New long line rail

A new type of rail head technology, used in tracks, roads, buildings, etc., can solve the problems of economic waste, fatigue fracture, fatigue fracture of long core rails, etc., to achieve the effect of close fit, improve structural strength, and improve section strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

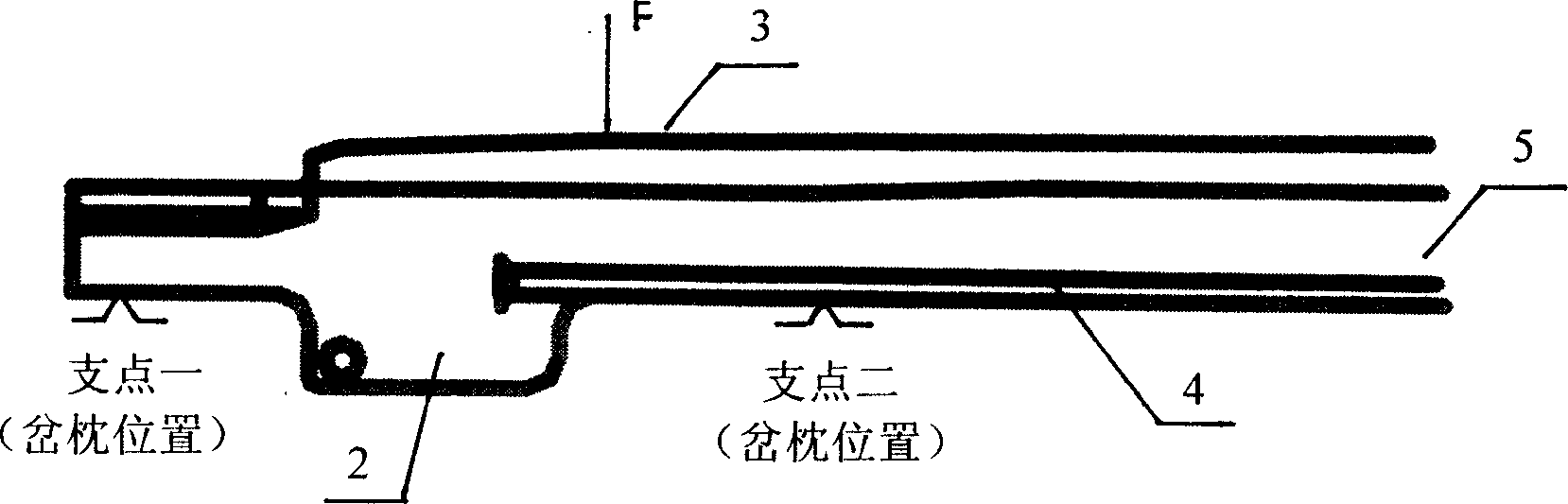

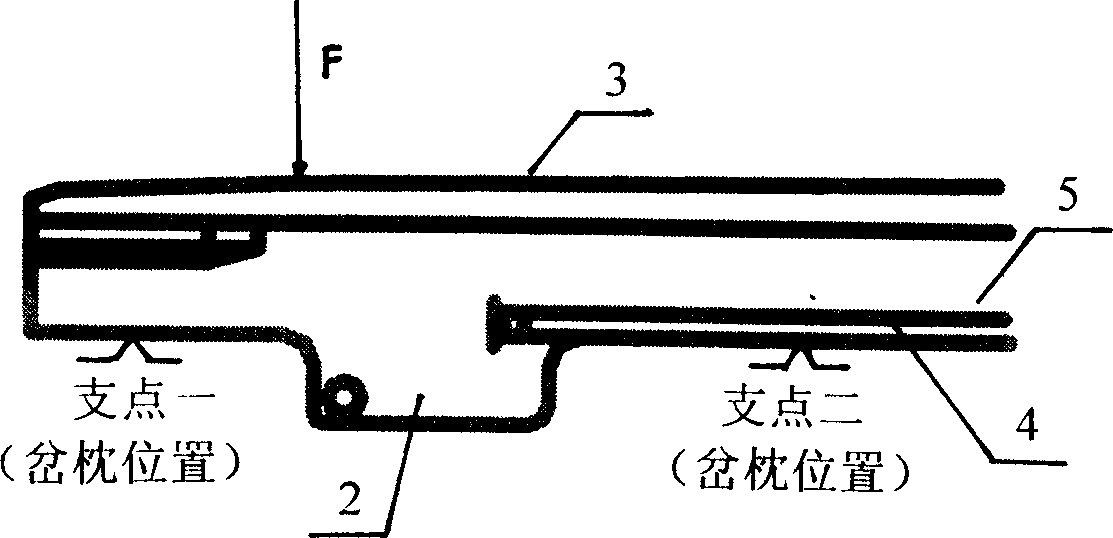

[0012] Embodiment 1: with reference to attached figure 1 with 2 . 1. Measures and process steps: Process flow: blanking → sawing → machining of the press section of the conversion handle → hot forging of the conversion handle → hot forging of the anti-jump platform → normalizing → straightening → sawing head → heel heating Forging→Milling the contour of the transfer handle→Milling both sides of the transfer handle→Milling both sides of the anti-jump platform→Number hole→Drilling→Horizontal milling of the bottom of the side rail of the short leg→Horizontal milling of the bottom of the side rail of the long leg→Milling of the anti-jump surface Surface→CNC milling working side of long leg rail head→CNC milling short leg rail head working side→CNC milling top surface of rail→Heel-end profiled section rail top surface and both sides planing→planing short leg side closely with short core rail The side of the rail head of the pasting section → correct the processing deformation an...

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, the end face of the rail head tread 3 lags behind the end of the anti-jump platform 1 at any point within the range of 100-1000mm.

Embodiment 3

[0014] Embodiment 3: On the basis of Embodiment 1, the end face of the rail head tread (3) lags behind any point within the range of 100-160 mm from the fulcrum in the anti-jump platform (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com