Patents

Literature

74results about How to "Increase fluid resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

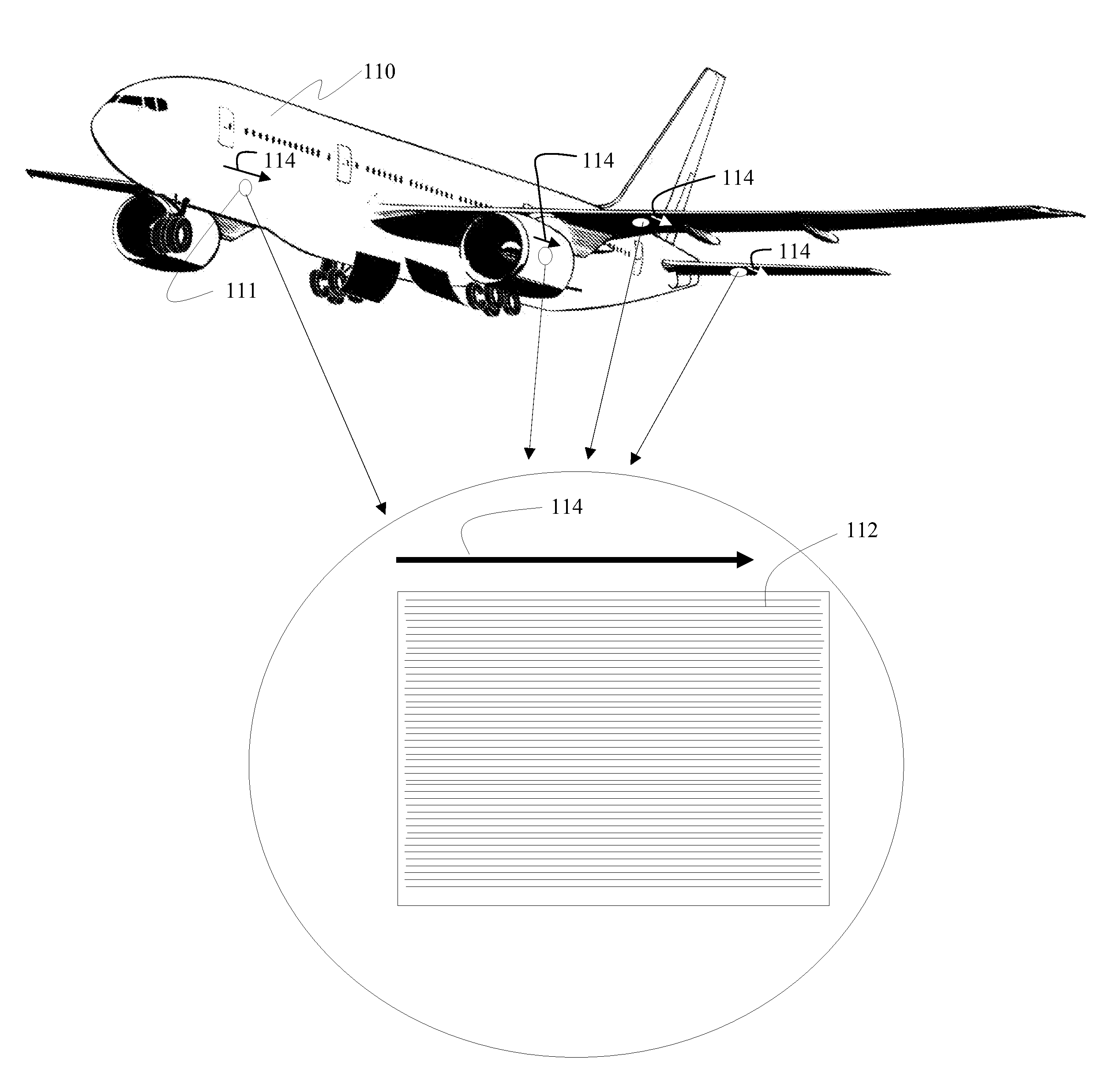

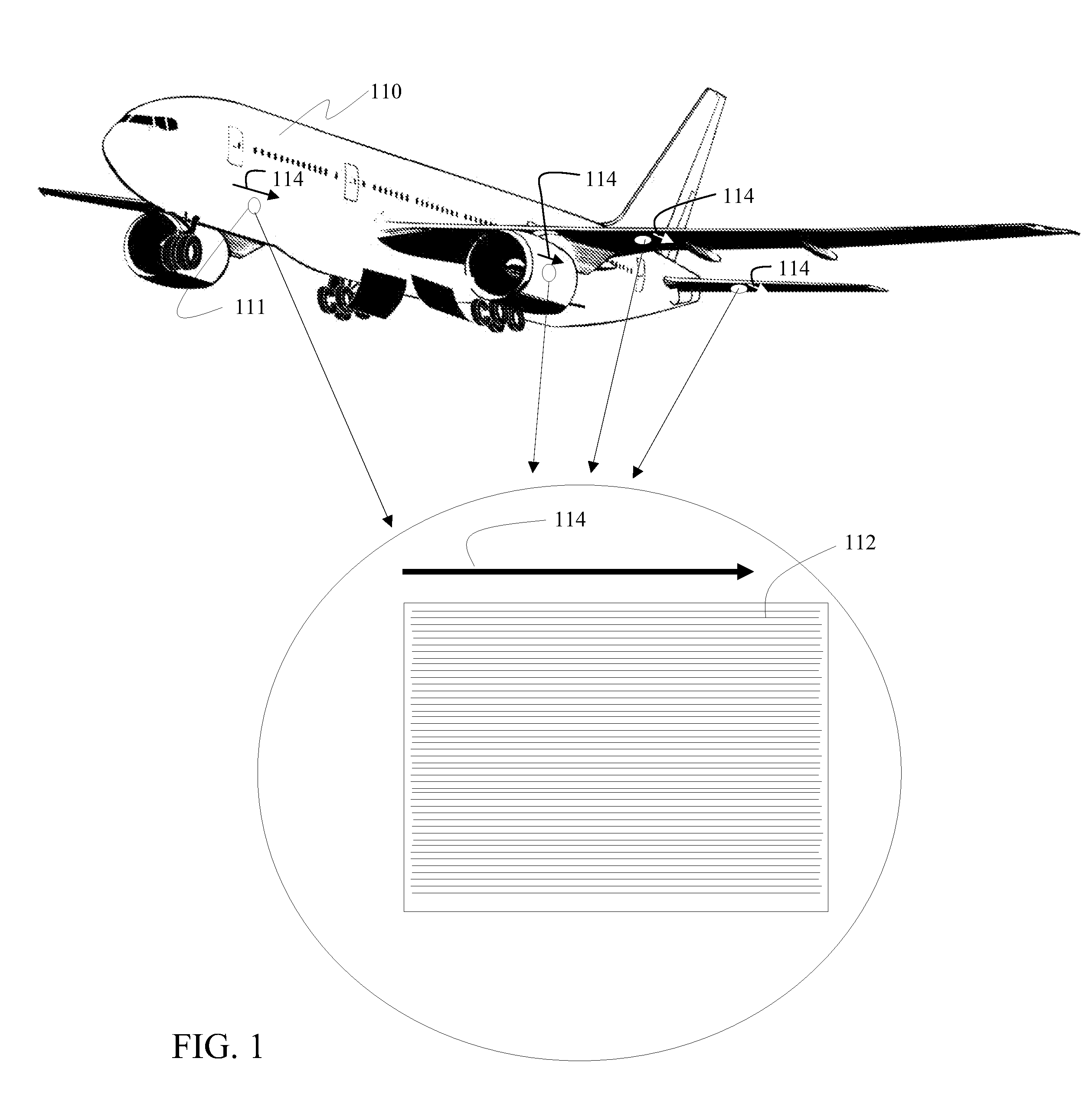

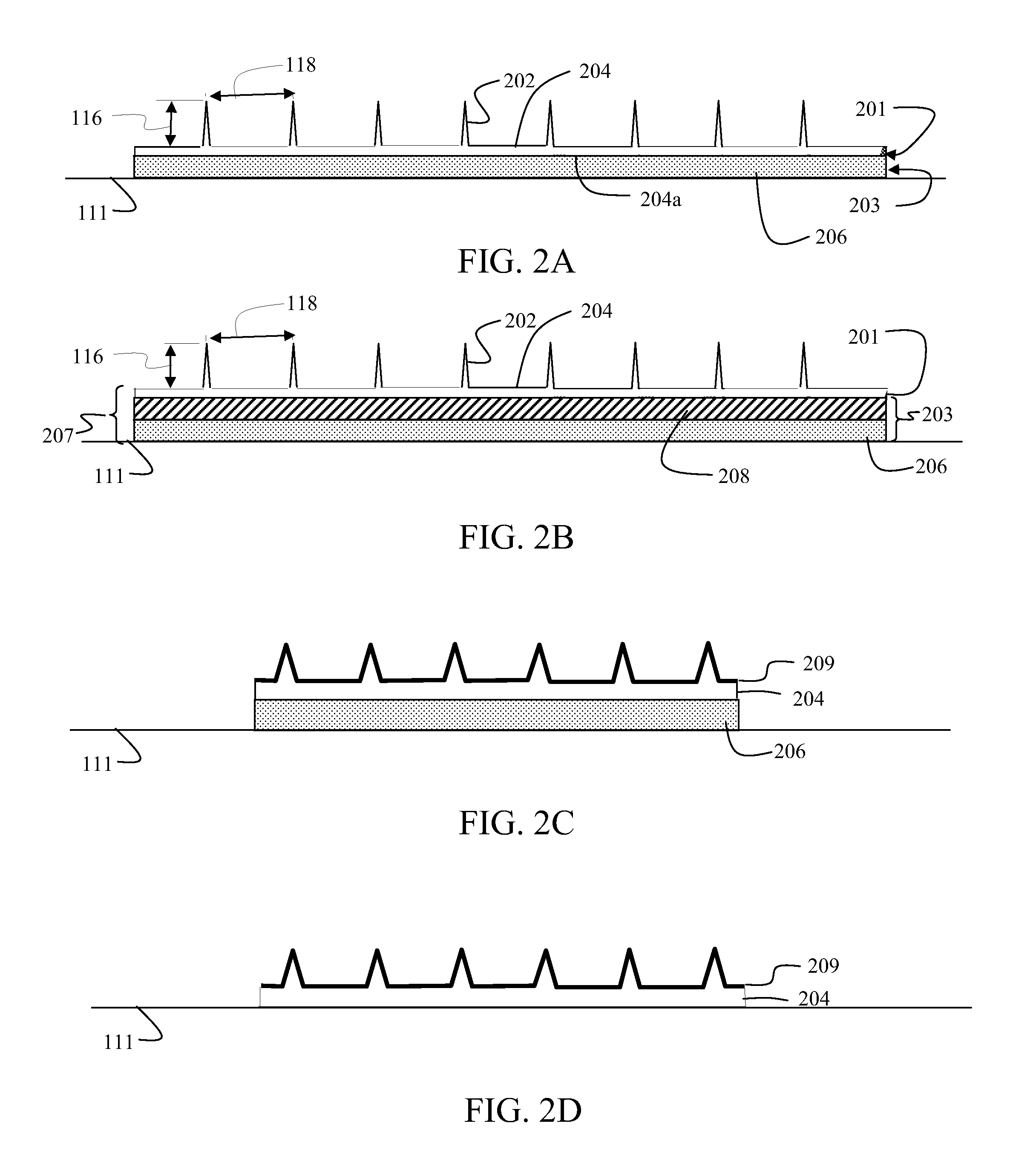

Elastomeric riblets

ActiveUS20100282909A1Increase fluid resistancePromote oxidationVehicle componentsCoatingsMetal foilEngineering

An array of aerodynamic riblets incorporates a high elongation elastomeric layer having spaced tips and optionally a protective cladding. The elastomeric layer may be adhered to an aerodynamic surface directly or as an appliqué in combination with one or more of an adhesive layer, one or more supporting polymer layers and a metal foil layer.

Owner:THE BOEING CO

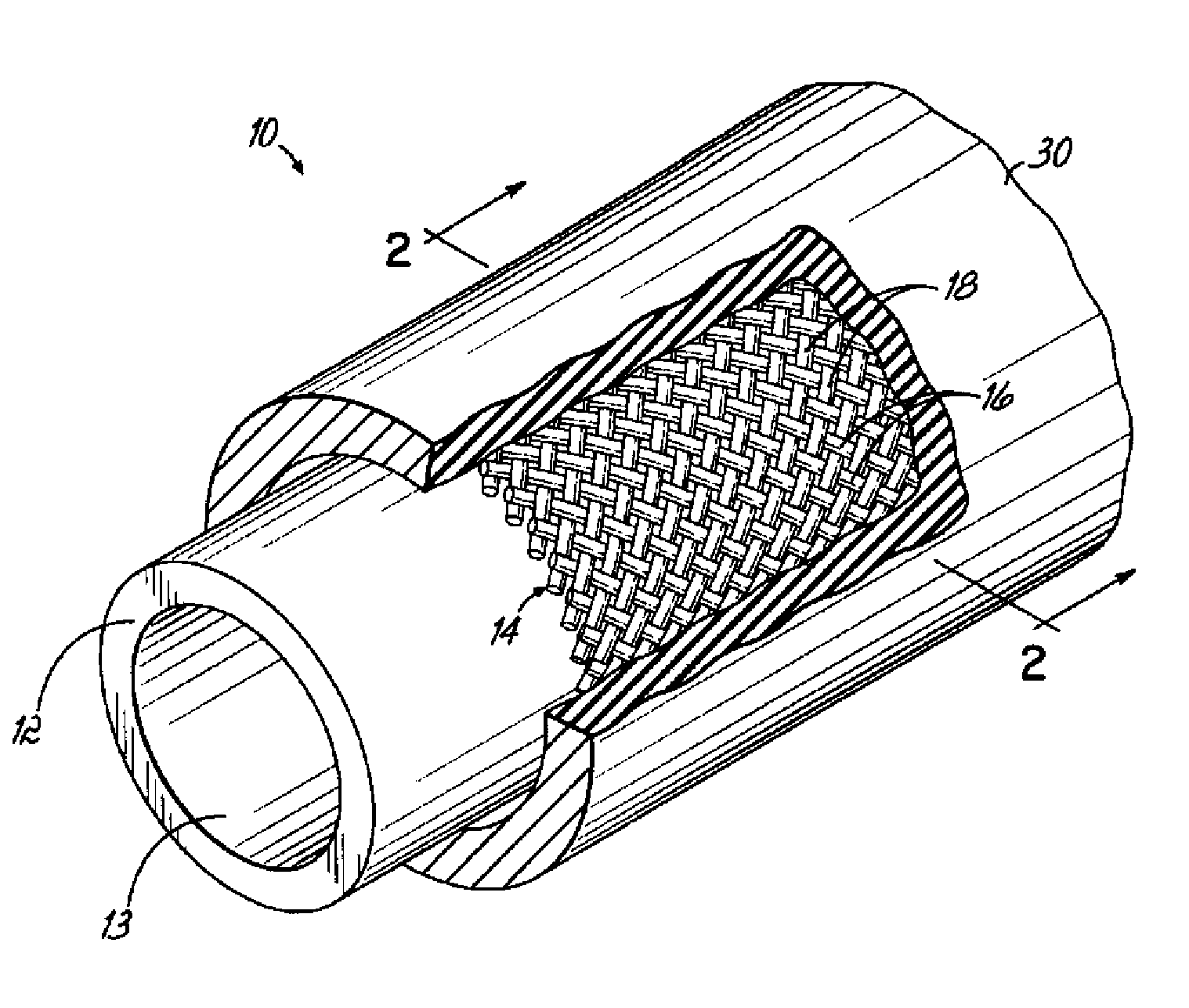

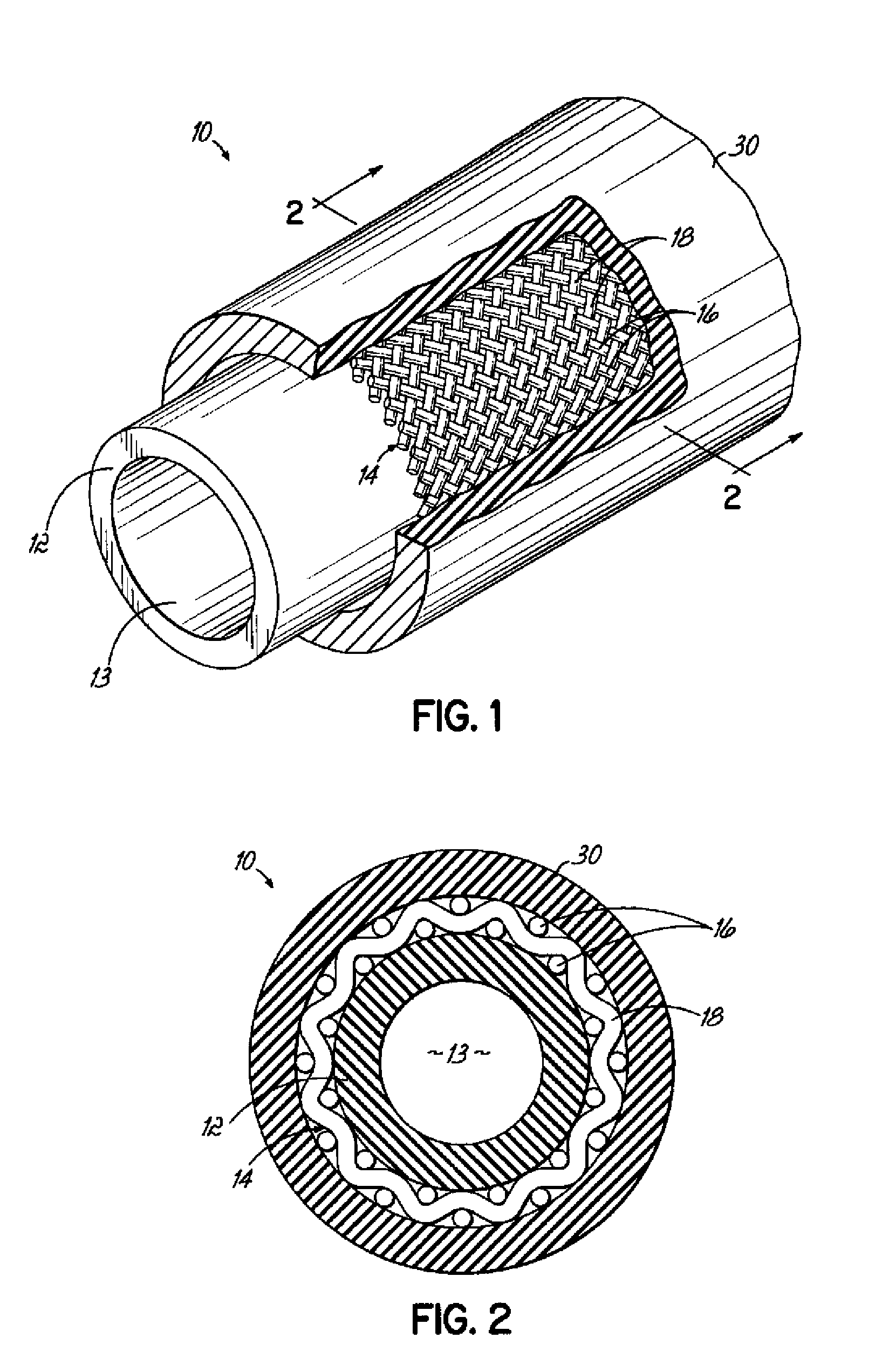

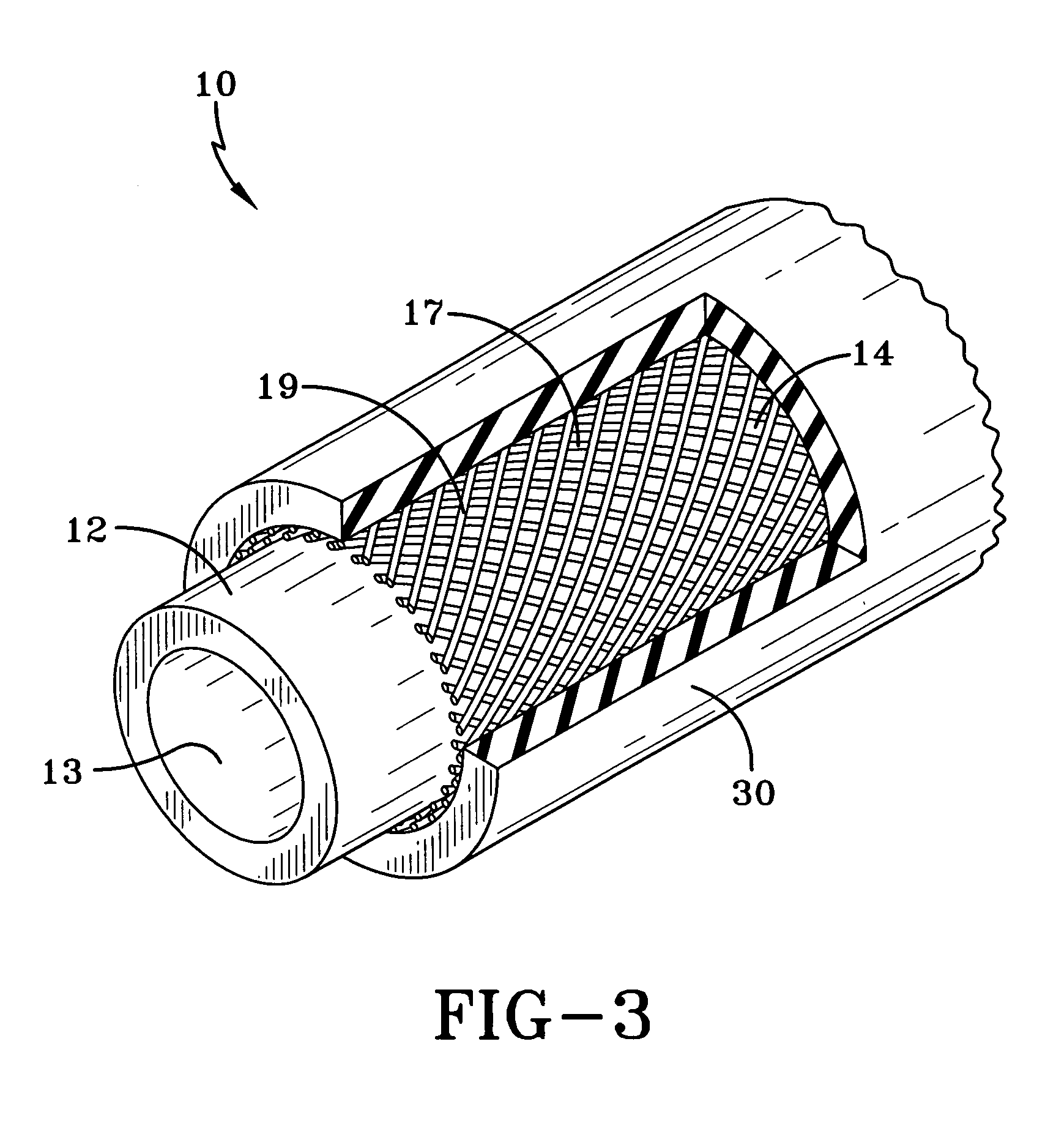

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20050059764A1Improve impermeabilityGood oil resistanceSynthetic resin layered productsSpecial tyresElastomerPolymer science

A heat tolerant, pressure resistant elastomeric composition comprising a blend of a first ethylene-vinyl ester copolymer and a second copolymer selected from the group consisting of chlorosulfonated polyethylene (CSM), chlorinated polyethylene (CPE), polychloroprene (CR), ethylene-acrylic elastomer (AEM), alkyl-acrylate copolymer (ACM), polyvinyl acetate (PVA), nitrile-butadiene rubber (NBR), hydrogenated nitrile-butadiene rubber (HNBR), and mixtures thereof, a hose manufactured therefrom; and a method for preparing the hose are described.

Owner:FLUID ROUTING SOLUTIONS

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20060263556A1High-temperature and pressure resistanceImproved hydrocarbon fluid resistanceLayered productsFibre treatmentElastomerAcrylic rubber

A vinyl ester composition; a tubular structure such as a hose for conveying fluids in an automotive engine cooler, transmission oil cooler, power transmission cooler, radiator or heater; and a method for preparing the tubular structure are described. The tubular structure includes a single layer of a heat tolerant, pressure resistant, hydrocarbon fluid impermeable composition comprising a copolymer of a first vinyl ester and a second vinyl ester, and one or more additives. The composition may, optionally contain a second polymeric component such as an ethylene-vinyl ester of a C2 to C6 carboxylic acid, chlorinated polyolefins, chlorosulfonated polyolefins, polychloroprene, ethylene-acrylic rubber, alkyl acrylate copolymer, polyvinyl acetate, acrylonitrile-butadiene rubber, hydrogenated acrylonitrile-butadiene rubber, ethylene-propylene-diene terpolymer, styrene-butadiene rubber, ethylene-propylene rubber, butyl rubber, cis-polybutadiene, cis-polyisoprene, polyurethane, polyamide and combinations thereof.

Owner:YH AMERICA

Fluid resistant high temperature hose

InactiveUS20120090720A1Improve the immunityWithout compromising flexural characteristic and burst strengthSynthetic resin layered productsFlexible pipesElastomerBursting strength

The present invention is based on the unexpected discovery that the fluid resistance of hoses can be greatly enhanced by adding a chlorinated paraffin to a chlorinated polyethylene elastomer or a chlorosulfonated polyethylene elastomer which is used as the tubular inner core layer of the hose. Hoses made using this approach offer the advantage of having improved resistance to modern automotive fluids, including power steering fluid, transmission fluid, and the like, without compromising flexural characteristics or burst strength. Accordingly, the hoses of this invention provide a longer service life and better reliability then hoses made utilizing conventional technology. The present invention more specifically discloses a hose which is comprised of (1) an elastomeric tubular inner core layer defining a lumen, (2) a friction layer, and (3) an elastomeric cover, wherein the elastomeric tubular inner core layer is comprised of (i) a chlorinated elastomer selected from the group consisting of epichlorohydrin, polychloroprene, chlorinated polyethylene and chlorosulfonated polyethylene, (ii) 1 phr to 50 phr of a chlorinated paraffin, and (iii) 30 phr to 120 phr of carbon black. It is typically preferred for the chlorinated elastomer to be chlorinated polyethylene or chlorosulfonated polyethylene.

Owner:CONTITECH USA INC

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS20050059763A1High-temperature and pressure resistanceIncrease fluid resistanceSpecial tyresFlexible pipesElastomerPolyolefin

A vinyl ester composition; a tubular structure such as a hose for conveying fluids in an automotive engine cooler, transmission oil cooler, power transmission cooler, radiator or heater; and a method for preparing the tubular structure are described. The tubular structure includes a single layer of a heat tolerant, pressure resistant, hydrocarbon fluid impermeable composition comprising a copolymer of a first vinyl ester and a second vinyl ester, and one or more additives. The composition may, optionally contain a second polymeric component such as an ethylene-vinyl ester of a C2 to C6 carboxylic acid, chlorinated polyolefins, chlorosulfonated polyolefins, polychloroprene, ethylene-acrylic rubber, alkyl acrylate copolymer, polyvinyl acetate, acrylonitrile-butadiene rubber, hydrogenated acrylonitrile-butadiene rubber, ethylene-propylene-diene terpolymer, styrene-butadiene rubber, ethylene-propylene rubber, butyl rubber, cis-polybutadiene, cis-polyisoprene, polyurethane, polyamide and combinations thereof.

Owner:DAYCO PROD INC

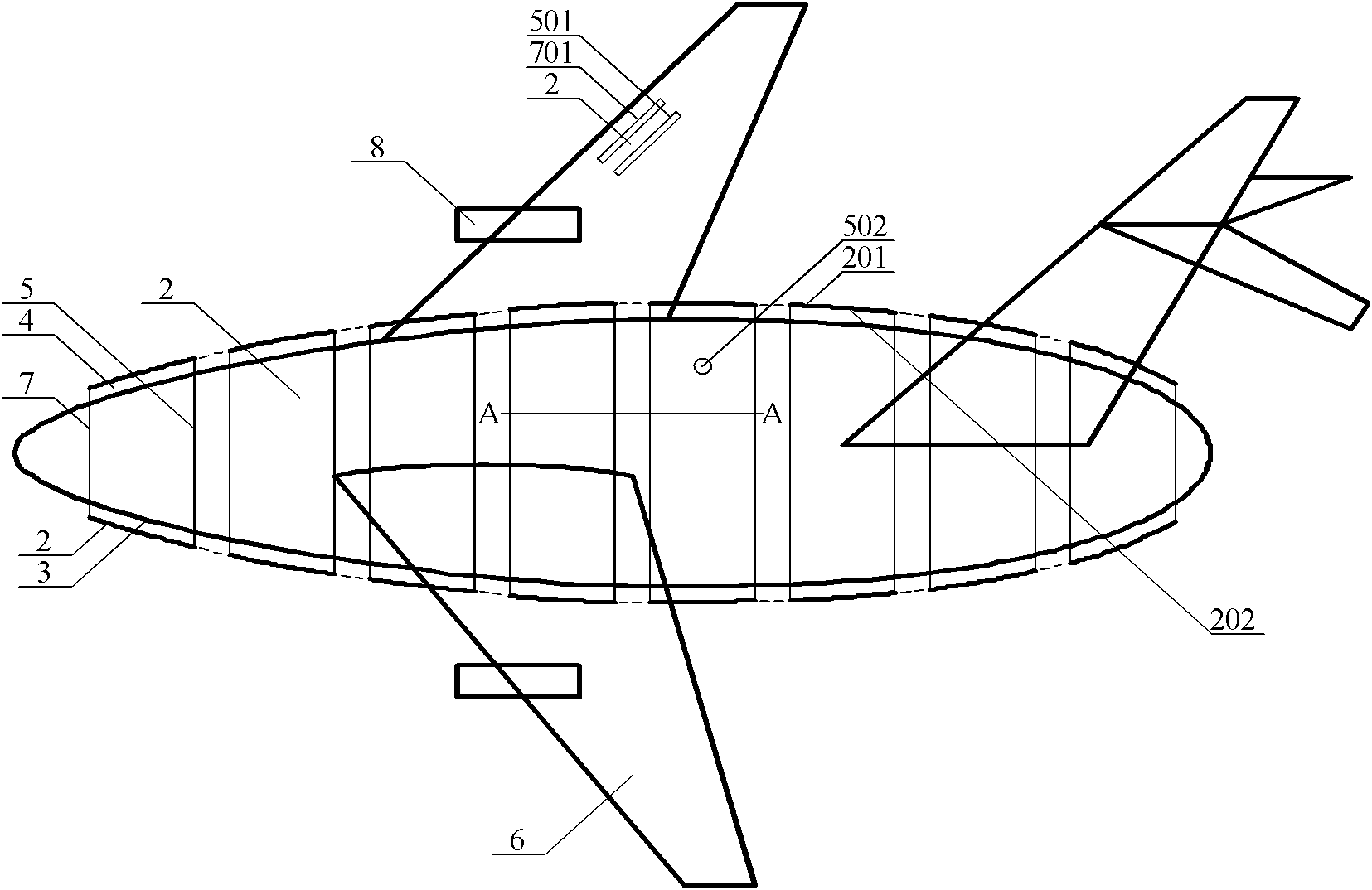

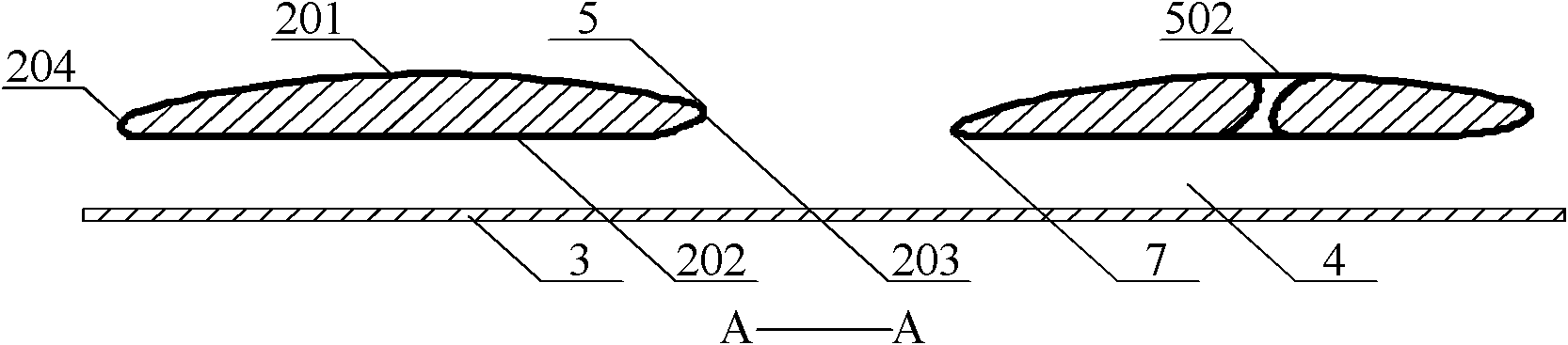

Flying device

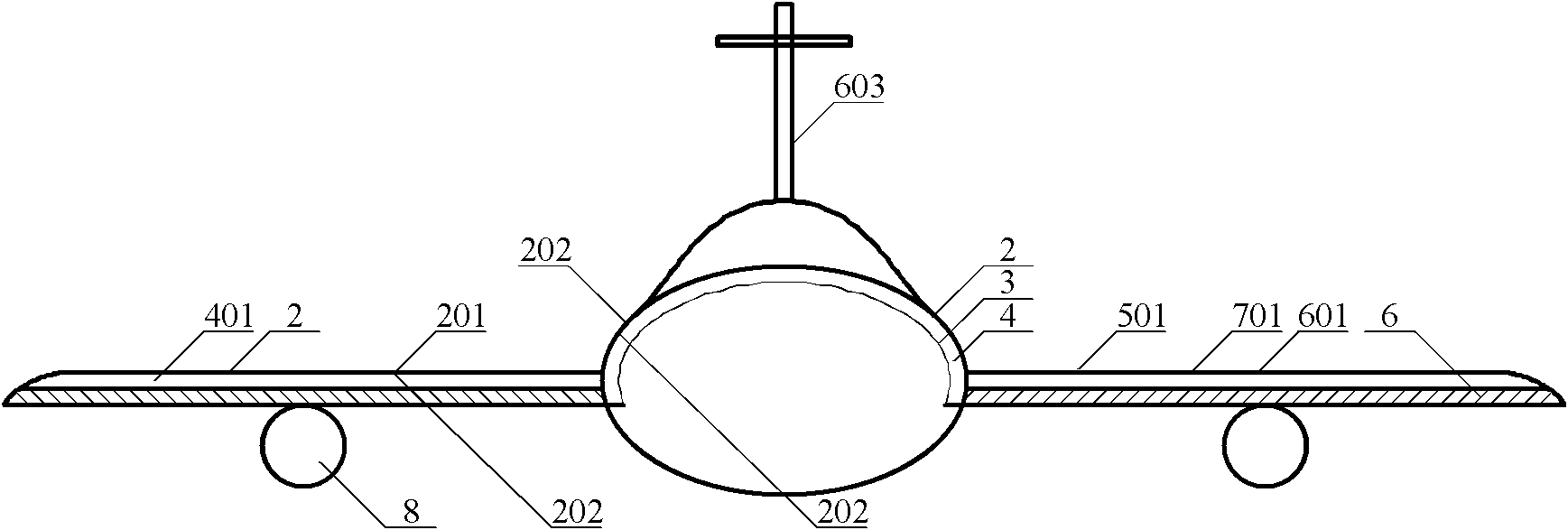

ActiveCN101941522AOvercome consumptionEasy to liftWing adjustmentsHeat reducing structuresFlight directionEngineering

The invention discloses a flying device which comprises a device main body, a sealed inner shell located on the device main body and an outer shell located outside the inner shell. An air channel is arranged between the inner shell and the outer shell; the outer shell located on the upper part of the device main body comprises a plurality of spoilers, and a guide inlet and a guide outlet which are communicated with the outside are arranged between every two spoilers or on each spoiler per se. The air channel is communicated with the guide inlet and the guide outlet respectively; the surface path passed by fluid on the external surfaces of the spoilers is longer than the air path in the air channel on internal surfaces of the spoilers in a corresponding zone, therefore, a high pressure zone produced by low flow rate in the air channel is transferred to a low pressure zone produced by high flow rate outside the outer shell from the guide outlet; and the surface path passed by fluid on the outer shell part at the upper part of the wing is longer than the surface path of the outer shell part at the lower part of the wing in the flying direction. The invention can increase the speed ofthe flying device and can save energy.

