Patents

Literature

35results about How to "Improve section strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

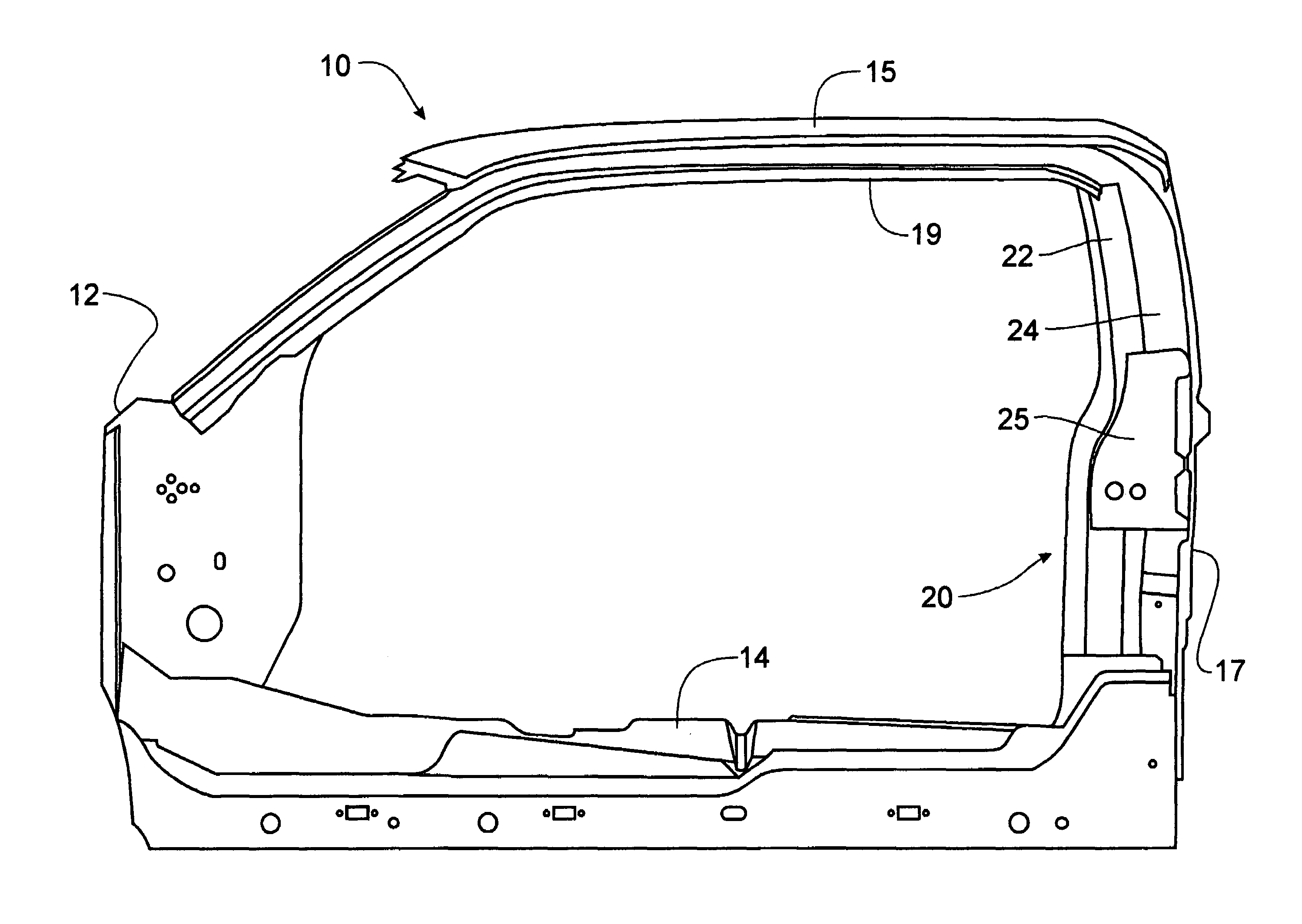

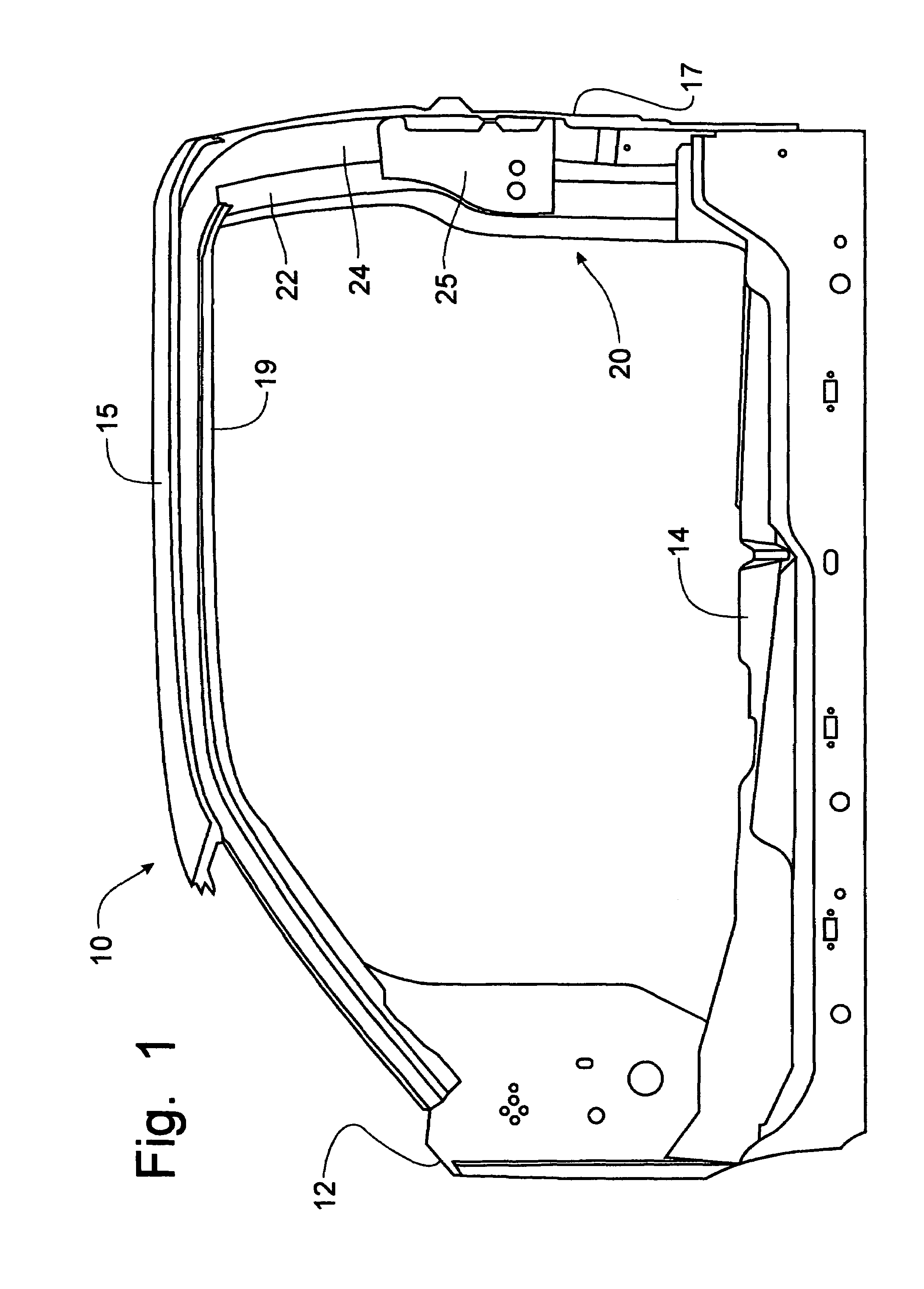

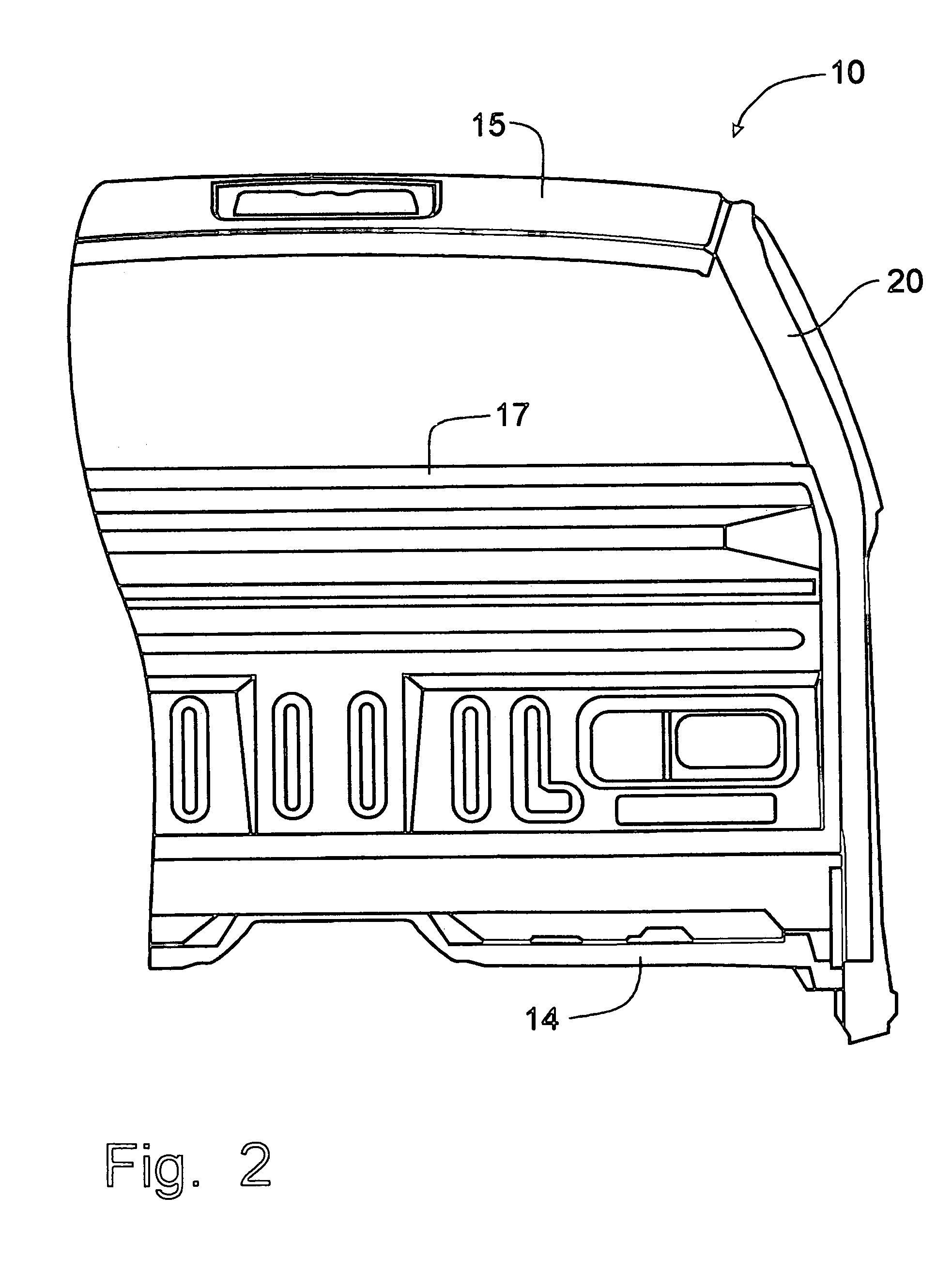

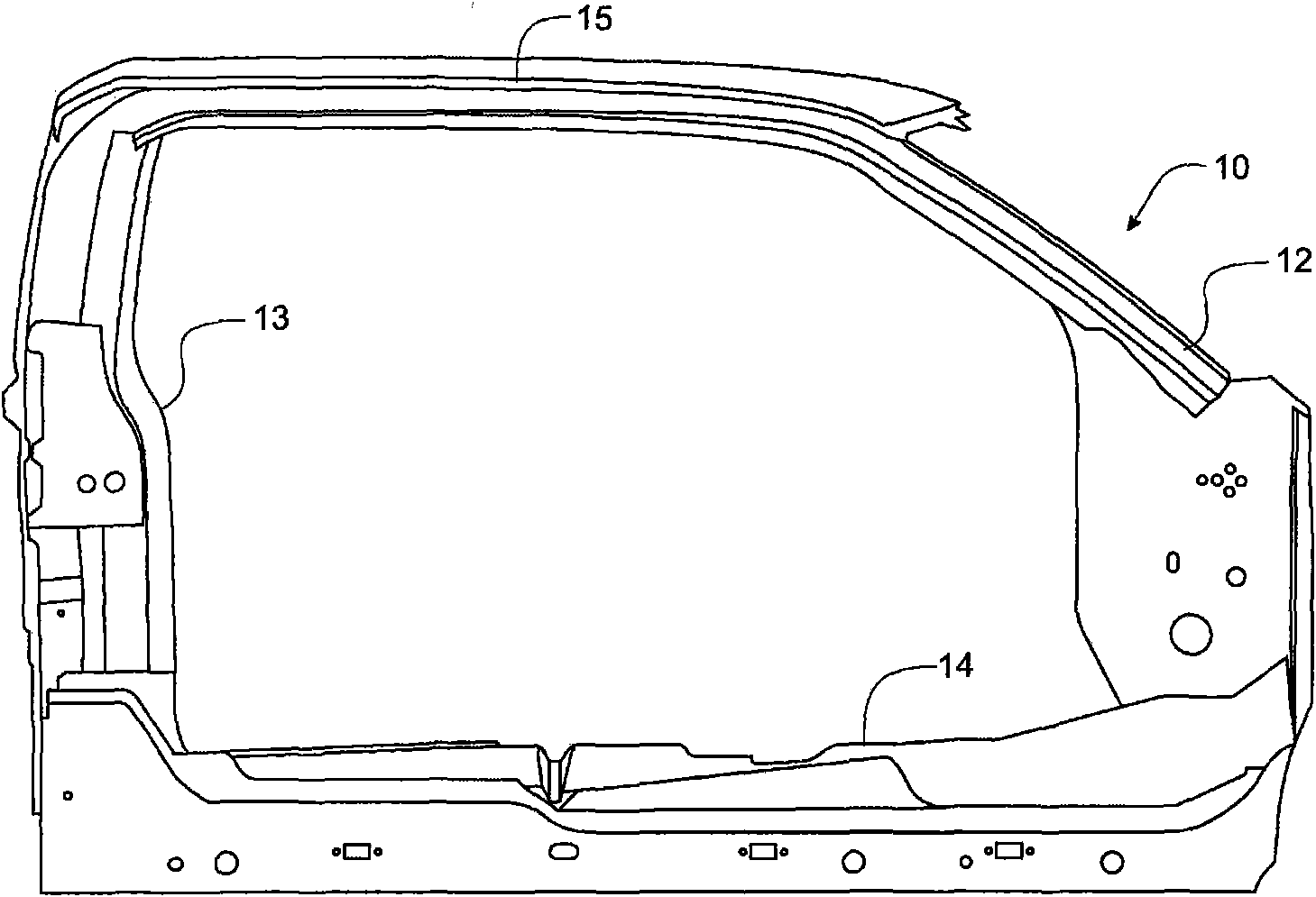

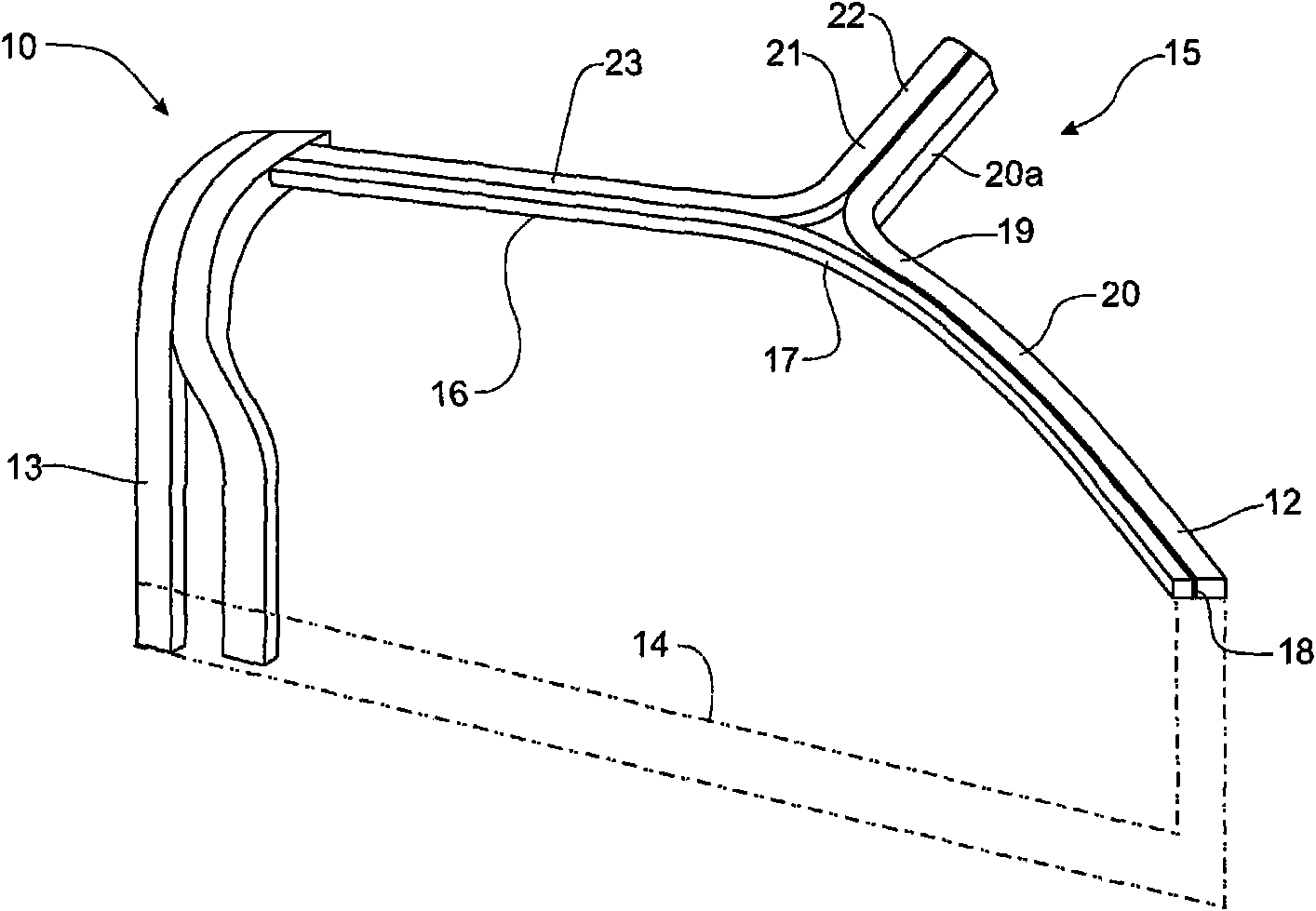

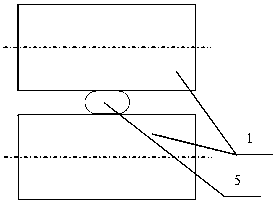

Dual cell rear corner pillar for automobiles

InactiveUS7543882B2High strengthImprove section strengthVehicle seatsUnderstructuresEngineeringFlange

A dual cell rear corner pillar for the operator's compartment of a pick-up truck is formed with longitudinally oriented front and rear tubular members. The dual cell tubular construction increases section strength for the rear corner pillar while maintaining packaging constraints for the rear pillar design. The front tubular member is nested against the rear tubular member to provide support therefor longitudinally and vertically. The forward tubular member is welded to the door opening panel seal flange, while the rearward tubular member is welded to the window flange and the back panel flange. The forward and rearward tubular members are also welded to one another to form a strong pillar structure. The dual cell configuration resists buckling and shares loading. The rear tubular member wraps around the front tubular member and transitions into the roof rail area, shortening the unsupported moment arm of the rear tubular member.

