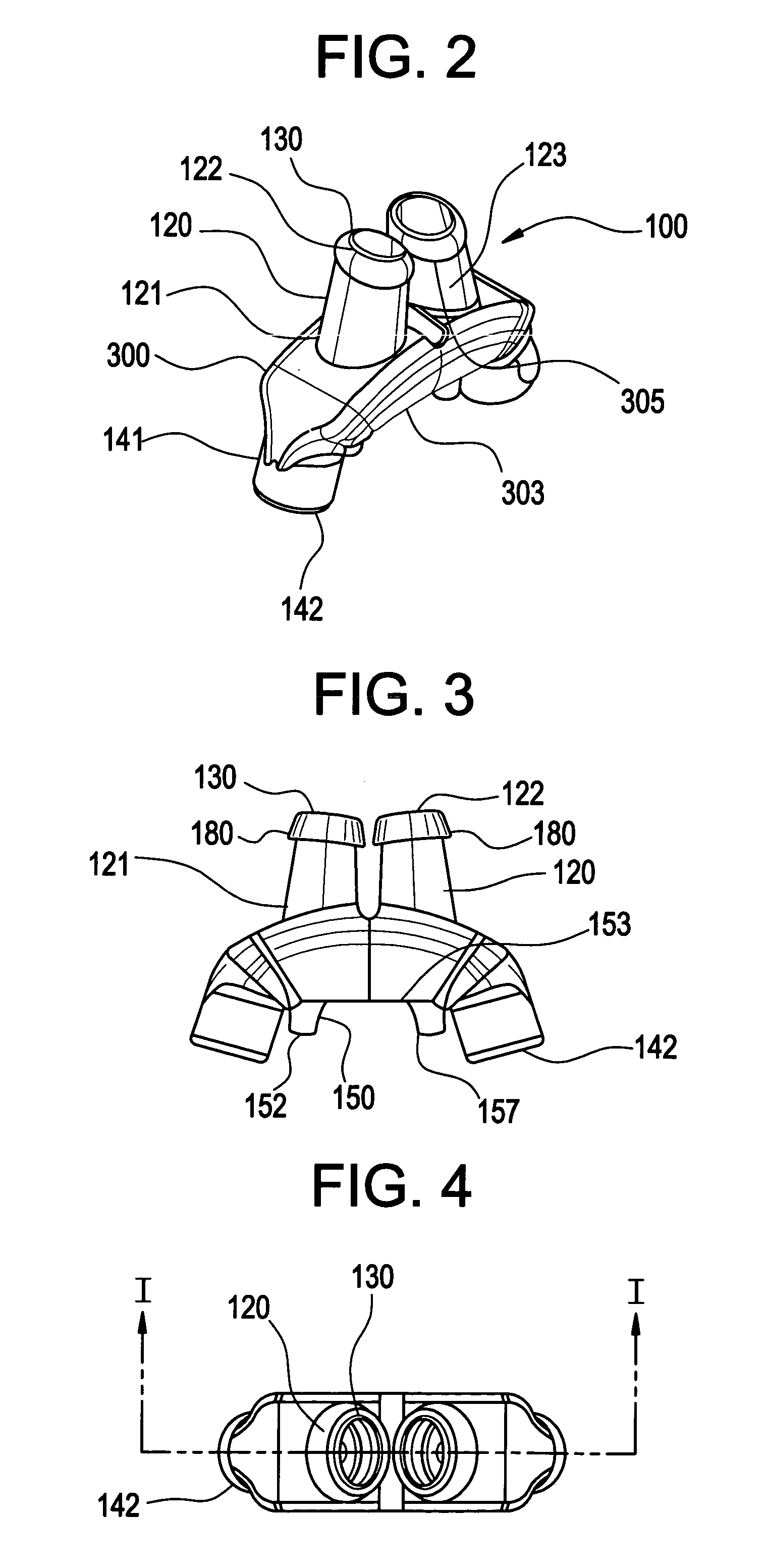

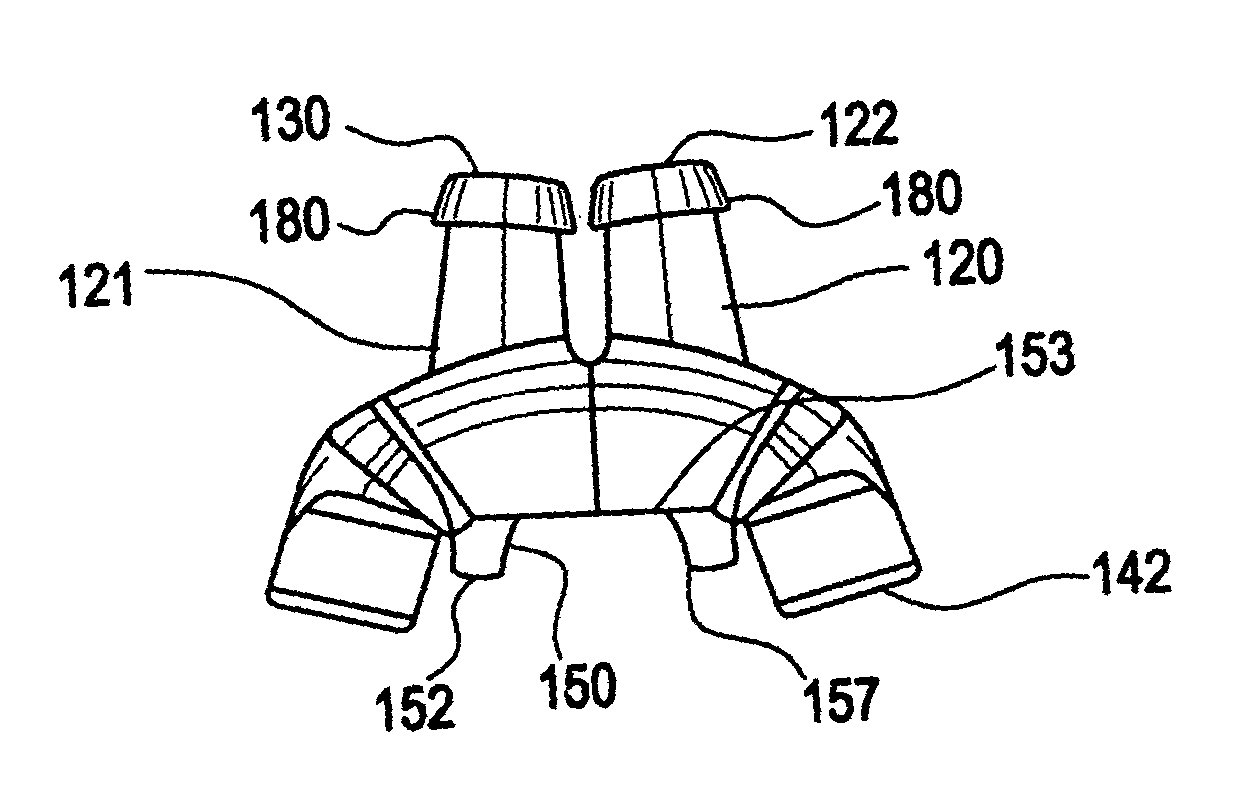

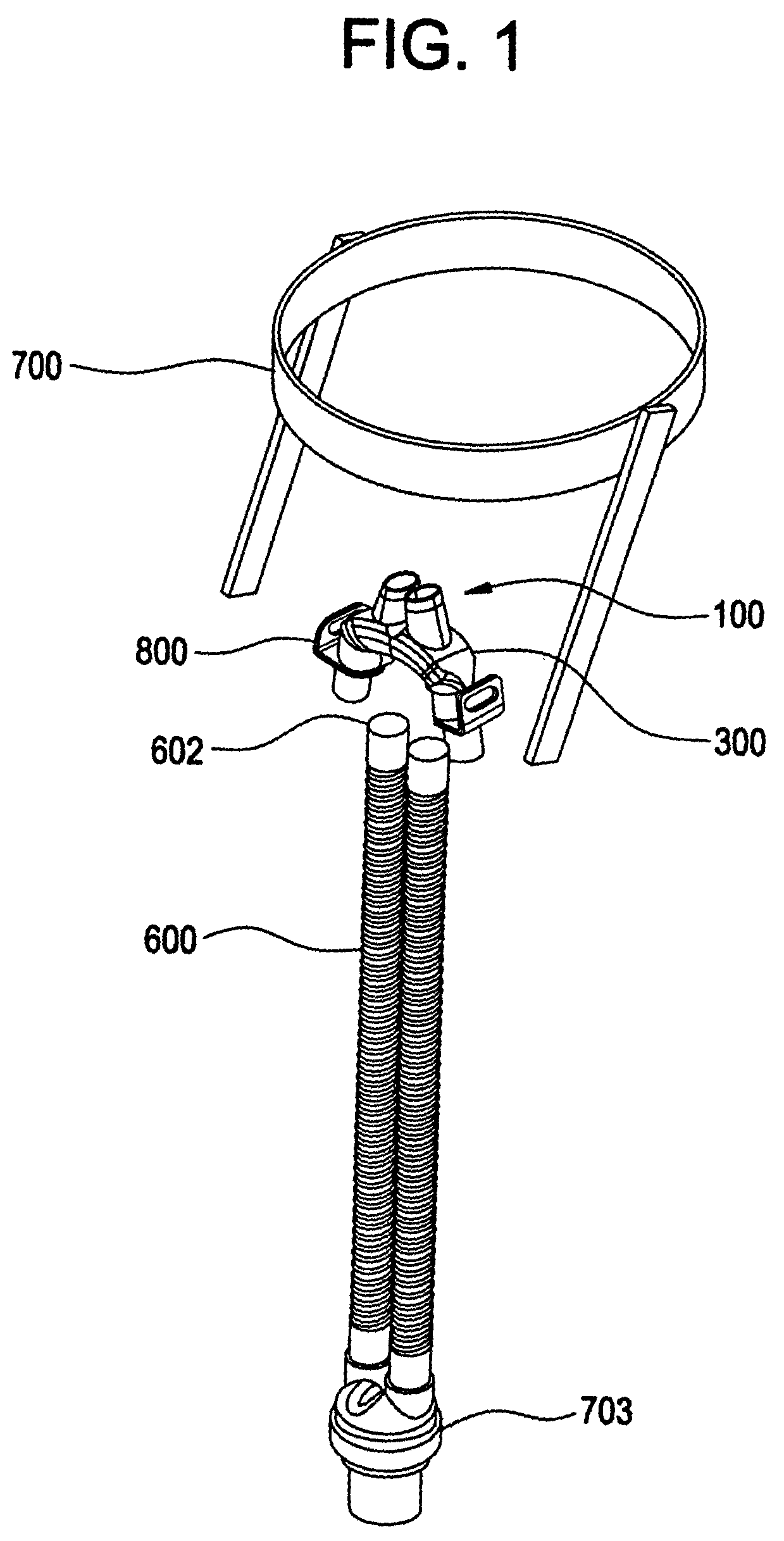

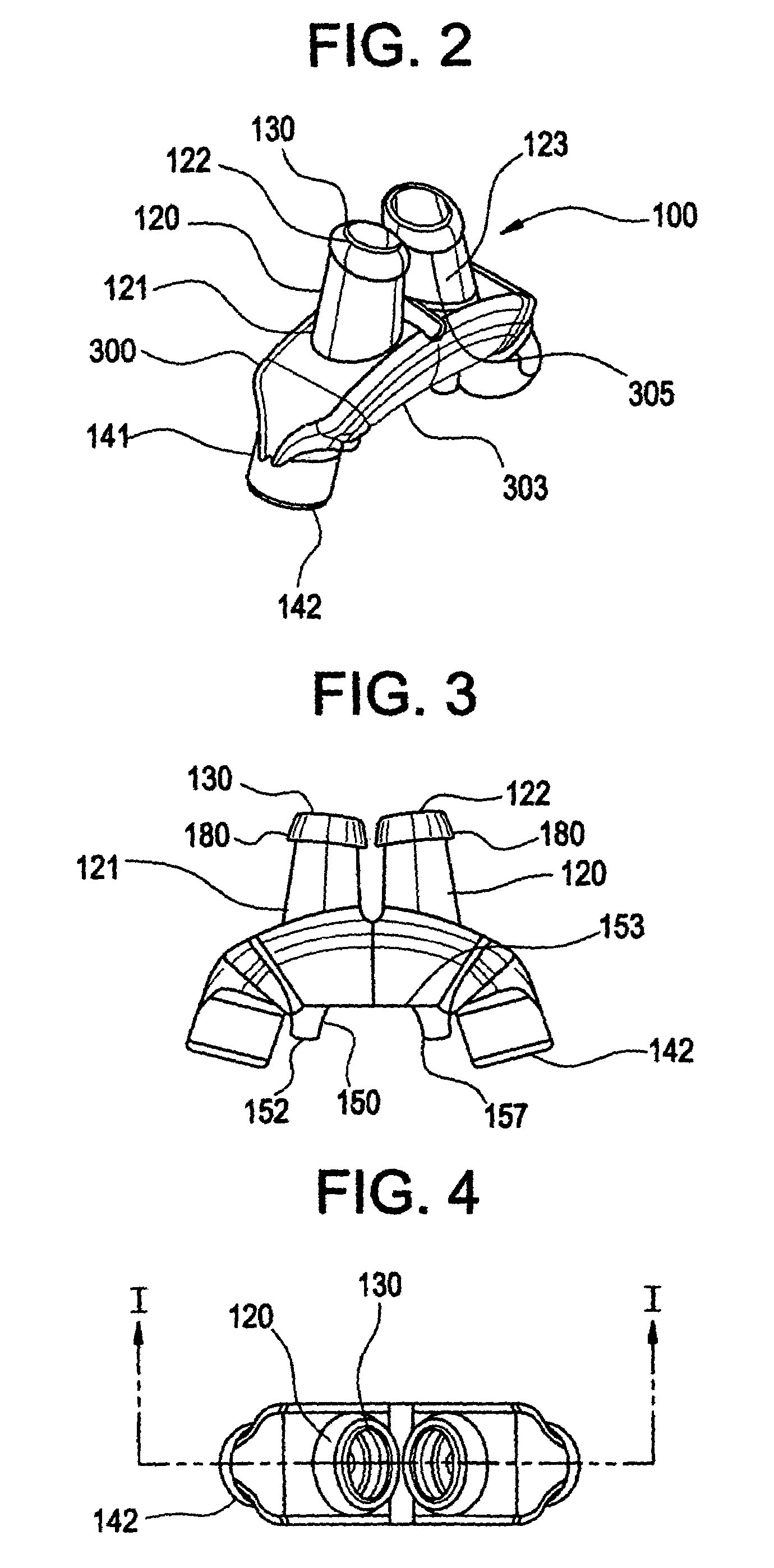

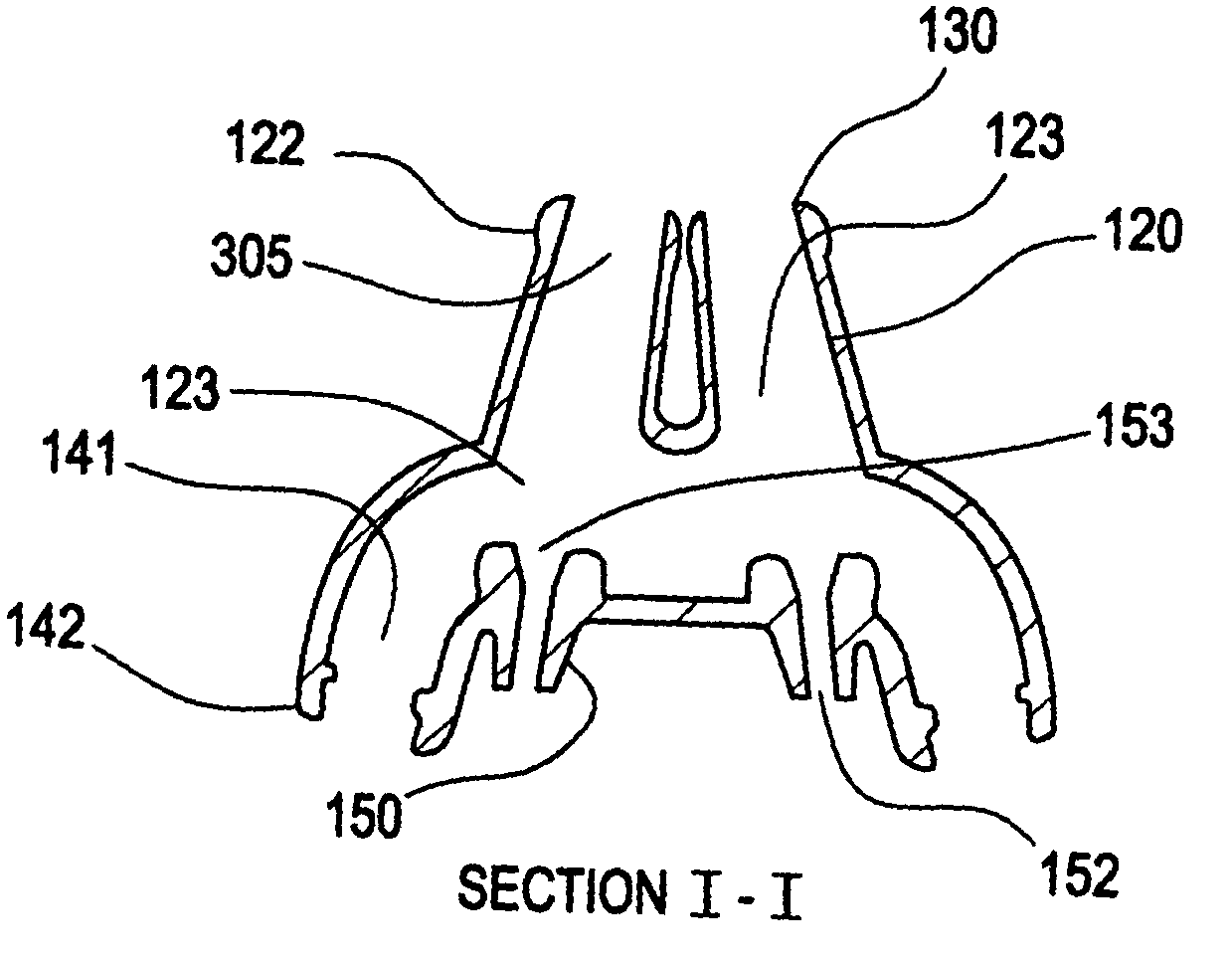

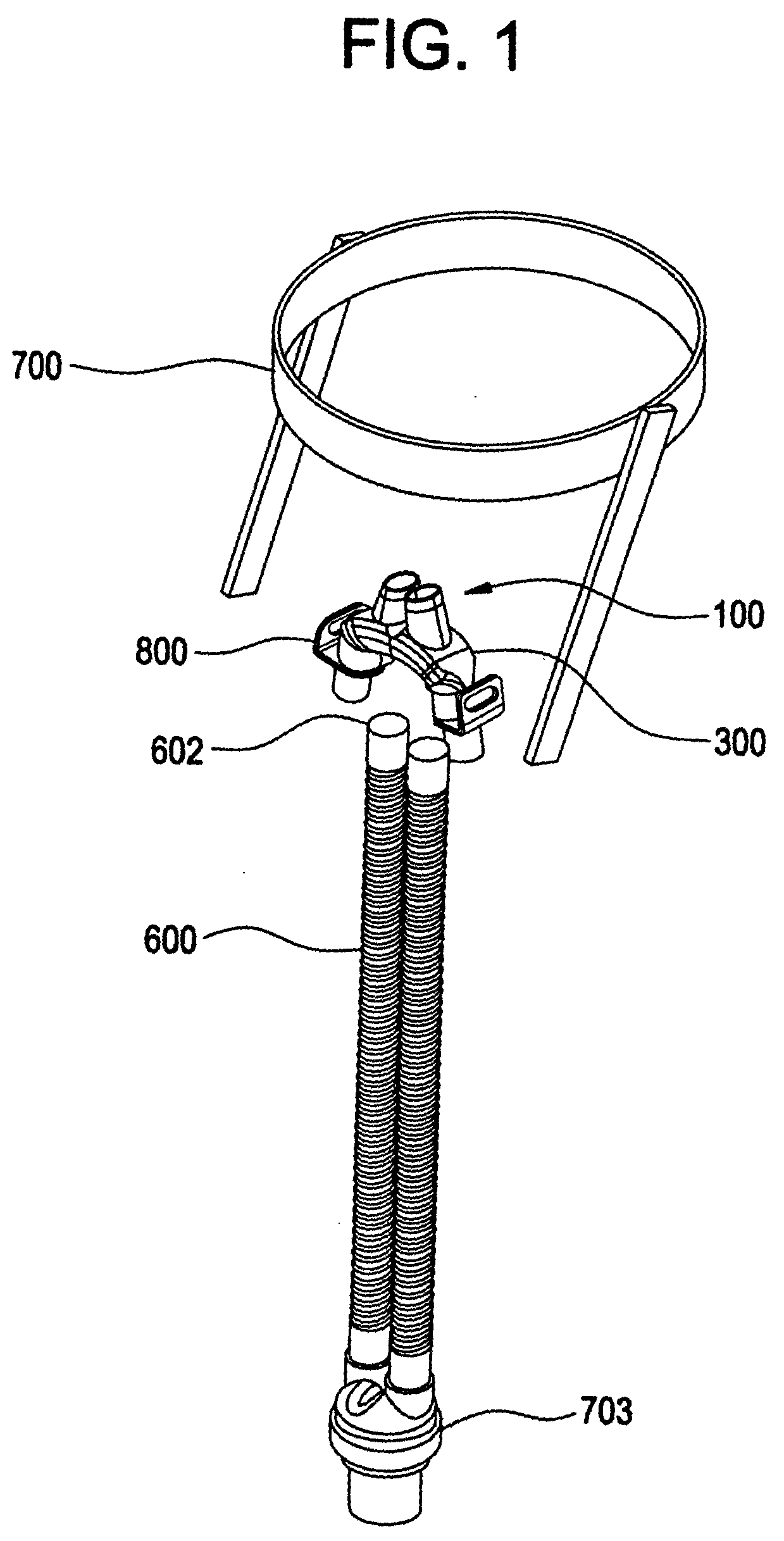

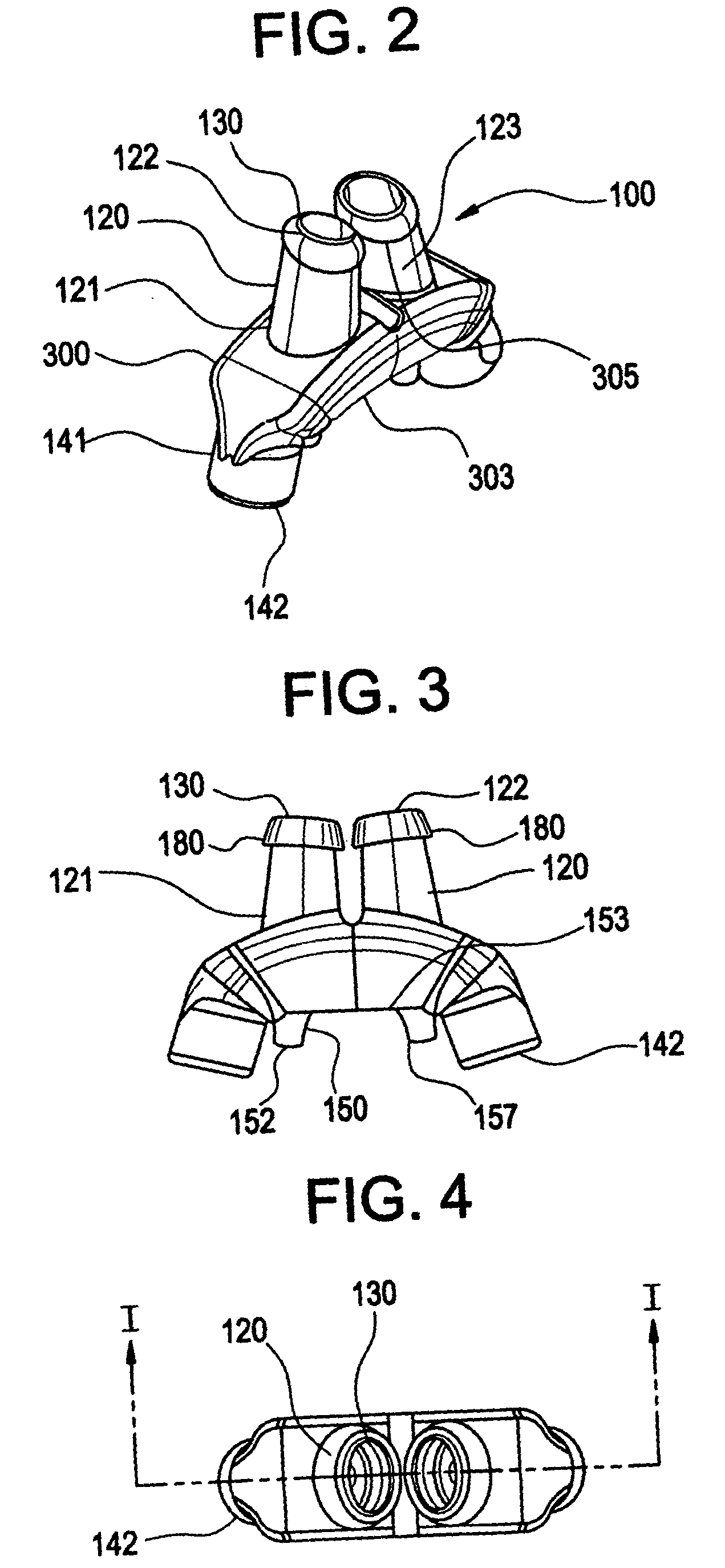

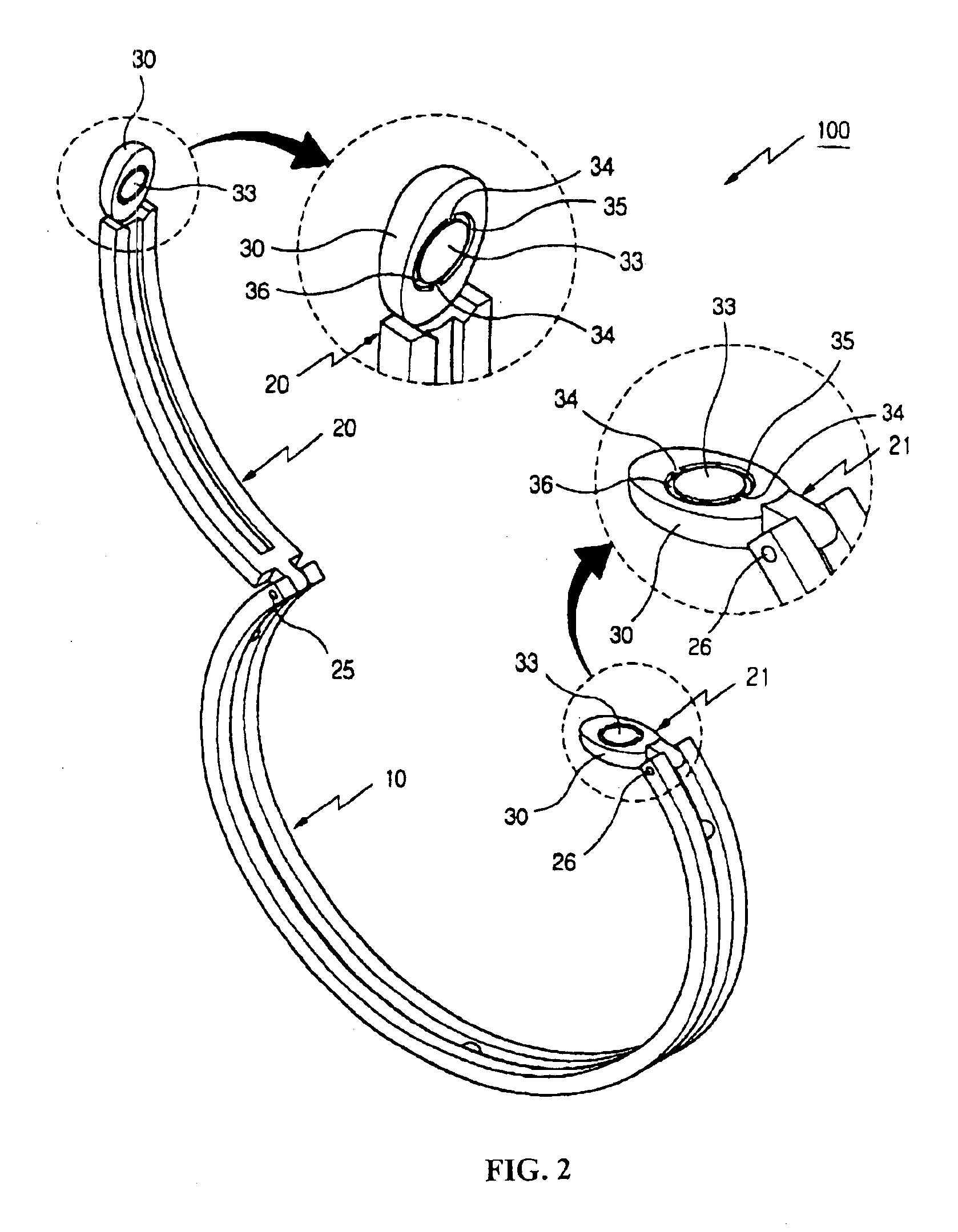

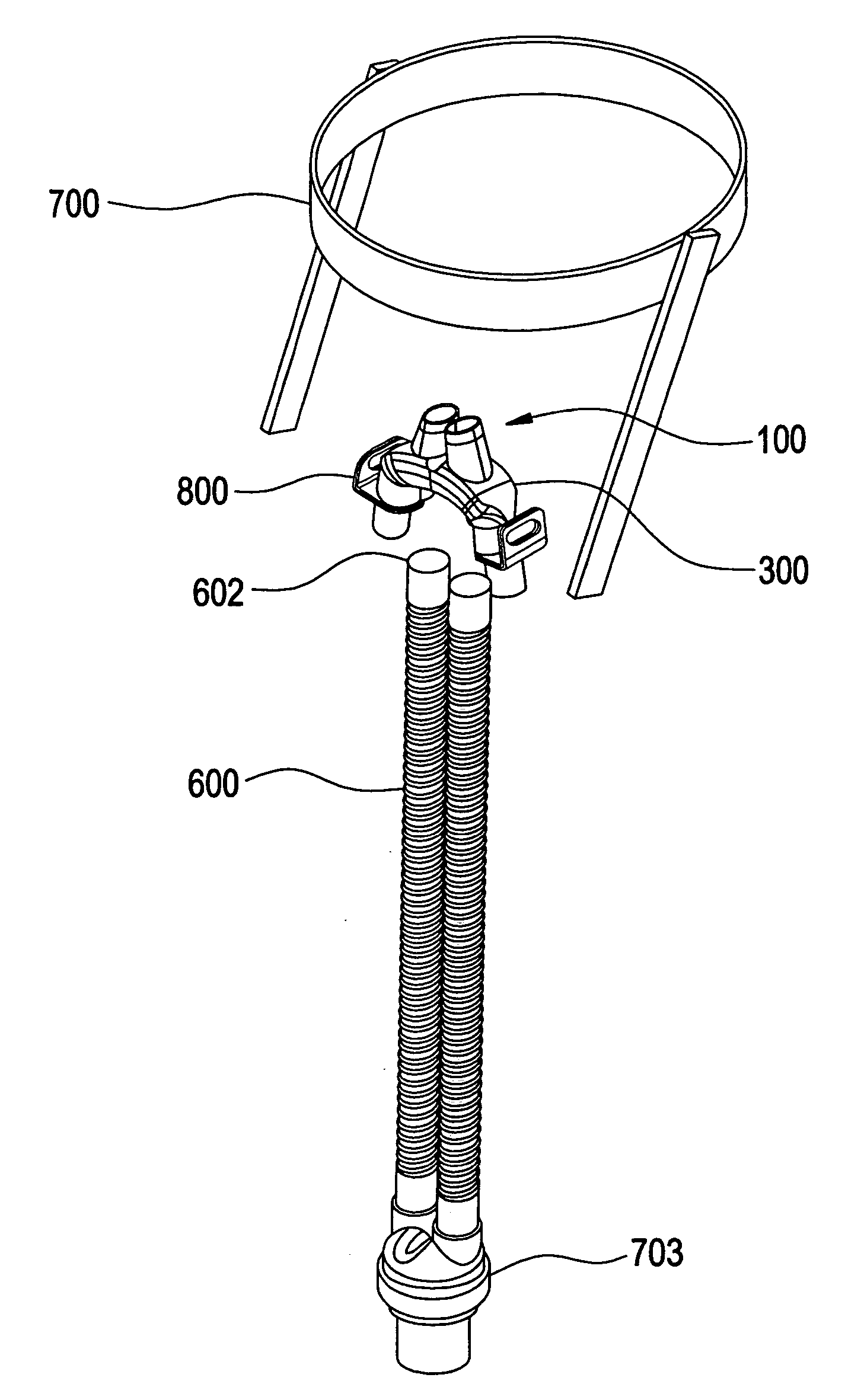

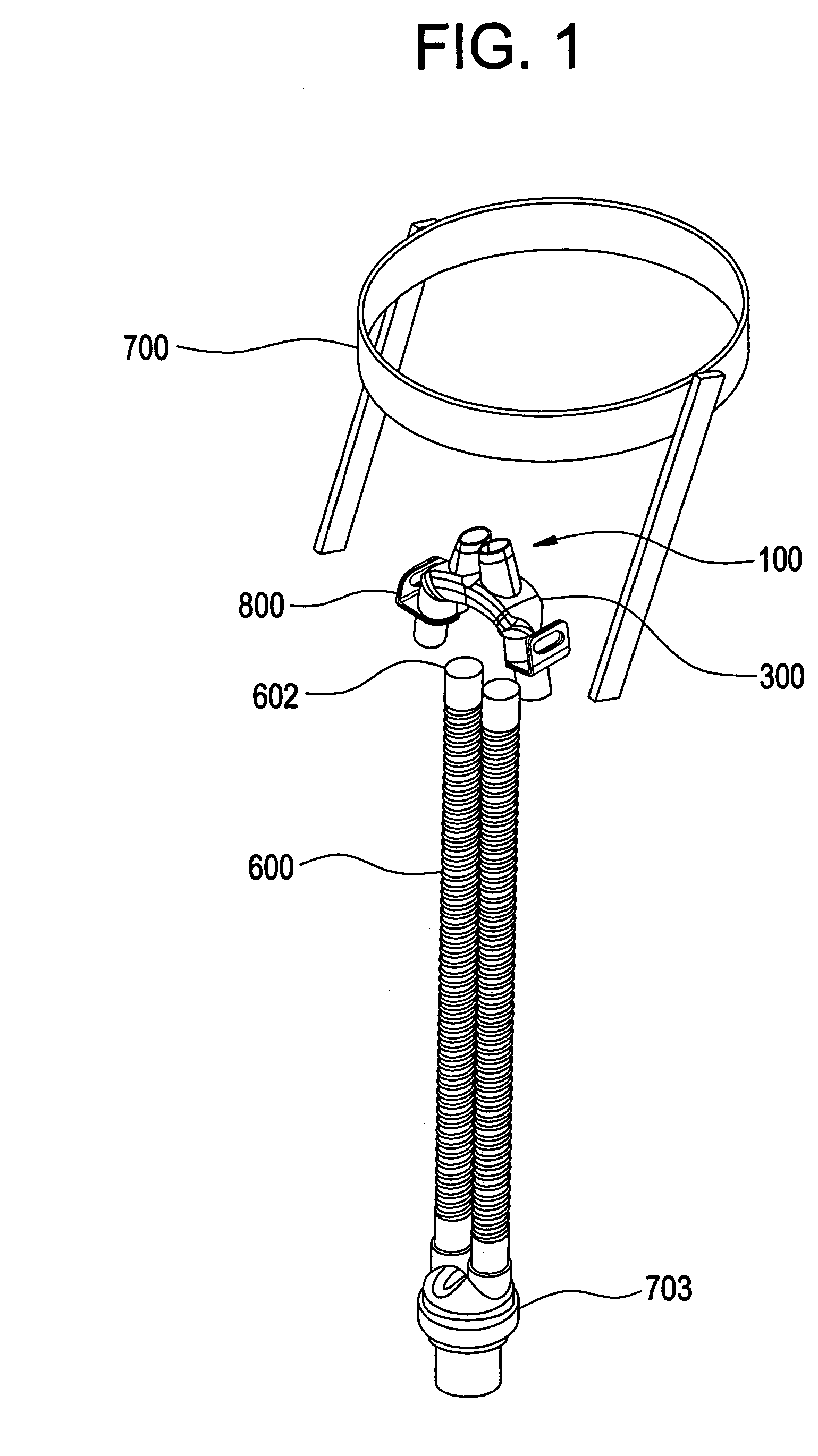

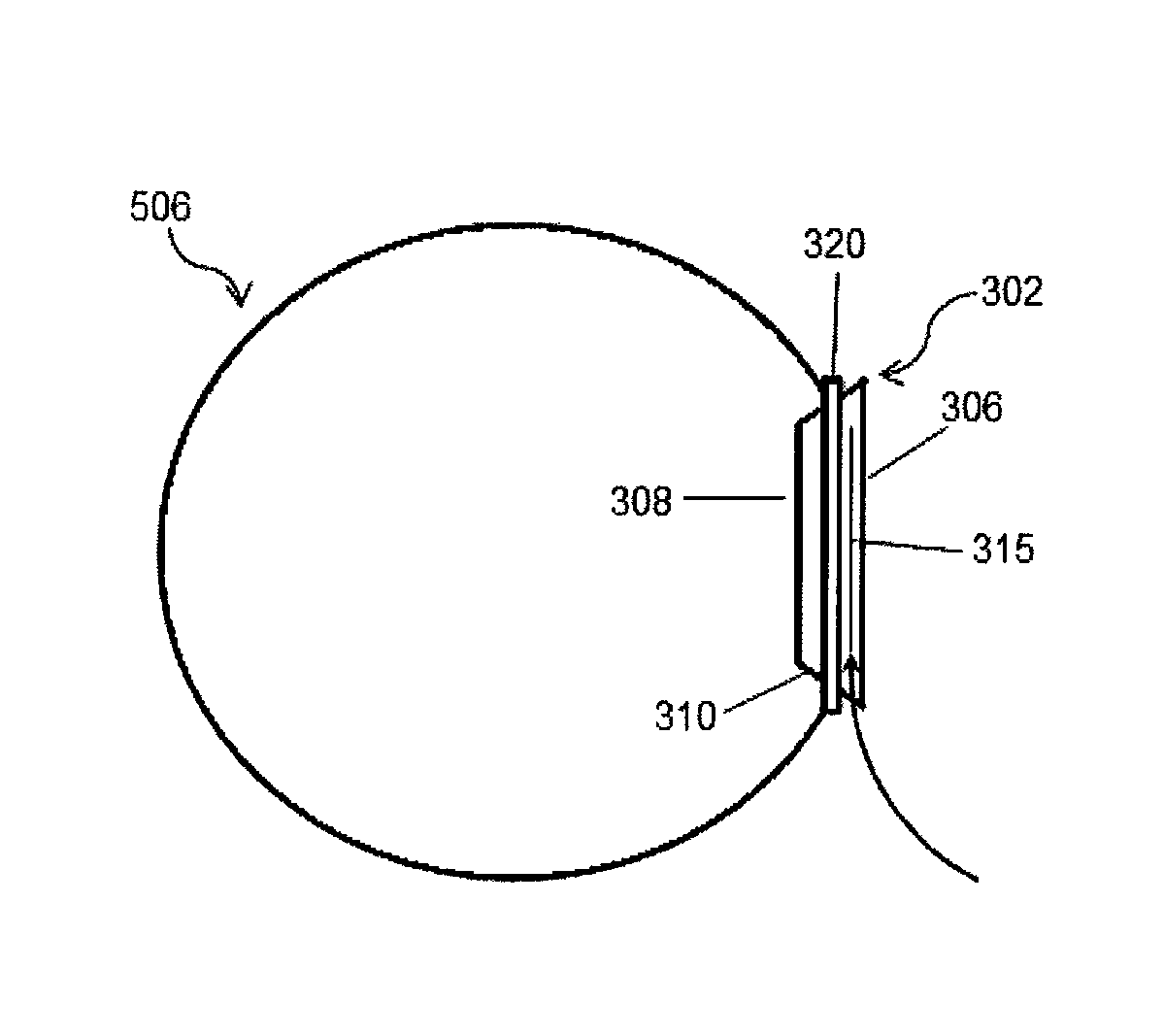

Nasal interface and system including ventilation insert

A ventilation or CPAP interface system adapted to be inserted into a nares of a user to secure the interface. A cannula adapted to be connected to a source of ventilation gas forms a first portion of an input gas flow passage to supply the ventilation gas to the user. A nasal insert adapted to be inserted the nares of the user forms a second portion of the input gas flow passage from the cannula to a distal end of the nasal insert. A seal portion adapted to engage a portion of the first naris is provided adjacent the distal end of the nasal insert. Ventilation interface system may optionally include feed tubes, y-connector, tube holder, and headgear.

Owner:SALTER LABS LLC

Nasal interface and system including ventilation insert

A ventilation or CPAP interface system adapted to be inserted into a nares of a user to secure the interface. A cannula adapted to be connected to a source of ventilation gas forms a first portion of an input gas flow passage to supply the ventilation gas to the user. A nasal insert adapted to be inserted the nares of the user forms a second portion of the input gas flow passage from the cannula to a distal end of the nasal insert. A seal portion adapted to engage a portion of the first naris is provided adjacent the distal end of the nasal insert. Ventilation interface system may optionally include feed tubes, y-connector, tube holder, and headgear.

Owner:SALTER LABS LLC

Nasal interface and system including ventilation insert

A ventilation or CPAP interface system adapted to be inserted into a nares of a user to secure the interface. A cannula adapted to be connected to a source of ventilation gas forms a first portion of an input gas flow passage to supply the ventilation gas to the user. A nasal insert adapted to be inserted the nares of the user forms a second portion of the input gas flow passage from the cannula to a distal end of the nasal insert. A seal portion adapted to engage a portion of the first naris is provided adjacent the distal end of the nasal insert. Ventilation interface system may optionally include feed tubes, y-connector, tube holder, headgear and a headgear flange.

Owner:SALTER LABS LLC

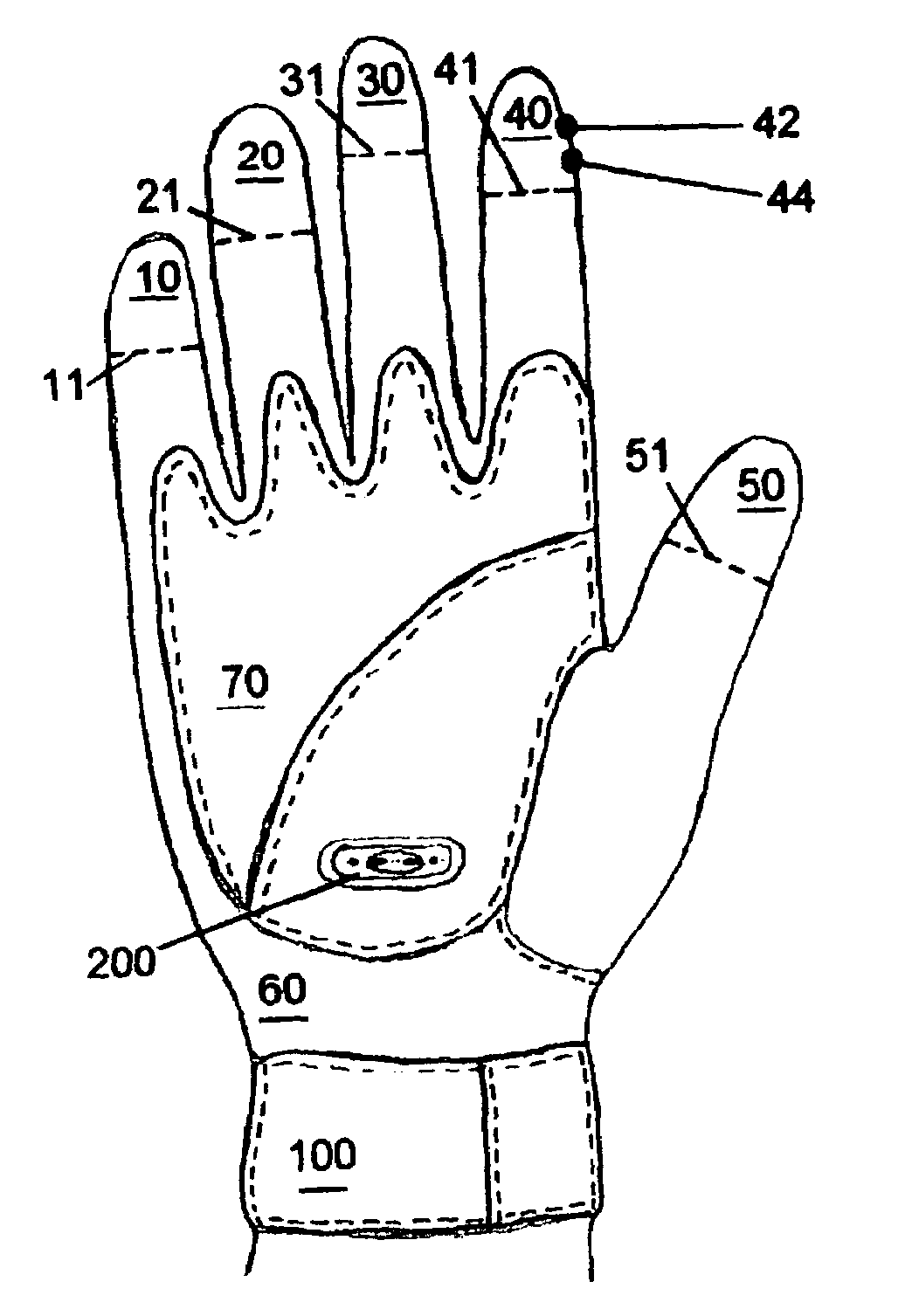

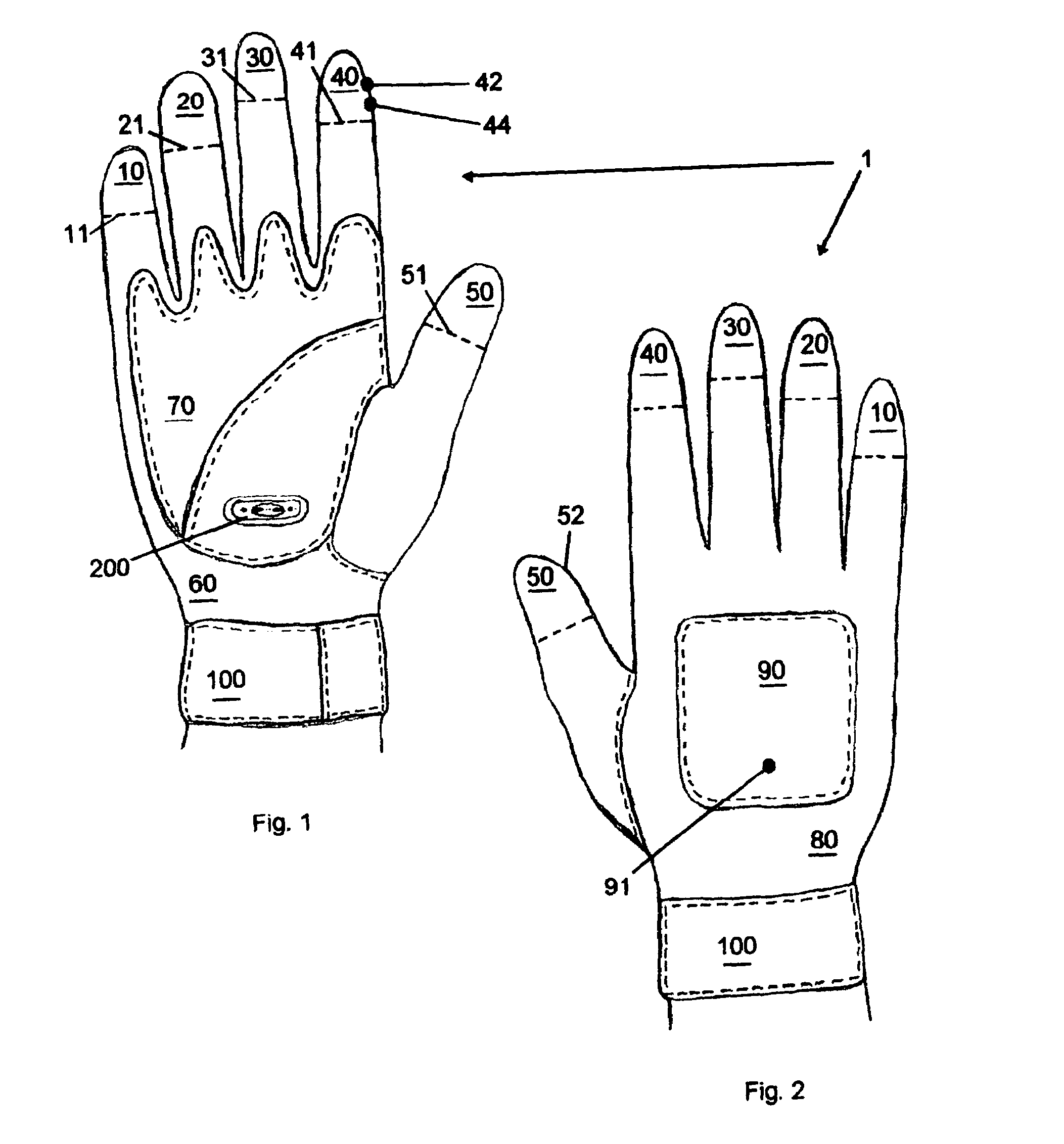

Versatile stun glove

InactiveUS7012797B1Promote activationWithout unnecessary delayElectric shock equipmentsApparelSTUNIndex finger

