Patents

Literature

663results about How to "Reduce static" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

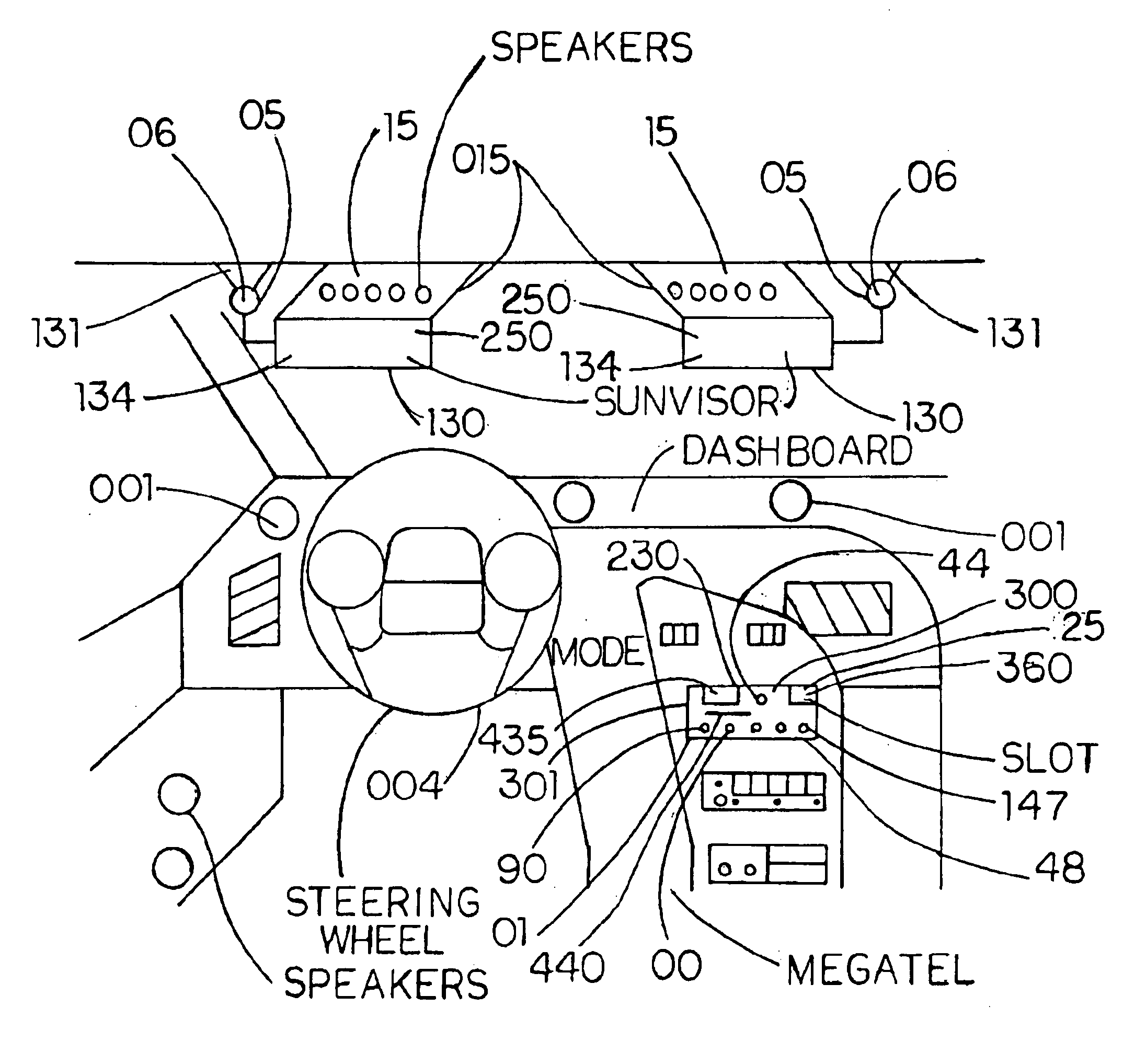

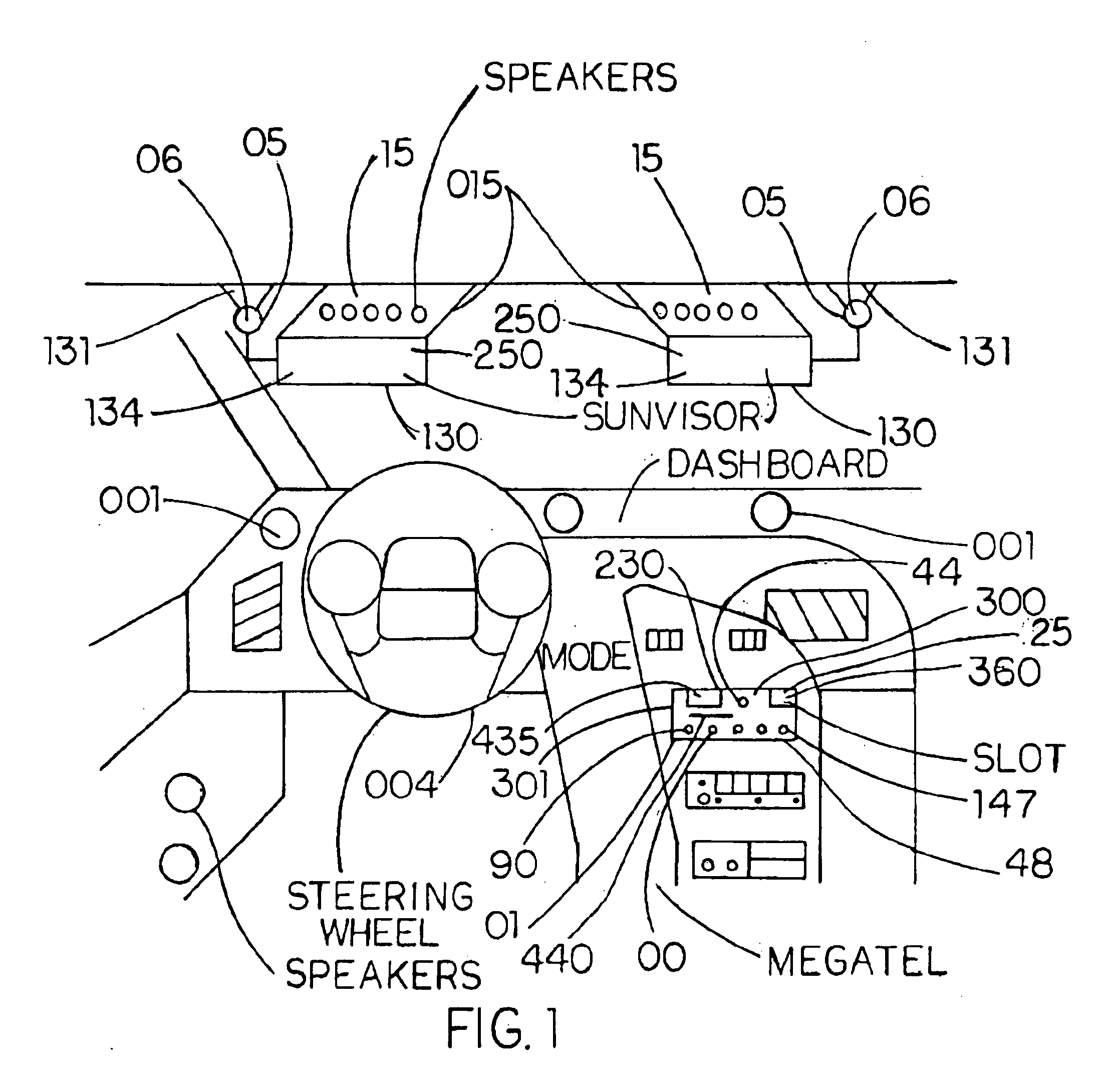

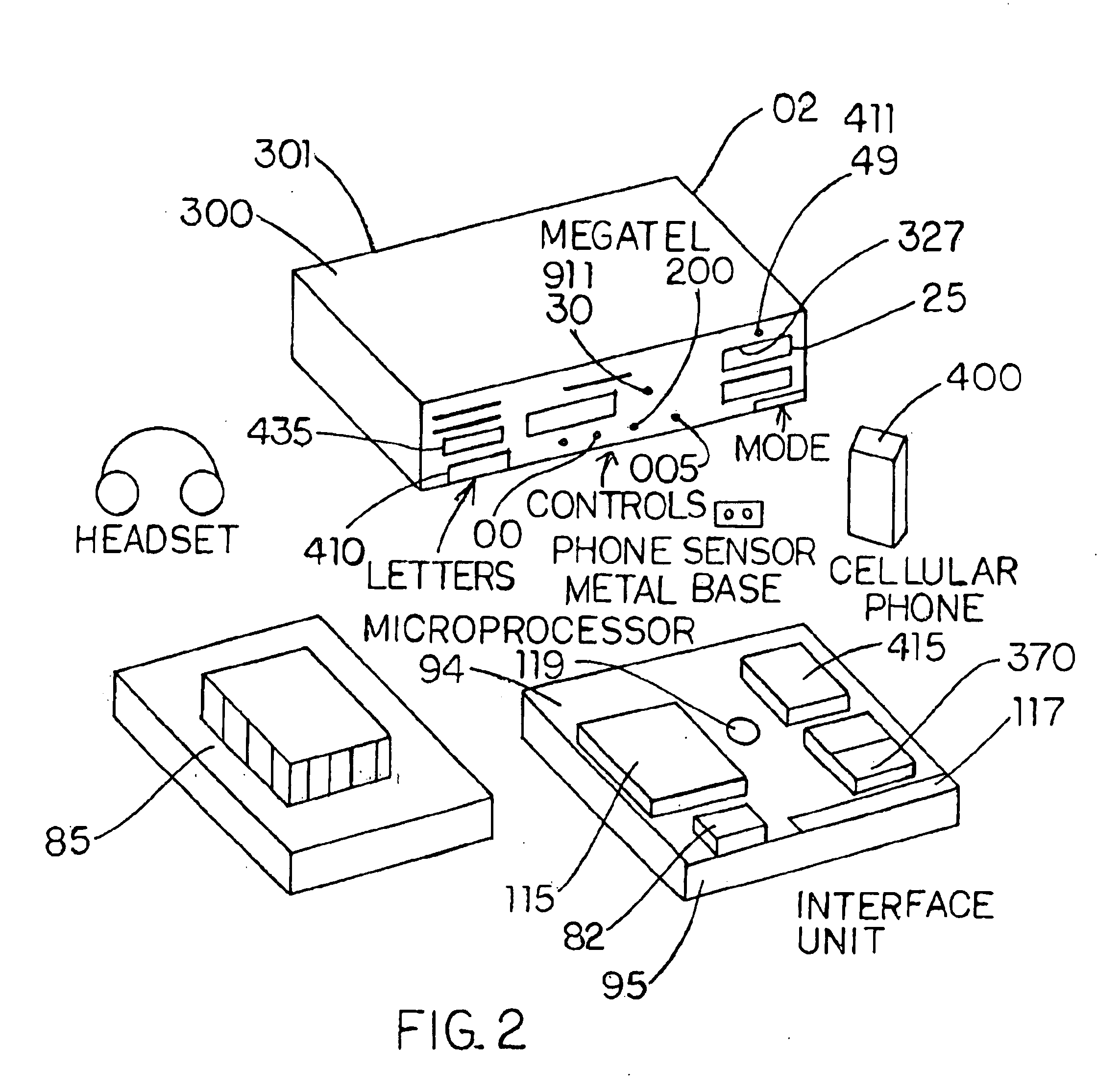

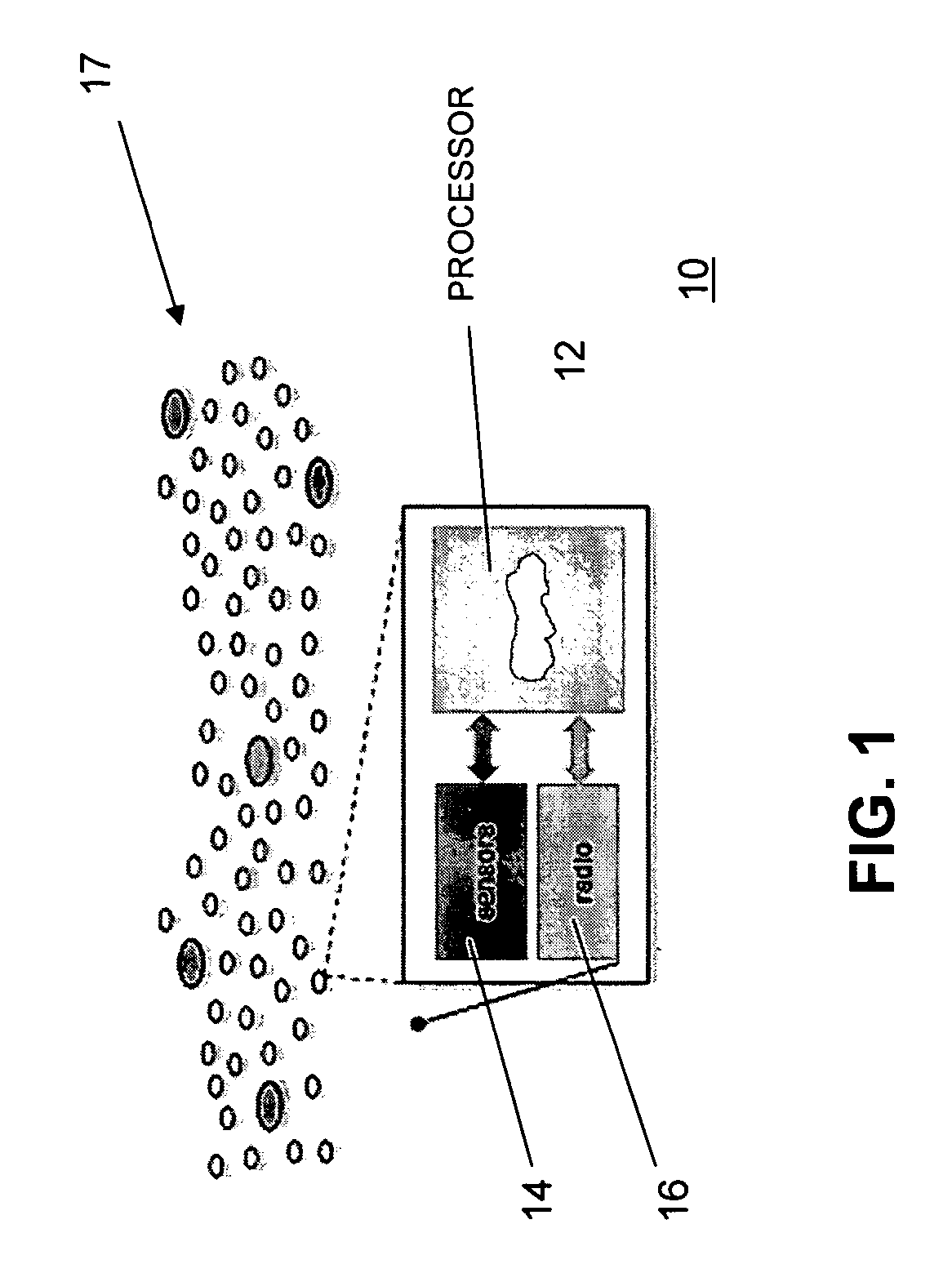

Megatel communication information system

InactiveUS6782240B1Reduction of pressure effectEnhanced informationSubstation speech amplifiersRadio transmissionThe InternetHands free

An entertainment device for vehicles adaptable to include various telecommunication and Internet applications, a sunviser monitoring screen for viewing, with an electronic screen protector for protecting the screen. The device, which is referred to as megatel, incorporates receivers and transmitters to enable cell phone and Internet transmission via the radio wave of an entertainment device radiated towards the antenna to the megatel body and output to the CPU. The signal to the CPU is controlled by the controller so that transmissions for the radio, the cell phone, and the Internet is separated and output to the monitoring screen and the speakers of the entertainment device so as to allow hands free communication while driving.

Owner:TABE JOSEPH A

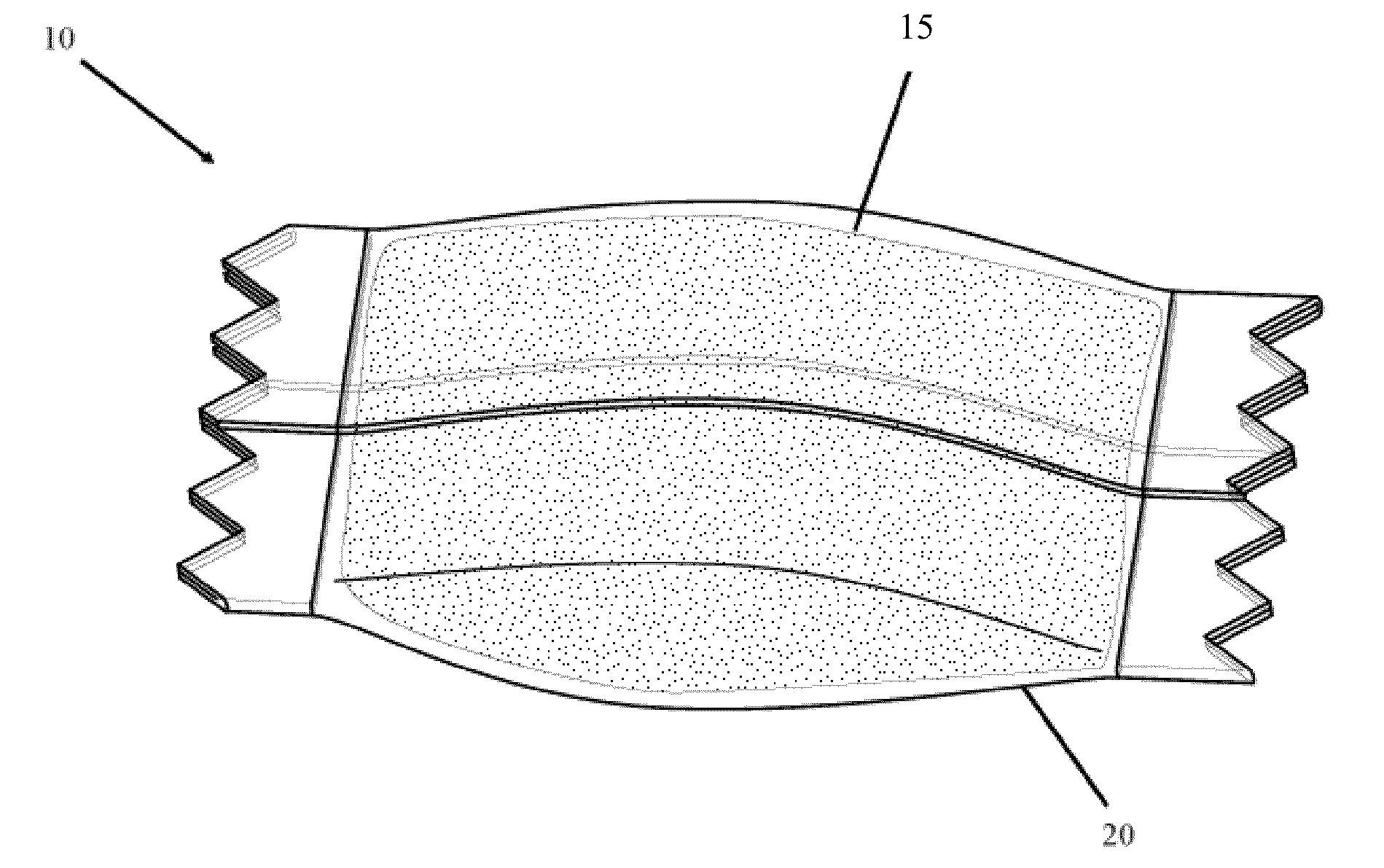

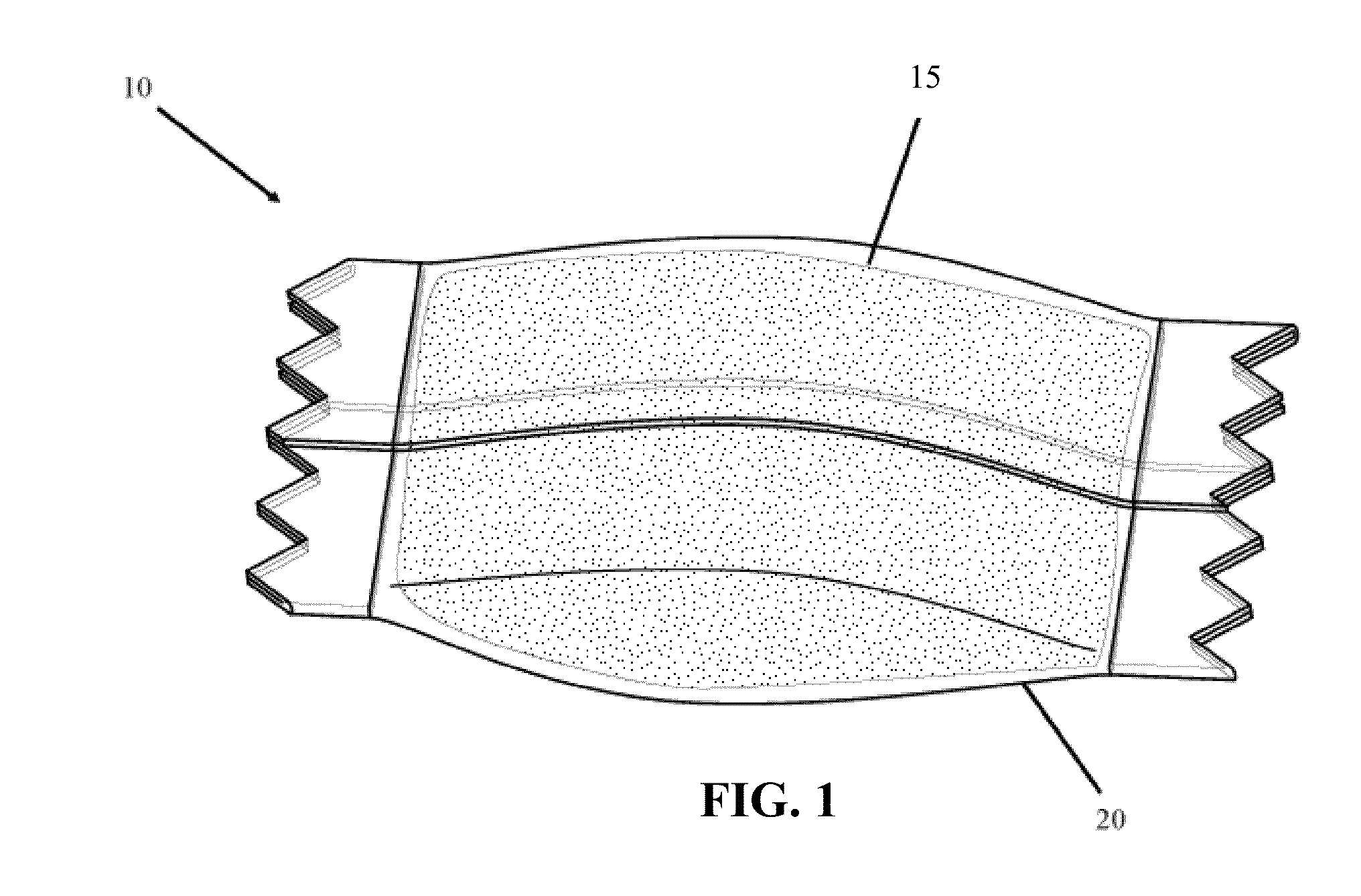

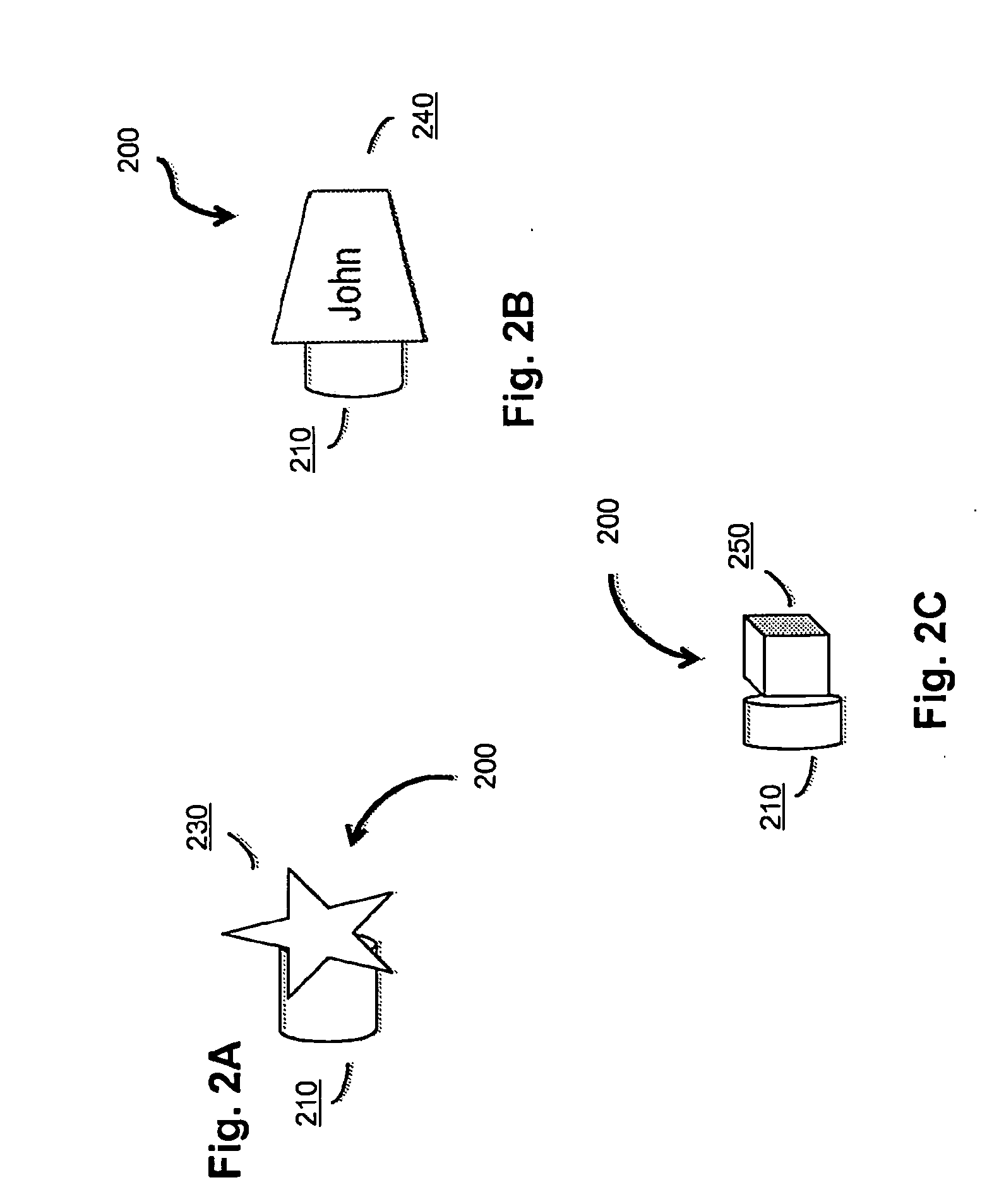

Oral pouch products

PendingUS20160192703A1Reduce and dissipate static chargeStrong and cost-effectiveTobacco treatmentTransportation and packagingFiberBiomedical engineering

A pouched product configured for insertion into the mouth of a user of that product is provided herein. The pouched product can include an outer water-permeable pouch defining a cavity containing a composition adapted for oral use and having a surface area, wherein the outer water-permeable pouch can include a nonwoven spunlaid web comprising a plurality of continuous filament heat sealable fibers.