Owner:FORD MOTOR CO

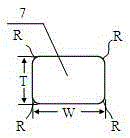

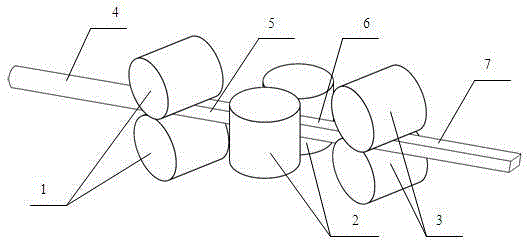

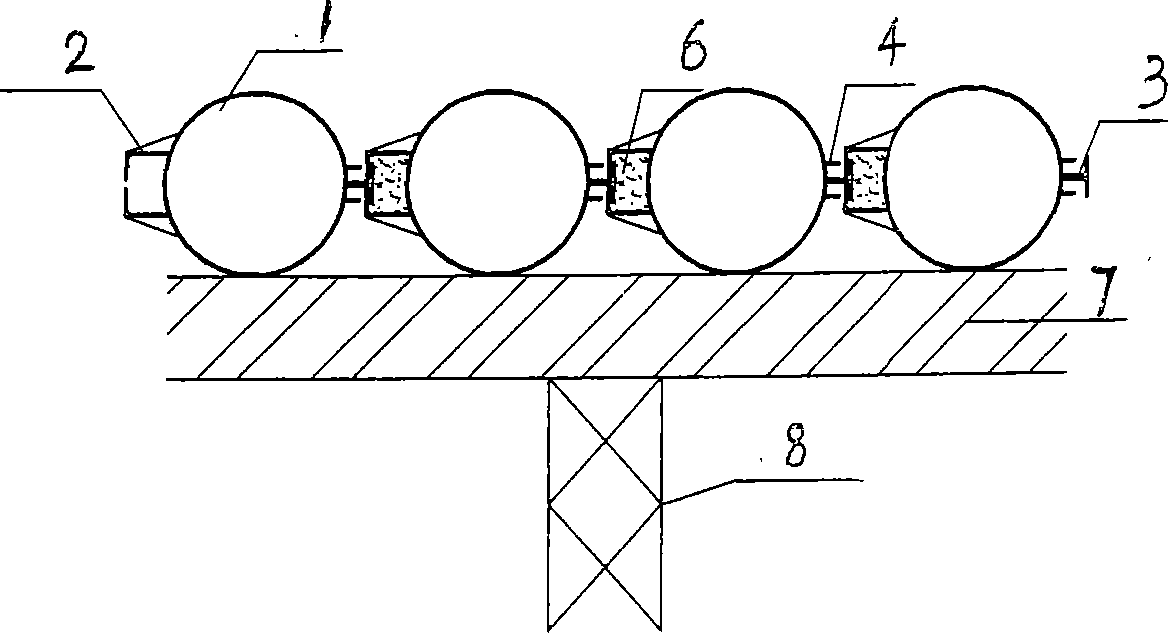

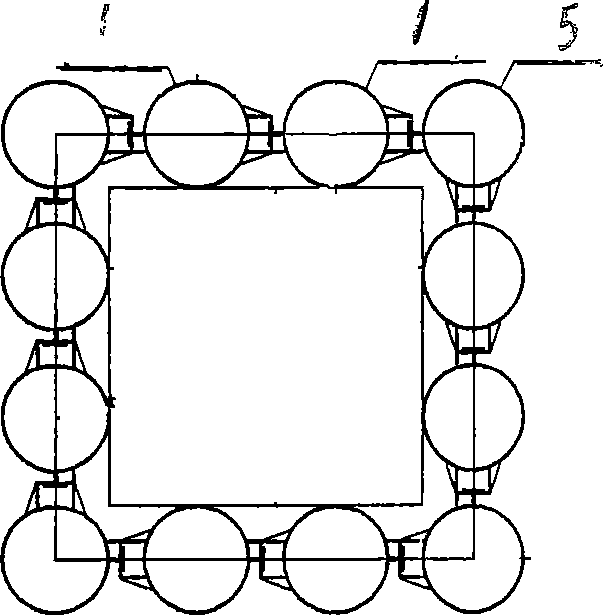

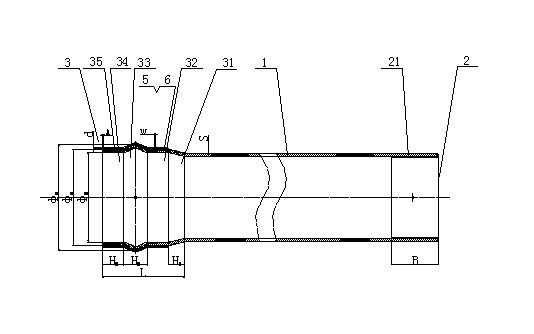

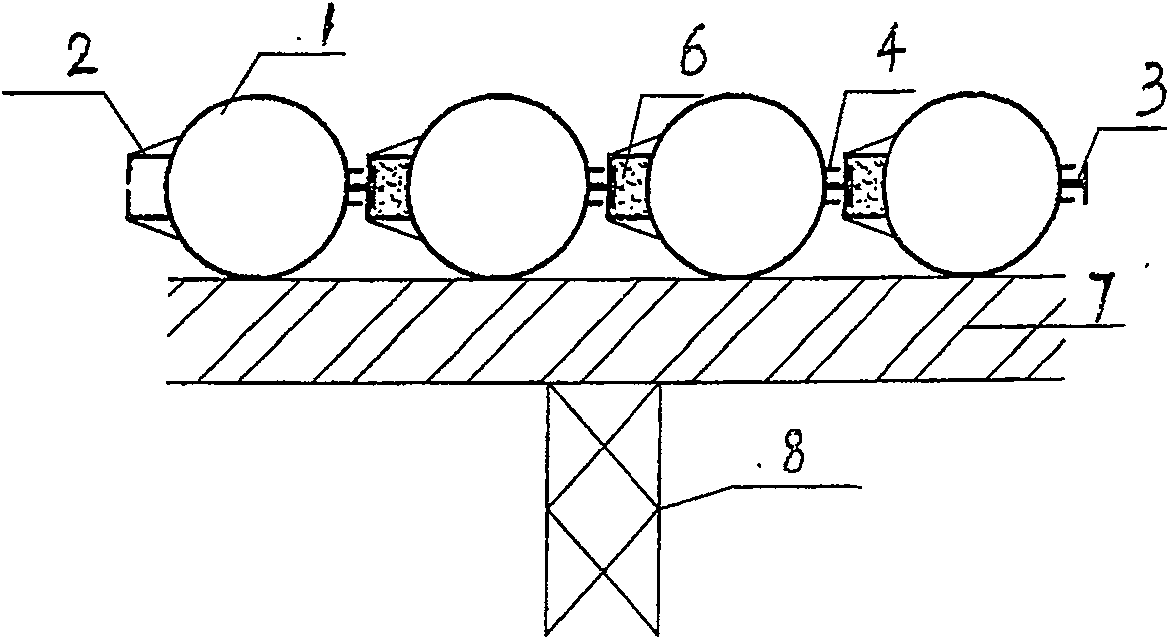

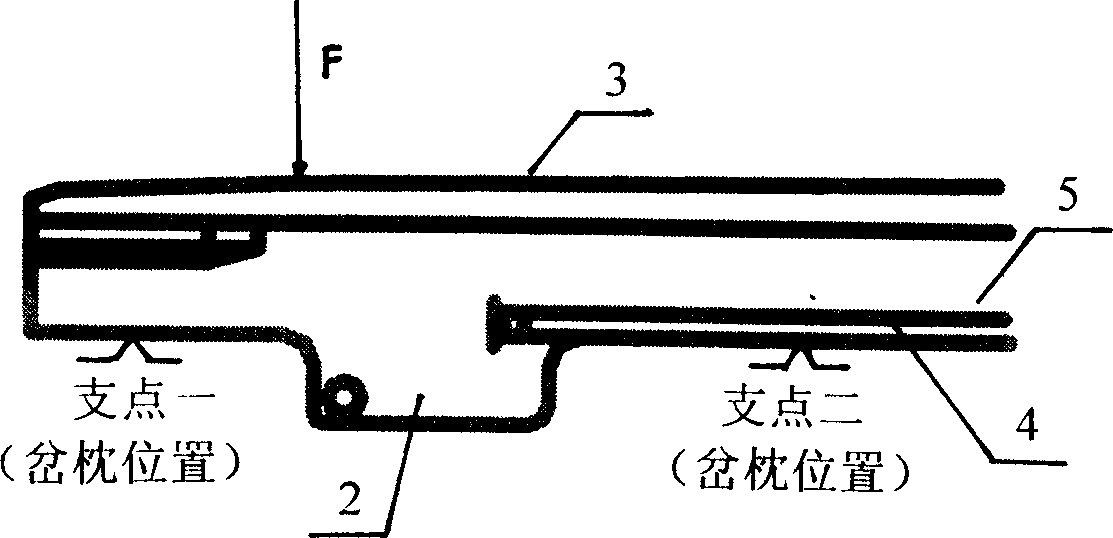

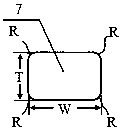

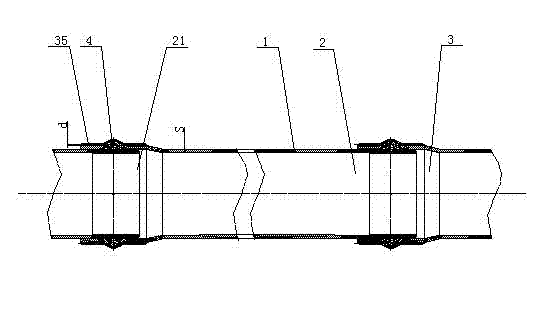

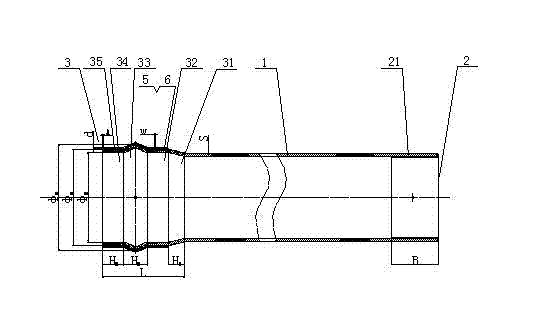

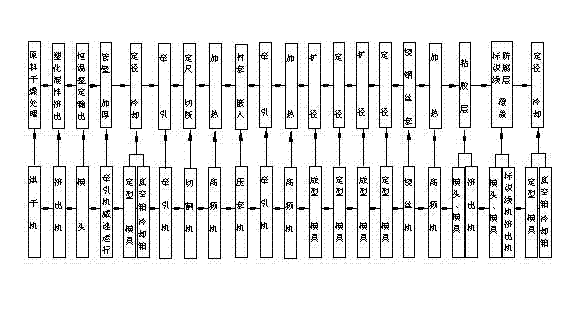

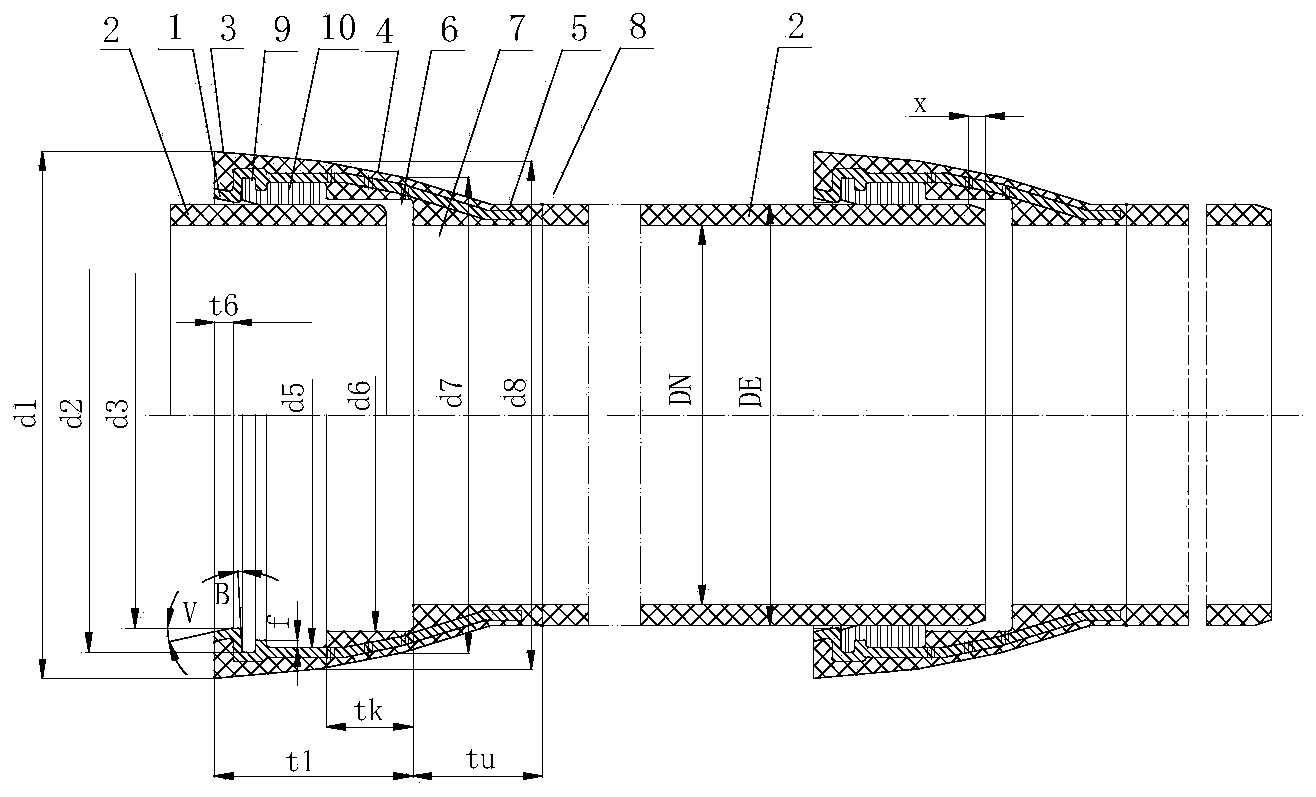

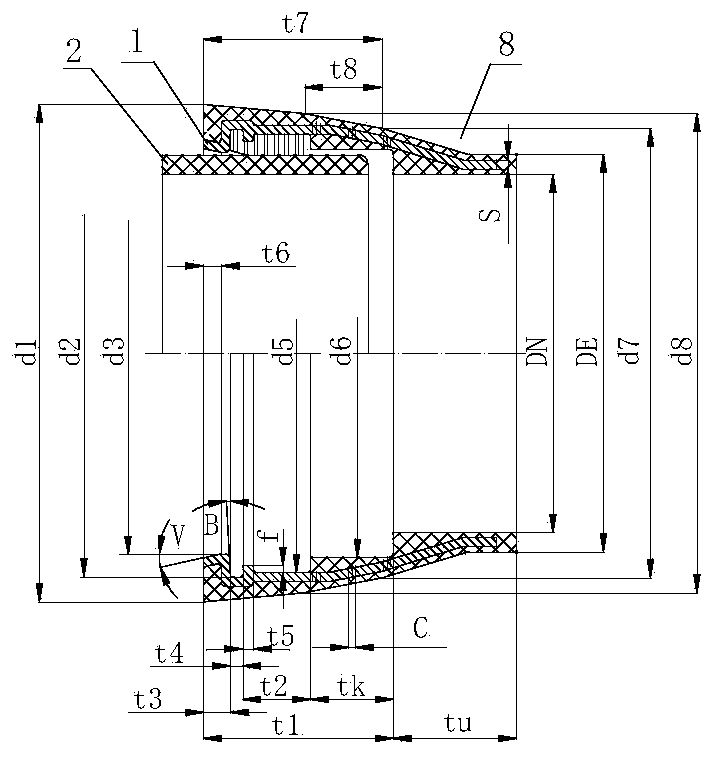

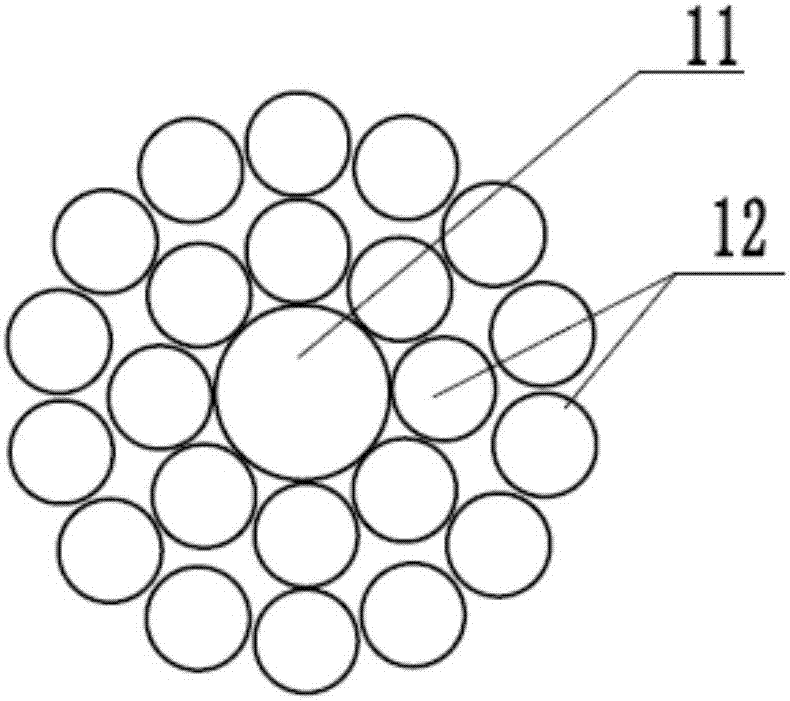

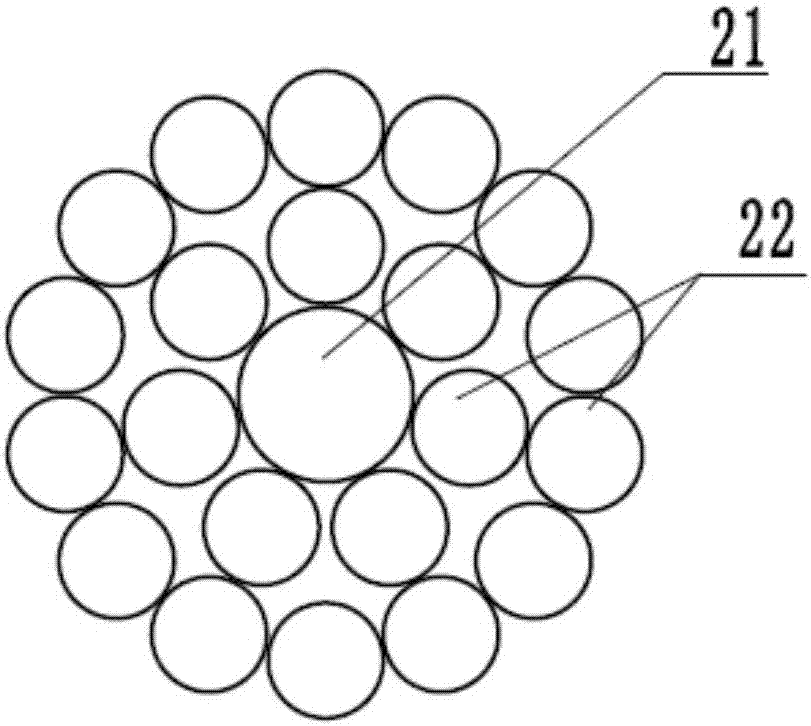

Rectangular cross-section steel wire for radial tire and method for manufacturing steel wire ring thereof

ActiveCN105383227AReduce contact stressImprove section strengthTyre beadsTear resistanceWear resistance

The invention discloses a rectangular cross-section steel wire for a radial tire and a method for manufacturing a steel wire ring thereof. The rectangular cross-section steel wire is manufactured by adopting a round cross-section high-carbon steel wire in a roller-drawing mode and undergoes surface galvanization and tempering treatment, and m rectangular steel wires are twined side by side in n layers and are bundled by straps for forming the steel wire ring. The steel wire ring serves as a tire bead core of the radial tire and is small in cross section area; surface contact is adopted between the steel wires, and therefore the geometrical shape stability is good; the contact stress between the steel wires is small, the cross section strength between the steel wires is high, and therefore the wear resistance and the tearing resistance of a tire bead can be improved, and the manufacturing cost of the tire can be reduced.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Construction method of opening locked steel tube pilecofferdam

ActiveCN101182717AFlexible connectionImprove section strengthBridge structural detailsFoundation engineeringPile capSludge

A cofferdam construction method of locking steel pipe piles, which is carried out in accordance with the following steps: ①Processing steel pipe piles: respectively processing a female buckle and a male buckle on a spiral pipe; Lift the steel pipe columns one by one to the design position, and then use mechanical aid to sink to the design position; ③ grouting at the lock; line the lock of the male buckle and the female buckle with a cloth bag, and fill the bag with slurry; ④ Set up the inner support of the cofferdam; ⑤ Pouring concrete for the bottom cover. The present invention has the following advantages and positive effects: 1. The connection is flexible and can be used for various forms of cofferdam assembly. 2. High section strength and rigidity, simple and convenient support. 3. The processing is simple, no large-scale machinery and equipment is required, no large-scale floating facilities are required, and it can be carried out simultaneously with the pile foundation construction. 4. Easy to operate, not restricted by deep water and silt. 5. It has enough rigidity to meet the rigidity and strength of mechanical sinking. 6. Strong sealing.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