Owner:朱晓义

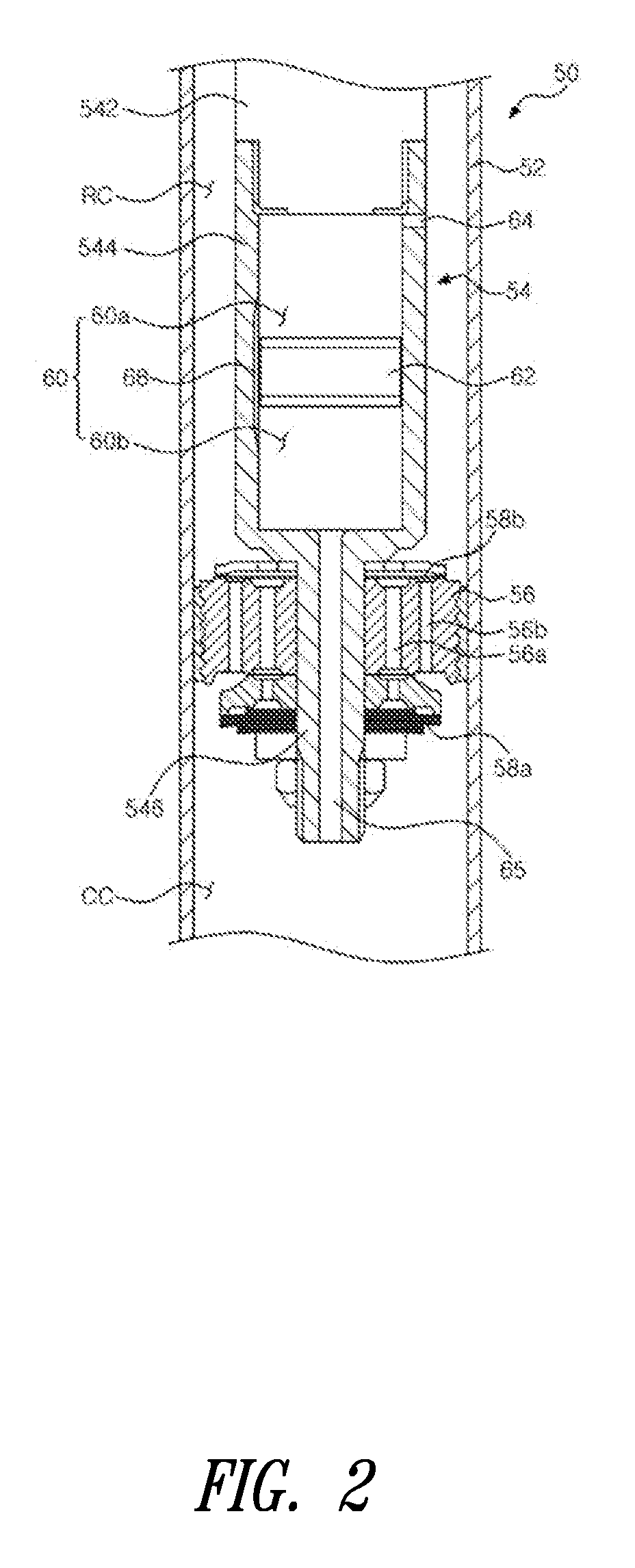

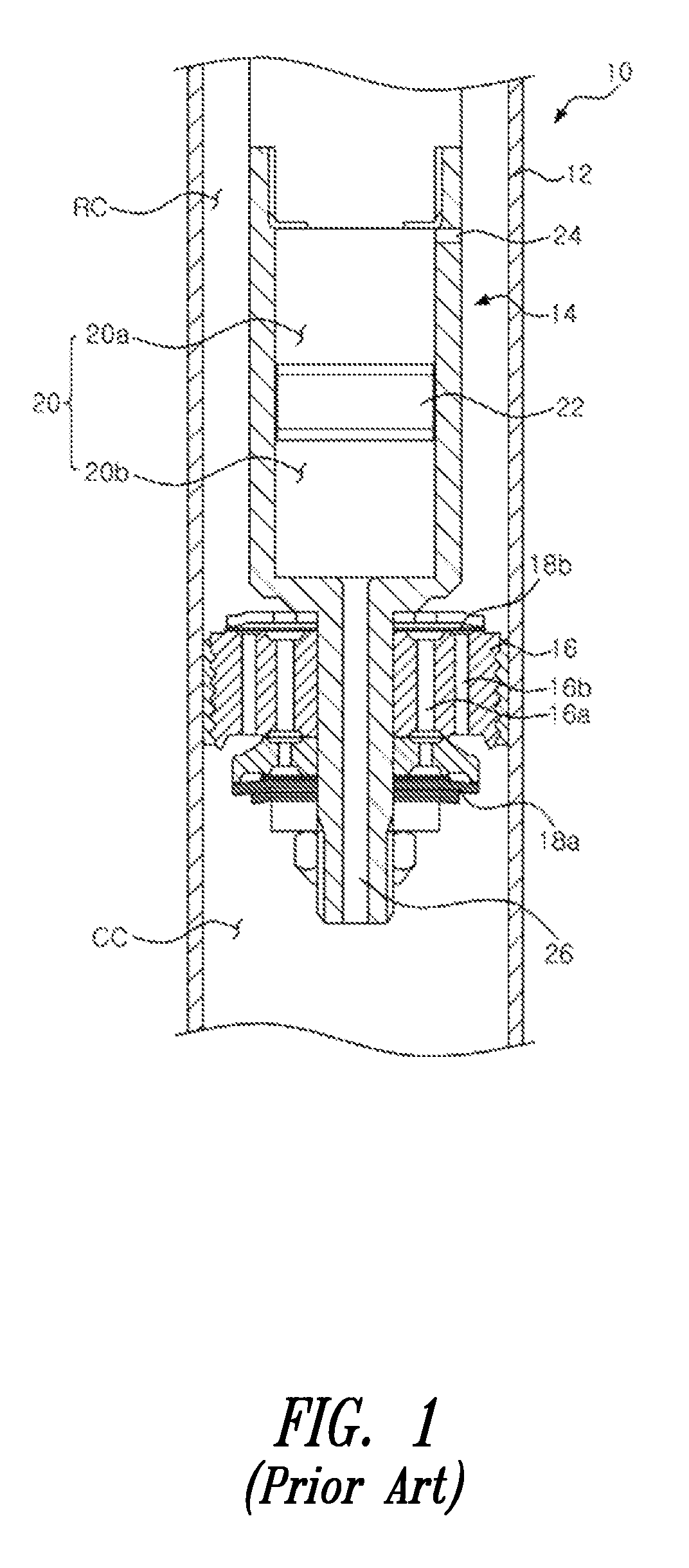

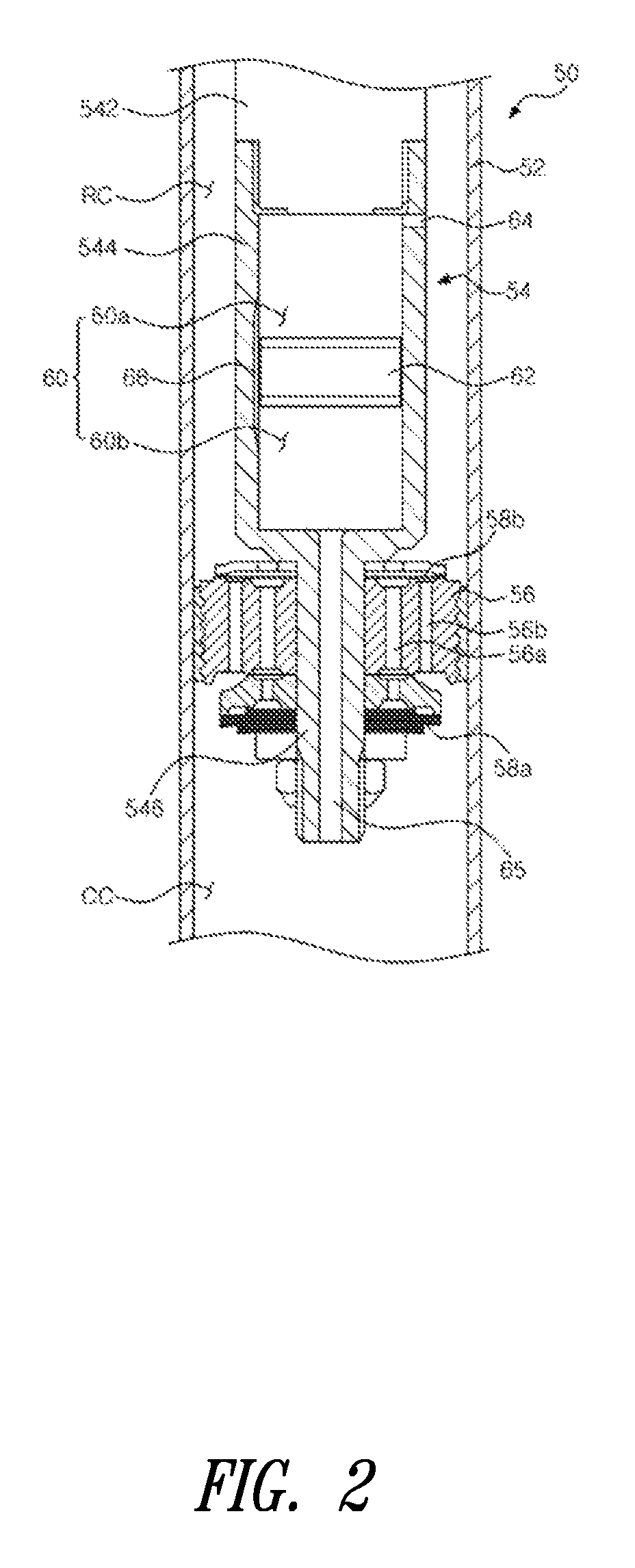

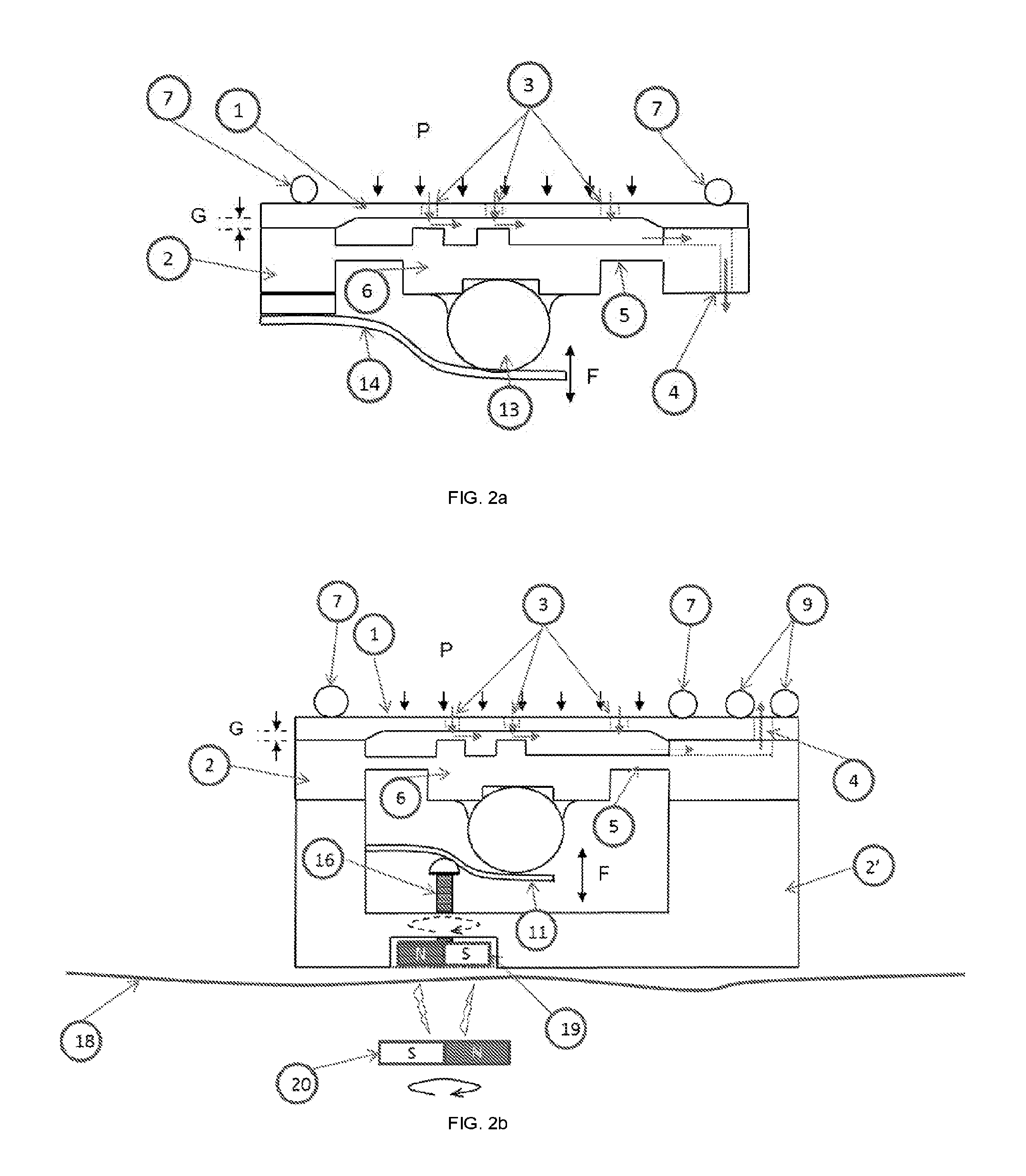

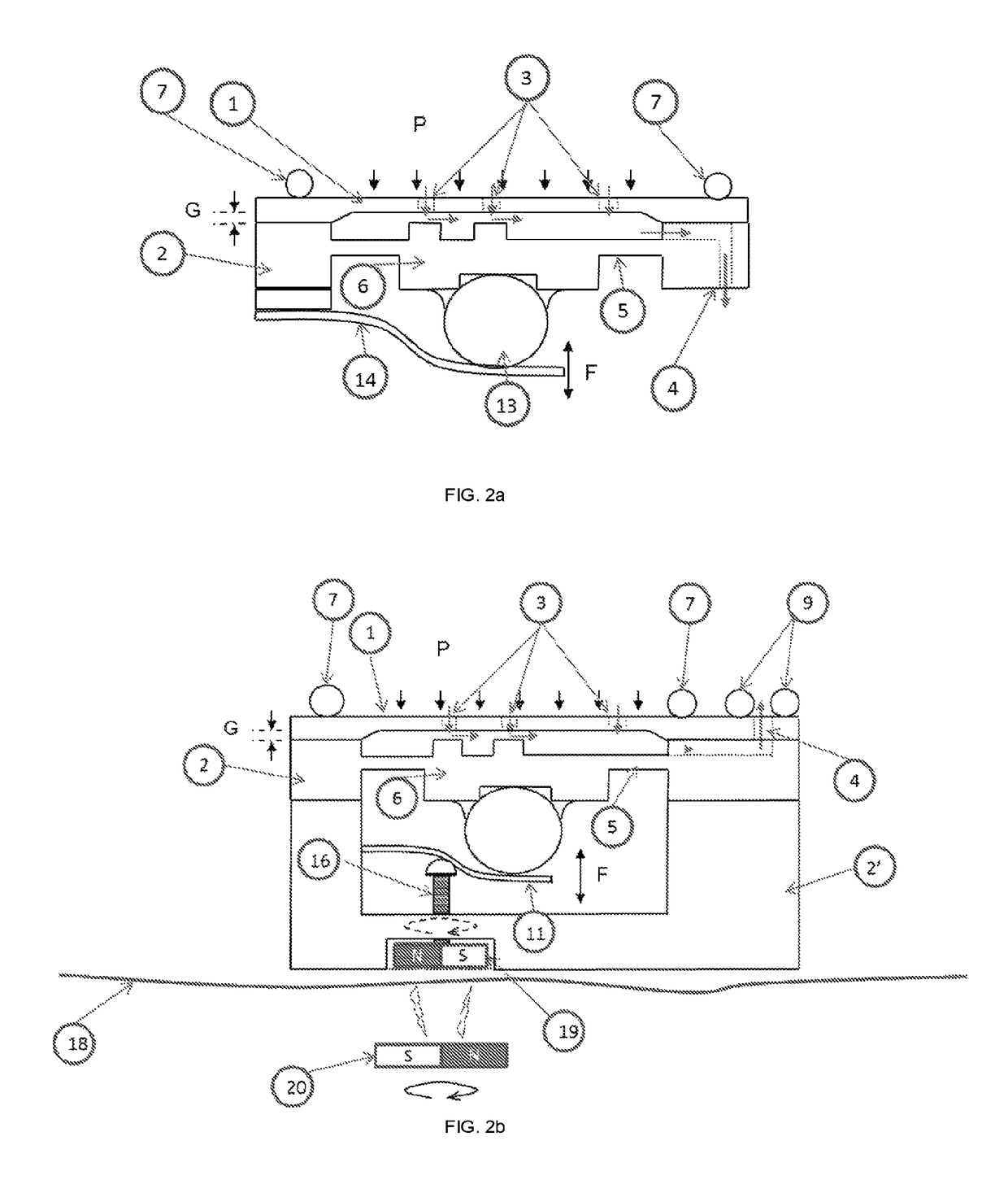

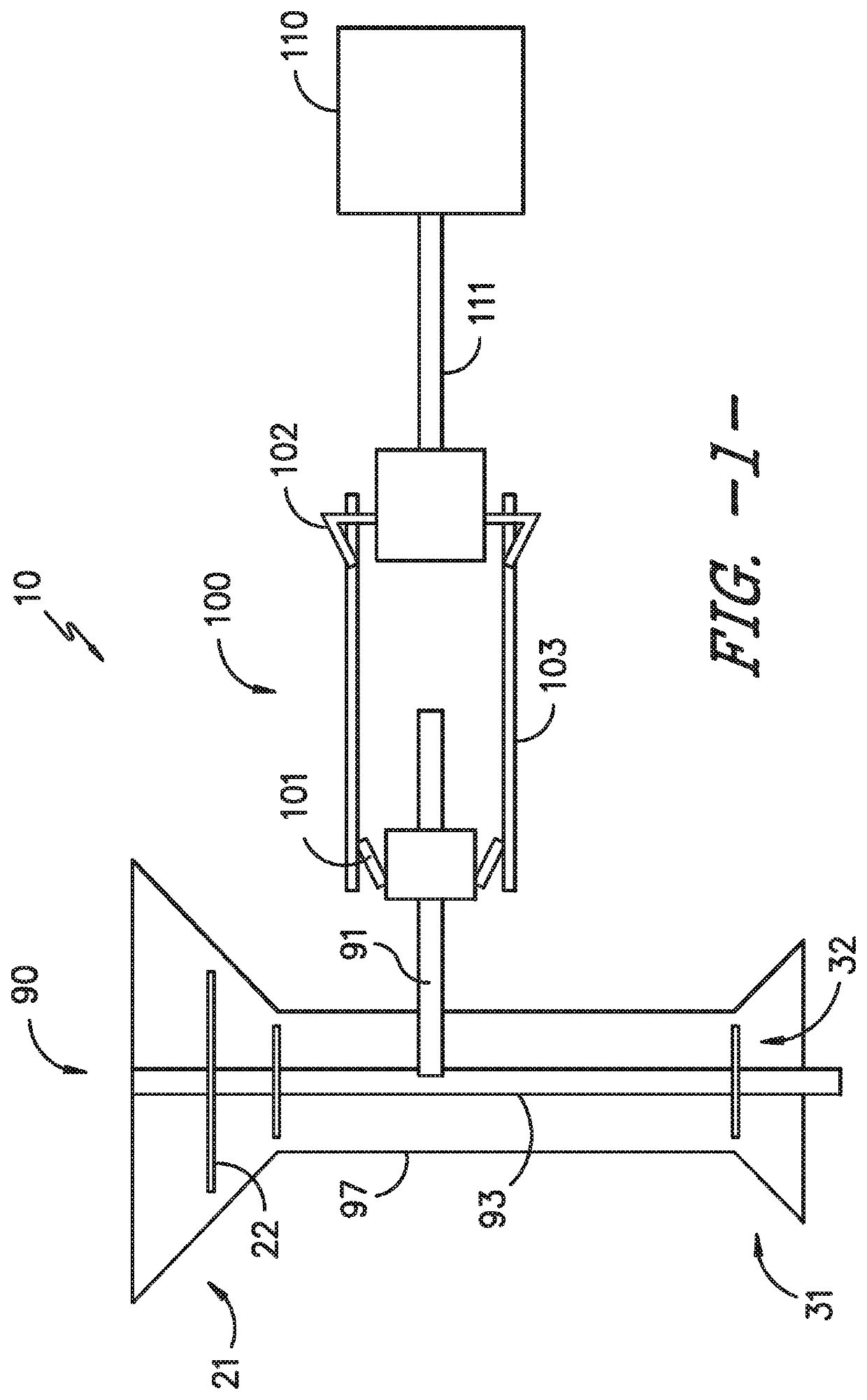

Microdispensing pump

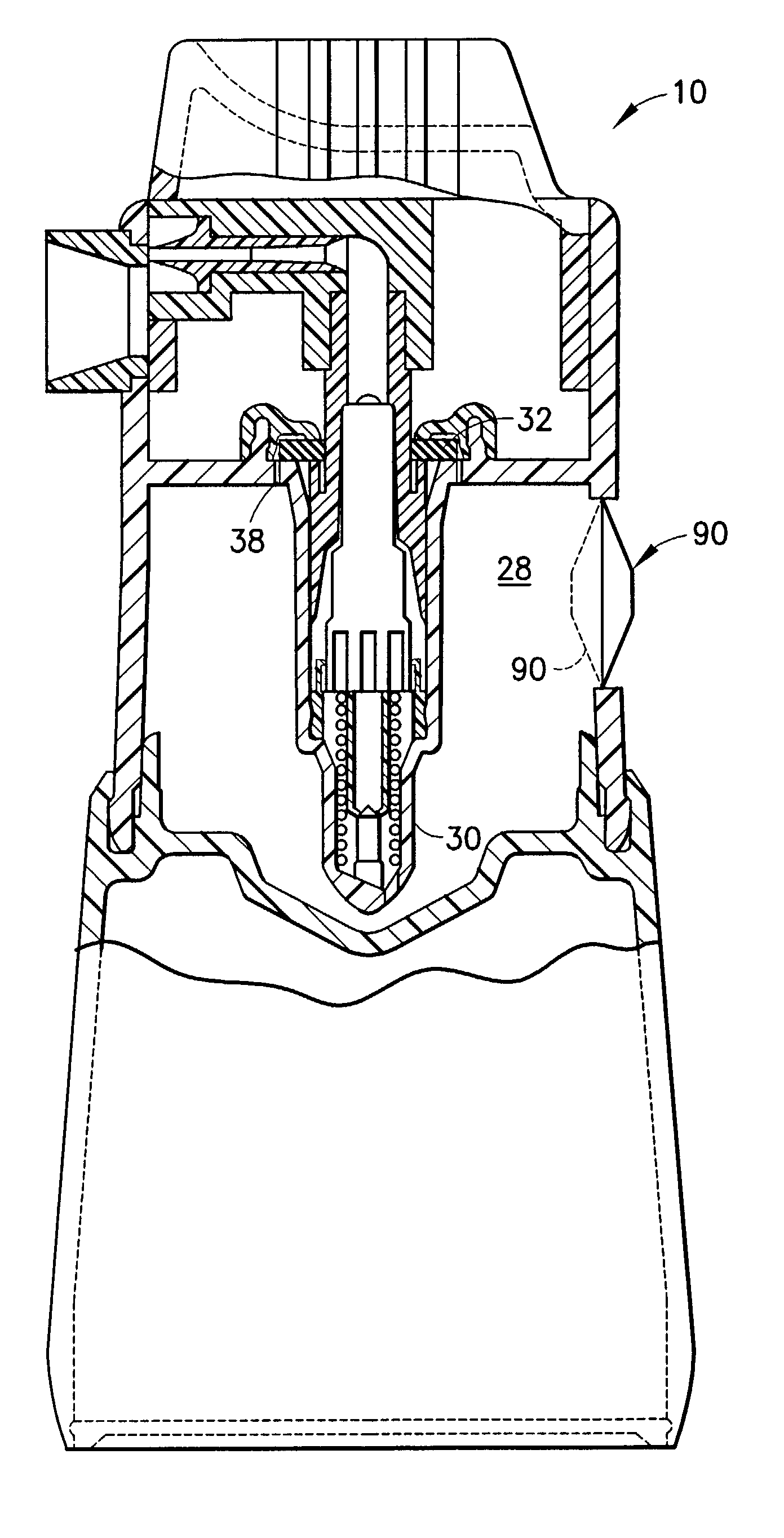

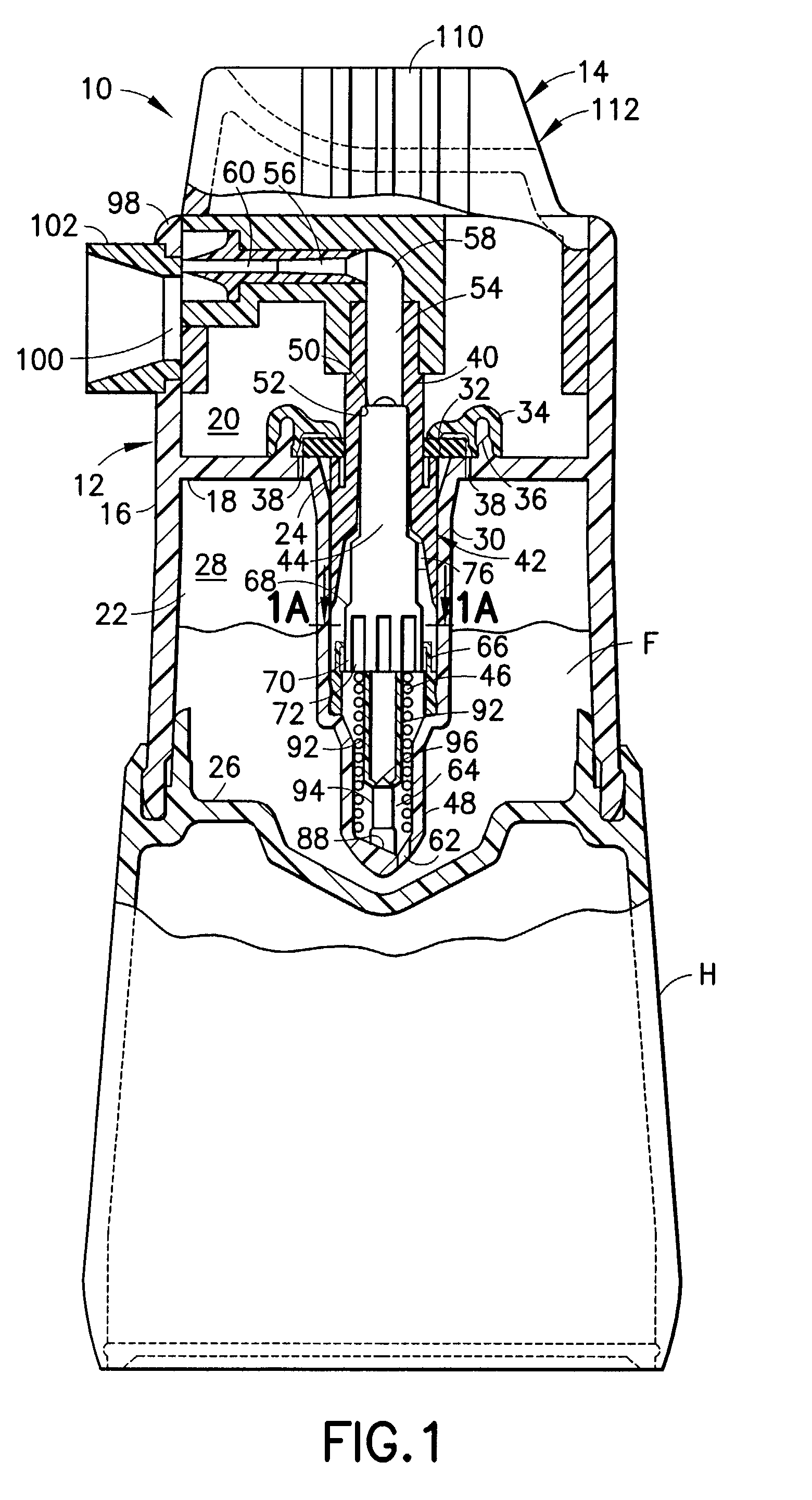

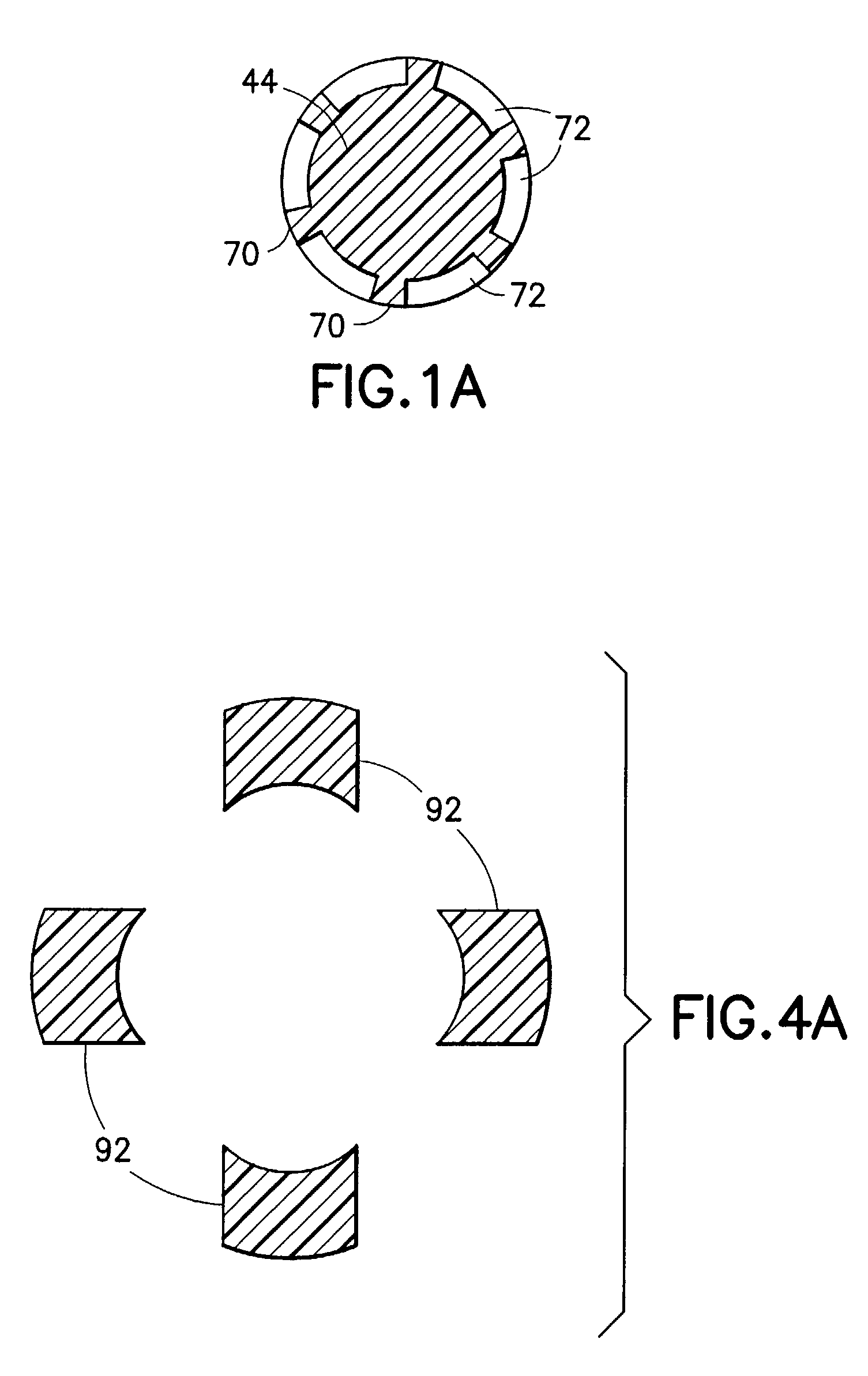

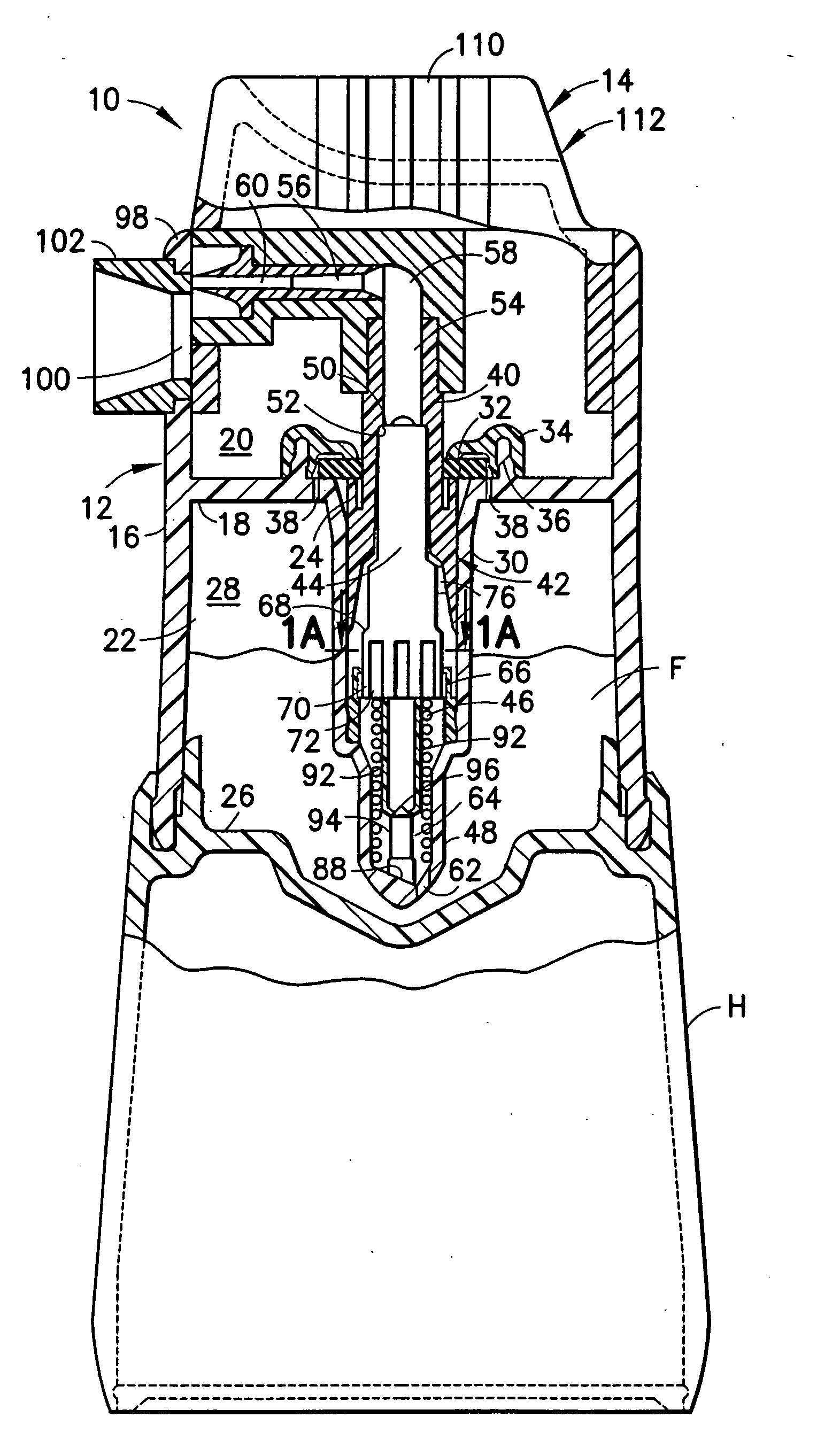

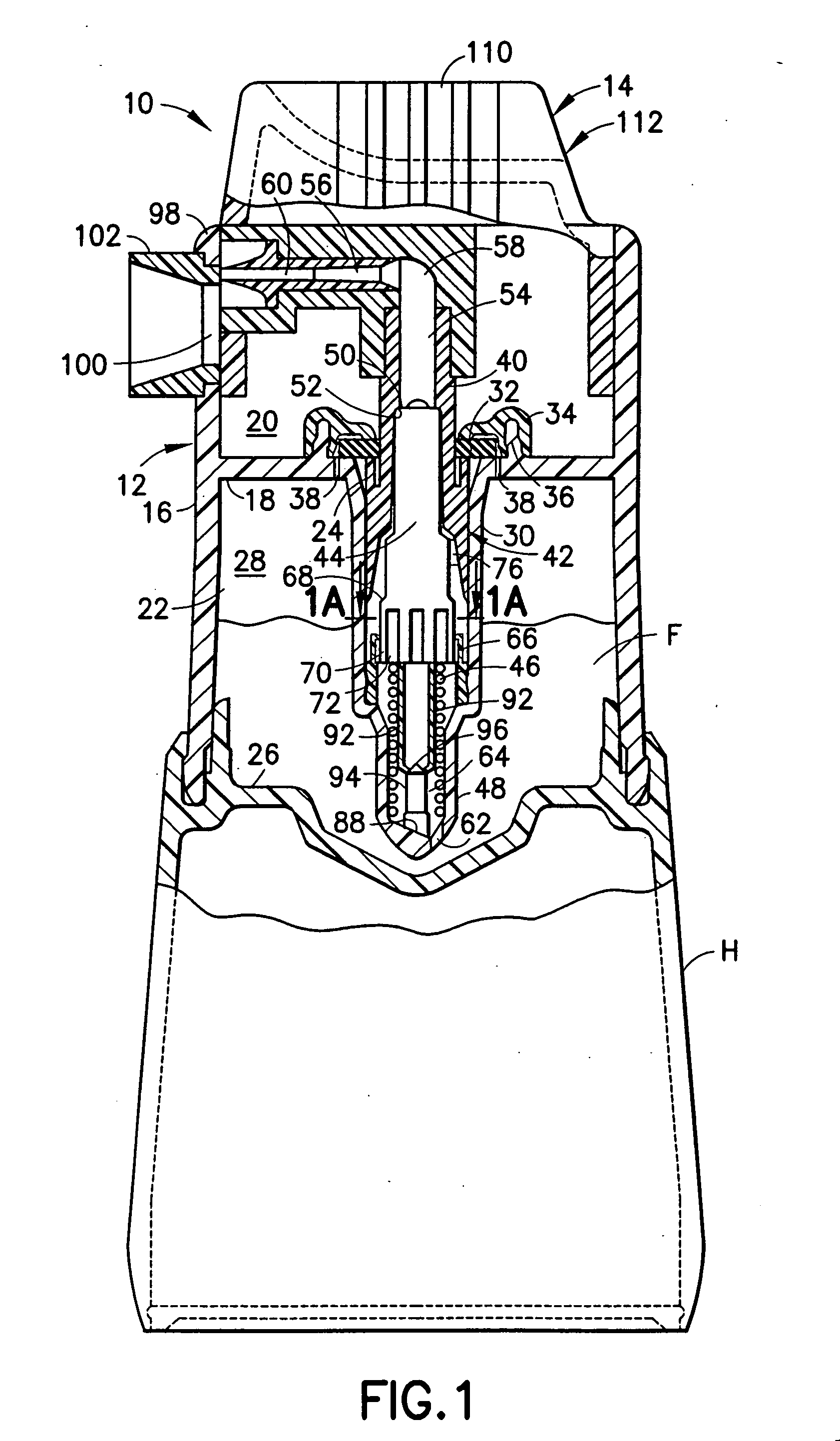

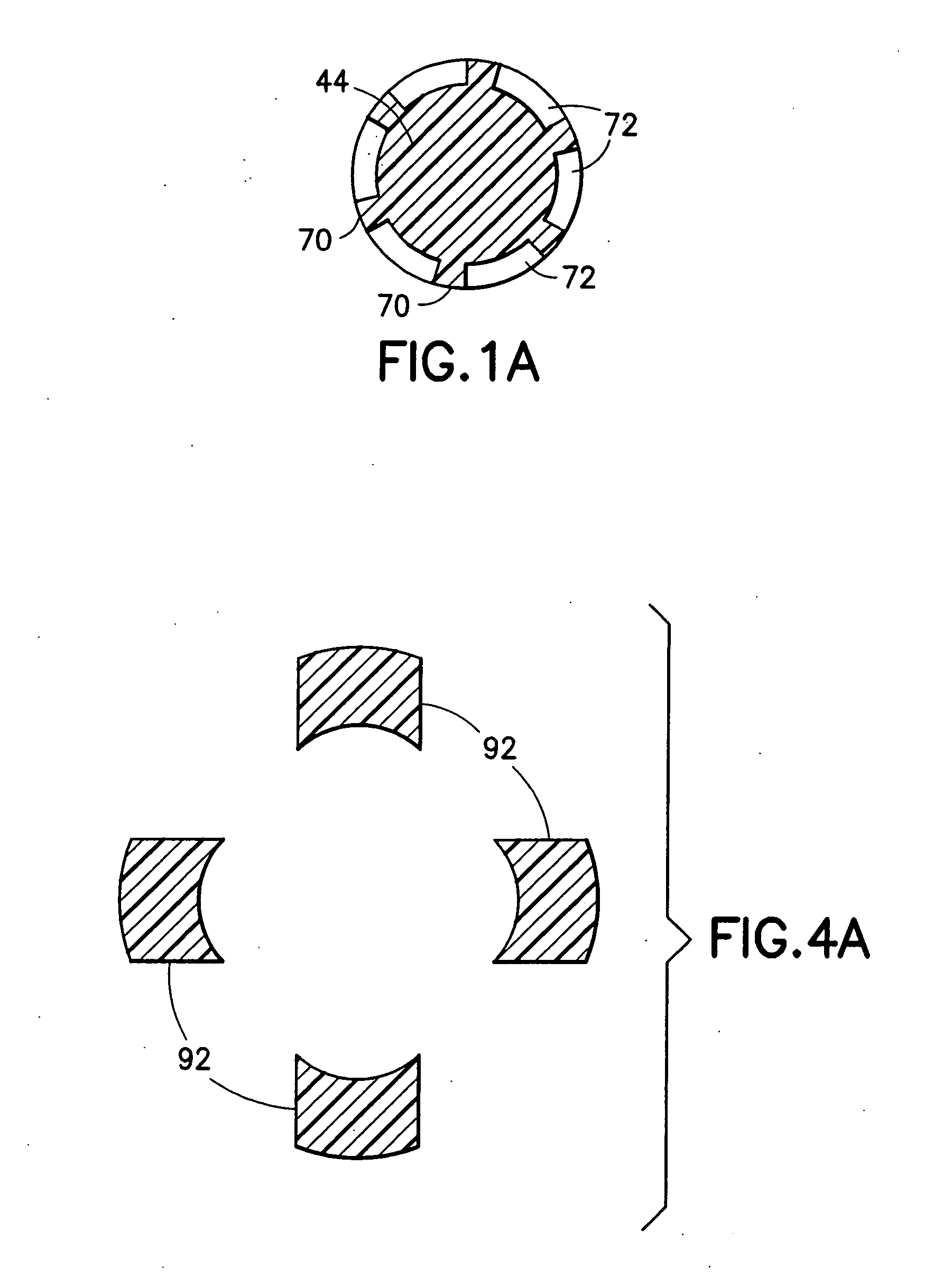

InactiveUS7014068B1Inhibit atomizationMinimizing throttlingLarge containersSingle-unit apparatusMomentumPre compression

A pre-compression pump (10) dispenses microdoses of fluid (F). The pump minimizes pulsing due to pressure fluctuations. The pump is provided with the following to limit pulsing: a low force slow return velocity return spring (46); enlarged fluid passage (58); elastic bumper (74); and, a ratchet tooth (76) bearing against the stem (44). Further, a deflectable diaphragm (90), a splined (70) stem (44), no dip tube, and an off-center, gravitational low-point pump inlet (62) assist in priming the pump. The pump includes a stem (44) with delfectable fingers (92) to ensure sufficient momentum in pump operation. Detents (118) and grooves (120) selectively lock a nozzle cap (14) in an inoperative position. To ensure cleanliness, nozzle (60) cleaning is provided, wiping of the nozzle to remove meniscus (M) therefrom, cuts (104) formed in a shroud (98) assist in drawing excess fluid from the nozzle, and an empty volume (108) for collecting fluid run-off from the nozzle. A handle (H) is mounted to the pump providing a grip.

Owner:COHEN

Microdispensing pump

InactiveUS20060086760A1Inhibit atomizationMinimizing throttlingLarge containersSingle-unit apparatusMomentumPre compression

A pre-compression pump (10) dispenses microdoses of fluid (F). The pump minimizes pulsing due to pressure fluctuations. The pump is provided with the following to limit pulsing: a low force slow return velocity return spring (46); enlarged fluid passage (58); elastic bumper (74); and, a rachet tooth (76) bearing against the stem (44). Further, a deflectable diaphragm (90), a splined (70) stem (44), no dip tube, and an off-center, gravitational low-point pump inlet (62) assist in printing the pump. The pump includes a stem (44) with deflectable fingers (92) to ensure sufficient momentum in pump operation. Detents (118) and grooves (120) selectively lock a nozzle cap (14) in an inoperative position. To ensure cleanliness, nozzle (60) cleaning is provided, wiping of the nozzle to remove meniscus (M) therefrom, cuts (104) formed in a shroud (98) assist in drawing excess fluid from the nozzle, and an empty volume (108) for collecting fluid run-off from the nozzle. A handle (H) is mounted to the pump providing a grip.