Owner:R J REYNOLDS TOBACCO COMPANY

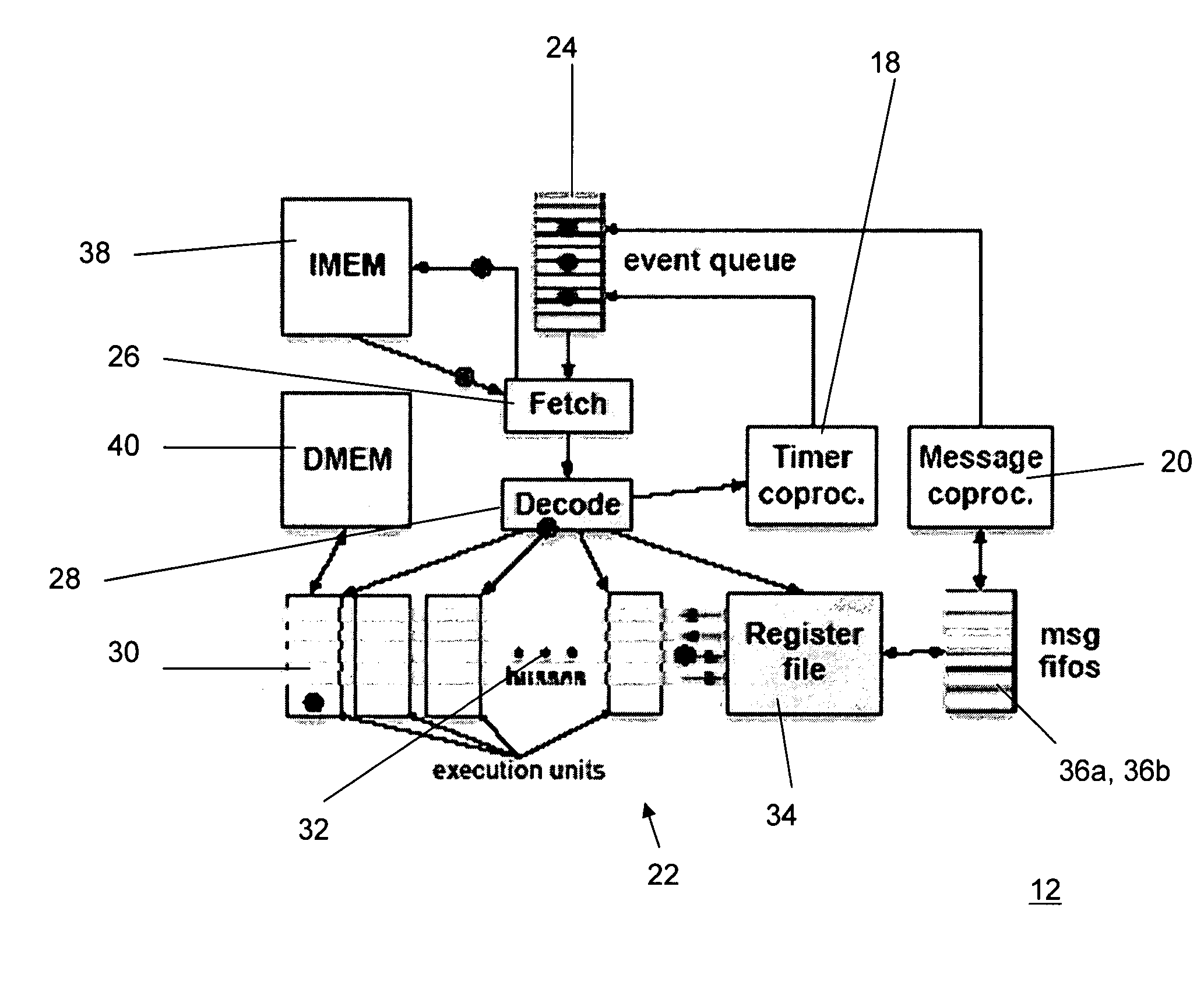

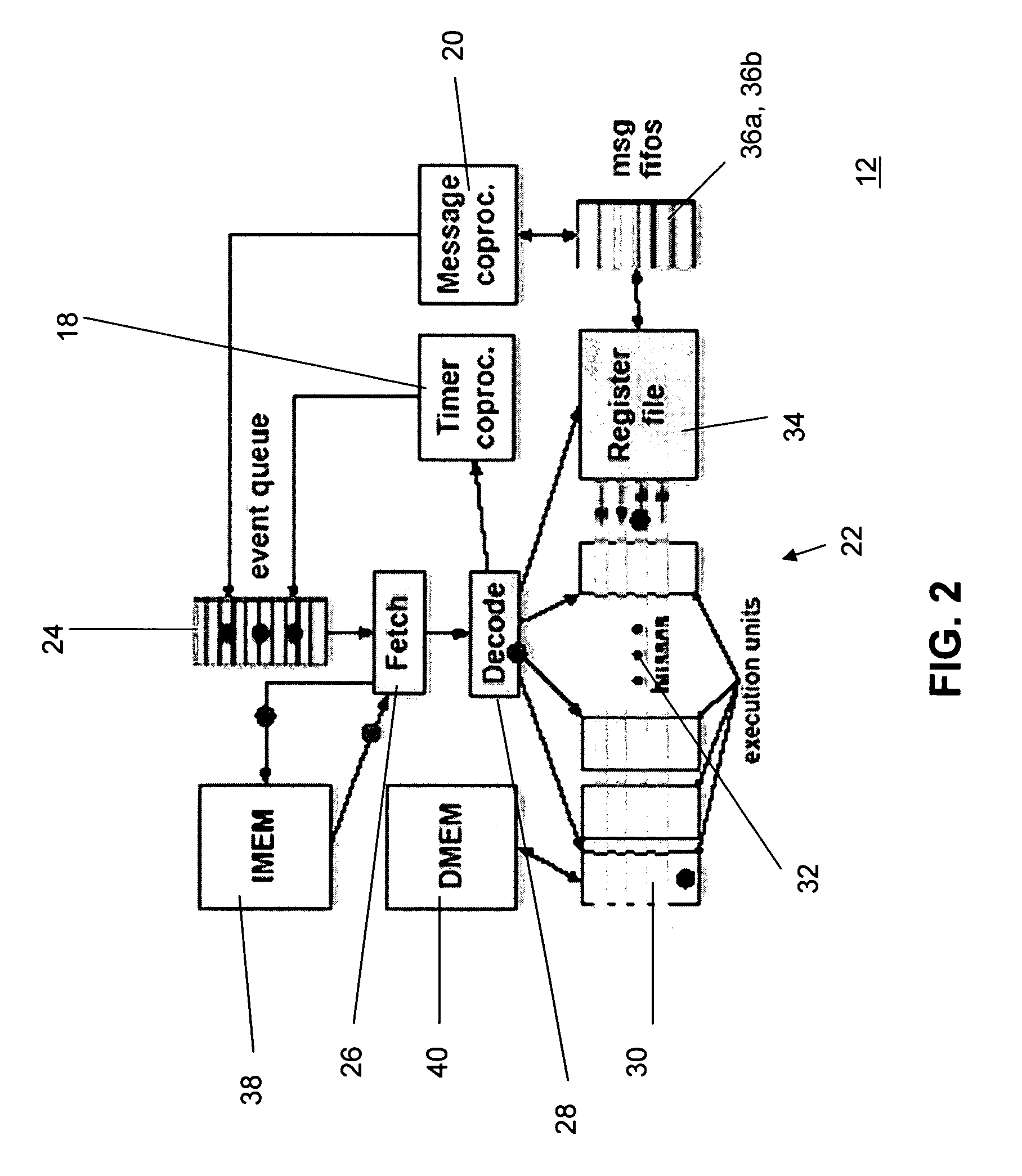

Sensor-network processors using event-driven architecture

InactiveUS20060075210A1Life maximizationLow-overhead transitionsPower managementMeasurement devicesMultiple sensorNetwork simulation

Event-driven processor architectures are particularly suited for use in multiple sensor node networks and simulators of such networks. A first variation of the processor is particularly suited for use in a sensor node in a wireless sensor network. Through use of the event-driven architecture and special message and timing coprocessors, this embodiment of the invention is optimized for low energy requirements and data monitoring operations in sensor networks. A second embodiment of the invention includes modifications necessary for use of the processor in a network simulation protocol.

Owner:CORNELL RES FOUNDATION INC

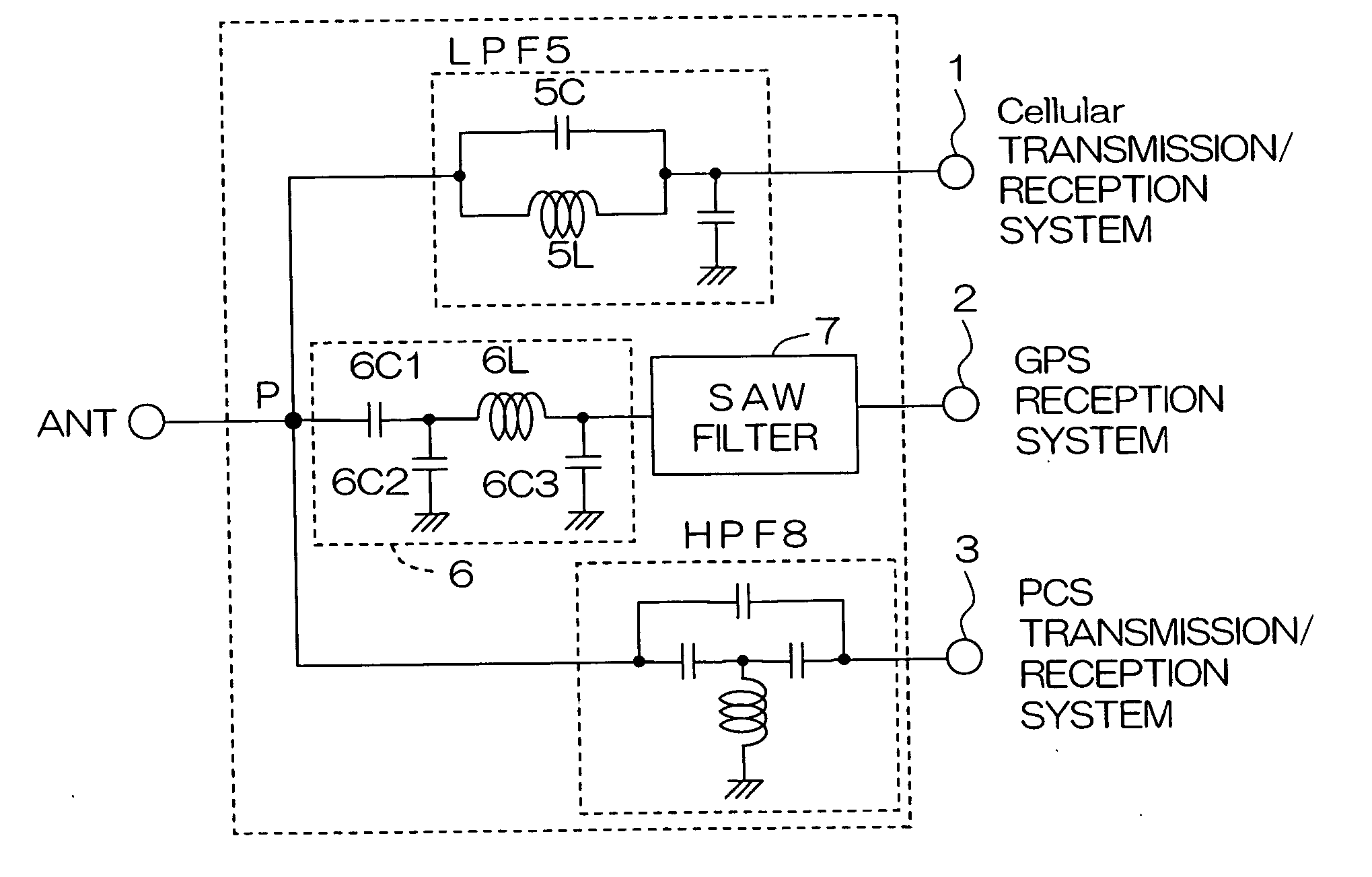

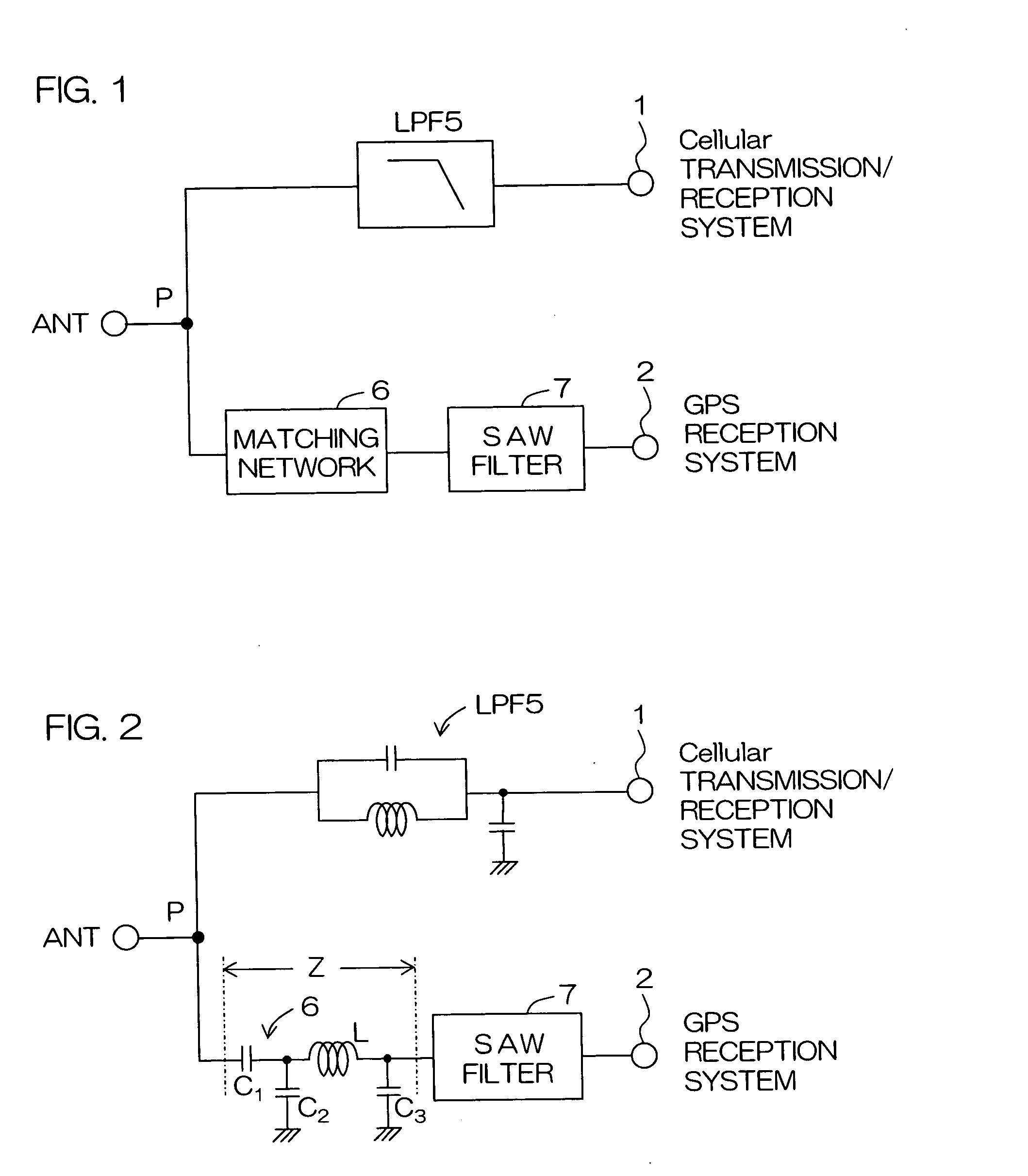

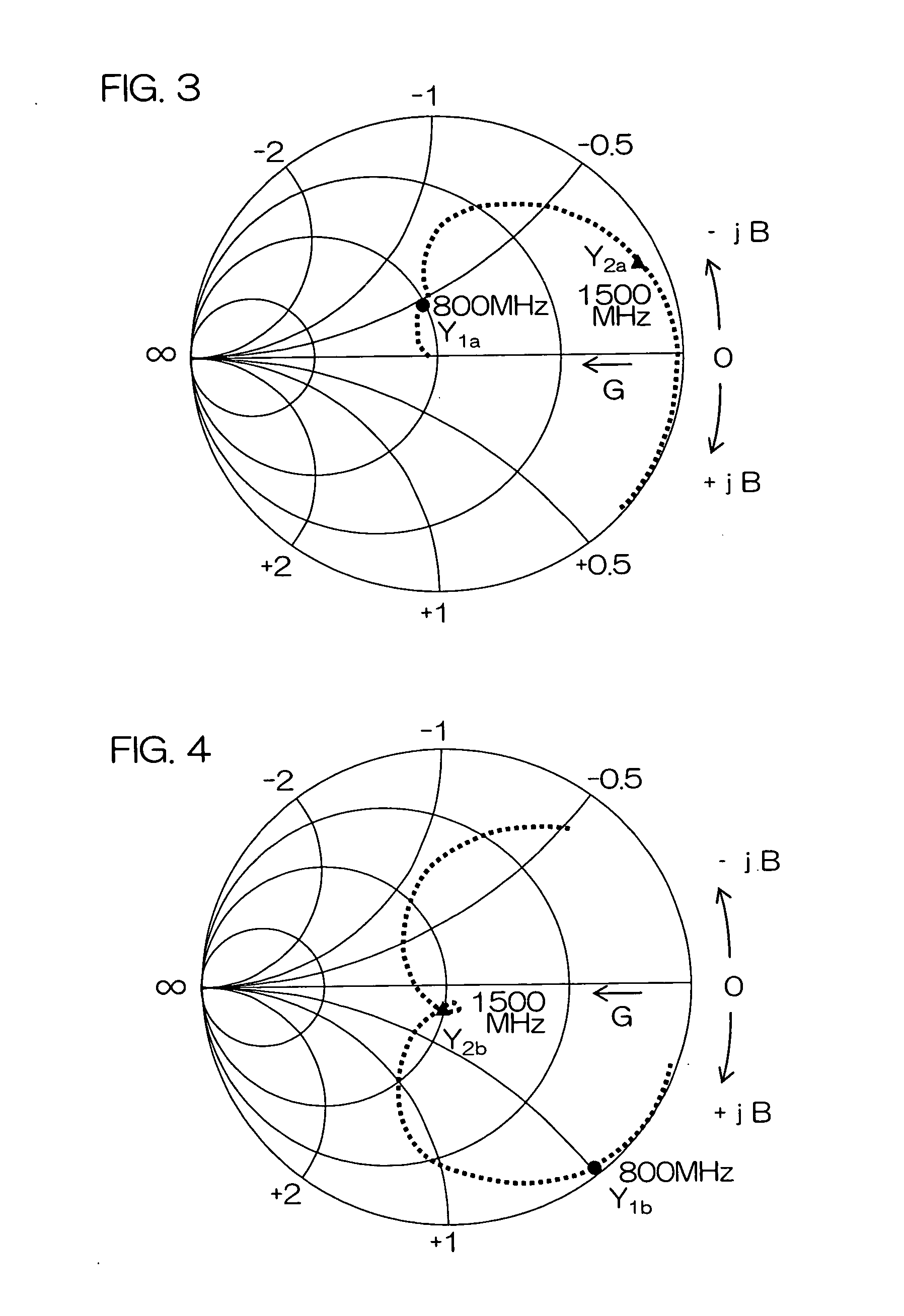

Composite multiplexer circuit and chip component, high-frequency module and radio communication apparatus using the same

InactiveUS20050281210A1Low transmission lossHigh reliabilityMultiple-port networksElectronic switchingHigh frequencyAcoustic wave

In a composite multiplexer circuit designed to multiplex plural frequency bands by interconnecting plural multiplexer circuits in parallel, a multiplexer circuit for extracting a frequency band of a GPS reception system includes a matching network including an inductor and a capacitor, and a surface acoustic wave filter connected in series with the matching network. The multiplexer circuit for the GPS reception system can be so set as to have infinite impedances at the other frequency bands than the frequency band thereof. This prevents signals in the other frequency bands from leaking into the multiplexer circuit for the GPS reception system.

Owner:KYOCERA CORP

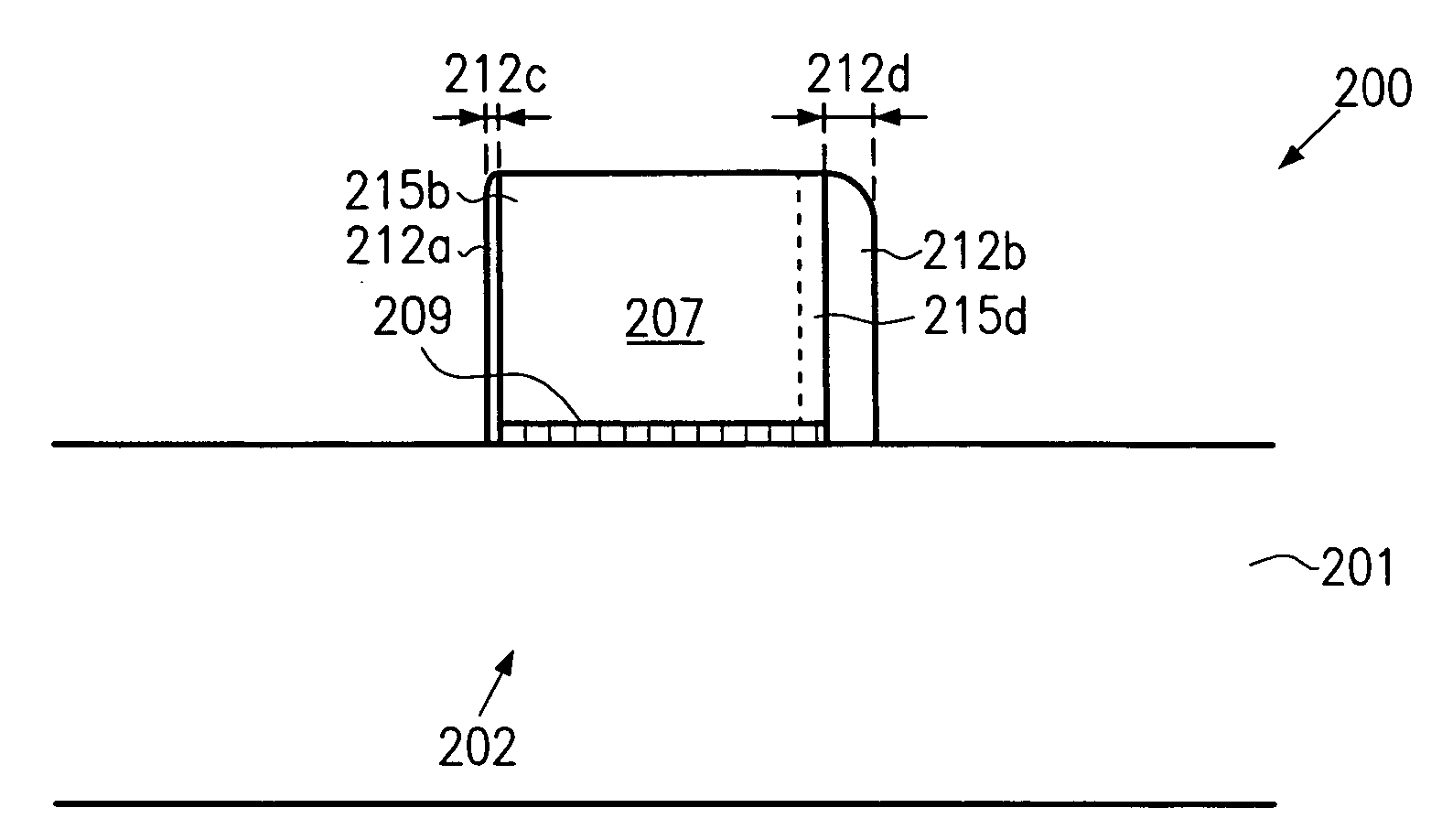

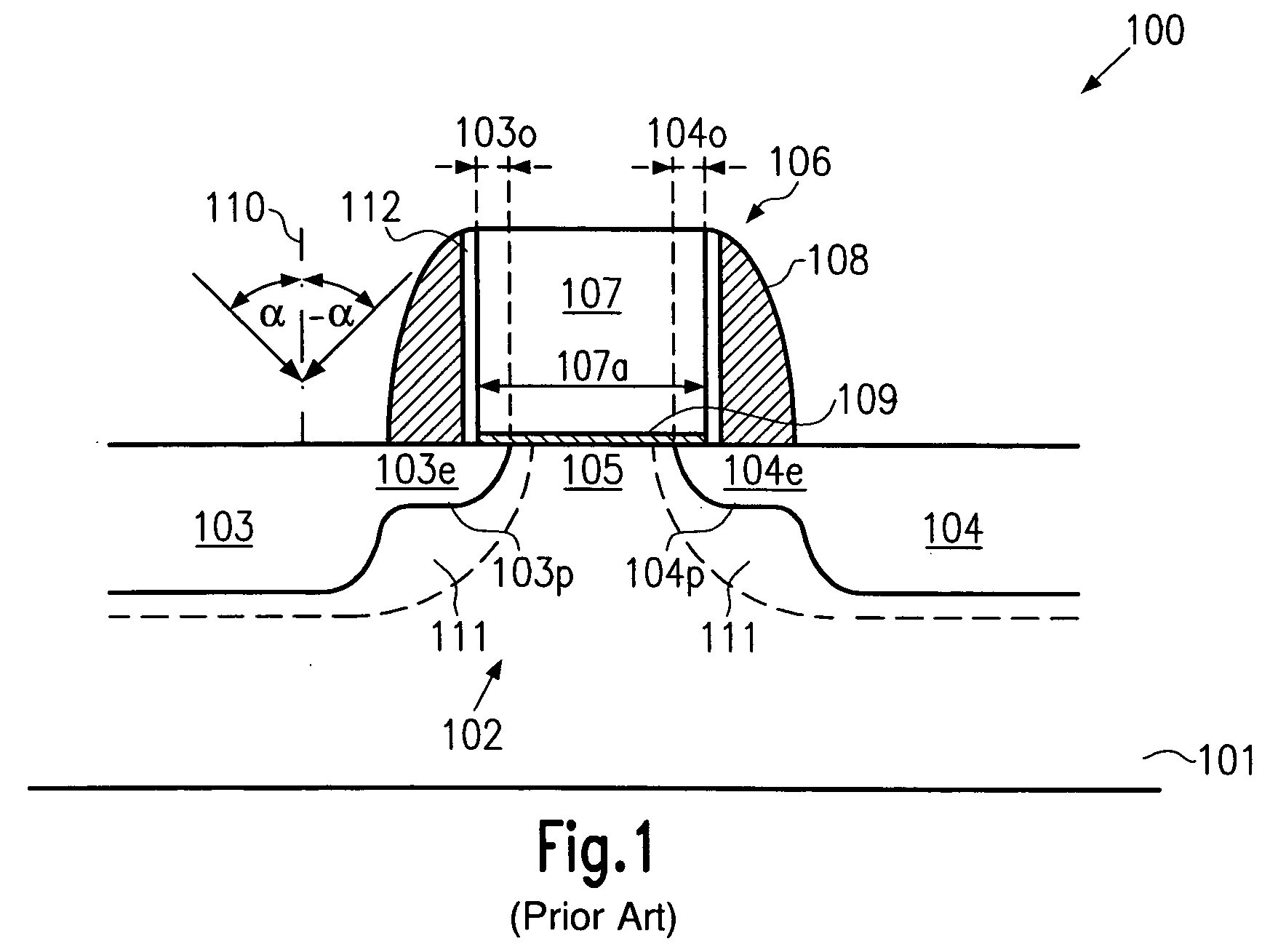

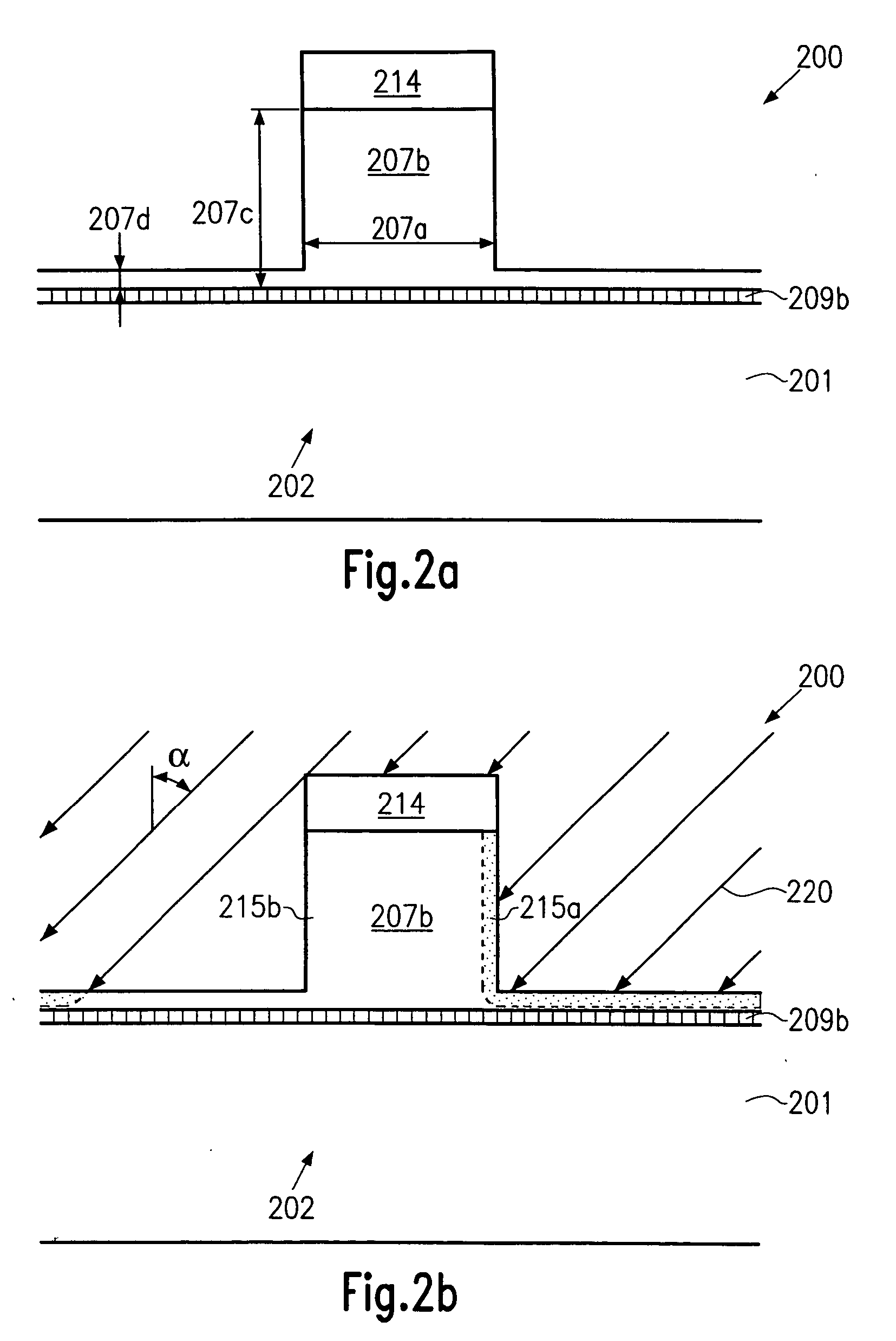

Gate structure and a transistor having asymmetric spacer elements and methods of forming the same