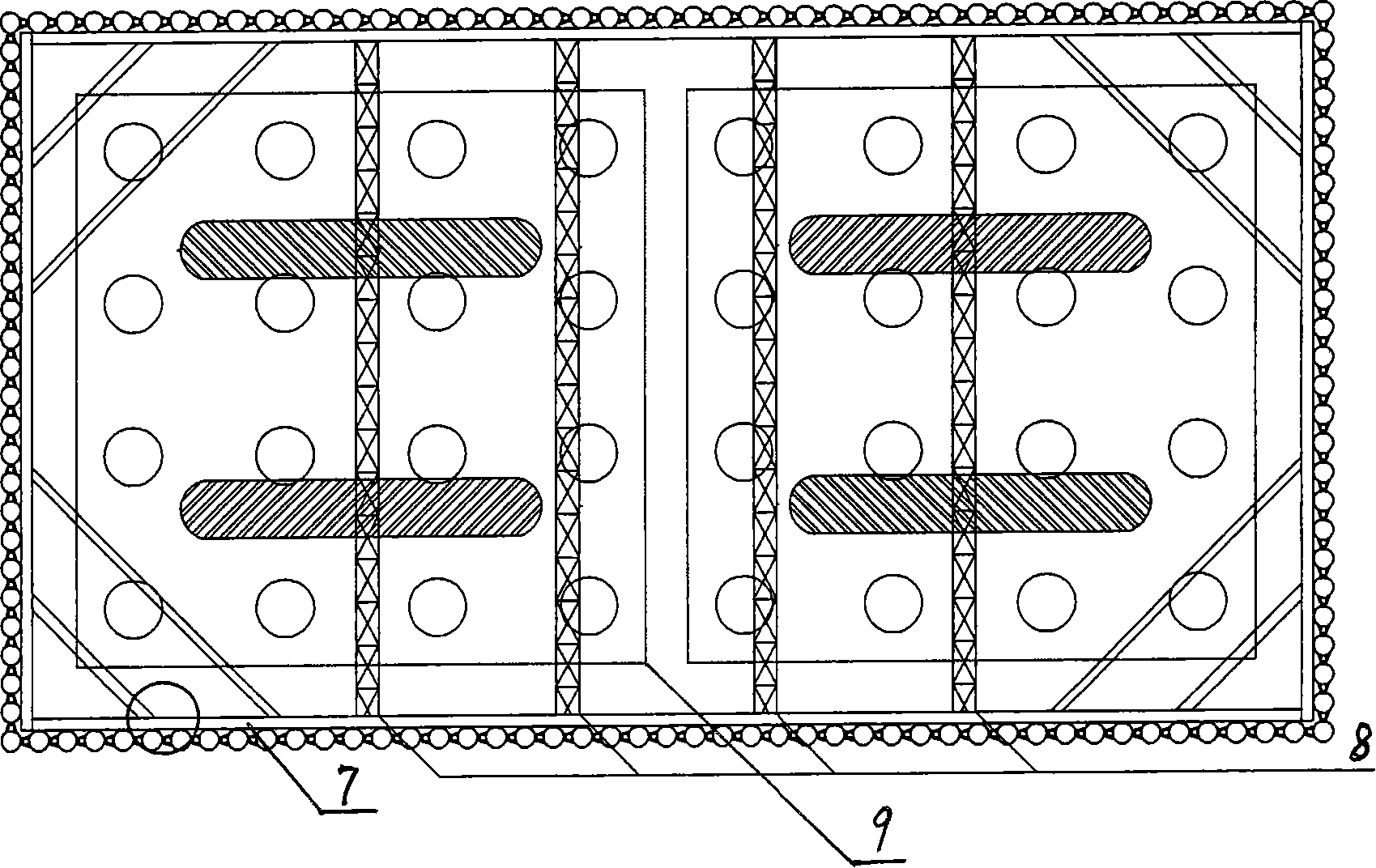

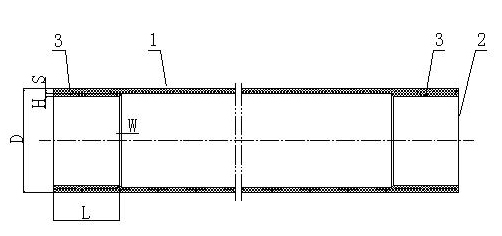

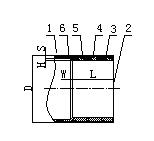

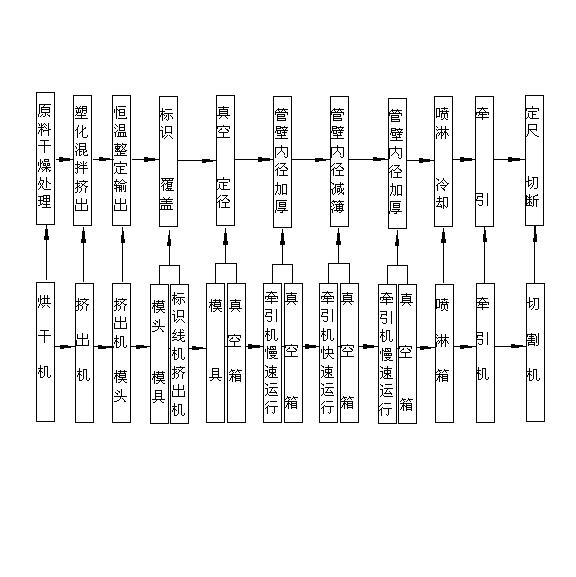

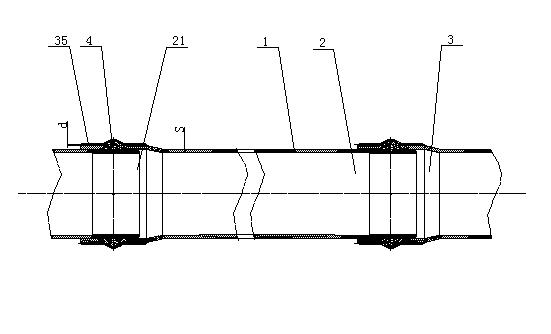

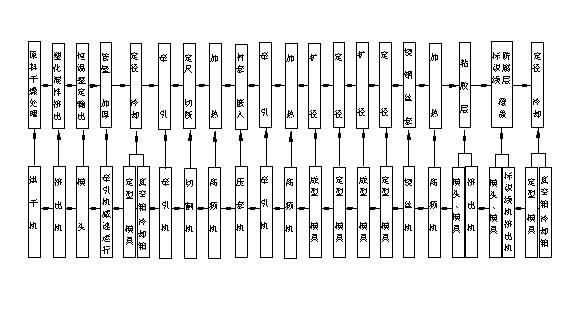

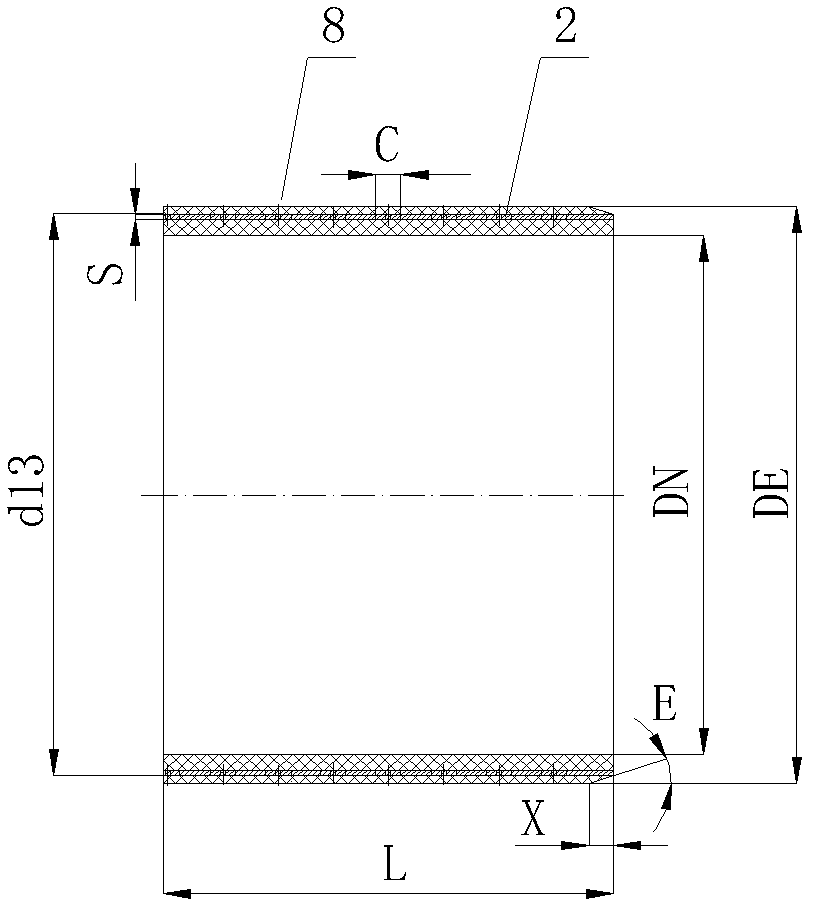

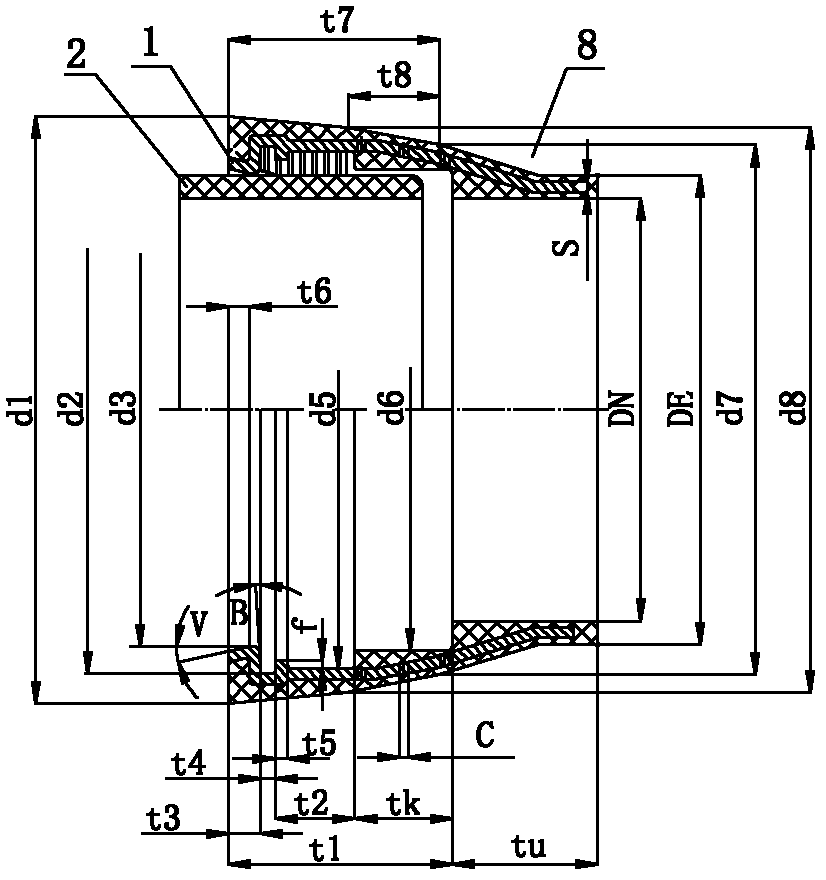

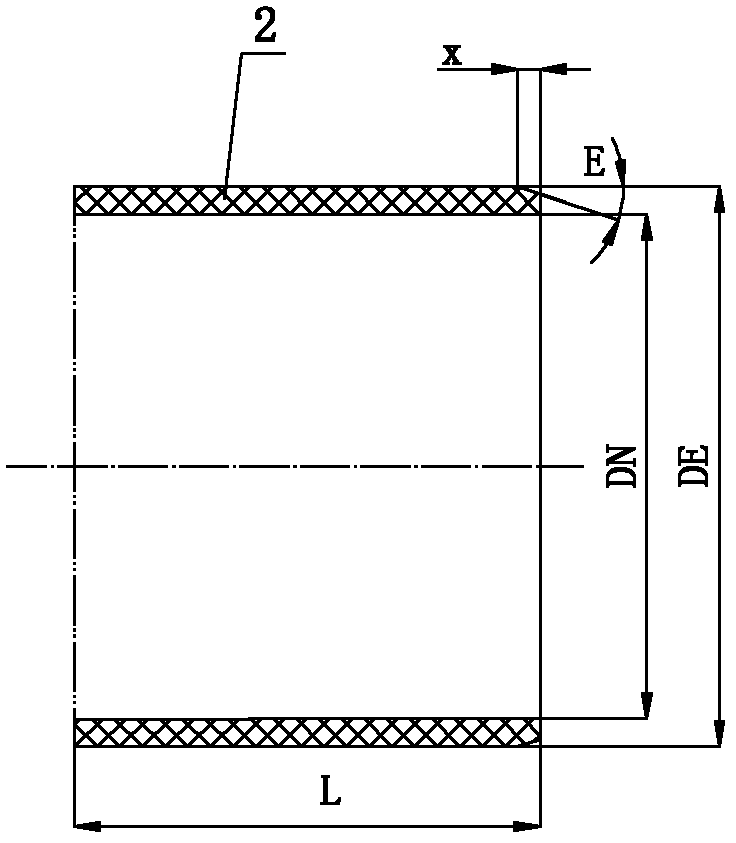

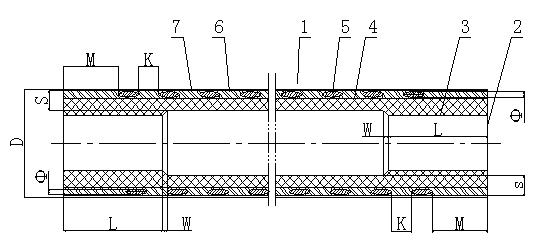

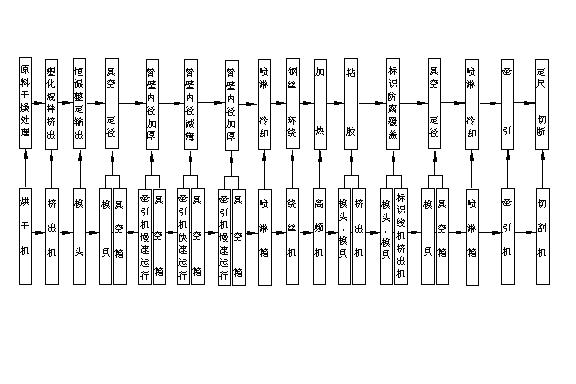

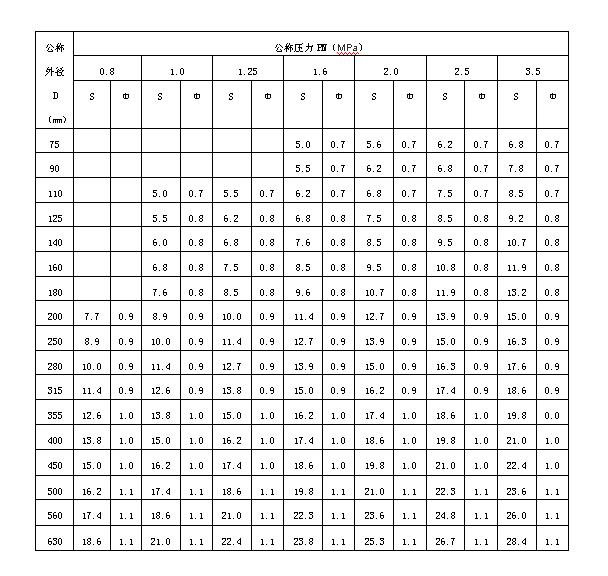

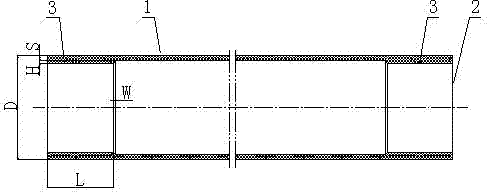

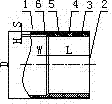

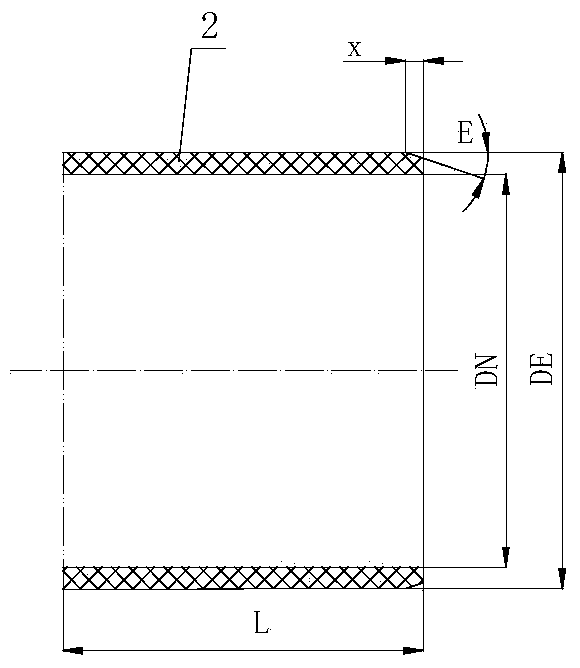

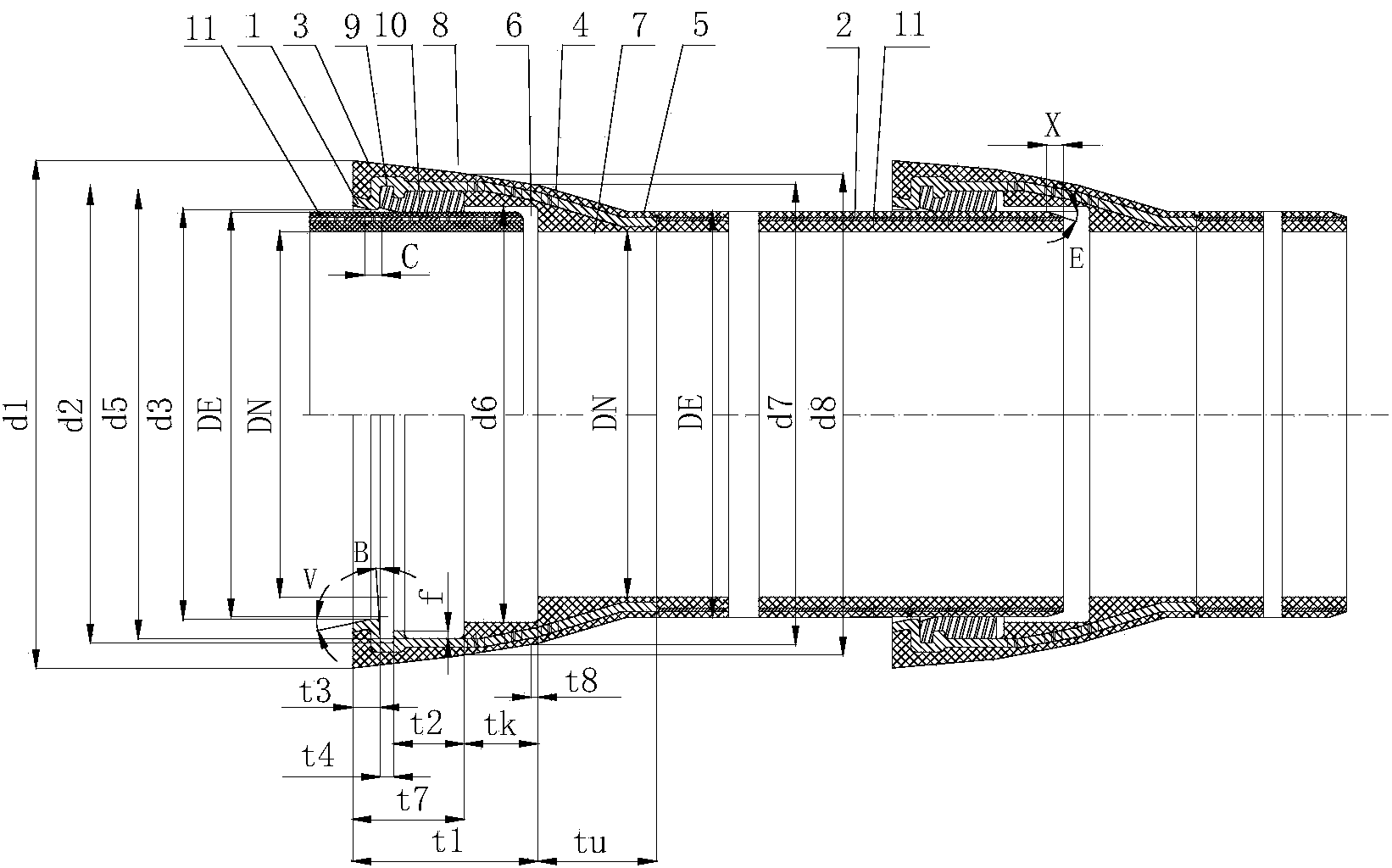

Socket reinforced composite plastic pipe and manufacturing process thereof

ActiveCN101788084ASimple structureSimple manufacturing processRigid pipesProcess engineeringWater leak

The invention relates to a socket reinforced composite plastic pipe and a manufacturing process thereof, and the socket reinforced composite plastic pipe comprises a pipe wall and a socket, wherein a convex ring is arranged at the pipe wall with the inner diameter of L at the end part of the socket, plastics and resin are mixed for being taken as raw materials, and the technical scheme simultaneously produces a product under the synchronous control of a drying machine, an extrusion machine, a mold head, a mold, a vacuum box, a spraying box, a traction machine, a cutting machine and other equipment. The socket reinforced composite plastic pipe can overcome the defects that the strength and the rigidity of the cross section at the butt joint between the pipe and the socket can not bear the internal pressure in the pipe for the existing polyethylene resin composite pipe-PE pipe, thereby causing expansion, deformation and cracking of the pipe wall of a pipe, further resulting in water leakage and gas leakage of a pipeline and causing difficult maintenance of a water supply system, a gas supply system and a liquid supply system, serious loss of resources, environmental pollution caused by gas leakage and the like; and the socket reinforced composite plastic pipe is applicable to being used as connecting pipe for various water transportation projects and gas transportation projects, in particular to socket thickening and reinforcing of PE, PVC-U, PVC-M and other plastic pipes.

Owner:HUNAN ZHENHUI PIPE IND

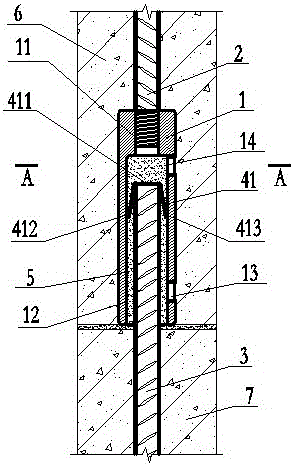

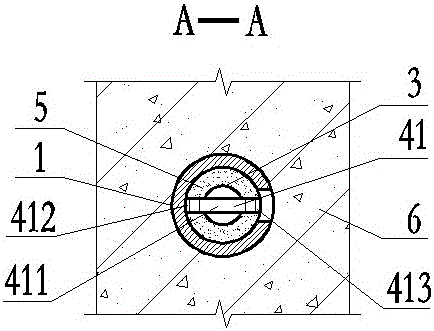

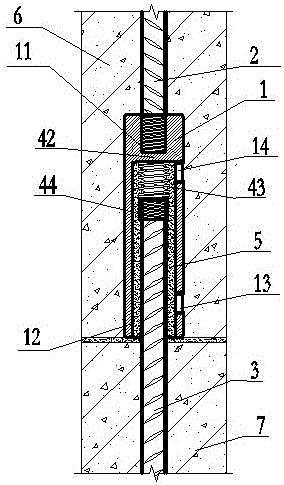

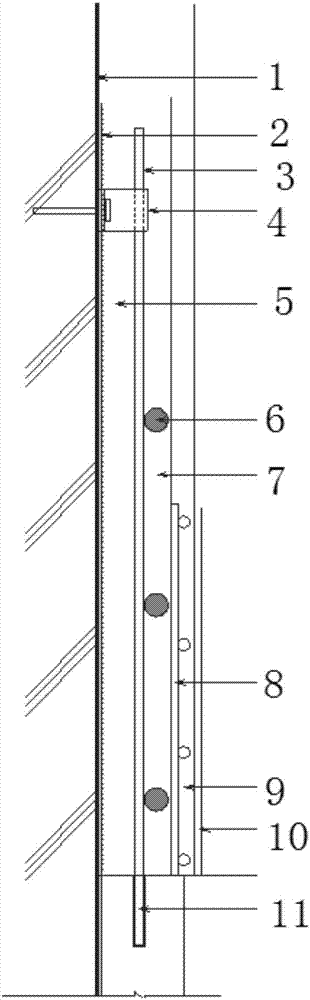

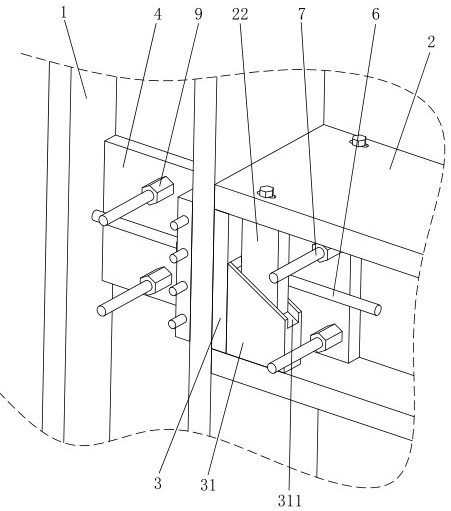

Sleeve connection device and construction method for lightning protection and grounding of structural steel bars in industrialized buildings

ActiveCN105064521BImprove section strengthGuaranteed reliable mechanical propertiesBuilding material handlingRebarLightning

The invention provides a sleeve connecting device with lightningproof grounding structure steel bars in industrial building. The sleeve connecting device comprises a grouting sleeve, a structure steel bar A, a structure steel bar B and a lightningproof connecting mechanism, wherein one end of the grouting sleeve is connected with one end of the structure steel bar A; the grouting sleeve and the structure steel bar A are embedded in a structure component A; the structure steel bar B is embedded in a structure component B; one end of the structure steel bar B extends out of the end surface of the structure component B; and the grouting sleeve is connected with the structural steel bar B through the lightningproof connecting mechanism. The construction method of the sleeve connecting device comprises the following steps of: processing the grouting sleeve; prefabricating the structure component A and the structure component B; processing the lightningproof connecting mechanism; connecting the lightningproof connecting mechanism into the grouting sleeve; hanging the structure component A and the structure component B in place; and completing the grouting. The structure steel bar A in the sleeve connecting device sequentially passes through the grouting sleeve and the lightningproof connecting structure to form a lightningproof conduction path with the structure steel bar B, so that the goal of using the structural steel bars of a vertical component in an assembled concrete structure as a lightningproof grounding downlead is achieved.