Owner:COHEN

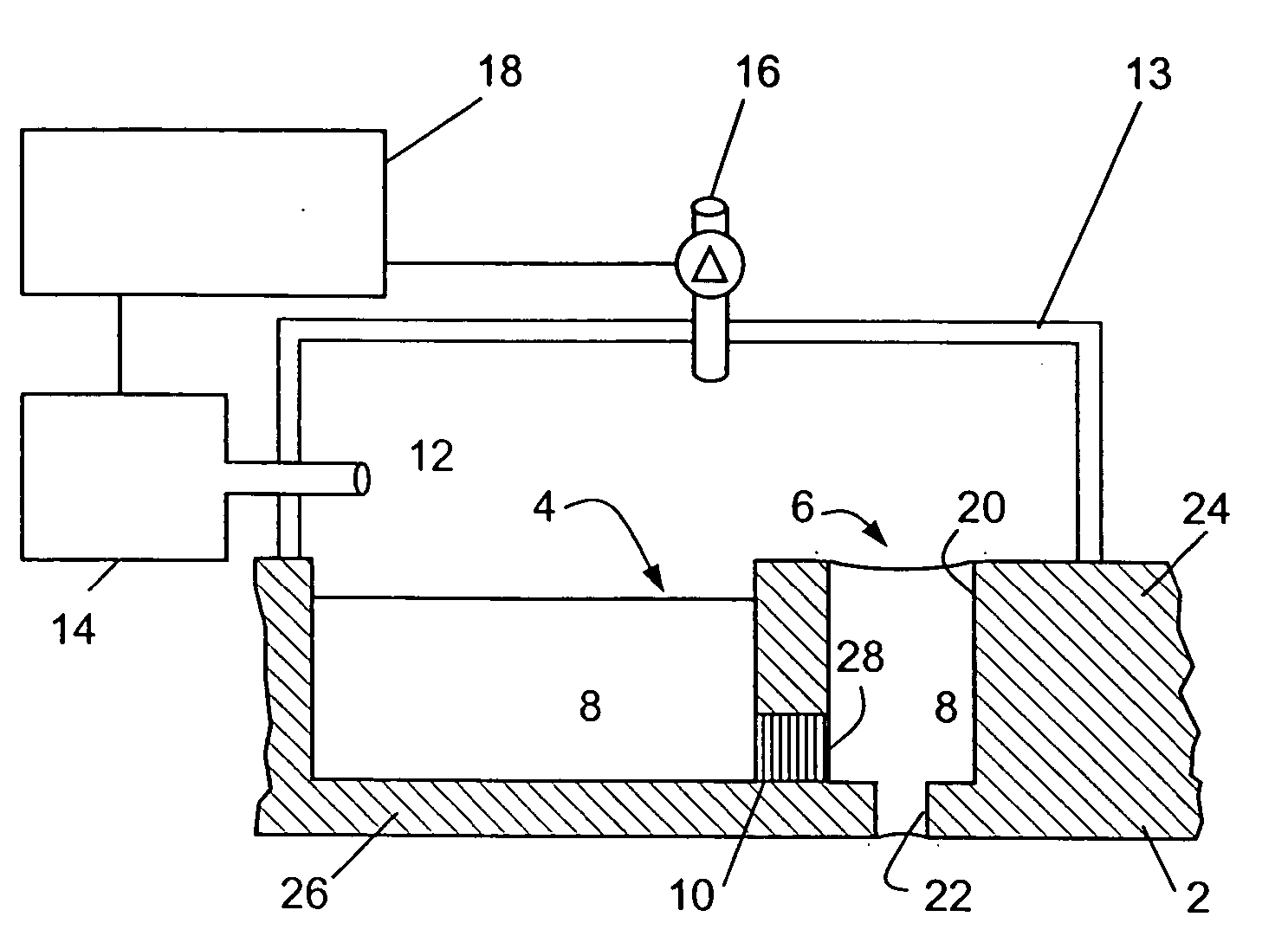

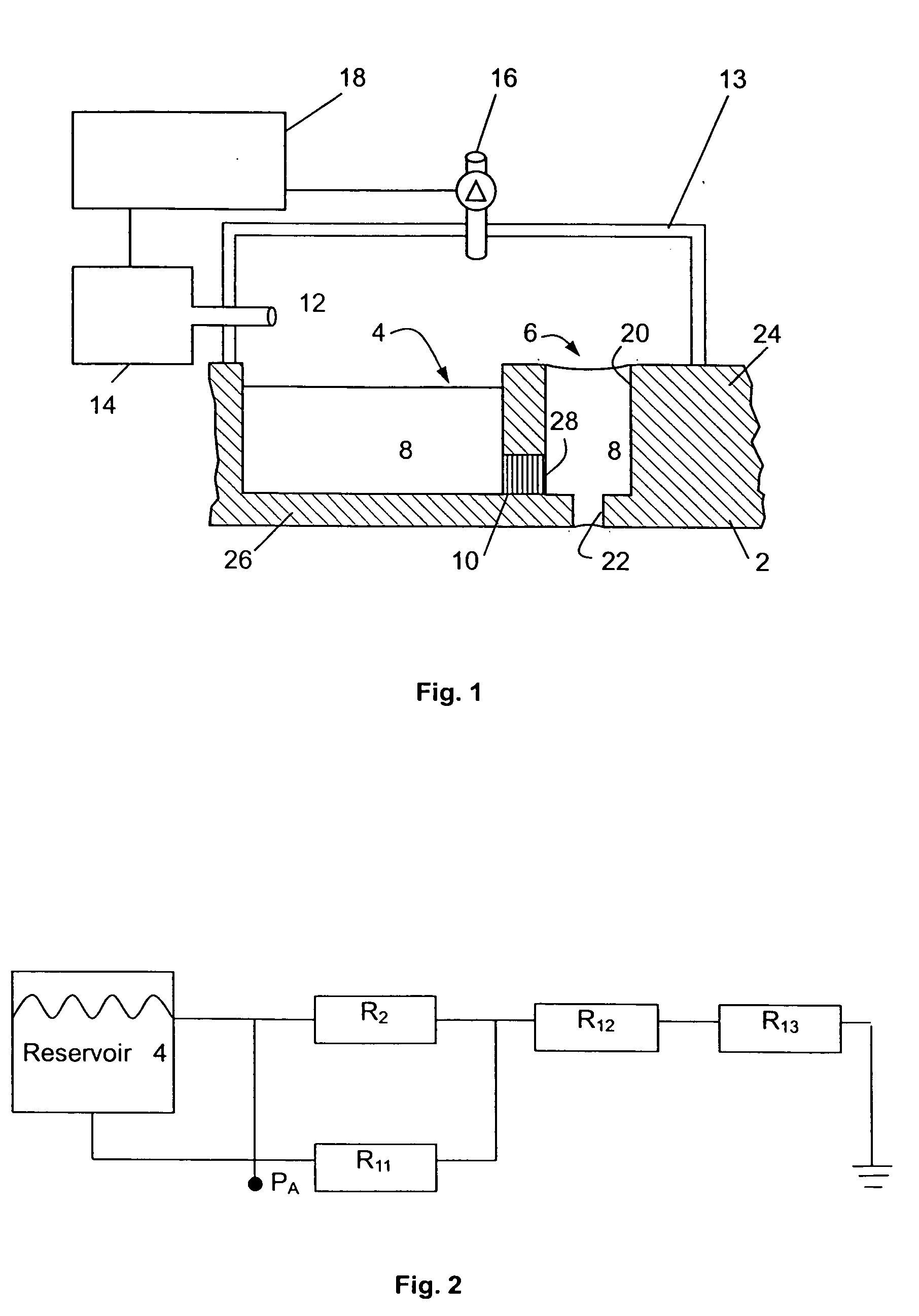

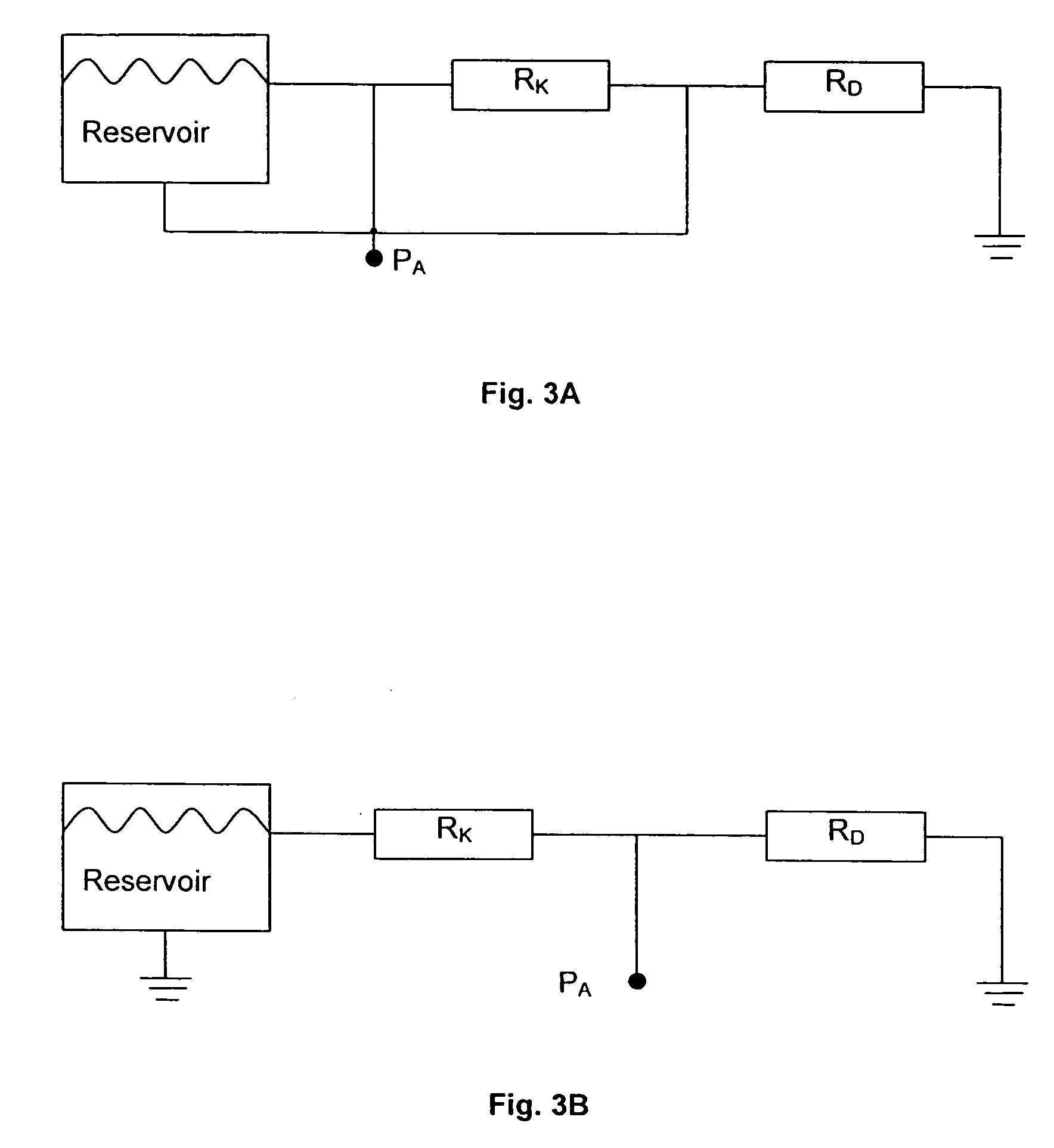

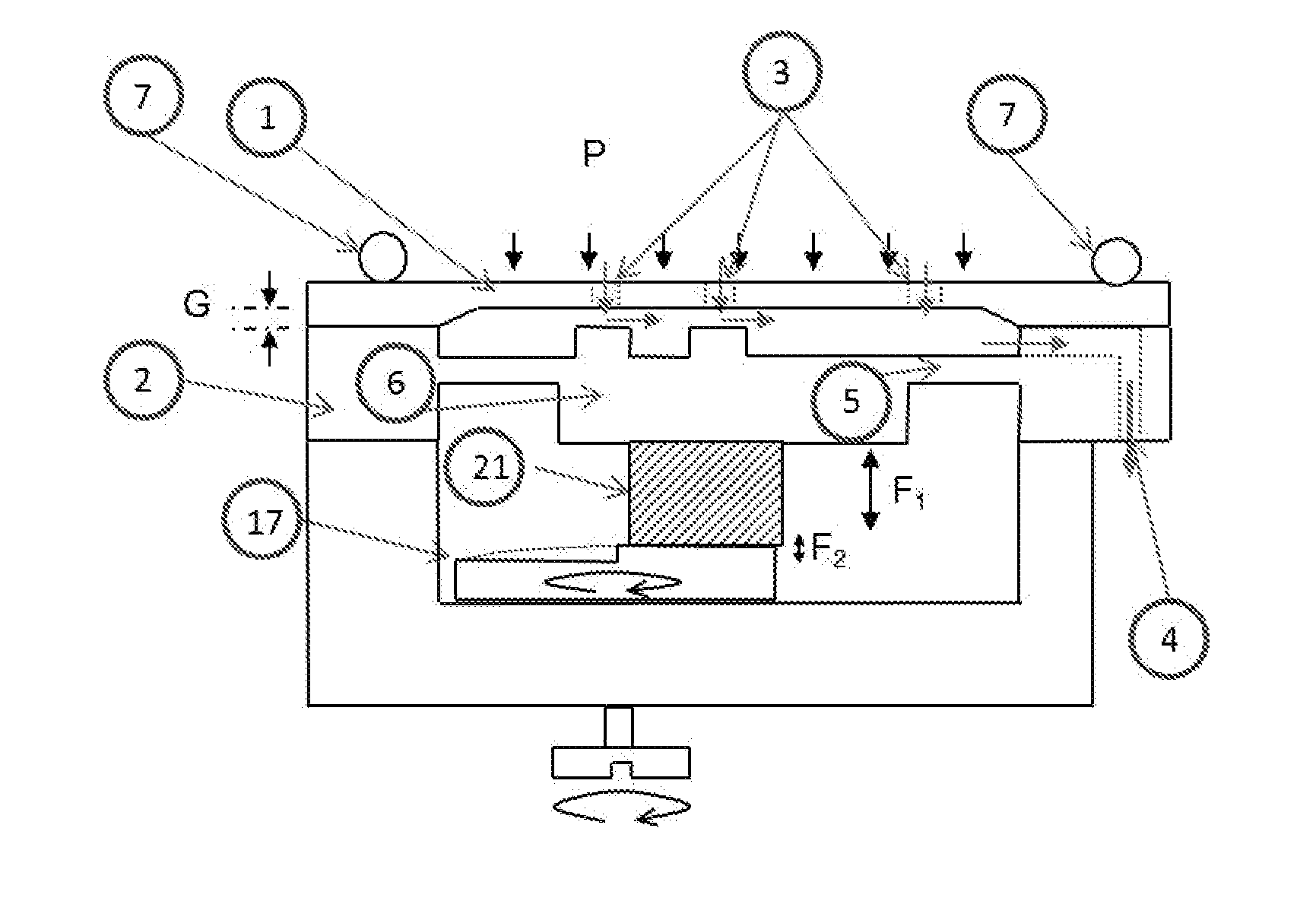

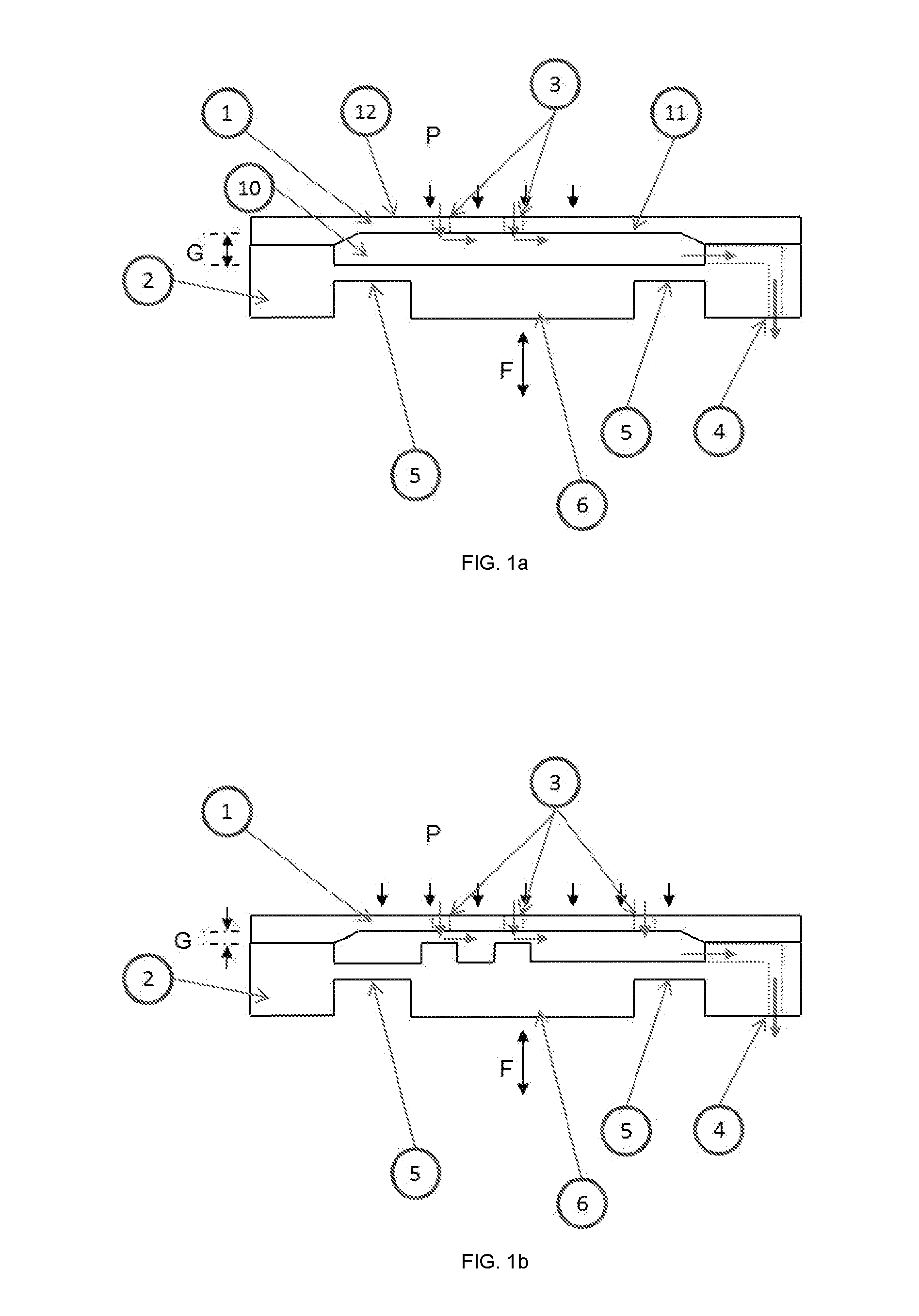

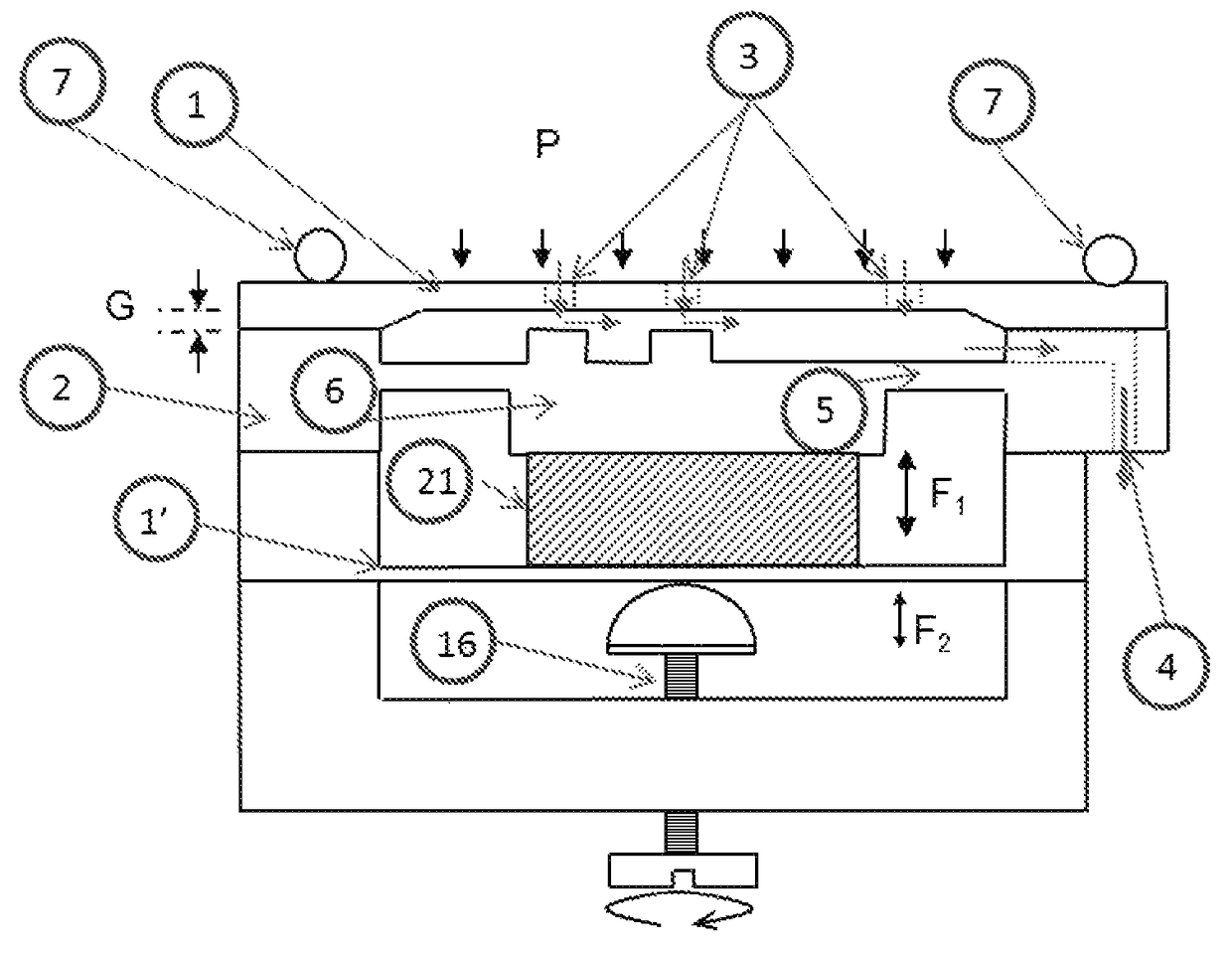

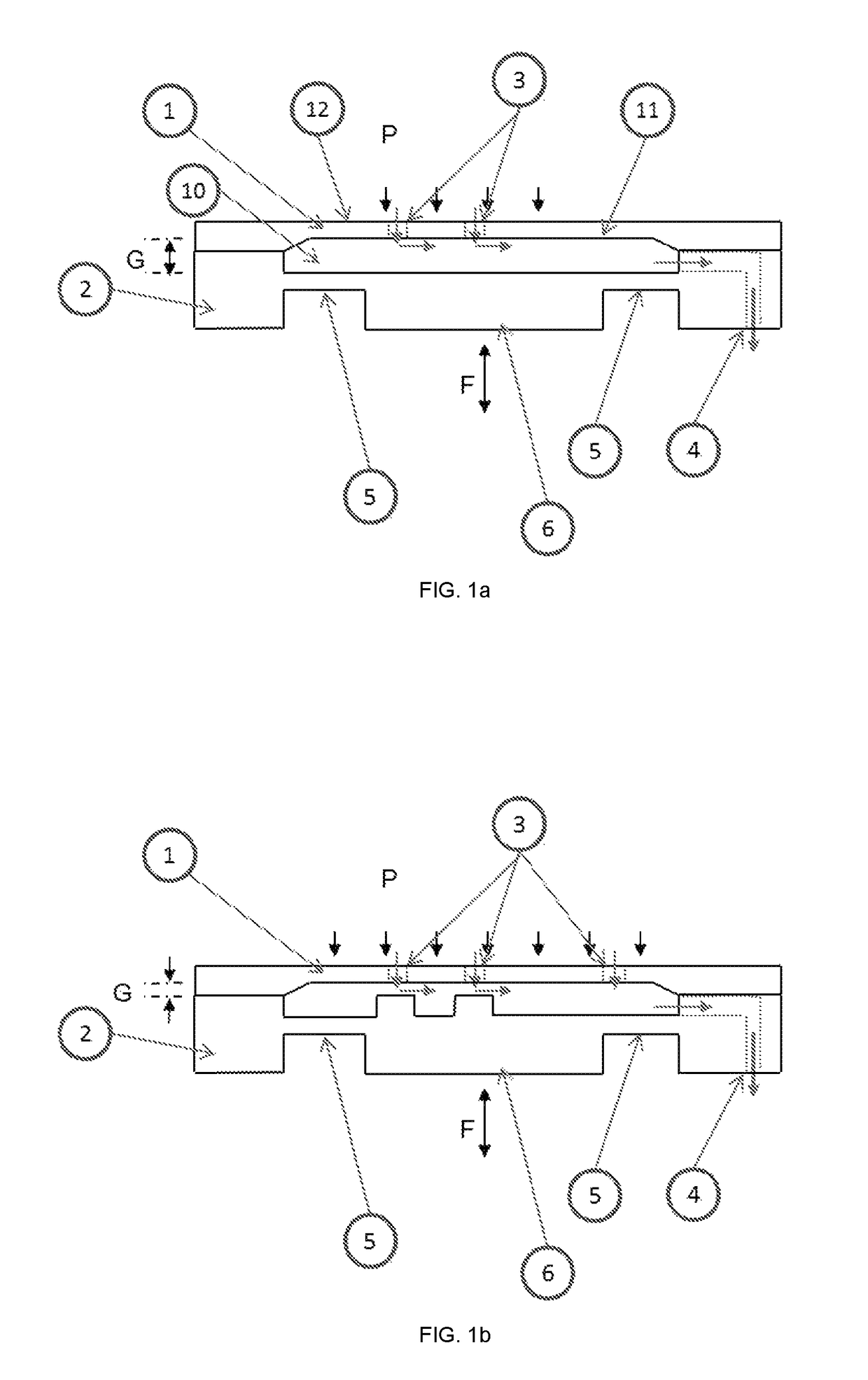

Device and method for dosing small amounts of liquid

ActiveUS20040074557A1Increase fluid resistanceEfficient separationSolid materialBurettes/pipettesNozzleEngineering

A microdosage device comprises a media reservoir used for accommodating a liquid to be dosed, a nozzle connected via a connecting channel to the media reservoir and adapted to be filled via said connecting channel with the liquid to be dosed, and a drive unit for applying, when actuated, to a liquid contained in the media reservoir and in the nozzle a force of such a nature that a substantially identical pressure will be exerted on said liquid contained in the media reservoir and in the nozzle. Flow resistances of the connecting channel and of the nozzle are dimensioned such that, in response to an actuation of the drive unit, a volumetric flow in the connecting channel will be small in comparison with a volumetric flow in the nozzle, said volumetric flow in the nozzle causing an ejection of the liquid to be dosed from an ejection opening of the nozzle.

Owner:BIOFLUIDIX

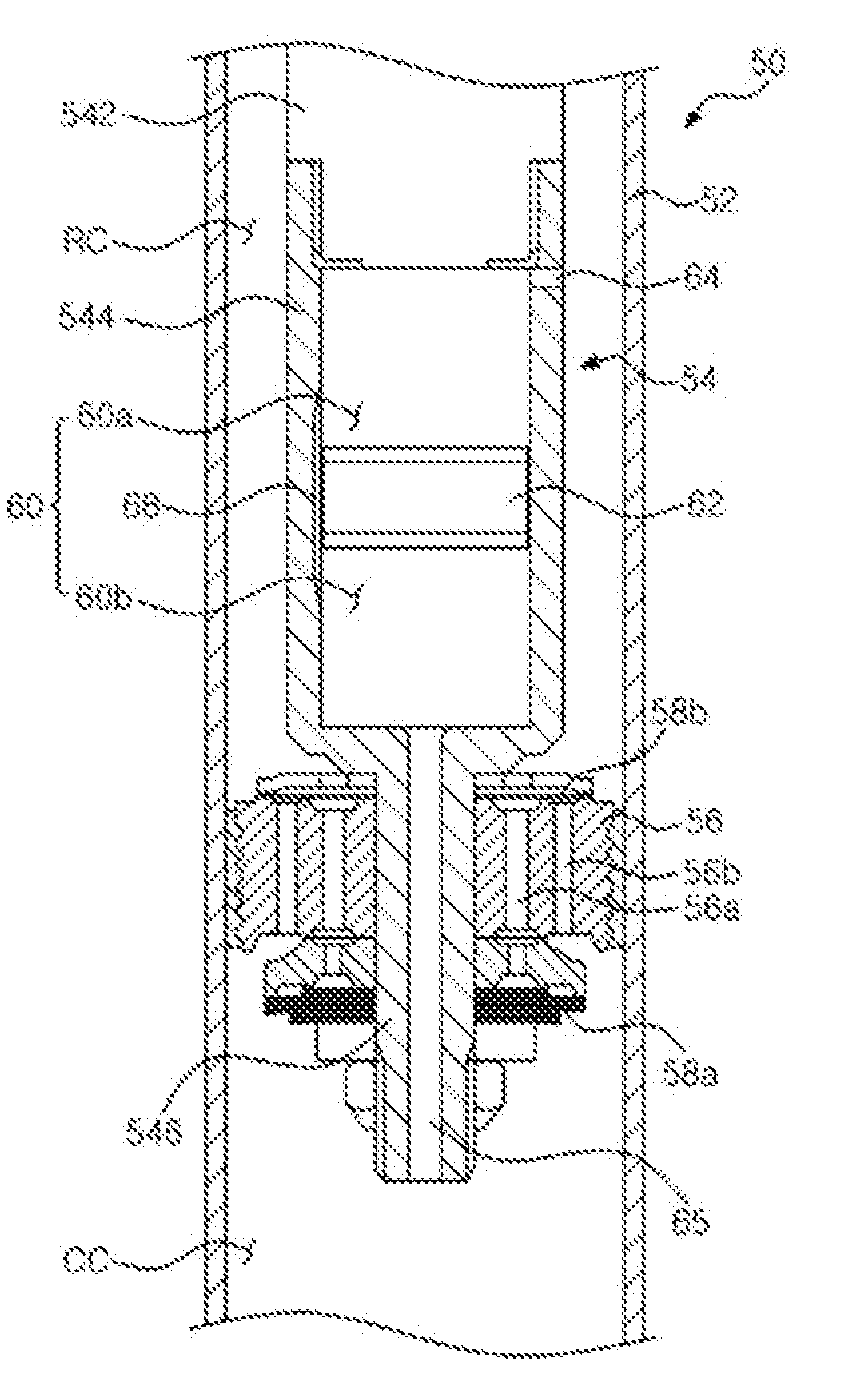

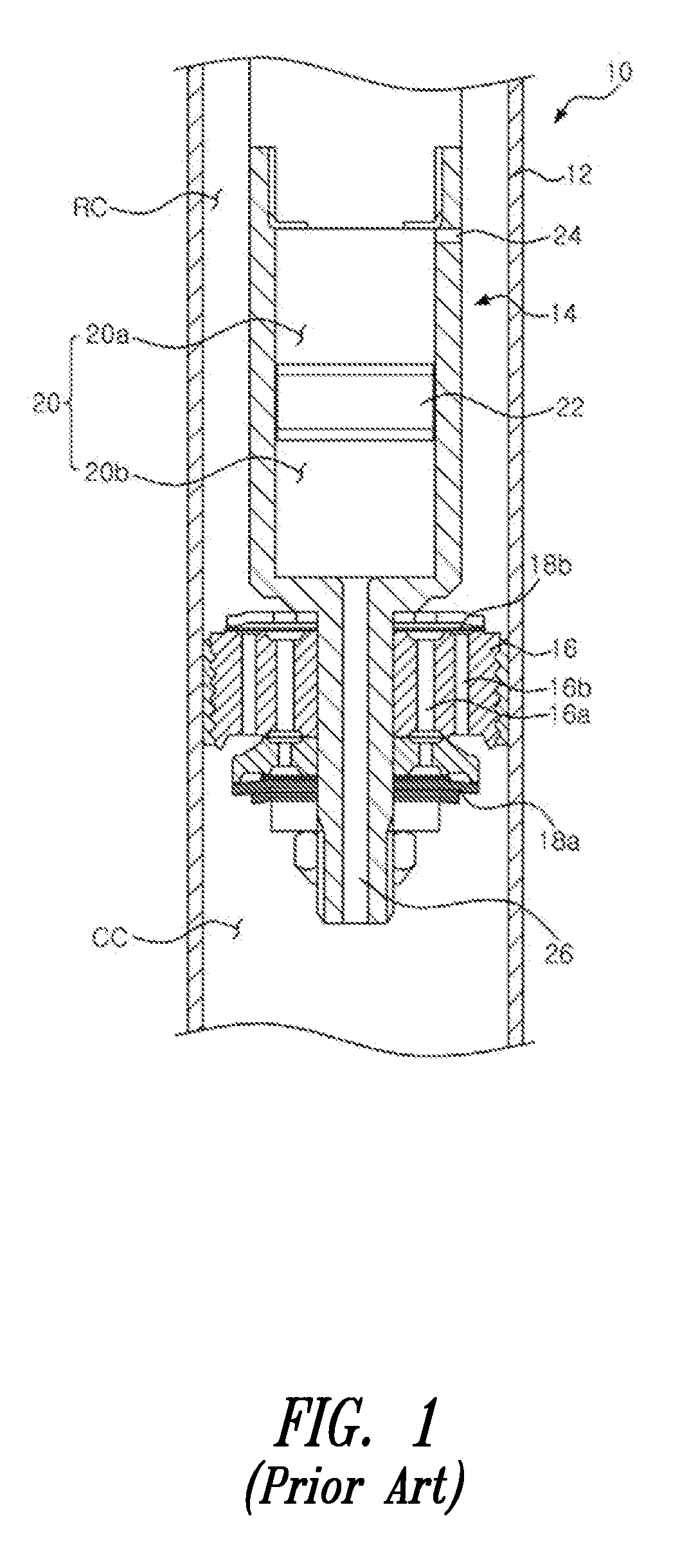

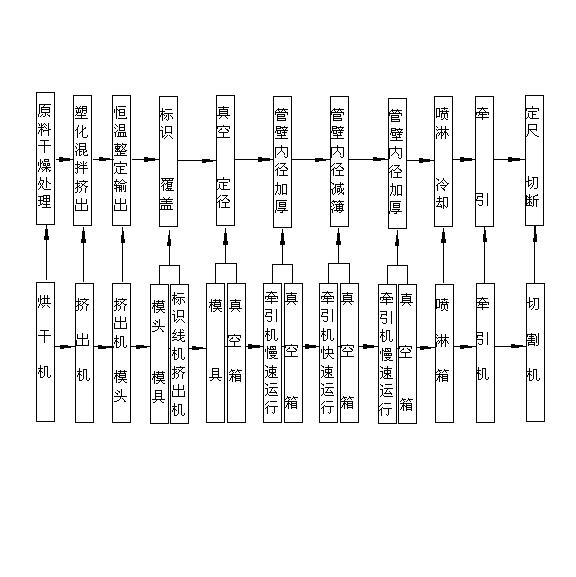

Shock absorber

ActiveUS20090145709A1Good sports characteristicsReduce damping forceSpringsShock absorbersEngineeringPiston rod

Disclosed herein is a shock absorber for damping vibration transmitted to a vehicle according to a road state. The shock absorber includes a cylinder and a piston valve disposed within the cylinder and connected to a piston rod to divide the cylinder into a first chamber and a second chamber. The