A versatile stun glove having at least two electrodes placed in the palm region, and / or on the back of the hand and / or on the fingers of the glove. A rechargeable power supply that uses simple thin diameter and thickness replaceable batteries for powering the electrodes. Batteries can include 9-volt battery, a double A, and triple A batteries. A thin watch battery can also be used so that no protrusions extend outward from the glove body. The power supply can be located in the palm region and / or on the back of the hand of the glove. The power supply can be accessed by a foldable panel cover that can be removed by hook and loop fasteners(Velcro®), snaps, a zipper and the like. The power can be activated by a simple switch located adjacent to the finger tip of the index finger of the user so that touching the tip of the thumb against the index finger tip activates the power. An alternative activation source can be a pressure sensor that is underneath one of the electrodes so that pressing the at least one electrode into an assailant activates the power. A novel stand and power supply recharge allows for the glove to be mounted to a vehicle cigarette lighter. The location of the stand allows for the glove to be easily accessible and reachable when needed by the user. A stun stick accessory can allow for the glove discharge to have greater reach to attackers and assailants.

Owner:C P D TECH

Nasal interface and system including ventilation insert

A ventilation or CPAP interface system adapted to be inserted into a nares of a user to secure the interface. A cannula adapted to be connected to a source of ventilation gas forms a first portion of an input gas flow passage to supply the ventilation gas to the user. A nasal insert adapted to be inserted the nares of the user forms a second portion of the input gas flow passage from the cannula to a distal end of the nasal insert. A seal portion adapted to engage a portion of the first naris is provided adjacent the distal end of the nasal insert. Ventilation interface system may optionally include feed tubes, y-connector, tube holder, headgear and a headgear flange.

Owner:SALTER LABS LLC

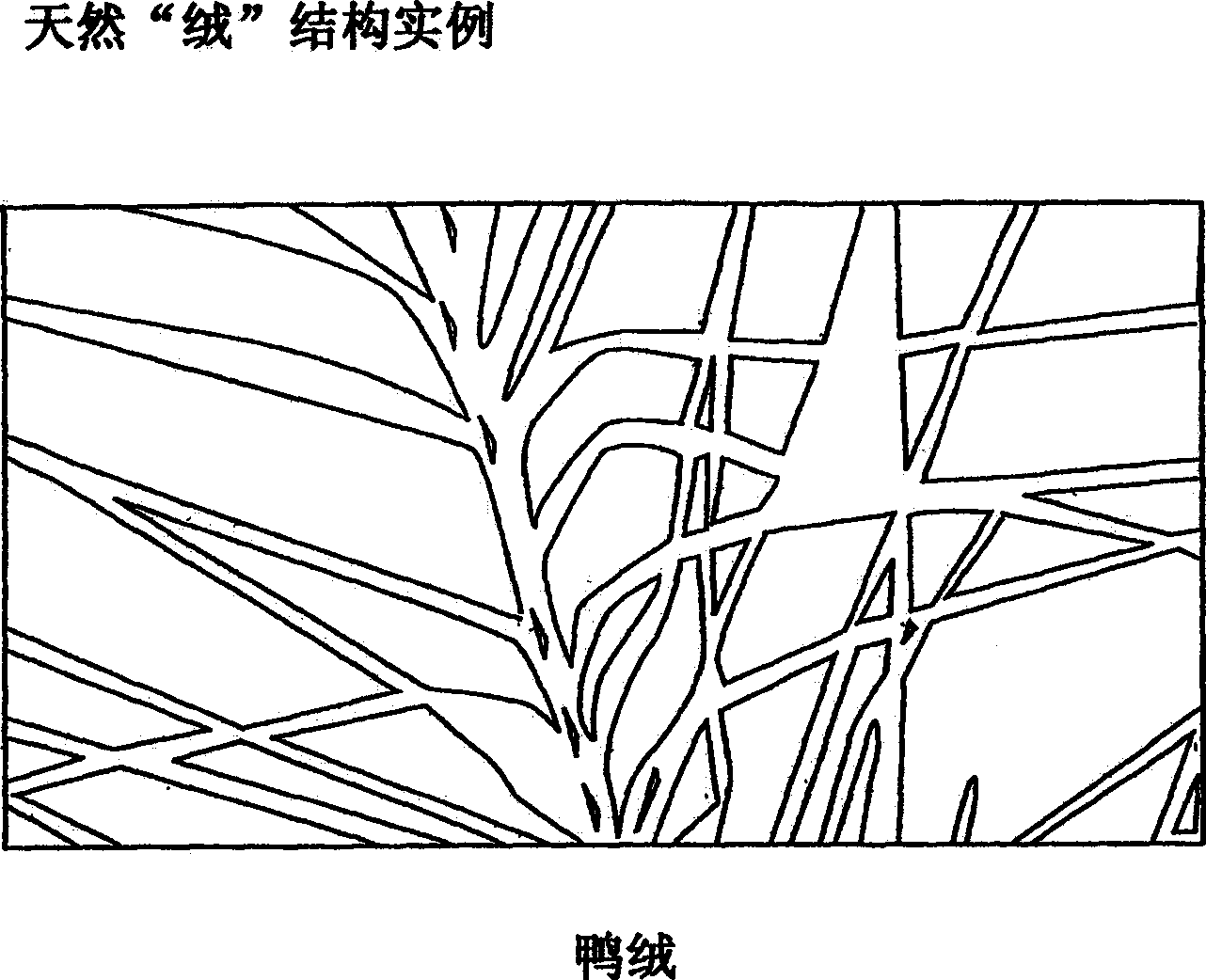

Antibacterial down feather and manufacturing method thereof

InactiveCN101611938APrevent mildew and insectsHigh antibacterial rateFibre treatmentDry-cleaning apparatus for textilesAntibacterial agentInflammation

The invention relates to an antibacterial down feather and a manufacturing method thereof. The manufacturing method comprises the steps of raw material stem removal, dust and sand removal, precise separation, washing, dehydration, drying, cooling and package, wherein an antibacterial agent comprises the following components in portion by weight: 6 to 10 portions of quaternary ammonium salt A, 1 to 2 portions of modified chitosan, 0.2 to 0.5 portion of silane coupling agent, 0.1 to 0.5 portion of solubilizing agent, and 0.3 to 0.6 portion of dispersing agent. The antibacterial down feather can effectively prevent mildew and attack of insects of the down feather in storage, transportation and use, and particularly when the antibacterial down feather serves as a filling material and is manufactured into articles for daily use, because of the antibacterial and bacteriostatic functions, the corresponding products have obvious functions of resisting bacteria, diminishing inflammation, deodorizing, resisting mildew, relieving itching and converging, and have no stimulation to skins, and the antibacterial rate of the obtained down feather to staphylococcus aureus bacteria reaches up to 99 percent, and after 10 times of washing, the antibacterial rate still reaches 92 percent.

