Full steel framework enhanced plug type composite pipe

An enhanced, socket-type technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of leakage, water leakage, air leakage, environmental secondary pollution at the socket connection, and improve the installation efficiency. , prolong the service life of the product, ensure the effect of continuous operation and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

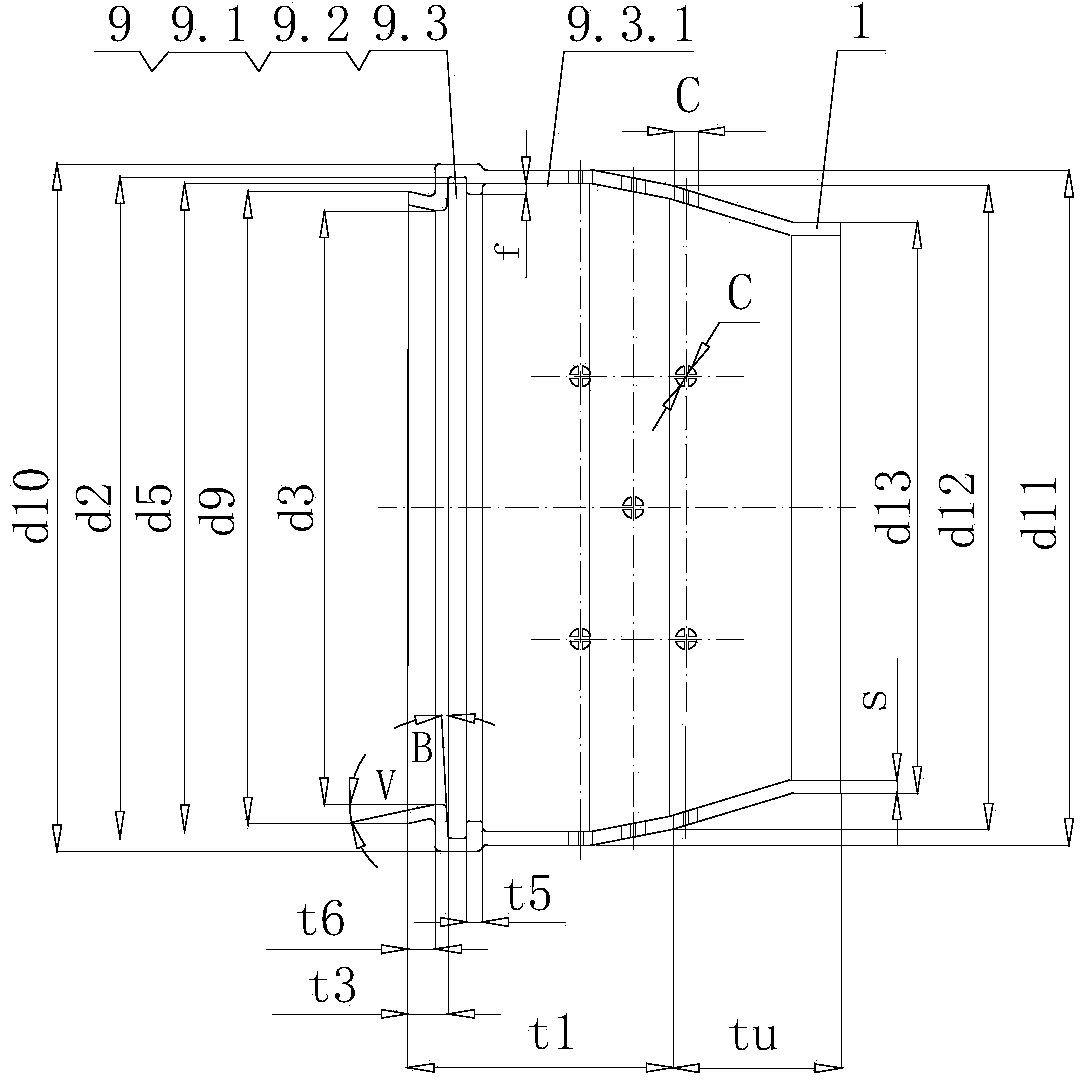

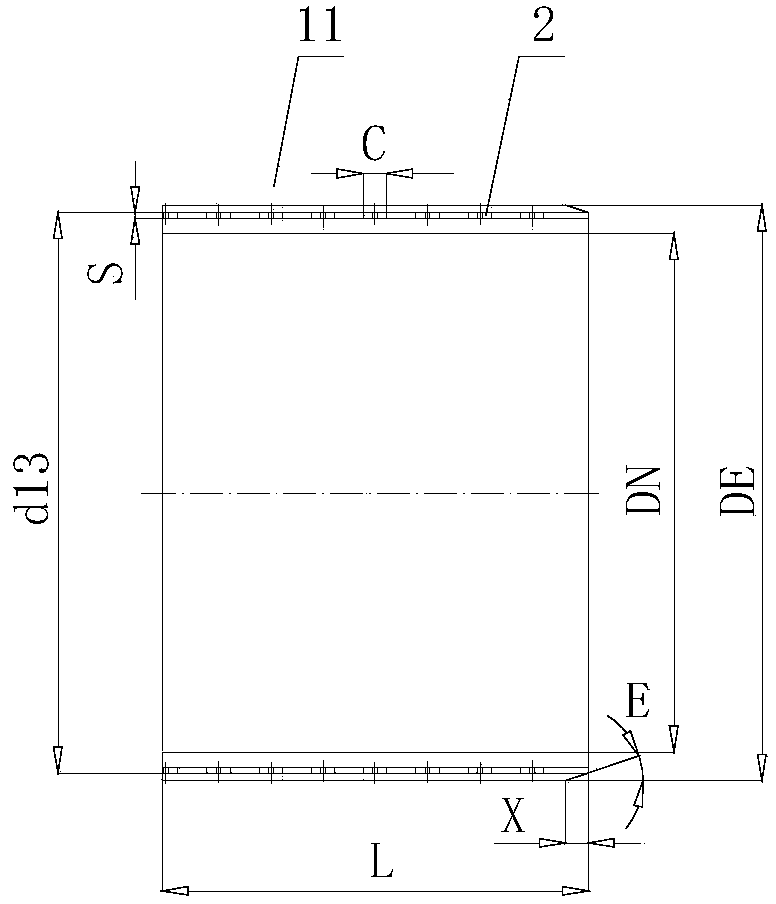

[0082] Table of main dimensions and parameter values of the embodiments of the present invention.

[0083] Table 1 is a value table of the main radial dimensions of the steel frame reinforced socket type composite pipe of the present invention.