shock absorber further includes a hollow chamber formed within the piston rod, a floating piston disposed within the hollow chamber to move up and down and to divide the hollow chamber into upper and lower chambers, first and second orifices formed in upper and lower ends of the hollow chamber and connected to the first and second chambers, respectively, and a resistance changing mechanism configured to cooperate with the floating piston and change a fluid resistance with respect to the floating piston where the resistance changing mechanism cooperates therewith.

Owner:HL MANDO CORP

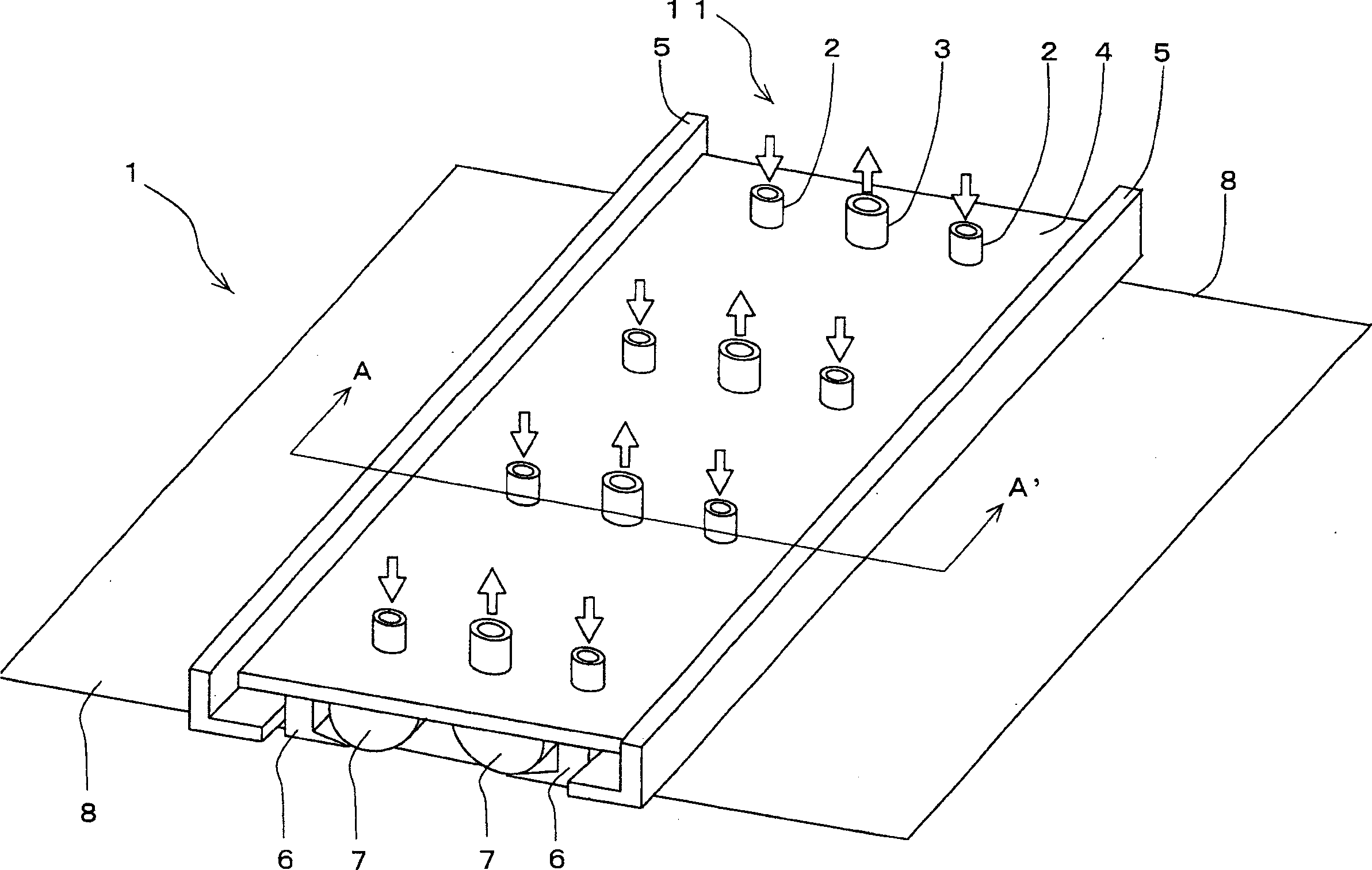

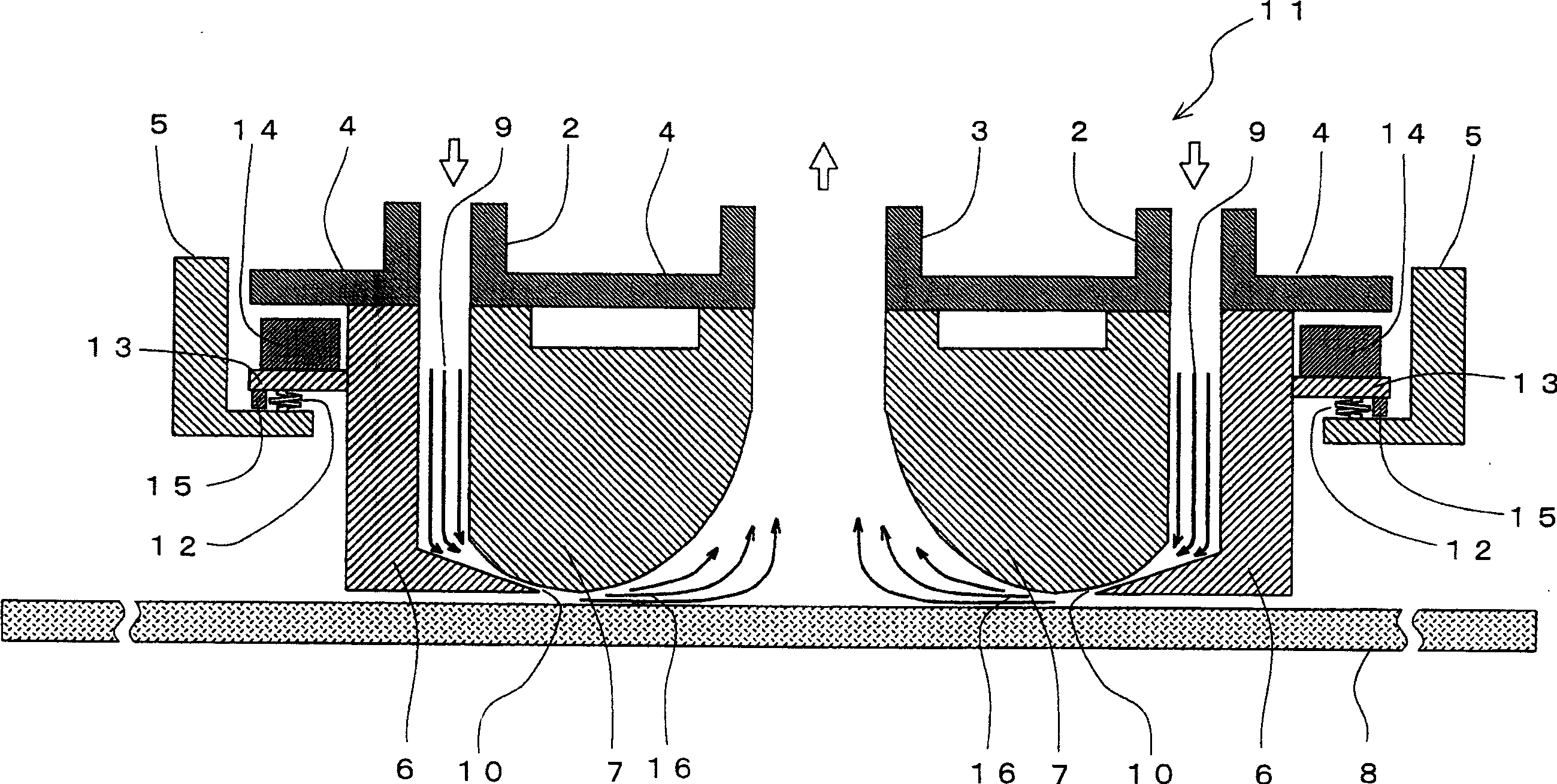

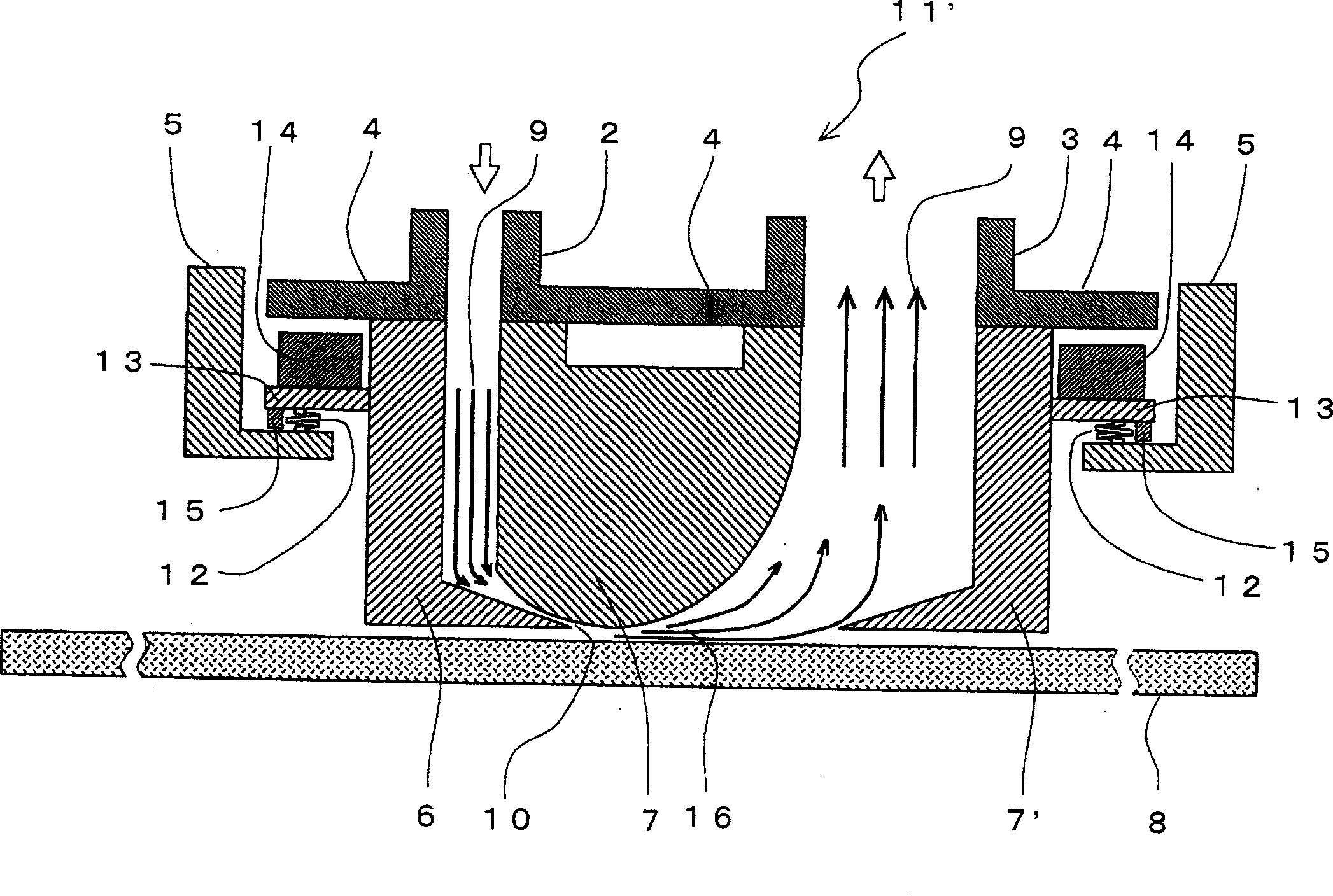

Wet treater

InactiveCN1751813AWon't spreadEasy dischargeSemiconductor/solid-state device manufacturingCleaning using liquidsBand shapeEngineering

To provide a wet treatment apparatus provided with a washing nozzle which is easy in the suction of a high viscosity fluid without using any ultrasonic wave, and has no left-over residue. A washing unit 11 arranged in the vicinity of a surface of a material to be washed 8, and having a supply port 2 with a slit discharge port 10 to discharge a fluid for cleaning 9 supplied from the outside in a belt shape on the surface of the material to be washed 8, and an outlet 3 discharging the fluid for cleaning 9 discharged from the discharge port 10 is provided. The washing unit where the cross-sectional area of the discharge port 10, the opening cross-sectional area of a tip portion to discharge the fluid for cleaning 9 toward the surface of the material to be washed 8, to the opening cross-sectional area of a supply port socket portion of the fluid for cleaning 9 supplied from the outside is one time a positive number exceeding one is arranged in a direction perpendicular to the moving direction of the material to be washed 8.