Owner:凌颖

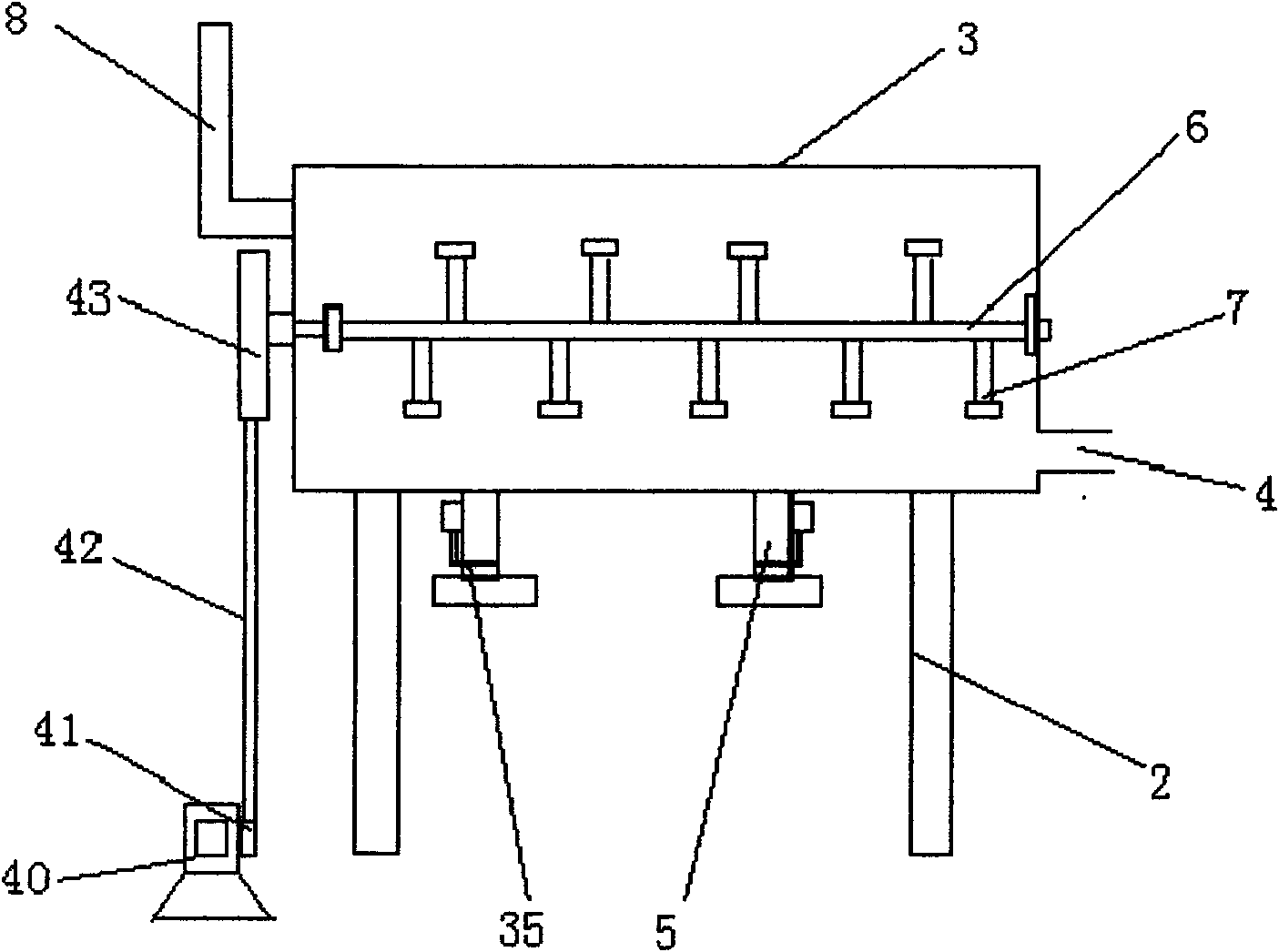

Method for processing and collecting down feather from feather and rinsing down feather

The invention discloses a method for processing and extracting eiderdown from feathers and washing eiderdown. The method comprises the steps of carrying out feeding, extracting, dust removal, stem absorption, washing, rinsing, dehydrating, drying, cooling, impurity removal and packing on the feathers. The eiderdown extraction comprises: adopting an eiderdown extracting tower, throwing the feathers into the eiderdown extracting tower, and making the rotation speed of a stirring device in the chenille eiderdown extracting tower be 40-50 turns / min; the washing procedure comprises: putting the feathers into water added with a washing agent, stirring and cleaning the feathers; the rinsing procedure comprises: cleaning the washed feather slurry repeatedly by water; and the drying procedure comprises: drying the dehydrated feathers to 50 to 70 percent of dryness through steam, dampening the feathers, drying the feathers by the steam, and repeating the procedure frequently. The method reduces the down loss rate to 1 percent from 5 percent, and improves the high value contents of down in a feather sheet from 82 percent to 98 percent so as to reduce down mechanical loss and achieve the effects of improving quality and reducing loss. The fluffy degree of the 90 percent eiderdown is improved from 13 cm to 18 cm.

Owner:ANHUI LION GOOSE PROD

Down feather processing production technique

InactiveCN104172633ARealize the purpose of deodorization and disinfectionWash thoroughlyApparelMicrowavePulp and paper industry

The invention provides a down feather processing production technique. The down feather processing production technique includes steps of presorting, dedusting, separating, washing and drying of the down feather, soaking, secondary dewatering and drying, cooling, checking and packaging. The separating step includes separating dedusted down feather into nap, large, medium and small feather and large and small feather shafts; the washing step includes washing the feather more than five times by a feather washing machine by adding down feather detergent; the dewatering step includes dewatering until water content of the down feather is lower than 30%; the drying step includes drying the dewatered down feather at the temperature of 120 DEG C by a drying machine or microwaves, and deodorizing and disinfecting; the soaking step includes soaking the down feather in clean water added with natural essential oil; the secondary dewatering and drying step includes dewatering the down feather by a centrifugal machine and drying the dewatered down feather. By the down feather processing production technique, after presorting, dedusting and separating, the down feather is washed, and different kinds of down feathers can be thoroughly cleaned and disinfected; after washing, drying and disinfecting, via secondary soaking in the clean water with natural essential oil, the processed down feather has faint scent and a nerve soothing function.

Owner:江苏欣隆羽绒有限公司

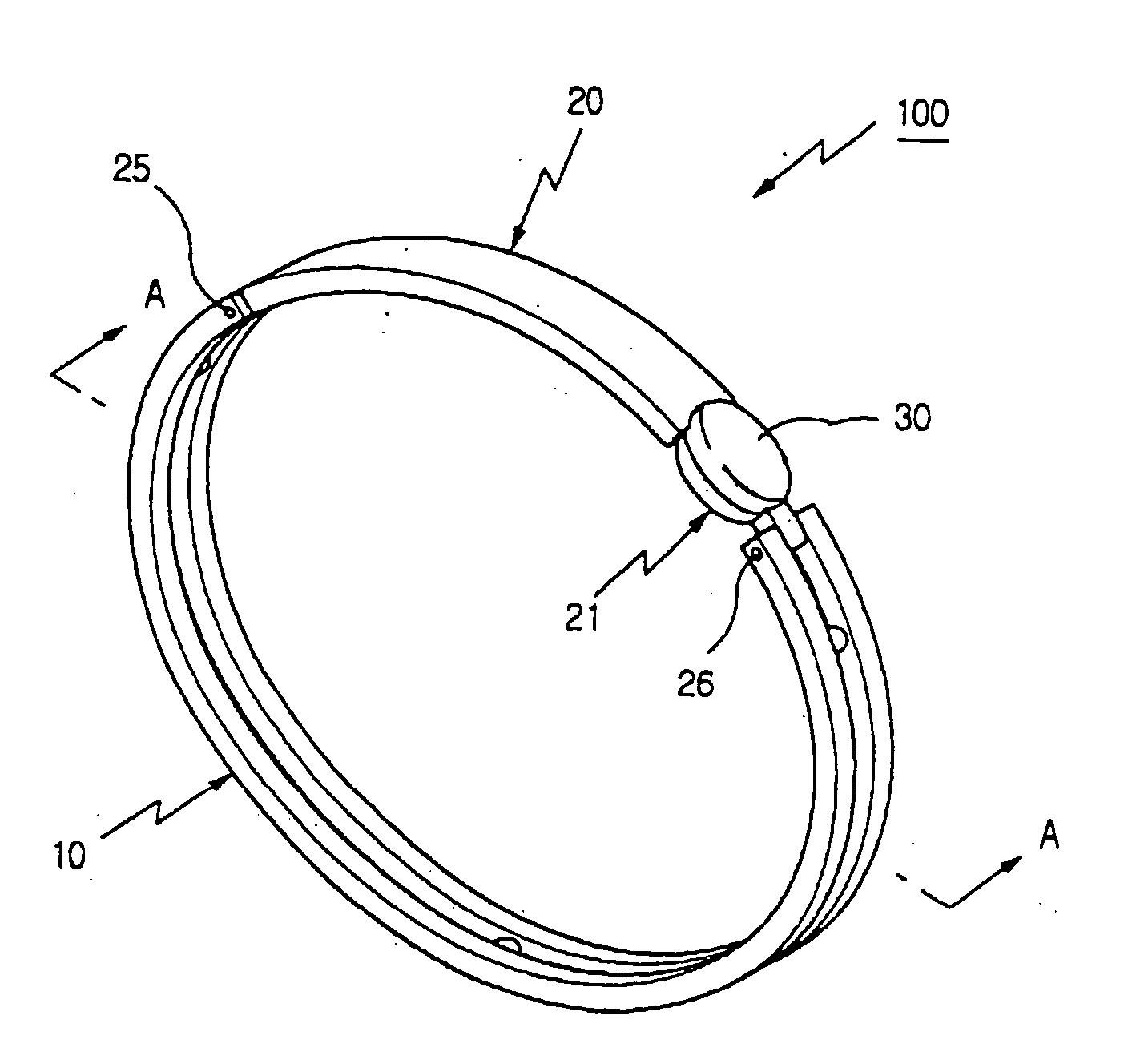

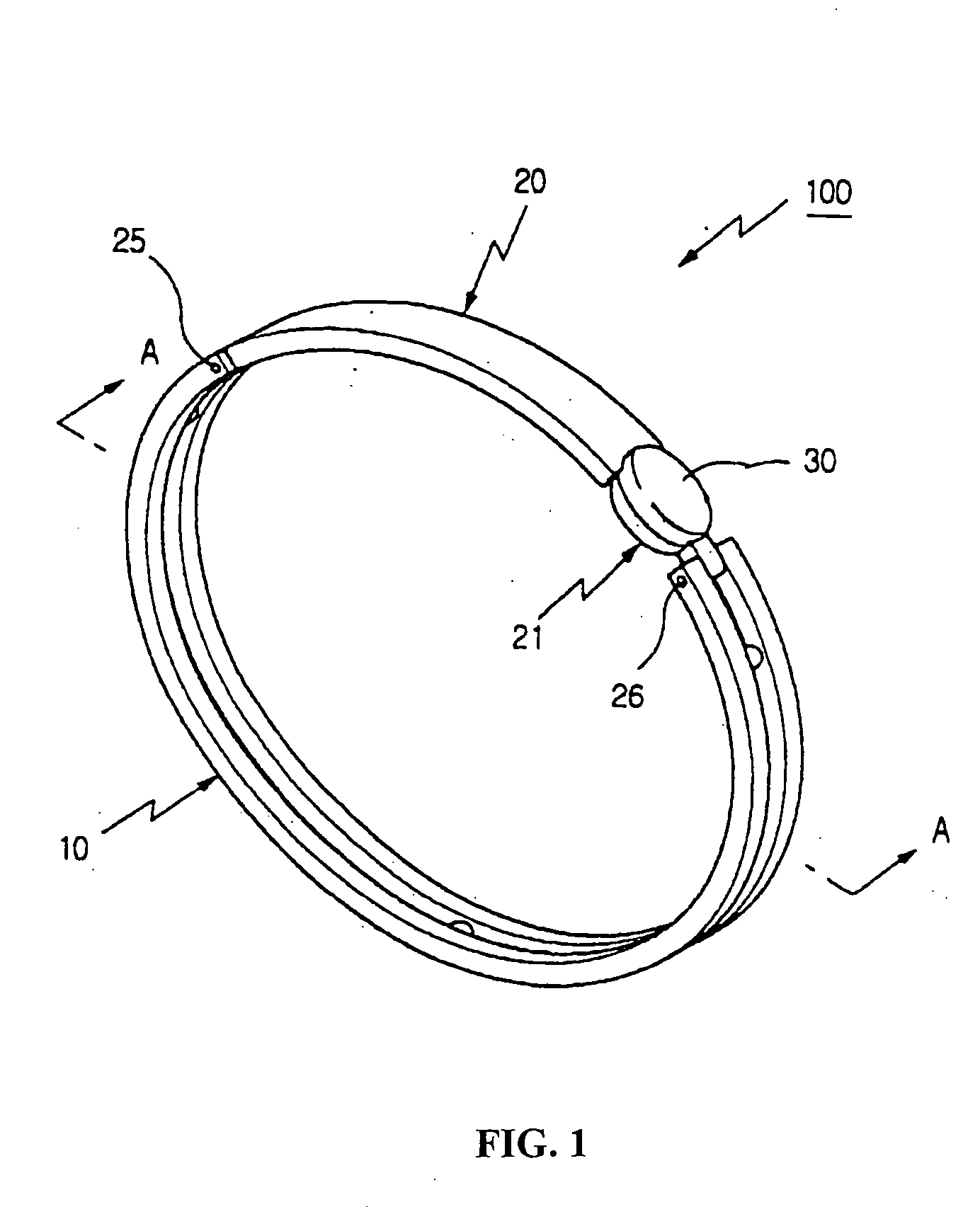

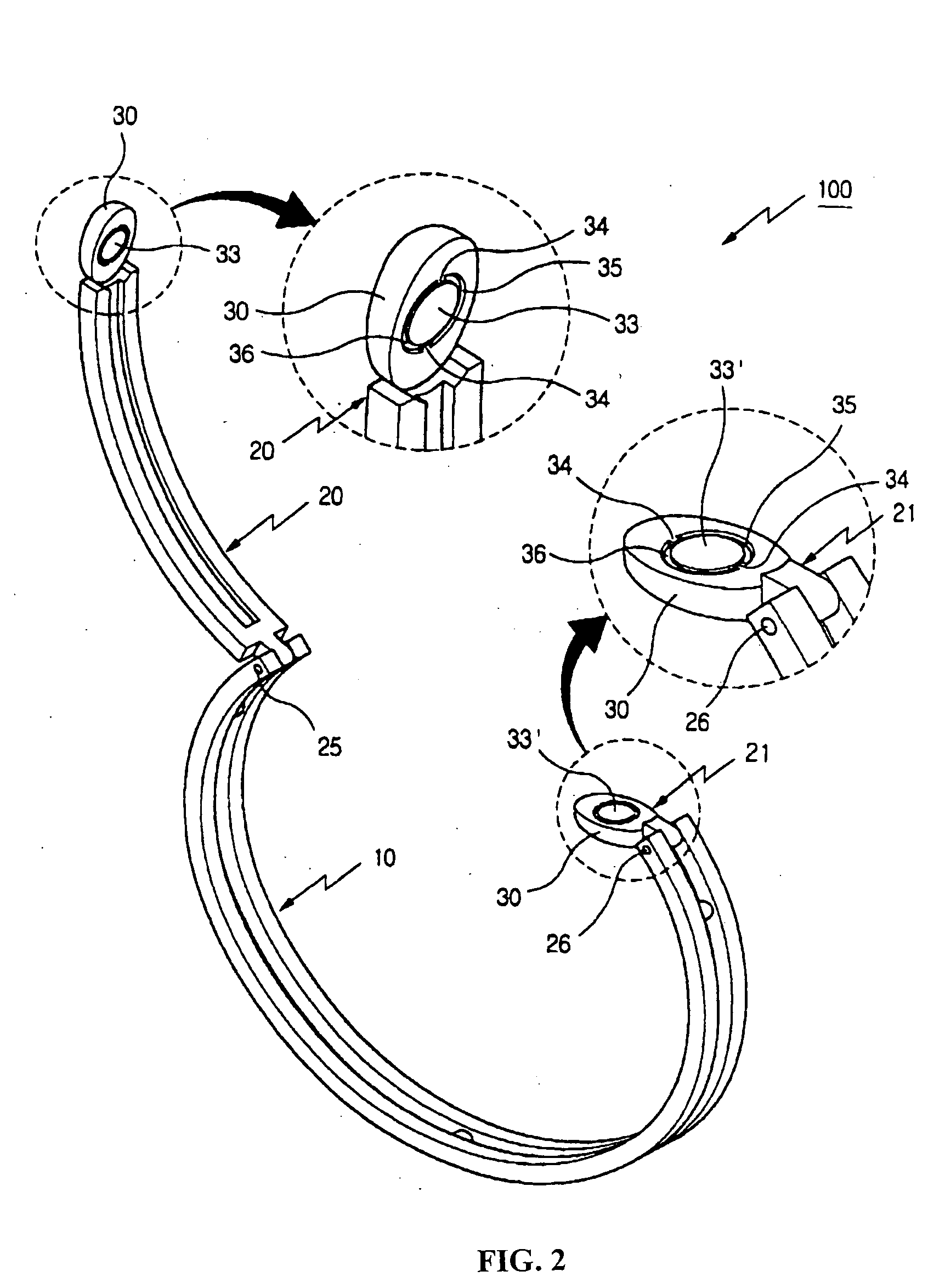

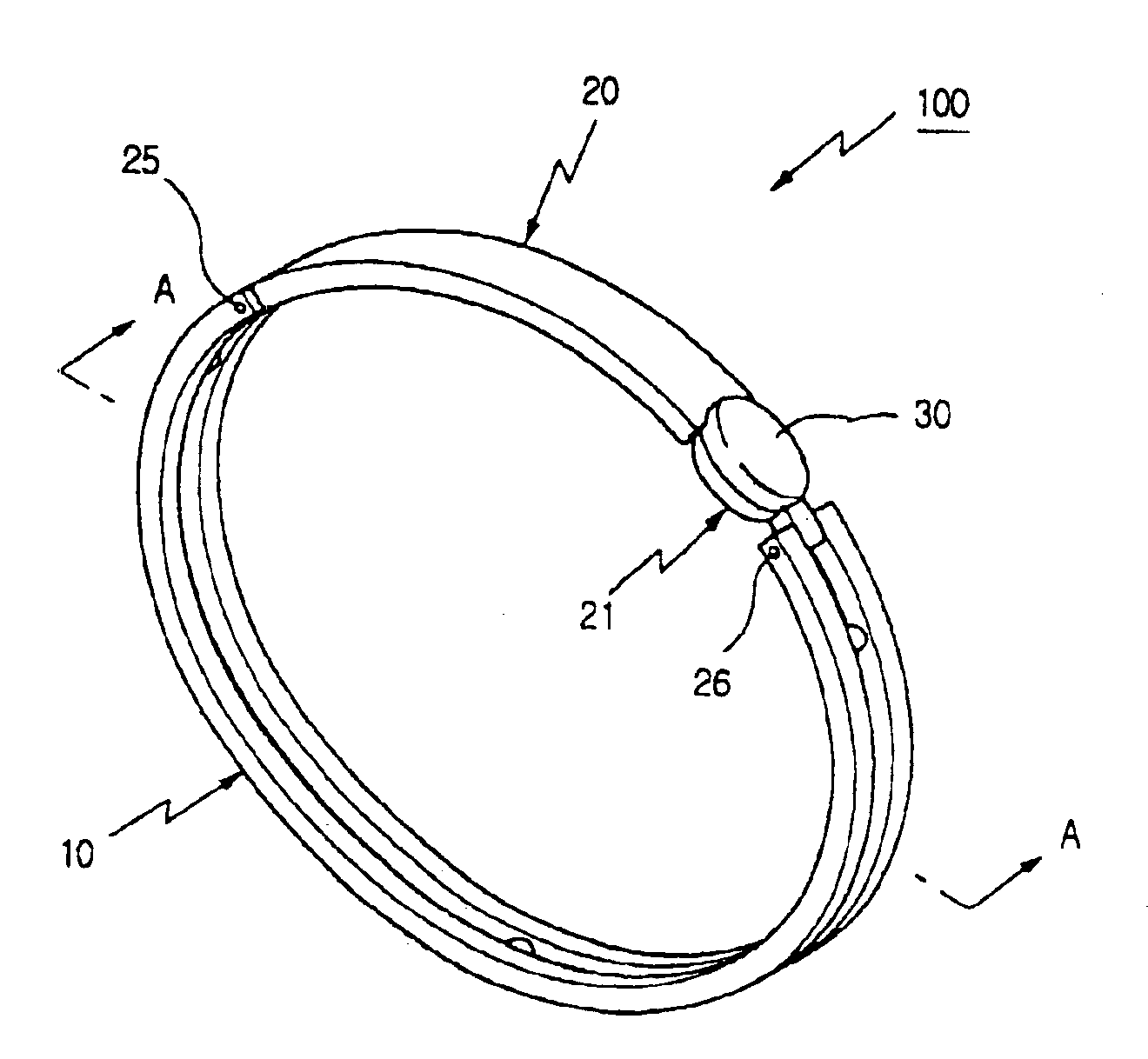

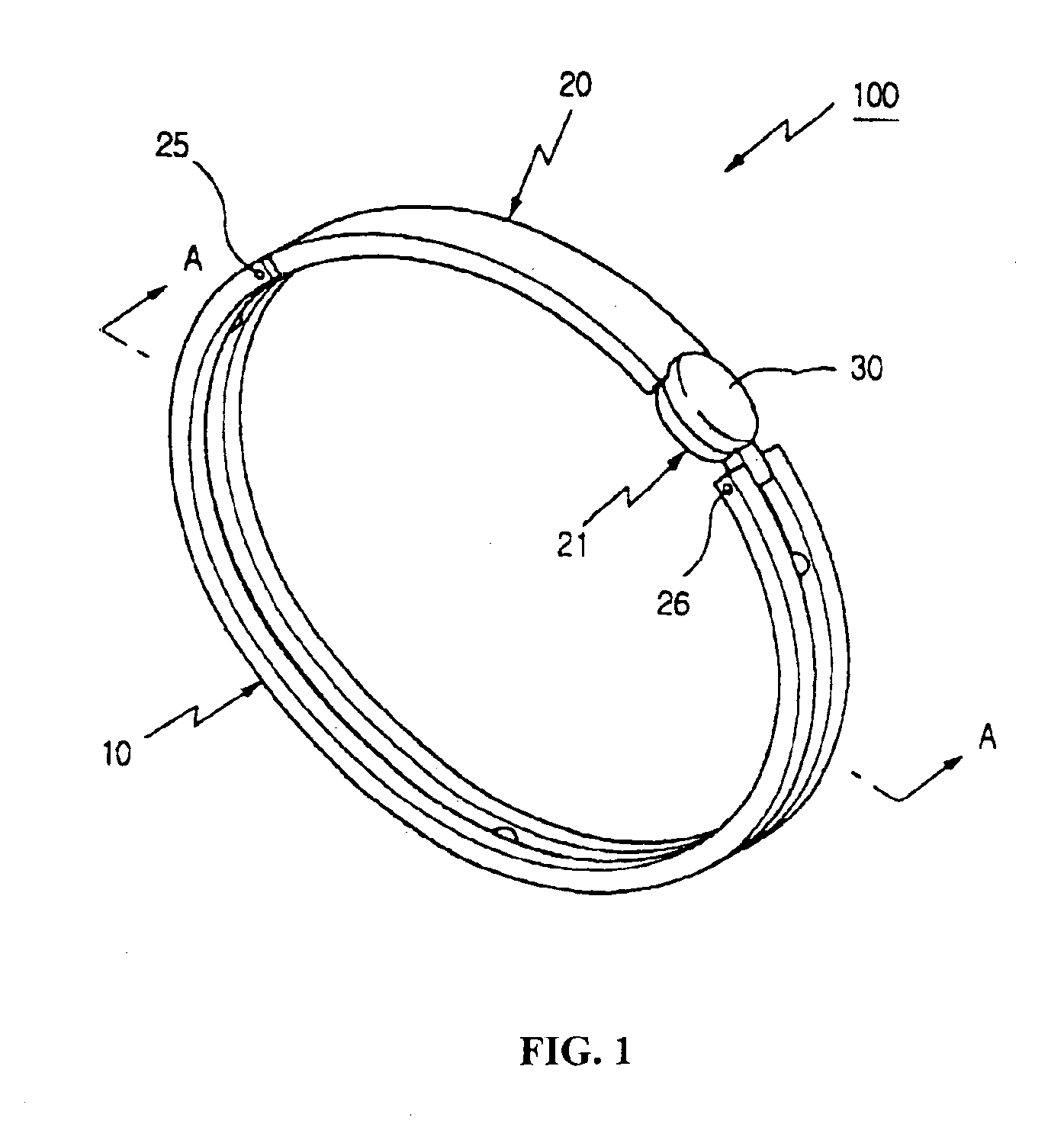

Bracelet that radiates anion and far infrared rays

The present invention is related to a bracelet irradiating anion and far infrared rays, comprising metal where anion-radiating material layer and gold plate layer are sequentially coated on the surface of a “C” shape core (10) with a connecting arm (20) and a clasp assembly including magnetic coupling clasps. This bracelet looks very elegant because of the gold plate on the exterior of the bracelet, and static electricity occurs due to the friction between the bracelet and the human hand, and it can irradiate anion and far infrared rays more effectively through sunlight, and by supplying the far infrared rays to the skin, the ion balance of the cell can be controlled, and it can change the electric potential of the skin to normal value, and can promote blood circulation and metabolism, complex biorhythm, and body cell is activated and blood pressure is lowered, increasing the tissue regeneration capacity, preventing the aging phenomena.