Owner:SICHUAN PROVINCIAL ARCHITECTURAL DESIGN & RES INST

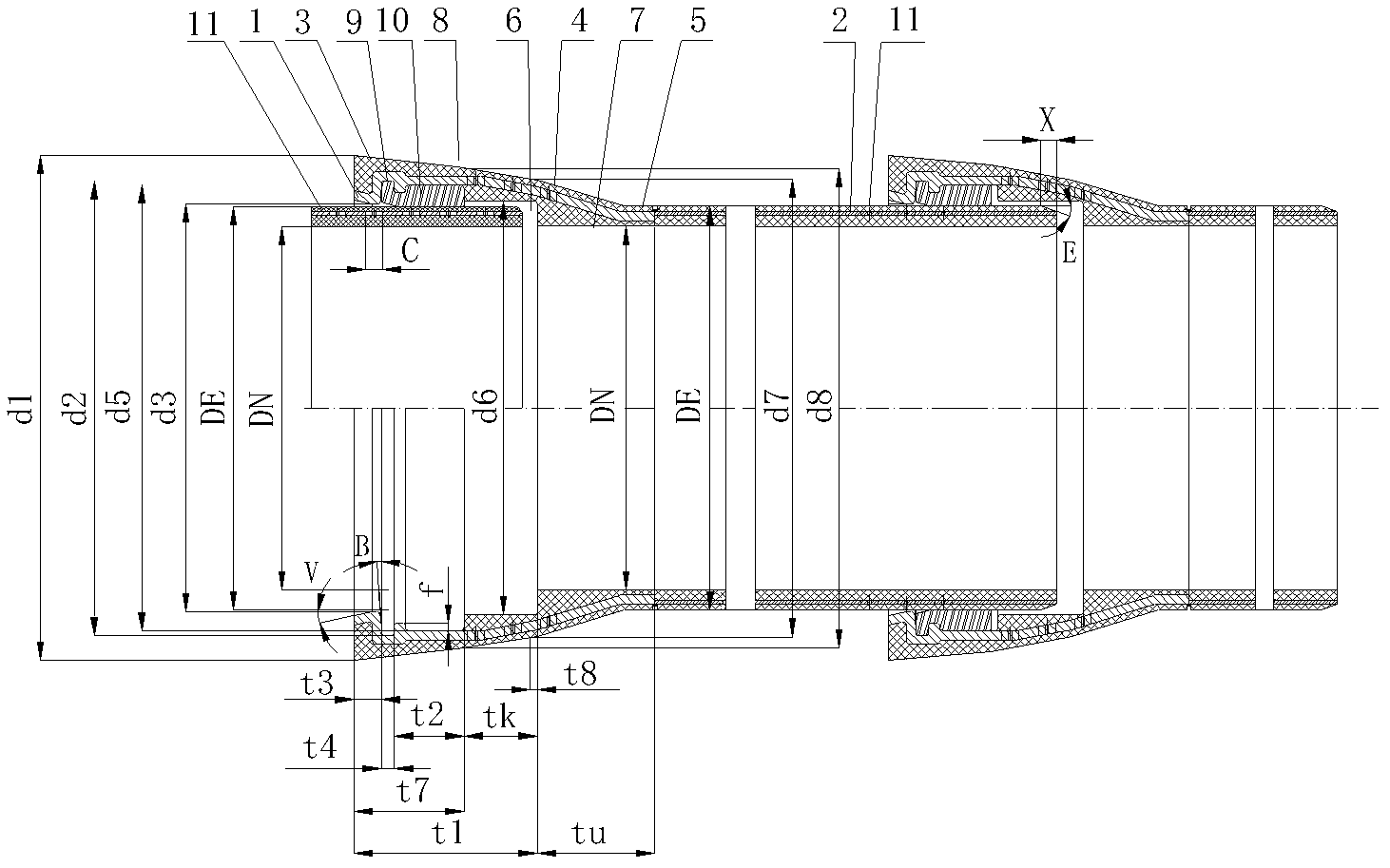

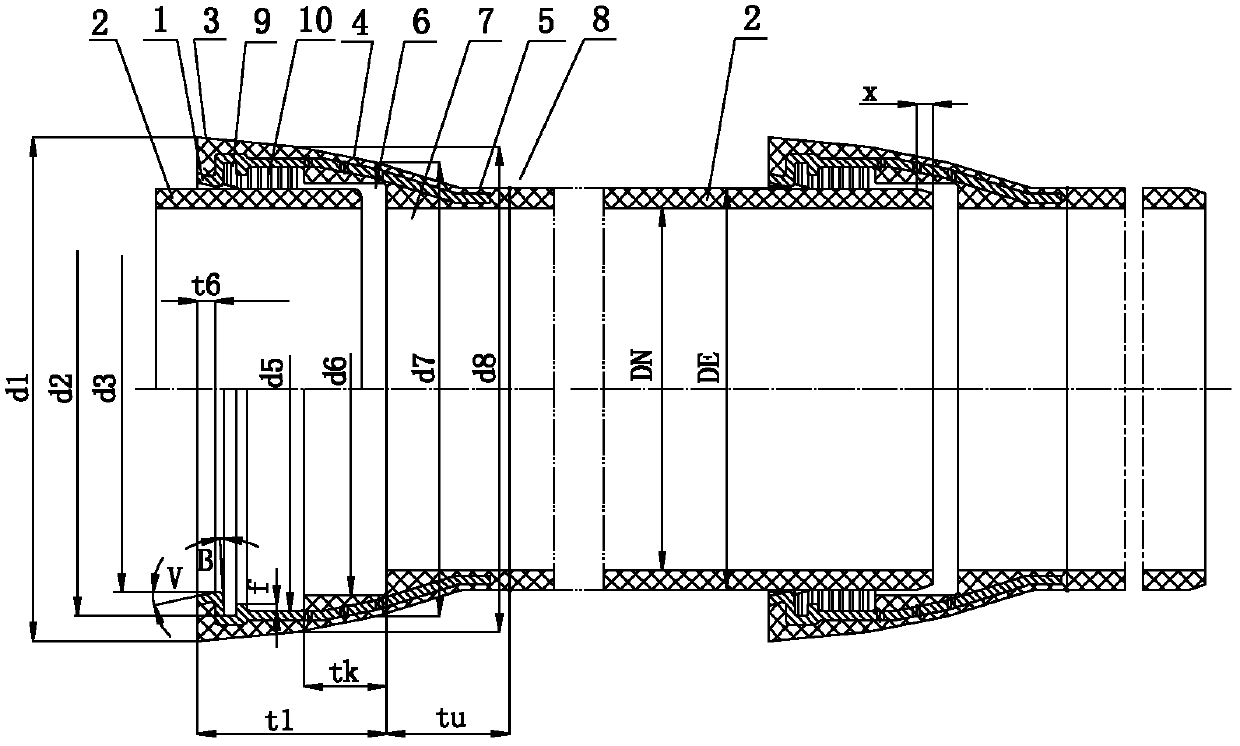

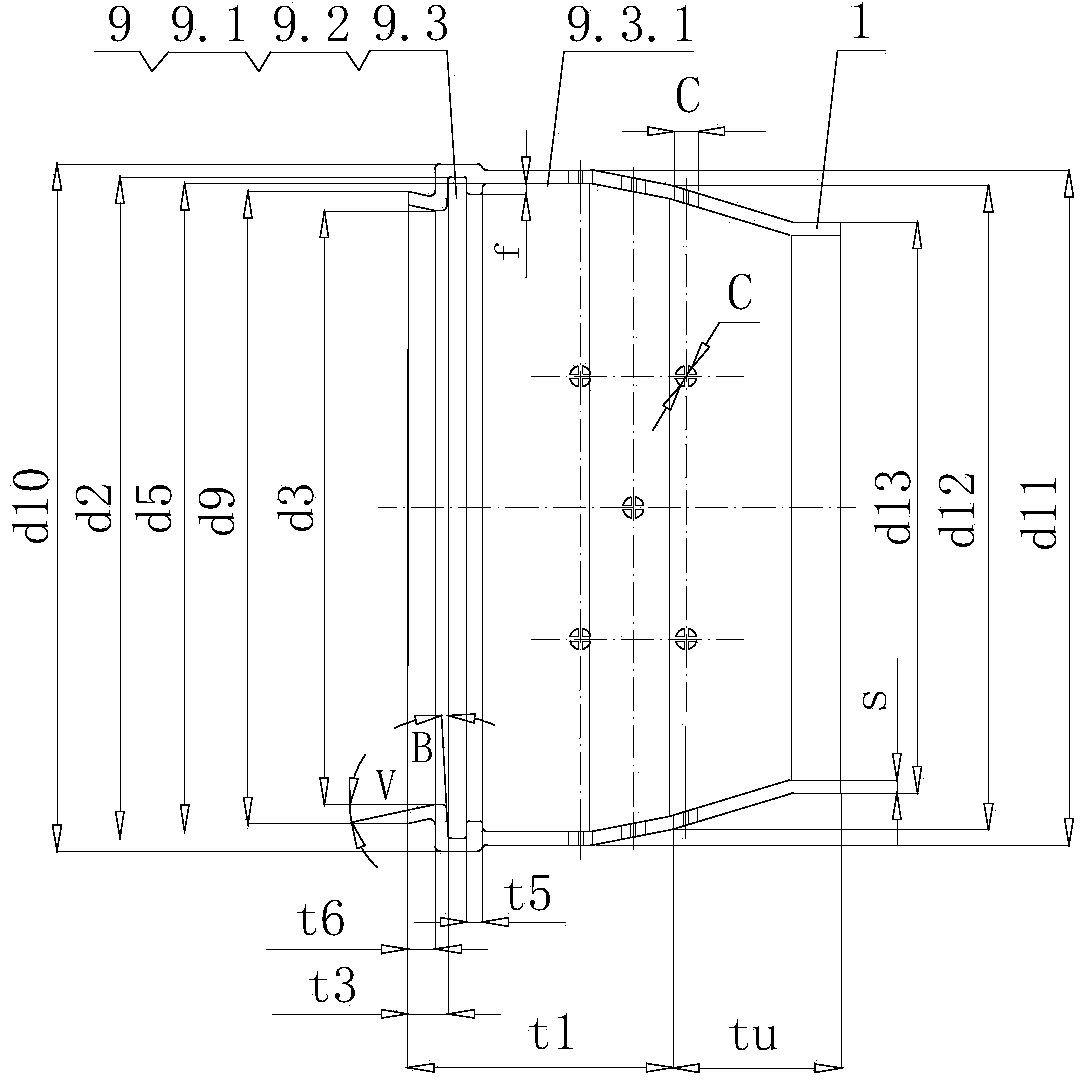

Steel wire enhanced bell and spigot composite plastic tube and fabrication process thereof

ActiveCN101881356ASimple structureSave raw materialsCorrosion preventionPipe protection against corrosion/incrustationConical tubePolyvinyl chloride

The invention relates to a steel wire enhanced bell and spigot composite plastic tube and a fabrication process thereof. The steel wire enhanced bell and spigot composite plastic tube is prepared by mainly enhancing an inner bell and spigot and an outer bell and spigot, reasonably configuring each corresponding ratio parameter and adopting the fabrication process. The steel wire enhanced bell and spigot composite plastic tube comprises the inner bell and spigot, a bush, the outer bell and spigot, a sealing ring adapted to the outer bell and spigot, a conical tube, a round tube A, an arc tube, a round tube B and a steel wire sleeve mainly covering the outer wall of the arc tube, wherein the inner bell and spigot and the bush are arranged at one end of the tube wall, the outer bell and spigot and the sealing ring are arranged at the other end of the tube wall, and the conical tube, the round tube A, the arc tube, the round tube B and the steel wire sleeve are sequentially connected to the tube wall. The invention overcomes the defects that in the traditional PE (Polyethylene) tube, a reticular enhancement mode and a bidirectional winding enhancement mode are adopted at the external of the tube wall to cause the axial rigidity of the tube to be too strong and enable the axial flexibility performance at the bell and spigot to be lowered, thereby influencing the geological subsidence resistance performance of a pipeline network system; the connecting part of the bell and spigots is easy to strain to break, thereby enabling maintenance of a water, gas and liquid supply system to be difficult; fuel gas leaks to cause environmental pollution and the like. The invention is suitable for various water conveyance projects and connecting tubes of the water conveyance projects and is particularly suitable for enhancing bell and spigots of PE plastic tubes, PVC-U (Unplasticizied Polyvinyl Chloride) plastic tubes, PVC-M (High Impact Polyvinyl Chloride) plastic tubes and the like.

Owner:HUNAN ZHENHUI PIPE IND

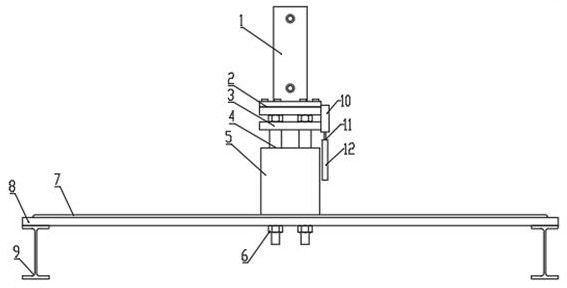

Full steel framework enhanced plug type composite pipe and manufacture technology thereof

ActiveCN102620064ASimple manufacturing processIncrease productivityPipe-jointsRigid pipesManufacturing technologyWater leakage

The invention provides a full steel framework enhanced plug type composite pipe and a manufacture technology thereof. The composite pipe comprises a main framework semi-product and an auxiliary framework semi-product which are respectively manufactured through a casting or stamping process, an injection molding process and a plastic spraying process, wherein the end parts of the semi-products are connected with each other, so as to form a product; the outer layer of the main framework is a plug main pipe outer wall formed by combining a front large tapered wall and a rear cylindrical wall with a middle small tapered wall; the plug main pipe inner wall comprises a plug cavity and a flow cavity; and a group of grooves are formed in the inner cavity of the main framework. Through the adoption of the technical scheme, the composite pipe has the advantages that the separation caused during the connection of conventional composite pipes due to different thermal expansion coefficients is avoided, so as not to enlarge the non roundness of the joints; fast stress crack, which is caused easily during welding, is reduced; the butting quality is guaranteed; defects such as water leakage, gas leakage, liquid leakage and the like caused by the connection of crack parts, which is longer than the length of a pipe plugging device, are overcome; and the composite pipe is suitable to serve as a connection pipe for various water conveying projects and gas conveying projects, and is particularly suitable for serving as an interchangeable connection plug for a plastic pipe made of PE, PVC-U, PVC-M or the like and a ductile cast iron pipe.

Owner:HUNAN ZHENHUI PIPE IND

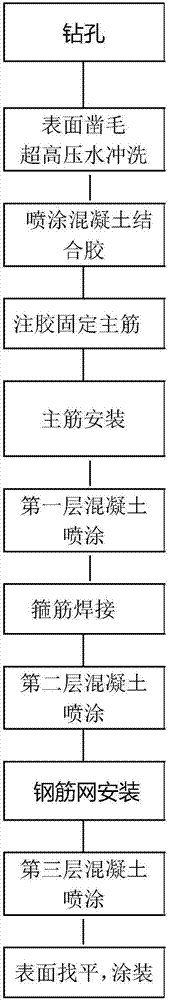

Tiny cross-section expanding method pier column reinforcing method and reinforcing structure

ActiveCN107237510AImprove section strengthReduce thicknessBuilding repairsBridge erection/assemblyEngineeringUltra high pressure

The invention discloses a tiny section expanding method pier column reinforcing method and a reinforcing structure. The tiny section expanding method pier column reinforcing method comprises the following constructing steps that S1, the surface of an original structure is roughed and washed cleanly by ultra high pressure water; S2; new and old concrete combining glue is sprayed on the surface to be constructed of the original structure; S3, a main steel bar is installed at the outer side of the original structure through anchoring bolts; and S4, 15-25mm of a first layer of concrete is sprayed on the outer side of the new and old concrete combining glue. According to the tiny section expanding method pier column reinforcing method and the reinforcing structure, the material character of high viscosity micro-expanding concrete is utilized sufficiently, and the expansion size of a section is reduced as much as possible. The problem of binding tightness of the new and old concrete is solved by utilizing the concrete combining glue.

Owner:DALIAN MUNICIPAL DESIGN & RES INST

Construction method of opening locked steel tube pilecofferdam

ActiveCN100575618CFlexible connectionImprove section strengthBridge structural detailsFoundation engineeringPile capSludge

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

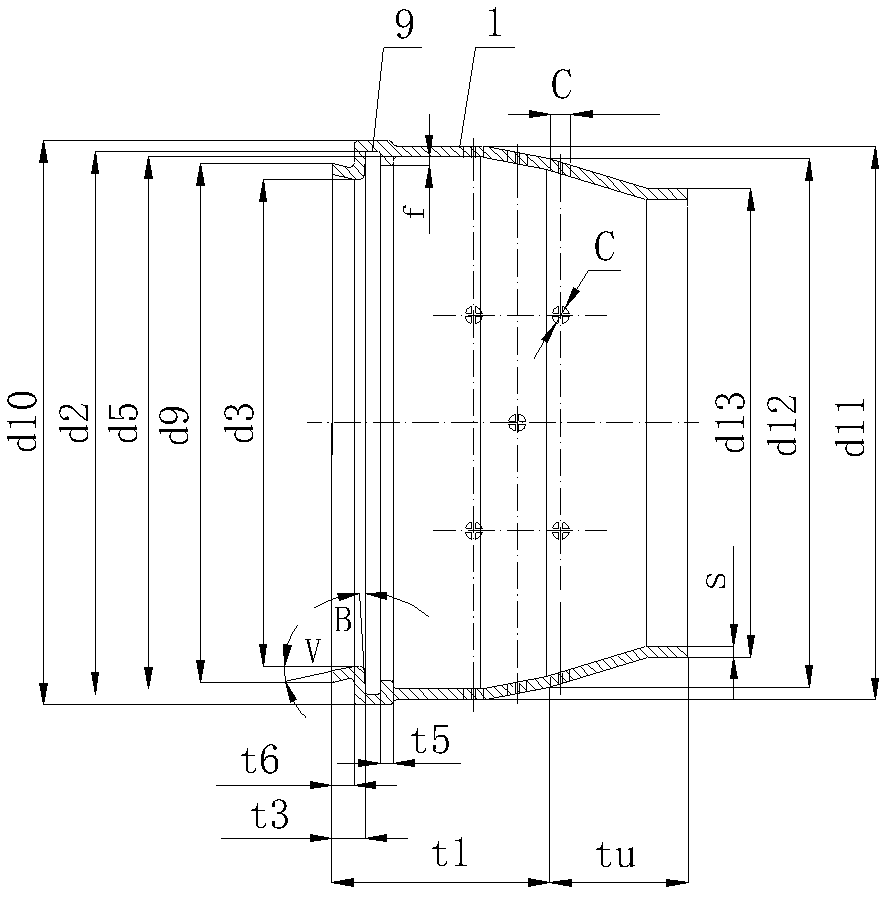

Half steel frame reinforcing type socket-and-spigot composite pipe and manufacture process thereof

ActiveCN102606809ASimple manufacturing processIncrease productivityPipe-jointsRigid pipesLeaking waterSteel frame

Provided are a half steel frame reinforcing type adapting type composite pipe and a manufacture process thereof. The manufacture process includes manufacturing a frame by adopting casting or stamping process, and respectively manufacturing a socket-and-spigot main pipe and a socket-and-spigot auxiliary pipe in injection molding and spraying mode and assembling the pipes. A frame outer layer is characterized in that an outer wall of the socket-and-spigot main pipe is formed by a large conical wall on the front portion, a cylindrical wall on the back portion and a middle small conical wall, the inner wall of the socket-and-spigot main pipe is composed of a socket-and-spigot cavity and an overflow cavity, a socket-and-spigot composite pipe is composed of the adapting main pipe and the adapting auxiliary pipe in adaptive fit mode, a group of grooves are arranged on a front end opening of the frame, and a sealing ring is arranged in the grooves respectively in fit mode. The half steel frame reinforcing type adapting type composite pipe overcomes the shortcoming that a polyethylene resin plastic composite pipe / polyethylene (PE) pipe is easy to separate due to the fact that expansion coefficient is different in connection installation, non-roundness at the abutting connection position is increased, the welding position generates quick stress cracking and causes the fact that the connection system of the cracking portion leaks water, gas and liquid, a cast-iron pipe and the PE pipe cannot be interchanged, old project modification is affected and the like. The composite type and the manufacture process are suitable for connection pipes of various water delivery and gas delivery projects and are especially suitable for interchangeable connection of plastic pipes such as PE, PVC-U and PVC-M and nodular cast iron pipes.

Owner:HUNAN ZHENHUI PIPE IND

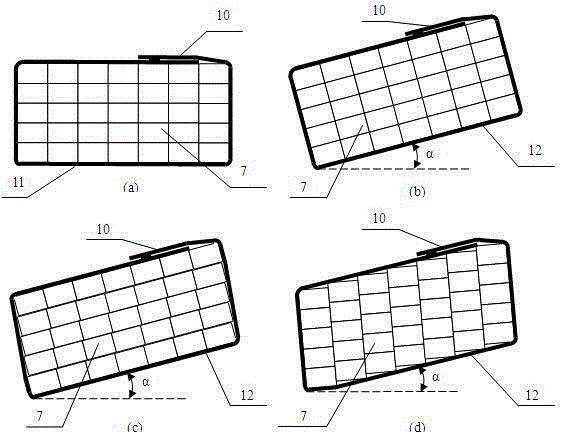

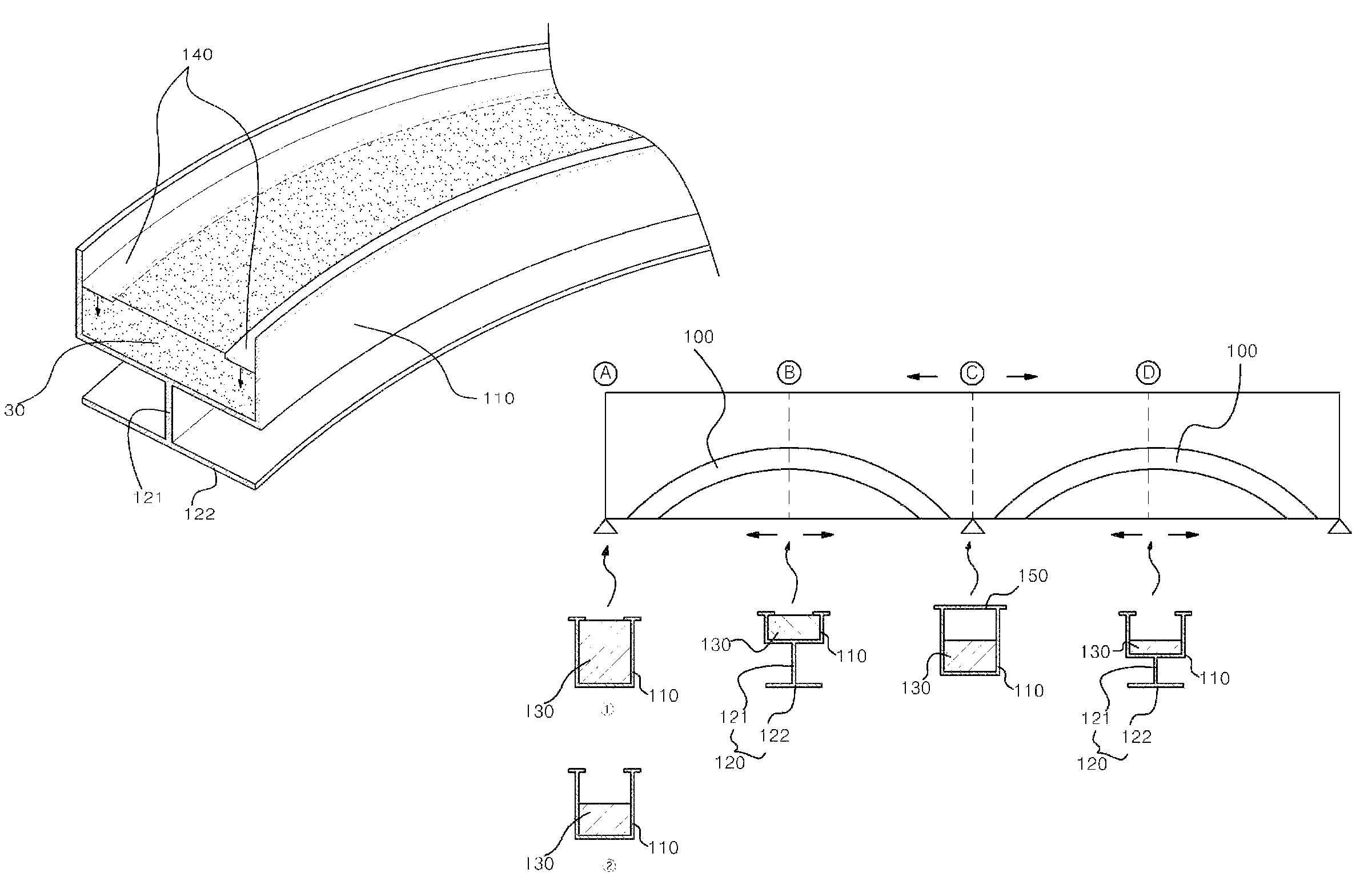

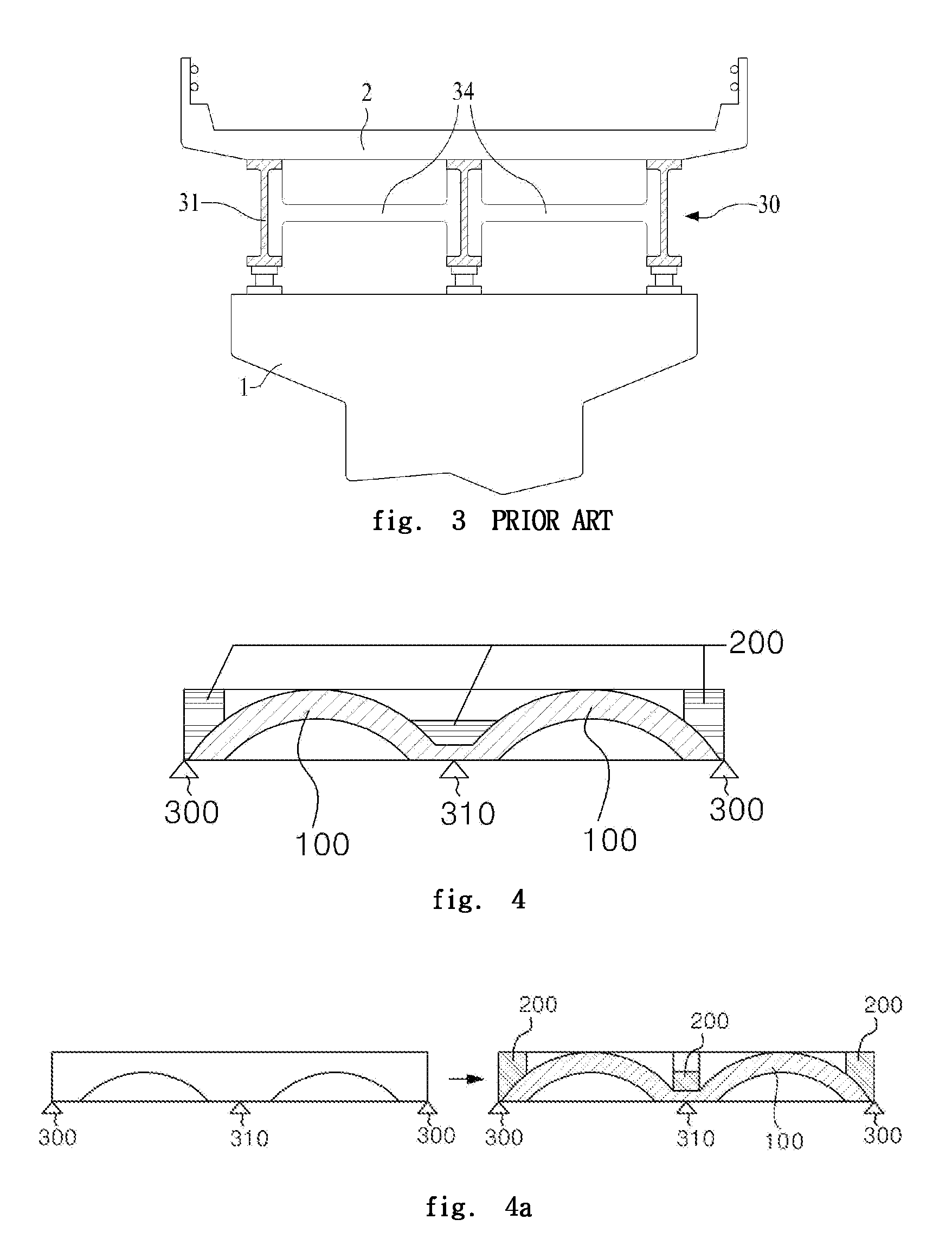

Composite girder for bridge construction

ActiveUS8544129B2Efficient compressionEffective tensionArched girdersBuilding roofsEngineeringUltimate tensile strength

The present invention pertains to a composite girder for bridge construction. More preferably, a girder is formed in a rectangular shape that is horizontally long and opened at the top portion thereof, wherein the girder is convexly curved in the center so as to be formed in the shape of an arch. The girder has a compression section, a web and a tension section, which are integrally composed together, and is filled with concrete inside the girder so as to increase the sectional strength of the girder. Simultaneously, a stopper is formed on the inside surface of the compression section to prevent the separation of the steel materials and the concrete.