Owner:FUTURE VISION

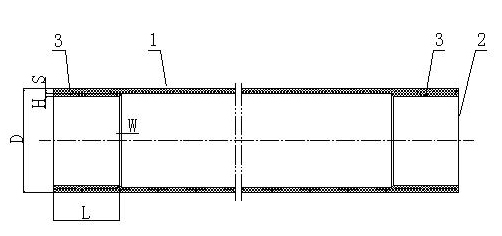

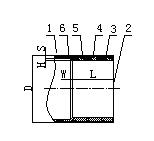

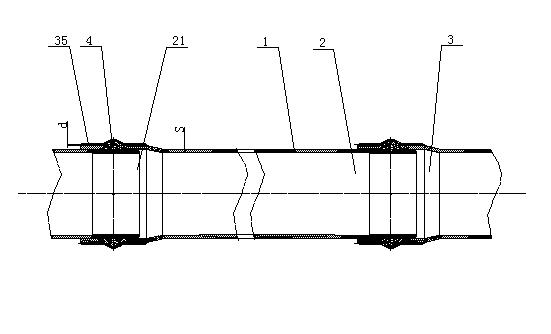

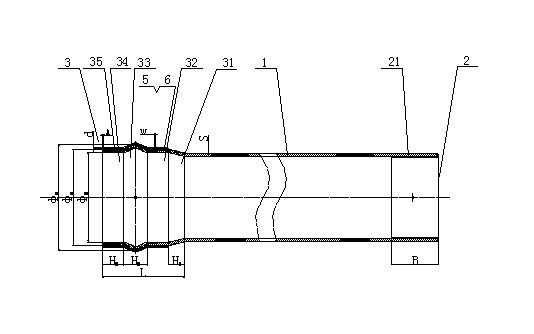

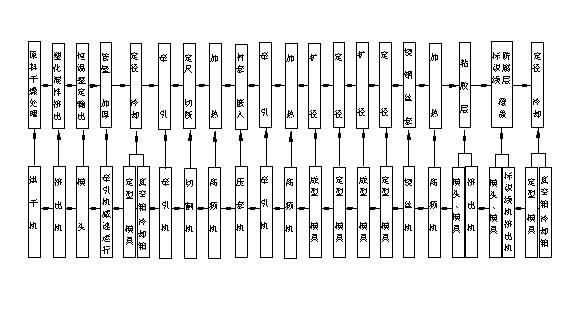

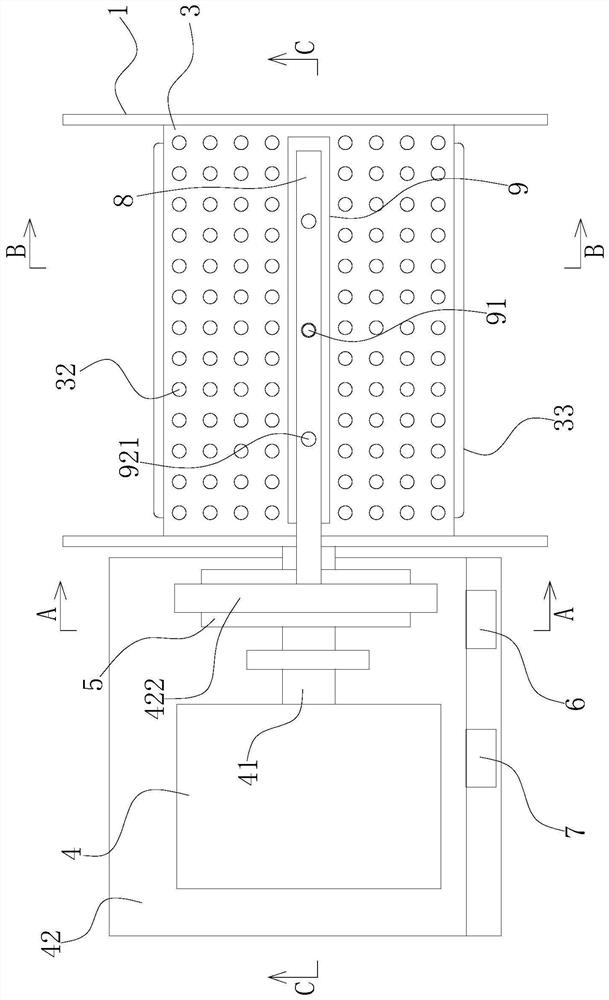

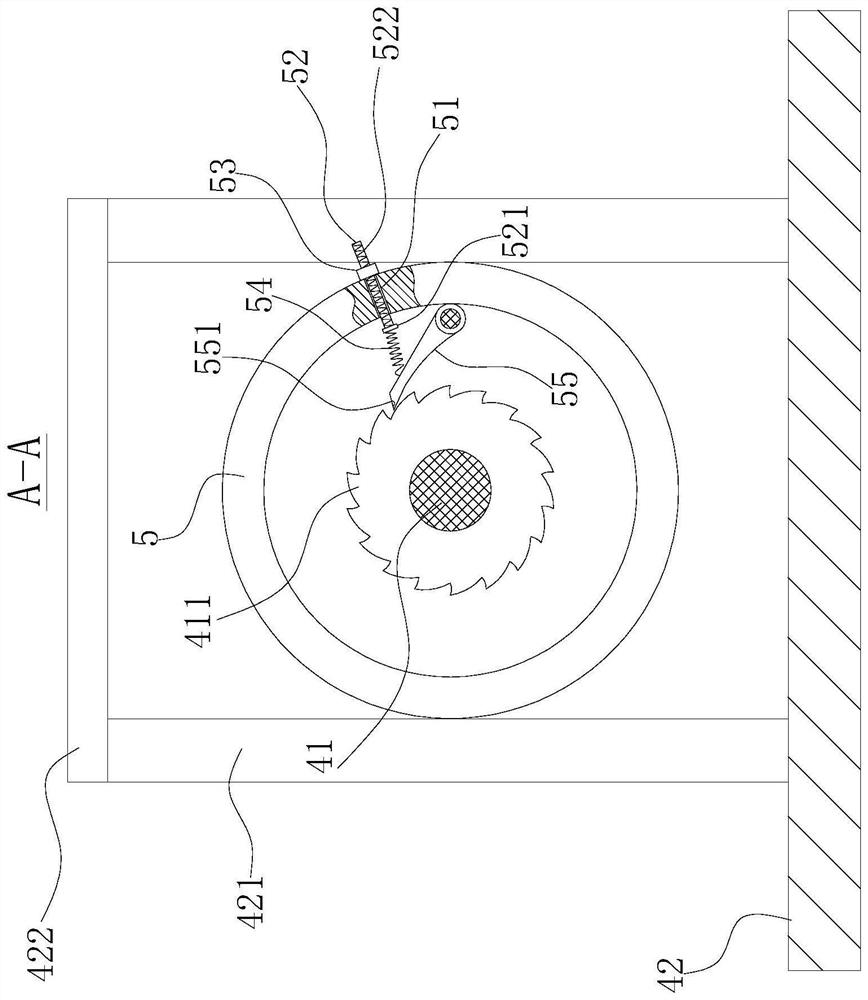

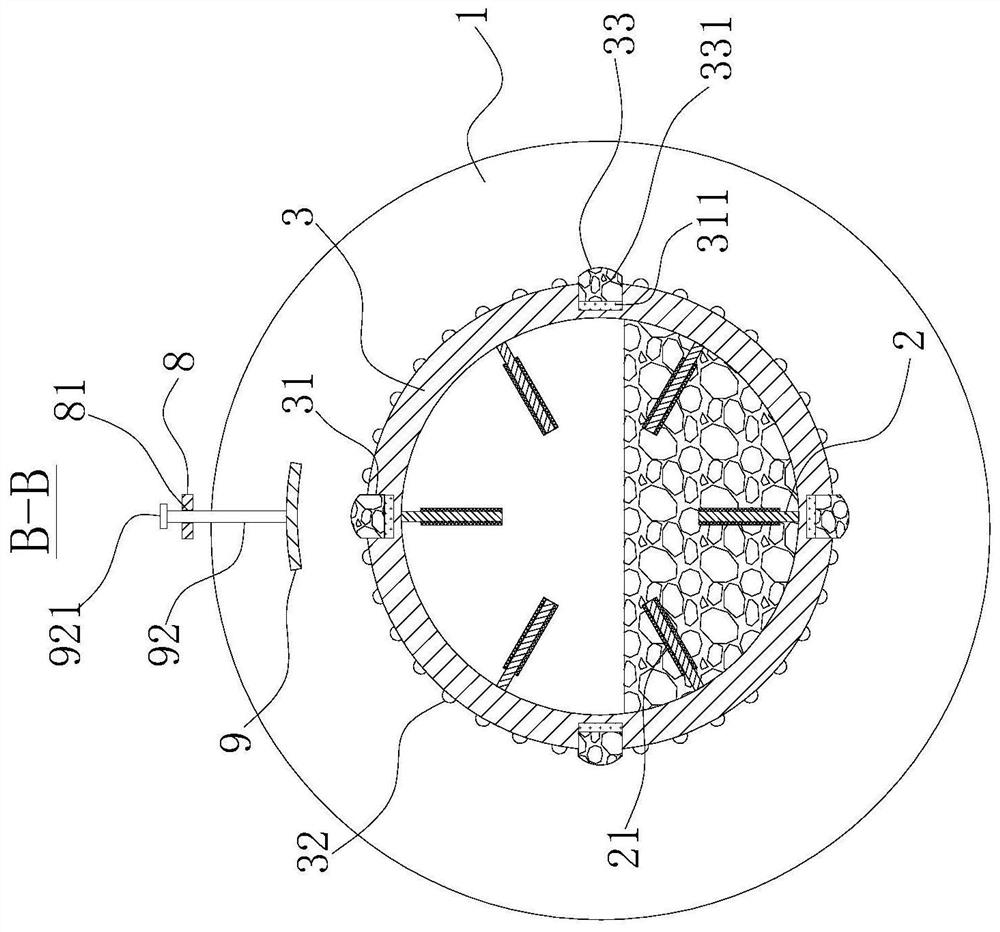

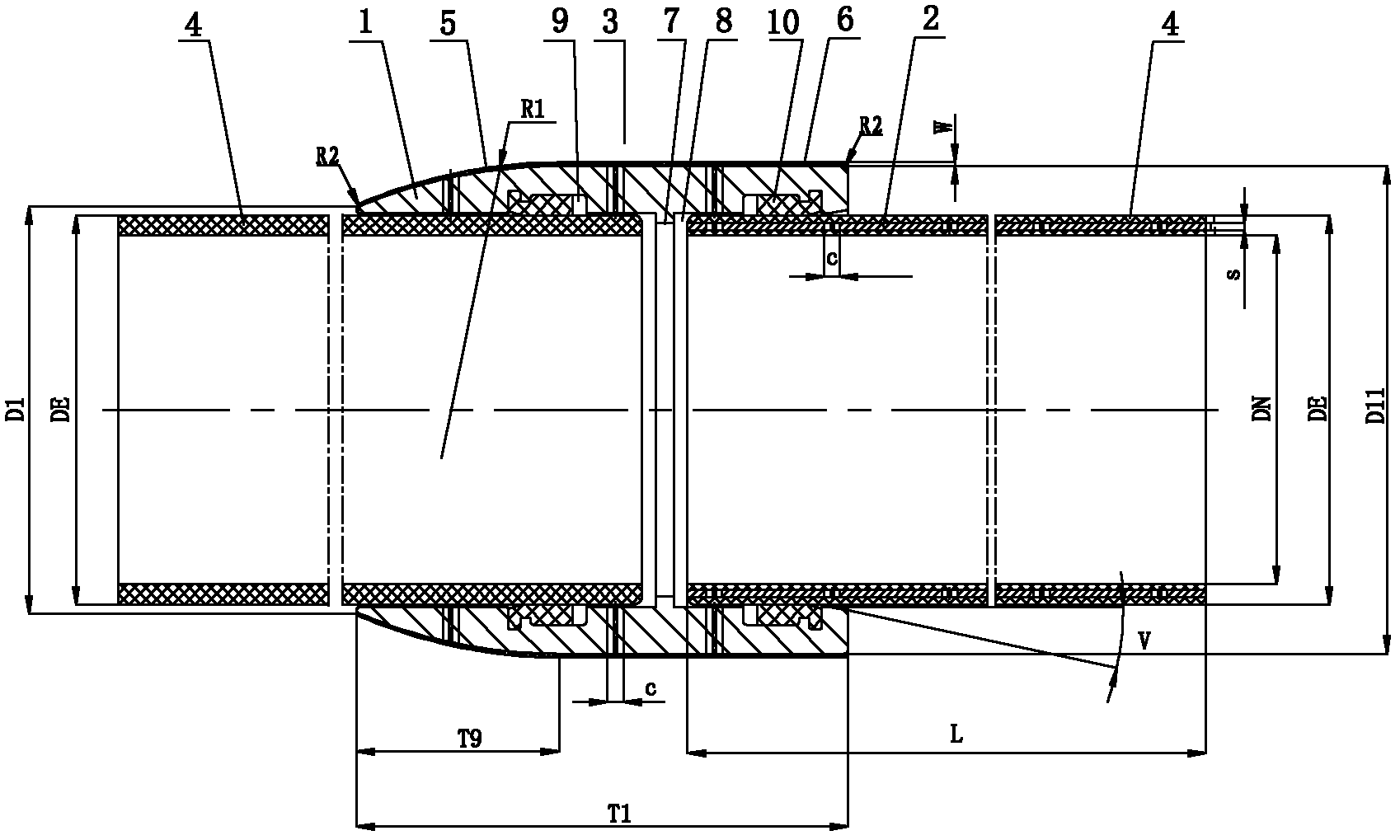

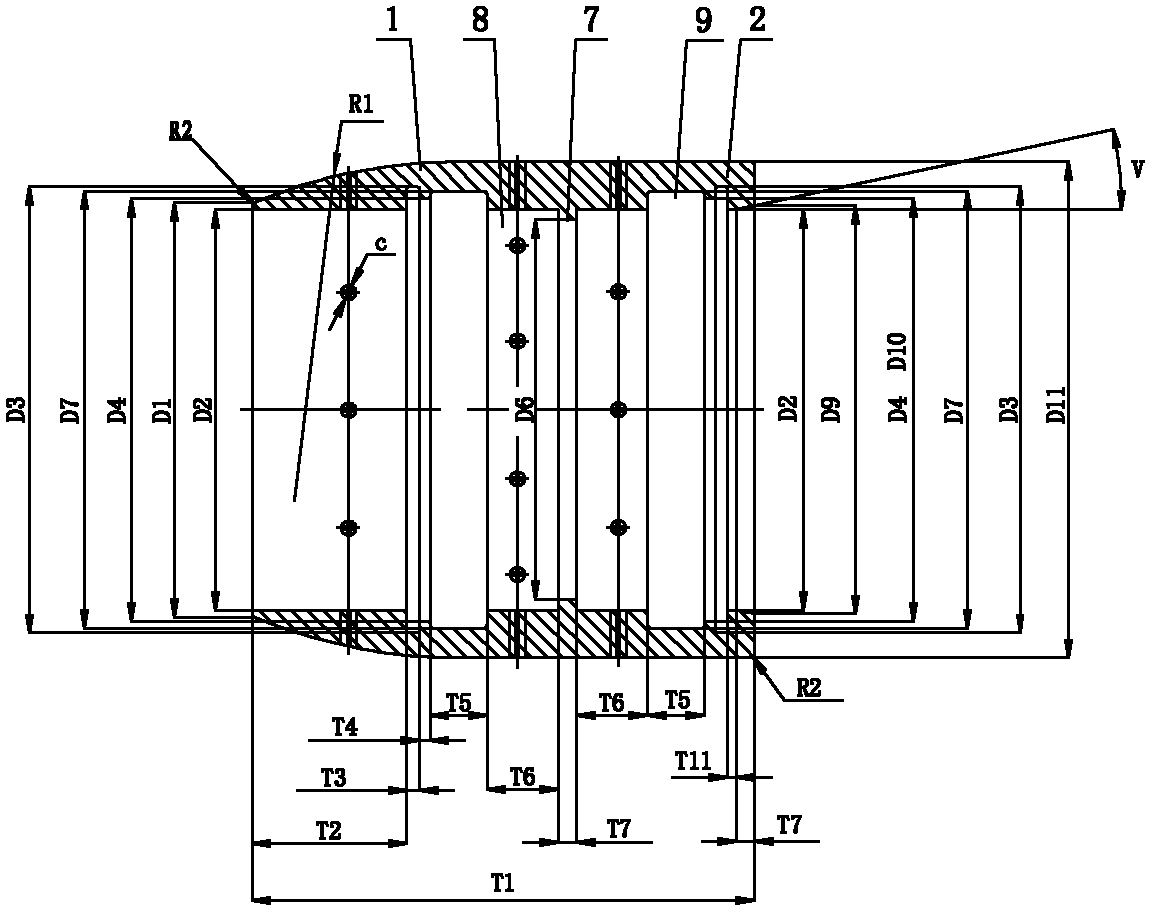

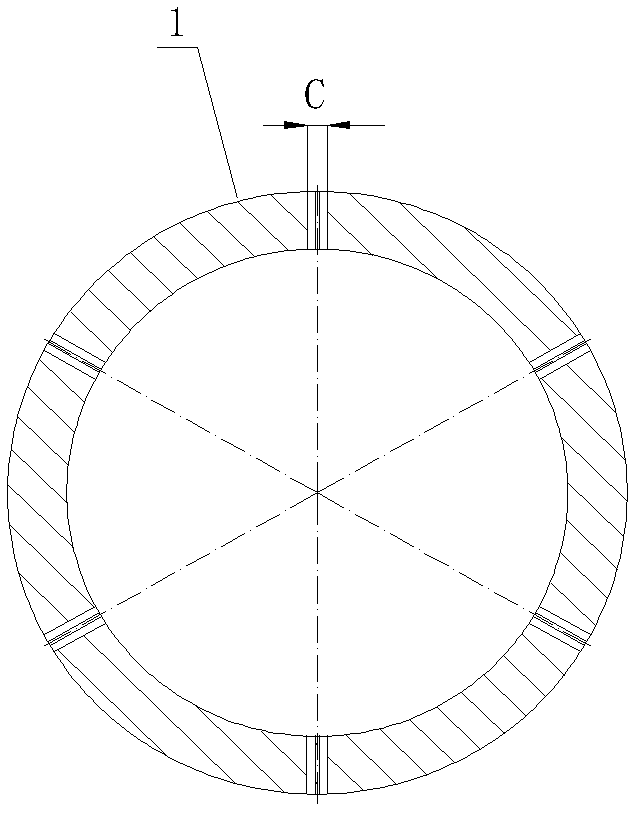

Socket reinforced composite plastic pipe and manufacturing process thereof

ActiveCN101788084ASimple structureSimple manufacturing processRigid pipesProcess engineeringWater leak

The invention relates to a socket reinforced composite plastic pipe and a manufacturing process thereof, and the socket reinforced composite plastic pipe comprises a pipe wall and a socket, wherein a convex ring is arranged at the pipe wall with the inner diameter of L at the end part of the socket, plastics and resin are mixed for being taken as raw materials, and the technical scheme simultaneously produces a product under the synchronous control of a drying machine, an extrusion machine, a mold head, a mold, a vacuum box, a spraying box, a traction machine, a cutting machine and other equipment. The socket reinforced composite plastic pipe can overcome the defects that the strength and the rigidity of the cross section at the butt joint between the pipe and the socket can not bear the internal pressure in the pipe for the existing polyethylene resin composite pipe-PE pipe, thereby causing expansion, deformation and cracking of the pipe wall of a pipe, further resulting in water leakage and gas leakage of a pipeline and causing difficult maintenance of a water supply system, a gas supply system and a liquid supply system, serious loss of resources, environmental pollution caused by gas leakage and the like; and the socket reinforced composite plastic pipe is applicable to being used as connecting pipe for various water transportation projects and gas transportation projects, in particular to socket thickening and reinforcing of PE, PVC-U, PVC-M and other plastic pipes.

Owner:HUNAN ZHENHUI PIPE IND

Elastomer compositions for use in a hydrocarbon resistant hose

InactiveUS7169842B2High-temperature and pressure resistanceHigh tensile strengthSynthetic resin layered productsPaper coatingElastomerPolyvinyl acetate

A heat tolerant, pressure resistant elastomeric composition comprising a blend of a first ethylene-vinyl ester copolymer and a second copolymer selected from the group consisting of chlorosulfonated polyethylene (CSM), chlorinated polyethylene (CPE), polychloroprene (CR), ethylene-acrylic elastomer (AEM), alkyl-acrylate copolymer (ACM), polyvinyl acetate (PVA), nitrile-butadiene rubber (NBR), hydrogenated nitrile-butadiene rubber (HNBR), and mixtures thereof, a hose manufactured therefrom; and a method for preparing the hose are described.

Owner:FLUID ROUTING SOLUTIONS

Shock absorber

ActiveUS8028813B2Good sports characteristicsImprove driving comfort and stability of vehicleSpringsShock absorbersEngineeringPiston rod

Disclosed herein is a shock absorber for damping vibration transmitted to a vehicle according to a road state. The shock absorber includes a cylinder and a piston valve disposed within the cylinder and connected to a piston rod to divide the cylinder into a first chamber and a second chamber. The shock absorber further includes a hollow chamber formed within the piston rod, a floating piston disposed within the hollow chamber to move up and down and to divide the hollow chamber into upper and lower chambers, first and second orifices formed in upper and lower ends of the hollow chamber and connected to the first and second chambers, respectively, and a resistance changing mechanism configured to cooperate with the floating piston and change a fluid resistance with respect to the floating piston where the resistance changing mechanism cooperates therewith.

Owner:HL MANDO CORP

Adjustable passive flow regulator

InactiveUS20150346732A1Increase fluid resistanceAvoid flowWound drainsCheck valvesHydrocephalusPain management

An adjustable passive flow regulator may be used in the field of drug delivery (liquid or gaseous, e.g. for pain management) or for draining cerebrospinal fluid (CSF) for hydrocephalus patient.

Owner:DEBIOTECH SA

Steel wire enhanced bell and spigot composite plastic tube and fabrication process thereof

ActiveCN101881356ASimple structureSave raw materialsCorrosion preventionPipe protection against corrosion/incrustationConical tubePolyvinyl chloride

The invention relates to a steel wire enhanced bell and spigot composite plastic tube and a fabrication process thereof. The steel wire enhanced bell and spigot composite plastic tube is prepared by mainly enhancing an inner bell and spigot and an outer bell and spigot, reasonably configuring each corresponding ratio parameter and adopting the fabrication process. The steel wire enhanced bell and spigot composite plastic tube comprises the inner bell and spigot, a bush, the outer bell and spigot, a sealing ring adapted to the outer bell and spigot, a conical tube, a round tube A, an arc tube, a round tube B and a steel wire sleeve mainly covering the outer wall of the arc tube, wherein the inner bell and spigot and the bush are arranged at one end of the tube wall, the outer bell and spigot and the sealing ring are arranged at the other end of the tube wall, and the conical tube, the round tube A, the arc tube, the round tube B and the steel wire sleeve are sequentially connected to the tube wall. The invention overcomes the defects that in the traditional PE (Polyethylene) tube, a reticular enhancement mode and a bidirectional winding enhancement mode are adopted at the external of the tube wall to cause the axial rigidity of the tube to be too strong and enable the axial flexibility performance at the bell and spigot to be lowered, thereby influencing the geological subsidence resistance performance of a pipeline network system; the connecting part of the bell and spigots is easy to strain to break, thereby enabling maintenance of a water, gas and liquid supply system to be difficult; fuel gas leaks to cause environmental pollution and the like. The invention is suitable for various water conveyance projects and connecting tubes of the water conveyance projects and is particularly suitable for enhancing bell and spigots of PE plastic tubes, PVC-U (Unplasticizied Polyvinyl Chloride) plastic tubes, PVC-M (High Impact Polyvinyl Chloride) plastic tubes and the like.

