Socket reinforced composite plastic pipe and manufacturing process thereof

A plastic pipe and composite technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as difficult maintenance of water supply, gas supply, and liquid supply systems, difficulty in ensuring the quality of butt joints, and water and air leakage in pipes, etc. , to achieve broad market prospects and promotion potential, significant welding effect, no increase in fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

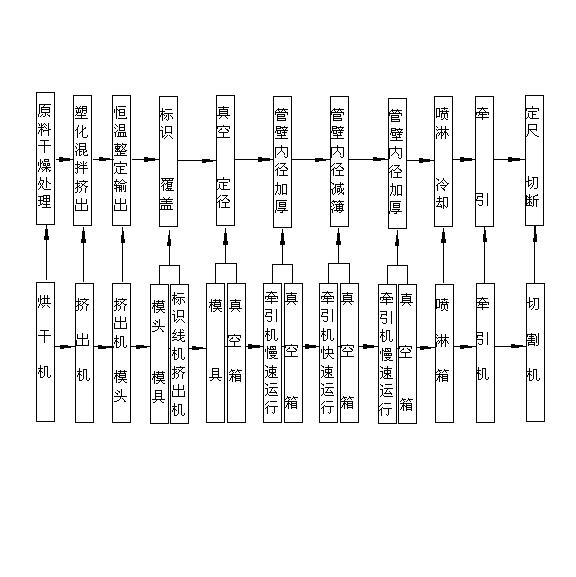

Method used

Image

Examples

Embodiment Construction

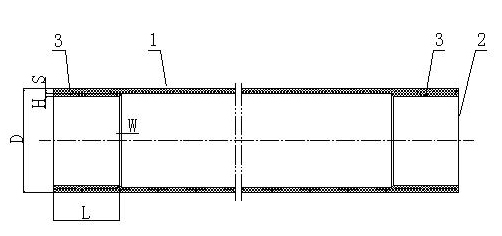

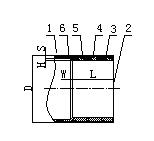

[0032] Referring to the drawings, a socket-reinforced composite plastic pipe includes a pipe wall 1 and a socket 2, and a convex ring 3 is provided on the pipe wall 1 with an inner diameter of L at the end of the socket 2.

[0033] By the attachment Figure 4 As shown, D-tube wall 1 outer diameter (mm), S-tube wall 1 wall thickness (mm), H-convex ring 3 ring thickness (mm), L-socket 2 end inner diameter length (mm). In order to further improve the overall performance of the pipe, the rigidity, strength, toughness, insulation, wear resistance, and corrosion resistance of the product can be greatly improved. For pipes with different sizes of outer diameter D, the corresponding convex ring 3 rings are used. Thickness H, wall thickness S of pipe wall 1. This embodiment provides the ratio range of the corresponding ratio between the ring thickness H of the convex ring 3 and the outer diameter D of the pipe wall 1 and the wall thickness S of the pipe wall 1 as follows:

[0034] In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com