Owner:SB ENG CO LTD

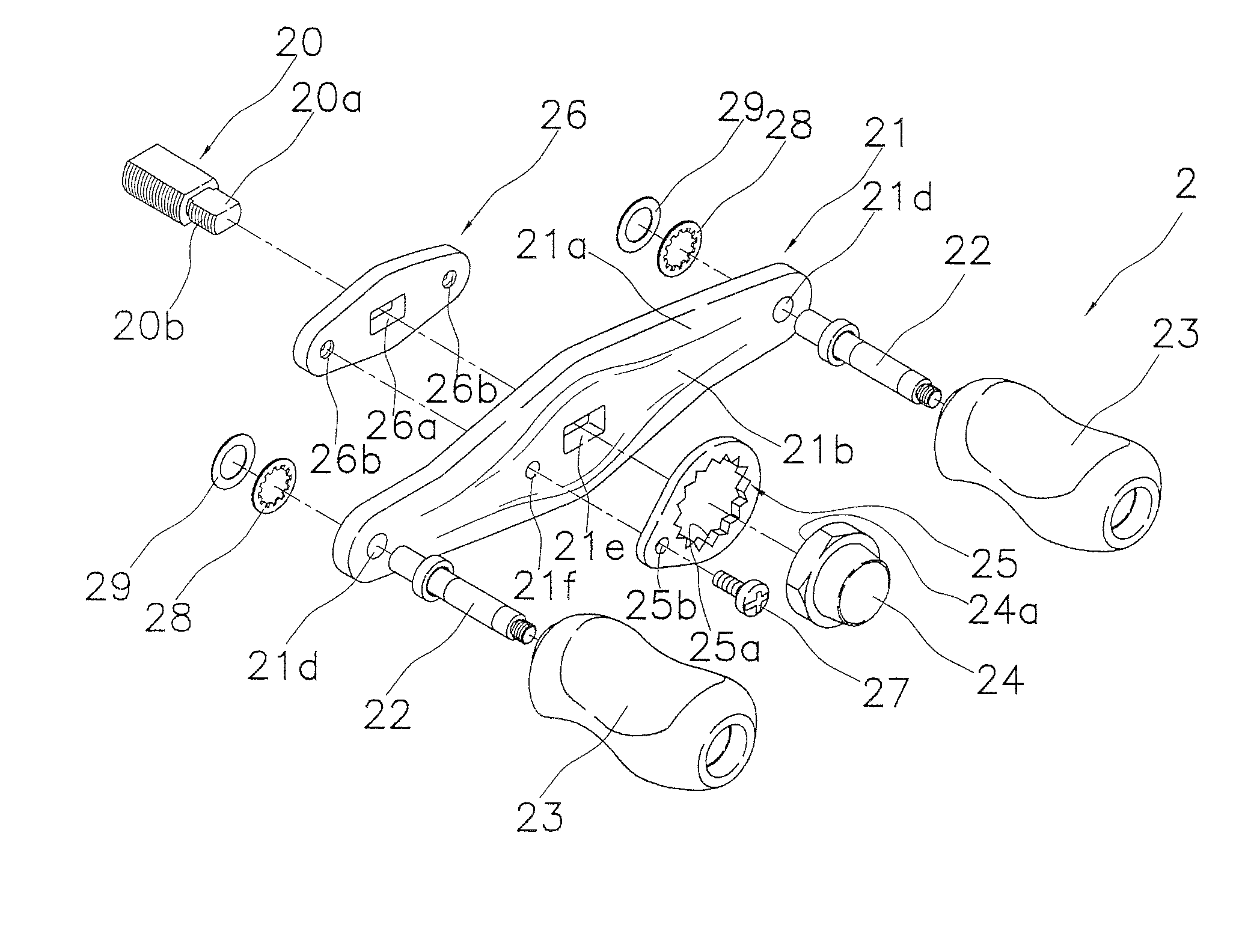

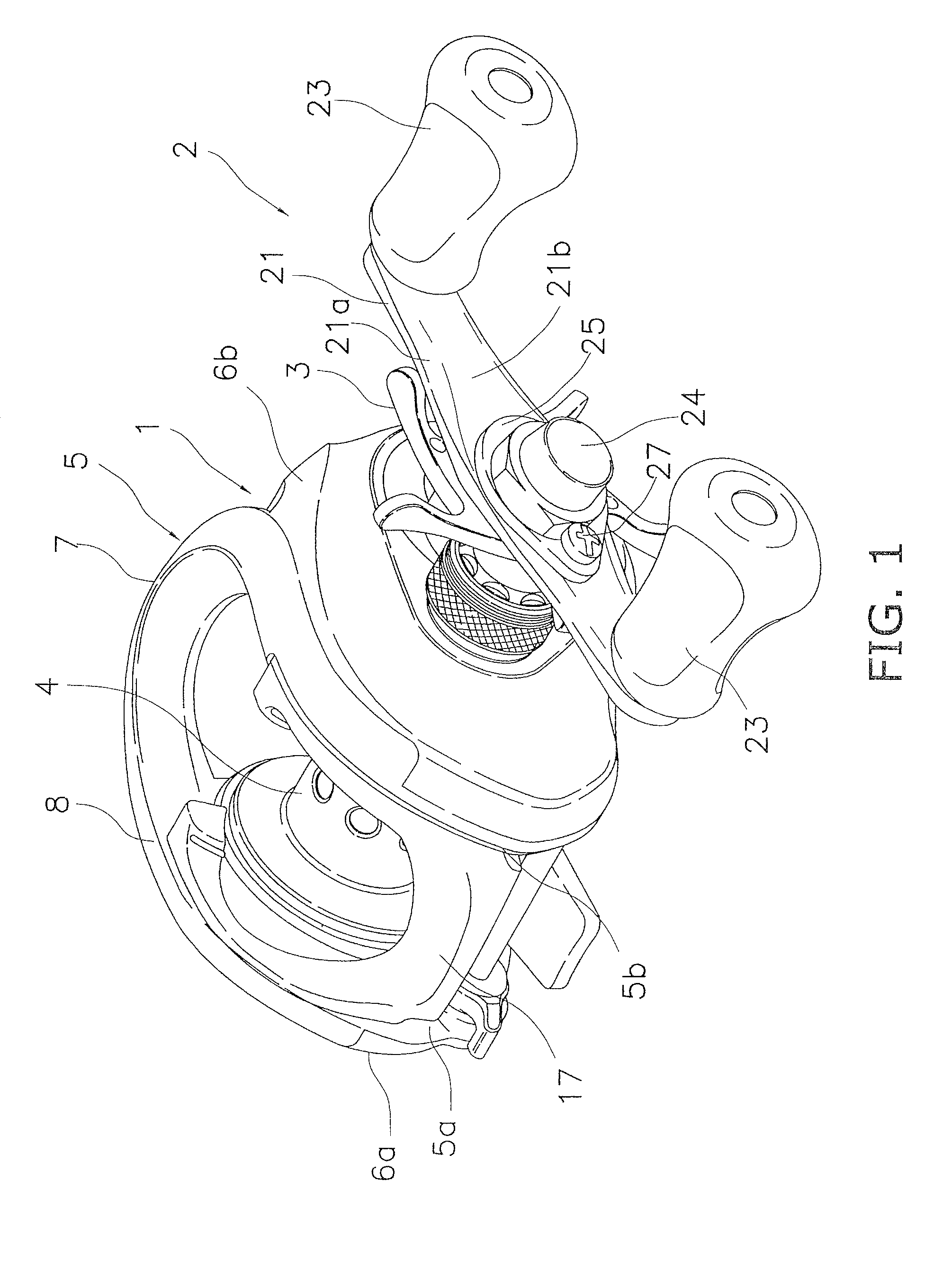

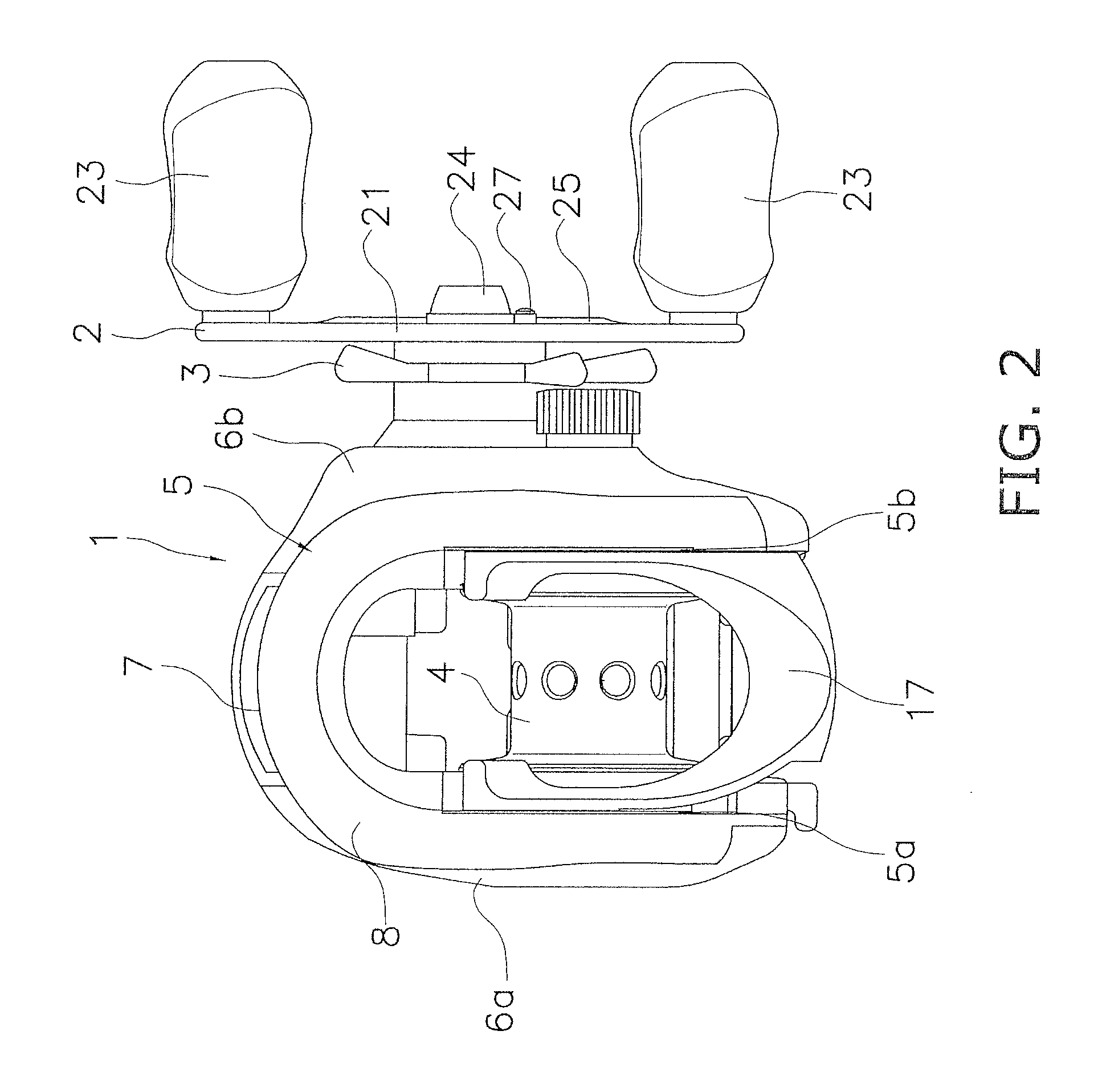

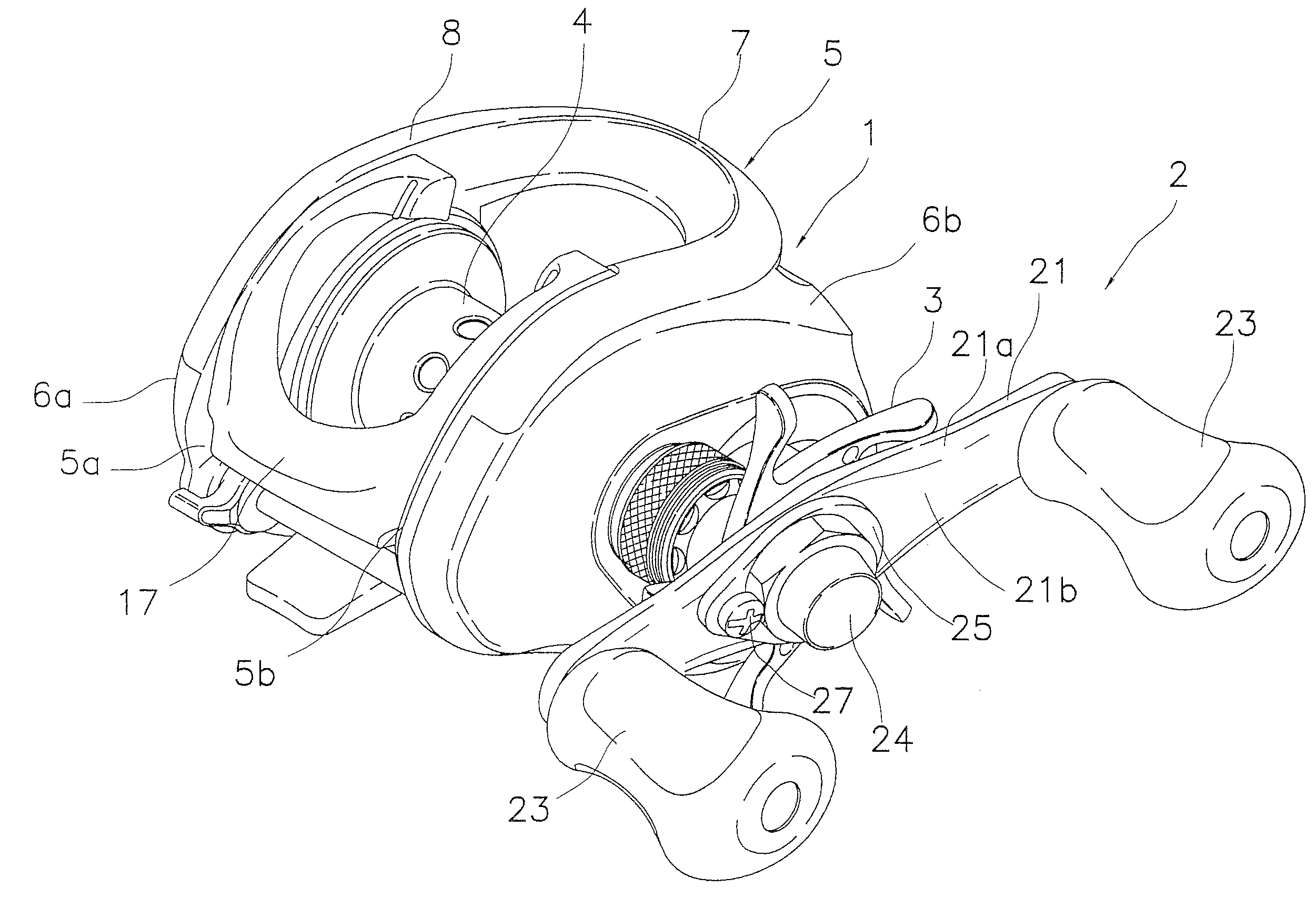

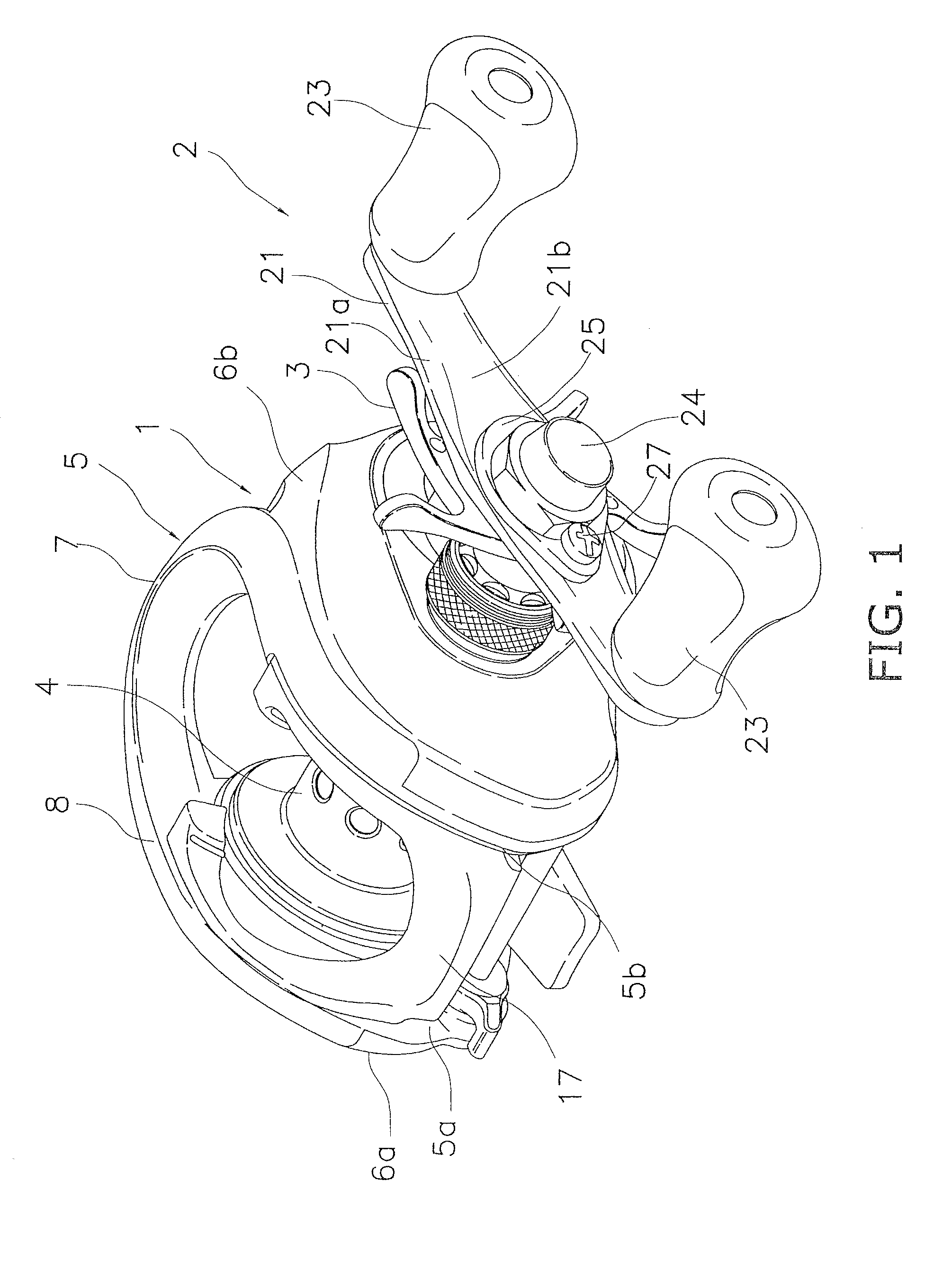

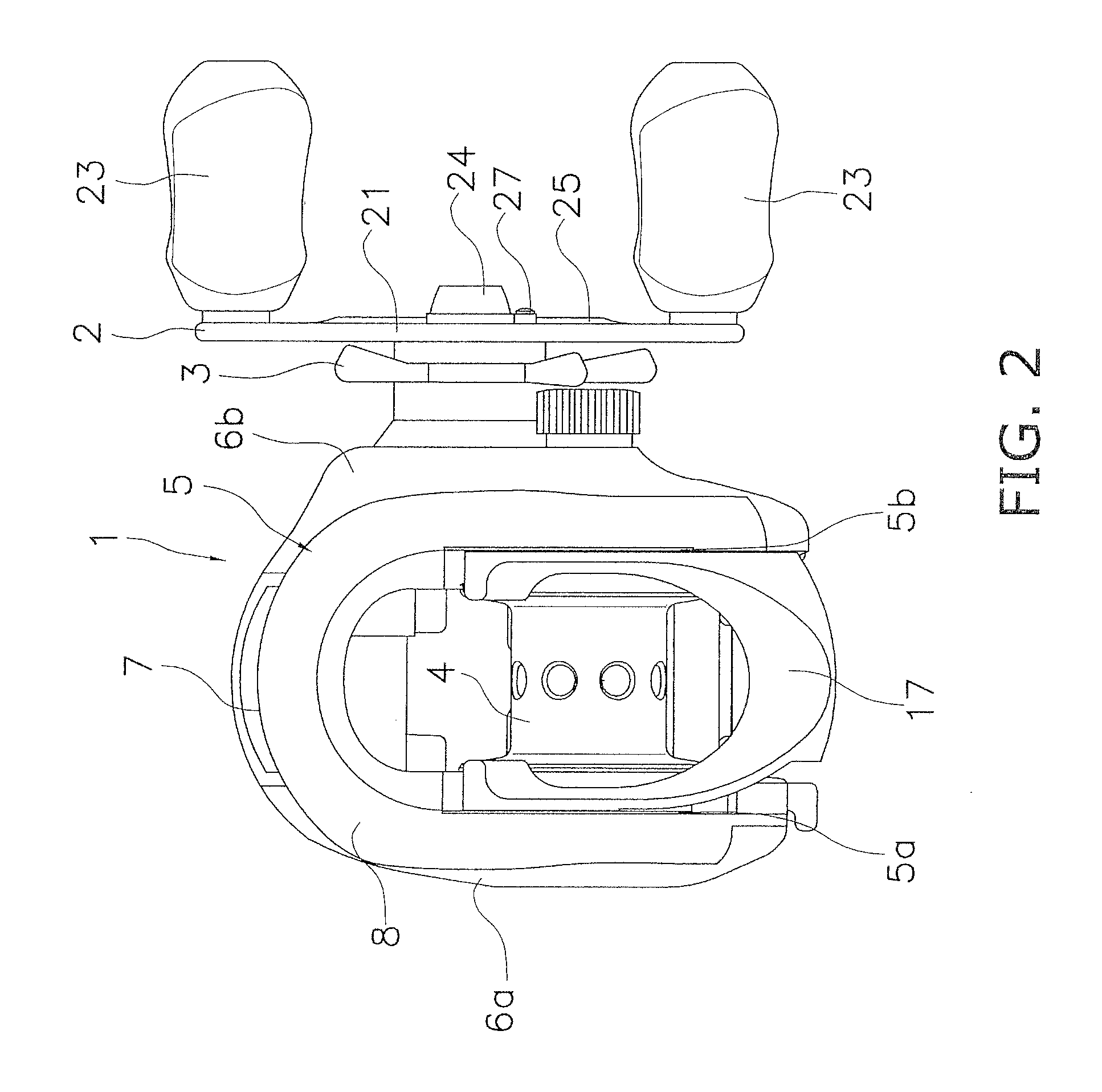

Fishing reel handle assembly

A fishing reel handle assembly has a handle arm, a knob shaft, and a handle knob. The handle arm is relatively non-rotatably attached to a distal end of the handle shaft. The knob shaft is fixed to an end of the handle arm and extends in parallel to the handle shaft. The handle knob is supported by the knob shaft to be rotatable relative to the handle arm. The handle arm includes a main body and a convexo-concave portion. The main body extends substantially perpendicular to an axial direction of the handle shaft, and is formed by laminating sheets of prepreg. The convexo-concave portion is convexly or concavely formed on at least either a front surface of the main body or a back surface of the main body. The front surface allows the handle knob to be attached thereto, the back surface disposed opposite to the front surface.