Owner:HUNAN ZHENHUI PIPE IND

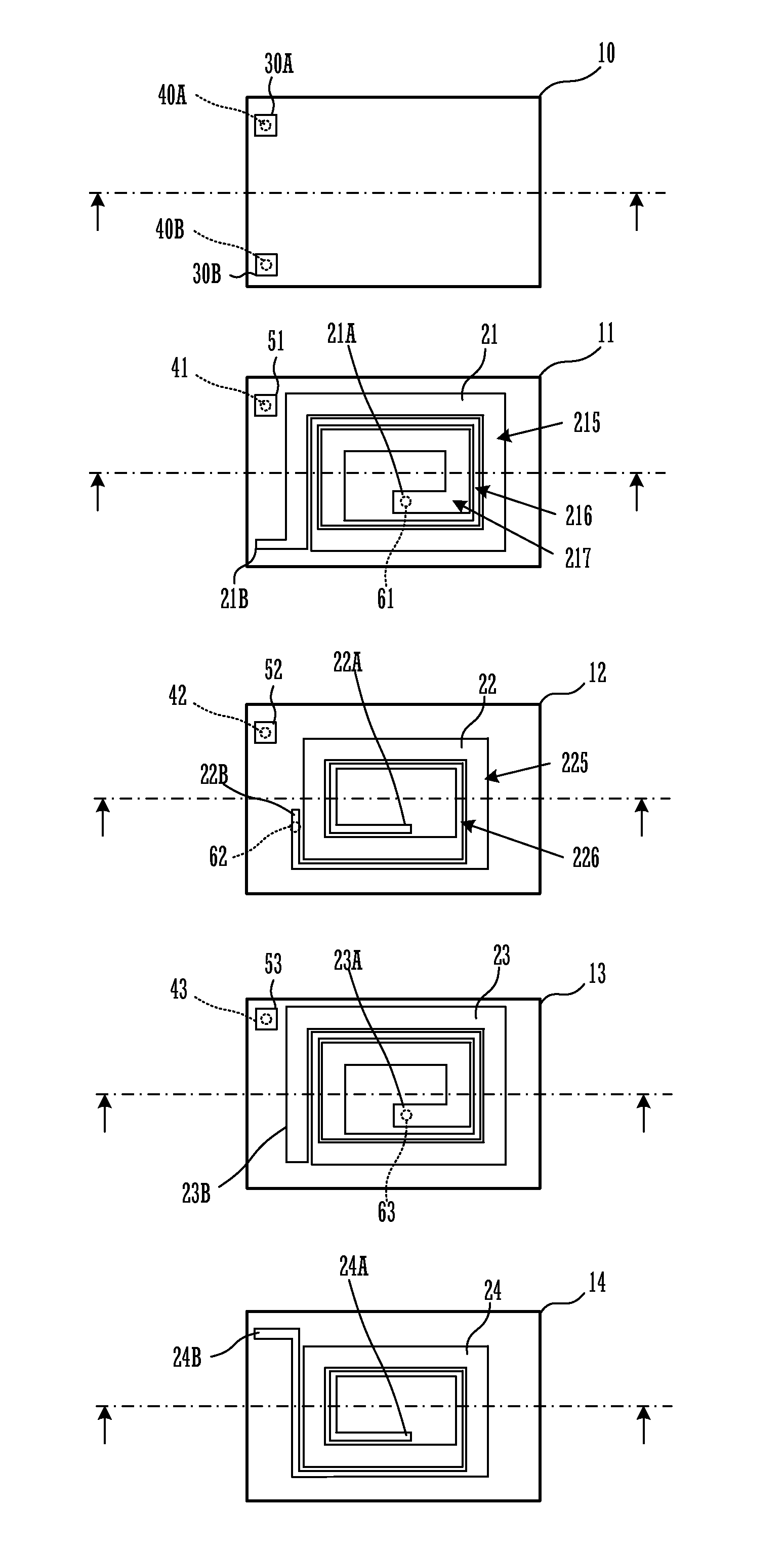

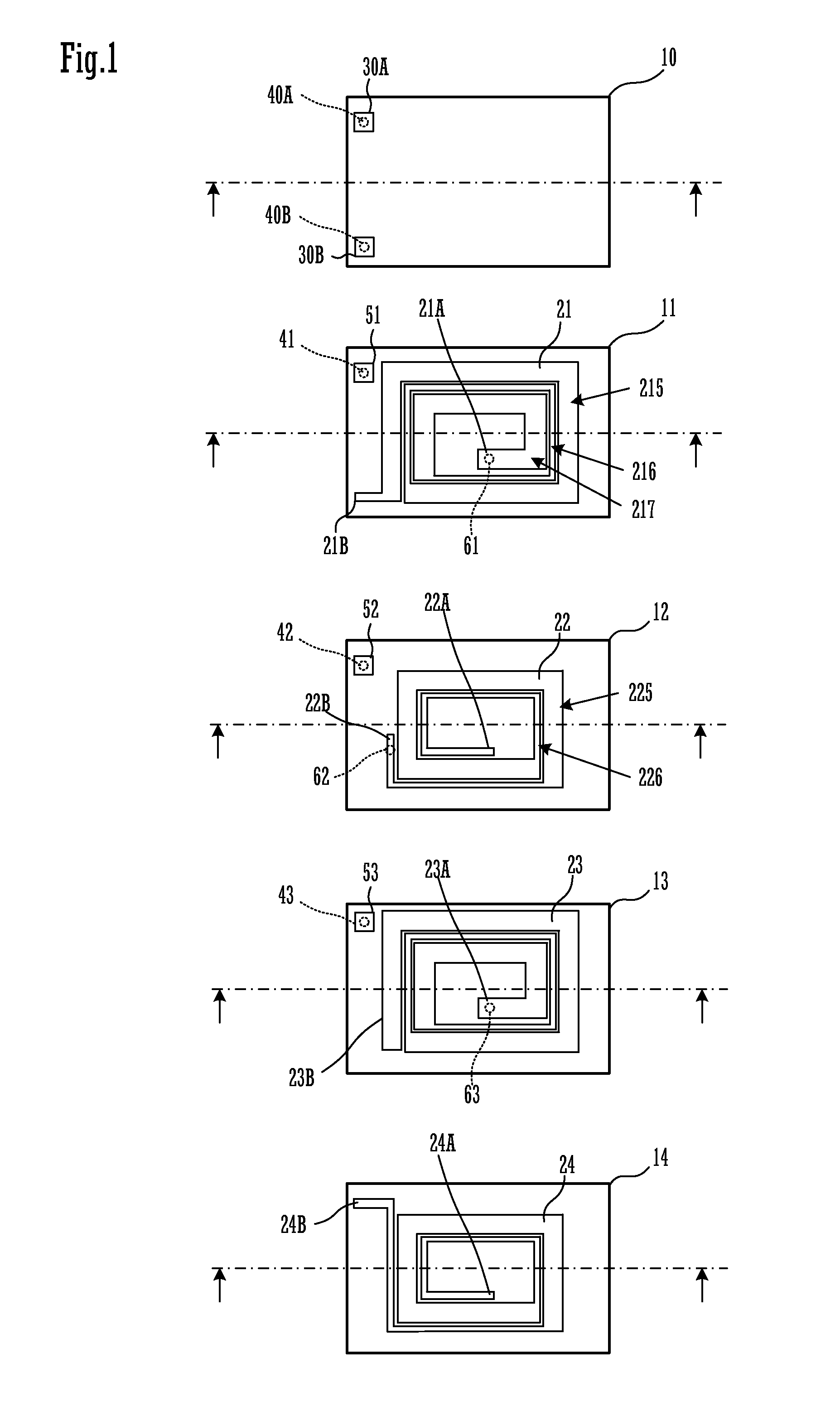

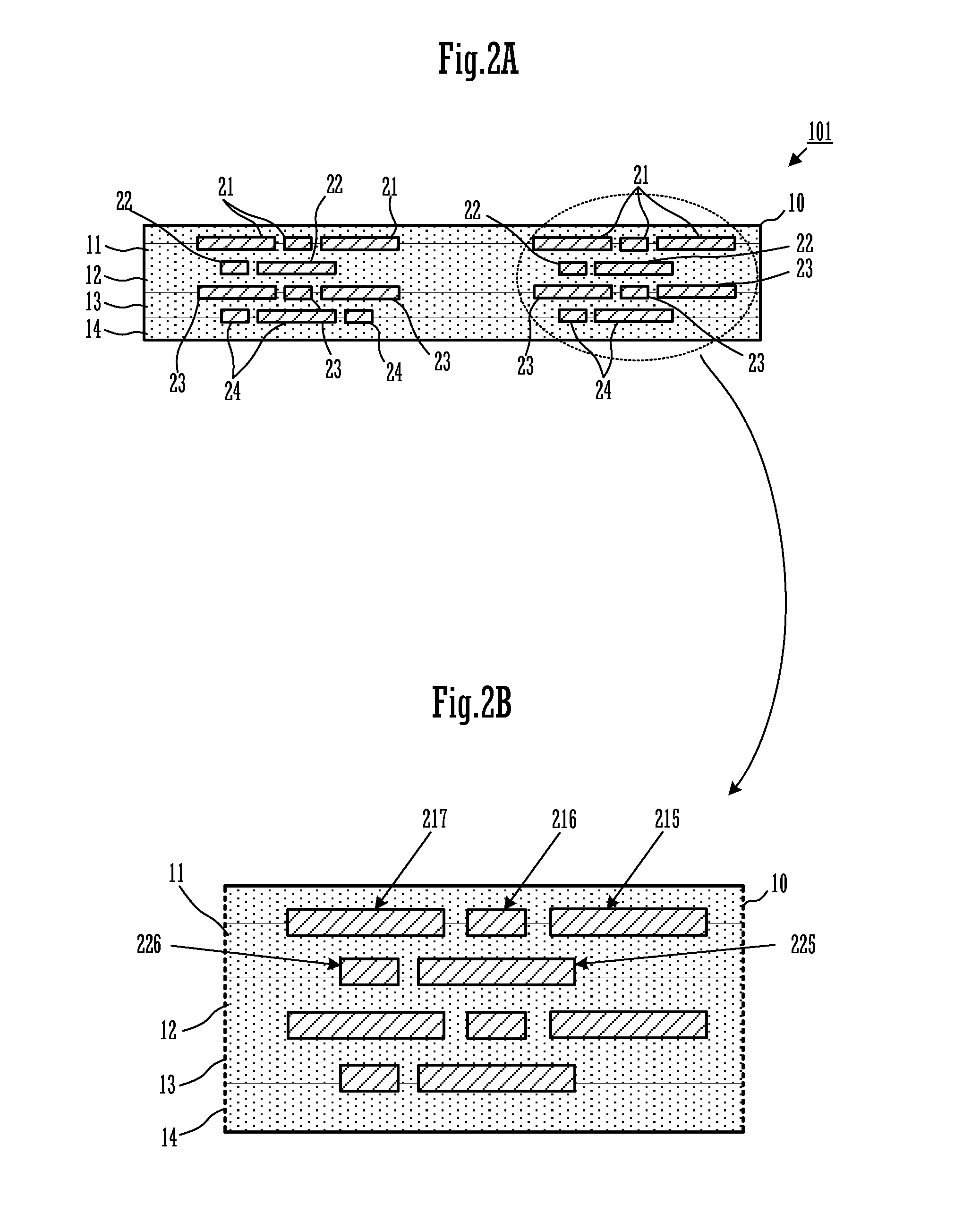

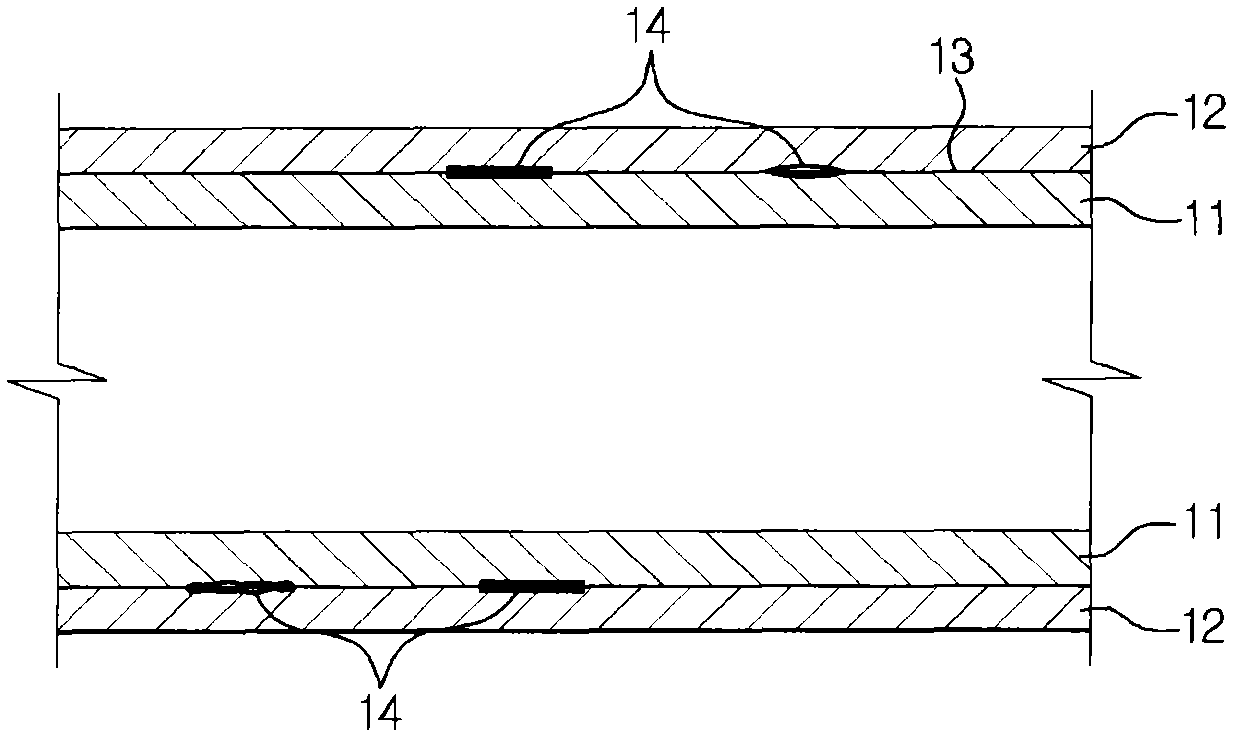

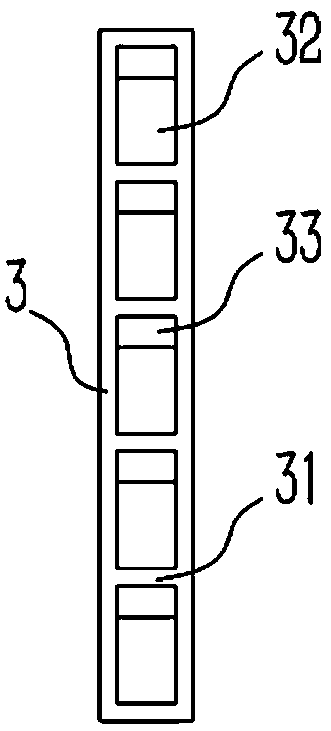

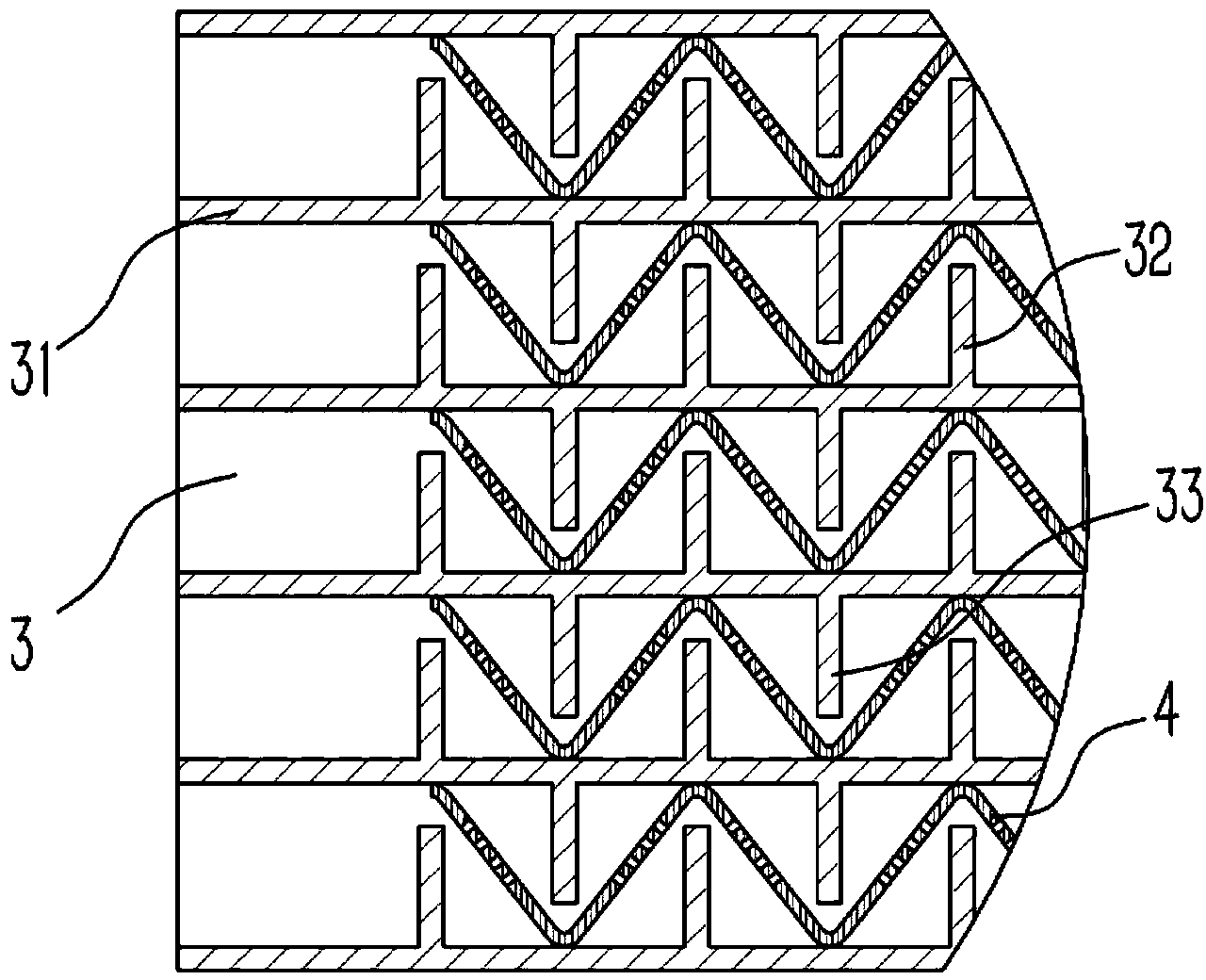

Method of manufacturing multilayer board, multilayer board, and electromagnet

ActiveUS20160027578A1Reduces and prevents tiltingAvoid tiltingPrinted circuit manufacturePrinted inductor incorporationLine widthEngineering

In a linear conductor forming step, a wide portion having a relatively large line width and a narrow portion having a relatively small line width are formed in each of a plurality of linear conductors. In addition, in a multilayer board, in base material layers adjacent to each other in a stacking direction, the wide portion overlaps the narrow portion on the adjacent base material layer, and end portions of the wide portions at both sides of the narrow portion in a line width direction, in a planar view. The wide portions are disposed such that the end portions thereof overlap each other in the stacking direction and resistance of a fluid thermoplastic resin increases. The narrow portion is located between the wide portions in the stacking direction.

Owner:MURATA MFG CO LTD

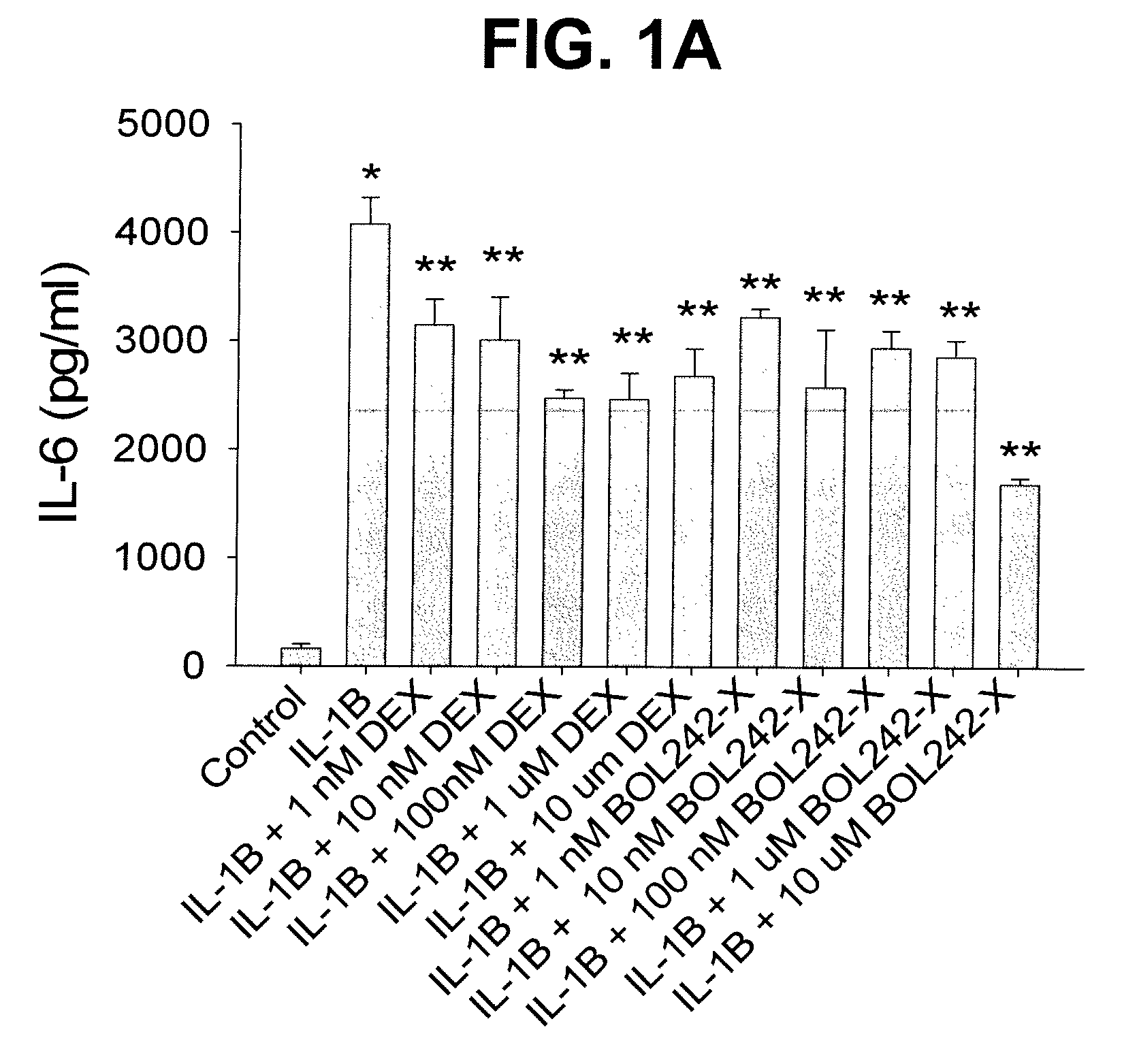

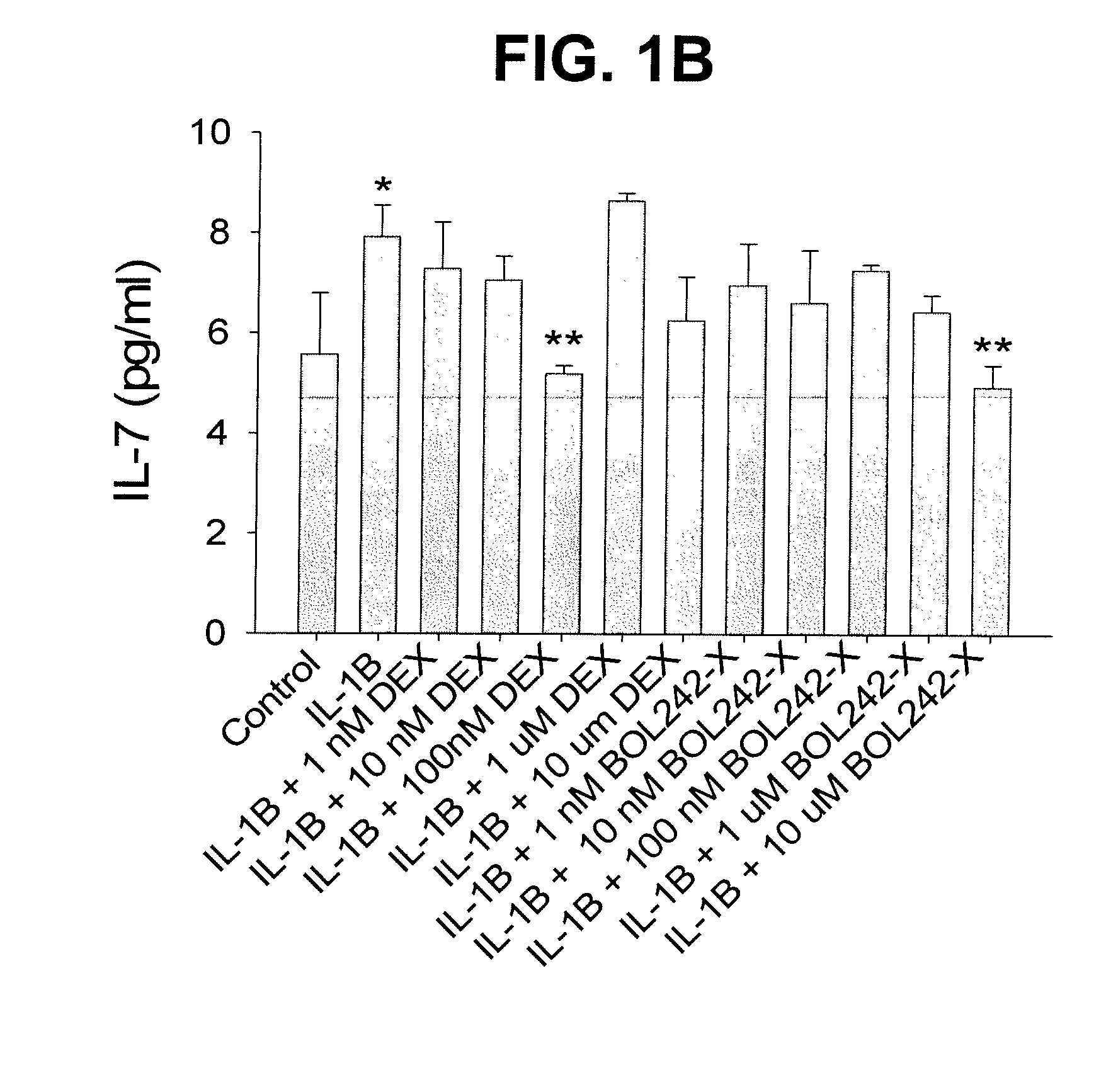

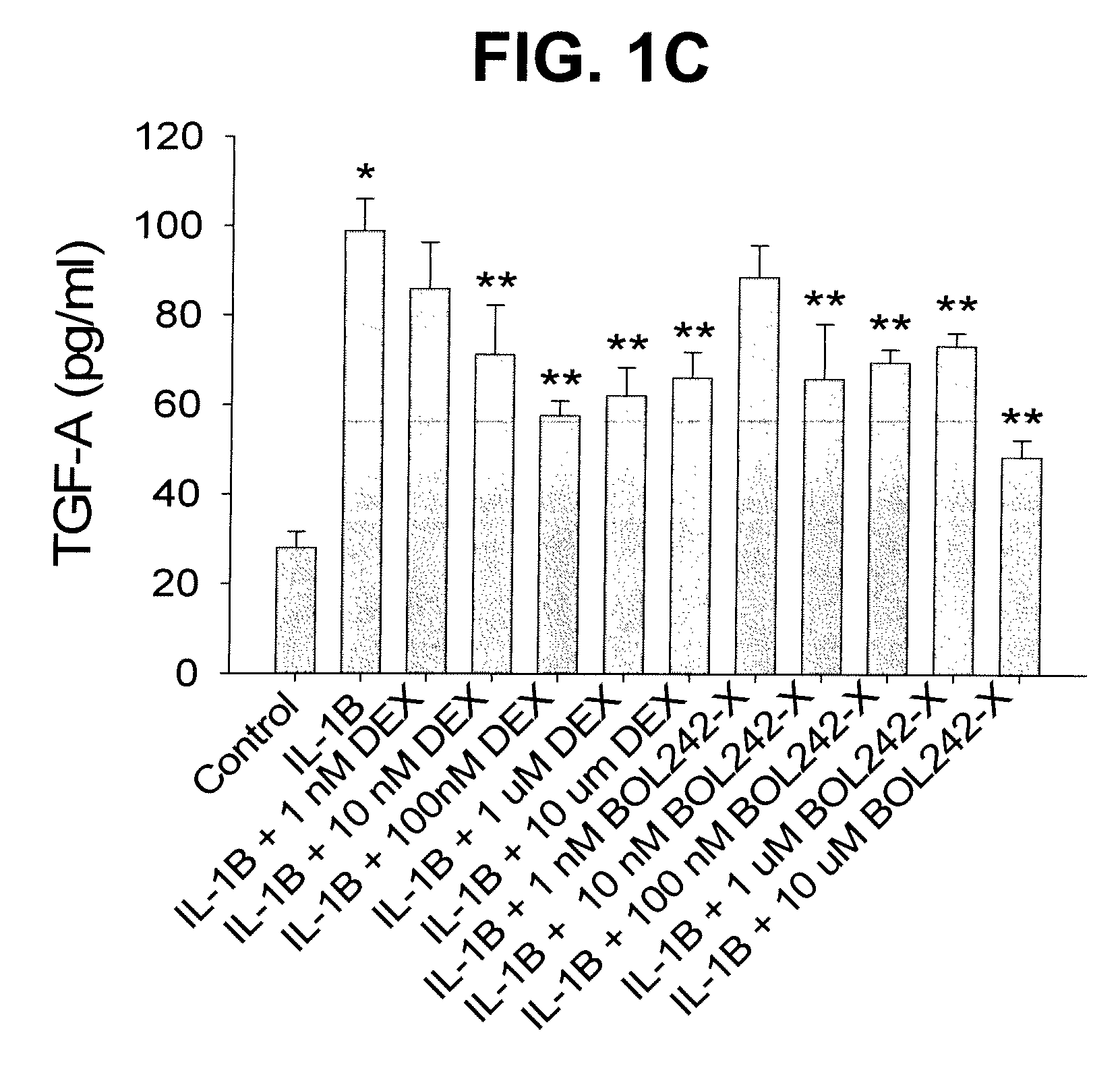

Compositions and Methods for Treating Ocular Inflammation with Lower Risk of Increased Intraocular Pressure

A composition for treating or controlling an ocular disease or condition comprises a dissociated glucocorticoid receptor agonist (“DIGRA”), which disease or condition has an etiology, or results, in inflammation. The composition can optionally include an anti-inflammatory agent, an anti-infective agent, or both. The composition can be formulated for topical application, injection, or implantation in an affected eye to treat or control the ocular inflammatory disease or condition.

Owner:BAUSCH & LOMB INC

Prevention of microbial growth in metal working fluids

InactiveUS20050059559A1Maximize resistanceIncrease fluid resistanceOrganic chemistryFatty substance preservation using additivesMetalworking fluidOil water

A method of preventing microbial growth in oil-water metalworking fluid in a machine wherein lubricating oil or hydraulic or tapping fluid can contaminate the metalworking fluid, comprises adding a partitionable anti-microbial agent, active against micro-organisms present in the metalworking fluid, to the lubricating oil or hydraulic or tapping fluid whereby an effective quantity of anti-microbial agent can migrate into the metalworking fluid to reduce micro-organism activity. A machine tool lubricating oil or hydraulic or tapping fluid composition comprises in a mineral oil or other lubricant base and an oil-water partitionable anti-microbial, active against micro-organisms present in oil-water metalworking fluids.

Owner:ILLINOIS TOOL WORKS INC

Adjustable passive flow regulator

InactiveUS9971358B2Easy to manageReduce sensitivityValve arrangementsWound drainsHydrocephalusPain management

An adjustable passive flow regulator may be used in the field of drug delivery (liquid or gaseous, e.g. for pain management) or for draining cerebrospinal fluid (CSF) for hydrocephalus patient.

Owner:DEBIOTECH SA

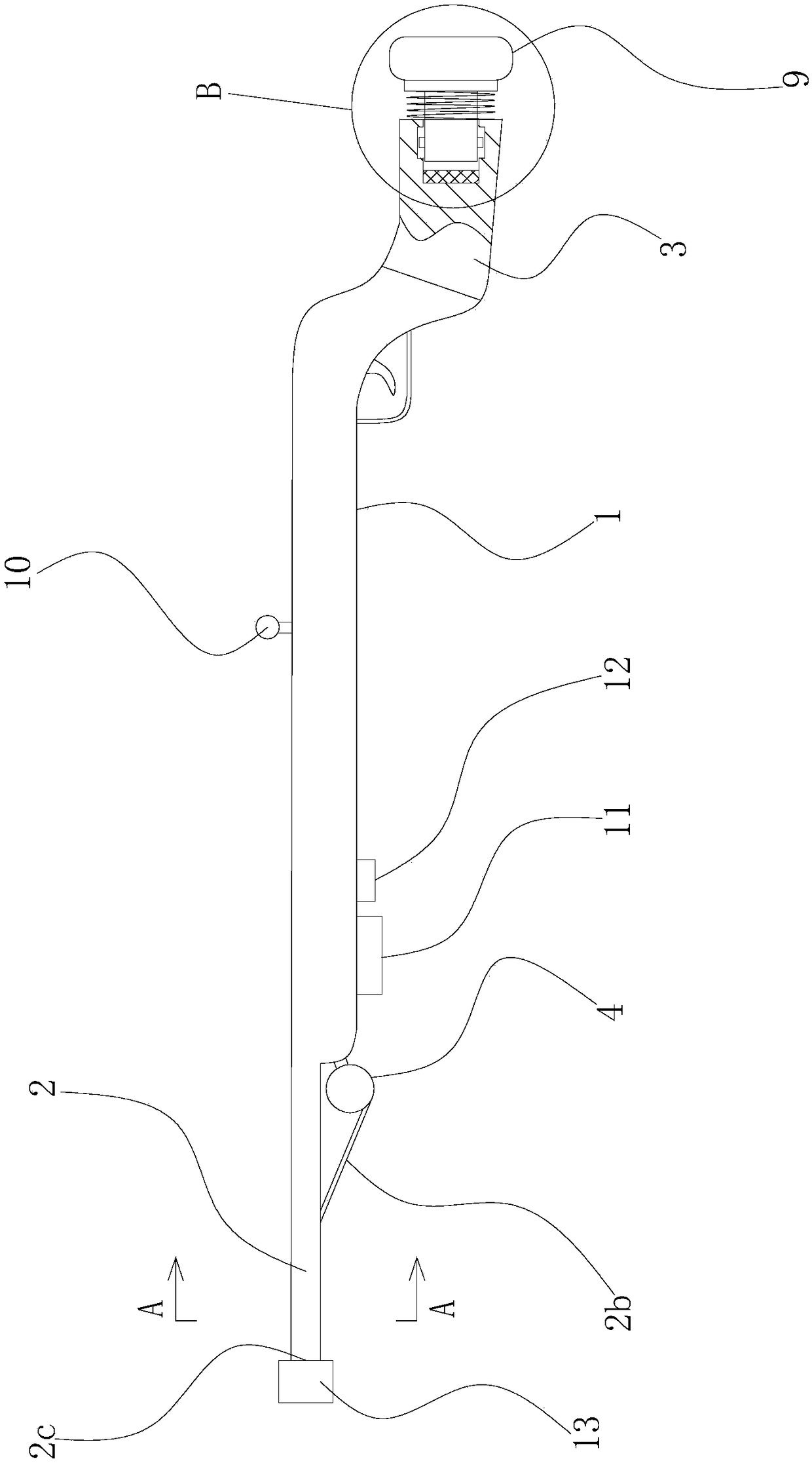

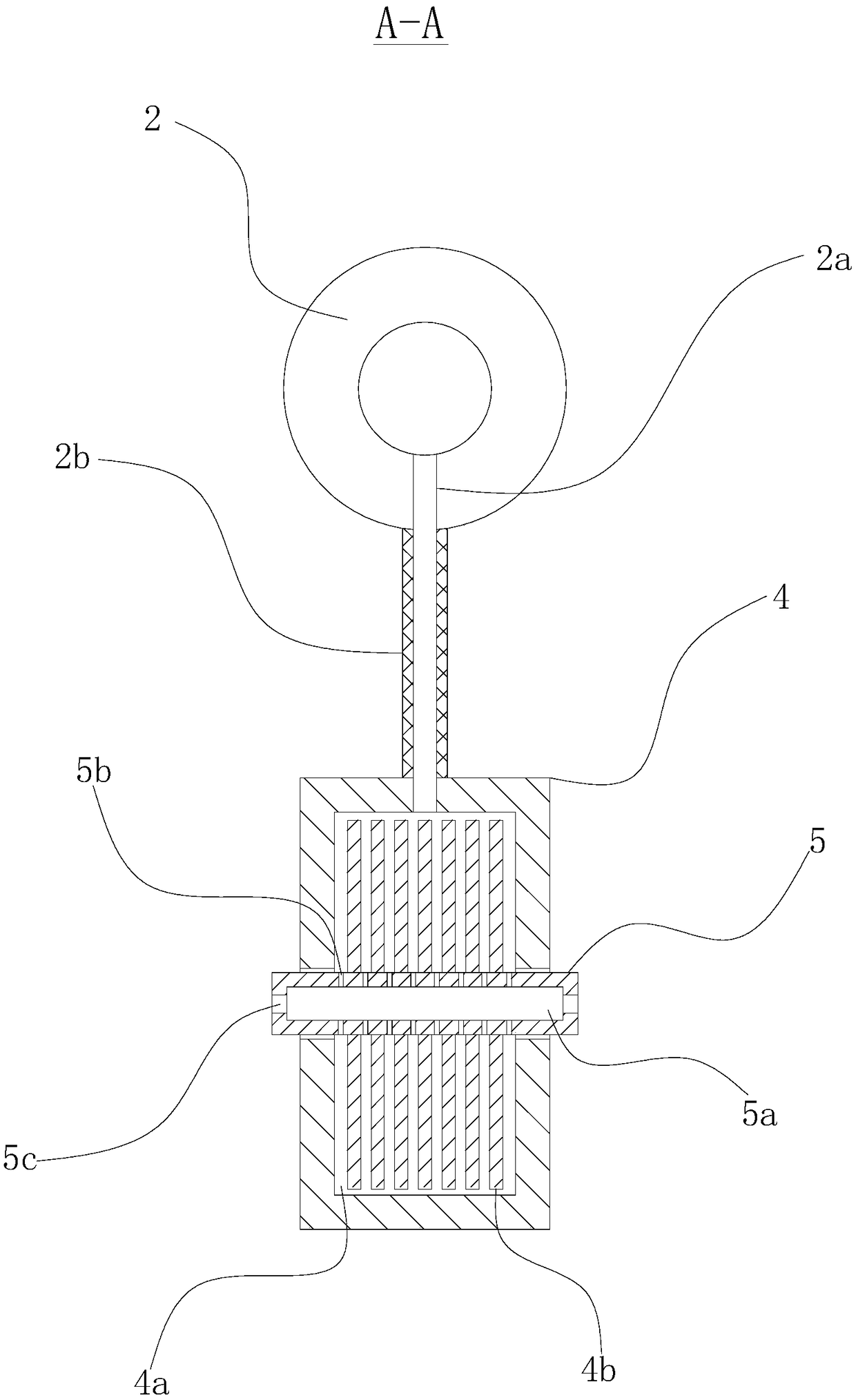

Electric winch with improved structure

PendingCN111847292APrevent slippingIncrease contact areaPiezoelectric/electrostriction/magnetostriction machinesWinding mechanismsElectric machineDrive motor

The invention provides an electric winch with an improved structure, and belongs to the technical field of winch devices. The electric winch with an improved structure comprises a base, a rotating shaft, a drive motor, a first round tube, a plurality of grooves and an anti-reverse mechanism. The rotating shaft is horizontally and rotatably arranged on the base through a base plate. The drive motoris fixedly arranged on the base. The drive motor is connected with the rotating shaft in a transmission mode. Both sides of the first round tube are fixedly provided with a side plate. One side plateis fixedly connected with one end of the rotating shaft. The first round tube and the rotating shaft are arranged coaxially. The outer side of the first round tube is provided with a plurality of rubber bumps. A plurality of grooves are arranged on the outer side of the first round tube along the circumferential direction. The length directions of the grooves are consistent with the length direction of the first round tube. A telescopic air bag is arranged in the grooves. The outer side of the telescopic air bag protrudes from the outer side wall of the first round tube. The telescopic air bag is filled with liquid. When the rotating shaft rotates counterclockwise, the anti-reverse mechanism can prevent the rotating shaft from rotating reversely. The electric winch can improve the anti-slide performance of a reel, and can also prevent the reel from turning over and damaging the drive motor.

