A method of assembling beam-column joints of prefabricated steel structures

A technology of steel structure beams and assembly methods, which is applied in the direction of building construction and construction, and can solve problems such as deformation of steel structure beams or steel structure columns, weakening the cross-sectional strength of steel structure beams and steel structure columns, and achieve enhanced structural strength and enhanced cross-section The effect of strength, reducing the possibility of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

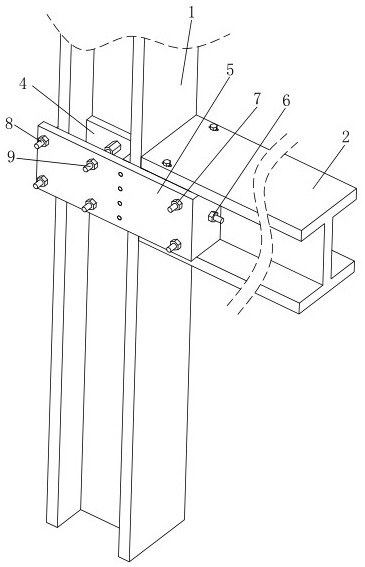

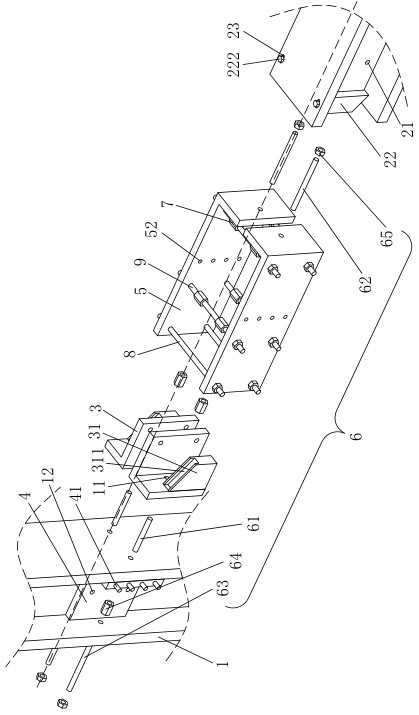

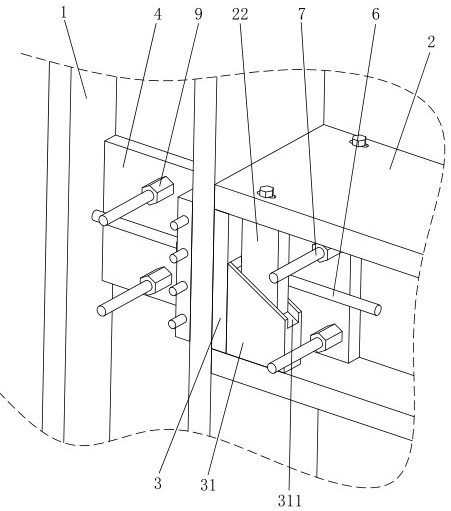

[0042] Attached to the following Figure 1-5 This application will be described in further detail.

[0043] The embodiment of the present application discloses a method for assembling a beam-column joint of an assembled steel structure.

[0044] A method for assembling a beam-column joint of an assembled steel structure, comprising the following steps:

[0045] S1 prefabricated steel structural column 1 and steel structural beam 2:

[0046] refer to figure 1 and figure 2 , the steel structure beam 2 and the steel structure column 1 are made of I-beam, and the steel structure beam 2 and the steel structure column 1 are both fixed by two side plates arranged in parallel and a web plate arranged vertically between the two side plates. . First communication holes are opened on both sides of the two side plates of the steel structure column 1 , and two fourth connection holes 12 are opened on the web plate of the steel structure column 1 , and the two fourth connection holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com