[0084] Table 2 is a value table of the main radial dimensions of the steel frame reinforced socket type composite pipe of the present invention.

[0085] Table 3 is a value table of the main axial dimensions of the steel frame reinforced socket type composite pipe of the present invention.

[0086] Table 4 is a value table of the main axial dimensions of the steel frame reinforced socket type composite pipe of the present invention.

[0087] Table 5 is a comprehensive size value table of the steel frame reinforced socket type composite pipe of the present invention.

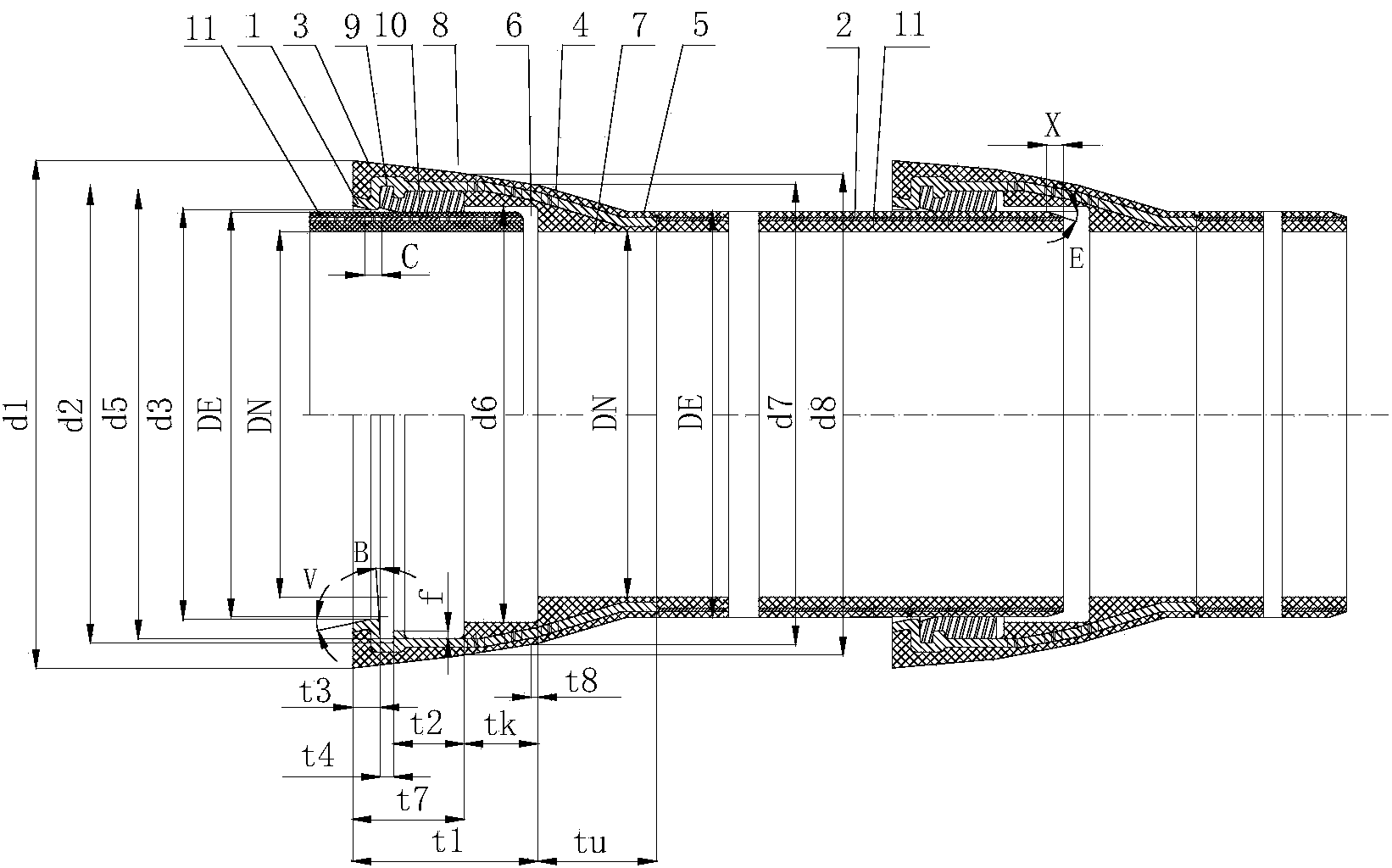

[0088] As shown in the drawings and tables, a steel skeleton reinforced socket type composite pipe includes a main skeleton 1 and a sub-frame 2 made by casting or st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com