Owner:ZHEJIANG OCEAN UNIV

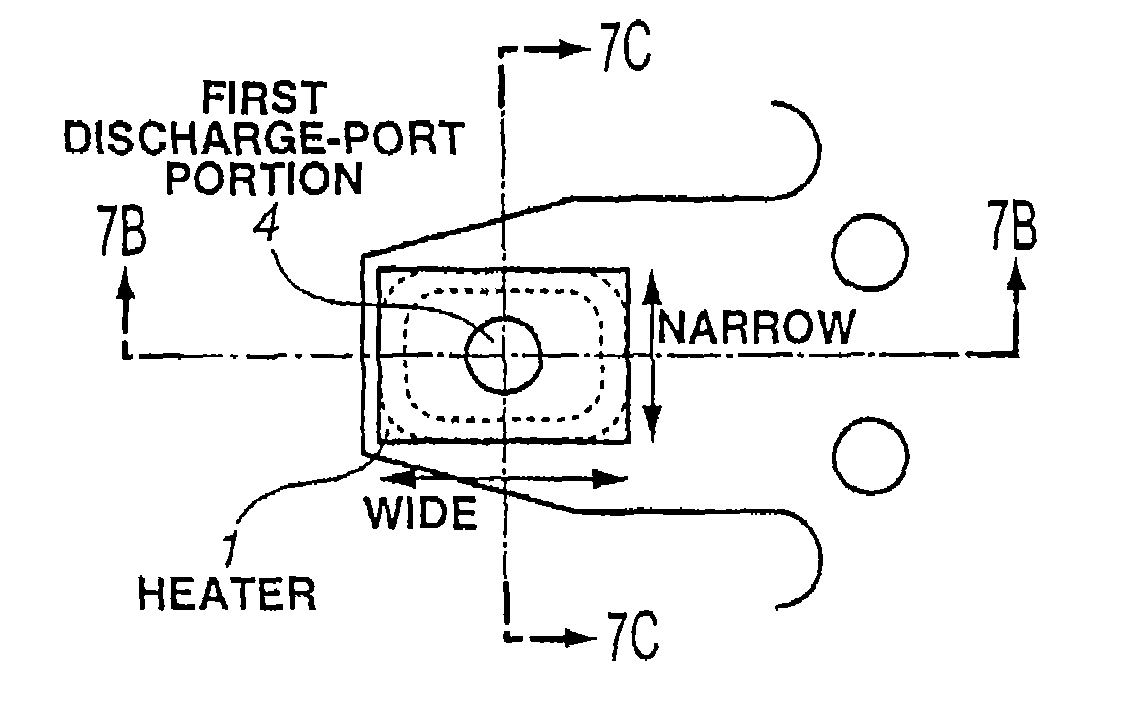

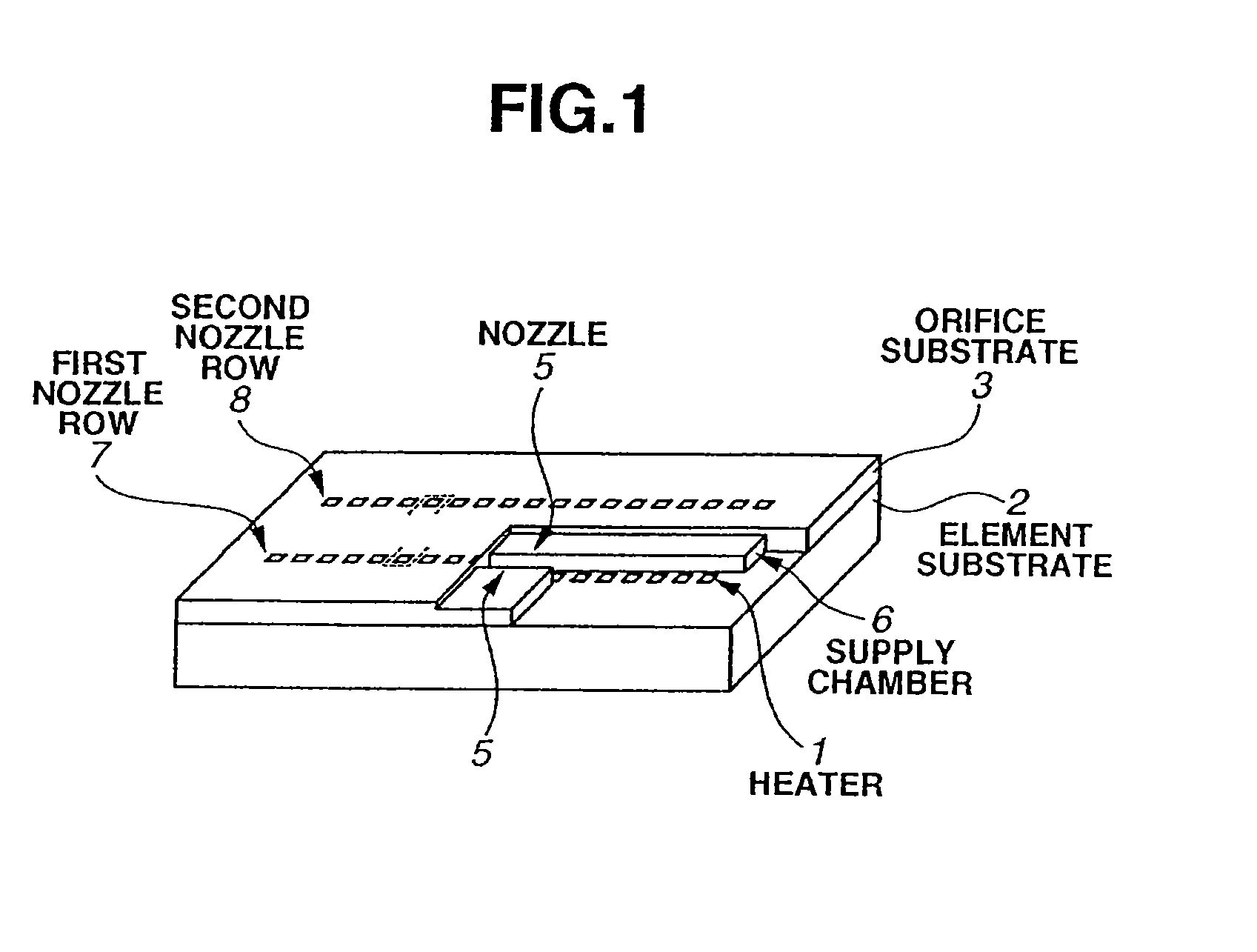

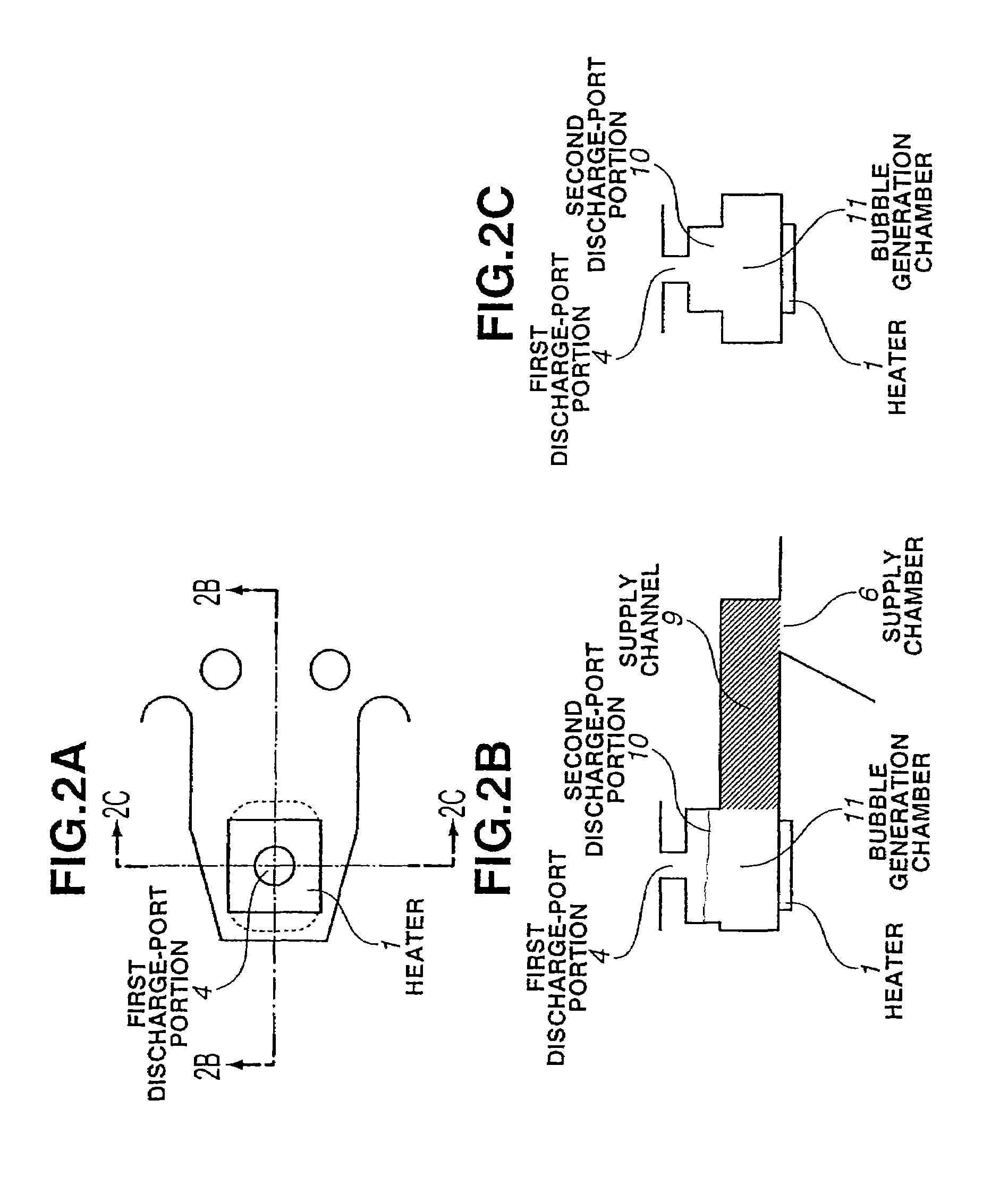

Ink-jet recording head

InactiveUS8083322B2Suppress reduction of flow rateAvoid attenuationPrintingEngineeringMechanical engineering

An ink-jet recording head includes a discharge-port portion including a first discharge-port portion continuing from a discharge port, and a second discharge-port portion communicating the first discharge-port portion with a bubble generation chamber. The second discharge-port portion has an end surface that includes a border portion bordering the first discharge-port portion and is parallel to a main surface of an element substrate. The cross-sectional area of the second discharge-port portion, anywhere from an opening surface facing the bubble generation chamber to an end surface facing the first discharge-port portion, that is parallel to the main surface of the element substrate, is larger than the area of the border portion. The cross-section of the opening surface of the second discharge-port portion has a length in a direction perpendicular to an arrangement direction of the discharge ports that is greater than its length in a direction parallel to the arrangement direction.

Owner:CANON KK

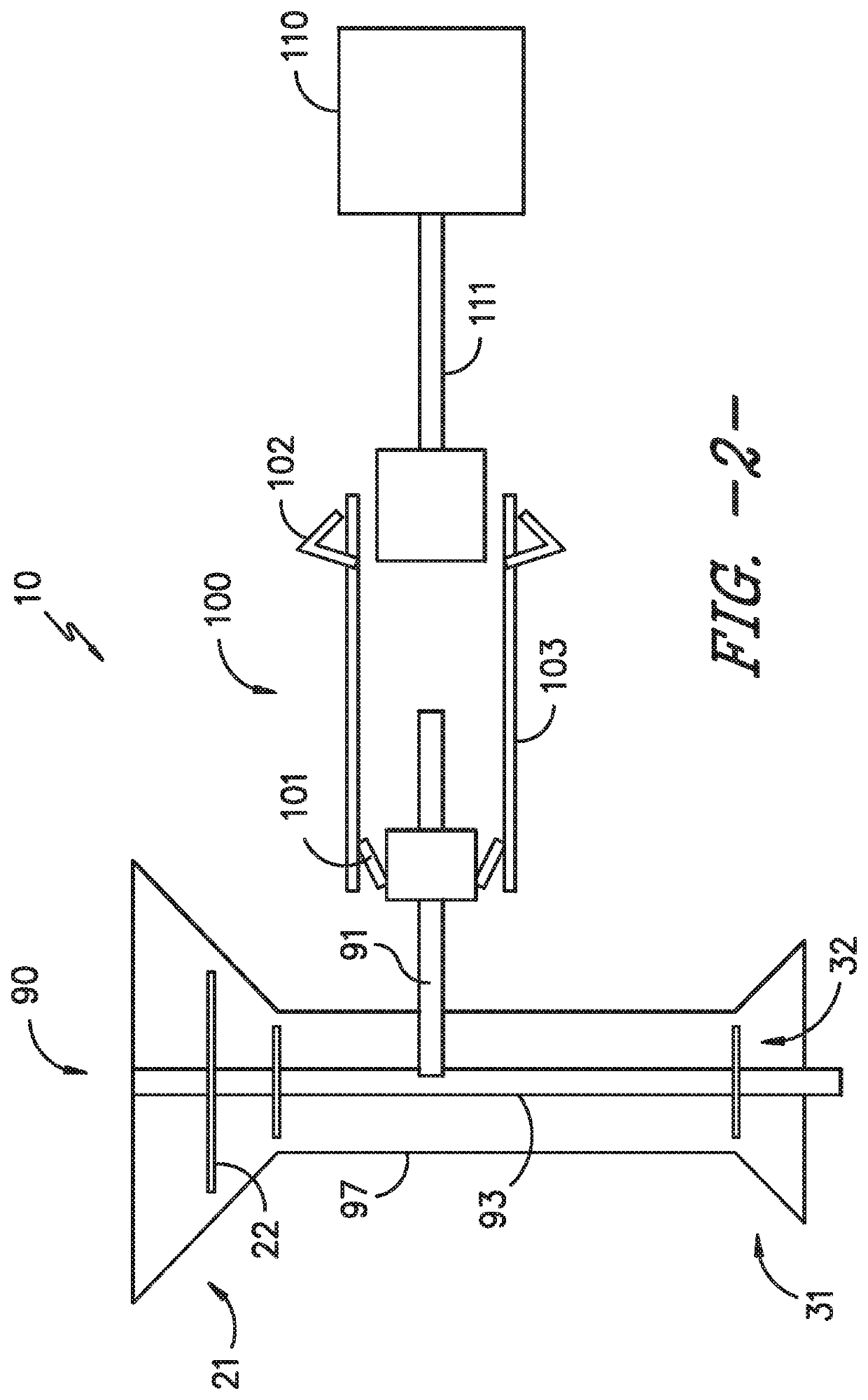

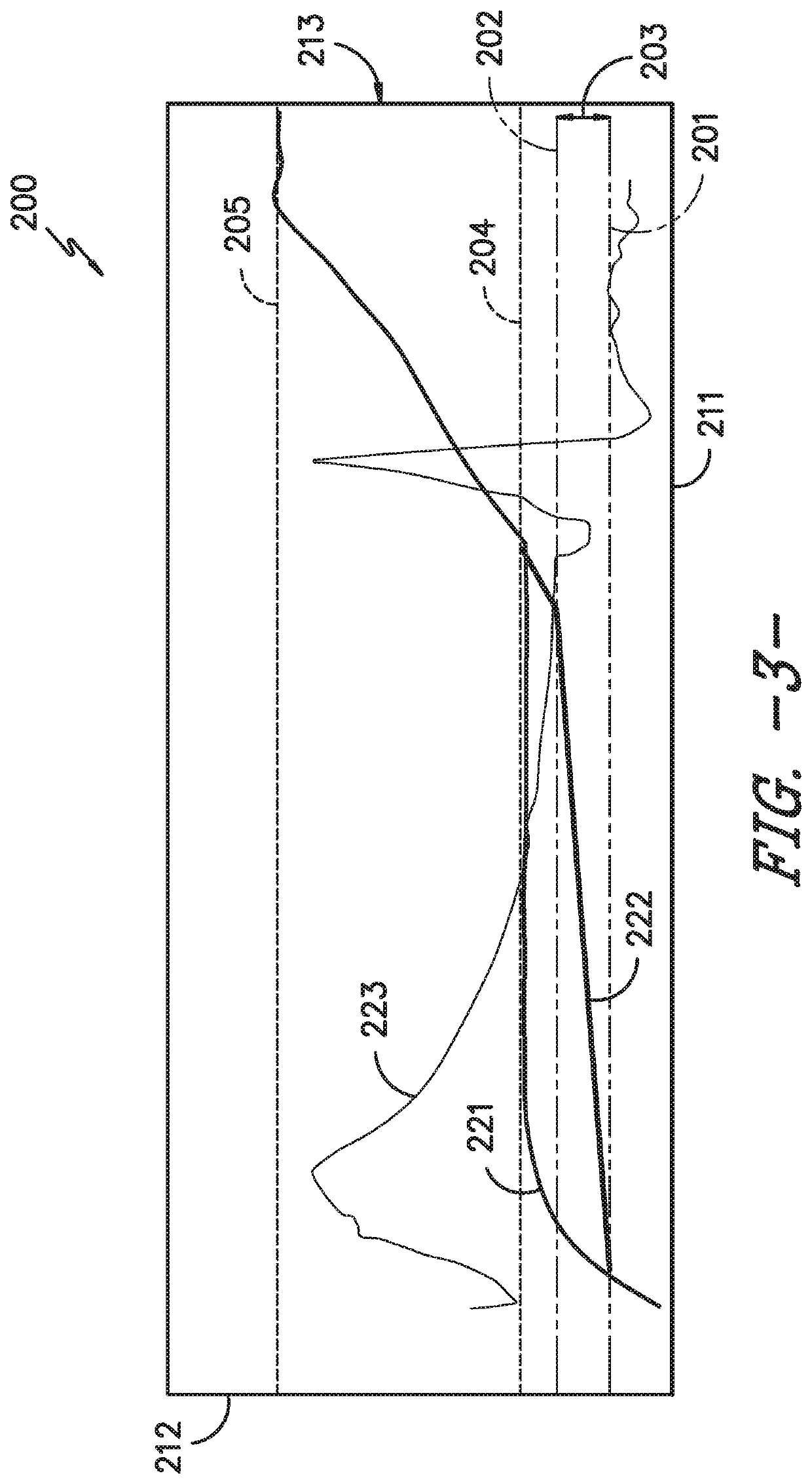

Method and system for mitigating bowed rotor operation of gas turbine engine

ActiveUS10718231B2Increase rotation speedIncrease fluid resistancePump componentsEngine fuctionsIdle speedControl theory

Embodiments of systems and methods for operating a gas turbine engine defining a bowed rotor condition are generally provided. The systems and methods include rotating a rotor assembly defining a bowed rotor condition from approximately zero revolutions per minute (RPM) to within a bowed rotor mitigation speed range, in which the bowed rotor mitigation speed range is defined by a lower speed limit greater than zero RPM and an upper speed limit less than or equal to an idle speed condition of the gas turbine engine; applying a load at the rotor assembly via an energy storage device; adjusting the load to limit rotational speed or acceleration of the rotor assembly to within the bowed rotor mitigation speed range for a period of time; and removing the load to enable rotation of the rotor assembly to the idle speed condition following the period of time.