Owner:SHIMANO INC

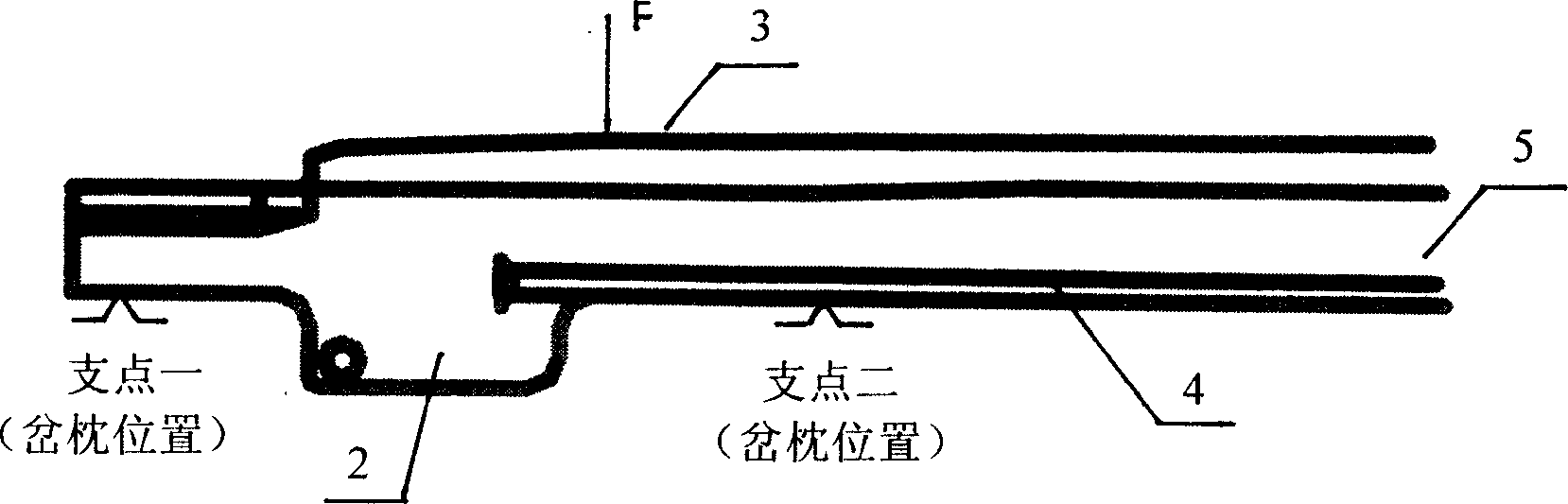

New long line rail

ActiveCN1587518AImprove structural strengthImprove section strengthRail switchesTongue structureEngineering

The present invention relates to the switch tongue structure of railway switch long core rail, and belongs to the field of railway switch manufacture technology. The long core rail has rail head tread with end surface lagging to the end of the hold-down stage. The present invention has the advantages of improved stress condition with 45 % lowered maximum stress and less stress concentration, raised cross section strength and long service life up to 8 years.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Fishing reel handle assembly

ActiveUS20110073696A1High strengthAvoid damageControlling membersReelsMechanical engineeringFishing lure

A fishing reel handle assembly has a handle arm, a knob shaft, and a handle knob. The handle arm is relatively non-rotatably attached to a distal end of the handle shaft. The knob shaft is fixed to an end of the handle arm and extends in parallel to the handle shaft. The handle knob is supported by the knob shaft to be rotatable relative to the handle arm. The handle arm includes a main body and a convexo-concave portion. The main body extends substantially perpendicular to an axial direction of the handle shaft, and is formed by laminating sheets of prepreg. The convexo-concave portion is convexly or concavely formed on at least either a front surface of the main body or a back surface of the main body. The front surface allows the handle knob to be attached thereto, the back surface disposed opposite to the front surface.

Owner:SHIMANO INC

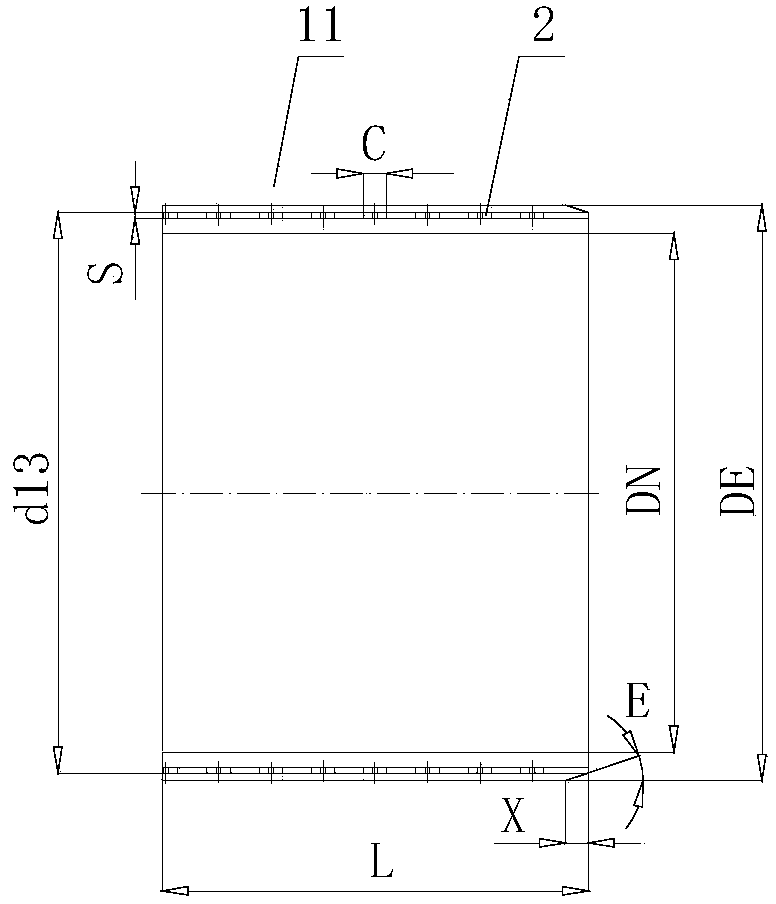

Composite type plastic pipe with wound netting wire and strengthened bell mouth and manufacturing process thereof

ActiveCN101788085AImprove performanceSave pipe wall materialsRigid pipesTubular articlesAdditive ingredientEngineering

The invention relates to a composite type plastic pipe with wound netting wires and strengthened bell mouths, and a manufacturing process thereof. The invention adopts the following technical scheme: the tube ball with a distance of the inner diameter length L to the end part of the bell mouth is a reinforced and thickened wall; the tube wall with a distance of the outer diameter length M to the end part of the bell mouth is a netting wire reinforced wall; and a viscose glue layer, a mark and a protection layer, the wall thickness S, diameter phi and outer diameter D are set according to corresponding ratios; plastic resin mulling-ingredient is utilized as the raw material; and simultaneously, products are manufactured under the synchronous control of a dryer, an extruder, a die head, a die, a vacuum box, a spraying box, a take-up winder, a high-frequency machine, a tractor, a cutter and the like. The technical scheme of the invention overcomes the defect that the axial rigidity of the existing pipe workpiece influences the axial flexibility, geology sinking resistance and tension resistance at the welding part of the bell mouth, as well as the defect that the non-roundness at the joint of the bell mouth leads the strength and rigidity at the cross section of the joint of the bell mouth of the pipe workpiece to be unable to load tubing pressure when the electrofusion pipe fittings are welded, and the like, thus being suitable for serving as connection pipe workpieces for various water delivery and gas transmission projects, and especially suitable for strengthening pipe walls and thickening the bell mouths of PE, PVC-U, PVC-M and the like.

Owner:HUNAN ZHENHUI PIPE IND

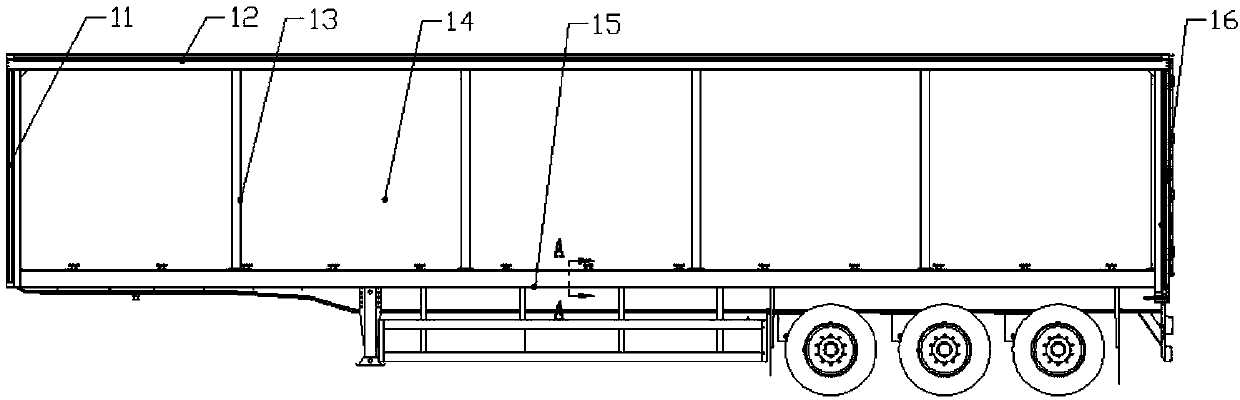

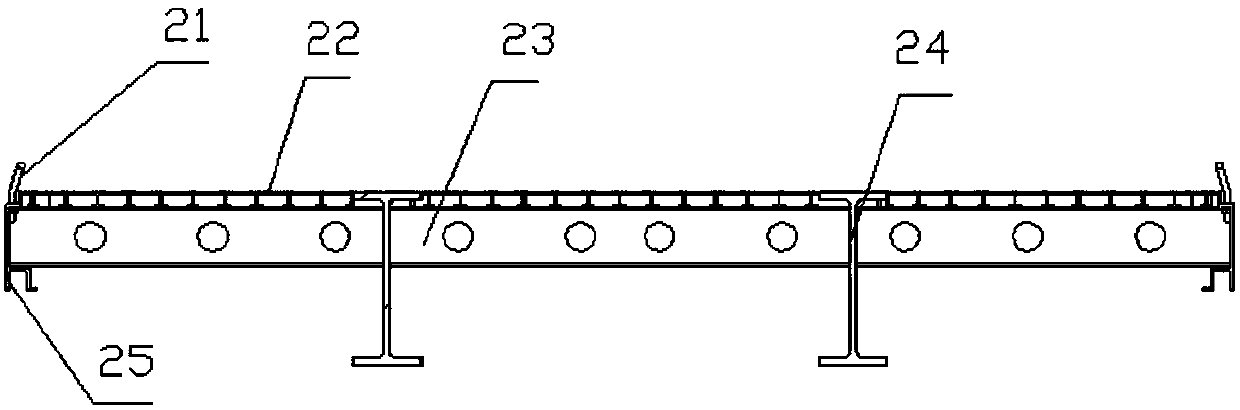

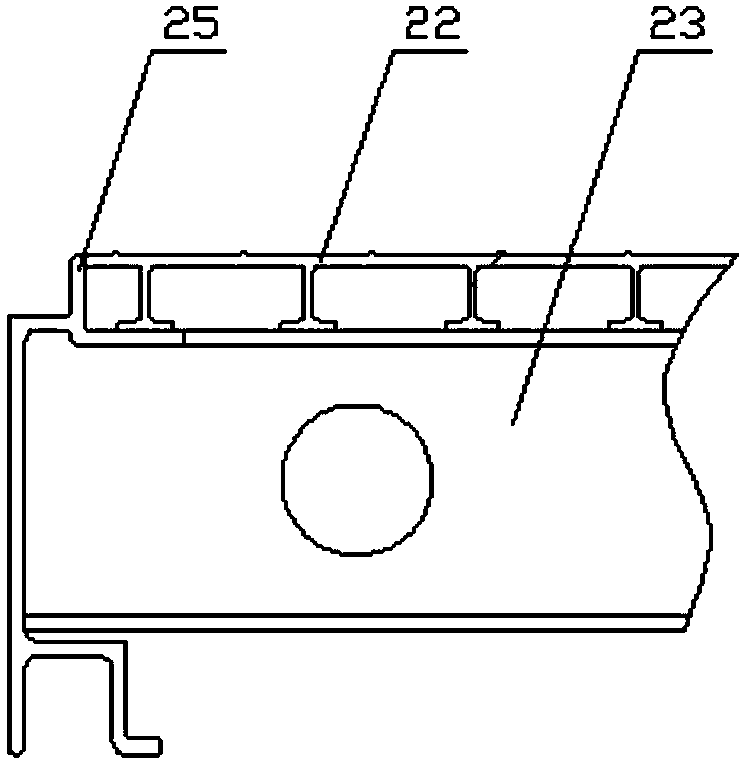

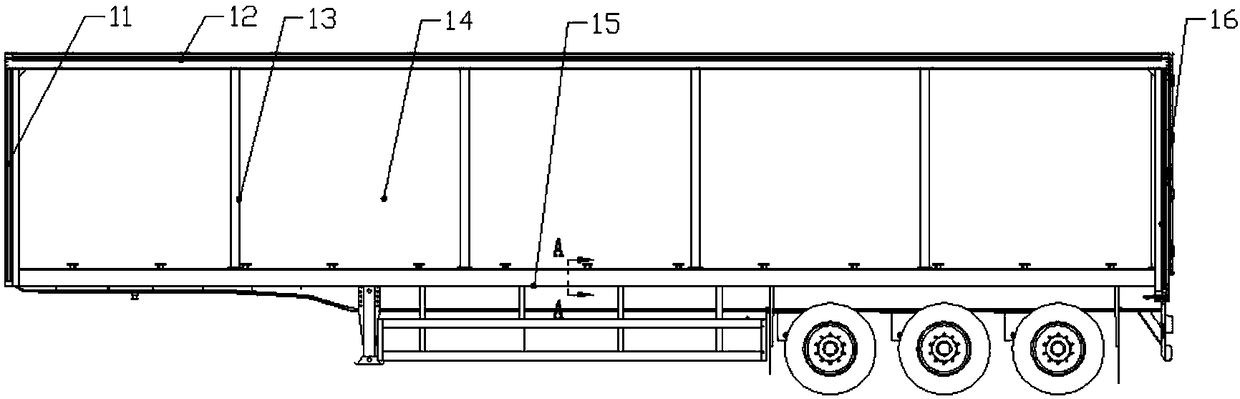

Section boundary beam aluminum alloy side curtain semi-trailer and rack of section boundary beam

PendingCN107738692AReduce the weight of side beamsImprove corrosion resistanceUnderstructuresSteel platesEdge surface

The invention discloses a section boundary beam of an aluminum alloy side curtain semi-trailer and a rack of the section boundary beam, and is applied to the field of trackless land vehicles. The section boundary beam comprises a first section boundary beam characteristic surface, a second section boundary beam characteristic surface, a third section boundary beam characteristic surface, a fourthsection boundary beam characteristic surface, a fifth section boundary beam characteristic surface and a sixth section boundary beam characteristic surface all made of an aluminum alloy material, andthe rack comprises the section boundary beam, a base plate and a rack cross beam. The section boundary beam mainly solves the problem that a steel structure is generally adopted by an I-beam or a steel plate welding part of an existing side curtain semi-trailer boundary beam, and the boundary beam is high in weight, poor in corrosion resistance and the like. The weight of the boundary beam can bereduced, and meanwhile, the corrosion resistance of the boundary beam is improved.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

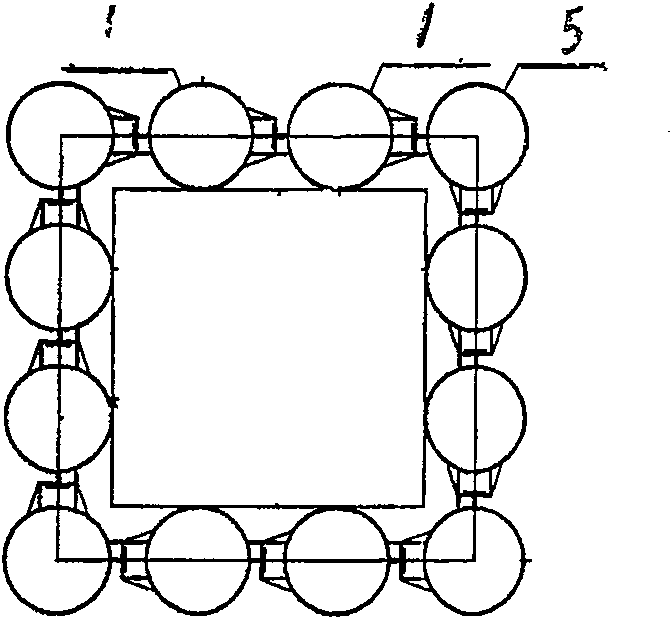

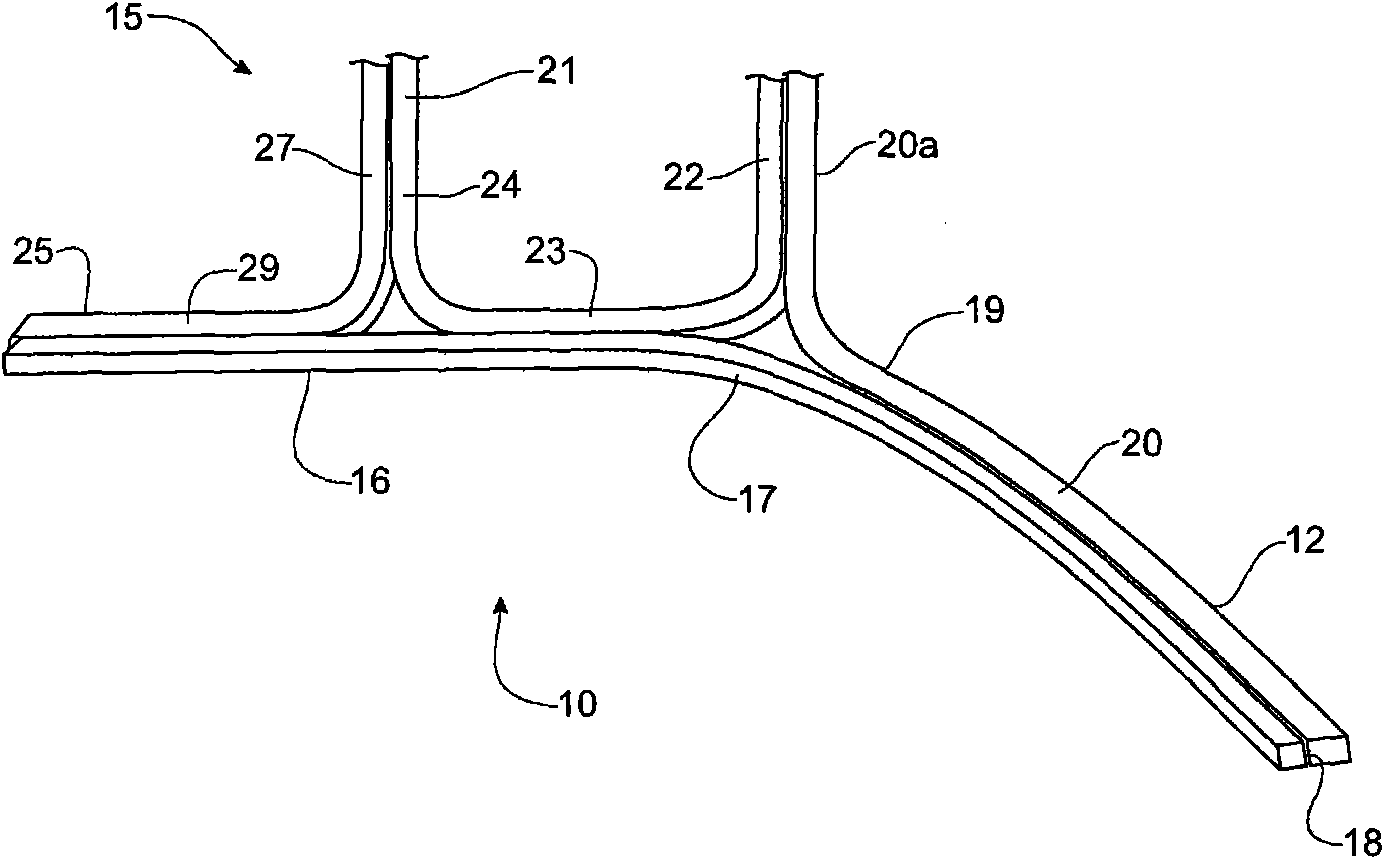

Dual cell body side rail for automotive vehicles

InactiveCN101638109AWeight increaseHigh strengthSuperstructure subunitsMonocoque constructionsMobile vehicleVolumetric Mass Density

A body side rail construction for an automotive vehicle is formed in a dual cell configuration. A reversed C-shaped channel is welded to the closed section of the conventional roof side rail member toenable the body side rail member to be a smaller section that is less susceptible to buckling as the body side rail member transfers load to the front and rear corner pillars. The C-shaped cross-sectional configuration presents advantages for manufacturing as it can be shaped to provide the attaching brackets and horns for mounting the front header, roof bow, and rear header members to the body side rail without the addition of individual end items to serve this function. From a shipping density standpoint, this design gives maximum structure while maintaining good rack density that enables relatively straight parts to be nested together while still providing the increased section strength required for enhanced roof performance.