ActiveUS20060194381A1Improve current drive capabilityReduce staticSemiconductor/solid-state device manufacturingSemiconductor devicesNon symmetricEngineering

Methods for forming asymmetric gate structures comprising spacer elements disposed on the opposed sides of a gate electrode and having a different width are disclosed. The asymmetric gate structures are employed to form an asymmetric design of a halo region and extension regions of a field effect transistor using a symmetric implantation scheme, or to further enhance the effectiveness of asymmetric implantation schemes. The transistor performance may be significantly enhanced for a given basic transistor architecture. In particular, a large overlap area may be created at the source side with a steep concentration gradient of the PN junction due to the provision of the halo region, whereas the drain overlap may be significantly reduced or may even be completely avoided to further enhance the transistor performance.

Owner:ADVANCED MICRO DEVICES INC

Low-smoke FDY (Fully Drawn Yarn) oiling agent and preparation method thereof

The invention discloses a low-smoke FDY (Fully Drawn Yarn) oiling agent and a preparation method thereof. The low-smoke FDY oiling agent comprises the following materials in percentage by weight: 50-60% of emulsifying agent, 10-30% of smoothing agent, 6-10% of antistatic agent, 1-3% of beam concentrating agent, 9-11% of moisture, and 0.1-0.2% of preservative. The low-smoke FFY oiling agent provided by the invention has such functions of lubricating fiber, concentrating beam, preventing static electricity and the like in a production process of FDY, has the characteristics of reducing broken yarns, broken filaments, reducing dyeing and the like in a pre-spinning process, and further has the characteristics of reducing broken yarns, broken filaments, static electricity and the like in a post-processing (weaving) process, and is an important auxiliary ingredient which is essential in the production process of chemical fiber.

Owner:ZHEJIANG TIANSHENG HLDG GROUP

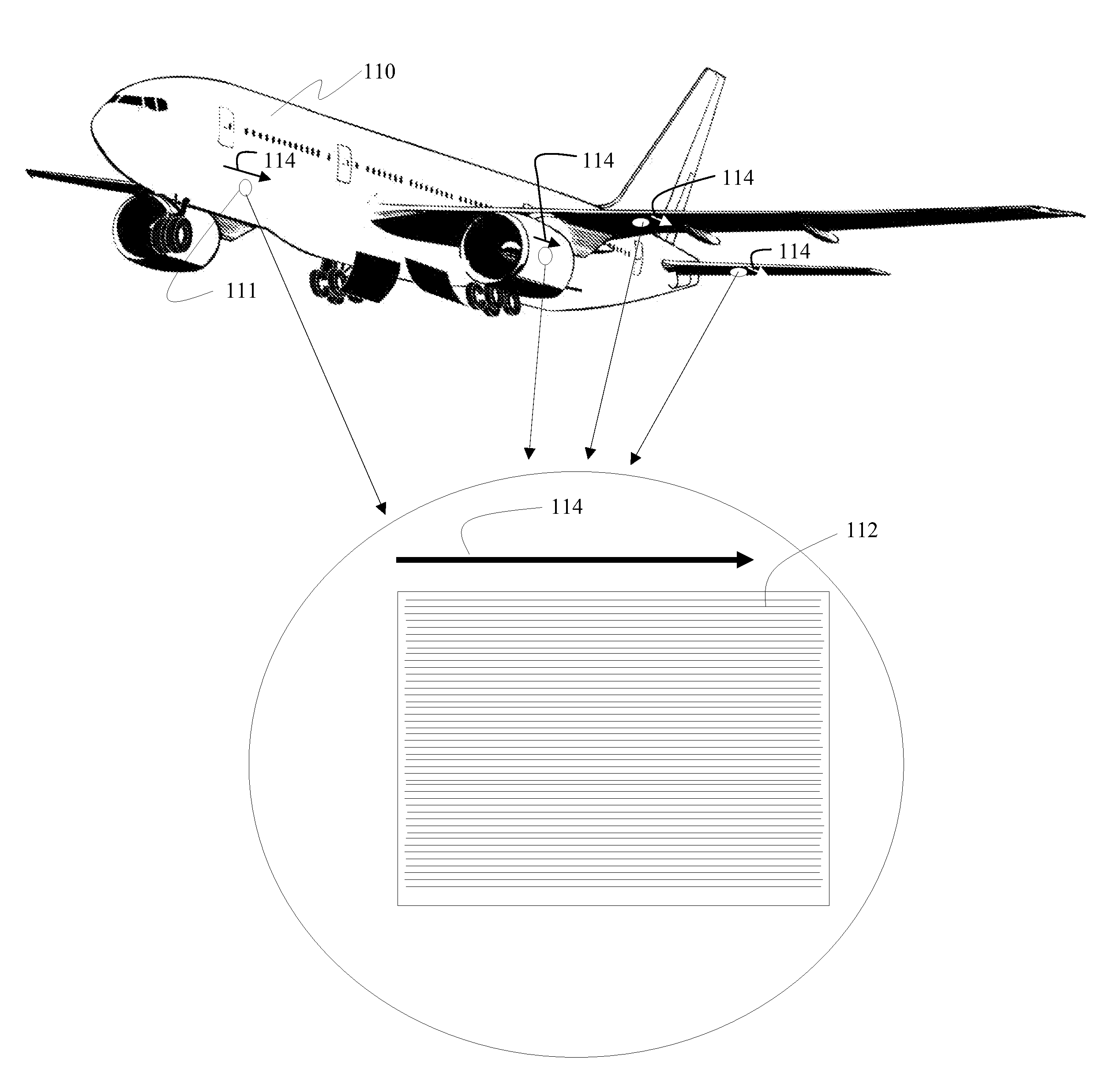

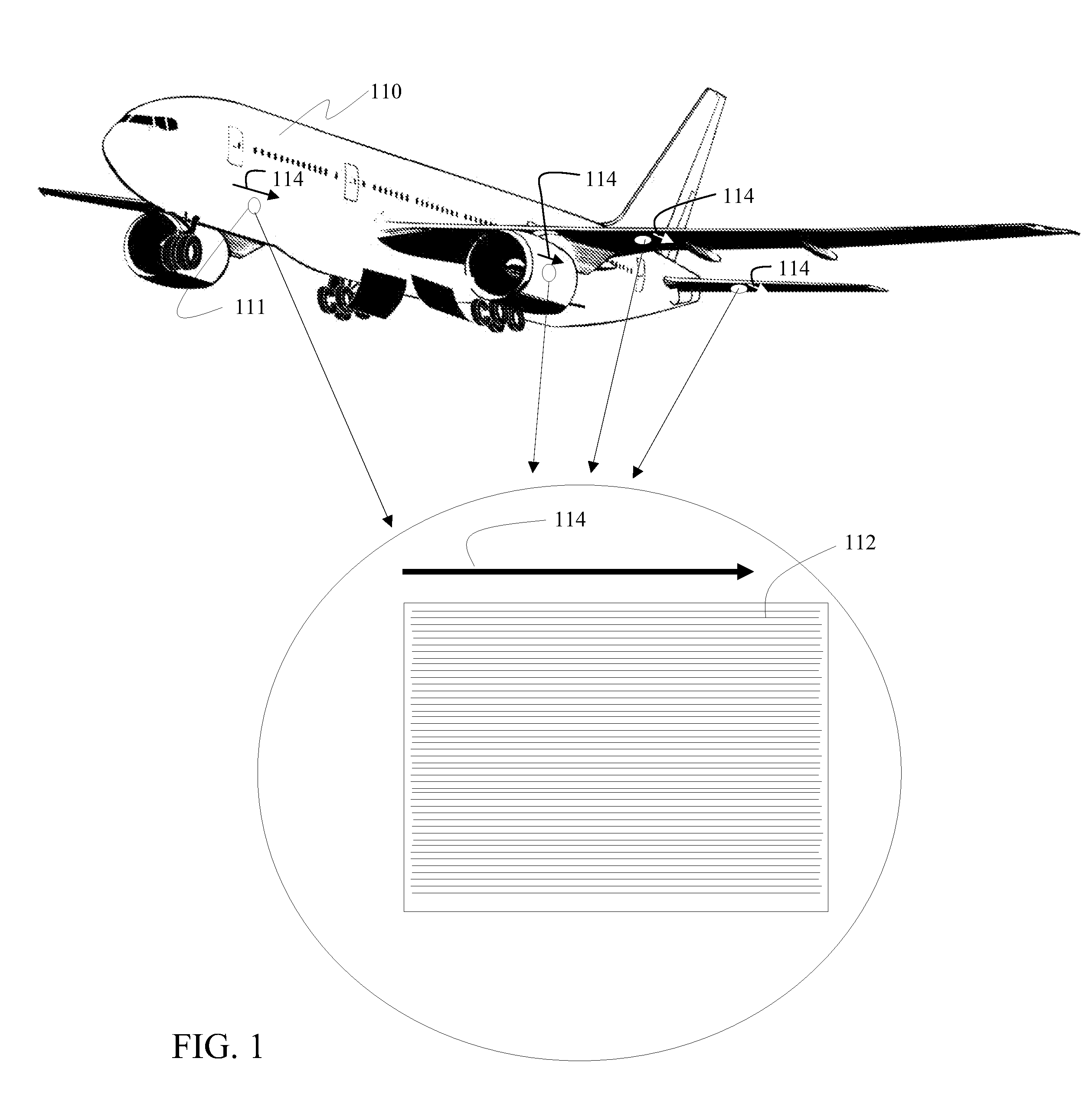

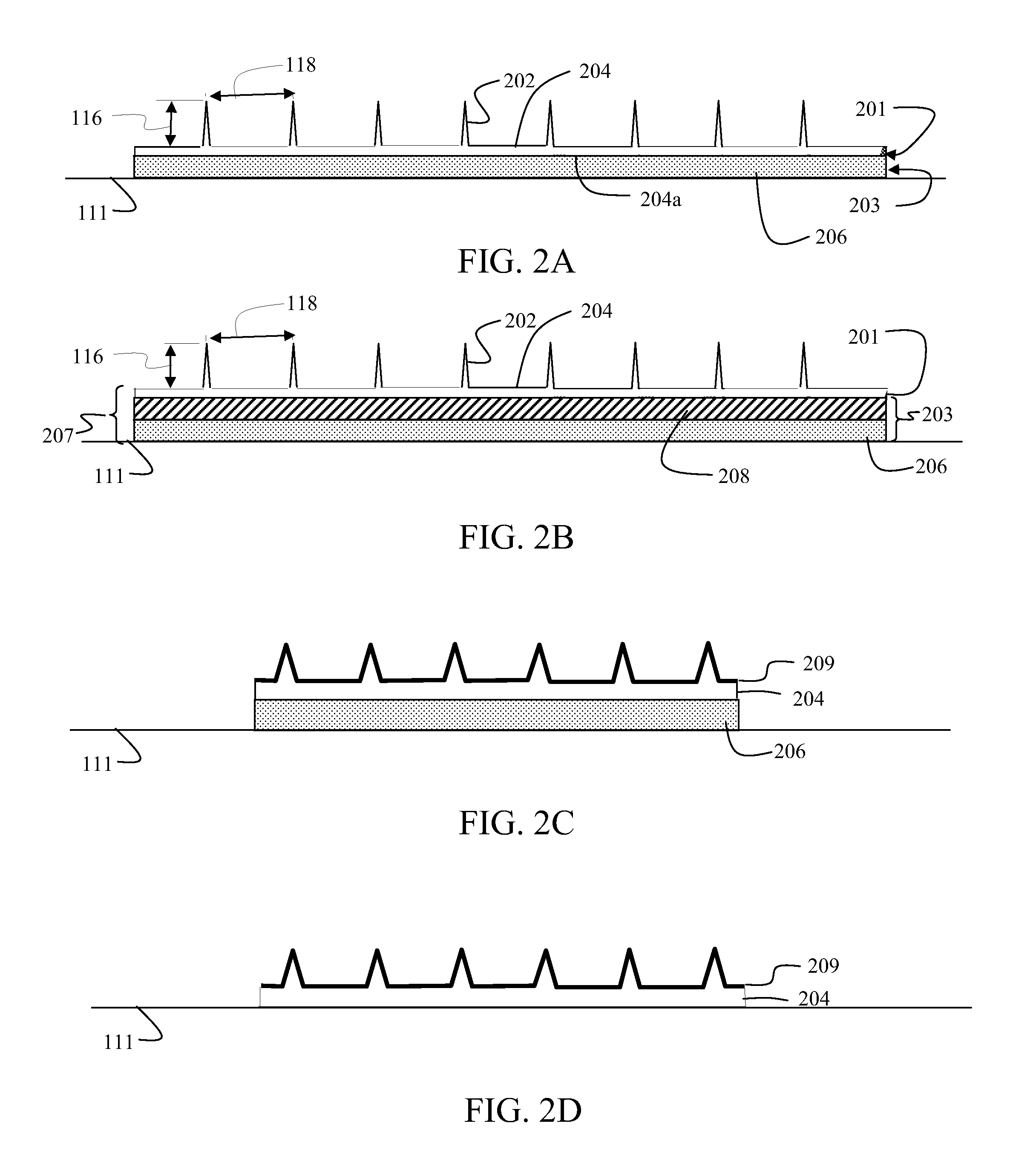

Elastomeric riblets

ActiveUS20100282909A1Increase fluid resistancePromote oxidationVehicle componentsCoatingsMetal foilEngineering

An array of aerodynamic riblets incorporates a high elongation elastomeric layer having spaced tips and optionally a protective cladding. The elastomeric layer may be adhered to an aerodynamic surface directly or as an appliqué in combination with one or more of an adhesive layer, one or more supporting polymer layers and a metal foil layer.

Owner:THE BOEING CO

Hair and scalp care formulations for treating and preventing acne and related skin conditions

InactiveUS20110256249A1Preventing and significantly reducing incidence of acneAggressive skin treatmentBiocideCosmetic preparationsSalicylic acidReducing agent

The present invention is directed to skin treatment formulations having salicylic acid and other secondary ingredients. The secondary ingredients may include: non-comedogenic essential oils and plant extracts and sebum reducing agents. Salicylic acid and the secondary ingredients are provided in amounts effective to provide a sufficiently aggressive skin treatment for unclogging pores and reducing inflammation, while maintaining levels of sebum on the exterior of the skin to form an operative water barrier on the skin and hair. Additionally, a method is provided that unclogs pores, reduces inflammation, and controls levels of sebum on the exterior of the skin to maintain an operative water barrier on the skin and hair. The method may include, applying a sufficiently aggressive product comprising salicylic acid, non-comedogenic plant extracts and essential oils, and a sebum reducing agent to hair and its surrounding areas.

Owner:CLEARSKIN RX INC

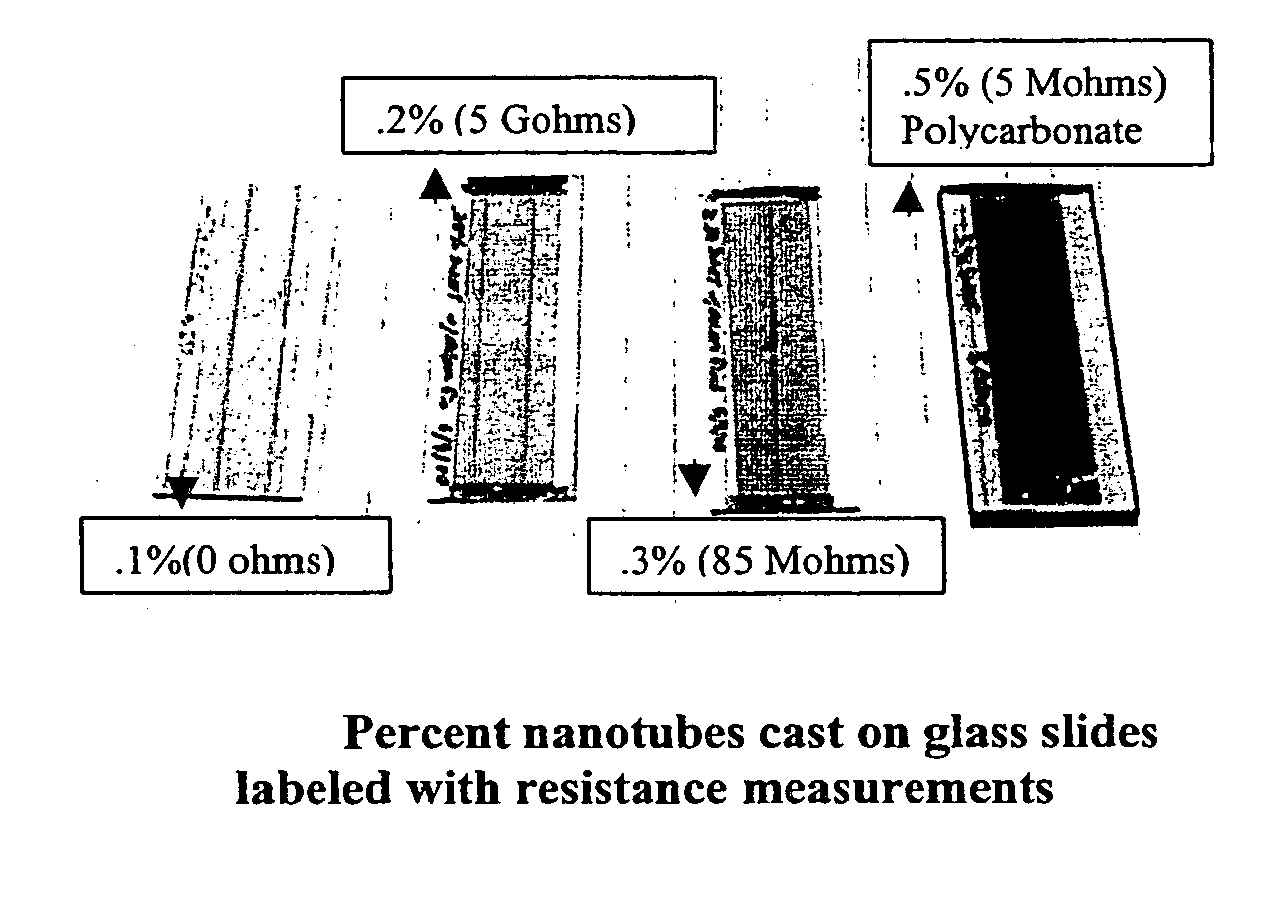

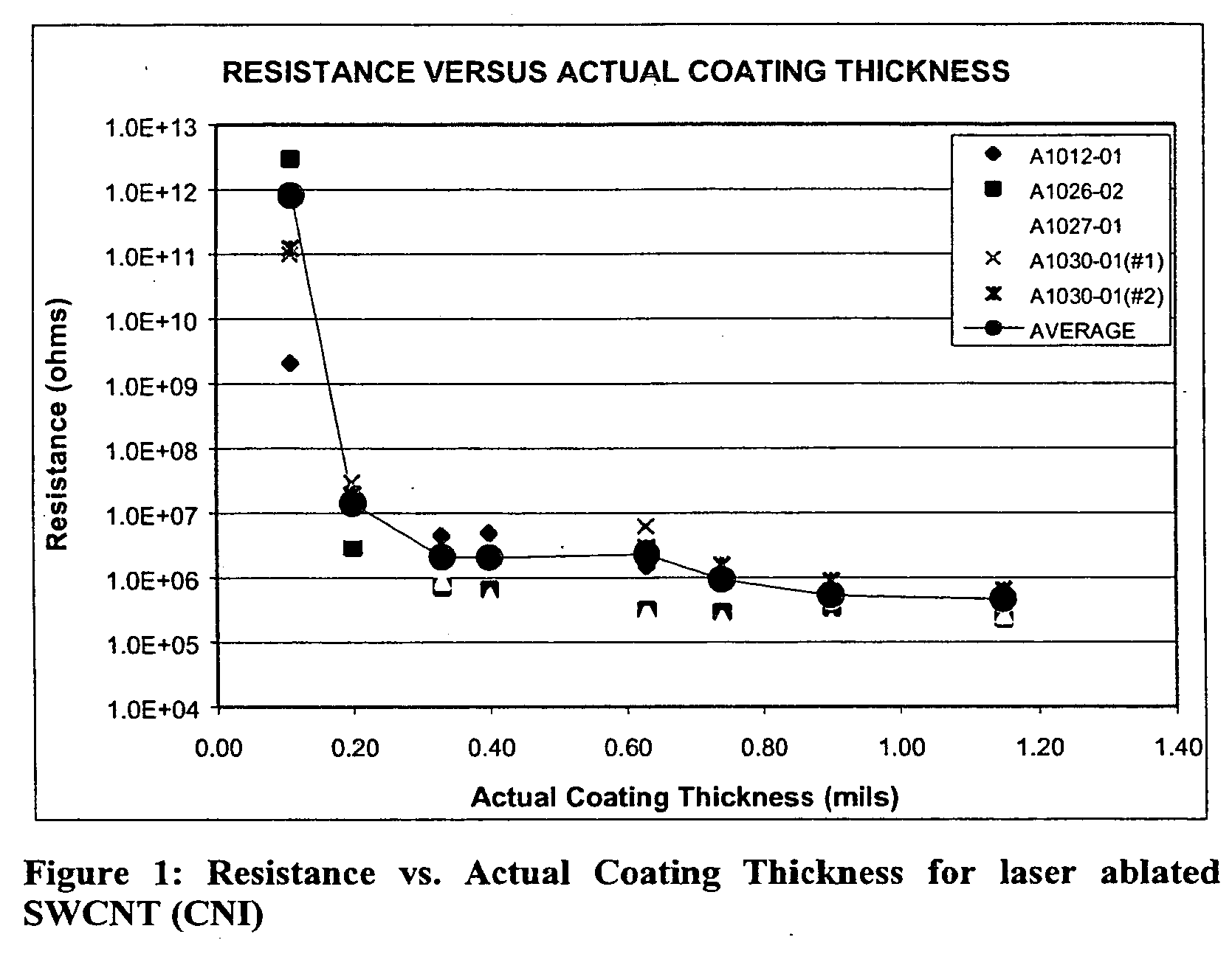

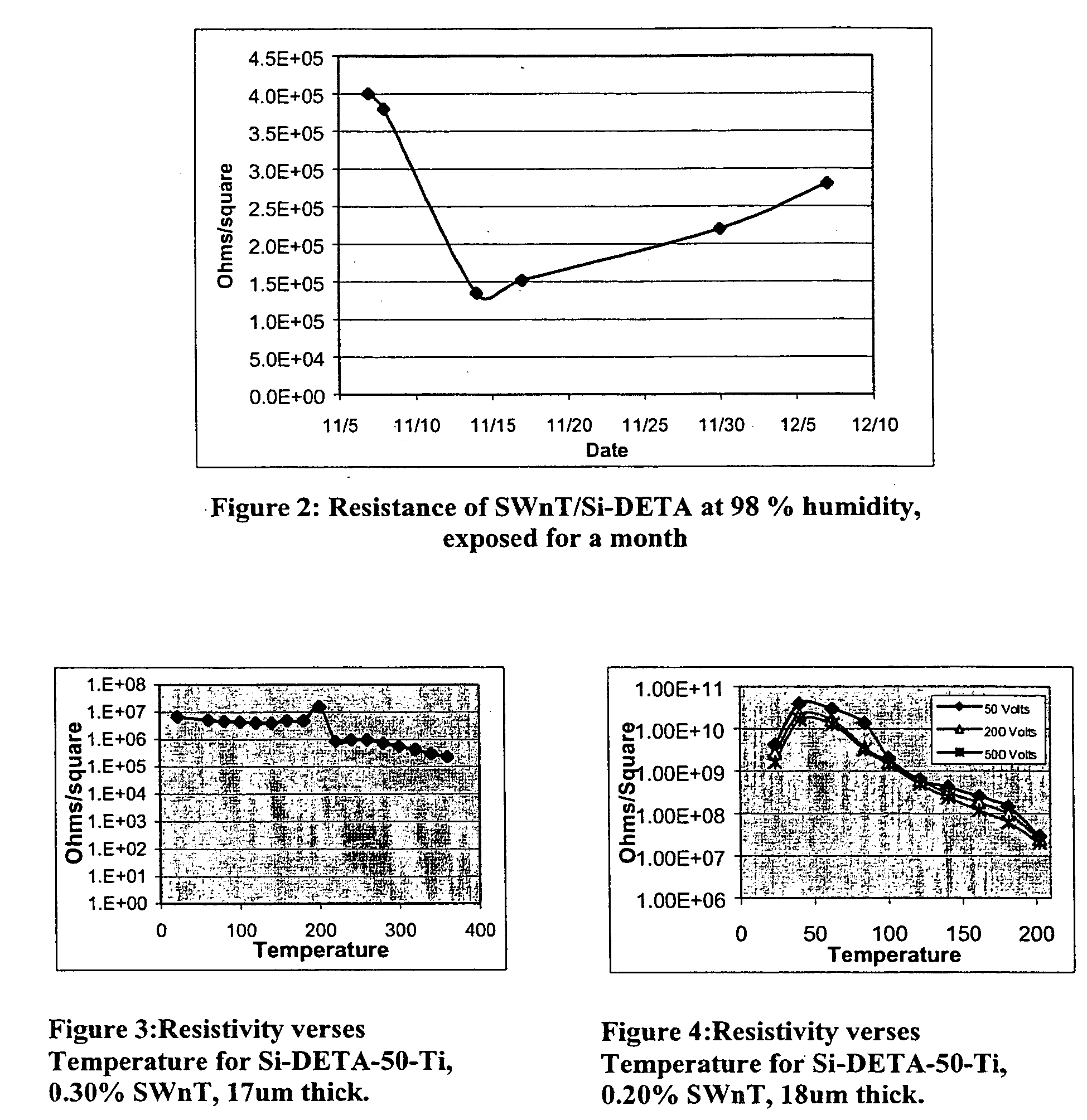

ESD coatings for use with spacecraft

InactiveUS20050230560A1Sufficient electrical conductivityMitigate static chargingMaterial nanotechnologyCosmonautic vehiclesCarbon nanotubeSpacecraft

Spacecraft with electrostatic dissipative surfaces are disclosed herein. The surface has layer which includes a plurality of carbon nanotubes to incorporate electrical conductivity into space durable polymeric layers without degrading optical transparency, solar absorptivity or mechanical properties.