Owner:CREATE

Down feather cleaning machine

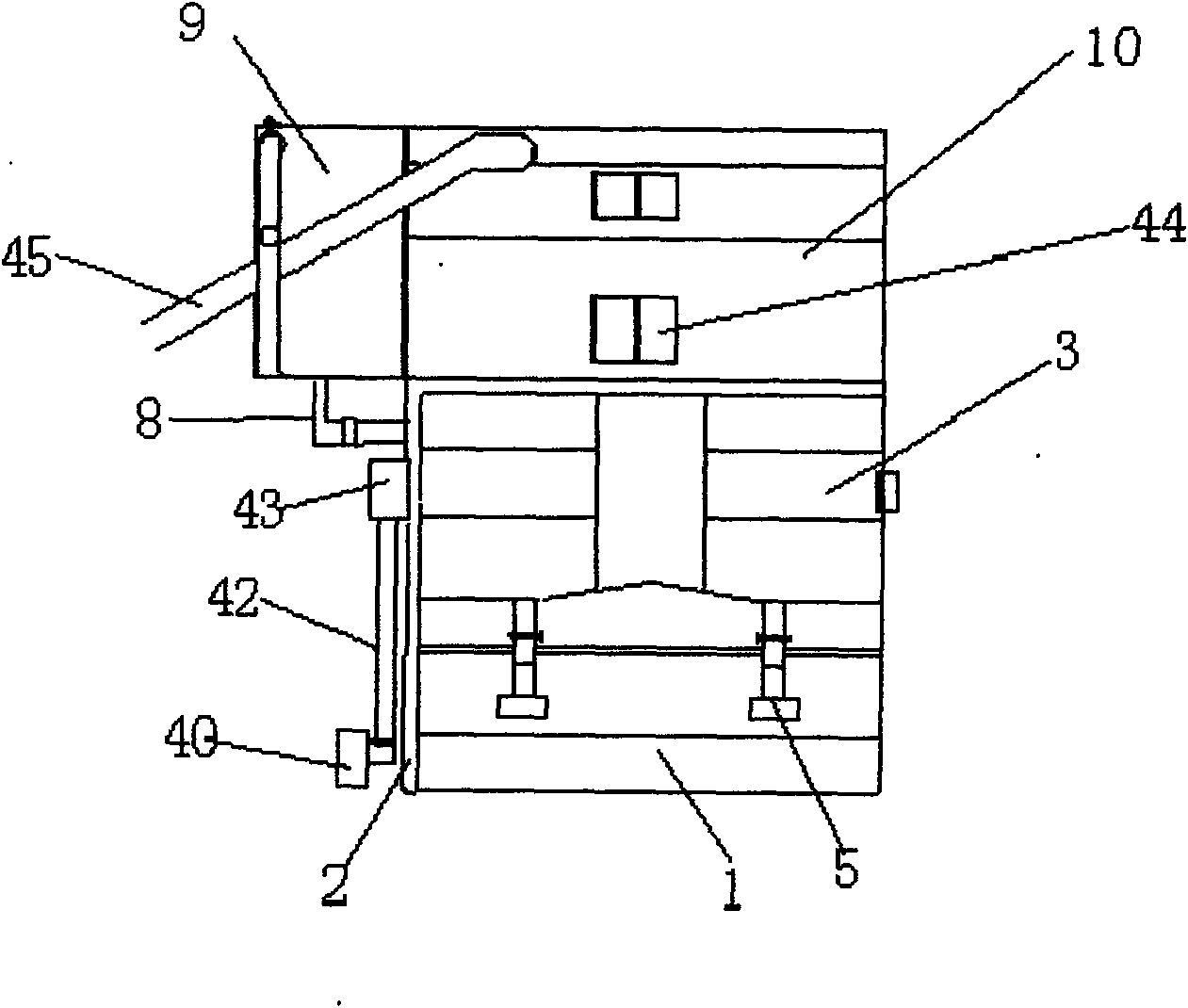

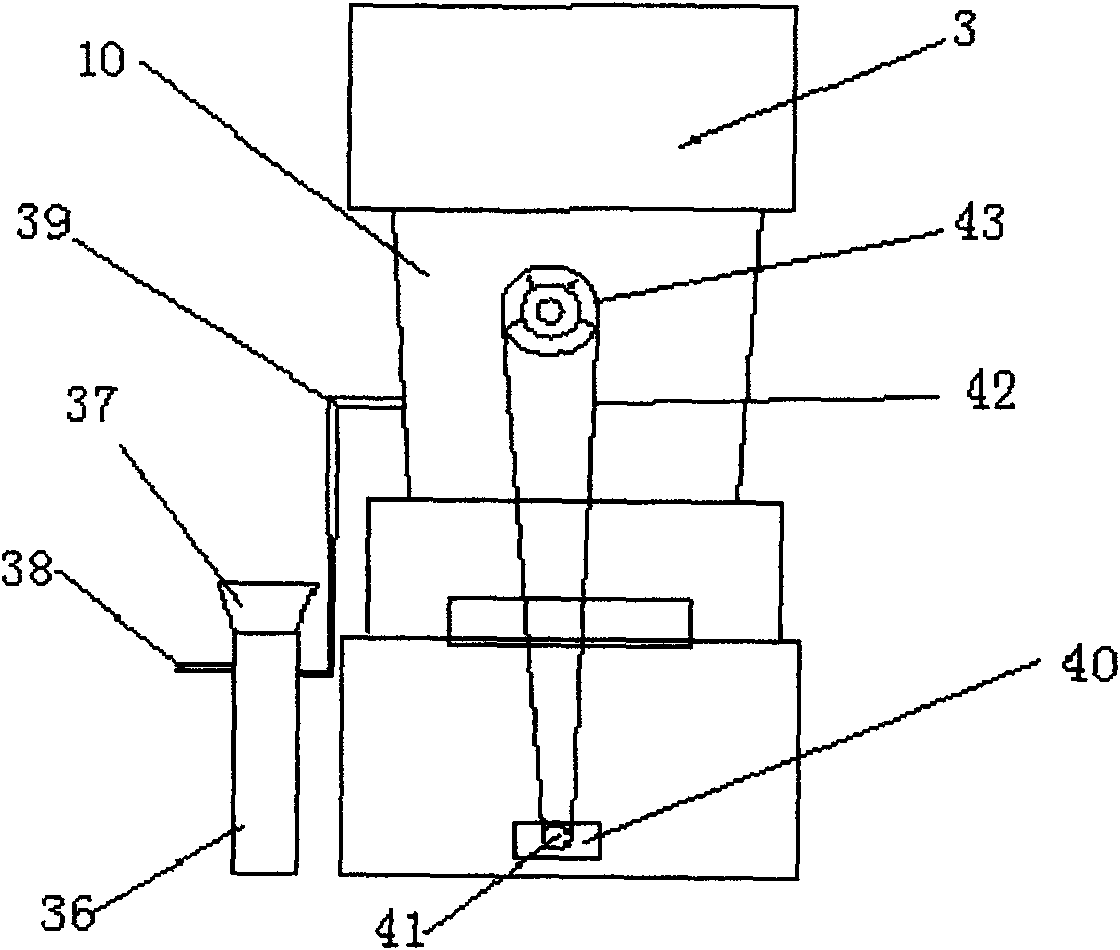

InactiveCN102115916AEasy to collectWool fibre washing/scouringApparelEngineeringMechanical engineering

The invention discloses a down feather cleaning machine, comprising a down feather cleaning device fixedly arranged on a draining pool. The down feather cleaning device comprises a cleaning cavity arranged on a support of the draining pool, the upper part of the cleaning cavity is provided with a discharge opening, a feed opening is communicated with a feed pipe, the lower part of the cleaning cavity is provided with a water outlet, the cleaning cavity is internally provided a rotation shaft rotating under the drive of a driving device, stirring rods are uniformly distributed on the rotation shaft, and the upper part of the cleaning cavity is further provided with a water inlet connected with a water tank on one side of the cleaning cavity. The down feather cleaning machine is characterized in that the upper part of the cleaning cavity is further connected with a feed device. A down feather loosening device is arranged below distribution openings of an outer cavity, the outer cavity is internally provided with a down feather hair loosening device, and the lower part of an air compartment is connected with an oscillating mechanism. The down feather cleaning machine can be used for evenly and smoothly conveying down feathers inside a feed conveying pipeline into processing equipment as required and also can be used for removing impurities and dust inside the down feathers so as to enable the down feather to be cleaner.

Owner:广东羽顺羽绒制品有限公司

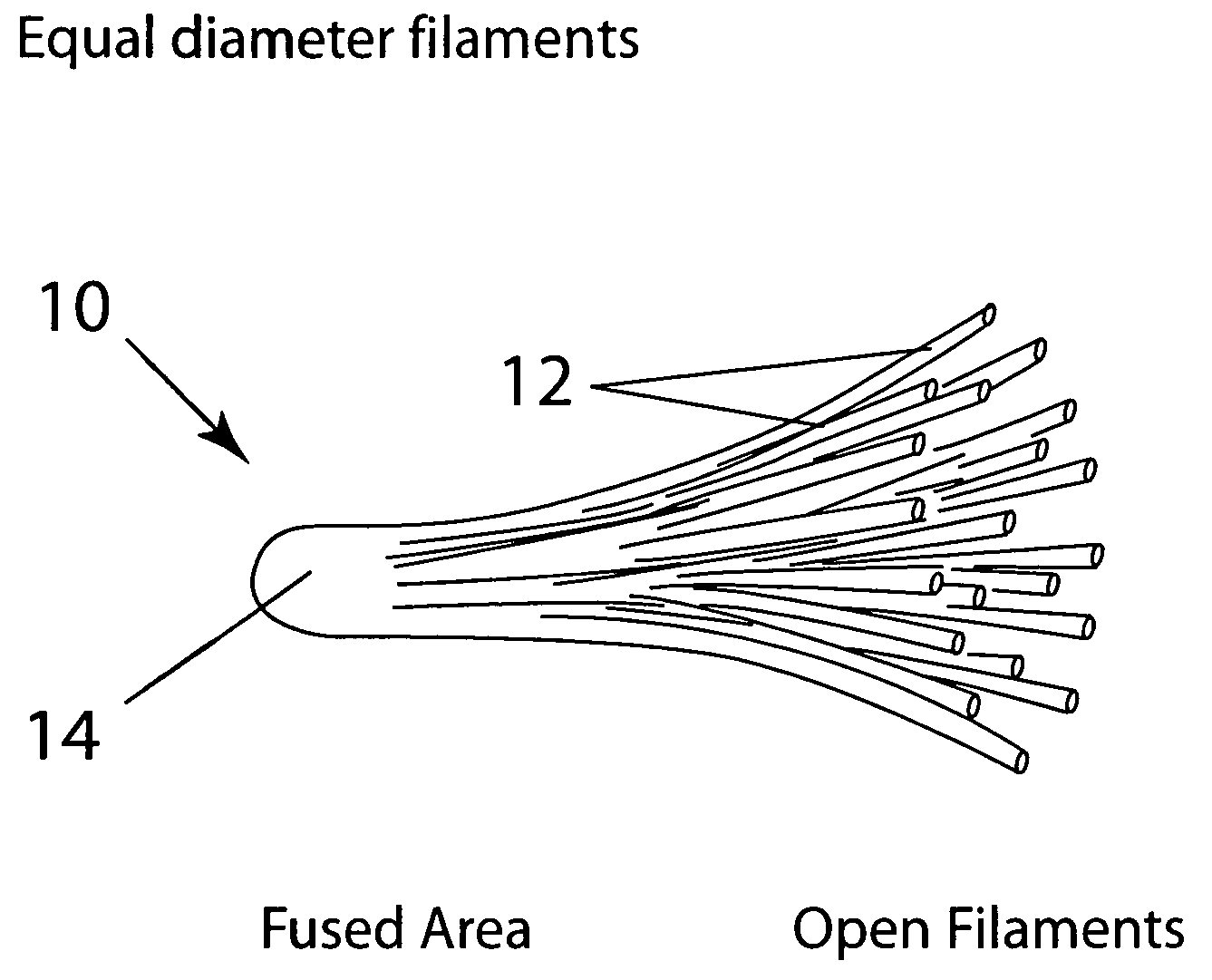

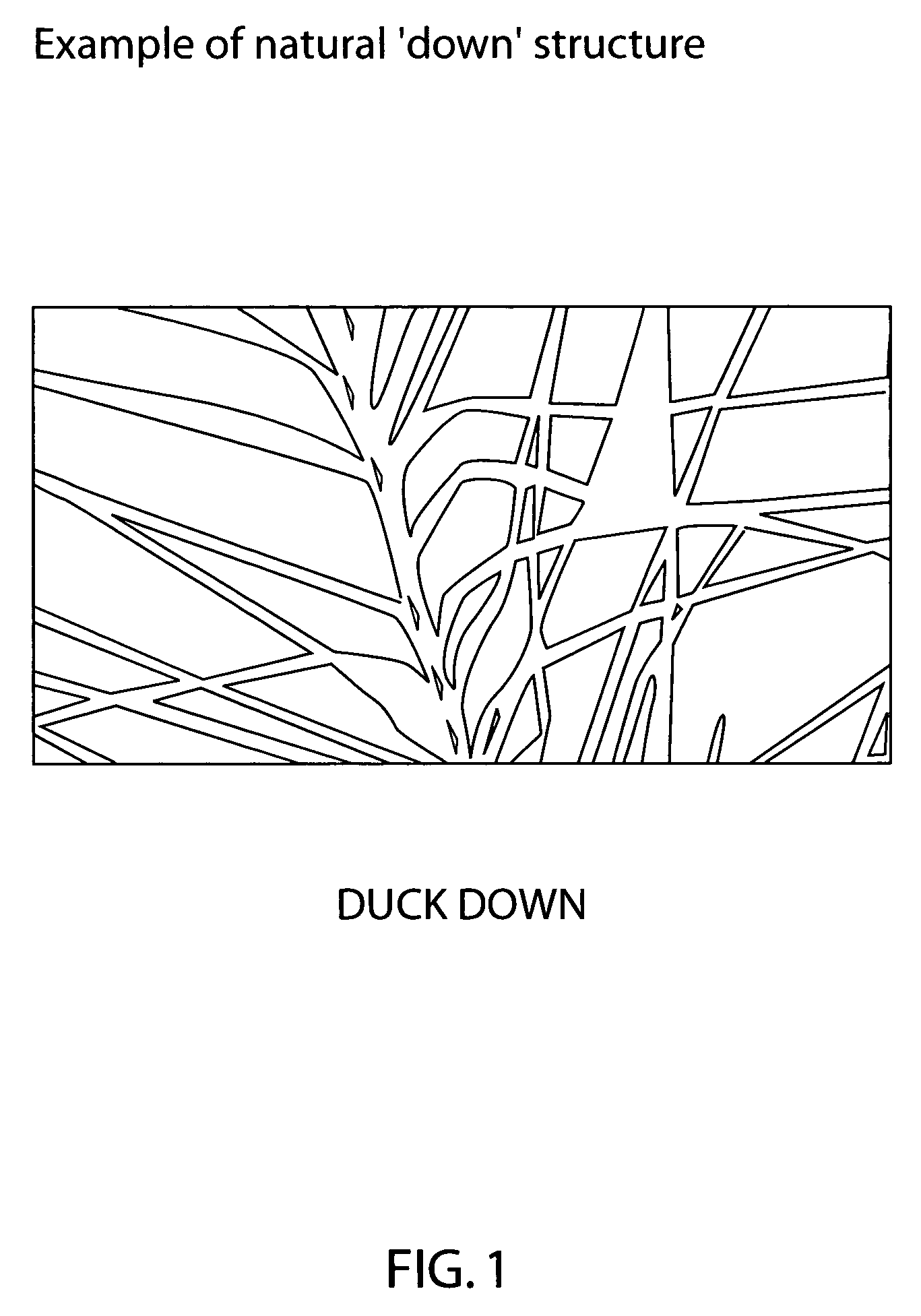

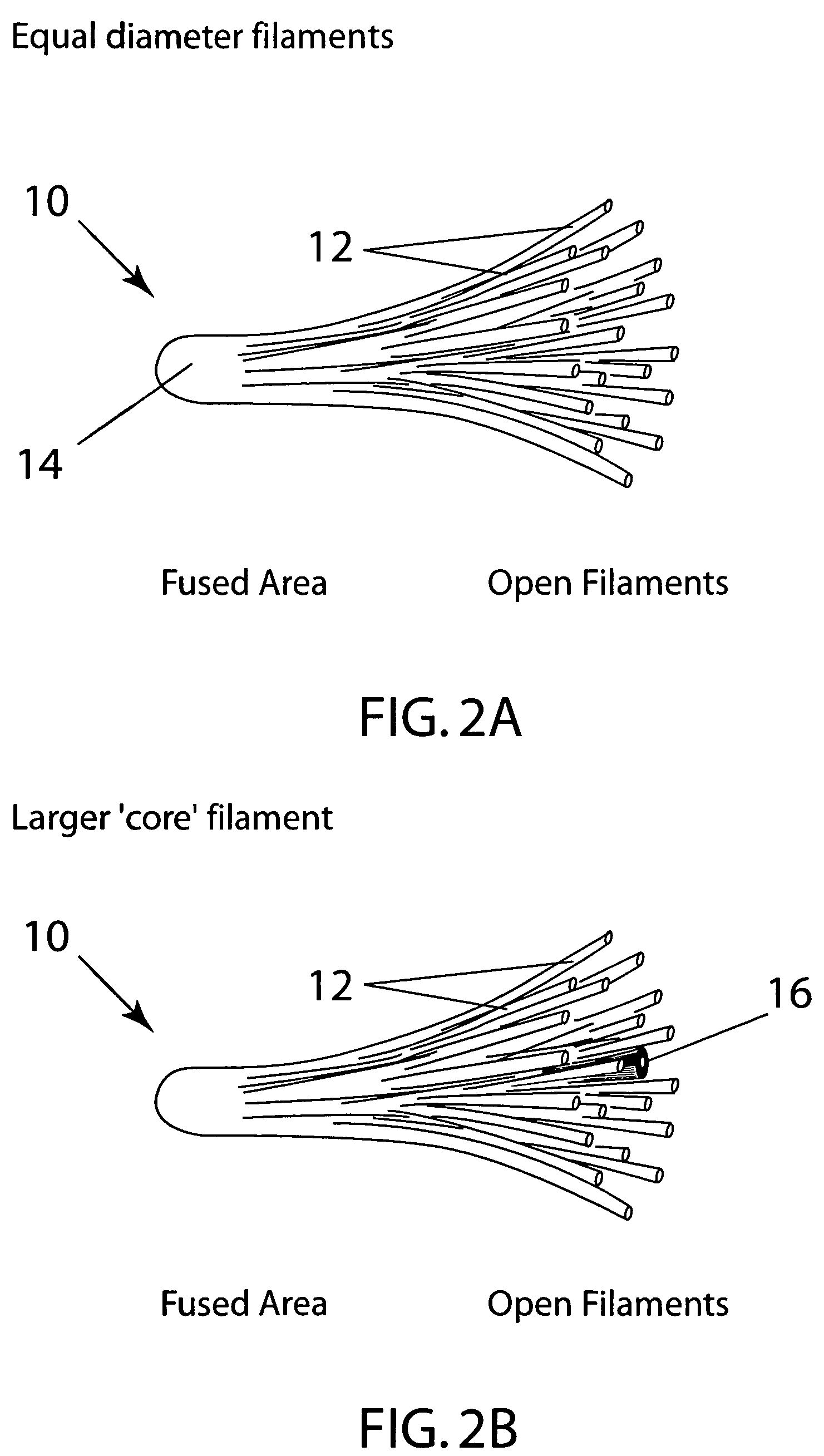

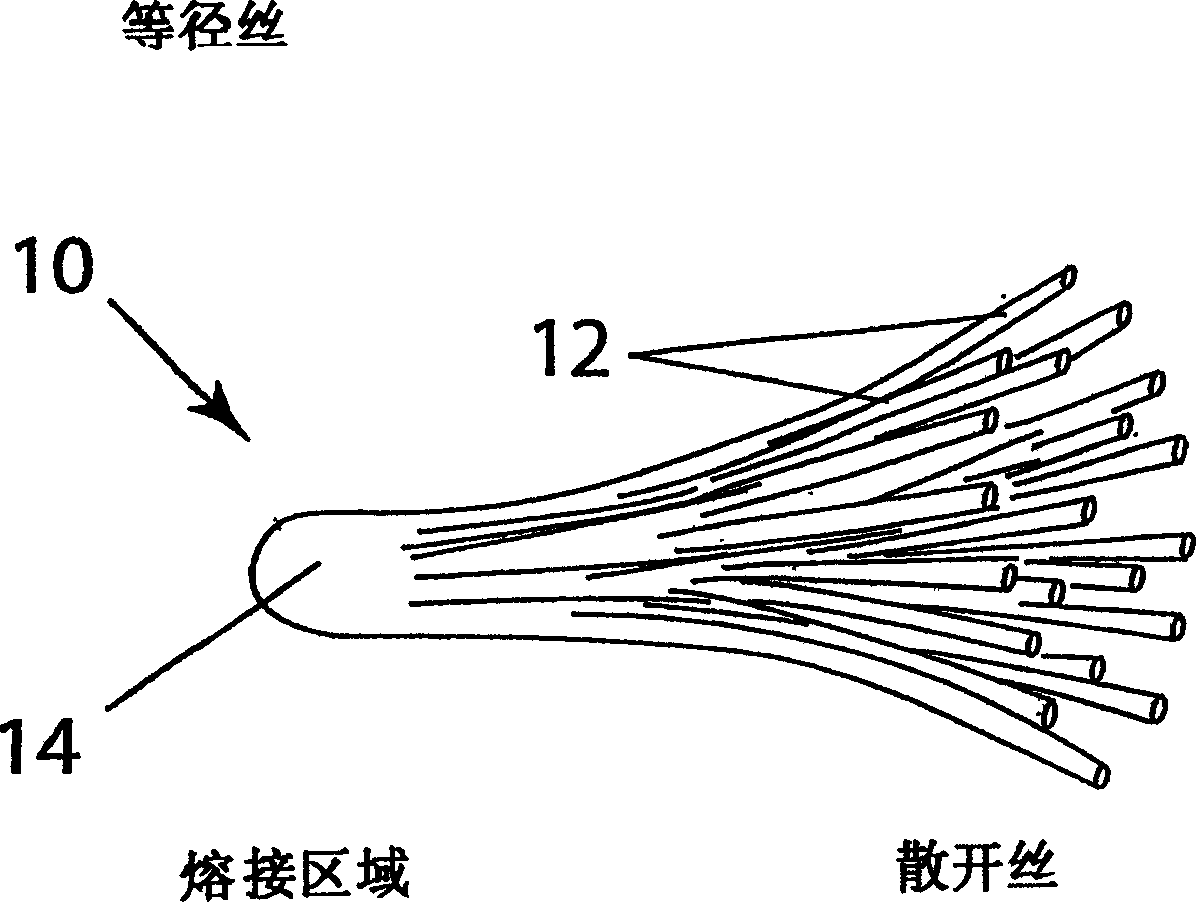

Synthetic blown insulation

ActiveUS7261936B2Superior thermal and loft and comfort and water absorption characteristicLow costLiquid surface applicatorsOrnamental textile articlesEngineeringTree structure

An insulation material having insulative properties of a synthetic down, while have a fir-tree structure more similar to natural down, and being in a blown form. The blowable insulation material is composed of plural units each having a number of filaments that are fused at one end of the unit and are open at an opposite end.

Owner:PRIMALOFT

Thin, forged magnesium alloy casing and method for producing same

InactiveUS20010020498A1Free movementImprove surface conditionExtrusion containersCasings/cabinets/drawers detailsCompression ratioCompression pressure

A thin, forged magnesium alloy casing is integrally constituted by a thin plate with projections on either or both surfaces, and the thin plate is as thin as about 1.5 mm or less. The thin forged casing can be produced by (a) carrying out a first forging step for roughly forging a magnesium alloy plate to form an intermediate forged product under the conditions of a preheating temperature of the magnesium alloy plate of 350-500° C., a die temperature of 350-450° C., a compression pressure of 3-30 tons / cm2, a compressing speed of 10-500 mm / sec. and a compression ratio of 75% or less; and (b) carrying out a second forging step for precisely forging the intermediate forged product under the conditions of a preheating temperature of the intermediate forged product of 300-500° C., a die temperature of 300-400° C., a compression pressure of 1-20 tons / cm2, a compressing speed of 1-200 mm / sec., and a compression ratio of 30% or less.

Owner:HITACHI METALS LTD

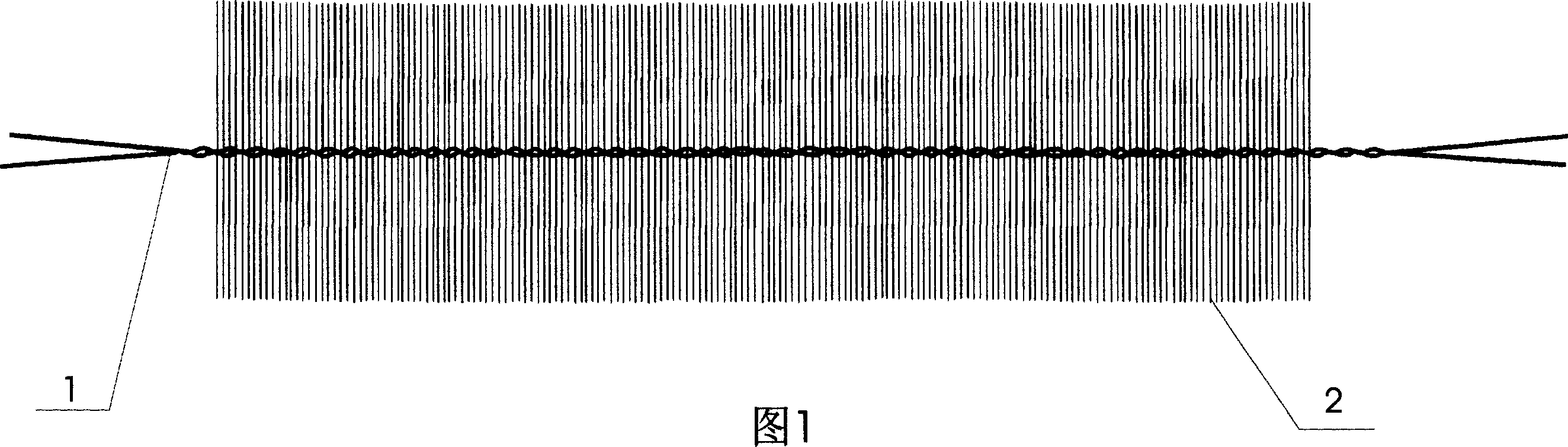

Chemical fiber down strip and its production method

InactiveCN1789532AFree from moisture and mildewSoft touchOrnamental textile articlesApparelFiberPolyester

The invention discloses the chemical fabrics corduroy and preparing method, which is made by ectochorion and interior wiring or ectochorion and PET and interior wiring. The method possesses the simple technology, high production efficiency and low cost, and the chemical fabrics corduroy can be made to many raw materials and adornments. The ectochorion is composed by PP chemical fabrics, nylon chemical fabrics, polyester chemical fabrics, PVC chemical fabrics, PET and knitting wool. The ectochorion is between interior wirings and radioactive distribution along with twisted wires, and the appearance is cylinder strip.

