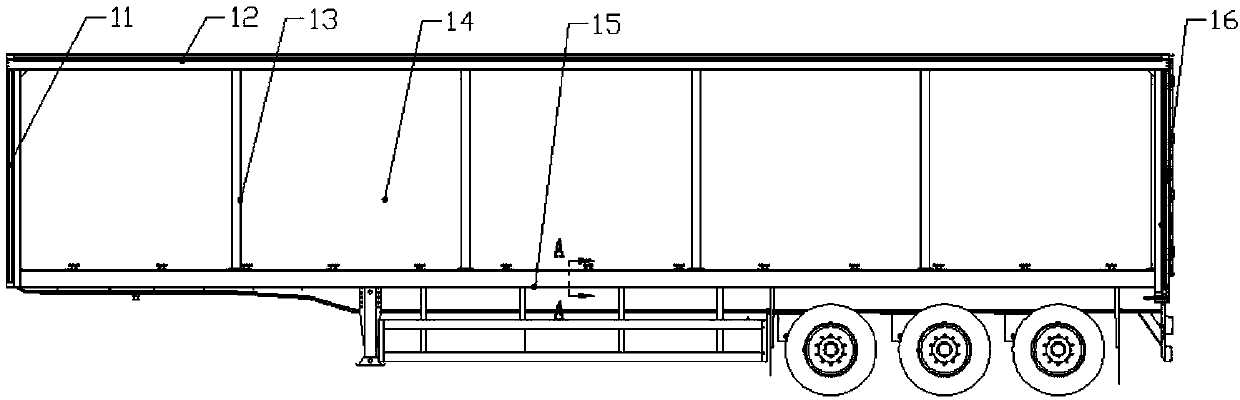

Section boundary beam aluminum alloy side curtain semi-trailer and rack of section boundary beam

An aluminum alloy material and aluminum alloy technology, applied in vehicle parts, substructure, transportation and packaging, etc., can solve the problems of heavy side beams and poor corrosion resistance, and reduce the weight of side beams, improve corrosion resistance, and improve The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

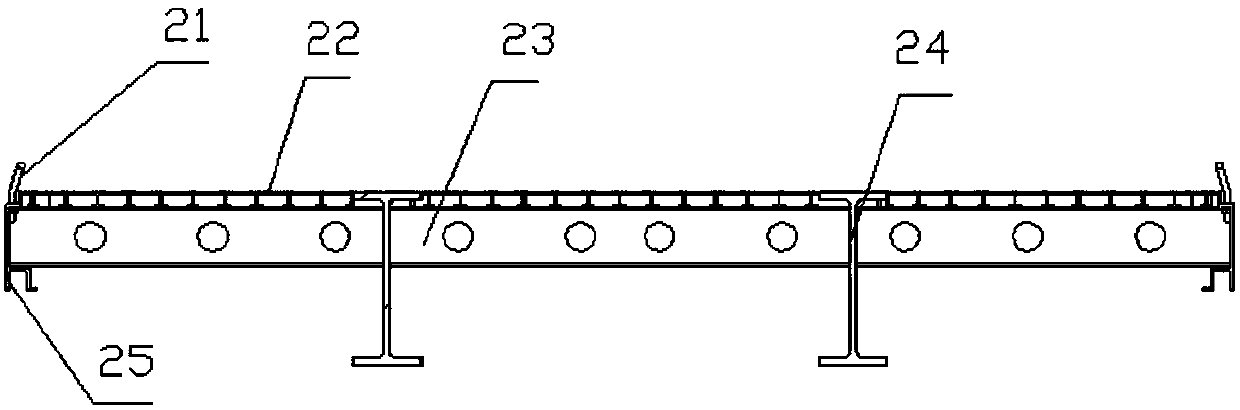

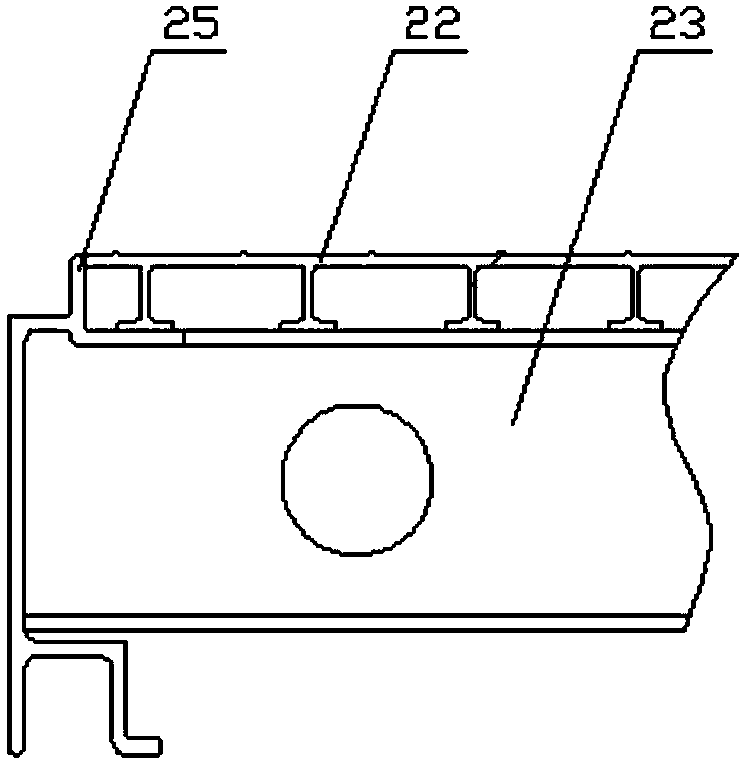

Embodiment 1

[0033] Such as Figure 4 As shown, a profile side beam of a side curtain semi-trailer, its structure includes profile side beam characteristic surface 1 41, profile side beam characteristic surface 2 42, profile side beam characteristic surface 3 43, profile side beam characteristic surface 4 44, profile Edge beam characteristic surface five 45, profile edge beam characteristic surface six 46, profile edge beam characteristic surface one 41, profile edge beam characteristic surface two 42, profile edge beam characteristic surface three 43, profile edge beam characteristic surface four 44, profile Aluminum alloy materials are used for structures such as the characteristic surface five 45 of the side beam and the characteristic surface six 46 of the profile side beam. This improvement reduces the weight of the side beam and improves the corrosion resistance of the side beam.

[0034] Wherein, the profile side beam characteristic surface 1 41 and the profile side beam characteri...

Embodiment 2

[0036] On the basis of the profile side beam of a side curtain semi-trailer described in Embodiment 1, the profile side beam characteristic surface one 41, the profile side beam characteristic surface two 42, the profile side beam characteristic surface three 43, and the profile side beam feature The connections between the sections such as surface four 44 , profile side beam characteristic surface five 45 , and profile side beam characteristic surface six 46 are integrally formed. This improvement reduces the number of connections, does not require welding, avoids welding defects, and simplifies the side beam structure.

Embodiment 3

[0038] On the basis of the profile side beam of a side curtain semi-trailer described in Embodiment 2, the profile side beam characteristic surface one 41, the profile side beam characteristic surface two 42, the profile side beam characteristic surface three 43, and the profile side beam feature The forming process of the connection between structures such as surface four 44 , profile edge beam characteristic surface five 45 , and profile edge beam characteristic surface six 46 is an aluminum extrusion process. This improvement improves the section strength of the component, improves the machining accuracy, and simplifies the production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com