Owner:GLATKOWSKI PAUL J +4

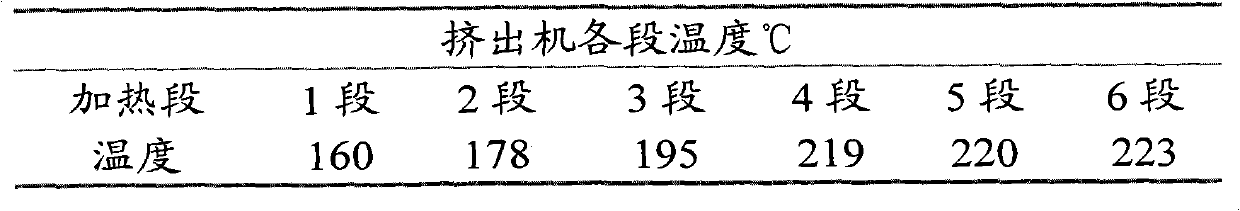

Preparation process for fine denier and superfine denier polypropylene fibers

InactiveCN101736416AReduce consumptionSave dyeing energyMonocomponent polypropylene artificial filamentMelt spinning methodsPolymer scienceAbnormal shaped

The invention mainly discloses a preparation process for fine denier and superfine denier polypropylene fibers, which comprises the following steps of: adopting a spinning special material of which the melting point is between 165 and 175 DEG C; in a spinning device, extruding and melting the spinning special material by a single screw extruder, wherein a melt flows evenly; performing spinning through a round or abnormal spinneret orifice of a spinneret plate of a spinning box, wherein the spinning speed is 2,200 miters per minute; cooling and oiling tows; and then performing hot drawing and winding to finally obtain the fine denier and superfine denier polypropylene fibers of 0.5 to 2 deniers, wherein the hot drawing temperature is between 45 and 105 DEG C, the drawing multiple is 1.5 to 4 times, and the winding speed is 80 meters per minute for overfeeding. The preparation process is a nuisanceless, environment-friendly, energy-saving and innovative process, and the finally obtained product has the advantages of light in texture, high strength, good abrasion resistance and elastic resilience, small static electricity, small coefficient of heat conductivity and good electrical insulating property.

Owner:绍兴前瞻化纤有限公司

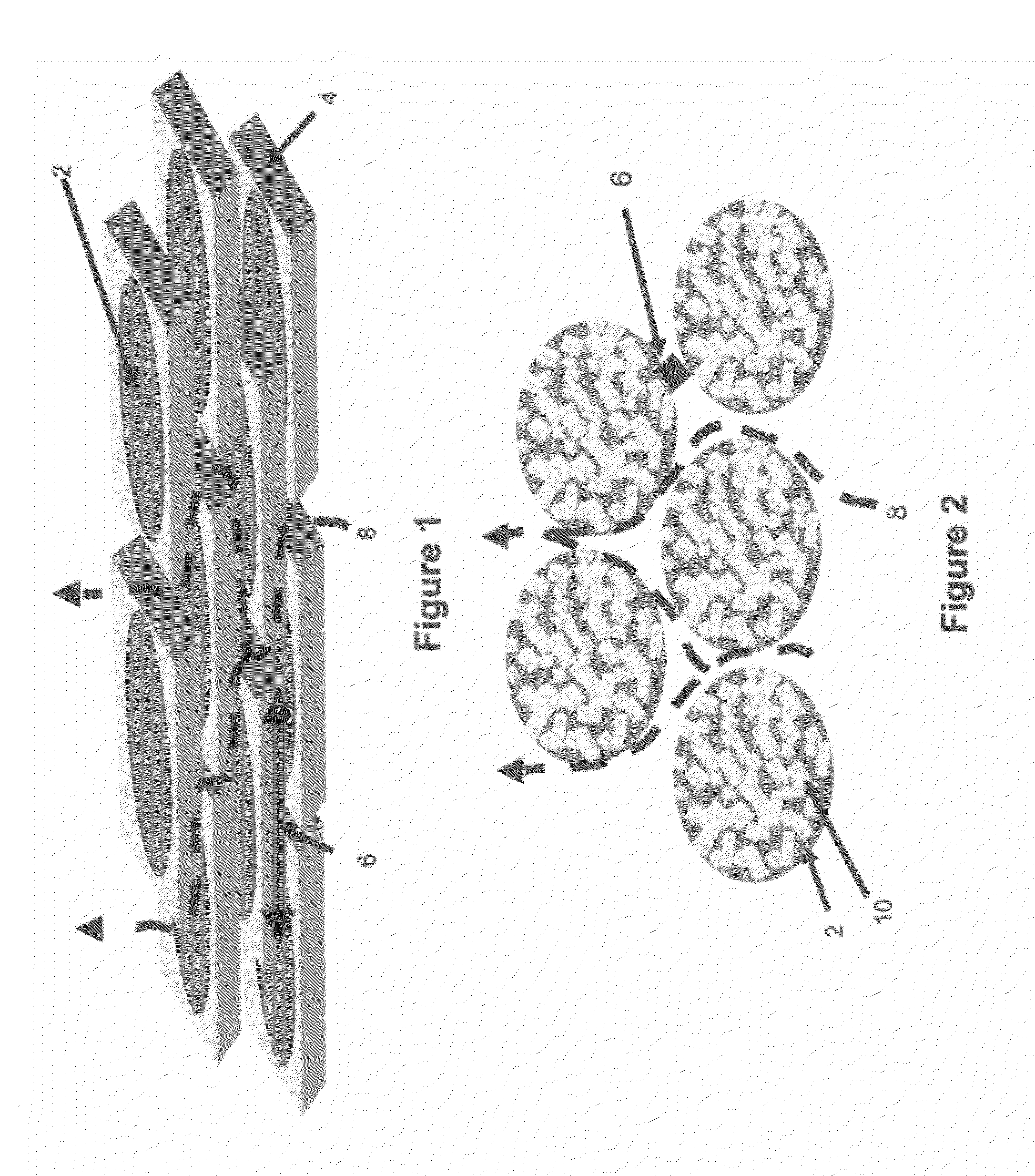

Lightweight Clumping Animal Litter and Method Thereof

ActiveUS20120260860A1Reduce staticReduce colorFlow mixersTransportation and packagingCelluloseSodium Bentonite

Animal litter having up to a sixty percent reduction in bulk density can be produced by combining flat-shaped cellulosic materials and sodium bentonite clay. Not only is the resulting litter lighter, but it also maintains a high clump strength as compared to clay-based animal litters that contain greater than ninety percent by weight sodium bentonite clay.

Owner:THE CLOROX CO

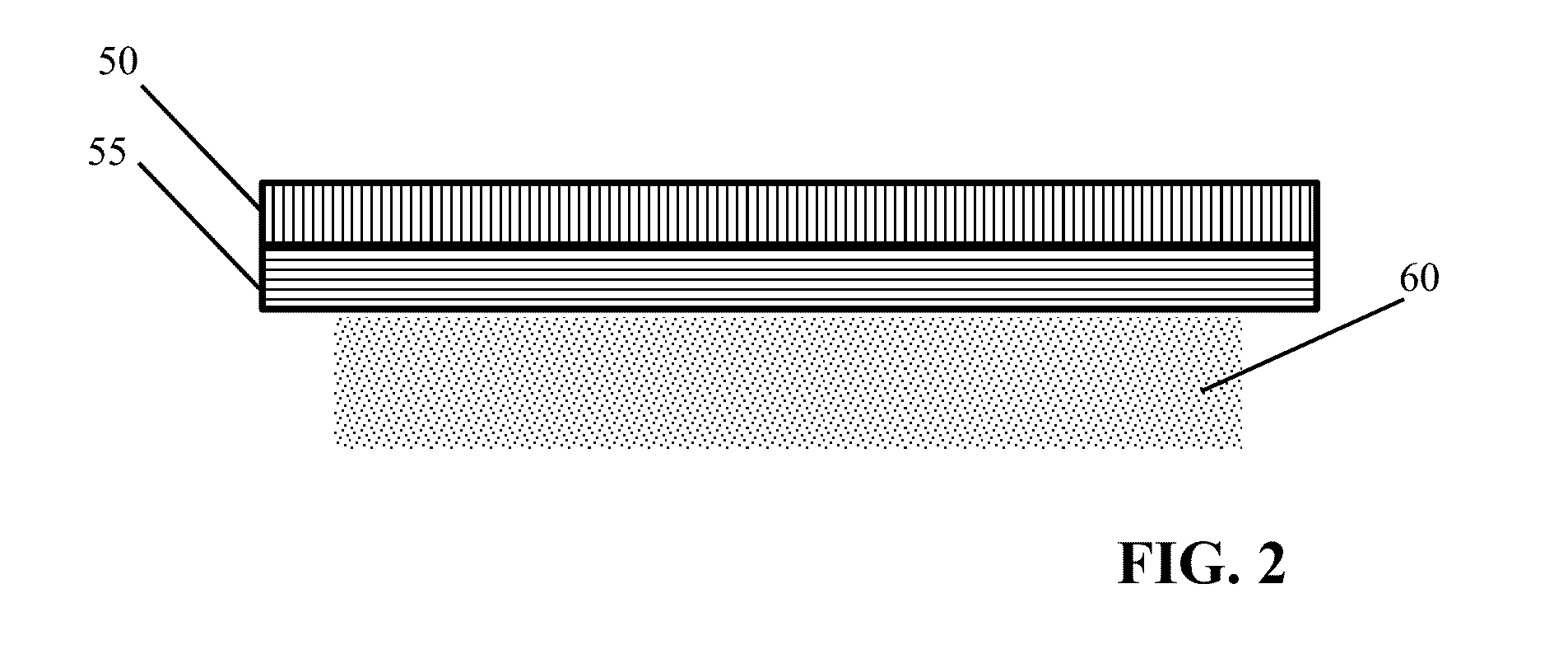

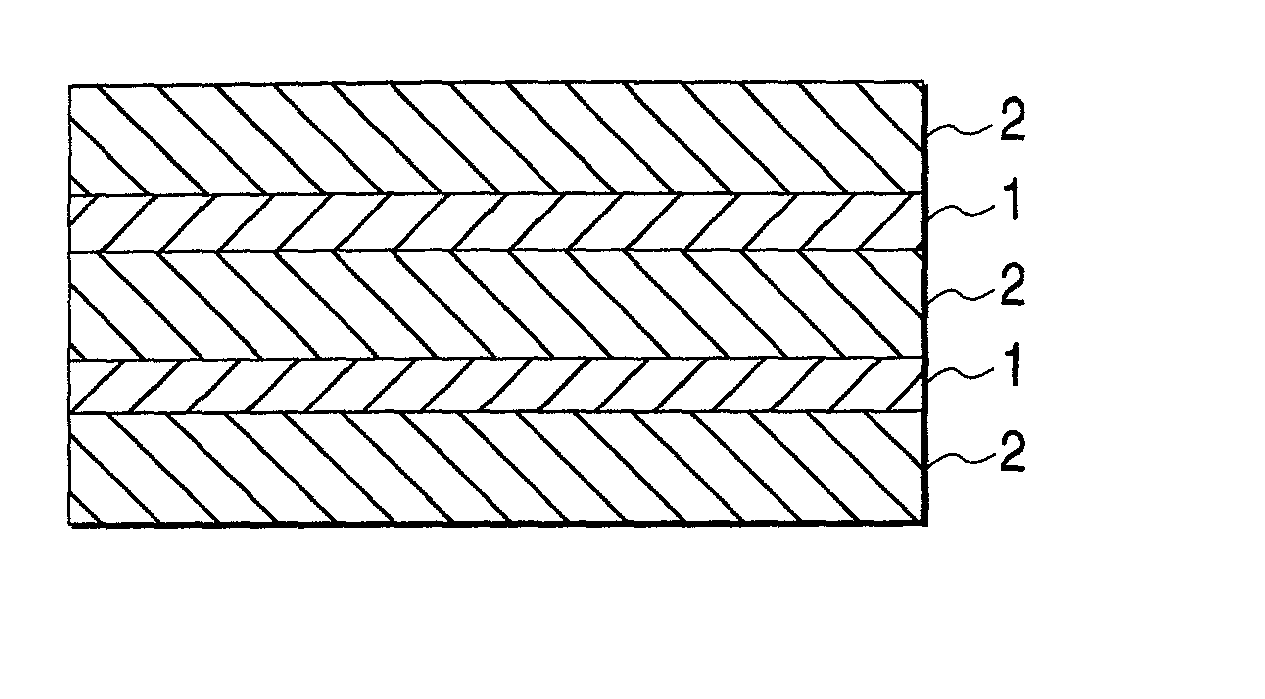

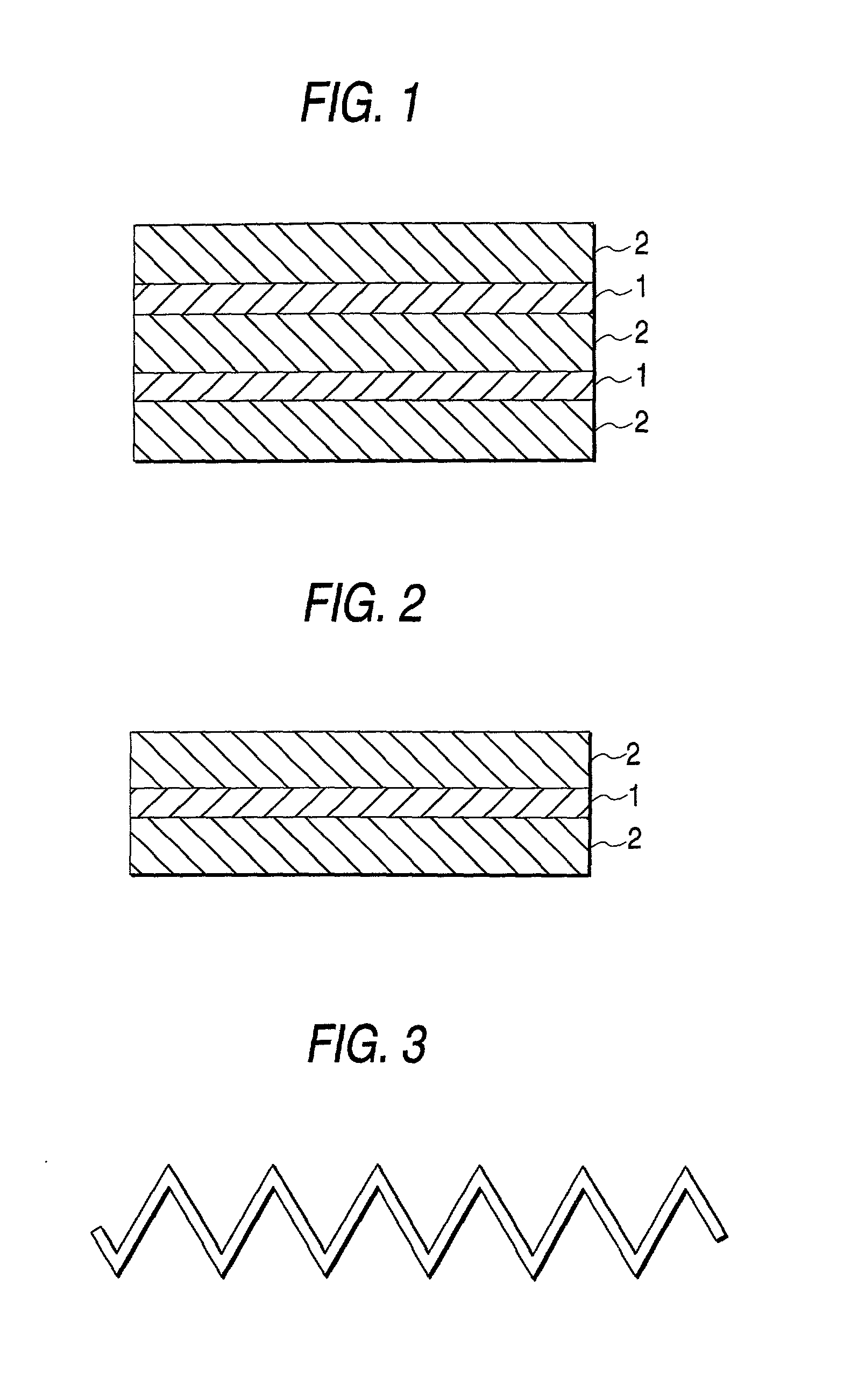

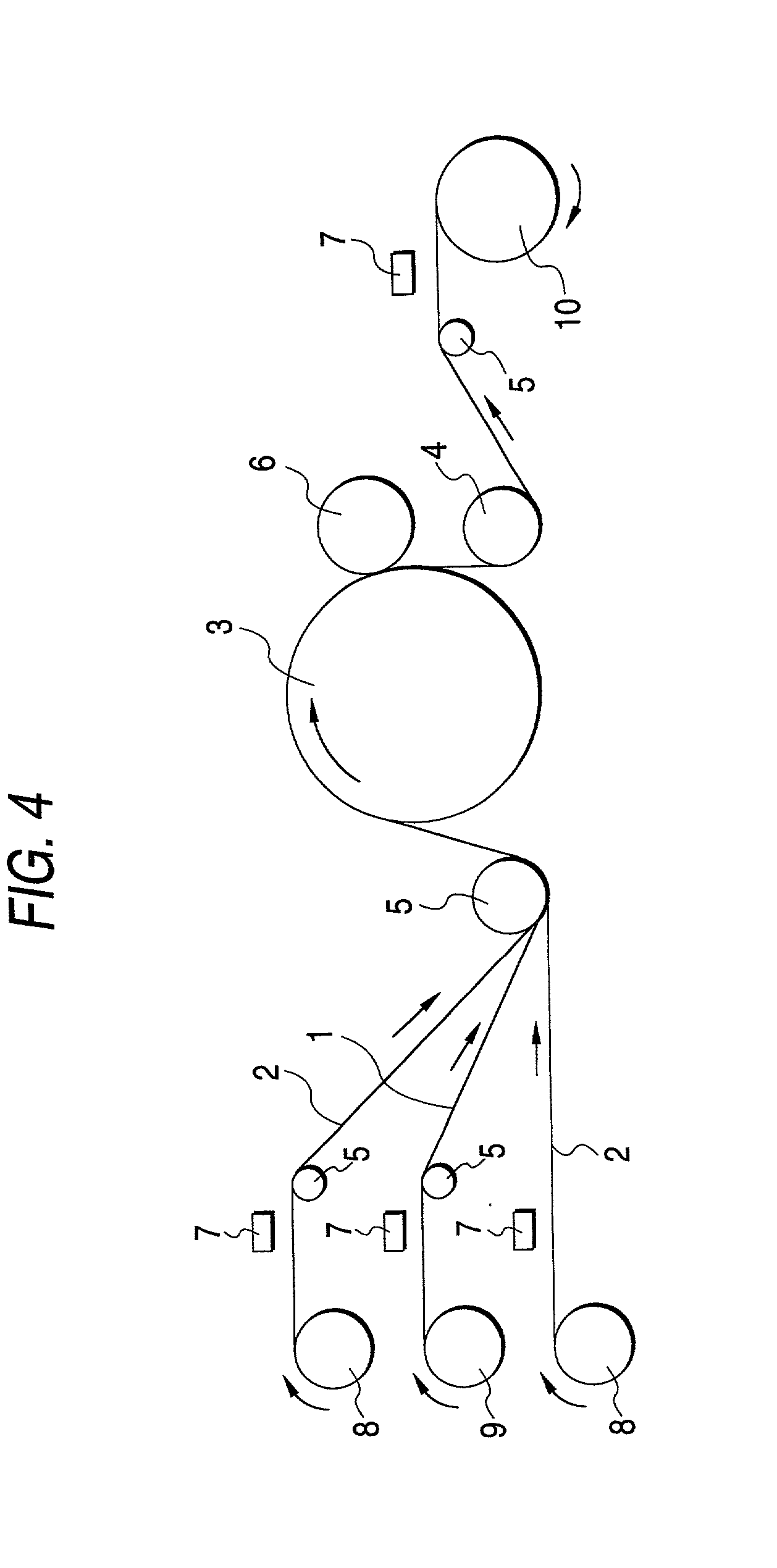

Filtering medium for air filter and process for producing the same

InactiveUS20020170434A1Easy to measureInhibition formationCombination devicesSemi-permeable membranesEngineeringPTFE - Polytetrafluoroethylene

A filtering medium for air filters, comprising a laminate including at least one porous polytetrafluoroethylene (PTFE) membrane and at least one air-permeable supporting member, the filtering medium having a surface potential of 0.3 kV or lower in terms of absolute value. By regulating the absolute value of surface potential so as to be within that range, the formation of a through-hole attributable to a discharge (spark) caused by, e.g., contact with a bare hand can be prevented. Thus, the leakage phenomenon observed in filtering media for air filter using a porous PTFE membrane can be inhibited.

Owner:NITTO DENKO CORP

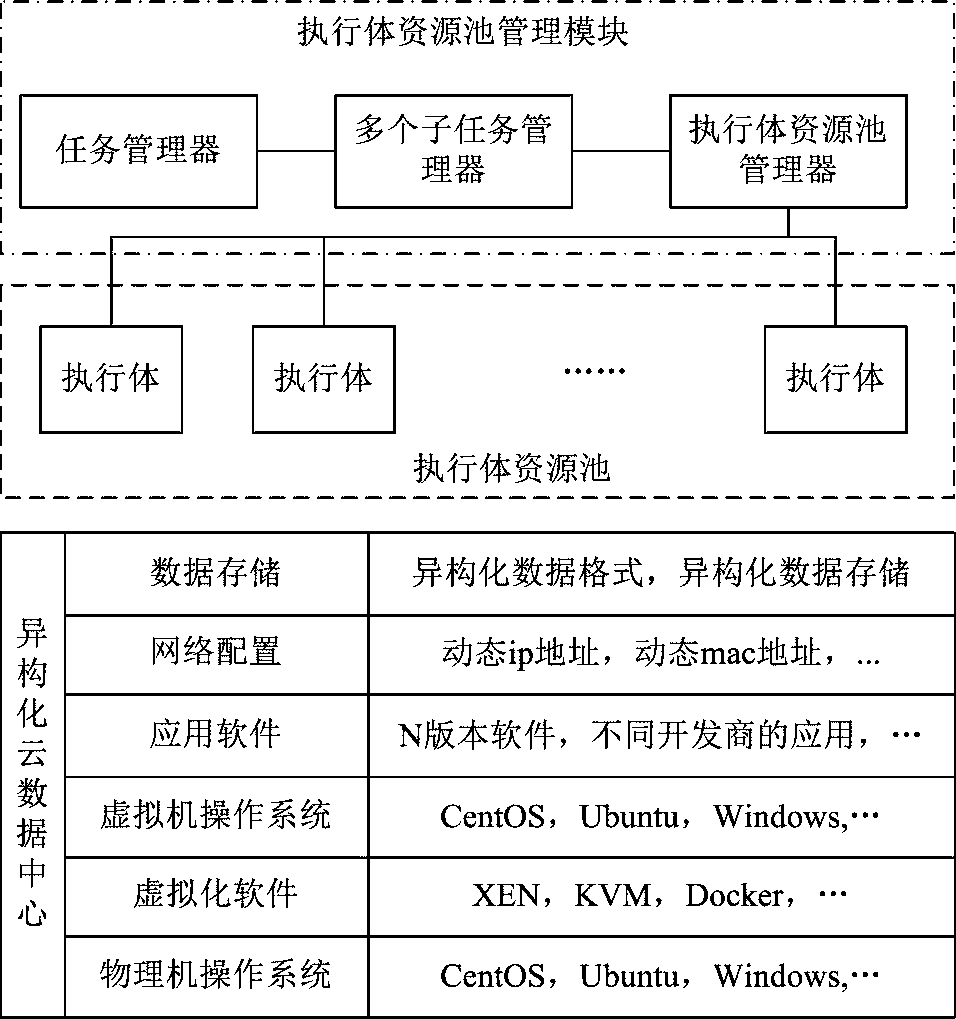

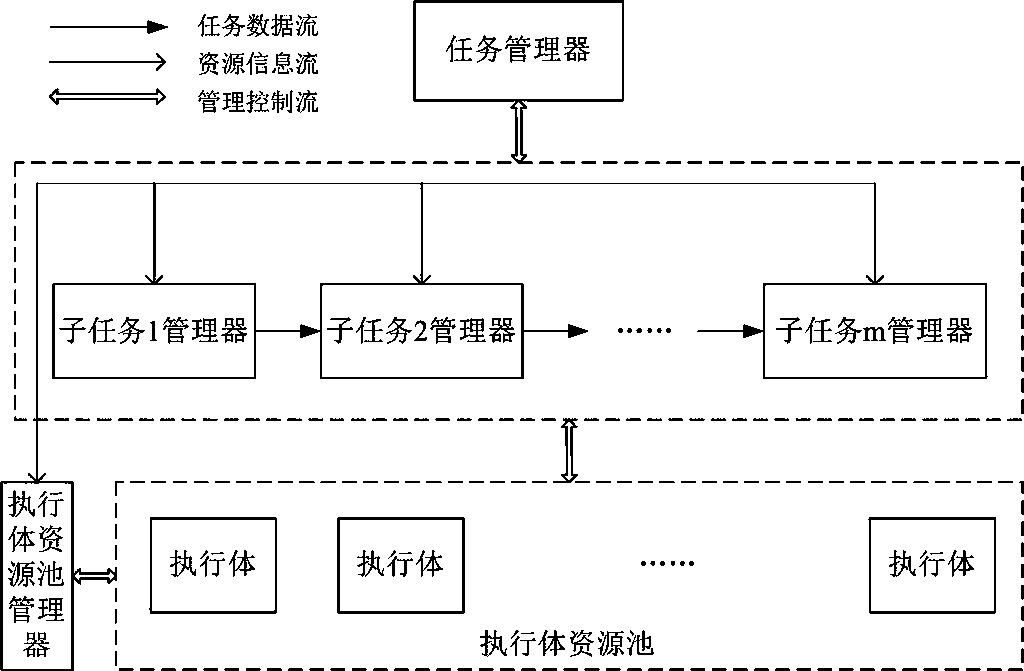

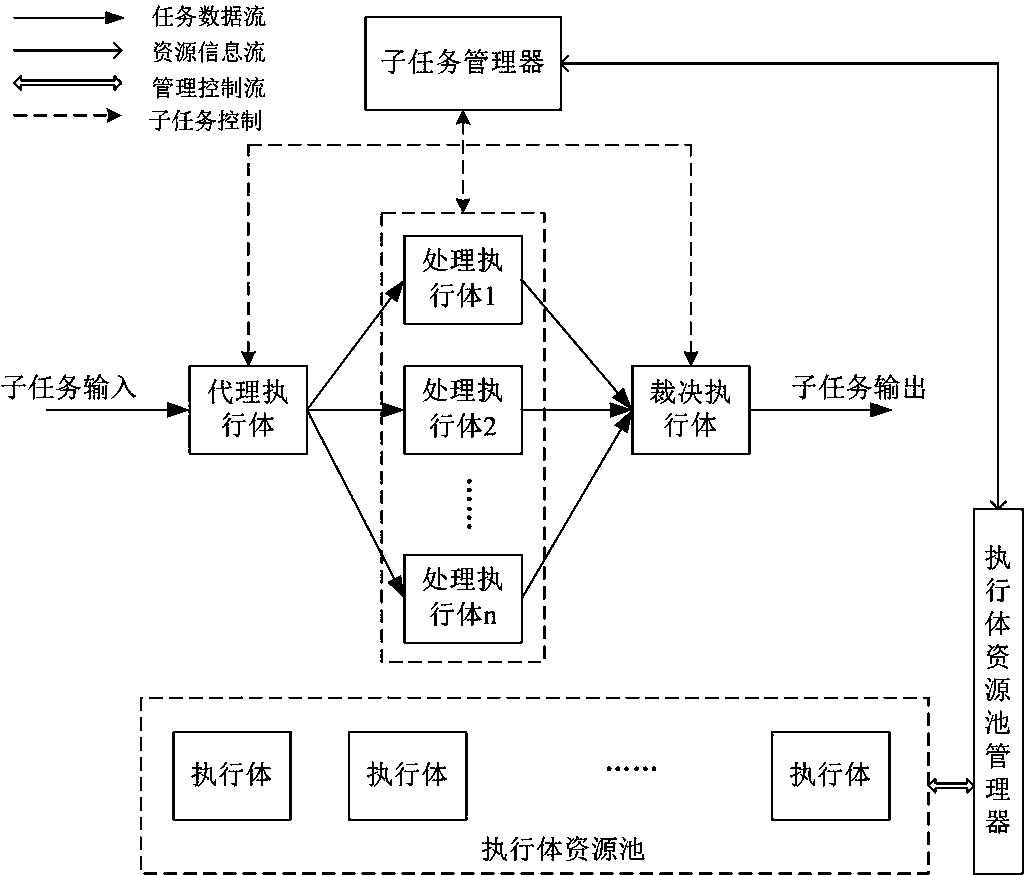

Endogenous-safety cloud task execution device and method

ActiveCN109150831AReduce vulnerability exposure timeReduce singularityResource allocationTransmissionResource poolDependability