Owner:FORD MOTOR CO

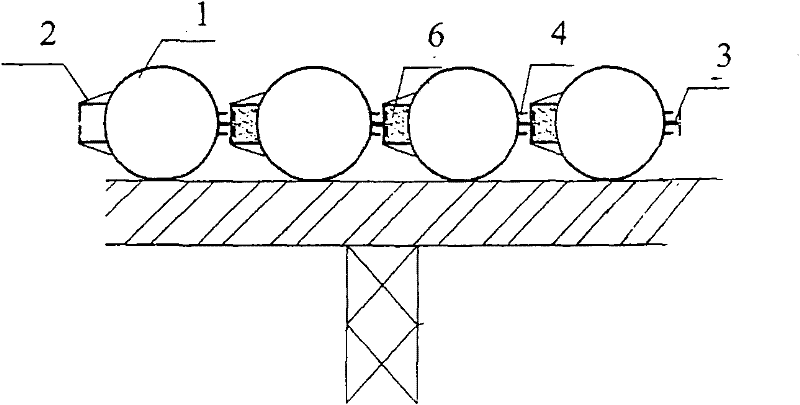

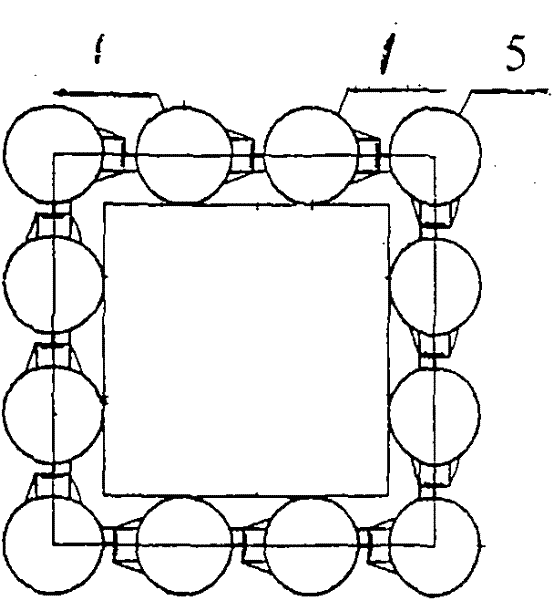

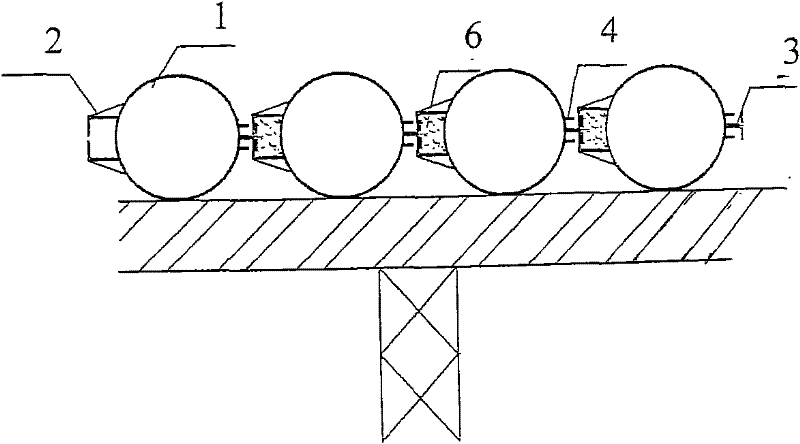

Rectangular section steel wire for radial tire and method for making bead ring

ActiveCN105383227BReduce contact stressImprove section strengthTyre beadsTear resistanceWear resistance

The invention discloses a rectangular cross-section steel wire for a radial tire and a method for manufacturing a steel wire ring thereof. The rectangular cross-section steel wire is manufactured by adopting a round cross-section high-carbon steel wire in a roller-drawing mode and undergoes surface galvanization and tempering treatment, and m rectangular steel wires are twined side by side in n layers and are bundled by straps for forming the steel wire ring. The steel wire ring serves as a tire bead core of the radial tire and is small in cross section area; surface contact is adopted between the steel wires, and therefore the geometrical shape stability is good; the contact stress between the steel wires is small, the cross section strength between the steel wires is high, and therefore the wear resistance and the tearing resistance of a tire bead can be improved, and the manufacturing cost of the tire can be reduced.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Steel wire enhanced bell and spigot composite plastic tube and fabrication process thereof

ActiveCN101881356BSimple structureSave raw materialsCorrosion preventionPipe protection against corrosion/incrustationConical tubeSystem maintenance

The invention relates to a steel wire enhanced bell and spigot composite plastic tube and a fabrication process thereof. The steel wire enhanced bell and spigot composite plastic tube is prepared by mainly enhancing an inner bell and spigot and an outer bell and spigot, reasonably configuring each corresponding ratio parameter and adopting the fabrication process. The steel wire enhanced bell andspigot composite plastic tube comprises the inner bell and spigot, a bush, the outer bell and spigot, a sealing ring adapted to the outer bell and spigot, a conical tube, a round tube A, an arc tube,a round tube B and a steel wire sleeve mainly covering the outer wall of the arc tube, wherein the inner bell and spigot and the bush are arranged at one end of the tube wall, the outer bell and spigot and the sealing ring are arranged at the other end of the tube wall, and the conical tube, the round tube A, the arc tube, the round tube B and the steel wire sleeve are sequentially connected to the tube wall. The invention overcomes the defects that in the traditional PE (Polyethylene) tube, a reticular enhancement mode and a bidirectional winding enhancement mode are adopted at the external of the tube wall to cause the axial rigidity of the tube to be too strong and enable the axial flexibility performance at the bell and spigot to be lowered, thereby influencing the geological subsidence resistance performance of a pipeline network system; the connecting part of the bell and spigots is easy to strain to break, thereby enabling maintenance of a water, gas and liquid supply system tobe difficult; fuel gas leaks to cause environmental pollution and the like. The invention is suitable for various water conveyance projects and connecting tubes of the water conveyance projects and is particularly suitable for enhancing bell and spigots of PE plastic tubes, PVC-U (Unplasticizied Polyvinyl Chloride) plastic tubes, PVC-M (High Impact Polyvinyl Chloride) plastic tubes and the like.

Owner:HUNAN ZHENHUI PIPE IND

A socket-reinforced composite plastic pipe and its manufacturing process

ActiveCN101788084BSimple structureSimple manufacturing processRigid pipesPipe waterSynchronous control

A socket-reinforced composite plastic pipe and its manufacturing process. It includes a pipe wall and a socket. A protruding ring is provided at the inner diameter of the L-length pipe wall at the end of the socket, and plastic resin mixed ingredients are used as raw materials. The technical scheme of making products under the synchronous control of drying machine, extruder, die head, mold, vacuum box, spray box, tractor, cutting machine and other equipment; it overcomes the existing polyethylene resin composite pipe-PE pipe, Because the cross-sectional strength and rigidity of the butt joint of the pipe socket cannot bear the pressure inside the pipe, the pipe wall will bulge, deform, and even crack, resulting in water leakage and air leakage in the pipe, resulting in difficulties in maintenance of water supply, gas supply, and liquid supply systems, serious loss of resources and gas consumption. Leakage causes defects such as environmental pollution; it is suitable for connecting pipes in various water transmission projects and gas transmission projects; it is especially suitable for thickening and strengthening sockets of plastic pipes such as PE, PVC-U, and PVC-M.

Owner:HUNAN ZHENHUI PIPE IND

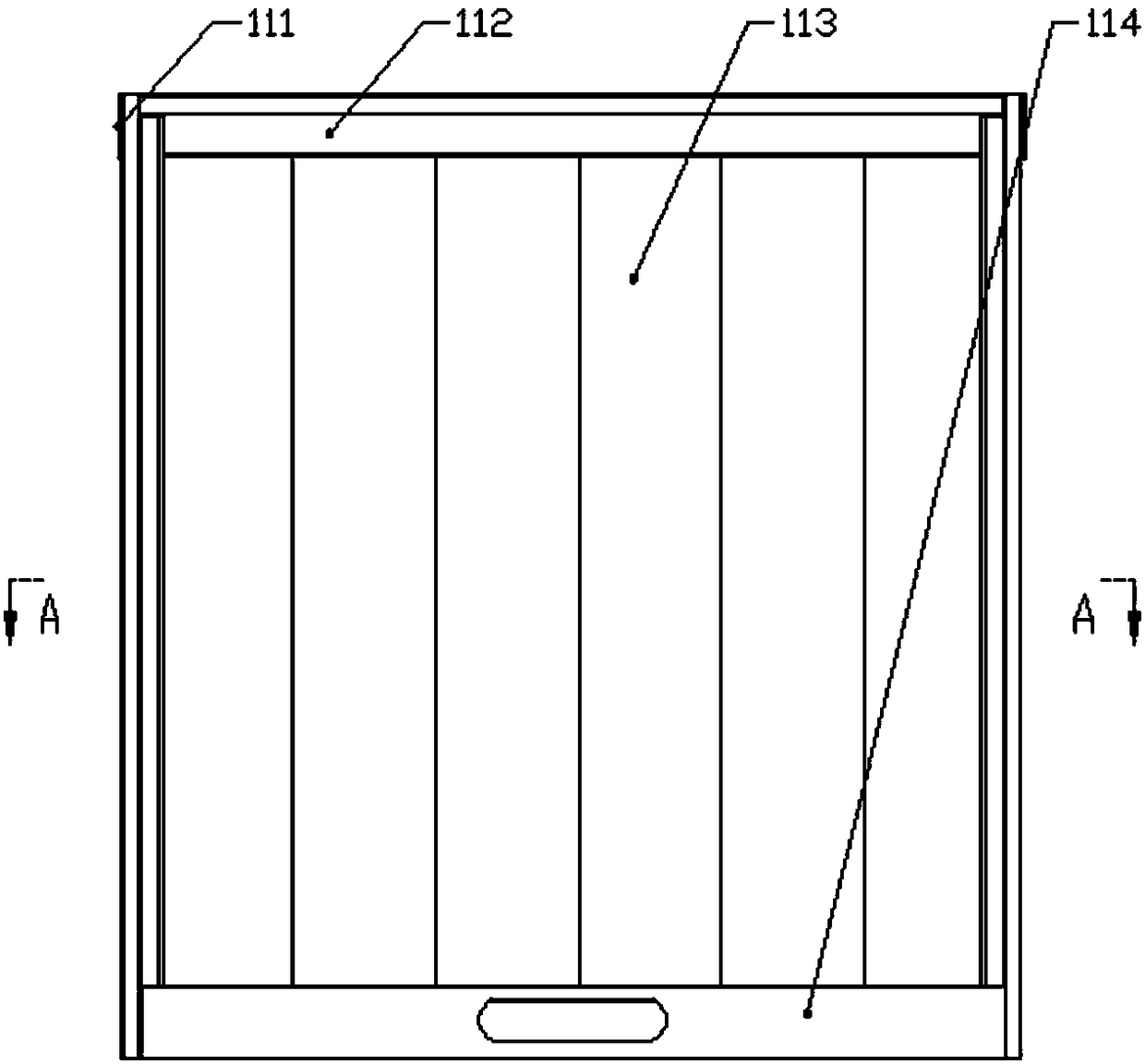

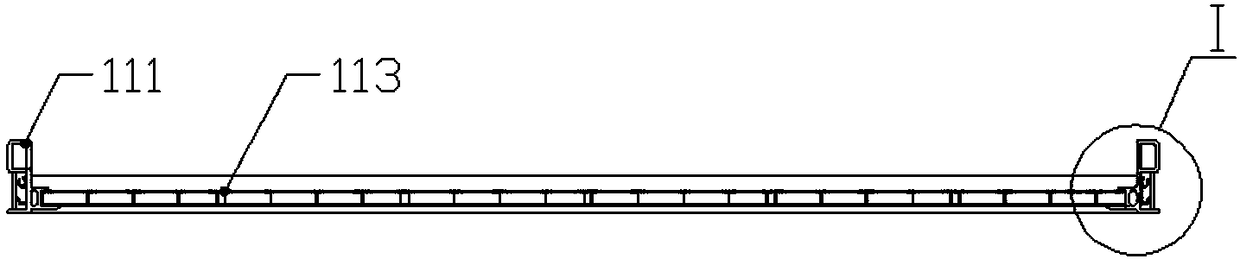

Aluminum-alloy lateral-curtain-semitrailer profile standing column and front box assembly thereof

PendingCN108100051AReduce weightImprove corrosion resistanceTractor-trailer combinationsLoading-carrying vehicle superstructuresAgricultural engineeringWall plate

The invention discloses an aluminum-alloy lateral-curtain-semitrailer profile standing column and a front box assembly thereof, is applicable to the field of trackless land vehicles, and aims to overcome the defects that a lateral-curtain-semitrailer profile standing column is normally of a steel structure, and the standing column is heavy and poor in corrosion resistance. The profile standing column comprises eight aluminum-alloy profile standing column feature faces, front box assembly profile standing columns, a front upper crossbeam, front wall plates, a front lower crossbeam, limit platesand curtain cloth tightening tubes. The aluminum-alloy lateral-curtain-semitrailer profile standing column and the front box assembly thereof can reduce the weight of the standing column and the front box assembly and increase corrosion resistance.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

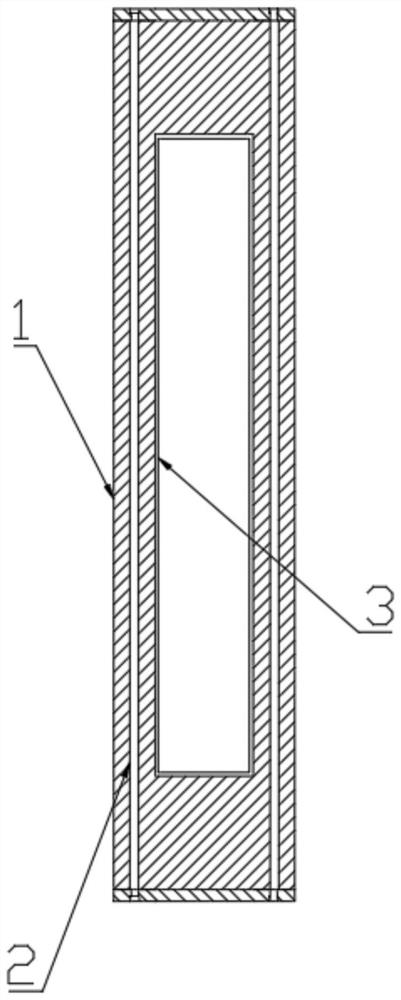

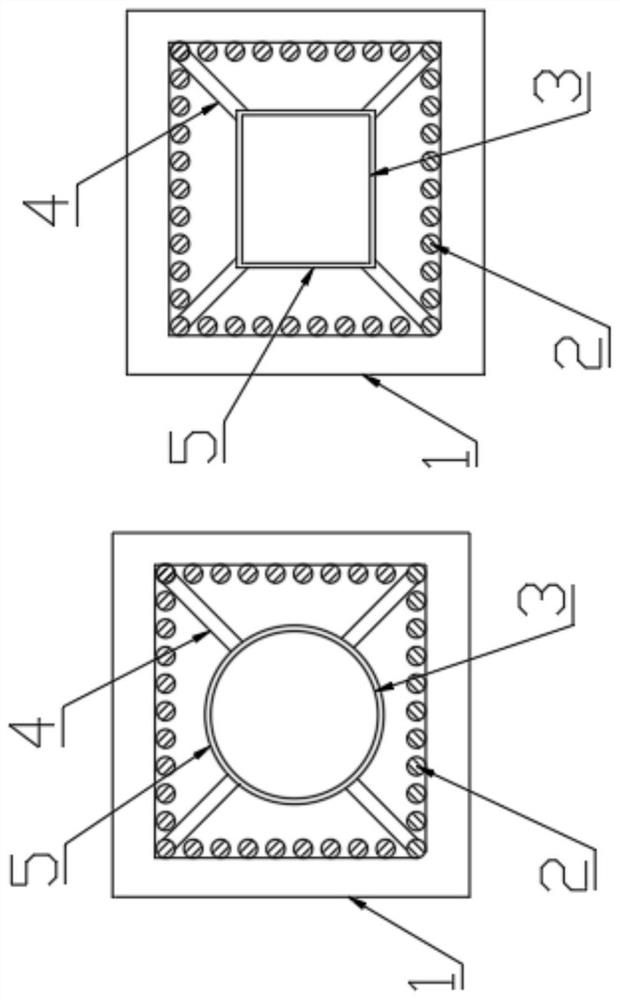

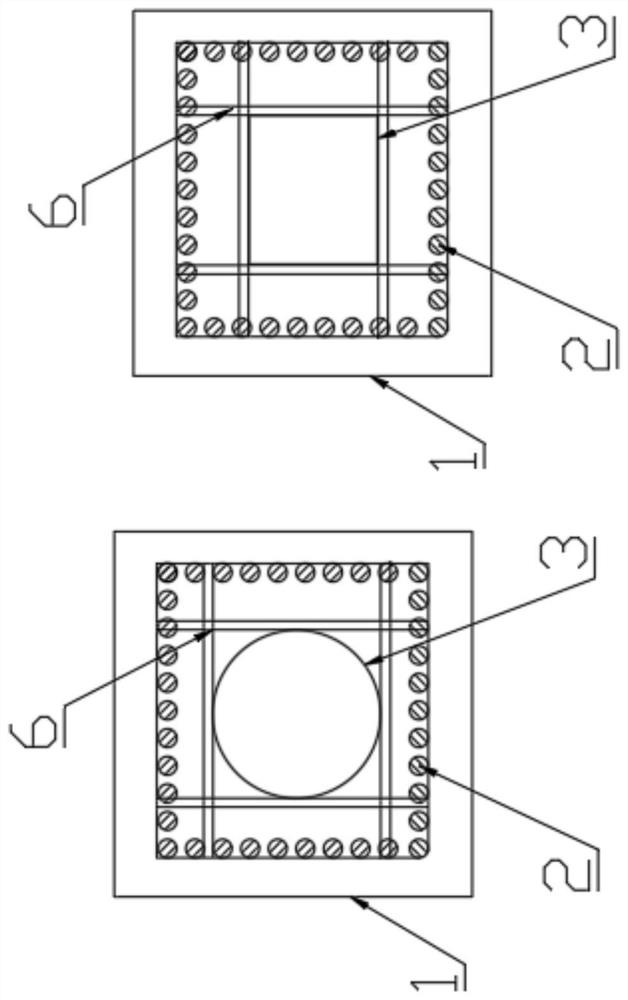

Hollow prefabricated concrete pile and machining method thereof

InactiveCN113026727AReduce dosageReduce weightCeramic shaping apparatusBulkheads/pilesArchitectural engineeringRebar

The invention relates to a hollow prefabricated concrete pile and a machining method thereof. The concrete pile comprises a pile body, a plurality of main ribs and a core pipe; the plurality of main ribs are arranged and bound into a reinforcement cage through spiral ribs; the distance between the main ribs and the outer surface of the pile body is 0-10mm larger than that of the existing standard; the main ribs are provided with pier heads and limited through end plates; the core pipe is connected with the reinforcement cage and then fixed to the center of the pile body; the core pipe is a hollow round pipe or a hollow square pipe; the two ends of the core pipe are closed; and the pile body is provided with a cavity with the section being round or square due to the core pipe. The machining method comprises the steps of concrete preparing, reinforcement cage manufacturing, core pipe installing, tensioning, pouring, steam curing and demolding. Compared with a hollow pile, the hollow prefabricated concrete pile can be used for corrosive geology, and the impact resistance of the end of the pile is improved during pile sinking; and compared with a solid pile, the usage amount of concrete is reduced, the weight of the concrete pile is reduced, cost is saved, transportation and construction are convenient, and meanwhile the difficulty of the manufacturing method is lowered.

Owner:盐城中桩预制构件有限公司

Steel pipe pile for rectangular pier cofferdam

InactiveCN102477735ASimple structureEasy to useBulkheads/pilesUltimate tensile strengthBuilding construction

The invention provides a steel pipe pile for a rectangular pier cofferdam. The steel pipe pile is characterized in that female buckles and male buckles are respectively processed on the two sides of spiral pipes. The steel pipe pile provided by the invention has the following advantages: the steel pipe pile has a simple structure and is convenient to use; and the section strength and rigidity of the cofferdam can be enhanced, the cofferdam can be simply and conveniently supported and the construction speed can be increased by using the steel pipe pile when the rectangular pier cofferdam is constructed.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

Half steel frame reinforcing type socket-and-spigot composite pipe and manufacture process thereof

Provided are a half steel frame reinforcing type adapting type composite pipe and a manufacture process thereof. The manufacture process includes manufacturing a frame by adopting casting or stamping process, and respectively manufacturing a socket-and-spigot main pipe and a socket-and-spigot auxiliary pipe in injection molding and spraying mode and assembling the pipes. A frame outer layer is characterized in that an outer wall of the socket-and-spigot main pipe is formed by a large conical wall on the front portion, a cylindrical wall on the back portion and a middle small conical wall, the inner wall of the socket-and-spigot main pipe is composed of a socket-and-spigot cavity and an overflow cavity, a socket-and-spigot composite pipe is composed of the adapting main pipe and the adapting auxiliary pipe in adaptive fit mode, a group of grooves are arranged on a front end opening of the frame, and a sealing ring is arranged in the grooves respectively in fit mode. The half steel frame reinforcing type adapting type composite pipe overcomes the shortcoming that a polyethylene resin plastic composite pipe / polyethylene (PE) pipe is easy to separate due to the fact that expansion coefficient is different in connection installation, non-roundness at the abutting connection position is increased, the welding position generates quick stress cracking and causes the fact that the connection system of the cracking portion leaks water, gas and liquid, a cast-iron pipe and the PE pipe cannot be interchanged, old project modification is affected and the like. The composite type and the manufacture process are suitable for connection pipes of various water delivery and gas delivery projects and are especially suitable for interchangeable connection of plastic pipes such as PE, PVC-U and PVC-M and nodular cast iron pipes.