Owner:范国卫

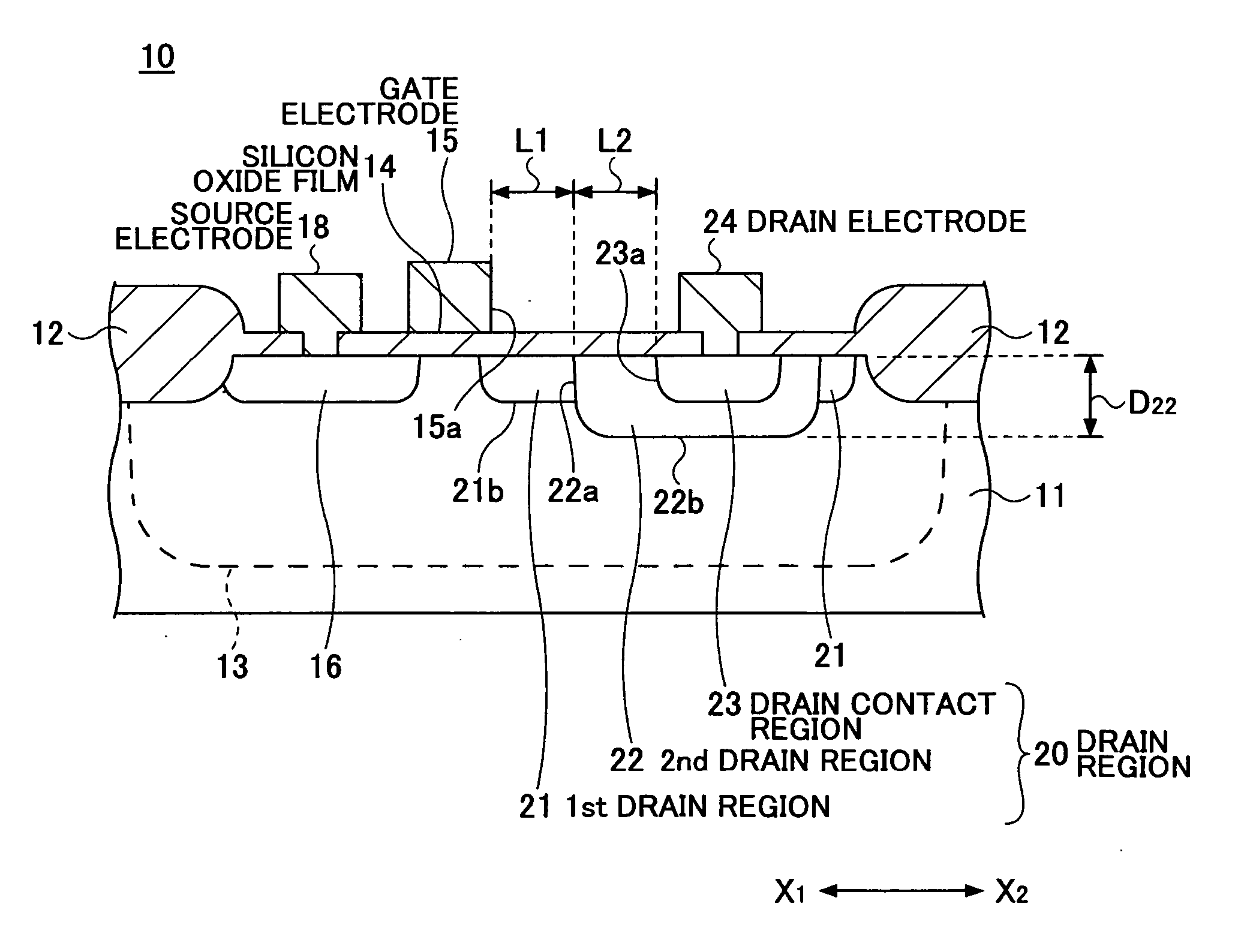

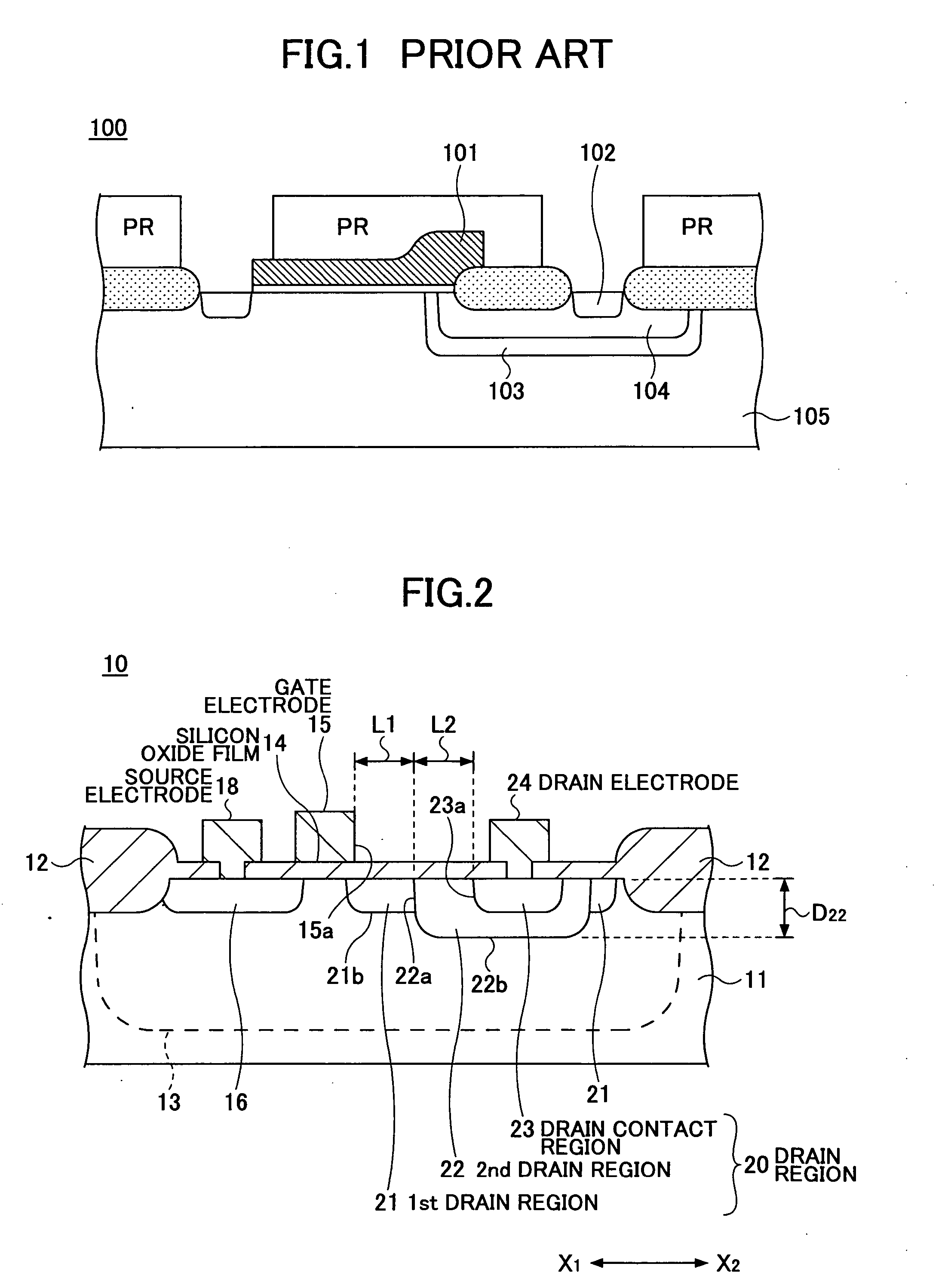

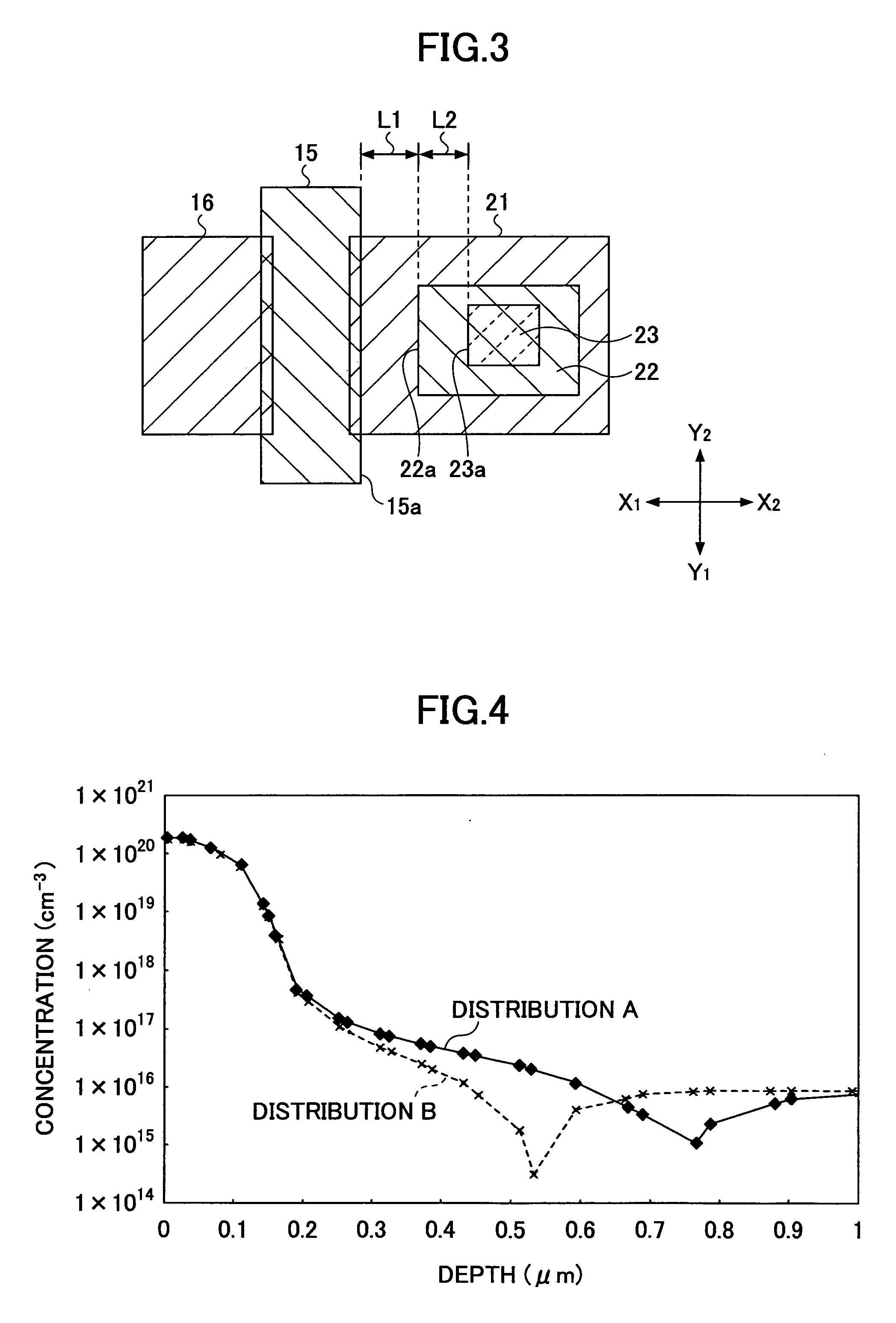

Semiconductor device and manufacturing method of the same

InactiveUS20060081924A1Avoid short channel effectsEasy to operateTransistorTravelling carriersDevice materialEngineering

A semiconductor device is disclosed that is capable of improving the drain breakdown voltage during operation. The semiconductor device includes a first drain region that is arranged to extend from the vicinity of an end portion of the gate electrode at the drain electrode side in a direction toward the drain electrode, a drain contact region that is formed within the first drain region and comes into contact with the drain electrode, and a second drain region that is formed around and underneath the drain contact region. The second drain contact region has an impurity concentration that is higher than the impurity concentration of the first drain contact region and lower than the impurity concentration of the drain contact region. An end portion of the second drain region at the gate electrode side is positioned away from the end portion of the gate electrode by a predetermined distance.

Owner:FUJITSU SEMICON LTD

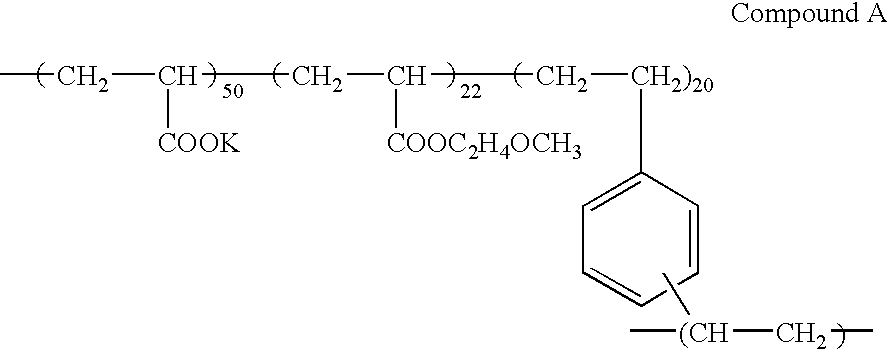

Magnetic recording medium

ActiveUS7108927B2Less adhesion of dustAvoid excessive adhesionProtective coatings for layersRecord information storageFerromagnetic orderNon magnetic

The present invention relates to a magnetic recording medium comprising a magnetic layer on at least one side of a nonmagnetic substrate, the magnetic layer containing magnetic particles of a CuAu type or Cu3Au type ferromagnetic ordered phase, wherein a conductive layer is provided on at least one side of the nonmagnetic substrate.

Owner:FUJIFILM CORP +1

Bracelet that radiates anion and far infrared rays

The present invention is related to a bracelet irradiating anion and far infrared rays, comprising metal where anion-radiating material layer and gold plate layer are sequentially coated on the surface of a “C” shape core (10) with a connecting arm (20) and a clasp assembly including magnetic coupling clasps. This bracelet looks very elegant because of the gold plate on the exterior of the bracelet, and static electricity occurs due to the friction between the bracelet and the human hand, and it can irradiate anion and far infrared rays more effectively through sunlight, and by supplying the far infrared rays to the skin, the ion balance of the cell can be controlled, and it can change the electric potential of the skin to normal value, and can promote blood circulation and metabolism, complex biorhythm, and body cell is activated and blood pressure is lowered, increasing the tissue regeneration capacity, preventing the aging phenomena.

Owner:CREATE

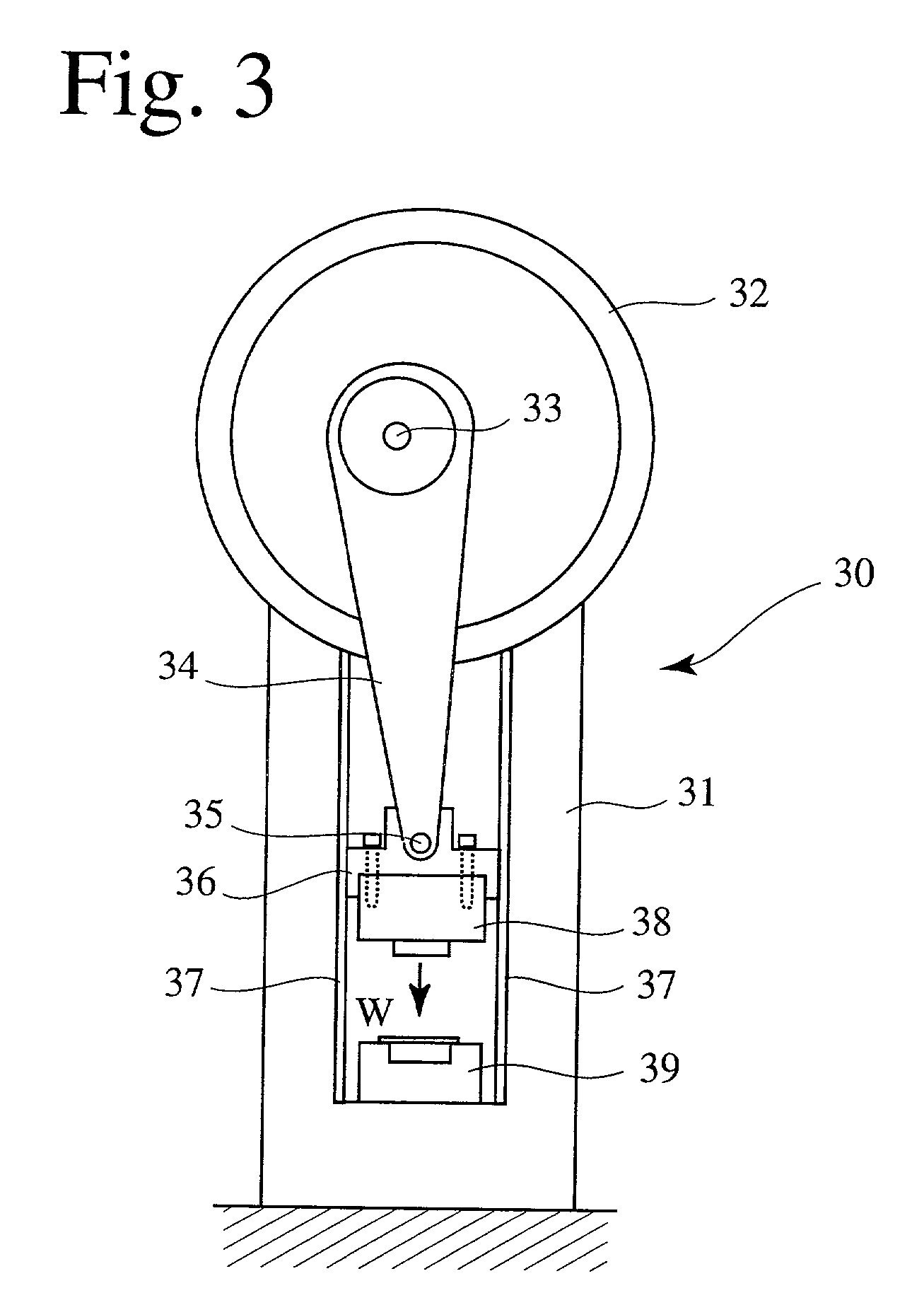

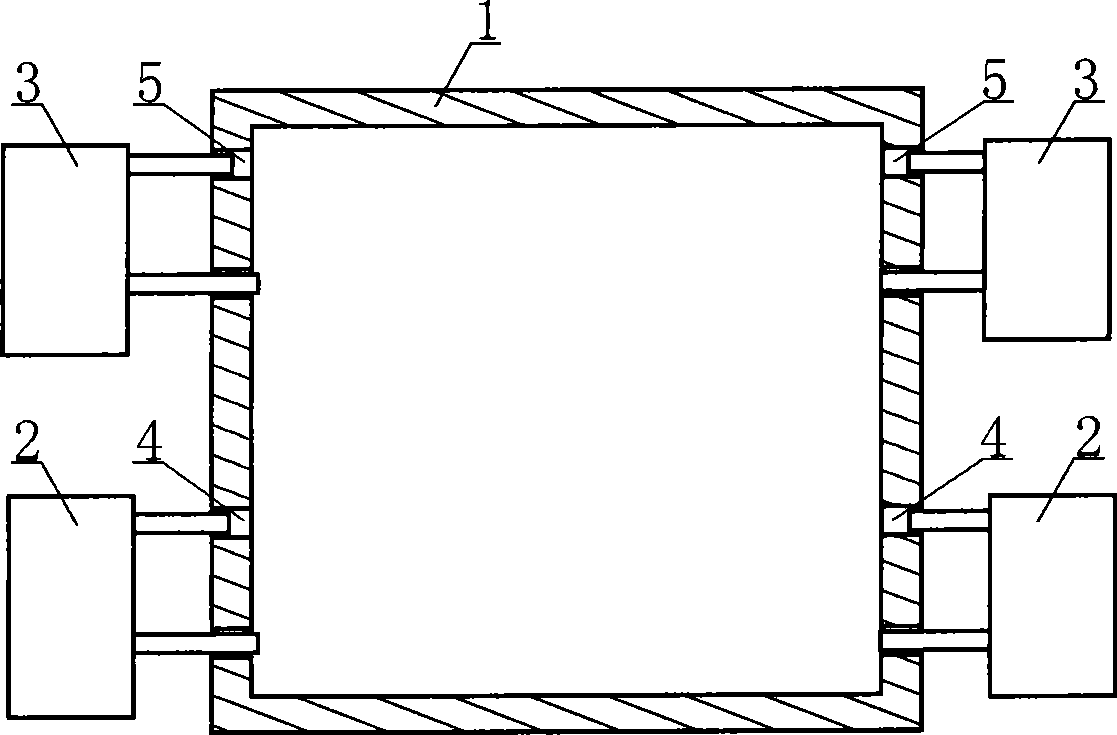

Down fiber-filtering system based on static

InactiveCN101496650AAccurate separationImprove qualityElectrostatic separationApparelFiberFiltration

The invention relates to a system for filtering eiderdown threads, in particular to a system for filtering the eiderdown threads based on static by using the static to control the form and the moving direction of the eiderdown threads in an electric field so as to achieve eiderdown thread removal, and belongs to the technical field of eiderdown thread processing. The system uses wind power to fully disperse eiderdown flowers and the eiderdown threads, and utilizes the static to control the form and the moving direction of the eiderdown threads in the electric field so as to accurately separate the eiderdown threads from the eiderdown flowers, achieve filtration of the eiderdown threads through a filter screen, and effectively improve the quality of the eiderdown by using the technique.

Owner:徐州远景羽绒有限责任公司

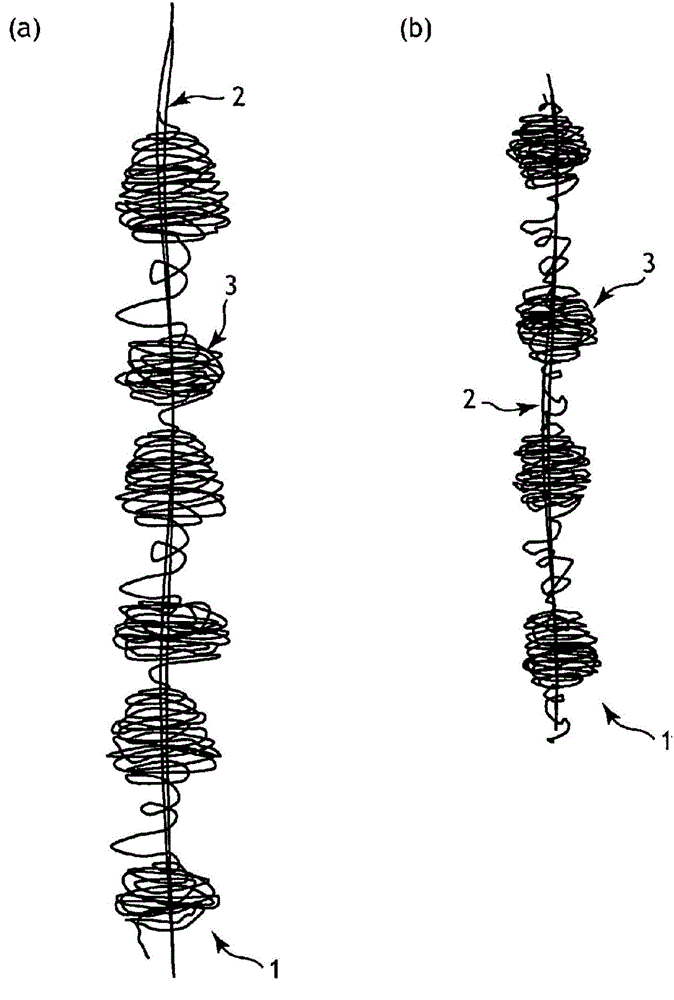

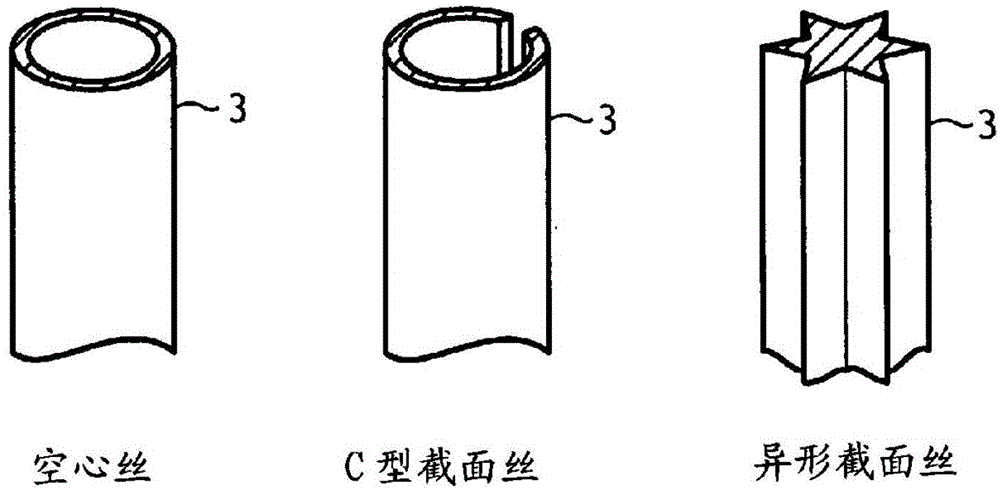

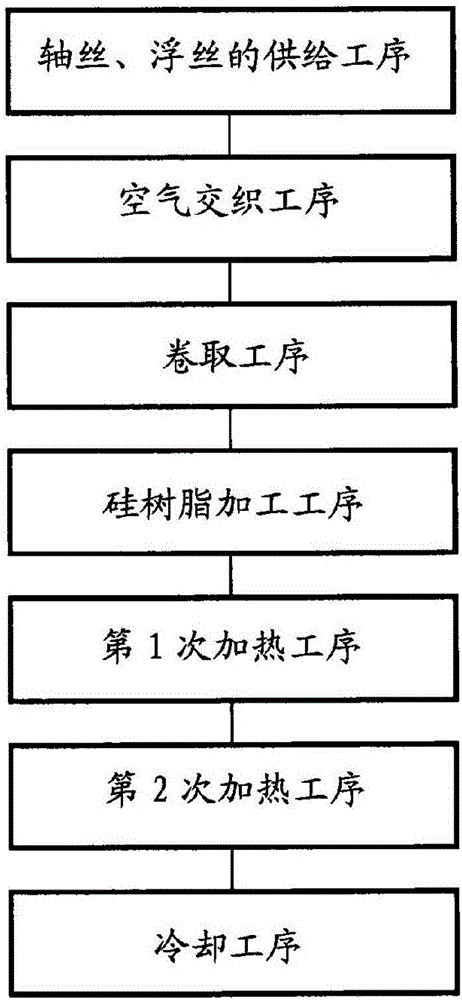

Down-like fiberfill material and manufacturing method therefor

ActiveCN106460255AIncrease in sizeImprove washing effectFibre typesHeating/cooling textile fabricsRaw materialFilament yarn

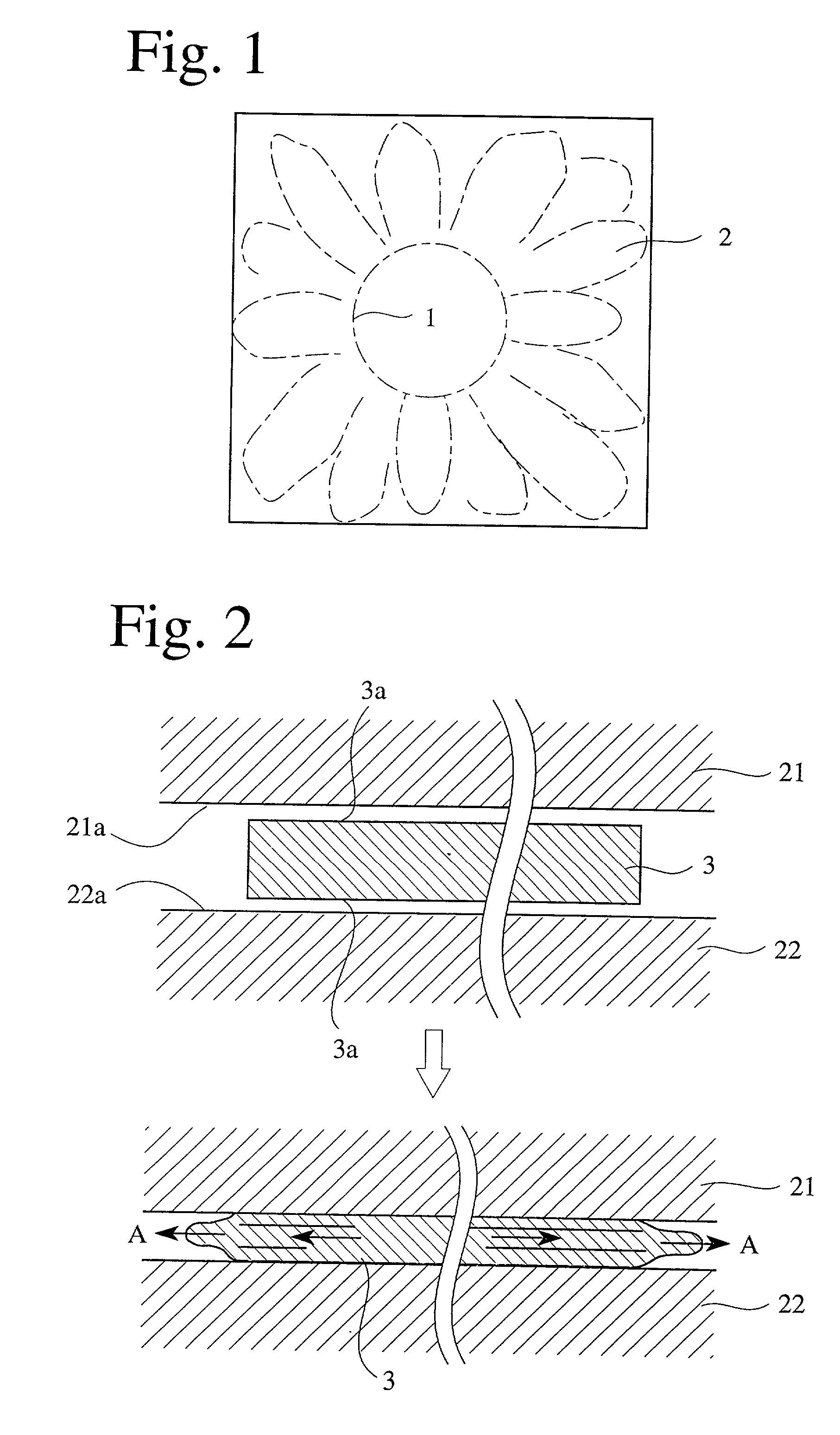

The present invention provides a novel down-like fiberfill material, which does not have odors that are characteristic of animals, and has a feeling of volume and bulk, excellent launderability, and excellent heat retention and insulating properties, and can be formed to be lightweight. This down-like fiberfill material (1) has a form, as a result of air-interlacing in an air-scattering environment, in which the filaments of an axial filament (2) and a float yarn (3) that use a polyester raw yarn are bundled, entwined, connected and integrated with each other while having down ball-like clusters at intervals that run in a row. The down-like fiberfill material is formed as long cotton-like fibers wherein the diameter of the down ball-like clusters is 1.0 - 3.5 cm and the down ball-like portions are consecutively disposed with a maximum interval of not more than 10 cm in the longitudinal direction of the axial filament.