The invention provides an endogenous-safety cloud task execution device and method. The device comprises a heterogeneous cloud data center, an executor resource pool and an executor resource pool management module, wherein the heterogeneous cloud data center comprises multiple heterogeneous levels, and each heterogeneous level is configured with at least one resource; the executor resource pool comprises multiple executors, and each executor is obtained when resources of the multiple heterogeneous levels are subjected to resource combination with a preset executor carrier as a carrier; and theexecutor resource pool management module comprises an executor resource pool manager, a task manager and multiple sub task managers, the executor resource pool manager is connected with the executorresource pool, and the multiple sub task managers are connected with the executor resource pool manager and the task manager respectively. The method adopts a dynamic execution and mimetic combinationmechanism and serially uses a multi-safety mechanism. Thus, the reliability and the safety of cloud task execution can be improved.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

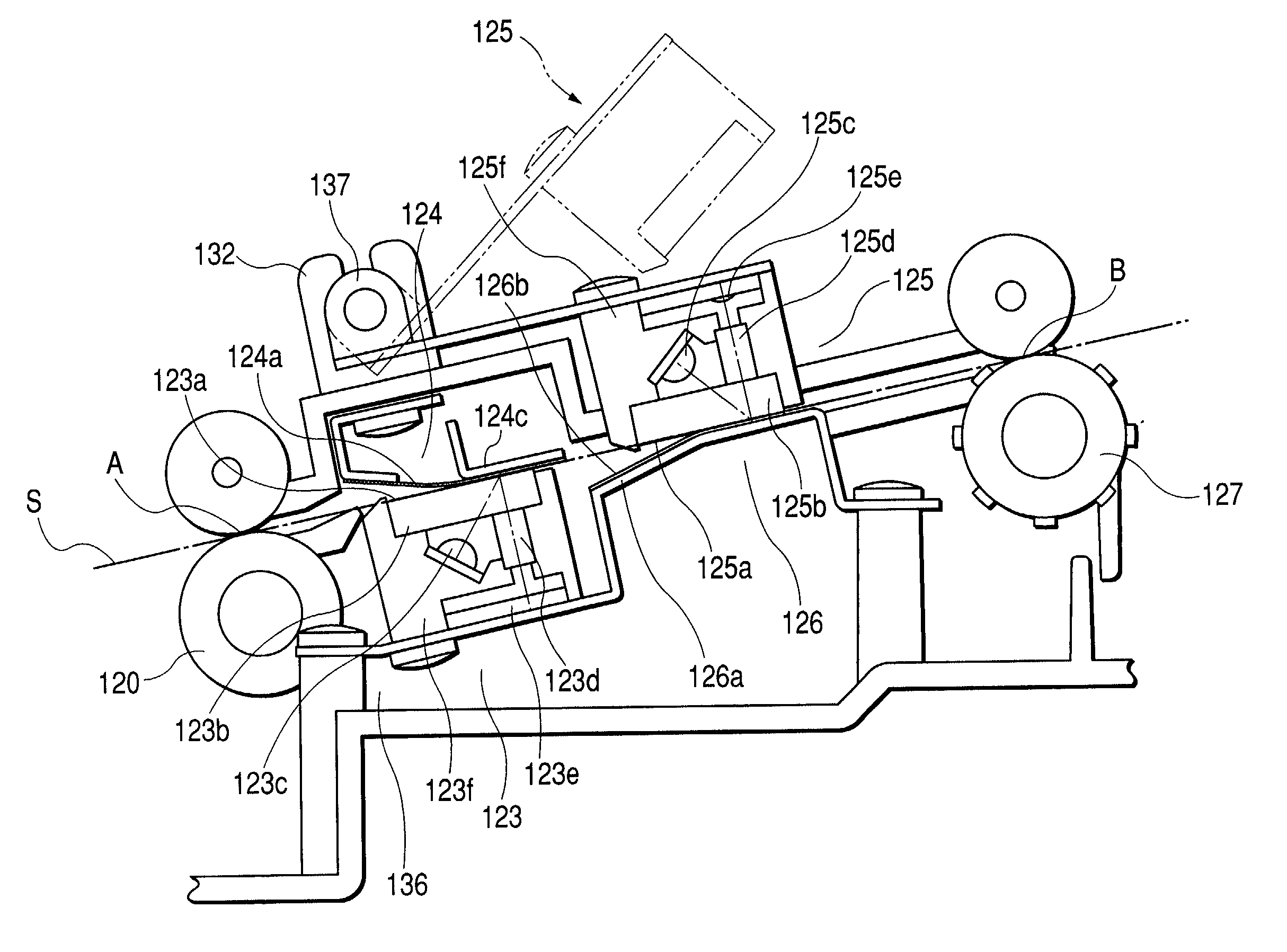

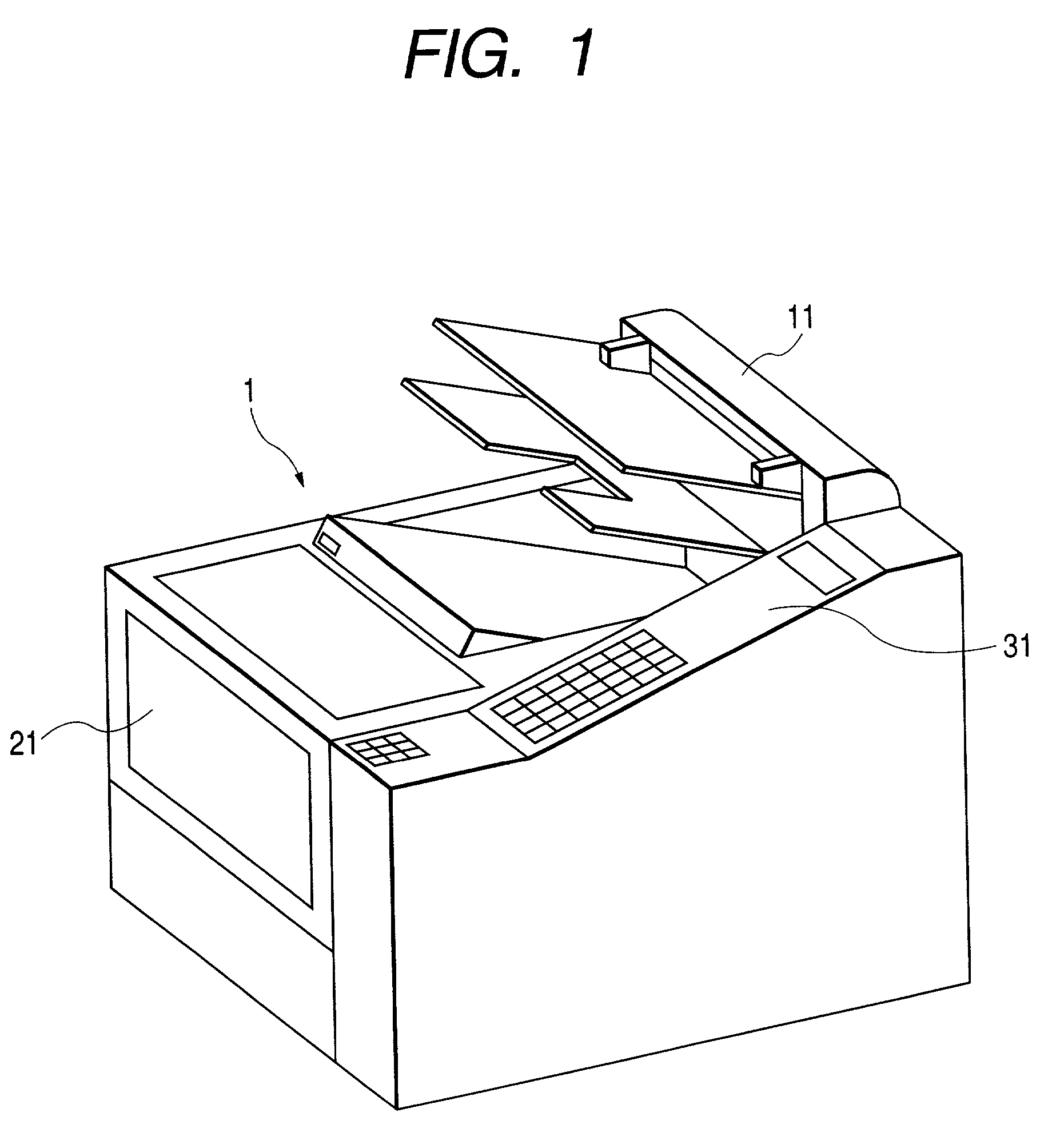

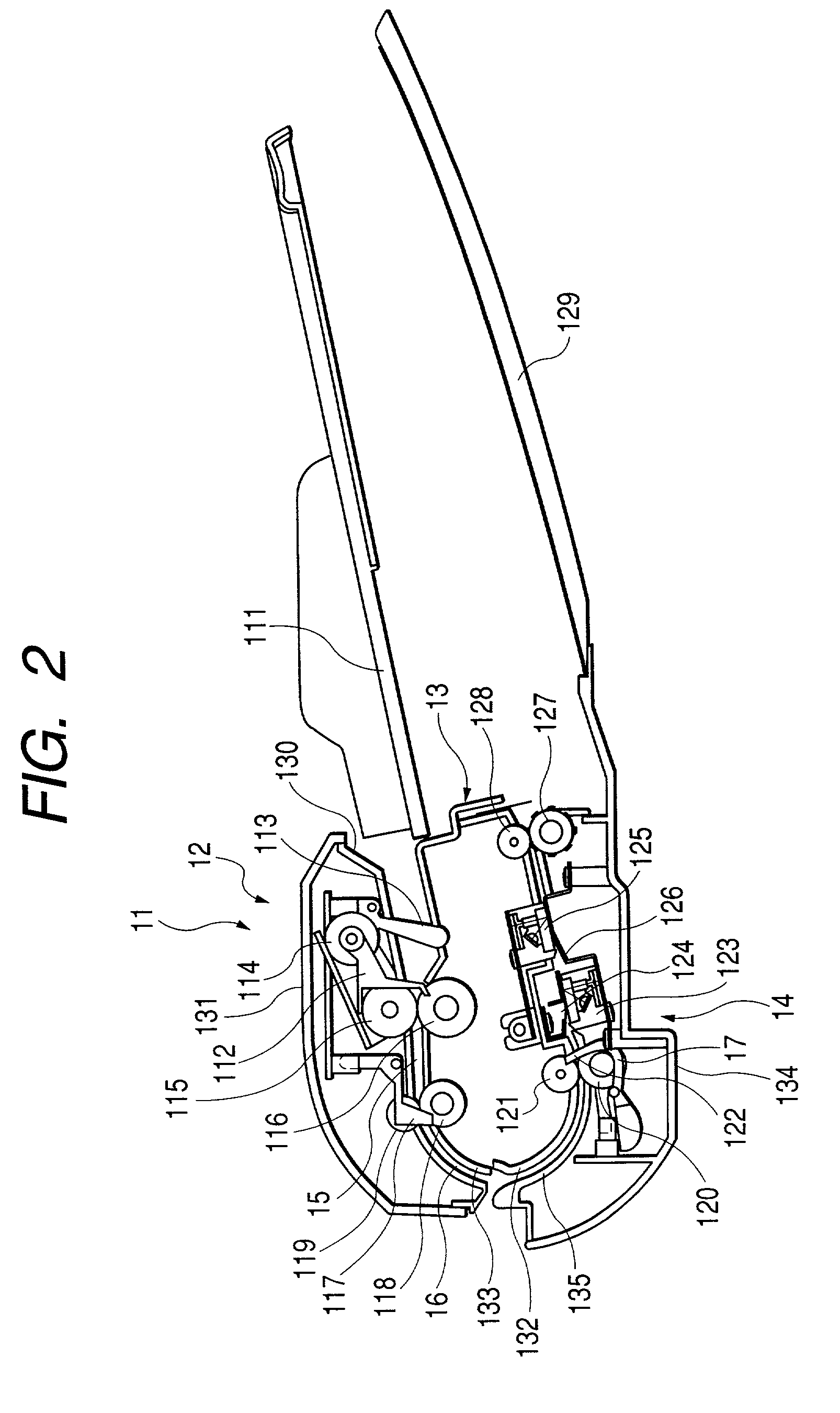

Duplex image reading apparatus

InactiveUS7110148B2Improve accuracyLow costBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansComputer science

Owner:CANON KK

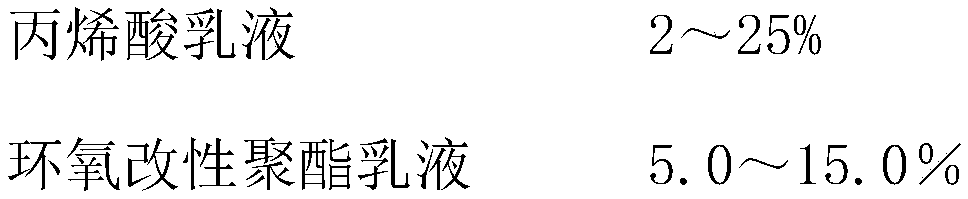

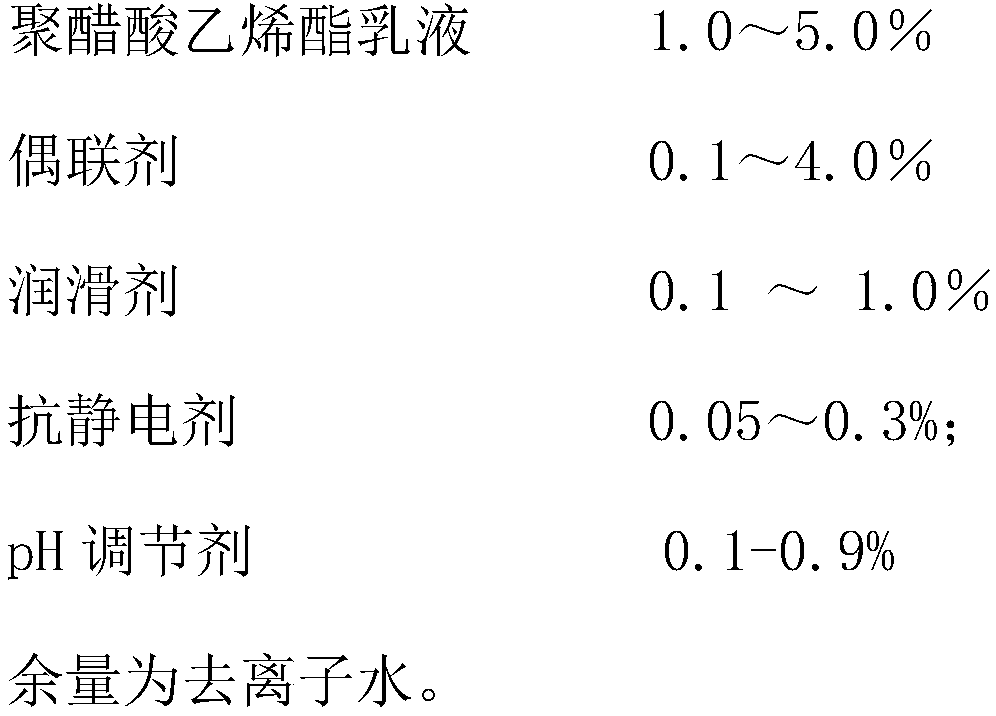

Impregnating compound for enhancing polypropylene plastic-glass fiber chopped yarn

The invention relates to an impregnating compound for enhancing polypropylene plastic-glass fiber chopped yarn. The impregnating compound is prepared from components in percentage by total mass of theimpregnating compound as follows: 3%-22% of an acrylic emulsion, 5.0%-15.0% of epoxy modified polyester emulsion, 1.0%-5.0% of a polyvinyl acetate emulsion, 0.1%-1.0% of a lubricating agent, 0.05%-0.3% of an antistatic agent, 0.1%-0.9% of a pH regulator and the balance of deionized water. Compared with the prior art, the provided impregnating compound can have a good compatibility with polypropylene plastic resin, the plasticity and stiffness of the glass fiber are enhanced, and the impregnating compound has small static electricity and adjustable hardness, can be compatible with multiple resin, is high in resin permeation speed and good in bondability with resin and endows a composite with excellent mechanical properties.

Owner:SHANDONG FIBERGLASS GRP

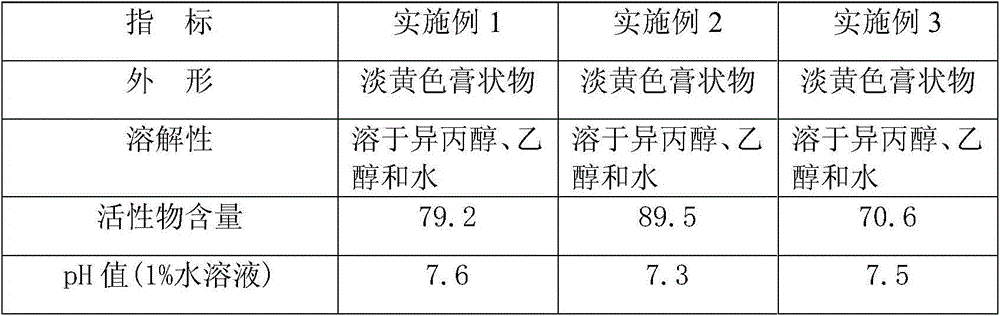

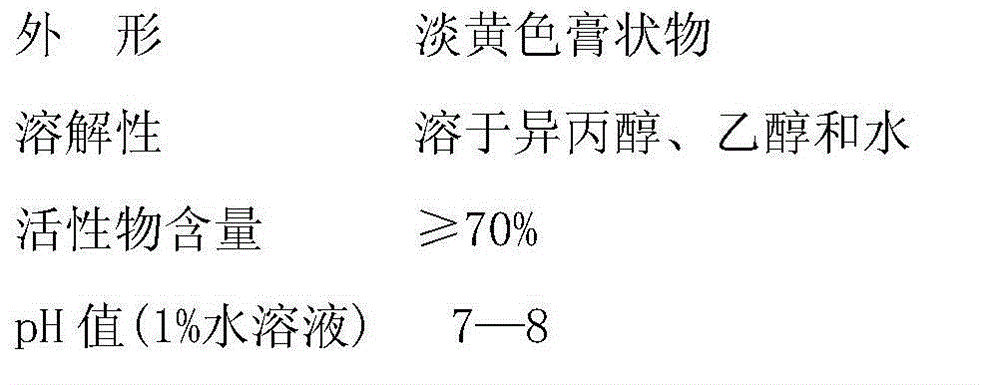

Multi-functional antistatic agent

ActiveCN104018345AImprove antistatic performanceWide range of usesFibre treatmentCoatingsCarbon numberFiber

The invention discloses a multi-functional antistatic agent. The multi-functional antistatic agent is prepared from the following components in percentage by weight: 40-60% of fatty amine polyoxyethylene ether, 20-40% of alkyl quaternary ammonium salt, and 10-30% of alcohols solvent, wherein the fatty amine of the fatty amine polyoxyethylene ether is processed by natural fat and has the carbon chain length of C16-18, the fatty amine can be cocoanut oil amine and tallow amine, the alkyl quaternary ammonium salt has alkyl carbon chain length of C2-18, and can be dioctadecyl alkyl quaternary ammonium salt and octadecyl alkyl quaternary ammonium salt, and the carbon number of the alcohols solvent is 2-4, and the alcohols solvent can be ethyl alcohol, isopropyl alcohol or butyl alcohol. The multi-functional antistatic agent is compounded by cationic and non-ionic antistatic agents, has the advantages of the cationic antistatic agent such as good antistatic performance and wide application, also has the advantages of the non-ionic antistatic agent such as good stability and long efficiency, can be diluted by solvent for fiber and plastic surface spraying, also can be used for fiber oil formula, and can be added into resin for achieving long-acting antistatic effect.