Owner:HUNAN ZHENHUI PIPE IND

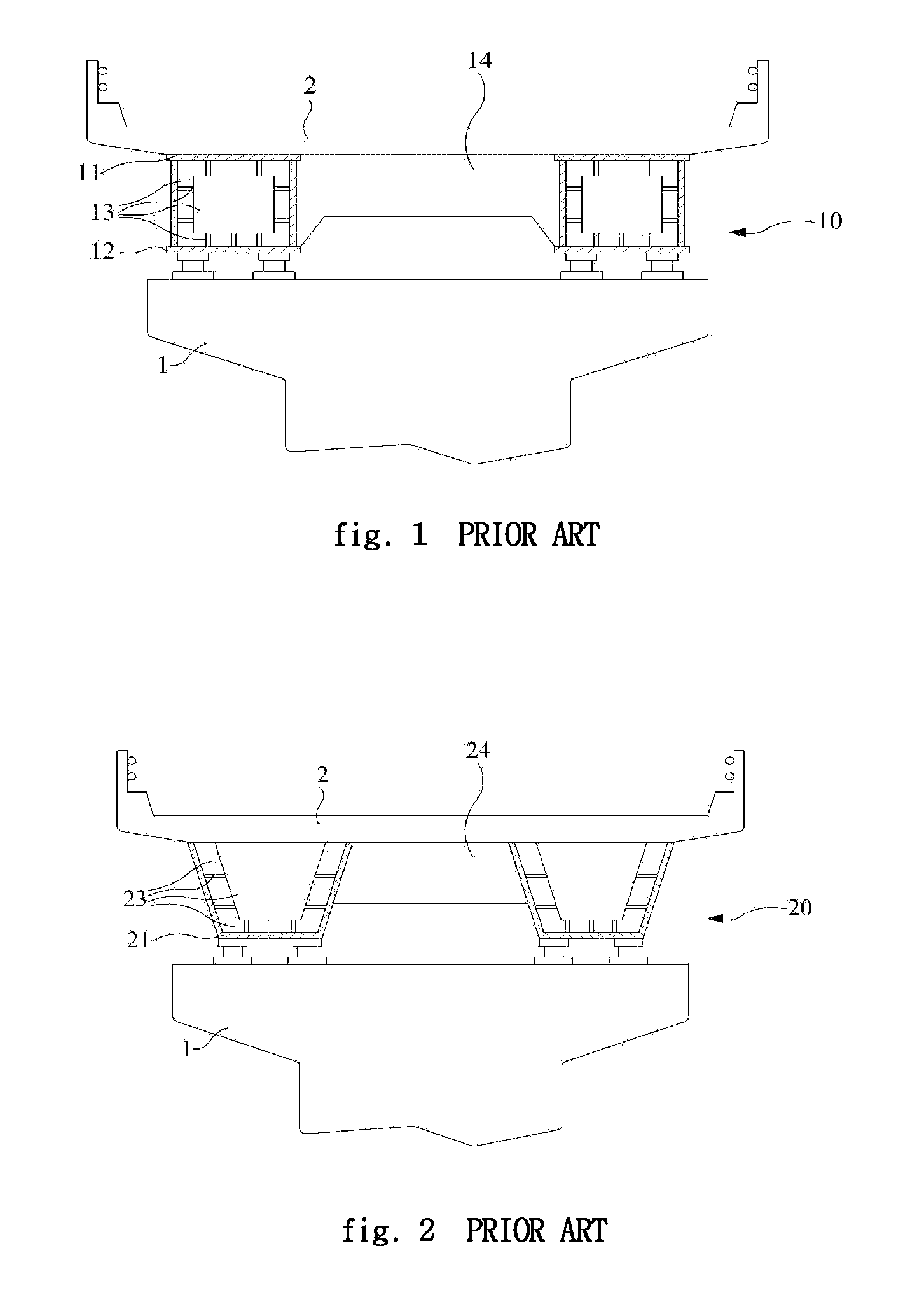

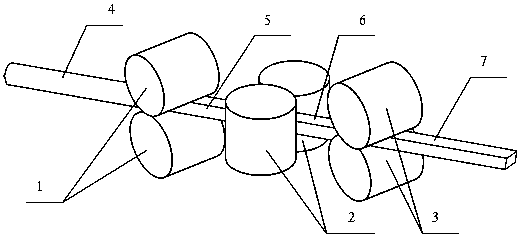

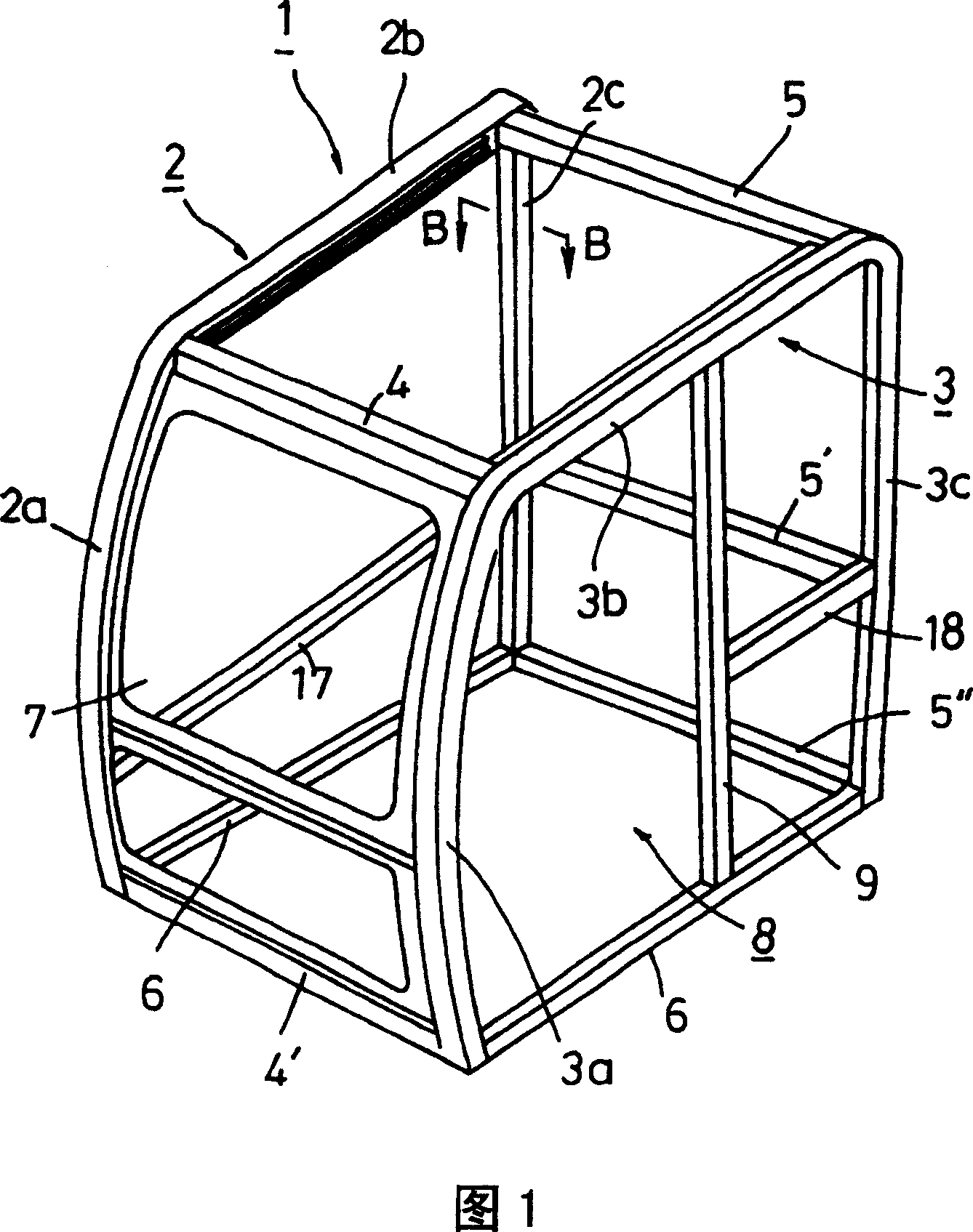

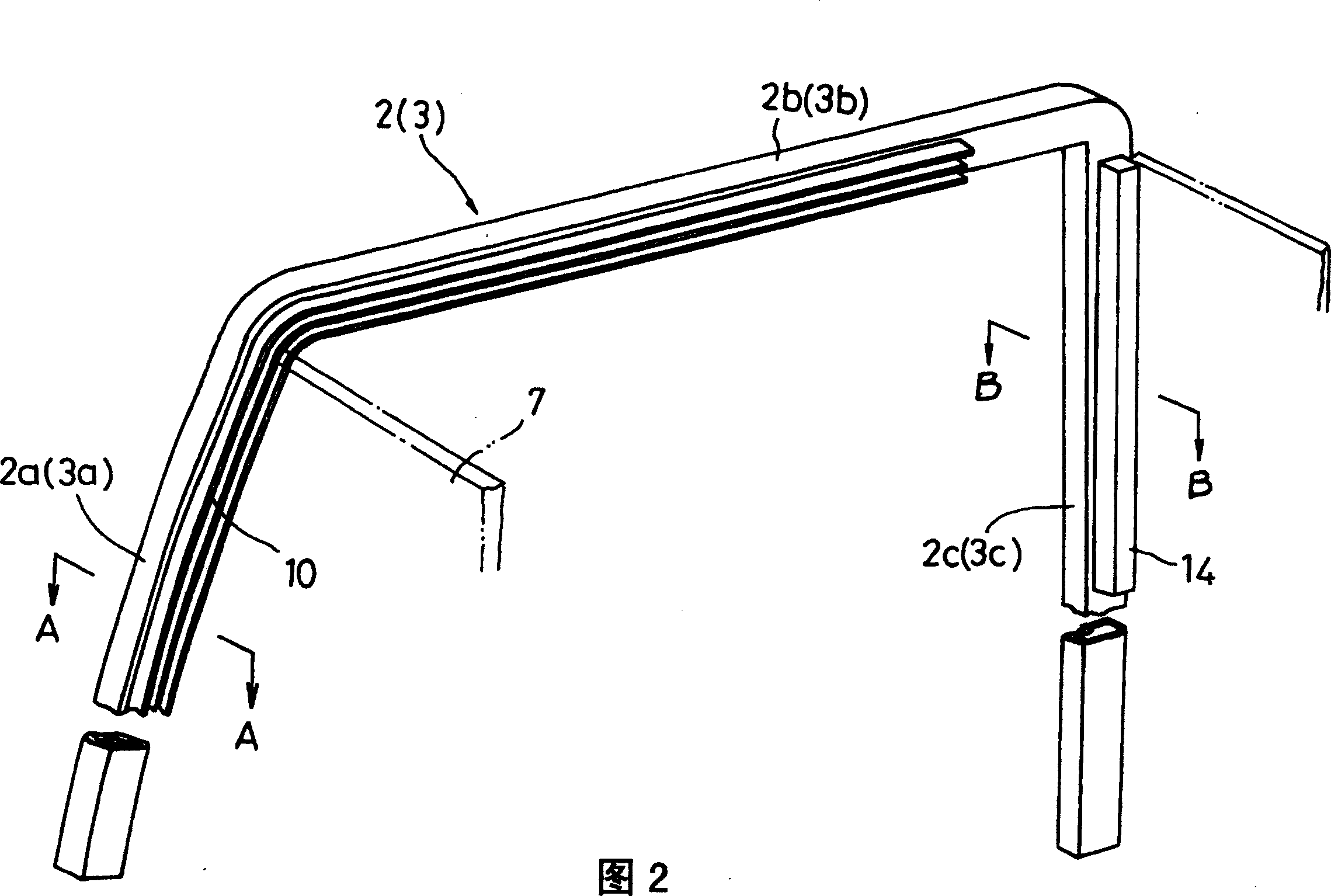

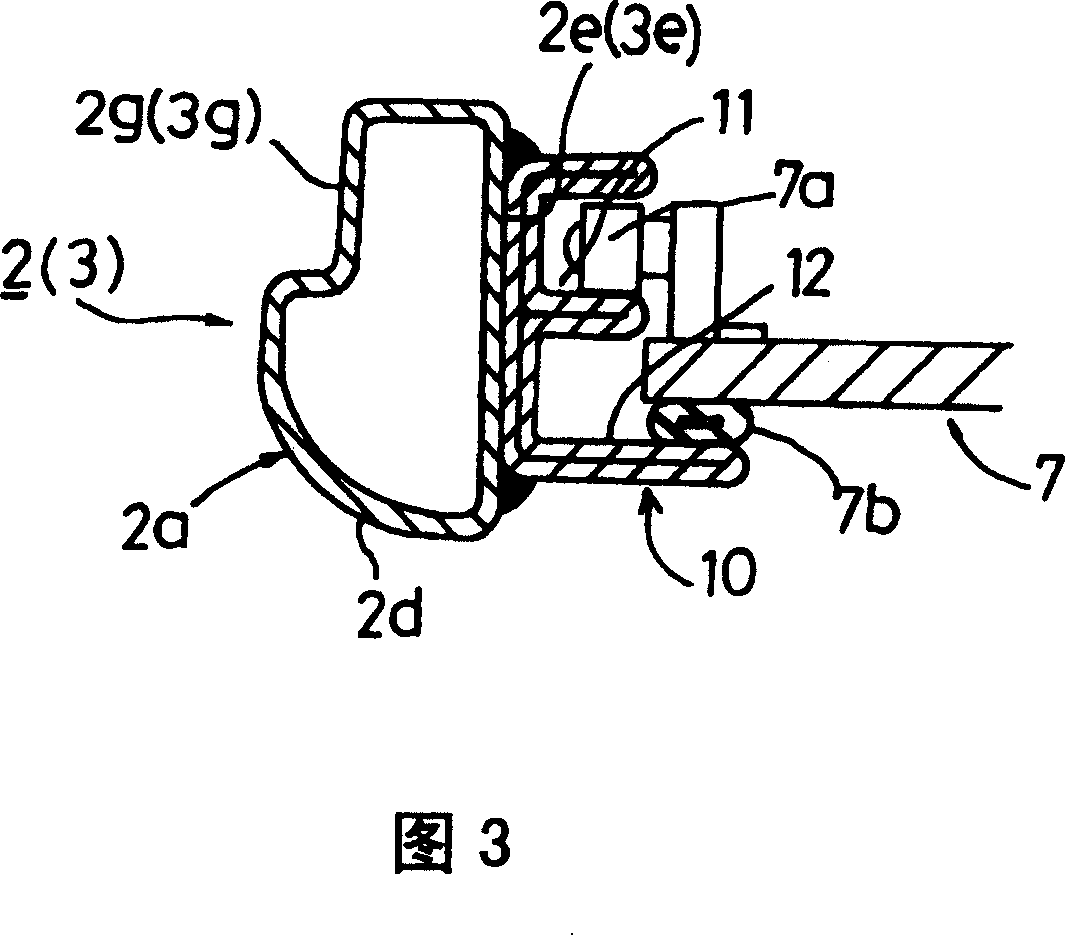

Driver's cab structure for load-carrying vehicle

InactiveCN100333957CImprove visibilityImprove section strengthWindowsWindscreensEngineeringMechanical engineering

A work vehicle cab structure is provided, which does not use members having a complicated sectional structure but uses a pipe member having a modified sectional structure and high workability, thereby achieving increased functionality as well as increased sectional strength for rational reinforcement. The main framework of a cab is constituted by a pipe member which has one flat face at least at a side face thereof and a member (side member) attached to the flat face, the side member having a sectional shape that provides functionality. The pipe member of the main framework constitutes a front supporting column, a ceiling longitudinal part and a rear supporting column which are integrally formed by bending, and the member (e.g., a guide rail and a pipe member for a window) having a sectional shape that provides functionality is welded to the flat face of the pipe member in a specified region, thereby forming an integral structure.

Owner:KOMATSU LTD

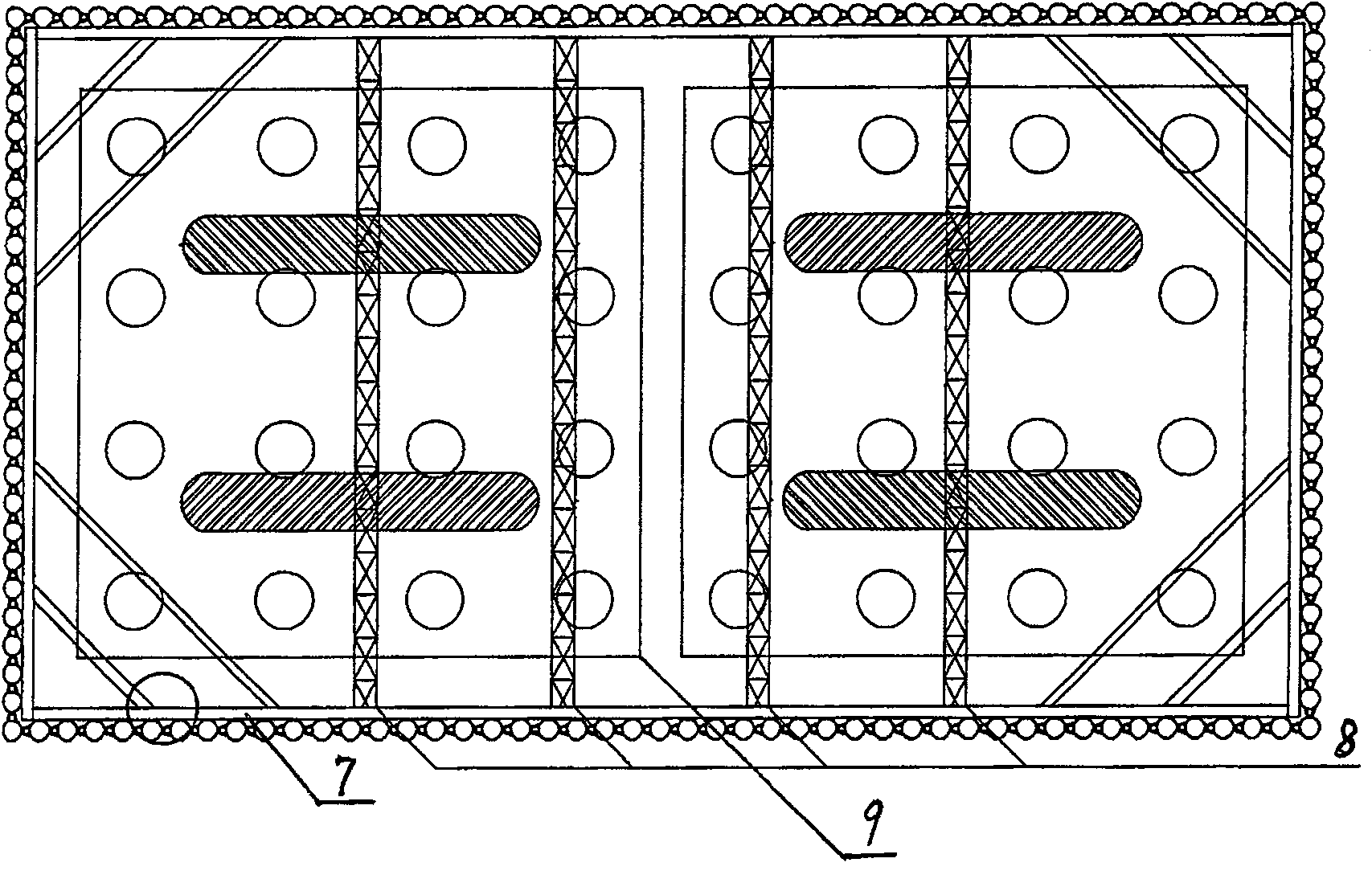

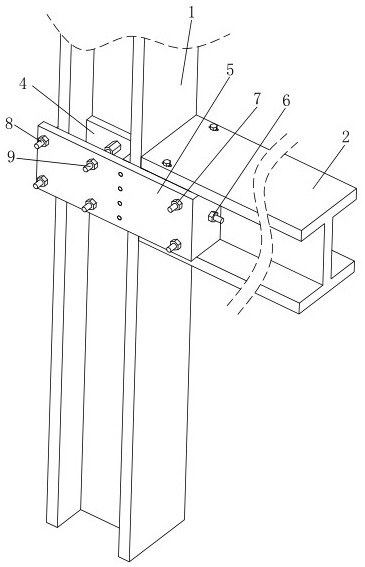

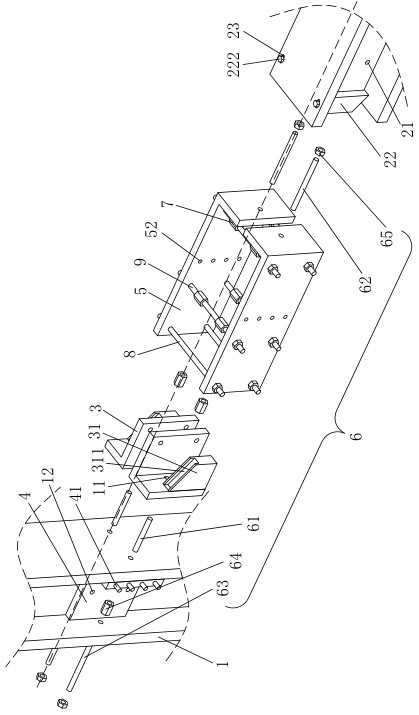

A method of assembling beam-column joints of prefabricated steel structures

ActiveCN113250319BImprove section strengthUniform force balanceBuilding constructionsClassical mechanicsEngineering

Owner:中铁建设集团华北工程有限公司

Lasting mutually promoting and win-win developing implementation scheme for wood plastic production, resource exploitation and environment protection

InactiveCN102241888AImprove textureIncrease the lengthWood working apparatusPulping with inorganic basesFiberEcological environment

The invention relates to a lasting mutually promoting and win-win developing implementation scheme for wood plastic production, resource exploitation and environment protection. The scheme is characterized in that: osier is planted in low-lying areas which are easy to be flooded, and sword iris is planted in saline-alkali lands; osier powder and sword iris fiber are used for replacing wood powder, such that the lasting mutually promotion and win-win development of wood plastic production, low-lying flooded area treatment, saline-alkali land treatment and ecological environment protection can be realized. With the scheme, wood plastic production is changed from a dependant industry into a leading industry; the dependence of wood plastic base material on wood is solved; a problem of insufficient biomass base material is solved; a history that wood products are dependant on deforestation is ended; the performance of wood plastic material is improved; wood plastic composite material with light weight and high toughness is produced; and ecological environment is obviously improved. With the scheme, an integral production system of osier powder, sword iris fiber and wood plastic composite material is established; and problems in each link can be coordinated and solved scientifically and quickly. Therefore, a lasting mutually promotion and win-win development of wood plastic production, resource exploitation and environment protection can be ensured.

Owner:翟云升

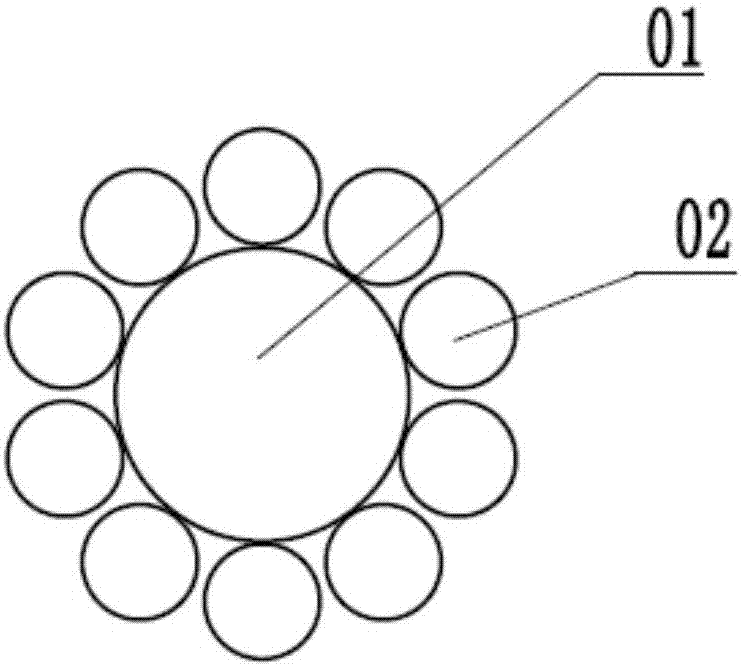

Cable type tire bead and tire

ActiveCN107953728AReduce stress concentrationExtend your lifeTyre beadsTextile cablesStress concentrationTire bead

The invention discloses a cable type tire bead and a tire. The cable type tire bead includes a core coil steel wire located at the middle position of the tire bead and at least one layer of outer winding steel wires wound around the outside of the core coil steel wire. All layers of the outer winding steel wires uniformly wind in the circumferential direction of the core coil steel wire. The cabletype tire bead is characterized in that a section of the outer winding steel wires is a flat surface with a long axis and a minor axis, the long axis is vertical to the radial direction of a sectionof the tire bead, and the minor axis is parallel to the radial direction of a section of the tire bead; the outer winding steel wires are in surface contact with the core coil steel wire; and when atleast two layers of the outer winding steel wires are arranged, line contact is formed between the outer winding steel wires. The cable type tire bead and the tire has the beneficial effects that thearrangement gap and the section size can be reduced, the section intensity is increased, the stress concentration in the tire bead is reduced, and the service life of the tire bead is prolonged.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Full steel framework enhanced plug type composite pipe

ActiveCN102620064BSimple structureCompact structurePipe-jointsRigid pipesWater leakageThermal expansion

The invention provides a steel framework enhanced plug type composite pipe, which comprises a main framework semi-product and an auxiliary framework semi-product which are respectively manufactured through a casting or stamping process, and a socket welding main pipe semi-product and a socket welding auxiliary pipe semi-product are respectively manufactured through an injection molding process and a plastic spraying process and are connected to form the product at the end of the two frameworks. In the main framework, the socket welding main pipe outer wall is formed by a large tapered wall, a small tapered wall and a cylinder wall, an inner layer front part of the main framework is the framework body and forms the front inner wall of the socket welding main pipe, and the socket welding cavity wall and an overflow cavity wall form the socket welding main pipe rear inner wall. A front end of the main framework is an inner cone V trumpet shape, and the rear end of the main framework forms a groove and a sealing ring adapted to the groove. The steel framework enhanced plug type composite pipe overcomes the defects such as polyethylene resin composite pipes and cast iron pipes, cast steel pipes, steel pipes, PE pipes, PVC pipes, PPR pipes and plastic pipes can not be exchanged, separation is caused by thermal expansion difference during connection, non-roundness increases at a joint position, it is easy to crack during welding and water leakage, gas leakage and pollution to the environment due to the breakage connection beyond the half section length.

Owner:HUNAN ZHENHUI PIPE IND

Foundation pile self-balancing bearing capacity load box overall waterproof performance detection and calibration device

PendingCN111827377AGuarantee the quality of groutingMeet the requirements of waterproof testingFoundation testingArchitectural engineeringSlurry

The invention relates to a load box waterproof performance detection and calibration device, and belongs to the field of civil engineering. The invention discloses a foundation pile self-balancing bearing capacity load box overall waterproof performance detection and calibration device. The detection and calibration device comprises a bearing plate device, an independent reverse stand column device and a dynamic water level testing device, wherein the bearing plate device comprises a bearing plate and a sealing strip, the bearing plate serves as a supporting plate of a load box, the sealing strip is used for preventing the load box from overflowing in the waterproof detection process, the independent reverse stand column device is fixedly mounted on the bearing plate and provides support for the dynamic water level testing device, and the dynamic water level testing device is used for recording the change condition of the liquid level in the load box. The method has the following advantages that 1, after the loading test of the load box is completed, the grouting quality outside a cylinder can be ensured; 2, the requirement for waterproofness detection of the I-type load box in theJiangxi province engineering construction standard is met; and 3, the waterproof performance of the product can be known in time, so that effective slurry is injected, and the pile body section strength is improved.

Owner:江西联保工程咨询有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com