Owner:저장아이더웜스뉴머티리얼컴퍼니리미티드

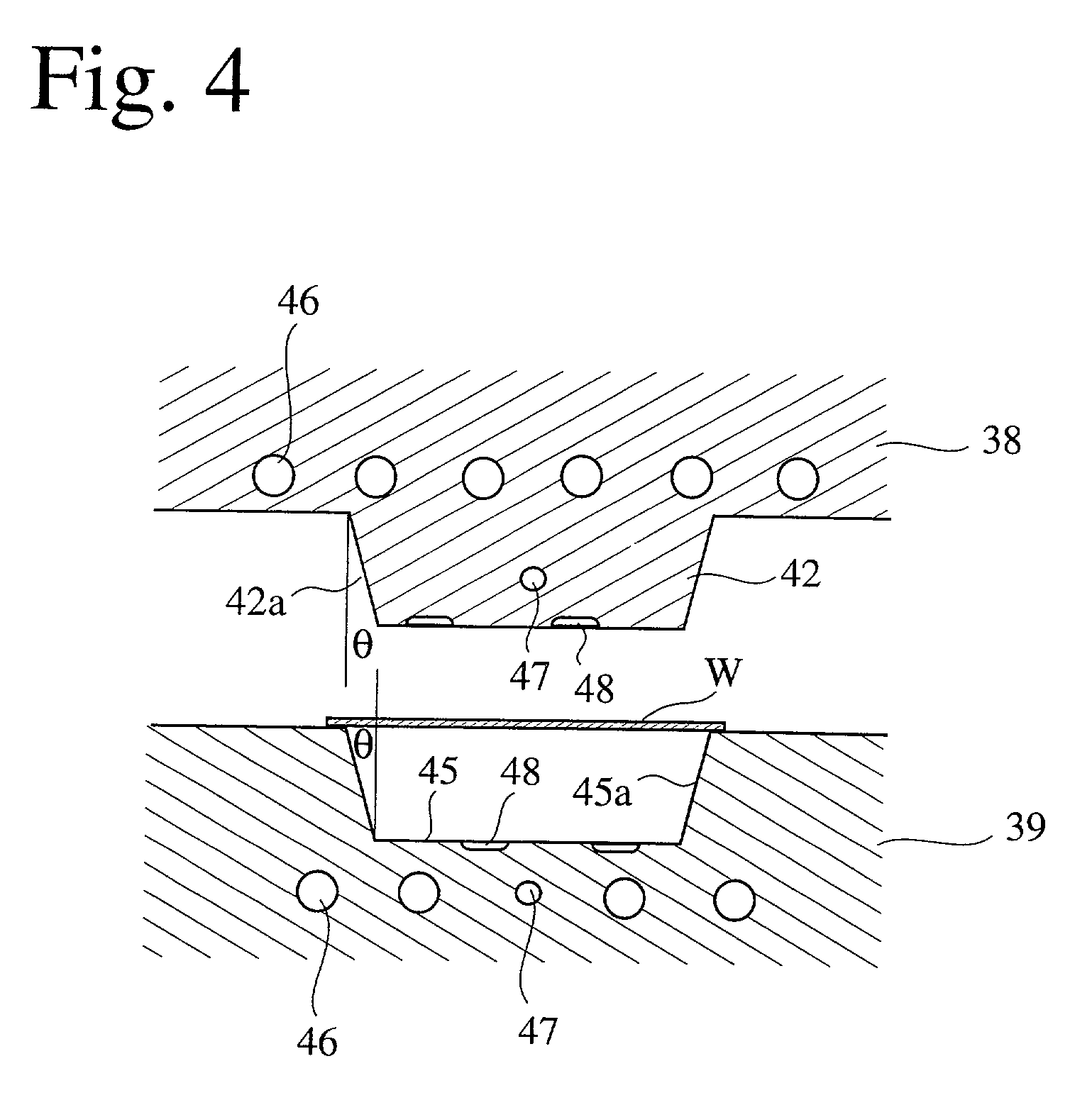

Rachis-free feather production process

InactiveCN103202563AQualified TransparencyQualified bulkinessFibre treatmentApparelFeatherDown feather

The invention relates to a rachis-free feather production process. The rachis-free feather production process sequentially includes selecting materials, washing with water for the first time, combing feathers and removing rachises and washing for the second time. By the four production procedures, qualified rachis-free feathers can be produced, and the standards of transparency being above 600 degrees, fluffy degree being 40% higher than that of feathers and softness of down feathers being 70% are met.

Owner:JIANGSU DACHENG DOWN PROD

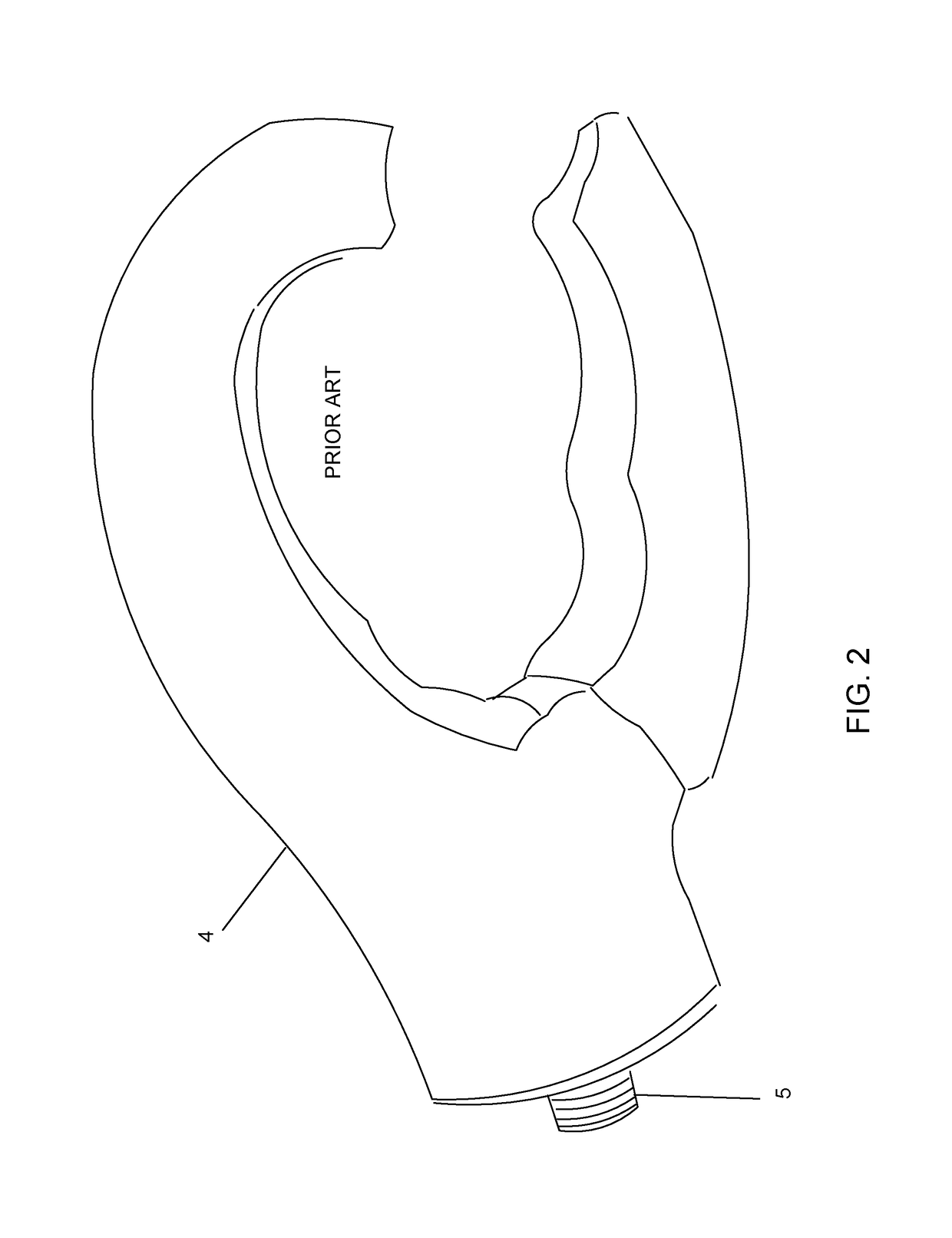

Nasal interface and system including ventilation insert

A ventilation or CPAP interface system adapted to be inserted into a nares of a user to secure the interface. A cannula adapted to be connected to a source of ventilation gas forms a first portion of an input gas flow passage to supply the ventilation gas to the user. A nasal insert adapted to be inserted the nares of the user forms a second portion of the input gas flow passage from the cannula to a distal end of the nasal insert. A seal portion adapted to engage a portion of the first naris is provided adjacent the distal end of the nasal insert. Ventilation interface system may optionally include feed tubes, y-connector, tube holder, and headgear.

Owner:INNOMED TECH

Synthetic blown insulation

InactiveCN1795139AImprove thermal insulationLow costStuffed mattressesOrnamental textile articlesEngineeringTree structure

An insulating material that has the insulating properties of synthetic down while having a fir tree structure that more closely resembles natural down, in a fan-out form. The spreadable barrier material consists of multiple units, each unit having filaments that are fused at one end of the unit and unraveled at the opposite end.

Owner:ALBANY INT CORP

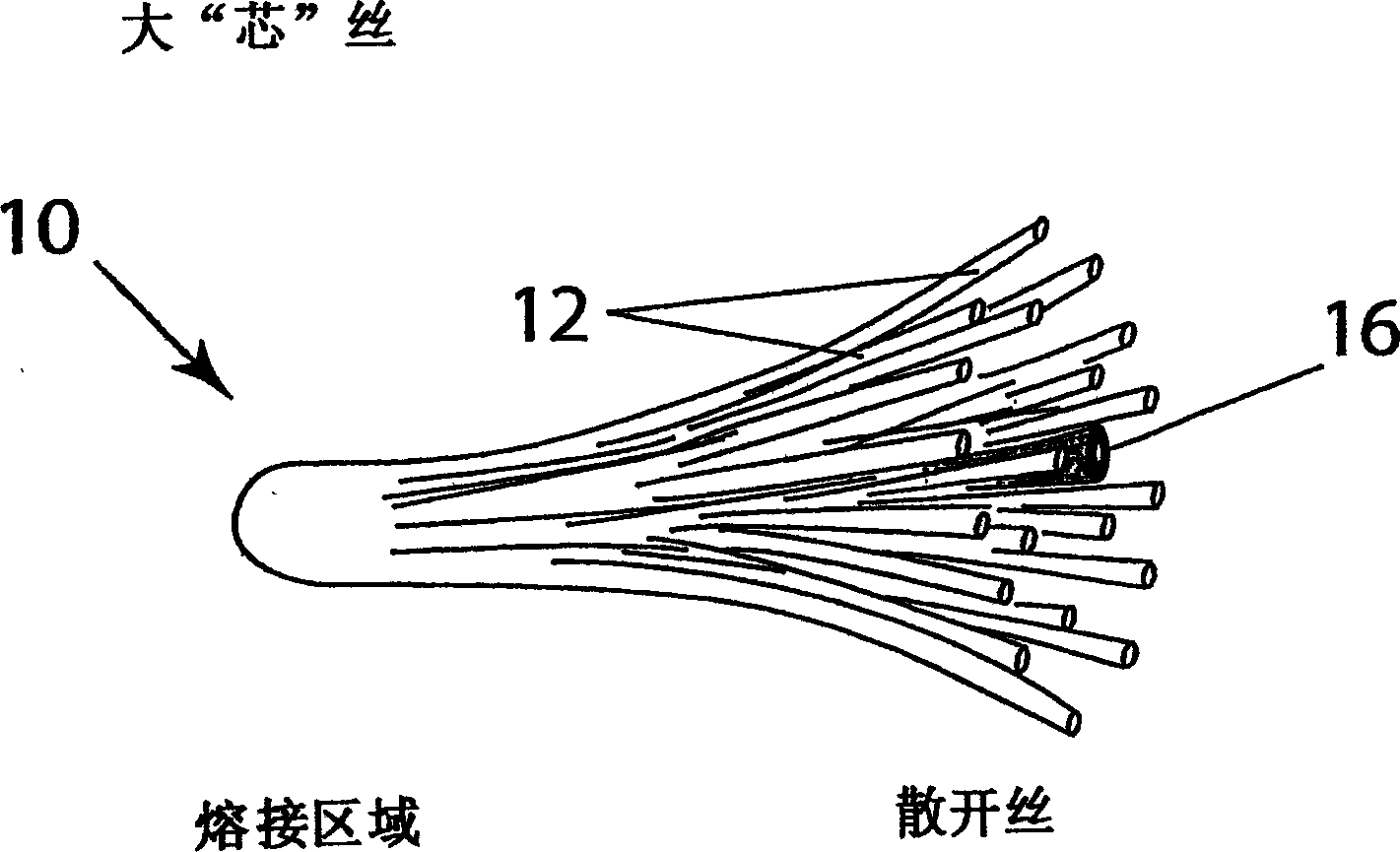

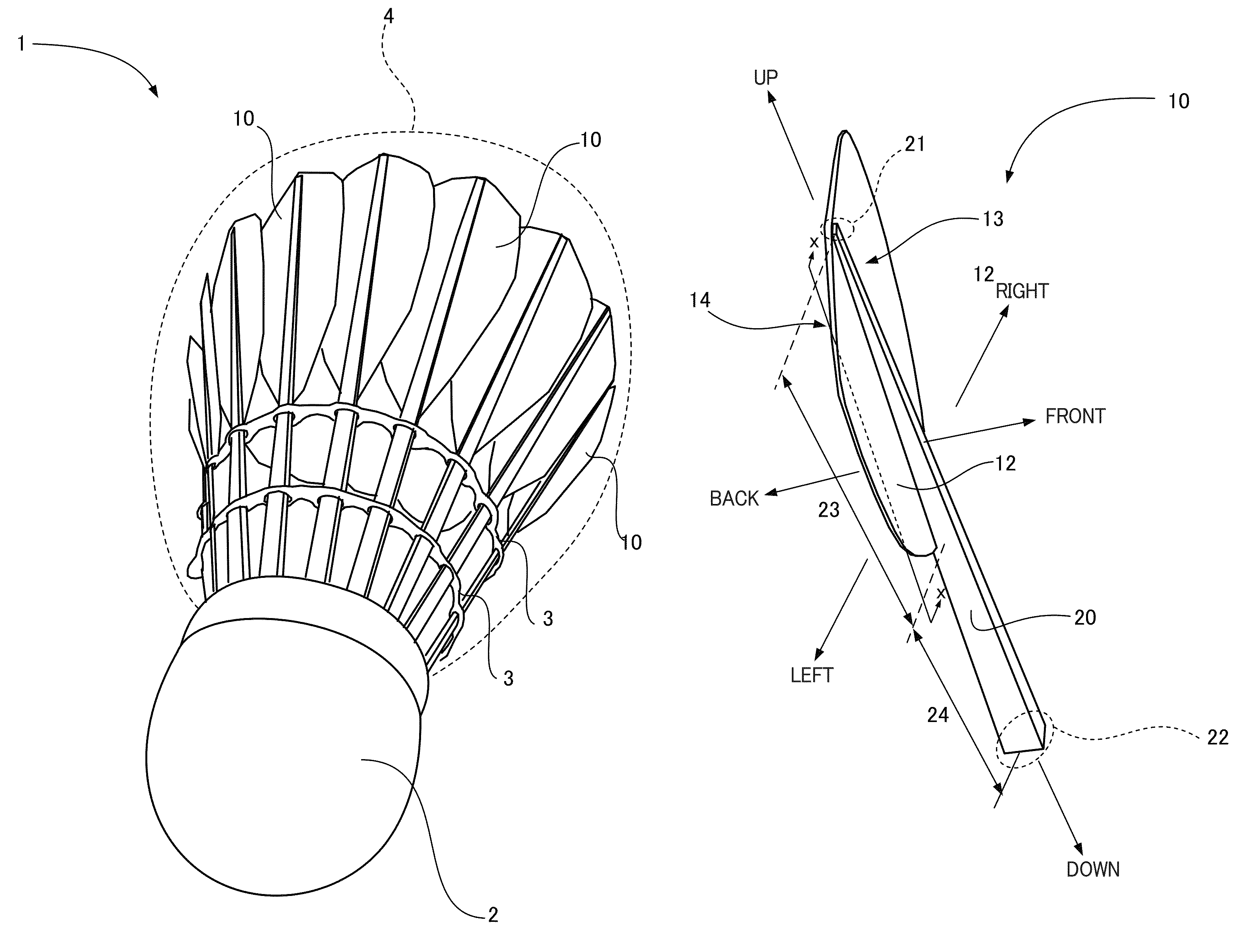

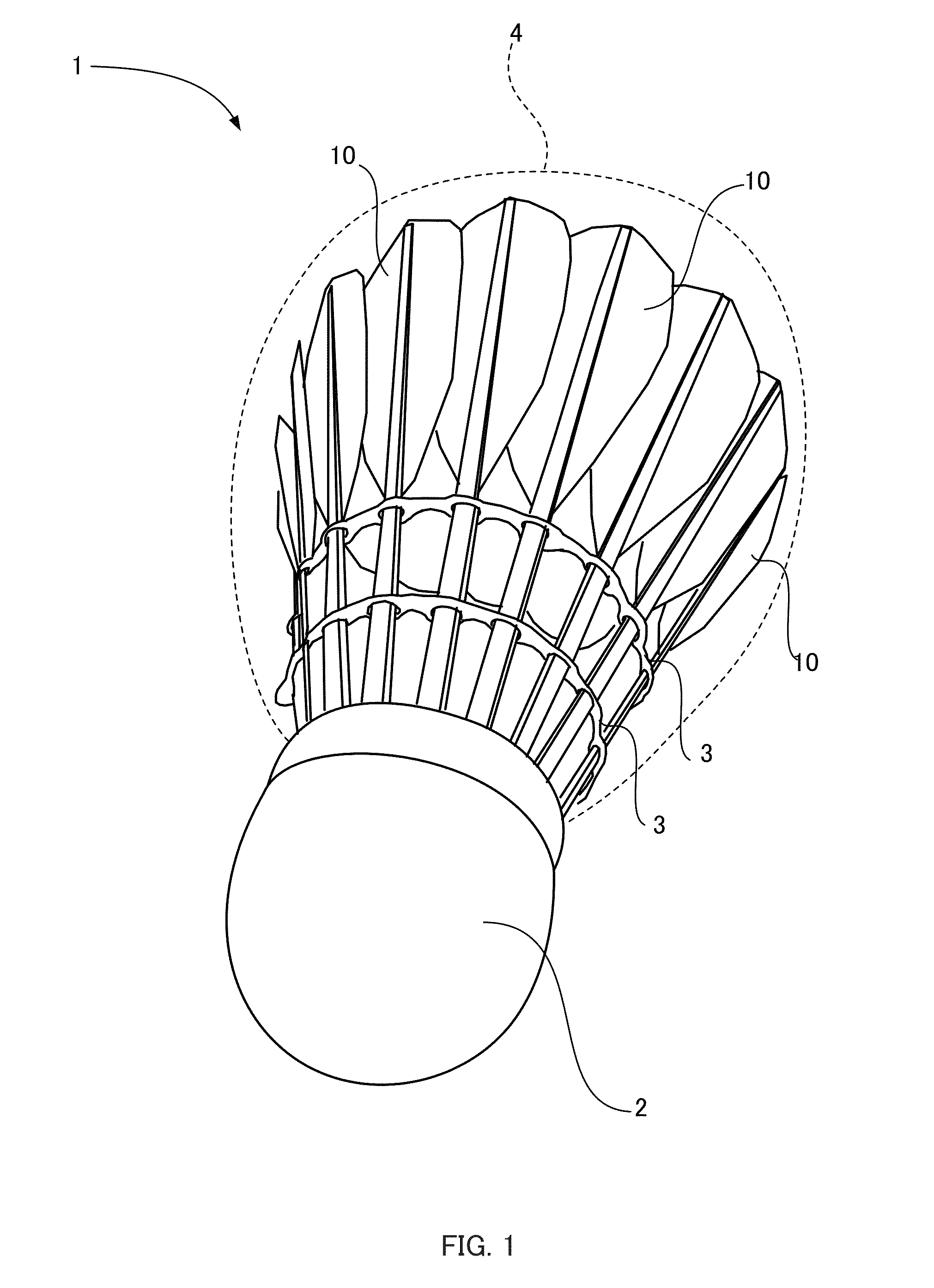

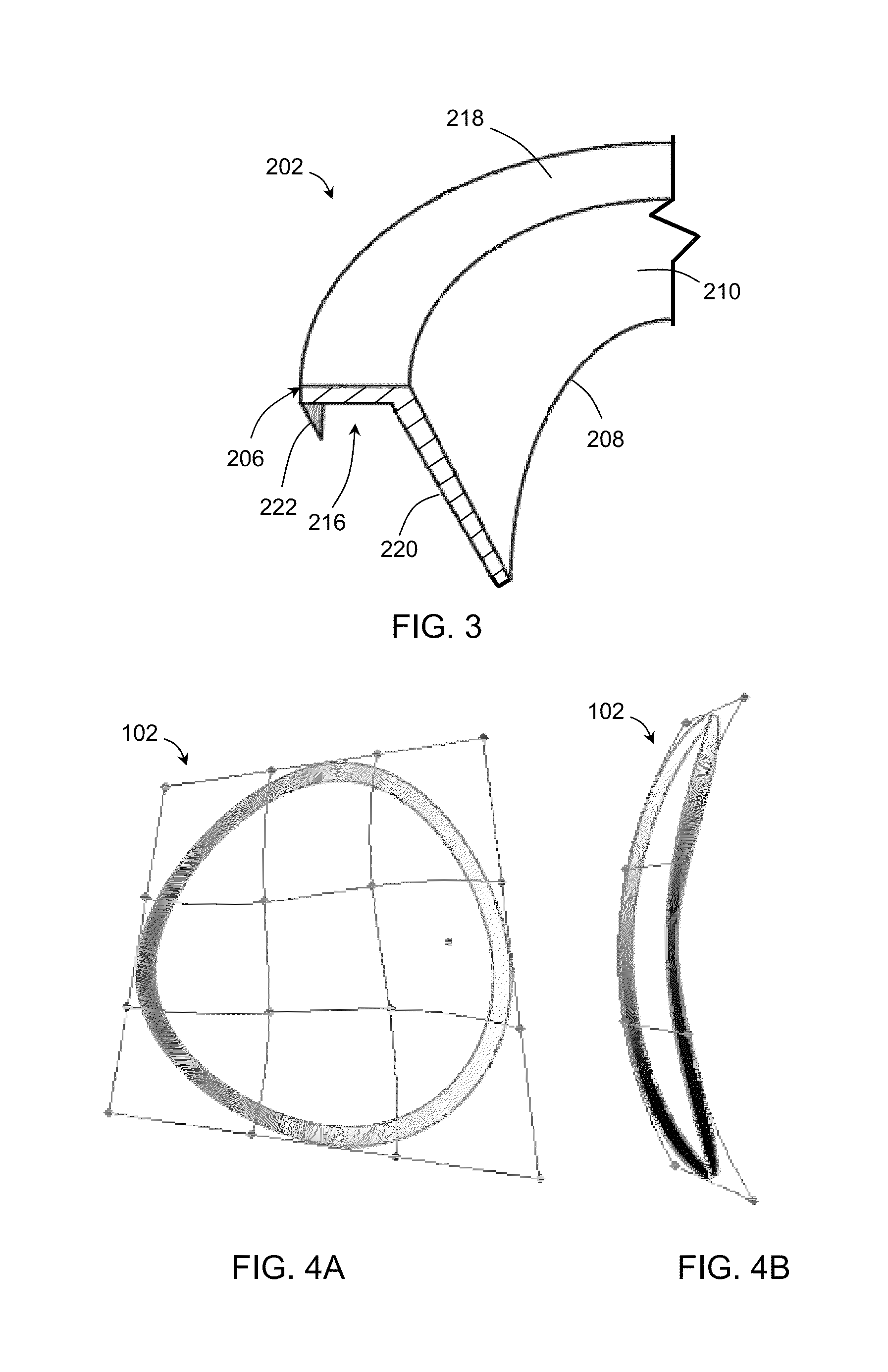

Artificial feather and manufacturing method

The present invention relates to the technical field for an artificial feather. The invention particularly relates to the artificial feather used for manufacture of a badminton and the similar product and the manufacture method. In the invention, according to disadvantages in current feather of high weight ratio, tended to break, tended to distortion, poor elasticity and poor restoration, a artificial feather of low weight ratio, fracture resistance, distortion resistance, excellent elasticity and excellent restoration and the manufacture method are provided. The artificial feather of the invention comprises a thermoplastic material of polyacrylamide and polyethylene, etc. The invention comprises a wing bar and a wing plate. The wing plate is fixed in the head of the wing bar and a plurality of hangnails are arranged in tail of the wing bar. Manufacture method of the invention is that the feather is made by one time forming and injection moulding with the thermoplastic material after thermoplastic heating, flowing under pressure, and cooling solidification.