Owner:湖北尚助化学有限公司

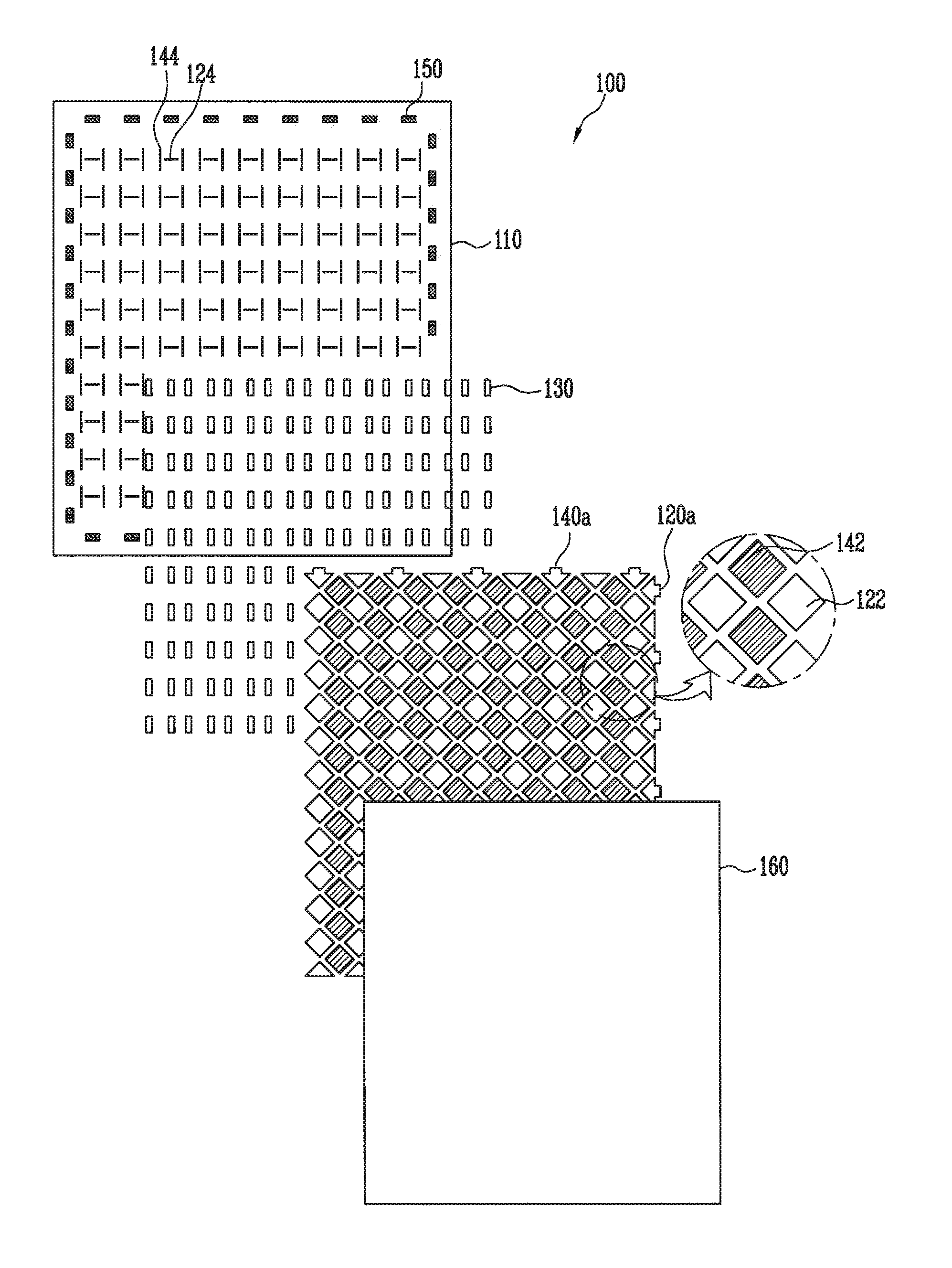

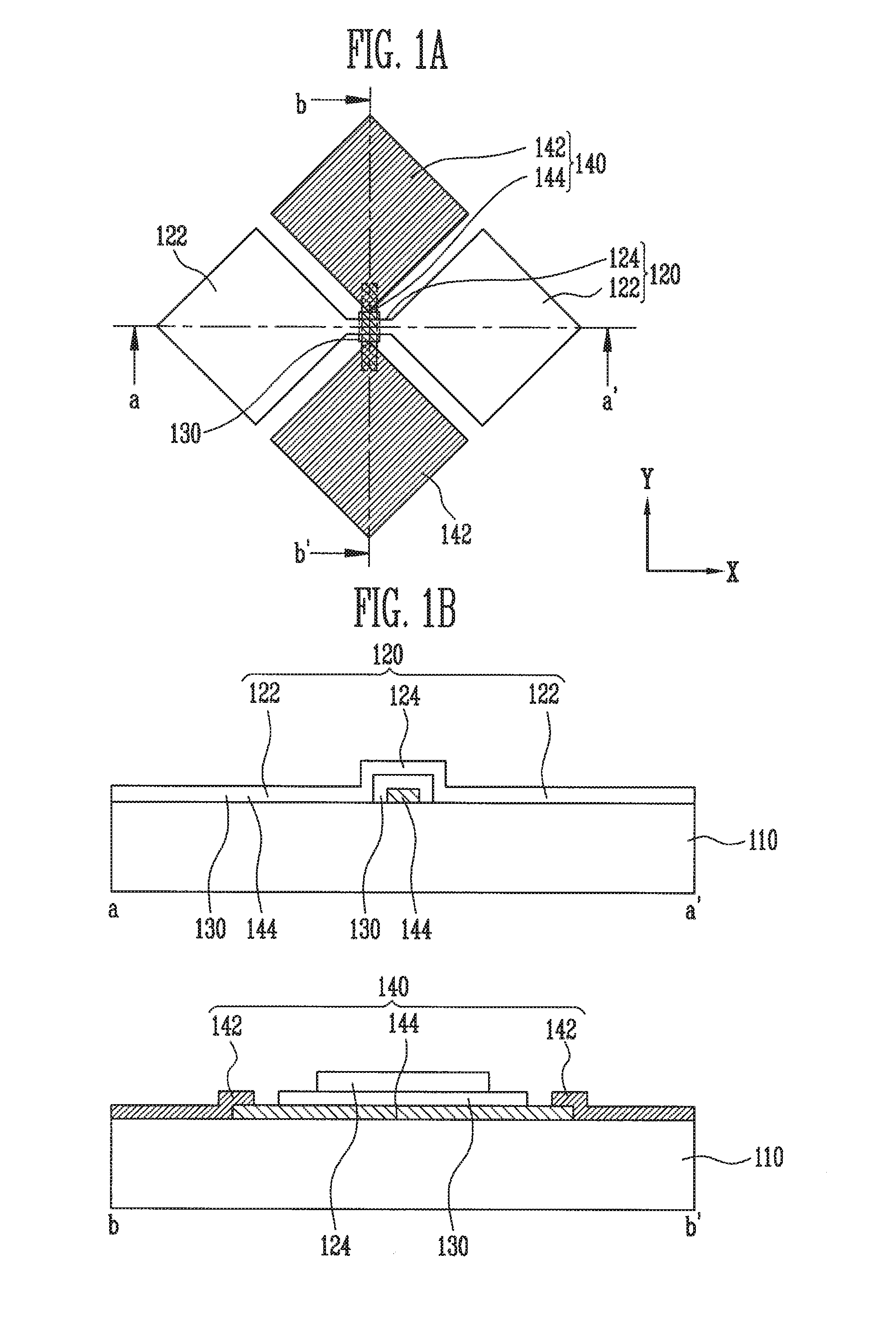

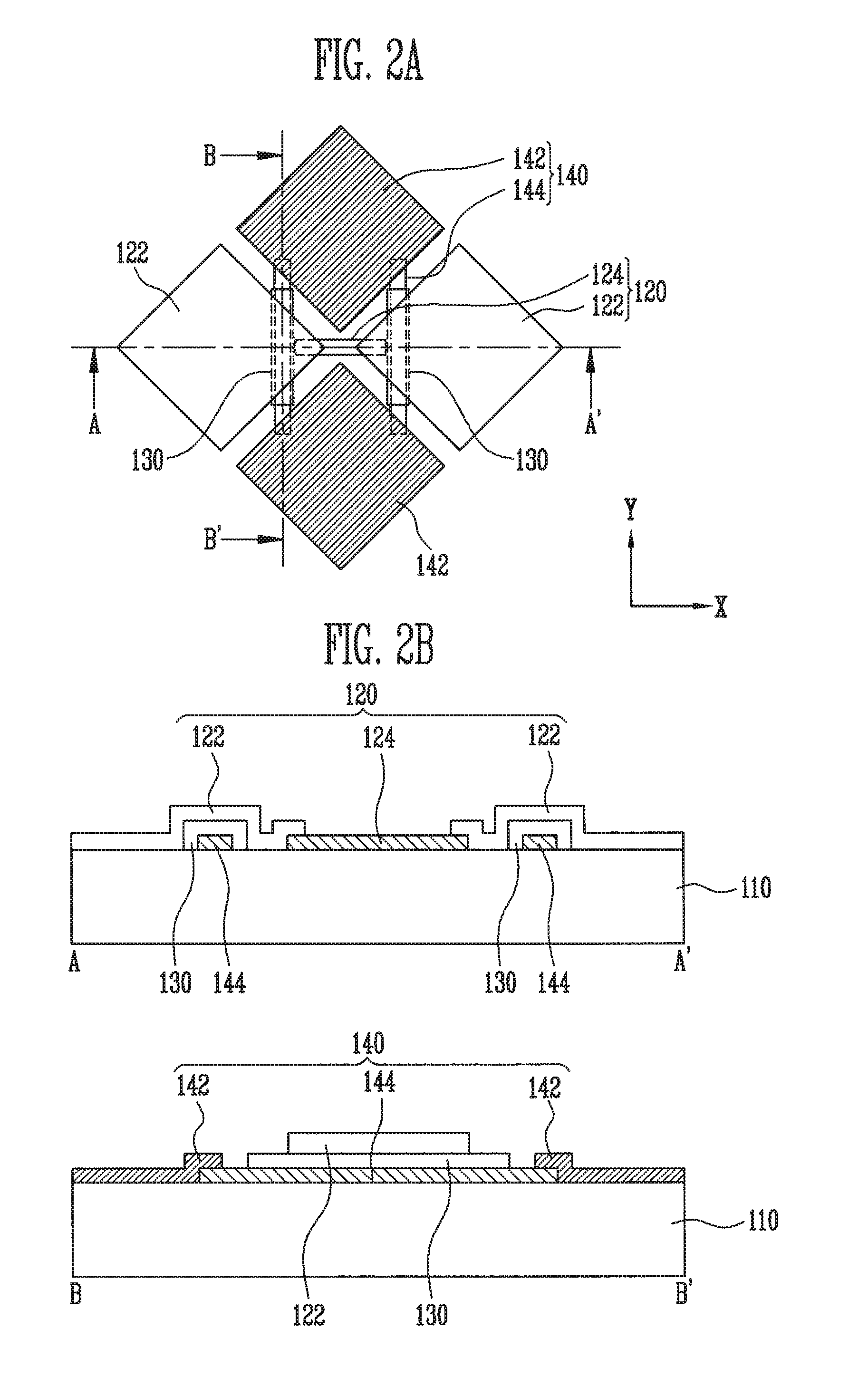

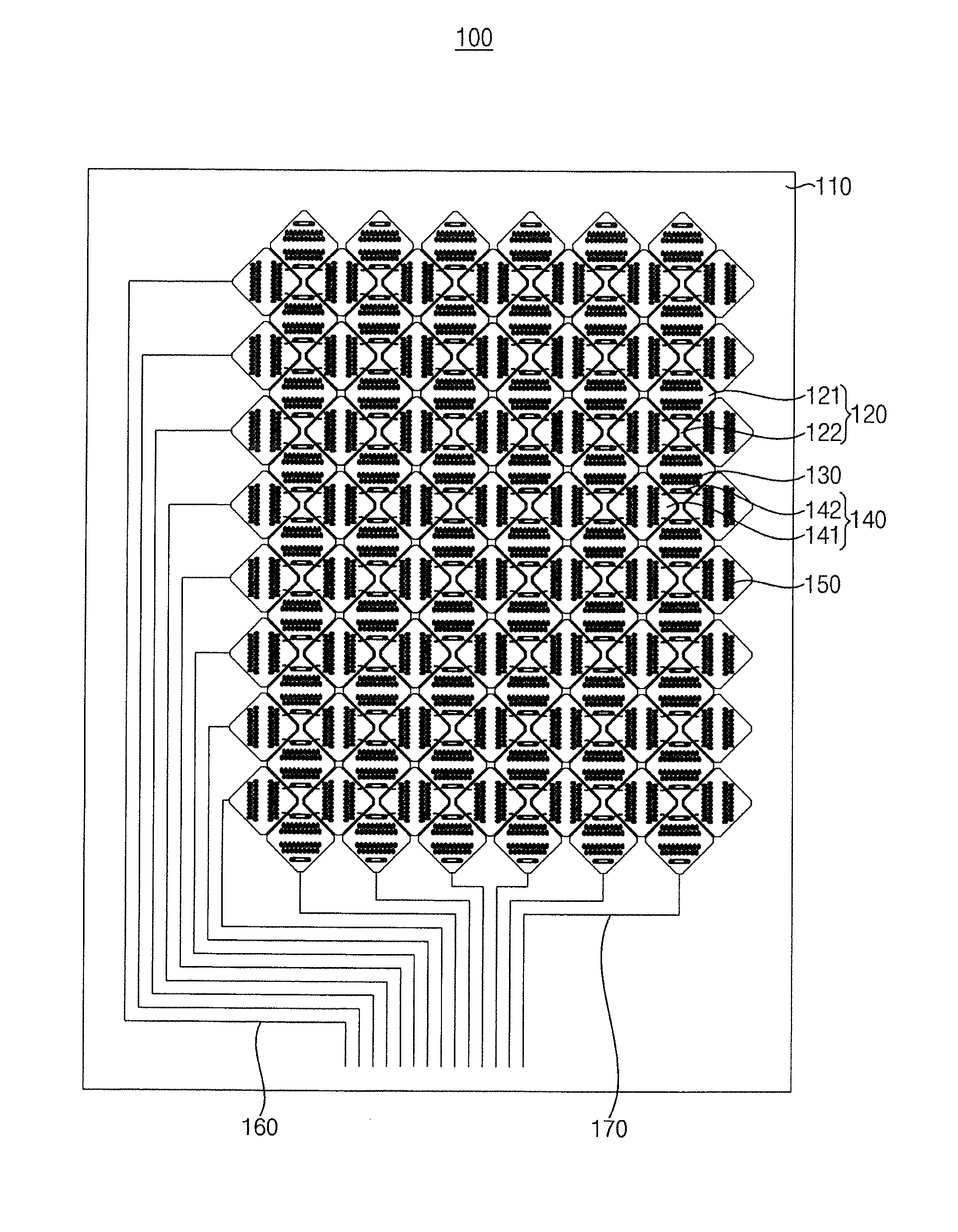

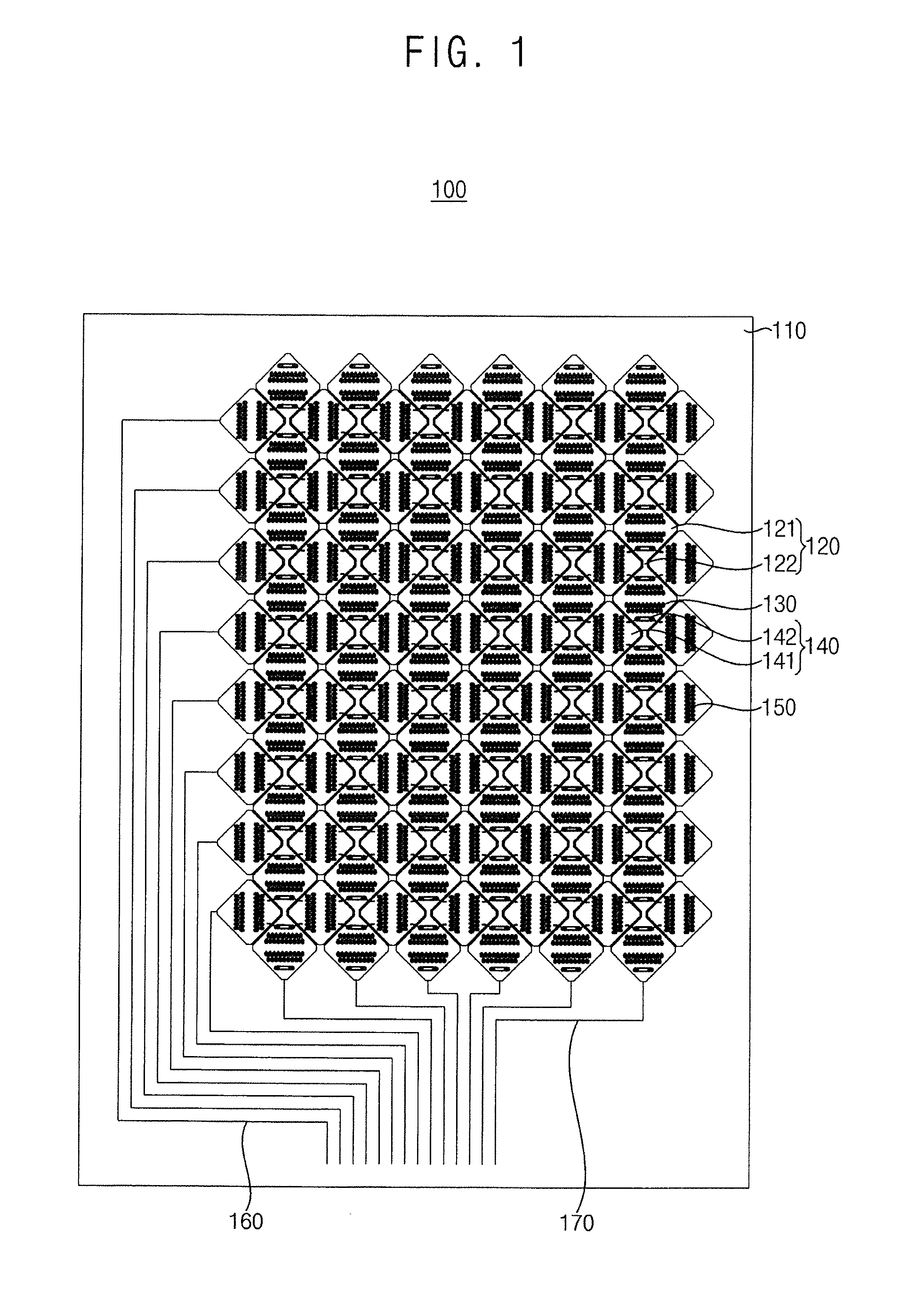

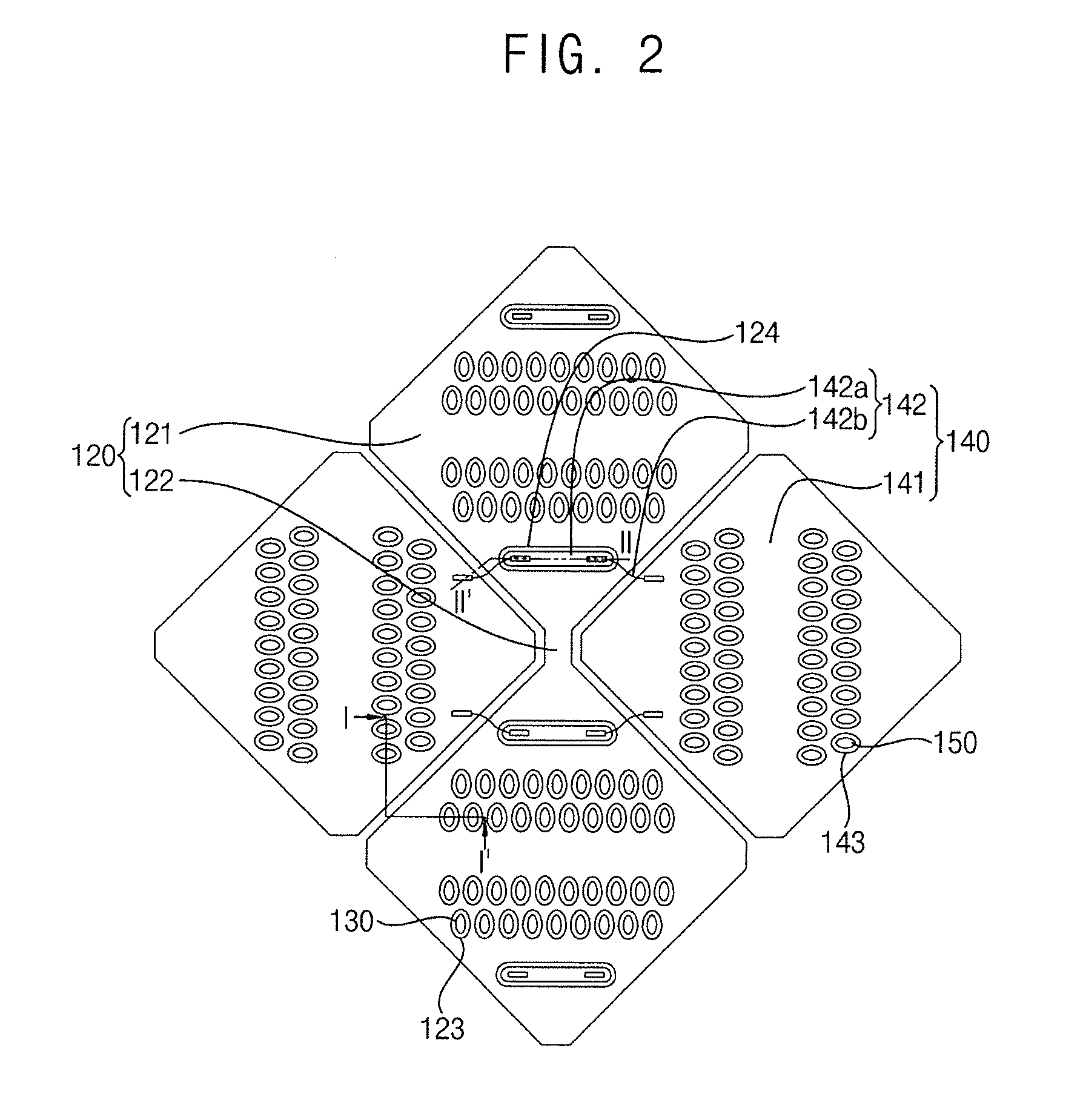

Touch screen panel

ActiveUS20110234512A1Reduce vulnerabilityOvercome problemsInput/output processes for data processingEngineeringFlat panel display

A touch screen panel includes: a flat panel display including an upper substrate, a lower substrate, and pixels arranged on a display region of the lower substrate in a stripe arrangement; first sensing cells arranged in a first direction on the upper substrate and second sensing cells arranged in a second direction on the upper substrate; first connection patterns electrically connecting adjacent ones of the first sensing cells to each other in the first direction, and second connection patterns electrically connecting adjacent ones of the second sensing cells to each other in the second direction, wherein at least one of the first connection patterns and the second connection patterns is inclined so that it partially overlaps with the pixels.

Owner:SAMSUNG DISPLAY CO LTD

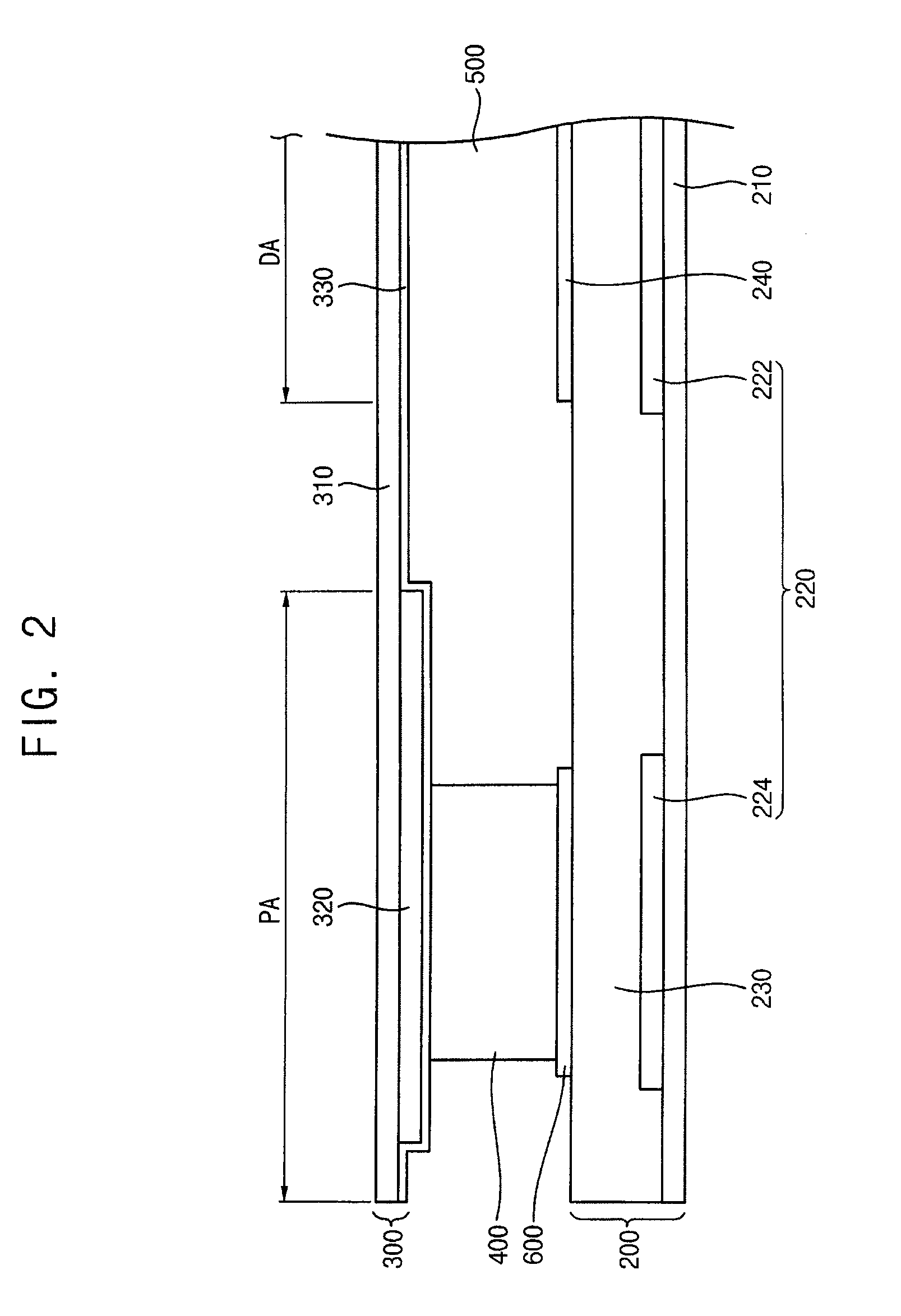

Display panel, method for manufacturing the same, motherboard for manufacturing the same and method for manufacturing a display substrate for the same

ActiveUS20080198287A1Avoid partialAvoid separationSolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerEngineering

A display panel includes a first substrate, a thin-film transistor (TFT), an organic layer, a second substrate, a seal line, and a conductive pattern. The first substrate includes a pixel part and a driving part connected to the pixel part. The TFTs are formed in the pixel part and the driving part. The organic layer is formed on the first substrate having the TFTs formed thereon. The second substrate is opposite to the first substrate. The seal line is disposed between an edge portion of the first substrate having the organic layer formed thereon and an edge portion of the second substrate. The seal line combines the first substrate with the second substrate. The conductive pattern is disposed between the seal line and the organic layer.