Owner:GENERAL ELECTRIC CO

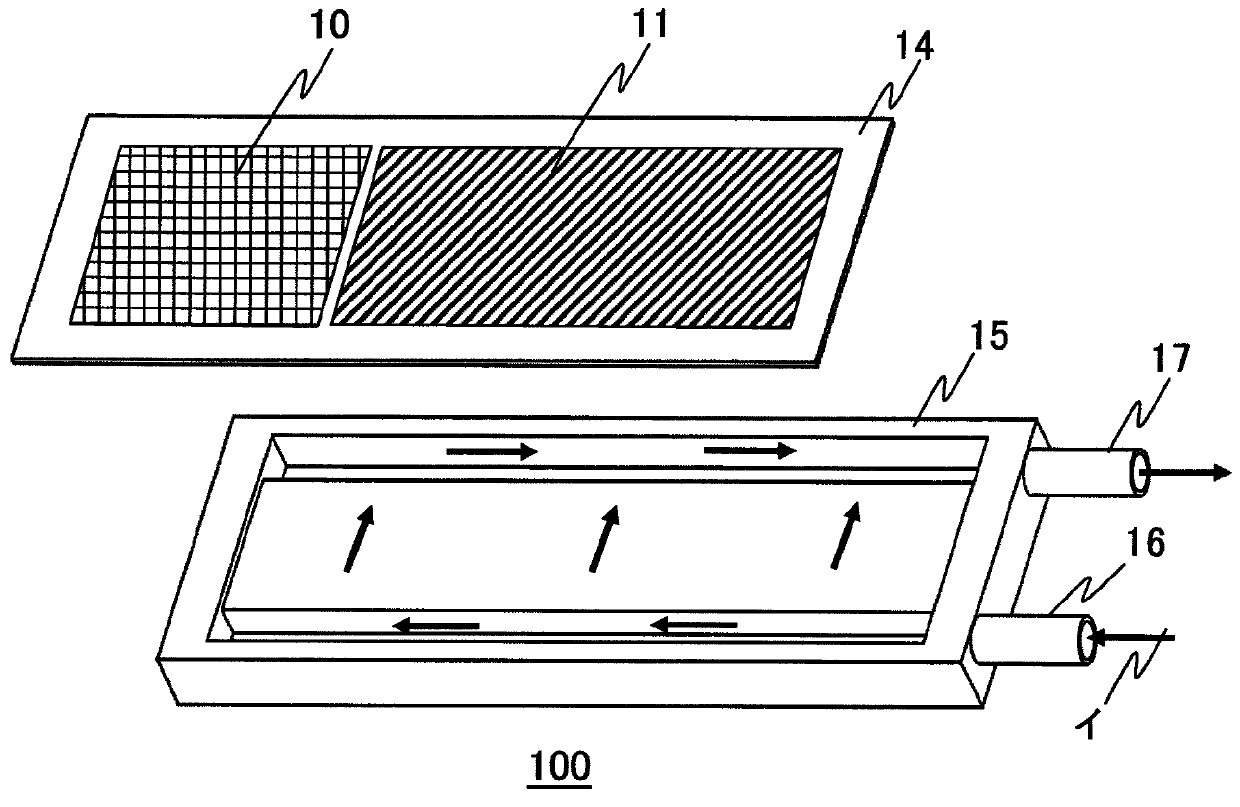

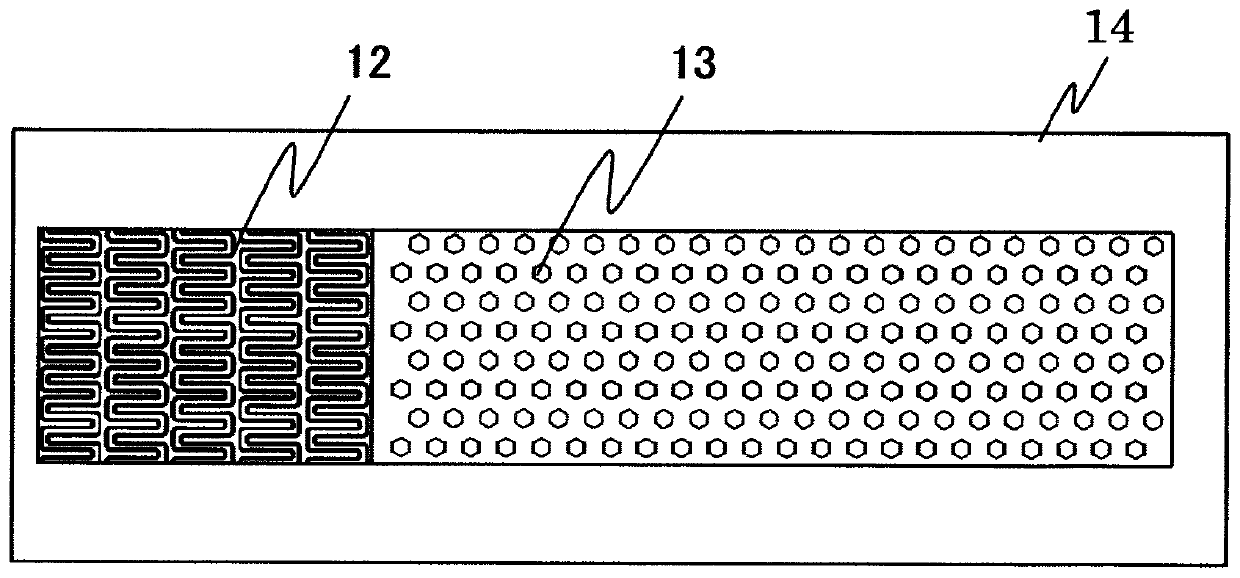

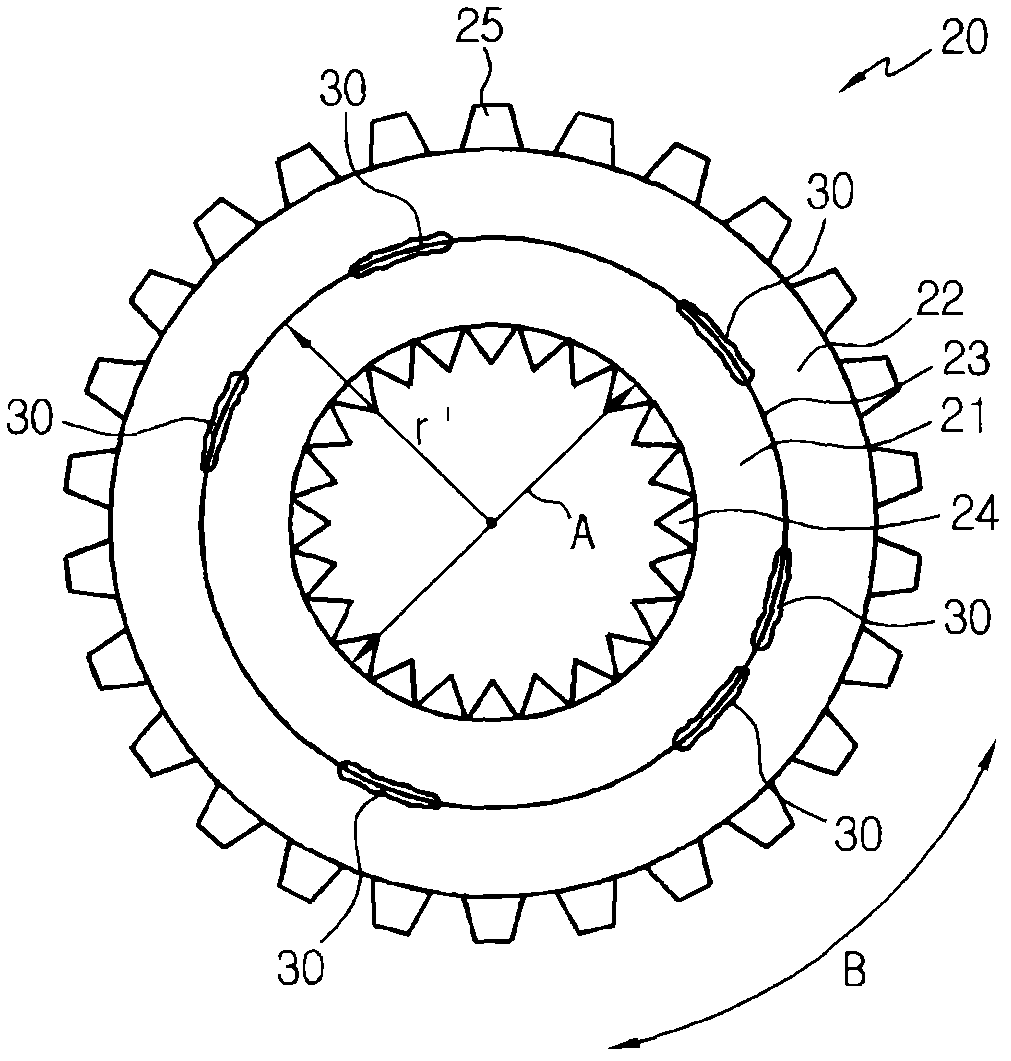

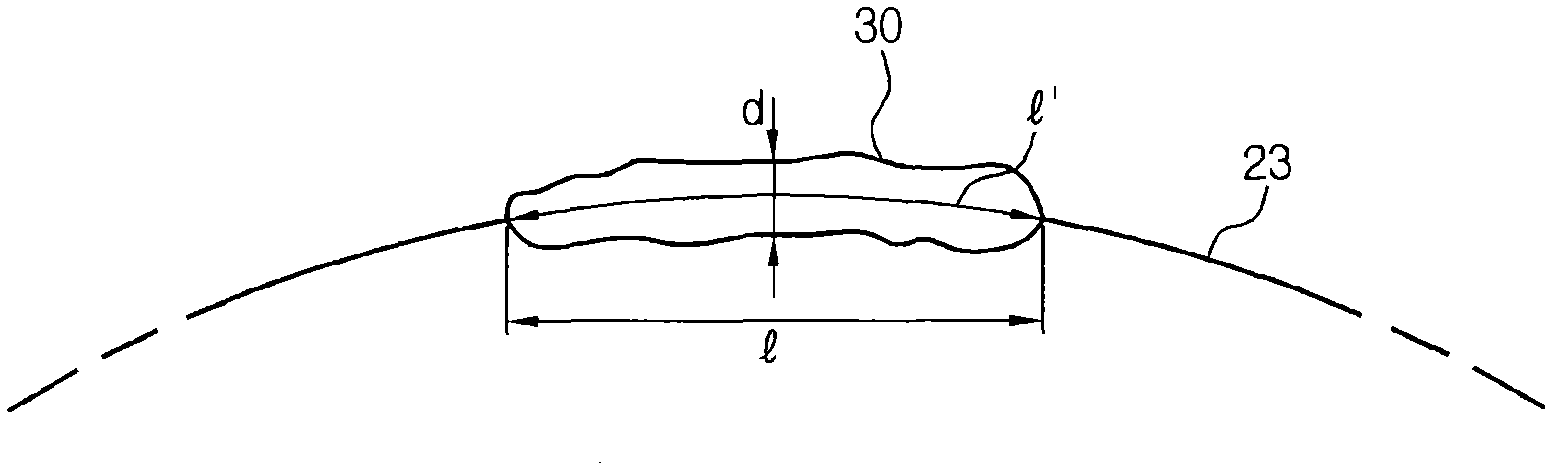

Heat sink

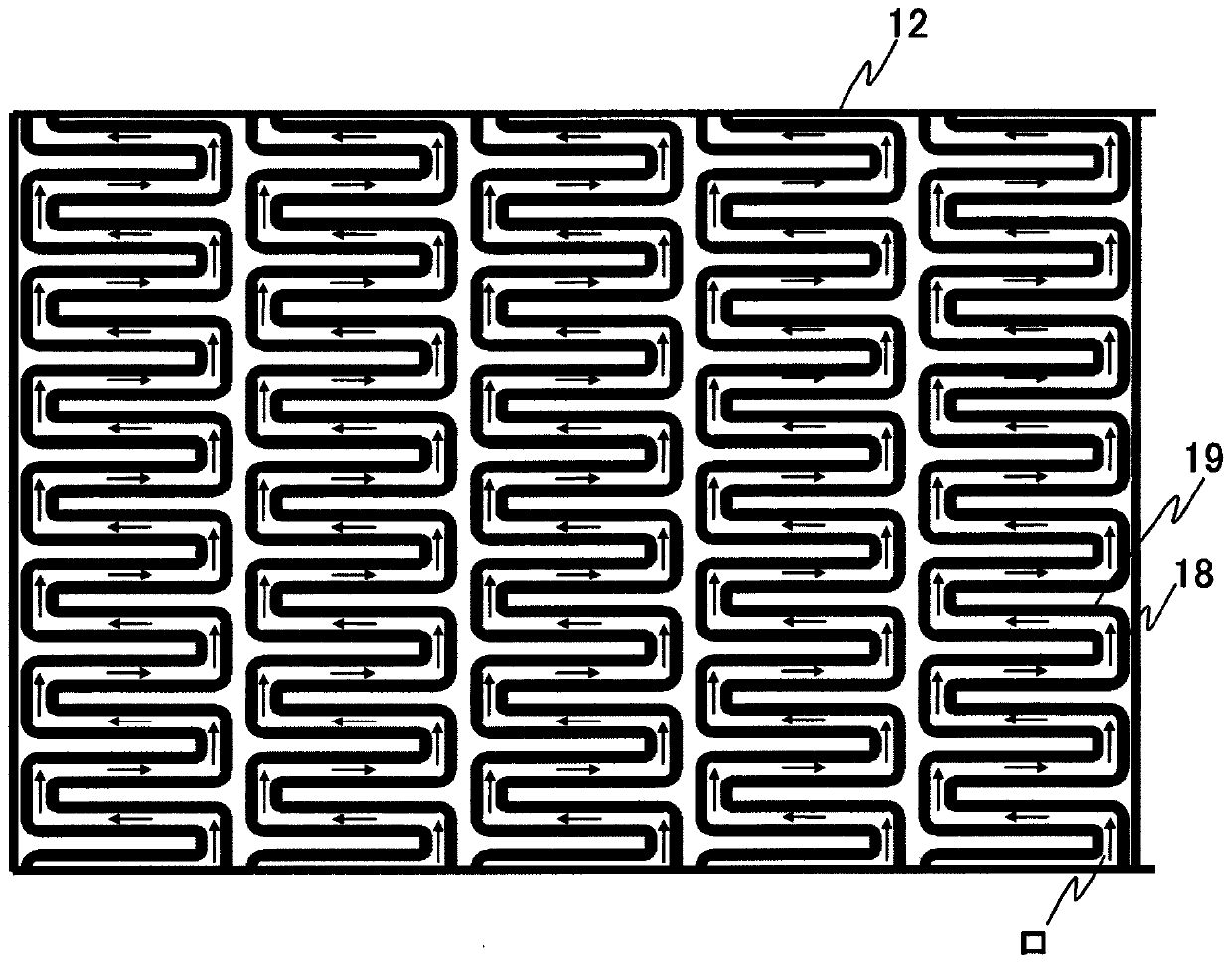

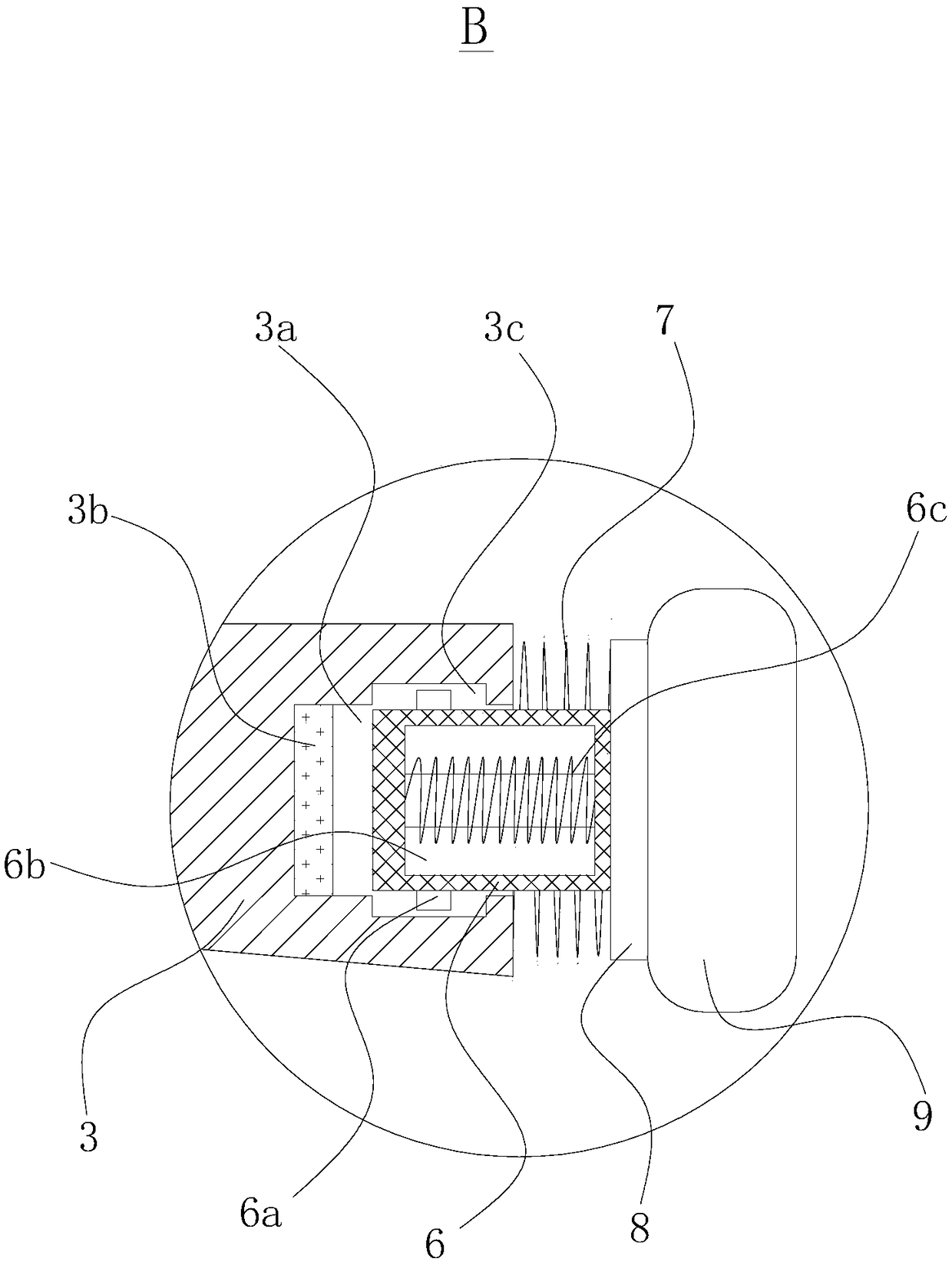

ActiveCN110226365AIncrease fluid resistanceLow fluid resistanceSemiconductor/solid-state device detailsSolid-state devicesRefrigerantHeat spreader

Provided is a heat sink, wherein: a first radiating fin (12) having a low fluid resistance and formed in a pin shape is disposed in a region requiring high cooling performance; and a second radiatingfin (13) having a high fluid resistance and having a shape in which a plurality of rows of zigzag meandering grooves are arranged at a narrow pitch is disposed in a region not requiring high cooling performance. Furthermore, the first radiating fin (12) and the second radiating fin (13) are arranged in parallel to the direction of flow of a coolant.

Owner:MITSUBISHI ELECTRIC CORP

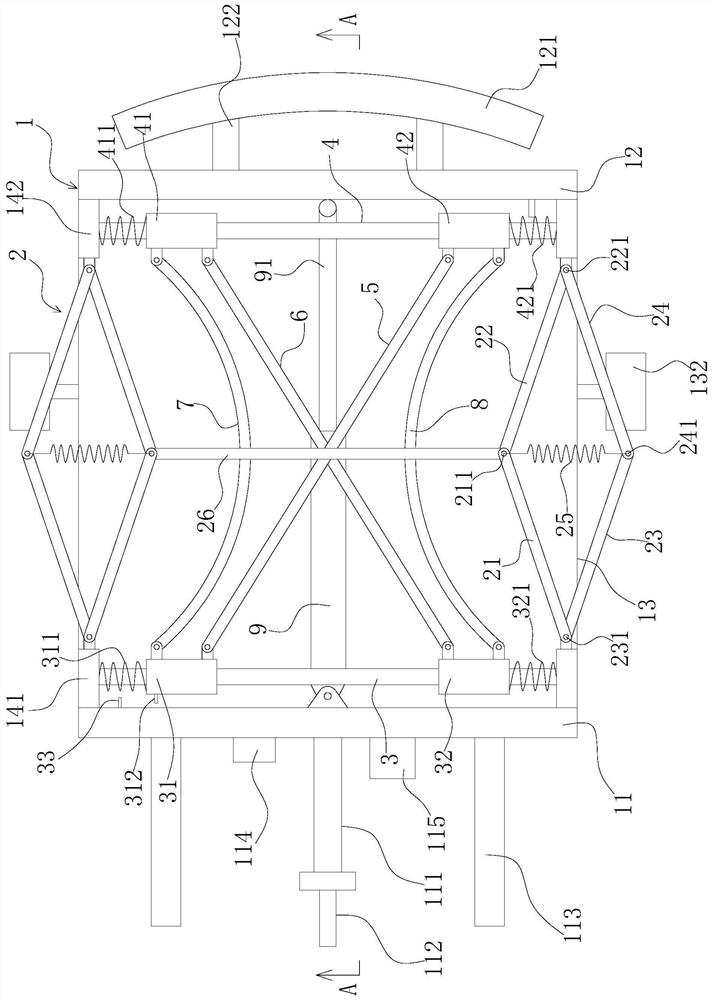

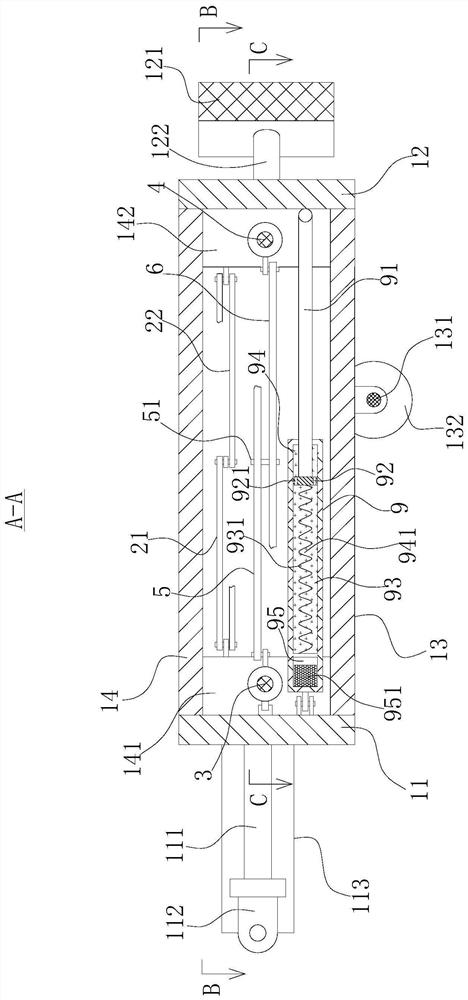

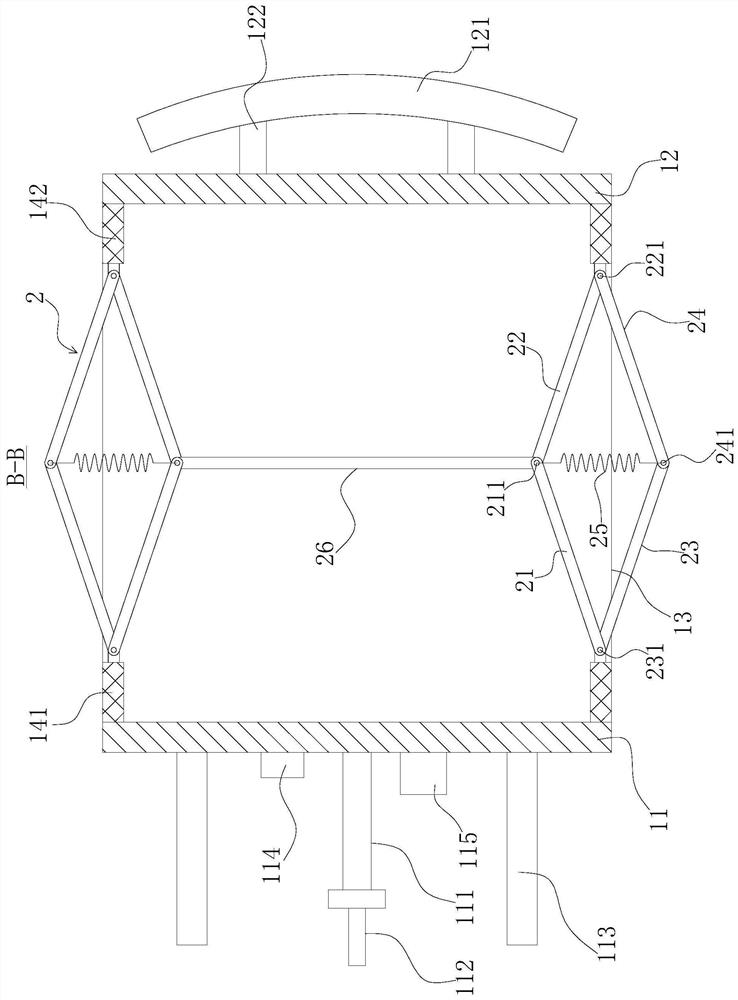

Anti-collision device for anti-collision buffer vehicle

ActiveCN112550195AImprove securityPlay an auxiliary supporting roleBumpersMechanical engineeringRoad construction

The invention provides an anti-collision device for an anti-collision buffer vehicle, and belongs to the technical field of traffic equipment. The device comprises a frame body, a first sliding rod, asecond sliding rod, a first rotating rod, a second rotating rod, an elastic supporting mechanism and an auxiliary supporting mechanism, the frame body comprises a first connecting plate and a secondconnecting plate, a towing hook is fixedly arranged on the front side face of the first connecting plate, and the first sliding rod and the second sliding rod are symmetrically arranged on the first connecting plate and the second connecting plate; the middles of the first rotating rod and the second rotating rod are hinged together, the front end of the first rotating rod and the front end of thesecond rotating rod are arranged on the first sliding rod in a sliding mode, the rear end of the first rotating rod and the rear end of the second rotating rod are arranged on the second sliding rodin a sliding mode, and the elastic supporting mechanism can restrain the first connecting plate and the second connecting plate from getting close to each other. The auxiliary supporting mechanism canplay an auxiliary supporting role on the first connecting plate and the second connecting plate. The anti-collision device has multiple anti-collision buffer functions, and the safety of road construction can be improved.

Owner:ZHEJIANG OCEAN UNIV

Compound heat pipe, method of manufacturing the same, heat exchanger and heat exchanger system using the same

ActiveCN102538544AIncrease the areaIncrease fluid resistanceEnergy efficient heating/coolingIndirect heat exchangersEngineeringPhysical property

The compound heat pipe according to the present invention may overcome physical limits, which a single metal pipe might have, by integrally joining different metal pipes having different physical properties, forming ridges on an inner surface thereof the pipe and protrusions on an outer surface thereof and may first increase heat transfer capability by increasing the heat transfer area between the pipe and fluid. Further, the compound heat pipe according to the present invention may secondly increase the heat transfer capability by setting the noncontact rate to be 30% or less so that the heat transfer rate of the compound heat pipe in the radial direction may be optimized.

Owner:LG ELECTRONICS INC

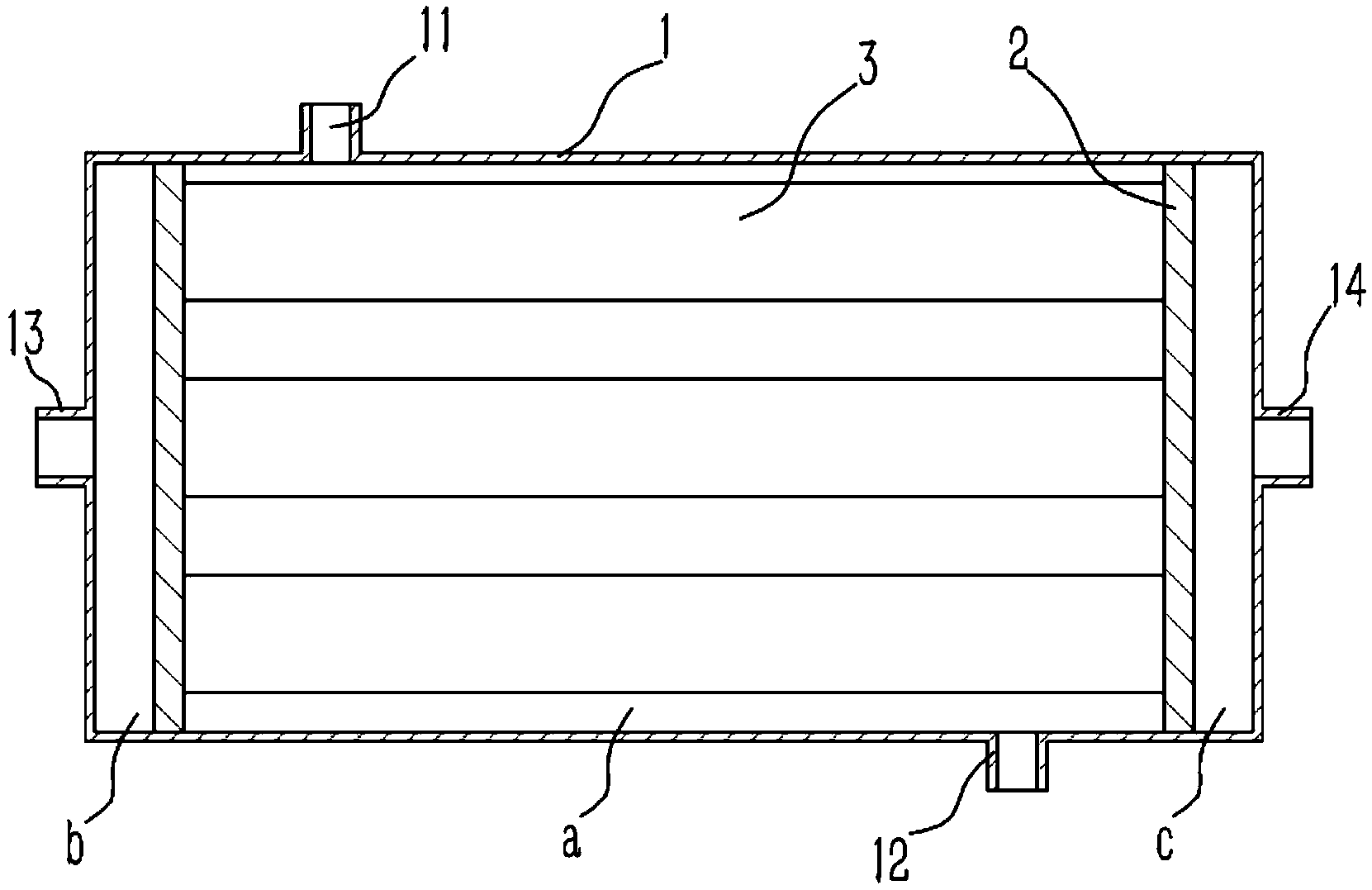

Water tank structure of heat exchange water tank

ActiveCN104266505AIncrease fluid resistanceEfficient heat transferStationary conduit assembliesTubular elementsInlet valveThermal water

A water tank structure of a heat exchange water tank comprises a valve body, wherein a cylindrical valve cavity is formed in the valve body. An air inlet and an air outlet communicated with the valve cavity are formed at the upper end and the lower end of the valve body respectively. A reamed hole is formed on the inside wall of the valve body close to the air outlet end, and threads are formed on the inside wall of the reamed hole. A valve plate is arranged in the valve cavity of the valve body, a boss is formed on the upper end surface of the valve plate, a barrel-shaped protection cover is fixedly inserted and sleeved on the boss, a plurality of air inlet holes are formed on the protection cover, and the protection cover is connected into the air inlet of the valve body in an inserting way. Sealing pads are fixed on the valve plate surrounding the boss and press against the upper bottom surface of the valve body. A protection structure is added at the air inlet end on the basis of the existing hot water pollution discharge air inlet valve, the inner structure of the valve body is correspondingly modified, and therefore the pollution discharge air inlet valve has the function of preventing large-particle sundries from blocking the air inlet.

Owner:巨浪(苏州)热水器有限公司

Practice gun with improved structure

The invention provides a practice gun with an improved structure, and belongs to the technical field of firearm equipment. The practice gun with the improved structure comprises a gun body, a gun barrel and a gun stock. The gun barrel is connected with the gun stock through the gun body, an installation blind hole is horizontally formed in the end, away from the gun body, of the gun stock, and theinstallation blind hole is internally and slidably provided with a movable block. One end of the movable block extends out the installation blind hole and a top plate is fixedly arranged at the end of the movable block, a resetting spring is arranged on the movable block in a sleeving mode, one end of the resetting spring is fixedly connected with the top plate, and the other end of the resettingspring is fixedly connected with the gun stock. An elastic air bag is arranged on the side, away from the movable block, of the top plate, and a stabilizing mechanism which can prevent the gun body from shaking left and right under the influence of recoil when a bullet is fired is arranged on the lower side face of the gun body. According to the practice gun with the improved structure, the recoil of firearms can be reduced, and left-right shaking of the gun body when firing is prevented.

Owner:ZHEJIANG OCEAN UNIV

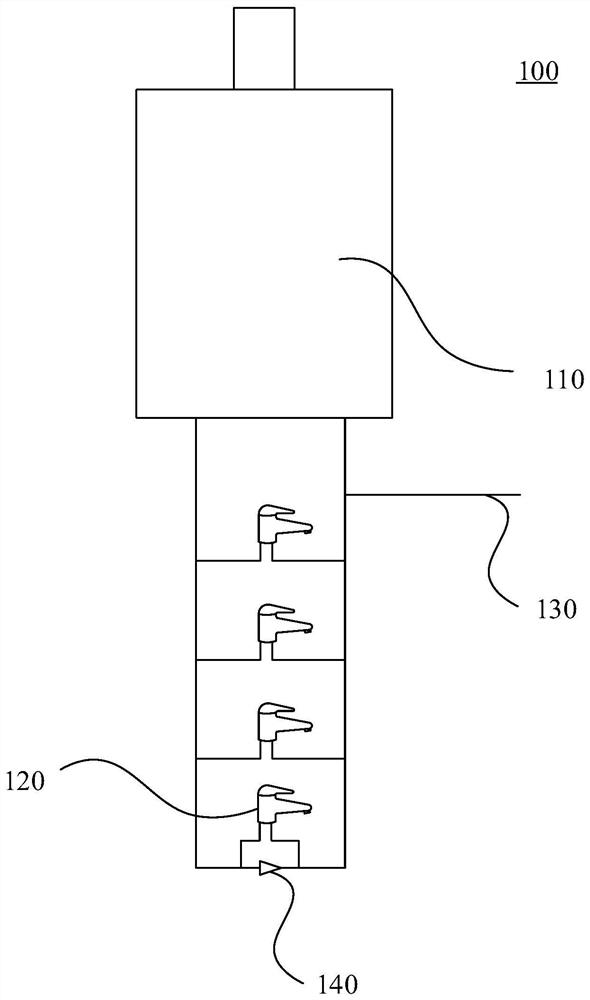

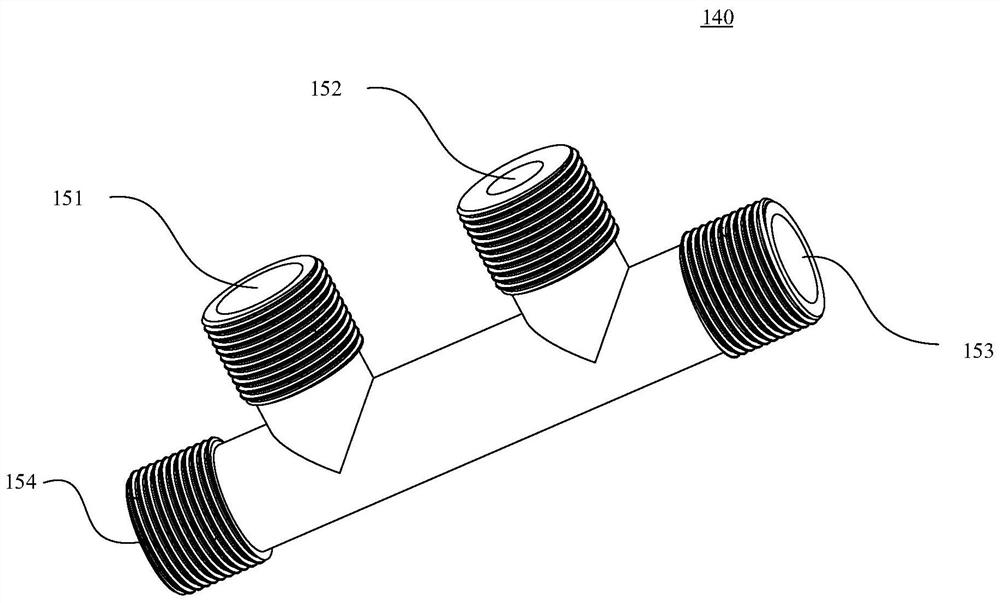

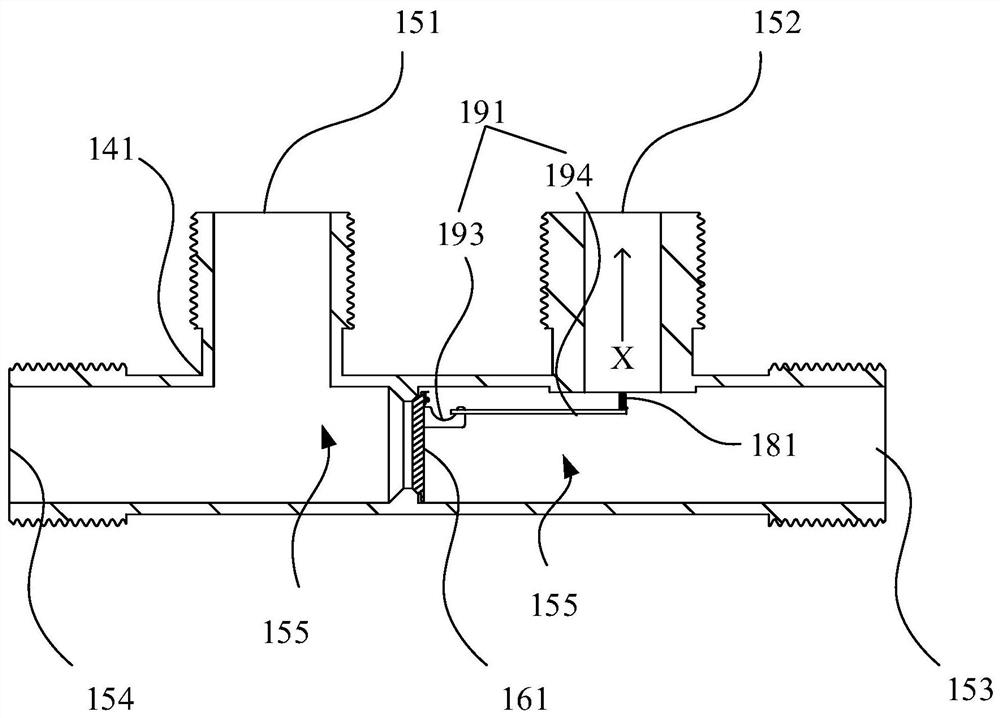

One-way valve and gas water heater system comprising same

ActiveCN112228592AIncrease fluid resistanceReduce resistanceFluid heatersCheck valvesWater useWater flow

The invention discloses a one-way valve and a gas water heater system comprising the same. The one-way valve comprises a shell, a valve plug, a linkage mechanism and a resistance component, wherein the valve plug, the linkage mechanism and the resistance component are arranged in the shell; the shell is provided with a first fluid outlet and a second fluid outlet; the valve plug is arranged between the first fluid outlet and the second fluid outlet and used for opening and closing a main flow channel between the first fluid outlet and the second fluid outlet; the resistance component is arranged at the second fluid outlet; and the linkage mechanism is connected with the valve plug and the resistance component and arranged to drive the resistance component to be switched from a first position to a second position when the main flow channel is opened by the valve plug. The one-way valve prevents the water outlet resistance from being too small when water flows out of the second fluid outlet of the one-way valve. The gas water heater system using the one-way valve can avoid accidental starting of a water heater due to the fact that resistance of a cold water connector at a water usingend is smaller than that of a hot water connector.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Bidirectional bell and spigot clad pipe based on enhanced steel skeleton and process for producing clad pipe

Disclosed are a bidirectional bell and spigot clad pipe based on an enhanced steel skeleton and a process for producing the clad pipe. The producing process includes the technical scheme of producing a main skeleton and a secondary skeleton by the process of casting and stamping, producing a bell-and-spigot main pipe and a bell-and-spigot secondary pipe by the process of injection molding and powder coating, then performing bidirectional adaptive connection and assembling to form a set of bell-and-spigot clad pipe, and performing protection treatment, wherein a covering layer is arranged outside the main skeleton of the bell-and-spigot main pipe, a separation convex ring is arranged in the inner cavity of the main skeleton of the bell-and-spigot main pipe, bell-and-spigot cavities which are in an adaptive connection with the bell-and-spigot secondary pipe are arranged on two sides of the separation convex ring respectively, a set of grooves are arranged in each of the bell-and-spigot cavities, and adaptive sealing rings are arranged in the grooves. According to the bidirectional bell and spigot clad pipe based on the enhanced steel skeleton and the producing process thereof, the defects are overcome that the existing cast-iron pipes, cast-steel pipes, poly ethylene pipes and plastic pipes and the like can not be interchanged, when the pipes are connected and installed, electricity has to be provided, rapid stress cracking is easy to happen in welding, and when the connection of breakage portions exceeds the length of half pipe, water leakage, gas leakage, fluid leakage and environment pollution are caused. The bidirectional bell and spigot clad pipe is applicable to various connection pipes in water transportation and gas transportation engineering and particularly applicable to interchange connection bell and spigot of ductile iron pipes and plastic pipes such as poly ethylene pipes, rigid polyvinyl chloride pipes and modified polyvinyl chloride pipes.

Owner:HUNAN ZHENHUI PIPE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com