Owner:丁有星

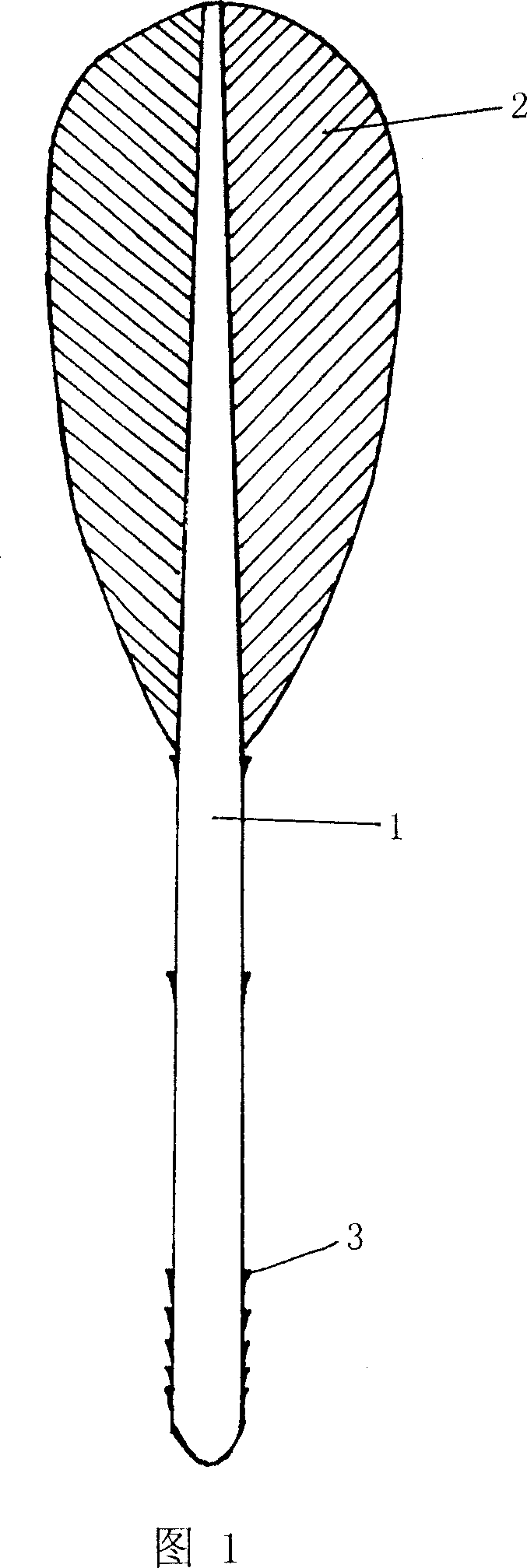

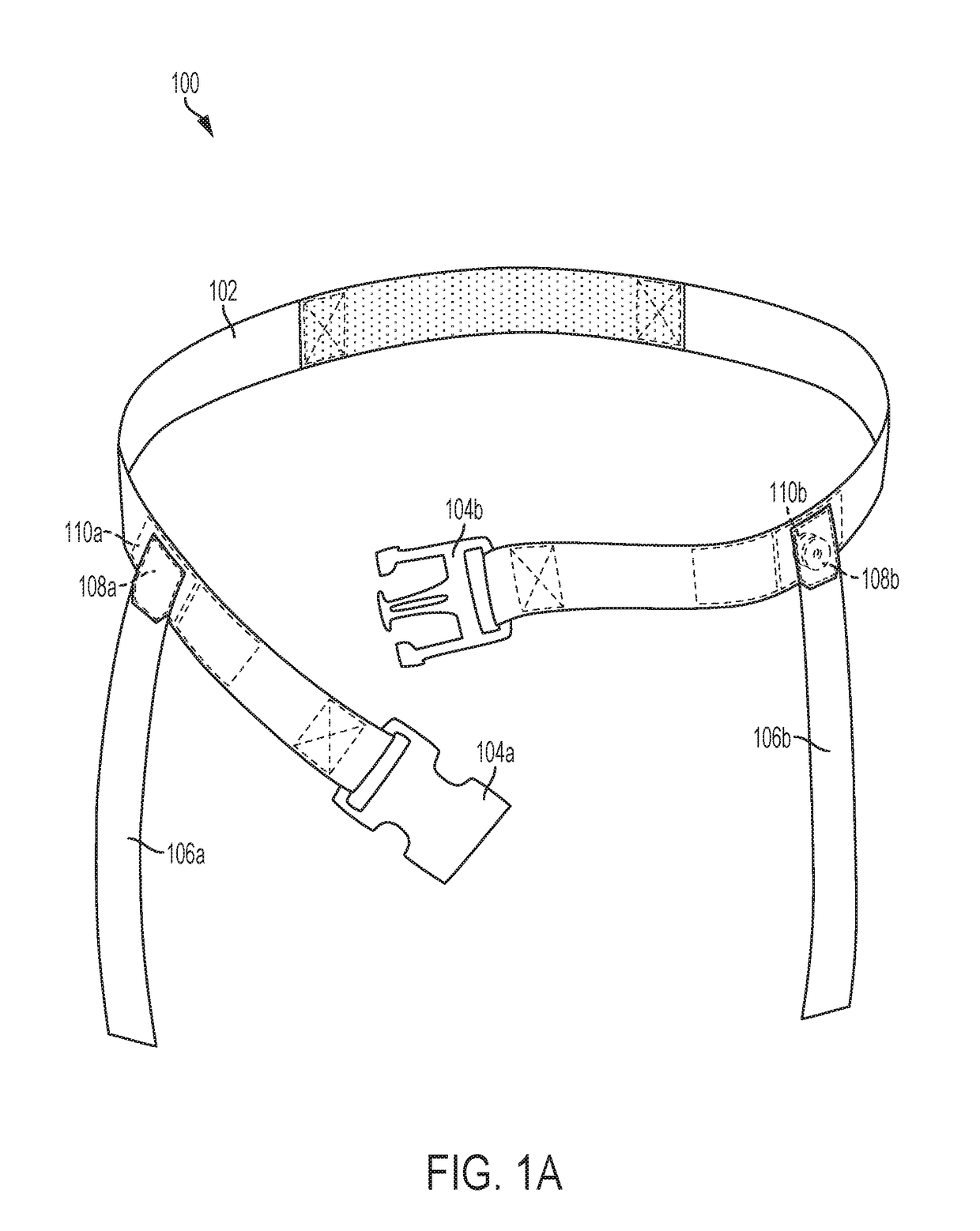

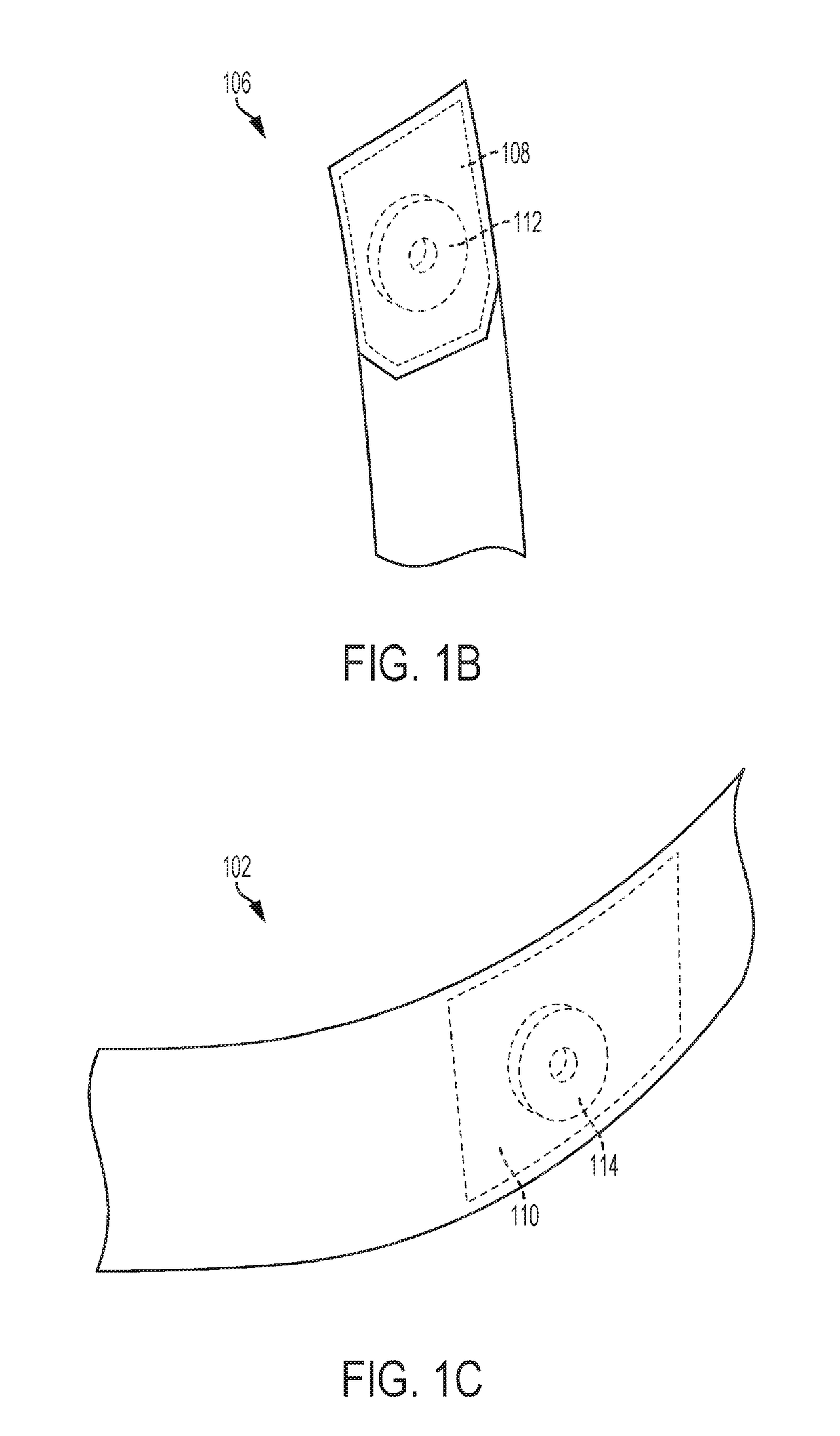

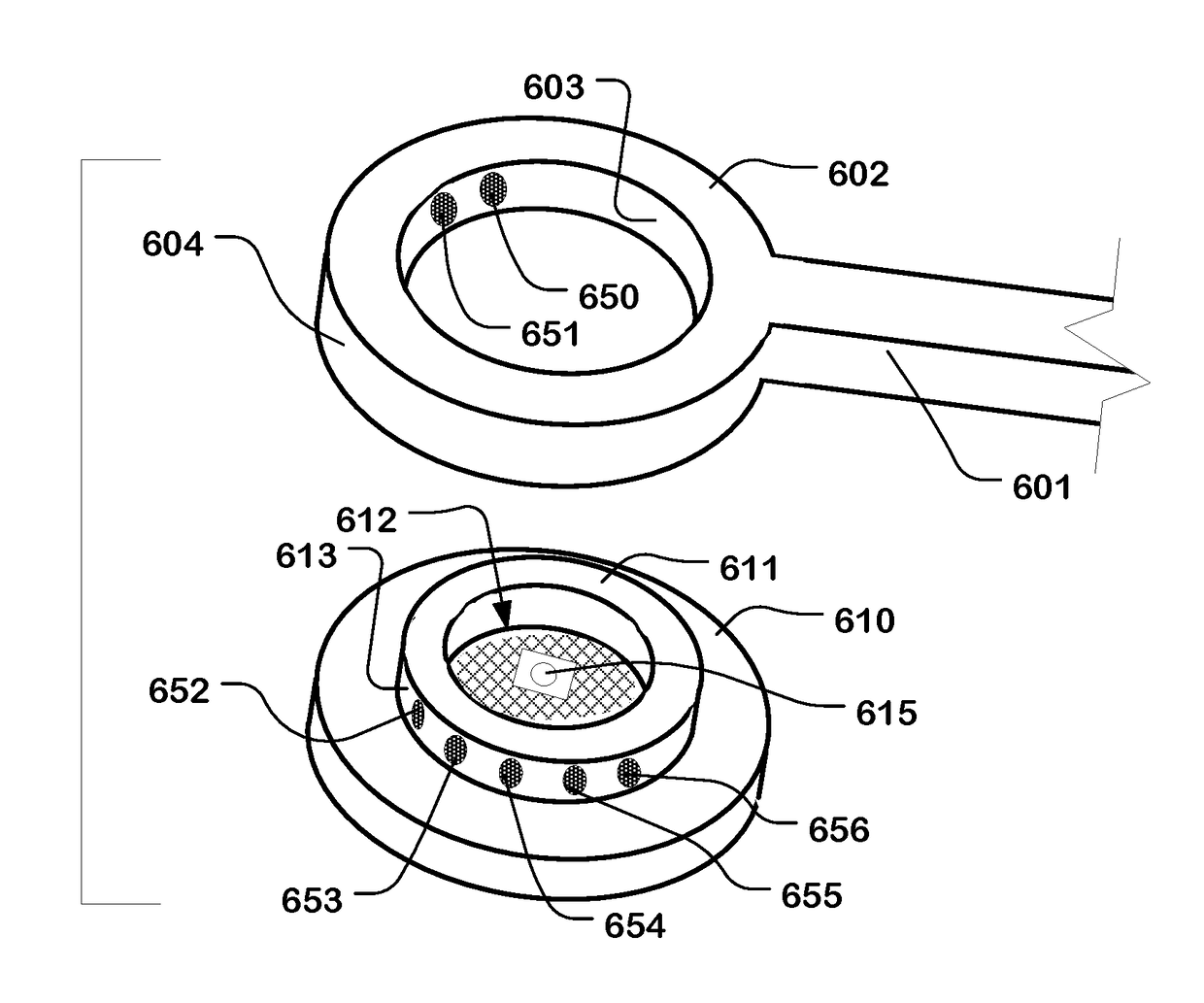

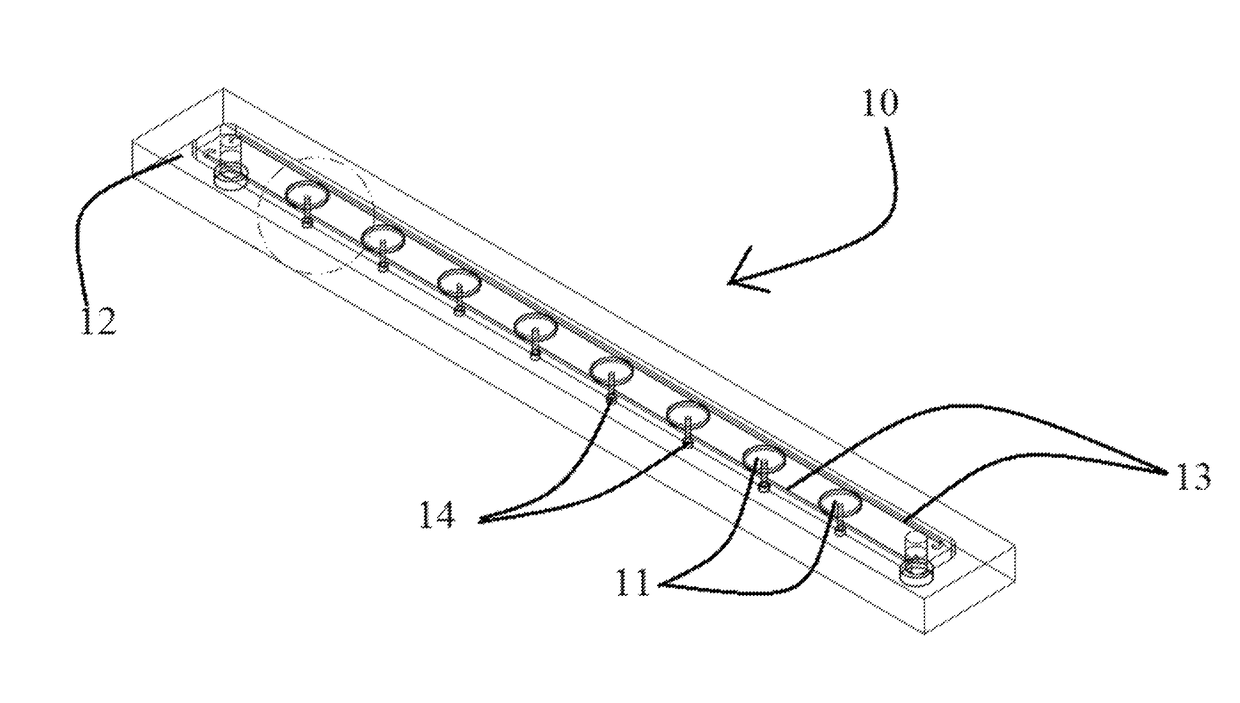

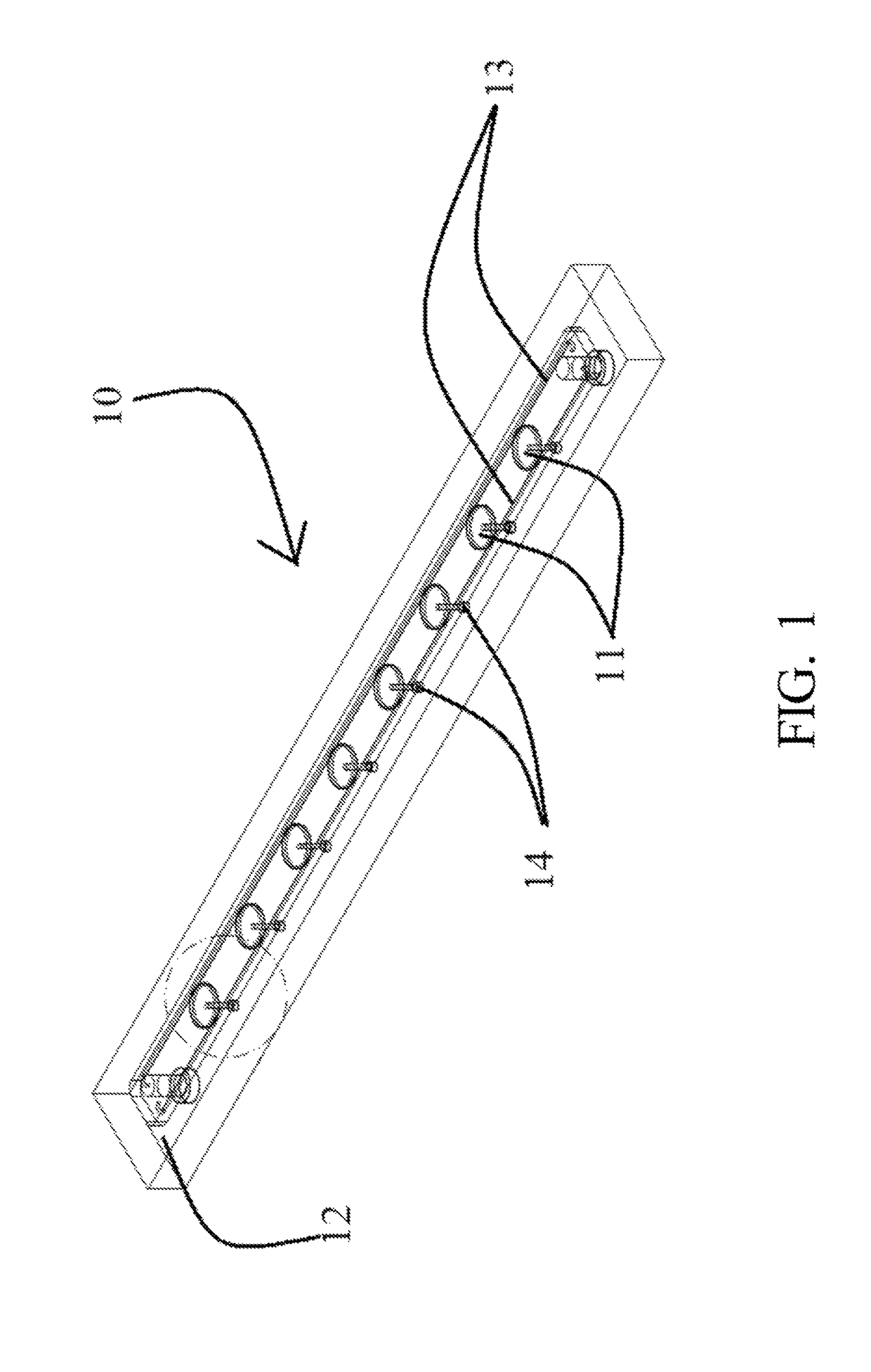

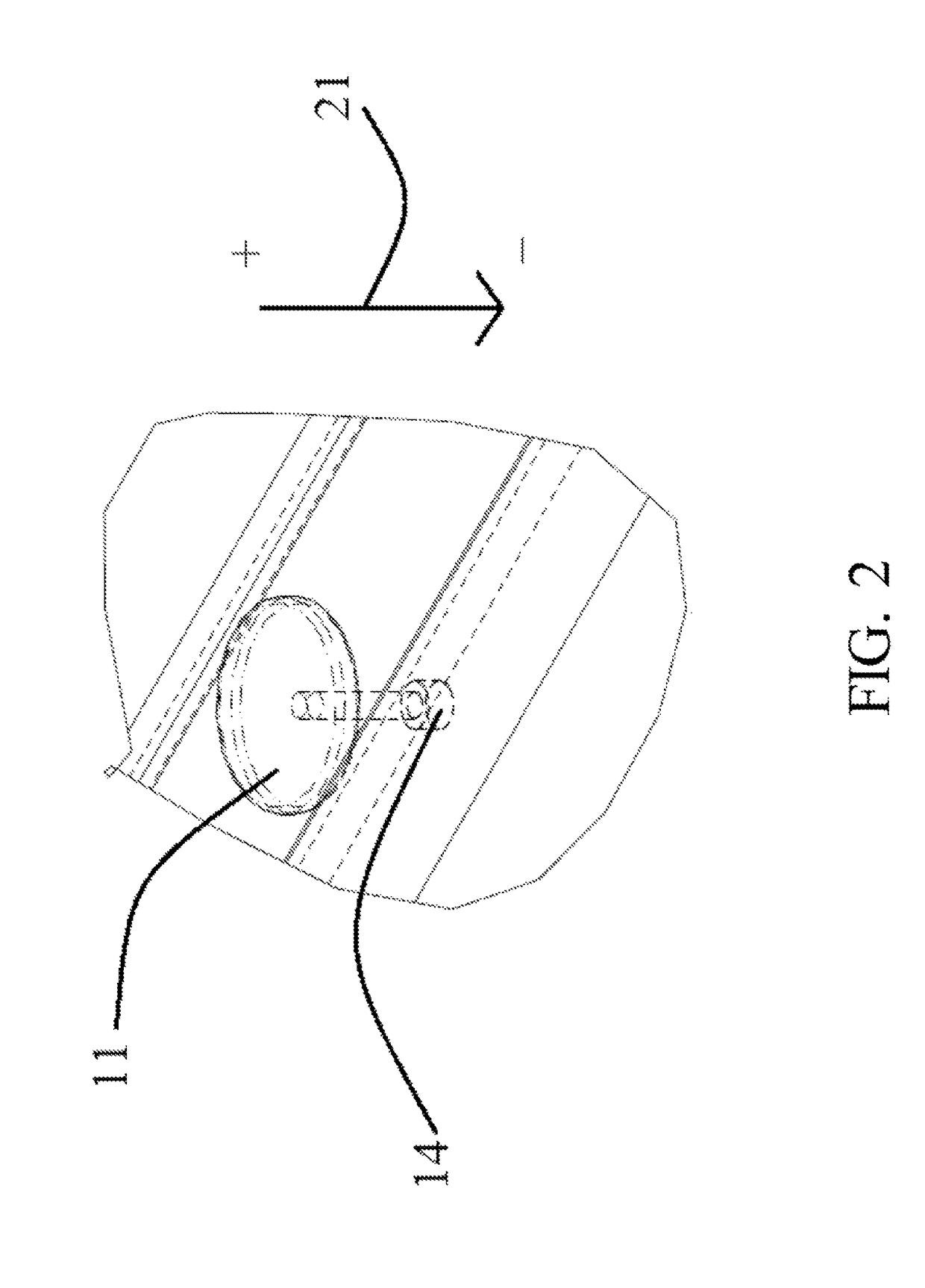

Flag football system

ActiveUS20180289138A1Higher magnetic flux outputAccurately and quickly and reliably and efficiently determiningTravelling carriersHoldersEmbedded systemMagnetic components

Systems and methods described herein may provide an adjustable magnetic attachment force for flag football and for determining a location in flag football. In some embodiments, a system comprises a flag and a wearable item, wherein the flag and the wearable item are configured such that a magnetic attachment force exerted between a first connector and a second connector attaches the flag to the wearable item. In some embodiments, a set comprises one or more flags and one or more wearable items, wherein an adjustable magnetic attachment force attaching the flags and wearable items is adjusted by replacing one or more magnetic components. In some embodiments, a system comprising a flag and a wearable item is configured to detect that contact between a first connector and a second connector has been broken and to automatically indicate a location associated with the contact being broken.

Owner:AFFL ASSOC LLC

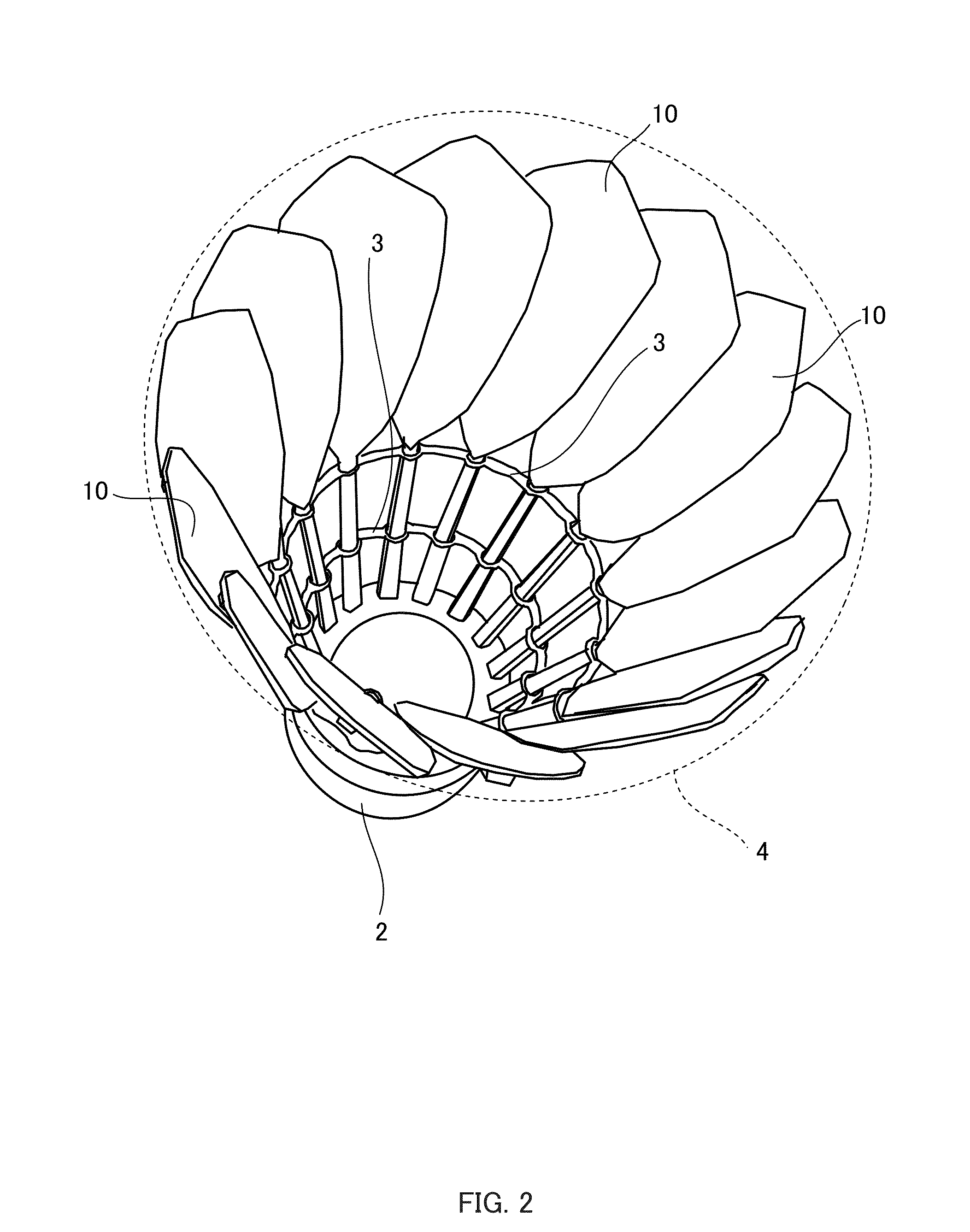

Artificial feather for shuttlecock, shuttlecock, and method of manufacturing artificial feather for shuttlecock

ActiveUS8992355B2Good shape retentionIncrease production capacityMouldsBall sportsEngineeringMechanical engineering

An artificial feather for a shuttlecock including a vane portion in a thin film form, corresponding to a vane, and a rachis portion in a bar form extending integrally and continuously from an upper tip end to a lower distal end, corresponding to a rachis, to imitate a natural feather, the vane portion being made of thermoplastic resin having interconnecting bubbles therein, and having low specific gravity and low elasticity relative to the rachis portion, the rachis portion being made of thermoplastic resin being fixed to the vane portion at a vane support portion, having the vane support portion set as an area that is fixed to the vane portion along the tip end to a bottom end of the vane portion, and having a calamus portion set as an area that protrudes to a lower side of the vane portion and spans from a bottom end of the vane support portion to the distal end, to correspond to a calamus of the natural feather.