Owner:SAMSUNG DISPLAY CO LTD

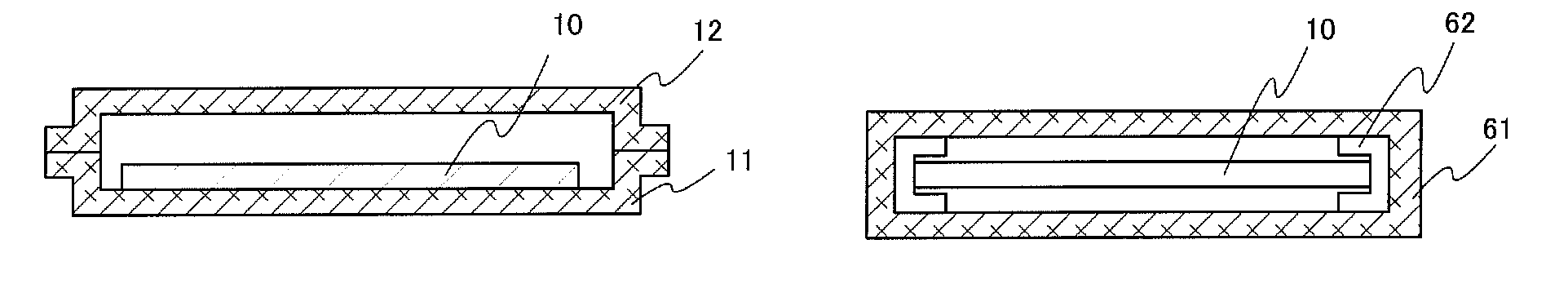

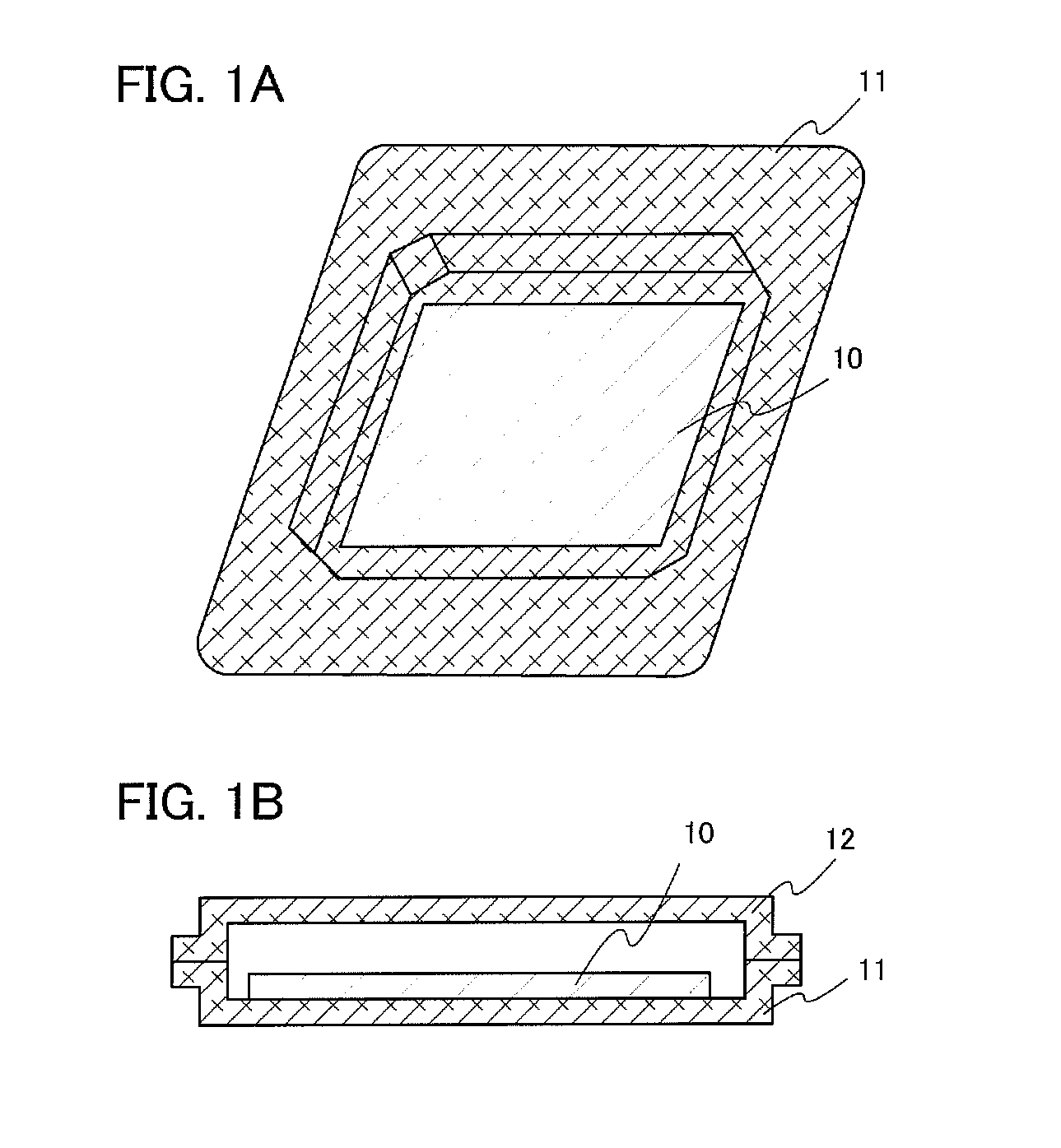

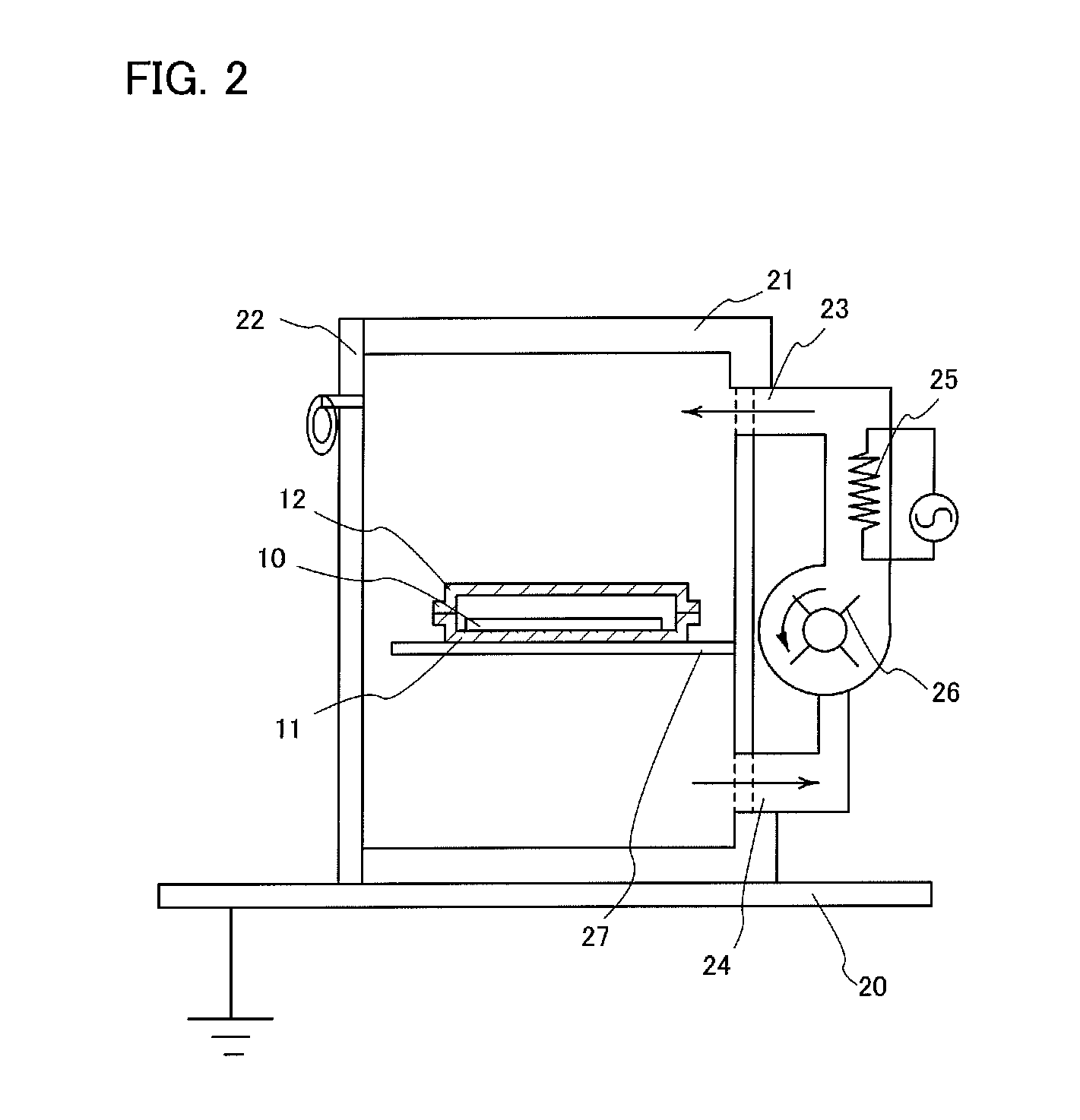

Method for removing electricity and method for manufacturing semiconductor device

ActiveUS8268642B2High yieldIncrease productionSemiconductor/solid-state device testing/measurementSolid-state devicesElectricityPower semiconductor device

An object is to suppress a significant change in electrical characteristics of thin film transistors and a deviation thereof from the designed range due to static electricity, and to improve the yield in manufacturing semiconductor devices. In order to prevent a substrate from being charged with static electricity by heat treatment or to favorably reduce static electricity with which a substrate is charged in a manufacturing process of a semiconductor device, heat treatment is performed with a substrate provided with a thin film transistor stored in a conductive container. In addition, a heating apparatus for performing the heat treatment is electrically connected to a ground potential, and the container and the substrate are also electrically connected to the ground potential.

Owner:SEMICON ENERGY LAB CO LTD

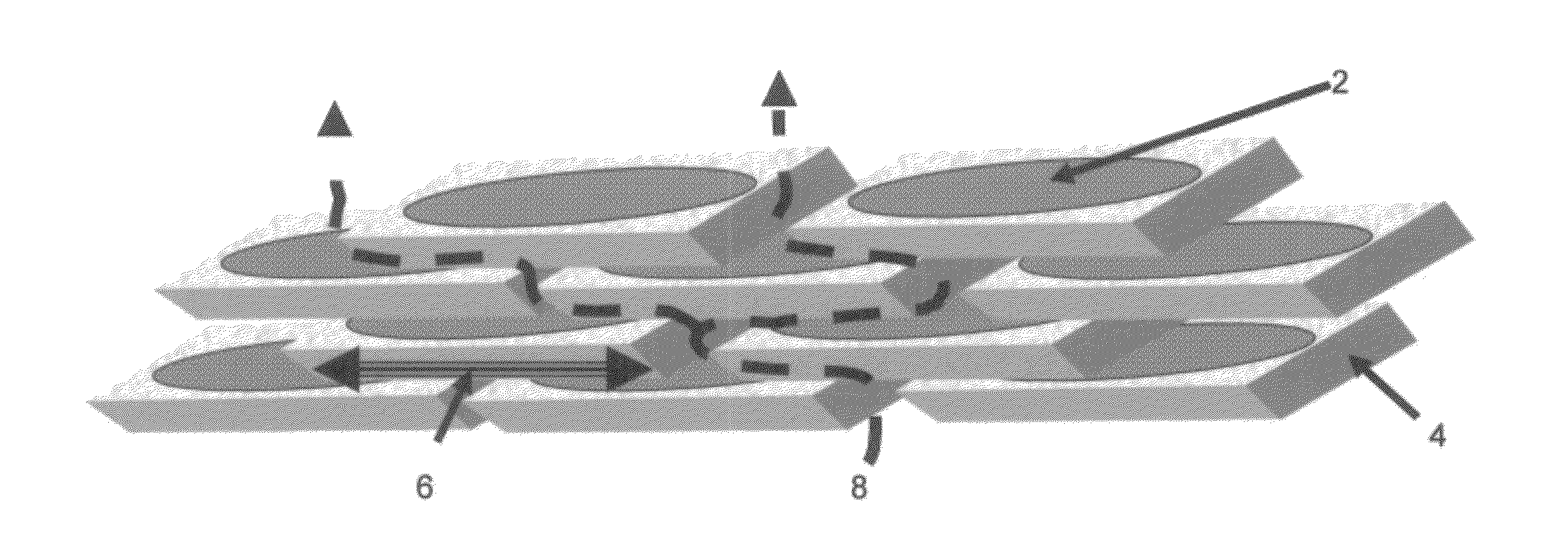

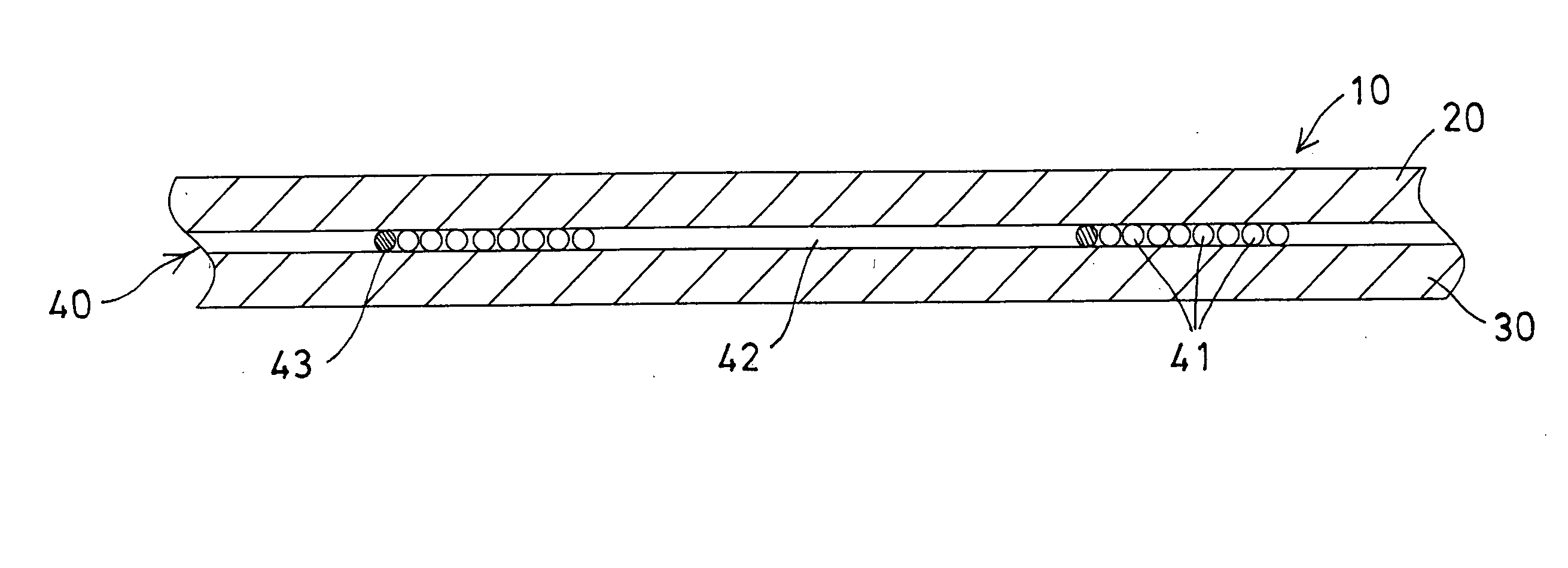

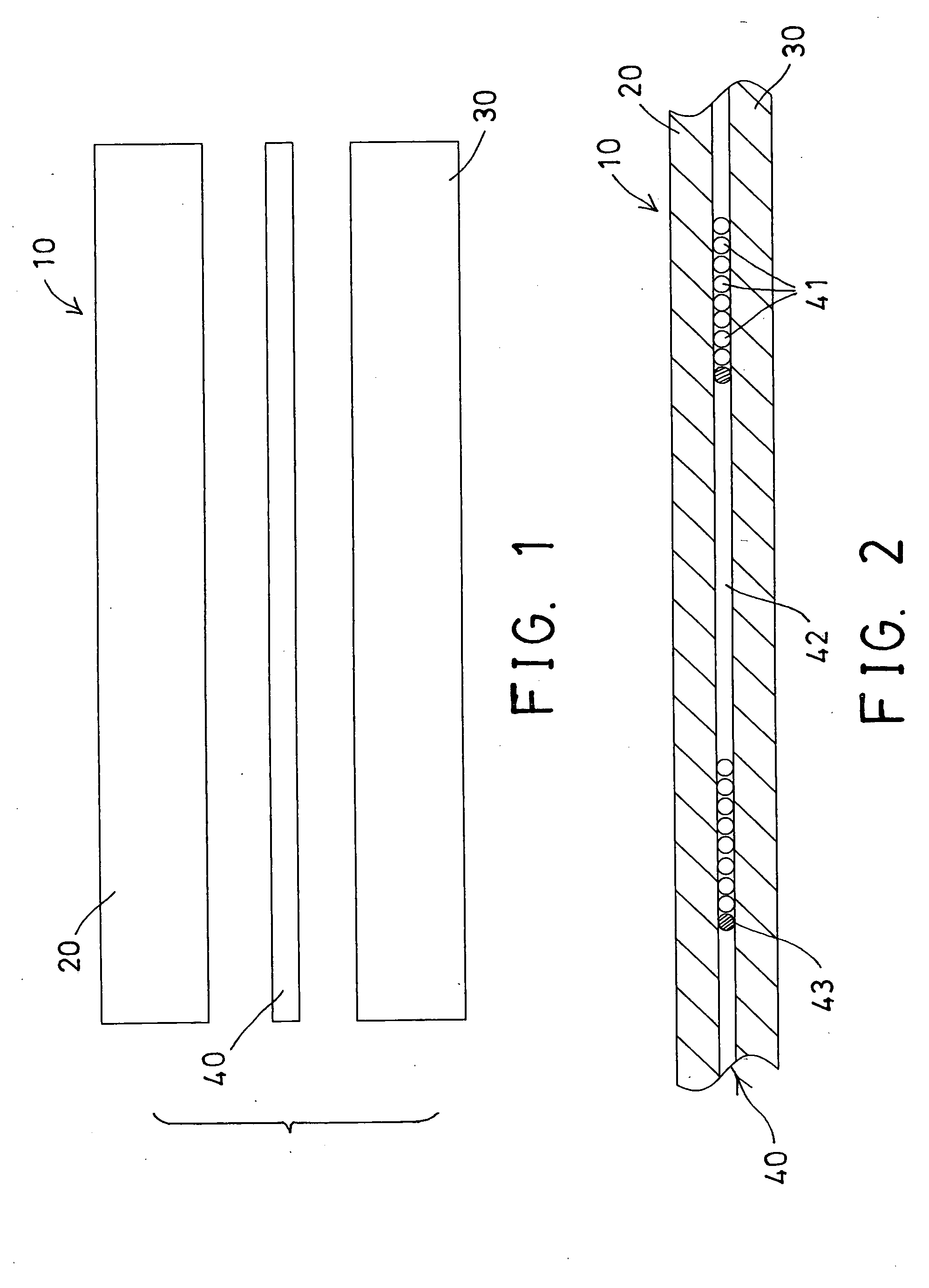

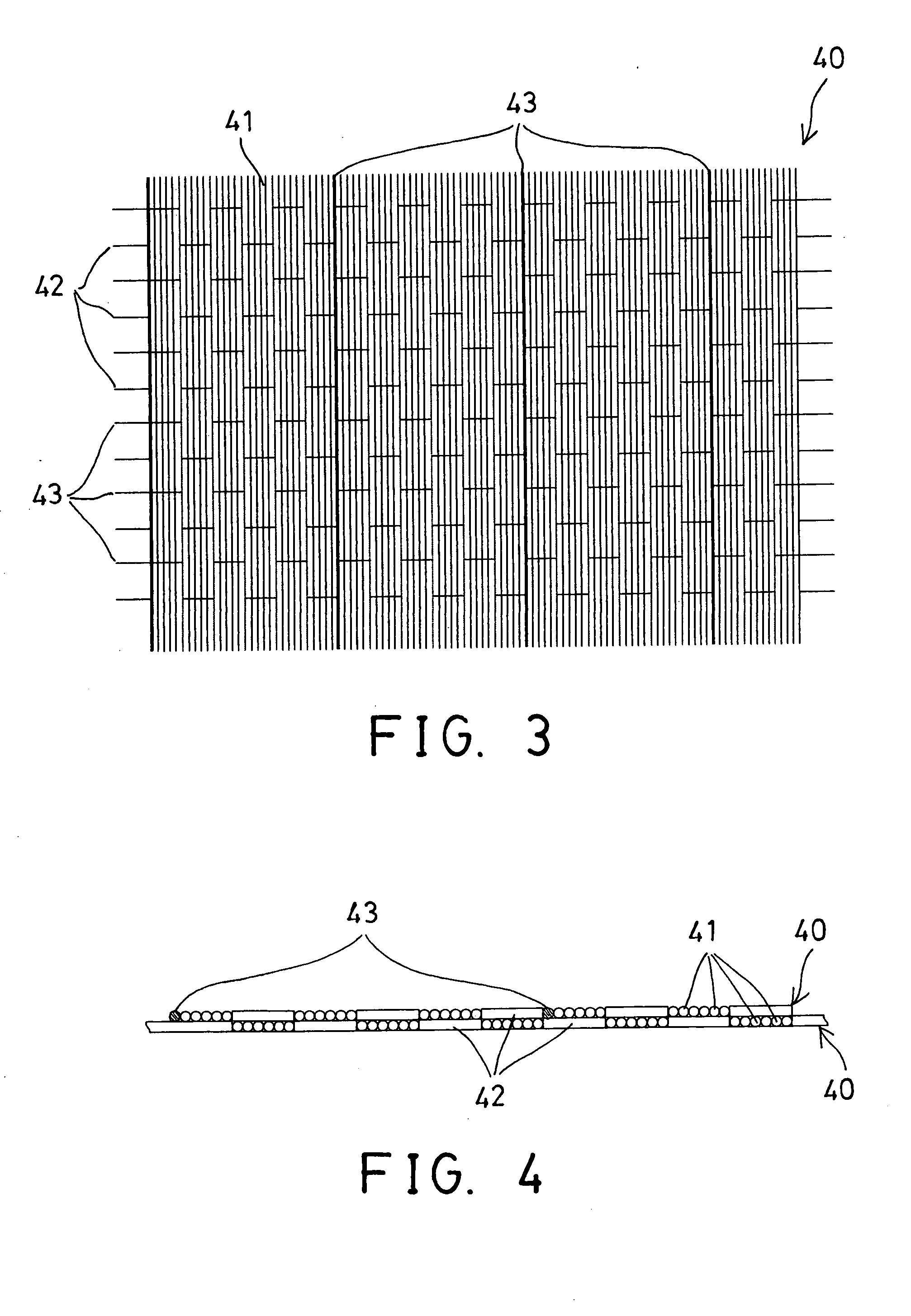

Endless belt for treadmill

InactiveUS20070167292A1Reducing and eliminating static electricityEffectively sensedConveyorsMovement coordination devicesFiberInter layer

A belt device includes one or more intermediate layers each having one or more conductive wires for reducing or for eliminating static electricity. The intermediate layers each includes a number of longitudinal fibers arranged parallel to the conductive wire, and / or includes a number of lateral fibers arranged parallel to the conductive wire. An outer peripheral layer may be attached onto the intermediate layer, or having the intermediate layer engaged into the outer peripheral layer, or an inner peripheral layer may be attached onto the intermediate layer, for allowing the intermediate layer to be disposed between the outer and the inner peripheral layers.

Owner:KUO HAI PIN

Sizing process of fine denier circular hole bright polyamide multifilament

InactiveCN102828369AReduce incidenceImprove flatnessLiquid/gas/vapor removalBeaming machinesPolyamideEngineering

The invention discloses a sizing process of a fine denier circular hole bright polyamide multifilament. By adjusting the technological parameters of four procedures such as warping, sizing, re-beaming and weaving, a good size film is formed on the surface of the fine denier circular hole polyamide filament and is convenient for weaving, the production efficiency is above 95% and a series of problems such as low weaving efficiency of multifilament woolen fabrics of fine denier circular hole bright polyamide multifilament series are solved.

Owner:WUJIANG FUHUA WEAVING

Array substrate and liquid crystal display device

InactiveCN104698710AReduce staticSmall footprintSolid-state devicesNon-linear opticsCapacitanceLiquid-crystal display

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Method for preparing cotton-like fabric through alkali decrement

InactiveCN102433729AThe texture of the cloth surface is dense and smoothSofter and fluffier than ultra cottonFibre typesFiberThermal insulation

The invention discloses a method for preparing cotton-like fabric through alkali decrement. The method comprises the steps of: a. first conducting unwinding treatment to polyester grey fabric, then carrying out sanding treatment; b. performing high temperature alkali decrement treatment in a high-temperature high-pressure overflow dyeing machine; c. dyeing and bleaching the treated fabric; d. carrying out shaping treatment to the dyed fabric for stabilizing the dimension; e. examining and packing a finished product. The high temperature alkali decrement technology consists of: with 10-15g / L of sodium hydroxide and 1g / L of a detergent, controlling the bath ratio at 1:15, first raising the temperature to 120-130DEG C at a speed of 2-5DEG C / min, conducting thermal insulation for 20-30min, then lowering the temperature to 50-80DEG C at a speed of 2-4DEG C / min, carrying out thermal insulation for 30-60min, and then lowering the temperature to normal temperature at a speed of 0.5-2.5DEG C / min. The fabric prepared by the method of the invention has the advantages that: 1. the fabric surface has dense and flat lines, the handfeel is soft and fluffy and surpasses cotton; 2. fibers have a strong fluffy feel, the luster is gentle, and the fabric surface can generates diffuse reflection to light and has gentle luster; 3. the fabric surface is smooth, has good permeability, and can improve chemical fibers, static resistance and stuffy feeling; the product can compare favorably with cotton fabric in terms of performances, and has lower price.

Owner:潘润华

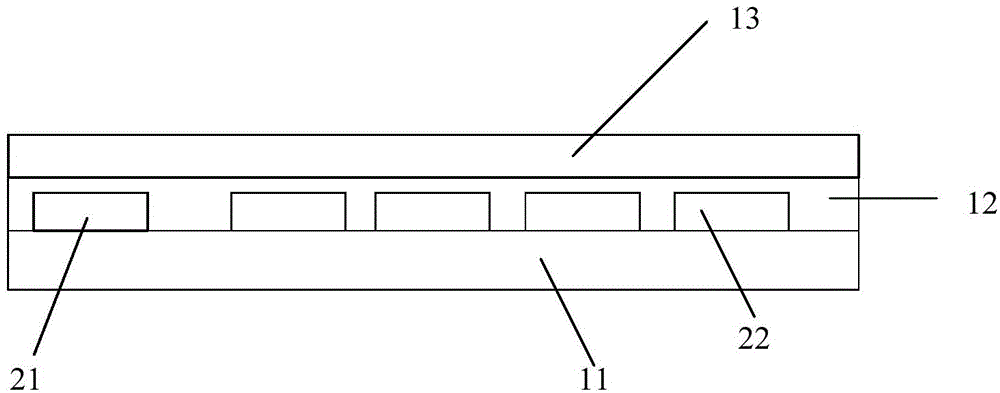

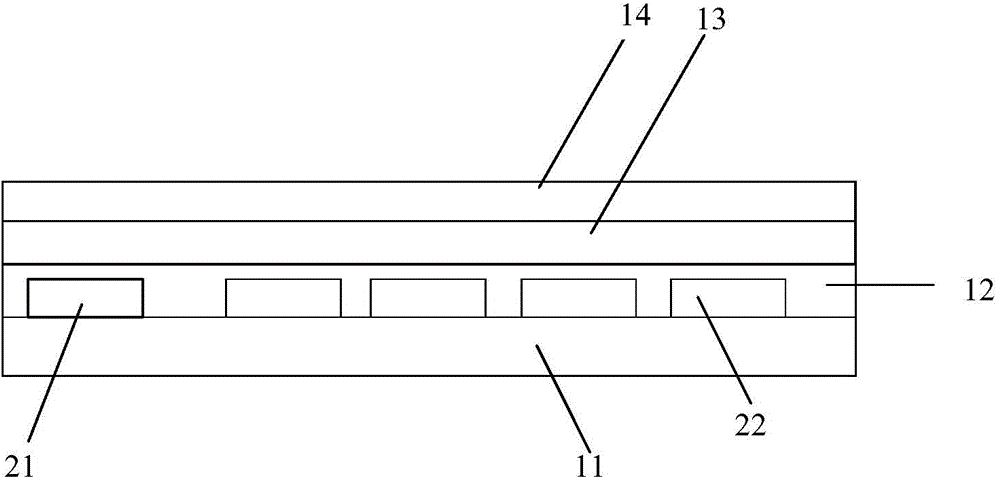

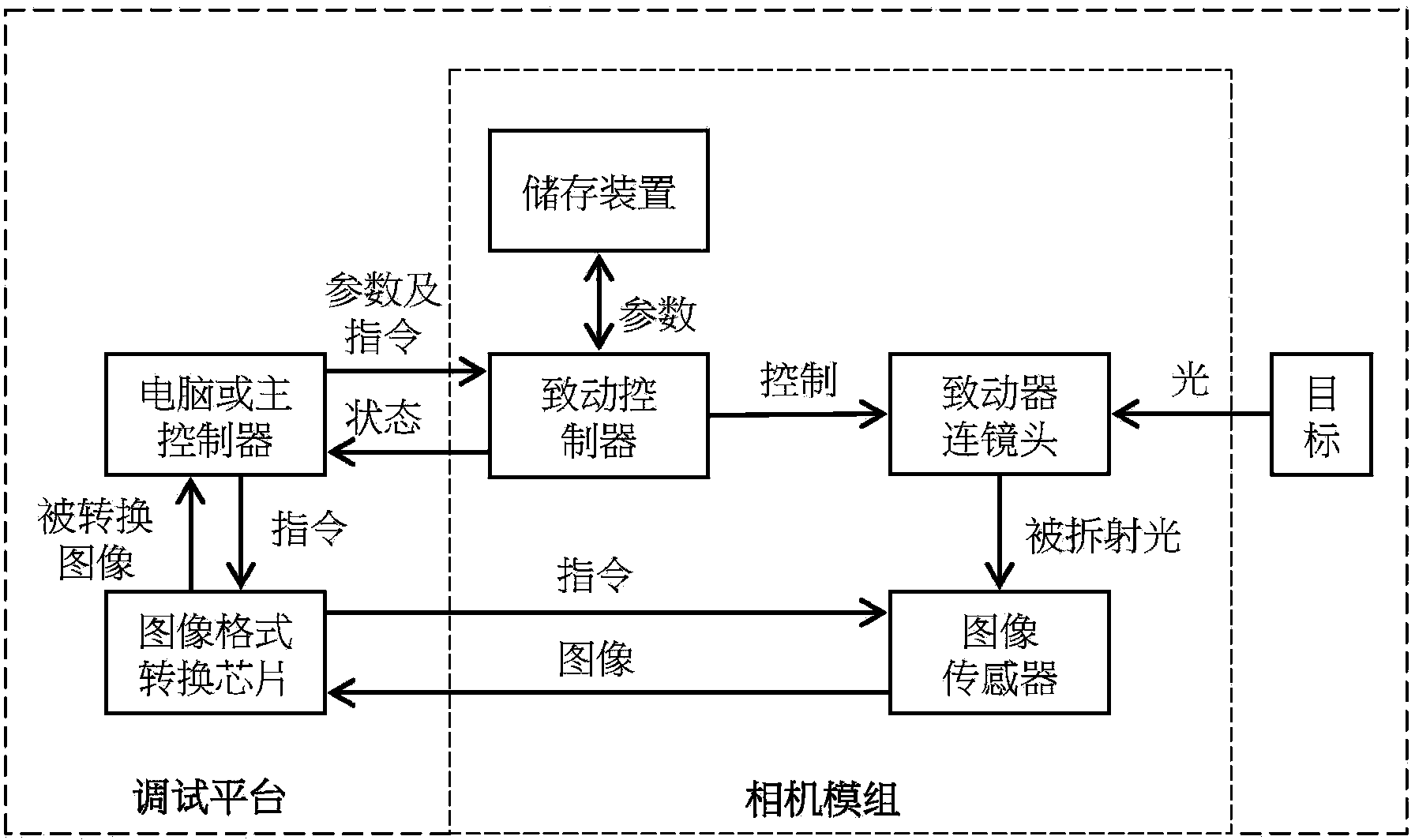

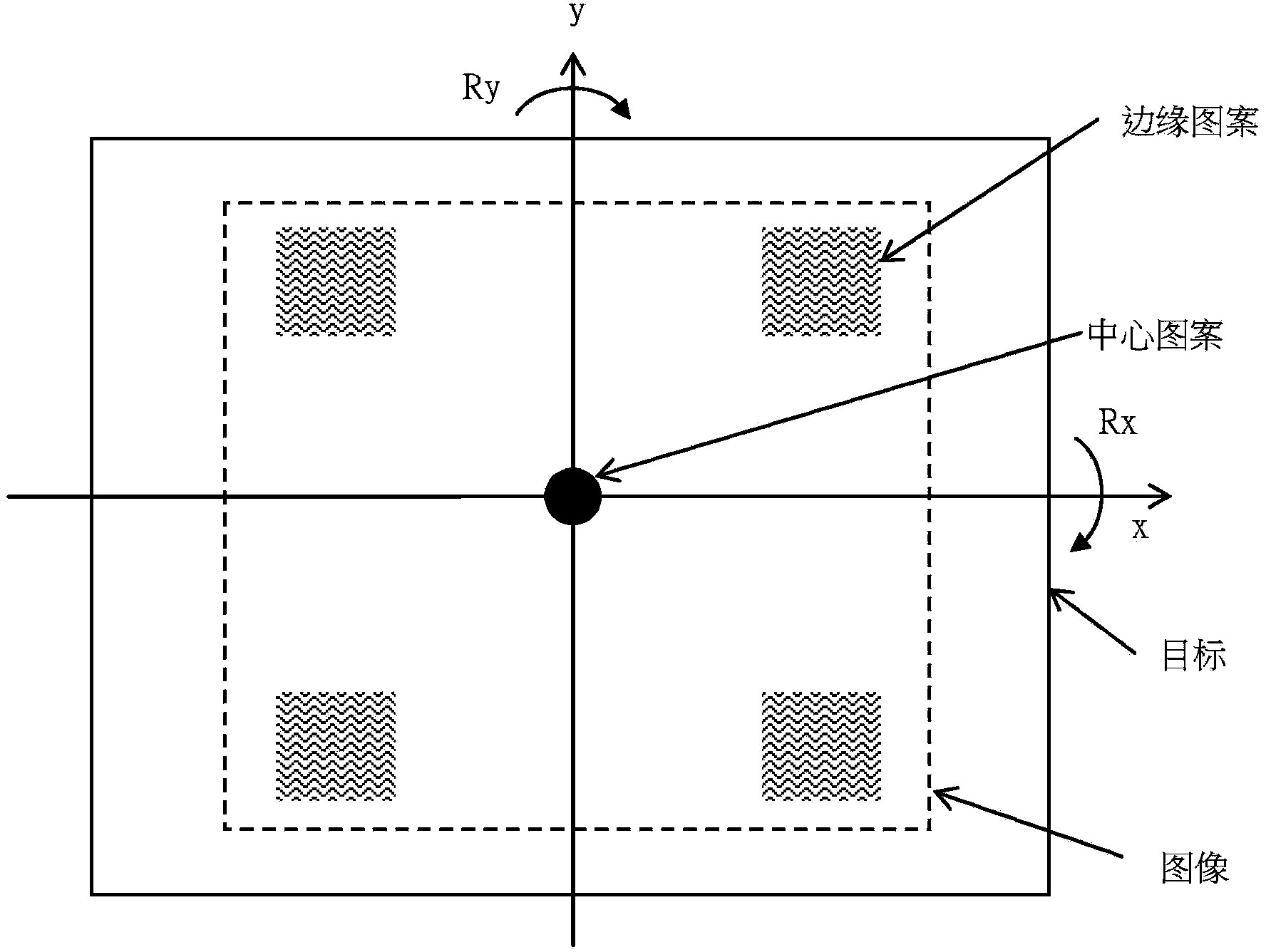

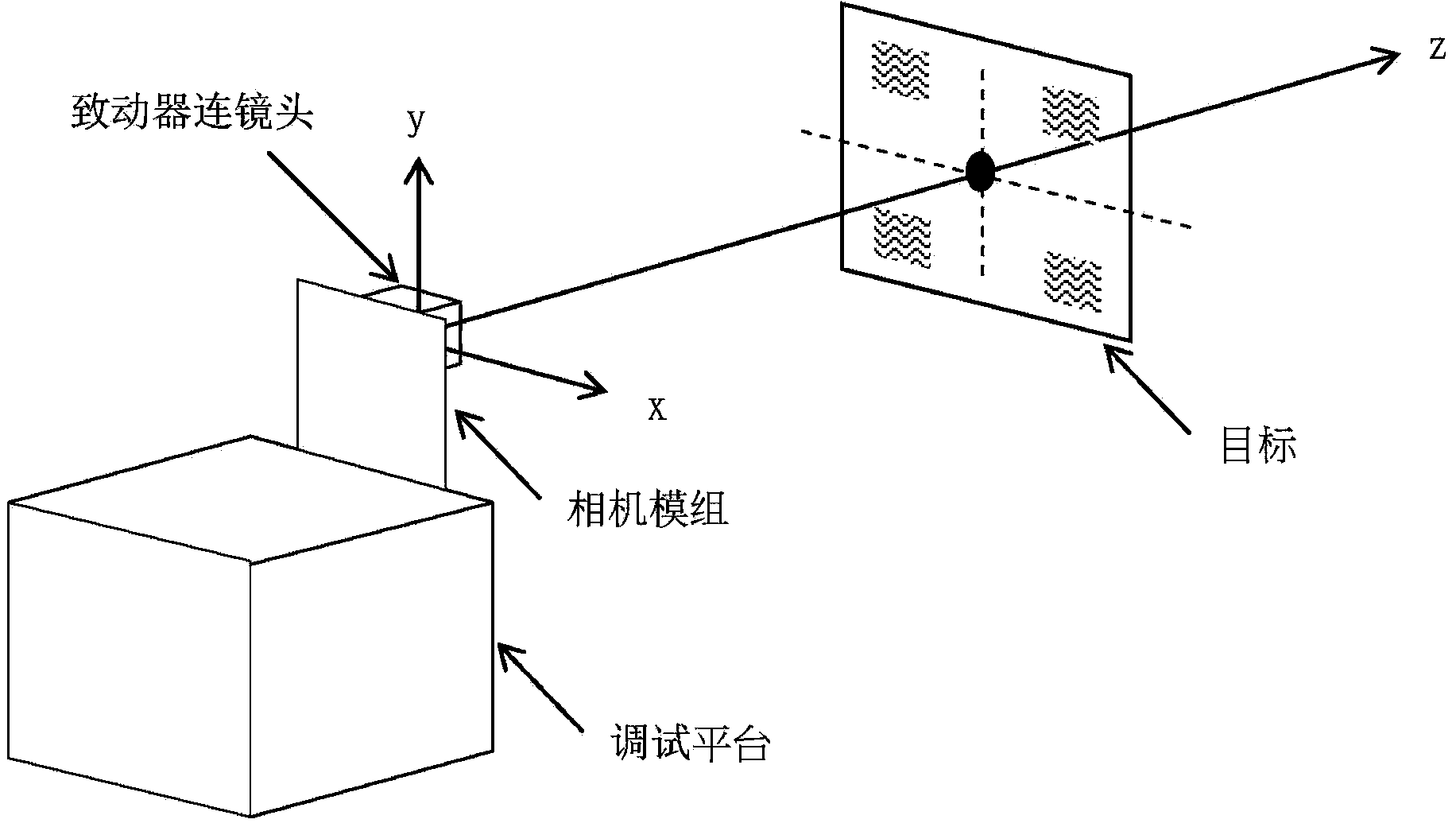

Adjustment and application method for tilting compensation control of lens of automatic focusing camera module

The invention discloses an adjustment and application method for the tilting compensation control of a lens of an automatic focusing camera module. In the adjustment process, a system will find out the needed tilting compensation control and store relevant data to a storage device, after adjustment and when the camera module is used, an actuator controller will read the data and use the data, and the purpose of tilting compensation is achieved. As relevant actuator control is changed at different lens strokes (or focusing positions), the tilting angle of the lens is decreased, the tilting angles at the different positions are considered, and the static and dynamic tilting angles can be effectively decreased. In addition, the adjustment process is the full-automatic adjustment process, so that manpower needed in the mass production is reduced effectively, the operating cost is lowered, the frequency of the quality problem caused by manual errors can also be reduced, the operating cost is further lowered, and the product consistency is improved. According to the method, the needed space is small, cost is low, and mass production is facilitated.

Owner:AP PHOTONICS SHEN ZHEN

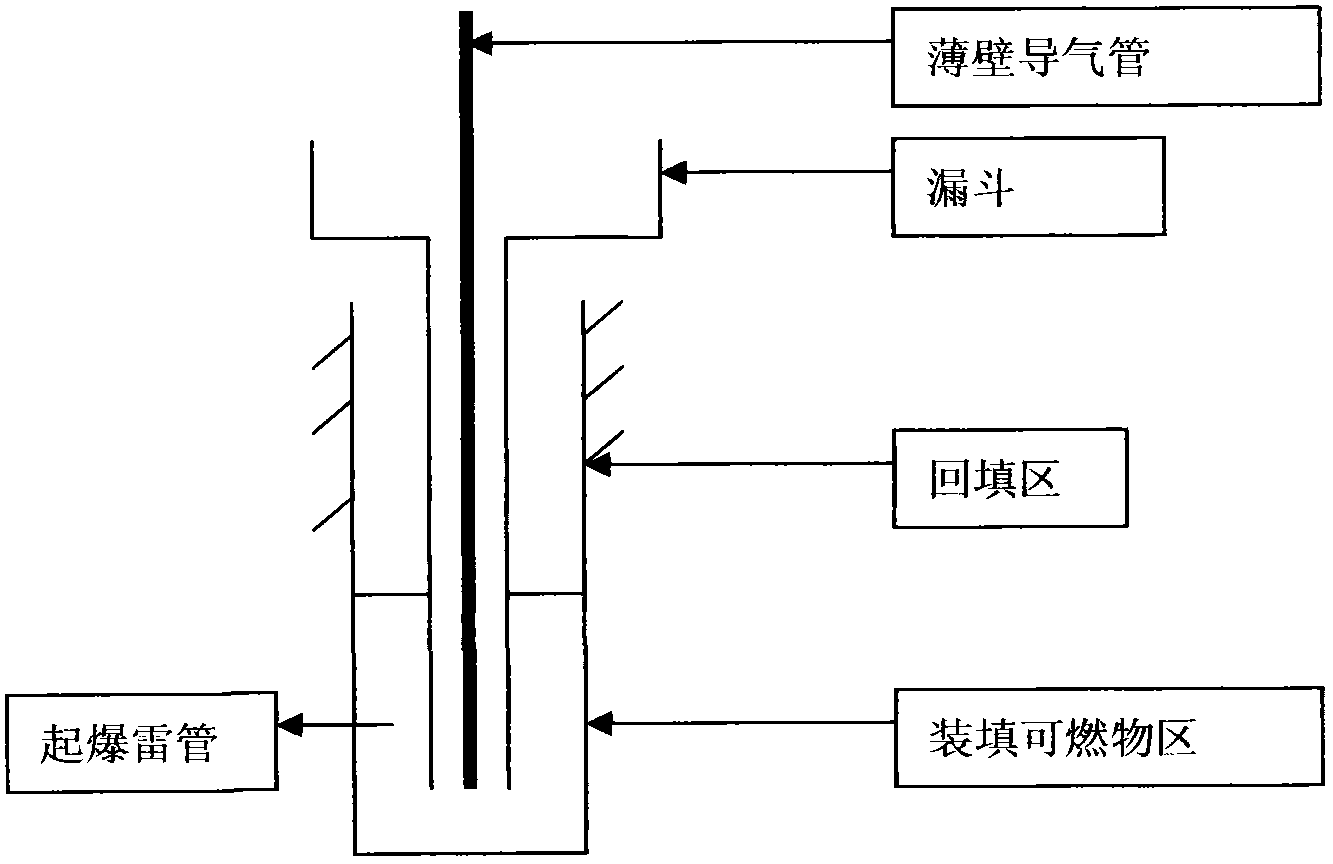

Liquid oxygen explosive composite and liquid oxygen explosive

The invention discloses a liquid oxygen explosive composite and liquid oxygen explosive, belonging to the technical field of liquid oxygen explosive materials containing fuel and enough oxidants to generate high-speed chemical changes after being exploded to generate substances used for detonation. A liquid oxygen explosive composite comprises liquid oxygen and a combustible, wherein the combustible is composed of 50-70% by mass of pulverized coal and 30-50% by mass of wet sawdust or combustible fiber, and the wet sawdust is prepared by humidifying sawdust to 5% by using a sodium chloride solution with concentration of 20%. The liquid oxygen explosive composite and liquid oxygen explosive disclosed by the invention have the advantages of preventing generation of static electricity and explosion possibility, reducing the explosive sensitivity and ensuring the explosive to be safer.

Owner:乔新明

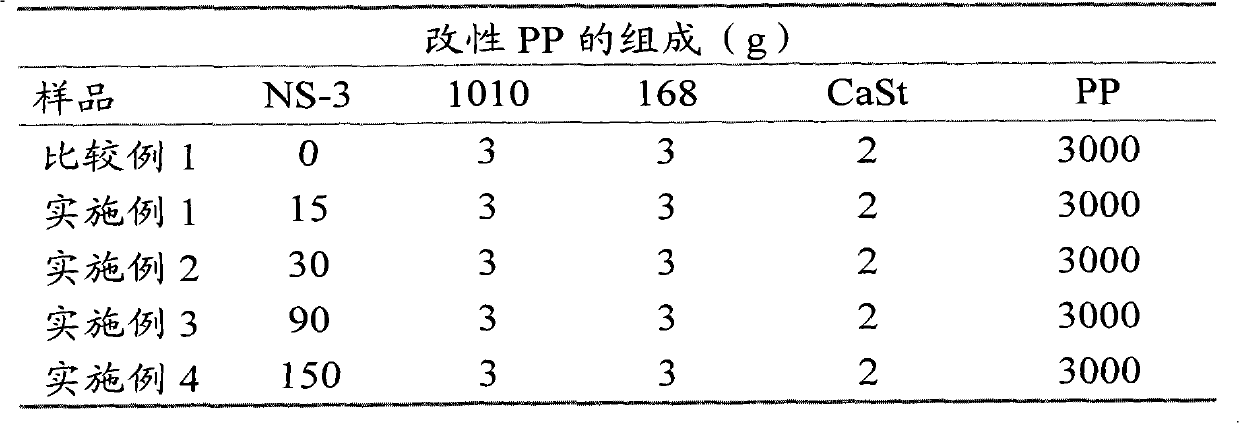

Nano-modified polypropylene soft packaging material

ActiveCN102020796AImprove mechanical propertiesImprove printing effectProcedure AgentsPolymer science

The invention provides a packaging polyolefin processing agent composition which is a mixture of nano silicon dioxide and ethylene-vinyl acetate copolymer, wherein the mass of the nano silicon dioxide accounts for 10-40% of the total mass of the processing agent composition, and the mass of the ethylene-vinyl acetate copolymer accounts for 60-90% of the total mass of the processing agent composition. The invention also provides packaging polyolefin modified by the processing agent composition. The modification of the nano silicon dioxide has greater influences on the mechanical property, the crystallization property, the polarity, the printing property, the composite property, the residue of organic solvent, and other indexes of the polypropylene. A result shows that after the polypropylene soft packaging material is subjected to nano modification, the toughness of the polypropylene soft packaging material is greatly enhanced; meanwhile, the polarity, the printing ink adhesive force and the peel strength of the material are improved; the adsorption of the modified polypropylene on toluene is greatly reduced. After nano modification, the using performance of the polypropylene used as the soft packaging material can be greatly improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

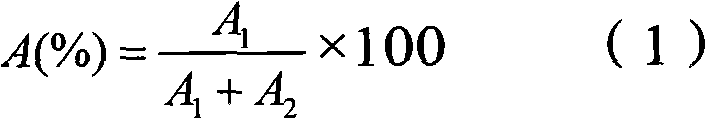

Multipurpose magnetic couplings

InactiveUS20130048827A1Reduce static electricityPrevent noiseStampsStands/trestlesMagnetDrinking straw

The present invention includes a unique magnetic coupling that can be used as a drink identification system as well as a myriad of other useful purposes. In one embodiment, two magnets are connected by a connector. Each of the magnets have at least one surface with an opposite polarity from the other magnet to induce a magnetic attraction. When the magnets are close in proximity, they come together due to the polarity, and effectively produce a loop. The magnets can be attached to the rim of a cup. Decorative charms attached to a small ring or loop can be put onto the connector. Alternatively, the decorative charm can have a magnet attached to it. The charm can then be magnetically attached to the outer magnet of the coupling. A monogram or name tag can be substituted in lieu of a decorative charm. The magnetic coupling can be used for other purposes, such as securing objects in a drink (a decorative umbrella or drinking straw).

Owner:GLOBAL CONNECT TECH

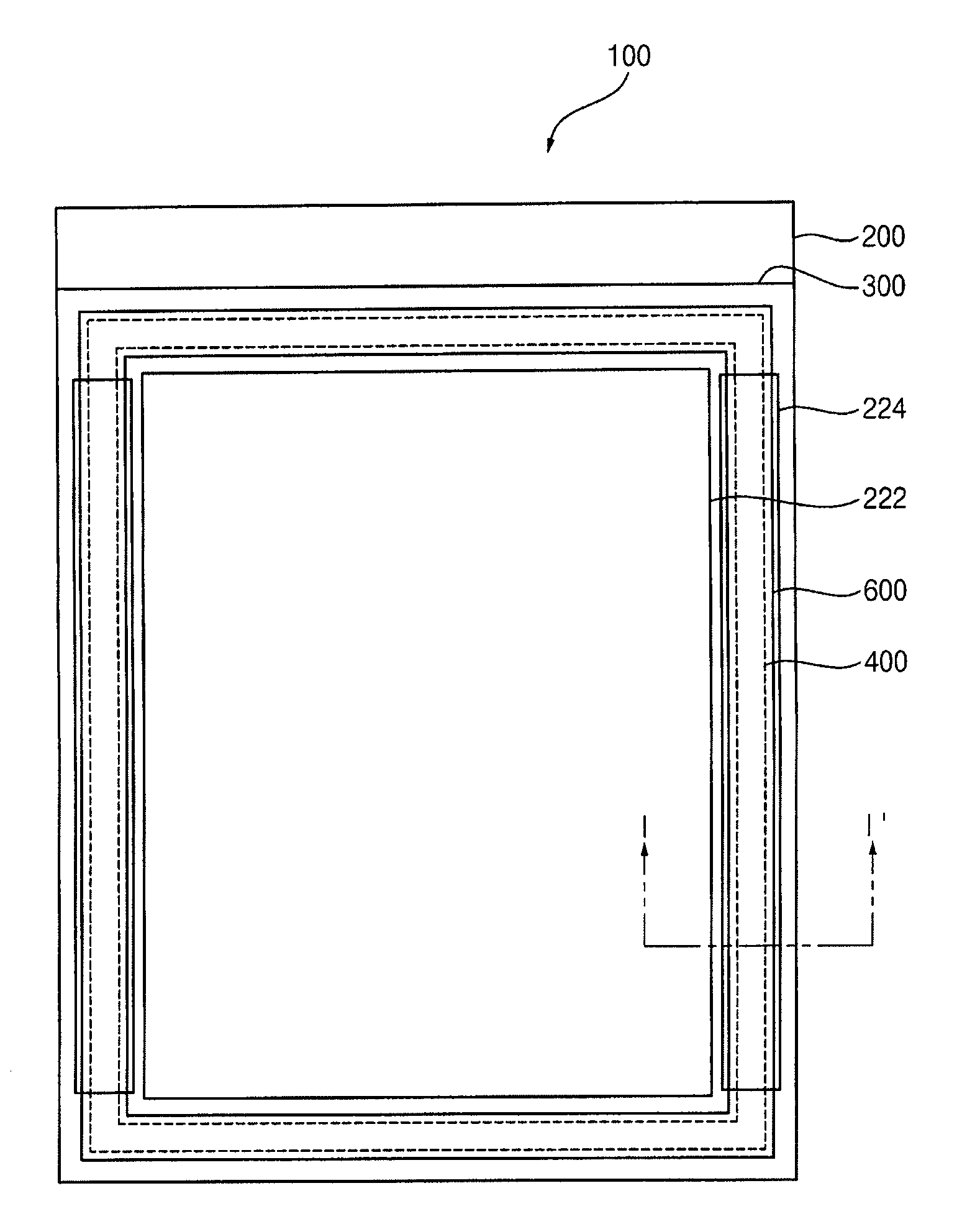

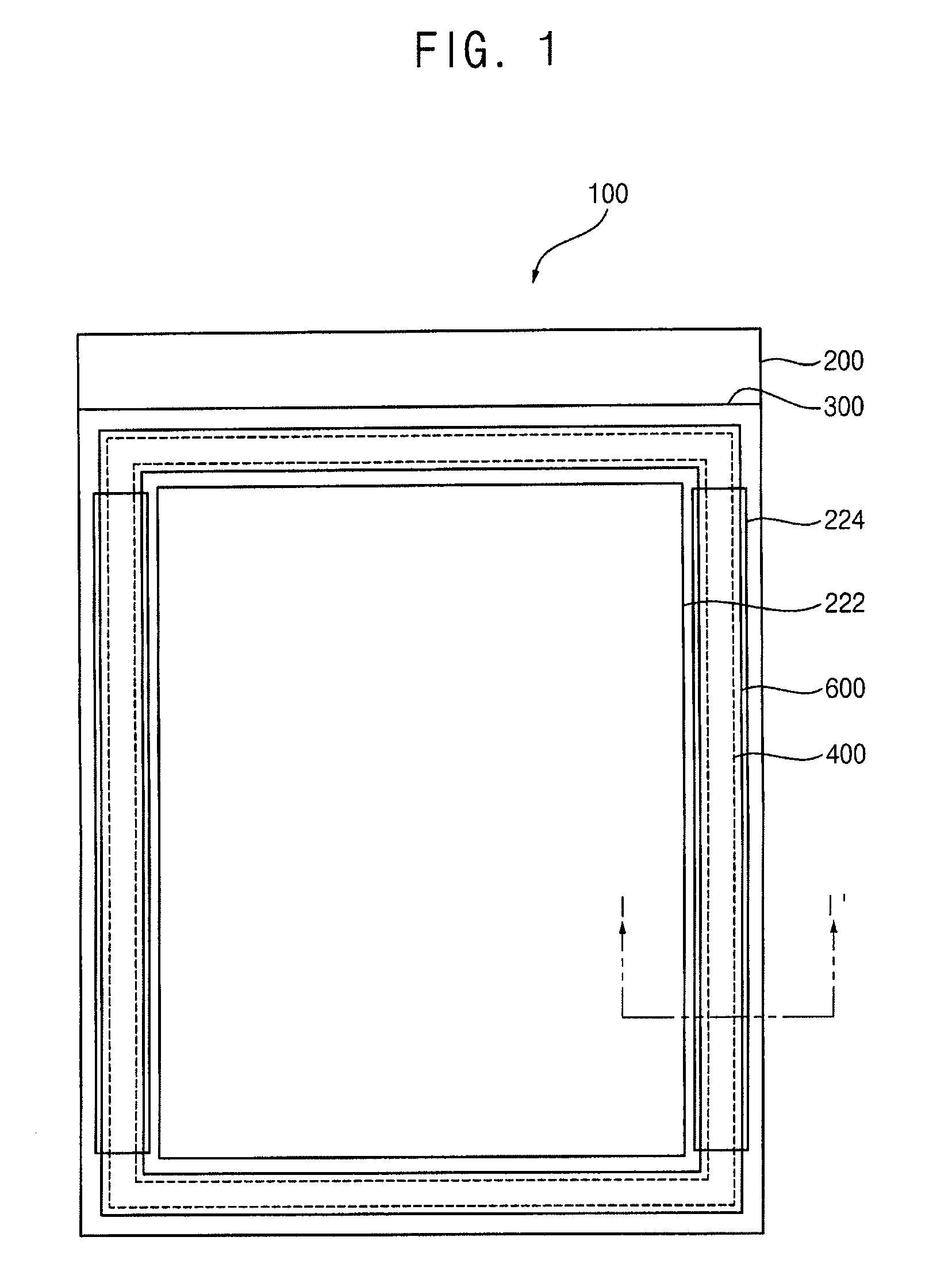

Touch screen panels

ActiveUS20130328830A1Prevent and reduce damageAvoid failureInput/output processes for data processingEngineeringTouchscreen

A touch screen panel includes a transparent substrate, a first sensing line and a second sensing line. The first sensing line includes first sensing cells arranged along a first direction and first connection patterns coupling the first sensing cells. The second sensing line includes second sensing cells arranged in a second direction substantially perpendicular to the first direction, and second connection patterns coupling the second sensing cells. At least one of the first and the second sensing cells includes openings and conductive patterns located in the openings.

Owner:SAMSUNG DISPLAY CO LTD

Copper-free ceramic type friction material and preparation method thereof

InactiveCN101948673AImprove thermal conductivityImprove friction performanceOther chemical processesCeramic shaping apparatusFiberAlkaline earth metal

The invention discloses a copper-free ceramic type friction material and a preparation method thereof. The friction material at least comprises 2 to 30 mass percent of alkaline earth-based metallic compound and 2 to 30 mass percent of carbon fiber, wherein the alkaline earth-based metallic compound is MxFeyTiOz, M is alkaline earth metallic element, namely Be, Mg, Ca, Sr or Ba, x is 0.2 to 2, y is 1 to 2, and z is 4 to 16. The friction material prepared by the method has the advantages of: high friction and wear property, higher heat conductivity, high performance of resisting high-temperature recession, and capacity of efficiently reducing the temperature of a friction surface in the braking process.

Owner:南京钛威科技有限公司 +1

Method for producing blended yarn of Shengma fiber and cotton

The invention relates to a method for producing blended yarn of Shengma fiber and cotton. A required cone yarn is produced by selecting suitable Shengma fibers and cotton fibers, combining the Shengma fibers with a cotton comber on a drawing after blowing, carding and predoubling, and performing a roving process, a spinning process and a winding process. In the method, the blowing process has the characteristics of carding more and beating less, catching frequently and rarely, low beater speed, less fly fiber, and heavier pressure; the carding process has the characteristics of suitable carding; the drawing process has the characteristics of light quantitation, heavy pressure, low speed, primary predoubling and secondary blending; the roving process has the characteristics of light quantitation, heavy pressure, low speed and high twisting degree; and the spinning process has the characteristics of low speed, high twist factor and suitable temperature and humidity. A plus material of the blended yarn of the Shengma fiber and the cotton produced by the method of the invention has cotton texture; a fabric has the characteristics of soft, smooth and fluffy handfeel, high moisture adsorption performance and ventilation property, high warmth retention property, high bacteria and mildew resistance, high drapability, bright color and luster, plump and smooth fabric surface organization, lightness and comfort for a wearer, and capacity of being used for knitted underwear, leisure wear, towel supplies, beddings and the like.

Owner:JIHUA 3509 TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com