Owner:YONEX CO LTD

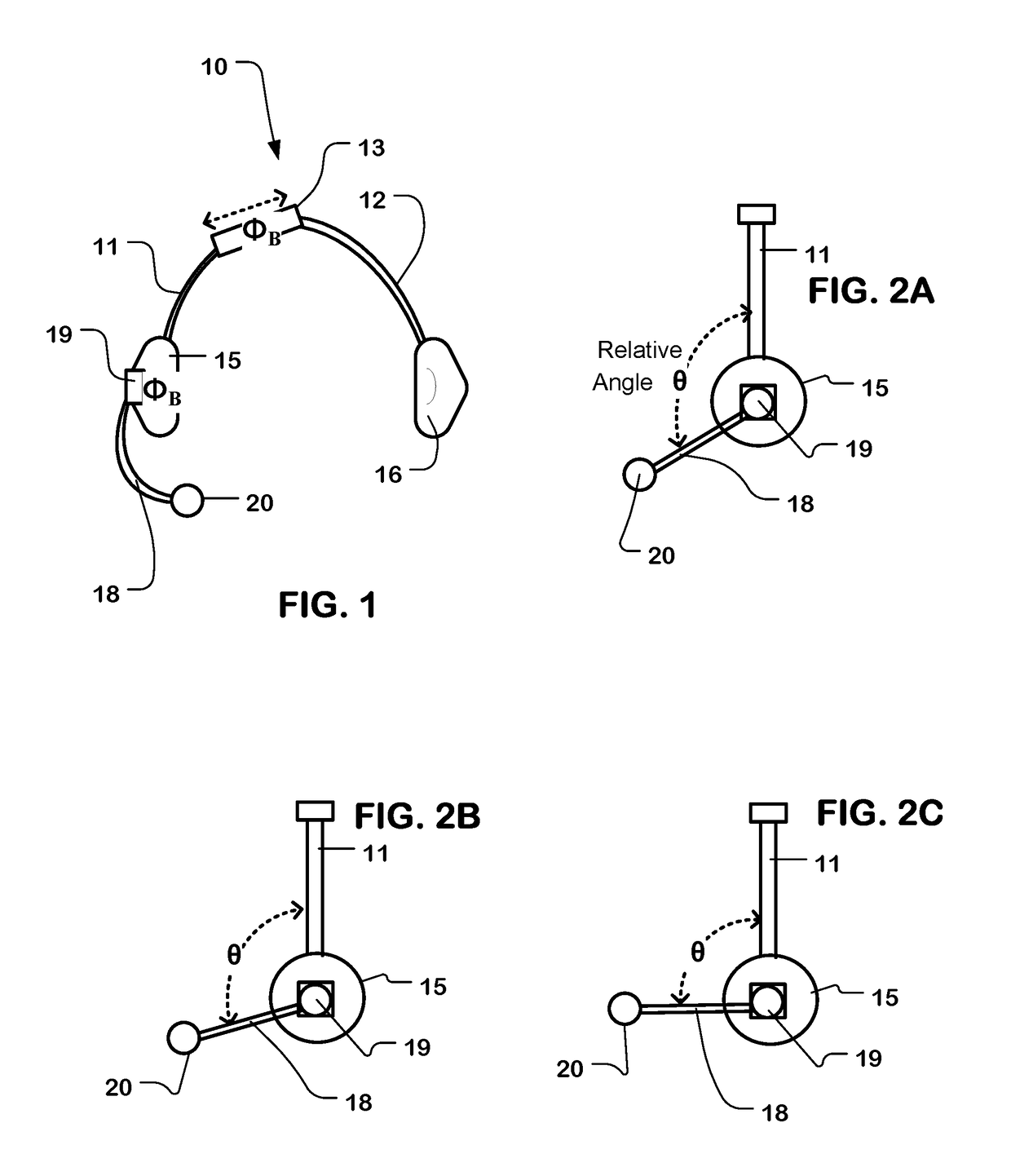

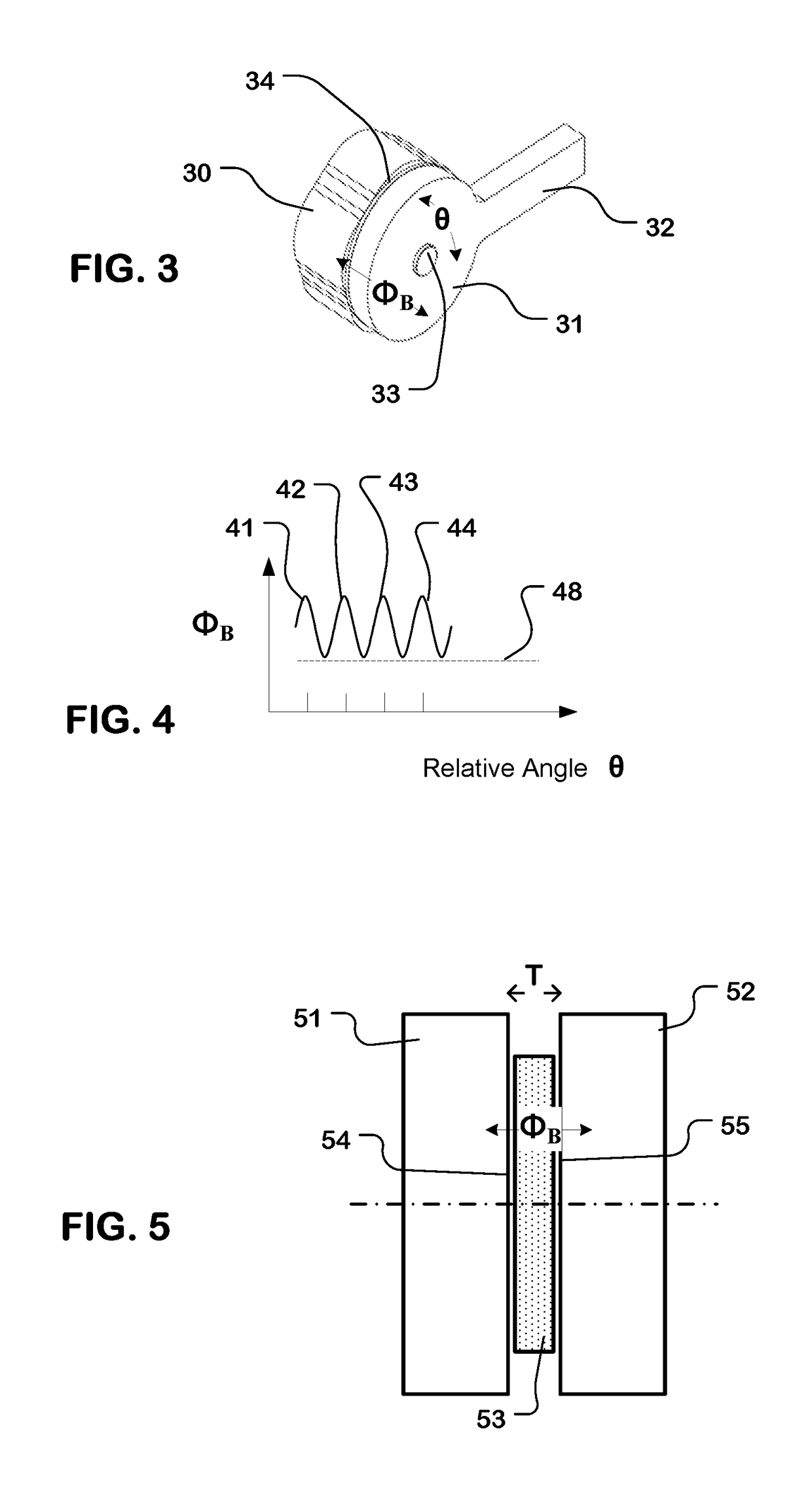

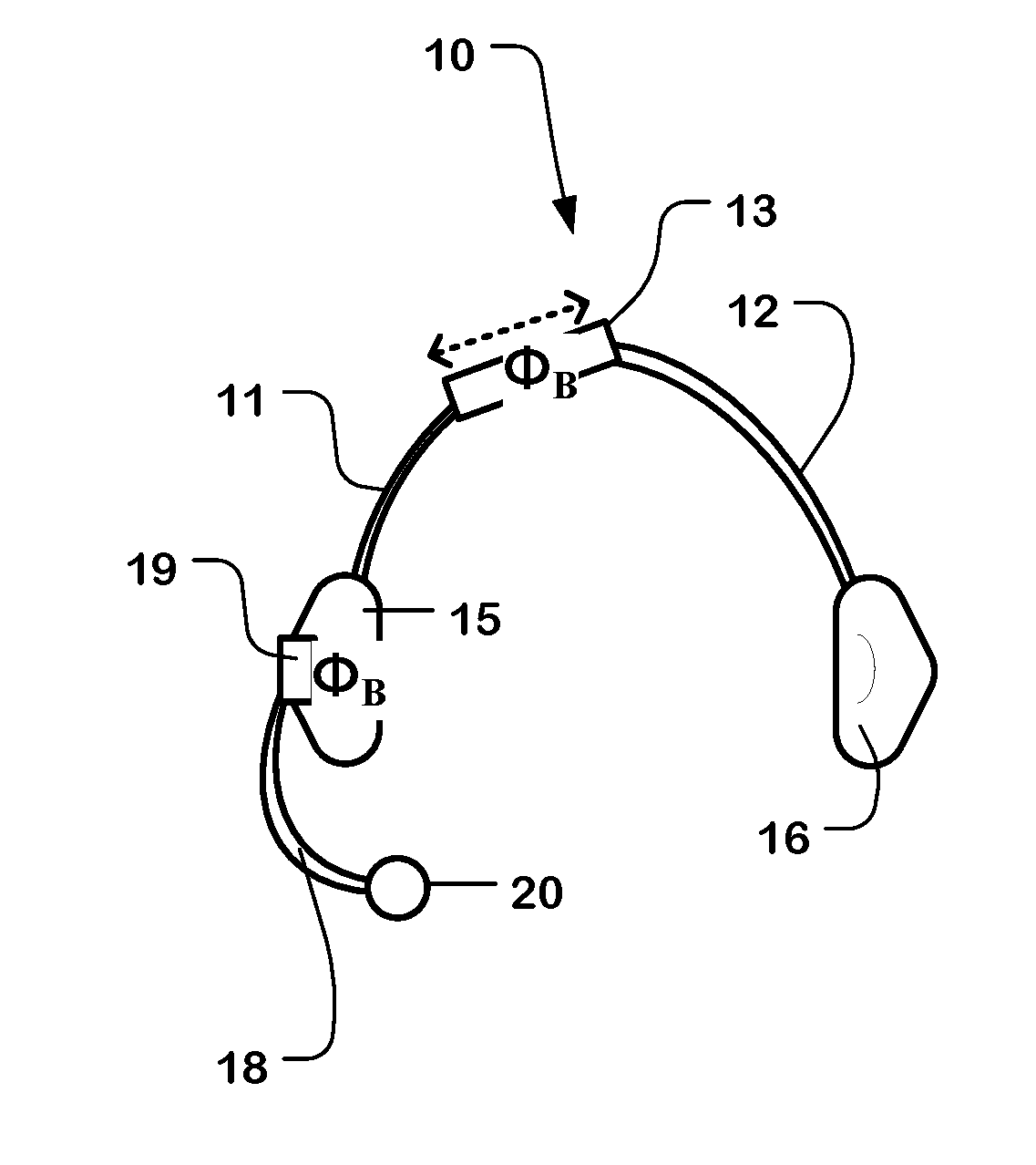

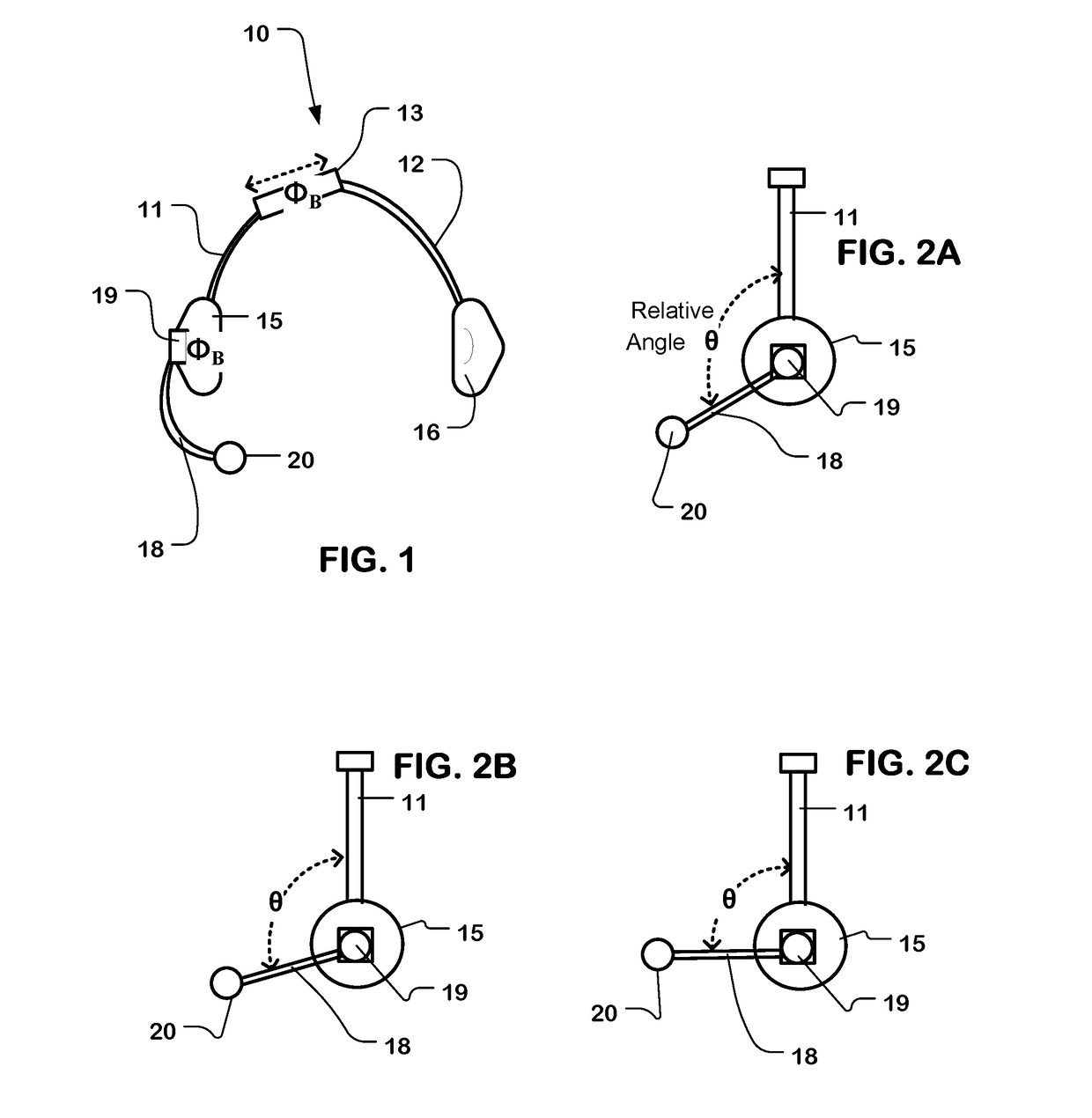

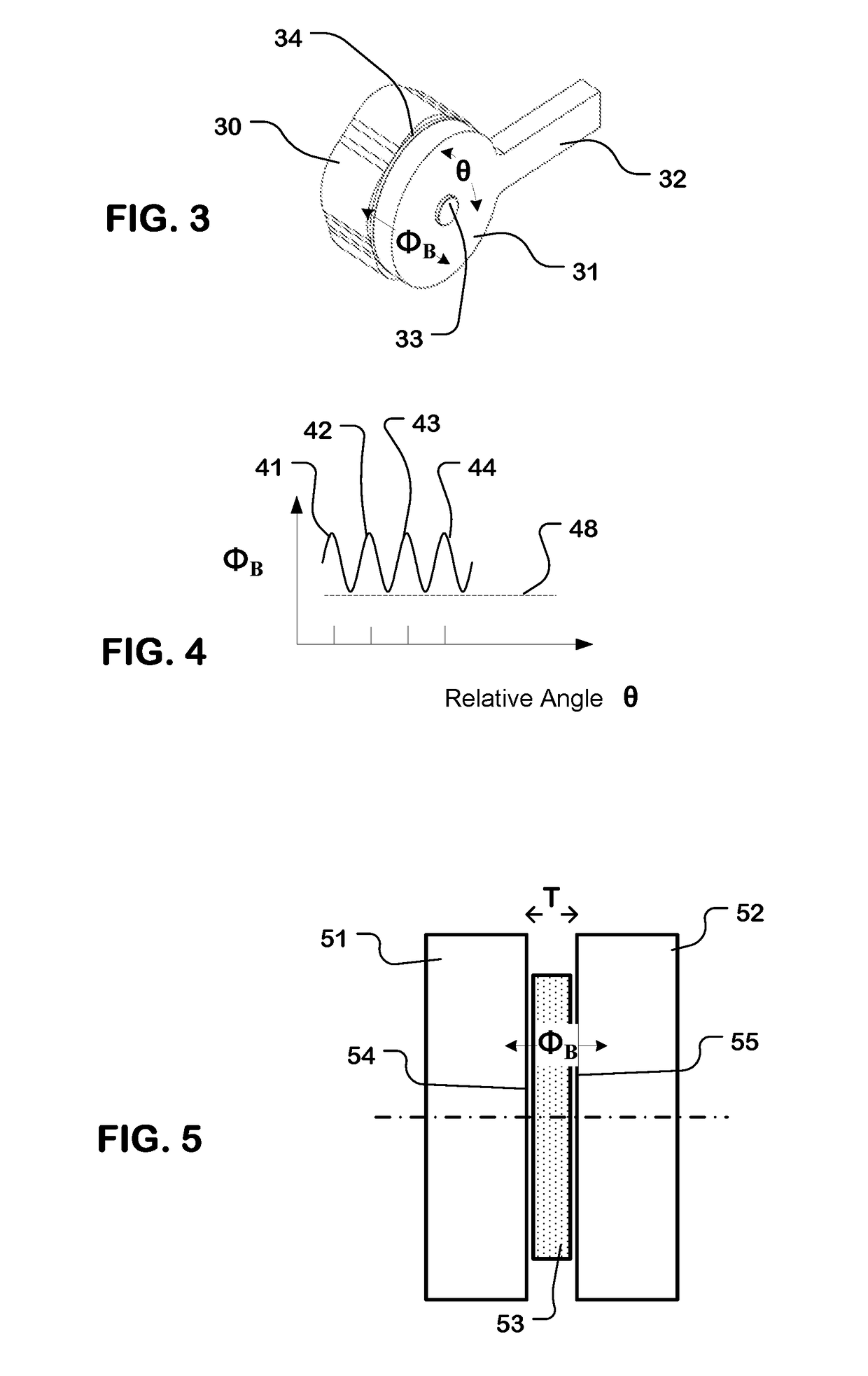

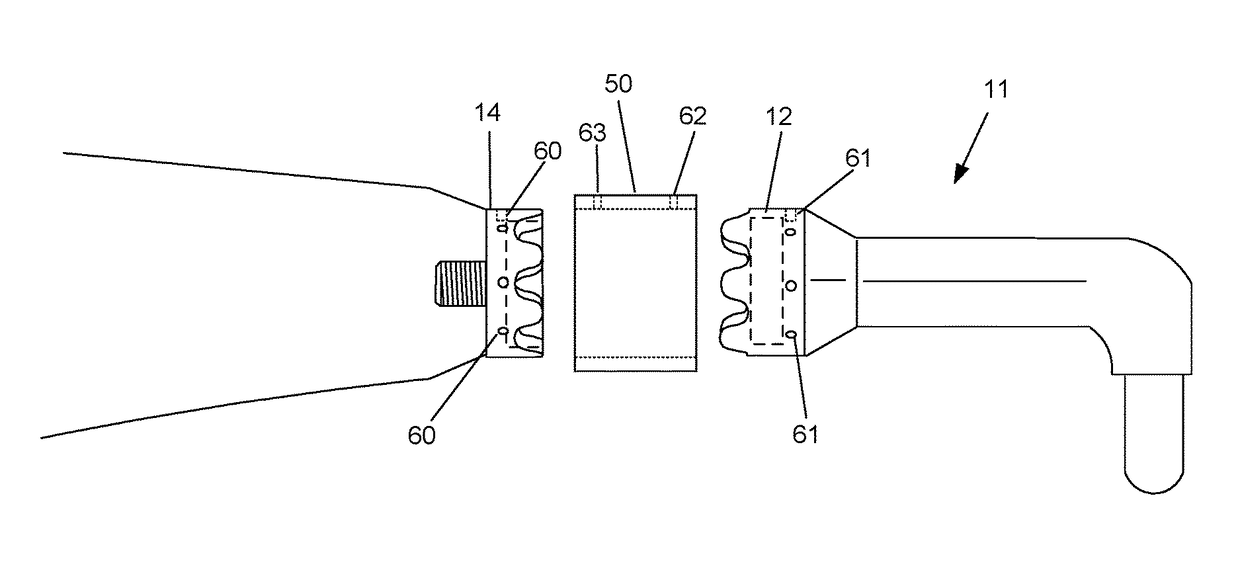

Headset with magnetic frictional coupler

A headset is described that utilizes magnetic frictional couplers. A coupler includes a first member having a first engagement surface and a second member having a second engagement surface disposed for relative positioning of the first and second members along a line of adjustment. One or more magnetic elements are arranged on the first and second members to establish a magnetic flux between the first engagement surface and the second engagement surface, and thereby establishing a frictional force tending to hold the relative positions of the first and second members. The magnetic flux varies as a function of relative position of the first and second members along the line of adjustment, and has peaks at a plurality of detent positions along the line of adjustment.

Owner:HEWLETT PACKARD DEV CO LP

Method for preventing static electricity during down processing and device thereof

The invention discloses a method for preventing static electricity during down processing and a device thereof. The method comprises the following steps: controlling the temperature in a down distribution box at 23-27 DEG C, keeping a certain humidity in the down distribution box at the same time; spraying water vapor into the down distribution box to raise the temperature in the box by a constant temperature humidor when the temperature is below 22 DEG C; and spraying water mist into the down distribution box to lower the temperature in the box when the temperature is above 27 DEG C; the constant temperature humidor consists of a vapor generator and a water mist generator; the vapor generator is connected with a plurality of evenly distributed vapor injection holes on two side walls of the down distribution box; and the water mist generator is connected with a plurality of evenly distributed water mist injection holes on two side walls of the down distribution box. As the constant temperature humidor is arranged on the down distribution box, the device can reduce the static electricity and conduct a little static electricity generated away in time, which eliminates the static electricity carried by the down, improves the production efficiency of down processing devices and lowers the energy consumption.

Owner:BENRUSON DOWN PROD CO LTD GUANGDONG

Magnetic band and associated methods thereof

ActiveUS9914615B2Easy accessPossess frictional resistancePermanent magnetsApparelMagnetic tapeEngineering

Owner:WOOLDRIDGE DAVID MARKS +2

System and method for decorating a pumpkin

ActiveUS9207527B1Carving time can be shortenedImprove securityStampsProjectorsEngineeringLight source

A system and method for decorating a vegetable, such as a pumpkin, is provided. The system includes a base frame disposed within an aperture defined in the pumpkin, and a cover having a design or image associated therewith that is selectively coupled to the base frame. The base frame may be a flexible, frusto-conical ring that has an outer edge positioned adjacent to an outer surface of the pumpkin. The outer edge may be at least partially formed of a magnetic material, and the cover may be formed of a material that is attracted to the magnetic material of the base frame to selectively attach the cover to the base frame. The system may include a colored sheet positioned behind the cover, and a protective backing positioned behind the colored sheet to provide protection from the heat generated from the light source within the pumpkin.

Owner:SHOOSHAN RYAN

Headset with Magnetic Frictional Coupler

A headset is described that utilizes magnetic frictional couplers. A coupler includes a first member having a first engagement surface and a second member having a second engagement surface disposed for relative positioning of the first and second members along a line of adjustment. One or more magnetic elements are arranged on the first and second members to establish a magnetic flux between the first engagement surface and the second engagement surface, and thereby establishing a frictional force tending to hold the relative positions of the first and second members. The magnetic flux varies as a function of relative position of the first and second members along the line of adjustment, and has peaks at a plurality of detent positions along the line of adjustment.

Owner:PLANTRONICS

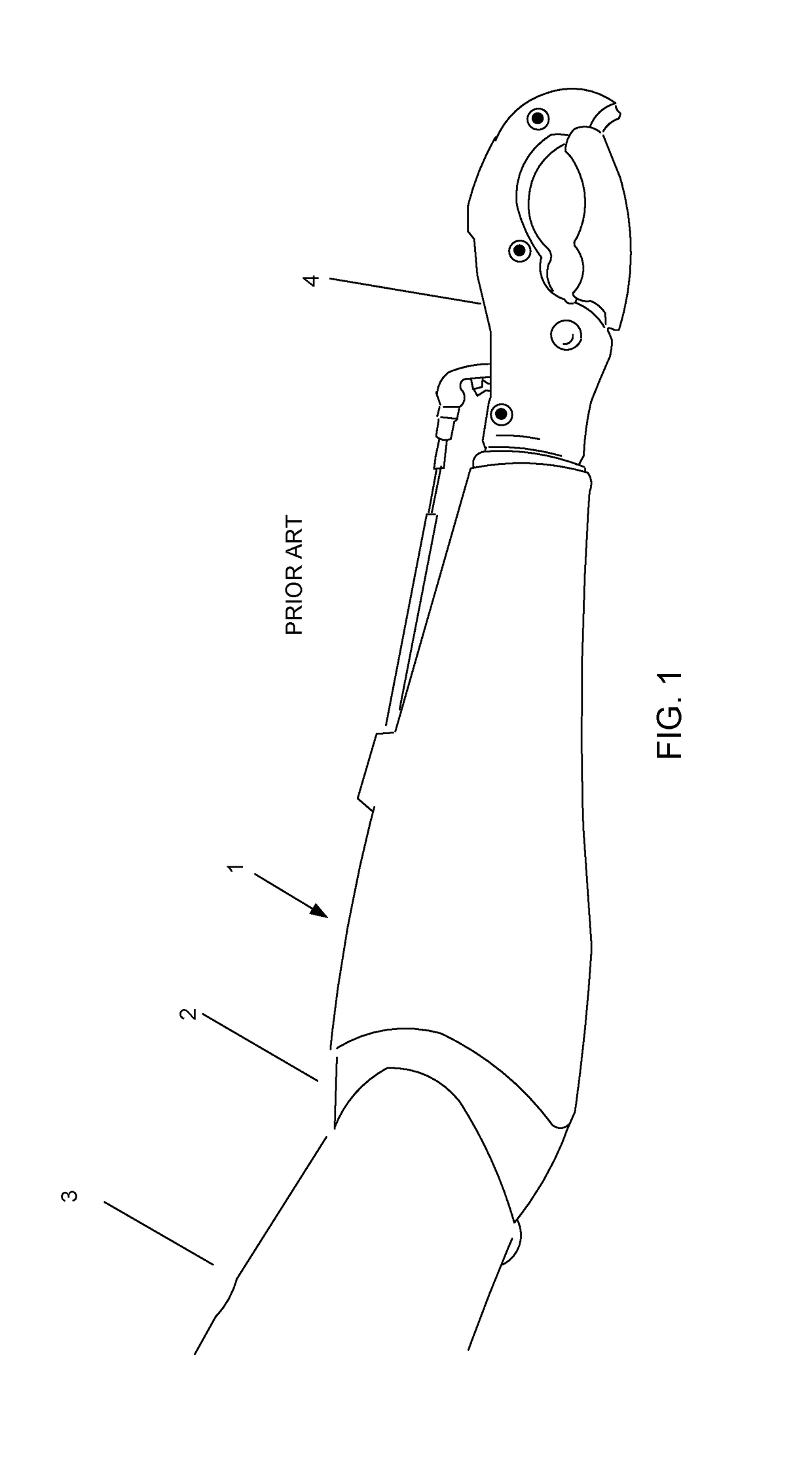

Prosthetic attachment

A prosthetic attachment for a prosthetic limb. A base is attached to the prosthetic limb. The base has a magnet that is surrounded by base valleys and base peaks. An attachment piece is attached to the prosthetic attachment. The attachment piece also has a magnet that is surrounded by attachment piece valleys and attachment piece peaks. The magnetic force between the base magnet and the attachment piece magnet attracts the prosthetic attachment to the prosthetic limb so that the base peaks and valleys mates with the attachment piece peaks and valleys for a secure removable attachment. In a preferred embodiment a locking device is used to further secure the prosthetic attachment to the prosthetic limb. In a preferred embodiment the prosthetic attachment is a prosthetic hand and the prosthetic limb is a prosthetic arm.

Owner:ARMBRUSTER MICHAEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com